Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2701results about How to "Improve printing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

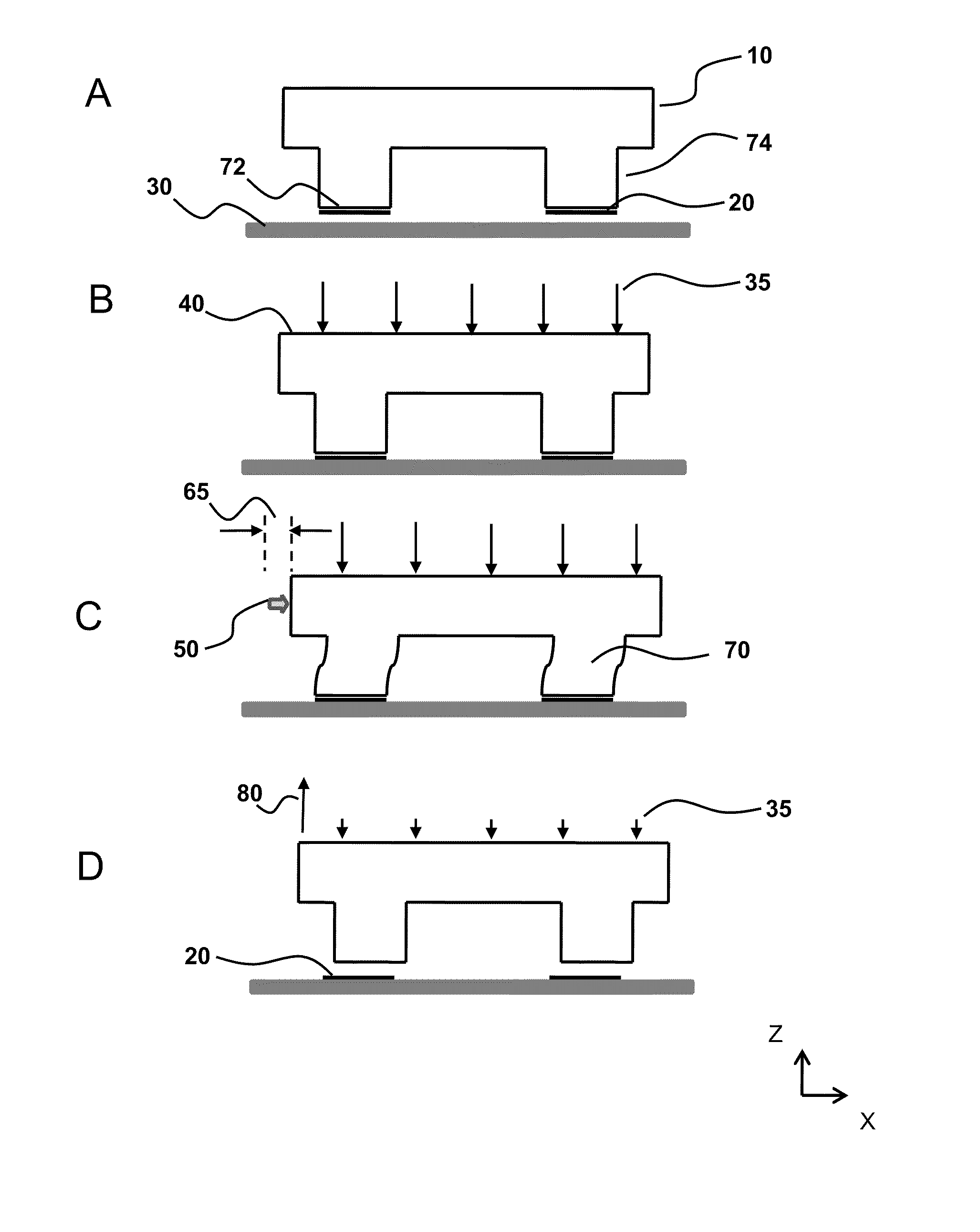

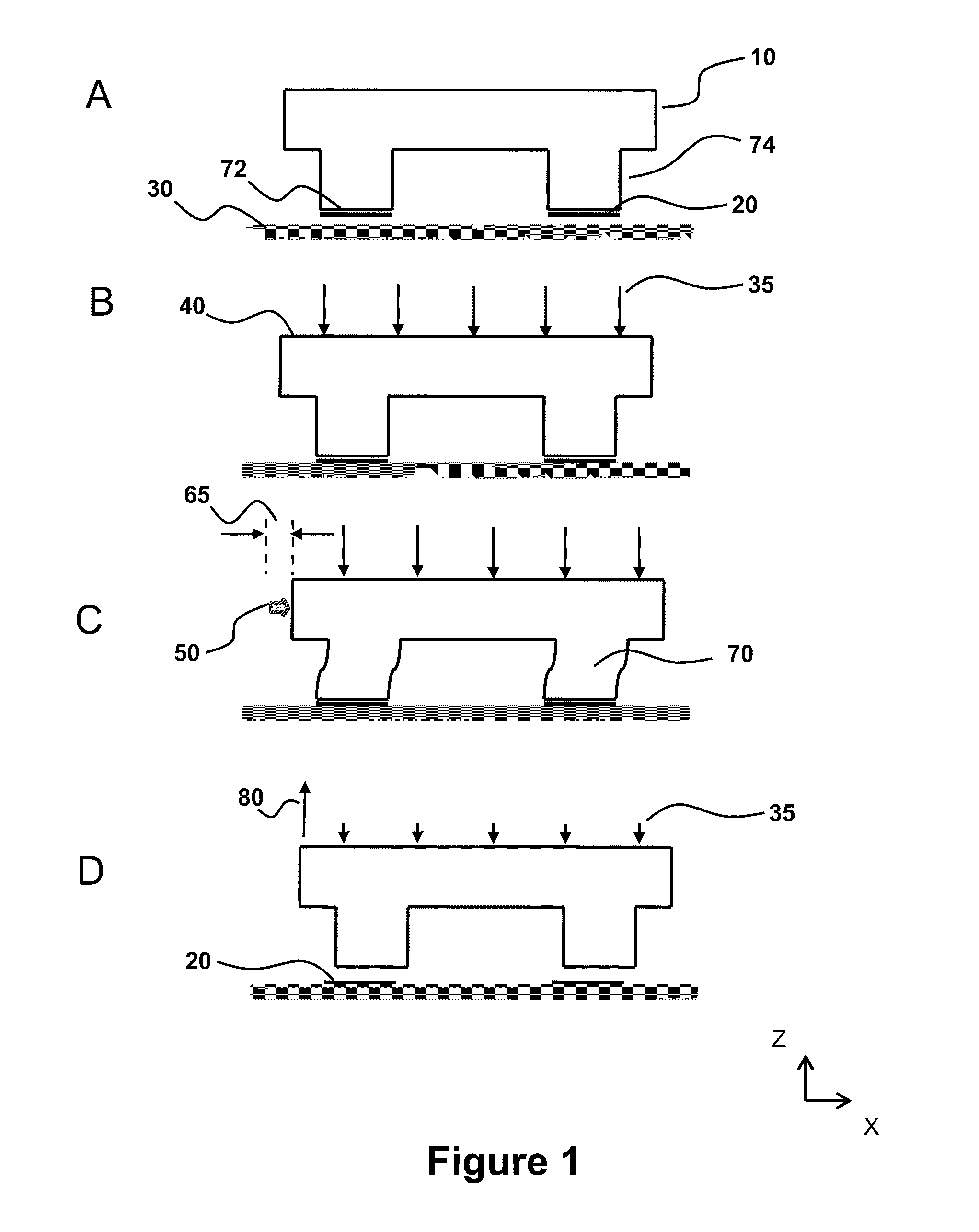

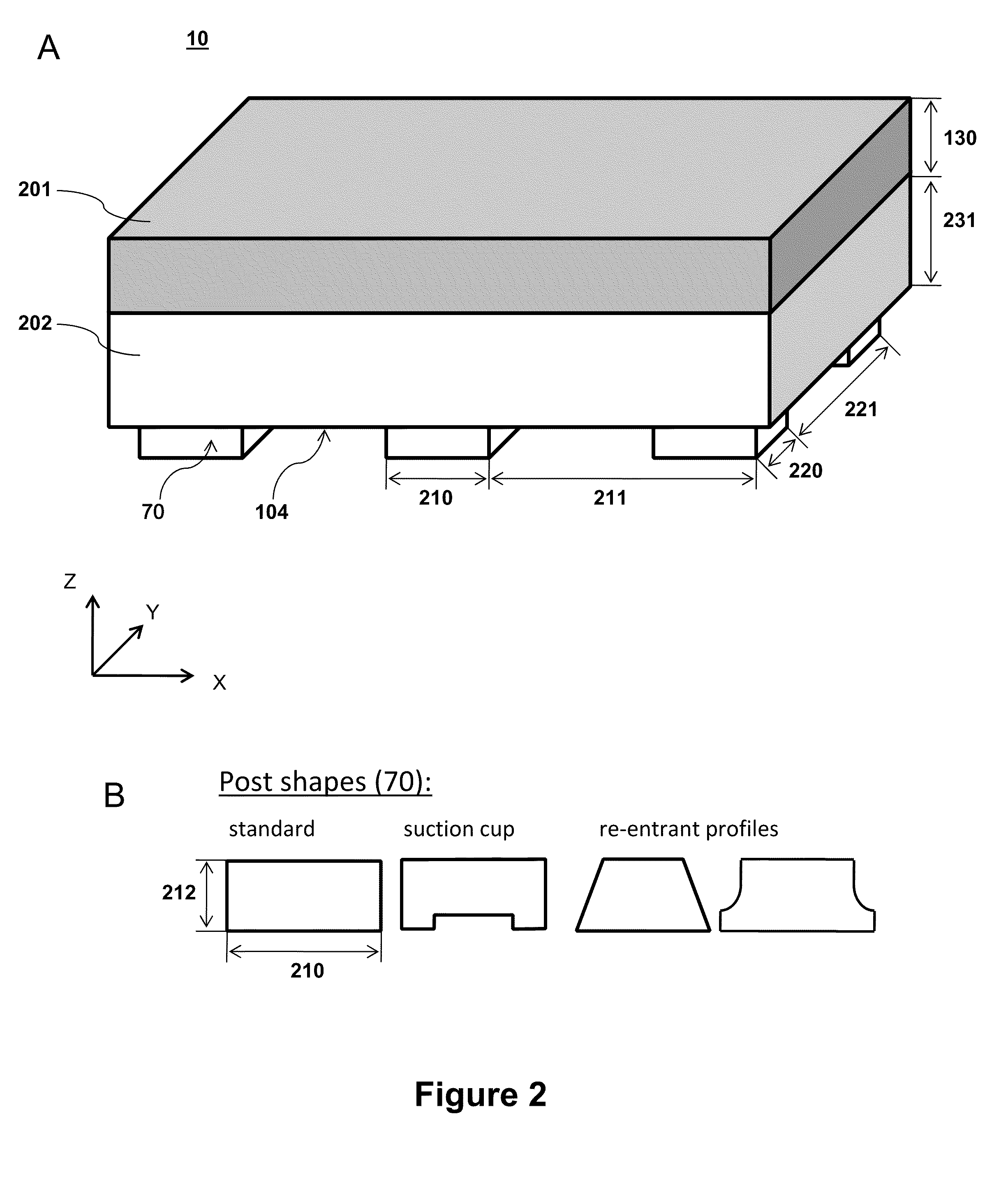

Printing semiconductor elements by shear-assisted elastomeric stamp transfer

ActiveUS8506867B2Sacrificing printing yield and accuracyIncrease chanceConfectionerySolid-state devicesEngineeringVertical displacement

Provided are methods and devices for transfer printing of semiconductor elements to a receiving surface. In an aspect, the printing is by conformal contact between an elastomeric stamp inked with the semiconductor elements and a receiving surface, and during stamp removal, a shear offset is applied between the stamp and the receiving surface. The shear-offset printing process achieves high printing transfer yields with good placement accuracy. Process parameter selection during transfer printing, including time varying stamp-backing pressure application and vertical displacement, yields substantially constant delamination rates with attendant transfer printing improvement.

