Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Control coating amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

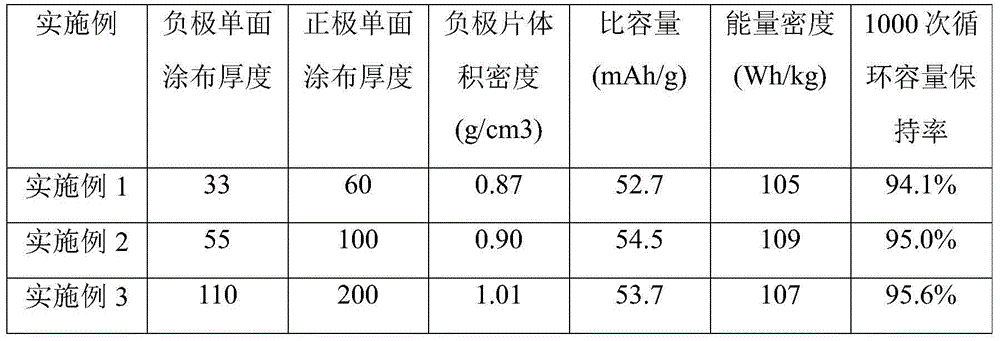

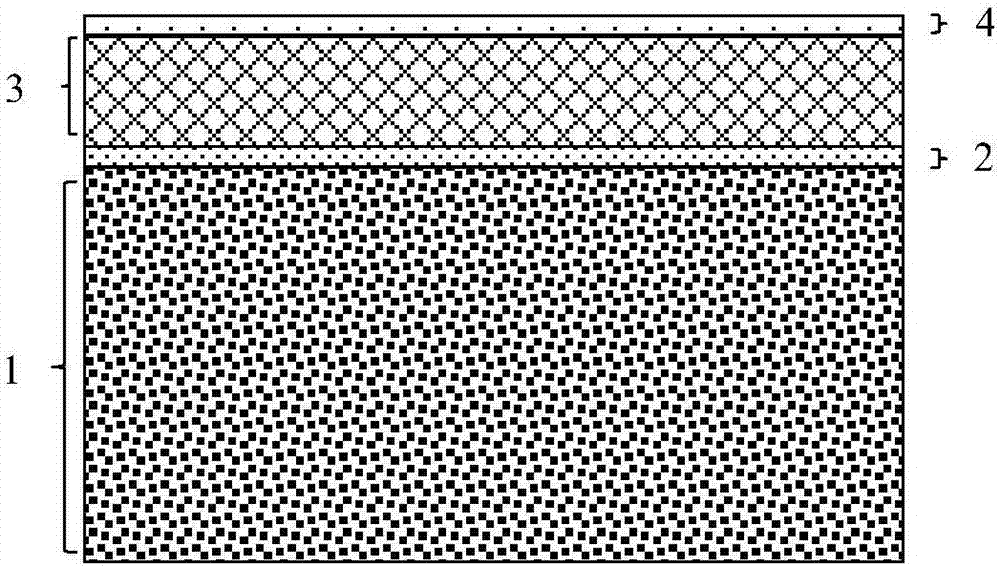

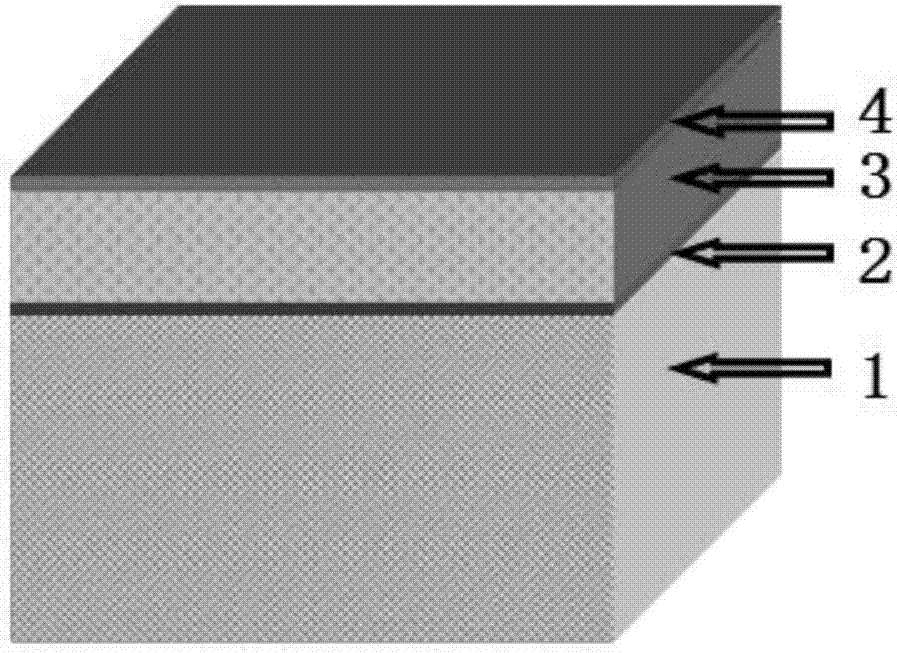

Cathode plate for lithium-ion capacitor and production method of cathode plate

InactiveCN104409224AExact energy matchExact mass matchingHybrid capacitor electrodesDouble layer capacitorsActivated carbonLithium metal

The invention relates to a cathode plate for a lithium-ion capacitor. The cathode plate comprises a current collector, a bottom coating and an upper coating. The bottom coating coats two sides of the current collector, and the upper coating coats the bottom coating. The bottom coating comprises a carbonaceous active material, a conductive agent and a binding agent I. The upper coating comprises stabilized lithium metal powder and a binding agent II. The invention further relates to a method for producing the cathode plate. The method is simple in production process, easy to operate on a large scale and capable of achieving pre-embedding without harsh environments; meanwhile, energy matching between the cathode plate and an activated-carbon anode plate of the lithium-ion capacitor is achieved easily by adjusting the coating thickness.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

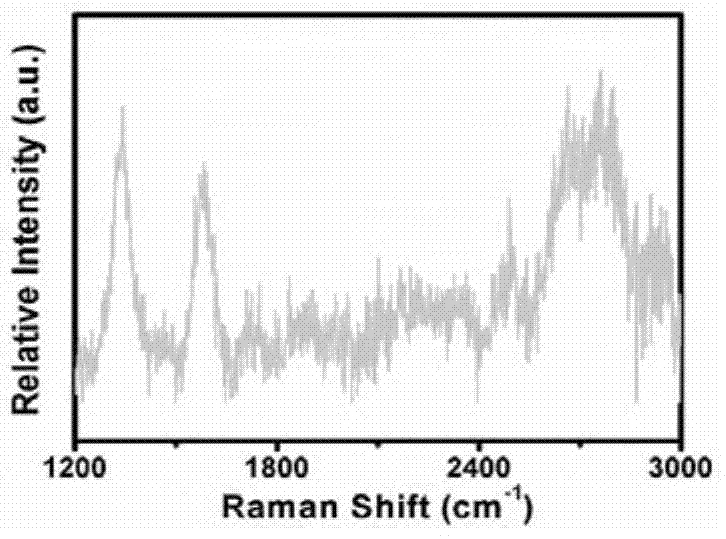

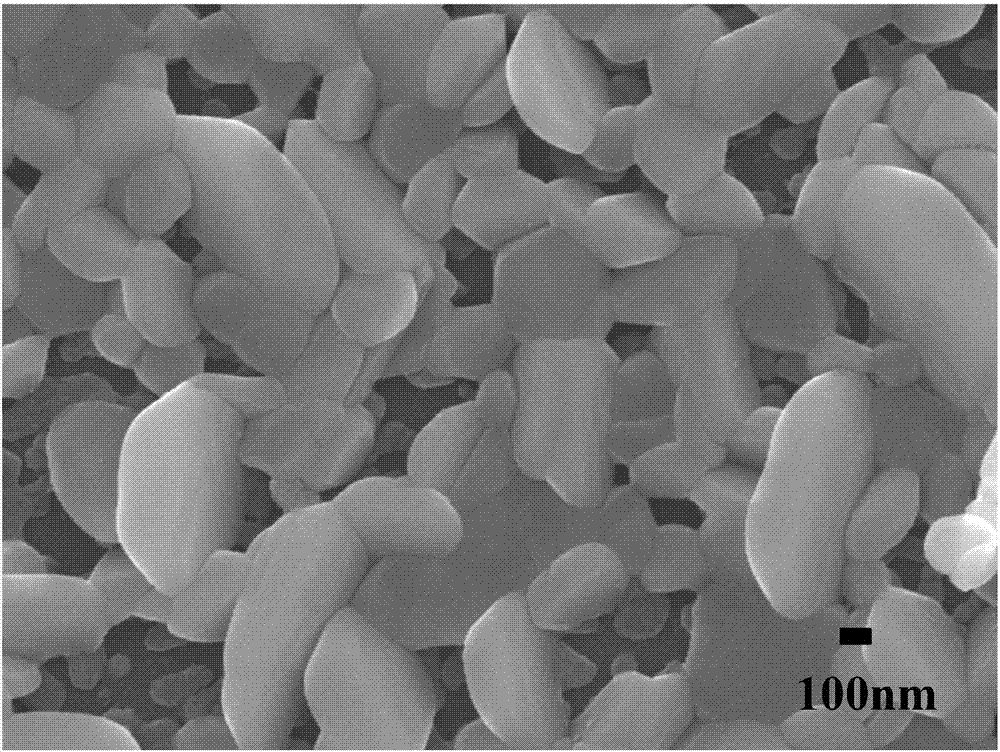

Graphene composite electrode material and preparation method and application thereof

InactiveCN107026259AImprove controllabilityControl coating amountMaterial nanotechnologyCell electrodesComposite electrodeGraphene

The invention discloses a graphene composite electrode material and a preparation method and application thereof. The graphene composite electrode material comprises a lithium ion battery electrode material and graphene, wherein the graphene is coated on a surface of the lithium ion battery electrode material, and the thickness of the graphene is 0.3-5 nanometers. The preparation method of the graphene composite electrode material comprises the following steps of 1) calcining a lithium ion battery electrode raw material, and reducing a temperature after calcination is completed; and 2) rising the temperature of the lithium ion battery electrode material processed in the step 1), and introducing a carbon source for chemical vapor deposition reaction, thereby obtaining the graphene composite electrode material. The preparation method is simple, is high in controllability and is suitable for industrial continuous production.

Owner:PEKING UNIV

Wire drawing film coating machine

InactiveCN102698923AQuality improvementControl coating amountLiquid surface applicatorsCoatingsFilm-coated tabletFilm coating

The invention belongs to the technical field of film coating equipment, and particularly relates to a wire drawing film coating machine. The wire drawing film coating machine comprises an coiling set, a conveyor set, a coating machine set, a drying device and a take-up machine set, wherein the coating machine set comprises a micro gravure coating device; the micro gravure coating machine comprises a base; a material trough is arranged above the base; a micro gravure coating roller is arranged above the material trough; a scraper device is arranged on one side of the micro gravure coating roller; a film roller lifting mechanism is arranged above the micro gravure coating roller, and is connected with a driving device; reticulate patterns which are formed by interlacing cross grains with 40 to 65 degrees is arranged on the surface of the micro gravure coating roller; and the diameter of the micro gravure coating roller is 50 to 70mm. The wire drawing film coating machine has the characteristics of high coating accuracy and good coating effect, and can be used for coating wire drawing films imitating an metal effect.

