Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Solve heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick detecting method of edible vegetable oil quality

ActiveCN103245628ANot harmful to healthNo pollution problemPreparing sample for investigationColor/spectral properties measurementsVegetable oilHeating time

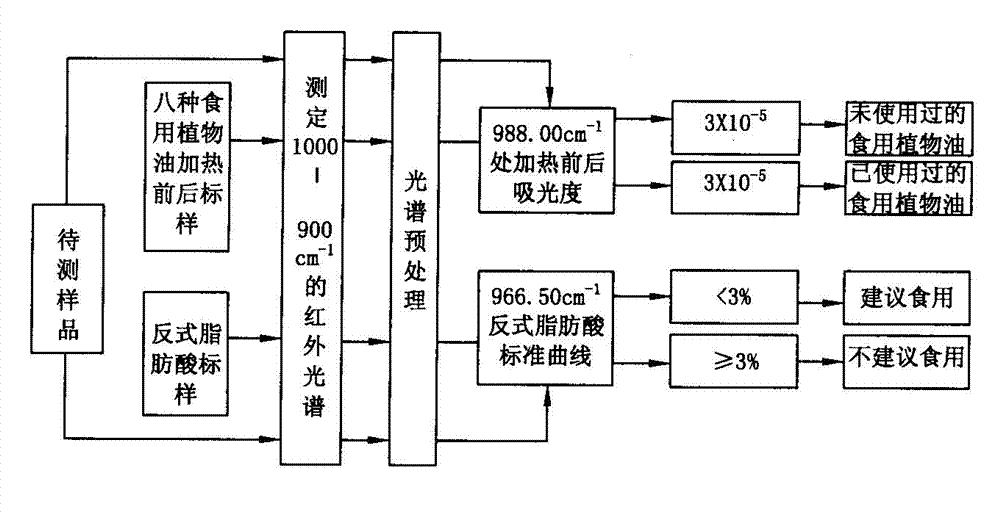

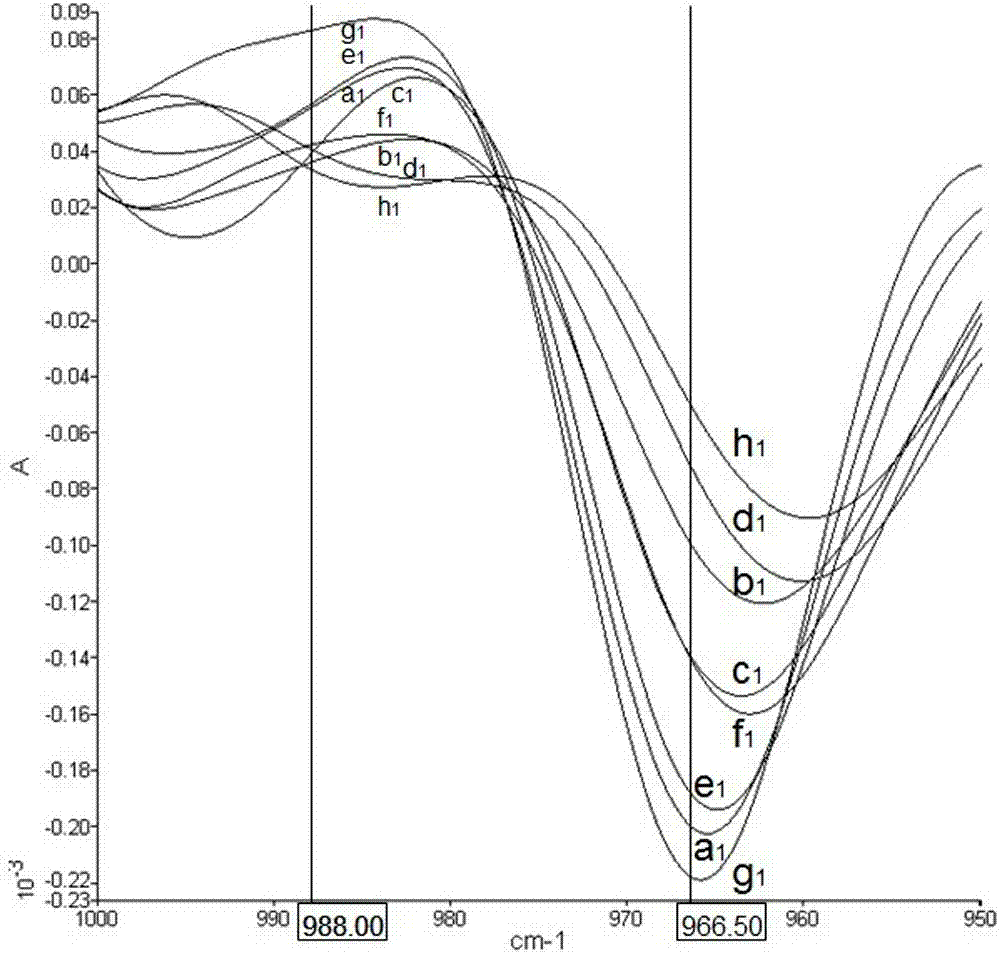

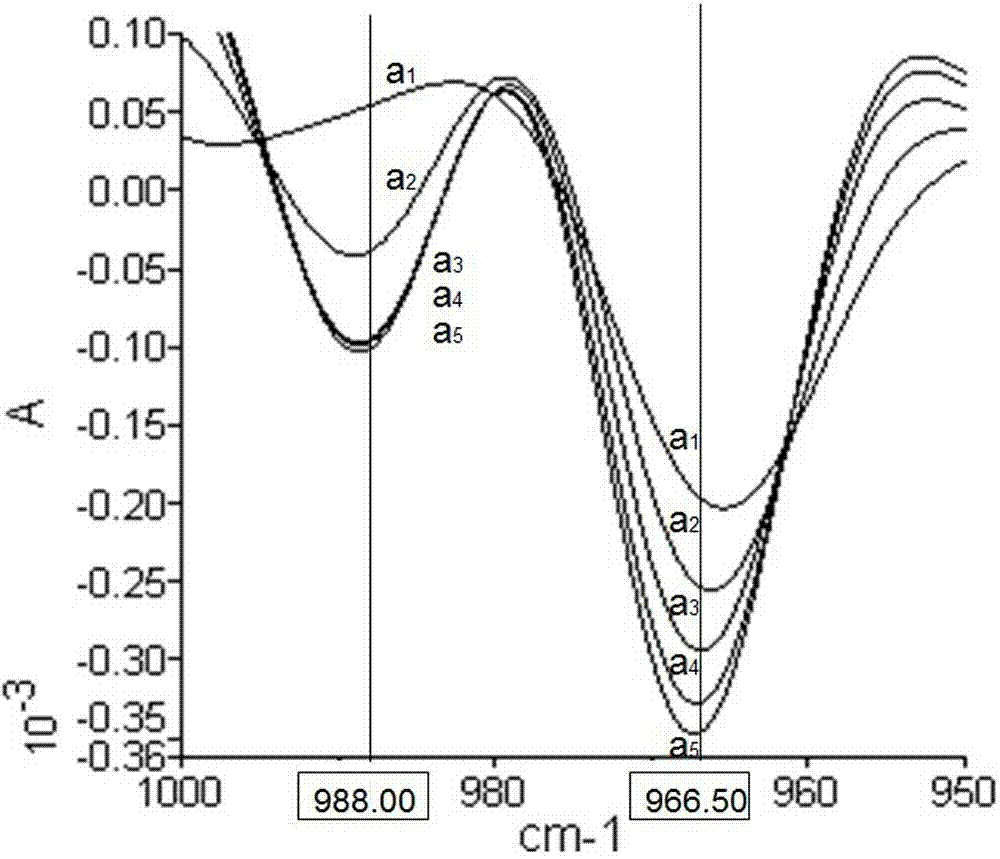

The invention discloses a quick detecting method of the edible vegetable oil quality through using an attenuated total reflection Fourier infrared spectroscopy, and the problems that the current detecting method can not verify whether the edible vegetable oil is repeatedly heated at high temperature or whether swill-cooked dirty oil is mixed in fresh edible vegetable oil can be solved. The method comprises the steps of: indicating the change of oil ingredients by fully utilizing the changes of the peak shape and the peak height of an infrared second derivative spectrometry; measuring the content of trans-fatty acids in the edible vegetable oil through absorbance of a characteristic absorption peak at 966.50cm<-1>; judging whether the edible vegetable oil is heated through the change of the characteristic peak at 988cm<-1>, and calculating the heating time; and determining whether the edible vegetable oil is swill-cooked dirty oil through the change of the characteristic absorption peak at 988cm<-1>. The quick detecting method of the edible vegetable oil quality is simple in operation, low in cost, free of pollution, high in detecting precision, and quick and accurate and can be capable of judging an edible vegetable oil sample to be detected which is repeatedly heated at the high temperature, the swill-cooked dirty oil and the swill-cooked dirty oil mixed in the fresh edible vegetable oil.

Owner:辽宁省分析科学研究院

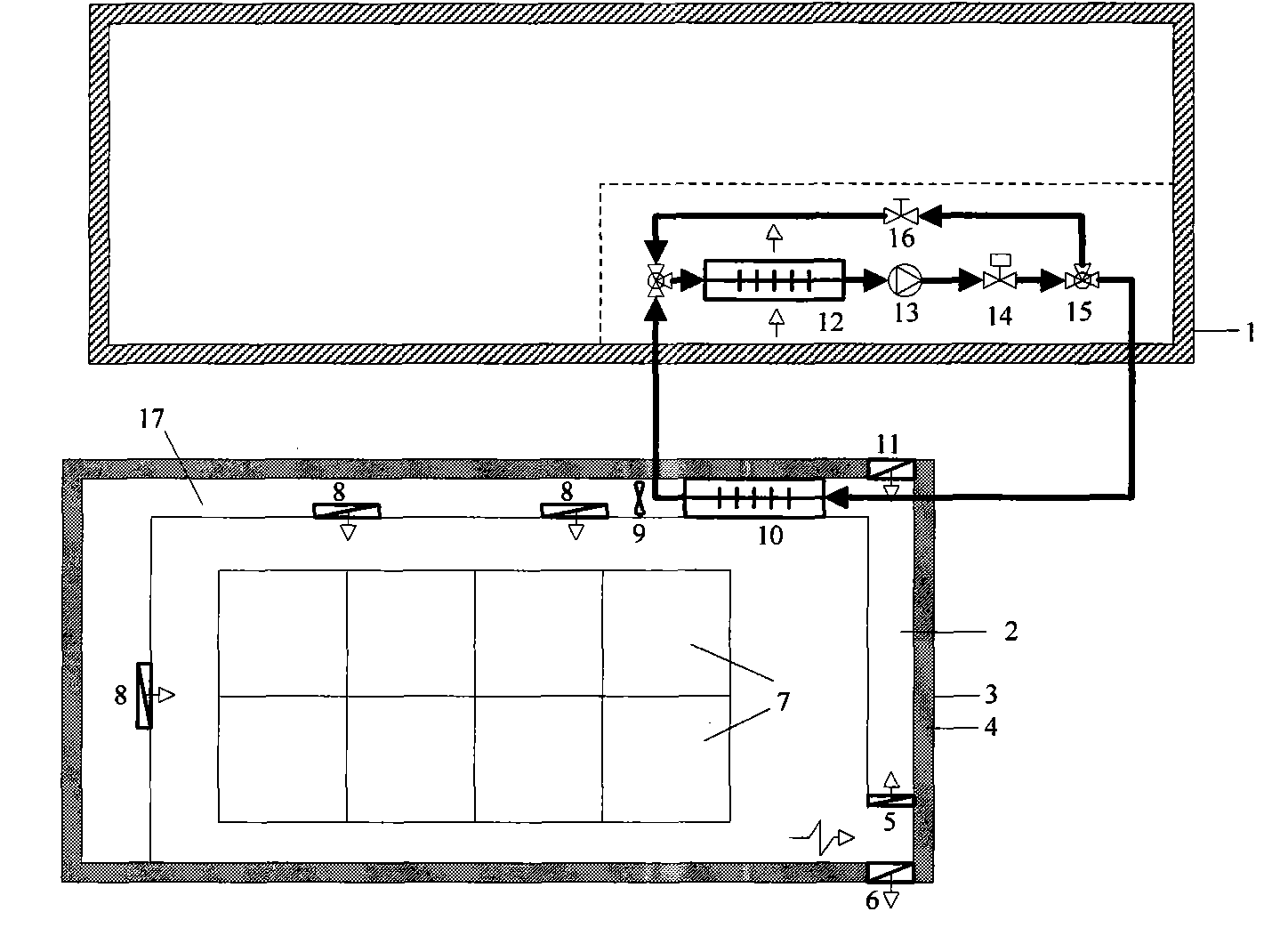

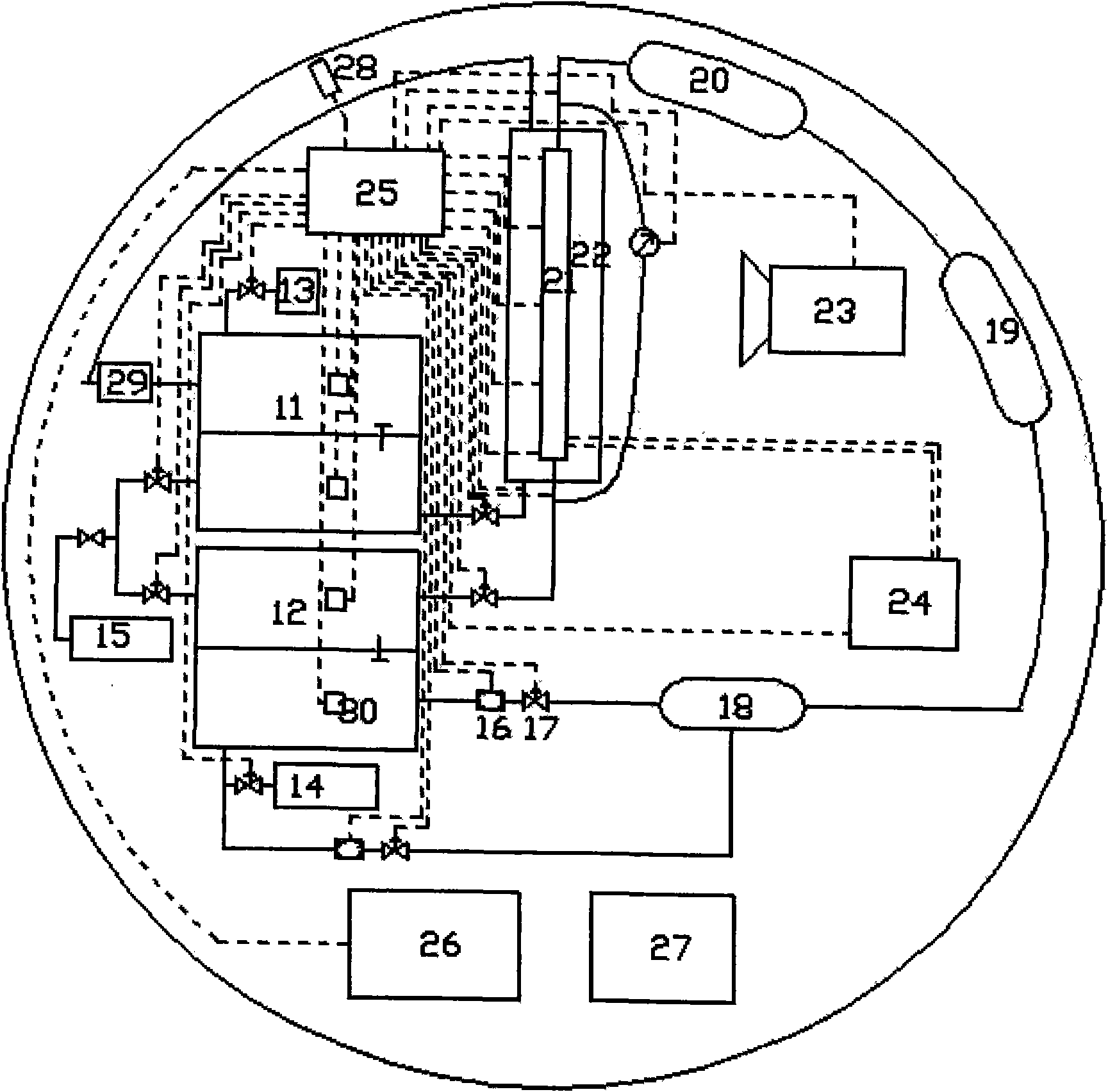

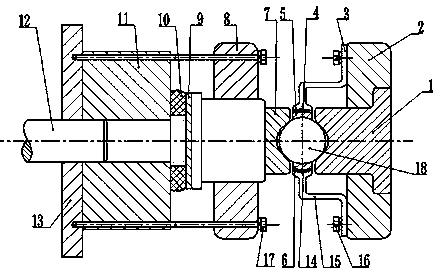

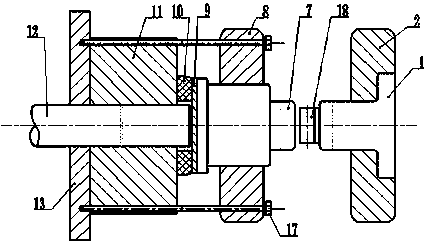

Two phase flow ground simulation test method and device under flight load function

InactiveCN101221086ARealize the ground experimentNot easy to damageHydrodynamic testingRotation velocityEngineering