Owner:X DISPLAY CO TECH LTD

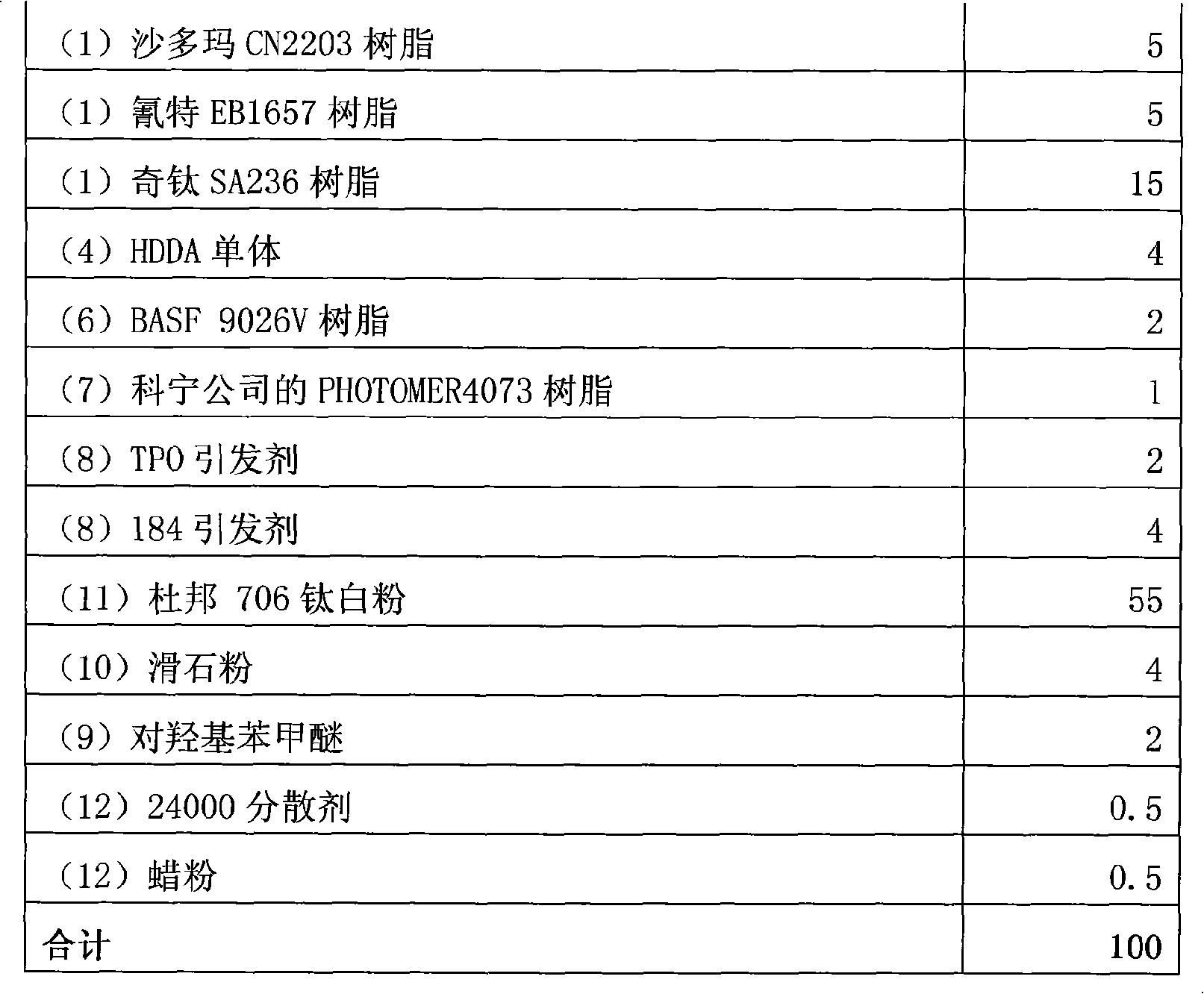

Ultraviolet light curing offset printing ink and preparation method thereof

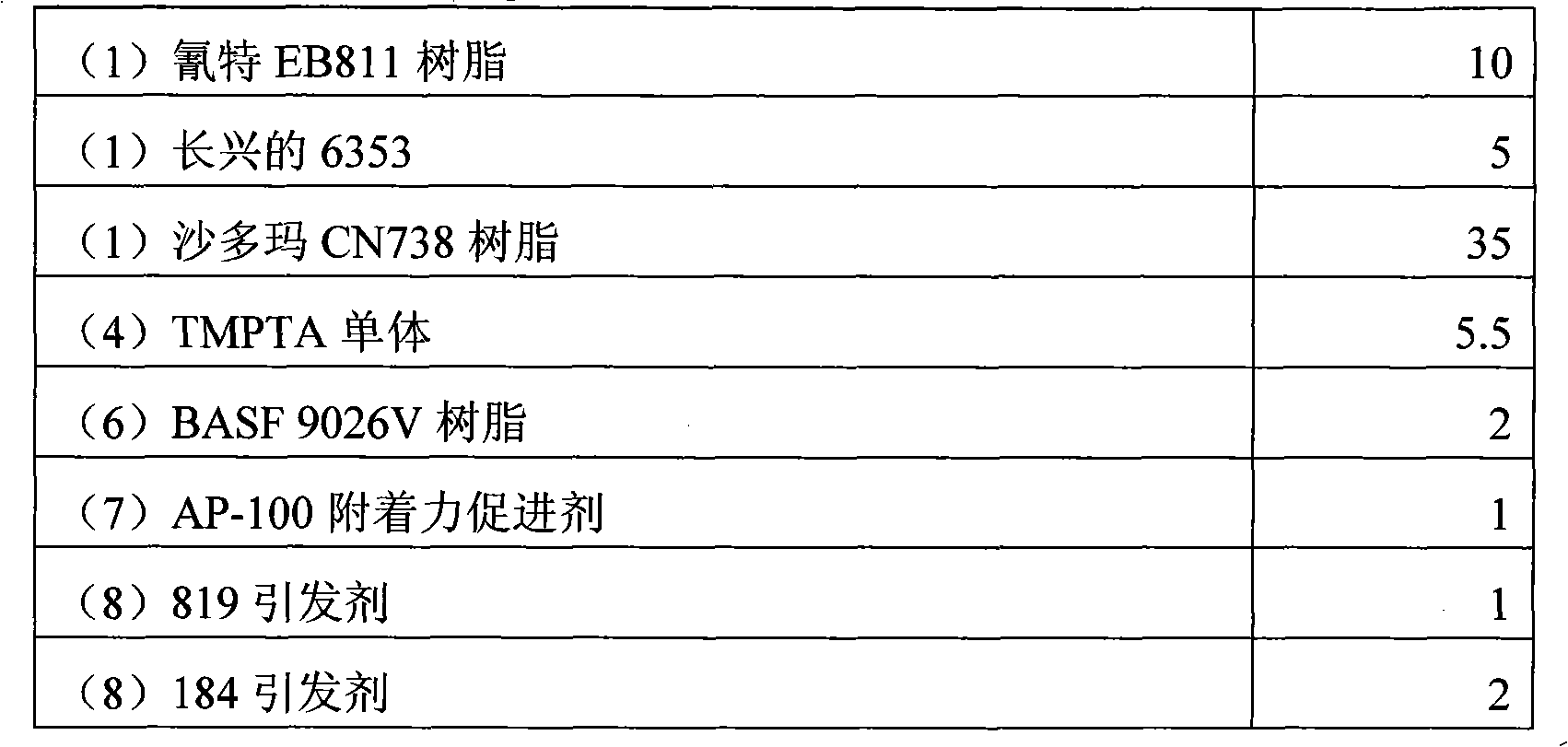

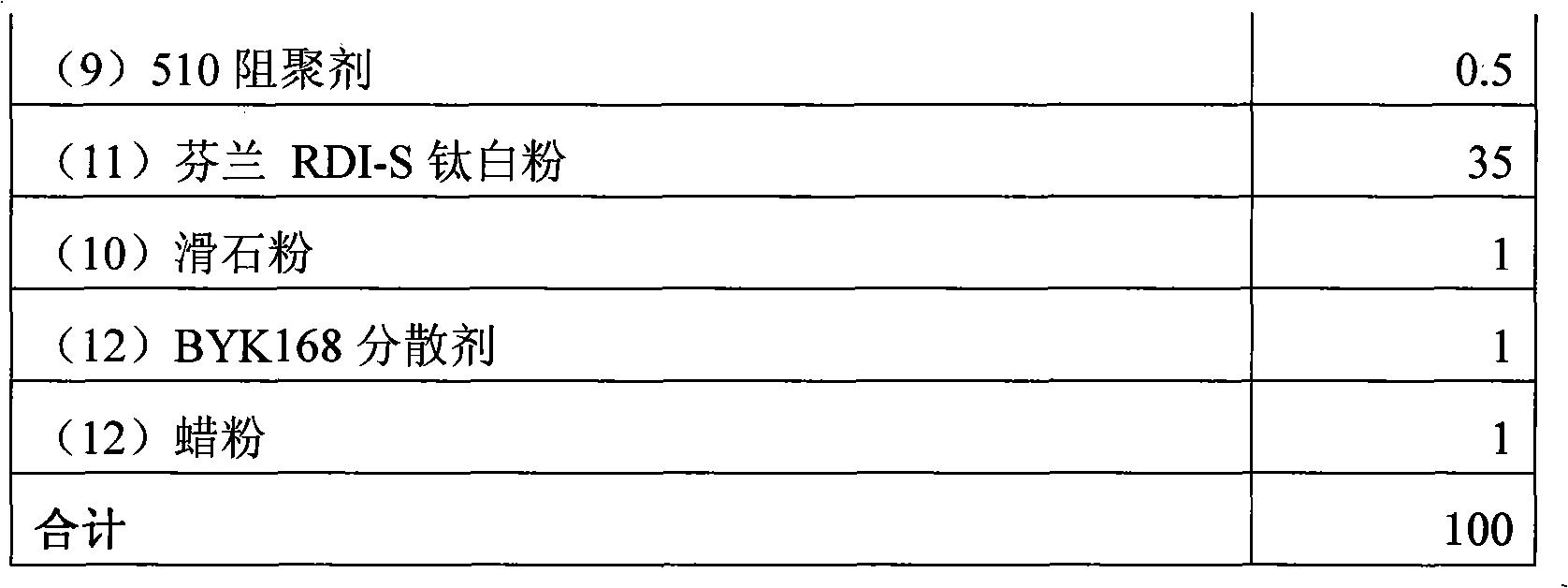

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

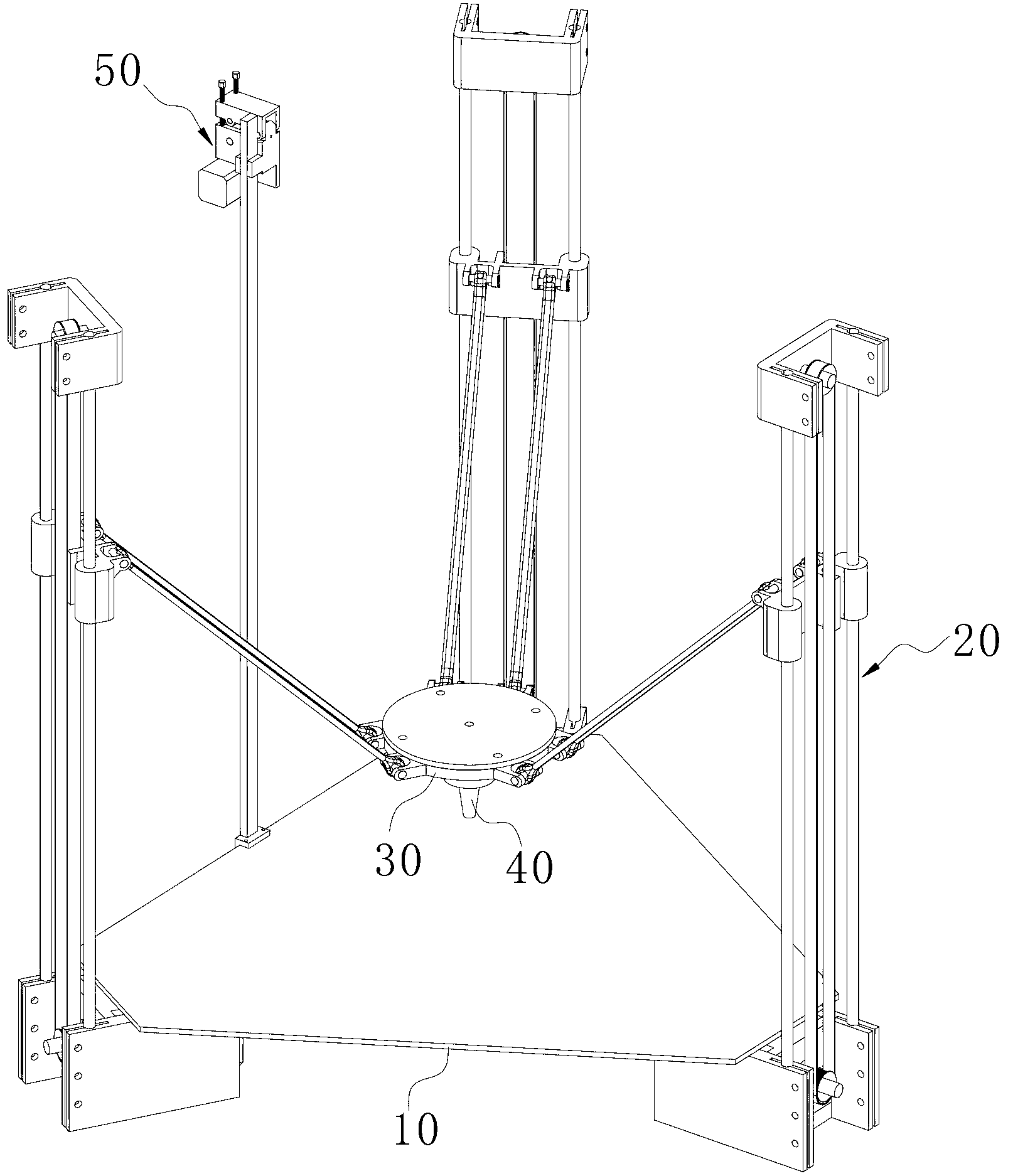

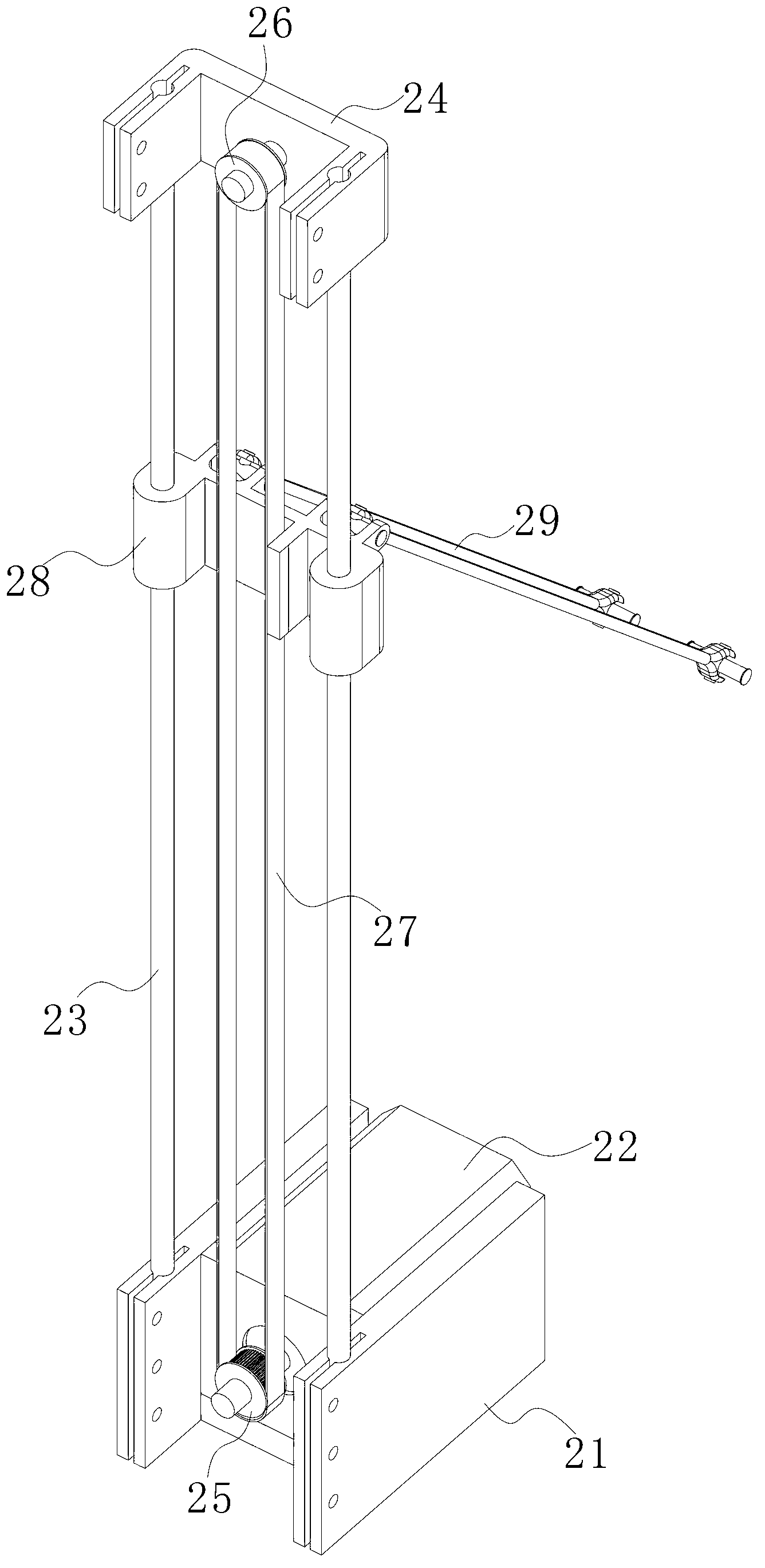

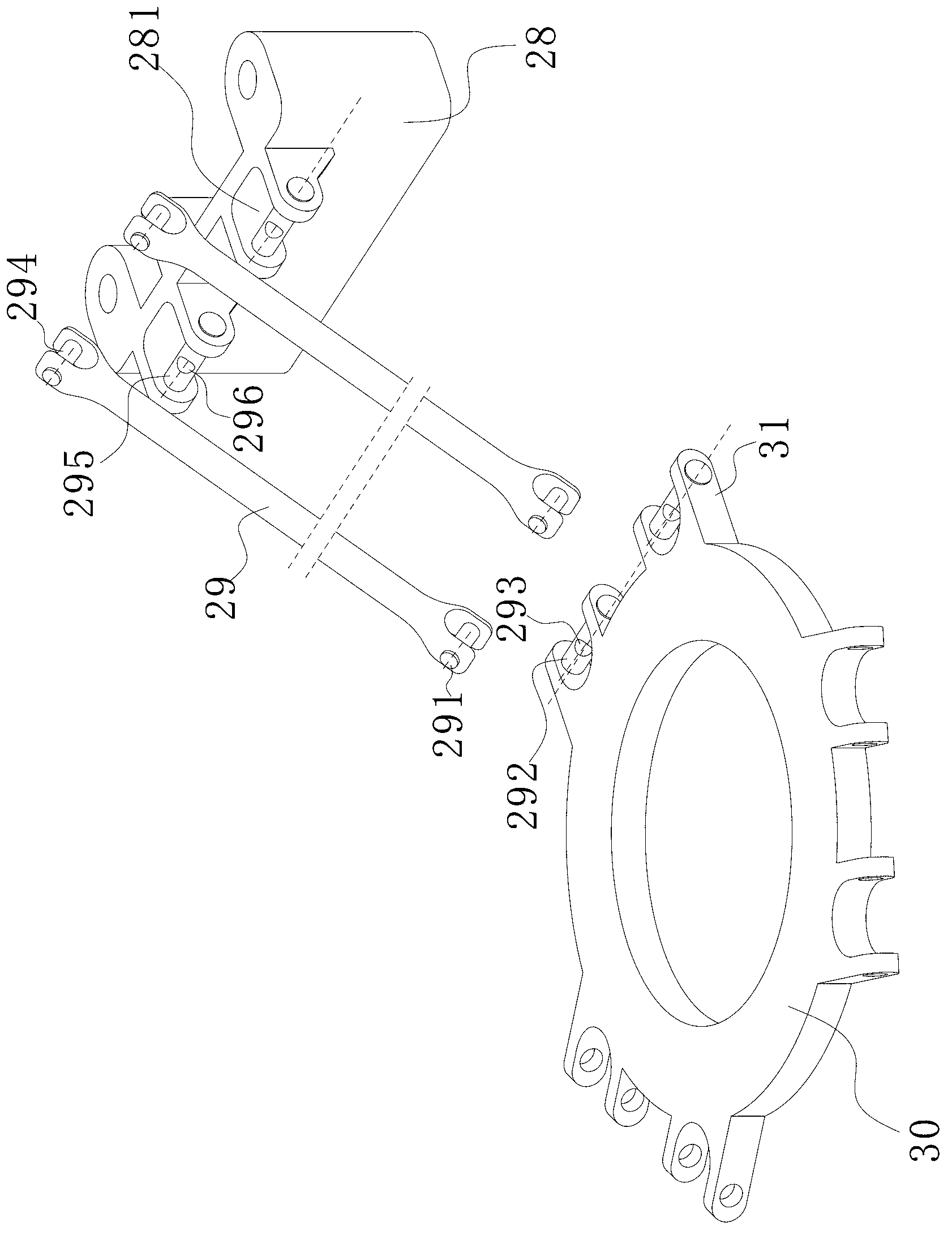

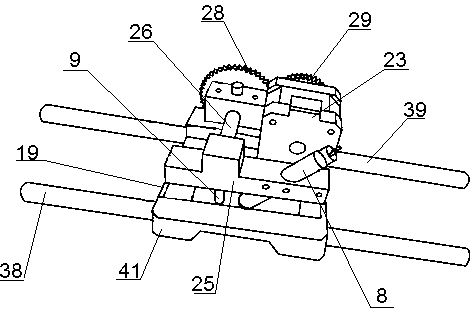

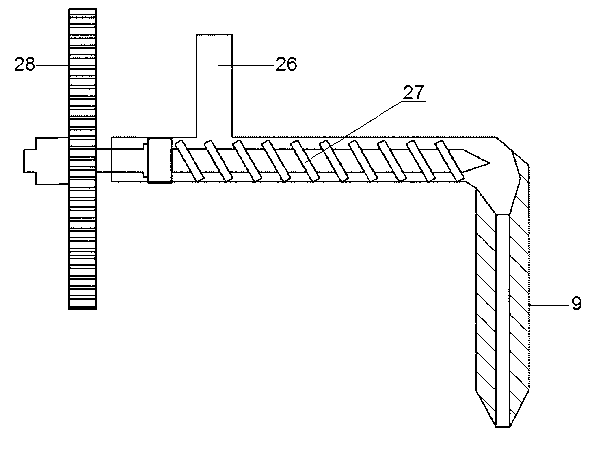

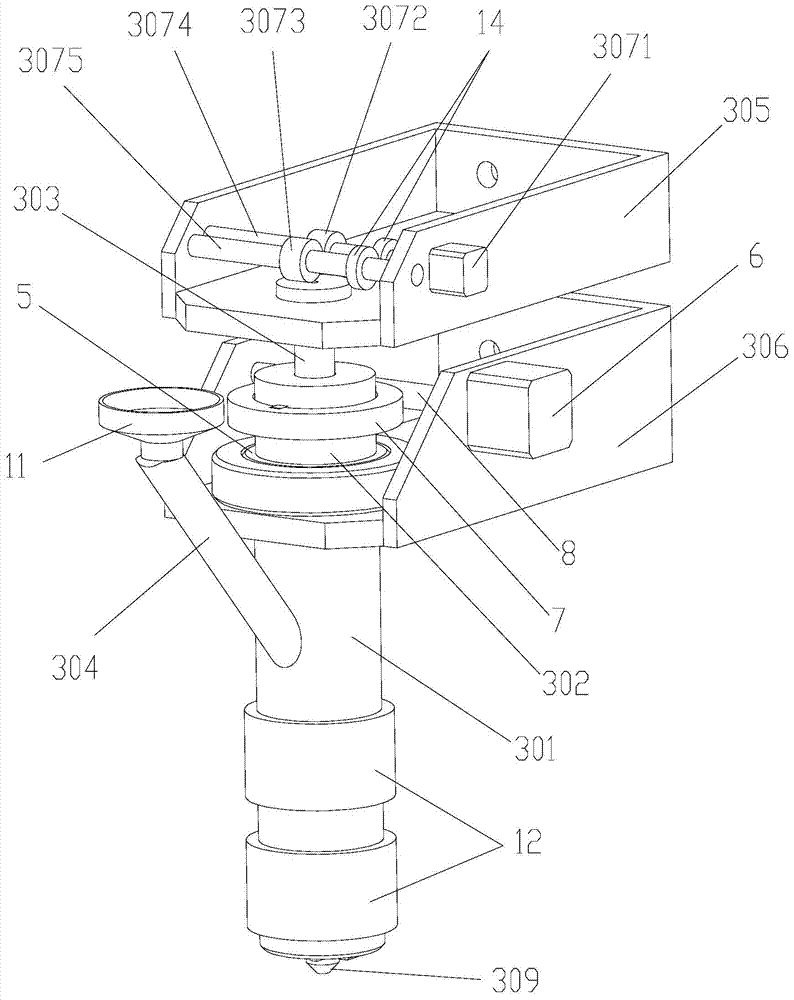

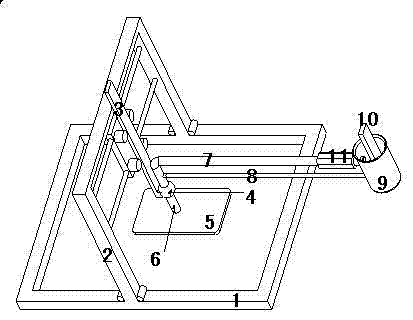

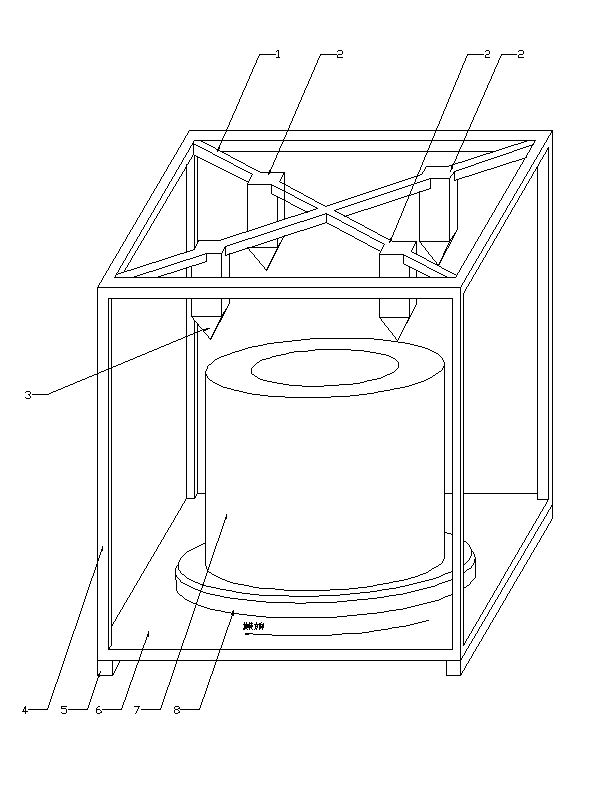

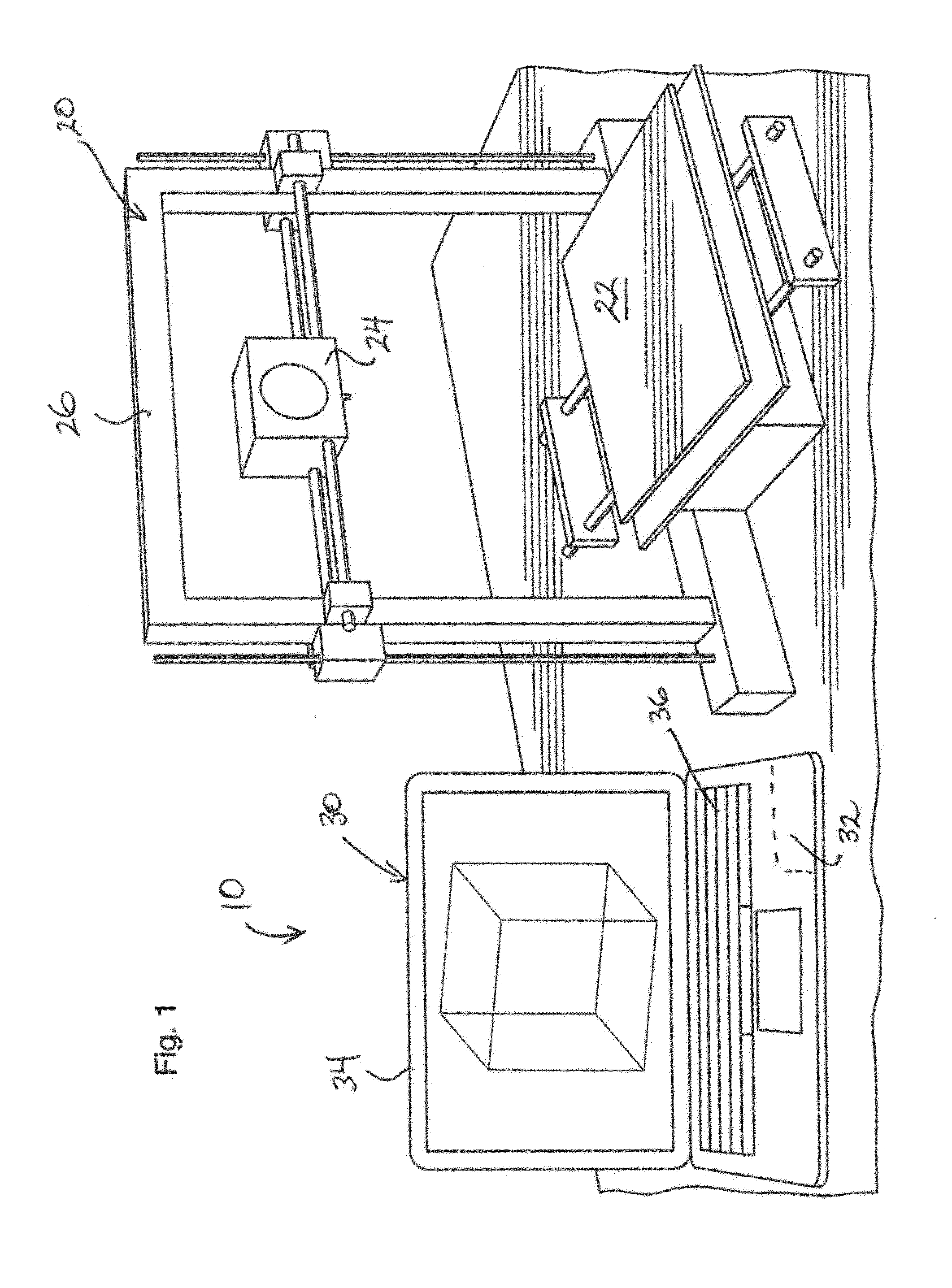

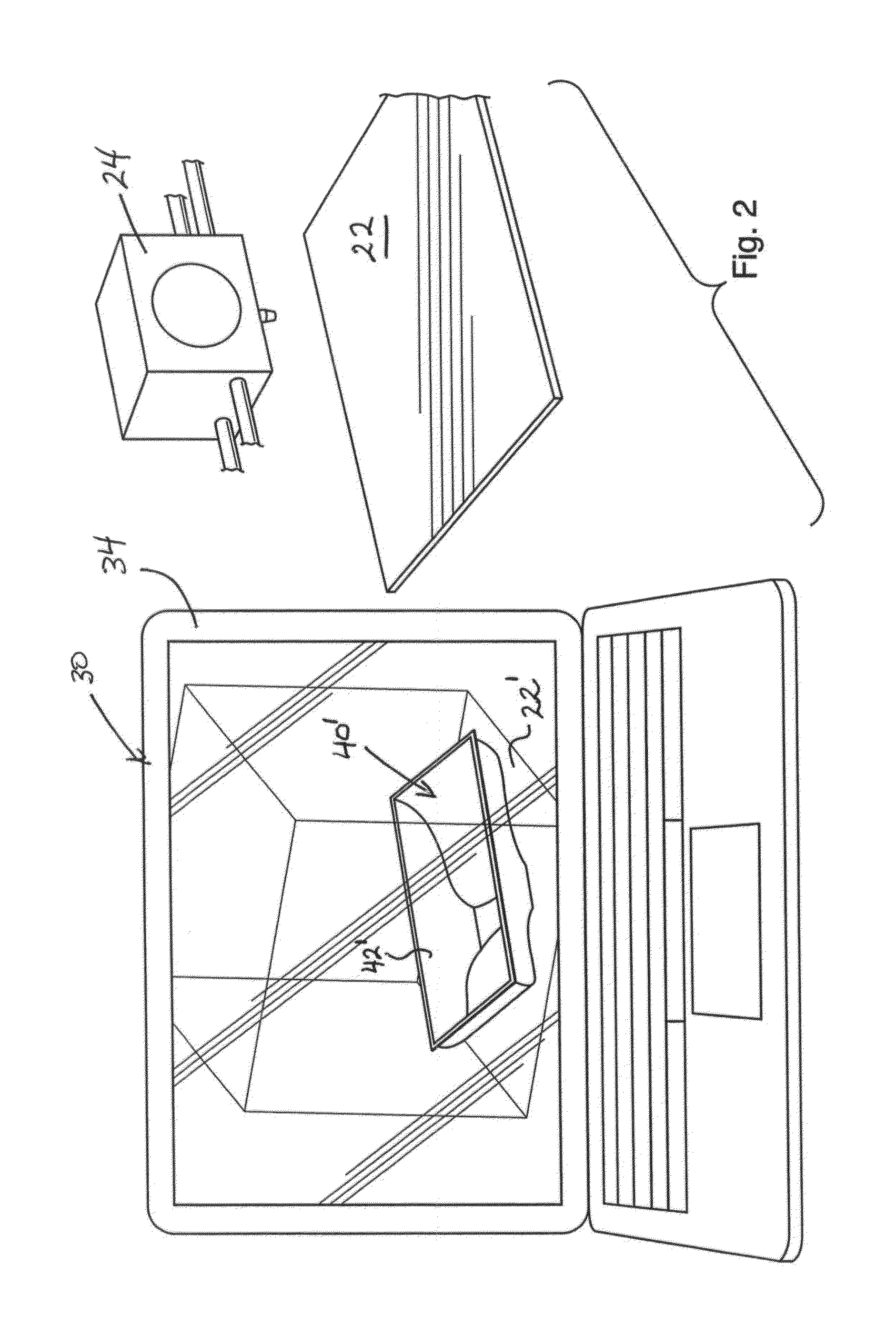

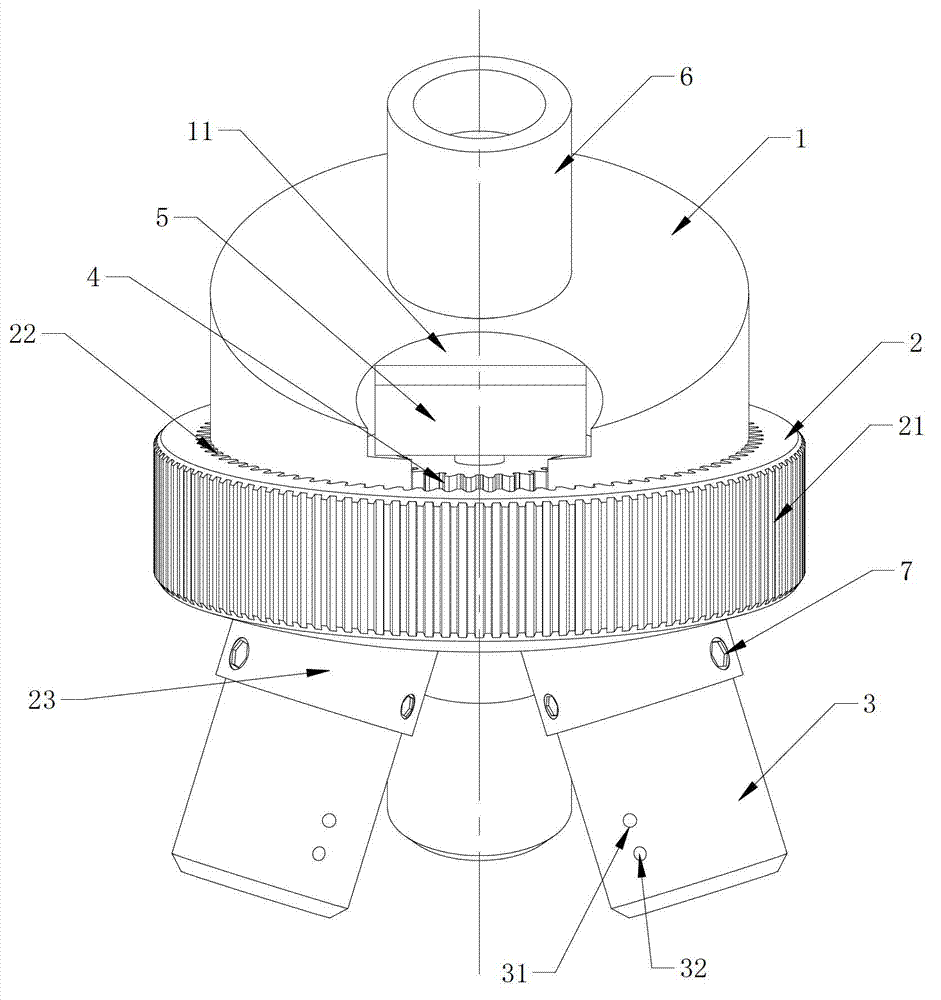

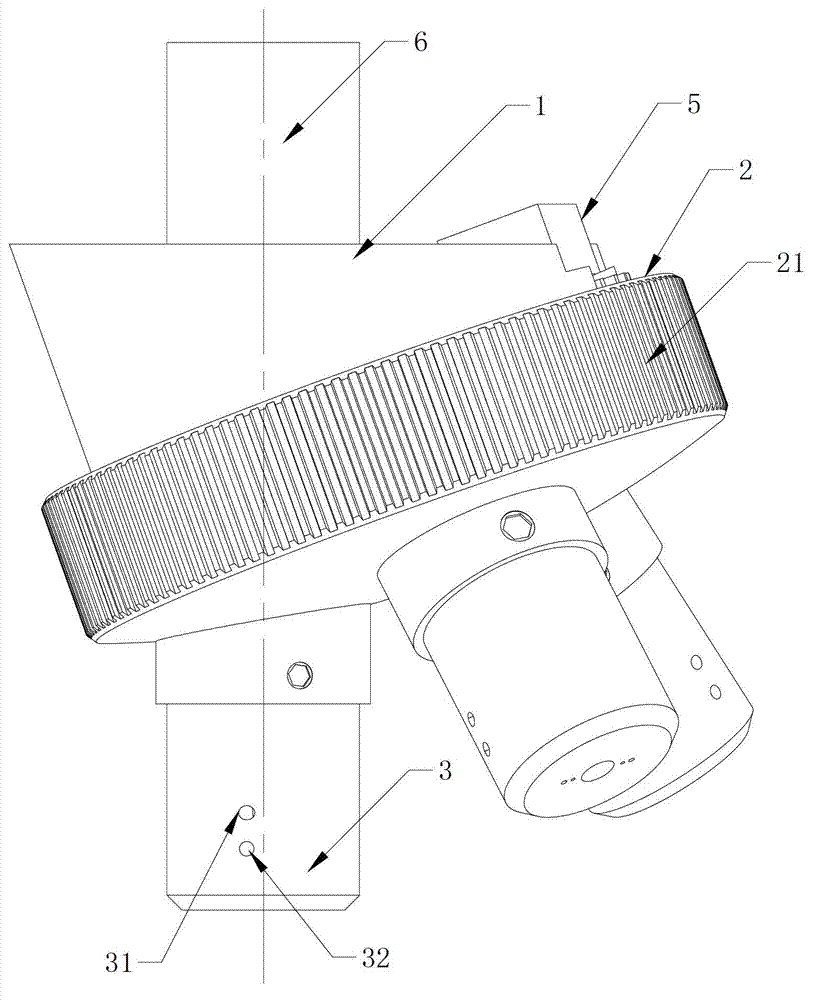

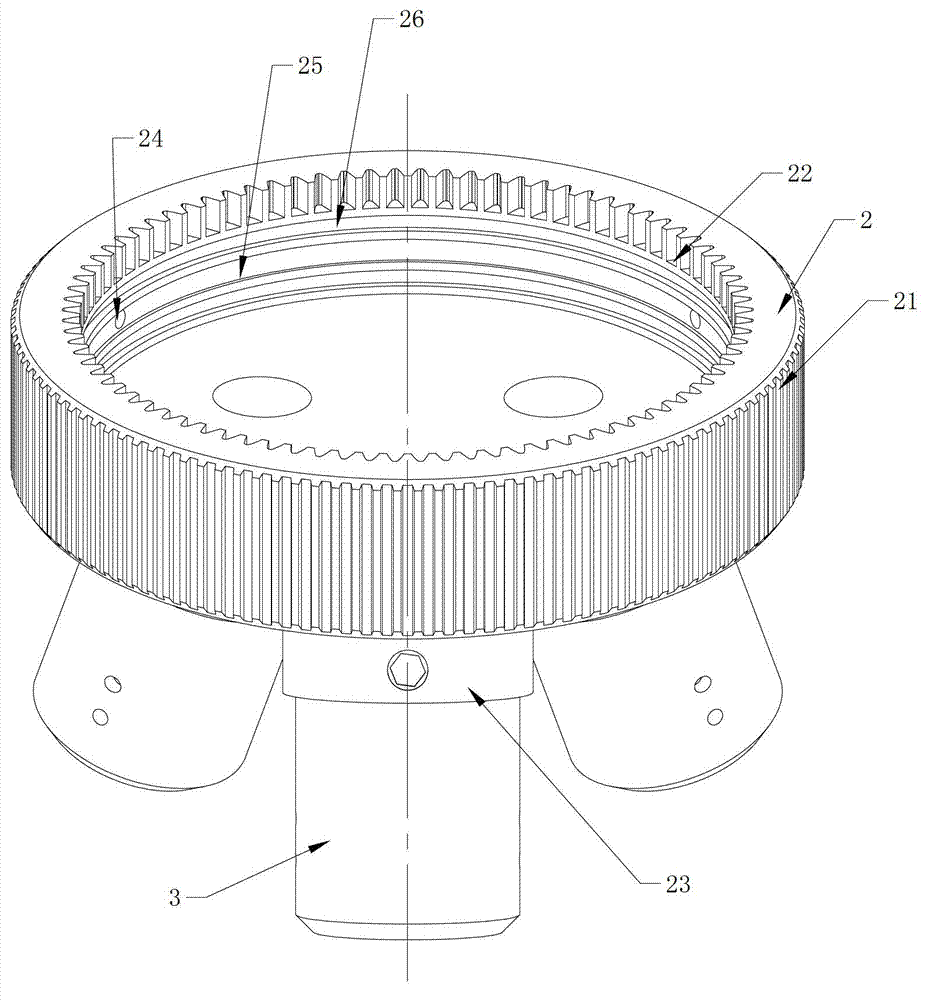

Nozzle transmission mechanism for 3D printer and 3D printer with same

The invention discloses a nozzle transmission mechanism for a 3D printer. The nozzle transmission mechanism comprises a platform used for holding a workpiece, a mounting seat which is positioned above the platform and is used for fixing a nozzle, more than three transmission components distributed at the periphery of the platform, and a controller used for controlling each driving motor, wherein each transmission component comprises a guide rod which extends along the height direction, a sliding seat arranged on the guide rod in a sliding mode, a driving motor used for driving the sliding seat to move up and down along the guide rod, and a connecting rod; and two ends of the connecting rod are respectively connected with the mounting seat and the sliding seat in a universal hinge mode. Three or more than three guide rods in the vertical direction are arranged only, the sliding seat on the guide rods is driven by the motor, the nozzle is driven to move in the height direction and the horizontal direction through differential motion among the sliding seat, and compared with the conventional three-axis association transmission mechanism, the nozzle transmission mechanism has the advantages of simple structure, small occupied space, high operating precision and the like, the 3D printing efficiency can be improved, and the defective percentage of the workpiece is reduced.

Owner:J H TECH ELECTRONICS GZ LTD

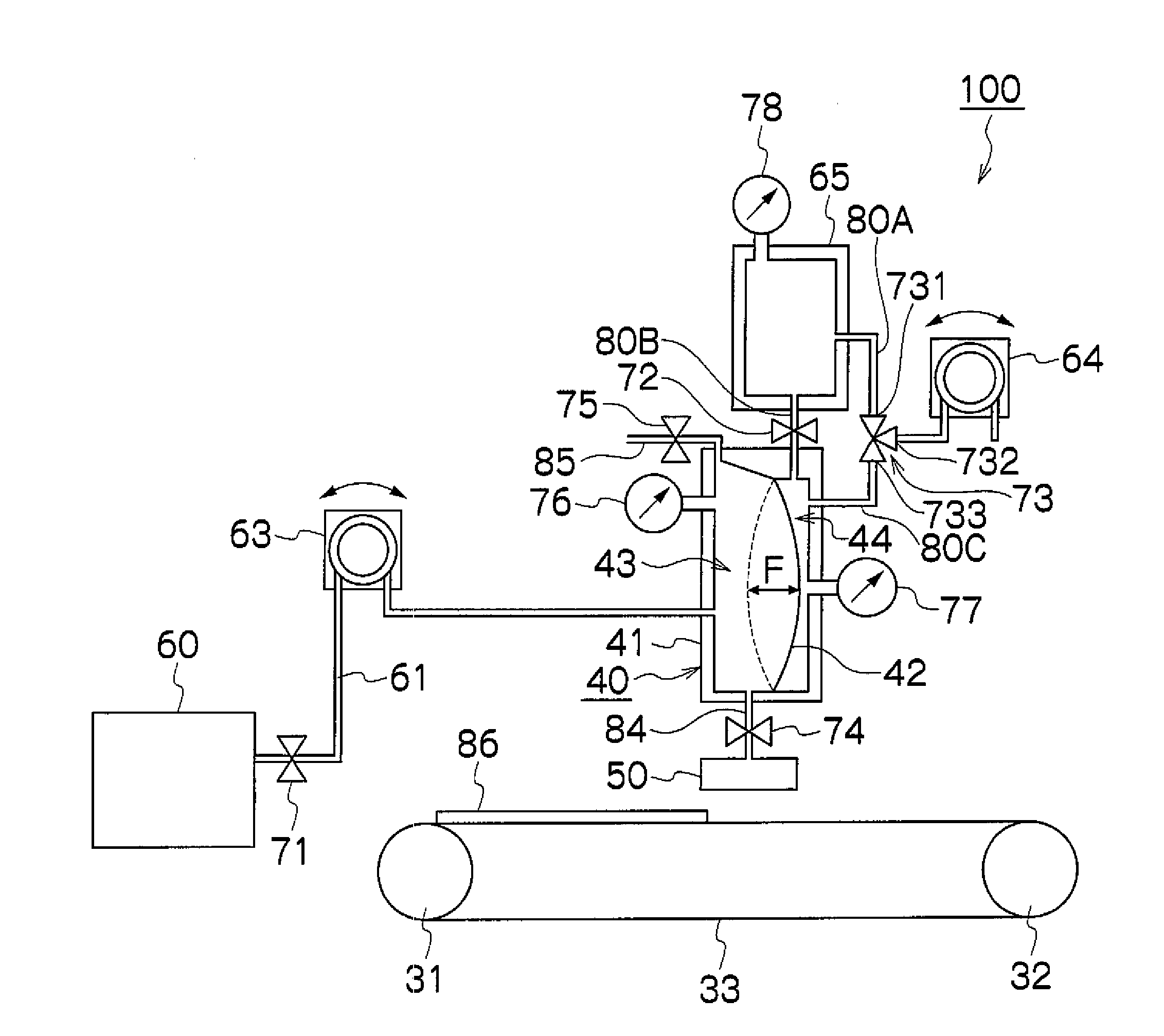