Owner:东莞市施乐威尔光电科技有限公司

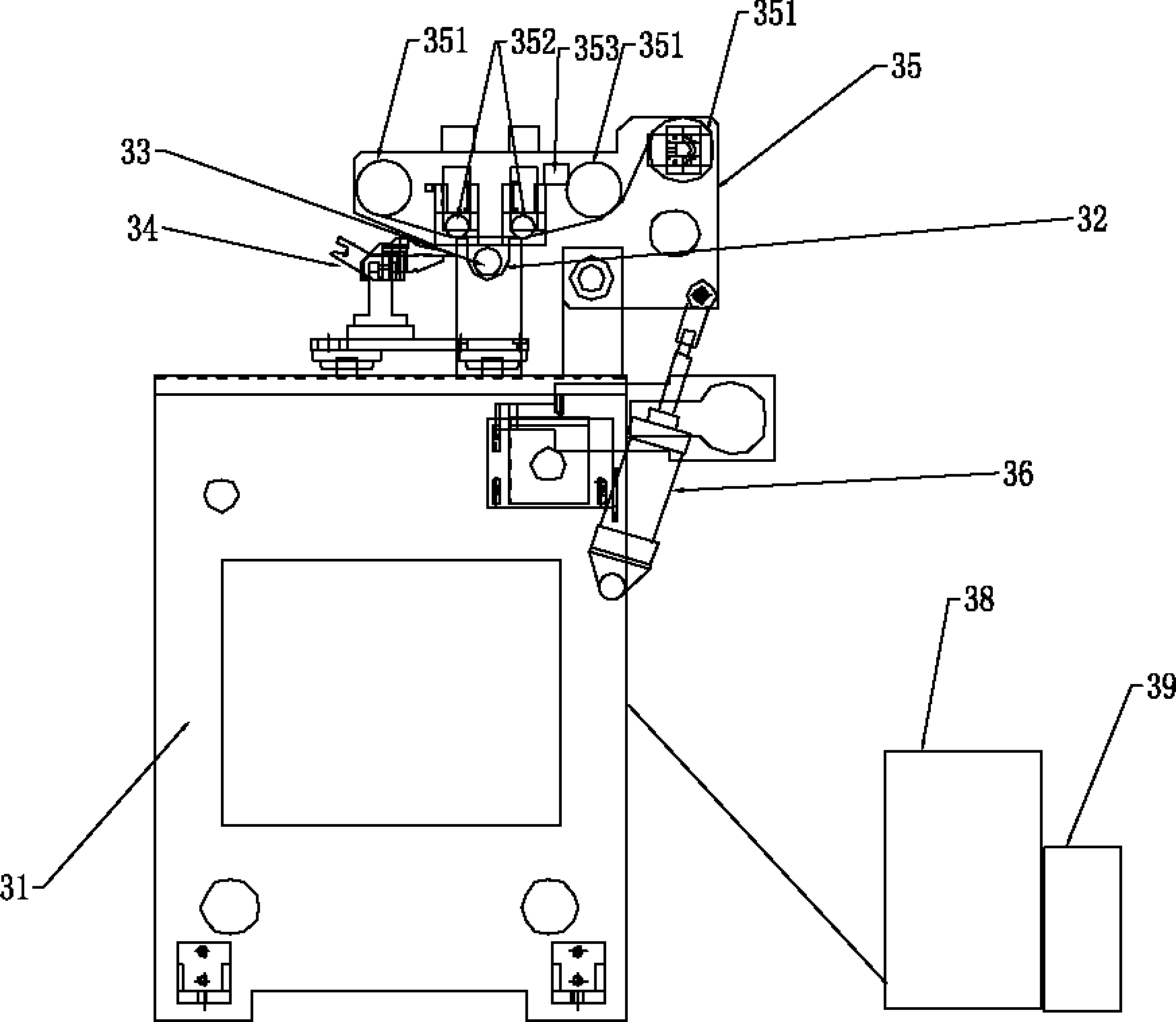

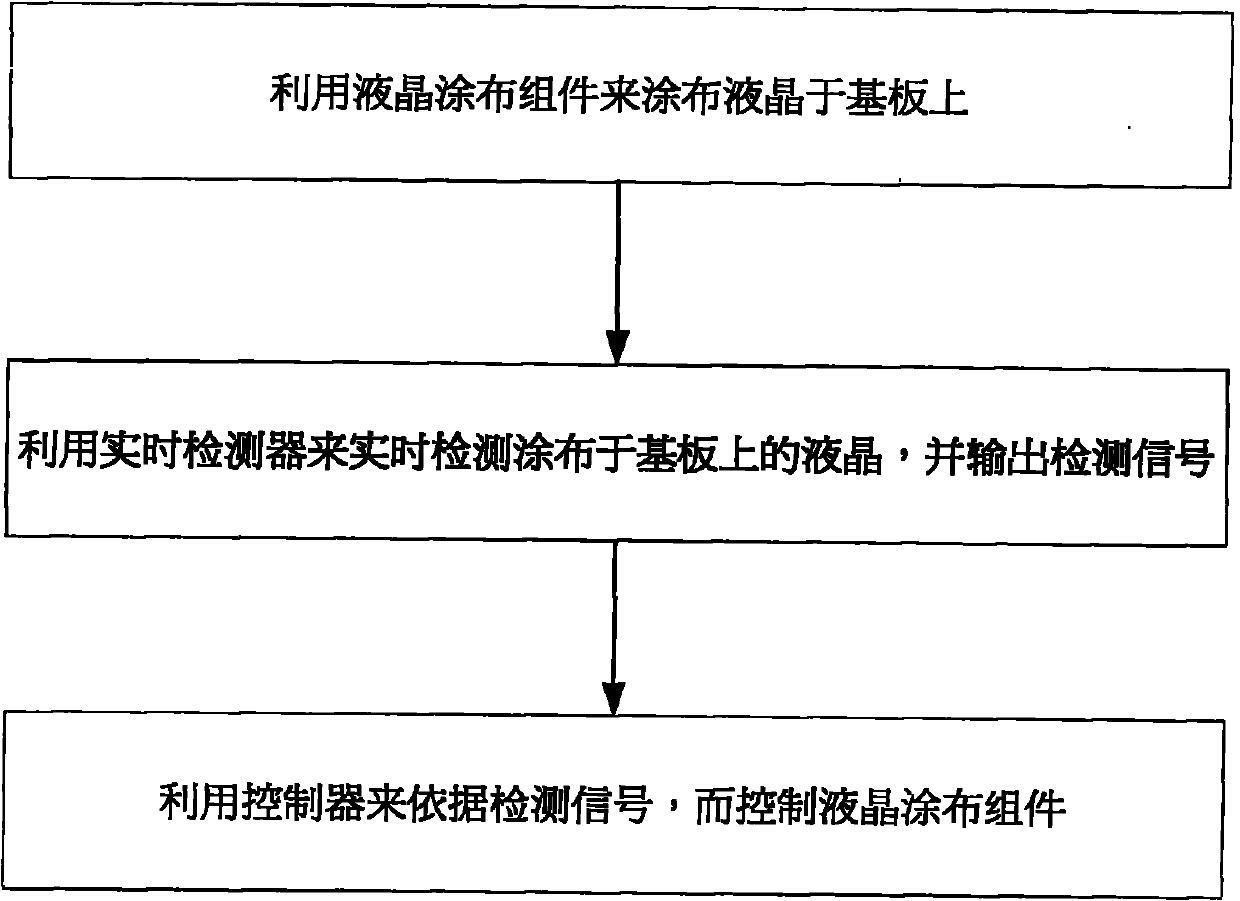

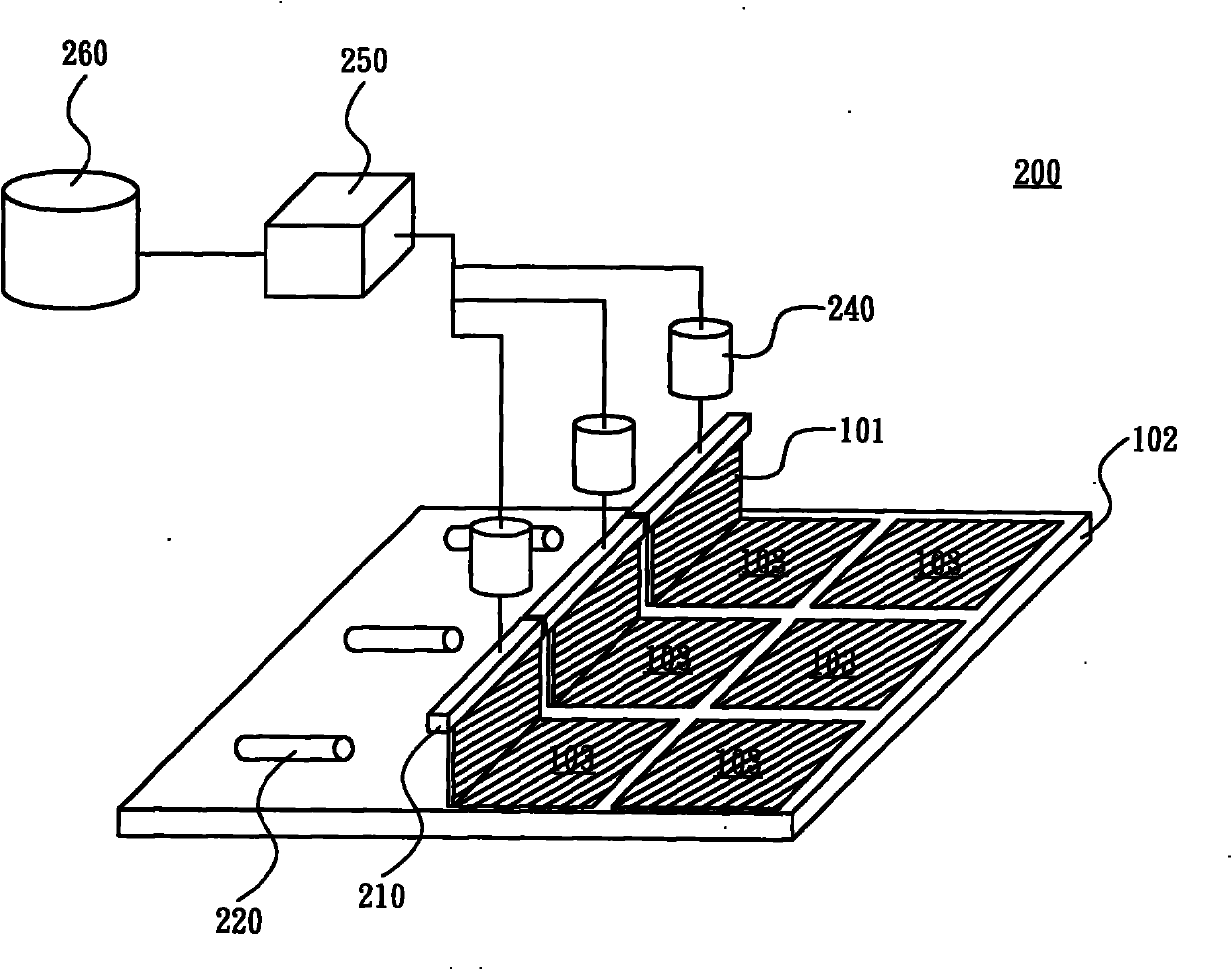

Liquid crystal coating device and liquid crystal coating method

ActiveCN102000652AControl coating amountControl thicknessLiquid surface applicatorsCoatingsLiquid-crystal displayMaterials science

The invention provides a liquid crystal coating device and a liquid crystal coating method. The liquid crystal coating device comprises a liquid crystal coating component, a real-time detector and a controller. The liquid crystal coating method comprises the following steps of: coating a liquid crystal onto a substrate by using the liquid crystal coating component; detecting the liquid crystal coated onto the substrate in real time by using the real-time detector, and outputting a detection signal; and controlling the liquid crystal coating component according to the detection signal by usingthe controller. By the liquid crystal coating device and the liquid crystal coating method, liquid crystal coating situations can be monitored in real time, and uniform liquid crystal films can be coated and formed.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

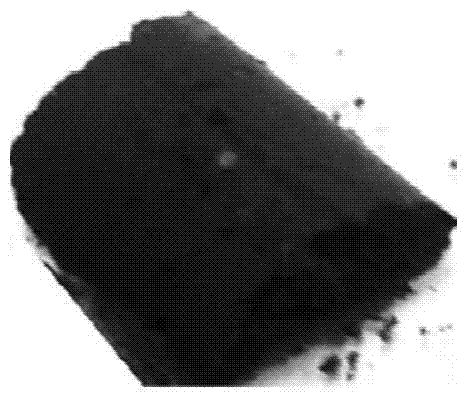

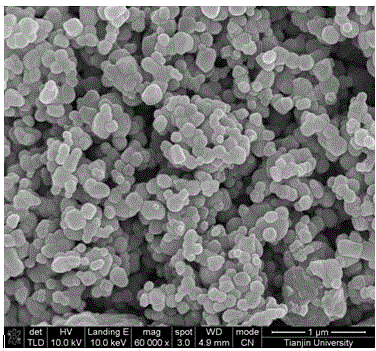

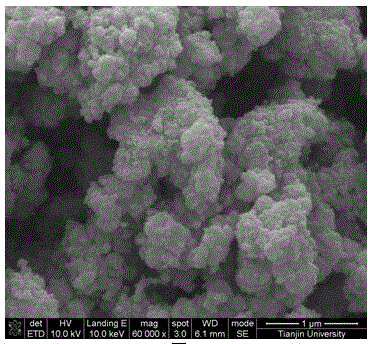

Antimony-doped tin oxide cladding titanium dioxide composite conductive material and preparation method

InactiveCN103985430AUniform compositionHigh purityConductive layers on insulating-supportsOxide conductorsTin dioxideDispersity

The invention discloses an antimony-doped tin oxide cladding titanium dioxide composite conductive material and a preparation method of the antimony-doped tin oxide cladding titanium dioxide composite conductive material. The antimony-doped tin oxide cladding titanium dioxide composite conductive material is composed of antimony-doped tin oxide cladding and titanium dioxide, wherein the percentage composition ratio of the molar content of the antimony-doped tin oxide in the cladding to the molar content of the titanium dioxide is 0.3-0.9:1. The preparation method comprises the following steps that the titanium dioxide is added into deionized water, so that suspension liquid 1 with the molar concentration of 10-20% is prepared; crystal tin chloride and antimony butter are added into a hydrochloric acid solution, so that a solution 2 is prepared; sodium hydroxide is added into deionized water, so that a solution 3 is prepared; the suspension liquid 1, the solution 2 and the solution 3 are mixed, centrifugation, washing, drying and calcinations are conducted on the mixed solution after aging, and the composite conductive material is obtained. The antimony-doped tin oxide cladding titanium dioxide composite conductive material and the preparation method of the antimony-doped tin oxide cladding titanium dioxide composite conductive material have the advantages that the composite conductive material prepared through a coprecipitation method is simple in synthetic process, the prepared powder is uniform in composition, high in purity and controllable in stoichiometric ratio, and prepared conduvtive power materials are high in purity, light in color, small in grain size and good in dispersity.

Owner:TIANJIN UNIV

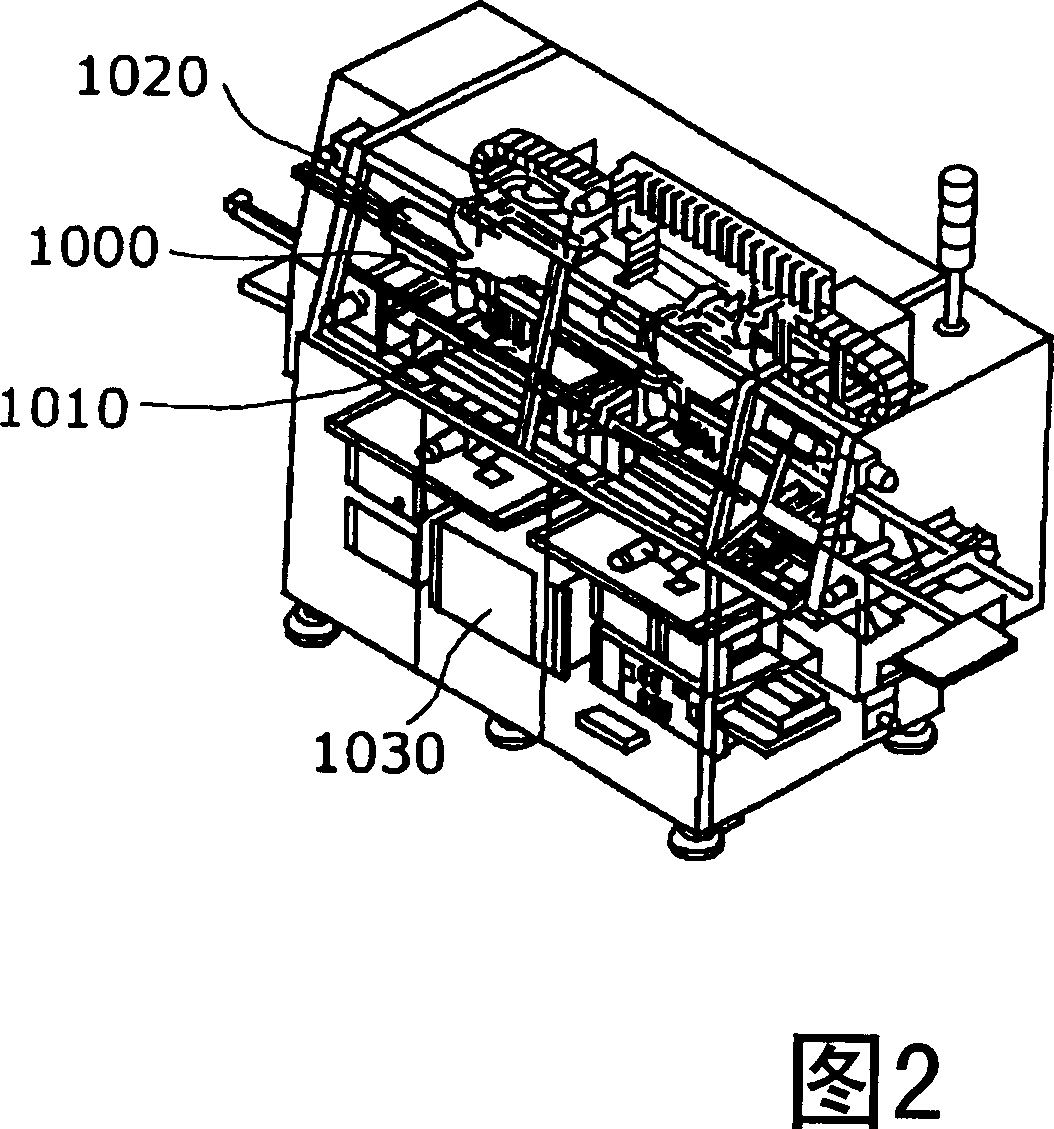

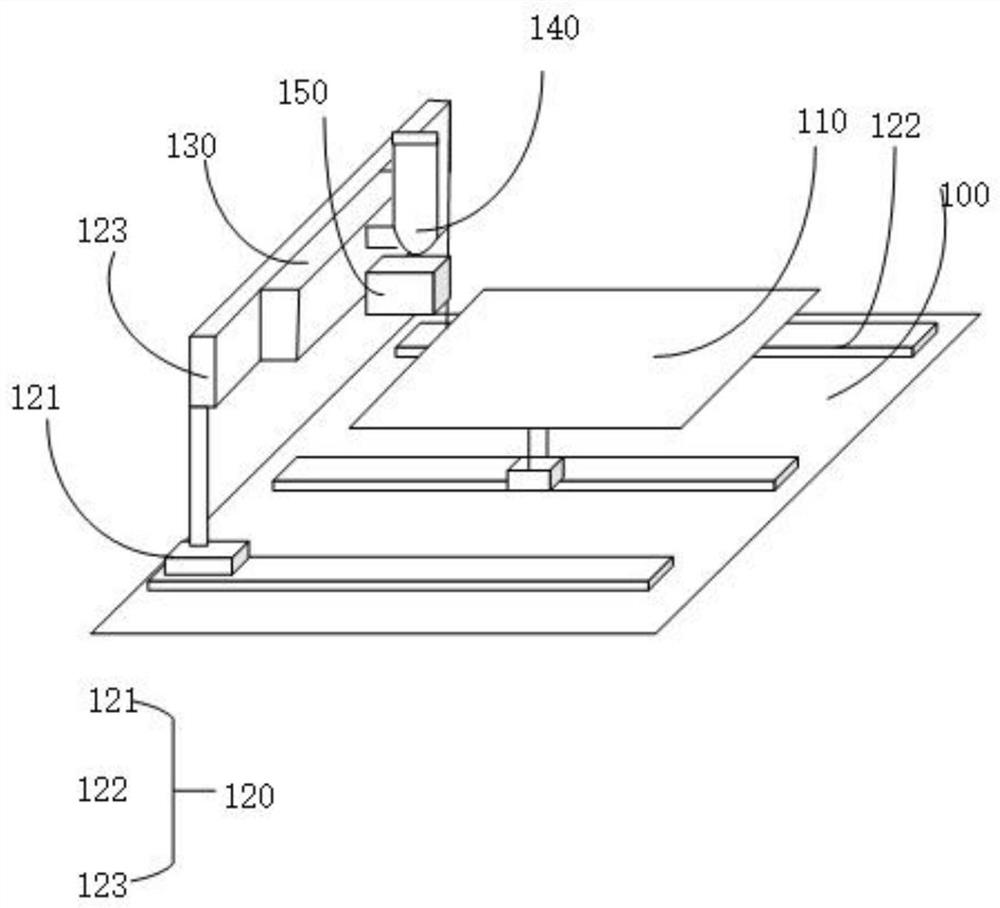

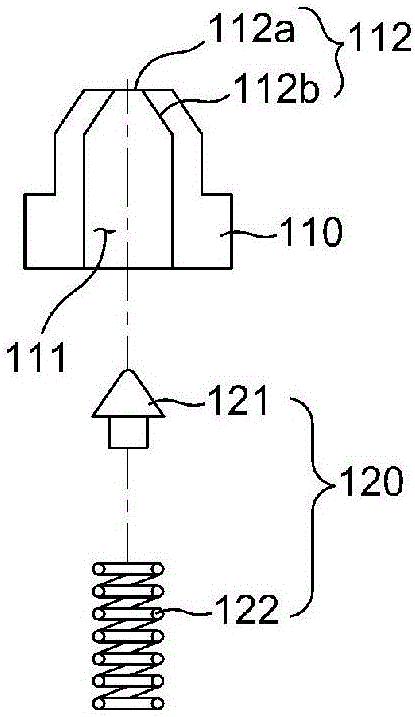

Viscous fluid application method

InactiveCN1946487AImprove production efficiencyHigh utility valueSolid-state devicesPretreated surfacesManufacturing efficiencyEngineering

A viscous fluid application device capable of increasing production efficiency of a semiconductor package without worsening positional accuracy in application and without reducing the degree of freedom in design. The device has an application head (100) having an application section (101) for applying a viscous fluid to a substrate (140a) and a supply section (102) for supplying the viscous fluid to the application section (101), an X-axis section (110), a Y-axis section (120), a Z-axis section (130), a substrate conveyance section (140), a head height detection sensor (150), and a control section (160). When the application section (101) moves in the Y-direction, the supply section (102) moves in the Y-direction in conjunction with the movement of the application section (101), and when the application section (101) moves in the X- and Y-directions, the supply section (102) stays still independent of the movement of the application section (101).

