Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

382results about "Silk filament obtaining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precursor silk feedstock for forming filaments

InactiveUS7041797B2Contamination of the silk feedstock solution by other body fluids is substantially reduced or preventedImprove mechanical propertiesPeptide/protein ingredientsMonocomponent fibroin artificial filamentZoologyArthropod

The application relates to a method of obtaining silk feedstock solution from a gland of a silkworm or another silk-producing arthropod in which the body of the silkworm or the other silk-producing arthropod is cut open and the gland removed. The silk feedstock solution is subsequently extracted from the gland and used for extrusion, spinning or moulding of objects.

Owner:SPINTECH ENG

Silk Thread Containing Spider Thread Protein and Silk Worm Producing the Silk Thread

InactiveUS20080287651A1Maintain good propertiesHigh strengthPeptide/protein ingredientsImmunoglobulinsBiotechnologyHigh intensity

A transgenic silkworm having transferred therein a gene which encodes spider thread protein having desired properties of high strength and high elasticity while leaving the silkworm fibroin H chain gene intact, by means of utilizing a transposon function, is used to produce in the transgenic silkworm a spider thread protein having the desired properties without lowering the strength or elasticity of silk thread produced by the transgenic silkworm, thereby providing hybrid silk of spider and silk threads having the desired properties.

Owner:TORAY IND INC +1

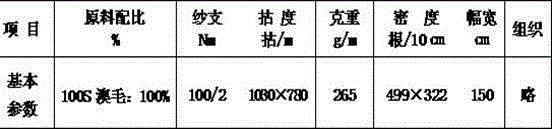

Low-temperature cocoon cooking method for mulberry cocoon with little sericin

InactiveCN101831714AImprove efficiencyWith energy saving and emission reductionSilk filament obtainingSocial benefitsEconomic benefits

The invention discloses a low-temperature cocoon cooking process for a mulberry cocoon with little sericin, which comprises a step of soaking dry mulberry cocoon with little sericin in water at the temperature of 35 DEG C under vacuum, wherein the water temperature of the I soaking section on an upper groove of a cocoon cooking machine is 35 DEG C; the water temperature of the II soaking section is 45 DEG C; the cooking temperature is 80 DEG C; the temperatures of a middle section, a vibrating section and a statically cooking section on a cooking part are 50 DEG C, 40 DEG C and 30 DEG C respectively; the temperature of an outlet part is 30 DEG C; the cocoon cooking time is 14 minutes; and the difference between the reelability percentage of the low-temperature cocoon cooking process and the reelability percentage of a high-temperature cocoon cooking process is no more than 5 percent. Matched with the popularization of new products of the mulberry cocoon with little sericin, the low-temperature cocoon cooking process realizes energy conservation and emission reduction in a reeling process and has direct economic benefit and wide social benefit for creating an energy-saving and emission-reducing 'low-carbon' society.

Owner:SUZHOU UNIV

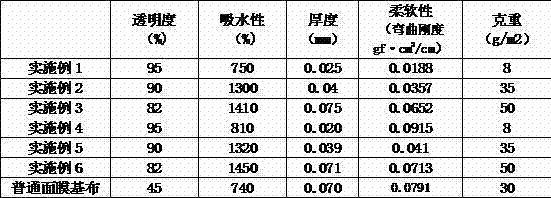

Natural silk facial mask base cloth and preparation method thereof

ActiveCN104762756AGood use strengthAvoid sex changeFabric breaking/softeningSilk filament obtainingFiberPolymer science

The invention discloses natural silk facial mask base cloth which is made of a 100% natural silk filament sheet. The silk filament sheet is subjected to deoiling and softening treatment and then subjected to hot rolling by a roller so that sericin left on the surfaces of silk filaments can be fixed in a bonding mode, and then the natural silk facial mask is formed. The natural silk facial mask base material is of a filament structure and is good in transparency, water absorbency and water-retaining performance and soft and is closely attached to the skin without fiber tows; moreover, sericin protein left on the surface of silk has various beautifying functions of whitening, absorbing ultraviolet light and the like, and the natural silk facial mask base cloth can be used in cooperation with beauty fluid and can also be used independently, is an ideal material for making a beauty make and has good market prospects.

Owner:肖家涛

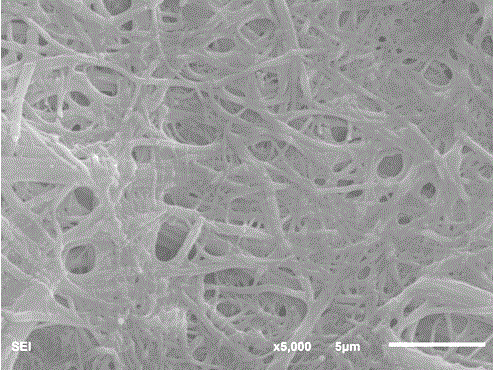

Silk nanofiber manufacturing method

InactiveCN104532365APromote swellingAvoid influenceAnimal materialSilk filament obtainingInorganic saltsFiber

The invention relates to a silk nanofiber manufacturing method, and belongs to the technical field of nano material manufacturing. The manufacturing method includes the steps that silk obtained after degumming treatment is transferred to a solution composed of an inorganic salt or weak acid or weak alkali small molecule compound, deionized water and alcohols, after binding force between nano fibrils in the silk is weakened through soaking, the silk solution is transferred to a high-voltage cell crushing machine or an emulsification machine or a pulp refiner or a crushing machine of a high-speed stirring device, and the soaked silk is mechanically crushed to obtain silk nanofibers. A silk nanofiber solution obtained through the method is similar to the shape of hydrogel, the silk nanofibers are obtained through centrifuging or filtering separation, manufacturing time is short, equipment is simple, operation influence factors are few, and control is convenient. The adopted small molecule compound avoids influences of strong acid or strong alkali on the silk nano fibrils, and the crushing machine can be used for quickly manufacturing the silk nanofibers on a large scale.