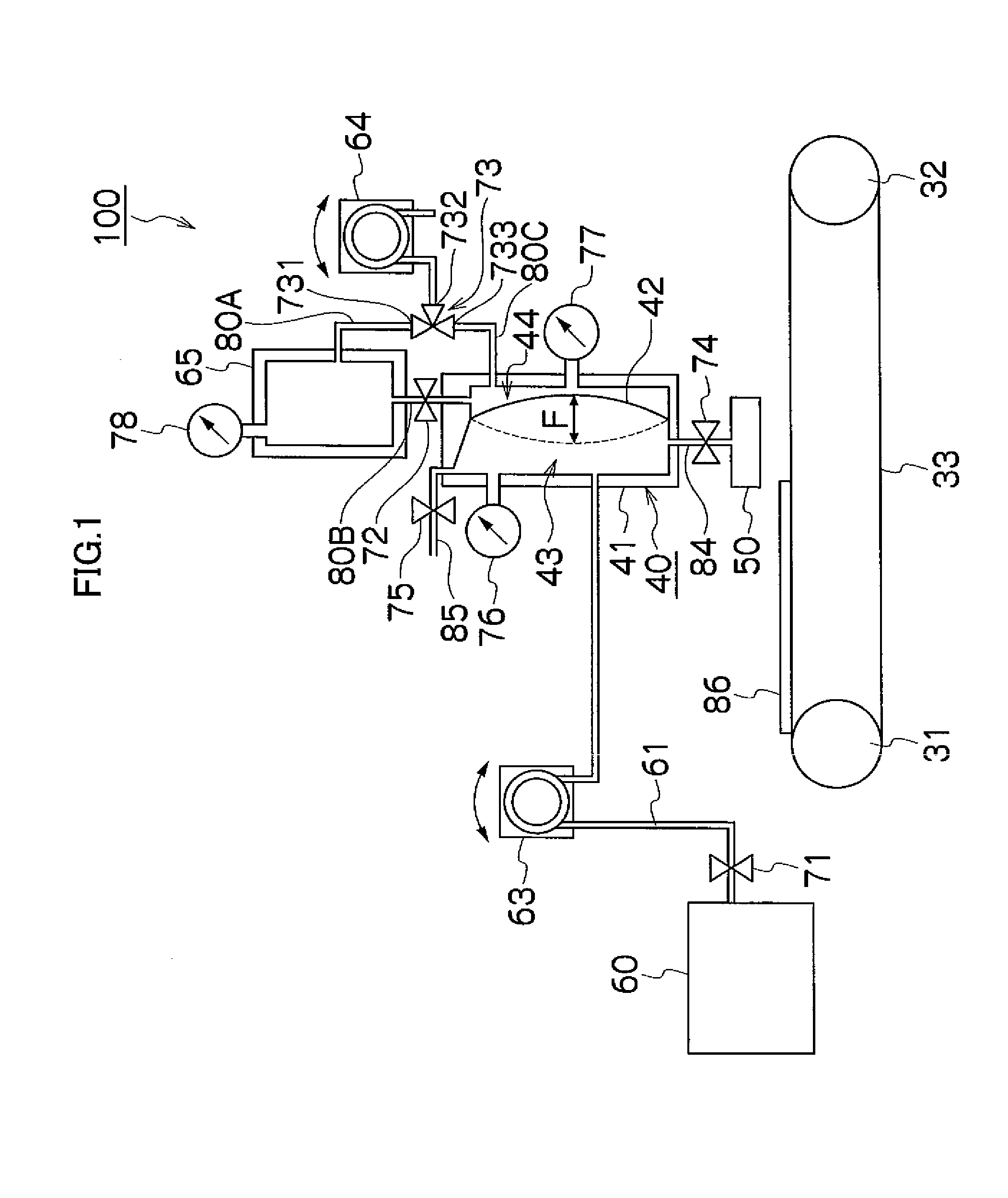

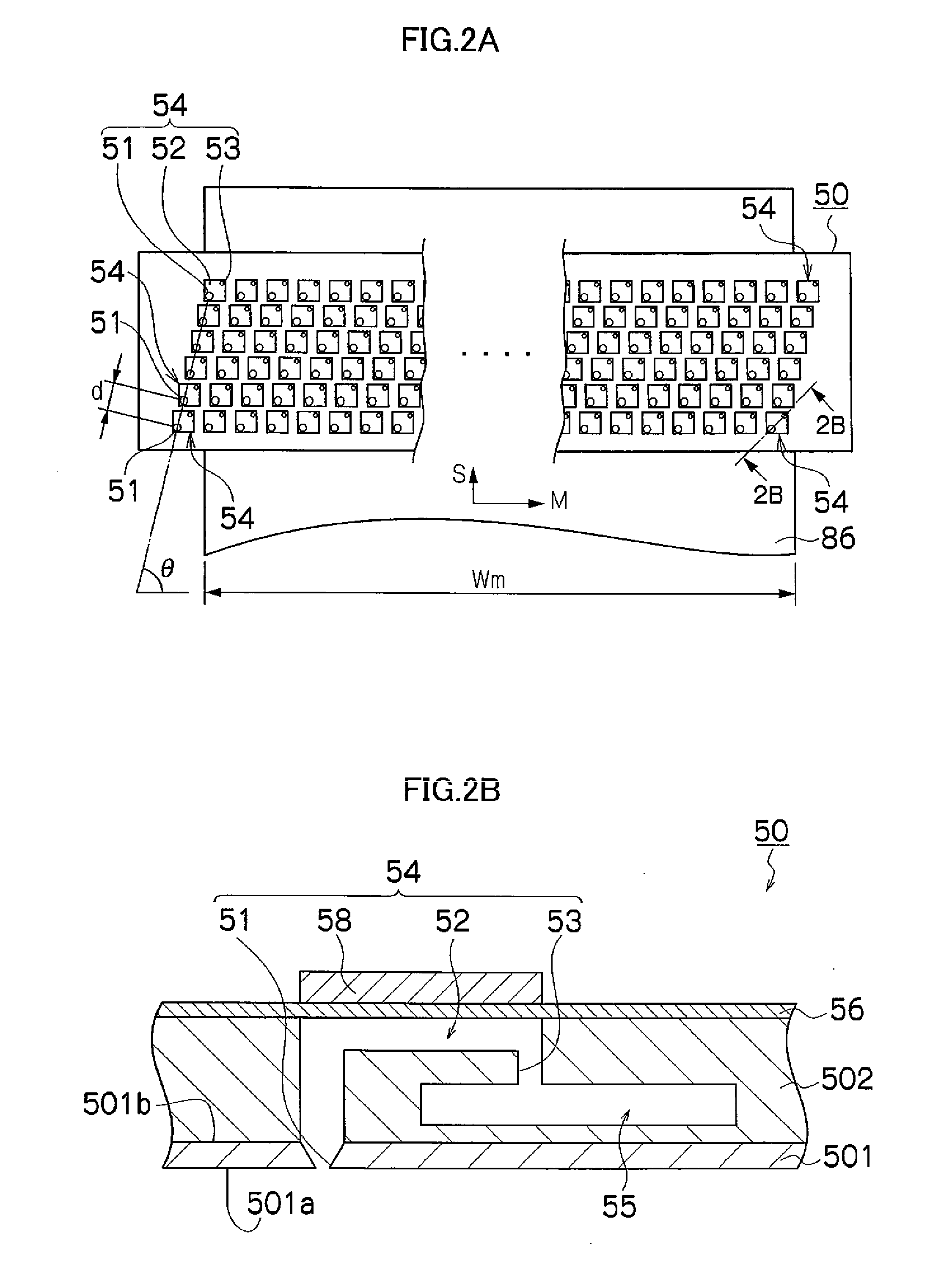

Pressure adjustment apparatus and image forming apparatus, and pressure adjustment method and liquid remaining amount determination method

InactiveUS20080198207A1Reduce flowShorten the timeOther printing apparatusHermetic sealImage formation

A pressure adjustment apparatus for adjusting a pressure of liquid inside a liquid ejection head including nozzles and flow channels includes: a tank; a pump; a buffer chamber; a first switching device; and a second switching device. The tank includes a movable film and a hermetically sealed container of a prescribed volume, the movable film dividing the hermetically sealed container into a gas chamber filled with gas and a liquid chamber filled with the liquid to be supplied to the liquid ejection head. The pump changes a pressure of the gas inside the gas chamber so as to adjust a pressure of the liquid inside the liquid chamber. The buffer chamber is filled with the gas and damps gas-flow pulsations caused by the pump. The first switching device connects and disconnects the buffer chamber and the gas chamber. The second switching device switches between a state where the pump is connected to the gas chamber without through the buffer chamber, and a state where the pump is connected to the buffer chamber.

Owner:FUJIFILM CORP

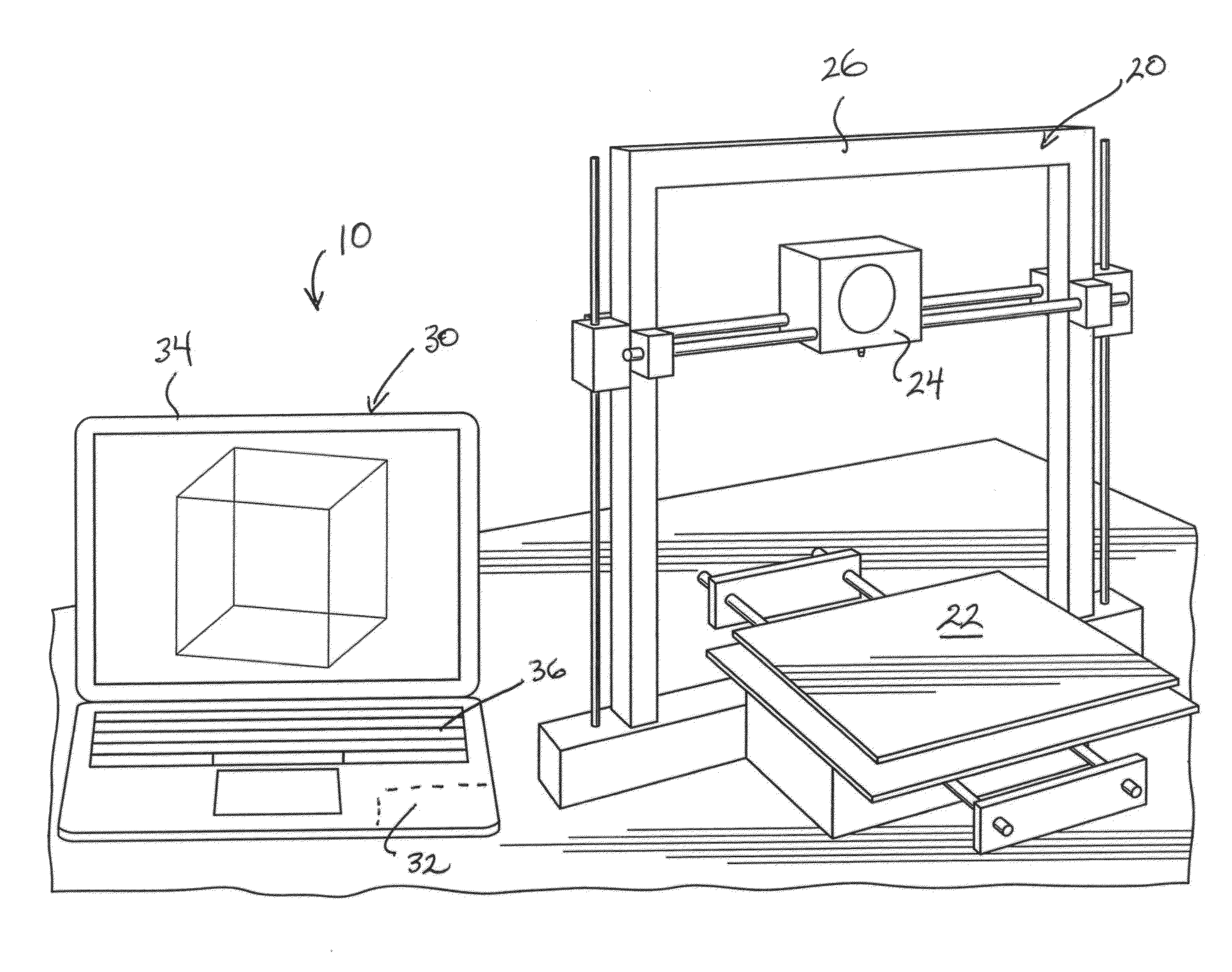

Three-dimensional (3D) printer and method for preparing three-dimensional products by use of 3D printer

The invention discloses a three-dimensional (3D) printer, the 3D printer comprises an X-Y working platform, spray heads installed on the X-Y working platform, light-emitting diode (LED) ultraviolet (UV) light sources, moving supporting frames, a base, fixed supporting frames, a supporting platform and UV resin material-feeding units, wherein the fixed supporting frames and the supporting platform are installed on the base, and the spray heads are connected with the UV resin material-feeding units. Through use of the 3D printer, one-way single-layer printing and one-way multi-layer printing can be carried out, multi-material printing, color printing, coating printing and other effects can be realized, and the printing efficiency is improved by times compared with that of the traditional 3D printers.

