Compound curing agent for dredged silt and preparation method thereof

A technology of compound solidifying agent and dredging sludge, applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc. Good performance, good curing effect and economical effect, good early strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

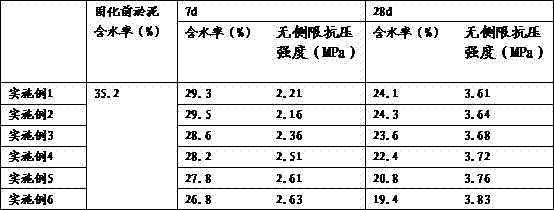

Examples

Embodiment 1

[0034] A composite curing agent for dredging silt, comprising the following components by weight: 20 parts of aluminum sulfate cement clinker, 30 parts of expandable graphite, 7 parts of organic bentonite, 6 parts of pozzolanic materials, 1 part of calcined diatomite, reinforced 3 parts of aggregate, 10 parts of quicklime, 10 parts of sodium hydroxide, 8 parts of the expansion resin, 6 parts of water glass, and 5 parts of carbon fiber. The expansion temperature range of expandable graphite is 200~400 degrees Celsius. The pozzolanic material is blast furnace slag. The swelling resin is sodium polyacrylate.

[0035] Its preparation method comprises the following steps:

[0036] (1) Mix aluminum sulfate cement clinker, pozzolanic materials, calcined diatomite, reinforced aggregate, quicklime and sodium hydroxide evenly, and set aside;

[0037] (2) Heat the expandable graphite to keep it in an expanded state, then add the mixture described in step 1 and mix well;

[0038] (3) ...

Embodiment 2

[0040] A composite curing agent for dredging silt, comprising the following components in parts by weight: 25 parts of aluminum sulfate cement clinker, 32 parts of expandable graphite, 5 parts of organic bentonite, 3 parts of pozzolanic materials, 2 parts of calcined diatomite, reinforced 4 parts of aggregate, 6 parts of quicklime, 12 parts of sodium hydroxide, 9 parts of the expansion resin, 7 parts of water glass, and 6 parts of carbon fiber. The expansion temperature range of expandable graphite is 200~400 degrees Celsius. The pozzolanic material is fly ash. The expansion resin is polyacrylamide. The preparation method is the same as in Example 1.

Embodiment 3

[0042] A composite curing agent for dredging silt, comprising the following components by weight: 30 parts of aluminum sulfate cement clinker, 34 parts of expandable graphite, 6 parts of organic bentonite, 5 parts of pozzolanic materials, 3 parts of calcined diatomite, reinforced 5 parts of aggregate, 8 parts of quicklime, 13 parts of sodium hydroxide, 10 parts of the expansion resin, 5 parts of water glass, and 7 parts of carbon fiber. The expansion temperature range of expandable graphite is 200~400 degrees Celsius. The pozzolanic material is fly ash. The expansion resin is polyacrylamide.

[0043] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com