Owner:WUHAN TEXTILE UNIV

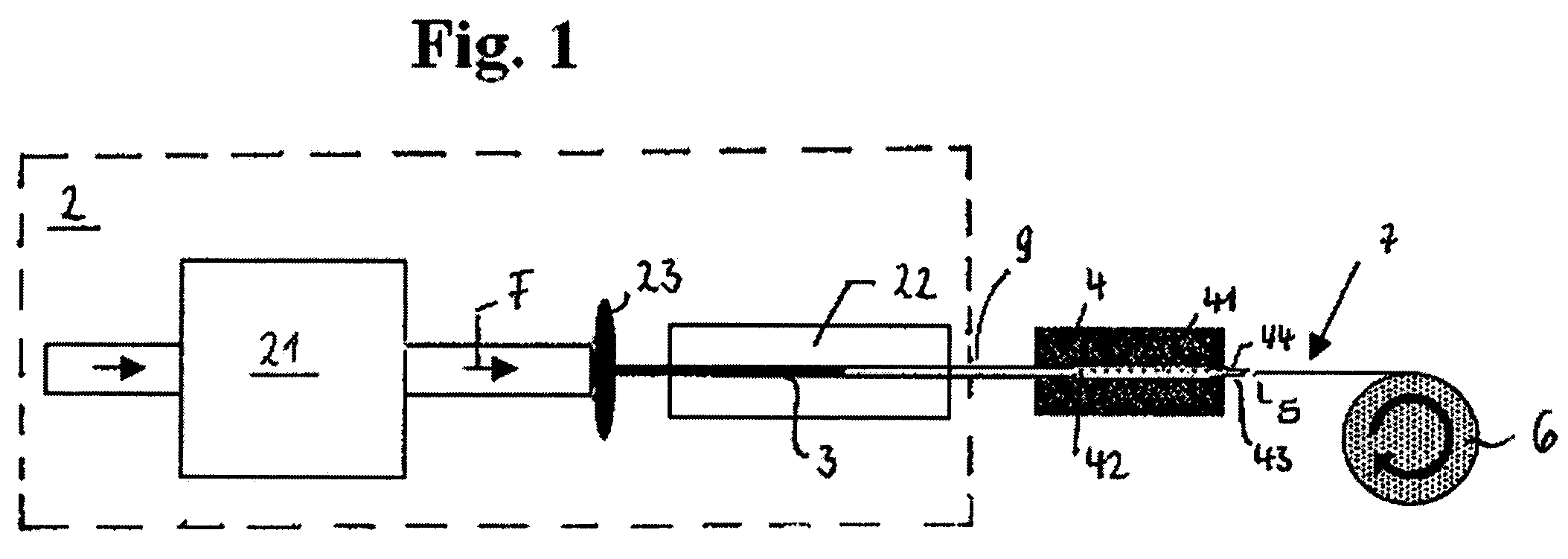

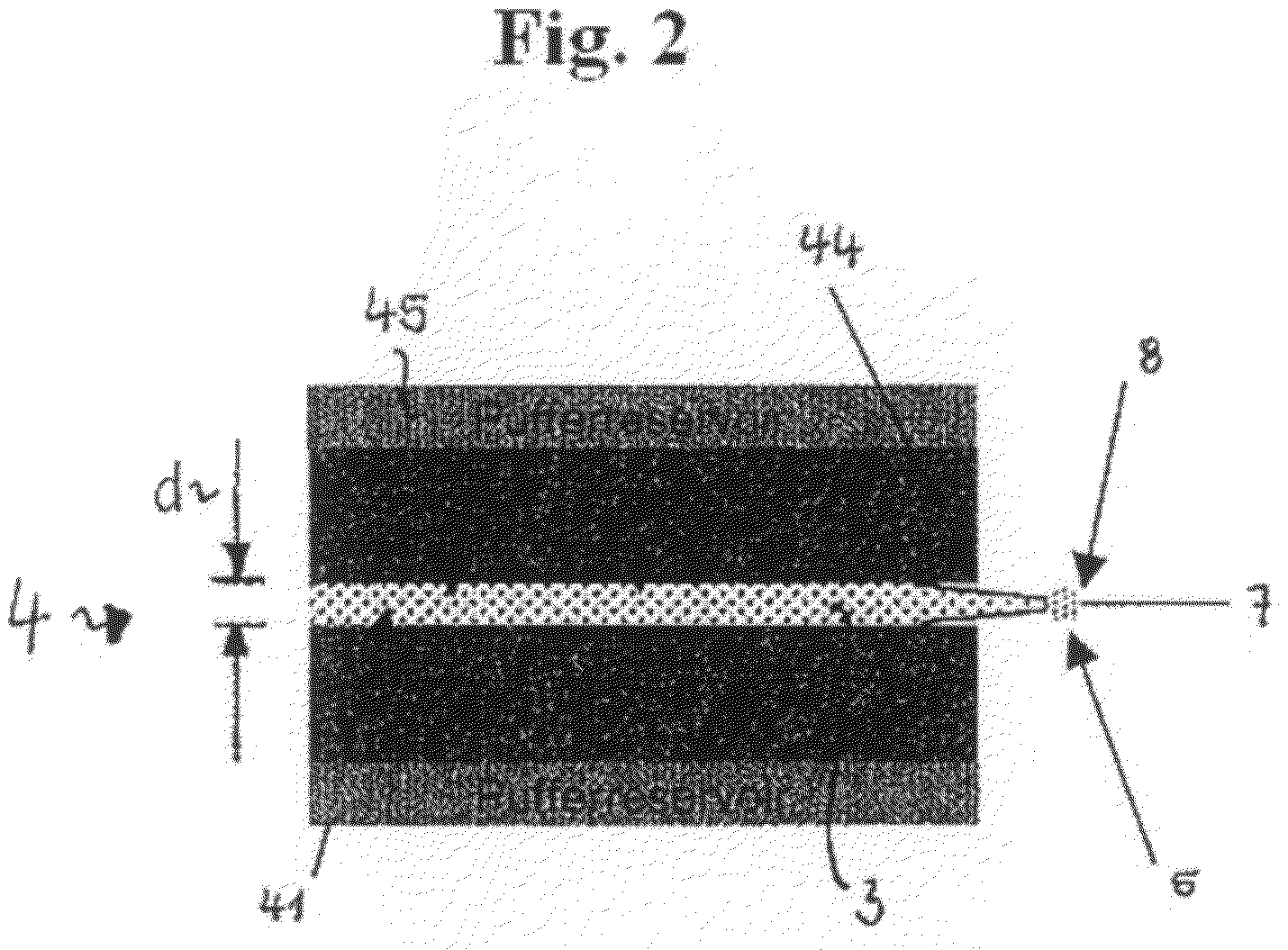

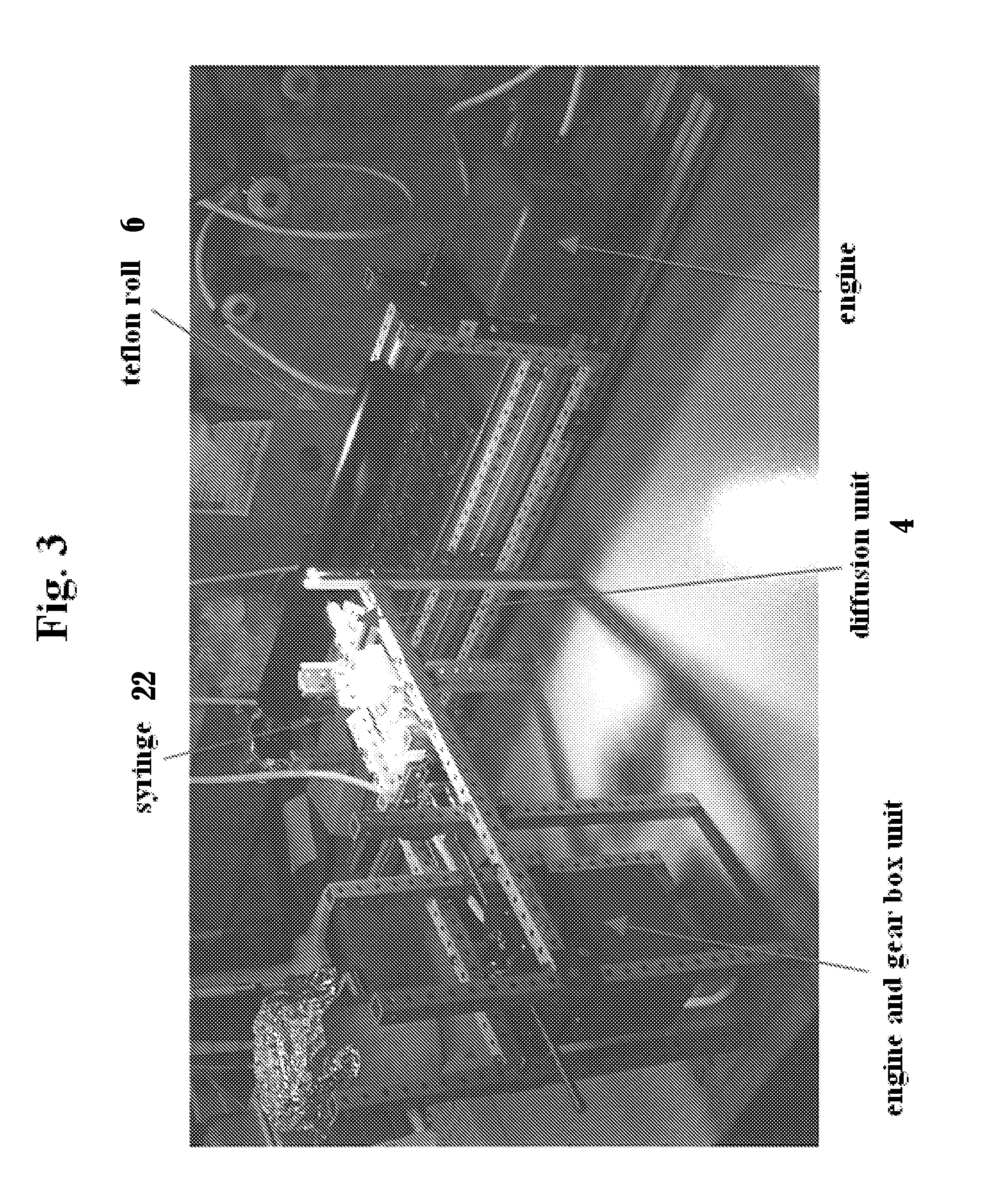

Method and device for producing a thread from silk proteins

ActiveUS7868146B2Enhancing stability and processabilityEnsure continuous processingPeptide/protein ingredientsMonocomponent fibroin artificial filamentProduction lineEngineering

The present invention relates to a thread preparation process from silk proteins including an apparatus which is appropriate for performing the method. Furthermore, the invention is directed to the threads obtained therewith as well as the use thereof. The invention uses a diffusion unit leading to the production of high-quality silk threads with high yield.

Owner:AMSILK

Cleaning cocoon cooking method

InactiveCN103225112ANo emissionsThe total amount is controllableSilk filament obtainingChemical preparationDissolution

The invention discloses a cleaning cocoon cooking method. The method comprises the processes of: external vacuum infiltration, cooking by an automatic cooker, cocoon steaming, and adjustment, wherein a reelability agent originally used for cocoon cooking replaces a penetrating agent for penetrating to be used in the external vacuum infiltration cocoon cooking process; in the condition with 30-50 DEG C water temperature, the reelability agent can only have infiltration function with water to be adsorbed between cocoon layers and on the surface of a cocoon filament; and in the cocoon cooking process and in the condition with 60-80 DEG C water temperature, the reelability agent can promote the cocoon filament sericin dissolution to reduce adhesion between cocoon filaments for the smooth dissociation of the cocoon filaments, so that the reelability agent has the reelability function in the cocoon cooking process. One chemical preparation achieves two functions, the chemical preparation is less and easily controlled in dose, process is simple, operation is convenient, and production cost is low.

