Viscous fluid application method

A viscous fluid and coating device technology, which is applied in the direction of surface coating liquid devices, coatings, electric solid devices, etc., can solve the problem of reduced design freedom, increased space occupation of the coating head, and decreased coating positioning accuracy And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

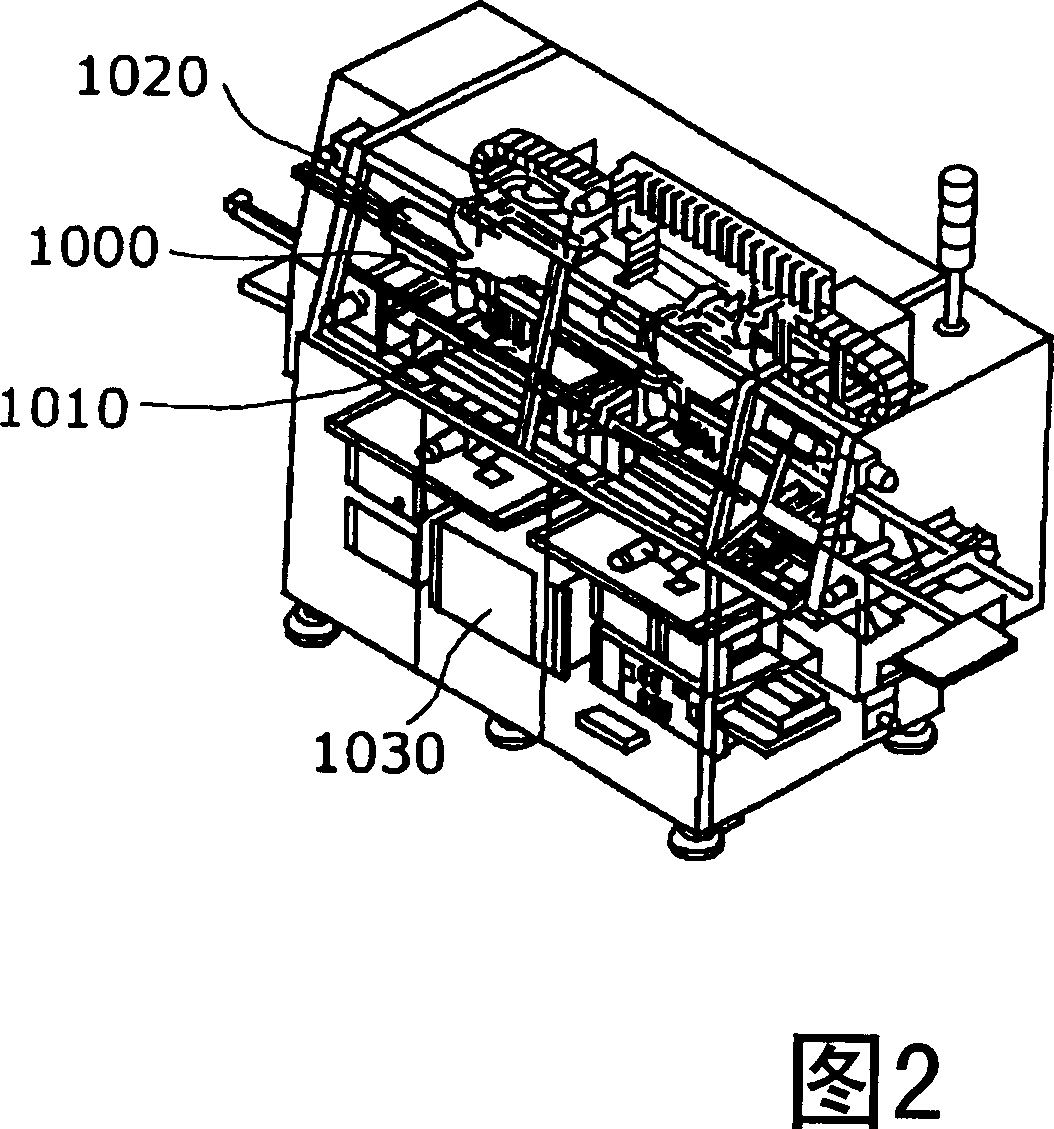

[0117] Next, a viscous fluid application device according to an embodiment of the present invention will be described with reference to the drawings.

[0118] FIG. 4 is an external view of a viscous fluid application device according to this embodiment, and FIG. 5 is a diagram for explaining the structure of the viscous fluid application device.

[0119] The viscous fluid coating device of this embodiment includes: a coating head 100 for coating a viscous fluid on a substrate 140a; and a first shaft portion 110 (for example, an X-axis portion) for moving the coating head 100 in the first axial direction. Positioning; the second shaft part 120 (such as the Y-axis part), carries out the mobile positioning of the coating head 100 on the second shaft direction perpendicular to the first shaft direction; the third shaft part 130 (such as the Z-axis part), performs coating The movement and positioning of the application head 100 in the third axis direction perpendicular to the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com