Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2034 results about "Color printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color printing or colour printing is the reproduction of an image or text in color (as opposed to simpler black and white or monochrome printing). Any natural scene or color photograph can be optically and physiologically dissected into three primary colors, red, green and blue, roughly equal amounts of which give rise to the perception of white, and different proportions of which give rise to the visual sensations of all other colors. The additive combination of any two primary colors in roughly equal proportion gives rise to the perception of a secondary color. For example, red and green yields yellow, red and blue yields magenta (a purple hue), and green and blue yield cyan (a turquoise hue). Only yellow is counter-intuitive. Yellow, cyan and magenta are merely the "basic" secondary colors: unequal mixtures of the primaries give rise to perception of many other colors all of which may be considered "tertiary."

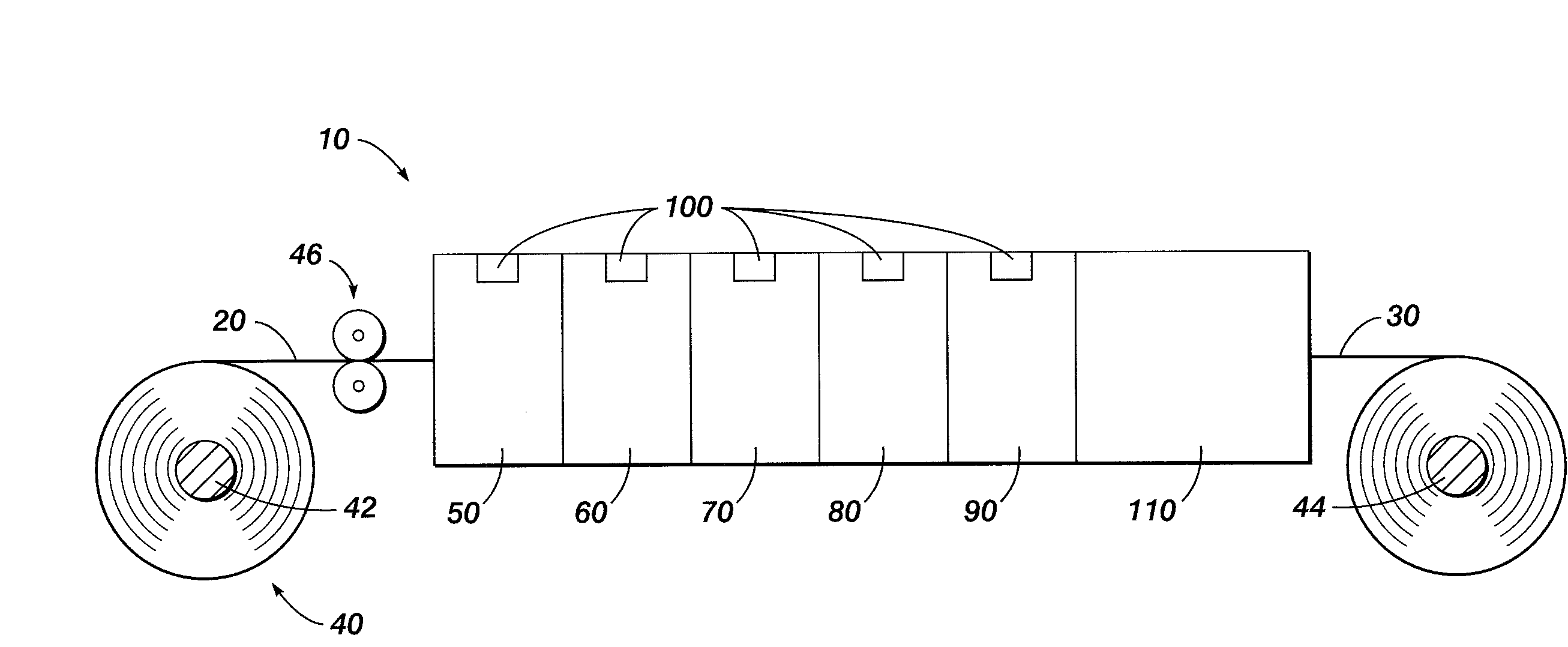

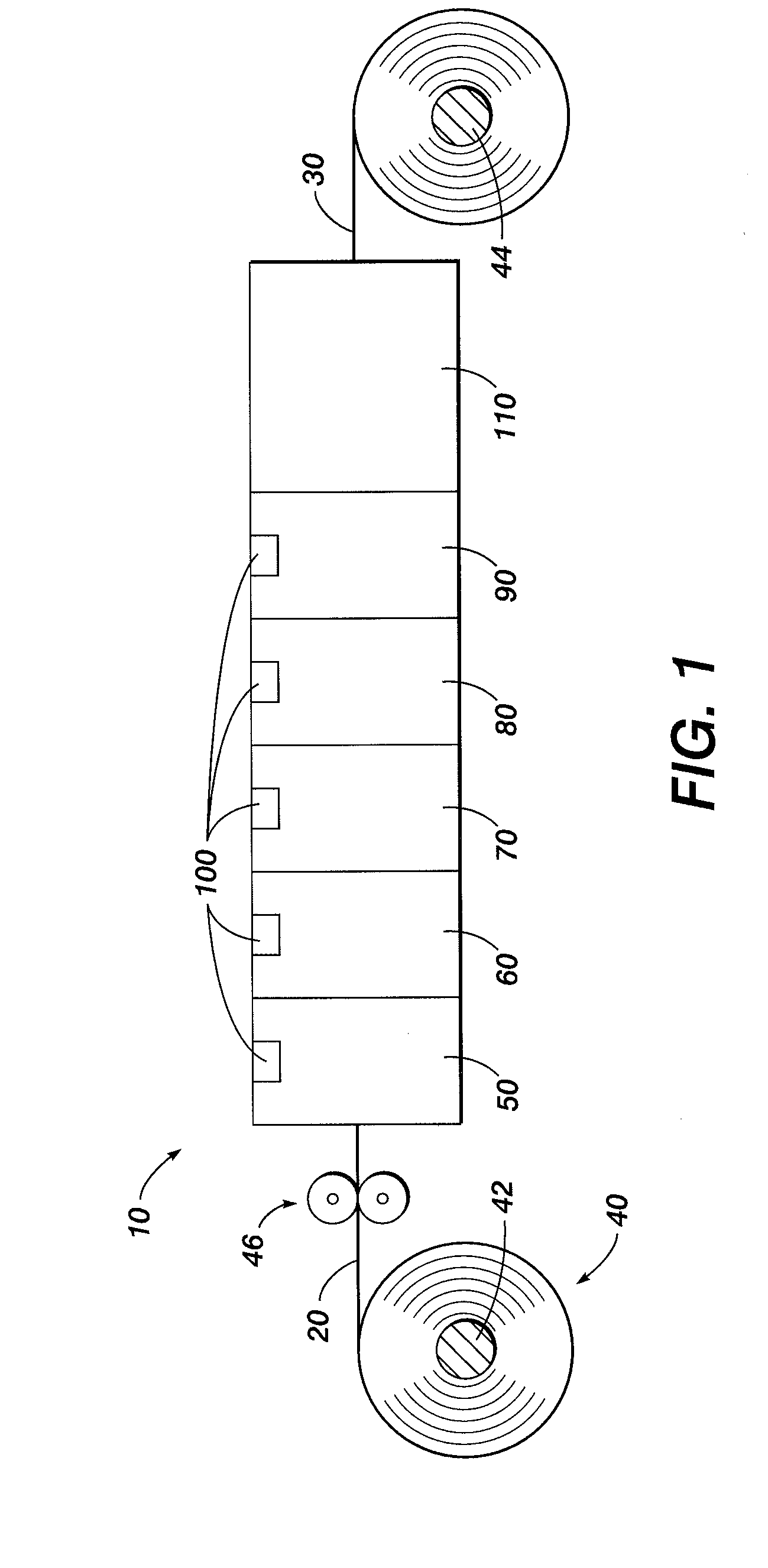

Method and apparatus for printing using a tandem electrostatographic printer

ActiveUS20060133870A1High glossImprove color gamutElectrographic process apparatusElectrographic processes using charge patternColor imageGamut

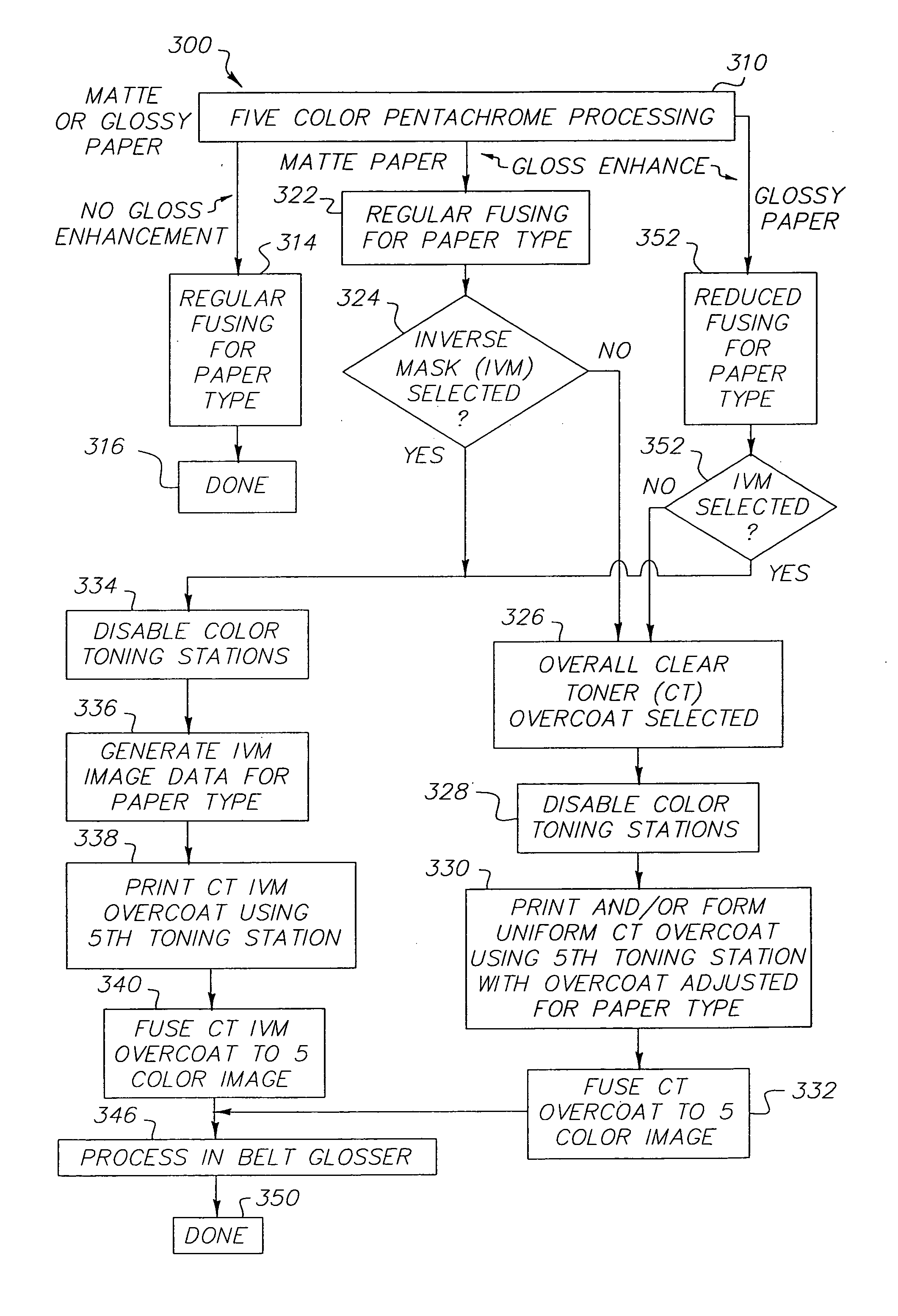

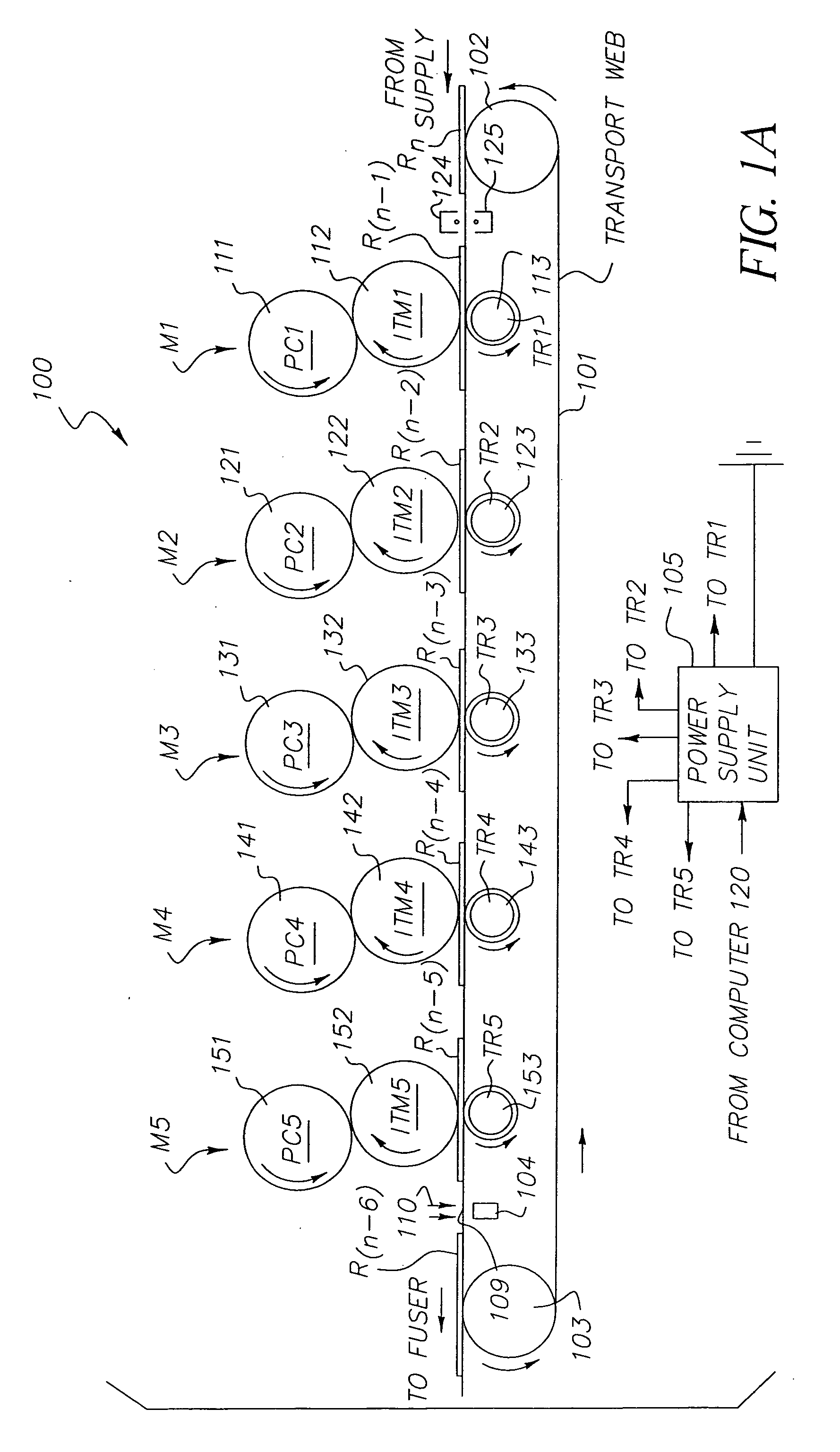

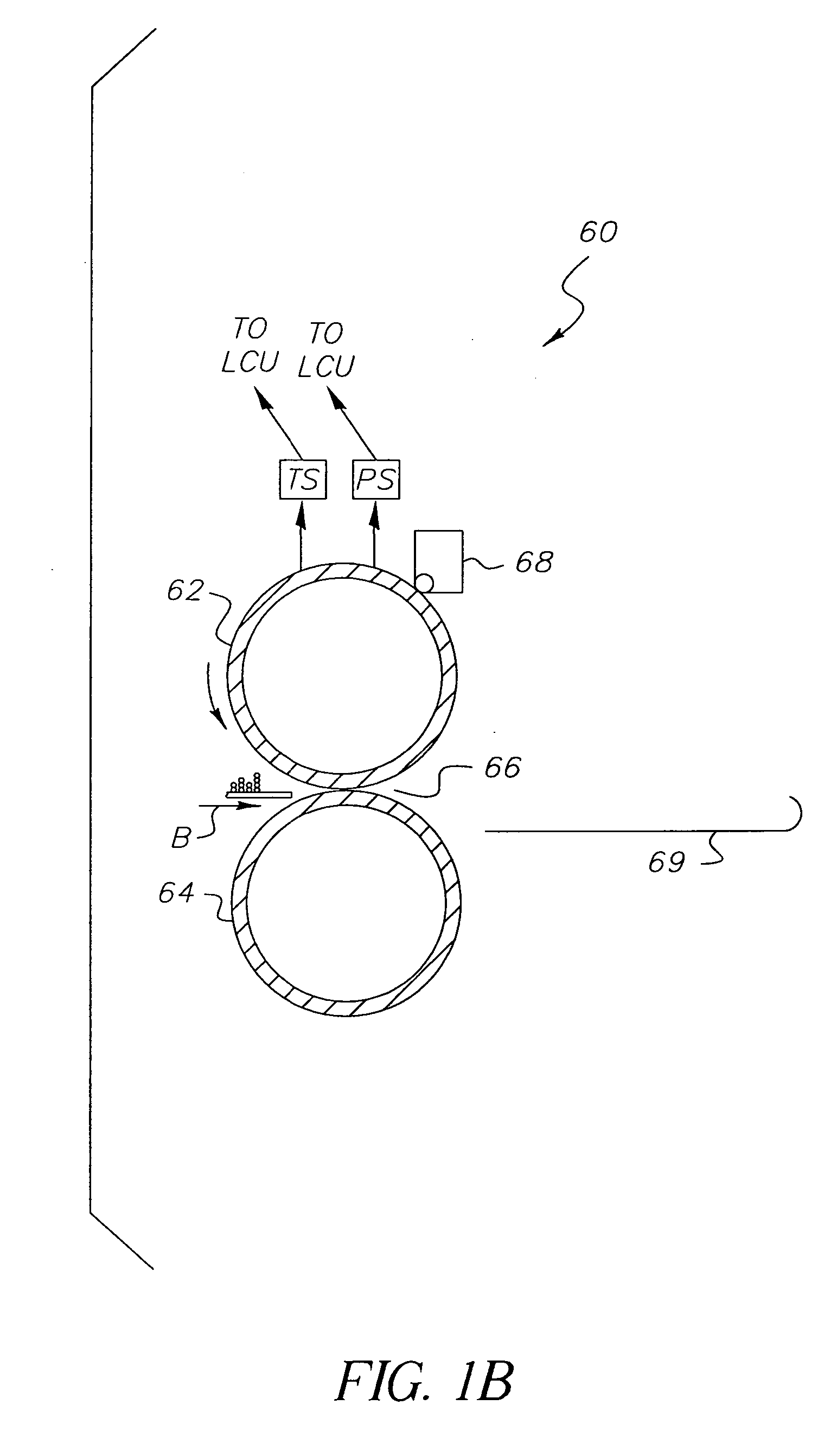

A tandem color electrostatographic printer apparatus has five or more color printing stations or modules for applying respective color separation toner images to a receiver member to form a pentachrome color image in a single pass. A fuser station fuses the pentachrome color image. A clear toner overcoat is then applied to the fused pentachrome toner image and enhanced glossing of the image is provided by a belt glosser to improve color gamut.

Owner:MIDWEST ATHLETICS & SPORTS ALLIANCE LLC

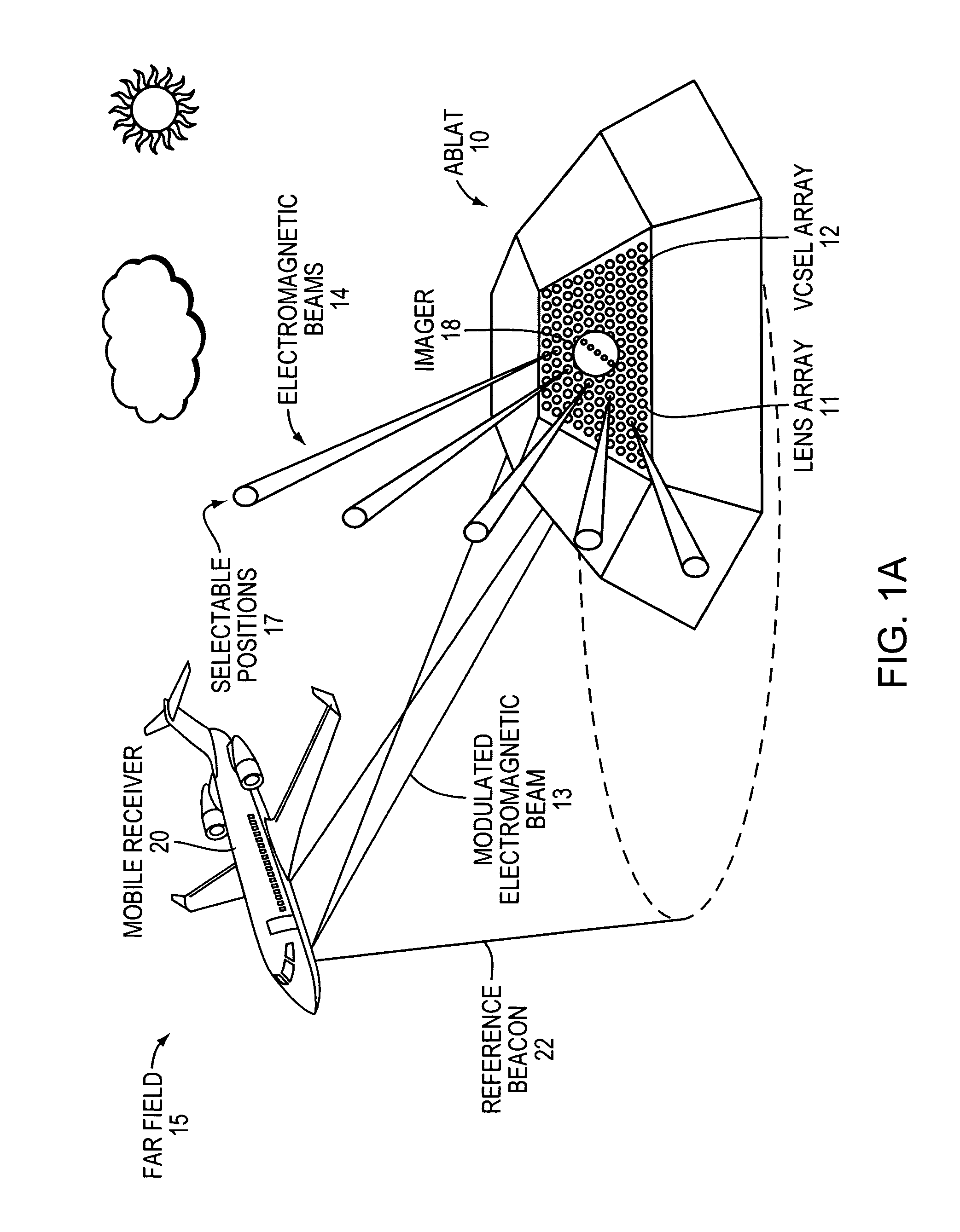

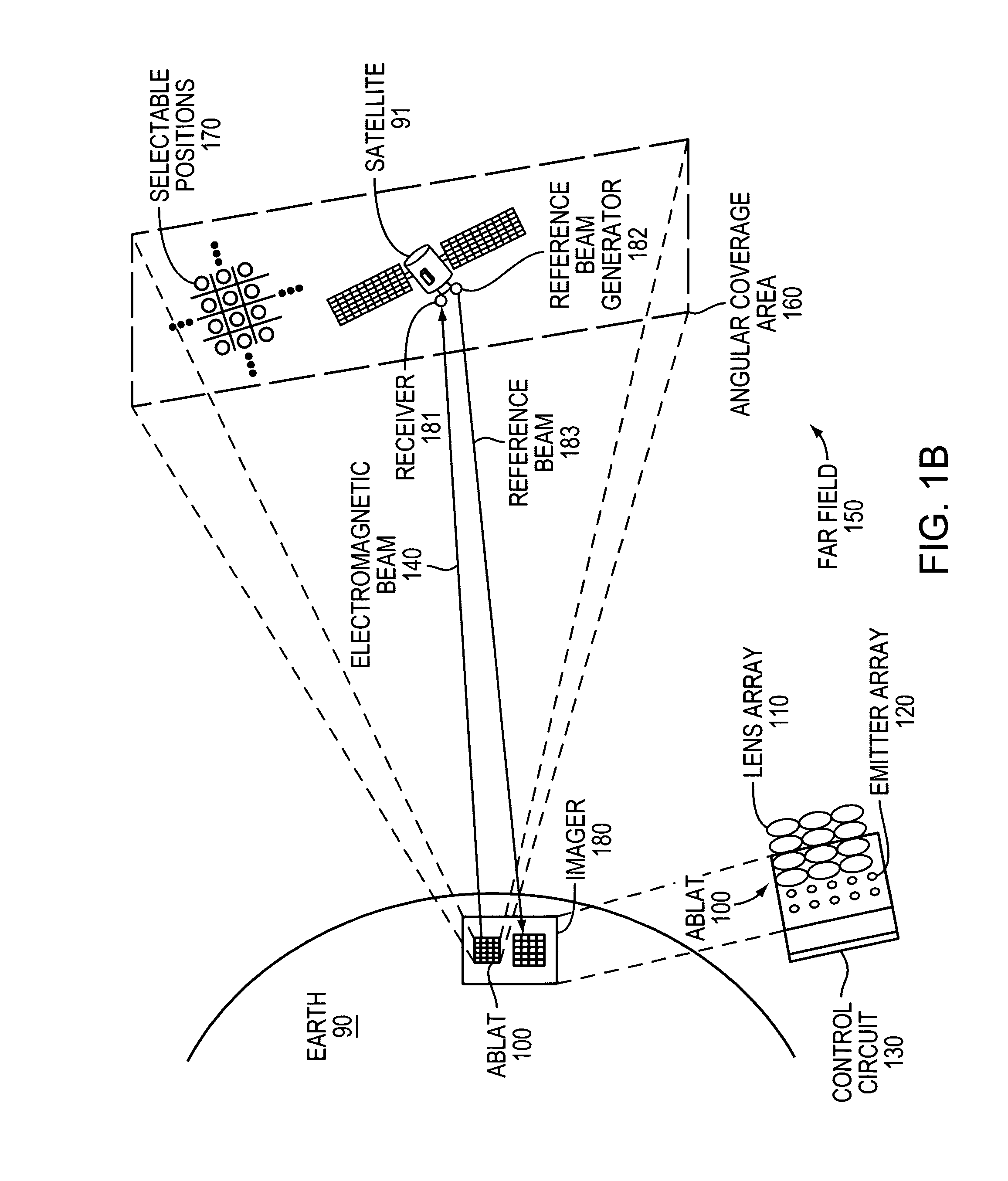

Agile-beam laser array transmitter

ActiveUS20100046953A1Turn fasterWide field of viewWave based measurement systemsWavelength-division multiplex systemsLaser arrayColor printing

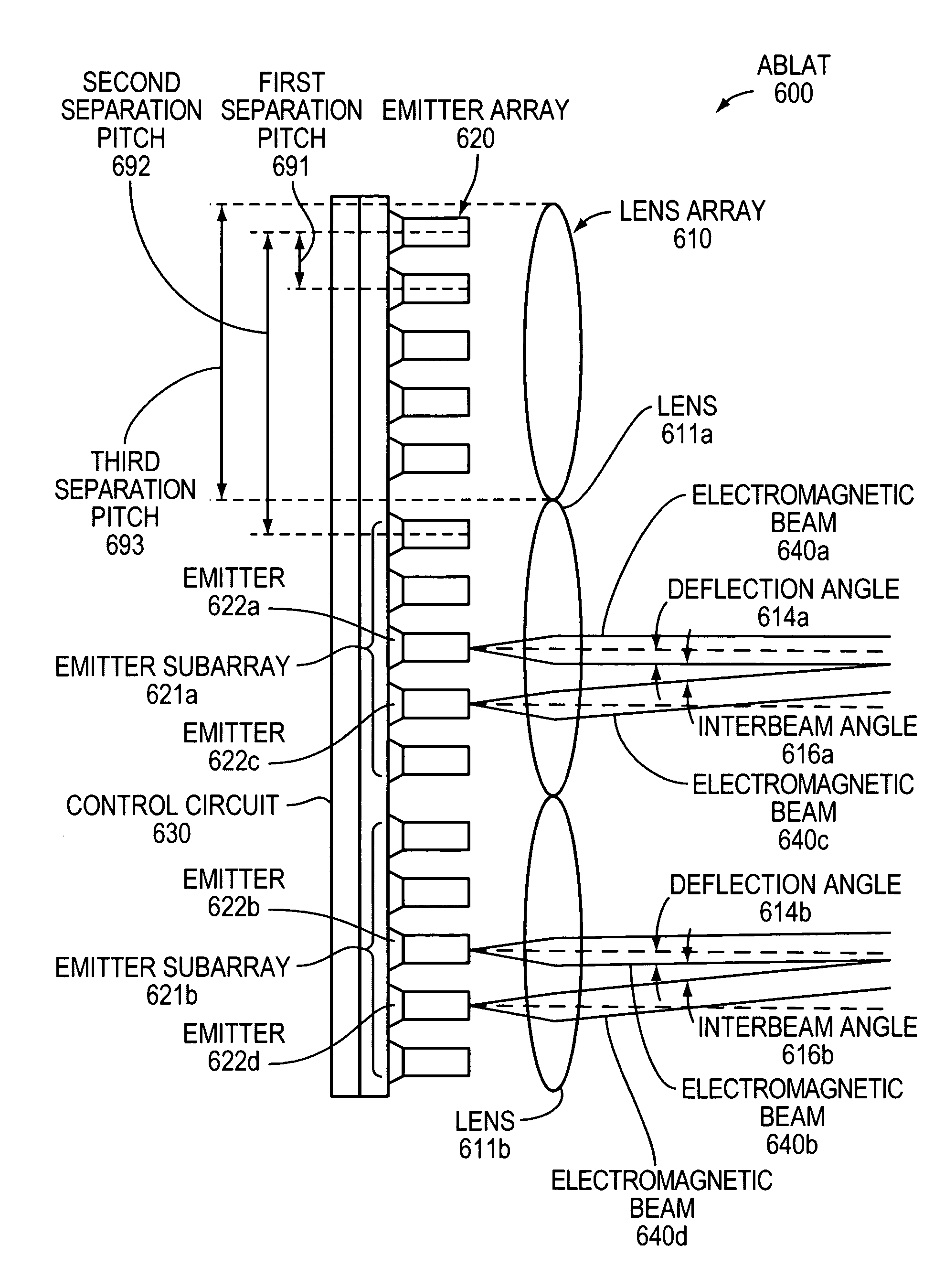

An Agile-Beam Laser Array Transmitter (ABLAT) uses an array of emitters and an array of lenses to project electromagnetic beams over a wide angular coverage area in the far field. Differences in the separation pitches of the two arrays allows the ABLAT to project beams to contiguous and / or overlapping positions, depending on the ratio of the separation pitches and the lens focal length. Compared to other beam steering technology, the ABLAT is a smaller, lighter, and more efficient means of projecting beams over wider angular coverage areas. Various embodiments can be used in any beam steering application, including, but not limited to: free-space optical communications; light detection and ranging (lidar); optical scanning (e.g., retinal or bar-code scanning); display projection; image capture; optical character recognition; scanning laser microscopy; non-destructive testing; printing; facsimiles; map making; web inspection; color print processing; phototypesetting and platemaking; laser marking; material processing; DNA analysis; and drug discovery.

Owner:MASSACHUSETTS INST OF TECH

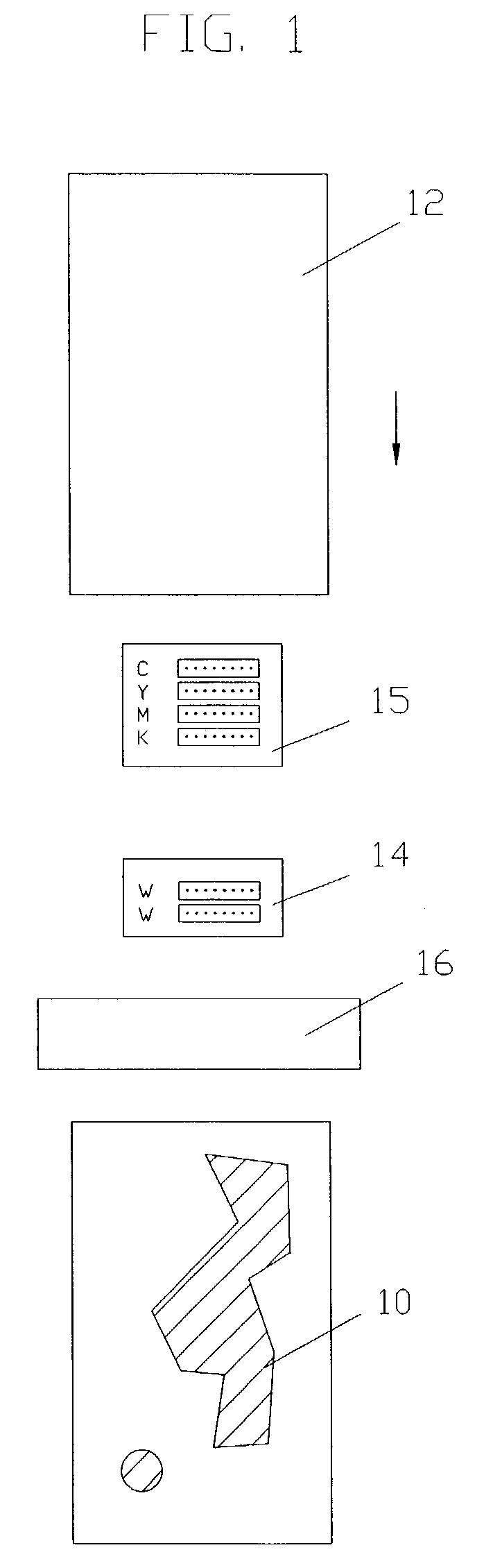

Method for image printing on a dark textile piece

InactiveUS7134749B2Measurement apparatus componentsTransfer printing processColored whiteColor printing

A method and apparatus for color printing on a dark textile piece, the method including the steps of digitally applying a white ink layer directly onto a textile piece, optionally curing the white ink layer, and digitally printing a colored image on said ink layer.

