Graphene composite electrode material and preparation method and application thereof

A graphene composite and electrode material technology, applied in the field of materials, can solve problems such as unfavorable electron transmission and poor cycle performance, and achieve the effect of simple process, high controllability and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

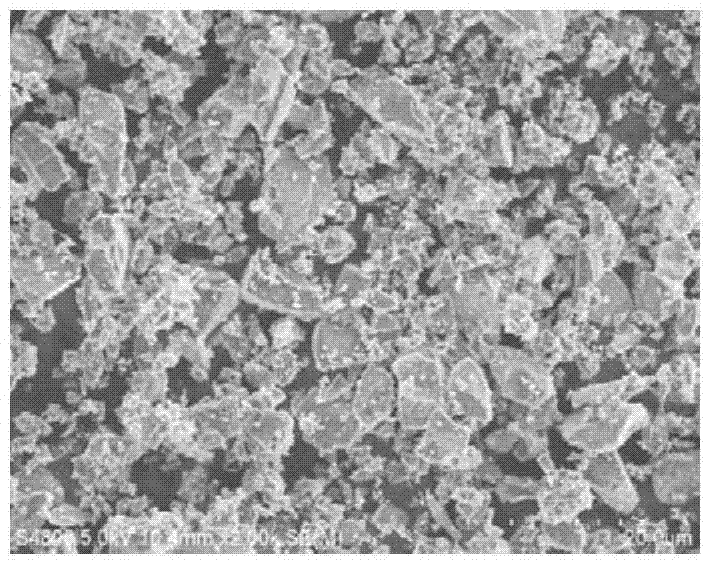

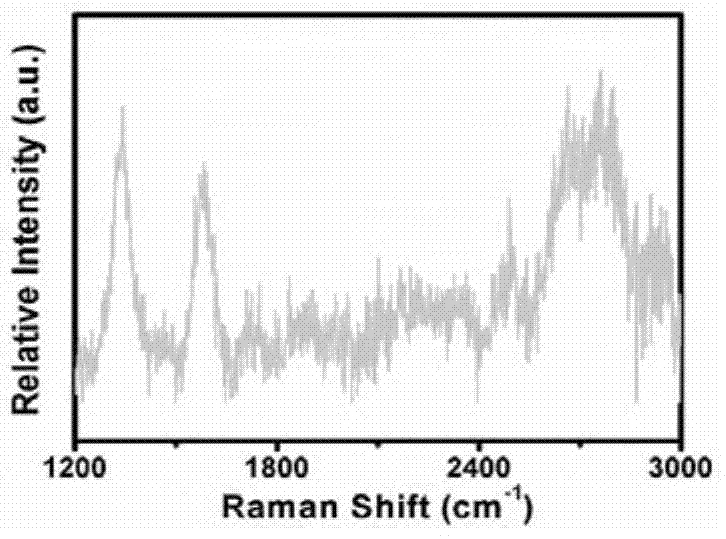

[0040] Embodiment 1, prepare silicon monoxide-graphene composite electrode material

[0041] 1) Put the silicon monoxide powder in an atmospheric tube furnace and pre-calcine at 1200°C for 5 hours under an argon atmosphere, so that the disproportionation reaction of silicon monoxide occurs, and a mixed phase of silicon dioxide, silicon and silicon oxide is obtained, and the temperature is lowered to 25°C;

[0042] 2) Put the mixed phase obtained in step 1) into a quartz boat, and put it into a chemical vapor deposition furnace. The equipment is heated to 1000°C at a heating rate of 20°C / min, and then methane is introduced under the protection of argon and hydrogen (the mixture of argon and hydrogen is also used as the carrier gas of methane, and the carbon source gas methane accounts for the carbon source and the carrier gas. The percentage of total gas volume is 0.5%) to react, and methane performs chemical adsorption, nucleation and growth on the surface of pre-calcined sil...

Embodiment 2

[0047] Embodiment 2, using titanium dioxide as growth substrate to prepare titanium dioxide-graphene composite electrode material

[0048] 1) Precalcining the titanium dioxide powder in an atmospheric tube furnace at 200°C for 1 hour in an air atmosphere, removing surface moisture, and cooling down to 25°C;

[0049] 2) Put the calcined titanium dioxide powder into a quartz boat and put it into a chemical vapor deposition furnace. The equipment is heated to 800°C at a heating rate of 20°C / min, and then ethylene is fed under the protection of argon and hydrogen for reaction. Ethylene is a gaseous reaction precursor for chemical adsorption, nucleation and growth on the surface of pre-calcined titanium dioxide. , the reaction time is 60min, and the percentage of carbon source gas ethylene accounting for carbon source and carrier gas (the mixed gas of above-mentioned argon and hydrogen) total volume is 2%;

[0050] 3) After the reaction is over, wait for the equipment to cool down...

Embodiment 3

[0051] Example 3, Preparation of SiO2-Graphene Composite Electrode Material Using Nanoscale SiO2 Powder

[0052]1) Pre-calcine the silica powder in an atmospheric tube furnace at 100°C for 1 hour in an air atmosphere, remove surface moisture, and cool down to 25°C;

[0053] 2) Put the calcined silica powder into a quartz boat and put it into a chemical vapor deposition furnace. The equipment is heated to 600°C at a heating rate of 20°C / min, and then ethylene is passed through under the protection of argon and hydrogen for reaction. Acetylene is a gaseous reaction precursor for chemical adsorption and nucleation on the surface of pre-calcined silica and growth, the reaction time is 60min, and the carbon source gas acetylene accounts for 2% of the total volume of the carbon source and the carrier gas (a mixture of the above-mentioned argon and hydrogen);

[0054] 3) After the reaction is completed, the temperature of the equipment is lowered to 25° C. to obtain a black powder m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com