Owner:安徽绩溪县花神丝绸有限公司

Method for manufacturing silk quilt

InactiveCN101744484AQuality improvementImprove performanceUpholstery manufactureHand sewingHuman bodyBiomedical engineering

The invention relates to a method for manufacturing a silk quilt, which comprises the following process steps: purchasing raw materials and manufacturing silk floss; sewing a silk floss sleeve; and manufacturing the silk quilt. The silk quilt manufactured by the method is natural and environmental-friendly, and has reliable quality, stable performance and durability; the inner floss is not rolled, exposed or shrunk; and the silk quilt also has the effects of preventing insects, moulds and dusts and resisting static. The silk quilt has the characteristics of fine, smooth, fluffy and soft feelings, coolness in summer and warmness in winter, and affinity with skin, capacity of nourishing cells, promoting the blood circulation, improving the sleeping state, being beneficial to a human body after long-time use, and a best healthcare product in the modern house.

Owner:隋日宽

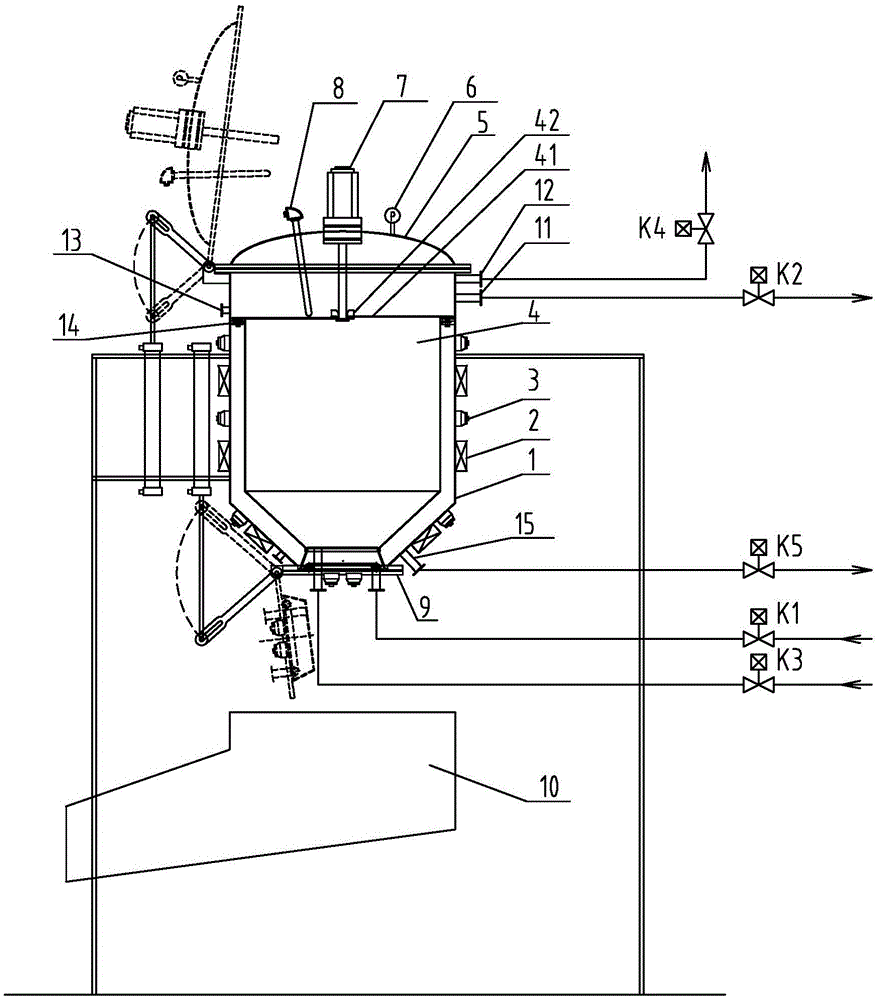

Method and equipment for automatically cooking silkworm cocoons

InactiveCN101824659AStrengthen scientific managementHigh degree of production automationSilk filament obtainingAutomatic controlMan machine

The invention relates to an intelligent method and equipment for automatically cooking silkworm cocoons, which can effectively improve the cooking uniformity of silkworm cocoons. The equipment used for realizing the method of the invention for automatically cooking silkworm cocoons comprises a silkworm cocoon treatment tank, a top cover of the treatment tank and a silkworm cocoon storage tank and is characterized in that a water replenishing tank is also arranged between the silkworm cocoon treatment tank and the silkworm cocoon storage tank. By variably setting different technological parameters, operating man-machine conversation by a touch screen and automatically controlling the time, the water level and the temperature for soaking, steaming and cooking cocoons by a computer and an actuating mechanism, the invention completes the whole processes of feeding, permeating, cocoon steaming, cocoon cooking, cooling protection and cocoon forming in the same barrel, changes the traditional mode of constant action of each section in the traditional circulating cocoon cooking machine, and overcomes the defects of high operation requirements on workers, untimely manual operation and unstable cocoon cooking quality.

Owner:广西立盛茧丝绸有限公司

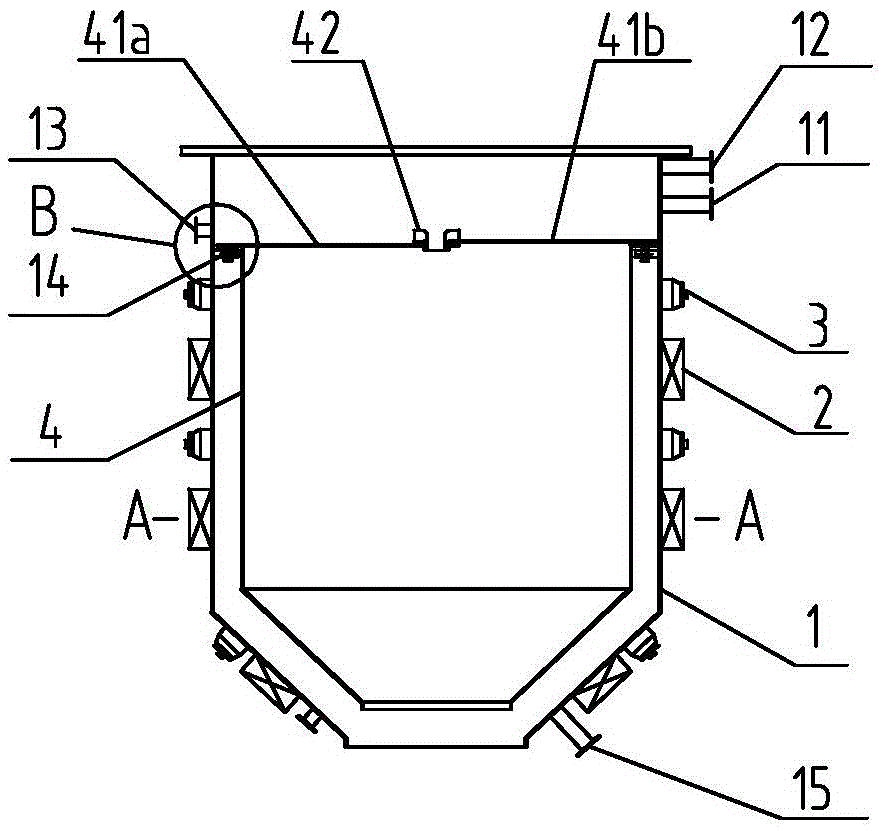

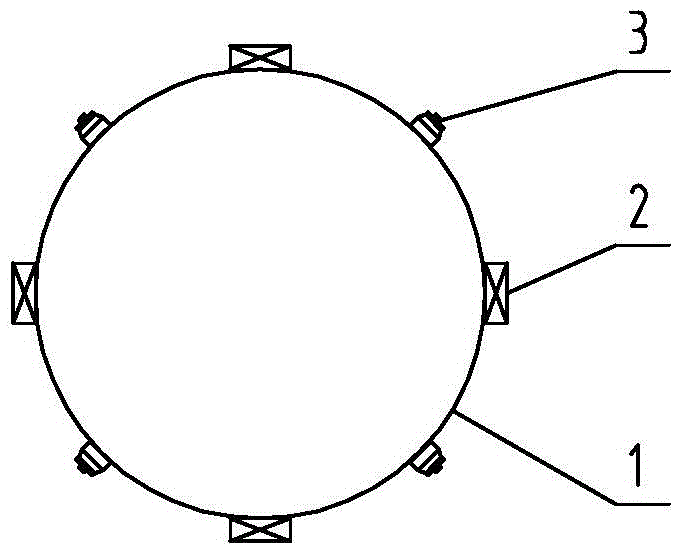

Microwave and ultrasonic wave assisted cocoon cooking device and method for cooking cocoons

ActiveCN105648542ASolve for uniformitySolve heatingSilk filament obtainingUltrasonic assistedCoupling