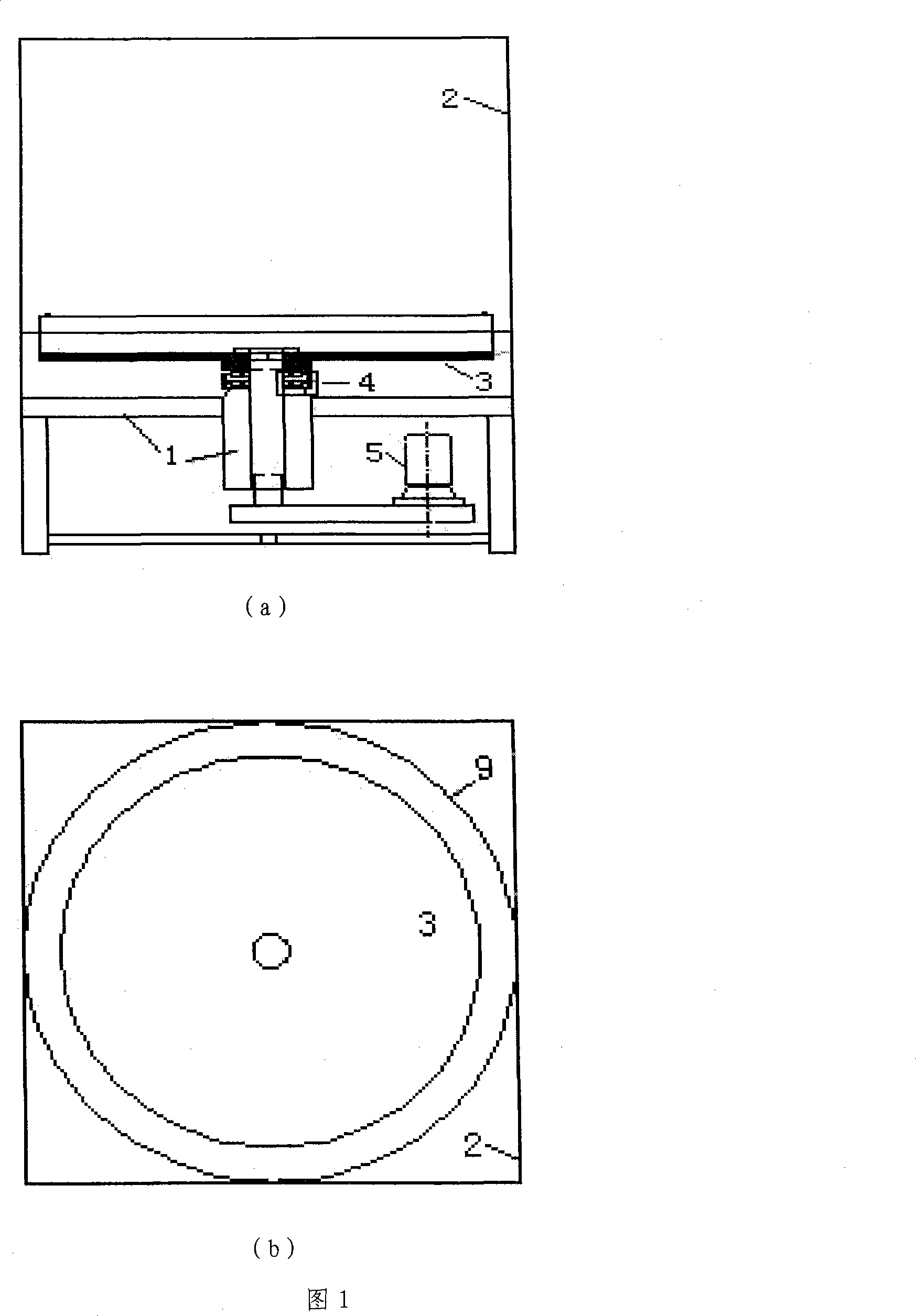

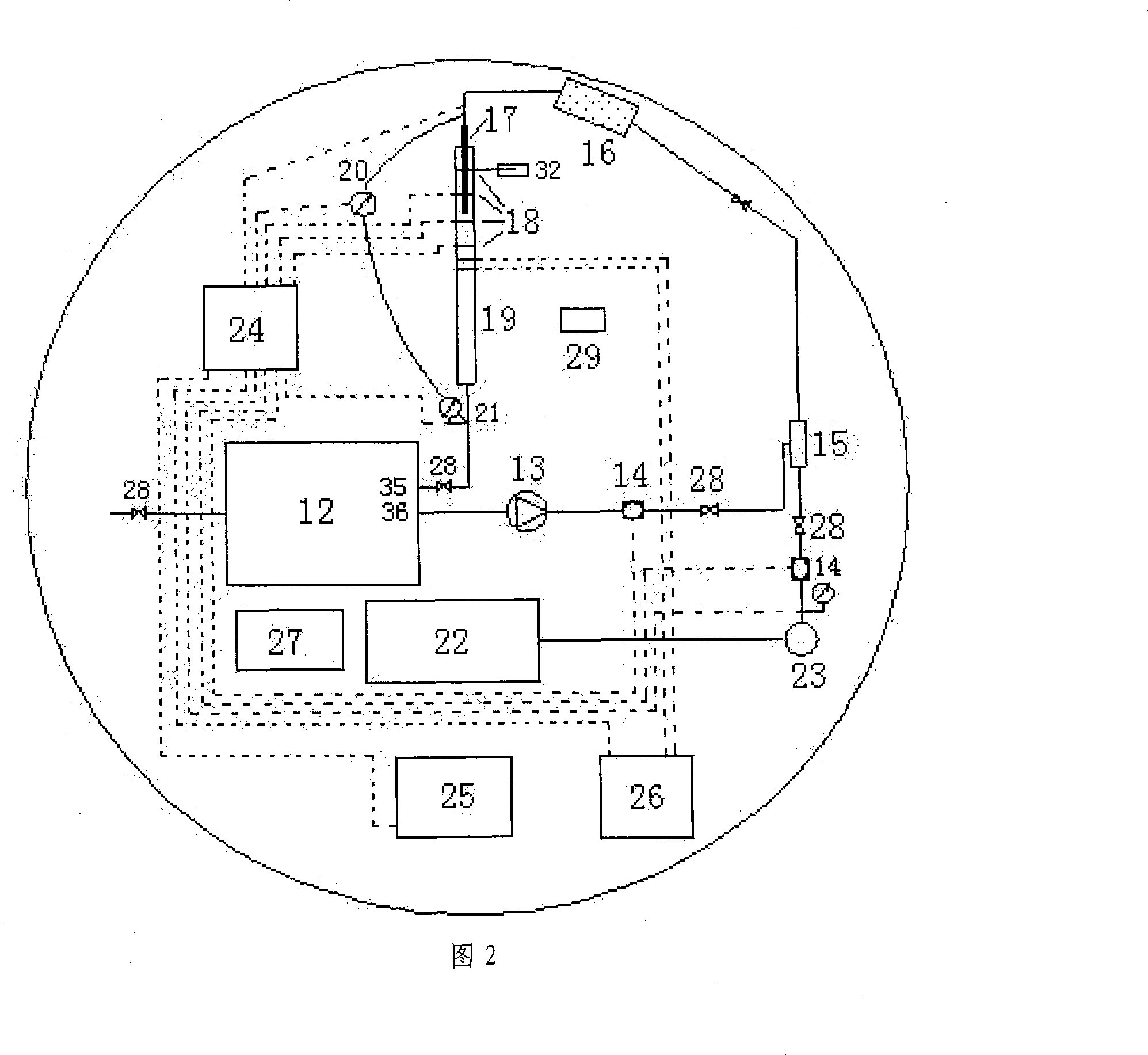

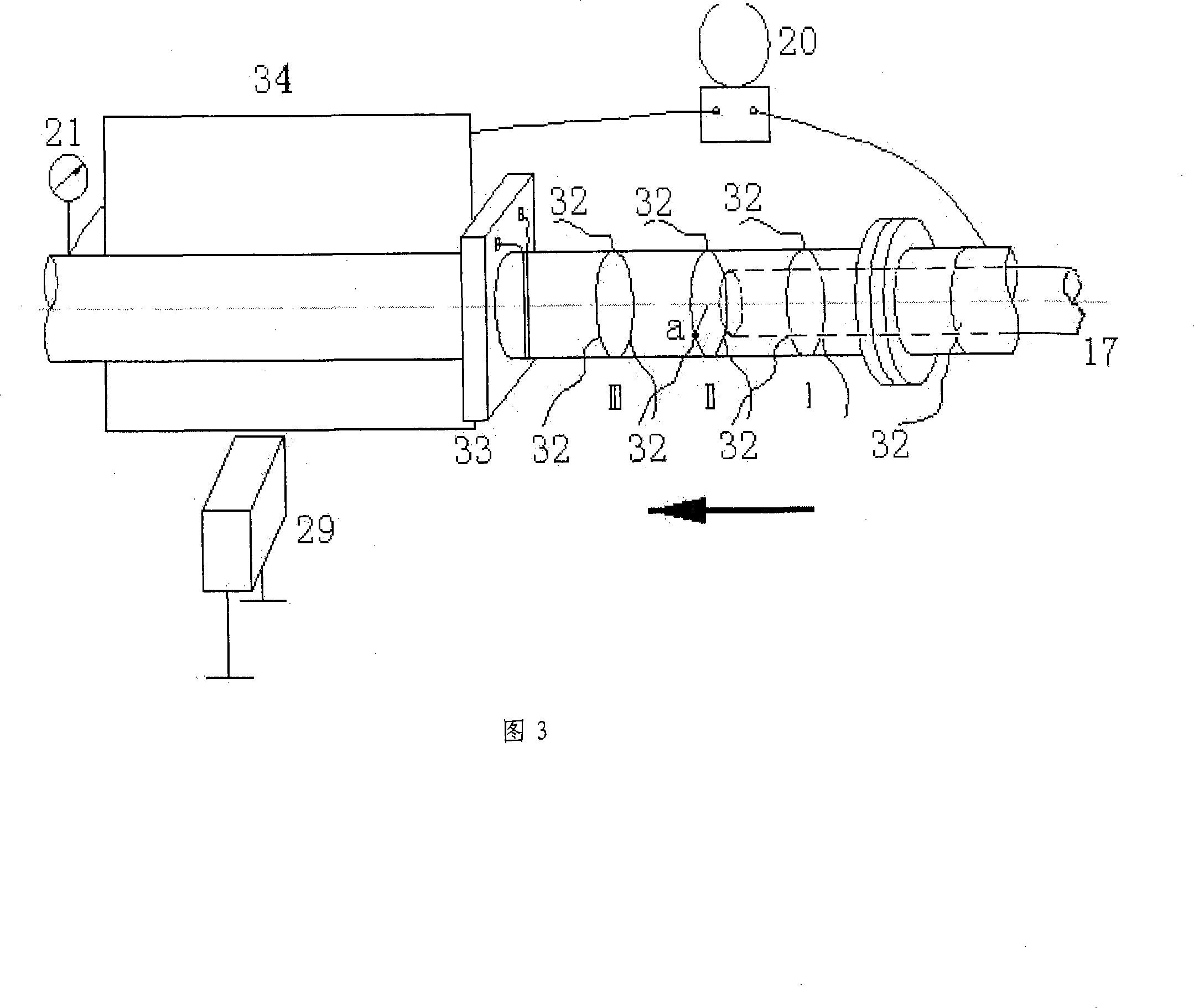

A two phase flow ground simulation test method and a device under a flying loading action belongs to the technical field of measuring two phase flow. The method utilizes a flying dynamic loading simulation platform to simulate the dynamic loading state of an airplane and acquires different centripetal accelerations through adjusting the rotary speed of a dial so as to simulate the flying loading state. The device consists of the flying dynamic loading simulation platform and a two phase flow test system; wherein, the two phase flow test system consists of a floating water circulating system, a liquid parameter measuring system and a data collecting and storing system. The method and the device can carry out the two phase flow ground simulation test under the flying loading action on the ground.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

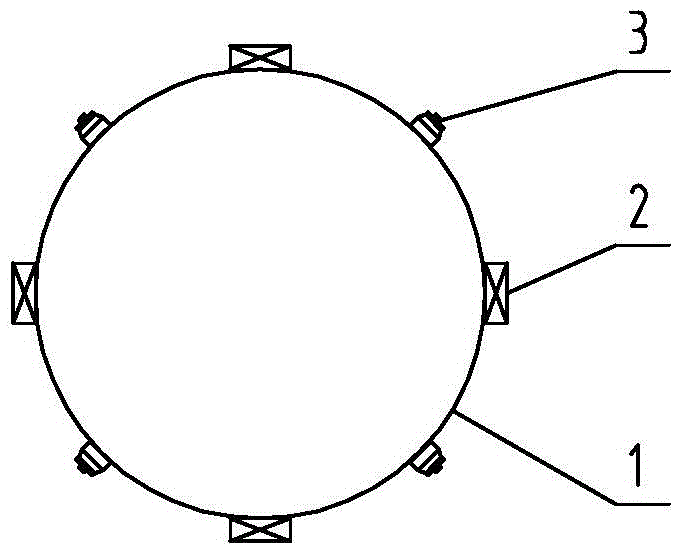

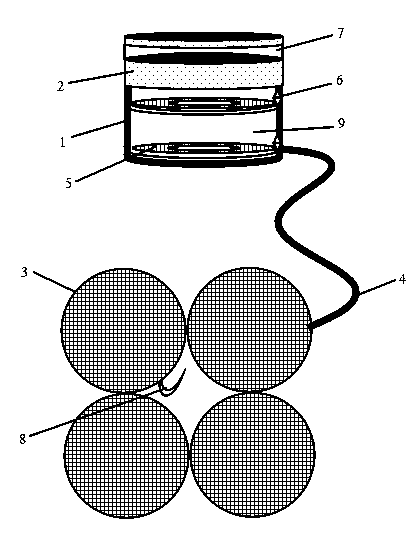

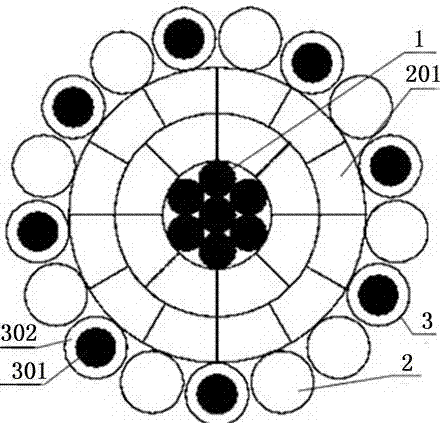

Microwave and ultrasonic wave assisted cocoon cooking device and method for cooking cocoons

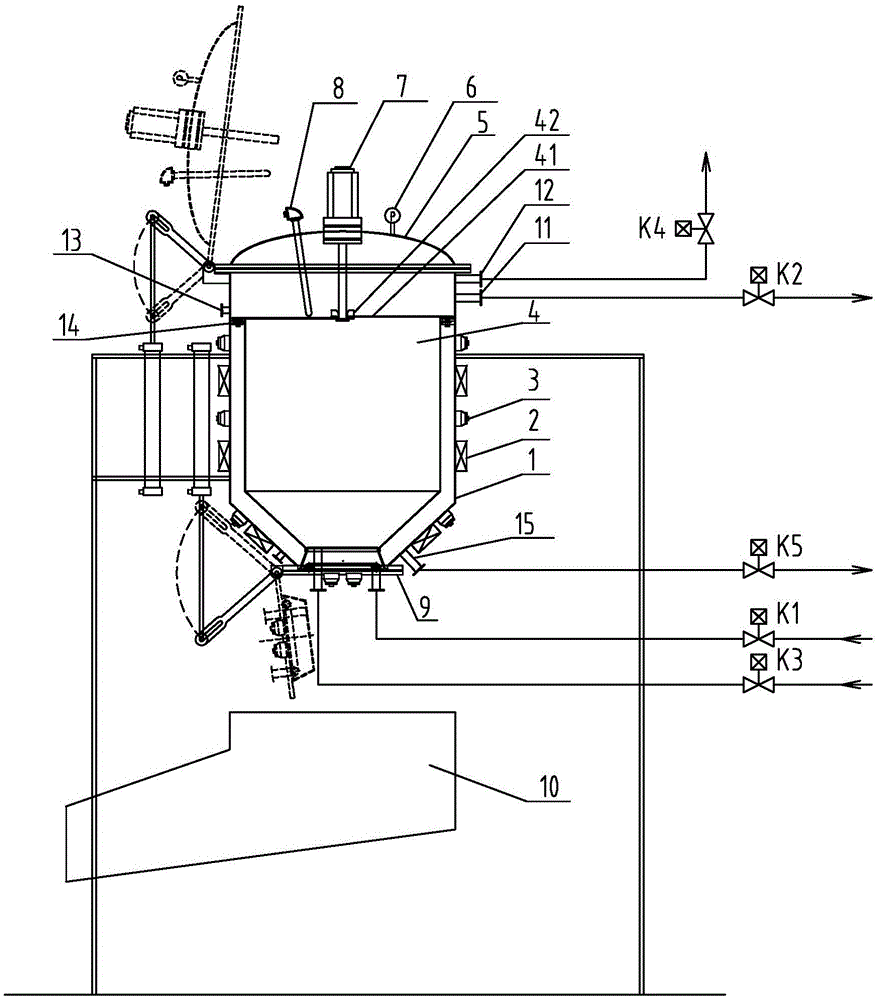

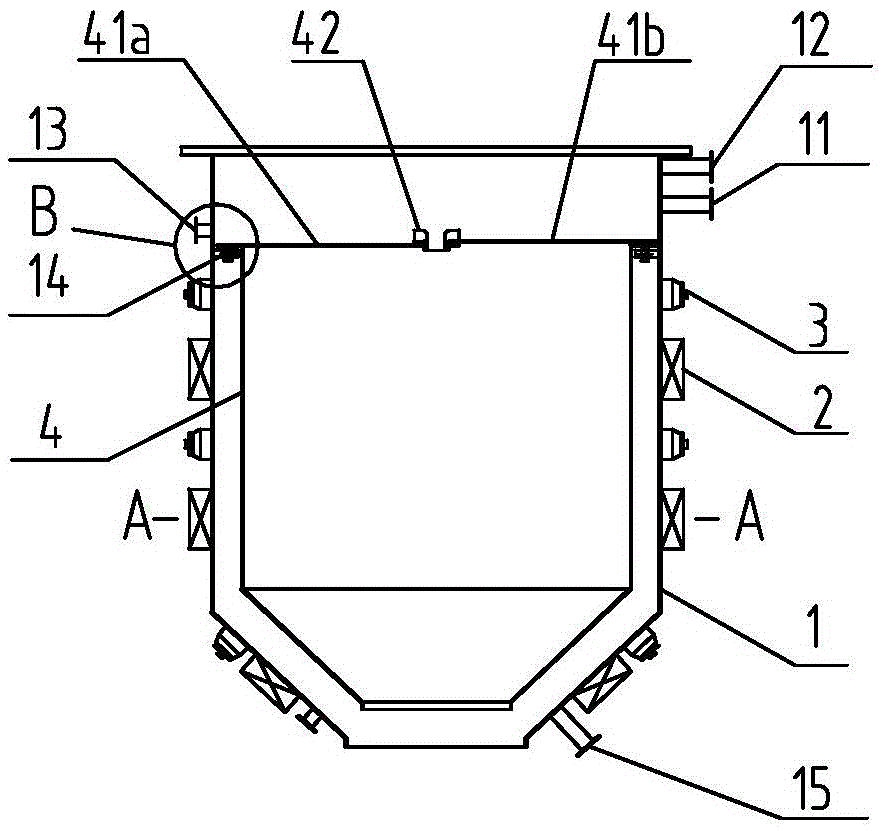

ActiveCN105648542ASolve for uniformitySolve heatingSilk filament obtainingUltrasonic assistedCoupling

A microwave and ultrasonic wave assisted cocoon cooking device comprises a cocoon cooking barrel outer drum, a microwave generator, an ultrasonic wave generator, a cocoon cooking barrel inner drum, an upper cover of the cocoon cooking barrel outer drum, a lower cover of a cocoon cooking barrel discharge opening, and a cocoon cooking barrel; a plurality of microwave generators and ultrasonic wave generators are distributed on the outer side of the cocoon cooking barrel outer drum; the cocoon cooking barrel inner drum is made of punching hole meshes or mesh materials, and a cover of the cocoon cooking barrel inner drum consists of two semi-circular sector cover plates made of punching hole meshes or mesh materials and connected through a coupling at the circle center; the cover of the cocoon cooking barrel inner drum can be opened or closed in a rotational manner; a pressure gage and a temperature measurer are mounted on the upper cover of the cocoon cooking barrel outer drum; the lower cover of the cocoon cooking barrel discharge opening is connected with a hot water inlet pipe and is equipped with a porous steam coil and the ultrasonic wave generator; the filature cocoon cooking device has a compact and reasonable structure and is high in integration, and a cocoon cooking of the device adopts a microwave assisted direct-streaming technology and an ultrasonic wave assisted cocoon cooking technology at the same time, so that inner, middle and outer layers of cocoons are heated uniformly, the energy is saved, the consumption is reduced, and the cocoon cooking is shortened.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Perforation cartridge case manufacturing process

The invention discloses a perforation cartridge case manufacturing process which comprises the following steps of (1) medium frequency heating: performing the medium frequency heating on round steel with a medium frequency furnace, and heating the round steel to 1150 DEG C to 1200 DEG C, (2) round steel blanking, (3) cake upsetting: allowing the middle of the head of the round steel to form a spherical concave, (4) stamping forming: keeping the stamping temperature higher than 1100 DEG C, and ensuring that the final forging temperature is higher than 850 DEG C, (5) normalizing, (6) cold pressing, (7) shape finish turning, (8) groove milling, and (9) oil stain and burr removal, and surface electroplating. The perforation cartridge case manufacturing process effectively solves the technical problems of nonuniform heating, high stamping rejection rate, and greater internal stress of a perforation cartridge case material.

Owner:宁波宇恒能源科技有限公司

Method and device for cooling and heating power cell of electric automobile

InactiveCN102386459ASolve the cooling effectSolve heatingAir-treating devicesSecondary cellsMicro nanoTemperature control

The invention discloses a method and a device for cooling and heating a power cell of an electric automobile based on phase-change slurry circulation. A phase-change material is subjected to micro-nano capsule encapsulation, and then, is prepared into phase-change slurry together with a liquid solvent; the phase-change slurry is subjected to heat exchange closed circulation between a power cell encapsulating chamber and an air conditioner compartment chamber of the electric automobile; and the transfer beneficial flowage of heat between the cell encapsulating chamber and the air conditioner compartment chamber is achieved by utilizing the heat absorption or the heat release phenomenon of the phase-change material occurring in a heat exchange solid-liquid phase-change process. The method and the device for cooling and heating the power cell of the electric automobile are the temperature control and the heat management techniques of the power cell of the electric automobile, and the cooling problem in the condition of a high-temperature climate (an ambient temperature is more than 40 DEG C) and the heating problem in the condition of a low-temperature climate (the ambient temperature is less than 0 DEG C) for the power cell of the electric automobile can be effectively solved.

Owner:张兄文

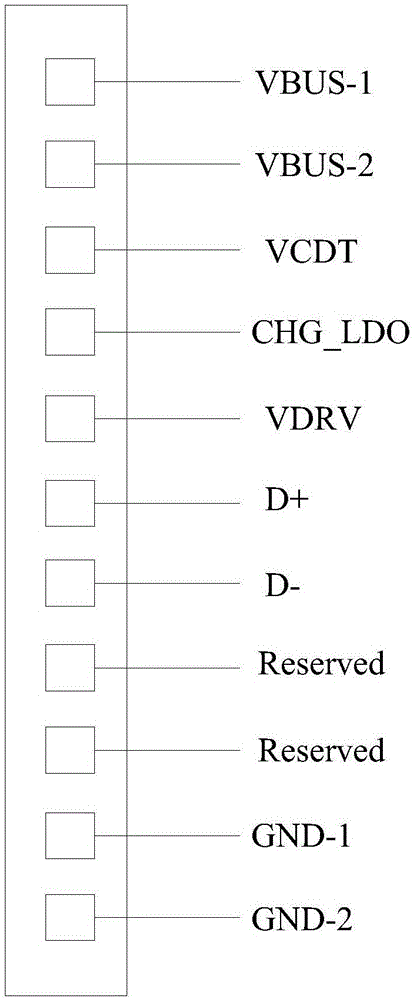

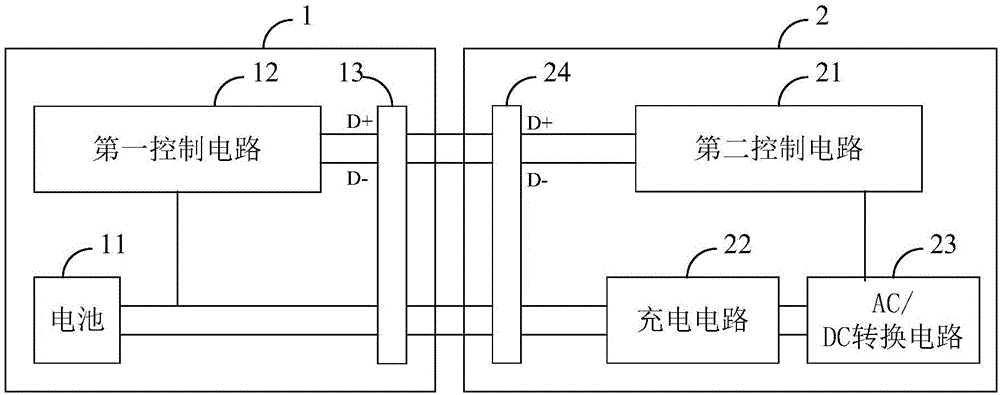

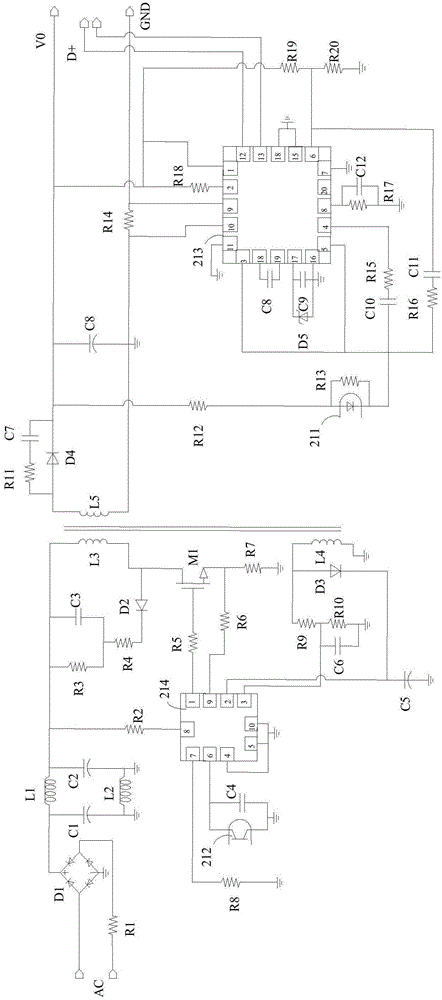

Charging system

InactiveCN105098883ASolve heatingSolve heating problemsBatteries circuit arrangementsElectric powerEngineeringControl circuit

The invention discloses a charging system, which comprises a mobile terminal and a charger, wherein the charger is used for charging a battery of the mobile terminal; the mobile terminal comprises a first control circuit; the charger comprises a second control circuit and a charging circuit; the first control circuit is coupled to the second control circuit; the charging circuit is coupled to the battery; and when the first control circuit and the second control circuit establish handshake communication, the charging circuit charges the battery. In the manner, the charging circuit is arranged on the charger, so that the problem of temperature rise of the mobile terminal can be solved.