Owner:PANASONIC CORP

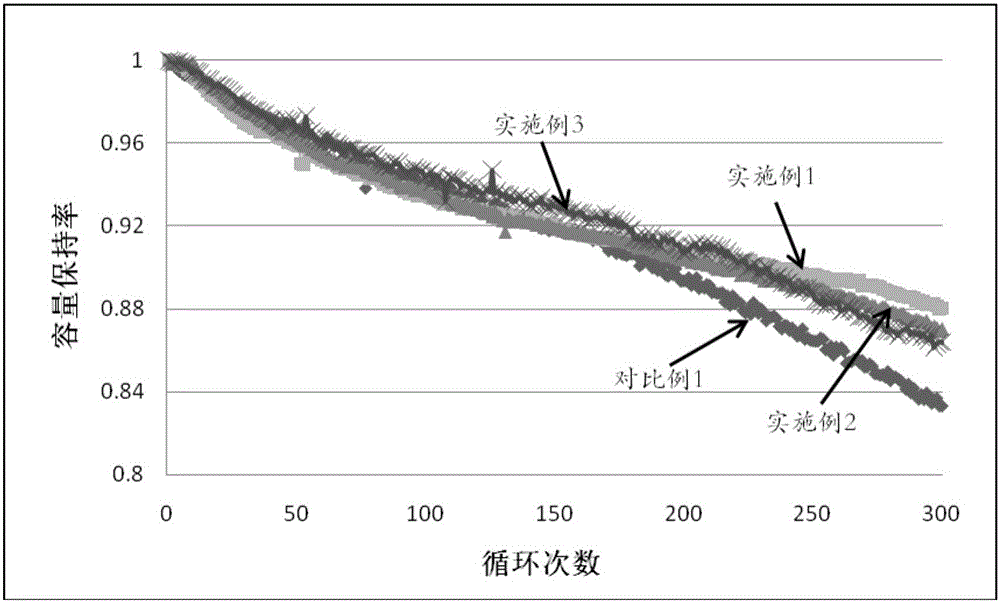

Modified anode material and preparation method thereof as well as lithium ion battery

InactiveCN105006566AThere will be no problem of cycle performance degradationImprove solubilitySecondary cellsPositive electrodesHigh temperature storageState of art

The invention provides a preparation method of a modified anode material. The preparation method comprises the following steps: stirring an anode material and a hydroxyl alumina sol in water for reacting, and drying by distillation to obtain a powder product; roasting the powder product to obtain the modified anode material. According to the preparation method of the modified anode material, the hydroxyl alumina sol is adopted as an aluminum source to perform water cladding on the anode material; compared with the prior art that alumina is adopted to perform surface cladding on the anode material, the preparation method has the advantages that the attenuation of the cycle performance of the anode material caused by lithium loss due to water cladding cannot occur, the contact area between the anode material and electrolyte can be effectively reduced, the dissolving of the anode material in a high temperature cycling process is improved, and the cycling capacity keeping capability is enhanced; therefore, a lithium ion battery prepared by the modified anode material which is prepared by the method has better cycling performance and high temperature storage performance. The invention also provides the modified anode material and the lithium ion battery.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

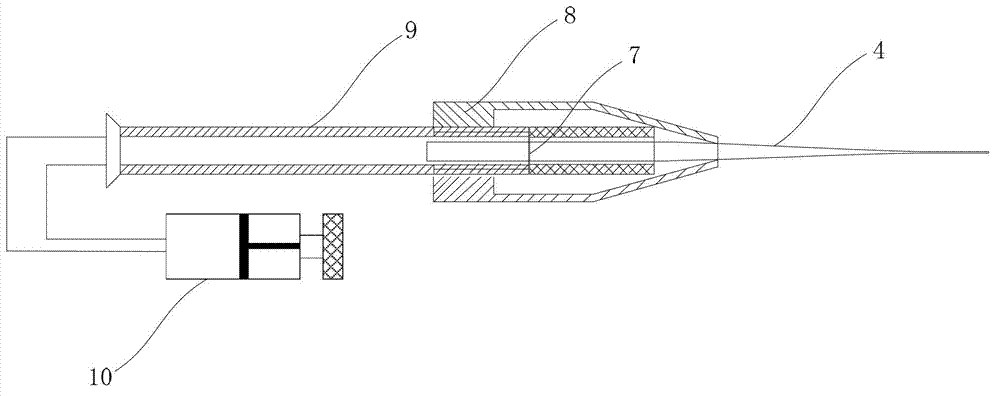

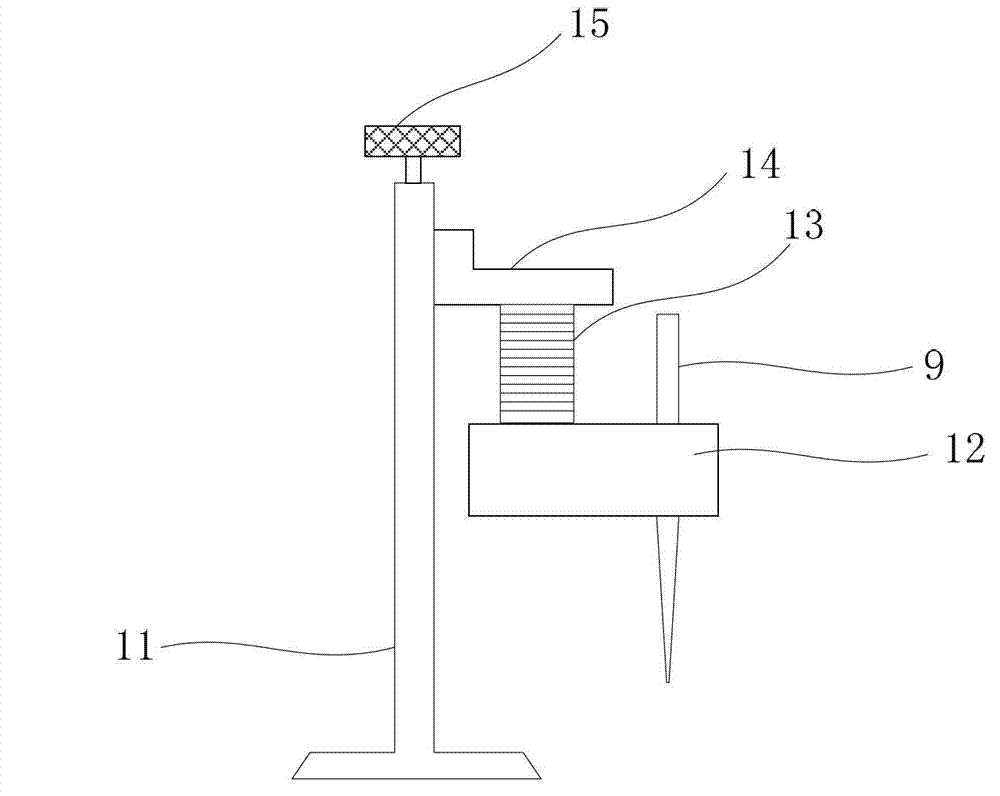

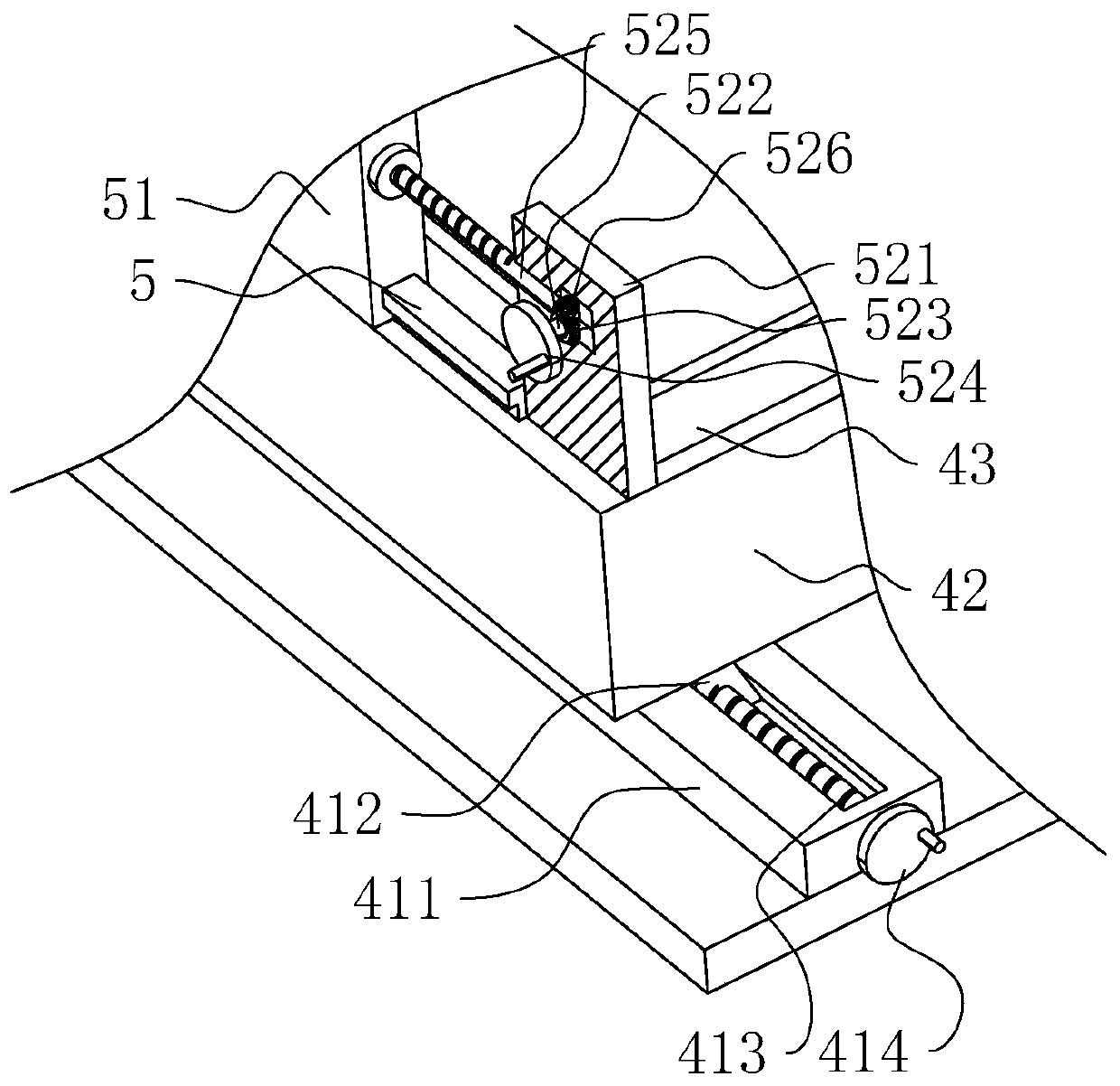

Equipment and method for coating sensitive material on micro-heater

ActiveCN102755942AControl coating amountReal-time adjustment of coating positionLiquid surface applicatorsCoatingsElectricitySpray nozzle

The invention provides equipment and a method for coating a sensitive material on a micro-heater. The equipment comprises a loading device and a coating device; the loading device comprises a micro-nozzle for loading the sensitive material, a sleeve sleeved at a loading end of the micro-nozzle, and a pressure adjuster for generating a negative pressure in the micro-nozzle; the coating device comprises the micro-nozzle loaded with the sensitive material, a piezoelectric driver for driving the micro-nozzle, a connecting piece for clamping and fixing the micro-nozzle so that a feeding end and a discharge end of the micro-nozzle vertically aligns to the surface of the micro-heater, and a rack connected with the piezoelectric driver; and the rack is provided with a sliding groove where the piezoelectric driver and the micro-nozzle move along the vertical direction. The invention further provides the method for coating the sensitive material on the micro-heater. With the adoption of the equipment and the method for coating the sensitive material on the micro-heater provided by the invention, a coating amount of the sensitive material can be controlled, and a coating position of the sensitive material is adjusted in real time, so that the problem that the sensitive material cannot be quantitatively and uniformly coated on the surface of the micro-heater in prior art can be solved.

Owner:RAE SYST SHANGHAI +1

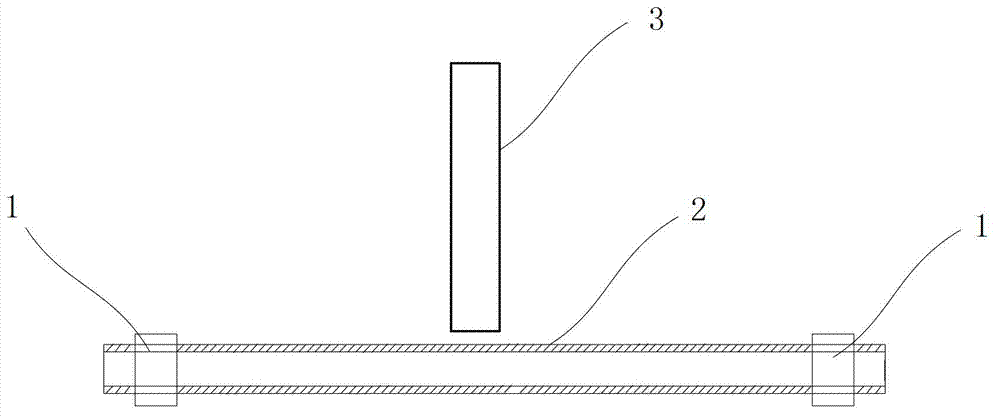

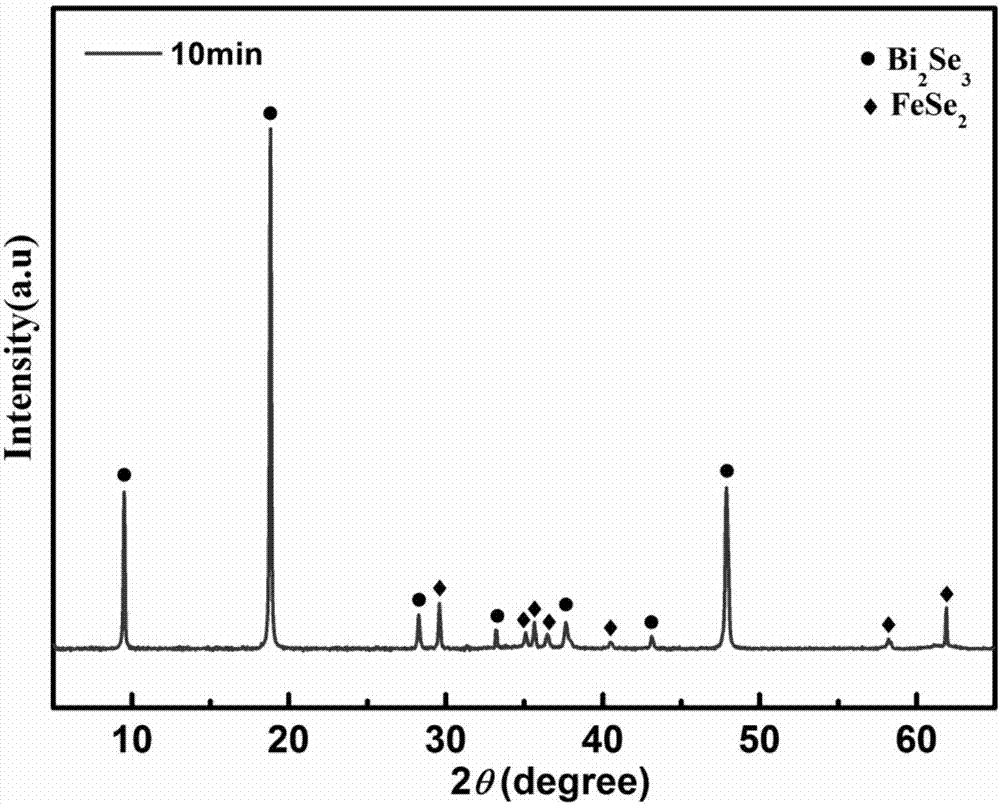

Preparation method of topological insulator Bi2Se3/FeSe2 alloplasmic structure thin film