A microwave and ultrasonic wave assisted cocoon cooking device comprises a cocoon cooking barrel outer drum, a microwave generator, an ultrasonic wave generator, a cocoon cooking barrel inner drum, an upper cover of the cocoon cooking barrel outer drum, a lower cover of a cocoon cooking barrel discharge opening, and a cocoon cooking barrel; a plurality of microwave generators and ultrasonic wave generators are distributed on the outer side of the cocoon cooking barrel outer drum; the cocoon cooking barrel inner drum is made of punching hole meshes or mesh materials, and a cover of the cocoon cooking barrel inner drum consists of two semi-circular sector cover plates made of punching hole meshes or mesh materials and connected through a coupling at the circle center; the cover of the cocoon cooking barrel inner drum can be opened or closed in a rotational manner; a pressure gage and a temperature measurer are mounted on the upper cover of the cocoon cooking barrel outer drum; the lower cover of the cocoon cooking barrel discharge opening is connected with a hot water inlet pipe and is equipped with a porous steam coil and the ultrasonic wave generator; the filature cocoon cooking device has a compact and reasonable structure and is high in integration, and a cocoon cooking of the device adopts a microwave assisted direct-streaming technology and an ultrasonic wave assisted cocoon cooking technology at the same time, so that inner, middle and outer layers of cocoons are heated uniformly, the energy is saved, the consumption is reduced, and the cocoon cooking is shortened.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Cocoon shell recombinant nonwoven fabrics and manufacturing. method thereof

InactiveCN101481850AImprove breathabilityGood moisture permeabilitySilk filament obtainingNon-woven fabricsState of artHot melt

The invention discloses a cocoon recombination non-woven fabric and a manufacturing method thereof, and belongs to the daily necessity field. The materials of the prior art are thicker and have narrow breadth and limited application range, or are adhered by adding chemicals to short silk fiber. The manufacturing method comprises the following steps: oval cocoons are taken as a raw material; and the cocoon recombination non-woven fabric is formed by the steps of cocoon cutting, cocoon stripping, laying, humidifying, hot pressing, patching and the like. The manufacturing method has the advantages that a layered cocoon shell flake is superposed with high temperature for hot pressing and cocoon silk gum hot melt adheres adjacent cocoon shell flakes to form the non-woven fabric, and the non-woven fabric is characterized by wide breadth, no chemical additive, natural and environmental protection, low manufacturing cost, recyclable and degradable product and wide use.

Owner:ZHEJIANG SCI-TECH UNIV

Cooking method for fresh cocoons

InactiveCN104894655AEasy to cleanGood relaxing effectAnimal materialSilk filament obtainingEngineeringCooking methods

The invention discloses a cooking method for fresh cocoons. The cooking method is characterized by including the technological steps of cocoon selection, tea bran water soaking, permeation, enzymolysis, cocoon cooking and cocoon picking. The cooking method for the fresh cocoons has the advantages that the method is simple in technology, convenient to operate and low in production cost; after the method is used for cooking the cocoons, silk yielding rate and quality of obtained cooked cocoons are high; quality index level of the cooked cocoons is improved greatly, and cleanness, spotlessness, strength and cohesion indexes are improved by above one grade.

Owner:广西立盛茧丝绸有限公司

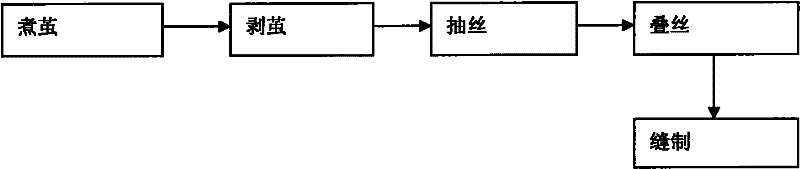

Making method of silk quilt

The invention relates to a making method of a silk quilt. The making process comprises cocoon cooking, cocoon peeling, spinning, silk overlapping and sewing. The making method is characterized by comprising the following steps: a, cooking cocoon, namely, injecting 20kg of fresh water in a pot and placing 5% sodium bicarbonate, placing cocoon and cooking, and sealing for 3-4 hours after water boils; b, peeling the cocoon, namely peeling the boiled cocoon, taking out pupa in the cocoon, and covering the cocoon on a finger, and drawing silk head or lightly pulling the cocoon with fingers to form a mesh shape; c, spinning, namely overlapping the expanded mesh-shaped silk to 5-6 layers and pulling to form square small silk pieces; d, overlapping the silks, namely covering 7-8 small silk pieces on an arch-shaped tool with a bamboo arch-shaped tool made in advance so that a pocket-shaped silk floss pocket is obtained, and then pulling the silk floss by four persons; and e, sewing, namely, overlapping multiple layers of silk floss meshes together according to the required thickness and then placing in lining cloth, and threading on the lining cloth until the internal silk flosses are stabilized and not piled together.

Owner:董辉

Processing method for keeping color of color silks

InactiveCN101979725AWon't be lostAchieve color fixation effectSilk filament obtainingDe-gumming silkComputer sciencePigment

The invention discloses a processing method for keeping the colors of color silks. The method comprises the following steps of: (1) fully blending, peeling and selecting each batch of color cocoons to guarantee that reeled cocoon silks have a uniform color; (2) selecting the common collective control sample meeting control requirements; (3) soaking the cocoon silks accordant with the common collective control sample in hot water of which the temperature is 90 to 100 DEG C for 60 to 80 minutes, and steaming the cocoon silks in a steamer at the temperature of between 95 and 150 DEG C and the humidity of between 80 and 100 percent for 30 to 60 minutes; and (4) performing the traditional degumming treatment and subsequent traditional processes on the steamed cocoon silks. By the method, pigments can enter the interior of fibroin through steaming and does not fade after the silks are washed, so that color fixing effect is achieved.

Owner:GUANGXI GUIHUA SILK CO LTD

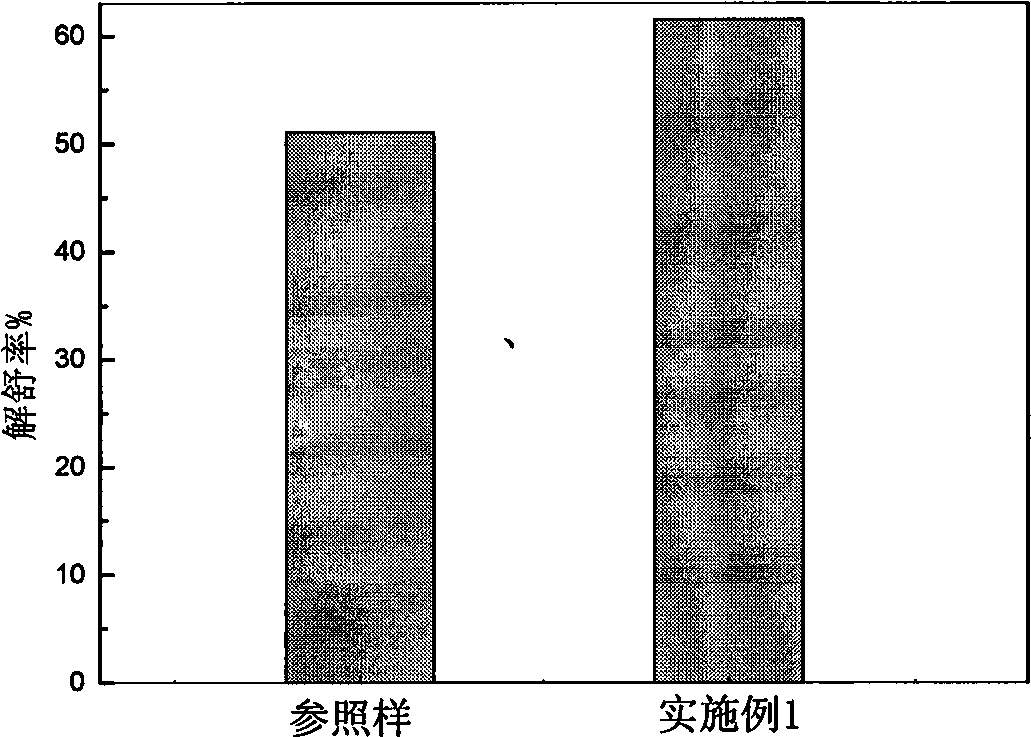

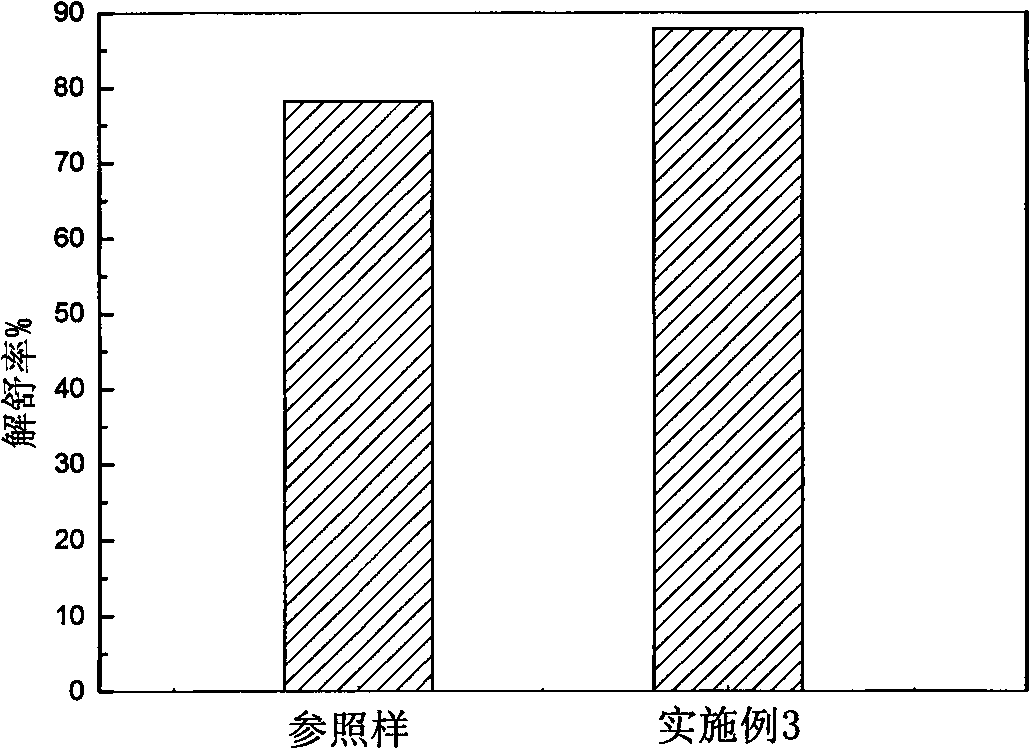

Nano-zinc oxide feeding silkworm rearing method for manufacturing high-performance silk and product thereof