Owner:KORNIT DIGITAL LTD

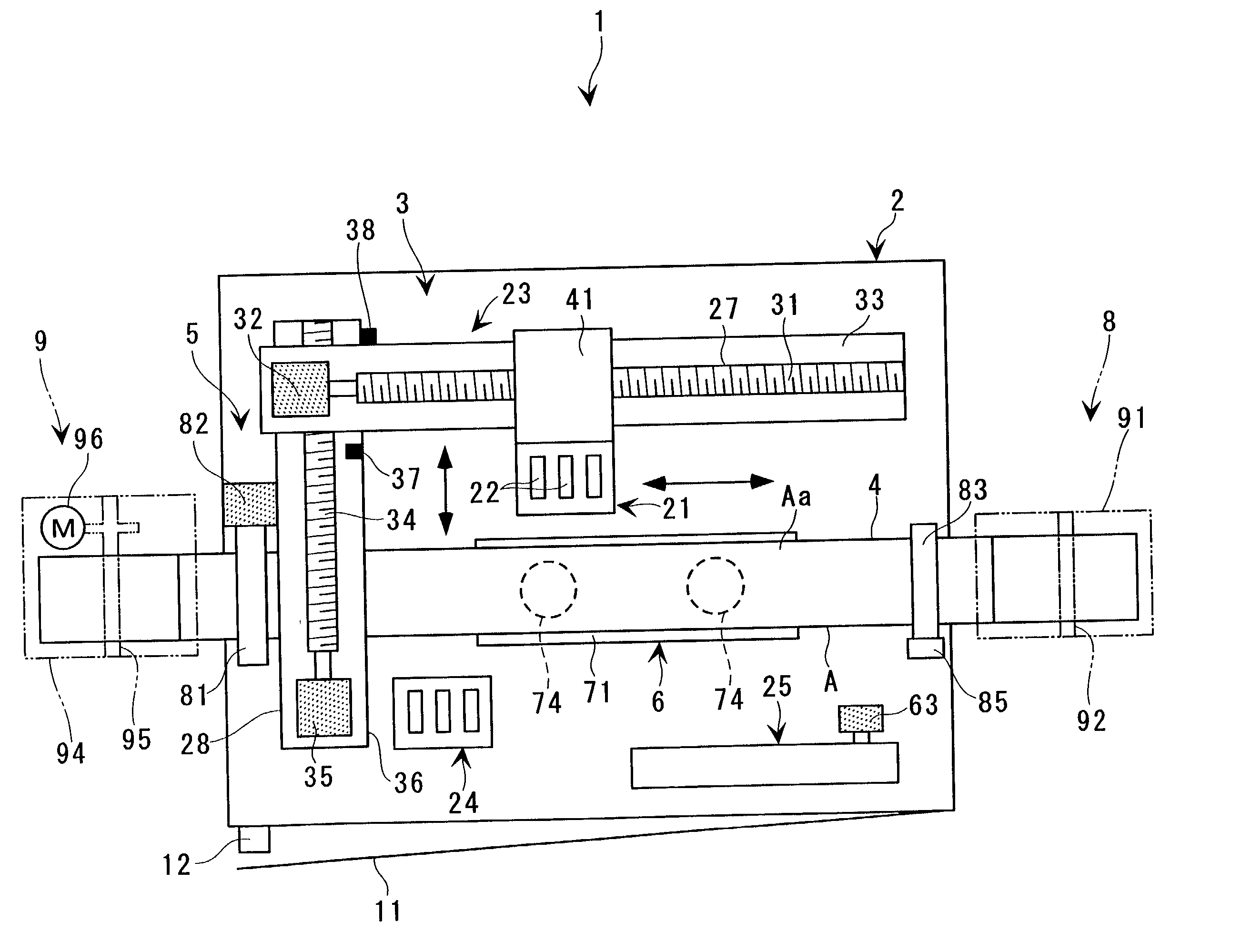

Positional deviation correction using different correction values for monochrome and color bi-directional printing

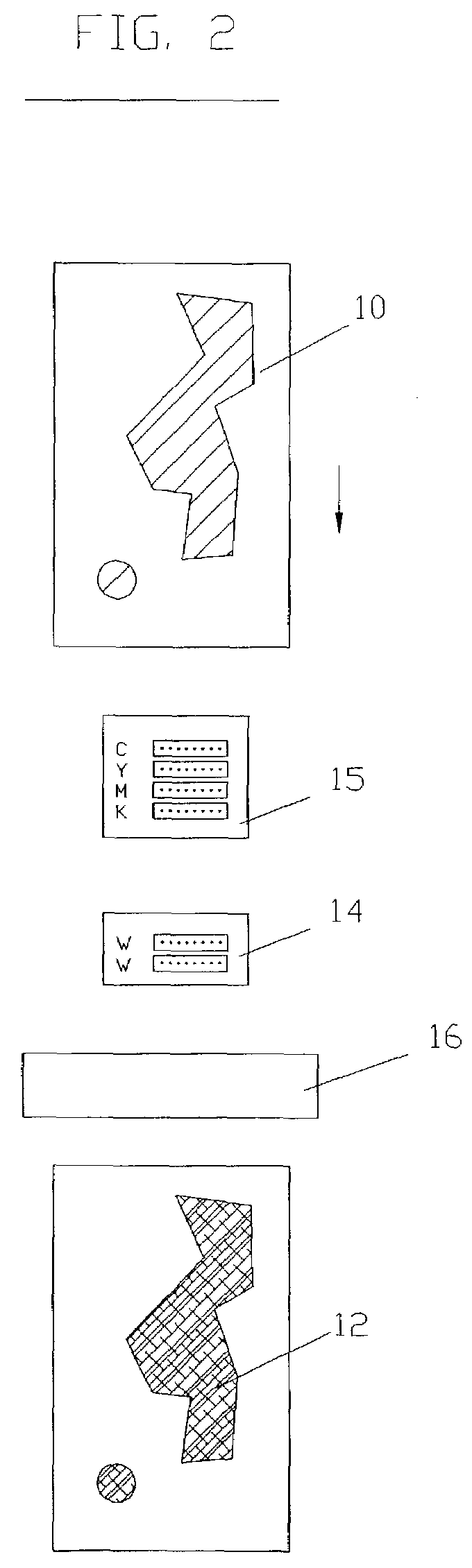

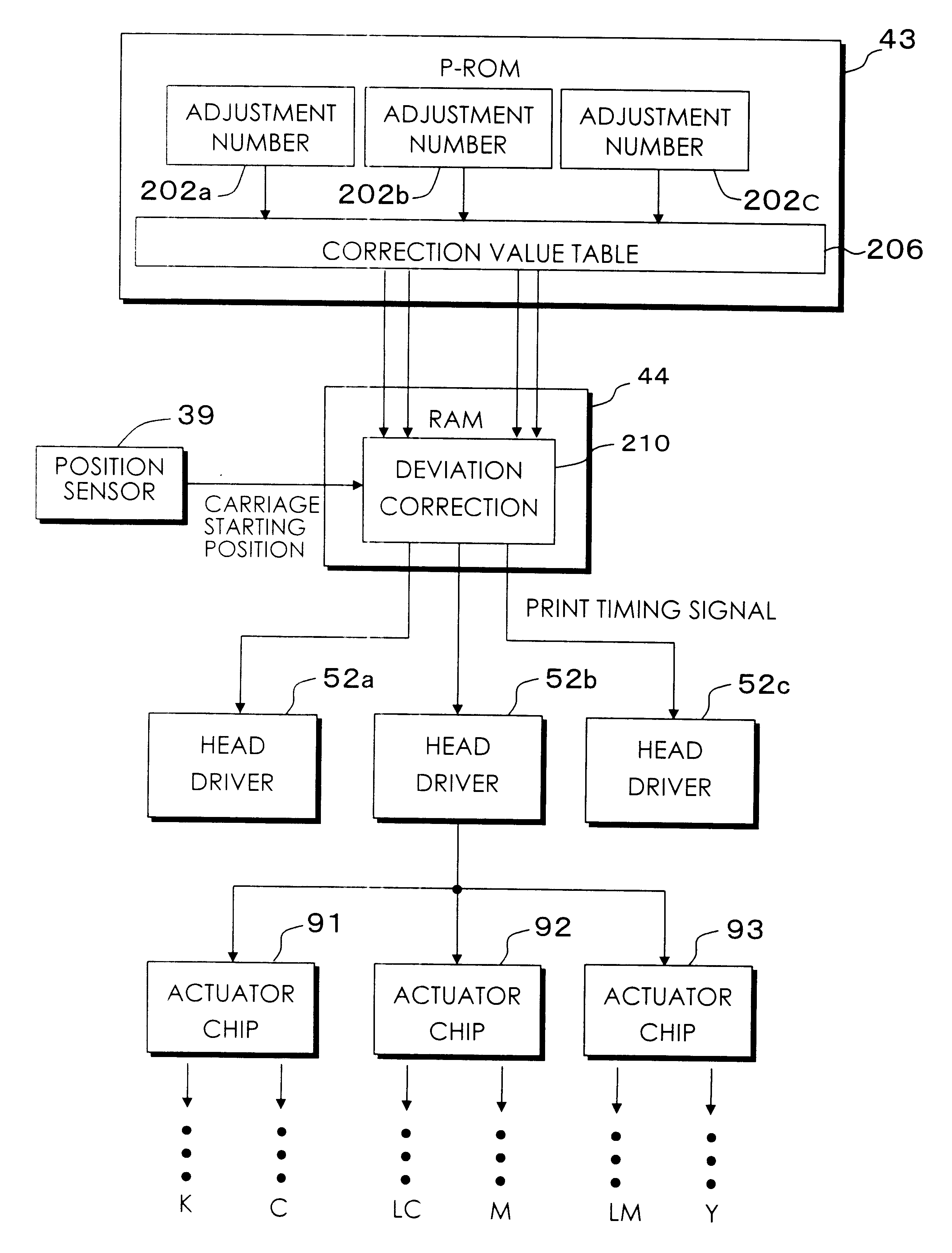

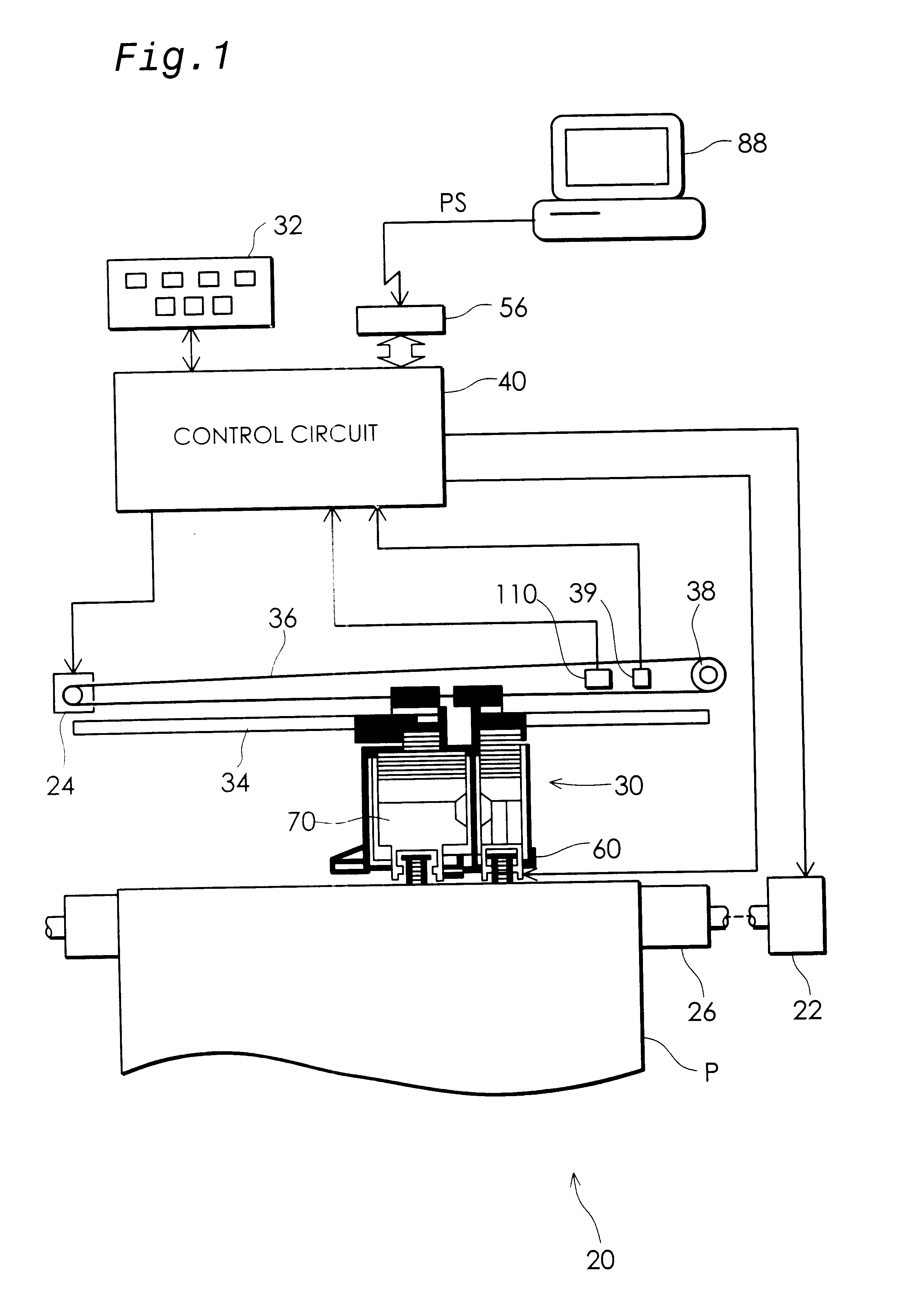

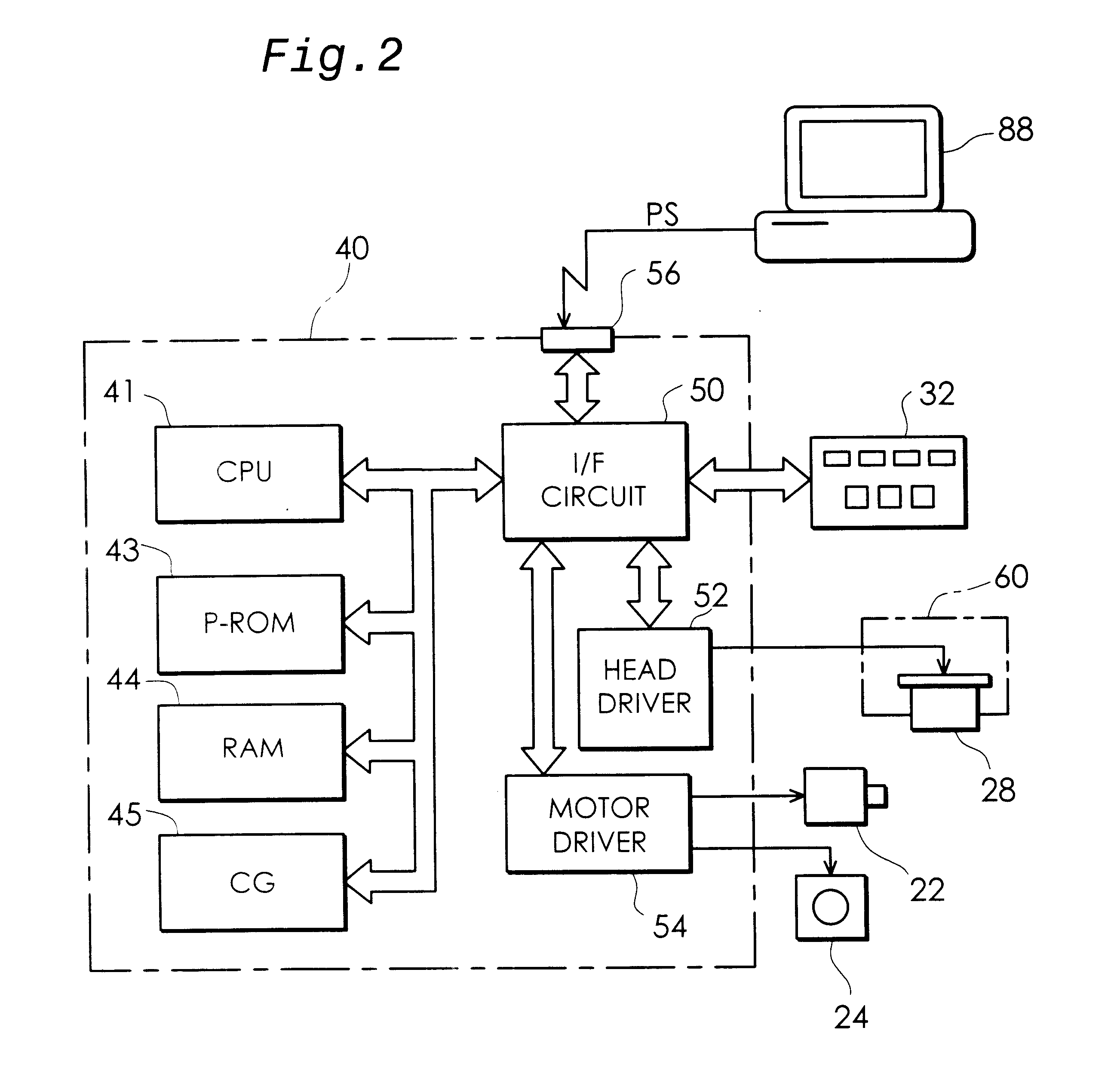

In monochrome printing mode, a first correction value is set for correcting printing positional deviation between ink droplets printed during forward and reverse main scanning passes. In color printing mode, a second correction value is set for correcting printing positional deviation between ink droplets printed during forward and reverse main scanning passes. An adjustment value is determined for reducing printing positional deviation during forward and reverse main scanning passes. For this, in monochrome printing mode the first correction value is used as an adjustment value, and in color printing mode at least a second correction value is used to determine an adjustment value. Following this, the adjustment value is used to adjust printing positions during forward and reverse main scanning passes.

Owner:SEIKO EPSON CORP

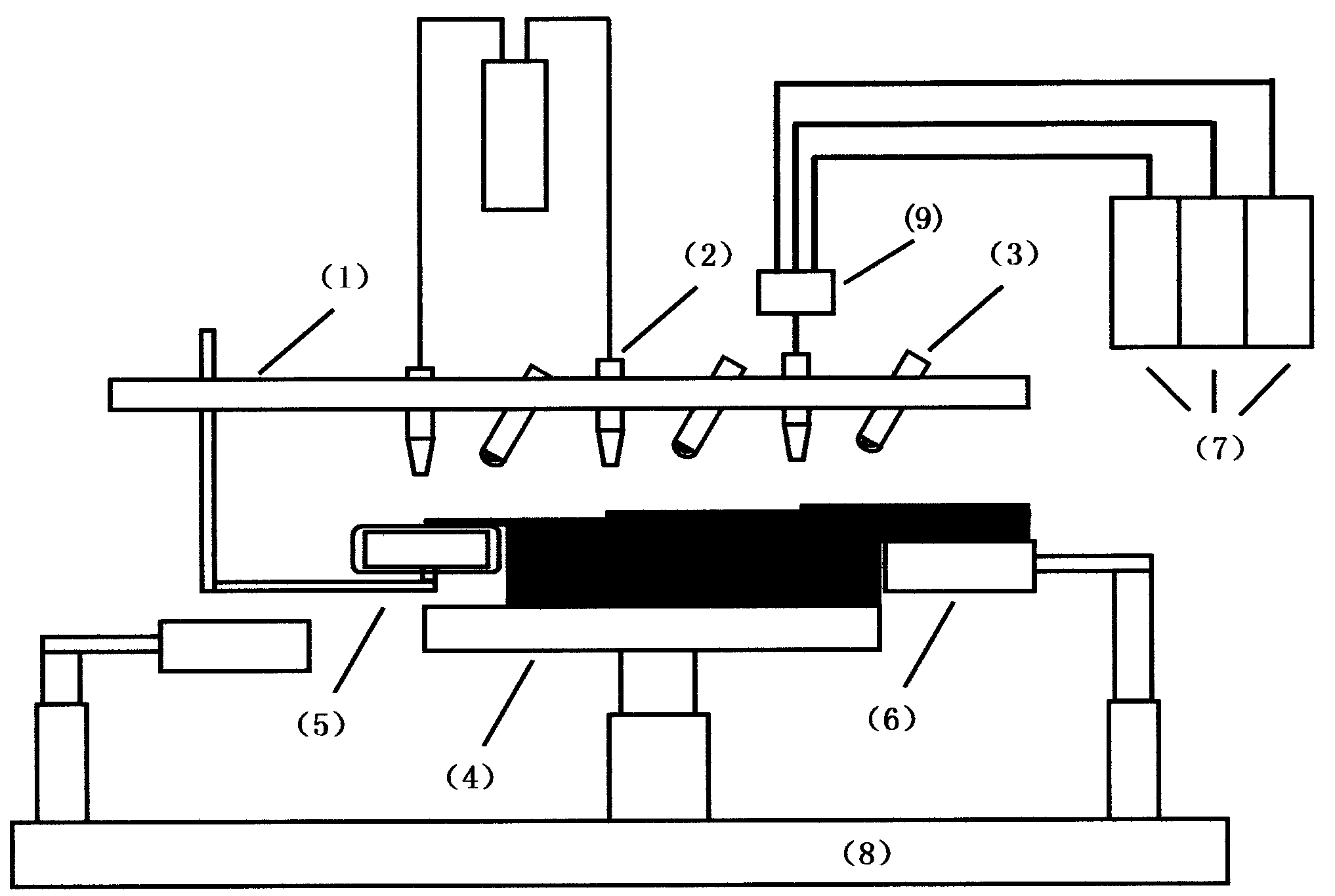

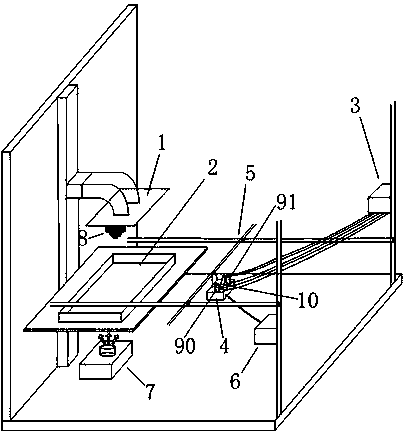

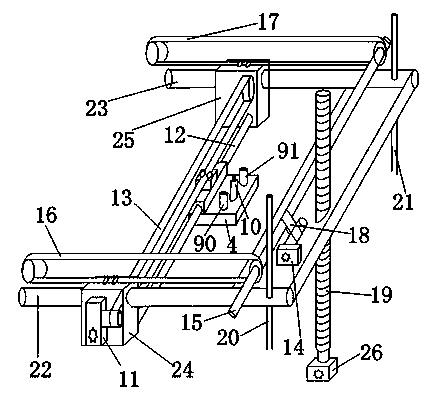

Three-dimensional (3D) printer and method for preparing three-dimensional products by use of 3D printer

The invention discloses a three-dimensional (3D) printer, the 3D printer comprises an X-Y working platform, spray heads installed on the X-Y working platform, light-emitting diode (LED) ultraviolet (UV) light sources, moving supporting frames, a base, fixed supporting frames, a supporting platform and UV resin material-feeding units, wherein the fixed supporting frames and the supporting platform are installed on the base, and the spray heads are connected with the UV resin material-feeding units. Through use of the 3D printer, one-way single-layer printing and one-way multi-layer printing can be carried out, multi-material printing, color printing, coating printing and other effects can be realized, and the printing efficiency is improved by times compared with that of the traditional 3D printers.

Owner:徐州泰铭电气有限公司

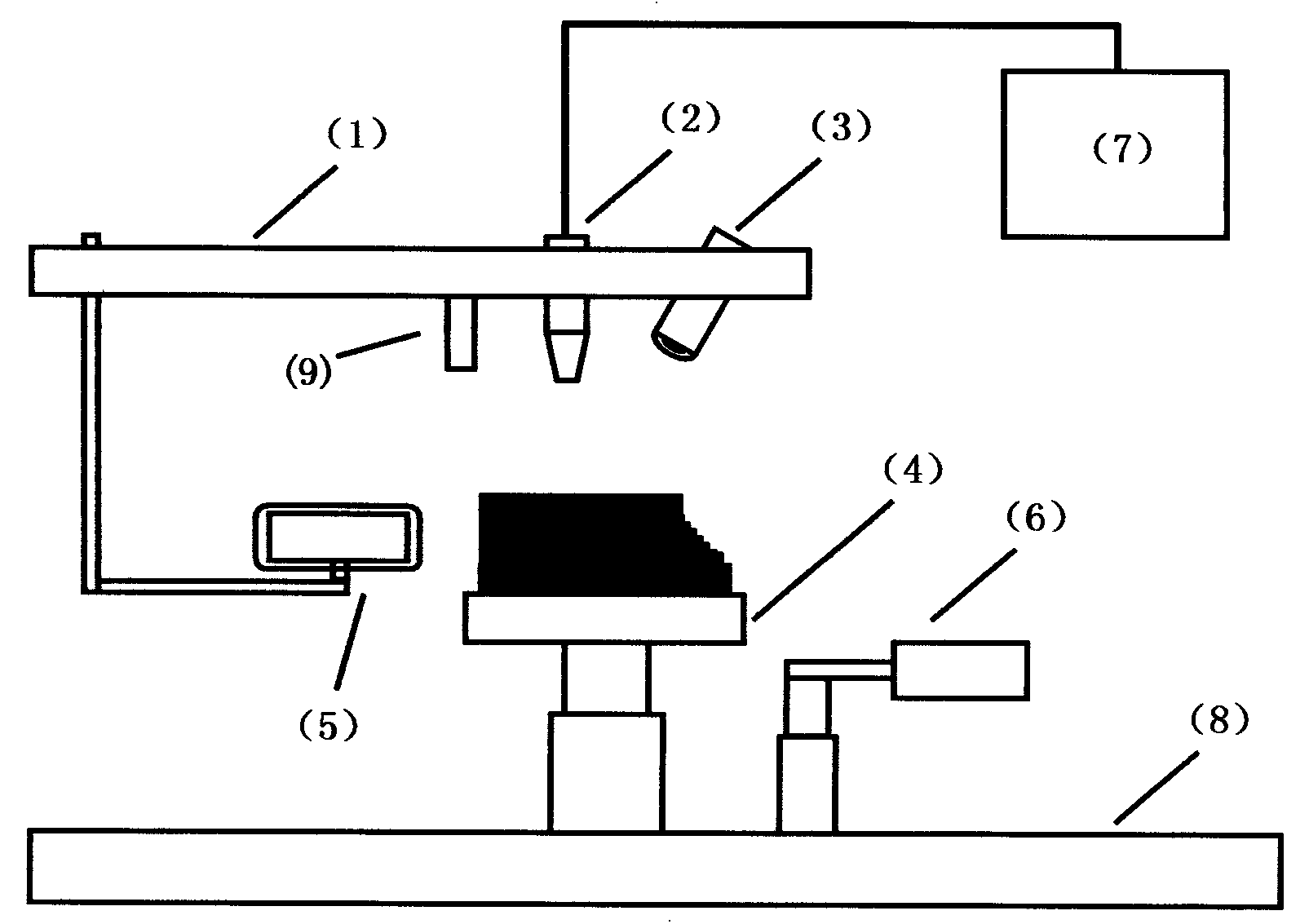

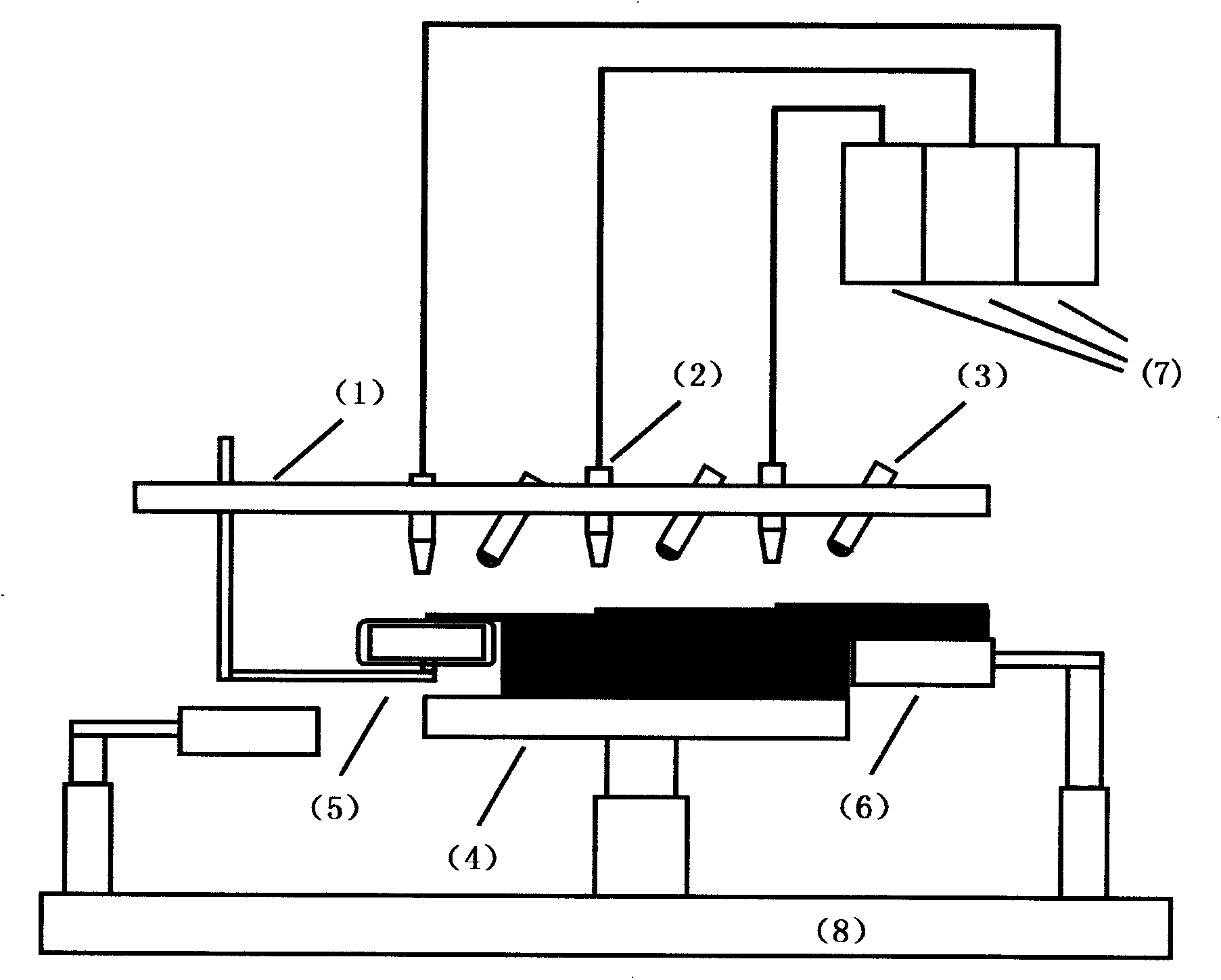

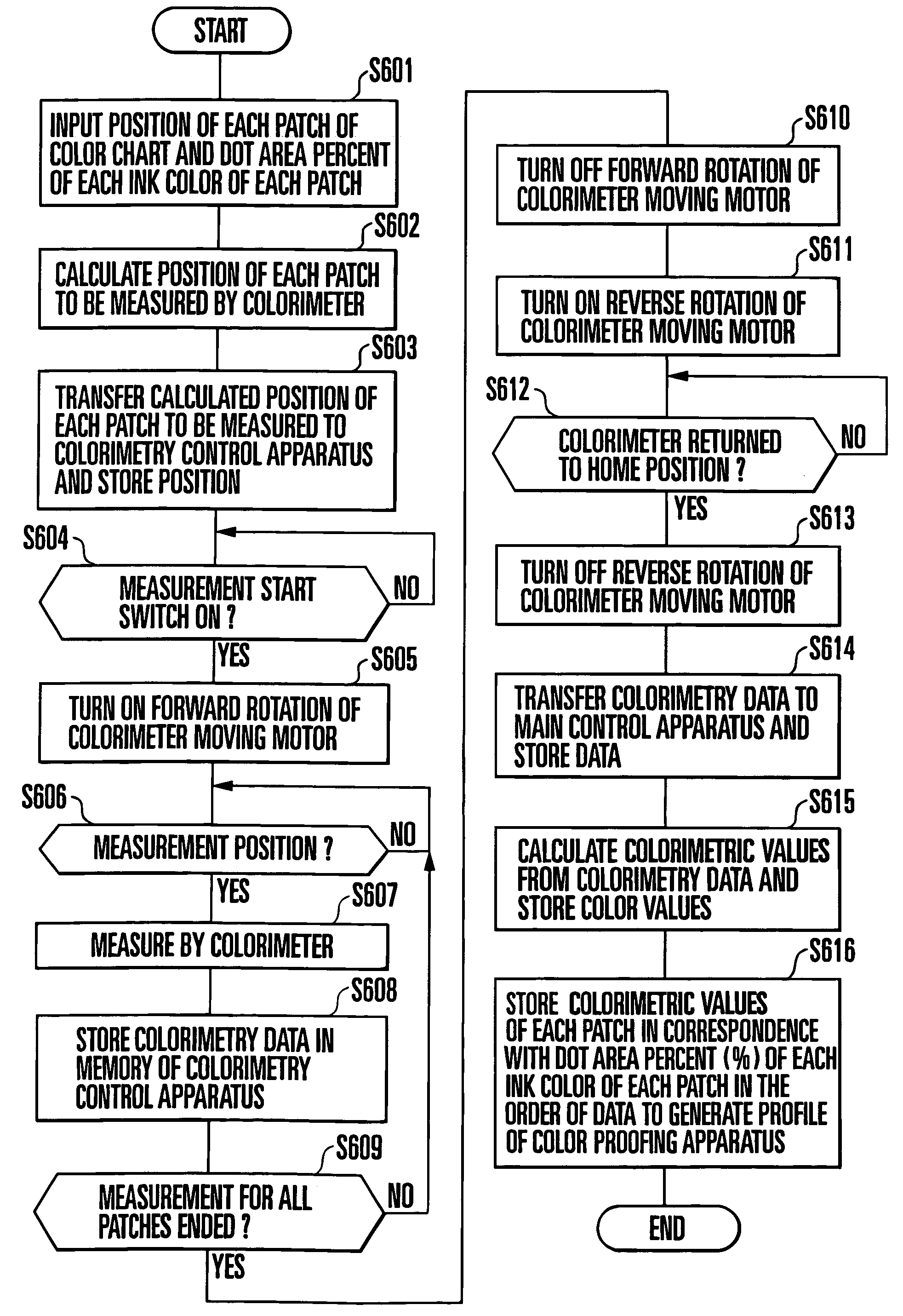

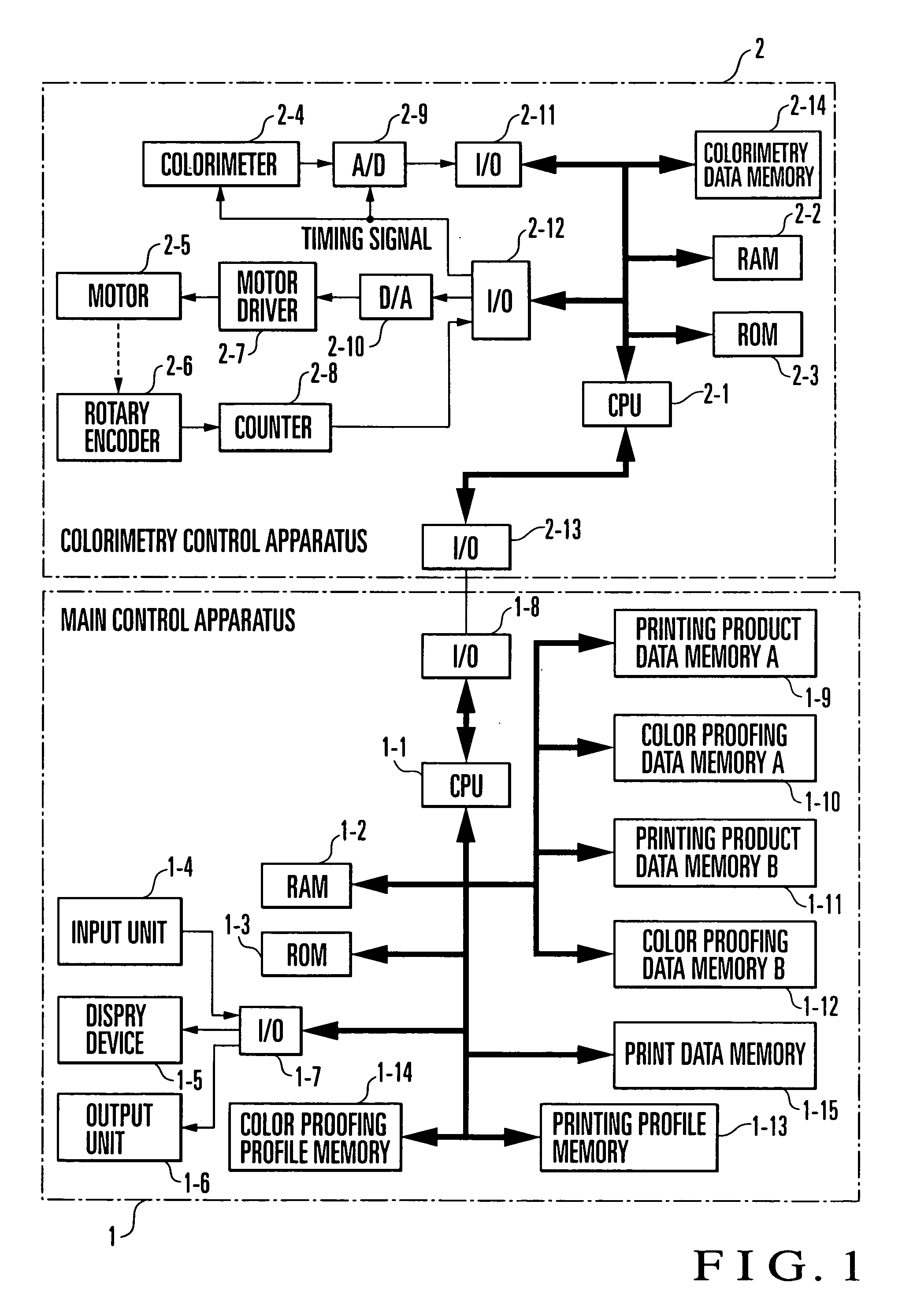

Color management method and apparatus for printing press

InactiveUS7031022B1Exact matchShort profileDigitally marking record carriersDigital computer detailsColor printingEngineering

In a color management method for a printing press, a color chart formed from a plurality of patches is printed by multi-color printing using the printing press and a plurality of ink colors. Each of the patches has a predetermined combination of dot area percent of the ink colors. The printed color chart is automatically scanned using a calorimeter to sequentially obtain color data of all the patches. A first profile representing a color reproduction characteristic of the printing press is generated on the basis of the obtained color data of the patches and the dot area percent of the ink colors set in the patches. A color management apparatus is also disclosed.