Owner:徐州泰铭电气有限公司

3D printing method and 3D printer

The invention discloses a 3D (three dimensional) printing method and a 3D printer. The method includes the steps of: making use of 3D modeling software in a computer to conduct modeling for an object needing printing; controlling the rise of a lifting platform by the computer; controlling a constant upper surface height of the liquid UV light cured resin in a liquid storage tank by the computer; carrying out printing from a first layer to the shell of a last layer in order, and in the shell printing process, letting the computer control descending of the lifting platform by one layer height in order through a Z-axle motor, making the liquid UV light cured resin in the liquid storage tank flow into the shell, and filling the shell; at the end of shell printing, controlling a wire extrusion device and making it stop extruding pasty UV light cured resin by the computer, and controlling an ultraviolet lamp in terms of irradiating the shell for a period of time by the computer so as to make the liquid UV light cured resin in the shell cured. With high printing efficiency, the 3D printing method and the 3D printer provided in the invention can ensure that the printed object has high density and is easy to damage while guaranteeing the printing efficiency.

Owner:温州启龙电子科技有限公司

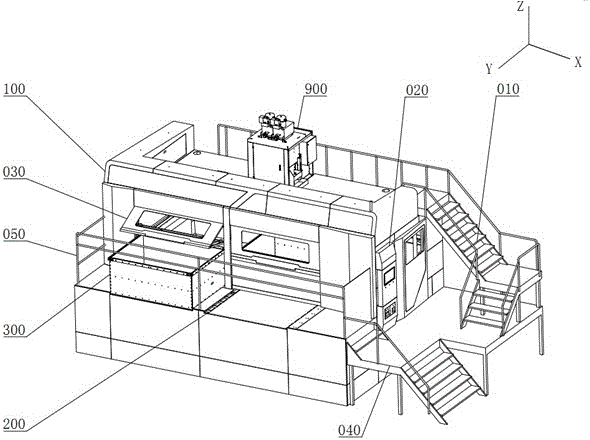

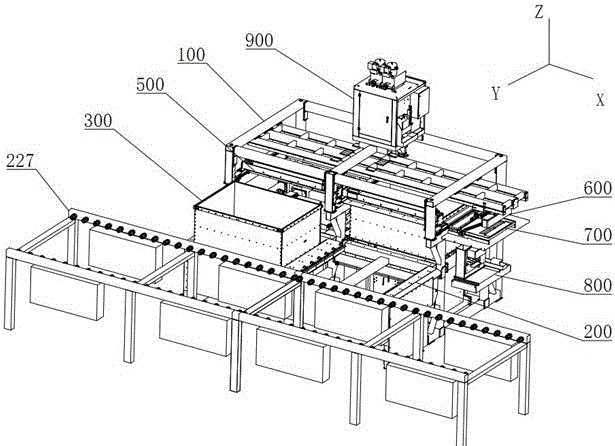

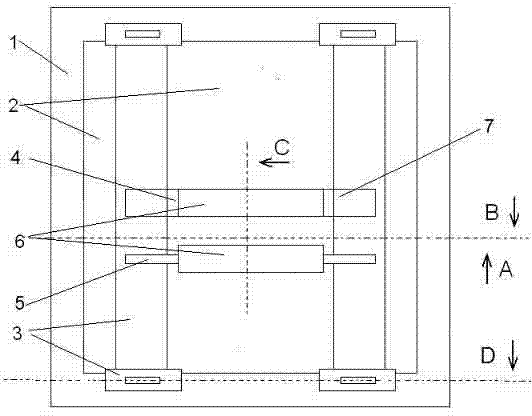

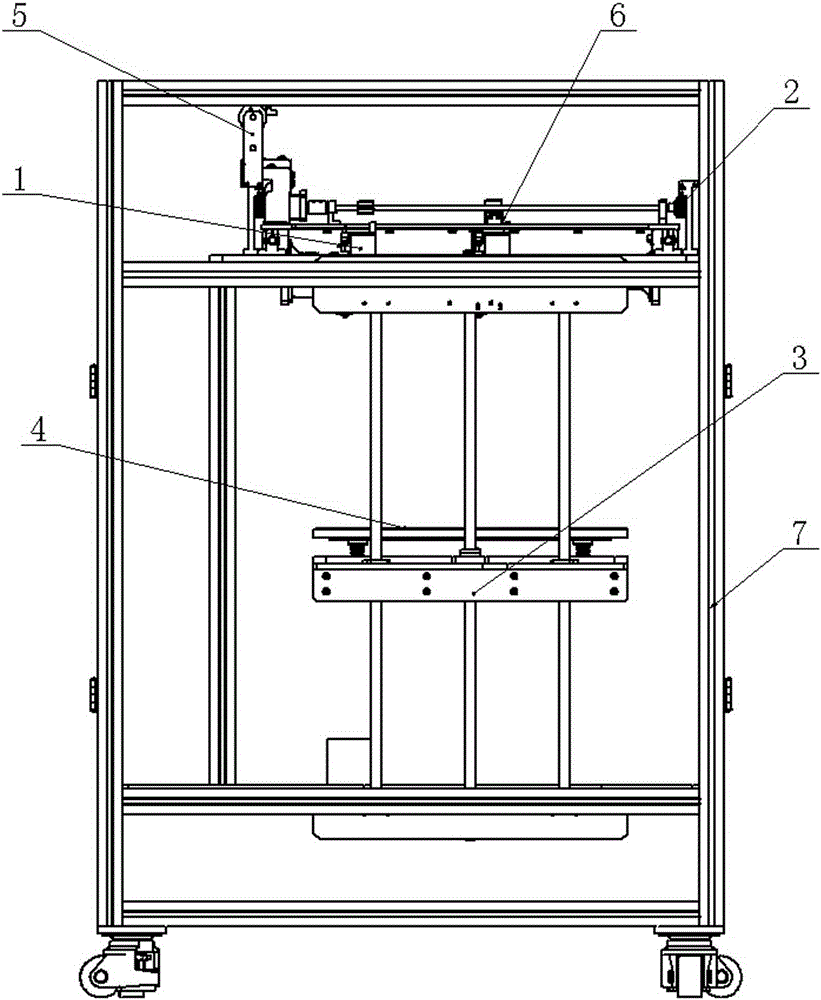

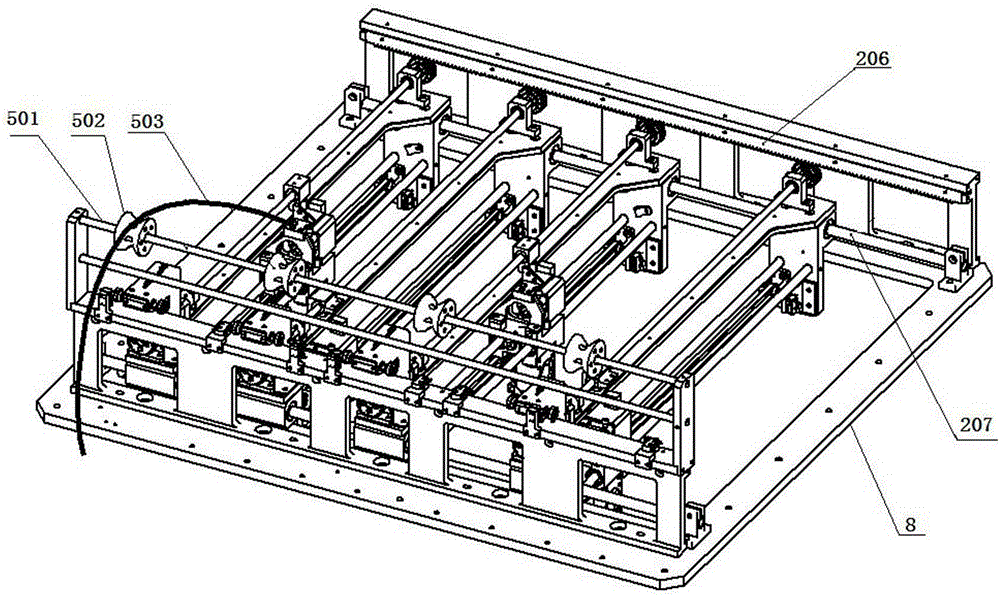

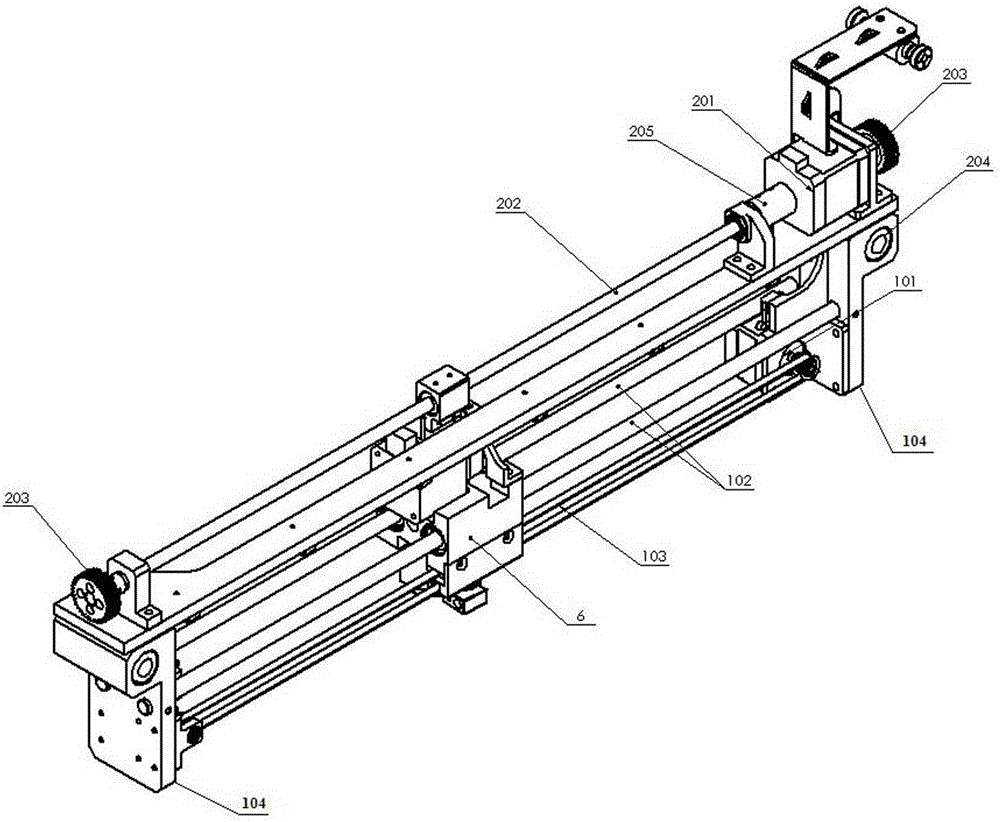

Multi-working box sand mould 3D printing equipment

ActiveCN105710294ALow costImprove printing efficiencyAdditive manufacturing apparatusFoundry mouldsEngineeringMaterial system

The invention relates to multi-working box sand mould 3D printing equipment. The multi-working box sand mould 3D printing equipment comprises a main body framework (100), a working box conveying systems (200), working boxes (300), working box jacking mechanisms (400), sand laying devices (500), a printing head (600), a cleaning device (700), a liquid material system (800), a sand mixing device (900) and an electric system. The multi-working box sand mould 3D printing equipment provided by the invention comprises two or more working boxes which are combined with sand mixing pots, the synchronous operation sand laying devices, the penetration-type printing head, the working box synchronous jacking mechanisms and the electric system which are matched with the working boxes; the two or more working boxes work simultaneously during sand laying and printing operation; and compared with single-working box sand mould 3D printing equipment with the same specification, the multi-working box sand mould 3D printing equipment has the advantages that in the same time period, the printing efficiency can be improved by times, so that the cost of sand moulds can be effectively lowered, and production requirements can be met more rapidly.

Owner:NINGXIA KOCEL MOLD

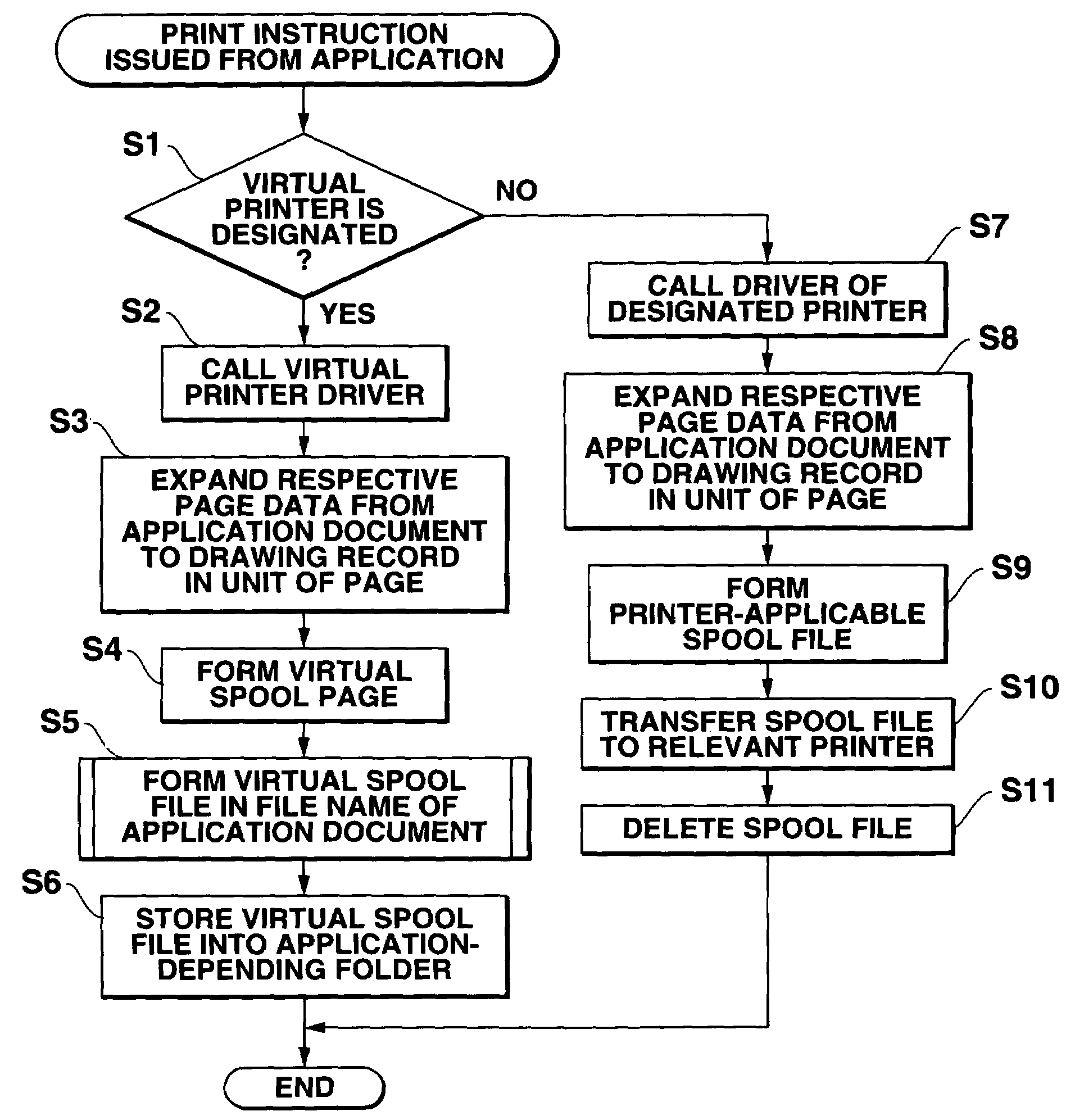

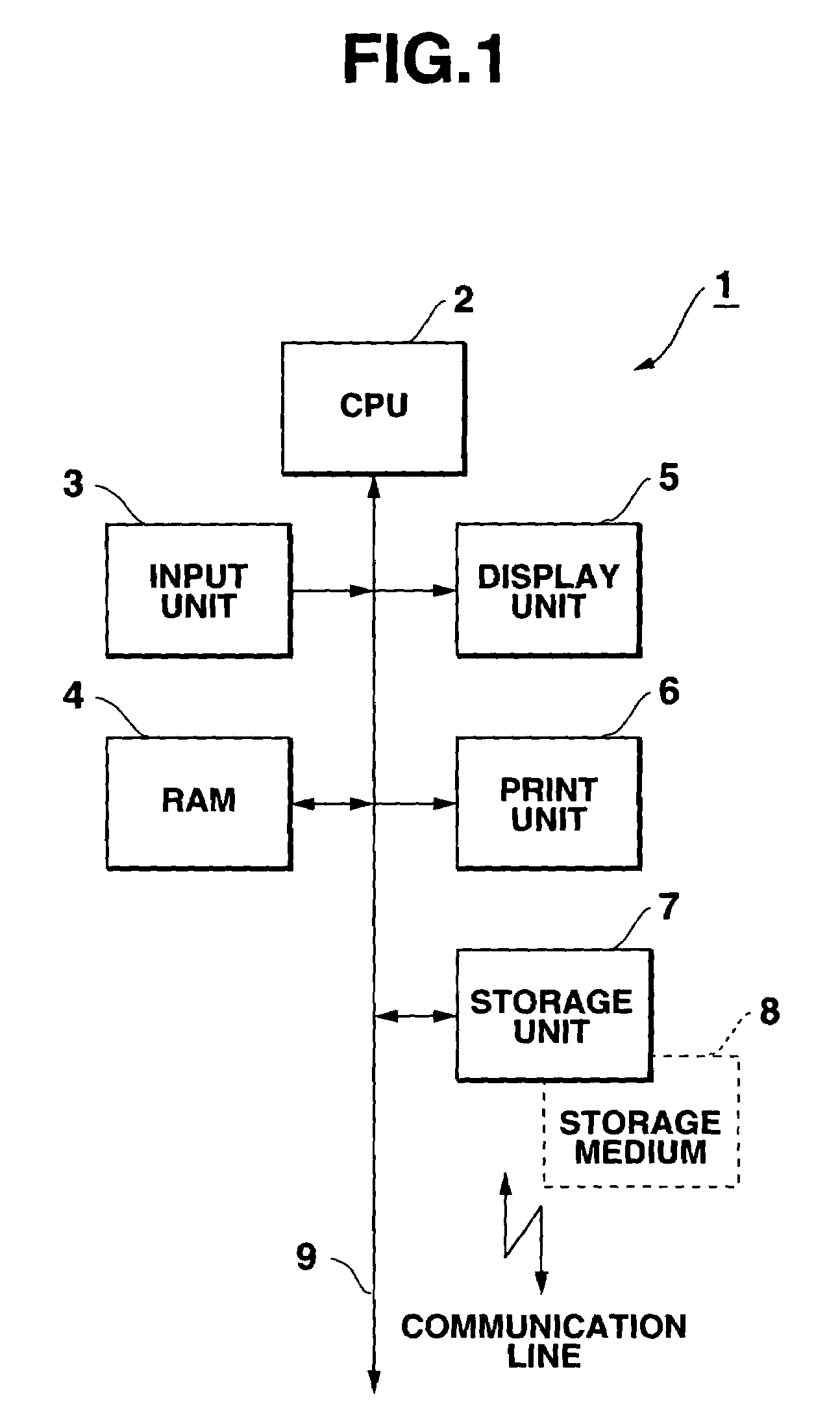

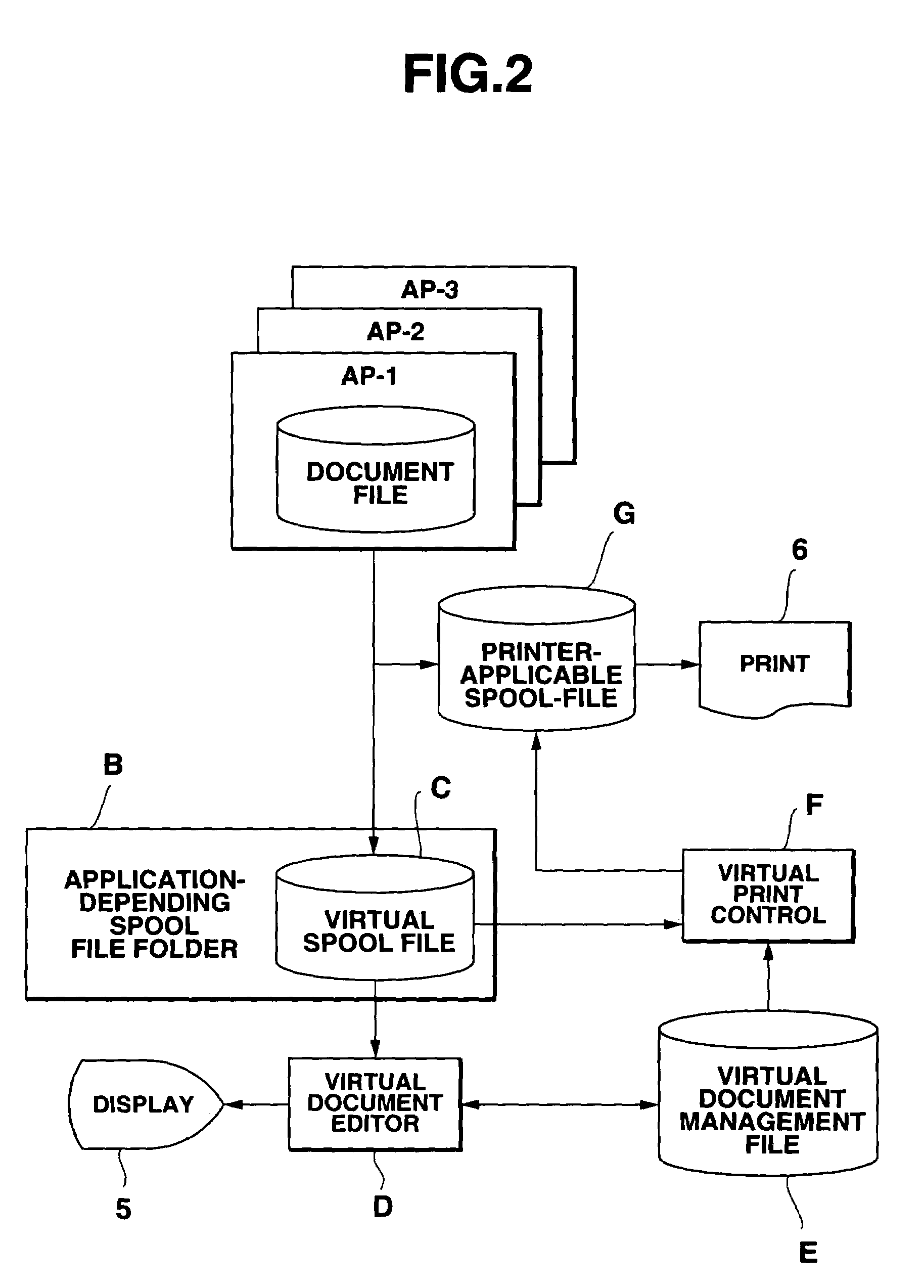

Document processing apparatus capable of increasing printing efficiency by forming virtual document and storage medium

InactiveUS7043688B1Improve printing efficiencyEasy to operateDigital computer detailsVisual presentationDocument preparationMultiple applications

When a document is printed and this document contains plural sorts of data such as a document, a presentation material, and a drawing, a virtual document is formed by which these plural data can be printed in a batch mode in a document processing apparatus. A printing operation is carried out in accordance with a print control content of this virtual document. To this end, the document data having various formats and formed by using a plurality of application programs are converted into page document data to be outputted in a common format. This page document data is SPOOL-stored. Such a virtual document file is formed among these output page document data SPOOL-stored. A designation sequence and an output sequence are set to these virtual document files. As a result, the document data can be outputted in accordance with the designated output sequence, which is designated by the SPOOL-stored output page document data, by merely designating this virtual document file.