The invention relates to a nano-zinc oxide feeding silkworm rearing method for manufacturing high-performance silk and a product thereof. The nano-zinc oxide feeding silkworm rearing method includes steps of adding nano-zinc oxide into artificial feed of silkworms, feeding nano-zinc oxide into silk gland of silkworms by an absorbing and converting function of the silkworms and cocooning to obtain high-performance silk containing nano-zinc oxide. On the premise of not damaging natural quality of the silk, the silk is modified and has better mechanical performance and better sterilization and ultraviolet resistance property.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Cocoon cooking method for preparing high-quality grade-6A raw silk

InactiveCN102517644ASolve bottlenecksUniform penetrationAnimal materialSilk filament obtainingMolecular clusterCooking methods

The invention discloses a cocoon cooking method for preparing high-quality grade-6A raw silk, which comprises the following steps: firstly carrying out vacuum infiltration on a silkworm cocoon by utilizing alkaline ionized water with a pH value of 7.5-8.5, then impregnating the silkworm cocoon subjected to the vacuum infiltration by utilizing acidic ionized water with a pH value of 4.5-6.5, cooking the impregnated silkworm cocoon in a machine and adding a certain amount of acidic ionized water at the low-temperature infiltration part. Compared with the background art, the cocoon cooking method has the advantages that a water molecular cluster of the alkaline ionized water is small, the surface tension is small, the infiltration is strong, the water is easy to enter an adhesive part of silk glue, so that the infiltration on a cocoon shell is uniform to be beneficial to improving the clean index of the raw silk; and as the silkworm cocoon subjected to the vacuum infiltration is impregnated by utilizing the acidic ionized water, the surface of the silkworm cocoon subjected to the vacuum infiltration is converted from alkalescence to neutrality or weak acidity so as to be beneficial to reducing the silk glue melting loss on the outer layer of the silkworm cocoon, thereby the cohesion indicator of the raw silk is improved. The cocoon cooking method has the advantages of simplicity, environment friendliness and no pollution.

Owner:ZHEJIANG JIAXIN JINSANTA SILK KNITTING +1

Method for preparing natural functional silk by utilizing living silkworms to directly spin

InactiveCN102677182ASpecial functionalitySimple and fast operationAnimal feeding stuffSilk filament obtainingNatural productFood science

The invention relates to a method for preparing natural functional silk by utilizing living silkworms to directly spin. The method comprises the following steps: applying functional materials on mulberry leaves through spraying or coating to obtain functional mulberry leaves; and feeding silkworms with the functional mulberry leaves and utilizing the silkworms to directly spin, thus obtaining the natural functional silk. The method has the following beneficial effects that the method is simple and convenient to operate, is simple, is low in production cost and can be used for large-scale production; and the obtained natural functional silk is a natural product, retains the characteristics of natural silk, is harmless to human bodies and simultaneously has special functionality.

Owner:DONGHUA UNIV

Clean silkworm cocoon cooking method

ActiveCN106012037AGood relaxing effectQuality improvementSilk filament obtainingVacuum pressureMicrowave

The invention discloses a clean silkworm cocoon cooking method. The method comprises the following steps: putting selected silkworm cocoons in a home-made soaking agent to be soaked, then washing the silkworm cocoons with clear water and drying the silkworm cocoons by microwave and far infrared optical wave and then sending the silkworm cocoons to be directly steamed; putting the silkworm cocoons in a vacuum cocoon cooking permeator after direct steaming is completed, adding proper amount of unwinding agent, controlling the water temperature at 30-50 DEG C, carrying out vacuum permeation, and when the vacuum pressure is -0.1Mpa, taking out the silkworm cocoons to enter the next cocoon cooking procedure after continuing for 1-5 minutes, after cocoon cooking is completed, putting the obtained silkworm cocoons in a fast freezing tank at 23 DEG C to be fast frozen for seven hours, then putting the silkworm cocoons in an environment at minus 10.5 DEG C and with vacuum degree of 270pa to be sublimated for 230 minutes and sending the silkworm cocoons to a silk reeling workshop. The method has the beneficial effects that by adopting the cocoon cooking method to cook cocoons, the obtained cooked cocoons have high silk yields and good quality; the quality indicator levels of the cooked cocoons are greatly improved; the cleaning, strength and cohesion indexes are improved by more than or equal to one grade.

Owner:SHANGLIN ZHONGXING SILK

Method of manufacturing mind-calming silk quilt

The invention discloses a method of manufacturing a mind-calming silk quilt and relates to the silk processing field. The method comprises the steps of removing cocoon husks, cooking cocoons, reeling silk, drying, soaking, drying, swelling, drying and sewing; the husk cooking step comprises pouring 100 parts of clean water in a pot, adding 4-7 parts sodium bicarbonate and cooking cocoons for two hours; the soaking step comprises soaking cocoon husks and reeled silks with ethanol and liquor with lavenders, roses, cananga odoratas, vines of multiflower knotweed, rhizoma polygonati and cloves for 3-6 hours at the temperature of 38-45 degrees centigrade; the swelling step comprises mixing cocoon husks, ethanol, softening agent and swelling agent and sewing the reeled silks to form a needed shape. According to the method of manufacturing the mind-calming silk quilt, in the coordination of lavenders, roses, cananga odoratas, vines of multiflower knotweed, rhizoma polygonati and cloves, humans' sleeping quality can be improved effectively; moreover, the quilt has a delicate fragrance, is capable of removing miscellaneous smell of silks during silk extraction, is soft and breathable and ensures users' comfort and health.

Owner:安徽省广德新丰丝绸有限公司

Method for producing silk mask base cloth through cocoons and silk mask

ActiveCN104611838AThin and hiddenKeep aliveAnimal materialSilk filament obtainingAcetic acid solutionSericin

The invention discloses a method for producing silk mask base cloth through cocoons. The method comprises the following steps that (1), cocoon washing is performed, namely, the cocoons are washed with clean water to remove dust and debris; (2), wetting is performed, namely, the washed cocoons are soaked in water to be sufficiently wet; (3), alkali soaking is performed, namely, the wet cocoons are evenly placed in a steaming barrel, and alkali water which can right wet the cocoons is sprayed on the cocoons so that the cocoons can be wet again; (4), steaming is performed, namely, the cocoons are steamed with steam so that sericin can be completely swollen; (5), washing is performed, namely, the steamed cocoons are washed with clean water; (6), cocoon peeling is performed, namely, pupas are peeled off; (7), the cocoons with the pupas peeled off are made into arc-shaped silk net films; (8), the silk net films are bleached, neutralized with a glacial acetic acid solution, dried and finally stamped to form the silk mask base cloth. By means of the method, the activity of the sericin can be maintained to the maximum degree. The technological process is simple, the nutrients of silk can be sufficiently utilized, and the silk mask base cloth is a pure natural skin-whitening, moisturizing, anti-wrinkling and UV-resisting product.