Owner:KOMORI CORP

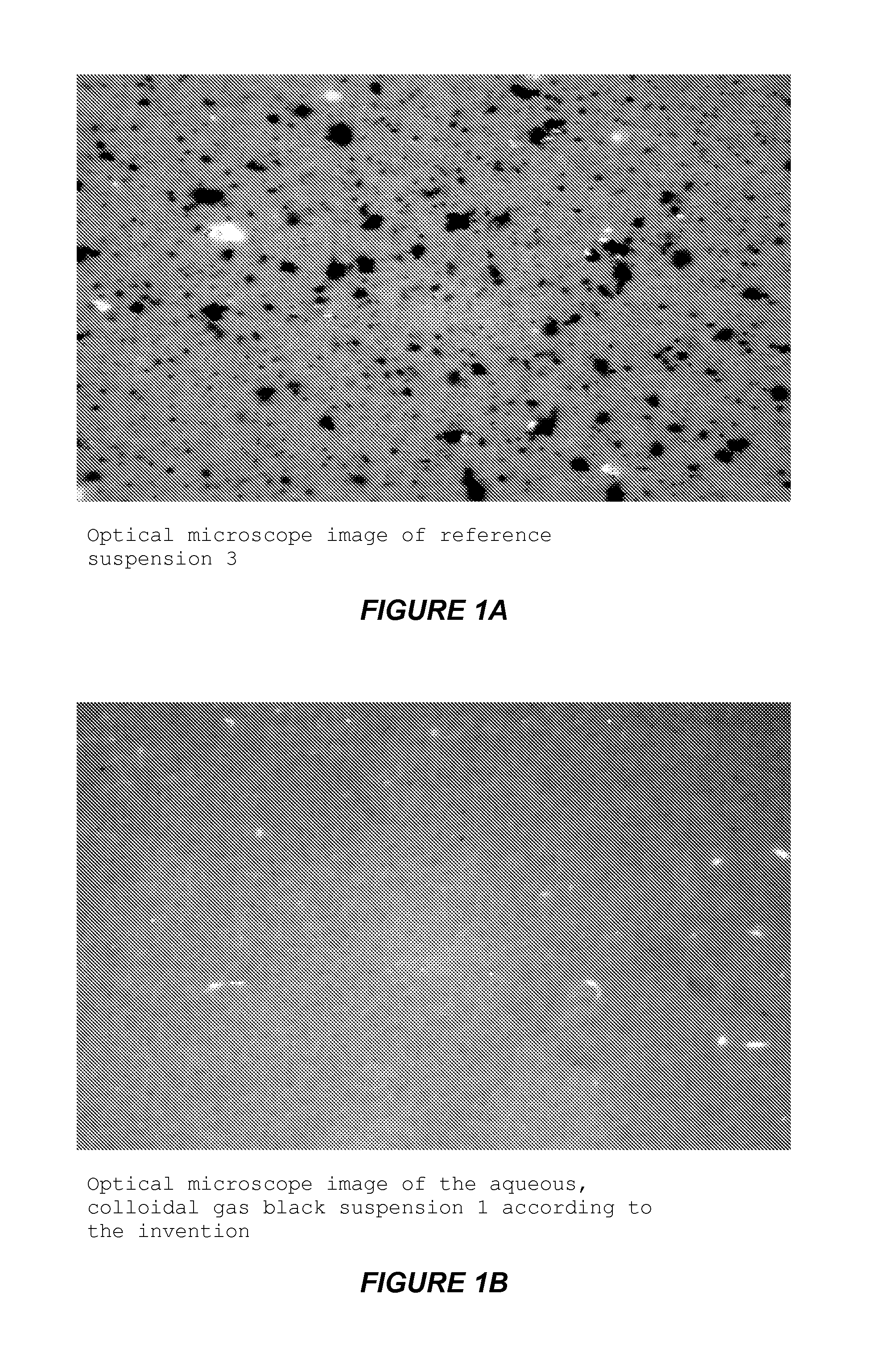

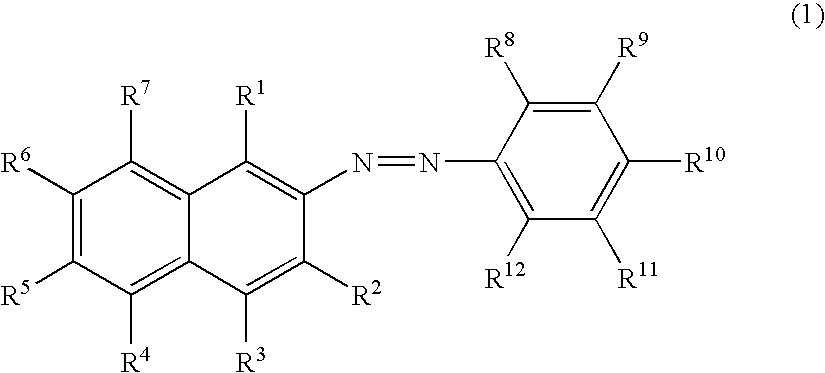

Aqueous, colloidal gas black suspension

ActiveUS7160377B2Improve suspension stabilityLow viscosityMaterial nanotechnologyPigmenting treatmentColloidPhotochemistry

Aqueous, colloidal gas black suspension containing:(a) a gas black, (b) an azo compound of the formula 1(c) and water. The aqueous, colloidal gas black suspension is produced by dispersing the gas black and the azo compound of the formula 1 in water. It can be used in the production of inks, ink-jet inks, surface coatings and colored printing inks.

Owner:UBS AG

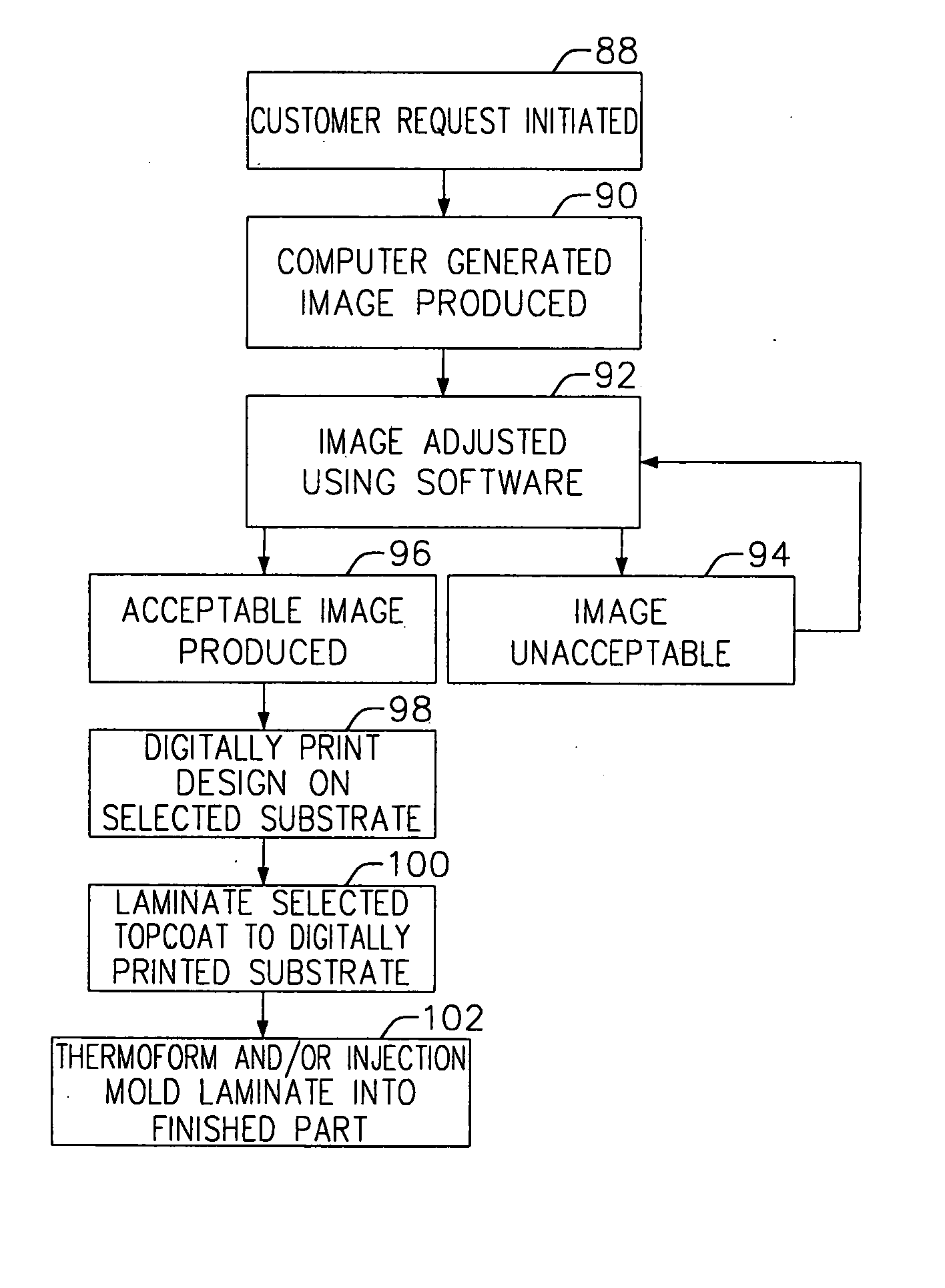

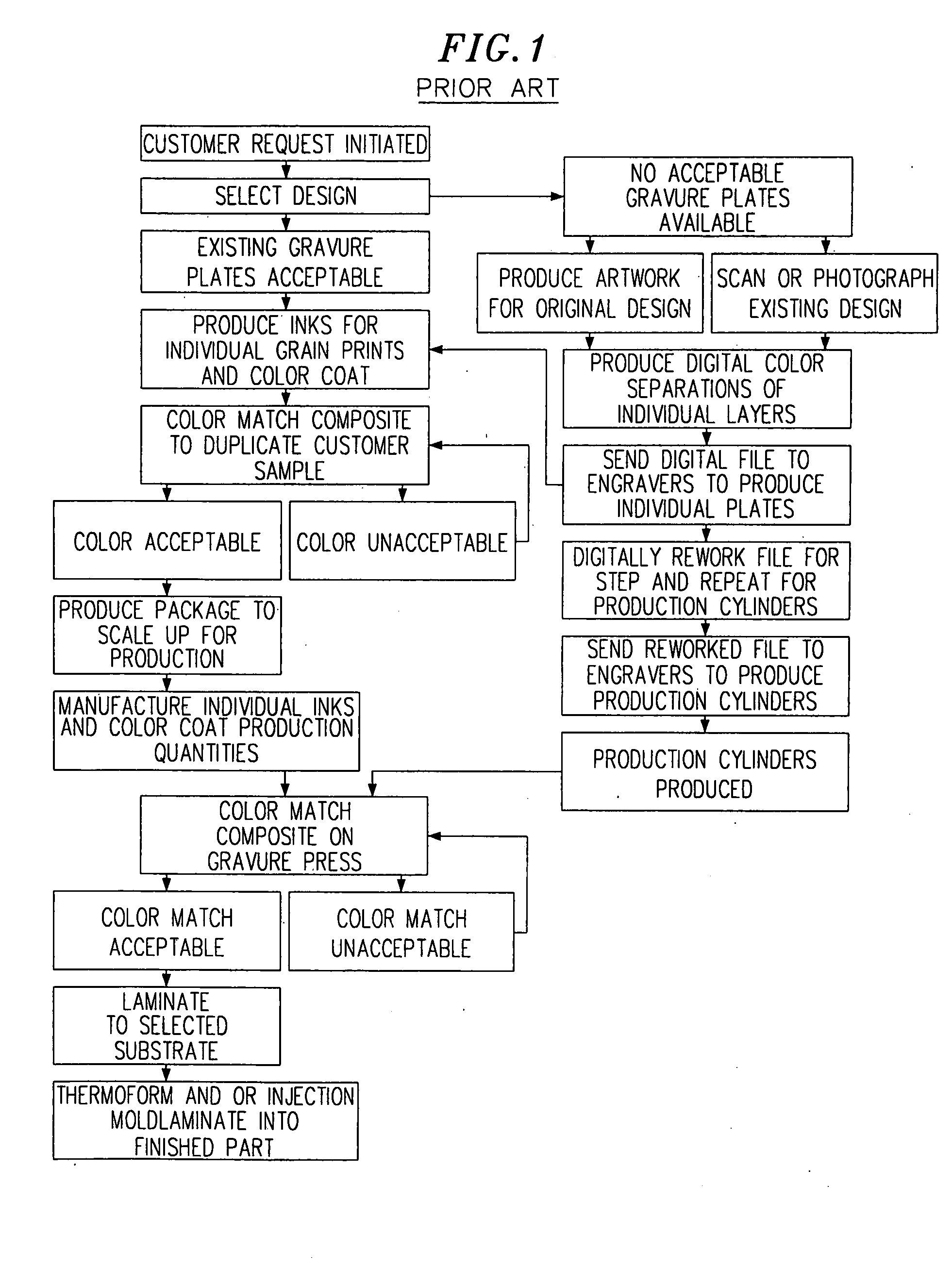

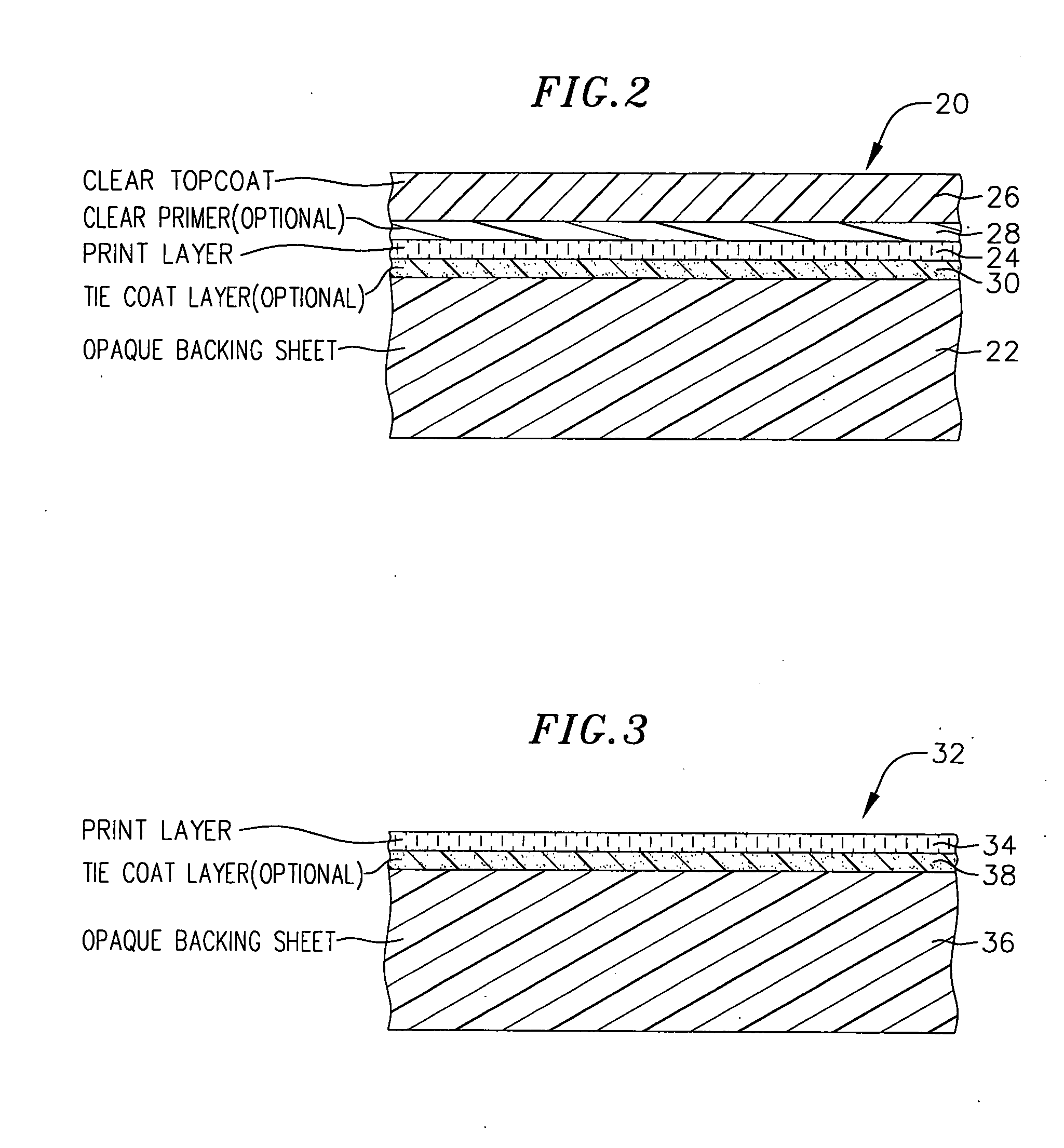

Digitally printed products and process

InactiveUS20070289705A1Speed color-matching processingExcellent abrasion resistanceLamination ancillary operationsDuplicating/marking methodsColor printingComputer printing

A process for manufacturing three-dimensionally shaped polymeric sheets and laminates with color-matched digitally printed full color ink jet images. A flexible thermoformable polymeric baseweb is placed in an ink jet printer and a solvent-based (non-aqueous) digital printing ink is applied directly to the baseweb, in the absence of an ink receptive layer on the baseweb, to form a decorative pattern in multiple colors in a single pass through the printer. The finished product can be thermoformed or injection molded to a three-dimensional shape. A protective topcoat can be laminated to the digitally printed sheet prior to the thermoforming and / or injection molding step. A process for making color-matched products comprises producing a software-driven image of a pattern on a screen representing a standard color print pattern; evaluating and adjusting the standard displayed on the screen using software-driven image related adjustments for hue, contrast, lightness / darkness, etc.; producing a test print by applying a decorative pattern to the baseweb by a digital ink jet printer and making an optional software-driven image-related adjustment in the standard to color match the standard to the test print image; and when the adjusted standard image displayed on the screen is acceptable, passing an image-related output to the digital ink jet printer for printing a decorative print color-matched to the accepted onscreen standard.

Owner:CCL LABEL INC

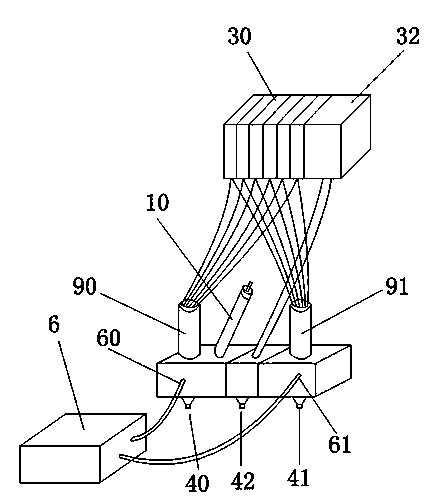

Color 3D printer and method for producing 3D product by color 3D printer

InactiveCN103434135AAchieve full color printingAchieve single-pass multi-layer color printingColor printingUltraviolet

The invention discloses a color 3D (Three-dimensional) printer which comprises an X-Y working platform, a spray head, an LED (Light-emitting Diode) ultraviolet (UV) light source, a movable support frame, a support table, a base and a fixed support frame, wherein the spray head, the LED UV light source and the movable support frame are mounted on the X-Y working platform; the support table and the fixed support frame are mounted on the base; at least one spray head is connected with a premixer; and the connected premixer is at least connected with three UV resin feed units. With the adoption of the color 3D printer, one-way multilayer color printing, and area color printing can be achieved, and the printing efficiency is multiplied compared with the traditional 3D printer.

Owner:孙勇磊 +4

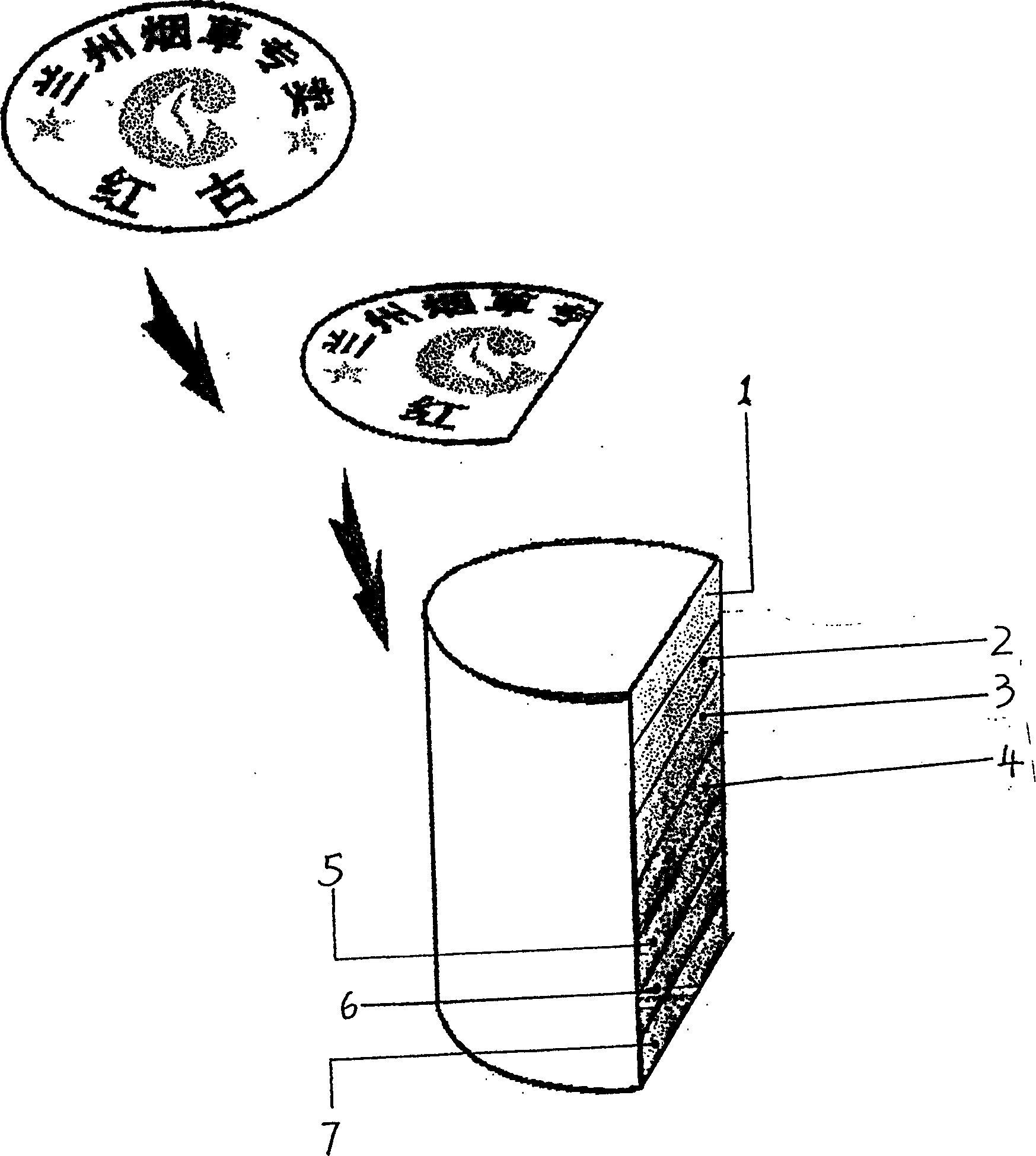

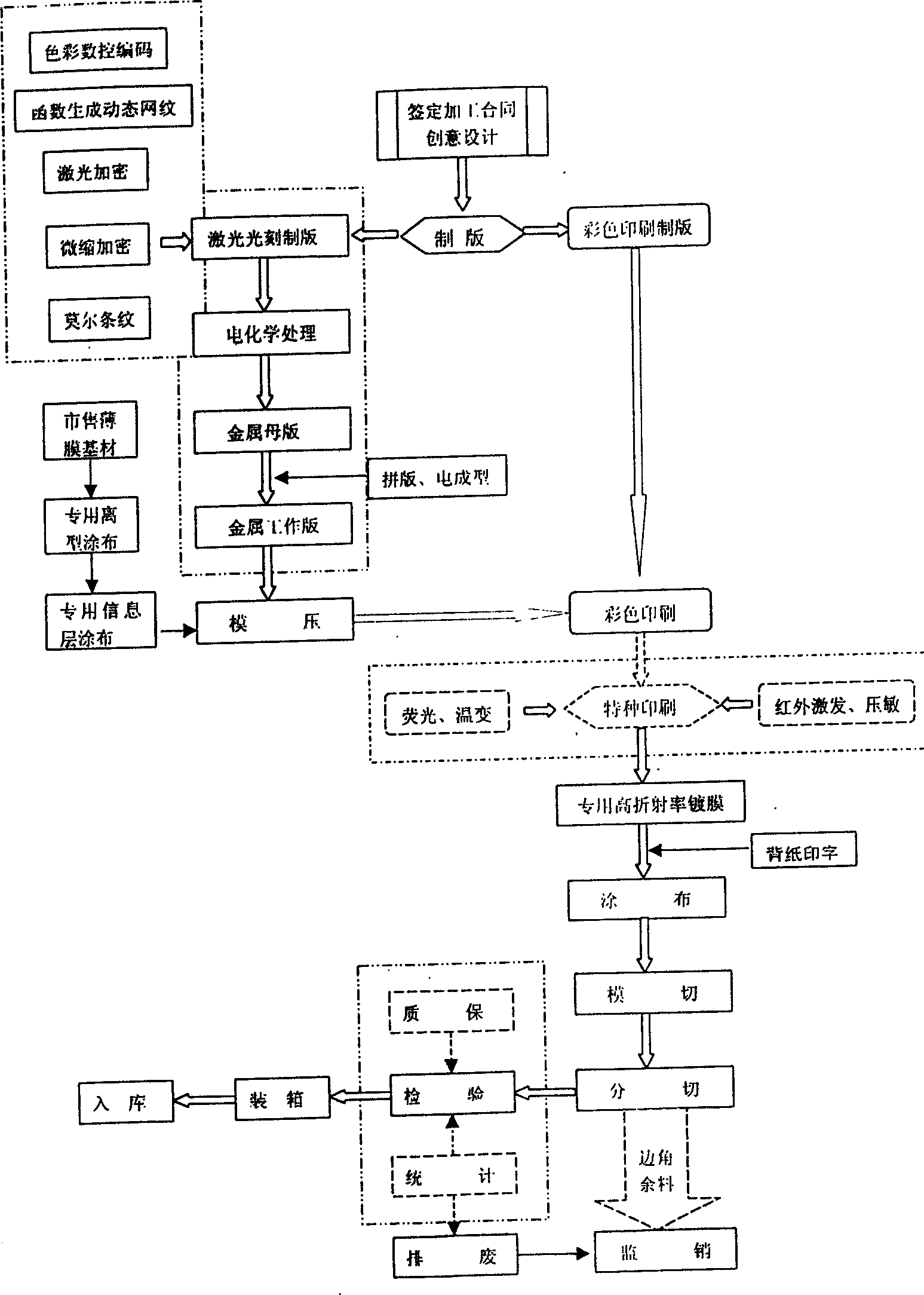

Holographic colour print antiforge mark and its production technology

InactiveCN1514423AIncrease investmentHigh anti-counterfeiting strengthStatic indicating devicesInformation layerColor printing

The invented antifalse mark is different from general color printing label and traditional holographic mark on aluminum foil. The mark includes basal lamina, information layer, isolation layer, color printing layer, special type printing layer and not dried glue layer etc. Technical flow includes following procedures: designing, plate making, raw materials preparing, die pressing, color printing, special type printing, glue spreading, die cutting, parting cut and checking up pack. The invention possesses advantages of integrating multiple antifalse techniques, easy of recognition and convenient use.