Owner:CASIO COMPUTER CO LTD

Color 3D printer and method for producing 3D product by color 3D printer

InactiveCN103434135AAchieve full color printingAchieve single-pass multi-layer color printingColor printingUltraviolet

The invention discloses a color 3D (Three-dimensional) printer which comprises an X-Y working platform, a spray head, an LED (Light-emitting Diode) ultraviolet (UV) light source, a movable support frame, a support table, a base and a fixed support frame, wherein the spray head, the LED UV light source and the movable support frame are mounted on the X-Y working platform; the support table and the fixed support frame are mounted on the base; at least one spray head is connected with a premixer; and the connected premixer is at least connected with three UV resin feed units. With the adoption of the color 3D printer, one-way multilayer color printing, and area color printing can be achieved, and the printing efficiency is multiplied compared with the traditional 3D printer.

Owner:孙勇磊 +4

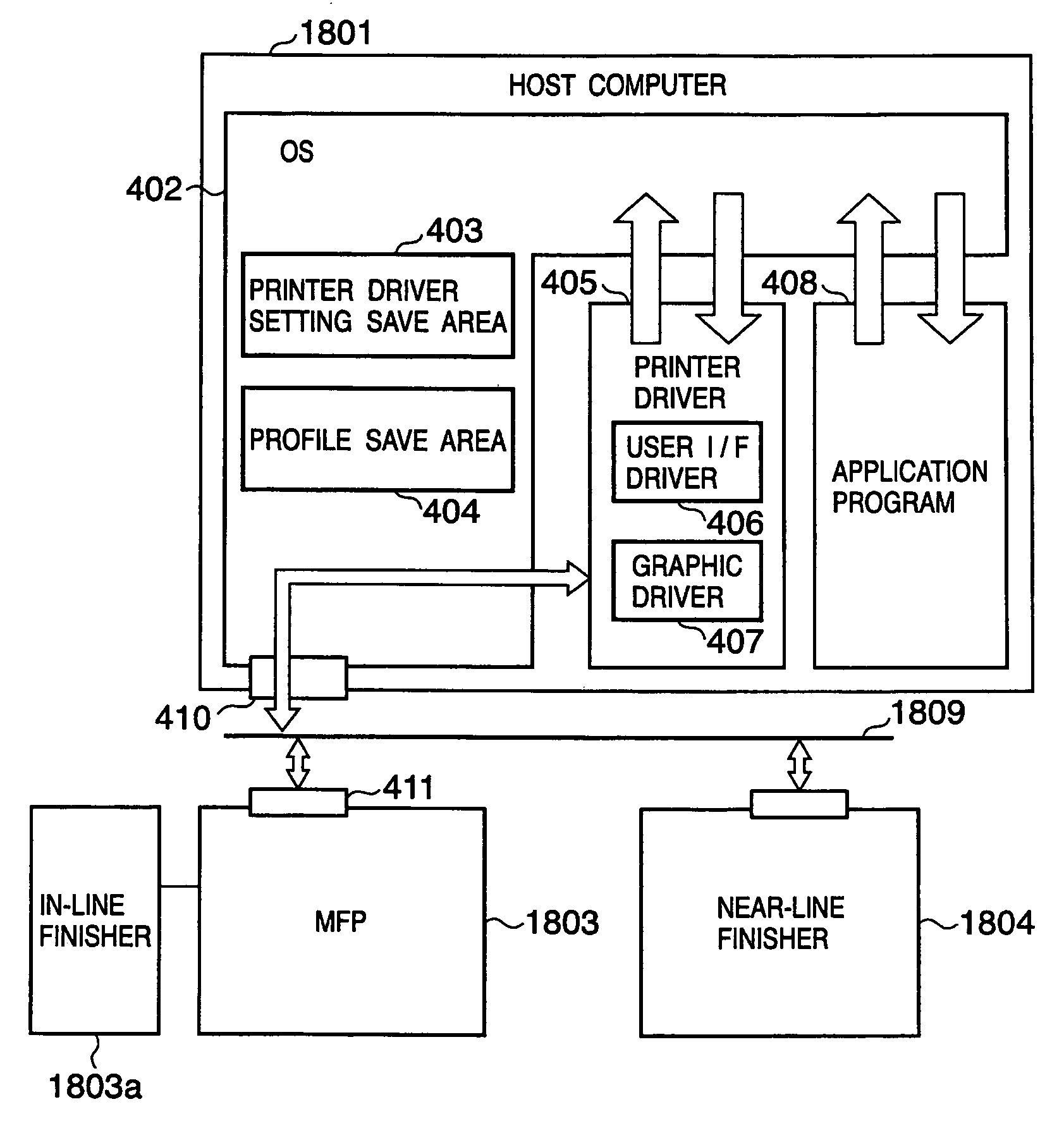

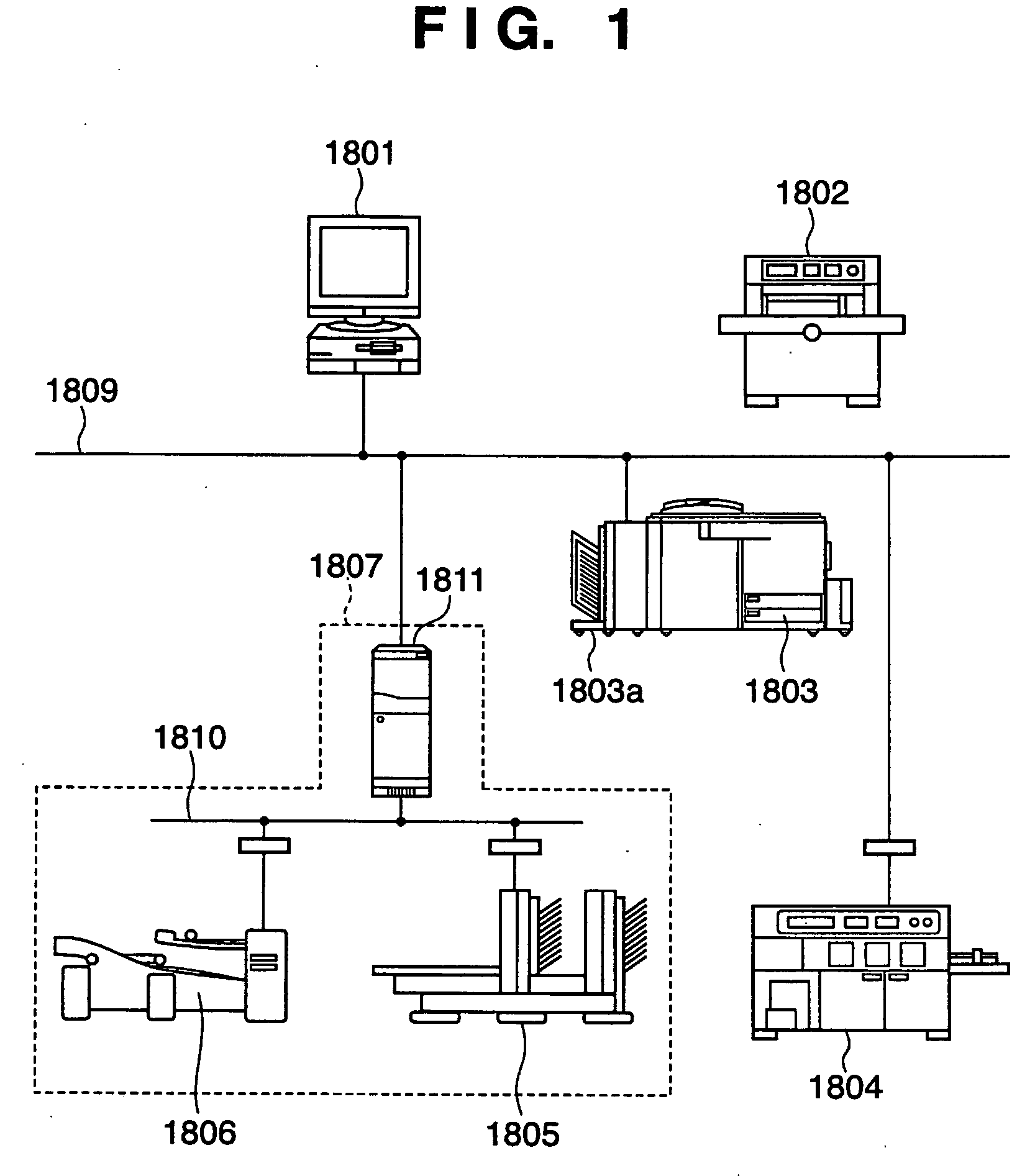

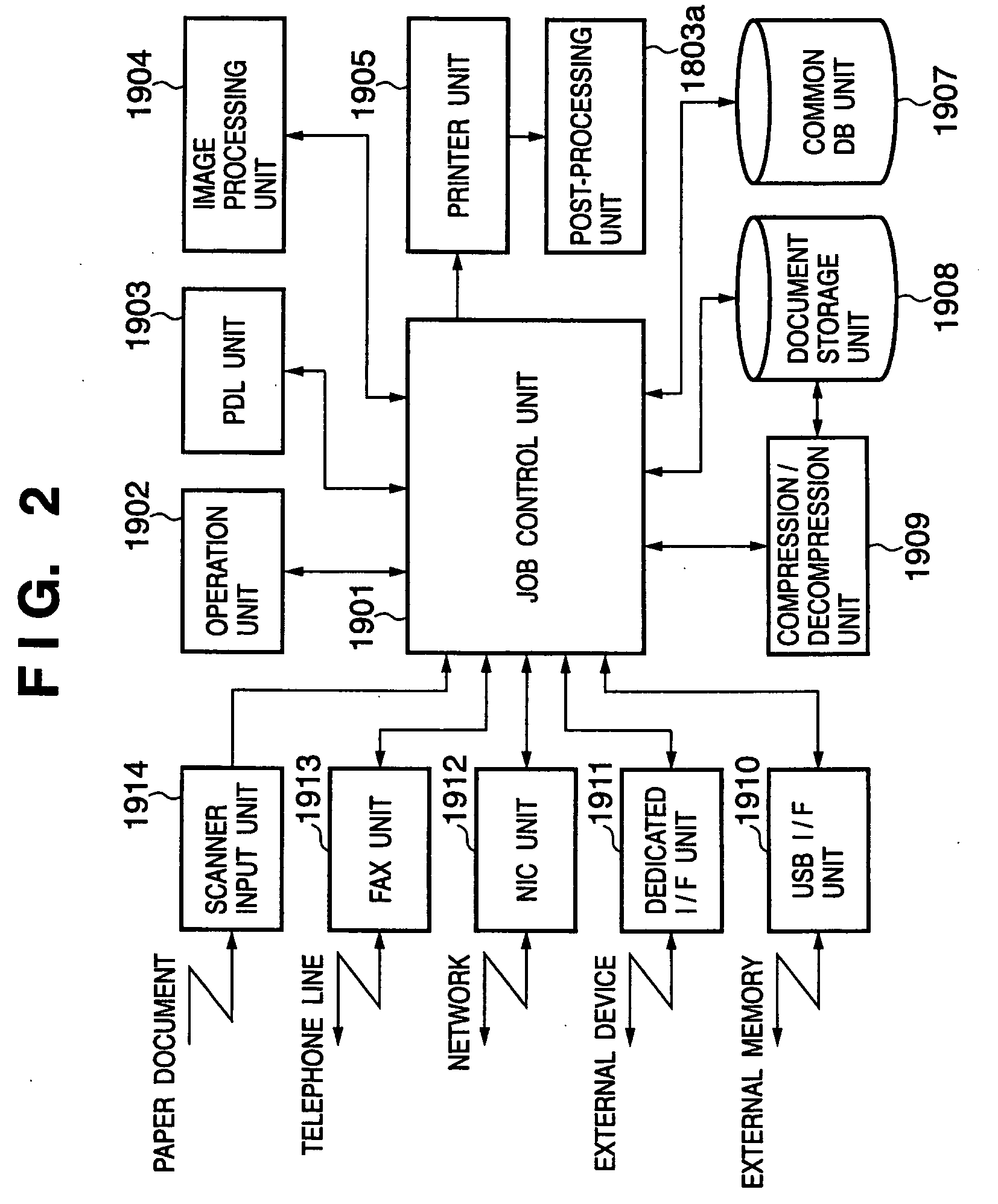

On-demand publishing system

ActiveUS20060238793A1Improve productivityAvoid it happening againVisual presentationPictoral communicationInformation processingComputer science

According to the present invention, an information processing apparatus comprises: a loading unit which loads function information representing a function of the post-printing processing device; an identification unit which identifies a printing function processible by the printing device and a post-processing function processible after printing by the post-printing processing device; a display control unit which displays a setting window for setting the printing function and post-processing function; a data generation unit which generates printing data to be printed by the printing device; and a setting information generation unit which generates post-processing setting information subjected to post-printing processing by the post-printing processing device, wherein the printing data is transmitted to the printing device, and the post-processing setting information is transmitted to the post-printing processing device.

Owner:CANON KK

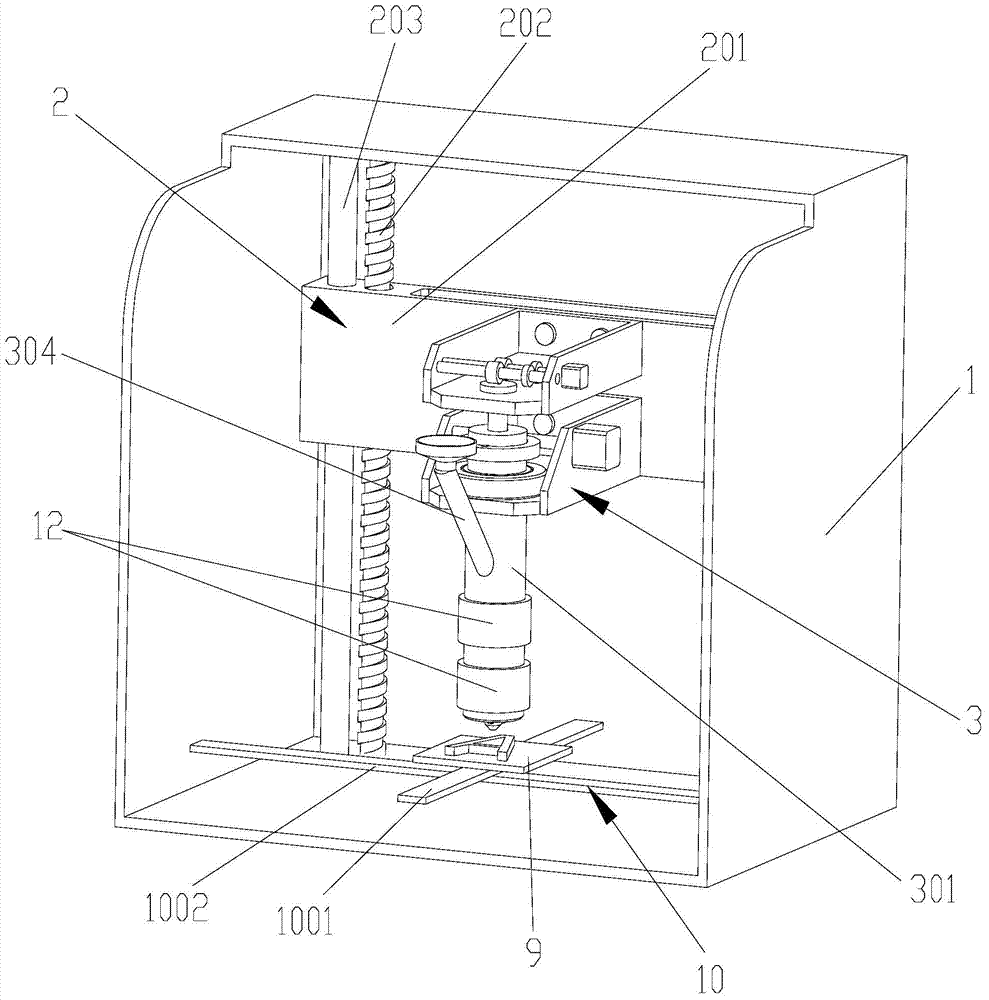

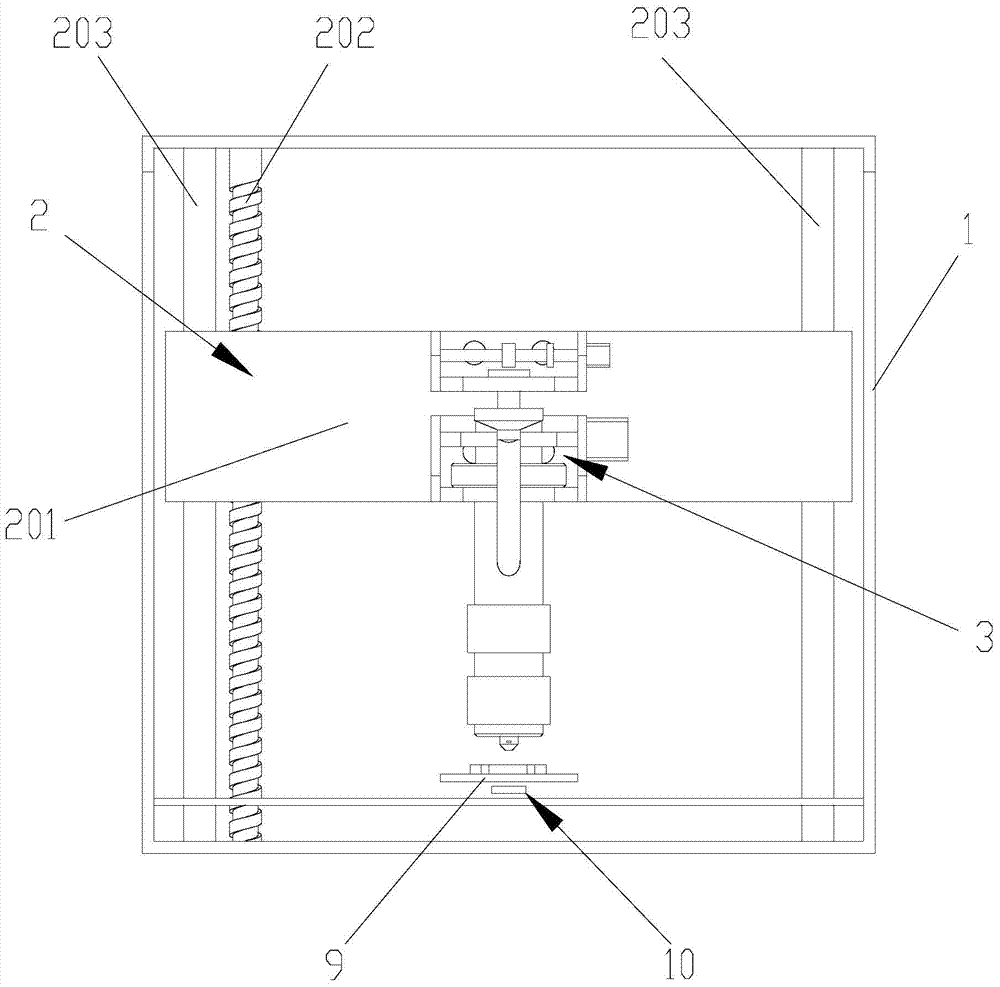

3D printer

The invention discloses a 3D (three dimensional) printer, which comprises a frame, a liquid storage pot with an upper end opening, as well as a first resin cylinder, a second resin cylinder, a lifting platform, a line extrusion device and an ultraviolet (UV) light point light source arranged on the frame. The first resin cylinder is loaded with liquid UV light cured resin, and the second resin cylinder is loaded with paste UV light cured resin. The lower part of the second resin cylinder is communicated with the line extrusion device that is provided with a nozzle, and the irradiation position of the UV light point source is located below the nozzle. The lifting platform includes a flat plate provided with a through hole in the middle part, the upper surface of the flat plate is provided with a metal net, and the flat plate is in sliding connection with two guide pillars on the frame. The lower part of the liquid storage pot is communicated with an upper end opened liquid storage box arranged on the flat plate lower surface through a duct. The 3D printer provided in the invention has high printing efficiency, and while ensuring the printing efficiency, it also can guarantee that the printed object has high density and is difficult to damage.

Owner:温州启龙电子科技有限公司

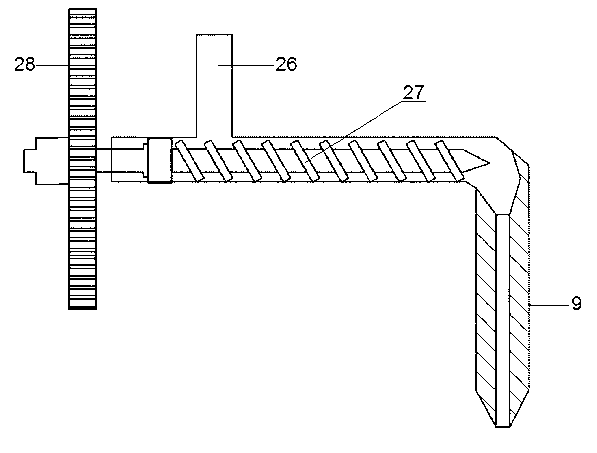

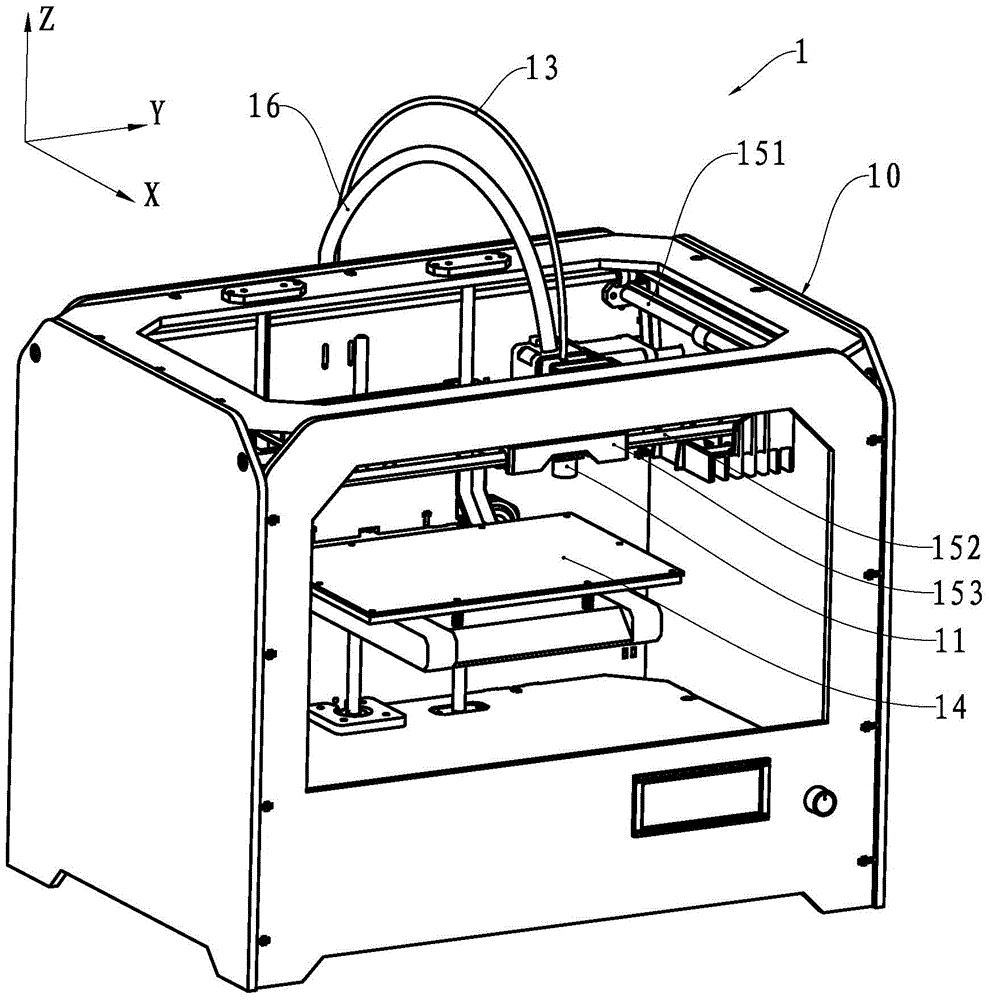

Fusion-deposition 3D printer and printing method thereof

The invention discloses a fusion-deposition 3D printer. The fusion-deposition 3D printer comprises a shell, a lifting mechanism and a composite extruding mechanism, wherein the lifting mechanism is mounted in the shell; the composite extruding mechanism comprises a machine cylinder, a screw rod and a long-fiber conveying pipe, a feeding pipe communicated with a material cavity of the machine cylinder is arranged on the side wall of the machine cylinder, the screw rod is rotatably mounted in the material cylinder and is provided with a mounting channel, and the upper and lower ends of the screw rod are communicated through the mounting channel; the long-fiber conveying pipe is inserted into the mounting channel and is provided with a conveying channel for conveying long continuous fibers; the conveying channel, the mounting channel and the material cavity are sequentially communicated. The invention further discloses a printing method of the fusion-deposition 3D printer. According to the fusion-deposition 3D printer and the printing method thereof, the long continuous fibers and printing materials packing the long continuous fibers are synchronously extruded to a working platform, so that the strength and surface flatness of a printed product are improved, and the machining efficiency is improved.