Owner:SHENZHEN TINNO WIRELESS TECH

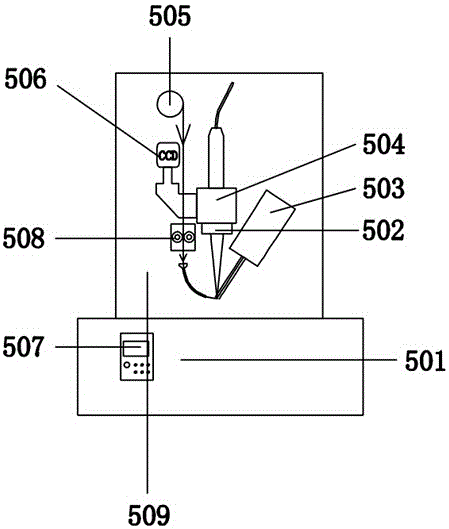

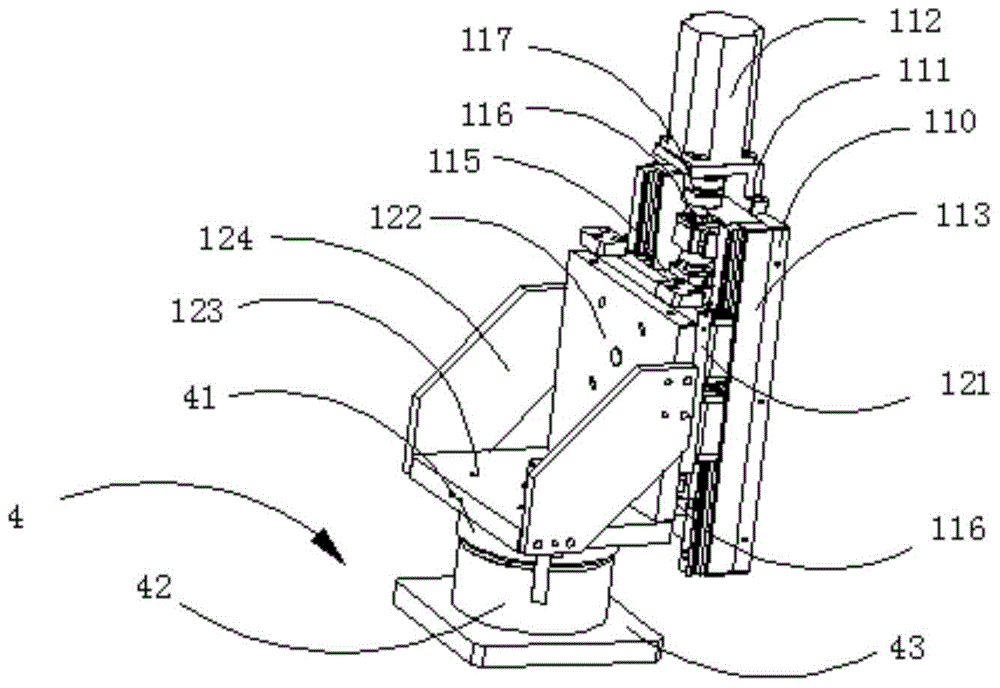

Laser tin soldering machine

InactiveCN106475649ASolve frequent replacement of welding headSolve heatingSoldering apparatusPrinted circuitsInductorEngineering

The invention provides a laser tin soldering machine which comprises a machine table body, a focusing mirror, a temperature inductor, a laser device, a soldering flux frame, a CCD monitor probe, a control device, a feeding device and a machining head fixing plate. The machining head fixing plate is arranged at the upper end of the machine table body. The laser device is arranged at the middle position of the machining head fixing plate. The CCD monitor probe is arranged on the left side of the fixing plate. The temperature inductor is arranged on the right side of the machining head fixing plate and is fixed in a bevel manner. The focusing mirror is arranged at the lower end of a laser. The soldering flux frame is arranged on the plane of the upper end of the left side of the machining head fixing plate. The feeding device is arranged at the lower end of the soldering flux frame. The control device is arranged at the upper end of the machine table body. According to the laser tin soldering machine, an electrical structure is used for control, solder wires, a triaxial working table, lasers are controlled, and therefore high precision and remote soldering are achieved, the service life is long, and the laser tin soldering machine is reasonable in design, simple in structure, reliable in operation and easy to operate.

Owner:KELUODE LASER EQUIP SHENZHEN +1

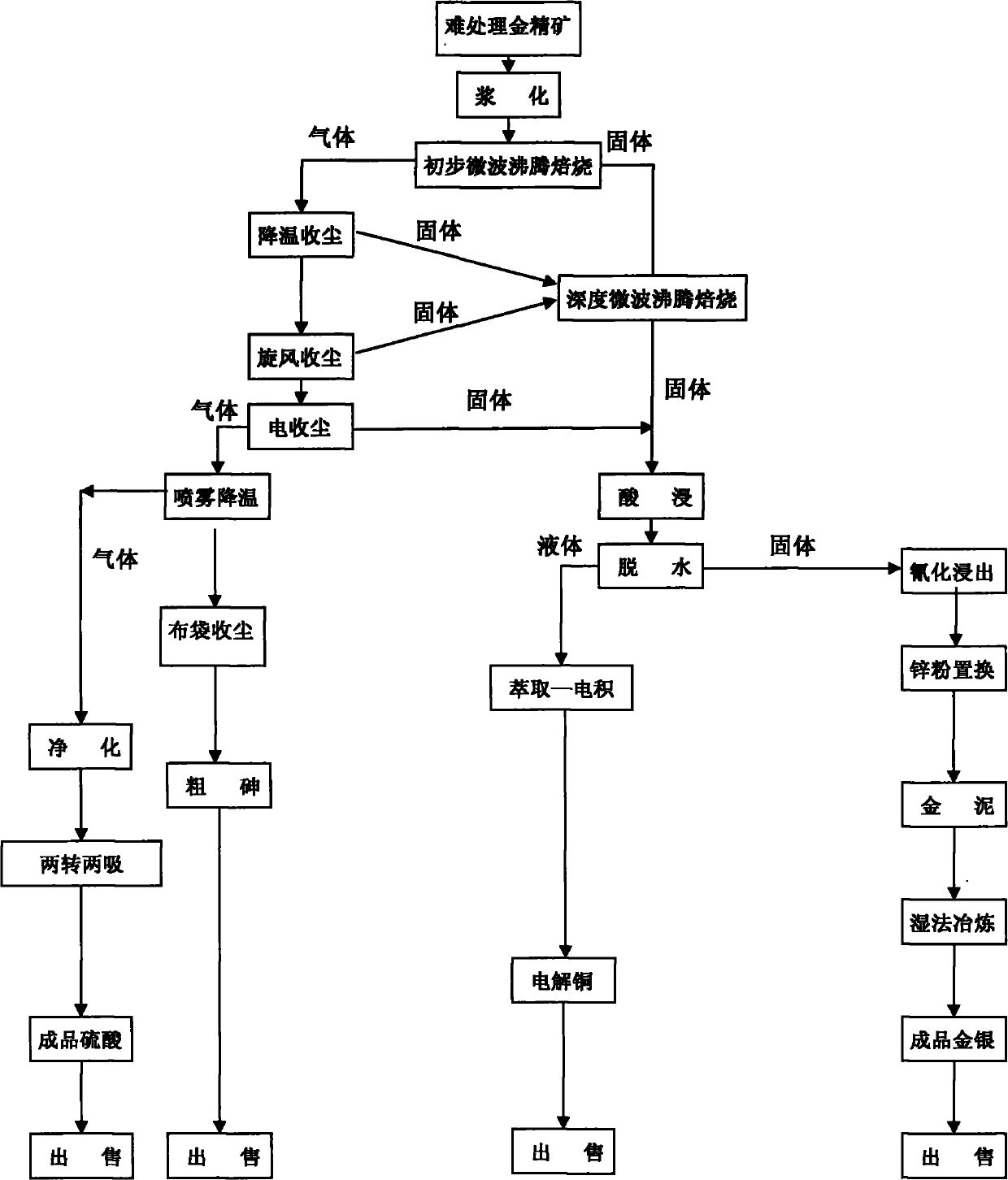

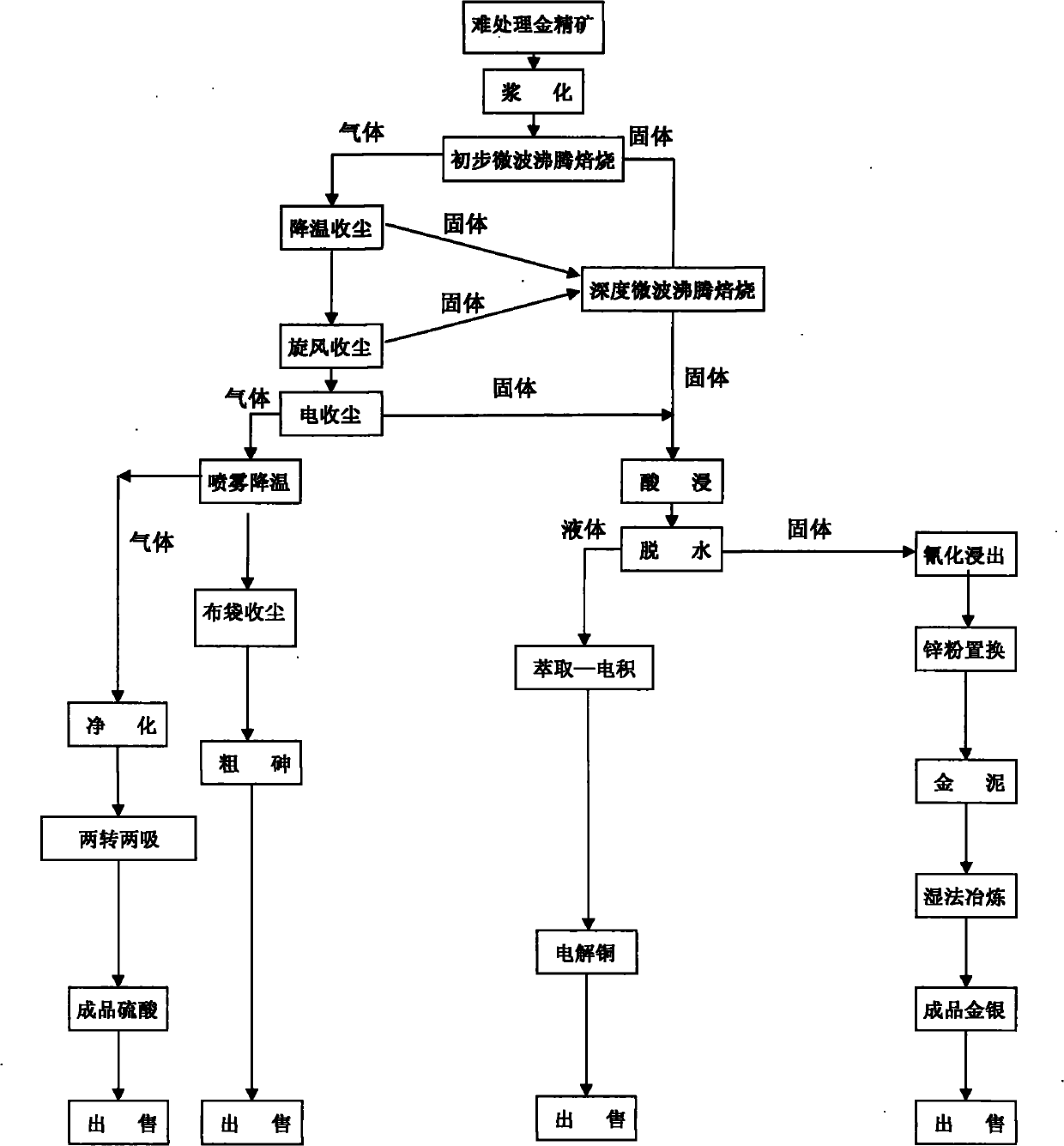

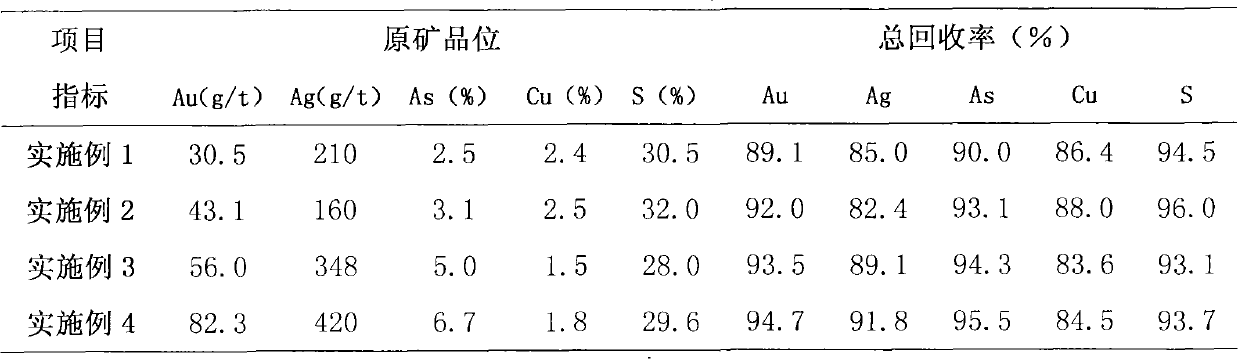

Gold recovery technology for processing arsenious S-C gangue coated gold concentrate by microwave fluidized roasting

InactiveCN101948954AImprove recycling effectPromote monomer dissociationProcess efficiency improvementMicrowaveSulfur

The invention discloses a gold recovery technology for processing arsenious S-C gangue coated gold concentrate by microwave fluidized roasting, which utilizes the characteristics of microwave to carry out selective auxiliary heating on the fluidized roasting of gold concentrate which is hard to process so as to gasify S and As, open gangue and oxidize organic carbon. Thus, gold can easily expose from the collated ore, which is favourable for subsequent cyaniding and leaching and improves gold recovery rate. In addition, efficient and quick microwave processing lowers energy consumption and improves the comprehensive recovery effect of As, S, Cu, Ag and the like.