Owner:SOUTHWEST UNIVERSITY

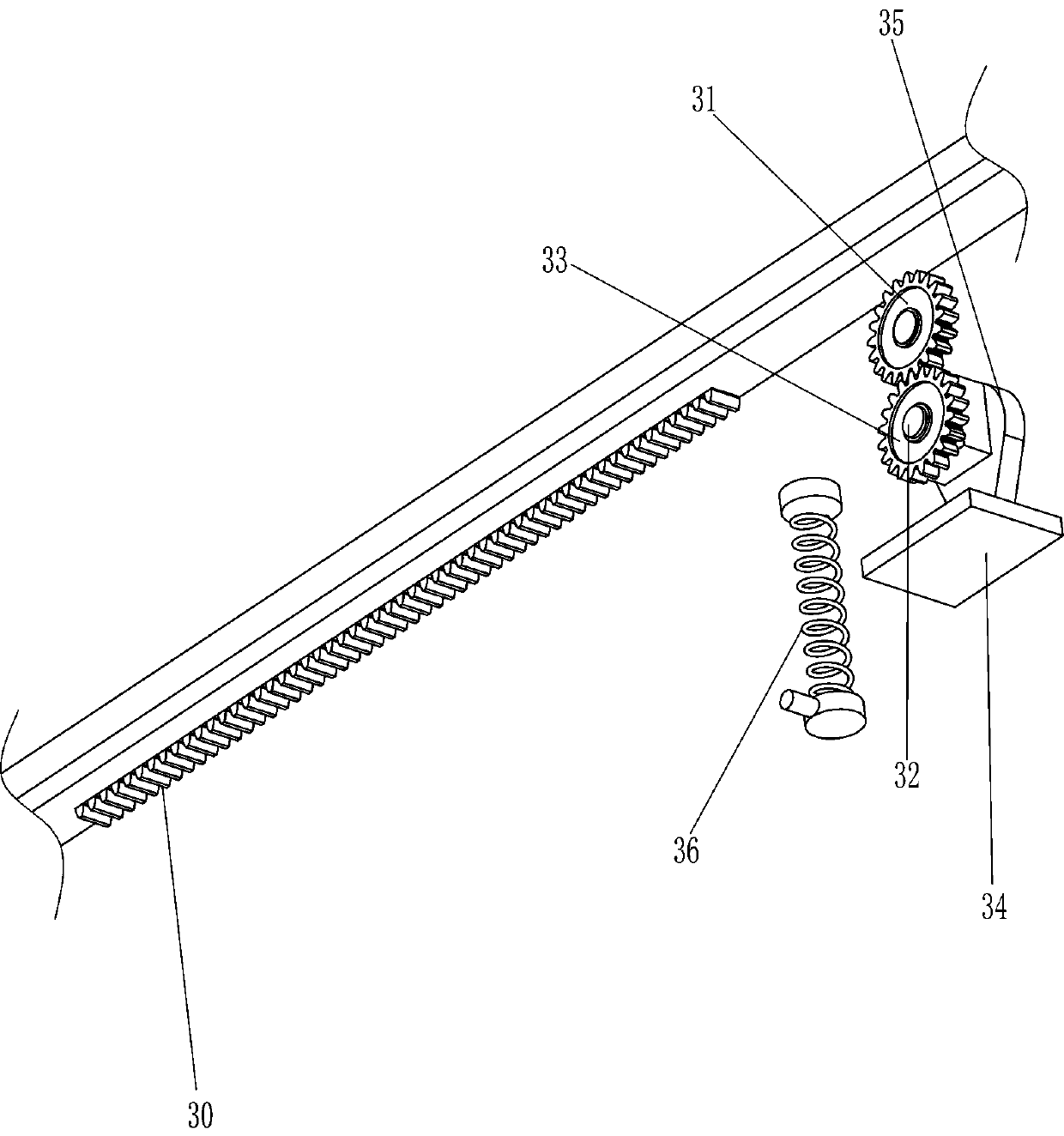

Batch silkworm cocoon removing machine for silk processing

ActiveCN110923822AShorten the timeFall off completelySilk filament obtainingProcess engineeringMechanical engineering

The invention relates to a batch silkworm cocoon removing machine, and in particular relates to a batch silkworm cocoon removing machine for silk processing. The invention aims at providing the batchsilkworm cocoon removing machine which has the advantage that silkworm cocoon on a cocooning frame can be completely taken out at one time, and thus time can be saved. The batch silkworm cocoon removing machine for silk processing comprises a bottom plate, first brackets, a frame body and the like, wherein the first brackets are fixedly connected to two sides of the top of the bottom plate, and the frame body is fixedly connected to the end parts of the first brackets on the two sides. Through a cocoon removing assembly, the cocooning frame in a placing frame can be subjected to cocoon removing, silkworm cocoon on the cocooning frame falls onto the bottom plate, so that all the silkworm cocoon on the cocooning frame can be taken out at one time, then time can be saved, through a scraper blade, residual silkworm cocoon on the cocooning frame can be scraped off, then the silkworm cocoon on the cocooning frame can fall off thoroughly, and under the effect of a discharging hopper, people can collect silkworm cocoon conveniently.

Owner:浙江华锋丝业股份有限公司

Preparation method of skin care fabric capable of caring whole body skin

ActiveCN105200801AImprove wear resistanceReduce accidental draftCosmetic preparationsToilet preparationsFiberFully developed

The invention discloses a preparation method of a skin care fabric capable of caring the whole body skin. The product takes silk fibroin, pearl powder, olive oil and vitamin A which are commonly used in a facial mask as core materials; after being enzymolyzed by alkaline protease, the silk fibroin is embrittled and can be ground into micron-grade powder conveniently; then the fibroin powder, the pearl powder, vitamin A and a small amount of olive oil are used as the core materials, and edible gelatin is used as a wall material, thus preparing a beautifying-gold-apsule which is wrapped by a acrylate thin film; the fabric is finished. The skin care fabric has a durable nutritional skin care effect, and fully develops the excellent characteristics that wool is warm, skin-friendly, flexible, elastic and smooth; therefore the skin care fabric is comfortable to wear, washable, nutritional, skin-friendly, moisture-maintaining, soft in handfeel, warm and breathable, and is a first clothing choice of making closed-fitting clothes of women.