Owner:余金文 +1

Screen printing device for solar batteries

InactiveCN102336051ASimple structural designLittle impact on deformabilityFinal product manufactureScreen printersScreen printingSlurry

The invention discloses a screen printing device for solar batteries. The screen printing device comprises a printing scraper, an auxiliary scraper, a feed back knife and a printing screen. The device is characterized in that two baffle structures are mounted on the printing screen, at two sides close to the ends of the printing scraper, wherein each baffle structure is mainly composed of a baffle surface, a baffle frame and an installation rack; the bottom of the baffle surface is in split type contact with a screen surface, or adhered to the screen surface through a flexible material; edges of the feed back knife, the printing scraper and the auxiliary scraper are in seamless contact with the baffle surface; a printing head drives the scrapers and the feed back knife to contact the baffle surface in a sliding manner, so that the paste moves in a range defined by the baffle surfaces at the two sides, the scraper and the feed back knife, and slurry is prevented from flowing to the two sides; and the device can ensure uniform fluidity, viscosity and thixotropy of the slurry and avoid the local drying and waste of the slurry, thereby improving electrode printing efficiency and printing quality.

Owner:NANCHANG UNIV

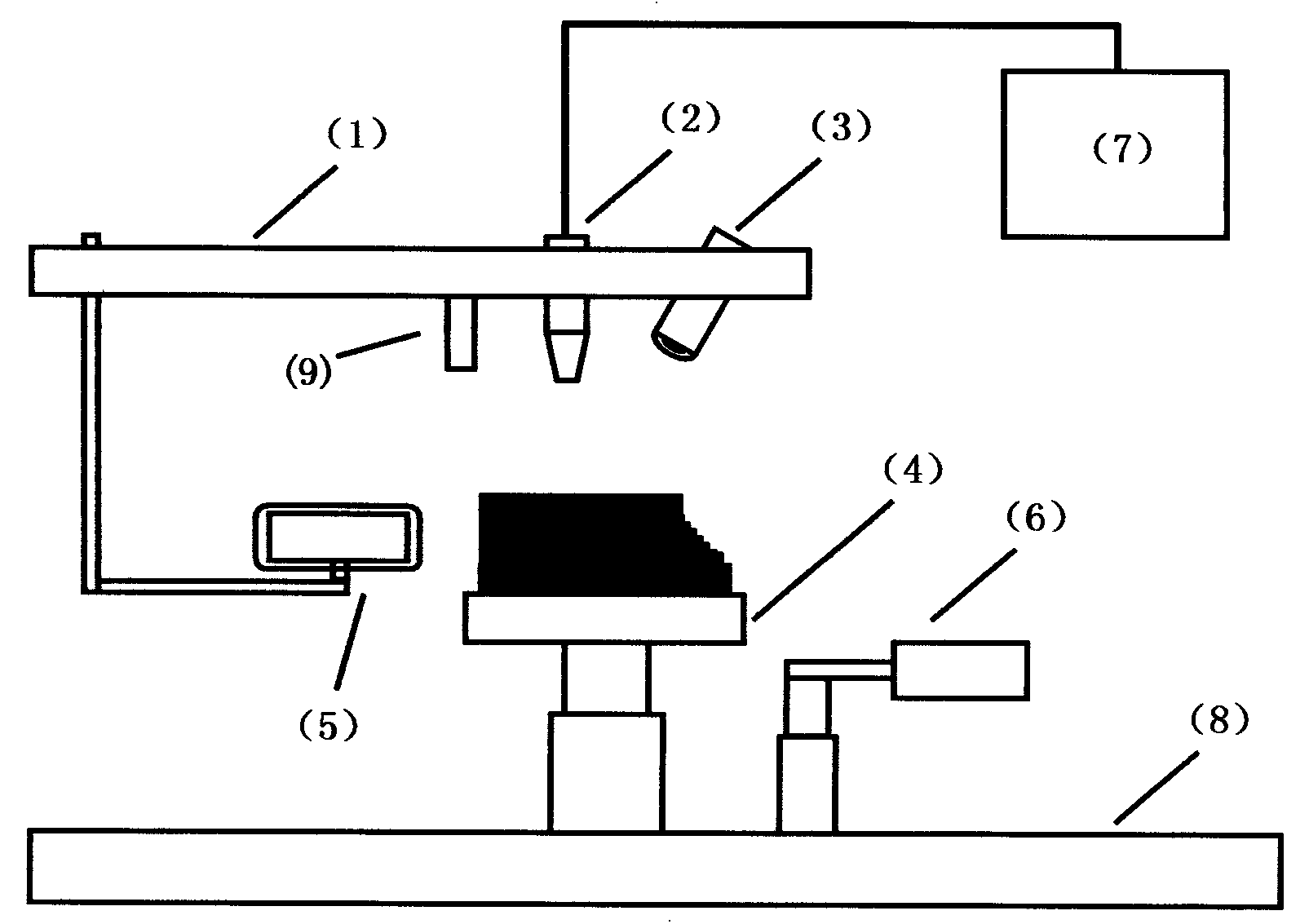

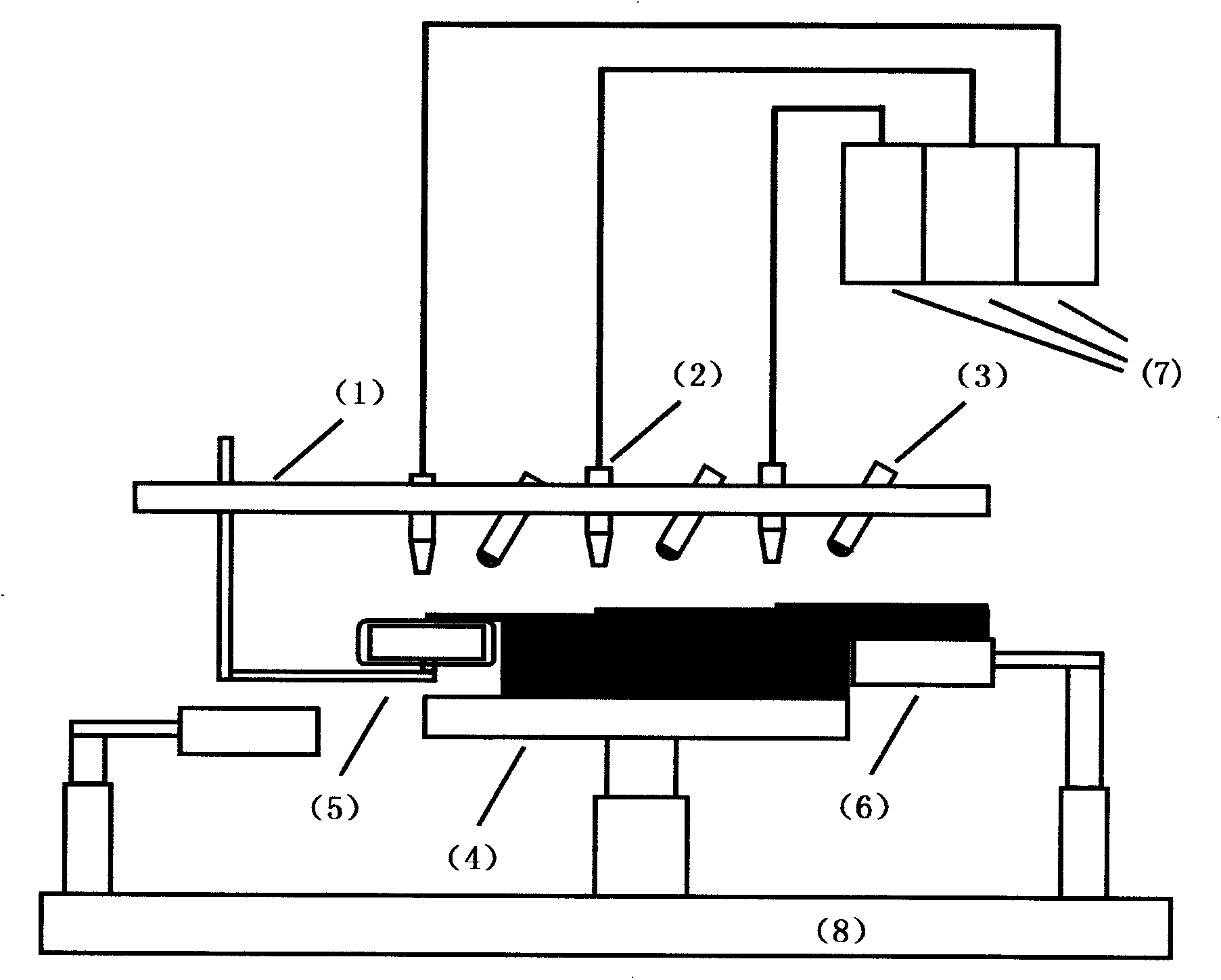

Multi-spray-head 3D printer and cooperative printing method thereof

ActiveCN105269819AThe number can be expanded arbitrarilyAvoid mutual interferenceAdditive manufacturing apparatusIndependent motionEngineering

The invention discloses a multi-spray-head 3D printer and a cooperative printing method thereof. The multi-spray-head 3D printer comprises a movement mechanism and a control unit, wherein the movement mechanism comprises a machine body, and an XY movement assembly and a Z-axis movement mechanism fixed on the machine body, and a printing platform positioned on the Z-axis movement mechanism; N X-axis movement mechanisms which move independently relative to each other, N Y-axis movement mechanisms which move independently relative to each other and N wire feeding mechanisms which work independently relative to each other are arranged on the XY movement assembly; N is greater than or equal to 1, and N is an integer; all spray heads share the printing platform; and the X-axis movement mechanisms and the Y-axis movement mechanisms are arranged in parallel along a Y-axis guide rod. According to the multi-spray-head 3D printer, the plurality of the spray heads share one printing platform to carry out partitioned cooperative printing; software realizes seamless connection among partitions by virtue of reasonable path planning; and the spray heads are prevented from interfering from one another, so that 3D printing efficiency of a large preparation part is improved.

Owner:深圳尤尼智康医疗科技有限公司

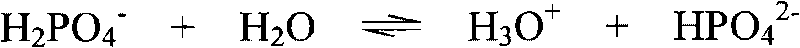

Offset printing fountain solution composition containing composite buffer system

InactiveCN101758680AAdapt to the needs of actual printingGood buffer tolerancePrinting pre-treatmentSodium citrateCitric acid

The invention relates to an offset printing fountain solution composition containing composite buffer system, which contains two buffer systems, wherein one of the buffer systems comprises citric acid and M2(I)HPO4, and in the molecular formula M2(I)HPO4, M is K plus, Na plus or NH4 plus ion; and the other buffer system comprises citric acid and potassium citrate, sodium citrate or ammonium citrate, components are as follows in percentage by weight: 1.0-10 percent of the citric acid, 1.0-10 percent of K2HPO4, Na2HPO4 or (NH4)2HPO4, 1.0-10 percent of the potassium citrate, the sodium citrate or the ammonium citrate, and the balance water. When 1 percent to 5 percent by weight of working solution prepared with the diluted fountain solution is used for printing, the change of pH value is less than 0.35, and when 1 percent to 2 percent of working solution is prepared, the change of pH value is less than 0.25. The ultrahigh buffering property of the fountain solution can significantly help to improve adaptability and tolerance during high-speed printing operation.

Owner:HUNAN NORMAL UNIVERSITY

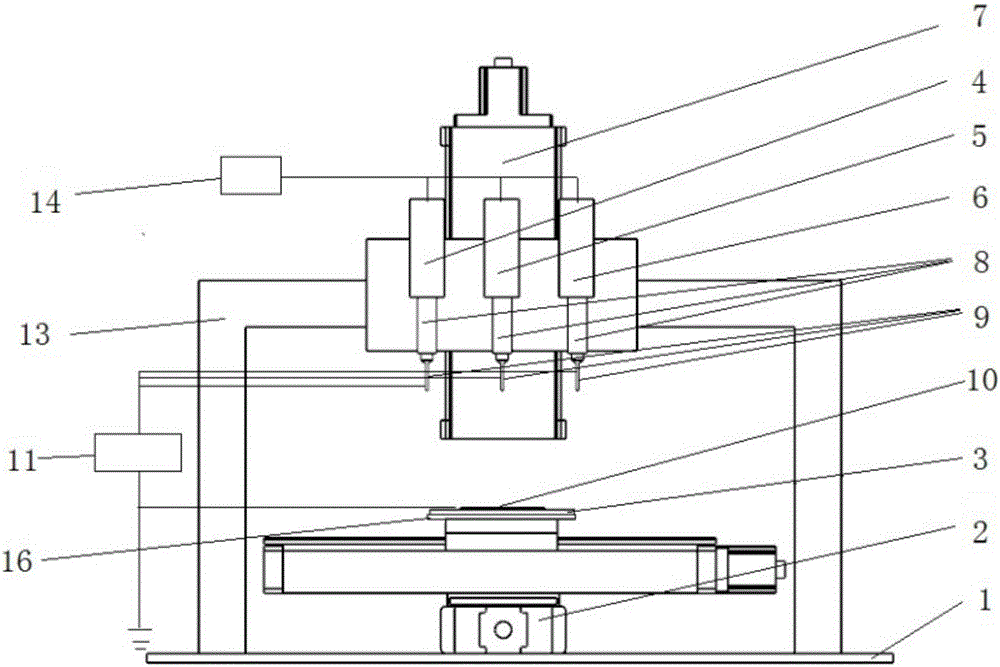

Micro-nano scale 3D printer and method

InactiveCN106738896AHigh resolutionLow costManufacturing driving means3D object support structuresMicro nanoSpray nozzle

The invention discloses a micro-nano scale 3D printer and a method. The 3D printer comprises a spraying head set, a printing tool, a controller and a three-dimensional movement mechanism. The spraying head comprises a plurality of spraying heads, and each spraying head applies a high-voltage pulse power supply between a corresponding electric conductive nozzle and an electric conductive base plate. Fluids are pulled from the nozzles by utilizing strong electric field force formed between the nozzles and the base plate to form Taylor Cones and stable conic jet flows. The controller controls the three-dimensional movement mechanism to drive the spraying head set and the printing tool to move relatively and meanwhile controls the movement of all the spraying heads to conduct micro-droplet spray printing on preset positions of the base material on the printing tool, and a model material, a release material and a supporting material are printed sequentially. Based on electrofluid power spraying printing (namely electric spraying printing), the micro-nano scale 3D printer solves the difficult problems that for micro-nano 3D printing, macro / micro cross-scale manufacturing cannot be achieved, the types of printable materials are few, and support is difficult to remove, and especially overcomes the deficiencies and the limitation, in the aspects of the cost, materials, resolution ratio, macro / micro cross-scale manufacturing, support removing and the like, of the of the current micro-nano scale 3D printing technology.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