Owner:广西地博矿业集团股份有限公司

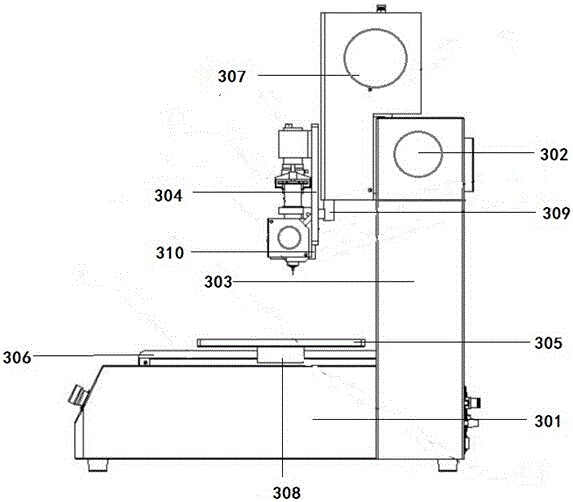

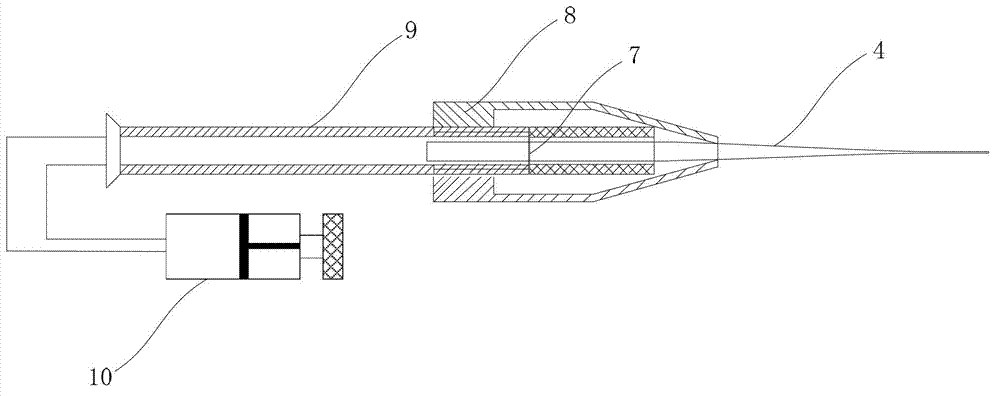

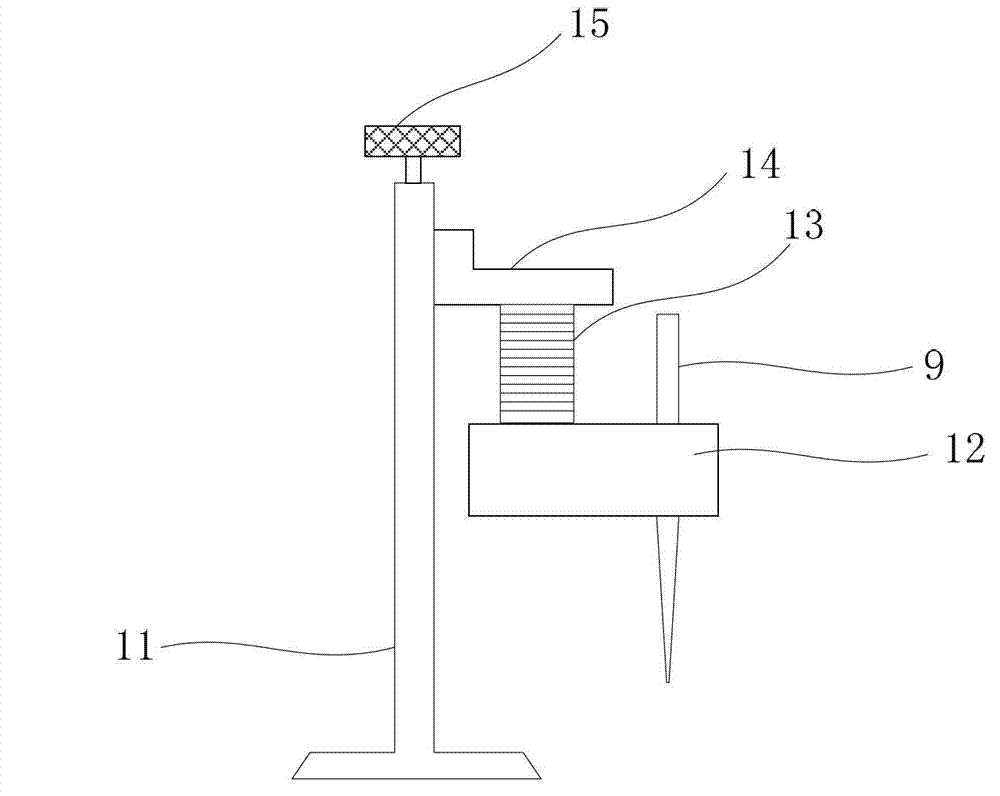

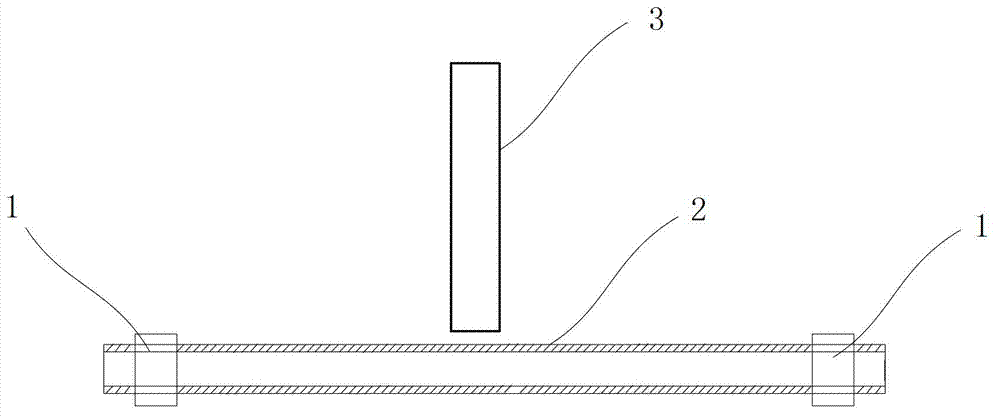

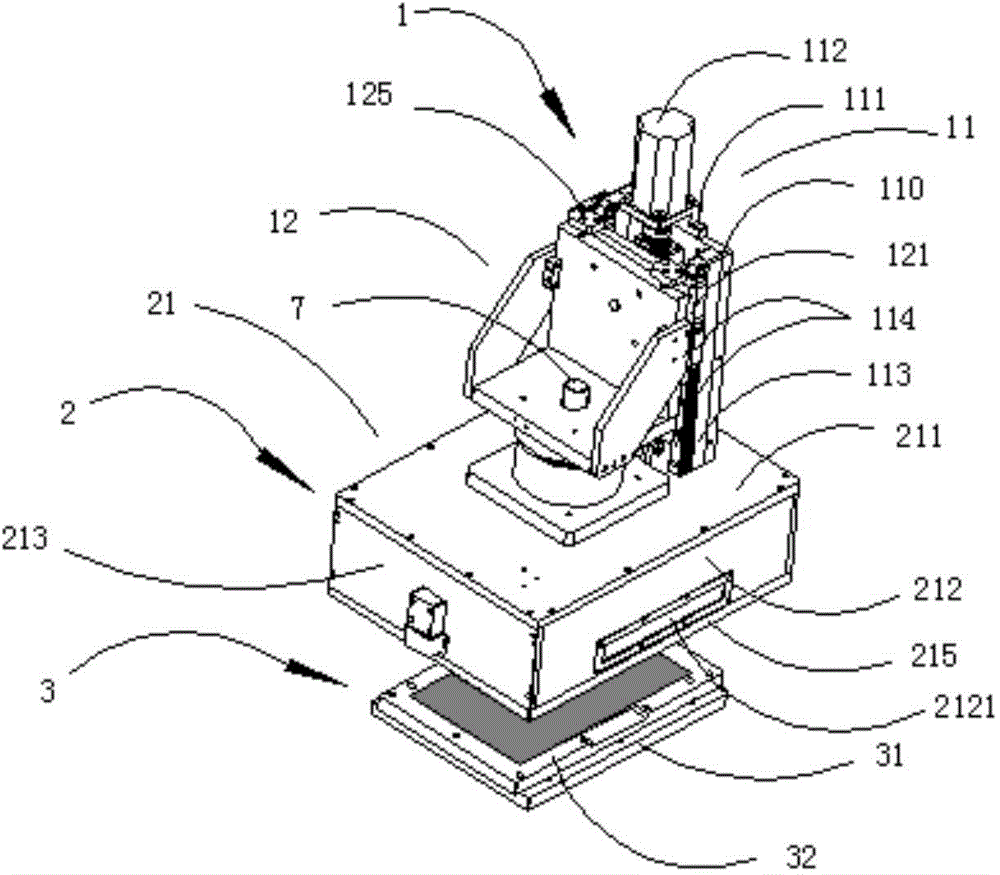

Equipment and method for coating sensitive material on micro-heater

ActiveCN102755942AControl coating amountReal-time adjustment of coating positionLiquid surface applicatorsCoatingsElectricitySpray nozzle

The invention provides equipment and a method for coating a sensitive material on a micro-heater. The equipment comprises a loading device and a coating device; the loading device comprises a micro-nozzle for loading the sensitive material, a sleeve sleeved at a loading end of the micro-nozzle, and a pressure adjuster for generating a negative pressure in the micro-nozzle; the coating device comprises the micro-nozzle loaded with the sensitive material, a piezoelectric driver for driving the micro-nozzle, a connecting piece for clamping and fixing the micro-nozzle so that a feeding end and a discharge end of the micro-nozzle vertically aligns to the surface of the micro-heater, and a rack connected with the piezoelectric driver; and the rack is provided with a sliding groove where the piezoelectric driver and the micro-nozzle move along the vertical direction. The invention further provides the method for coating the sensitive material on the micro-heater. With the adoption of the equipment and the method for coating the sensitive material on the micro-heater provided by the invention, a coating amount of the sensitive material can be controlled, and a coating position of the sensitive material is adjusted in real time, so that the problem that the sensitive material cannot be quantitatively and uniformly coated on the surface of the micro-heater in prior art can be solved.

Owner:RAE SYST SHANGHAI +1

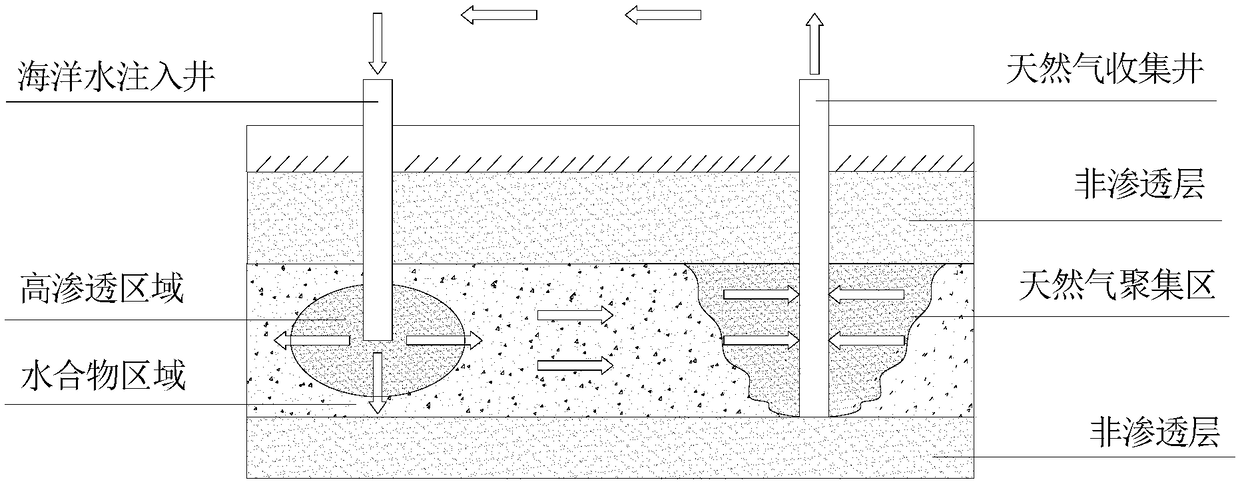

Method for marine natural gas hydrate exploitation through water flow erosion method combined with heat injection

InactiveCN108086961APromote partial decompositionPromotes continuous decompositionConstructionsFluid removalWater flowPressure difference

The invention provides a method for marine natural gas hydrate exploitation through a water flow erosion method combined with heat injection, and belongs to the technical field of marine natural gas hydrate exploitation. Firstly, two development wells are drilled in a natural gas hydrate exploitation area to the interior of a natural gas hydrate reservoir, and a water injection pump is used for injecting marine water into the first development well for heating the reservoir, so that part of a natural gas hydrate is decomposed to generate CH4, a gap channel is opened, and the permeability around the development wells is increased; the pressure difference between the two development wells is controlled by controlling the natural gas collecting speed of a natural gas collection well; stable flow of the marine water in the reservoir is controlled through the pressure difference, and continuous step-by-step composition of the hydrate is promoted under the displacement function in the waterflowing process. The method is easy to implement, high in efficiency and low in cost, and can be used for large-scale industrial exploitation of the natural gas hydrate.

Owner:DALIAN UNIV OF TECH

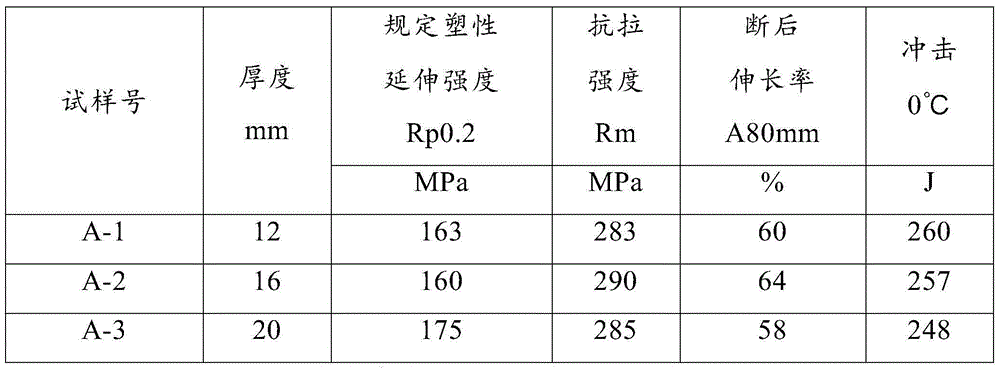

Method for preparing 160MPa grade low-yield-point building aseismicity steel

ActiveCN104087830ASolve heatingSolve the contradiction between high temperature final rolling and coilingChemical compositionLaminar cooling

The invention discloses a method for preparing 160MPa grade low-yield-point building aseismicity steel. The steel comprises the following chemical components in percentage by mass: 0.001-0.005% of C, less than or equal to 0.02% of Si, 0.10-0.8% of Mn, 0.01-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.004% of S, less than or equal to 0.004% of N, 0.01-0.08% of Ti, 0.0005-0.001% of B, and the balance of Fe and inevitable impurities. Through a series of processes of fine smelting, continuous casting, heating, rough rolling, electromagnetic sensation heating, fine rolling, laminar cooling, coiling and the like, the yield strength of the 160MPa grade low-yield-point building aseismicity steel achieves the 140-180MPa grade, the ductility is greater than 50%, good plastic deformation and impact toughness are achieved, and meanwhile an alloy is relatively low in cost and good in welding performance and low-cycle fatigue property, and the process is easy to achieve.

Owner:SHOUGANG CORPORATION

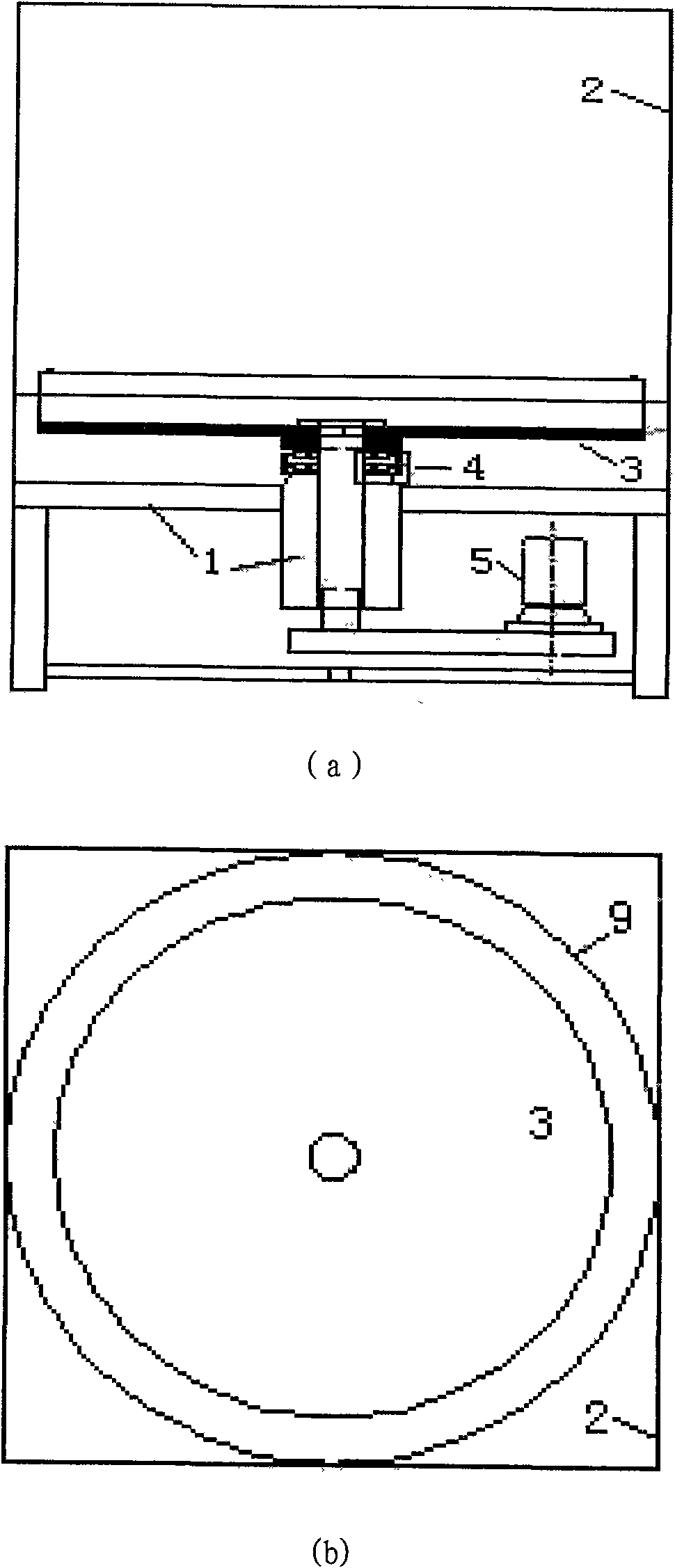

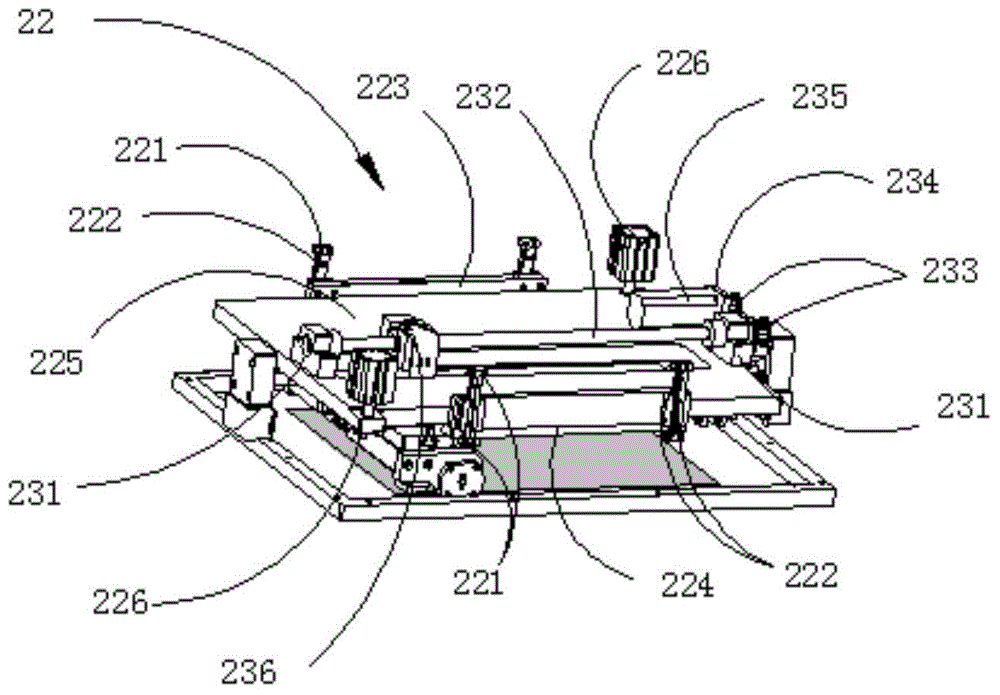

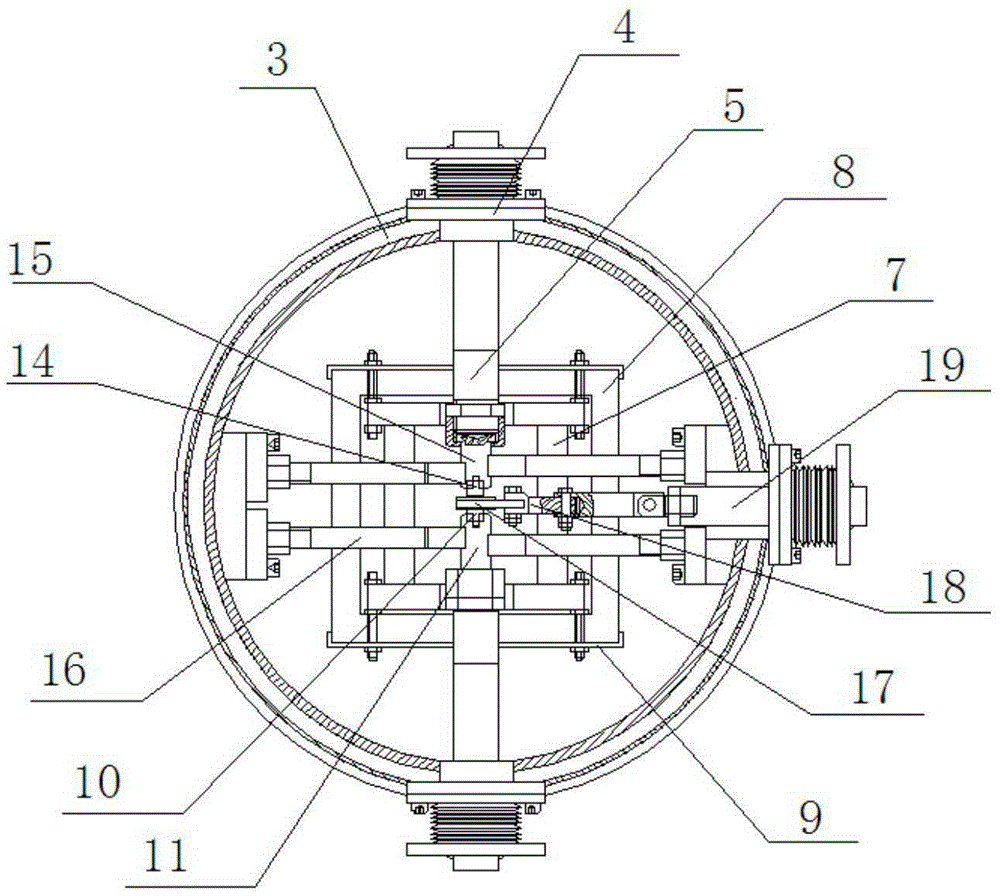

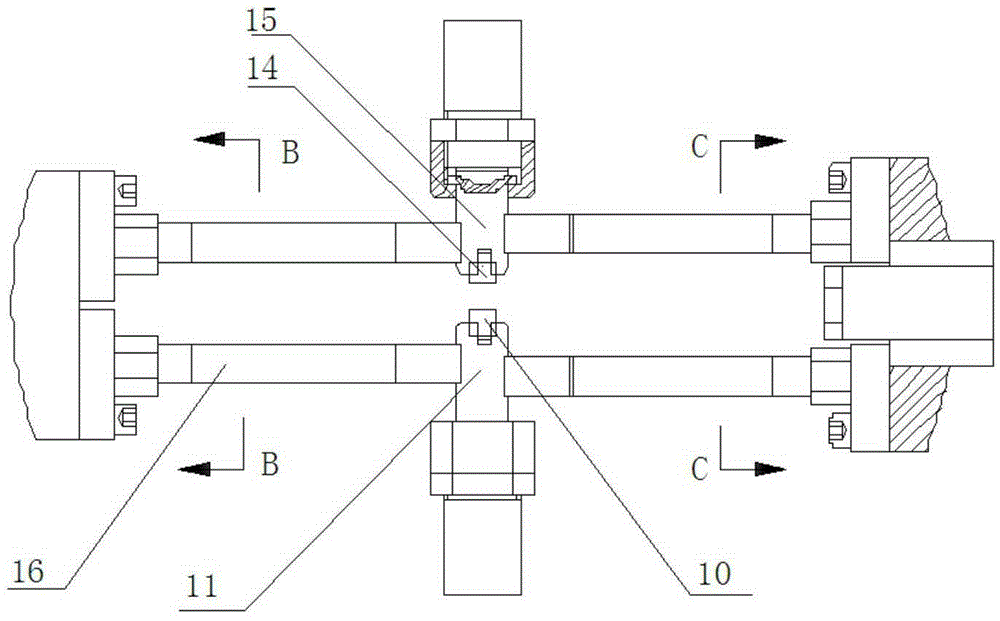

Ground simulation vapour condensation test device in the state of air movement load and method

InactiveCN101672811ARealize ground experiment researchNot easy to damageFlow propertiesMaterial heat developmentRotary stageAir movement

The invention provides a vapour condensation test method and a device by using a rotary stage to simulate the state of air movement load, belonging to the technical field of two-phase flow test. The movement load is obtained by stimulation of a ground rotary stage, and air dynamic load with different magnitudes can be obtained by regulating the rotary speed of the stage. The method mainly comprises the following four parts: a rotary table, a steam circuit, a coolant circuit, and experiment test and data acquisition storage equipment. The method and the device can simulate and research vapour condensation on air movement load in ground condition.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