Owner:JIANGSU JIANLU WOOLEN

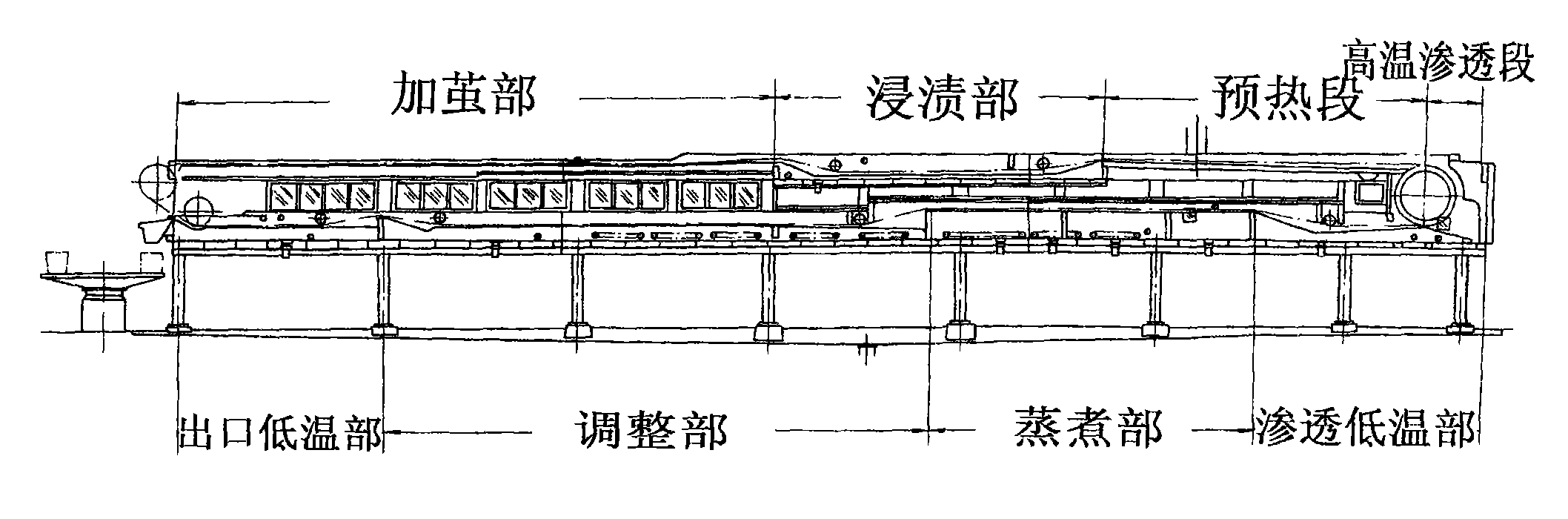

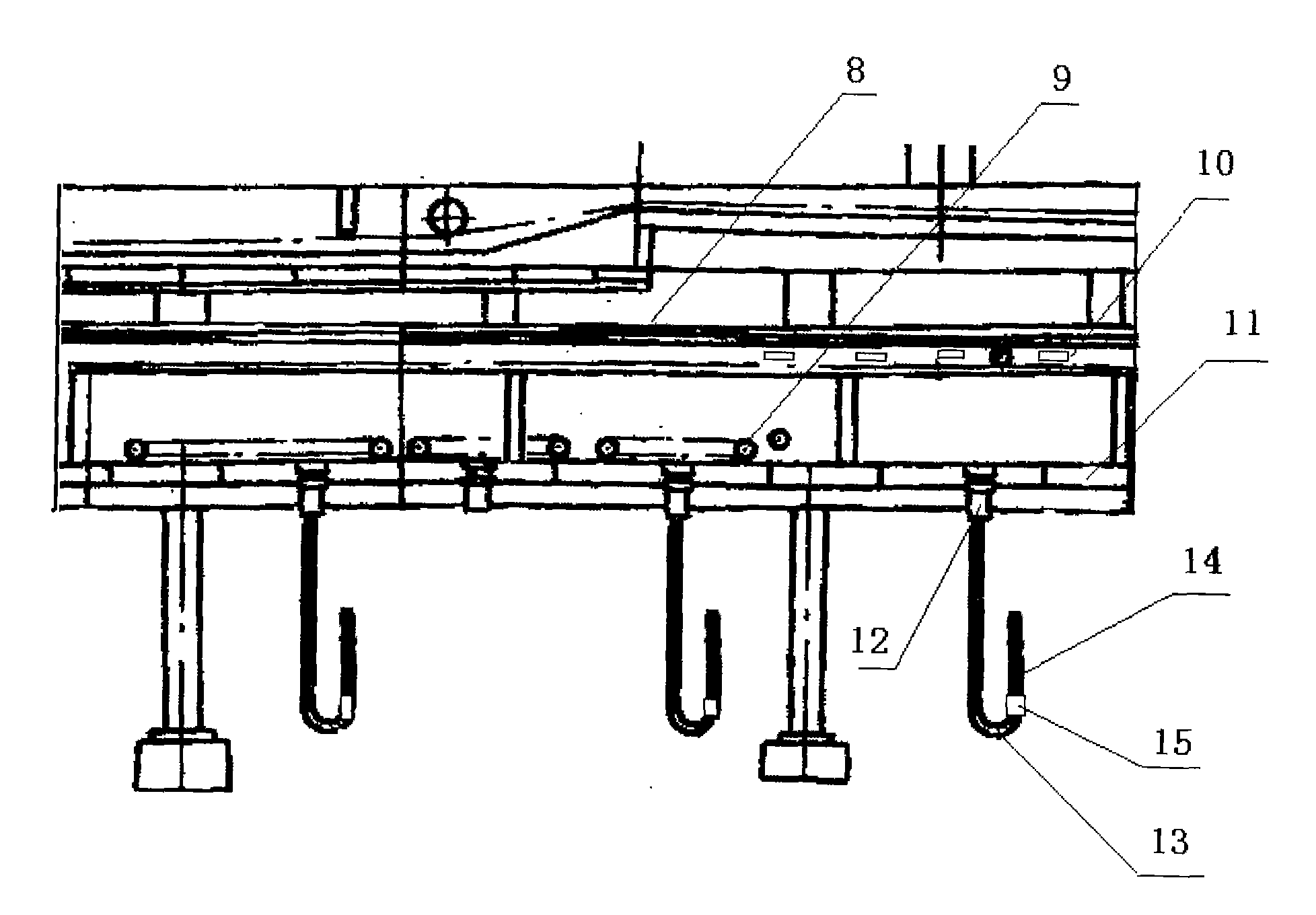

Steam cooking process for cocoon cooking and device thereof

InactiveCN101638809ACocoon cooking temperature increasedIncrease the maximum temperatureSilk filament obtainingStraight tubeSteam cooking

The invention discloses a steam cooking process for cocoon cooking and a device thereof, and particularly relates to a temperature adjustment method of a steam cooking part of a cocoon cooking machinewhich is capable of effectively improving cooking uniformity of silkworm cocoons and a device thereof. The length of the steam cooking part of the cocoon cooking machine provided by the invention is15.5 cages and the steam cooking part is divided into 2-5 sections for respectively arranging a heater and a pressure unit; bottoms of various sections of the steam cooking part are respectively provided with a drain outlet which is connected with a drain tube (12); and the pressure unit is connected with the drain tube by one end of a U-shaped tube (13), and the other end of the U-shaped tube isconnected with a straight tube (14) with the height of 250mm-1000mm. The pressure unit is capable of effectively improving pressure of the steam cooking part and raising the maximum temperature of thesteam cooking part by more than 0.5 DEG C. The method can help greatly reduce dropping end rate of inner layers of the cooked silkworm cocoons, facilitate the cooking uniformity of the silkworm cocoons and improve reelability percentage of raw silkworm cocoons. The device has advantages of simple structure and low manufacturing cost, and being capable of reconstructing the existing cocoon cookingmachine and facilitating popularization and application.