Owner:河南天畅防伪包装有限公司

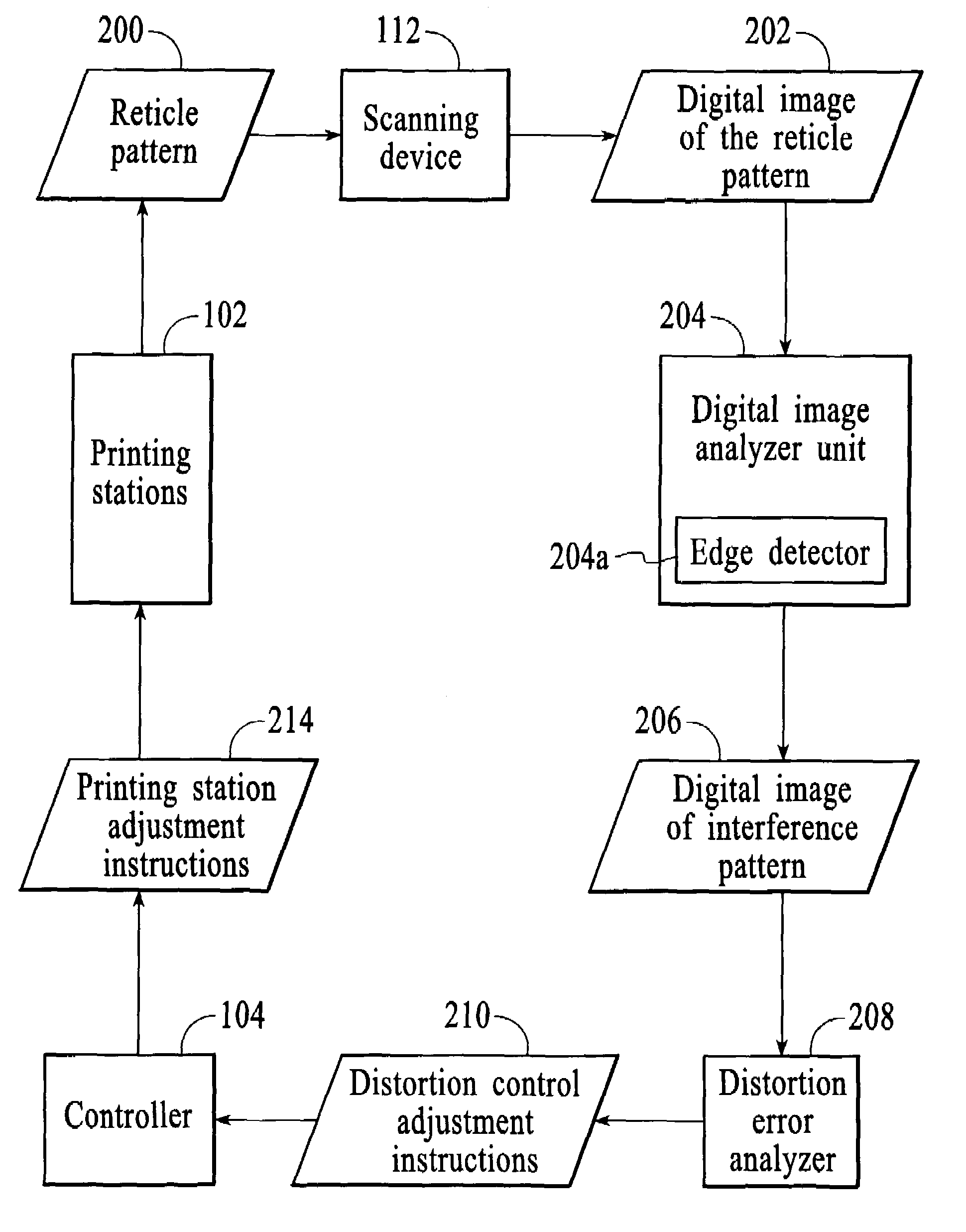

Method and system for minimizing the appearance of image distortion in a high speed inkjet paper printing system

ActiveUS6966712B2True colorPrecise registrationAddressographsPlaten pressesColor printingEngineering

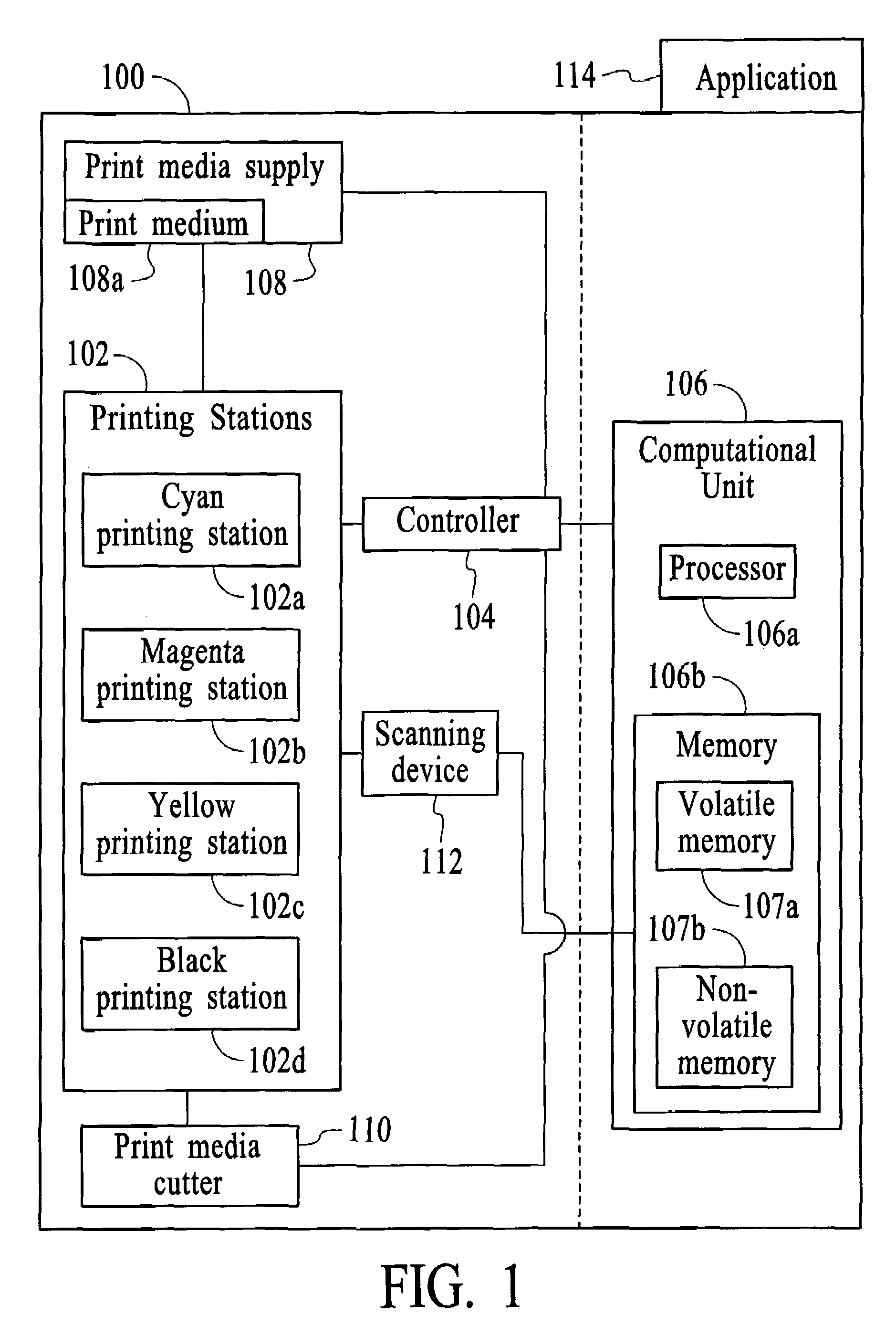

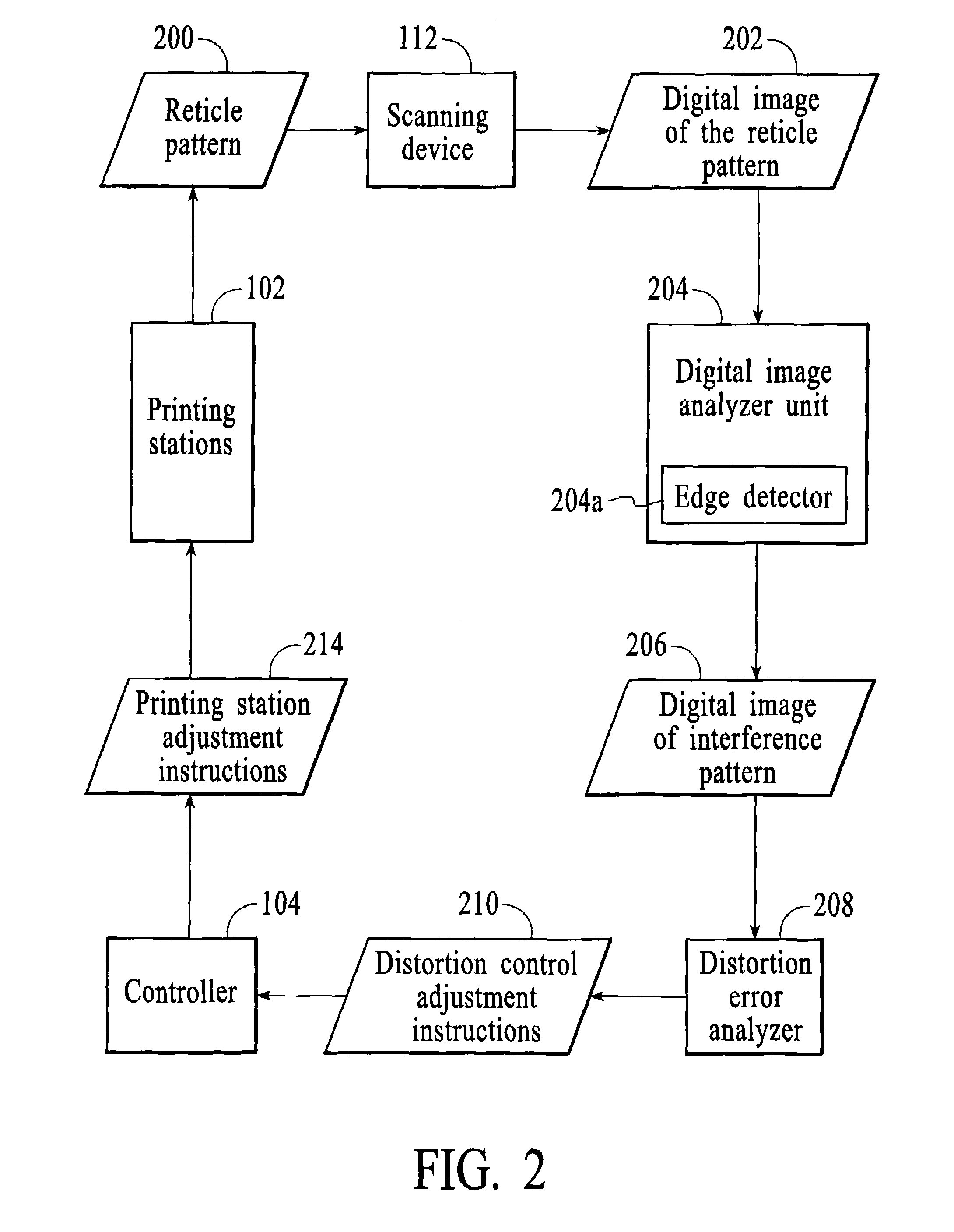

A method and system for a printing device is disclosed. The method and system comprise printing a test pattern on a print medium and generating a digital image of the printed test pattern by an imaging device. The method and system include analyzing an interference pattern to measure for distortion of the print medium and calibrating the printing device based upon the measured distortion.In a preferred embodiment, the present invention utilizes the reticle patterns, which are printed in the margins of the paper, which are measured real-time during printing. The interference or Moiré patterns created by superimposed reticles may be used to measure image distortion, process direction misalignment, and misregistration caused by web distortion. The advantage of this invention is that image distortion compensation, RIP (Raster Image Processor) parameters, timing, or other printer characteristics may be adjusted on-the-fly in a closed feedback system, for high-speed textile or paper color printing, utilizing on-the-fly distortion or stretch measurement for accurate color and / or duplex images registration. In a duplex printer, automatic images alignment front-to-back is obtained by combining optically or logically the two images for the evaluation of interference patterns and amount of distortion in the process and scan direction.

Owner:RICOH KK

Method for distinguishing false iris images based on robust texture features and machine learning

ActiveCN101923640AImprove stabilityRobustCharacter and pattern recognitionSupport vector machineColor printing

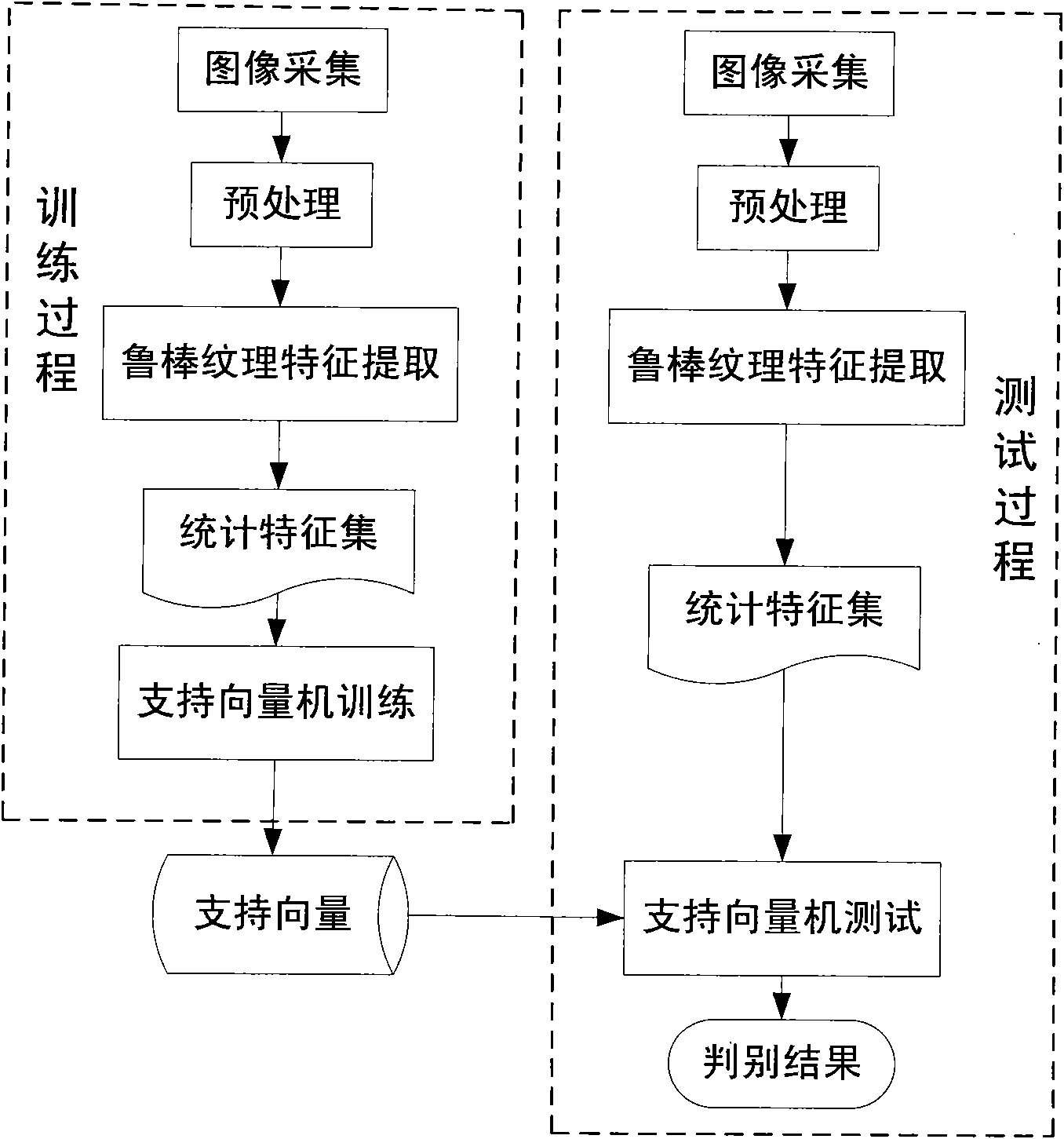

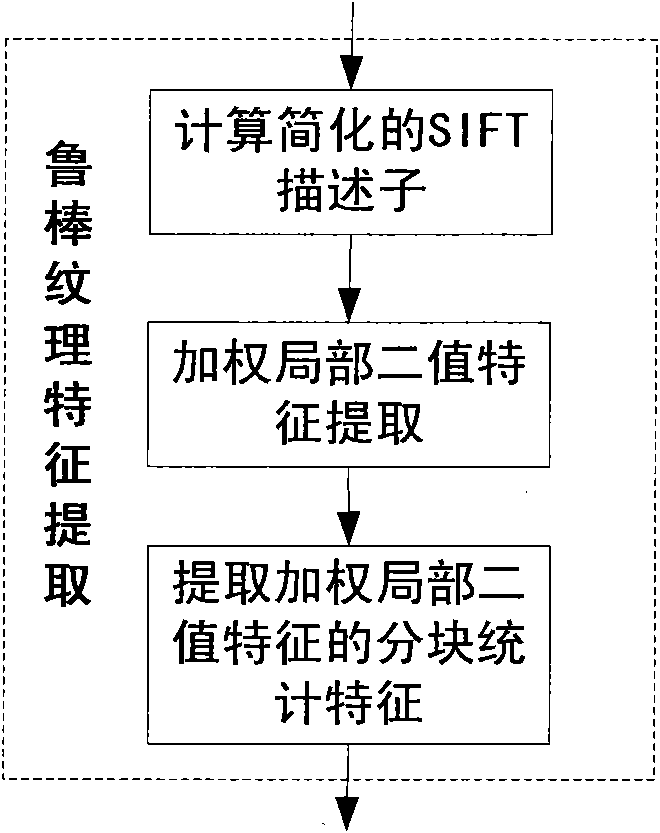

The invention relates to a method for distinguishing false iris images based on robust texture features and machine learning, which comprises the following steps: preprocessing true iris images or false iris images; extracting the partitioned statistical features of a robust weighted partial binary pattern; and carrying out training and sorting of a support vector machine, and judging whether thetest images are false iris images or not according to the output result of a sorter. The method of the invention combines SIFT descriptors and partial binary pattern features to extract the robust texture features, the description of textures is more stable because of the robustness of the SIFT to brightness, translation, rotation and scale change, and the support vector machine enables the method to have better universality. The invention can be used for effectively distinguishing the false iris images, has the advantages of high precision, high robustness and high reliability, can be used for distinguishing false irises such as paper printing irises, color printing contact lenses, synthetic eyes and the like, and can improve the safety of the system when being applied to the applicationsystem in which iris recognition is used for carrying out identification.

Owner:BEIJING IRISKING

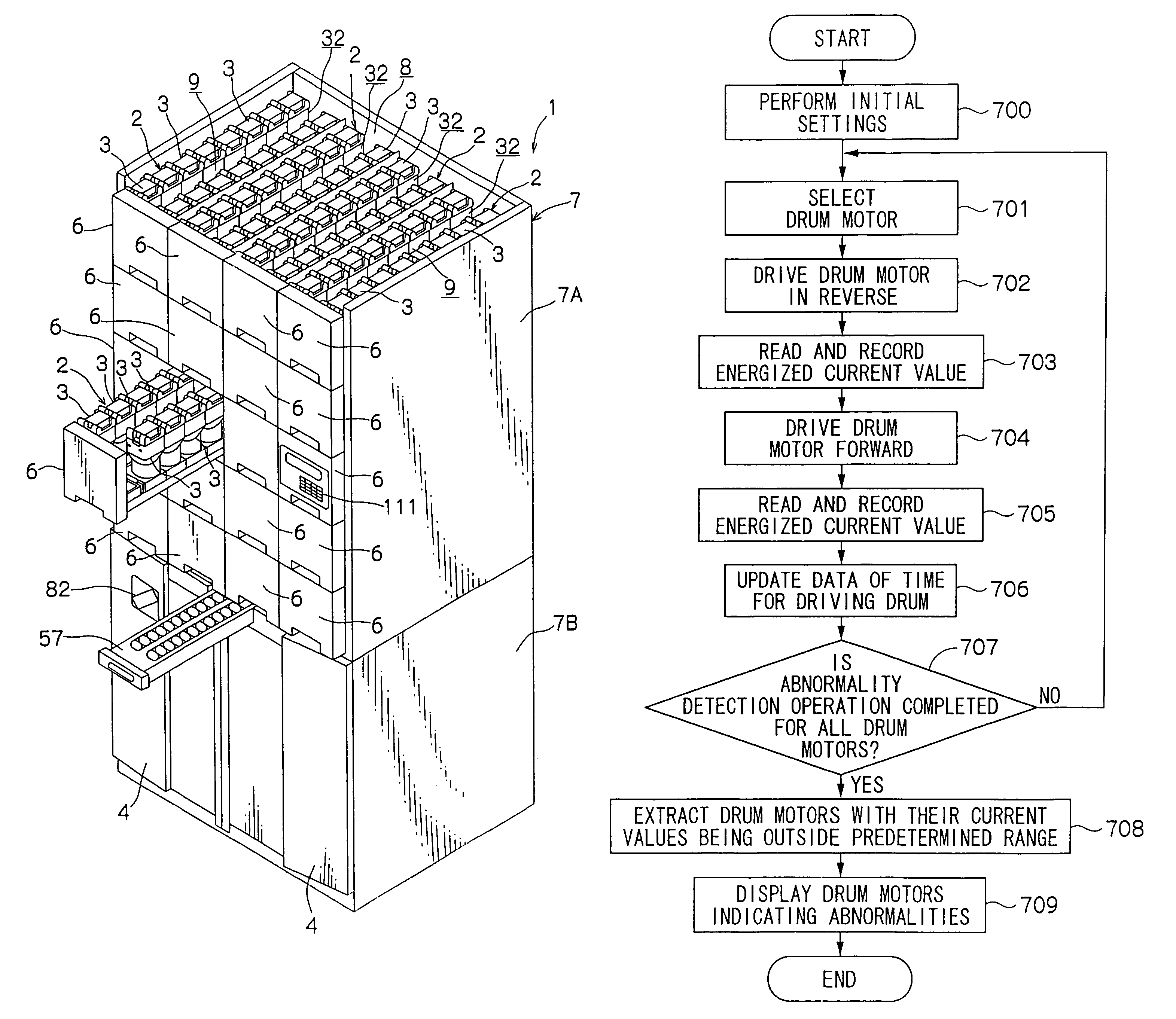

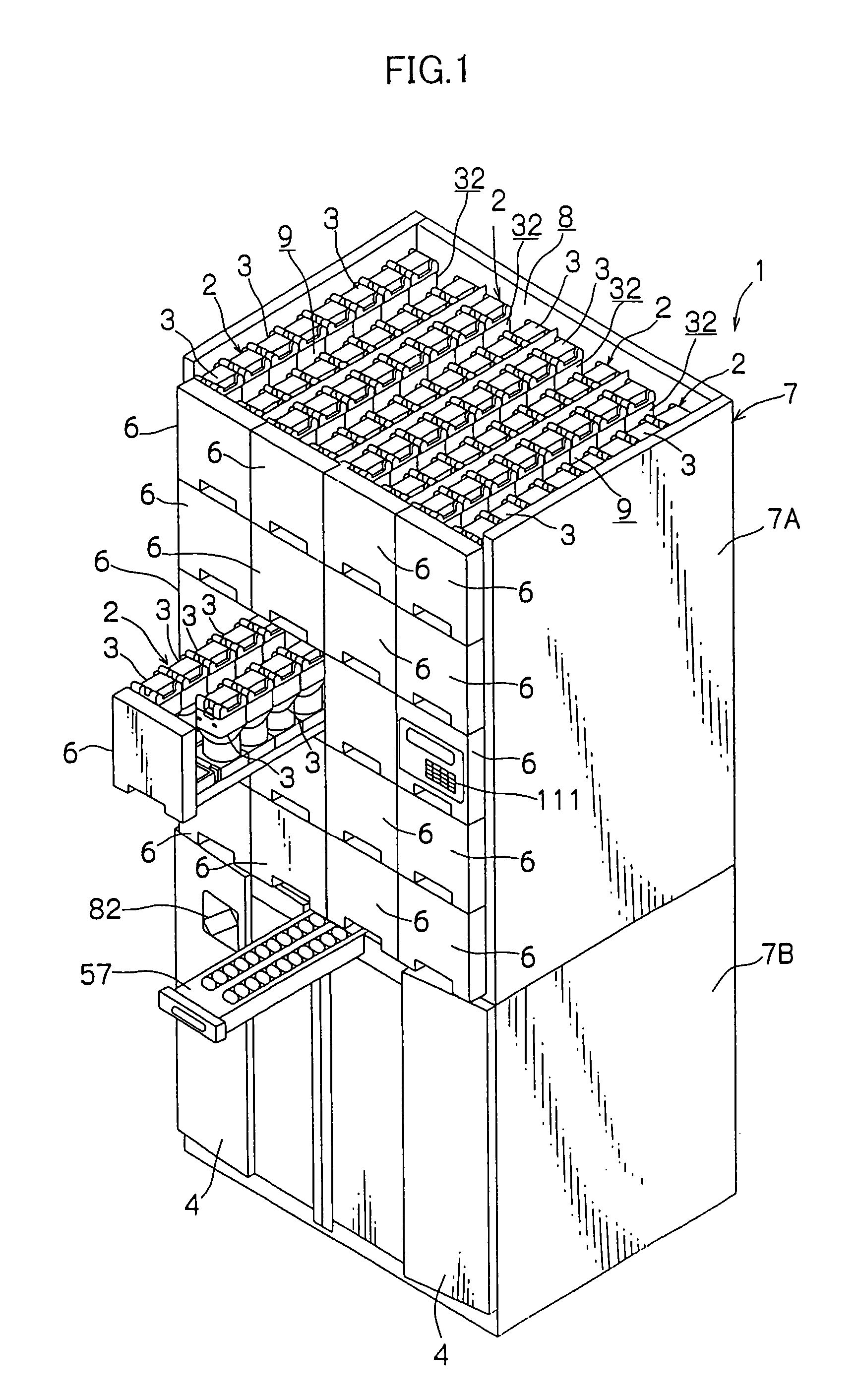

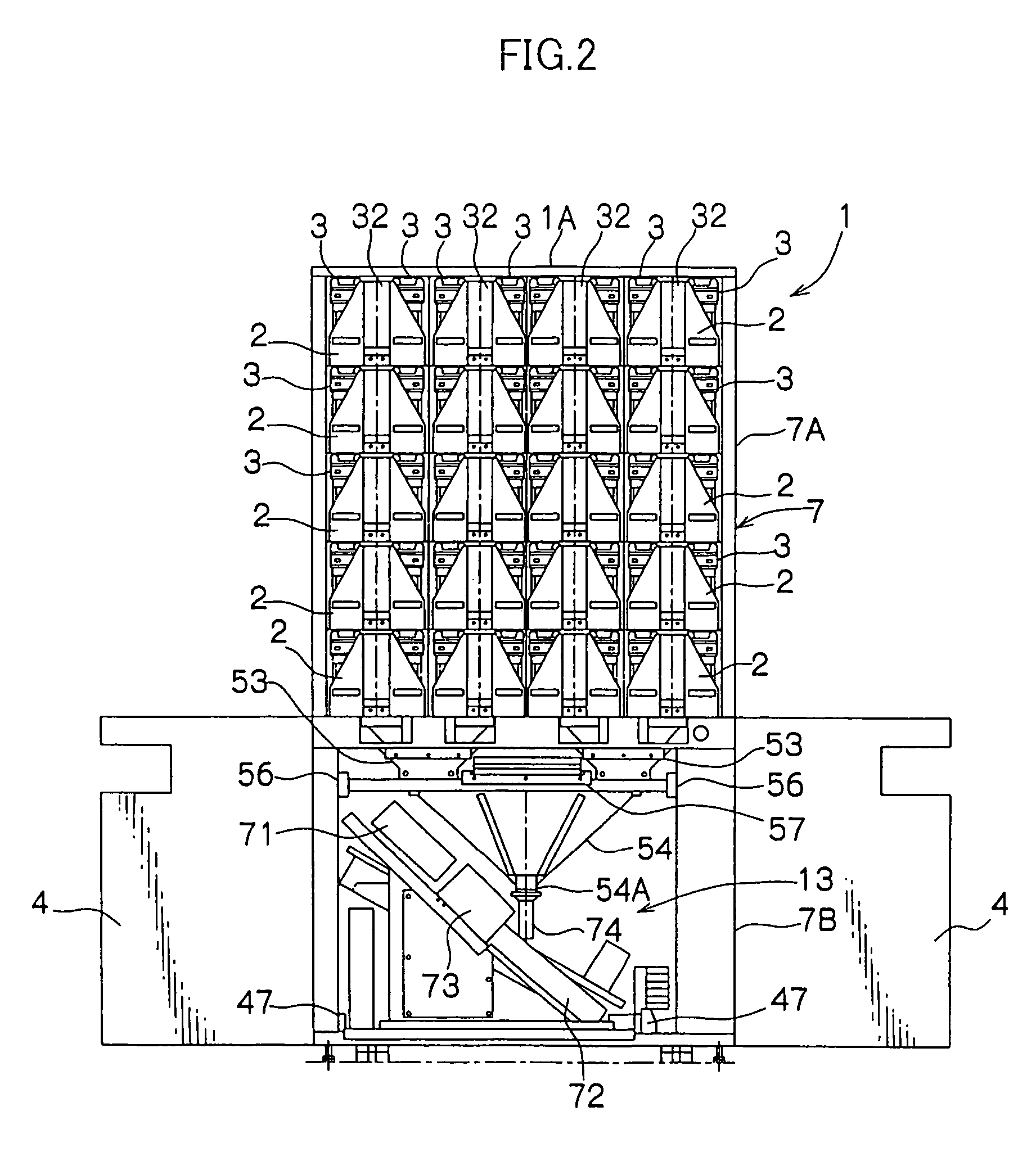

Medicine supply apparatus

ActiveUS7637078B2Improve business performanceSimple instructionsPackaging cigarettePackaging cigarsColor printingEngineering

A medicine supply apparatus which comprises, in a case accommodating section 8, a plurality of tablet cases 3 for accommodating medicine and charges or supplies medicine into a bag 72, which medicine has been discharged from each tablet case 3 based on a prescription. An identification code 26 is provided for each of the tablet cases 3 and read by an optical sensor 33 provided inside the case accommodating section 8, whereby discharge of medicine is controlled. A motor 14 for driving a discharge drum for the tablet case 3 is checked for disconnection by being regularly energized. The operating time and the frequency of operation of parts that wear out, such as the motors, are stored for use in failure prediction. Time slots in which medicine should be taken are printed, each in a different color, by a color printing mechanism 73 on the bag 72 into which medicine is charged.

Owner:PHC HLDG CORP

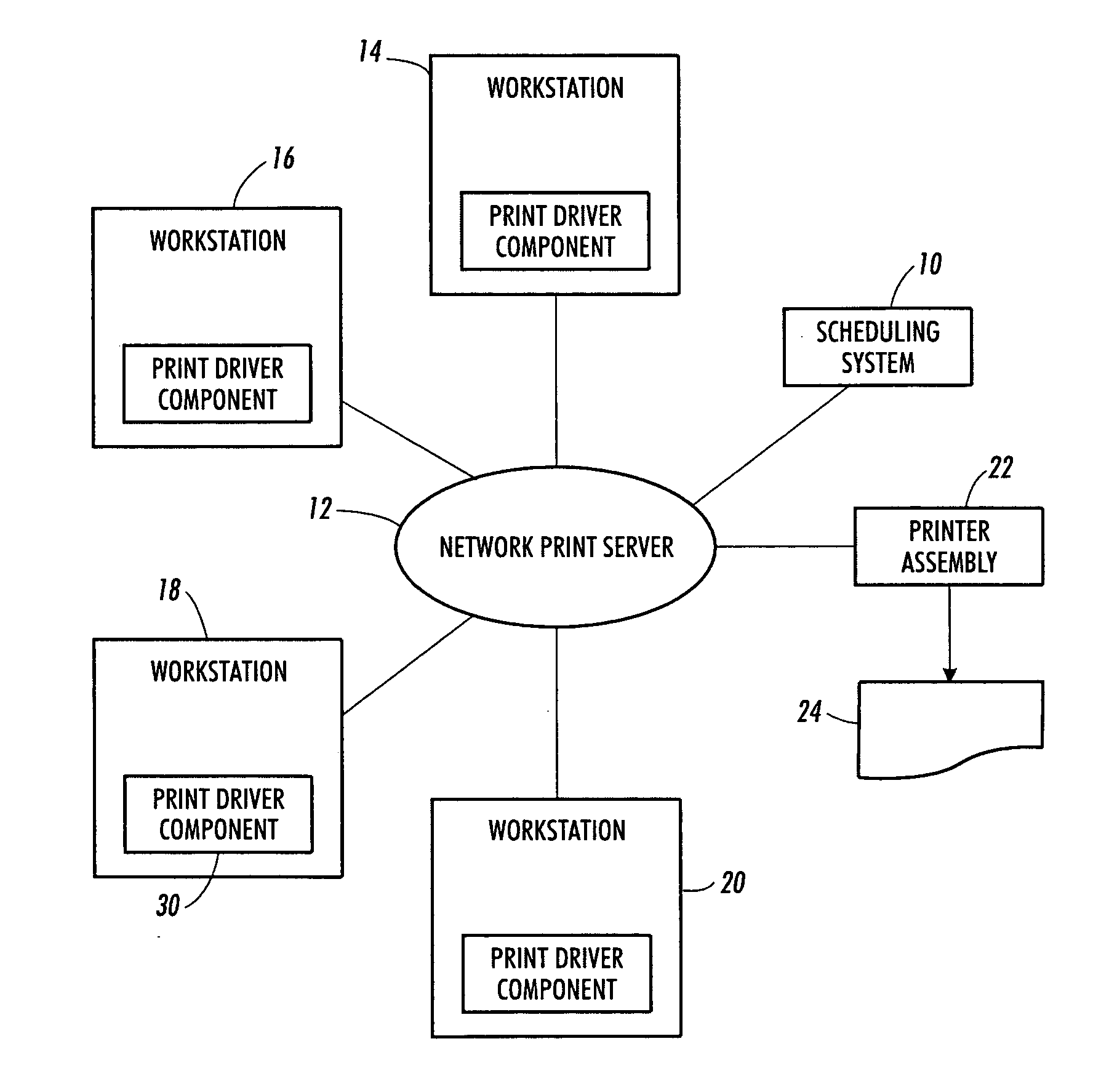

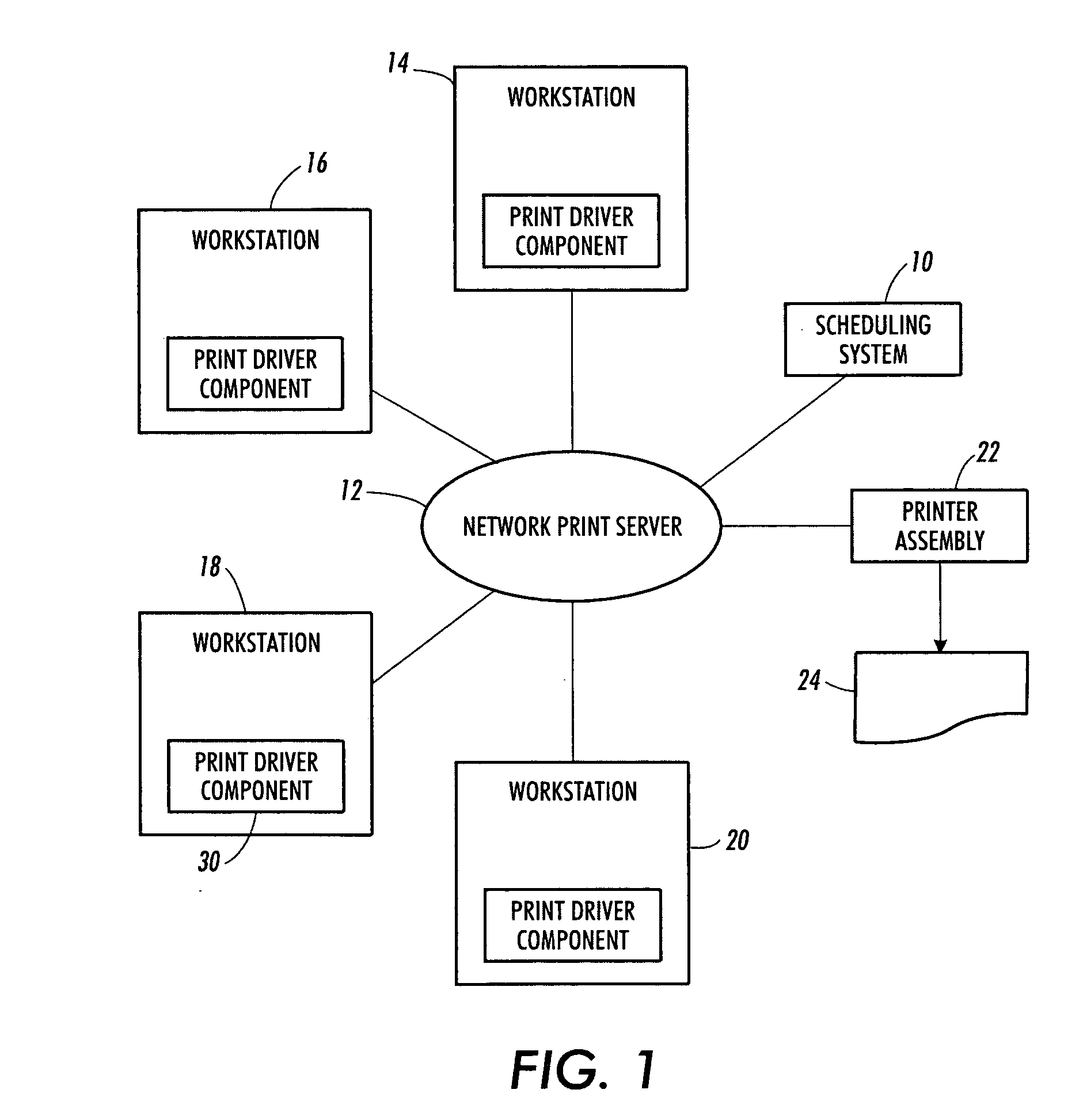

Print sequence scheduling for reliability

InactiveUS20060039026A1Maximizing continuous run timeMinimize period of timeDigitally marking record carriersDigital computer detailsColor printingComputer printing

A method for scheduling print jobs for a plurality of printers (40,42,44,46, 48, 50) includes, for each of a plurality of print jobs, determining a number of pages of a first print modality (such as black only printing) and of a second print modality (such as color printing) for the print job. A file header is determined, based on the number of pages of the first and second print modalities in the print job. The file header is associated with the print job and the print job transmitted, along with the file header, to a print job scheduler (10). The scheduler schedules a sequence for printing the plurality of print jobs by the plurality of printers, based on minimizing, for at least one of the plurality of printers, a number of periods of time during the sequence of printing where the at least one printer is in a non-operational mode; and / or maximizing continuous run time for at least one of the printers.