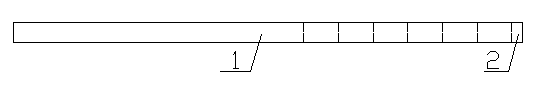

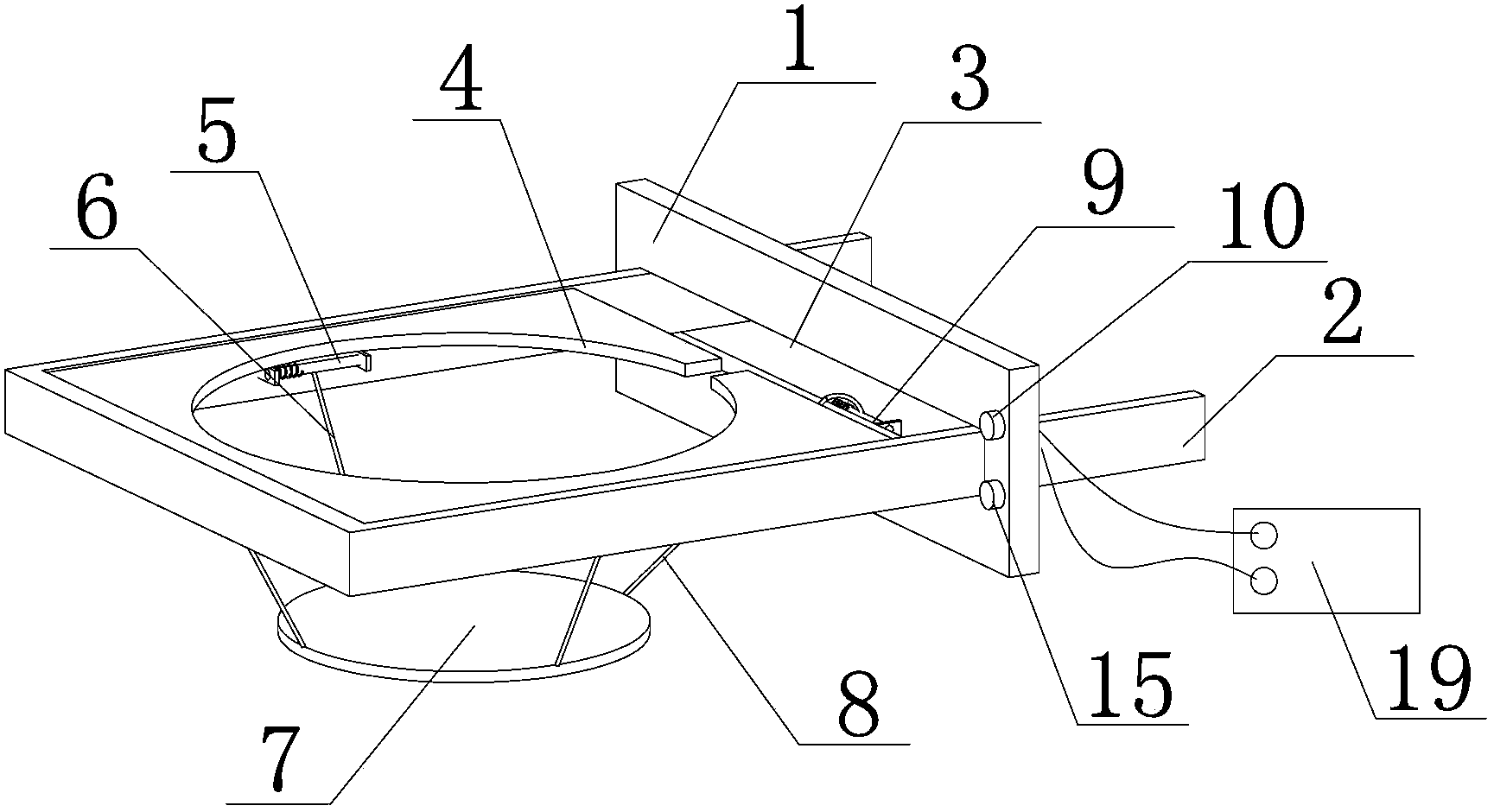

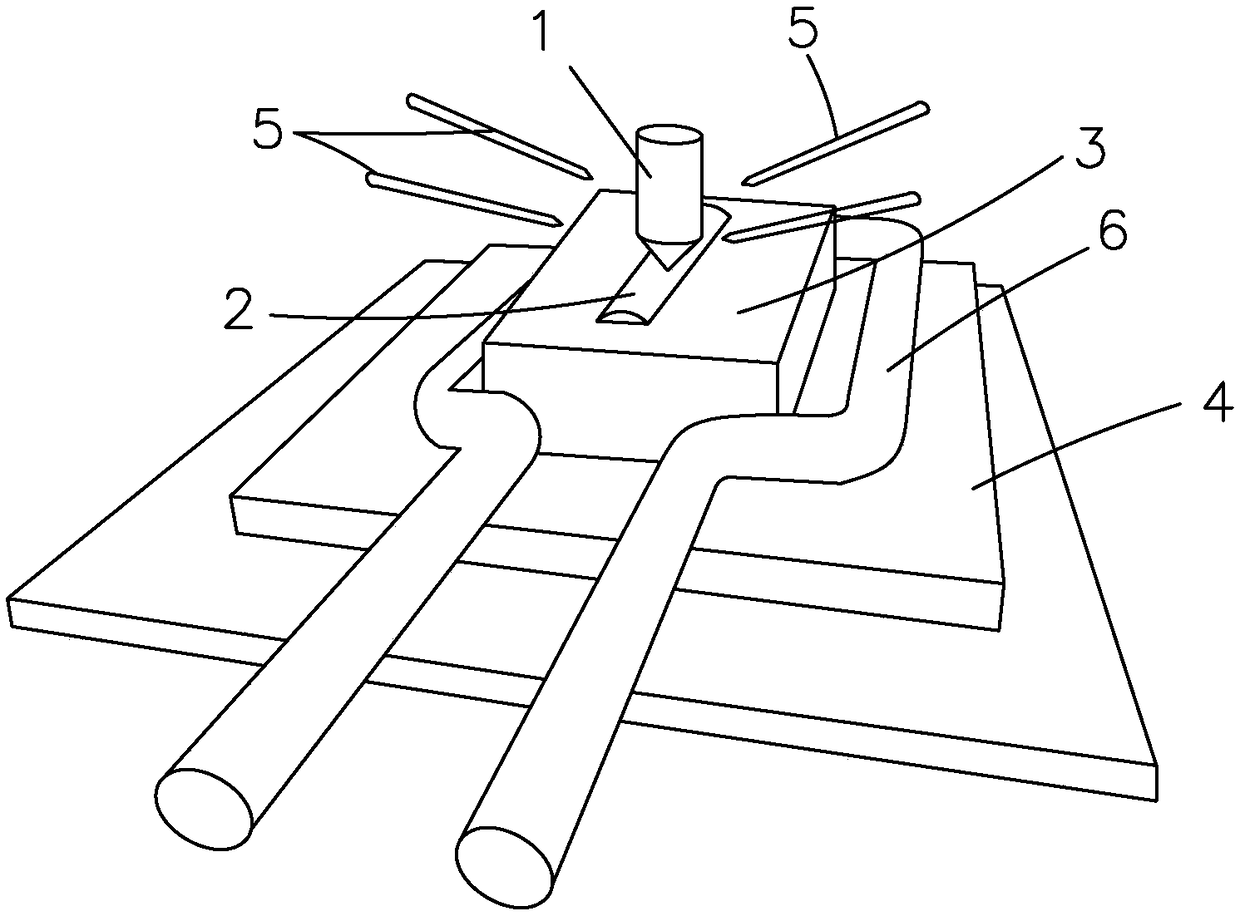

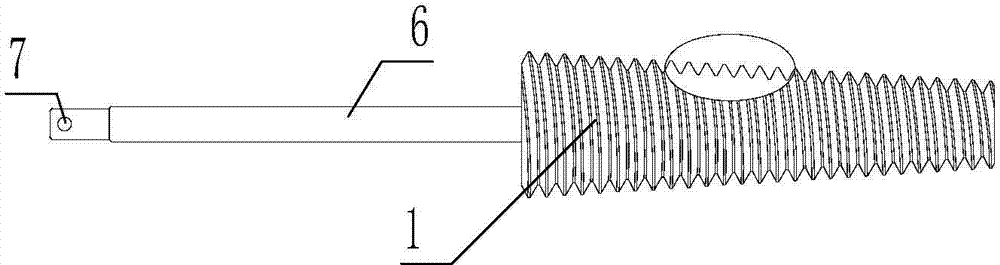

Automotive cup holder with heating function

InactiveCN103832307ASolve heatingSolve insulation problemsVehicle arrangementsElectric heatingElectricity

The invention discloses an automotive cup holder with the heating function. The automotive cup holder with the heating function comprises a center console mask (1) and a cup holder body (2), wherein a groove (3) is formed in the center console mask (1), the cup holder body (2) is arranged in the groove (3), and is connected with the groove (3) in a sliding mode, a circular cup groove (4) is formed in the cup holder body (2), three rope winding devices A (5) with the identical structures are arranged at the bottom of the circular cup groove (4), a rope (6) is arranged on each rope winding device A (5), the ropes (6) are connected with an electric heating base (7), a wire (8) is arranged on the electric heating base (7), and is wound around a wire winding device B (9), the end of the wire (8) is connected with a control switch (10), the control switch (10) is electrically connected with an automotive power source (19), the wire winding device B (9) is arranged in the center console mask (1), and the control switch (10) is arranged on the center console mask (1). The automotive cup holder with the heating function has the folding and unfolding function of a traditional automotive cup holder, and further has the heating function, the temperature of water in a cup can be kept, and a driver can drink warm water at any time; the automotive cup holder with the heating function has the advantages of being simple in structure and quite practical.

Owner:董金奎

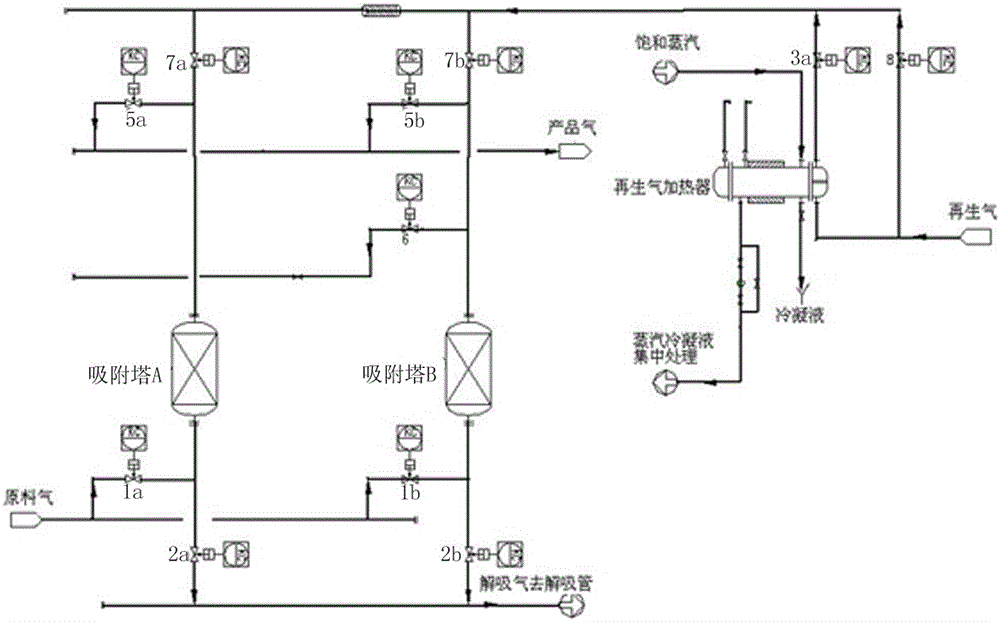

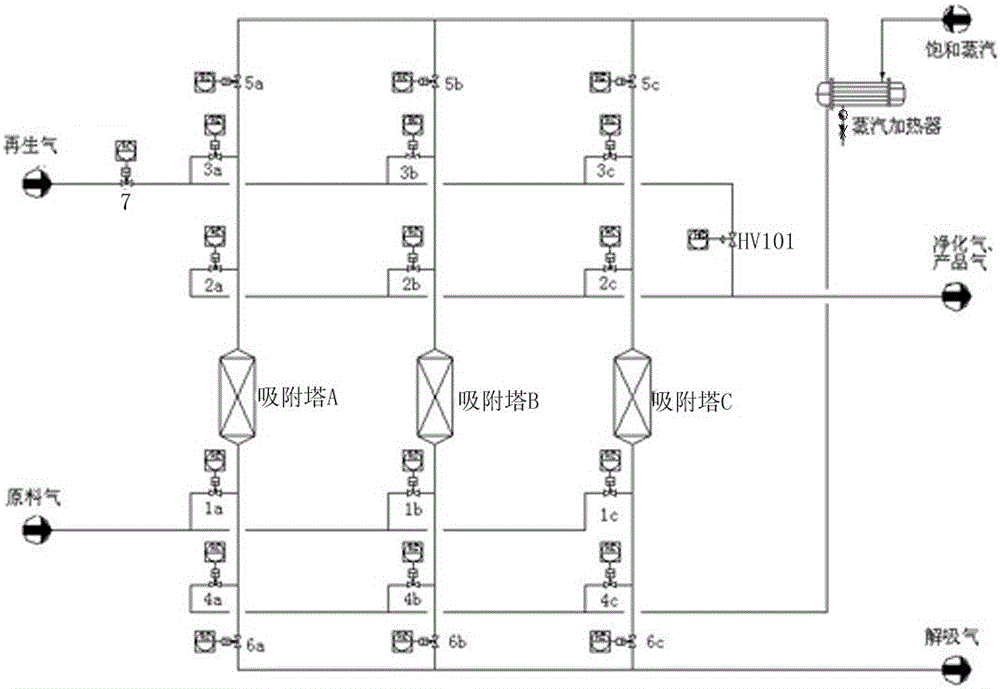

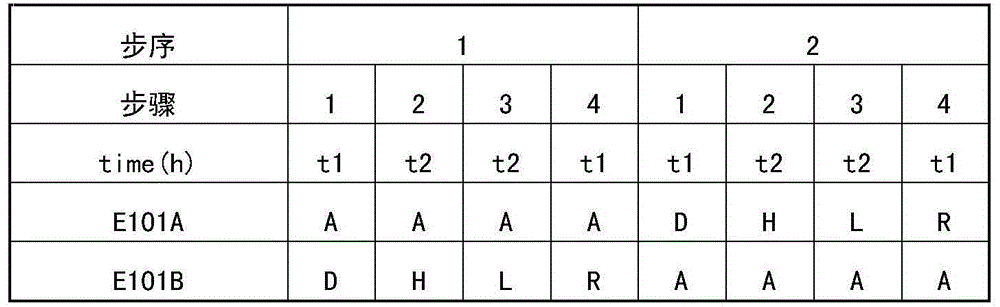

Novel temperature and pressure variable adsorption technology

InactiveCN105056708ASolve heatingSolve the contradictory relationship of the cold blowing stepDispersed particle separationDesorptionTower

The invention relates to the field of gas purification and concretely relates to a novel temperature and pressure variable adsorption technology. According to the adsorption technology, each adsorption tower finishes adsorption, reverse pressure reduction, heating, cooling and pressurization, wherein a desorption process is finished in reverse pressure reduction and heating. The adsorption technology comprises two or more adsorption towers, one or more regeneration gas heater, a fluid switching valve and pipes. The adsorption process comprises feeding raw material gas to be purified into the adsorption towers from top to bottom and adsorbing and removing impurities in the raw material gas at a normal temperature under adsorption pressure. The adsorption technology realizes simultaneous cold blowing and heating processes on different adsorption towers by resurgent gas and realizes optimal regeneration effects by effective utilization of resurgent gas. Time of the heating and cold blowing processes as key adsorption tower regeneration processes is 95% or more adsorption time so that optimal adsorption and desorption cooperation is realized.