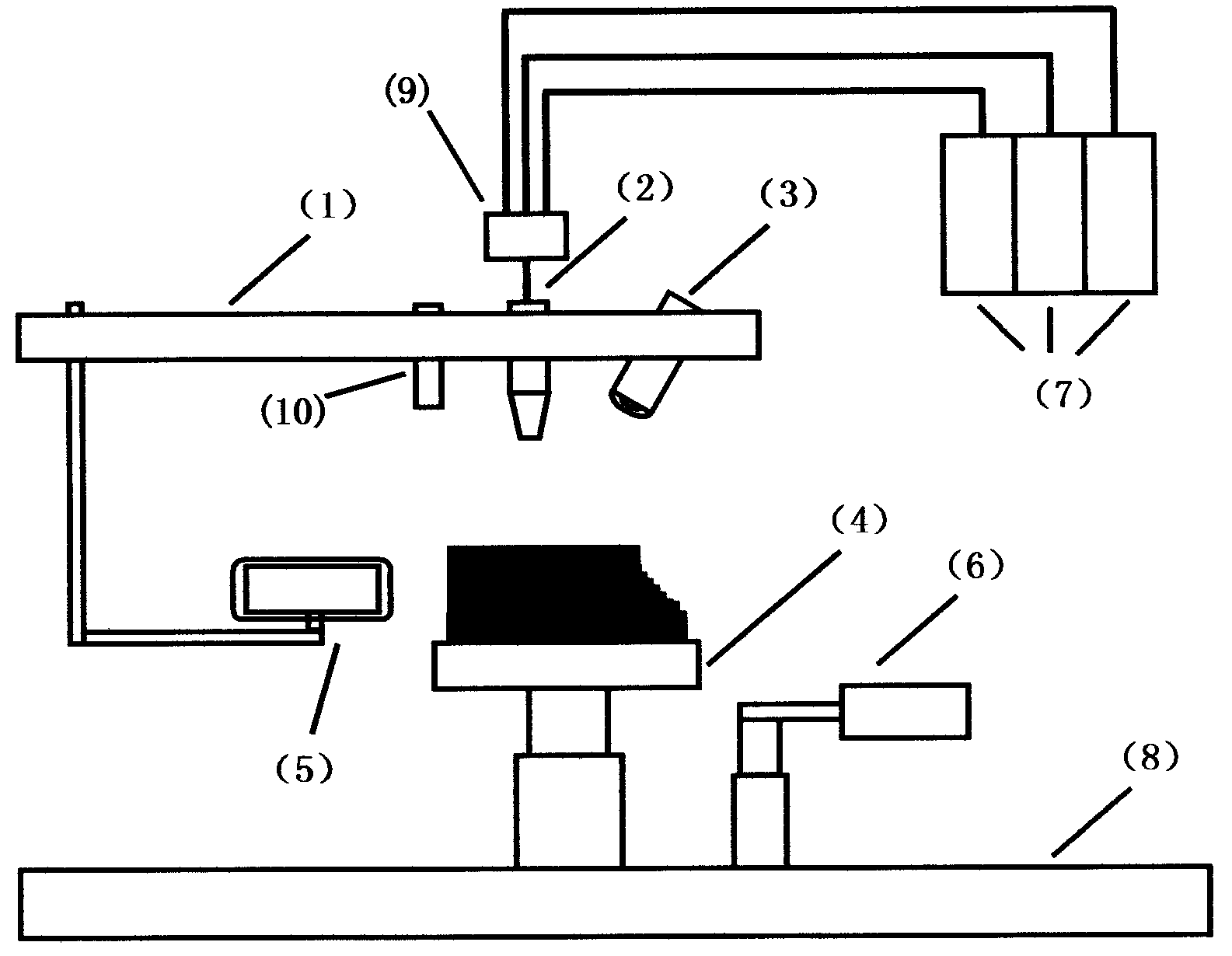

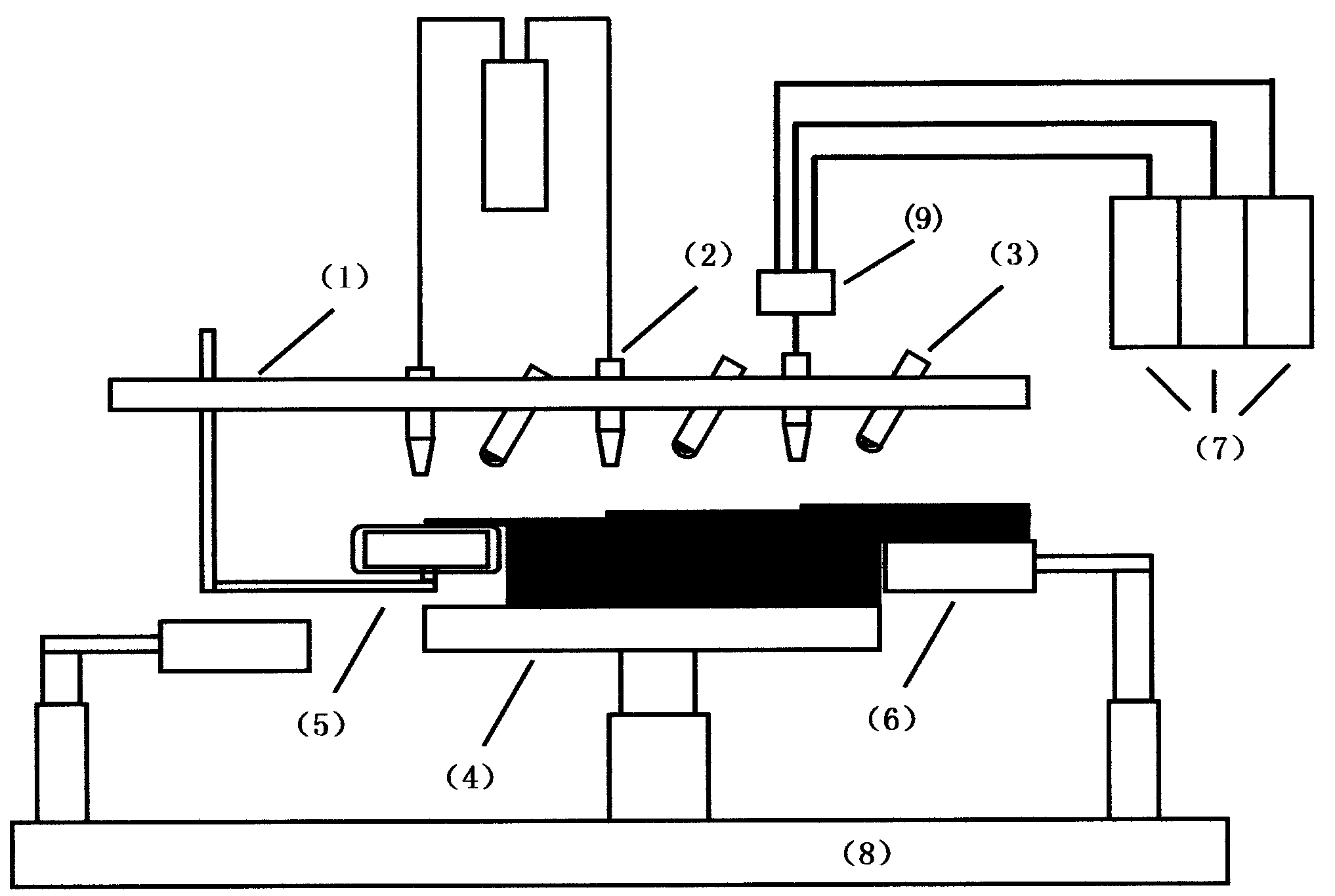

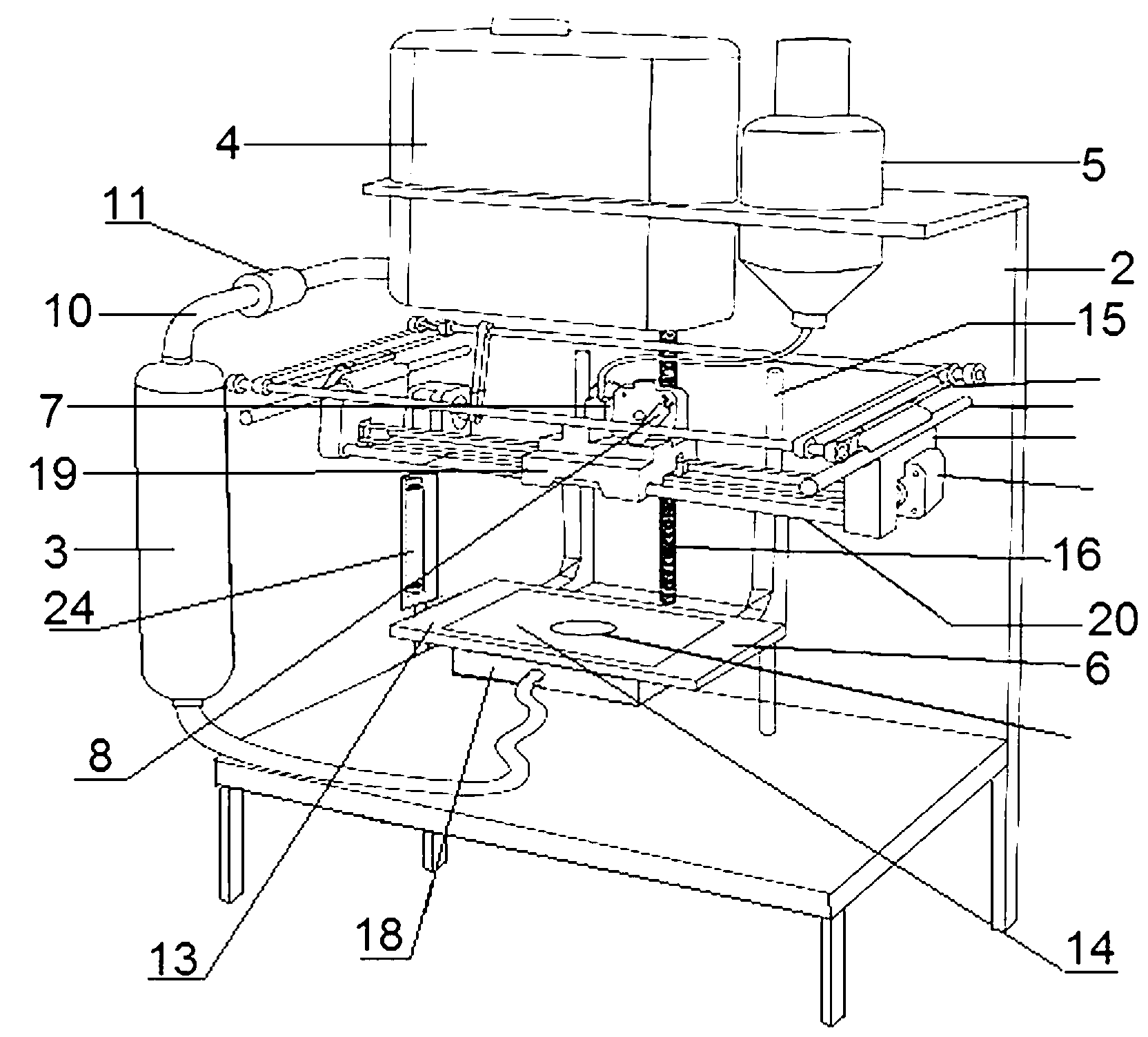

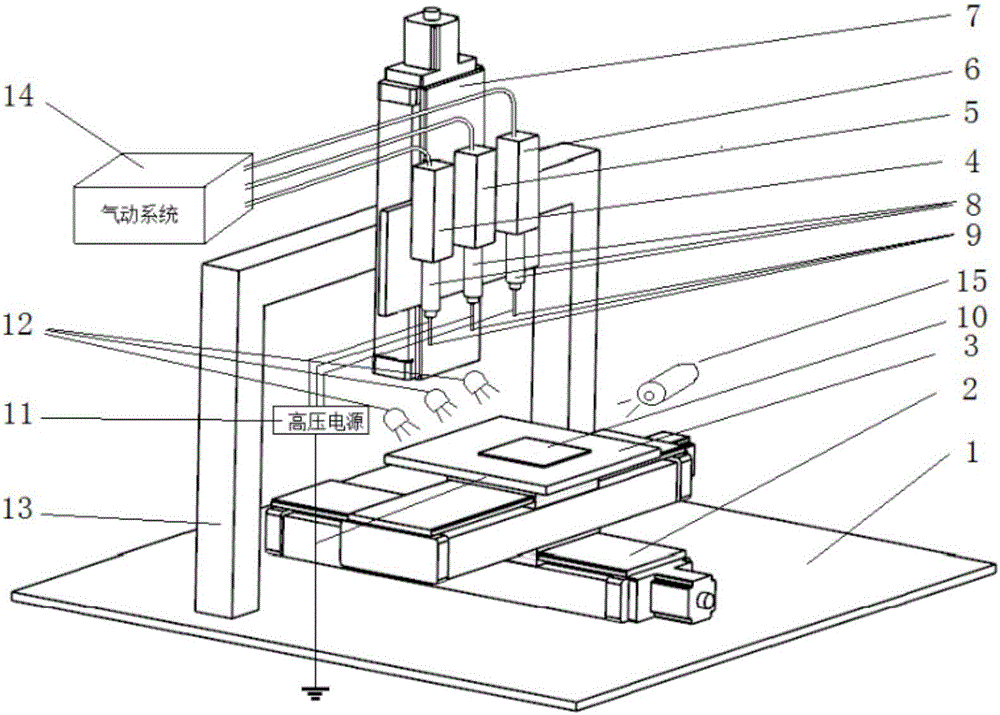

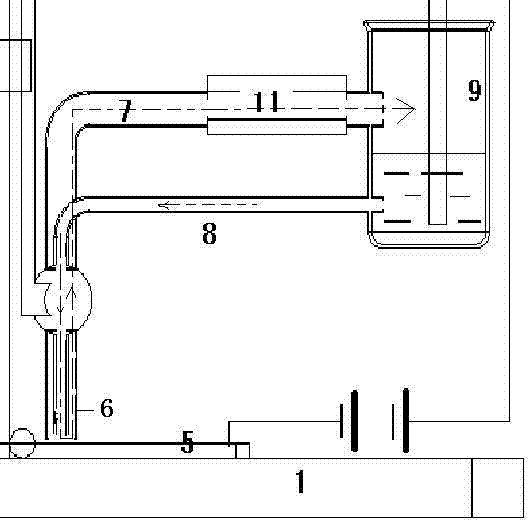

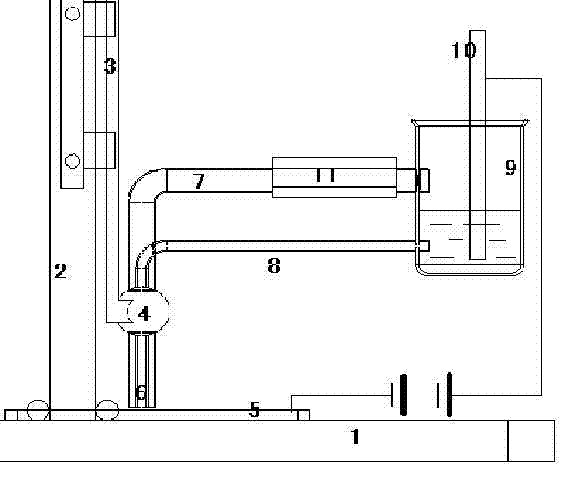

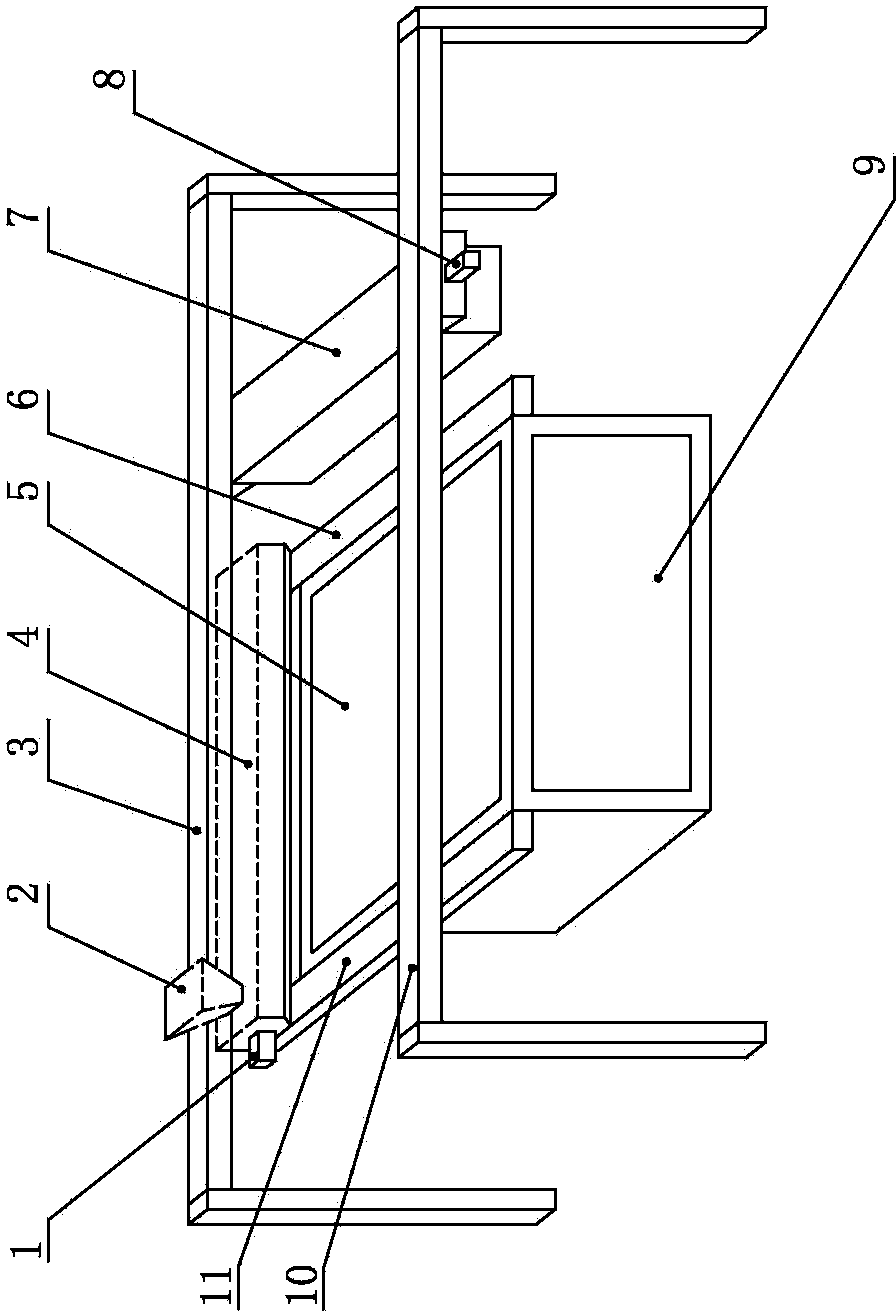

Electrolytic etching electroplating accumulation three-dimensional (3D) printer

ActiveCN103481672AHigh densityImprove printing efficiencyElectrolysis componentsTypewritersMetal coatingNumerical control

A three-dimensional (3D) printer is characterized by comprising an X-axis track frame (1), a Z-axis track frame (2), a Y-axis track frame (3), a universal numerical control steering frame (4), a conductive base plate (5), a coaxial sleeve printing head (6) installed on the universal numerical control steering frame (4), a backflow outer hose (7) connected with an outer tube of the coaxial sleeve printing head (6), an automatic-flowing inner hose (8) connected with an inner tube of the coaxial sleeve printing head (6), a storage tank (9) containing electrolyte, a metal electrode block (10) and a numerical control sucking pump (11) installed at the tail end of the backflow outer hose (7) and used for sucking the electrolyte into the storage tank (9). The metal electrode block (10), a electrolyte solution, the conductive base plate (5) and a direct-current power supply of the 3D printer form an electrolysis device, the electrolyte solution is electrolyzed on the conductive base plate (5), and a precipitated metal coating serves as an accumulation printing material. The shortcoming of lower printing efficiency of a 3D printer in the prior art is overcome, the accumulation printing material is low in price, an etching and accumulation method is simple, and the electrolytic etching electroplating accumulation 3D printer is high in printing speed.

Owner:陈泽进

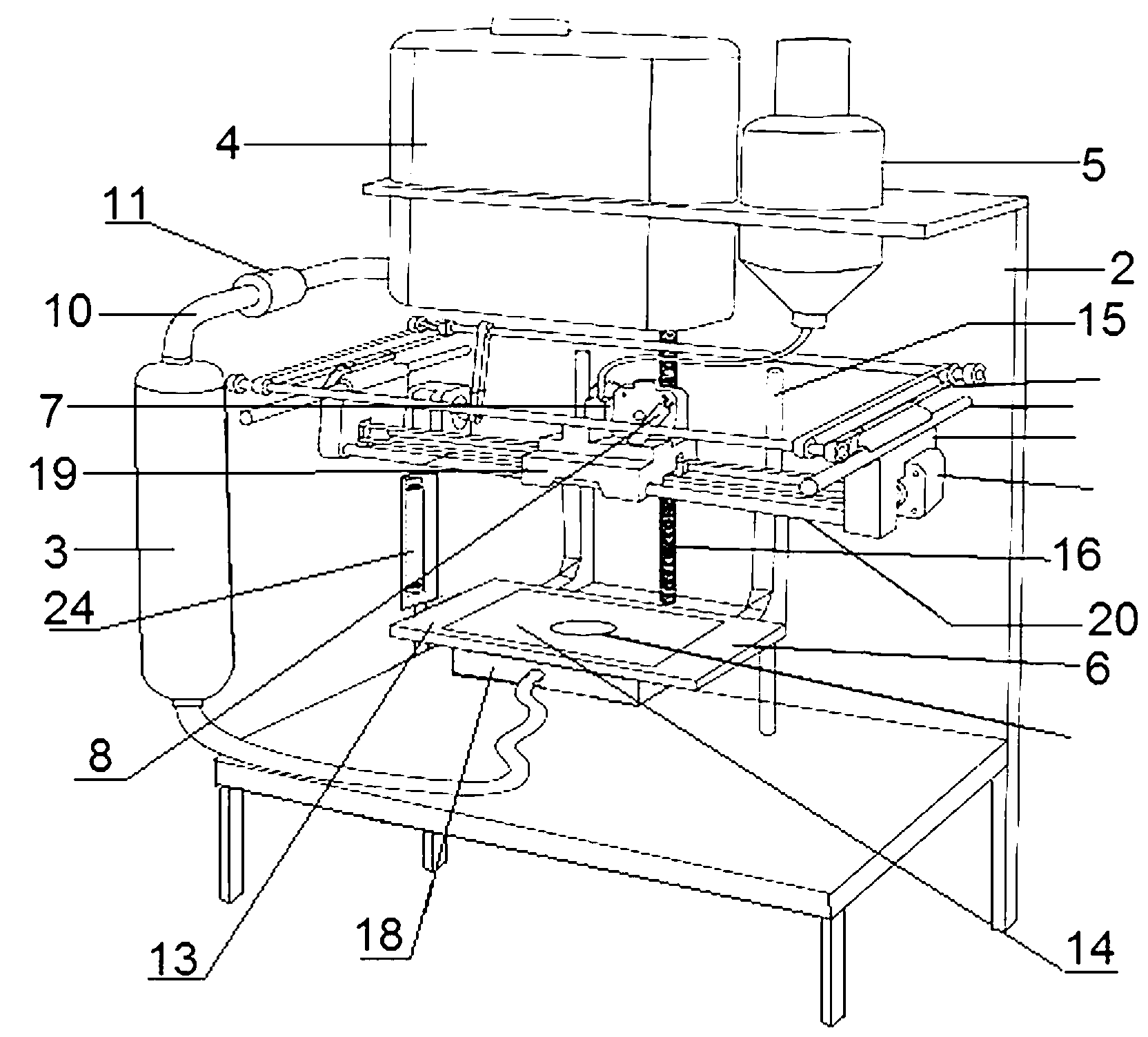

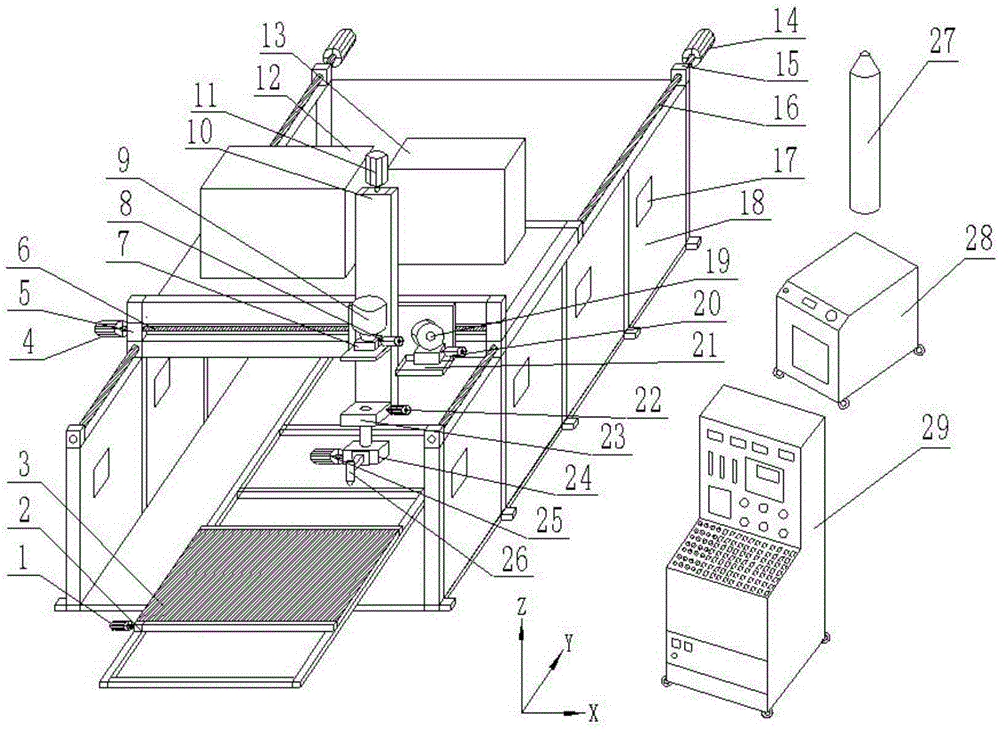

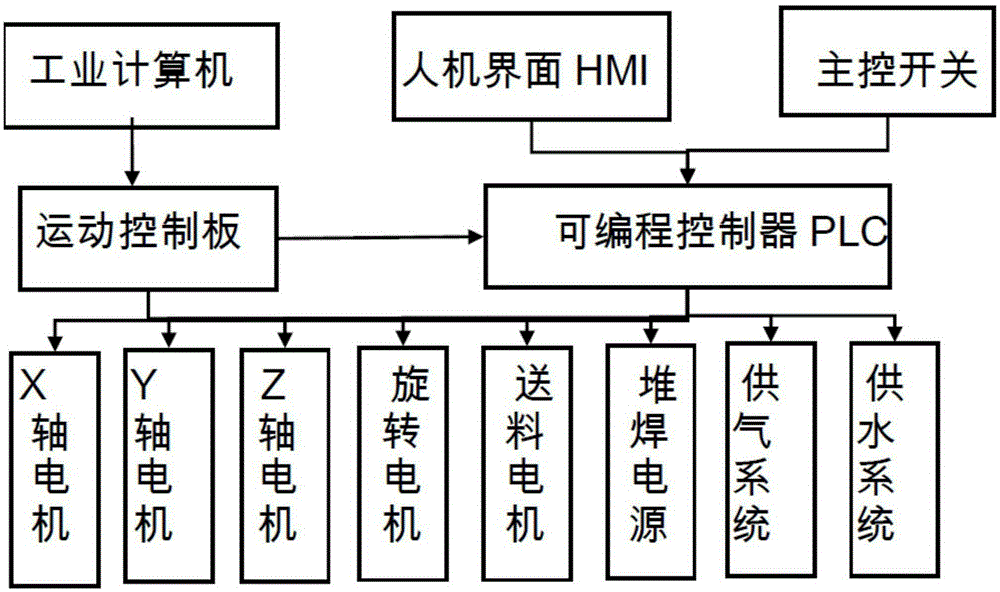

Gantry type high-power plasma arc 3D printing equipment and method

ActiveCN105234538AImprove printing efficiencyEasy to usePlasma welding apparatusHuman–machine interfaceDesign control

The invention discloses gantry type high-power plasma arc 3D printing equipment and a method. The printing equipment comprises a gantry type structure frame and elevated bearing walls, wherein a gantry platform of the frame is mounted at the upper ends of the elevated bearing walls at two sides. The printing equipment further comprises a printing machine head, a printing molding platform, an X-axle motion component, a Y-axle motion component, a Z-axle motion component, a powder feeding mechanism, an oscillator, a printing machine head rotating mechanism, a wire feeding device, a surfacing power supply and an electric cabinet. The printing method comprises the steps of three-dimensional modeling, layered slicing, process preparation and real-time printing. The plasma arc above 10kw is used for melting fed metal powder or wires to finish the 3D printing of large products under predesigned control programs, so that the 3D printing efficiency is greatly improved; the whole system adopts the full-digital control, and is provided with self-inspection and warning systems; and main process parameters are set by a human-computer interface, so that the use and the maintenance of operators are more convenient.

Owner:武汉高力热喷涂工程有限责任公司

Multi-printing-head third-dimensional (3D) printer technology of rotary platform

The invention relates to a new framework of a third-dimensional (3D) printer. The new framework of the third-dimensional printer comprises a printer body, a bracket, a rotary work platform and printing heads. The new framework is characterized in that a bottom rotary work platform drives a printing material to rotate; a group of printing heads at the upper end can carry out reciprocating motion along a printer head walking mechanism when rotating; all surfaces of the rotary platform can be covered by combining with the bottom platform to rotate; and a plurality of groups of printing heads are assembled at the upper end to distribute in a radial pattern by taking the bottom platform as the center. Thus, a plurality of printing work surfaces can be formed to print at the same time. The printing speed is improved in multiples; and a plurality of printing heads work at the same time, so that different materials or colors can be respectively printed; and the 3D printer technology has the characteristics that the bottom platform rotates and is matched with the plurality of printing heads to print.