Owner:XEROX CORP

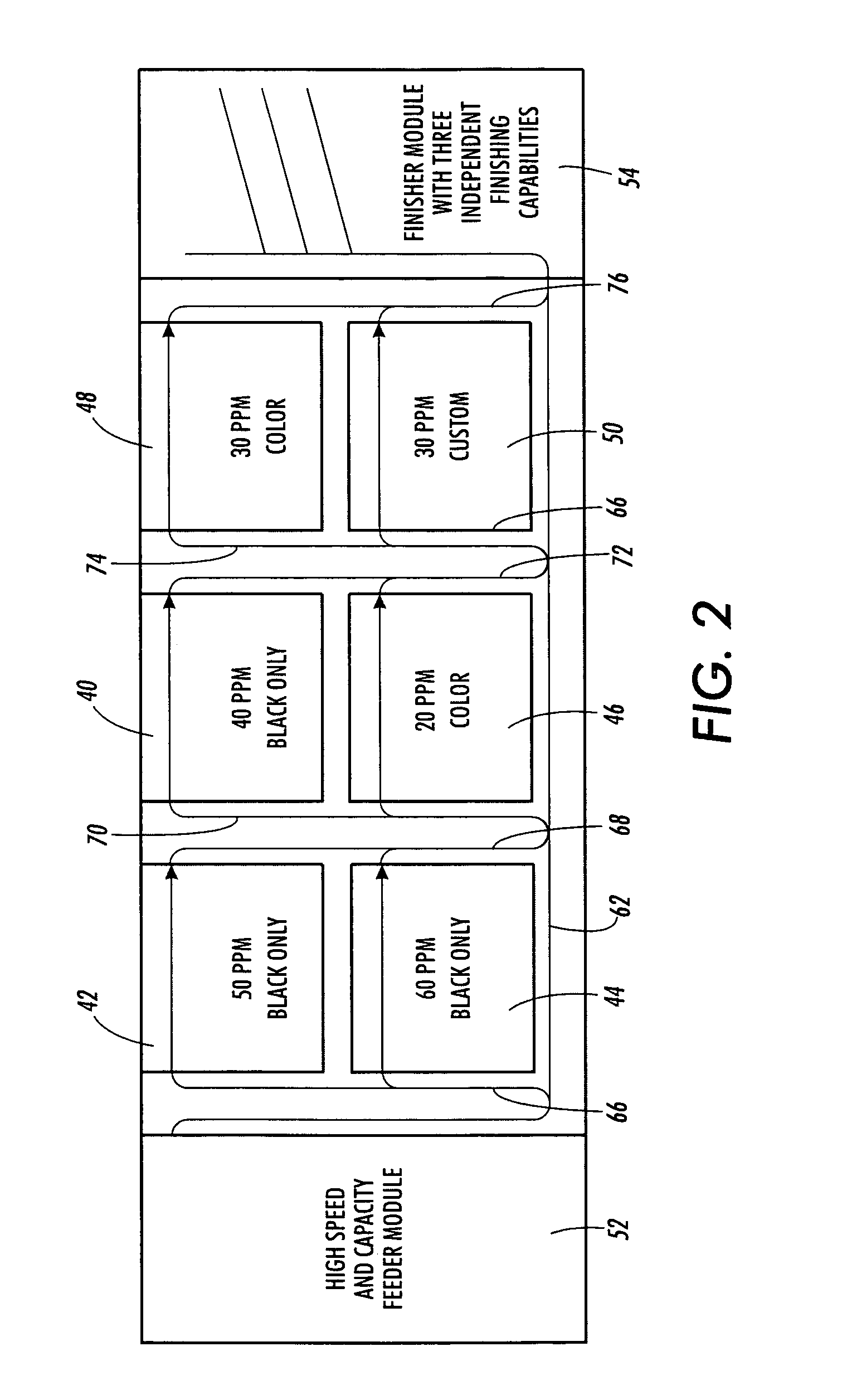

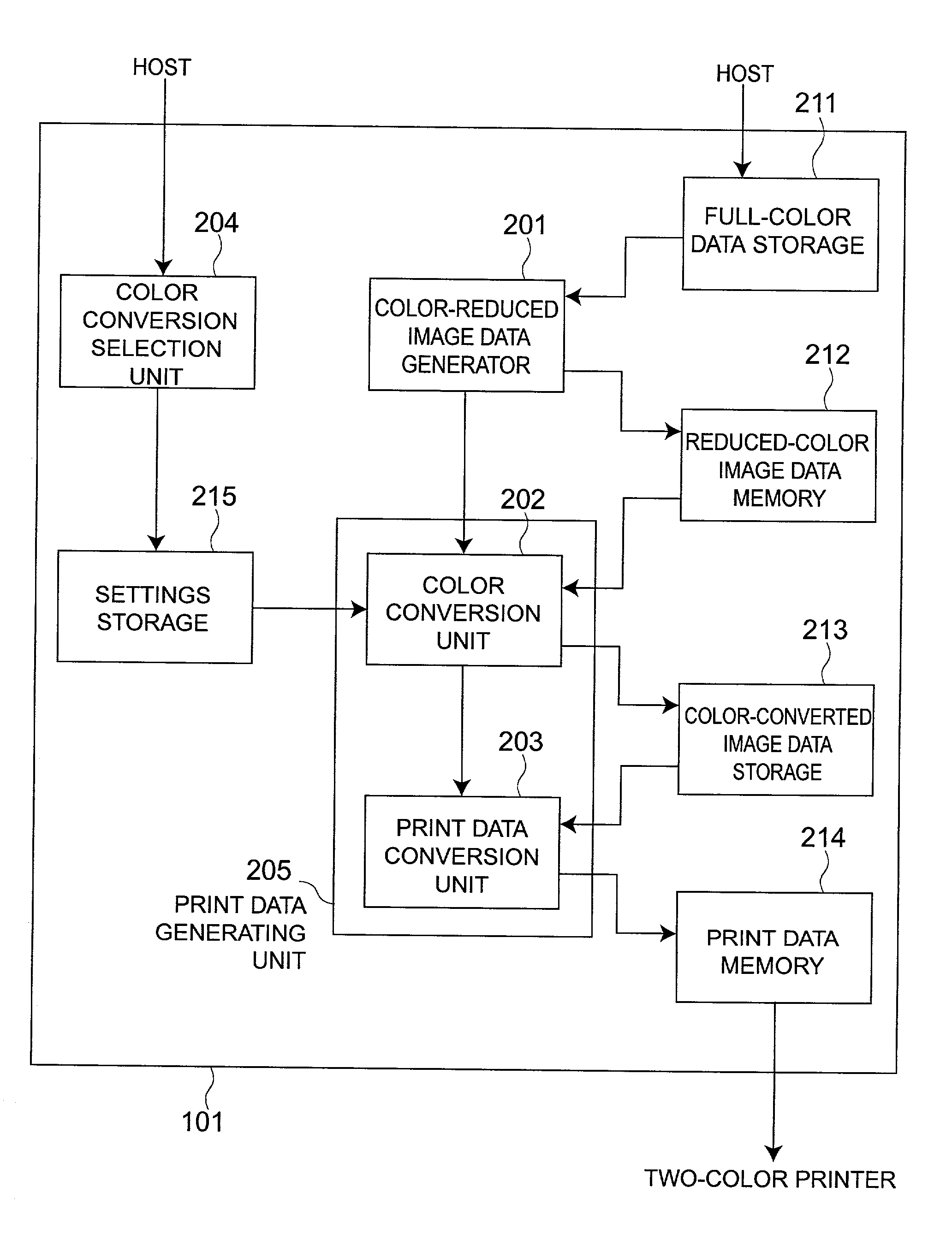

Apparatus for generating two color printing data, a method for generating two color printing data and recording media

InactiveUS20030002060A1Digitally marking record carriersDigital computer detailsColor imageColor transformation

[Problem] To provide a two-color print data generating apparatus, two-color print data generating method, and data storage medium for generating two-color print data based on color-converted image data in which the color of each pixel in full-color data that is the print object is converted to a print color printable by means of a background color, main color, or secondary color. [Means for solving the problem] color-reduced image data generator 201 converts data for a full-color image that is the print object to reduced-color image data reduced to a specific number of colors. color conversion unit 202 generates color-converted image data in which the specified colors to which the reduced-color image data is reduced are converted to colors that can be printed by the printer. print data conversion unit 203 converts the color converted color-converted image data to two-color print data that can be printed using two colors. color conversion selection unit 204 sets the color conversion method and sets specific color conversion parameters based on the selected color conversion method.

Owner:SEIKO EPSON CORP

Three-dimensional color printing device and method

ActiveCN105500700AImprove printing accuracyFast molding speedAdditive manufacturing apparatusAutomatic controlControl system

The invention discloses a three-dimensional color printing device and method. The three-dimensional color printing device comprises a print area, a feeding system, a nozzle group, a moving mechanism and an automatic control system, wherein the print area is provided with a forming plate and a forming work pool, and the forming plate is provided with a lifting mechanism which is used for drawing a workpiece curing layer; the feeding system comprises a support material feeding box and a solid material feeding box and is used for supplying print raw materials for the nozzle group; the nozzle group comprises at least one solid material nozzle and a support material nozzle, the solid material nozzle is connected with the solid material feeding box of the feeding system through a premixer, and the support material nozzle is connected with the support material feeding box of the feeding system; andthe moving mechanism is provided with motors and guide posts / rods on the X-axis direction, the Y-axis direction and the Z-axis direction and is used for driving the nozzle group for performing mobile printing on the three-dimensional direction. The three-dimensional color printing device has the characteristics of being high in print accuracy and smooth and clean in surface of formed products and can realize color printing and printing of different photosensitive materials.

Owner:QINGDAO ACADEMY OF INTELLIGENT IND

Imaging on flexible packaging substrates

InactiveUS20080218570A1Improve image qualityWell registered colorMeasurement apparatus componentsDuplicating/marking methodsUV curingPolymer science

Methods and devices for forming, such as by printing, high quality, high throughput, ultraviolet curable gel ink images on flexible substrates for packaging applications are disclosed. The methods and devices have excellent image quality and do not require pinning of the ink during color printing or nitrogen inerting during curing.

Owner:PALO ALTO RES CENT INC +1

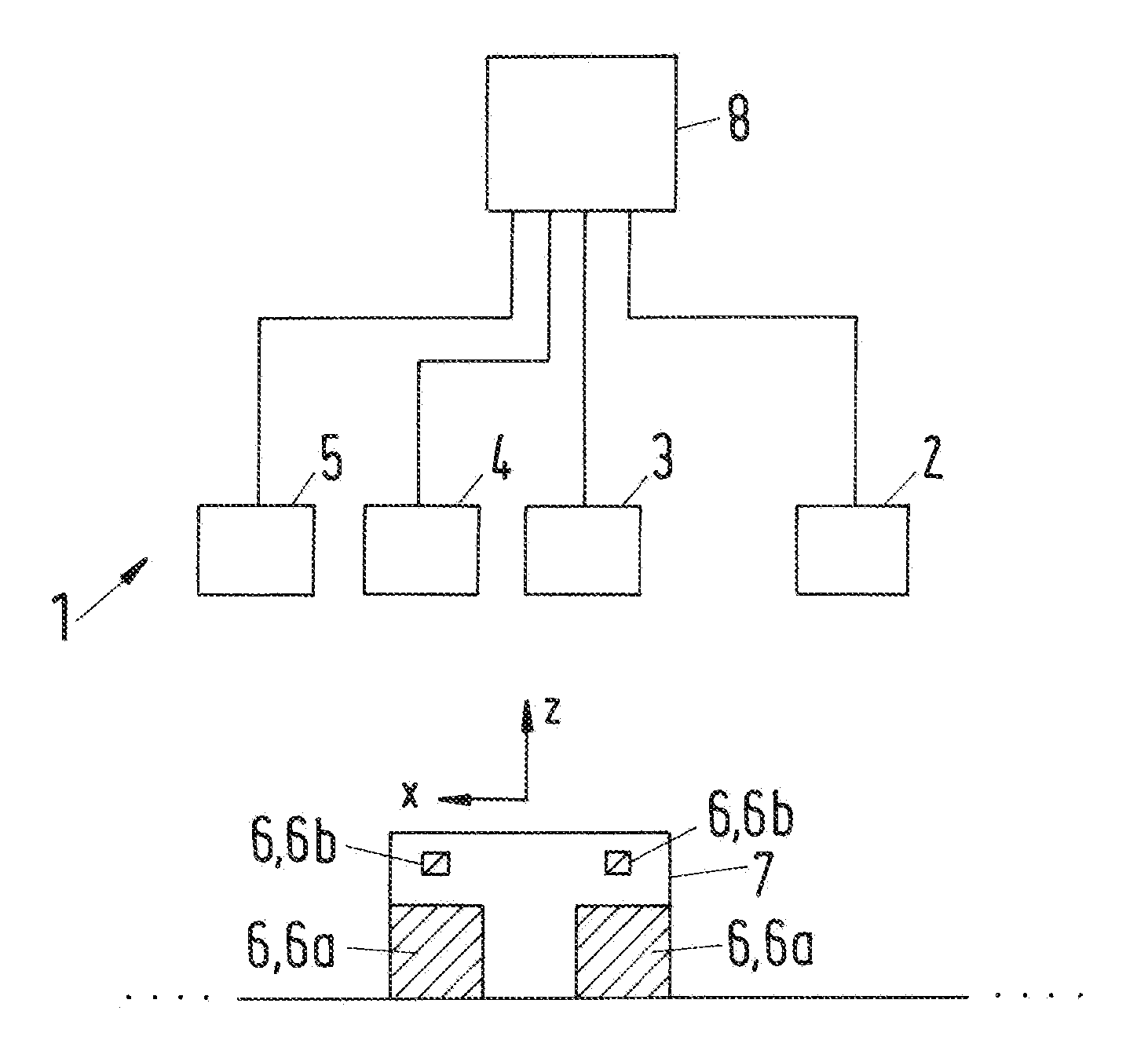

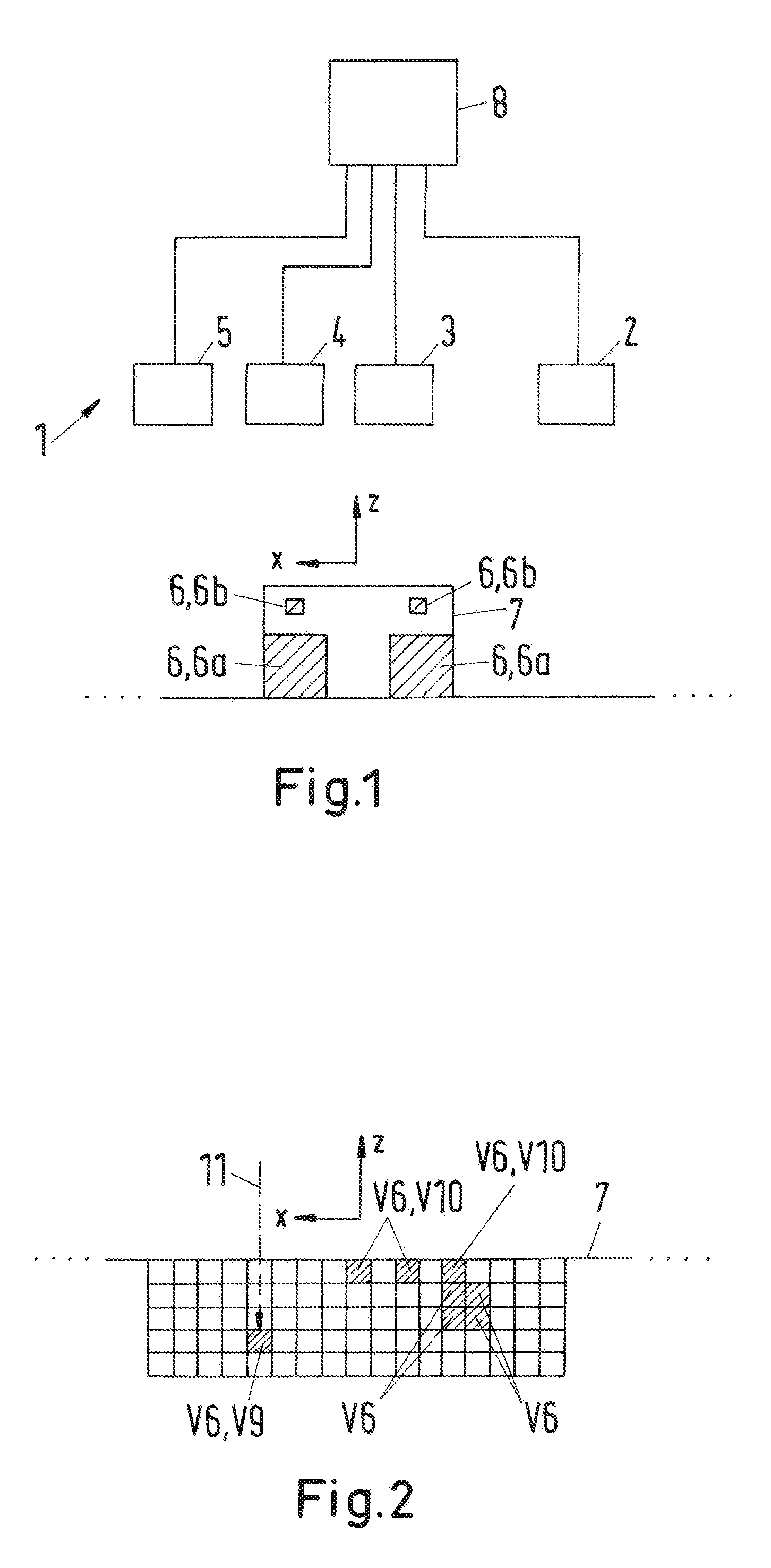

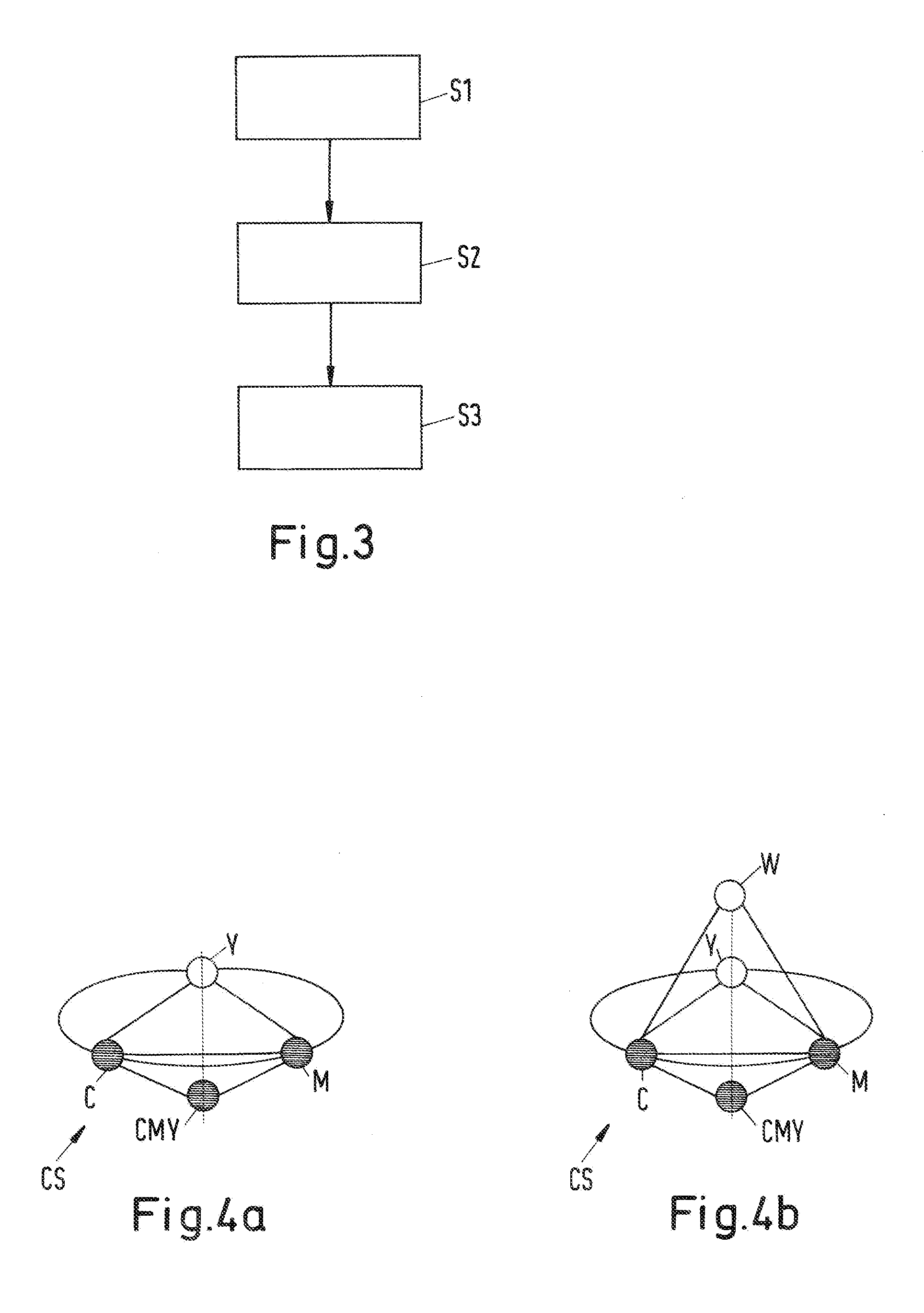

Method for three-dimensional color printing and a three-dimensional color printing device

ActiveUS20160151979A1Improve color gamutAdditive manufacturing apparatusConfectioneryColor printingEngineering

The invention relates to a method and a device for three-dimensional color printing, wherein at least a first printing material with a first printing material color and at least another printing material with another printing material color is used to construct a printing object (7), wherein an arrangement of the printing materials in a surface region and a near surface interior region of the printing object (7) is determined based on a desired color reproduction of the printing object.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

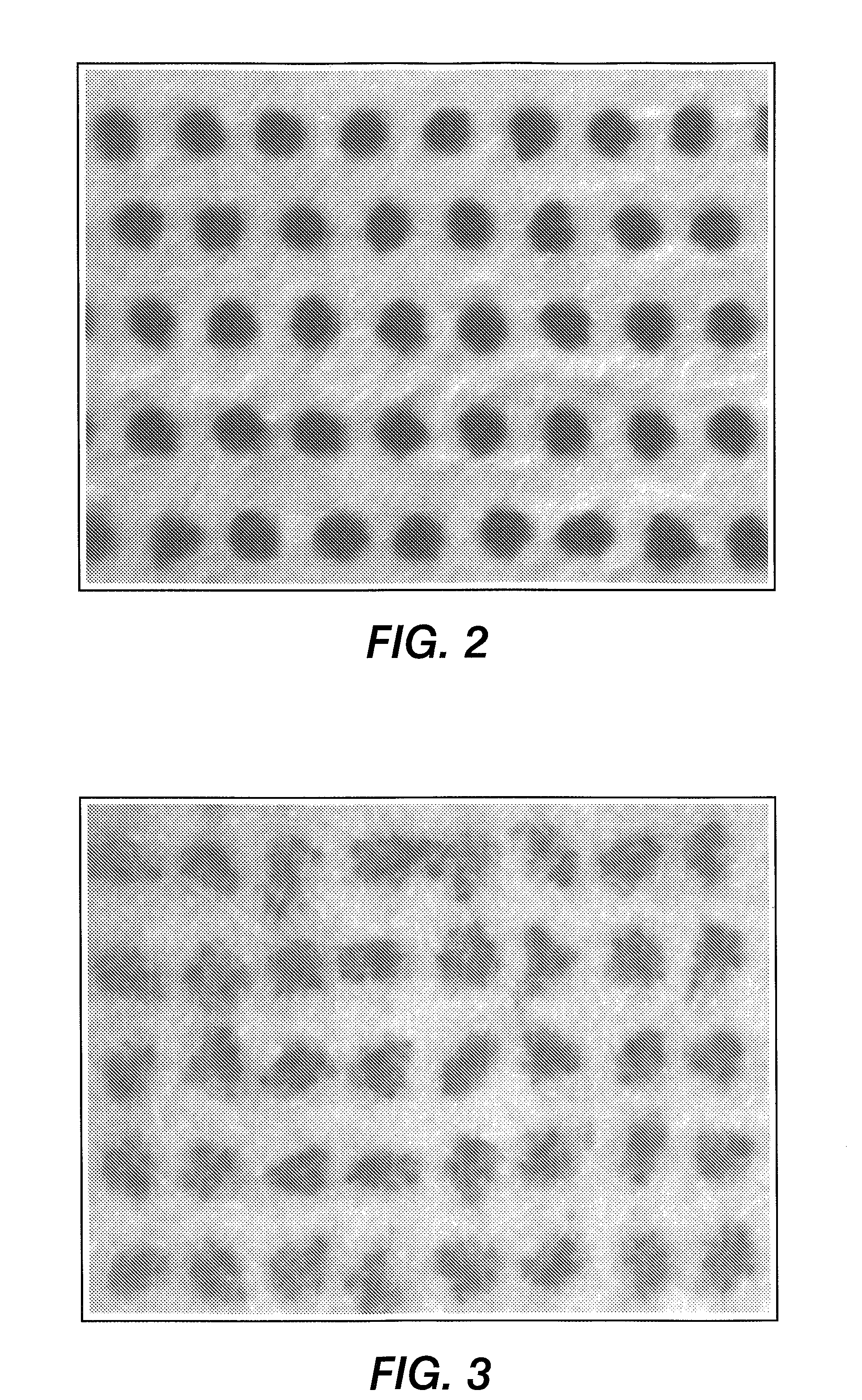

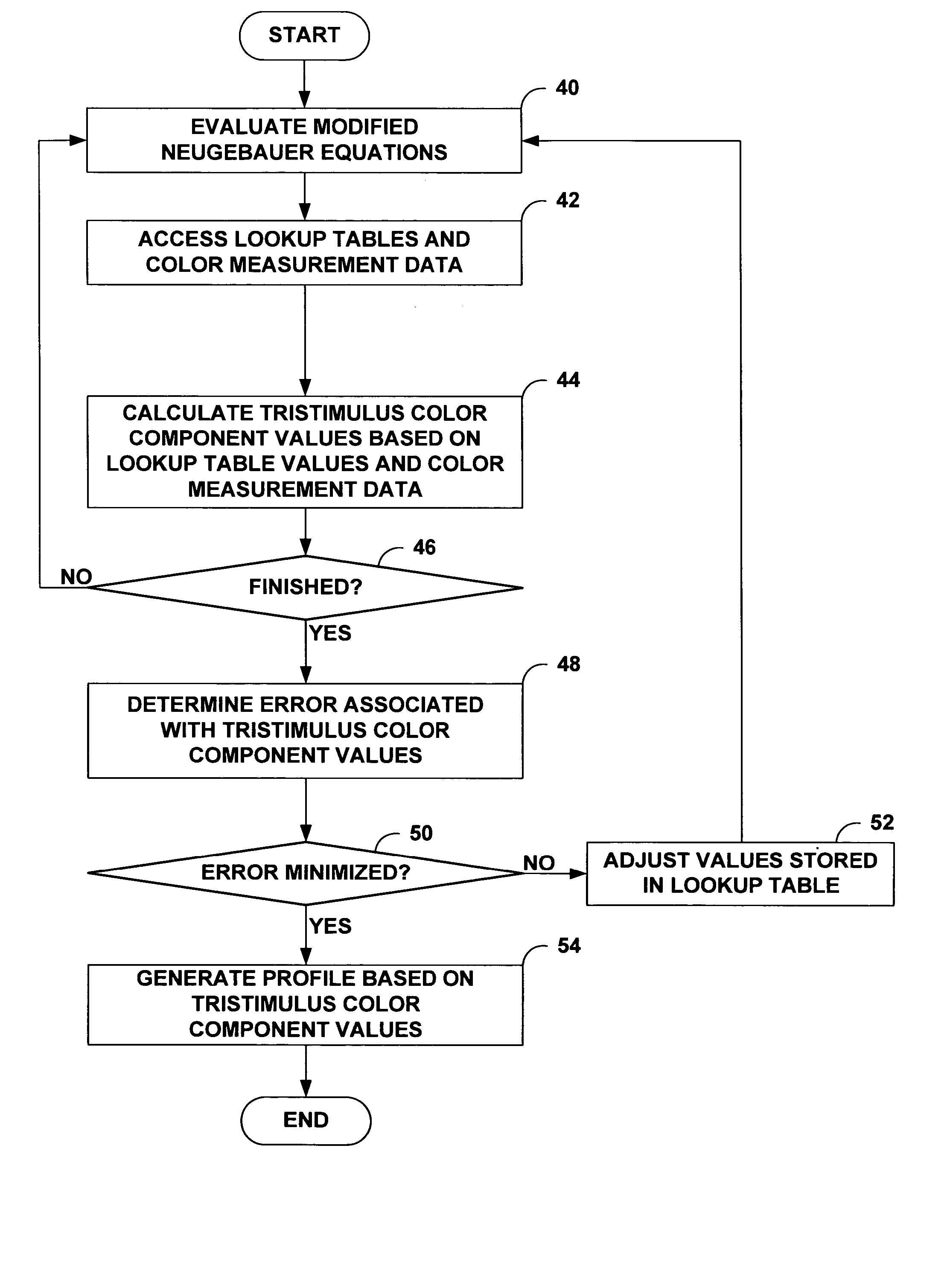

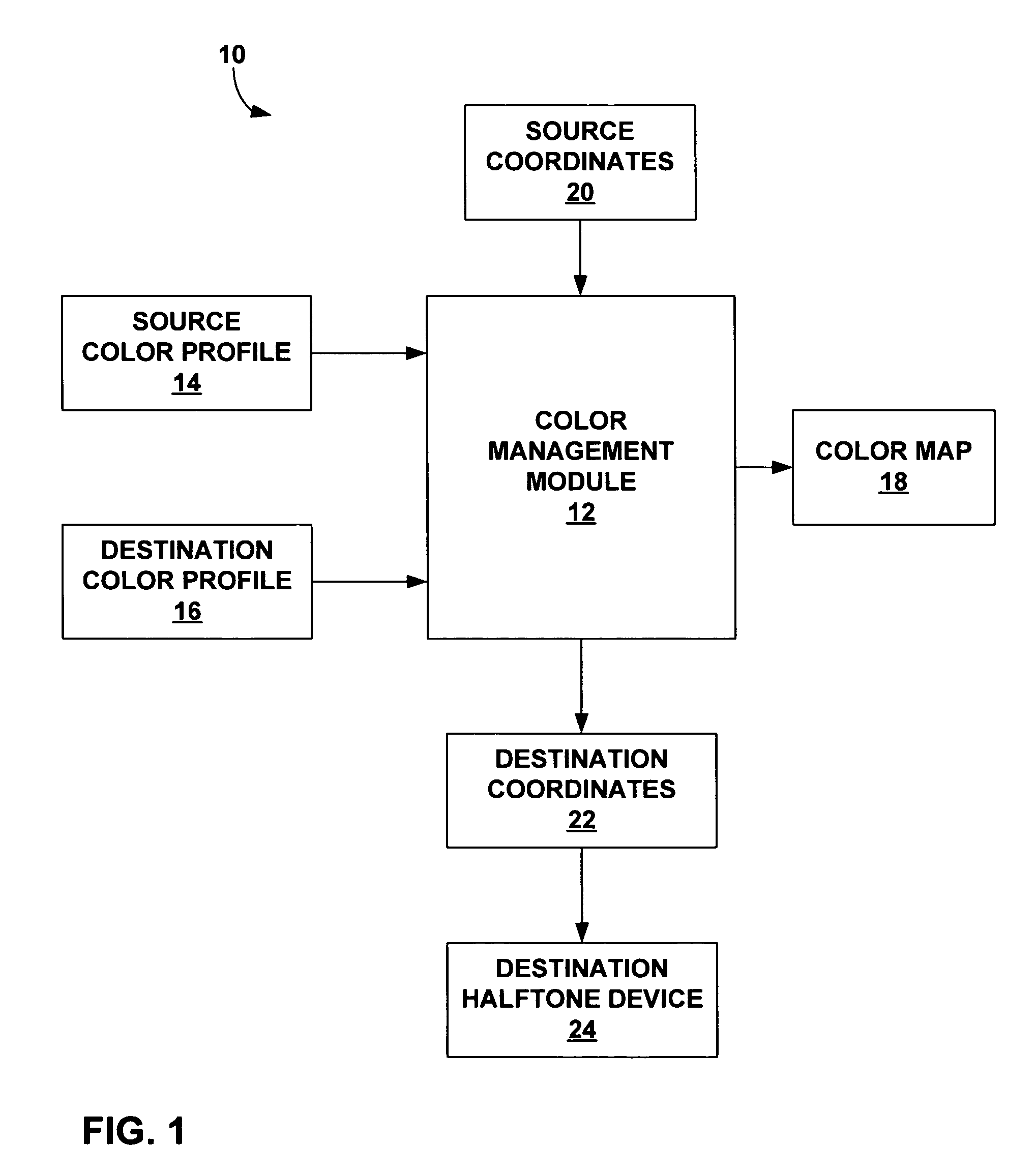

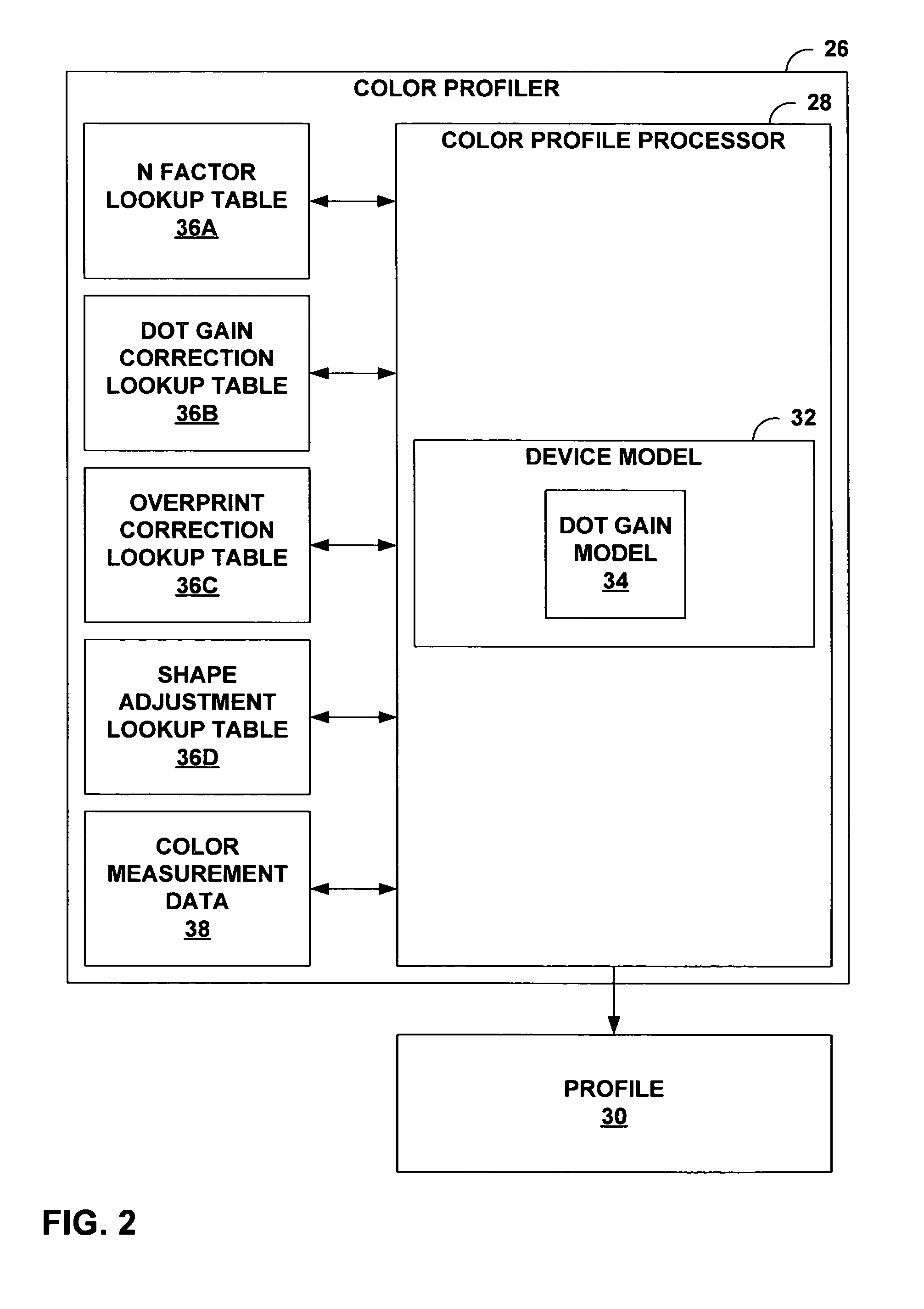

Modified neugebauer model for halftone imaging systems

ActiveUS20050036163A1Accurate and smooth characterizationAccuracyImage enhancementDigitally marking record carriersColor printingDot gain