Owner:SUZHOU UNIV

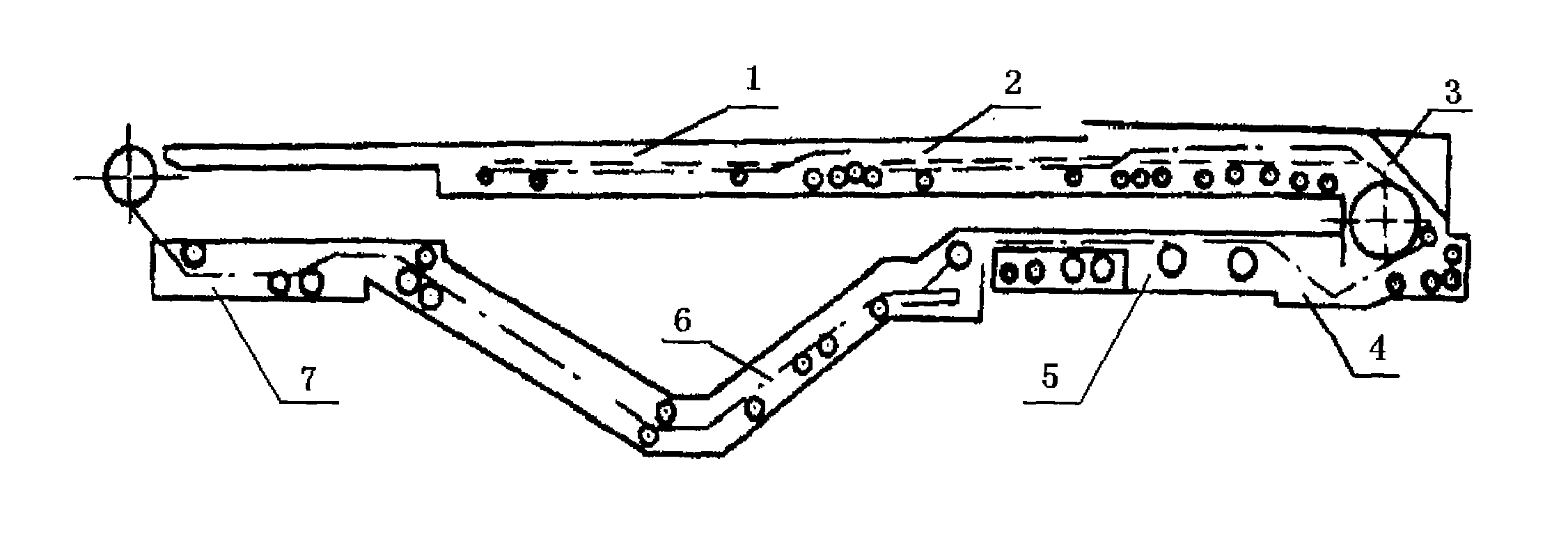

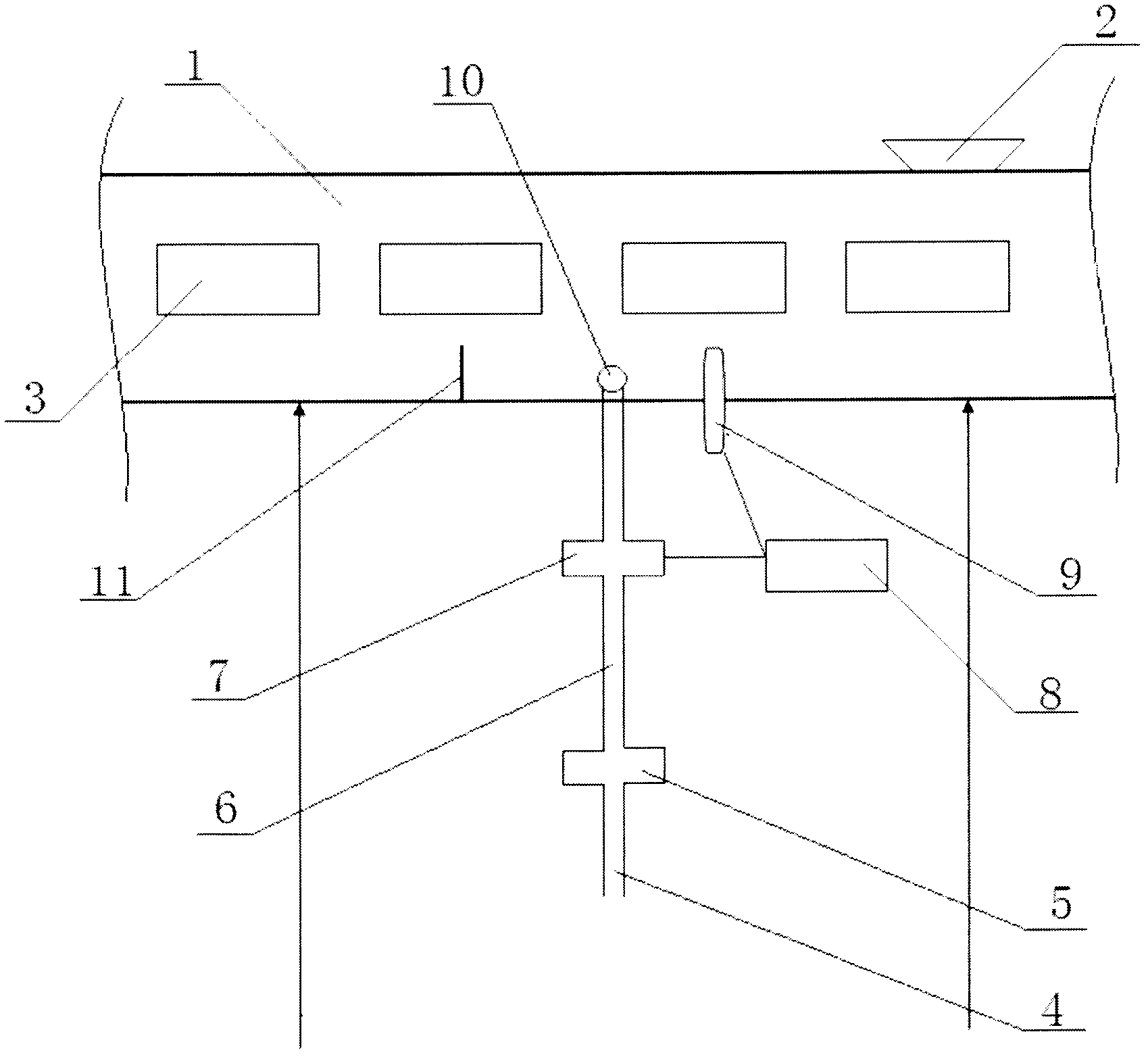

Method for direct silk drawing and beam collection from matured silkworm spinneret orifices and equipment thereof

ActiveCN106544740ASimple methodEasy to operateTextile/flexible product manufactureSilk filament obtainingEngineeringMechanical engineering

The invention provides a method for direct silk drawing and beam collection from matured silkworm spinneret orifices and equipment thereof. The equipment comprises a matured silkworm silk drawing device, a silk collecting hole, an infrared drying device, a rotating silk winding device and a headstock. The method comprises the following steps of (1) putting the matured silkworms about to spin into silk drawing rooms; covering back covers; (2) respectively drawing silk from the spinneret orifices of the matured silkworms in each silk drawing room; passing the silk through the silk collection hole, the infrared drying device and a moving silk guiding hook to be wound onto a silk rolling roller; then, turning on the infrared drying device for drying. A miniature motor arranged on the rotating silk winding device is started; the silk rolling roller is driven to rotate and complete the silk winding; the rotating wire winding device is provided with a guide rod; a moving silk guide hook is arranged on the guide rod and can do reciprocating movement on the guide rod to form the uniform package. The rotating silk winding device can rotate through being driven by a variable-frequency motor, and the silk can be properly twisted, so that the beam collection is convenient.

Owner:射阳县华宏丝绸有限公司

Method for pretreating fresh cocoon

InactiveCN101509150AAlleviate the problem of tight drying timeIncrease release rateSilk filament obtainingPretreatment methodDrying time

The invention discloses a pretreatment method for fresh cocoons, comprising the following steps: the fresh cocoons purchased from a cocoon station are fed into a conveyer belt before moths flying out; the conveyer belt brings the cocoons to the temperature of minus 2-minus 4 DEG C; after 0.15-0.75 hour, the cocoons are brought to the temperature of minus 5-minus 18 DEG C by the conveyer belt; after 2-48 hours, the cocoons are brought to the temperature of 0-4 DEG C by the conveyer belt; after 0.15-0.75 hour, the cocoons are brought to the normal temperature by the conveyer belt for 2-30 hours of natural balance; and then normal hot air drying or superheated steam drying is carried out. The invention adopts a dynamic freeze pretreatment and the pretreatment can be carried out continuously; after the fresh cocoons are pretreated, silkworm pupa can be killed, limited cocoon drying time can be relieved, in particular, the reliability percentage is enhanced, and the rushing-upon frequency per 10000m can be reduced; and damage of inner cocoon layers caused by the fact that immature cocoons are activated by heating in the cocoon drying process can be reduced.

Owner:ZHEJIANG SCI-TECH UNIV

Manufacturing method of Humian silk quilt

InactiveCN102370389ASilky and suppleStrong toughnessSilk filament obtainingBed-coversWaddingEngineering

The invention relates to a manufacturing method of a Humian silk quilt. The method comprises the following unique techniques of boiling cocoons, stripping cocoons, putting the stripped cocoons on a tambour, opening the cocoons, tearing silk wadding, and twisting silks in mesh shapes, and inspecting the silk wadding. The silk quilt manufactured by the method provided by the invention is soft, delicate and smooth in silk, strong in fiber flexibility and mesh forming degree, uniform in thickness, and is puffy and soft, and moreover, the silk quilt is not deformed, shortened, out of joint, frizzed after a long-term use, and is not required to be detached and revamped.

Owner:昭通市张蝴绵蚕丝制品有限公司

Method for producing washable fresh silkworm cocoon silk floss winter coat

InactiveCN104195647ASimple processing methodSimple equipmentSucessive textile treatmentsSilk filament obtainingBiologic ProductsBiological product

The invention discloses a method for producing a washable fresh silkworm cocoon silk floss winter coat. The method for processing silk floss winter coat raw materials through silkworm light defective cocoons includes the following steps of fresh cocoon treatment, alkali soaking, cocoon silk stripping, washing and dewatering, dipping in a degumming agent, washing and dewatering, dipping in a softening agent, dipping in silk protective essence, washing and dewatering, and drying. According to the method for processing the silk floss winter coat raw materials through fresh silkworm cocoons, the high-quality silk floss winter coat and fresh pupas are acquired, processed silk floss is soft and clean, the processing method and equipment are simple, production efficiency is high, production cost is low, the quality of the fresh pupas is good, and the pupas are good raw materials of food and biological products.

Owner:YIZHOU ZHUANGGE SILK

Circulating cocoon cooking machine

InactiveCN102321924AEnhance resistance to boiled cocoonsGood reliefSilk filament obtainingTemperature controlPipe fitting

The invention discloses a circulating cocoon cooking machine, which comprises a frame, a shell, a cocoon feeding part, a low-temperature part, a cooking part, a regulating part and an outlet part. A set of soup surface sprinkling device is arranged in front of the regulating part with a distance of 400-500 mm from a clapboard of a cooking room; the sprinkling device comprises a tap water switch, a solenoid valve, a temperature controller, a temperature control probe, a sprinkling pipe and pipe fitting, and the assembly sequence of all the members is as follows: the front end of the solenoid valve is connected with the tap water switch and the back end of the solenoid valve is connected with the sprinkling pipe; a coil of the solenoid valve is connected with the control output of the temperature controller and the temperature control probe is connected with a signal input end of the temperature controller; when the temperature is higher than a design temperature, the solenoid valve is automatically opened; when the temperature is lower than the design temperature, the solenoid valve is automatically closed; the surface of the sprinkling pipe is provided with two rows of holes, wherein one row of the holes are vertical to the soup surface and the other row of the holes are inclined to form an angle of 30-45 DEG in the direction which is opposite to the forward motion direction of a cocoon cage. According to the circulating cocoon cooking machine disclosed by the invention, the reelability percentage can be improved and rushing upon cocoons per 10000m can be reduced by about 2%; meanwhile, the yield and the quality of the cocoons are improved, the raw cocoon consumption is reduced, and the energy consumption is saved.

Owner:JIUJIU SILK CO LTD

Fiber having increased filament separation and method of making same

ActiveUS20060051574A1Improved filament separationImprove the immunitySevering to form staple fibresSilk filament obtainingPolymer scienceCarbon fibers

A flock material exhibiting an increased degree of filament separation prepared by cutting a fluoropolymer or carbon fiber yarn into lengths, introducing mechanical energy into the lengths in order to cause the lengths to separate into single-filaments fibers and removing or classifying at least a portion of the single-filament fibers from the lengths in order to obtain a flock having a particular fraction of single-filament, fluoropolymer or carbon fibers.

Owner:TORAY FLUOROFIBERS AMERICA

Storage method for bombyx mori cocoons

InactiveCN102605435AReduce cost inputEasy technical handlingSilk filament obtainingBombyx moriSaline solutions

The invention discloses a cold storage method for bombyx mori cocoons, which is characterized in that the cold storage method comprises the following steps of: collecting the bombyx mori cocoons mounted for 5-7 days, soaking the bombyx mori cocoons in saline solution with the concentration of 15-25% for 24-72h, and taking out the bombyx mori cocoons for natural dehydration to air drying; and in the soaking process, the bombyx mori cocoons are lifted every other 12h, and then immersed again. Compared with the prior art, the storage method has the advantages that the input cost is low, the technical processing is convenient, the reelability can be improved, the raw silk grade is increased, the production cost is lowered, and the shortage of labor is reduced.

Owner:如皋市蚕桑技术指导站

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com