Preparation method of topological insulator Bi2Se3/FeSe2 alloplasmic structure thin film

A technology of topological insulators and heterostructures, applied in the field of preparation of heterostructure thin films, can solve the problems of uneven coating process of heterostructure thin films, poor reproducibility of heterostructure thin films, and high preparation costs, so as to reduce preparation costs , good combination and reduced equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

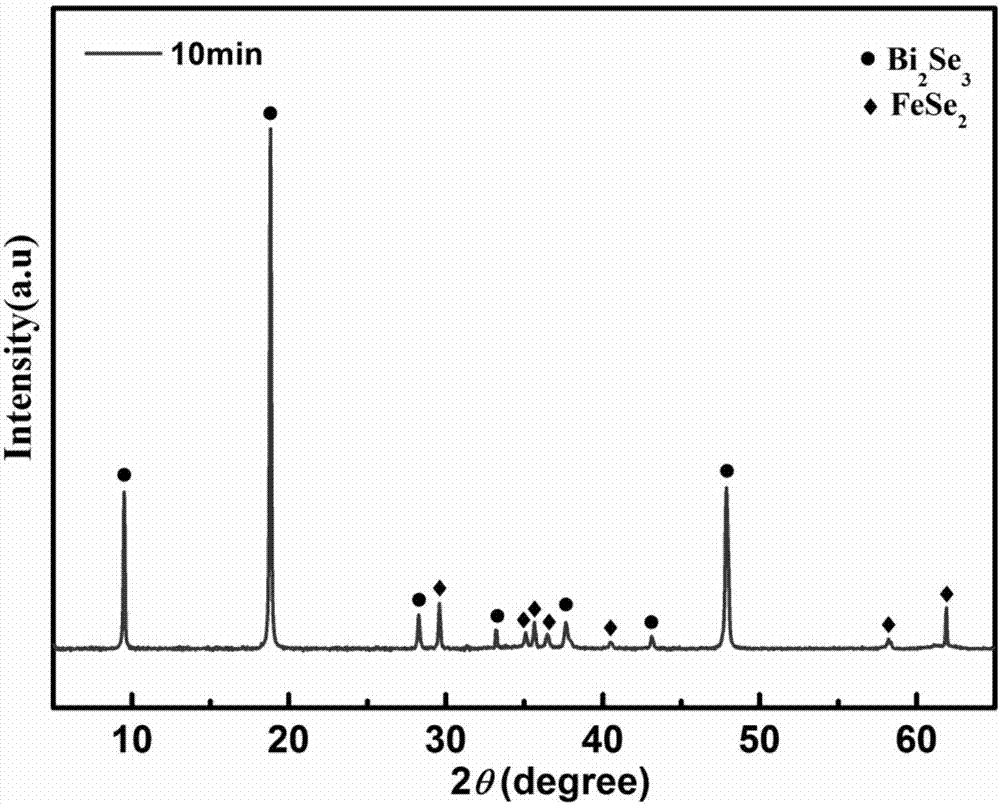

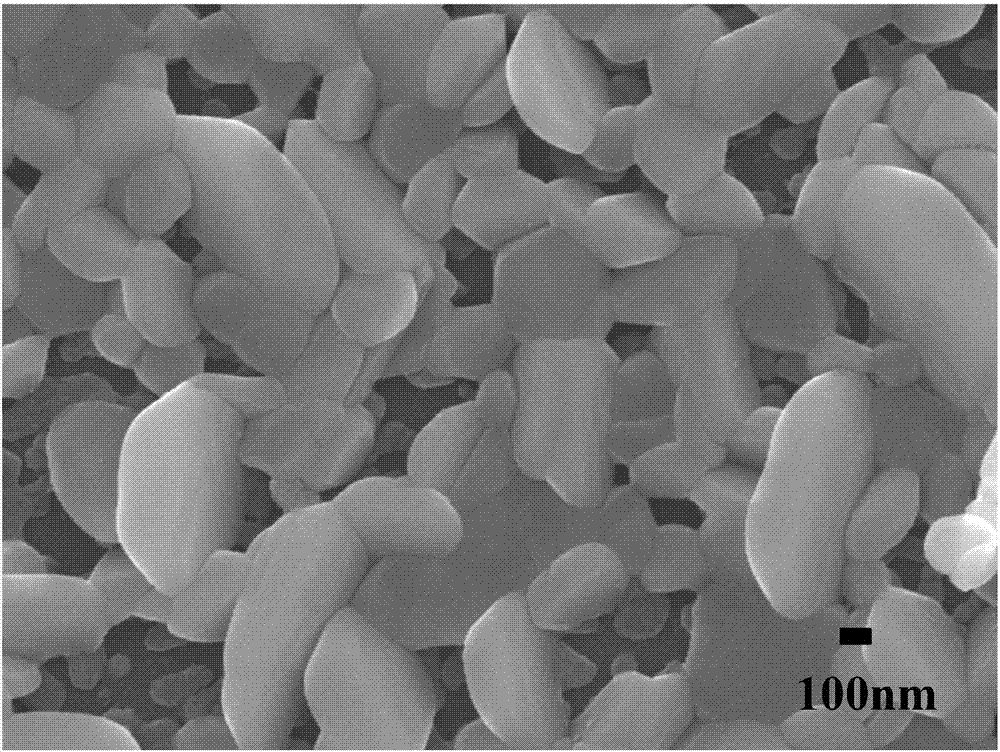

[0025] A topological insulator Bi 2 Se 3 / FeSe 2 A method for preparing a heterostructure thin film, the steps of which are:

[0026] a, the preparation of FeSe base film: take FeSe material as target material, form FeSe base film by magnetron sputtering on Si(100) substrate; The specific method of described magnetron sputtering is: the distance between substrate and target material The vacuum chamber of the magnetron sputtering equipment is evacuated to an air pressure of less than 2×10 -4 Pa, and then pass in analytically pure argon to make the pressure of the vacuum chamber 0.5Pa, adjust the substrate temperature to 420°C, and the sputtering power density to 3.31W / cm 2 , the sputtering time is 10min;

[0027] b. FeSe 2Annealing and phase formation: the substrate obtained in step a with the FeSe base film sputtered and selenium particles are sealed together with an air pressure of less than 1×10 -2 In the vacuum quartz tube of Pa, put the vacuum quartz tube in the heat...

Embodiment 2

[0035] A topological insulator Bi 2 Se 3 / FeSe 2 A method for preparing a heterostructure thin film, the steps of which are:

[0036] a, the preparation of FeSe base film: take FeSe material as target material, form FeSe base film by magnetron sputtering on Si(100) substrate; The specific method of described magnetron sputtering is: the distance between substrate and target material 6cm, the vacuum chamber of the magnetron sputtering equipment is evacuated to an air pressure of less than 2×10 -4 Pa, and then pass in analytically pure argon to make the pressure of the vacuum chamber 0.4Pa, adjust the substrate temperature to 400°C, and the sputtering power density to 3.05W / cm 2 , the sputtering time is 20min;

[0037] b. FeSe 2 Annealing and phase formation: the substrate obtained in step a with the FeSe base film sputtered and selenium particles are sealed together with an air pressure of less than 1×10 -2 In the vacuum quartz tube of Pa, put the vacuum quartz tube in th...

Embodiment 3

[0045] A topological insulator Bi 2 Se 3 / FeSe 2 A method for preparing a heterostructure thin film, the steps of which are:

[0046] a, the preparation of FeSe base film: take FeSe material as target material, form FeSe base film by magnetron sputtering on Si(100) substrate; The specific method of described magnetron sputtering is: the distance between substrate and target material 7cm, the vacuum chamber of the magnetron sputtering equipment is evacuated to an air pressure of less than 2×10 -4 Pa, and then pass in analytically pure argon to make the pressure of the vacuum chamber 0.6Pa, adjust the substrate temperature to 380°C, and the sputtering power density to 2.80W / cm 2 , the sputtering time is 30min;

[0047] b. FeSe 2 Annealing and phase formation: the substrate obtained in step a with the FeSe base film sputtered and selenium particles are sealed together with an air pressure of less than 1×10 -2 In the vacuum quartz tube of Pa, put the vacuum quartz tube in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com