A technique for profiling a color printing device employs a modified Neugebauer color mixing model. The modeling technique makes use of a variable dot gain value and “n factor.” The variable dot gain adjustment value may vary according to the particular tristimulus channel under evaluation. In addition, the variable dot gain value may vary according to the particular Neugebauer primary over which a halftone dot is printed. Accordingly, the technique may rely on an array of different dot gain values and n factors that correspond to different combinations of color channels and overprint conditions. As a further feature, the techniques may rely on a dot gain formula that relates halftone dot variation, i.e., fringe thickness, to the size of the halftone dot. This relationship tends to produce a dot gain model that more closely resembles the actual dot gain behavior on a printing press.

Owner:KODAK POLYCHROME GRAPHICS

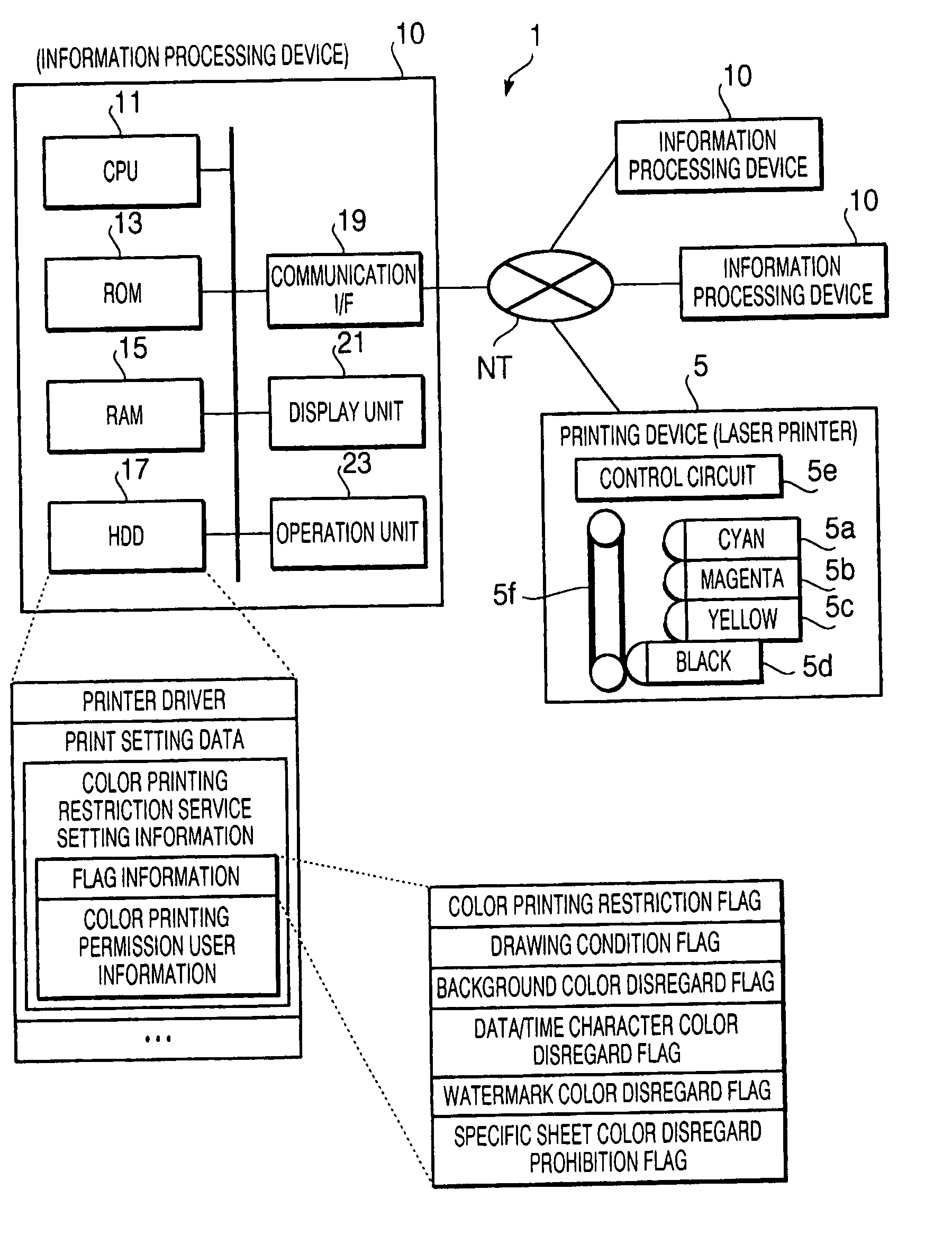

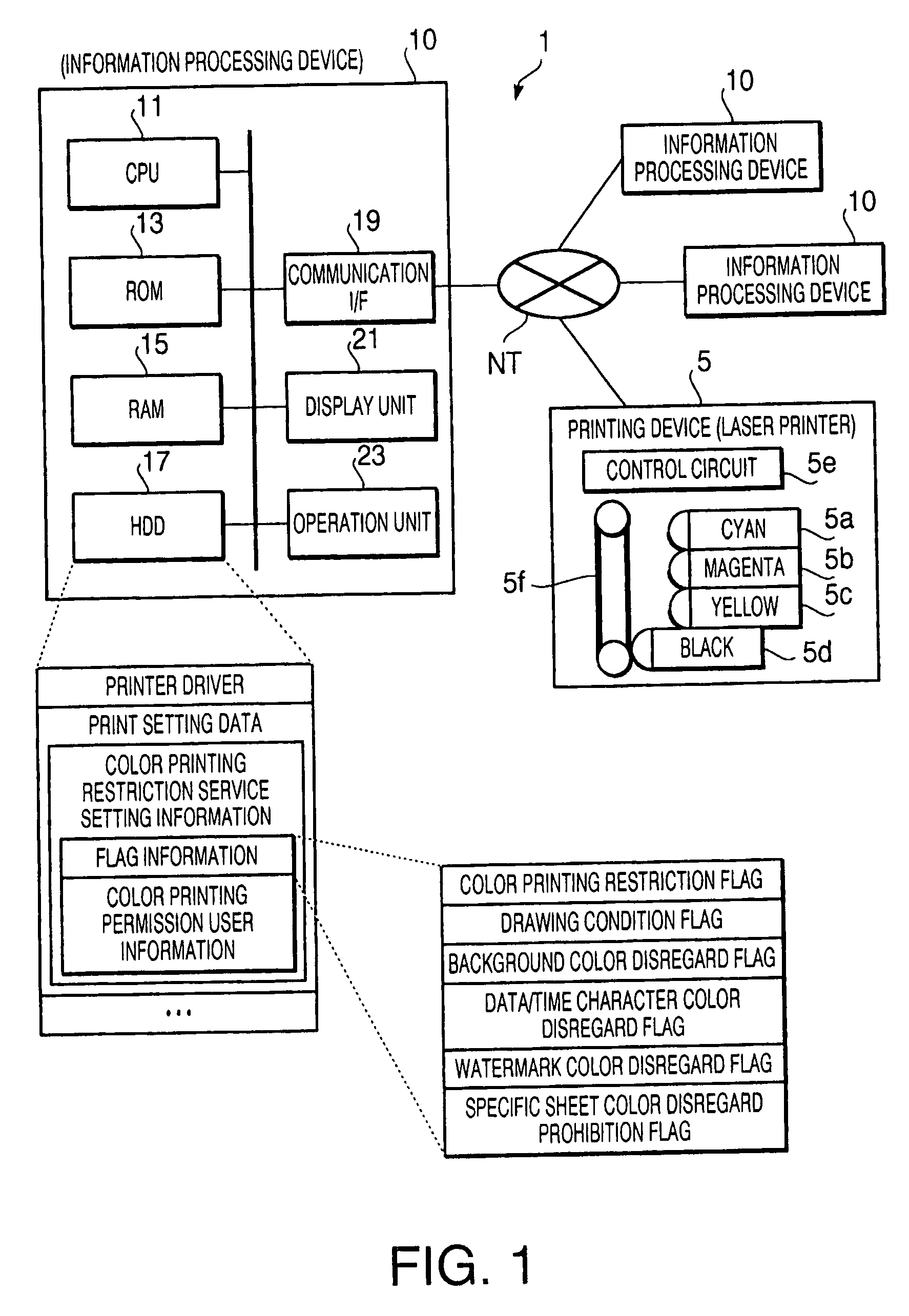

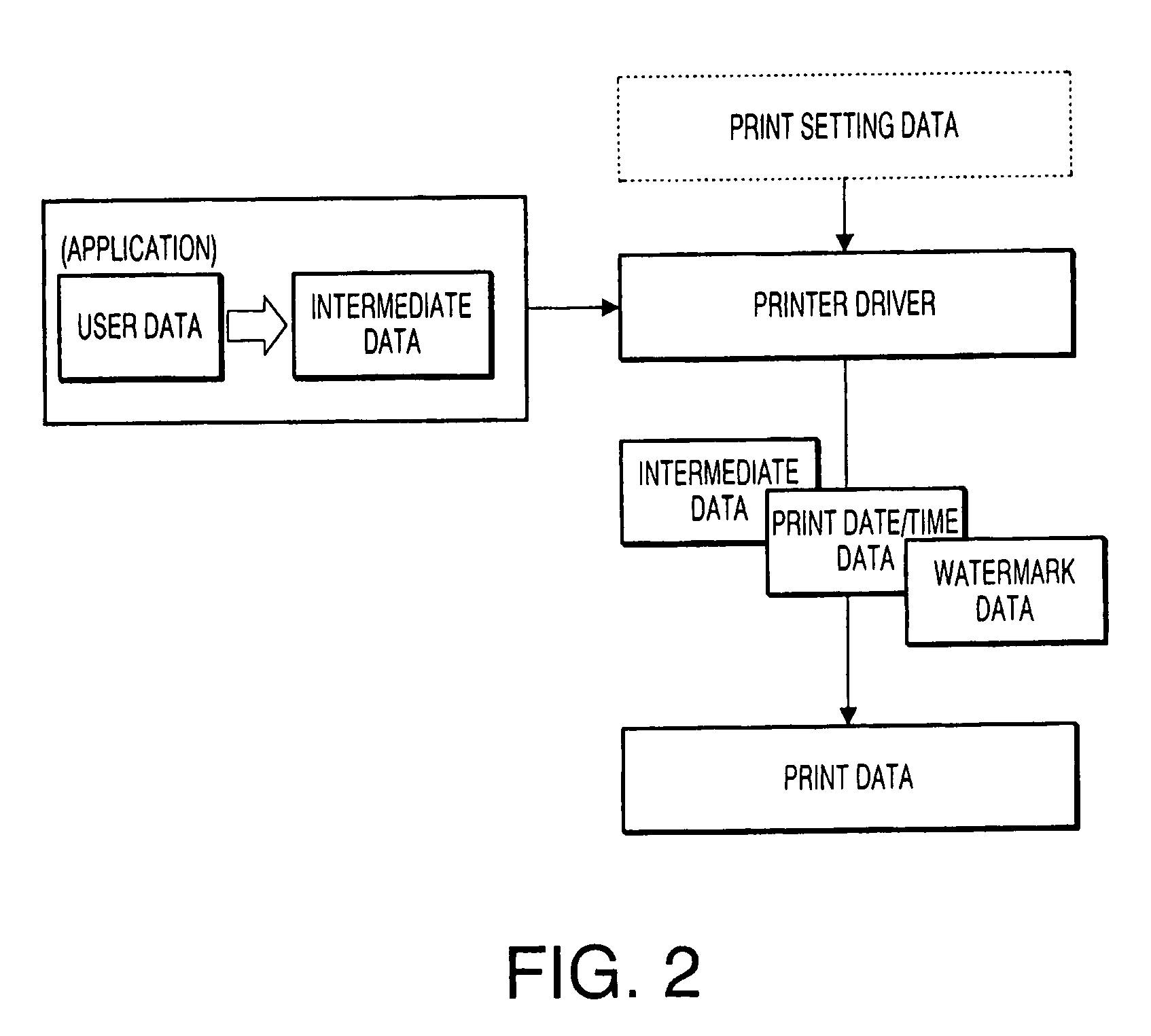

Print control device and program

InactiveUS20080080000A1Reduce executionHigh operating costsDigitally marking record carriersDigital computer detailsColor printingMonochrome

A print control device, controlling a printing device (capable of color printing and monochrome printing) to make the printing device print an image corresponding to print target data, comprises: a main data color / monochrome judgment unit which judges whether main data (included in the print target data which is made up of the main data and attached data) is color data or not when the print target data is specified, and a color restriction print control unit which makes the printing device execute the printing of the image corresponding to the print target data by the color printing when the main data is judged to be color data by the main data color / monochrome judgment unit, while making the printing device execute the printing by the monochrome printing irrespective of whether the attached data is color data or not when the main data is judged not to be color data.