ActiveCN107058964AHigh crystallinityGood crystallinity, good ferromagnetismVacuum evaporation coatingSputtering coatingSputteringOptoelectronics

The invention discloses a preparation method of a topological insulator Bi2Se3 / FeSe2 alloplasmic structure thin film. The preparation method includes the main steps that a, a FeSe base film is prepared, wherein the FeSe base film is formed on a base sheet through magnetron sputtering; b, FeSe2 annealing phase forming is carried out, wherein the base sheet obtained in the step a and selenium particles are sealed into a vacuum quartz tube with the air pressure smaller than 1*10<-2> Pa, annealing phase forming treatment is carried out, and an FeSe2 thin film is obtained on the base sheet; c, a Bi2Se3 base film is prepared, wherein on the base sheet obtained in the step b, magnetron sputtering is carried out to form a Bi2Se3 film, and then a Bi2Se3 / FeSe2 base film is formed on the base sheet; and d, Bi2Se3 annealing phase forming is carried out, wherein the base sheet obtained in the step c and selenium particles are sealed into a vacuum quartz tube with the air pressure small than 1*10<-2> Pa, annealing phase forming treatment is carried out, and the product is obtained. According to the method, the film coating amount is easily controlled, the formed alloplasmic structure thin film is smooth and good in performance. The preparing cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

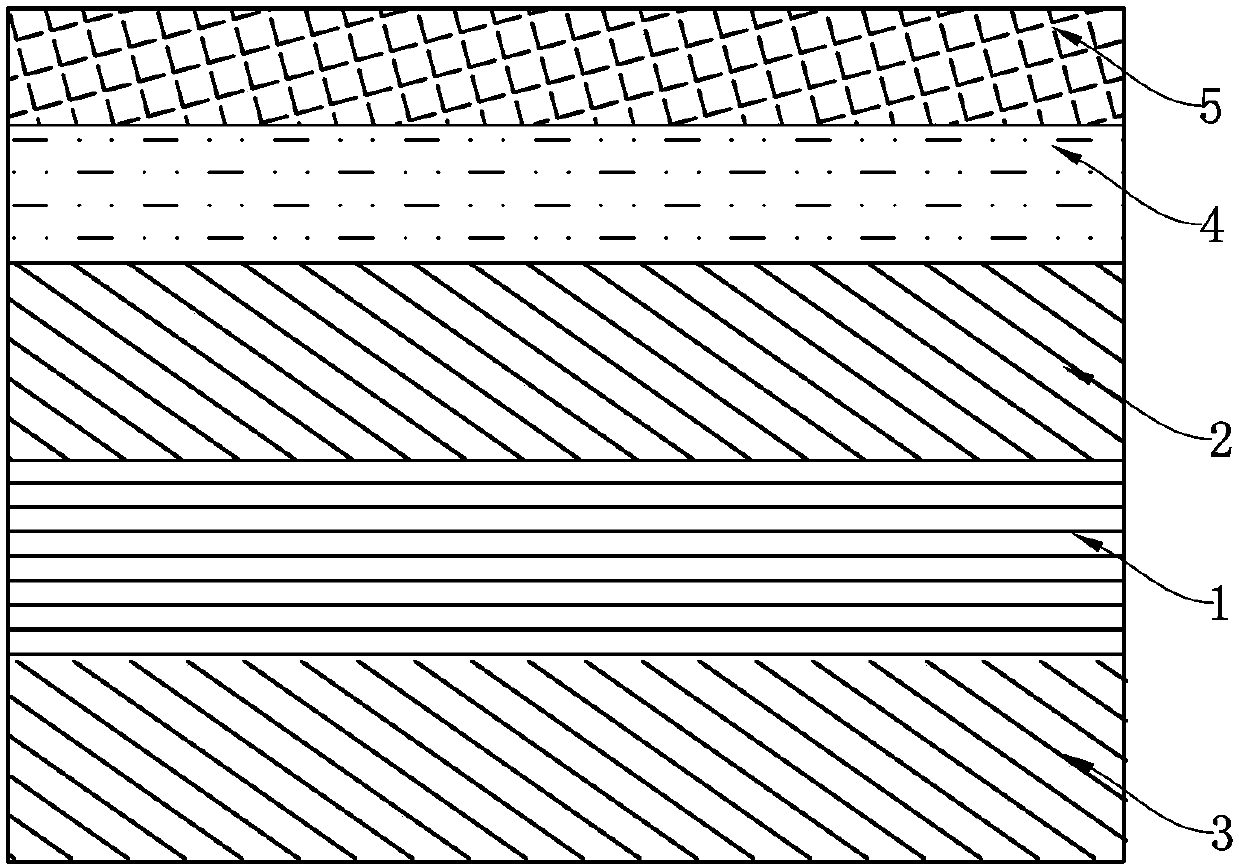

Special multifunctional prefabricated pavement brick

PendingCN106884362AAvoid uncontrollabilityControl coating amountSingle unit pavingsPavement lightsFiberBrick

The invention discloses a special multifunctional prefabricated pavement brick. The special multifunctional prefabricated pavement brick sequentially comprises a concrete plate body layer, a sticky layer, a light-emitting functional layer and a tail gas absorbing functional layer from bottom to top, wherein the concrete plate body layer is made of fiber concrete; the sticky layer is made of modified emulsified asphalt or resin material; the light-emitting functional layer is a graded light-emitting broken stone layer which is composed of a colorless cementing material and graded light-emitting broken stones; and the tail gas absorbing layer is made of anatase type nano silicon dioxide powder which synchronously spreads on the light-emitting function layer. The special multifunctional prefabricated pavement brick disclosed by the invention has the night light-emitting function and the function of absorbing automobile tail gas, realizes the purpose of absorbing and degrading automobile tail gas in daytime and emitting light at night; and through a prefabricating mode, the effect of the special multifunctional prefabricated pavement brick is sufficiently brought into play, the use is convenient and the practicability is high.

Owner:CHECC HIGHWAY MAINTENANCE & TEST TECH CO LTD +1

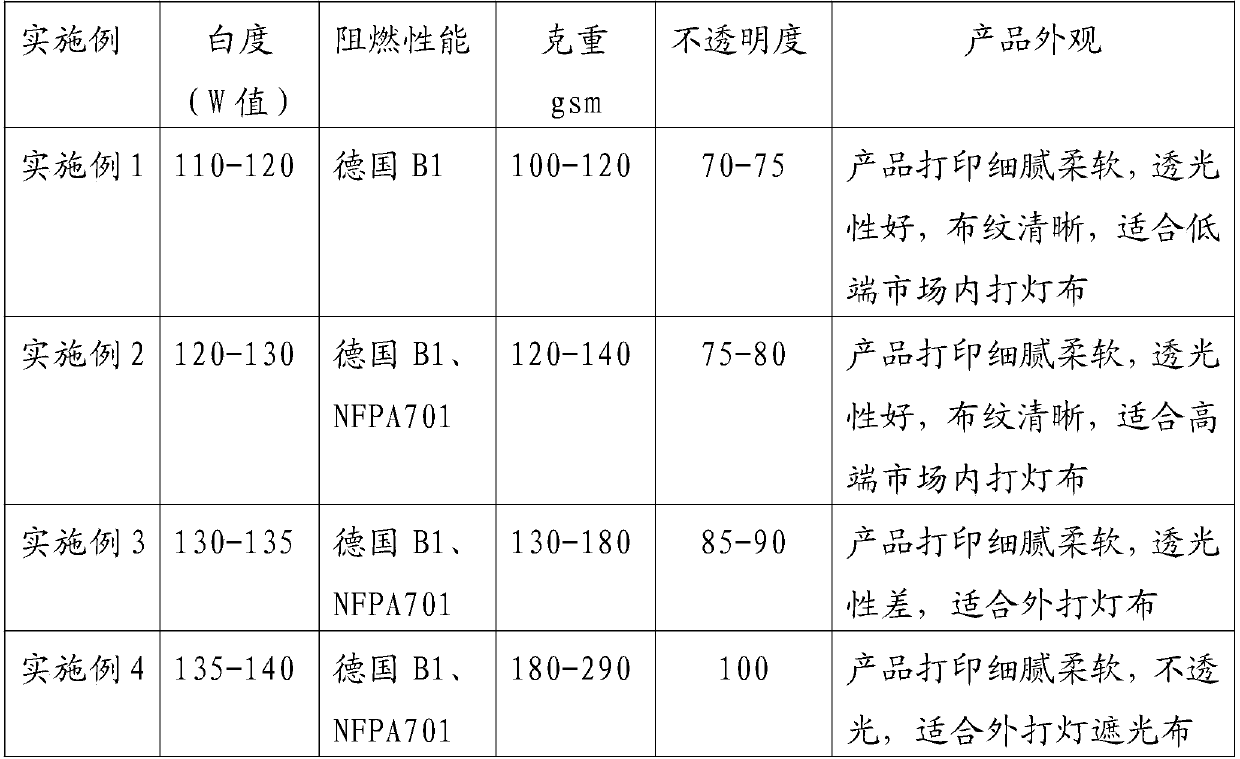

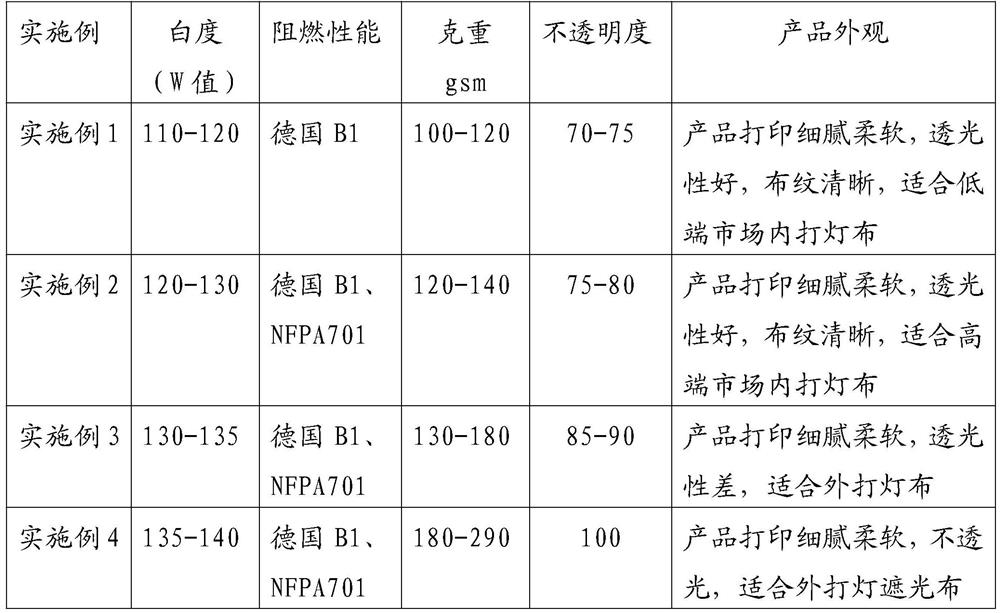

Foaming coating inner lighting advertising cloth and preparation technology thereof

ActiveCN107700232ALow densityReduce penetrationFireproof paintsTextiles and paperImaging qualityImage quality

The invention relates to an advertising cloth, especially to a foaming coating inner lighting advertising cloth. The foaming coating inner lighting advertising cloth comprises a base cloth layer, theupper side and lower side of the base cloth layer are respectively coated with a whitening waterproof layer, wherein the surface of a whitening waterproof layer on one side is coated with a foaming flame retardant coating, and the surface of the foaming flame retardant coating is coated with an ink absorption coating. The invention also discloses a preparation technology of the advertising cloth.The preparation technology includes coating of the whitening waterproof coating, coating of the foaming flame retardant coating, and coating of the ink absorption coating. The advertising cloth provided by the invention has the advantages of flame retardance, wrinkle resistance, light weight, good handfeel, and fine printed image quality.

Owner:柔识智能科技(山东)有限公司

Equipment for coating wood board with oil paint

PendingCN104549876AControl coating amountUniform thicknessLiquid surface applicatorsCoatingsWrinkle skinEngineering

The invention discloses equipment for coating a wood board with oil paint. The equipment comprises a lower roller and an upper roller, wherein the lower roller is used for conveying the wood board; the upper roller is positioned above the lower roller; a high-elasticity steel sheet tilting to the upper roller is arranged in front of the rotation direction of the upper roller; the upper surface of the steel sheet is a parabolic surface; the upper surface of the lower part of the steel sheet is close to the surface of the upper roller, and the closest distance is not smaller than the oil paint coating thickness of the wood board; the steel sheet is not shorter than the upper roller; a paint adding device for coating the oil paint is further arranged above the upper roller; the paint adding device is a spray pipe moving back and forth; the movement direction of the spray pipe is parallel to the direction of a roller shaft of the upper roller; a pipe orifice of the spray pipe is aligned with the surface of the upper roller. The equipment is simple in structure, and the thickness of the oil paint is uniform by virtue of the steel sheet used for uniformly scraping the oil paint; meanwhile, in order to prevent the surface of the upper roller from being probably scratched by the sharp edge of the steel sheet, the upper surface of the steel sheet is set as the parabolic surface, and the bulged surface of the steel sheet is close to the upper roller. The coating amount of the oil paint can be accurately controlled, knurls cannot be generated by reverse roll coating, and the phenomena of wrinkles and orange peels are avoided.

Owner:赵希洋

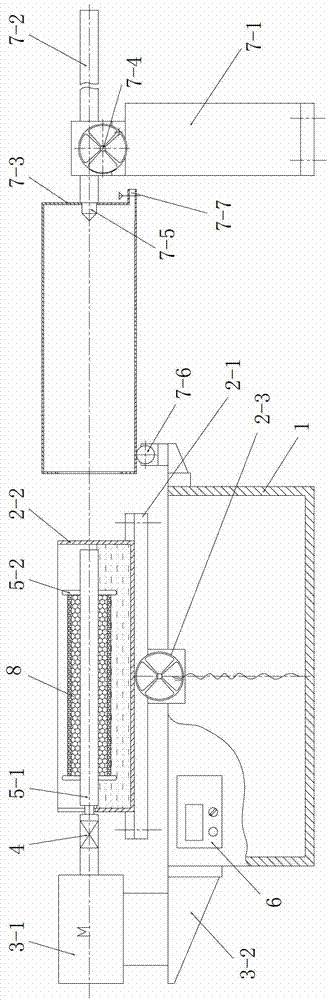

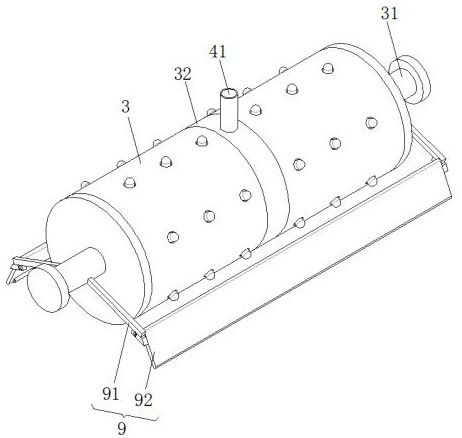

Soaking-centrifugalizing equipment

ActiveCN102962162ASimple structureEasy to operateLiquid surface applicatorsCoatingsControl systemEngineering

The invention discloses soaking-centrifugalizing equipment. The soaking-centrifugalizing equipment comprises a base, a soaking-centrifugalizing device and a slurry recovery device which is arranged at one side of the base and can move forwards and backwards in horizontal direction. The soaking-centrifugalizing device comprises a clamping tool which can continuously rotate and drive a foam filter tube precursor to synchronously rotate when rotating continuously, a soaking device which can move upwards and downwards, a rotary drive motor for driving the clamping tool to continuously rotate, and a control system for controlling and adjusting the rotation direction and the rotation speed of the rotary drive motor; the clamping tool is arranged above the base; a power output shaft of the rotary drive motor is connected with the clamping tool through a transmission mechanism; the clamping tool is arranged horizontally; and the foam filter tube precursor is horizontally arranged on the clamping tool. The soaking-centrifugalizing equipment is simple in structure, convenient to use and operate, safe and reliable in work and high in processing efficiency, realizes slurry recoverability and can be used for finishing the preparation process of various sizes of foam metal filter tubes conveniently and fast.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Leather patching method

InactiveCN109576420ASmooth grainIncrease coverageLeather surface finishingUltimate tensile strengthCoating

The invention relates to the technical field of leather chemistry and engineering and provides a leather patching method. A polyurethane foam resin material is introduced into a patching agent for patching to create a hollow-system patching agent, density of the patching agent is reduced while strength is excellent and stable, and accordingly an elastic stable object is formed. In addition, by combination of mechanical operations such as roller coating and press polishing, the patching agent can be firmly filled at defective or damaged parts of crust leather. The technical defects of lack of falling resistance and proneness to recessing of traditional patching coatings are overcome, a production cycle is shortened, and production efficiency is improved.