Owner:ALLY HI TECH CO LTD

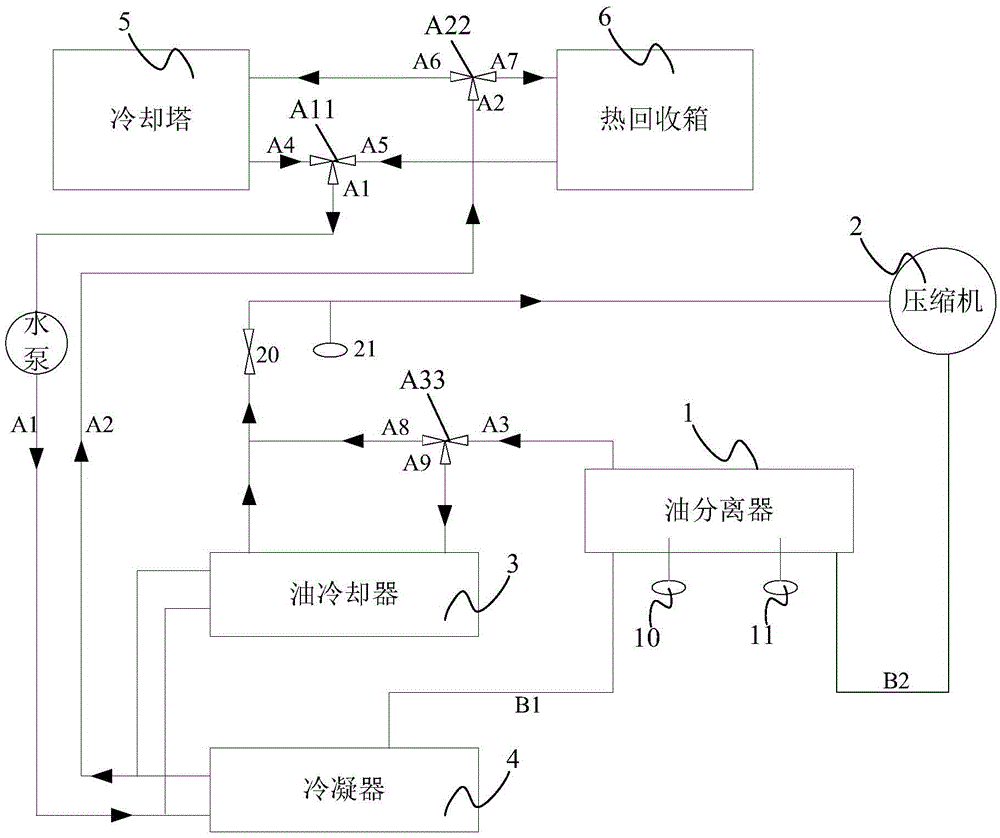

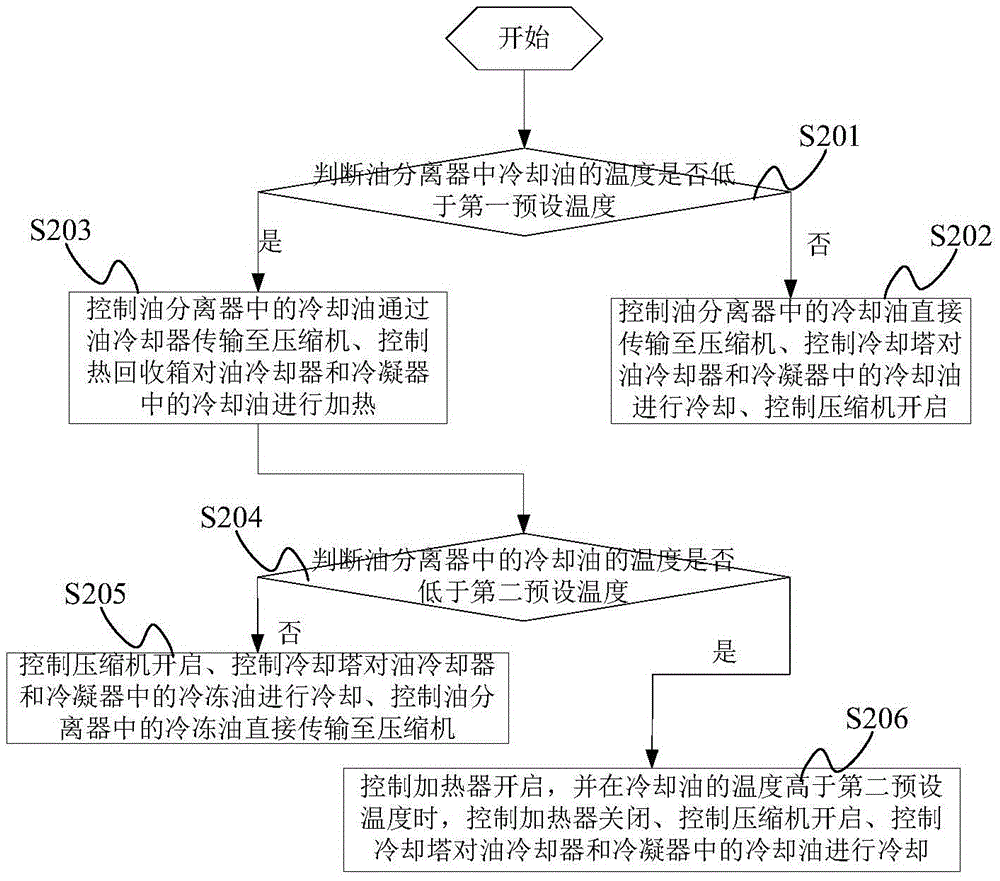

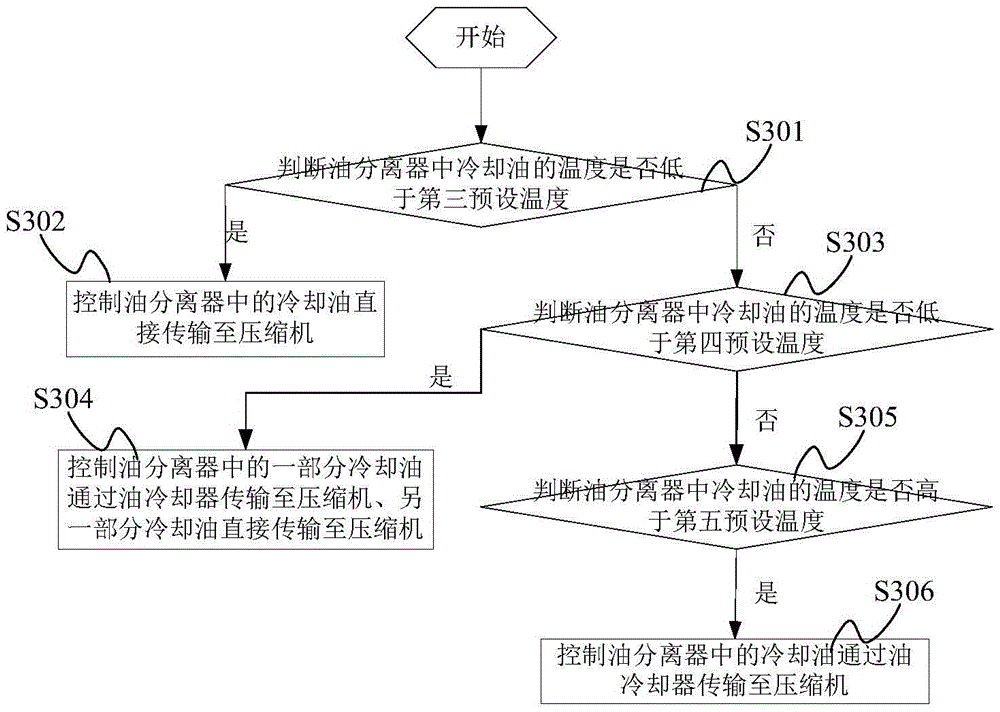

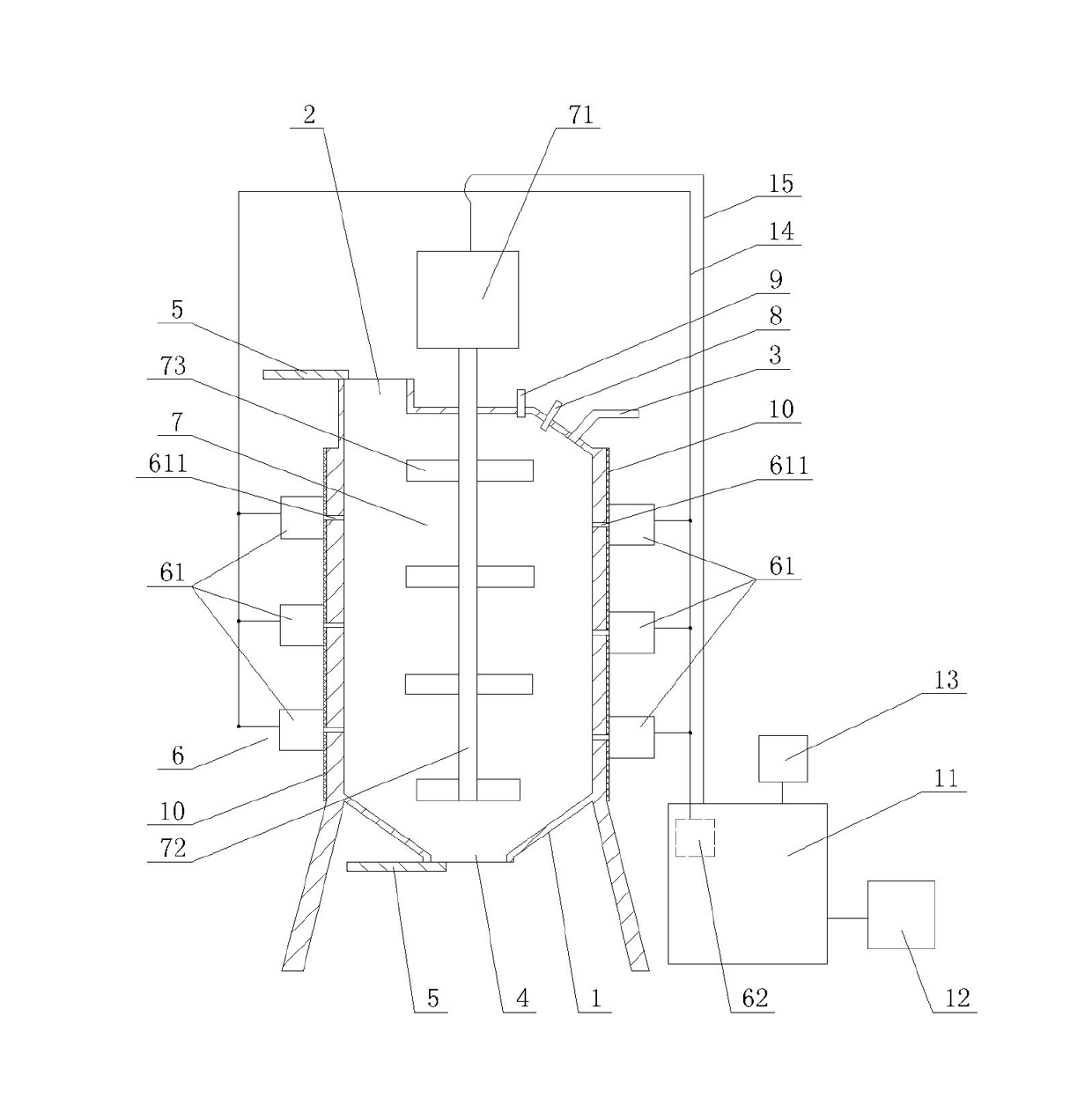

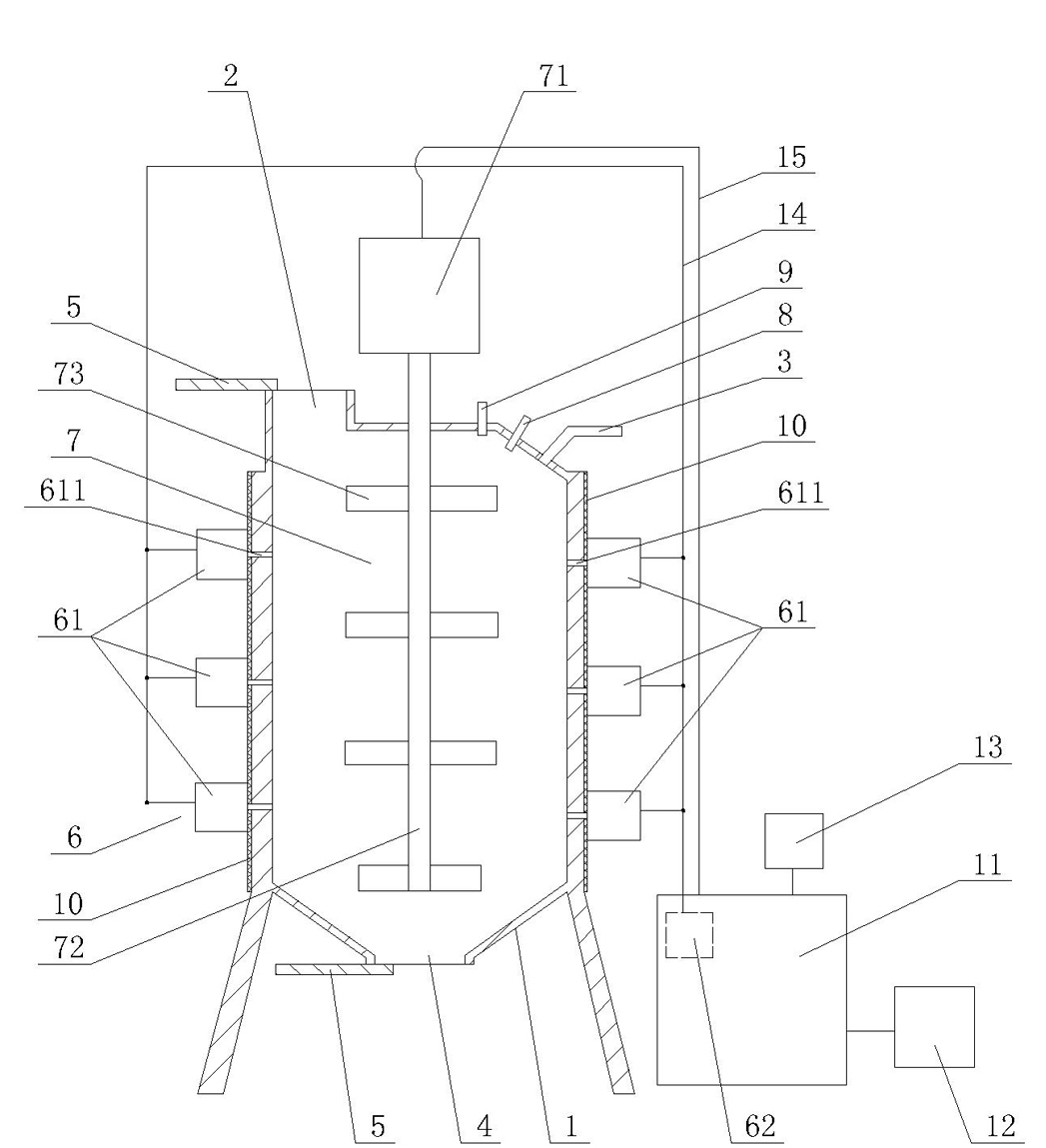

Refrigerating unit and control method and system thereof

ActiveCN105627614AEffect of heating effectReduce power consumptionMechanical apparatusFluid circulation arrangementElectricityCooling tower

The invention provides a refrigerating unit and a control method and system thereof. An oil separator is used for directly conveying refrigerant oil to a compressor or conveying the refrigerant oil to the compressor through an oil cooler. A cooling tower is used for cooling the refrigerant oil in the oil cooler and refrigerant oil in a condenser. A heat recycling bin is used for gathering heat of the refrigerant oil in the oil cooler and the condenser and heating the refrigerant oil in the oil cooler and the condenser through the heat. When the temperature of the refrigerant oil is high, the refrigerant oil in the oil separator can be controlled to be directly conveyed to the compressor, and at the moment, even if certain water flow of the refrigerating unit is kept, the heating effect on the refrigerant oil is not influenced. When the temperature of the refrigerant oil is low, the refrigerant oil in the oil separator can be controlled to be conveyed to the compressor through the oil cooler, at the moment, the refrigerant oil in the oil cooler and the condenser can be heated through the heat recycling bin or through the heat recycling bin and a heater, and the problems of high power consumption and a poor heating effect are solved.

Owner:GREE ELECTRIC APPLIANCES INC

Twin pipe type solar water heater in model of instant use once to turn it on

InactiveCN101004294ASolve the adjustmentSolve the problem of emergency wateLevel controlSolar heat devicesTemperature controlAutomatic control

The present invention discloses a double-pipe type solar water-heater. Its waterway is divided into upper and lower two water pipes, on the upper water pipe a water-supplying electromagnetic valve and a temperature-measuring probe are mounted, the electroheater in the water tank is controlled by temperature control regulation instrument, on the lower water pipe are successively mounted a pipe electroheater, booster pump and hot water valve, between upper water pipe and lower water pipe a circulation pipeline is connected so as to form a loop, the circulation electromagnetic valve is mounted on the circulation pipeline. Its electric circuit portion includes temperature-measuring probe, temperature sensor, temperature control regulation instrument, level sensor, electromagnetic valve, booster pump and automatic control instrument, etc. Besides, said invention also provides its working principle and its concrete operation method.

Owner:陈岩

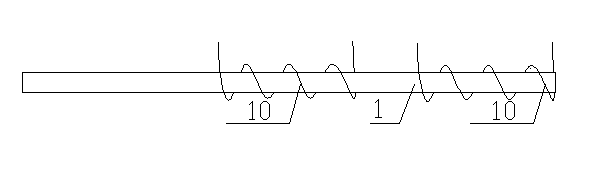

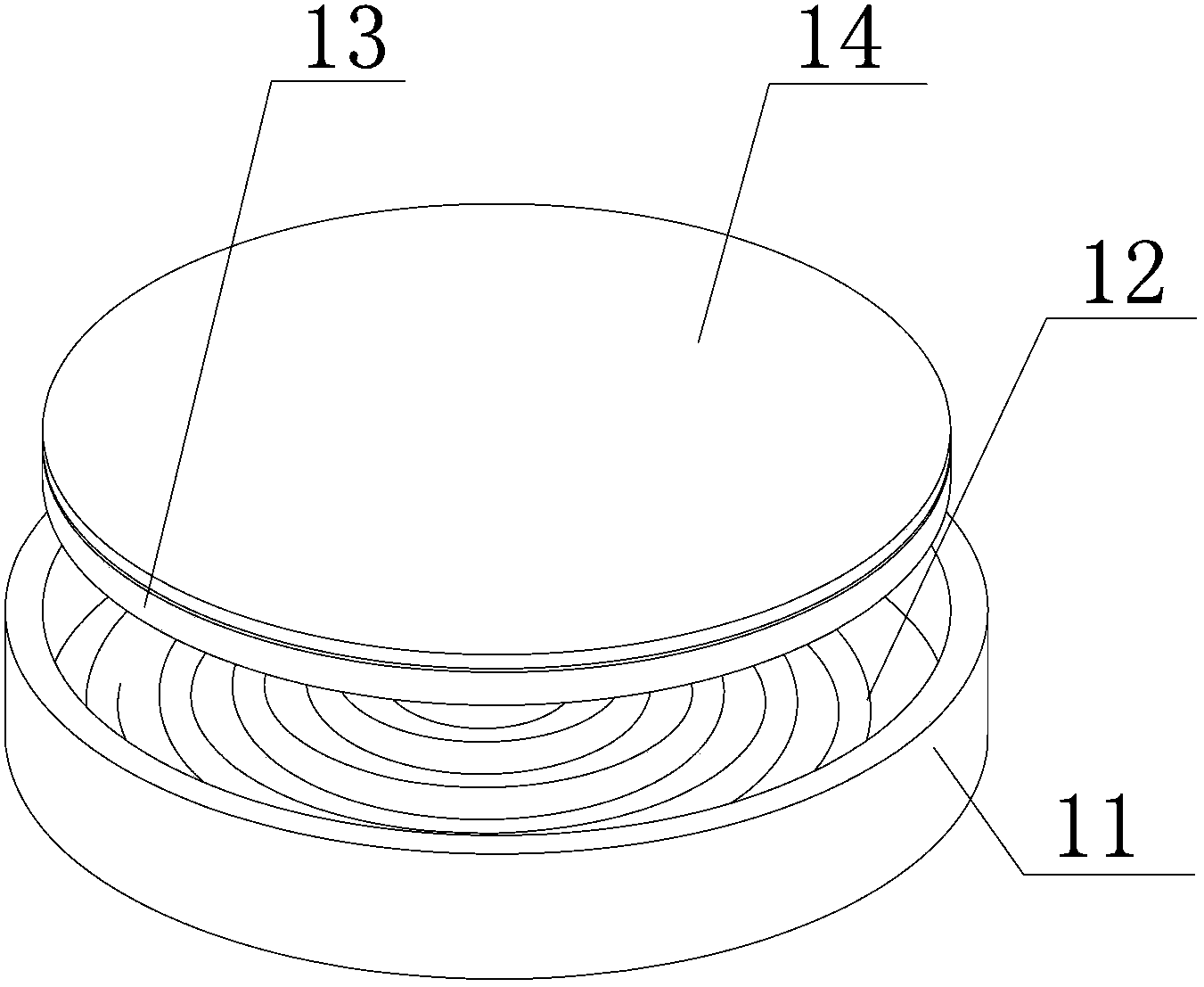

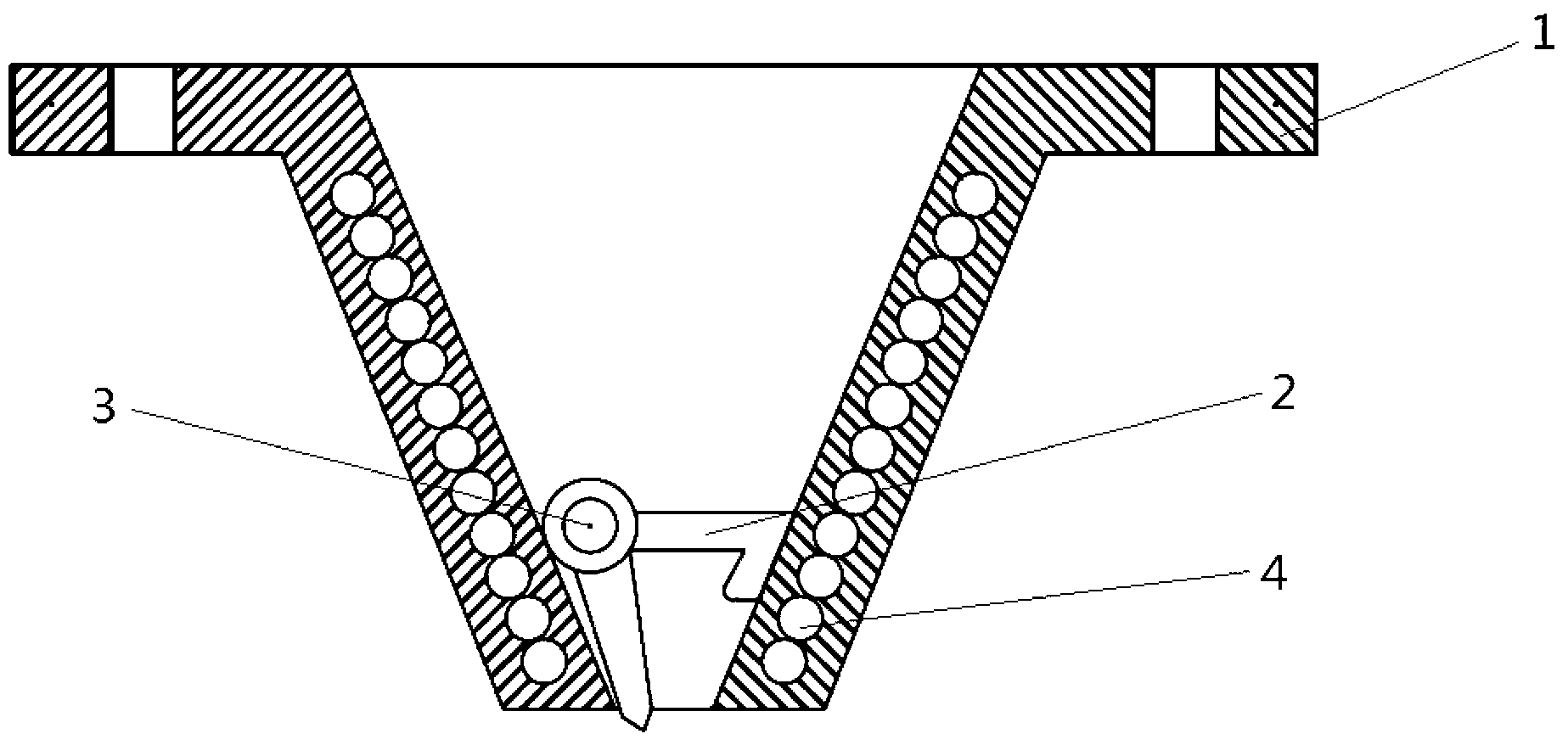

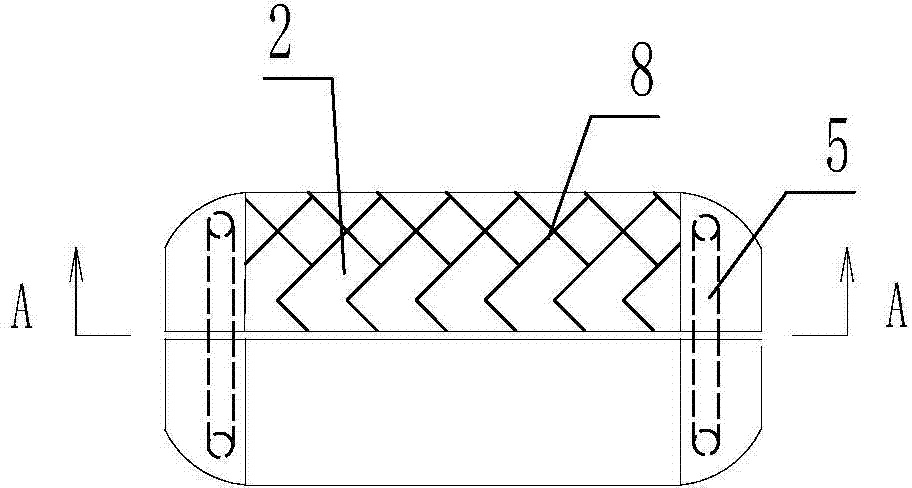

Rapid vulcanization die for building lamination shock insulation rubber bearing

InactiveCN103786282AAvoid heat transfer barriersAchieving direct heat conductionVulcanizationEngineering

The invention discloses a rapid vulcanization die for a building lamination shock insulation rubber bearing. The rapid vulcanization die comprises an inner heating die with a heat conduction strip, an outer heating die with a heat conduction strip, an excessive glue groove, heat conduction strips, an upper heating template, a lower heating template, a positioning shaft, a positioning hole and a positioning shaft mounting groove, wherein the lower heating template is mounted on a support, the outer heating die with the heat conduction strip is arranged on the upper surface of the lower heating template, the inner heating die with the heat conduction strip is arranged in the center of the outer heating die with the heat conduction strip, the height of the outer heating die with the heat conduction strip is equal to that of the inner heating die with the heat conduction strip, and the upper heating template is arranged at the tops of the outer heating die with the heat conduction strip and the inner heating die with the heat conduction strip. The rapid vulcanization die fully utilizes the structural principle of vulcanization equipment and a vulcanization target to realize rapid and uniform vulcanization and efficient mounting, is applicable to vulcanization processing of various rubber bearings, such as a standard rubber bearing, a pencil lead rubber bearing, a high damping rubber bearing and a stacked rubber bearing, and is high in vulcanization efficiency and rapid and convenient to mount and maintain.