Owner:BROTHER KOGYO KK

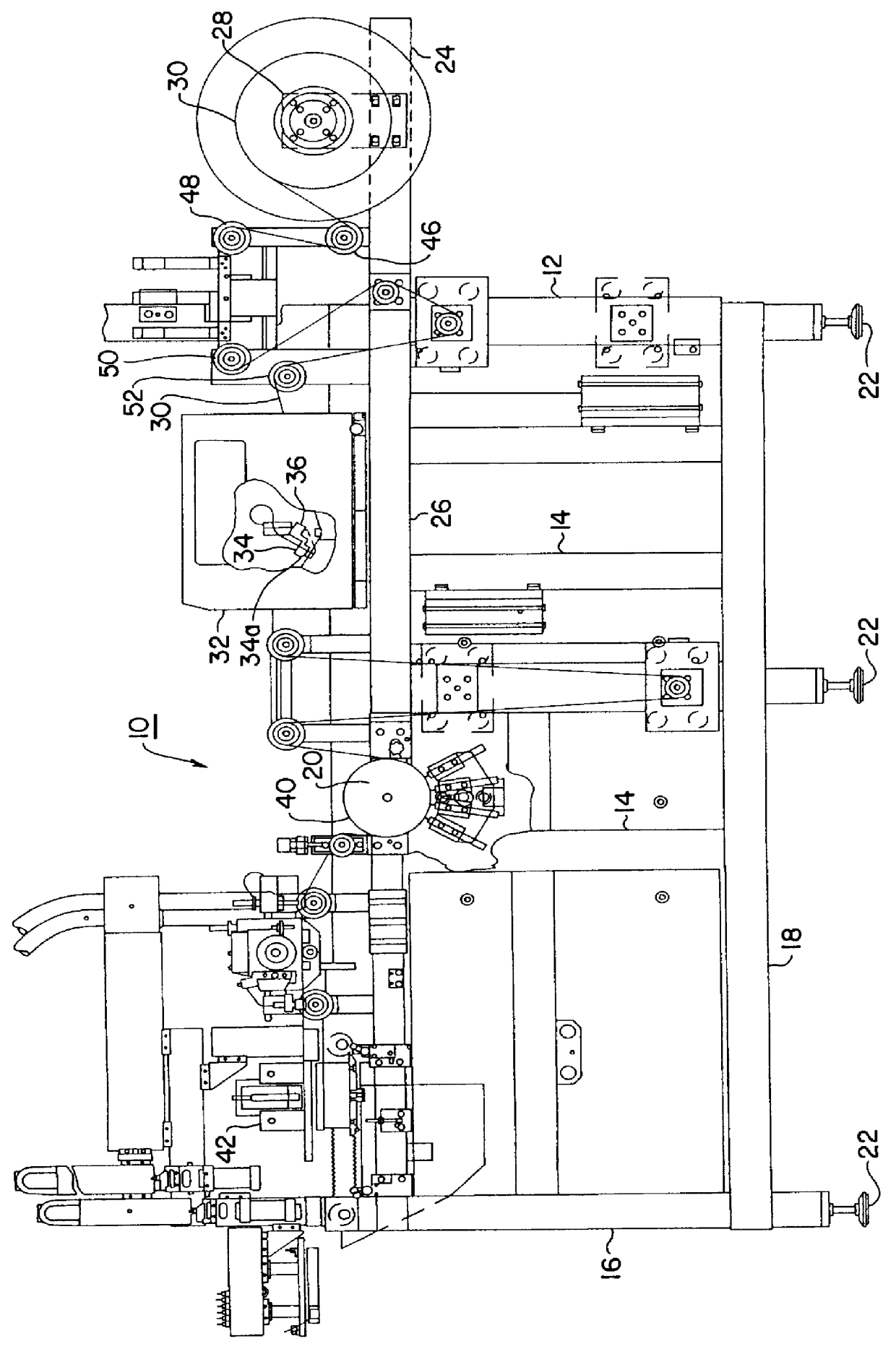

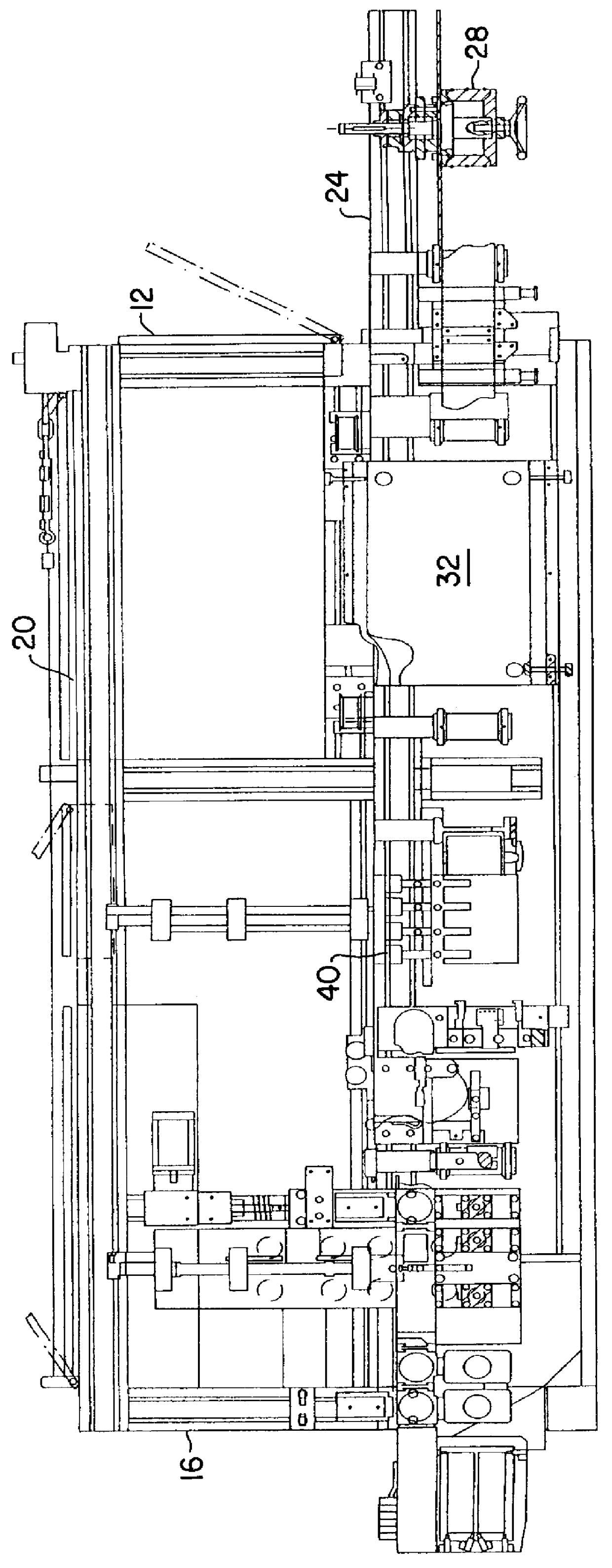

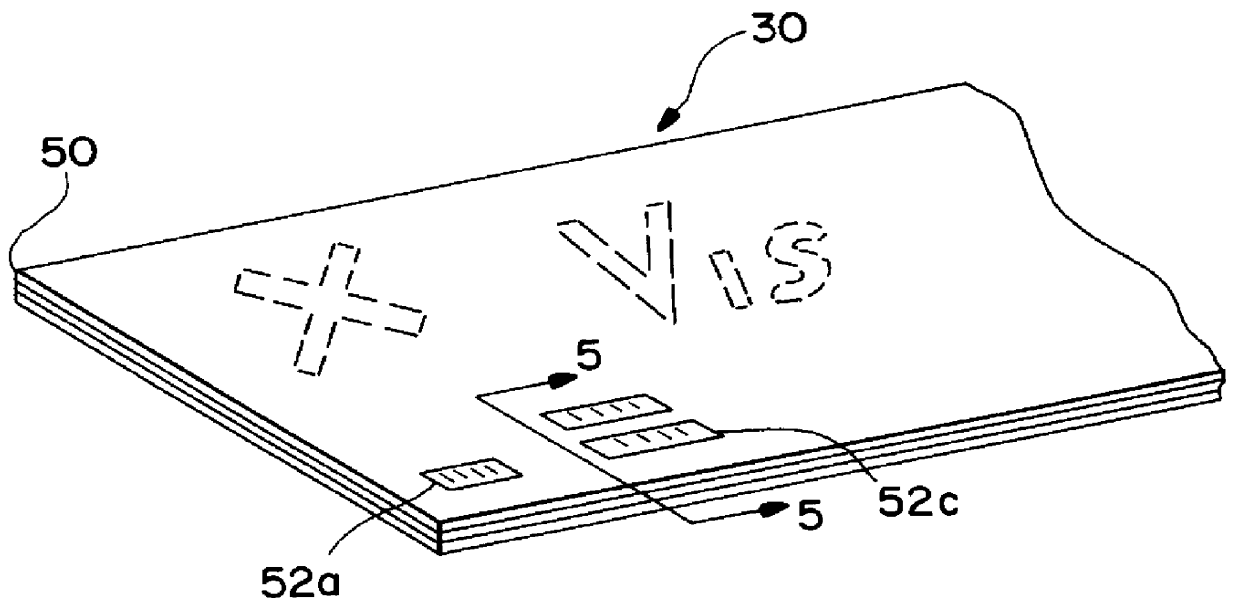

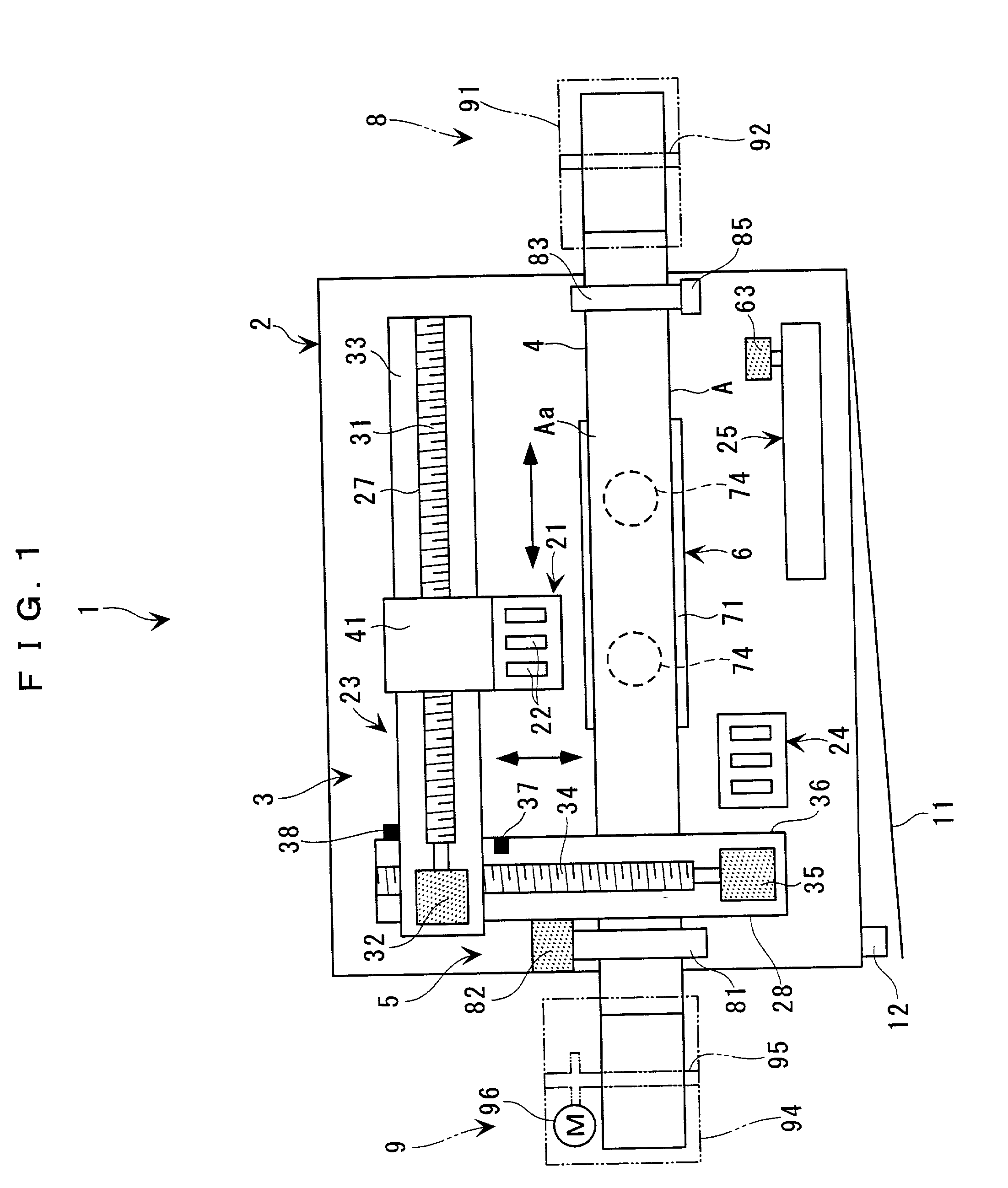

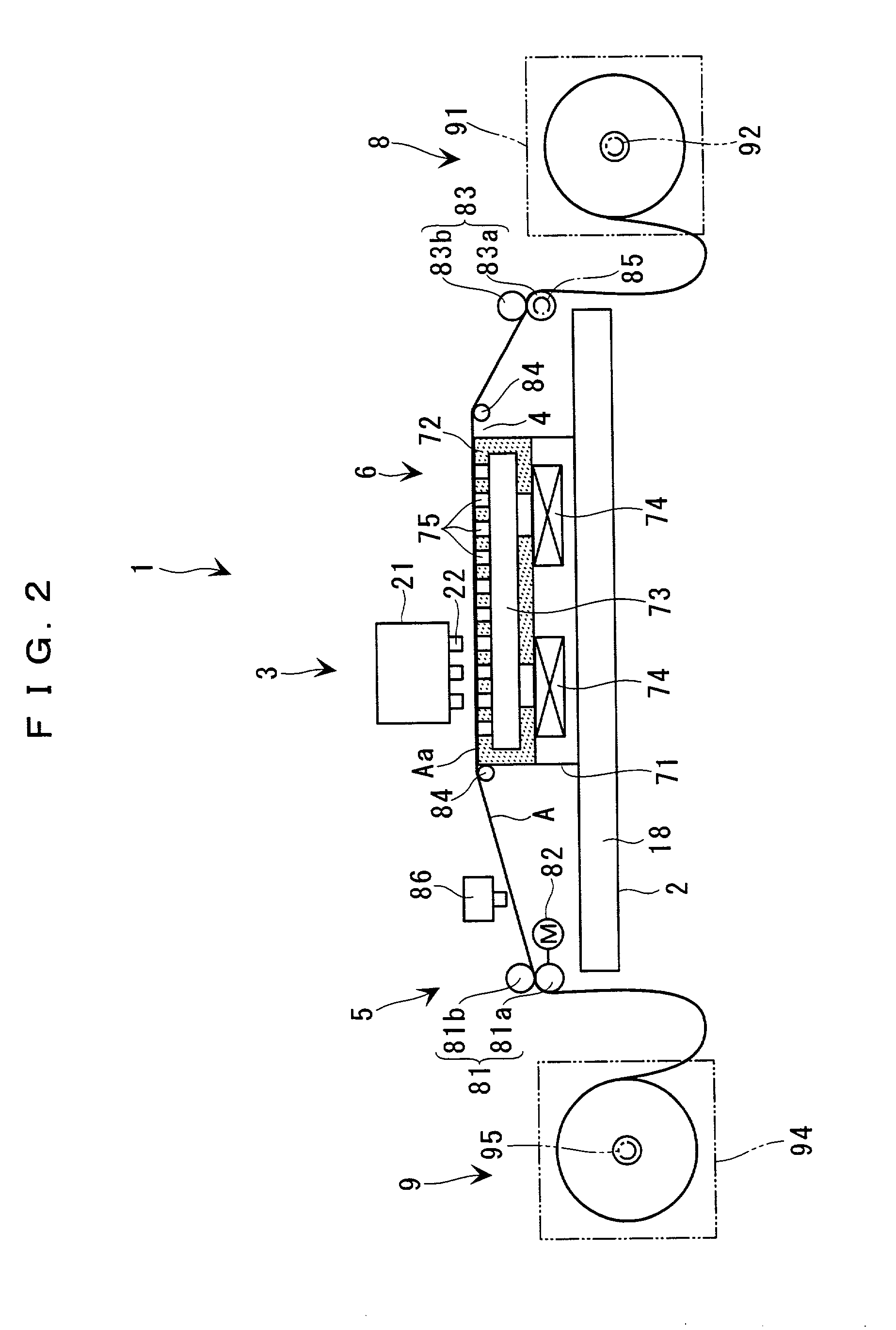

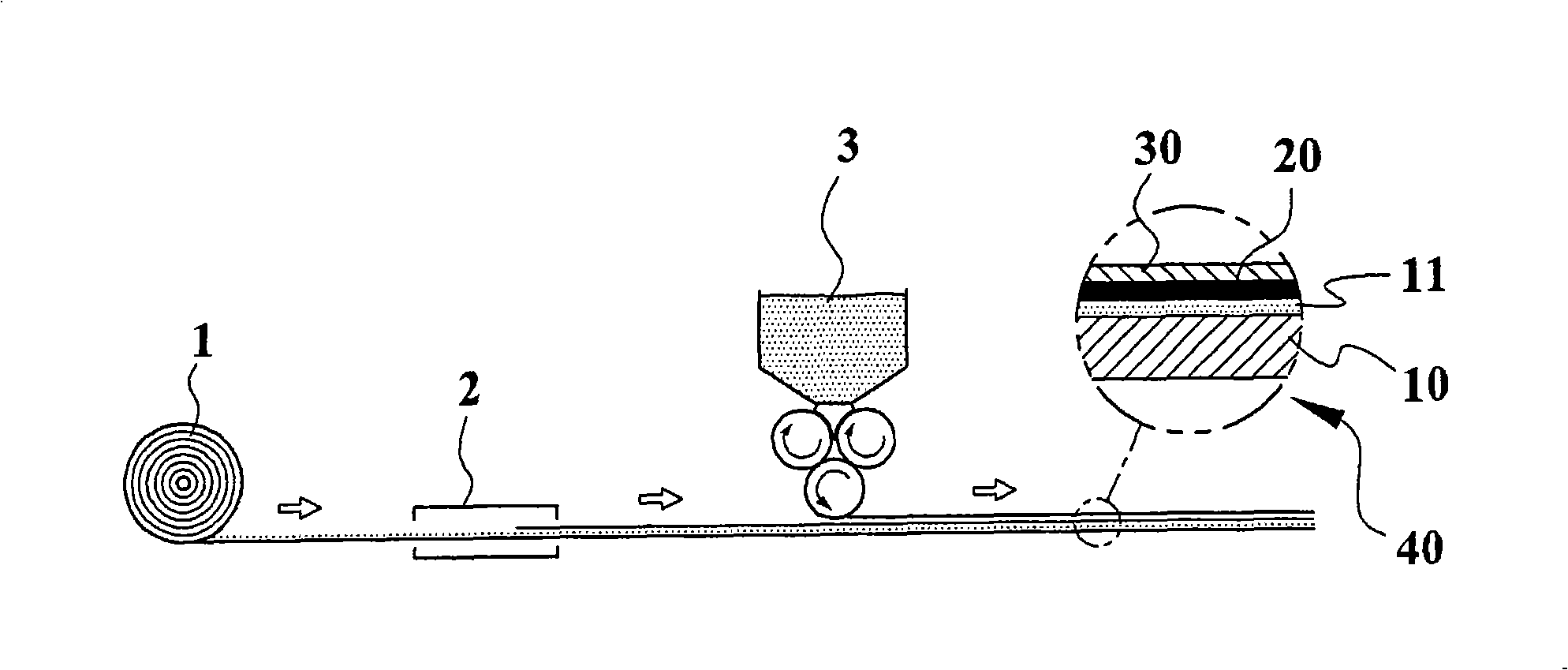

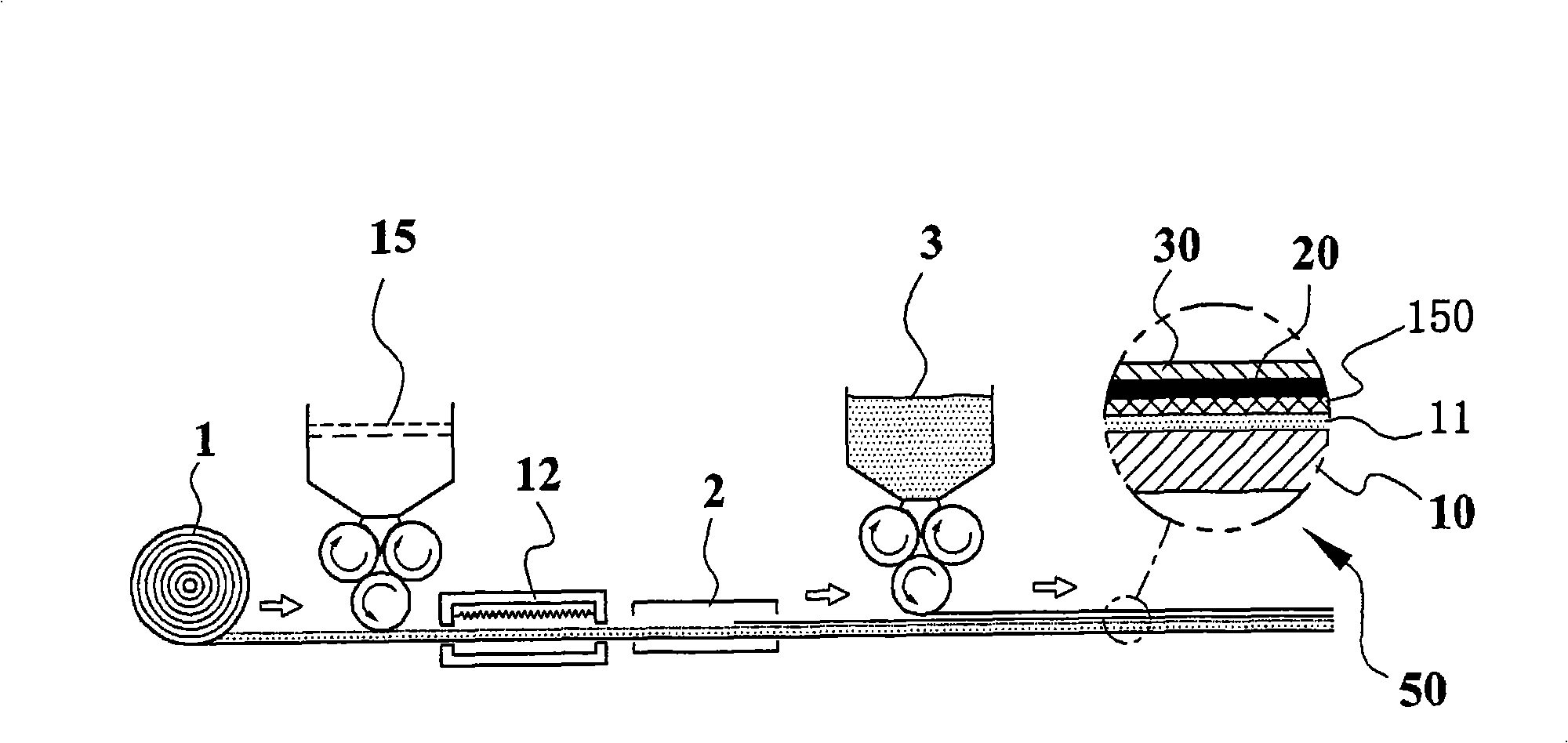

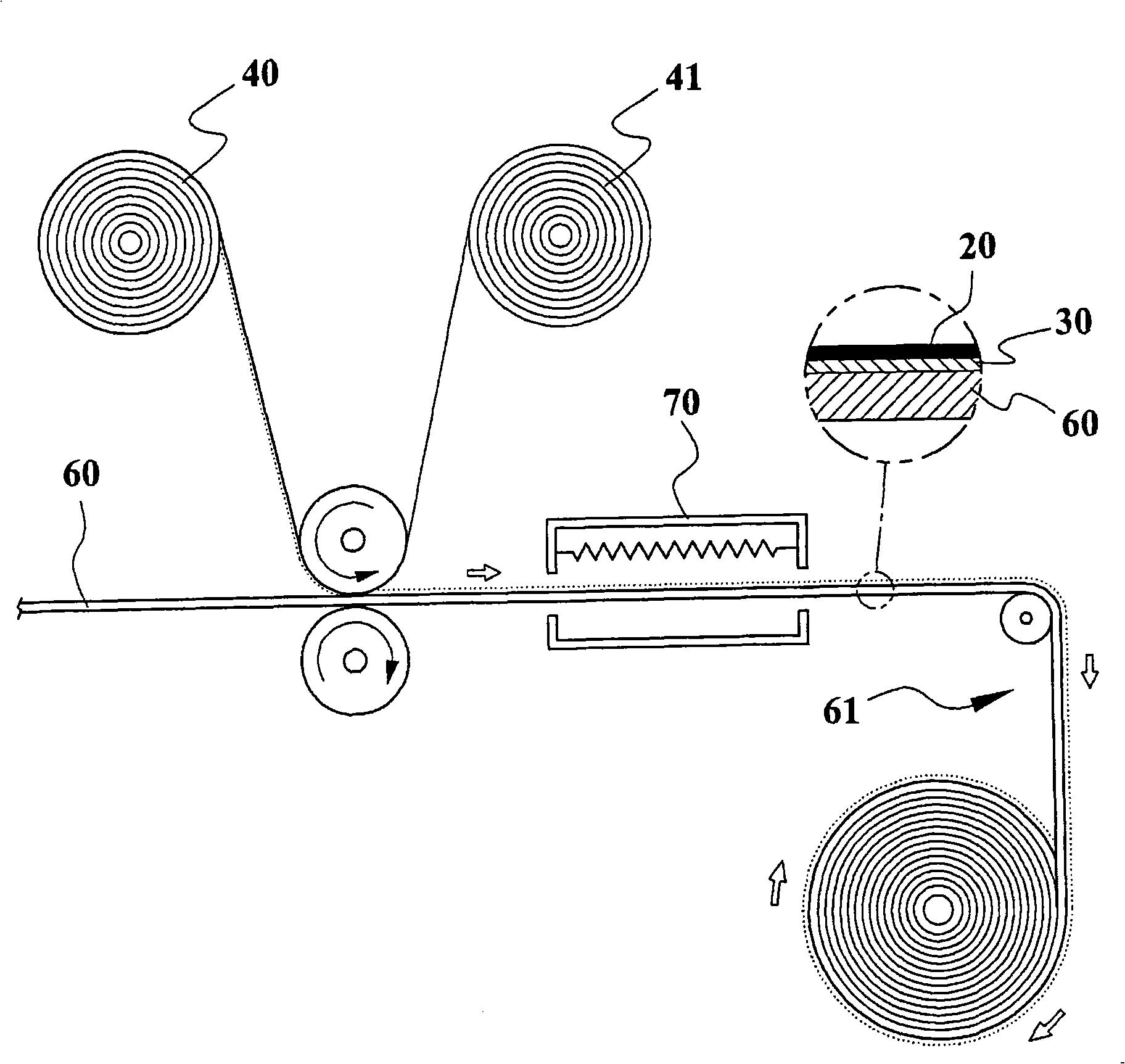

Production method and production line for pre-printed surface paper corrugated paperboards

ActiveCN102173162AAvoid direct contactAvoid damageMechanical working/deformationPaper/cardboard layered productsProduction lineColor printing

The invention provides a production method and production line for pre-printed surface paper corrugated paperboards, and the production method and production line provided by the invention can be used for solving the problem that the existing corrugated paperboard production line and process can not adapt to the production of pre-printed colorful corrugated paperboards. In the invention, because the bonding mode that surface paper is arranged on a single-sided corrugated paperboard is adopted, the direct contact between color-printing paper and a high temperature hot plate at a drying part can be avoided, thereby effectively preventing the damages on the materials, patterns, gloss oil and plastic films of the color-printing paper. The corrugated paperboard production method and corrugated paperboard production line disclosed by the invention can effectively adapt to the application requirements of pre-printed colorful paper on the premise of not increasing the cost.

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

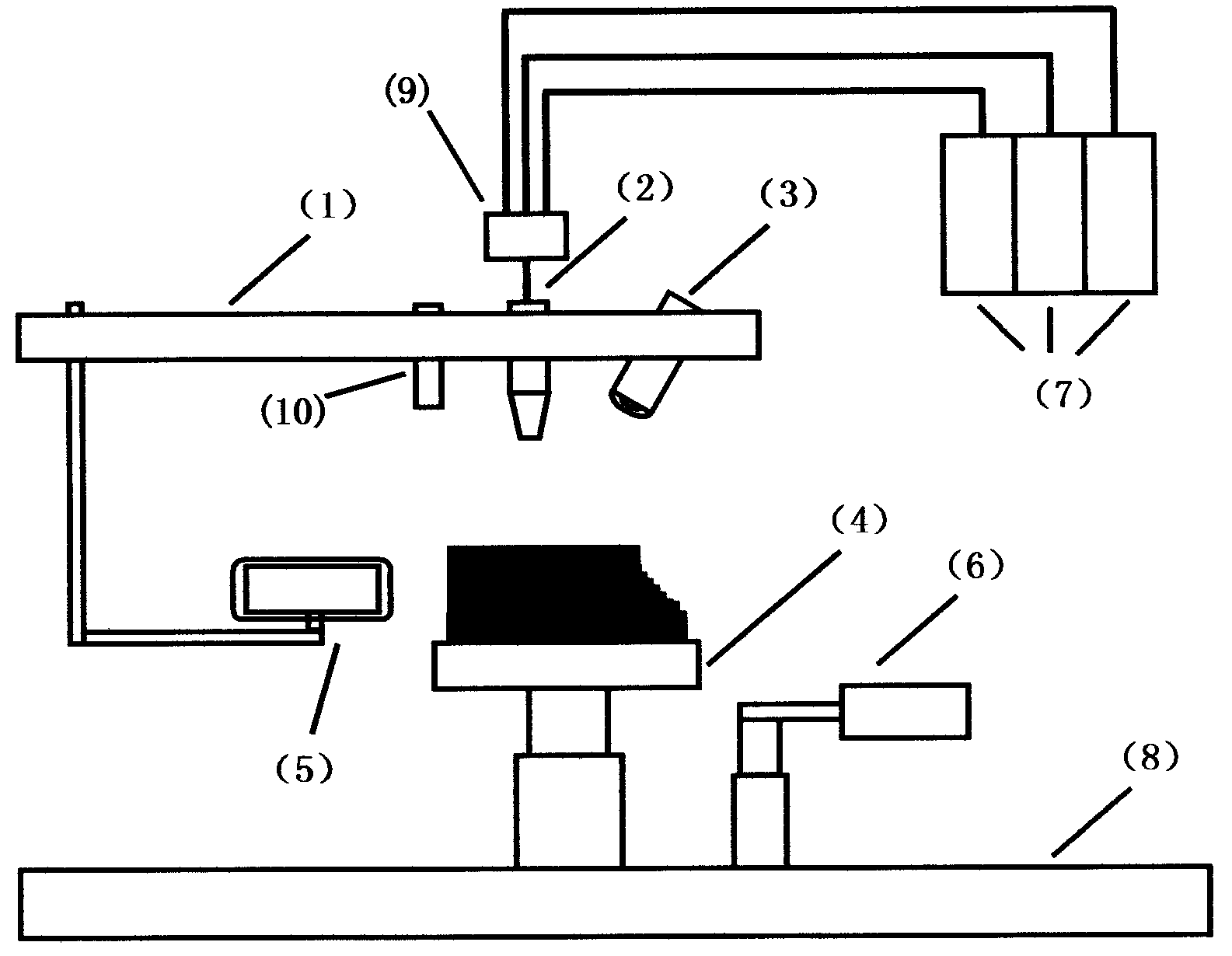

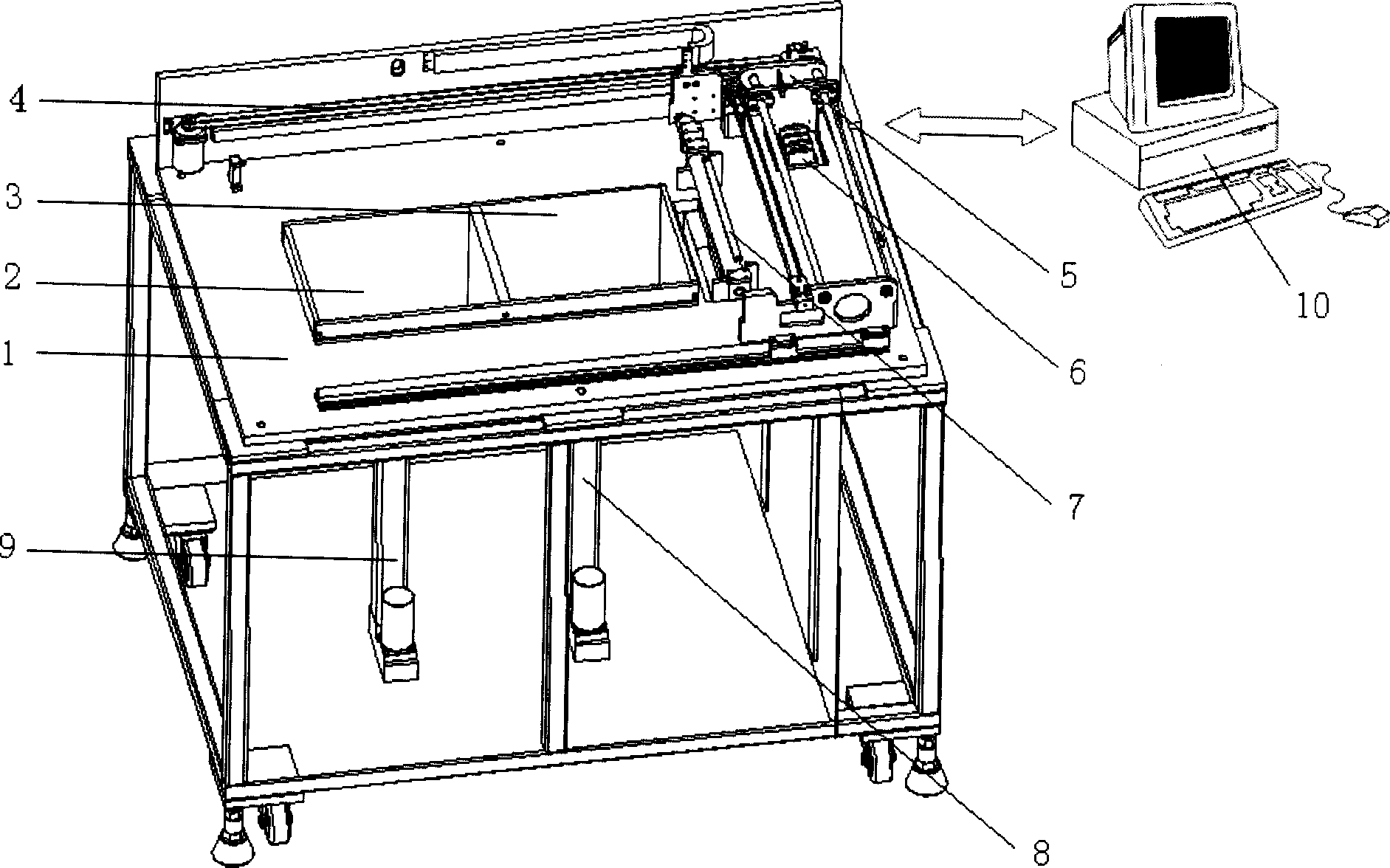

Three dimension color printing quick forming device and method

InactiveCN1857930ASimple processFast molding speedCeramic shaping apparatusPrintingColor printingLayer thickness

The present invention discloses a kind of 3D color printing and quick forming device and method. The 3D color printing and quick forming device includes an X-Y scanning platform and a Z motion mechanism. The X-Y scanning platform is provided with powder providing tank, forming tank, powder roller and printing head; and the Z motion mechanism includes pistons inside the powder providing tank and the forming tank. The quick forming process is one combination of quick forming technology and color printing technology and includes the following steps: jetting pigment of different colors with the precise printing head to the compact powder material inside the forming tank to form color cross section pattern, curing the powder material, lowering the powder material inside the forming tank by the height of one layer thickness while raising the powder material inside the powder providing tank by one layer thickness, forming one new powder material layer, and so on until forming the cured body.

Owner:XI AN JIAOTONG UNIV

Laminated foil package covering with double-sided printing

A multi-layered foil laminate having at least one layer, preferably an exterior layer which is constituted of a plastic film material, and which is provided with printing on both surfaces of the layer. In essence, the method of double-sided printing includes initially printing on a first side of an outer layer of a plastic film material, preferably such as polyester, wherein the printing is imparted to the side or surface of the plastic film material facing towards an underlying metallic foil to which it is to be adhered, and wherein the printing is applied to the plastic film material through the intermediary of reverse halftone color printing, whereby subsequent this particular printing on the one side of the outer plastic film layer having been completed, the plastic film material is adhesively fastened at the printed surface thereof to the underlying metallic foil, such as through the interposition of a suitable adhesive. Thereafter, in order to effectuate the printing on the opposite or external surface of the outer plastic film material, the laminated foil has thermal transfer printing imparted to the outer surface of the plastic film layer, preferably through the intermediary of a ceramic printing head, imparting further indicia indicative of specific information relative to the contents of a package which is to be equipped with the foil laminate.

Owner:JOHNSON & JOHNSON VISION CARE INC

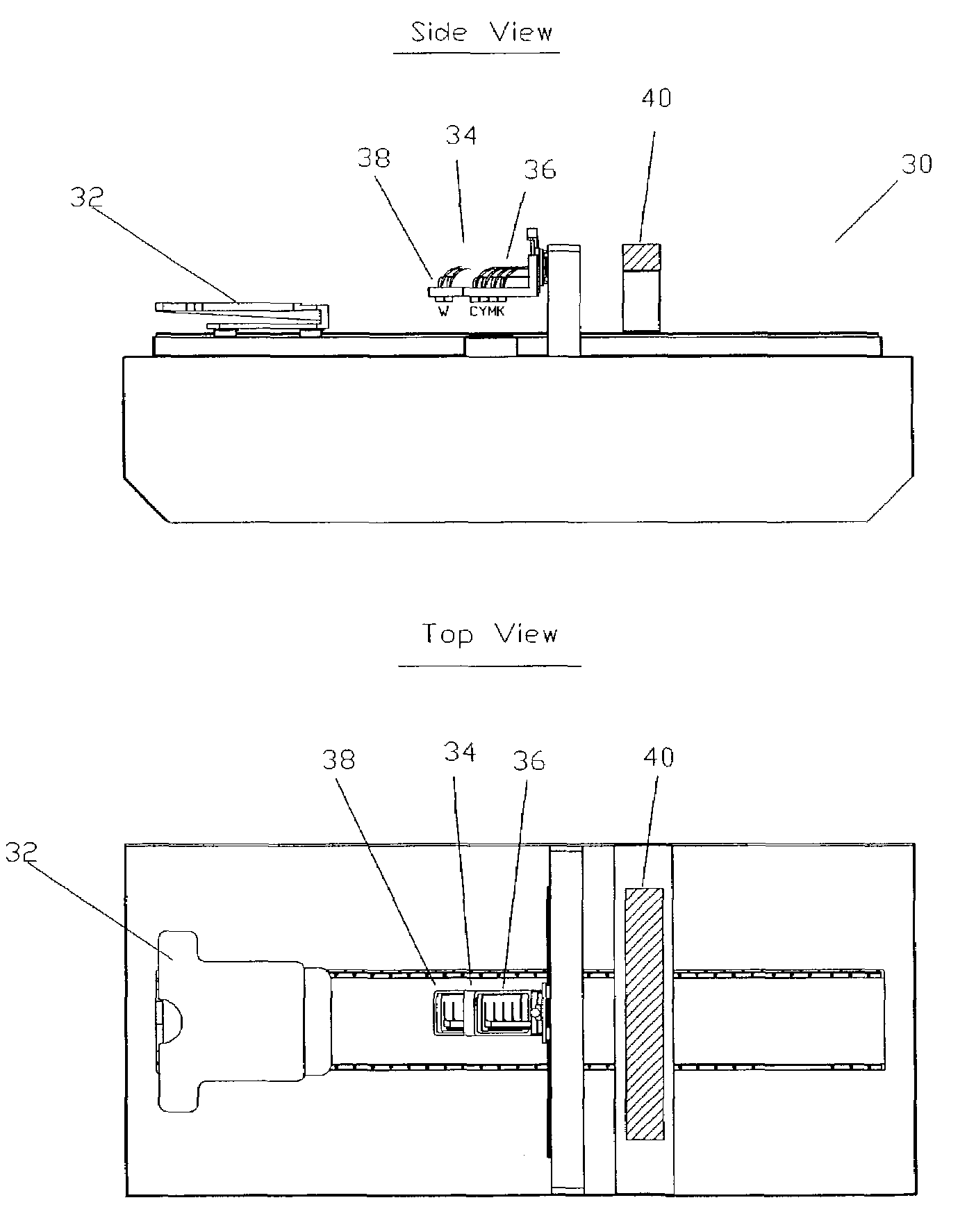

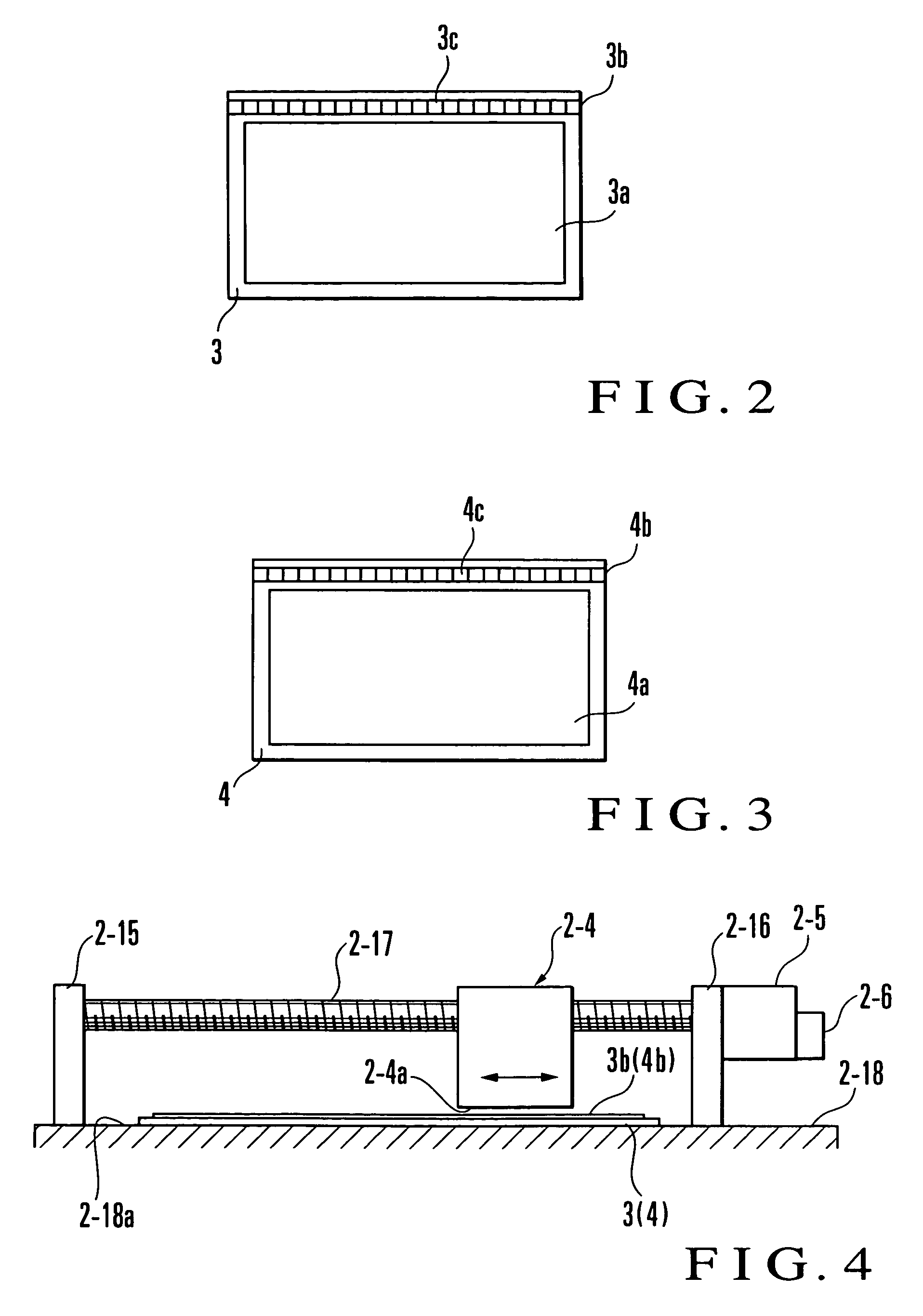

Ink jet head unit and ink jet printing apparatus incorporating the same

There are provided an ink jet head unit which is capable of incorporating a large number of ink jet heads with ease and precision, and an ink jet printing apparatus incorporating the ink jet head unit. The ink jet head unit performs printing color printing by using a plurality of ink nozzle arrays each for use in printing one line, the plurality of ink nozzle arrays corresponding to a plurality of basic colors. A plurality of head groups are each formed by a plurality of ink jet heads, and have the plurality of ink nozzle arrays arranged therein such that the plurality of ink nozzle arrays are divided among the plurality of head groups. A plurality of sub-carriages have respective ones of the plurality of head groups mounted thereon. A unitizing carriage has the plurality of sub-carriages mounted thereon.

Owner:SEIKO EPSON CORP

Heat-transferring die, manufacturing process and heat-transferring manufacturing process

InactiveCN101318420AGood film structure strengthDecorative surface effectsDuplicating/marking methodsEngineeringTemperature resistance

A thermal transfer film which can carry out continuous thermal transfer in a large area directly forms a single-color or colorful printing pattern with excellent layer film structure intensity on the transferred surfaces of various metal, glass or ceramic substances. The manufacturing technique of the thermal transfer film includes that printing is carried out a whole volume of continuous plastic film material or paper material the surface of which comprises a release layer with the ink of a high temperature-resistance dye by a gravure printer to generate the ink layer of the high temperature-resistance dye; the layer of a high temperature-resistance thermal reaction hot melt adhesive is coated on the surface of the ink layer of the high temperature-resistance dye. The thermal transfer steps include: a. the steps of degreasing, dust removing, purifying of the transferred surface of a substance; b. the step of fictitiously fixing: the thermal transfer film comprising the ink of the high temperature-resistance dye and the layer of the high temperature-resistance thermal reaction hot melt adhesive are taken to carry out thermal transfer on the transferred surface of the step a to lead the ink layer of the high temperature-resistance dye and the layer of the high temperature-resistance thermal reaction hot melt adhesive to be fictitiously fixed on the transferred surface; c. the step of roasting for leading the ink of the high temperature-resistance dye and the layer of the high temperature-resistance thermal reaction hot melt adhesive to be firmly combined with the transferred surface.