Owner:XINGYE LEATHER TECH CO LTD

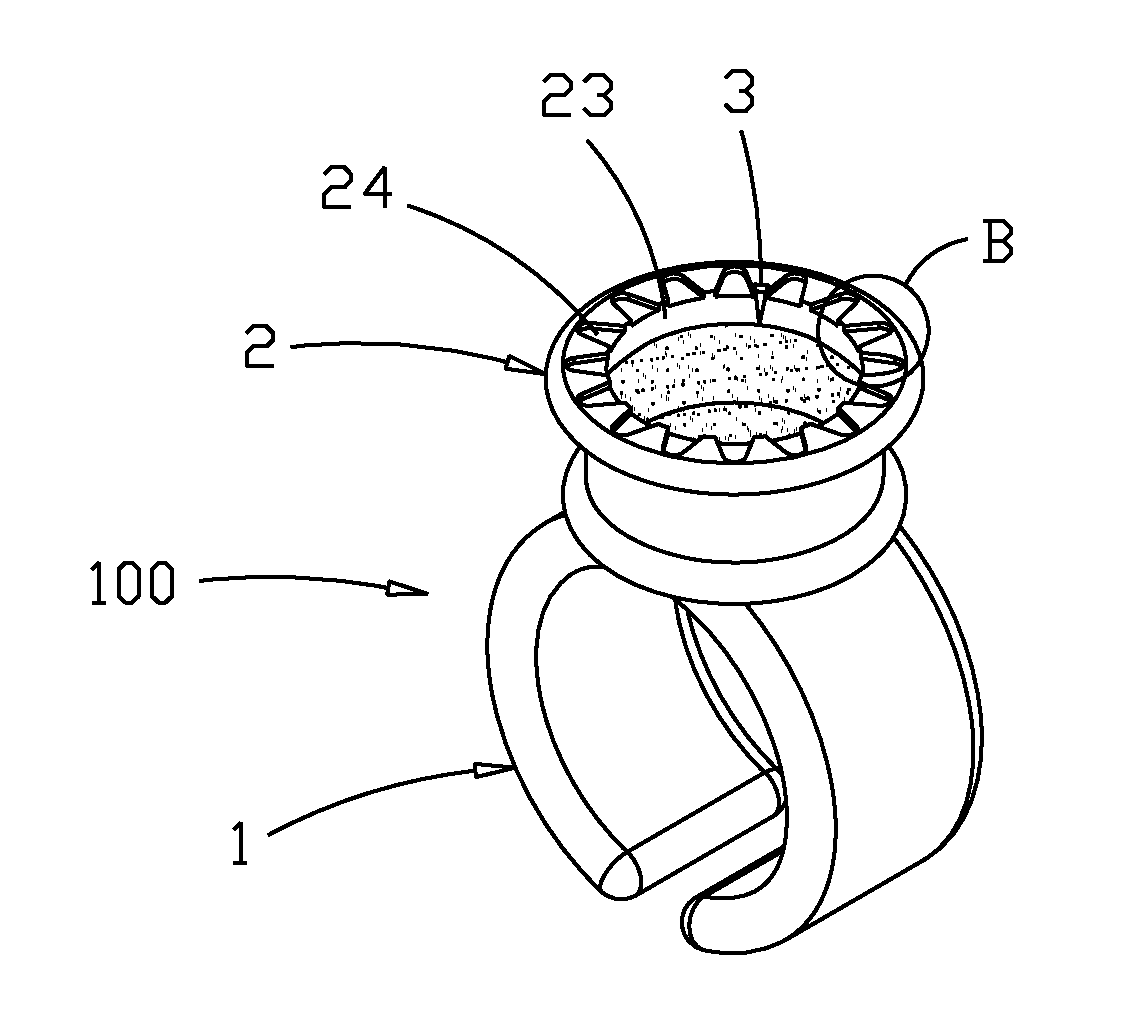

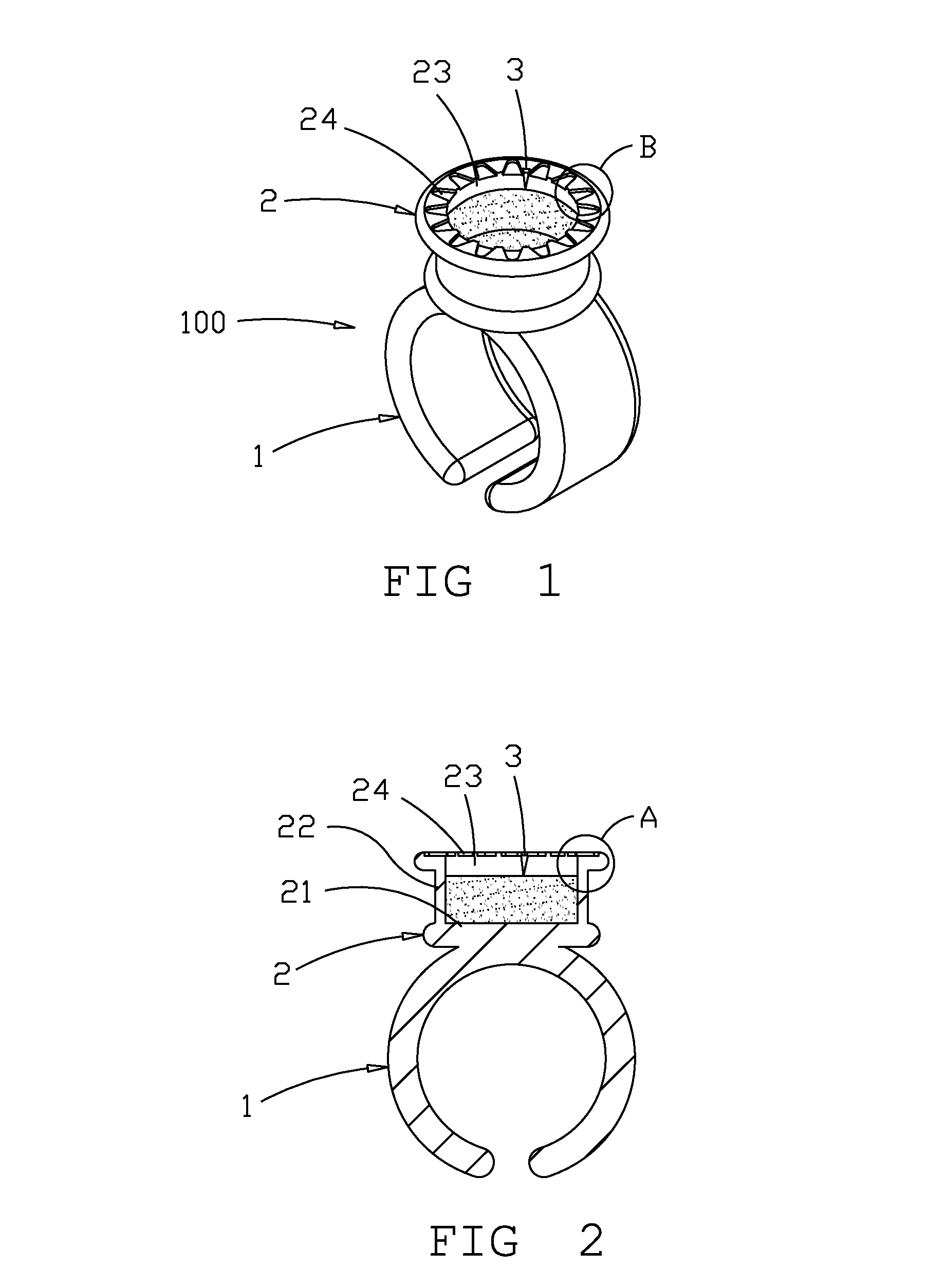

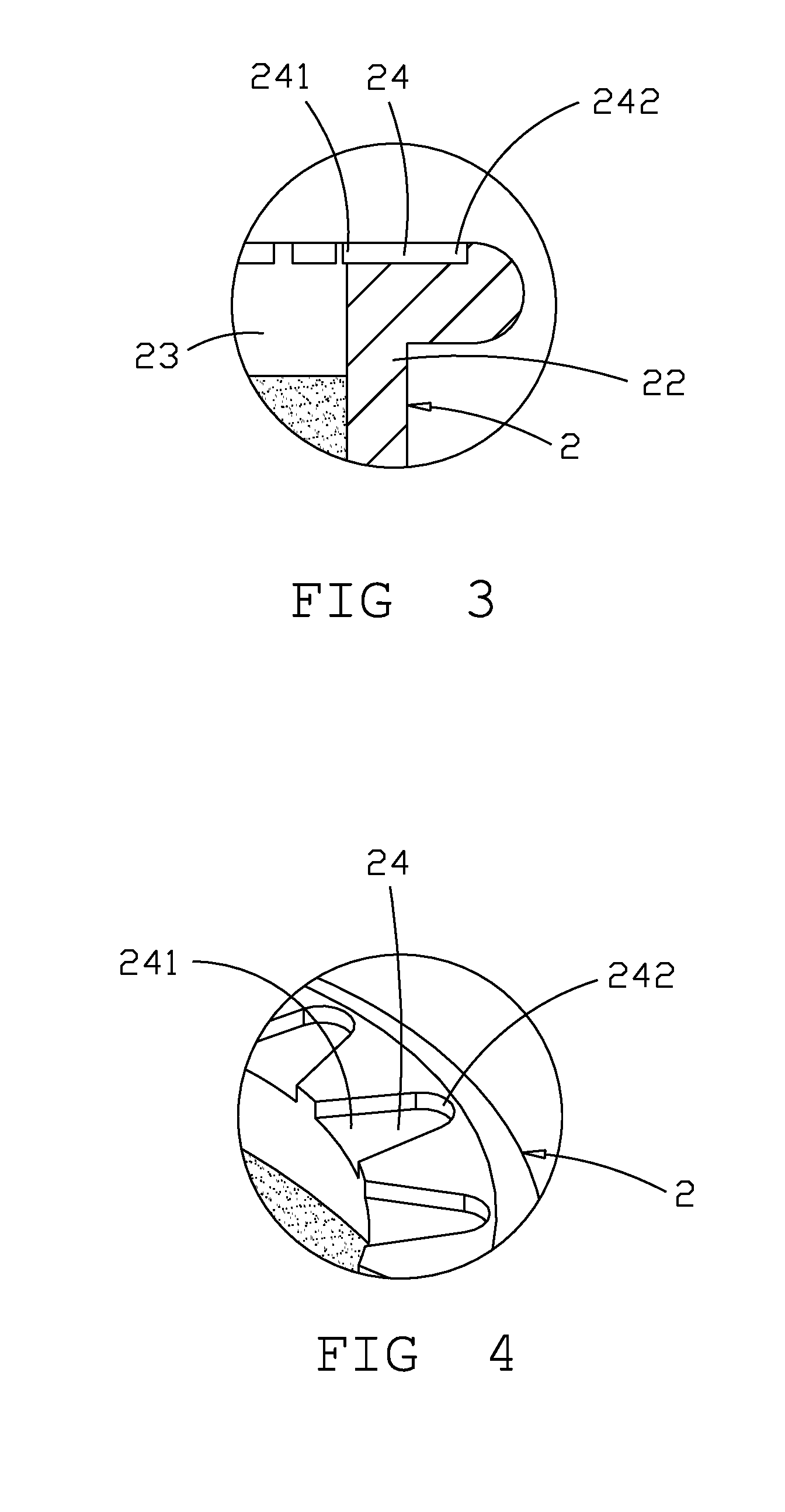

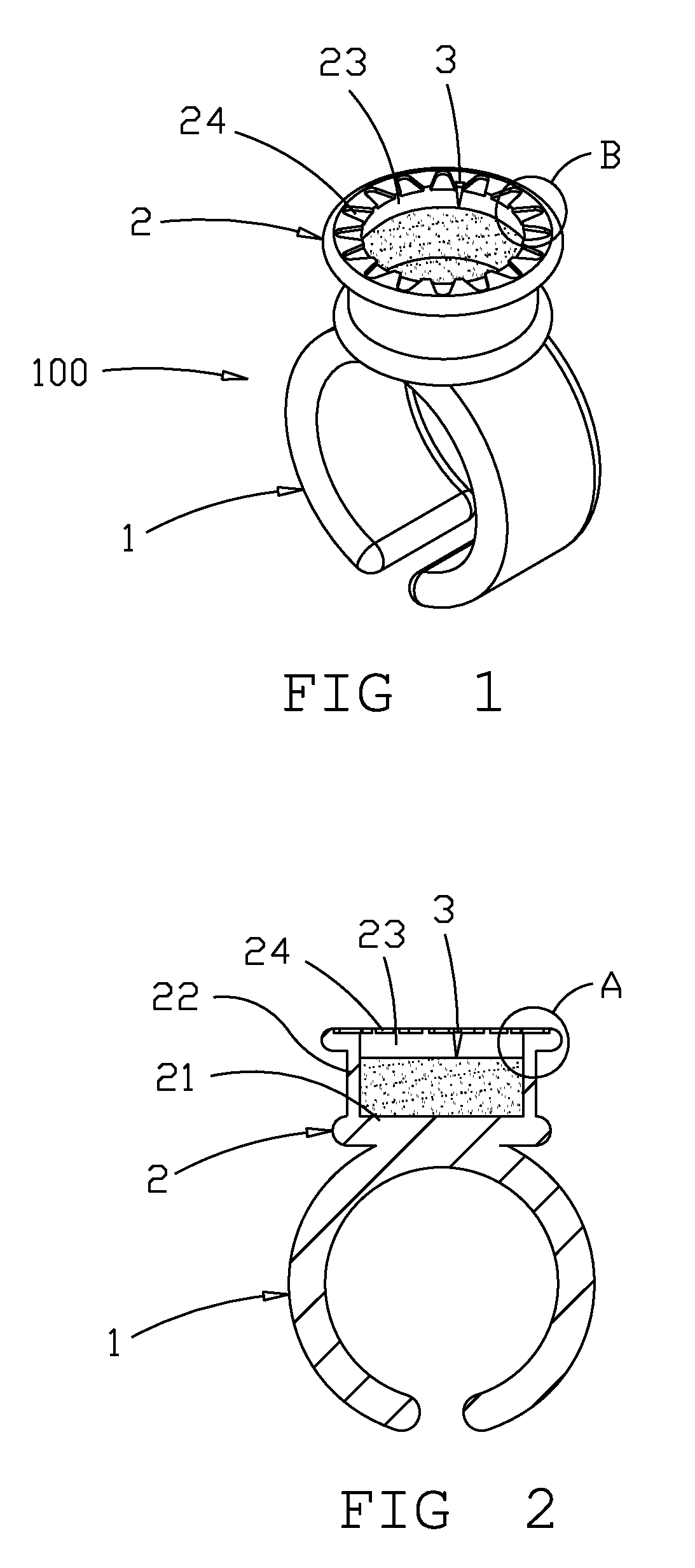

Adhesive holding system

ActiveUS20140116460A1Simple and safe processEasy to disassembleHair accessoriesToupeesAdhesiveEvaporation

A adhesive holding system comprises: a fixed component set in a destined place and a reservoir pedestal having a reservoir well for filling adhesive; it is characterized thereby: at the top of the reservoir well where there is at least one groove; because of the notch, it is easy for user to remove excess adhesive after coating lashes with adhesive. A second and smaller reservoir disk which has a narrower well surface area which prevents the adhesive coming in contact with natural air and atmosphere, therefore eliminating unnecessary waste of adhesive filling, reducing excessive evaporation of the adhesive and resulting in material and quality preservation of adhesive within the reservoir disk. Air flow into the reservoir disk is actually minimized, therefore the reservoir disk will hold the adhesive inside of the disk reservoir without allowing the adhesive to spill out thus promoting safety and eliminating potential safety hazards.

