Double-sided coating technology and device for metal coil

A technology for metal coils and coating processes, which is applied to devices and coatings for coating liquids on surfaces, and can solve problems such as low output, low work efficiency, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

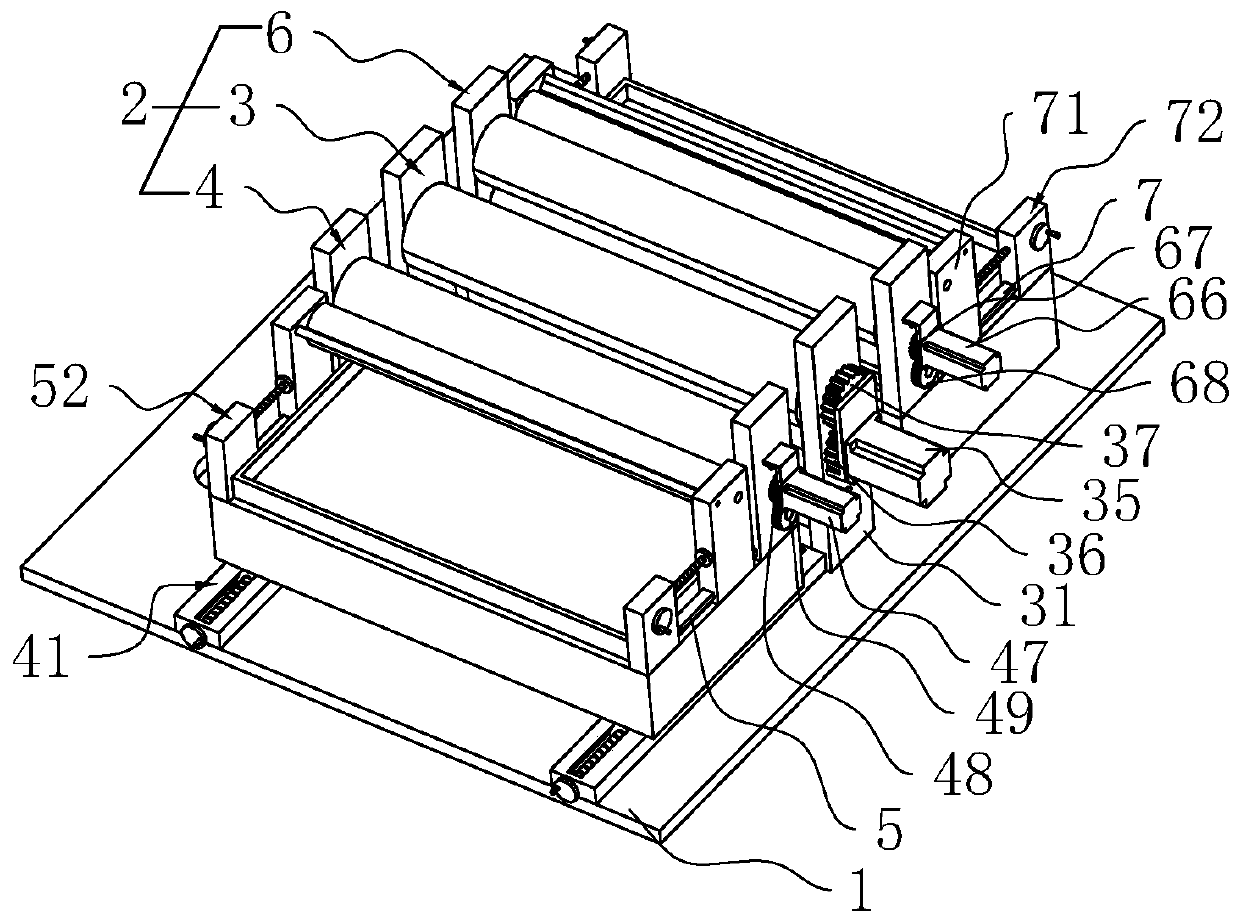

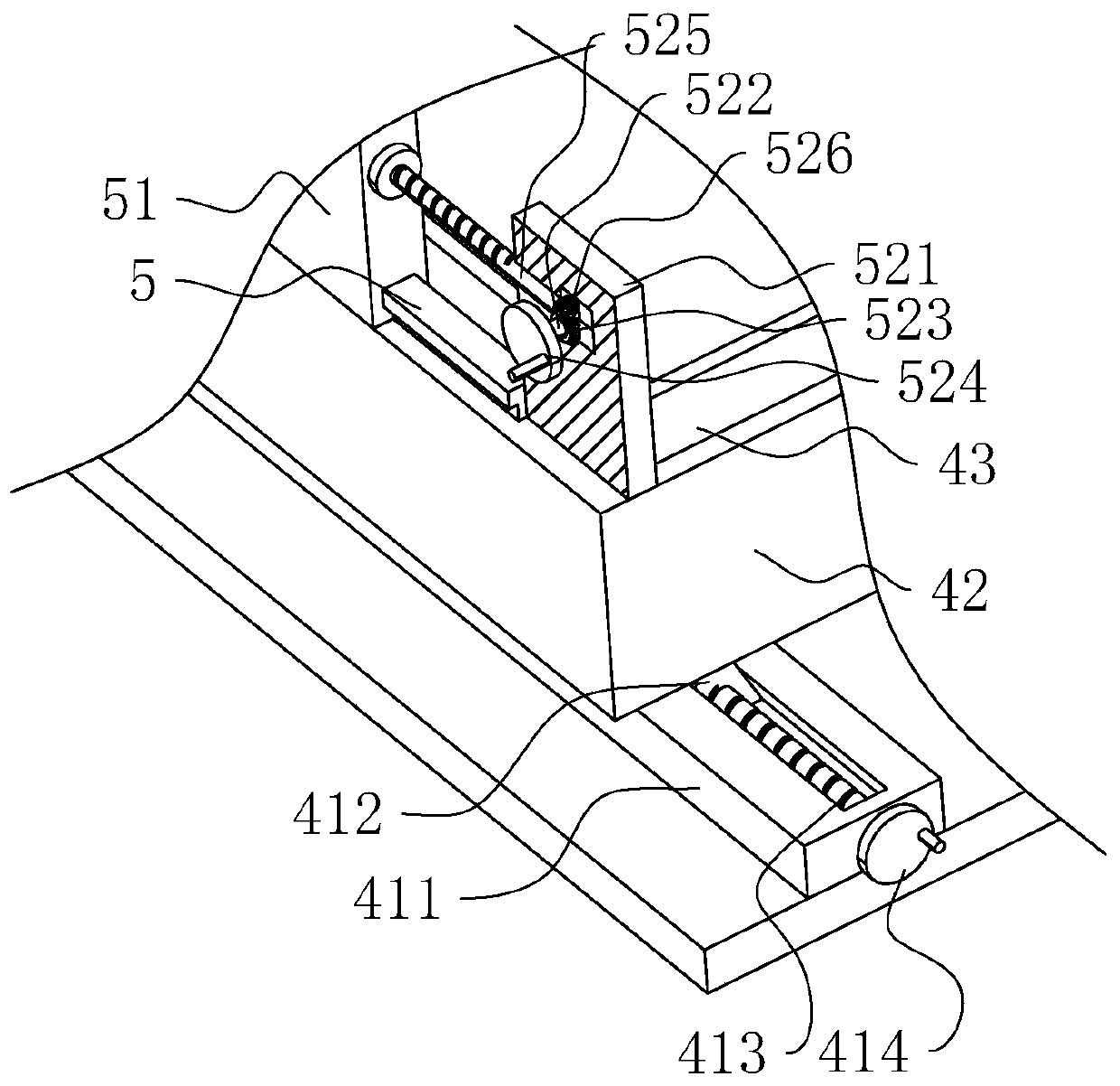

[0059] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0060] The invention discloses a double-sided coating process and equipment for a metal coil, comprising the following process steps:

[0061] S1: Unwinding the metal coil, specifically unwinding the metal coil through the unwinding unit.

[0062] S2: Adjust the tension of the metal coil unwound in step S1 through the tension unit.

[0063] S3: Pre-storing the metal coils whose tension has been adjusted in step S2 through the vertical looper.

[0064] S4: Adjust the tension and correct the deviation of the metal coil sent out by the vertical looper in step S3 through the tension unit with the deviation correction device.

[0065] S5: Perform double-sided spray cleaning on the metal coil that has undergone deviation correction and tension adjustment in step S4.

[0066] S6: Drying both sides of the metal coil that has been sprayed on both sides in step S5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com