Owner:彭勃

Device for preparing combustible gas from plant material at high temperature

InactiveCN101921605AShort gasification timeProlong vaporization timeSpecial form destructive distillationThermodynamicsCombustible gas

The invention discloses a device for preparing a combustible gas from a plant material at a high temperature. The device comprises a furnace body, a material inlet and a combustible gas outlet at the upper part of the furnace body and a waste outlet at the lower part, wherein a microwave heating device is connected on the furnace body. The microwave heating device is connected on the furnace body, and the interior of the furnace body can quickly reach a temperature required for plant material cracking gasification by heating of the microwave heating device, so the gasification time of the plant material is short, the cracking is complete, the gas yield is high, the temperature is easily controlled and the use is safe and reliable. A stirring device is arranged on the furnace body, and the stirring device does not produce interference to the microwave in the furnace body by asynchronous work of the stirring device and the microwave heating device, so the furnace body has better heating effect and safer use, and the gasification time of the plant material is shorter. The device also has the advantages of reasonable design, good sealing property, easy control and the like, and is particularly suitable for preparing the combustible gas by cracking gasification of plant straws.

Owner:任杰

Rolling and laminating device and laminating method of hot rollers

ActiveCN104608456ASolve winding, lineSolve heatingLamination ancillary operationsLaminationMechanical engineeringEngineering

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

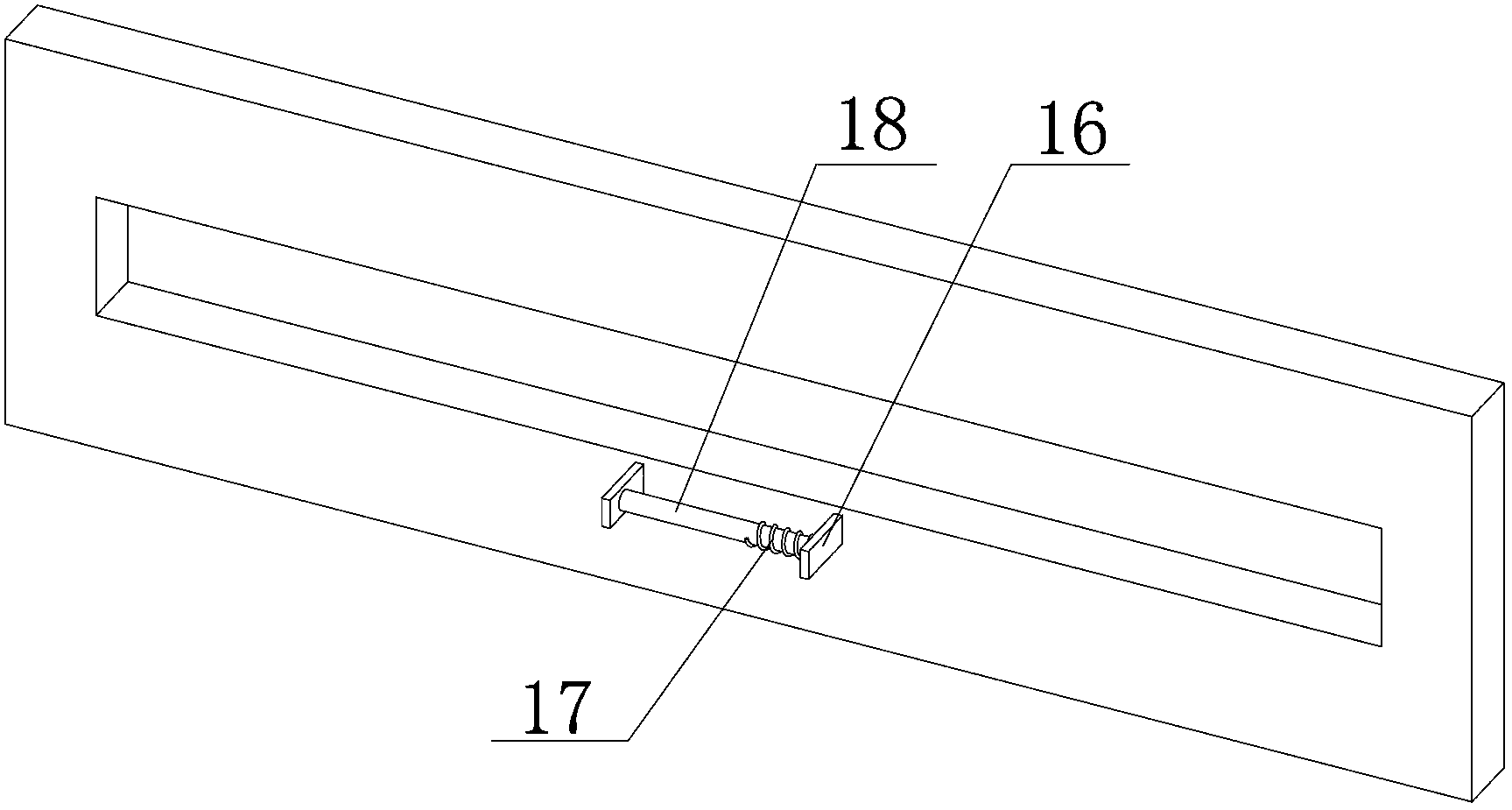

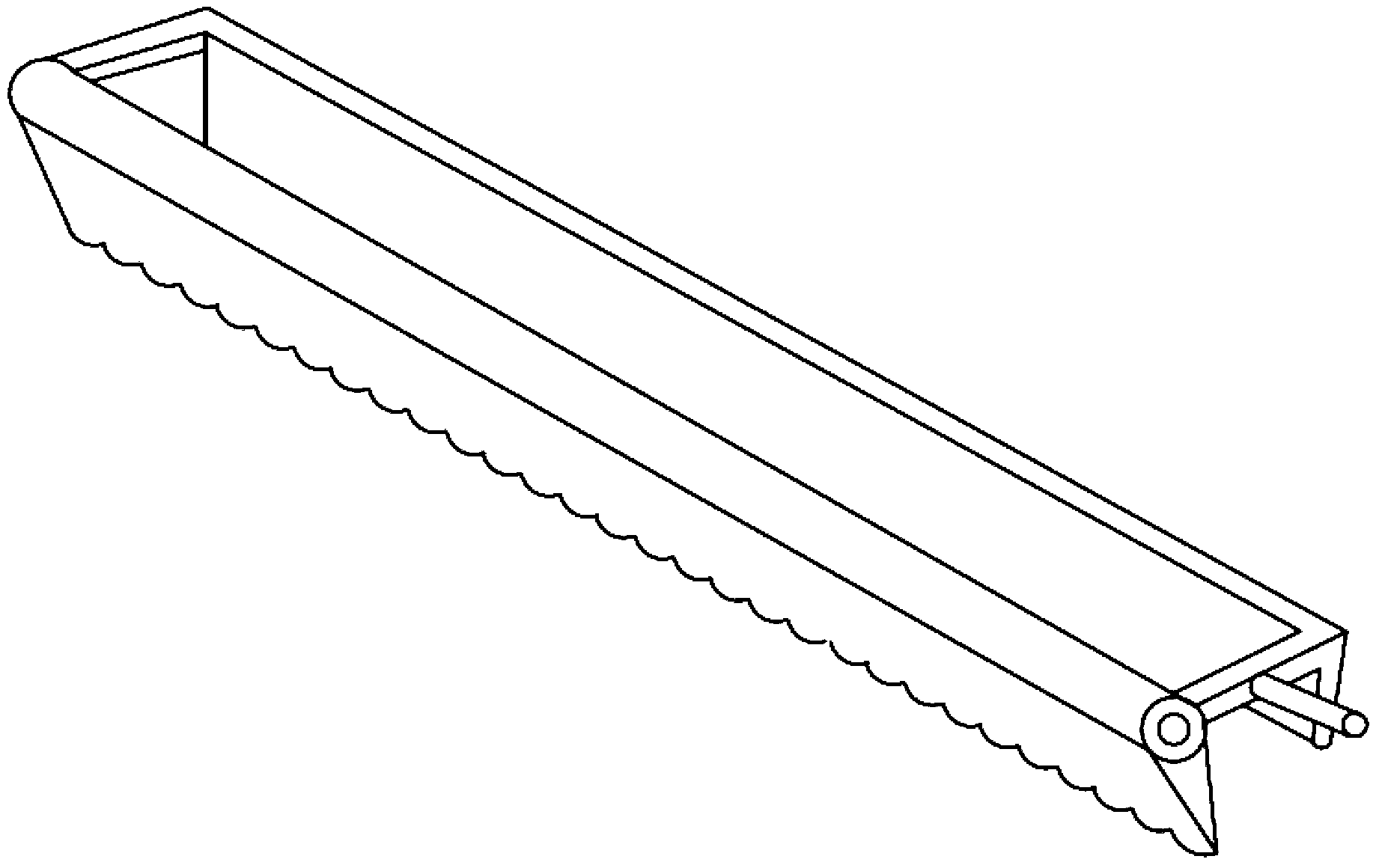

Novel efficient linear nozzle for electrostatic spinning

InactiveCN103320876ASolve heatingSolve the problem of difficult pressurizationFilament/thread formingTemperature controlHeat control

The invention discloses a novel efficient linear nozzle for electrostatic spinning. The novel efficient linear nozzle is characterized by comprising a heat control device and a conducting device; the heat control device is of a long cavity and a high-voltage electrostatic receiving end and is provided with a heating and temperature control device, and a linear nozzle is arranged at the bottom of the cavity; the conducting device is elongated and disposed in a cavity of the heat control device, connected with the high-voltage electrostatic receiving end of the heat control device and disposed at the linear nozzle of the bottom of the cavity, and saw-toothed protrusions are formed at the edge of the bottom of the conducting device. The novel efficient linear nozzle for electrostatic spinning has the advantages that the difficulty in synchronous heating and pressurizing of the nozzle of melt electrostatic spinning is overcome; the novel efficient linear nozzle is in the shape of a triangular prism, the mode of stacking single-hole or multi-hole nozzles is omitted, so that multiple spinning jet flows can be generated, productivity of electrostatic spinning is improved greatly on the premise of reducing processing difficulty; and the aperture of the nozzle is convenient to regulate so that outflow speed of spinning solution is convenient to control.

Owner:JIANGNAN UNIV +1

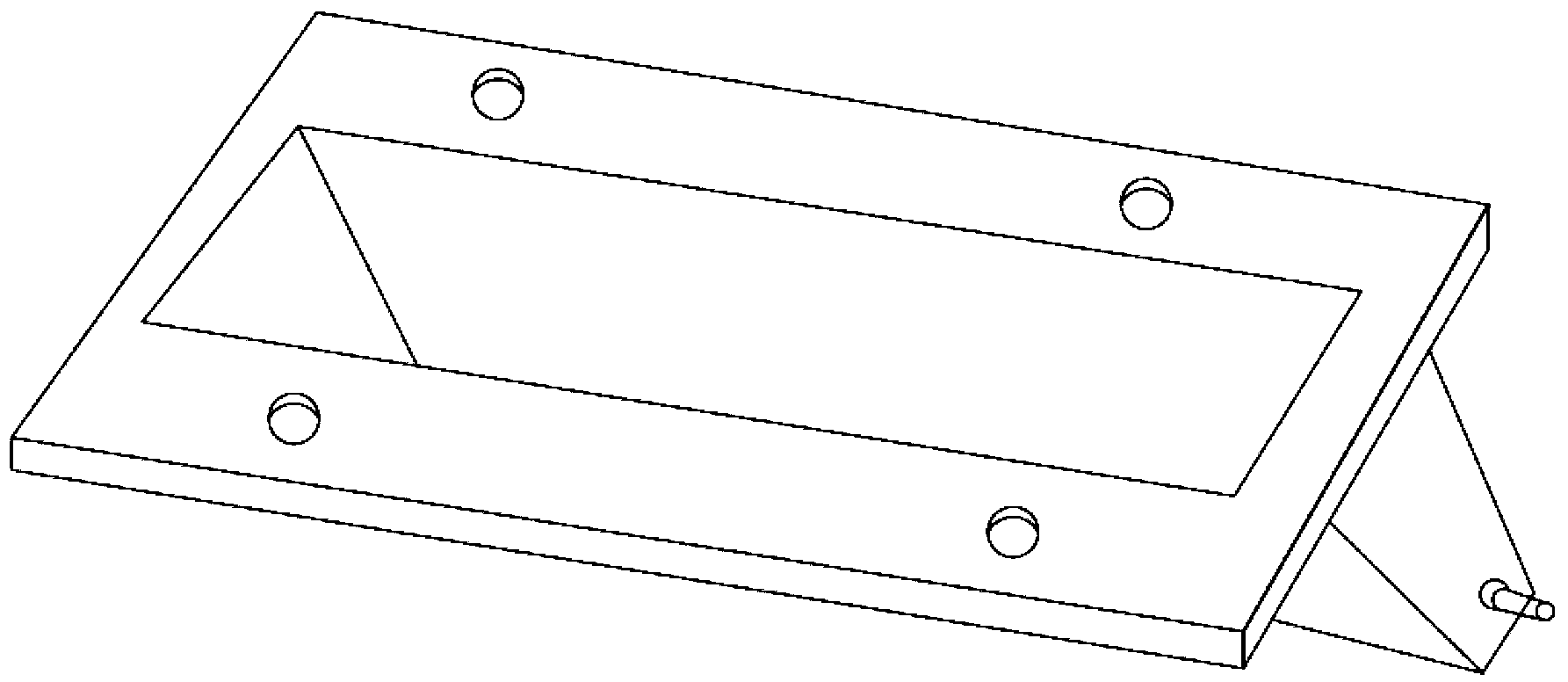

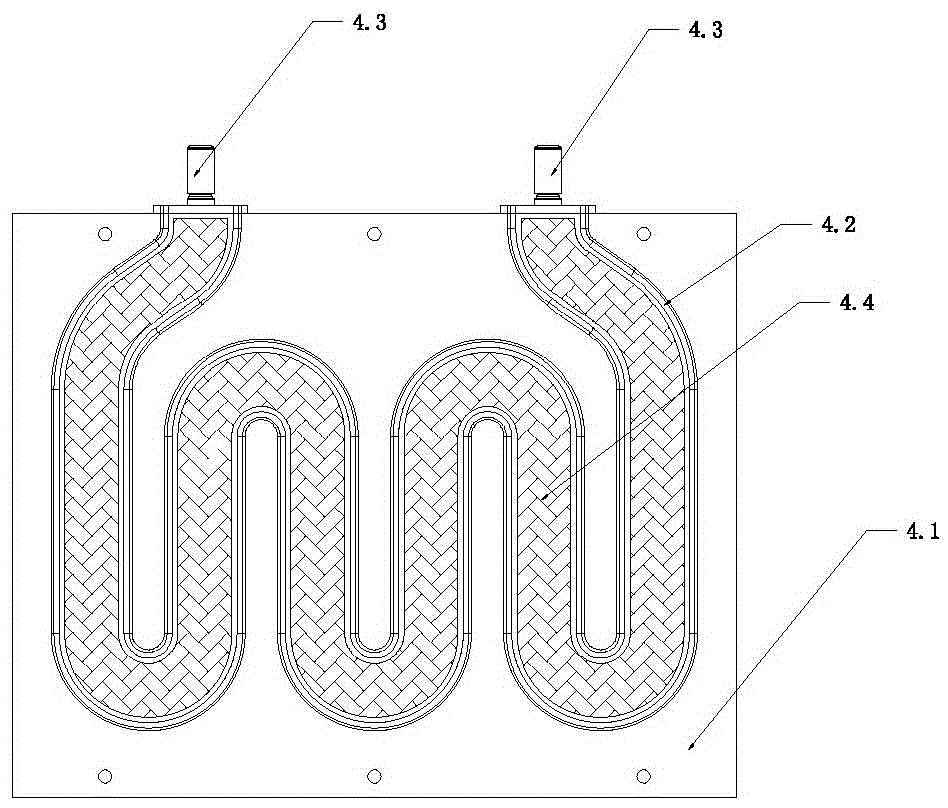

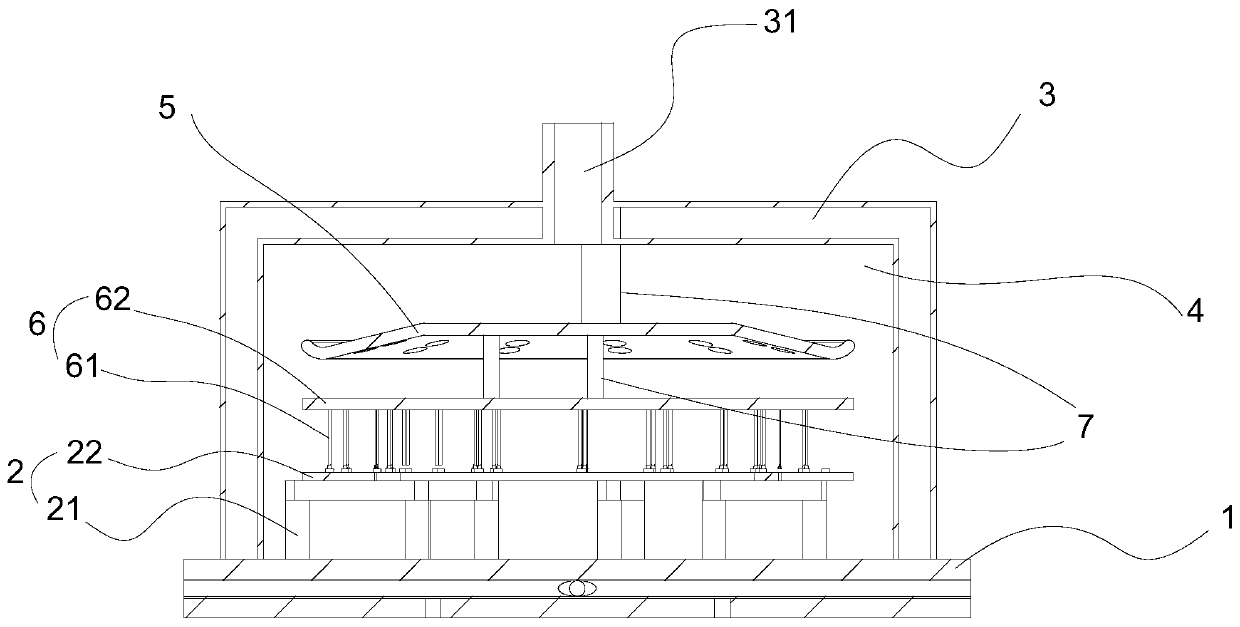

New energy automotive power battery heating and cooling integrated device

ActiveCN106058378AGood heatingGood coolingSecondary cellsVehicular energy storagePower batteryNew energy

The invention relates to a new energy automotive power battery heating and cooling integrated device which is characterized by comprising a water tank, a water pump, a heat radiator, a heat exchange plate, a heater and pipelines, wherein the heat exchange plate comprises a bottom plate, a flat thin pipe and pipe joints; the heater comprises a shell body, a liquid inlet pipe, a liquid outlet pipe, a heating core, a temperature sensor and a power supply connection device; a liquid outlet end of the water tank communicates with a liquid inlet end of the water pump through the pipeline; a liquid outlet end of the water pump communicates with a liquid inlet pipe of the heater through the pipeline; a liquid outlet pipe of the heater communicates with one pipe joint of the heat exchange plate through the pipeline, and the other pipe joint of the heat exchange plate communicates with a liquid inlet end of the heat radiator through the pipeline; and a liquid outlet end of the heat radiator communicates with a liquid inlet end of the water tank through the pipeline. The new energy automotive power battery heating and cooling integrated device has the advantages of simultaneously solving heating and heat dissipation of a new energy automotive power battery.

Owner:JIANGYIN HUILONG ELECTRIC HEATING APPLIANCE

Electronic component temperature detection device

InactiveCN110058102ARealize heating/coolingSolve heatingMeasuring interference from external sourcesMeasurement instrument housingEngineeringElectronic component

The invention relates to an electronic component temperature detection device. The electronic component temperature detection device comprises a base, a supporting assembly, a compressing assembly, agas flow-guiding plate and an upper cover plate; the base and the upper cover plate form a sealed testing cavity, an air inlet is formed in the upper cover plate, the supporting assembly is located inthe testing cavity and comprises a supporting bracket and a mounting plate in rigid connection with the supporting bracket, and the supporting bracket is mounted on the base; and the compressing assembly is arranged on the upper part of the mounting plate and comprises a compressing suction cup and a compressing suction cup fixing plate, the compressing suction cup fixing plate is fixedly connected with the gas flow-guiding plate, and the gas flow-guiding plate is mounted on the upper cover plate. According to the electronic component temperature detection device, the temperature field conduction direction can be changed according to the requirements of different electronic products, the problem that an original temperature testing box can only heat / cool a testing product unidirectionallyis solved, the temperature field conduction direction can be controlled in the testing process, and the electronic component temperature detection device is especially suitable for dynamic testing ofrapid temperature change of electronic components or electronic products with the small weight and volume.