Owner:MCKINSTRY LIN SHU HUI

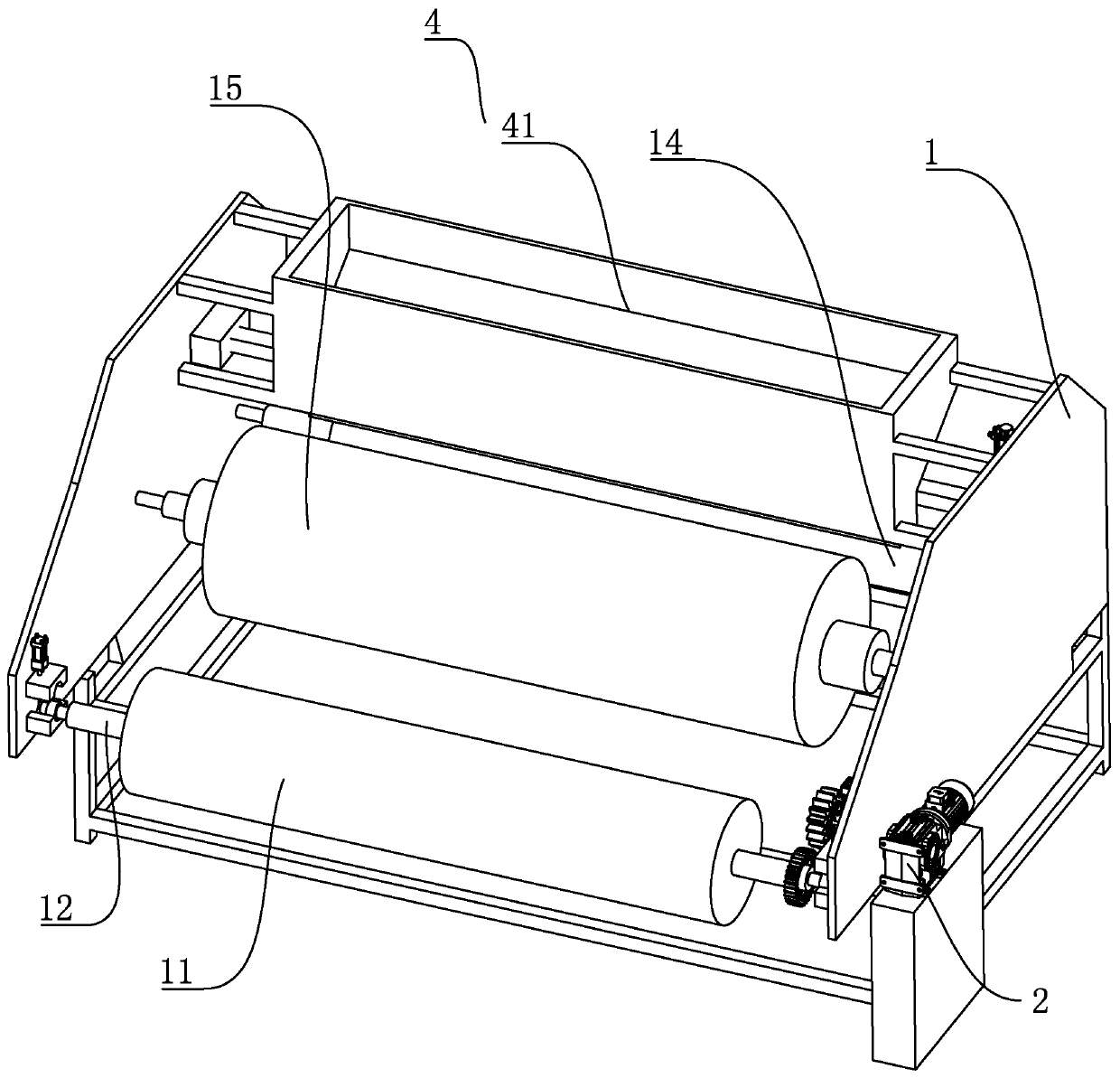

Aluminum foil paper coating winding device

PendingCN110841872AAvoid obstructionControl coating amountLiquid surface applicatorsCoatingsGear wheelPaper production

The invention discloses an aluminum foil paper coating winding device, and relates to the technical field of packaging paper production equipment. The aluminum foil paper coating winding device comprises a support, a material rolling roller rotationally connected to the support and a driving device used for driving the material rolling roller, the frame is further provided with a coating mechanism, the material rolling roller is rotationally connected to the frame through roller shafts arranged on two sides of the material rolling roller, a bearing member for connecting the roller shafts is arranged on the frame, the driving device comprises a driving gear and a driving member for driving the driving gear to rotate, the roller shafts are provided with a working gear, the frame is slidablyconnected with a movable seat, the movable seat is provided with an intermediate gear, and the two sides of the intermediate gear are meshed with the driving gear and the working gear correspondinglyduring working; the frame is further provided with a sliding piece for driving the movable seat to slide towards or away from one side of the driving gear, the whole working operation of the coating mechanism can not be influenced in the cooling time and the transfer time, the overall stagnation of the coating mechanism is avoided, the machining time cost is reduced, and the working efficiency isincreased.

Owner:无锡创越彩印包装有限公司

Adhesive holding system

A adhesive holding system comprises: a fixed component set in a destined place and a reservoir pedestal having a reservoir well for filling adhesive; it is characterized thereby: at the top of the reservoir well where there is at least one groove; because of the notch, it is easy for user to remove excess adhesive after coating lashes with adhesive. A second and smaller reservoir disk which has a narrower well surface area which prevents the adhesive coming in contact with natural air and atmosphere, therefore eliminating unnecessary waste of adhesive filling, reducing excessive evaporation of the adhesive and resulting in material and quality preservation of adhesive within the reservoir disk. Air flow into the reservoir disk is actually minimized, therefore the reservoir disk will hold the adhesive inside of the disk reservoir without allowing the adhesive to spill out, thus promoting safety and eliminating potential safety hazards.

Owner:MCKINSTRY LIN SHU HUI

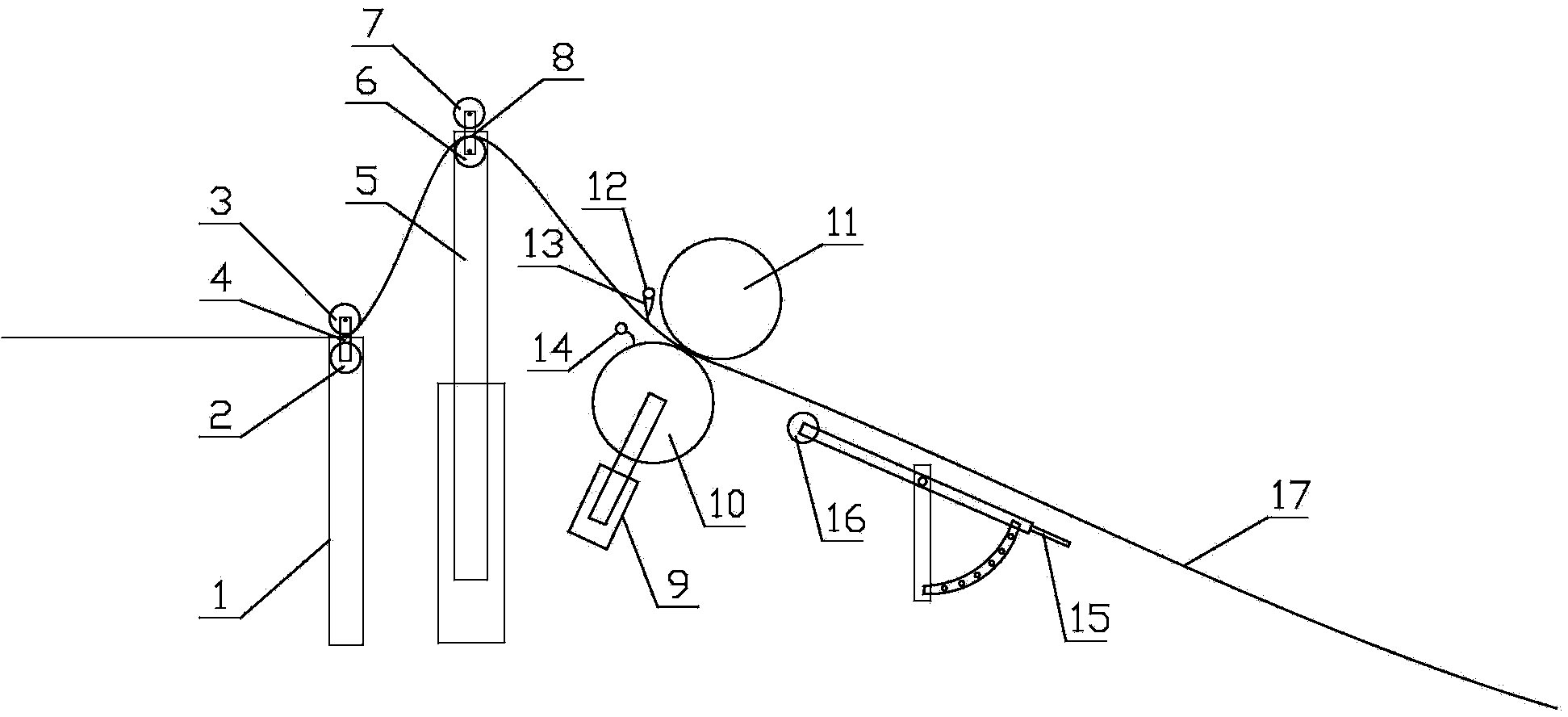

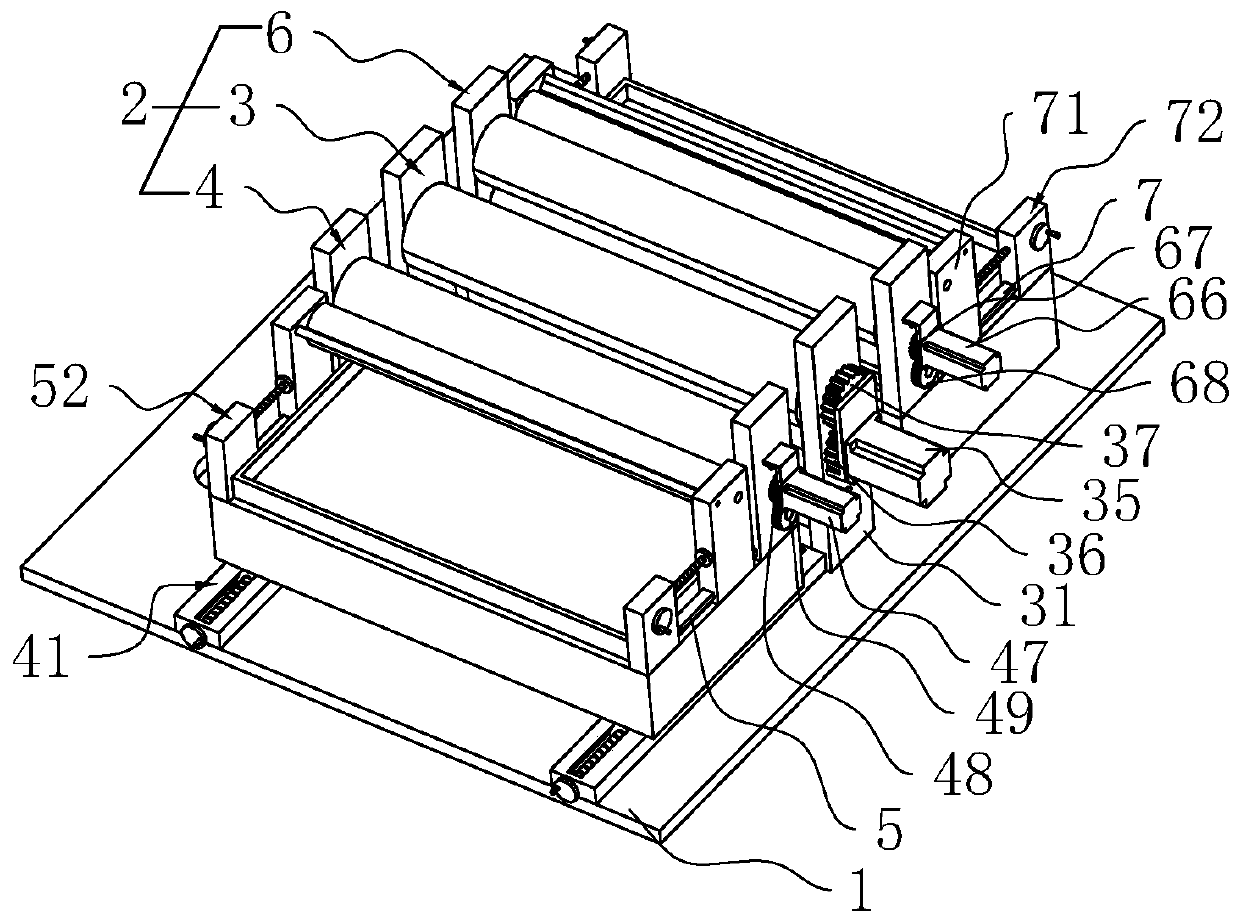

Coating machine capable of controlling coating amount of two surfaces and using method thereof

ActiveCN103447197AControl coating amountSimple structureLiquid surface applicatorsCoatingsEconomic benefitsPulp and paper industry

The invention relates to a coating machine capable of controlling coating amount of two surfaces. The coating machine comprises a fixed seat, a lower roll 1, an upper roll 1, a limiter 1, an air cylinder 1, a lower roll 2, an upper roll 2, a limiter 2, an air cylinder 2, a lower roll 3, an upper roll 3, a collecting pipe 1, a scratch board, a collecting pipe 2, a carrying device and a touch roll, wherein the top end of the fixed seat is provided with the lower roll 1 and the upper roll 1, and the lower roll 1 is connected with the upper roll 1 through the limiter 1; the top end of the air cylinder 1 is provided with the lower roll 2 and the upper roll 2, and the lower roll 2 is connected with the upper roll 2 through the limiter 2; the top end of the air cylinder 2 is provided with the lower roll 3 and the upper roll 3, and one sides of the lower roll 3 and the upper roll 3 are respectively provided with the collecting pipe 1 and the collecting pipe 2, and the scratch board is arranged at the collecting pipe 1; one end of the carrying device is provided with the touch roll. Compared with the prior art, the coating machine has the beneficial effects of being simple in structure, being scientific and practical, effectively controlling the amount coating of ]the upper surface and the lower surface of belt steel, reducing workload, improving working efficiency, reducing production cost, and creating a high economic benefit for enterprises.

Owner:ANGANG STEEL CO LTD

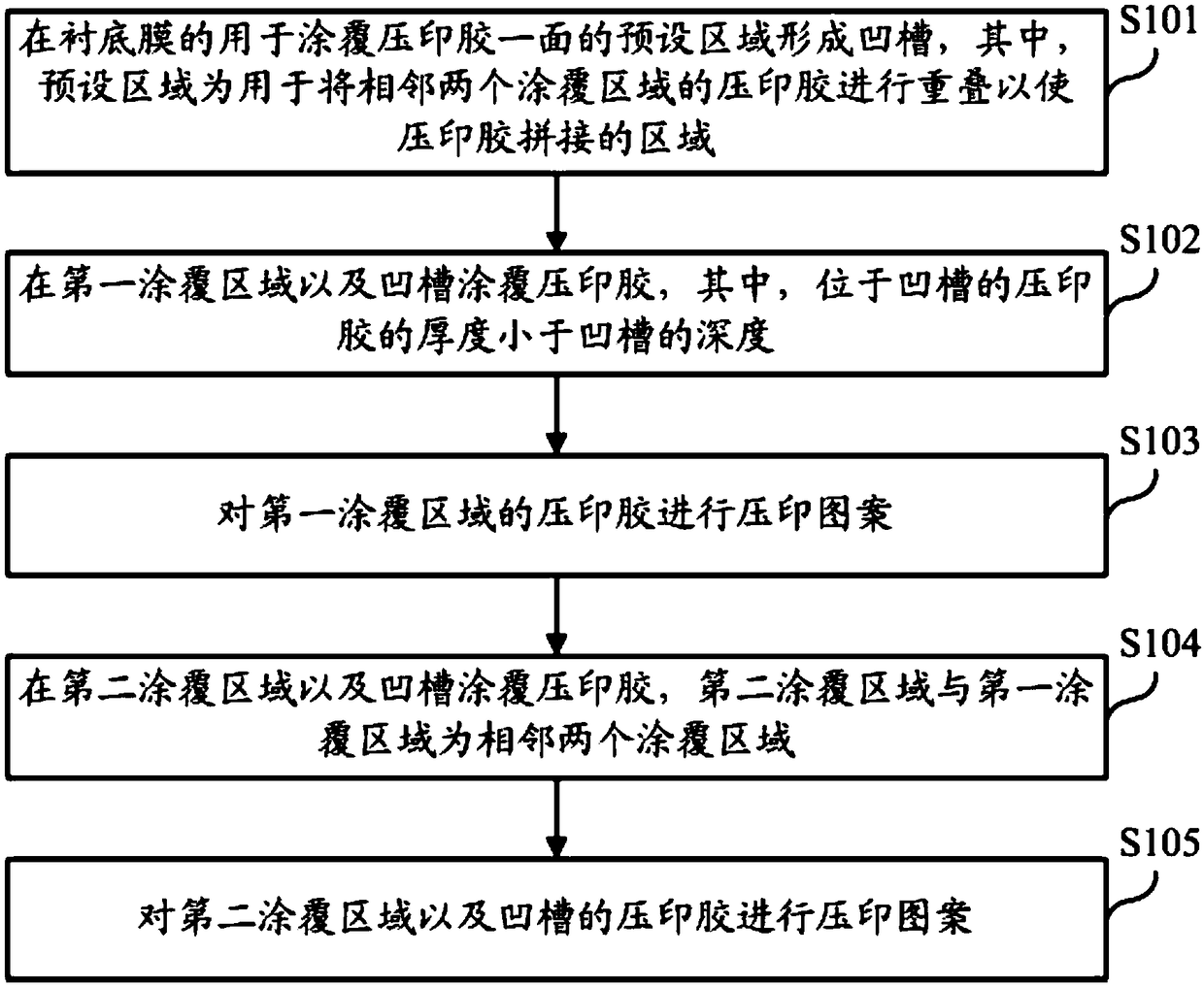

Nanoimprint template and manufacturing method thereof

PendingCN108873605AImprove poor peelingImprove the problem of poor peelingPhotomechanical apparatusAdhesiveEngineering

The invention discloses a nanoimprint template and a manufacturing method thereof, for solving the poor peeling problem due to the relatively high segment gap of the nanoimprint template in a joint overlap area in the prior art. The manufacturing method of the nanoimprint template comprises the steps of: forming a groove in a pre-set area on one surface of a substrate film used for coating an imprint adhesive, wherein the pre-set area is an area that the imprint adhesives in adjacent two coating surfaces are in joint overlap; coating the imprint adhesive in a first coating area and the groove,wherein the thickness of the imprint adhesive positioned in the groove is less than the depth of the groove; performing pattern imprinting on the imprint adhesive in the first coating area; coating the imprint adhesive in a second coating area and the groove, wherein the second coating area and the first coating area are adjacent two coating areas; and performing pattern imprinting on the imprintadhesives in the second coating area and the groove.

