Circulating cocoon cooking machine

A cocoon cooking machine and circulating technology, which is applied in mechanical processing, silk fiber production, textiles and papermaking, etc., can solve the problems of cleaning and cleaning not meeting customers, not being able to adapt to production requirements, increasing filament failures, etc., and achieving enhanced The effect of cocoon cooking resistance, reducing inner thread loss, and improving economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is realized in the following manner.

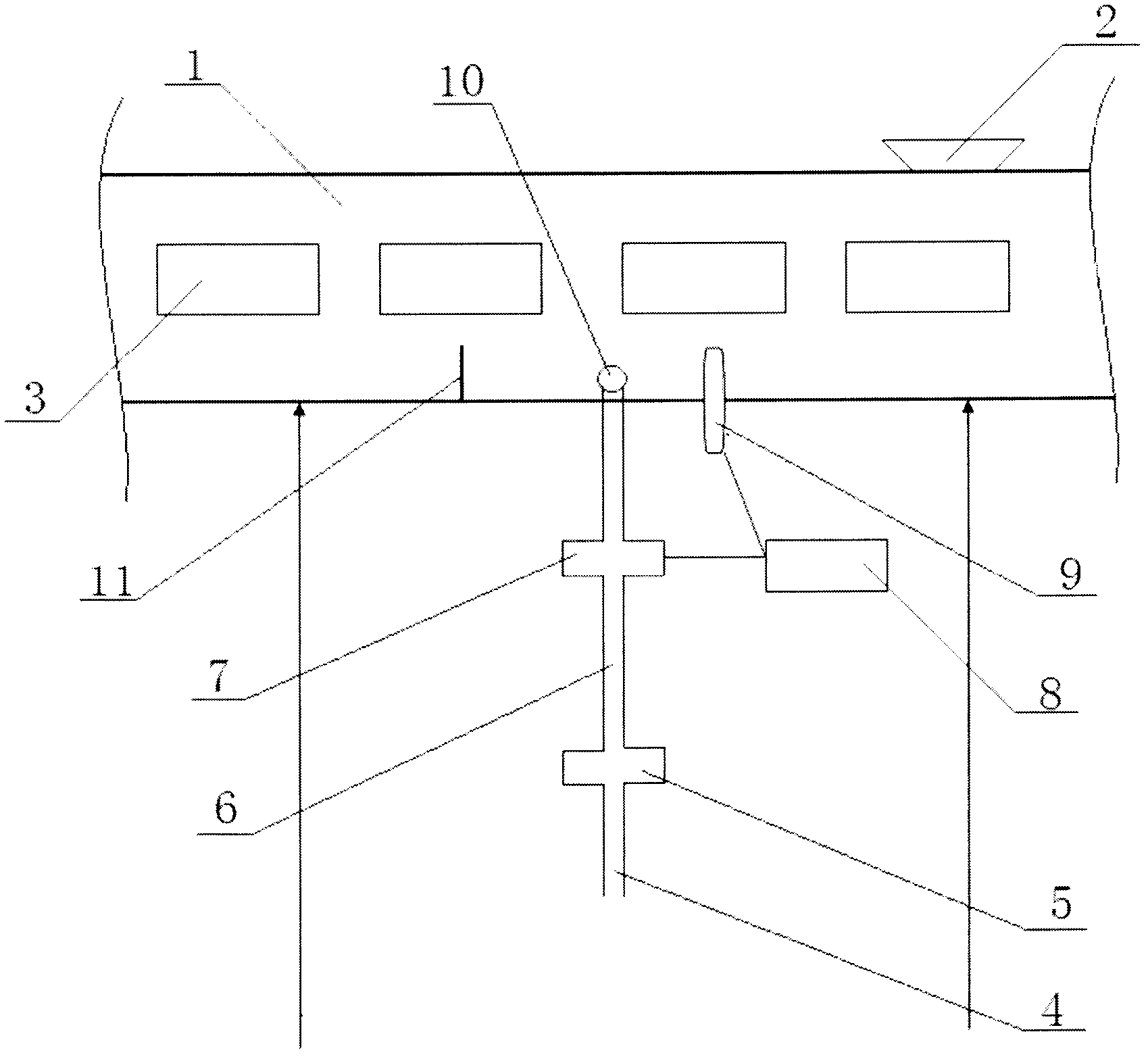

[0021] like figure 1 Shown: a noodle soup sprinkling device is installed at the rear 450mm of the cooking chamber partition 11, and the sprinkling device includes a solenoid valve 7, a temperature controller 8, a temperature control probe 9, a tap water switch 5, a water sprinkling pipe 10, a water inlet pipe 4 and The assembly sequence of the water pipe 6 is as follows: the front end of the solenoid valve 7 is connected to the tap water switch 5 through the water pipe 6, the rear end is connected to the sprinkler pipe 10, the solenoid valve 7 is connected to the control output of the temperature controller 8, and the temperature control probe 9 is connected to the temperature controller. Connect to the input signal terminal of instrument 8. When the temperature is higher than the design temperature, the electromagnetic valve 7 is automatically opened, and when the temperature is lower than the design tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com