Adhesive type laminated-core member manufacturing apparatus and adhesive applying unit

A technology for manufacturing devices and adhesives, which is applied in the direction of magnetic core manufacturing, lamination devices, electromechanical devices, etc., can solve the problems of nozzle outlet clogging, adhesive narrowing, and productivity reduction, and achieve stable discharge timing and prevent Poor adhesion between layers and leakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

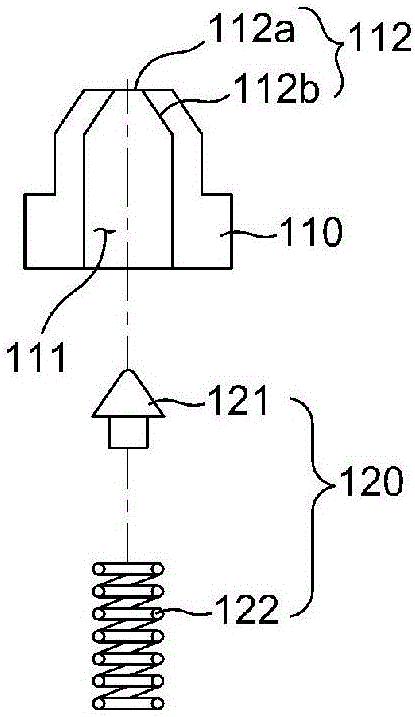

[0038] Below, refer to Figure 1 to Figure 6 The embodiments of the present invention will be described in detail. In describing the present invention, the same reference numerals are attached to the same constituent elements.

[0039] The present invention relates to a bonding-type laminated core member manufacturing apparatus and an adhesive coating unit, which blanks a band-shaped base material that is continuously transferred to form a laminated sheet of a predetermined shape, and makes the laminated sheet An adhesive-type core member manufacturing apparatus for manufacturing a laminated core member for a motor core by interlayer bonding to achieve integration, and a device for applying an adhesive to the base material for interlayer bonding of the laminated sheet Adhesive coating unit.

[0040] Below, refer to Figure 1 to Figure 9 An embodiment of the adhesive coating unit according to the present invention and an embodiment of an adhesive-type laminated core member manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com