Owner:黄先日

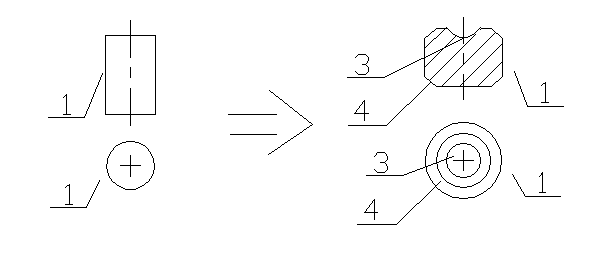

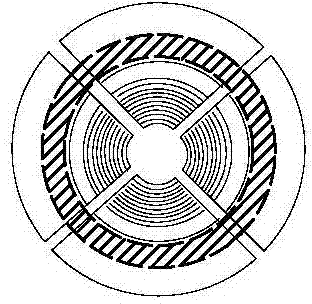

Ultrasonic and induction heating-assisted laser cladding method of composite nanometer coating

ActiveCN108588708ASolve the problem that it is easy to generate tensile stress and greatly increase the crack sensitivitySolve the problem of greatly increased crack susceptibilityMetallic material coating processesUltrasonic assistedOptoelectronics

The invention provides an ultrasonic and induction heating-assisted laser cladding method of a composite nanometer coating. A laser, a precoated layer, a base body, a working table, an ultrasonic vibrator and an induction heating coil are arranged. The ultrasonic and induction heating-assisted laser cladding method of the composite nanometer coating comprises the following concrete steps of (10) after preprocessing the base body, placing the precoated layer on the base body, placing the base body with the precoated layer onto the working table, and moving a laser head of the laser to a position to be cladded of the base body; (20) starting the induction heating coil, and using the induction heating coil for heating the base body and the precoated layer to 200 to 400 DEG C; (30) switching on the laser and the ultrasonic vibrator, wherein the laser is used for laser-cladding the base body through the laser head, and the ultrasonic vibrator is used for ultrasonic-assisting the laser cladding process; (40) after finishing laser cladding, switching off the ultrasonic vibrator and the laser; (50) switching off the induction heating coil; and (60) taking out the base body subjected to laser cladding.

Owner:FUJIAN UNIV OF TECH

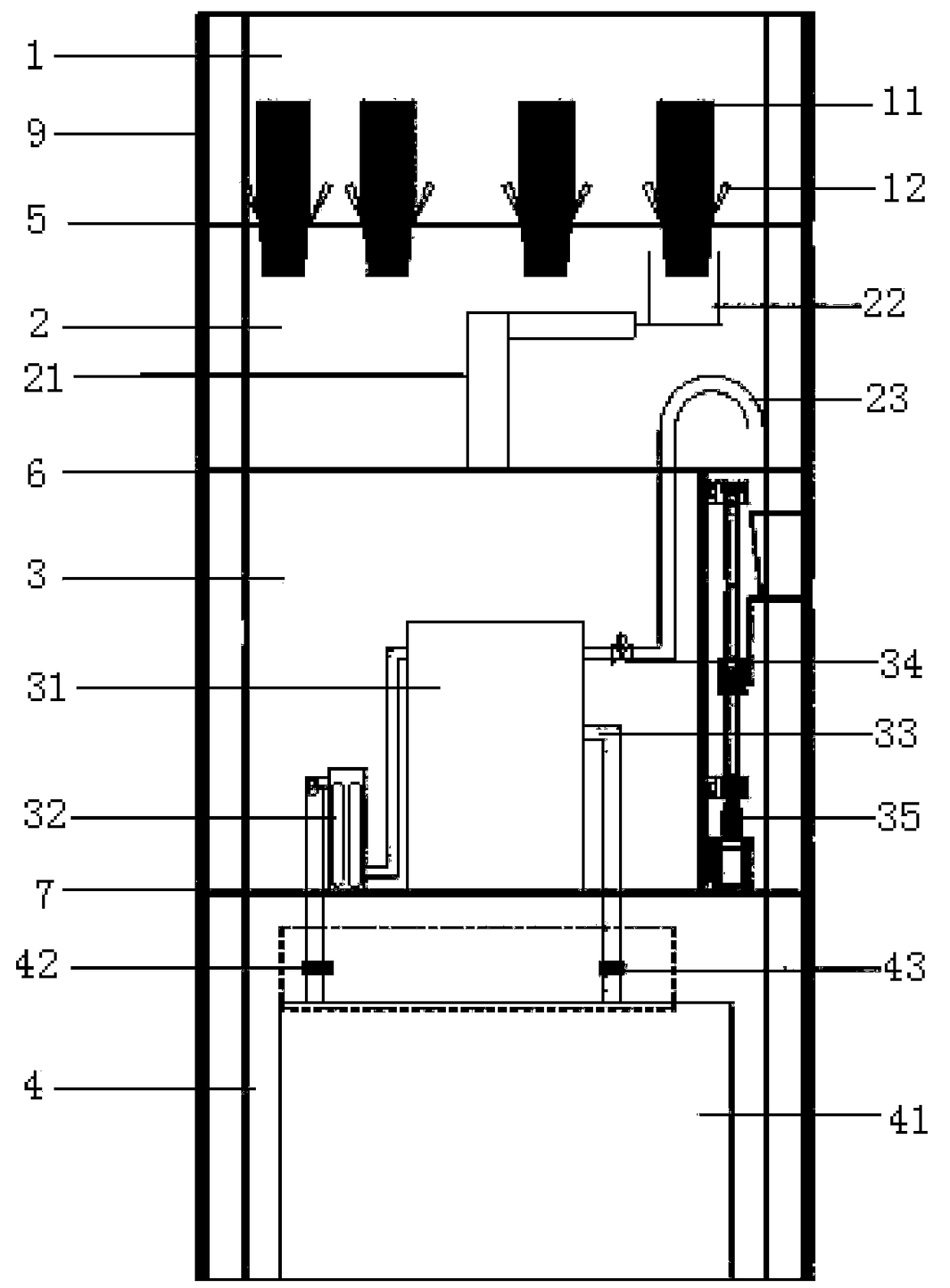

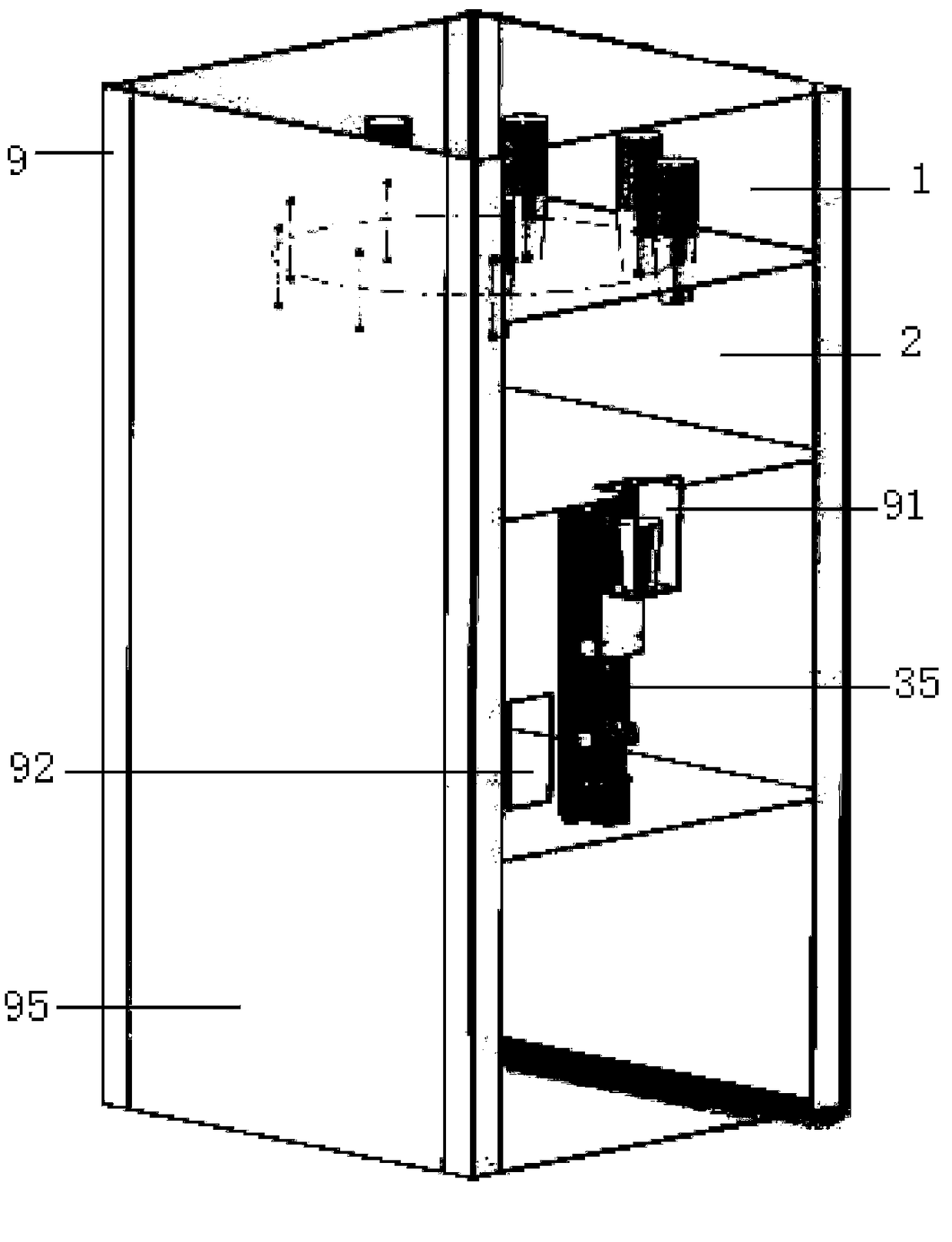

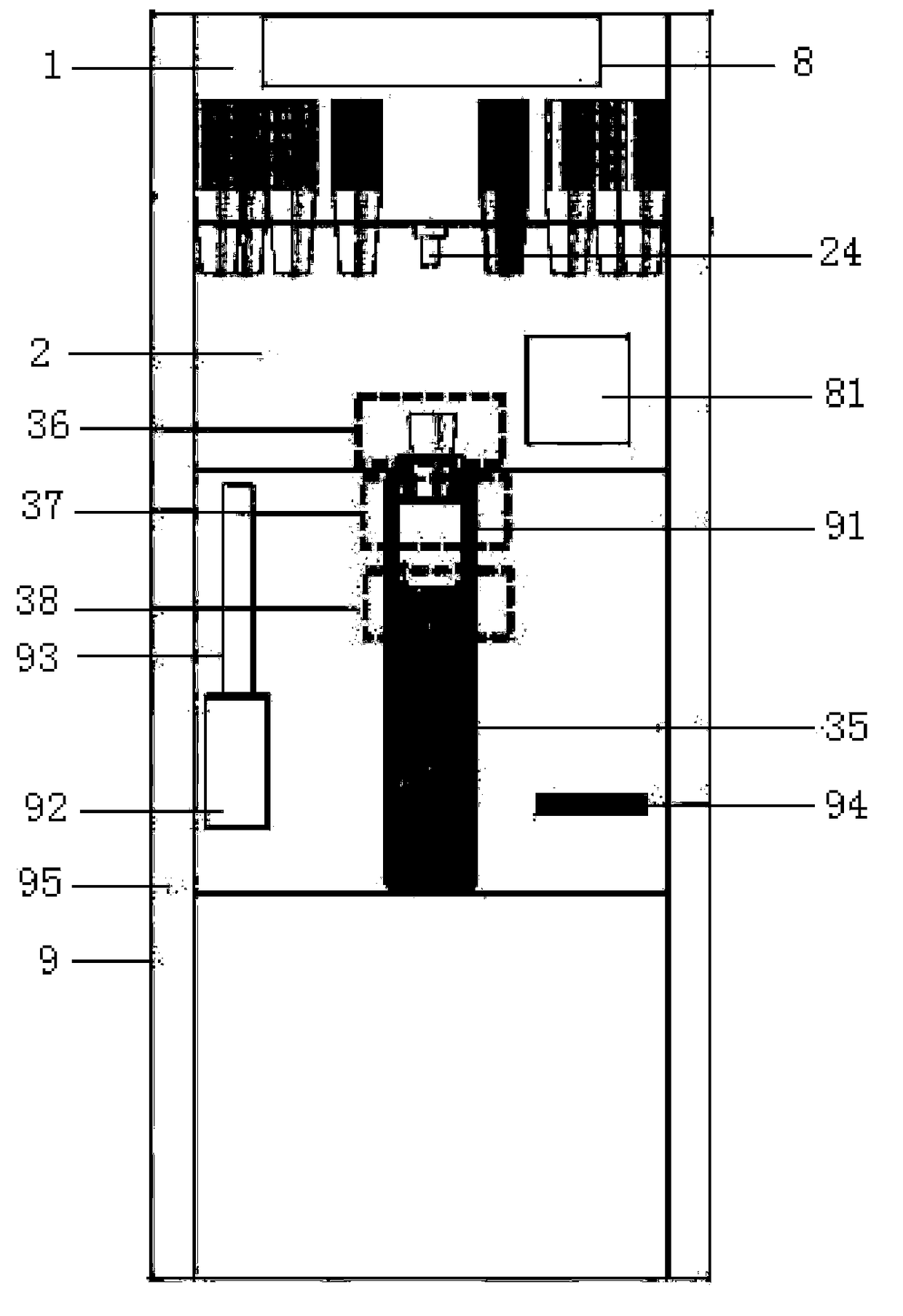

Instant-heating type self-service tea-drinking machine

PendingCN108742153AEasy to drink teaImprove consumer experienceBeverage vesselsApparatus for dispensing fluids/granular materialsWater storageEngineering

The invention discloses an instant-heating type self-service tea-drinking machine. The machine comprises a main body, a drying layer, a tea-making layer, a temperature-adjusting layer and a water storage layer. The drying layer, the tea-making layer, the temperature-adjusting layer and the water storage layer are orderly arranged from the top to the bottom in the interior of the main body. A firstpartition board is arranged between the drying layer and the tea-making layer and equipped with multiple cup holes. Edges of the cup holes are provided with cup-stuck parts. A tea cup group is arranged in each cup hole and comprises multiple tea cups holding tea. The tea cups are arranged in a sleeving and stacking manner. A manipulator, a water outlet and a water level detection device for cup inside are arranged in the tea-making layer. The temperature-adjusting layer comprises a temperature-adjusting water tank, a heating assembly, a cold water inlet pipe and an elevating device. The elevating device ascends and descends in the tea-making layer and the temperature-adjusting layer. Additionally, the elevating process of the elevating device passes a tea cup outlet arranged in the main body. The water storage layer is equipped with a water storage barrel. With the machine, hot water is not placed for a long term or heated multiple times. Different needs of drinking tea at different temperatures in four seasons are met.

Owner:金华汉驭文化创意有限公司

Solar heating lunch box

The invention provides a solar heating lunch box. The lunch box comprises a box body, a box cover, a solar cell panel, and an electric heating device; the upper part of the box cover is provided with a storage cavity, the solar cell panel can be folded and stored in the storage cavity; the electric heating device is arranged in the box body; and the solar cell panel is in an electric connection with the electric heating device. A conventional lunch box is improved by adopting the technical scheme provided by the invention, thus the lunch box can be heated by utilizing the foldable solar cell panel, so that the redundant temperature maintaining system of a conventional lunch box can be removed, furthermore, the food can be heated to reach a higher temperature, and the problem of how to provide a portable and self-heating lunch box is solved.

Owner:苏州罗马冯环保科技有限公司

High-temperature electric resistance furnace used for fretting wear tests

The invention provides a high-temperature electric resistance furnace used for fretting wear tests. Heating devices are fixedly arranged in a furnace body. An upper sample and a lower sample which are oppositely installed up and down are arranged in the furnace body. The upper sample is installed on a high-temperature connection rod through an upper sample base. The lower sample is fixedly installed on a high-temperature connection rod through a lower sample base. The high-temperature connection rods are installed on the side wall of the furnace body through corrugated pipe assemblies. A movable sample is installed on a movable sample base between the upper sample and the lower sample. The movable sample base is connected with an external reciprocating driving device through a driving rod. According to the high-temperature electric resistance furnace, a heating cavity with small volume is arranged in the furnace body and provided with a heat-insulating layer, so that the heating speed of the high-temperature electric resistance furnace is increased; a water cooling layer is additionally arranged on the furnace body, and the high-temperature electric resistance furnace is cooled by starting a cooling water pump after the temperature in the furnace reaches the limit, so that the problems of slow heating and uncontrollable temperature of the high-temperature electric resistance furnace are solved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

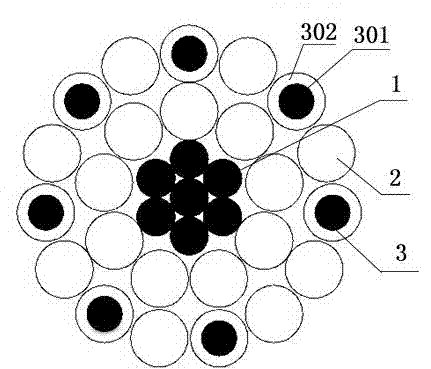

Anti-icing wire and manufacturing method thereof

InactiveCN104733077ASolve non-magneticSolve heatingNon-insulated conductorsCable/conductor manufactureFiberCarbon fibers

The invention provides an anti-icing wire and a manufacturing method thereof. The anti-icing wire comprises an inner carbon fiber core, annealed aluminum lines on the middle layer and the outer layer and low-Curie-point magnetic material wires coated with aluminum. The annealed aluminum lines on the outer layer and the low-Curie-point magnetic material wires coated with aluminum are distributed alternately. Each low-Curie-point magnetic material wire coated with aluminum is composed of an inner low-Curie-point magnetic material layer and an aluminum coating. The manufacturing method of the anti-icing wire comprises the steps that an aluminum rod is molten and extruded on the low-Curie-point magnetic material wires through an aluminum coating machine; a current generator is adopted for coating the inner low-Curie-point magnetic material layers with aluminum so that the aluminum coatings are formed; carbon fibers are used as the inner core, annealed aluminum wires are used as the middle layer and the outer layer, the low-Curie-point magnetic material wires coated with aluminum and the annealed aluminum wires on the outer layer are arranged alternately, and coaxial winding is conducted. The anti-icing wire and the manufacturing method thereof have the advantages that the construction difficulty and the operation cost are not increased, and the anti-icing wire is high in strength, light in weight, small in expansion linear coefficient, not prone to deformation and long in service life.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +2

Arc runner stirring tank

InactiveCN103753706AAvoid under-deposit corrosionAvoid early damageCement mixing apparatusEngineeringStructural engineering

The invention relates to the technical field of concrete tanks and relates to an arc runner stirring tank. The arc runner stirring tank comprises a drive flange and a tank body with an opening facing rightward, wherein the drive flange capable of driving the tank body to rotate is fixedly installed at the left end of the tank body, at least three spiral stirring diversion trenches from left to right are distributed adjacently along the circumference and inside the tank body, the cross section of each stirring diversion trench is U-shaped, and the overall trench surface is in smooth round corner transition. The arc runner stirring tank is reasonable and compact in structure, the stirring diversion trenches with the U-shaped cross sections are arranged in the tank body, so that the dead angle is effectively avoided, adhesions to the residual concrete are reduced, clearing to the residual concrete is avoided, and then the under-deposit corrosion damage of the tank is avoided, meanwhile, the flow resistance in the processes of stirring and unloading the concrete is also reduced, and the energy consumption is lowered; due to the arrangement of a circulating pipe or a jacket or an insulating layer, the tank body and the concrete in the tank body are heated or refrigerated or thermally insulated and controlled on temperature, so that the quality of the conveyed concrete is guaranteed.

Owner:XINJIANG JINYUXIN NEW MATERIAL CO LTD

Pipeline surface pit repair tool

The invention discloses a pipeline surface pit repair tool. The pipeline surface pit repair tool comprises a tapered lead screw and an annular tapping head; the annular tapping head is a section of cylinder with a cylindrical outer surface; a tapered threaded hole is formed in the center of the inner cavity of the cylinder in the axis of the cylinder; the cylinder is formed by a plurality of pieces opposite hooped together; the cylinder is divided into a plurality of pieces in the direction of the axis; the plurality of pieces of the cylinder are peripherally bundled up by use of an elastomer; the tapered lead screw is matched with the threaded hole of the inner cavity of the annular tapping head. The pipeline surface pit repair tool is portable, environment-friendly, easy to carry and convenient to operate. The tool is capable of repairing the pit parts of a stainless steel pipe, an aluminum pipe and a copper pipe in short time; the problems of need on oxy-acetylene flame for heating the metal pipelines, time and labor waste, difficult repair and the like are solved; in short, the pipeline surface pit repair tool has wide popularization and prospect and practical use significance.

Owner:STATE GRID CORP OF CHINA +2

Thermal simulation test auxiliary device for round bar metal forged piece and using method thereof

ActiveCN110376079ASolve the cardSolve heatingMaterial strength using single impulsive forceEngineeringRound bar

The invention provides a thermal simulation test auxiliary device for a round bar metal forged piece and a using method thereof. The auxiliary device comprises a fixed anvil head, a fixed base I, a clamping mechanism, a movable anvil head, a fixed seat II and a pushing mechanism. The fixed anvil head is installed on the fixed base I, the clamping mechanism is arranged between the fixed anvil headand the movable anvil head and is used for clamping a sample, the clamping mechanism comprises an upper clamping electrode and a lower clamping electrode, and the lower clamping electrode is arrangedjust under the upper clamping electrode. The movable anvil head and the fixed anvil head are oppositely arranged in a horizontal direction, the fixed seat II is provided with a mounting hole, and themovable anvil head is slidingly mounted in the mounting hole. The pushing mechanism comprises a moving shaft and a sleeve, an input end of the moving shaft is connected to a power system of a thermalsimulation test machine, and an output end of the moving shaft passes through the sleeve and is oppositely set to an input end of the movable anvil head. According to the device, the problems of the sample loading and heating, the high-speed movement of the anvil heads, the radial deformation of the sample and structures of the anvil heads are solved.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com