Owner:白洪城

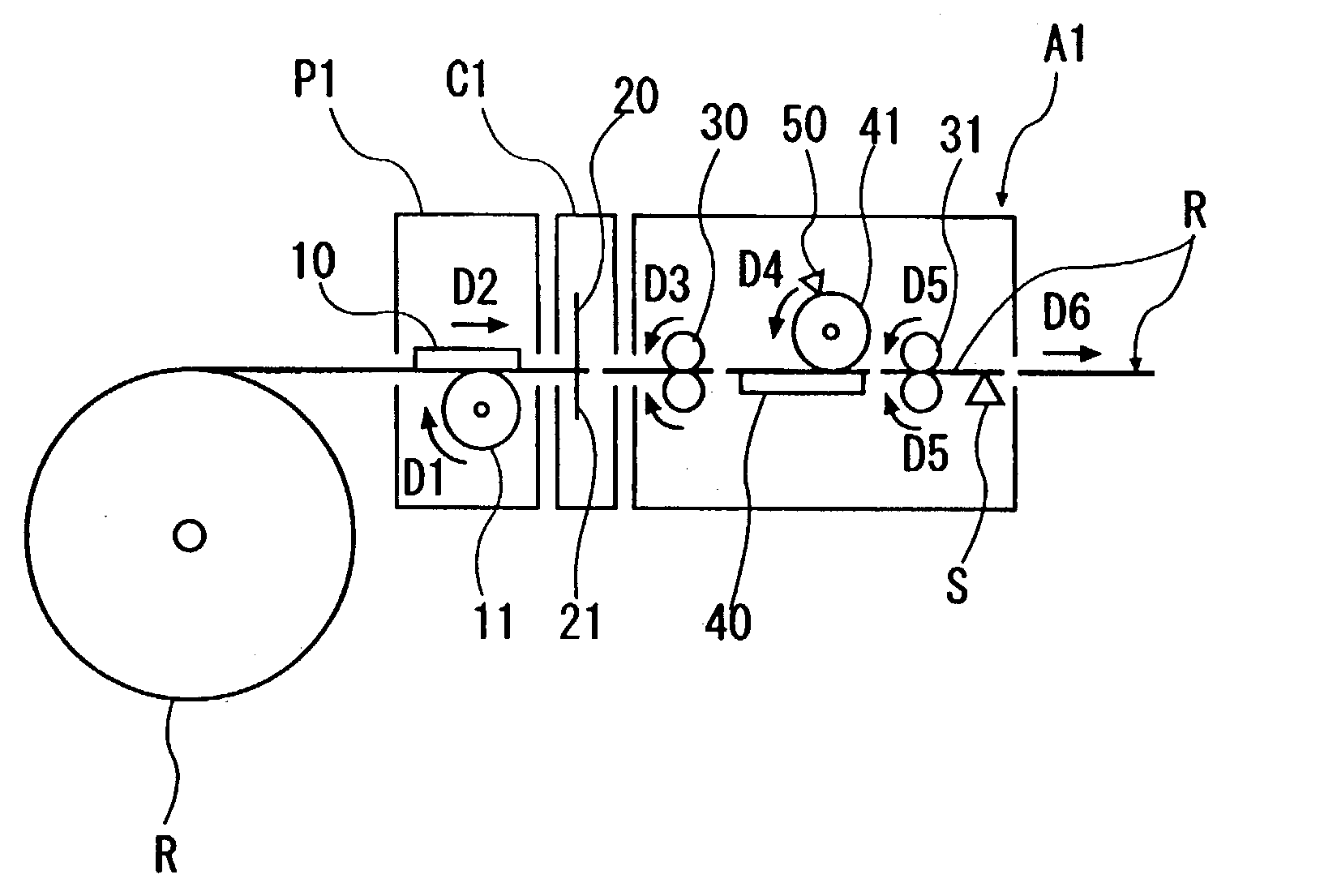

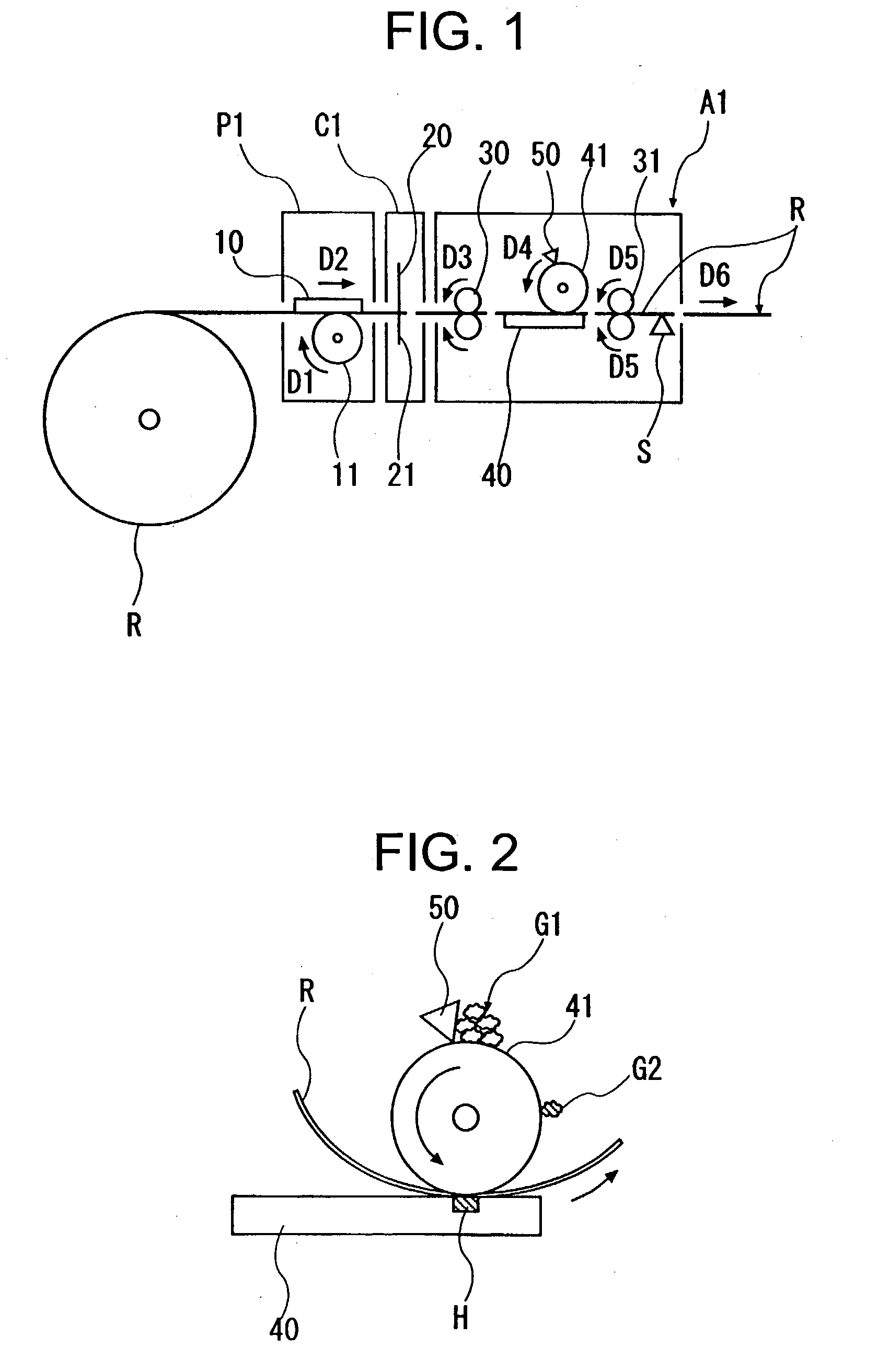

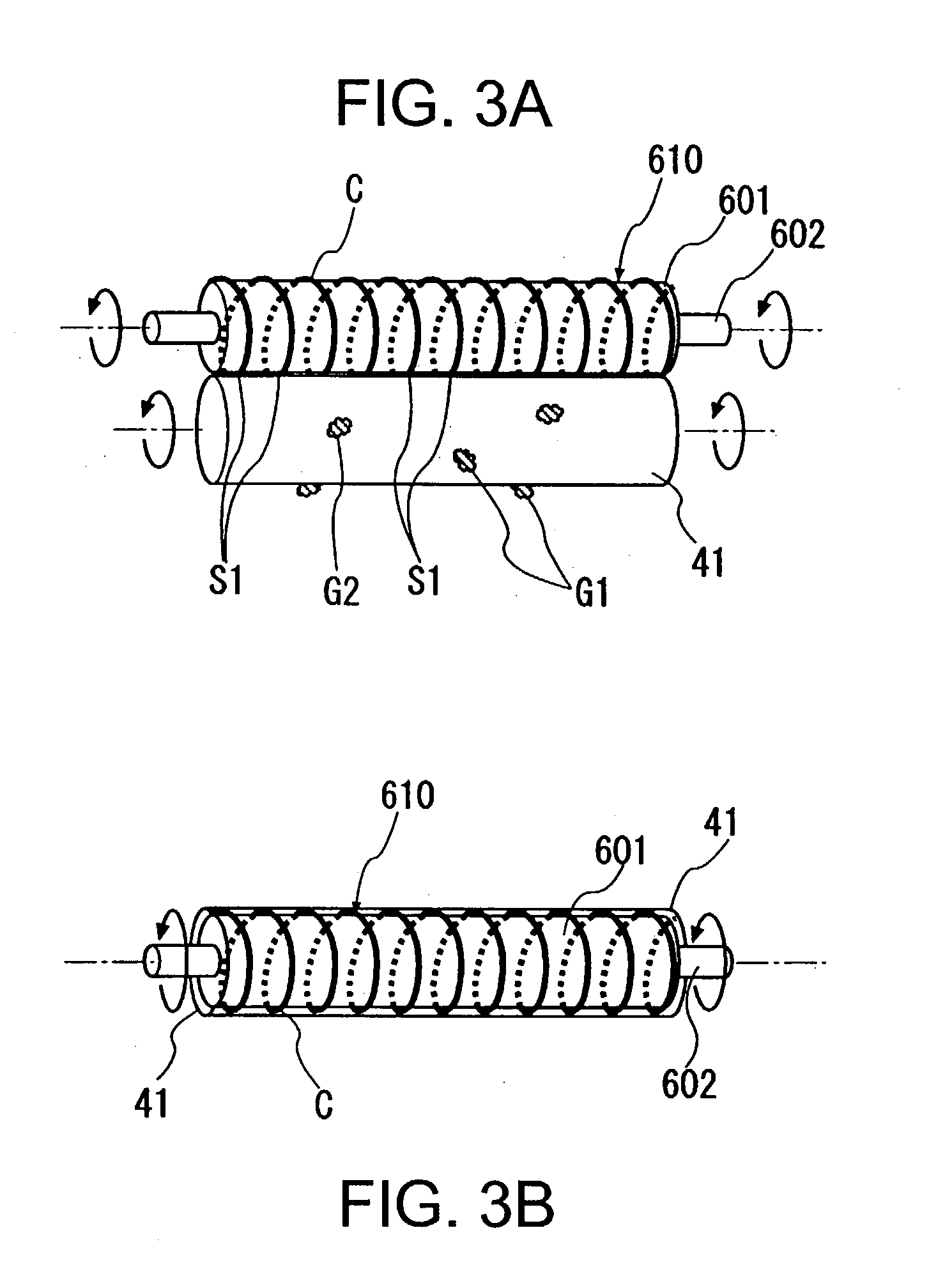

Thermal activator for heat sensitive adhesive sheet and printer apparatus utilizing the thermal activator

There is provided a thermal activator for a heat sensitive adhesive sheet capable of preventing or removing the heat sensitive adhesive and a product of denaturation of the heat sensitive adhesive from adhering to means for transporting the heat sensitive adhesive sheet and a printer apparatus utilizing the thermal activator. In a thermal activator for a heat sensitive adhesive sheet having at least heating means for activation (a thermal head 40 for thermal activation and a heating element H) for heating and activating a heat sensitive adhesive layer of a heat sensitive adhesive sheet (a heat sensitive adhesive label R) constituted of a printable surface (a thermal coat layer 501 and a color printing layer 502) and the heat sensitive adhesive layer (K) formed on one and another side of a base material (base paper 500) respectively and transport means (a platen roller 41 for thermal activation and the like) for transporting the heat sensitive adhesive sheet in a predetermined direction, there is provided anti-adhesion means (sheet materials 81 and 600 for cleaning) for preventing the heat sensitive adhesive or a product of denaturation of the heat sensitive adhesive from adhering to the transport means or removal means (a scraper 50, a rotary body 610 having a spiral groove or protrusion, a cylindrical rotary body 700 having a spiral blade, wires W, scraping tools 900 and 1100 in the form of a cutter blade, a transfer material 60, a cleaning roller 70, or the like) for removing the heat sensitive adhesive and the product of denaturation of the heat sensitive adhesive that have adhered to the transport means.

Owner:SAMBONGI NORIMITSU +5

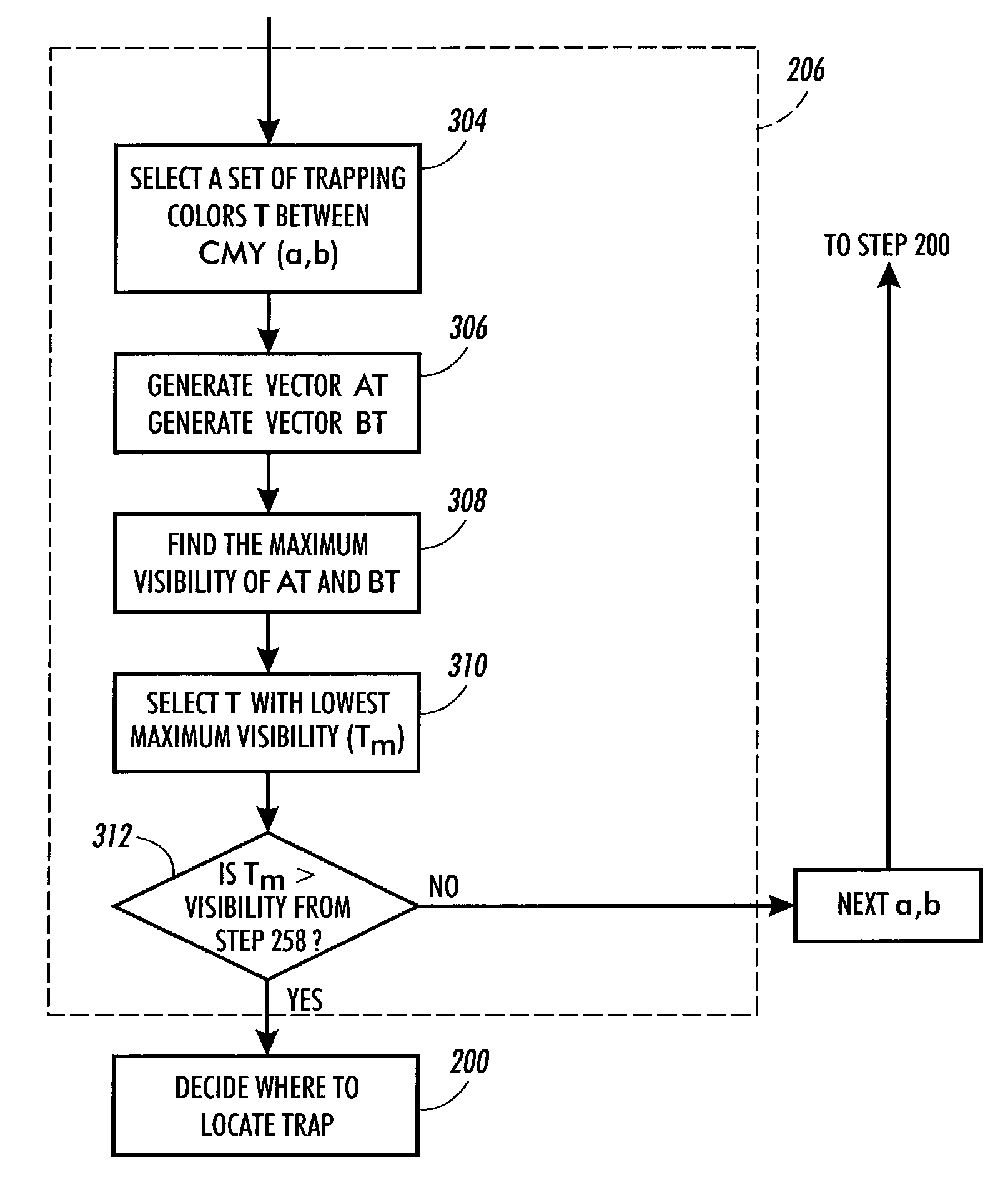

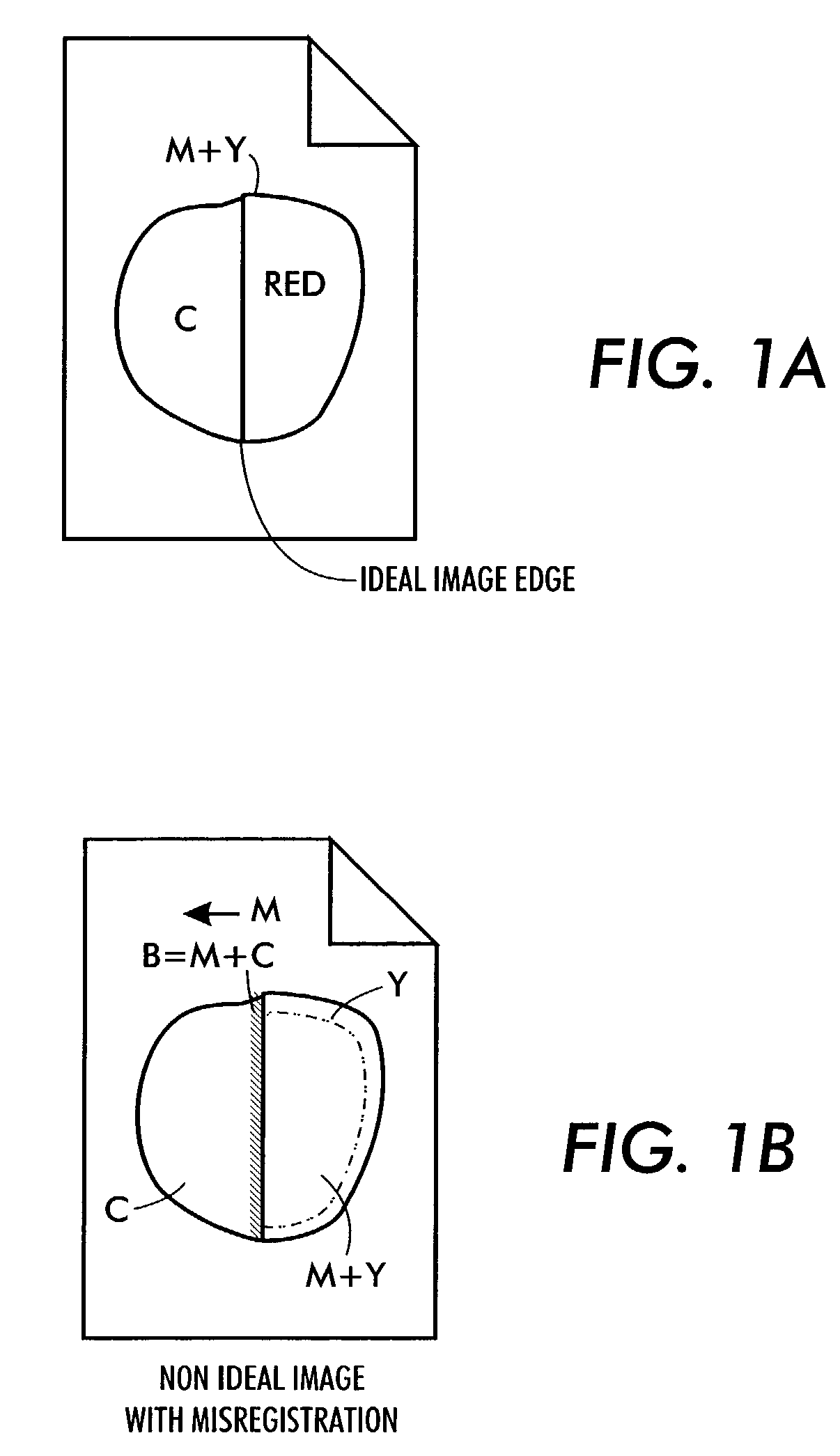

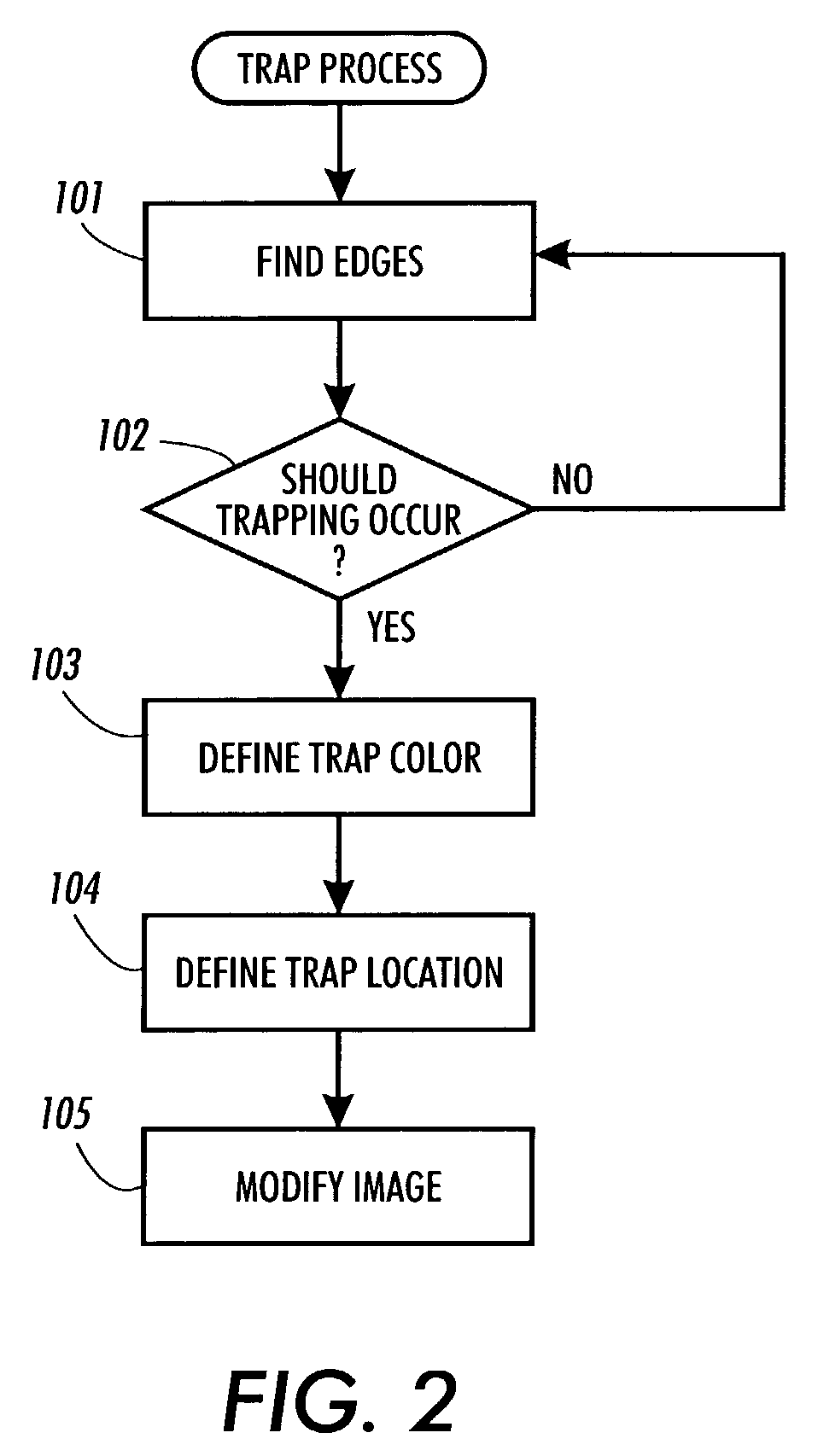

System and method of trapping for correcting for separation misregistration in color printing

InactiveUS7123381B2Work be limitDigitally marking record carriersDigital computer detailsVisibilityColor printing

A color printing system which deposits colors on a separation by separation basis provides trapping to correct misregistration between printer output colors due to imperfect placement of the separation colors. The system includes a trapping calculation processor, determining trapping requirements based on visibility, measured in a color space in which equivalent color differences in human color perception are approximately equivalent values.

Owner:XEROX CORP

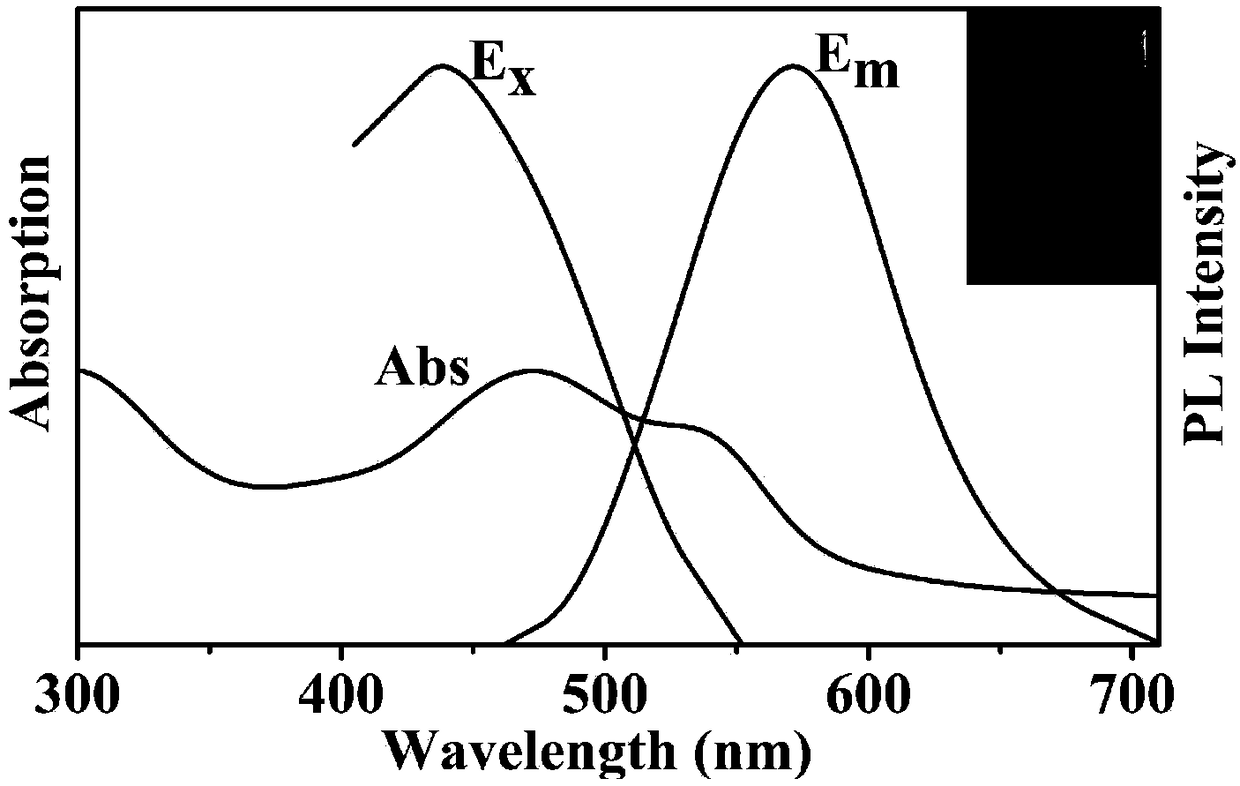

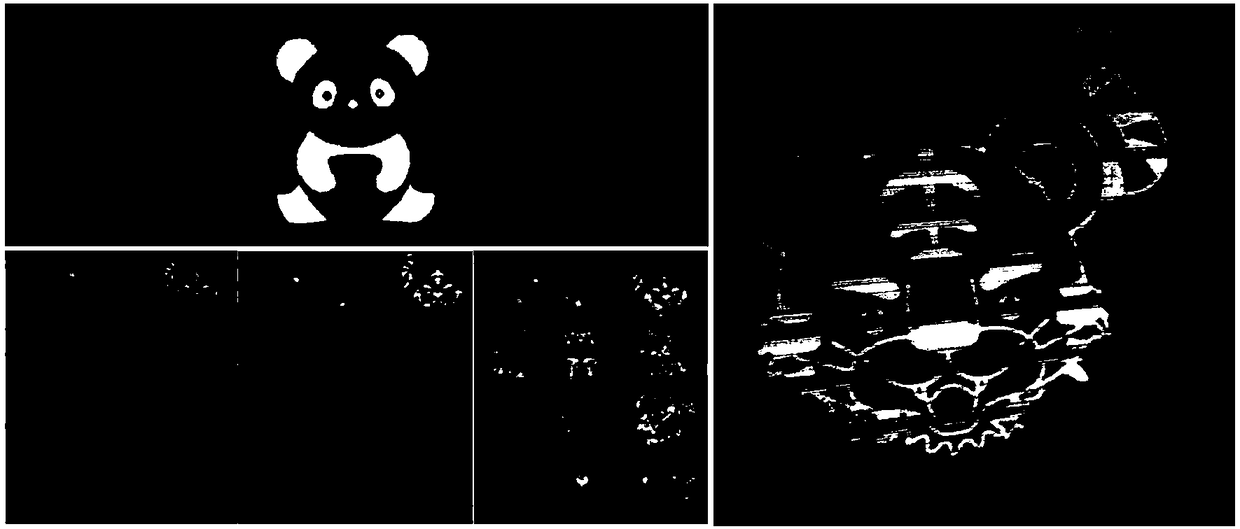

Preparation method and product of full-color carbon dots for multi-color fluorescent printing

ActiveCN108587615AEmission wavelength red shiftImprove stabilityInksNanoopticsSolubilityColor printing

Owner:JIANGNAN UNIV

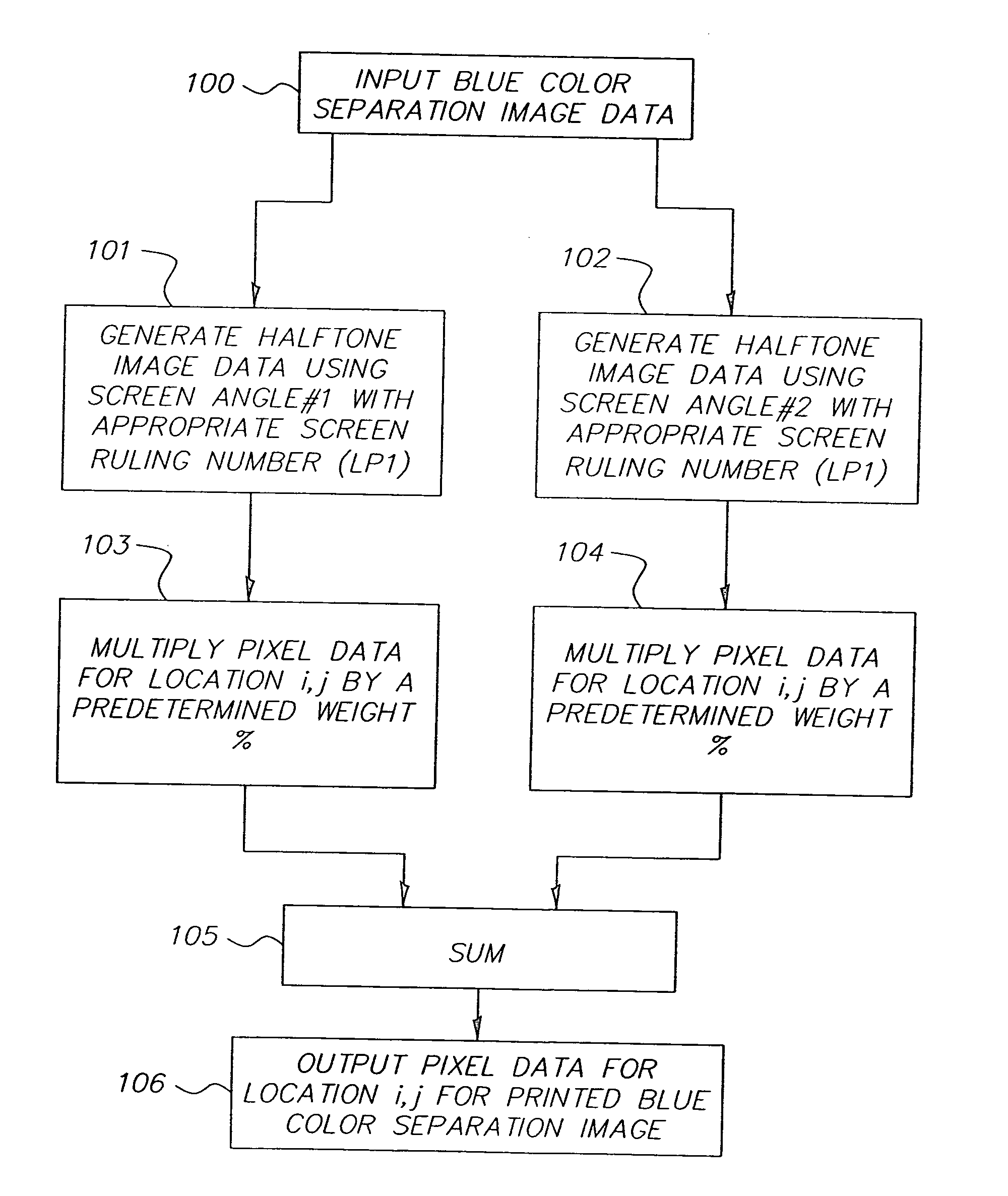

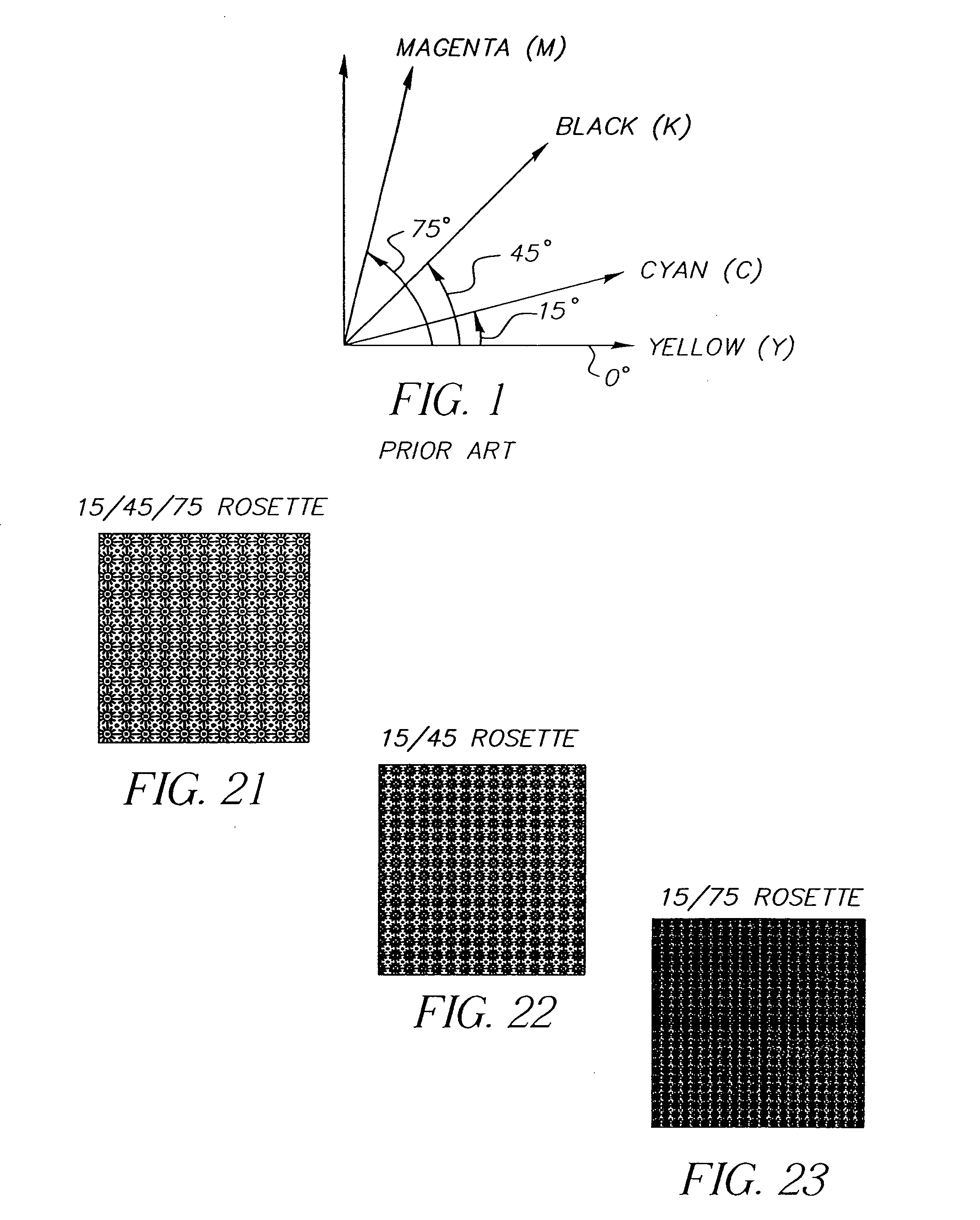

Method and apparatus for multi-color printing using a rosette or diamond halftone screen for one or more of the colors

InactiveUS20050243340A1Reduce Image ArtifactsIncrease the number ofImage enhancementDigitally marking record carriersColor printingComputer graphics (images)

A method and apparatus for processing image data representing a color separation or mono-color image includes processing the color separation image data or mono-color image data in accordance with first and second or more halftone screen processings at different screen angles and obtaining results of the processings and combining the results of the processings to generate composite image data of the first and second or more halftone screen processings. The resulting print of the composite image data forms relatively pleasing rosettes or diamond structures in the particular color.

Owner:EASTMAN KODAK CO

Network interface apparatus, control method, program, and image forming apparatus

InactiveUS20100079805A1Without deteriorating performanceAvoid disagreementDigital data authenticationEmergency protective arrangements for automatic disconnectionPoor Quality ImageComputer graphics (images)

A mechanism which can avoid, as much as possible, a difference of picture quality that is caused by restricting color printing according to an authority and forcedly performing monochromatic printing is provided. A mechanism which restricts the color printing according to the authority without deteriorating performance is also provided. The processing refers to a color restricting mode in user information or a color restricting mode in setting information. When the referred color restricting mode indicates “force”, if the user does not have the authority in which a color job can be printed, the job is forcedly converted into monochrome. In case of “analyze”, if the user does not have the authority in which a color job can be printed, the job is analyzed. If it is the color job, a forced monochromatic printing or print inhibition is performed.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com