Owner:BOE TECH GRP CO LTD

Method for avoiding thermal runaway of lithium ion battery

InactiveCN112332021AAvoid thermal runawayStop feverElectrode collector coatingNon-aqueous electrolyte accumulator electrodesPhysical chemistrySlurry

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a method for avoiding thermal runaway of a lithium ion battery. The method comprises the following steps: (1) surface activation of raw vermiculite powder: grinding raw vermiculite into powder, cleaning the raw vermiculite powder, dynamically soaking the cleaned raw vermiculite powder in an acidic solution or an alkaline solution, carrying out solid-liquid separation, and drying the material; (2) preparation of a dispersion liquid: fully mixing and dissolving a solvent, a surfactant, a dispersingagent and a binder, adding raw vermiculite powder, uniformly stirring, and then adjusting the viscosity of the slurry to 1000-20000 mPa.S; (3) coating and baking. By adopting the method, the safety performance of the lithium ion battery can be improved, and the thermal runaway phenomenon is avoided.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Gluing structure of adjustable coating machine

ActiveCN114749339AControl discharge speedControl coating amountLiquid surface applicatorsCoatingsLiquid storage tankAdhesive glue

The invention discloses a gluing structure of an adjustable coating machine, and relates to the technical field of coating machines. The gluing structure of the adjustable coating machine comprises a placement plate, a mounting plate and a gluing roller, the mounting plate is fixed to the top of the placement plate, sliding rods are rotationally mounted on the front side and the rear side of the gluing roller correspondingly, the sliding rods are slidably connected with sliding grooves formed in the mounting plate in a penetrating mode, and an annular connecting groove is formed in the center of the gluing roller in a penetrating mode. According to the gluing structure of the adjustable coating machine, glue can be conveyed into the gluing roller through the liquid inlet pipe by arranging the liquid storage tank, and the position of the pressurizing plug can be controlled by arranging the control screw rod and the fixing nut, so that the pressure in the liquid storage tank and the gluing roller can be adjusted, and the discharging speed of the glue in the gluing roller can be adjusted; and the glue on the surface of the thin film is distributed more uniformly through the adjusting mode, multiple times of follow-up slicking operation is not needed, and the coating efficiency is guaranteed.

Owner:江苏安斯邦新材料科技有限公司

Double-sided coating technology and device for metal coil

InactiveCN110665784AImprove work efficiencyReduce manufacturing costLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a double-sided coating technology and device for a metal coil, and belongs to the technical field of metal packaging coating technologies. The technology comprises the following steps of S11: unreeling; S2: adjusting tension; S3: pre-storing; S4: performing tension adjustment and deviation rectification; S5: performing double-sided spray washing; S6: drying the two surfaces; S7: coating on two sides; S8: drying; S9: cooling; S10: adjusting tension; S11: pre-storing; and S12: rolling to obtain the metal coil with double-side coating. The technology has the effect of coating both sides of the metal coil simultaneously.

Owner:浙江金马包装材料有限公司

Electrode coating method

The invention relates to an electrode coating method. The electrode coating method comprises the following steps: the viscosity value Rv1 and the elasticity modulus K1 of lithium ion battery paste of the previous batch at the coating speed of V1 as well as the gap value H1 of the lithium ion battery paste of the previous batch during coating are provided; the viscosity value Rv2 of the lithium ion battery paste of the current batch at the coating speed of V2 is determined; the elasticity modulus K2 of the lithium ion battery paste of the current batch at the coating speed of V2 is determined; the gap value H2 of the lithium ion battery paste of the current batch during coating is determined according to the following formula: H2=(V1*H1+V1*Rv1*H1 / K1) / (V2+V2*Rv2 / K2); the gap value of two rollers of double-roller coating equipment is set to be H2, and an electrode is coated with the lithium ion battery paste of the current batch. According to the method, the difference between the viscosity and elasticity properties of the lithium ion battery paste of different batches are taken into consideration, the gap value H2 is regulated pertinently, and the coating quantity of the lithium ion battery paste can be controlled better.

Owner:SHENZHEN BAK POWER BATTERY CO LTD +1

OLED packaging device

InactiveCN112191448AAvoid exposureEnsure electricalPretreated surfacesCoatingsPhoto irradiationUltraviolet lights

The invention provides an OLED packaging device. The OLED packaging device comprises a base, a bearing platform, a driving assembly, a glue storage pipe and a coating glue pretreatment assembly; the bearing platform is fixed to the base and used for bearing a packaging panel; the driving assembly is fixed to the base; the glue storage pipe is installed on the driving assembly and used for containing coating glue; and the coating glue pretreatment assembly is connected with the glue storage pipe and comprises a containing cavity, ultraviolet light sources, a glue pipe and a glue coating head, wherein the glue pipe is arranged in the containing cavity, a glue inlet of the glue pipe is connected with the glue coating head, and the ultraviolet light sources are arranged on the inner wall of the containing cavity. A packaging adhesive material in a coating component is subjected to ultraviolet irradiation and then coated so that the coating amount can be effectively controlled, waste is avoided, meanwhile, a first substrate is prevented from being irradiated by ultraviolet light in the packaging process, and the electrical property of the substrate is ensured.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

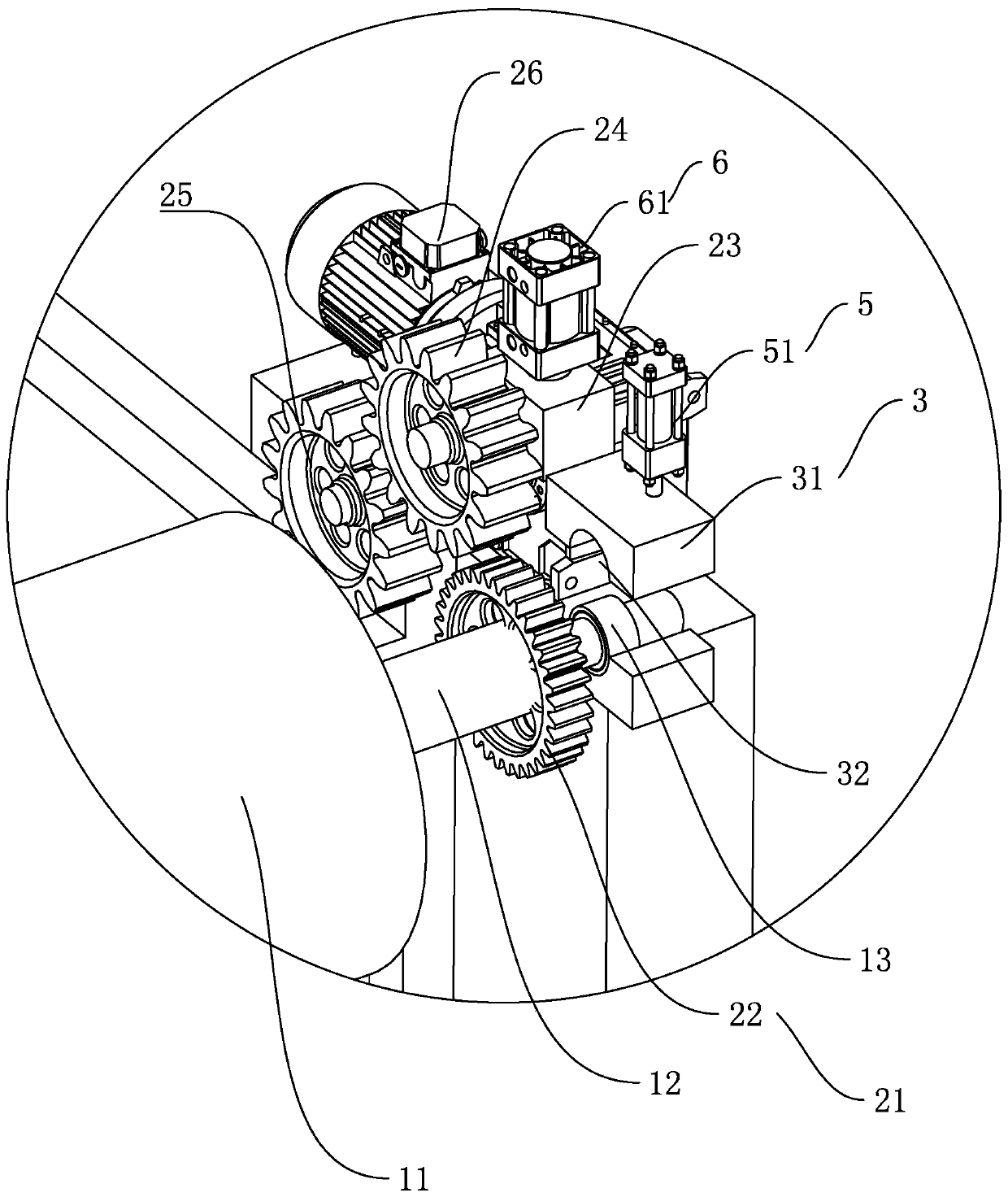

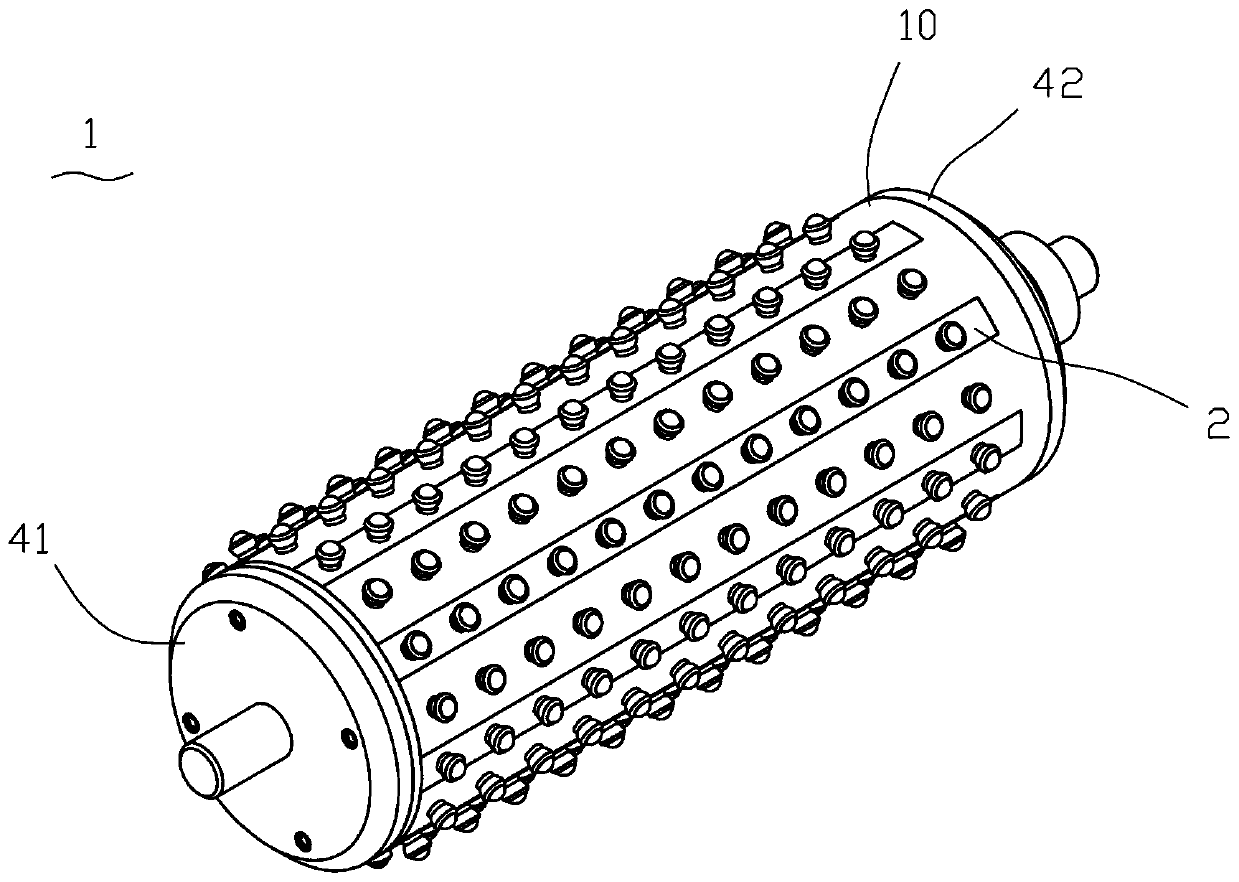

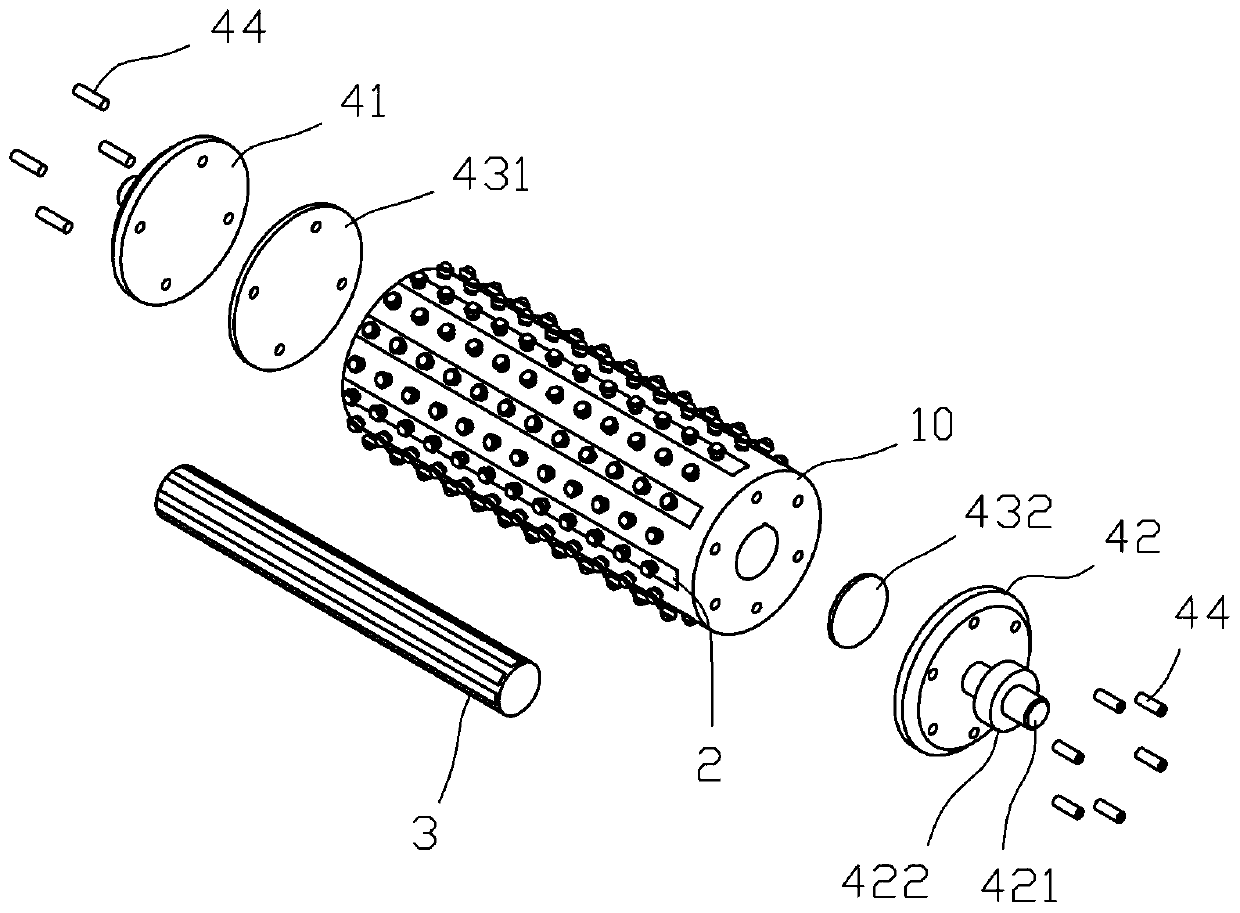

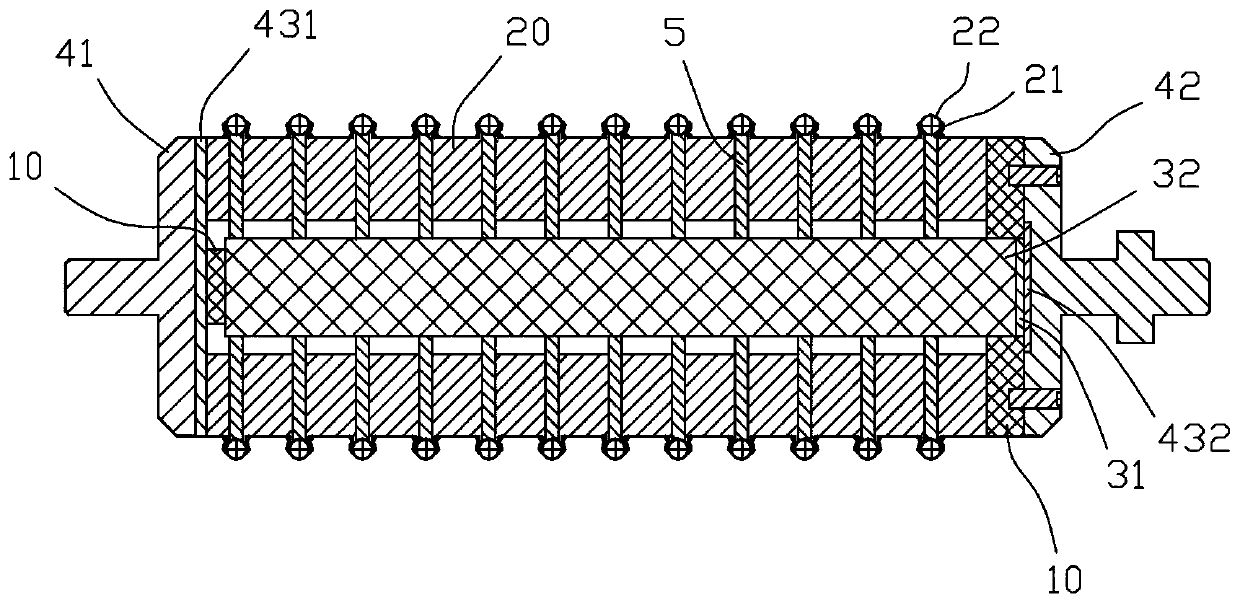

Adhesive type laminated-core member manufacturing apparatus and adhesive applying unit

InactiveCN106464098APrevent leakageControl coating amountLaminationLamination apparatusAdhesiveEngineering

Disclosed are an adhesive type laminated-core member manufacturing apparatus and an adhesive applying unit therefor, the adhesive type laminated-core member manufacturing apparatus comprising: an adhesive applying unit that is selectively opened to apply an adhesive to a continuously transferred material, for example, a material used to manufacture a motor core; and a blanking unit that sequentially forms laminar members having a predetermined shape by making the material subjected to blanking, wherein the apparatus manufactures a laminated-core member for a motor core by bonding the laminar members through inter-laminar bonding. In the present invention, the adhesive applying unit includes: an adhesive spreader having an outlet channel for discharging an adhesive; and a valve that closes the outlet channel, and opens the outlet channel when the material and the outlet channel closely approach each other. According to the present invention, an adhesive is discharged by a pressure of fluid (adhesive) in a nozzle at a time point when a material and the adhesive applying unit closely approach each other, more specifically, only when the adhesive applying unit is pressed by the material so that the surface of the material makes contact with the adhesive applying unit, namely, the outlet of the nozzle, and the outlet of the nozzle is closed when the material and the adhesive applying unit move away from each other so that leakage of the adhesive can be prevented, thereby uniformly controlling adhesive discharge time and an amount of an adhesive to be applied.

Owner:POSCO TMC

Massage roller and massager

PendingCN111529347AImprove convenienceControl coating amountRoller massageHuman bodyPhysical medicine and rehabilitation

The invention discloses a massage roller. The massage roller comprises a rotatable roller main body provided with a plurality of slots and a blind hole communicating with the slots, a plurality of medicine discharging massage assemblies inserted into the slots and an attachment storage assembly inserted into the blind hole, wherein the slots are open in one sides; a plurality of rolling balls capable of rolling and massaging the human body are arranged on the medicine discharging massage assemblies; and the attachment storage assembly can guide accommodated massage liquid to the balls, so thatthe massage liquid can be applied to the skin of the human body through the balls during massage on the human body. The massager has high integration degree, not only has good massage effect on skin,but also improves absorption efficiency of the human body to the massage liquid.

Owner:SUZHOU GUOKE MEDICAL TECH DEV CO LTD

Scraper device for coating

ActiveCN107983583AExpand the adjustment rangeAvoid formingLiquid surface applicatorsCoatingsMechanical engineeringCoating

The invention discloses a scraper device for coating. The scraper device comprises a scraper component, an x-axis regulating device, a left and right movement sliding rail and a z-axis regulating device, wherein the scraper component is arranged on the x-axis regulating device and is used for scraping off the excess glue on a coating mesh roller; the x-axis regulating device is arranged above theleft and right movement sliding rail and is used for enabling the scraper component to move forwards and backwards; the left and right movement sliding rail is arranged above the z-axis regulating device and is used for driving the scraper component to move left and right; and the z-axis regulating device is used for driving the scraper component to move up and down. In the scraper device, the scraper component can move up and down through the z-axis regulating device, therefore the regulating range of the scraper component is expanded, the scraped glue is prevented from forming a scraper line, and the coating weight is controlled.

Owner:常德洛恩全息材料科技有限公司

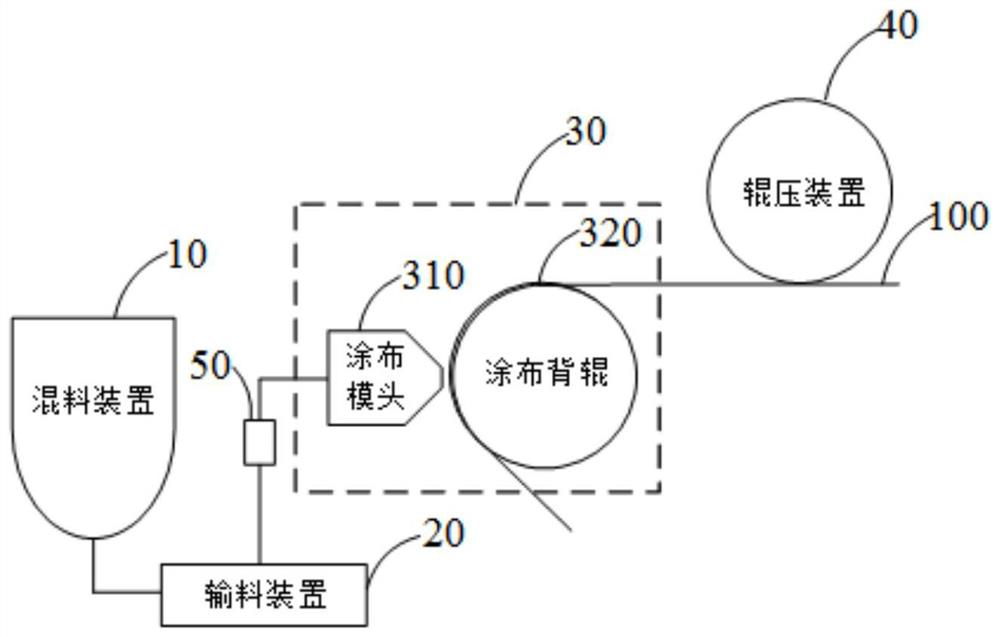

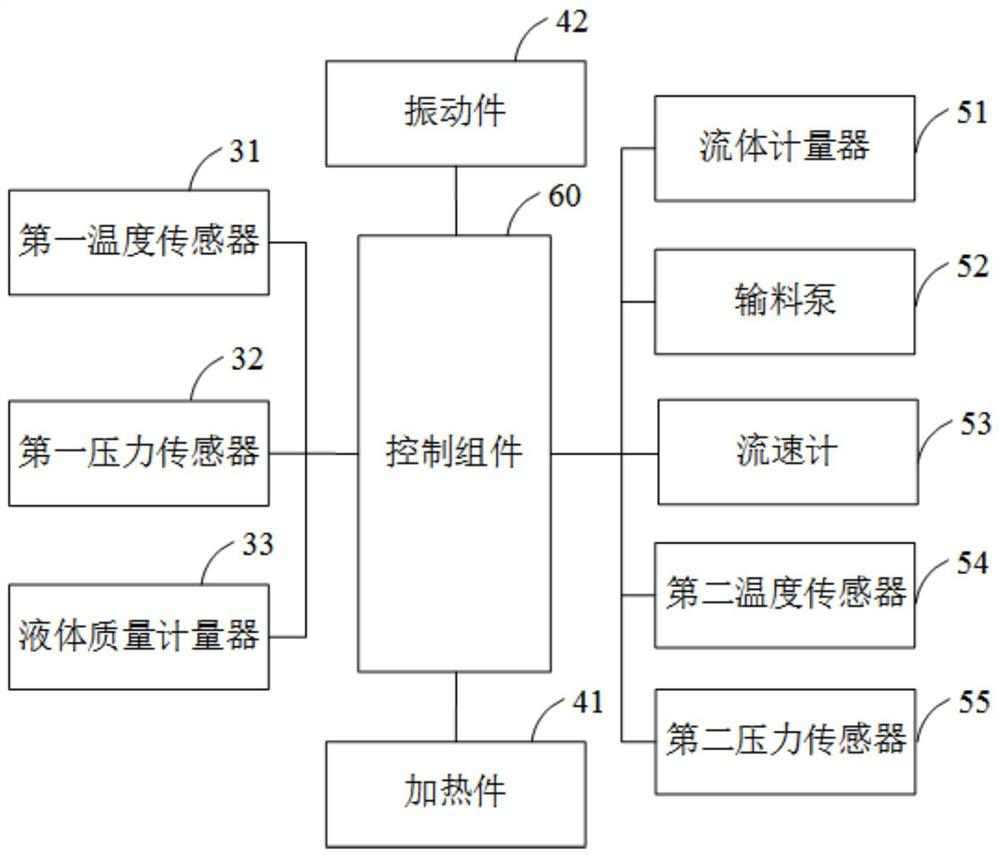

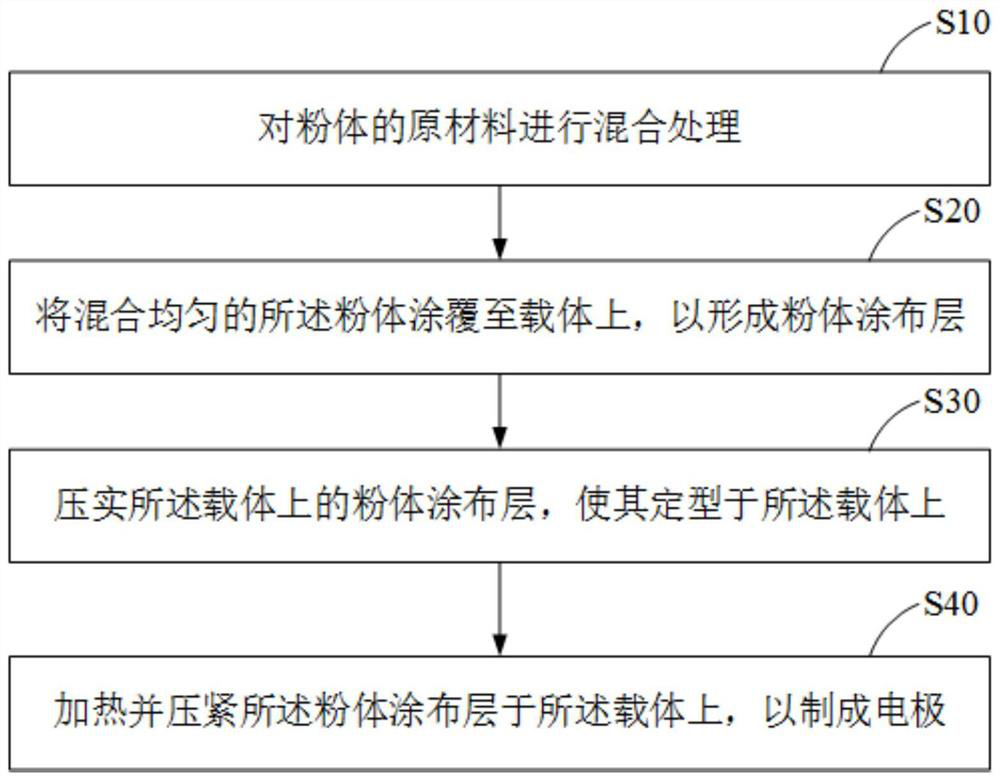

Coating system and coating method thereof

ActiveCN114178132AControl coating amountSolve the problem of difficult coatingLiquid surface applicatorsCell electrodesCoating systemManufactured material

The invention discloses a coating system and a coating method thereof. The coating system comprises a mixing device, a conveying device, a split-flow coating device and a rolling device, and the mixing device is used for mixing and dispersing various raw materials of a coating; the material conveying device is communicated with the material mixing device; the conveying device is used for driving paint to flow; the split-flow coating device is communicated with the material conveying device; the split-flow coating device is used for split-flow coating and uniformly coating a carrier with the split-flow coating; and the rolling device is used for compacting the coating on the carrier. The invention provides a coating system and a coating method thereof, and solves the problem that coatings such as high-viscosity slurry or powder materials are difficult to coat.

Owner:SHENZHEN MANST TECH CO LTD

Liquid crystal coating device and liquid crystal coating method

ActiveCN102000652BControl coating amountControl thicknessLiquid surface applicatorsCoatingsCrystallographyLiquid-crystal display

An apparatus and a method for coating liquid crystal are provided. The liquid crystal coating apparatus includes a liquid crystal coating module, a real-time detector and a controller. The liquid crystal coating method includes following steps: coating liquid crystal on the substrate by the liquid crystal coating module, detecting the liquid crystal coated on the substrate by the real-time detector, outputting detecting signals to the controller and controlling the liquid crystal coating module by the controller according to the detecting signals. The invention enables real-time monitoring of the liquid crystal coating operation and coating even liquid crystal film.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

A foam-coated interior lighting advertising cloth and its preparation process

ActiveCN107700232BLow densityReduce penetrationFireproof paintsTextiles and paperPolymer sciencePolymer chemistry

The invention relates to an advertising cloth, especially to a foaming coating inner lighting advertising cloth. The foaming coating inner lighting advertising cloth comprises a base cloth layer, theupper side and lower side of the base cloth layer are respectively coated with a whitening waterproof layer, wherein the surface of a whitening waterproof layer on one side is coated with a foaming flame retardant coating, and the surface of the foaming flame retardant coating is coated with an ink absorption coating. The invention also discloses a preparation technology of the advertising cloth.The preparation technology includes coating of the whitening waterproof coating, coating of the foaming flame retardant coating, and coating of the ink absorption coating. The advertising cloth provided by the invention has the advantages of flame retardance, wrinkle resistance, light weight, good handfeel, and fine printed image quality.

Owner:柔识智能科技(山东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com