Owner:陈明辉

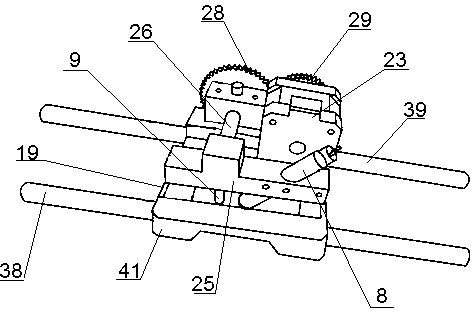

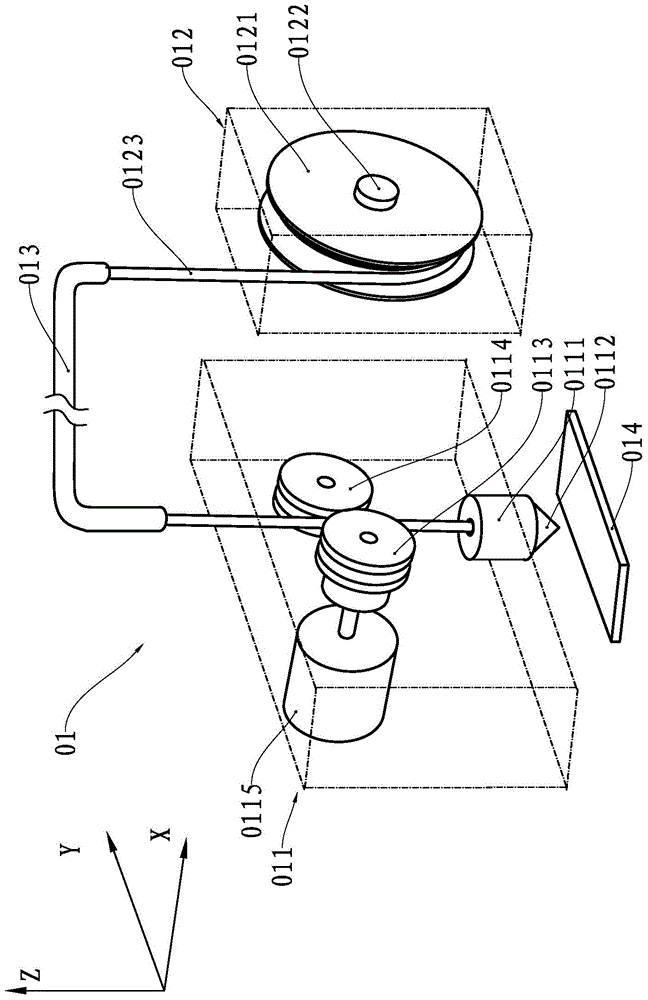

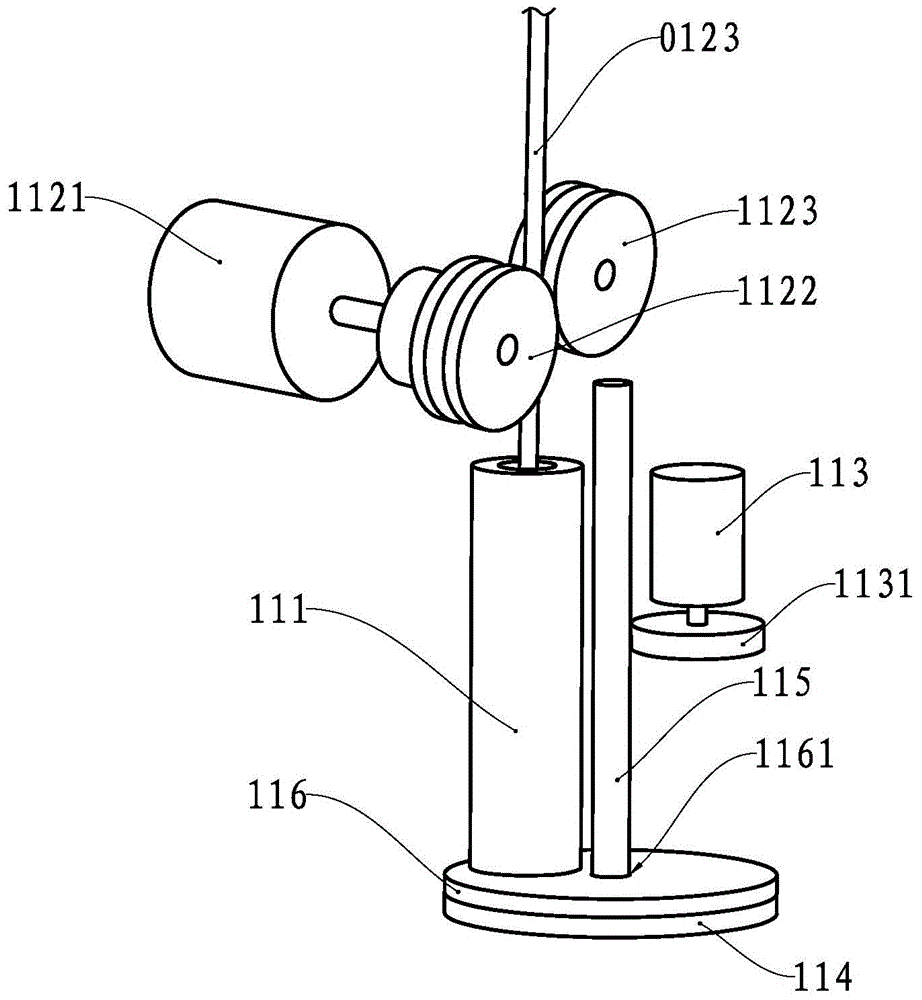

Printing head, three-dimensional printer and three-dimensional printing method

The invention relates to a printing head for a three-dimensional printer, and further relates to the three-dimensional printer constructed with the printing head and a method for printing a three-dimensional body by utilizing the three-dimensional printer. The printing head comprises a liquefier and an adjustment unit, wherein the adjustment unit comprises an adjustment disc; an upper disc surface of the adjustment disc is arranged below the liquefier in a mode of clinging to the end face of an outlet end of the liquefier; the adjustment disc can rotate around a vertical shaft relative to the liquefier; a first extrusion hole is formed in one of an end wall of the outlet end of the liquefier and the adjustment disc, and more than two second extrusion holes are formed in the other one of the end wall of the outlet end of the liquefier and the adjustment disc; the effective aperture of each second extrusion hole is different, and is less than or equal to that of the first extrusion hole; and through the rotation of the adjustment disc around the vertical shaft relative to the liquefier, the first extrusion hole is butted with one of the second extrusion holes selectively. According to the printing head, the effective apertures of the extrusion holes can be adjusted according to the requirements of the printing accuracy, and the printing efficiency of the three-dimensional printer is improved.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

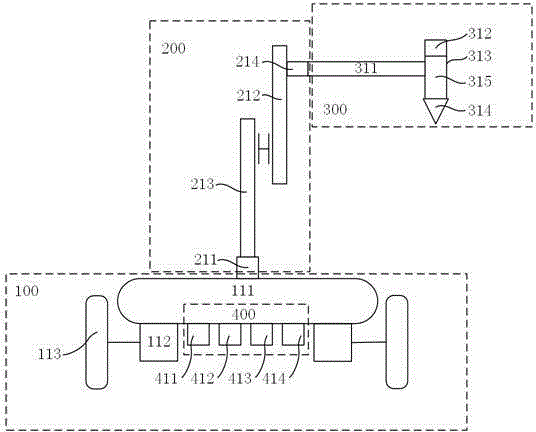

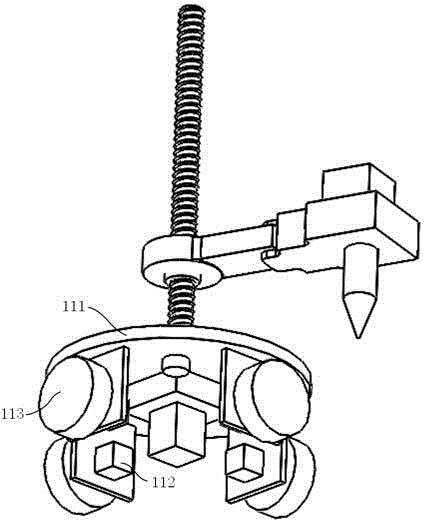

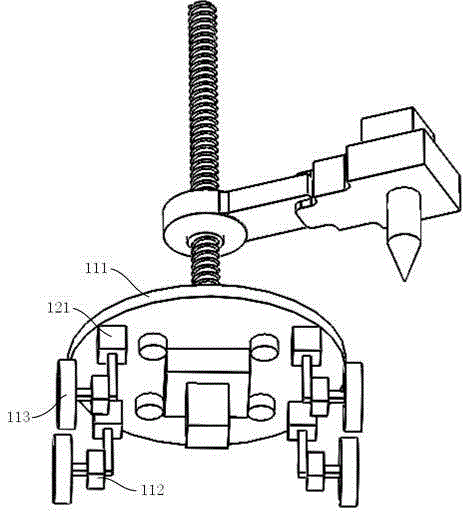

3D printing robot capable of freely moving

InactiveCN104527067ACompact structureReduce volumeAdditive manufacturing apparatus3D object support structuresLarge distanceEngineering

The invention relates to a 3D printing robot capable of freely moving. The 3D printing robot capable of freely moving comprises an omni-directional mobile platform mechanism, a Z-axis lifting mechanism, a 3D printing mechanism and a feedback / communication / control circuit. The 3D printing robot capable of freely moving is characterized in that the Z-axis lifting mechanism is fixedly connected to the omni-directional mobile platform mechanism, the 3D printing mechanism is fixedly connected to the Z-axis lifting mechanism, the feedback / communication / control circuit is installed on the omni-directional mobile platform mechanism simultaneously, and the omni-directional mobile platform mechanism and the Z-axis lifting mechanism are controlled by virtue of the feedback / communication / control circuit to drive the 3D printing mechanism to realize printing of a strip-shaped object without a dimensional limit in a three-dimensional space. The 3D printing robot capable of freely moving has the characteristics of compact structure, small size, no printed object dimensional limit of the traditional 3D printer, high movement flexibility and high printing speed; meanwhile, the cooperative communication of any multiple printing robots is realized, and the 3D printing efficiency is further enhanced. The 3D printing robot capable of freely moving is especially suitable for low-cost and high-efficiency printing of large-distance strip-shaped objects such as building walls.

Owner:SHANGHAI UNIV

Method of Reducing and Optimising Printed Support Structures in 3D Printing Processes

ActiveUS20160200051A1Sufficient vertical supportLower the volumeAdditive manufacturing apparatusCeramic shaping apparatusEngineering3d printer

A printed target model is formed by 3D printing by inputting target model data, and based on target model data, identifying surface portions requiring support. The surface portions are projected onto a virtual printer table, and one or more virtual support structures having a V-shaped cap portion and optionally a generally planar web are created therefore. The virtual model is then used to control a 3D printer to integrally print-form the target model and support structures.

Owner:UNIVERSITY OF WINDSOR

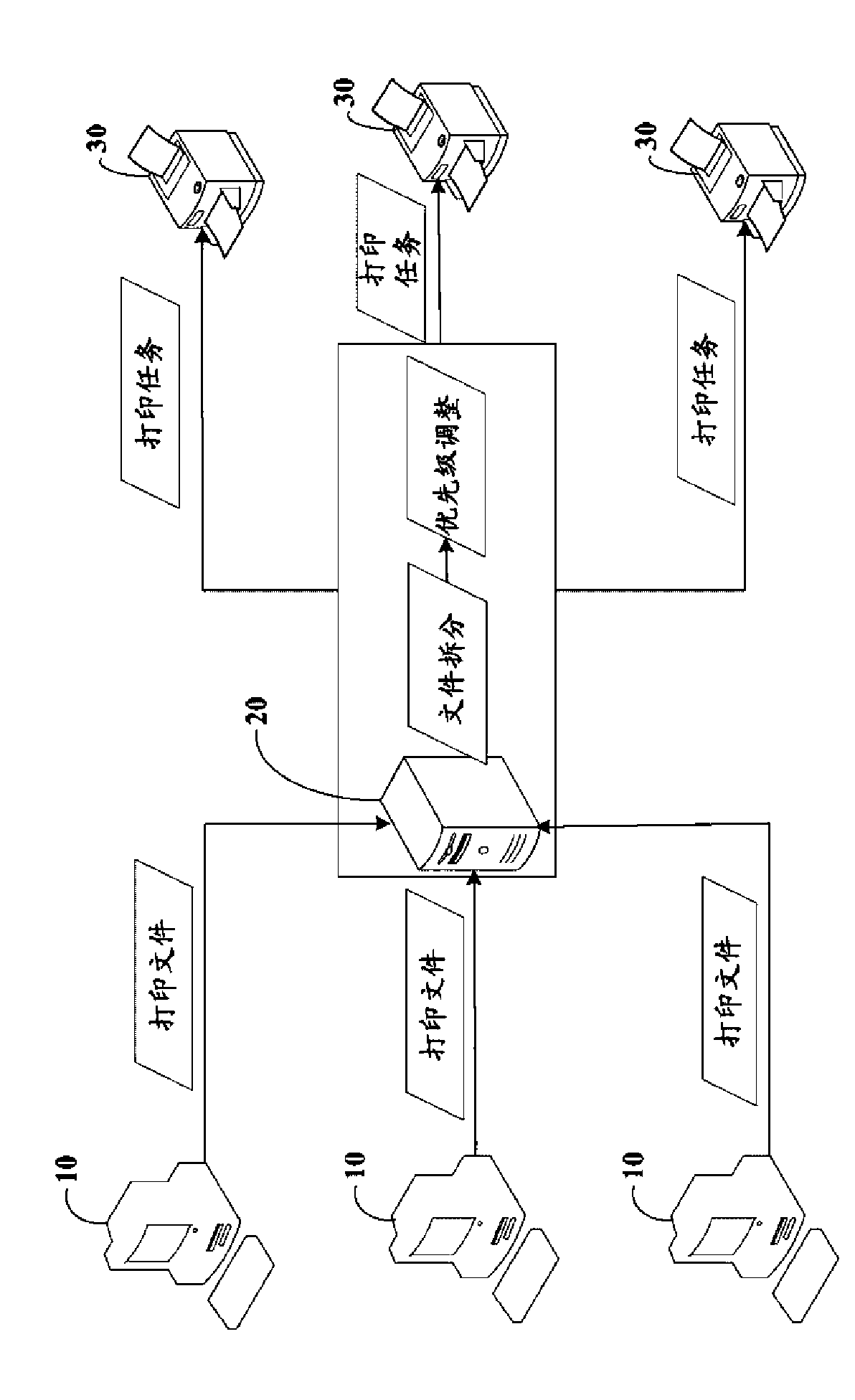

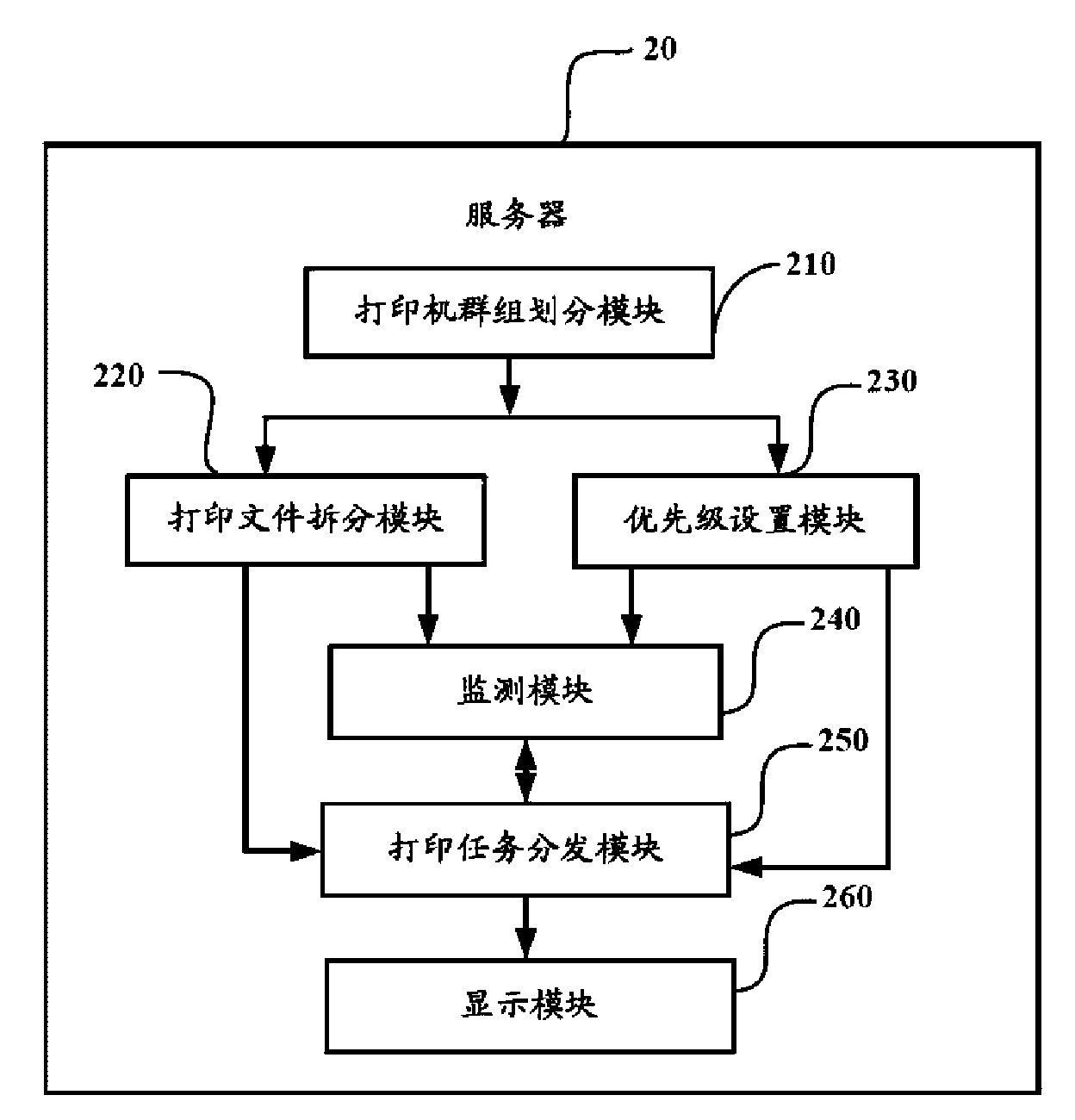

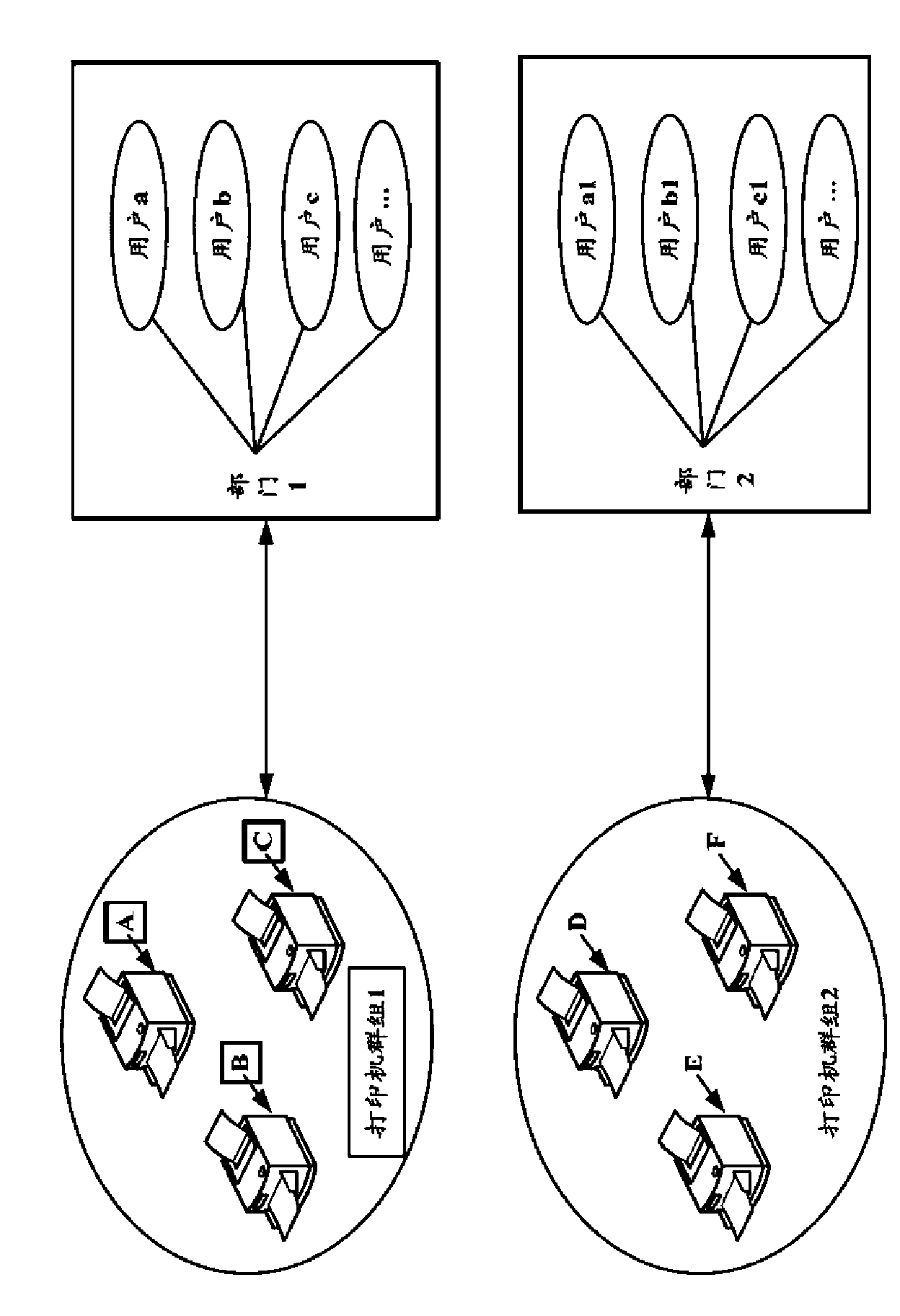

System and method for cluster printing

InactiveCN101593088ACollaborative workImprove printing efficiencyDigital output to print unitsPriority settingCooperative work

The invention provides a cluster printing system, which comprises a server. The server is connected with at least one user end computer and a plurality of printers, and comprises a printer group classification module, a printing file demounting module, a priority setting module, a monitoring module and a printing task distribution module. With the modules, the server can distribute printer groupswhich can be used by different user end computers, divide the received demounting files into task blocks according to the demounting conditions set by users, add the task blocks obtained by demounting to the corresponding position of a total task queue of the printer group according to the priority of the printing file set by the users, and sequentially distribute the task blocks to printers of the printer group in normal work according to the display sequence of the task blocks in the total task queue of the printer cluster. The cluster printing system can achieve the cooperative work of printing equipment and improve the printing efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

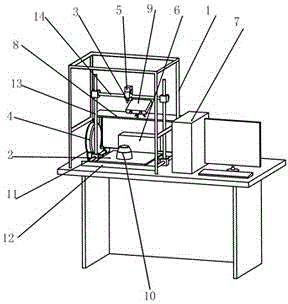

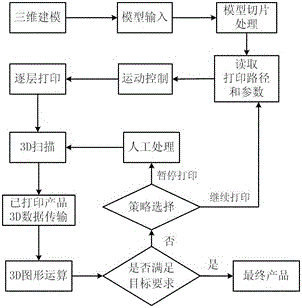

3D printing machine with three-dimensional figure feedback system and printing method of 3D printing machine

InactiveCN105666877AHigh precisionImprove printing efficiencyAdditive manufacturing apparatusGraphicsControl system

The invention discloses a 3D printing machine with a three-dimensional figure feedback system and a printing method of the 3D printing machine. The 3D printing machine comprises a rack, a printing platform, a printing spray head, a material box, a feeding device, a drive device, a control system, a computer, a support mounted on the outer side of the drive device and a 3D scanner which is arranged on the support and used for scanning a printed article. In the product forming process, the 3D scanner is used for scanning a semi-finished workpiece or a blank, the three-dimensional profile of the workpiece is obtained and compared with a three-dimensional model of a target product through graphics operation, the motion path and printing parameters of the printing machine are adjusted according to a result, and therefore feedback control of the printing process is achieved, and the 3D printing forming precision and the printing efficiency are improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Laser 3D (three-dimensional) printing device with multiple inkjet heads

The invention discloses a laser 3D printing device with multiple inkjet heads. The laser 3D printing device with multiple inkjet heads includes a laser generator, a laser inkjet head, a mechanical arm and a working table, wherein the laser inkjet head includes a laser head and a power inkjet head assembly, the power inkjet head assembly comprises a connecting base, a rotating disc and at least two power inkjet heads, the rotating disc is sleeved outside the periphery of the connecting base, the connecting base is provided with a laser through hole which is coaxially communicated with a laser jet hole of the laser head, the at least two power inkjet heads are detachably arranged on the rotating disc and are distributed relative to the periphery of the rotating center of the rotating disc, any power inkjet head is coaxially communicated with the laser jet hole when rotating to a working station, and a fixing unit is arranged between the rotating plate and the connecting base. The laser inkjet head of the laser 3D printing device with the multiple inkjet heads is provided with a plurality of powder inkjet heads and the plurality of powder inkjet heads can be used alternately so that the laser 3D printing device can use a plurality of metal powers to print under the condition that the laser inkjet head is not changed, and the laser 3D printing device meets the 3D printing requirements of FGM (Functionary Gradient Materials) metal pieces.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

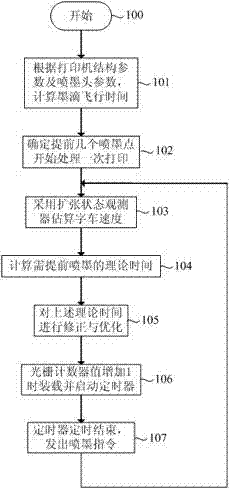

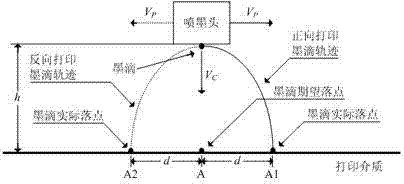

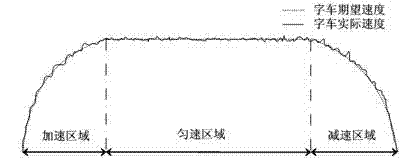

Ink droplet droppoint deviation compensation method in bidirectional printing of inkjet printer

The invention belongs to the technical field of inkjet printing, in particular to an ink droplet droppoint deviation compensation method in bidirectional printing of an inkjet printer. The invention is characterized in that: an adaptive compensation method is realized by seven steps; deviation of ink droplets in a character wheel constant speed area can be more precisely compensated, the printing speed is greatly improved, the printing quality is improved, a problem that printing cannot be carried out in a character wheel acceleration and deceleration area is solved, and the printing efficiency is improved while the cost is saved; and the method provides technical guarantee for high-speed high-precision printing.

Owner:XIDIAN UNIV

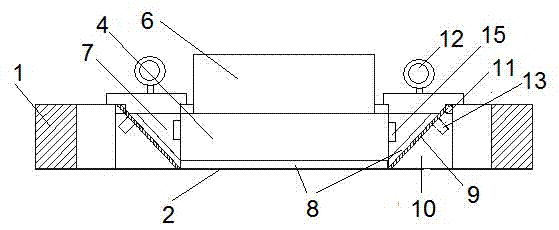

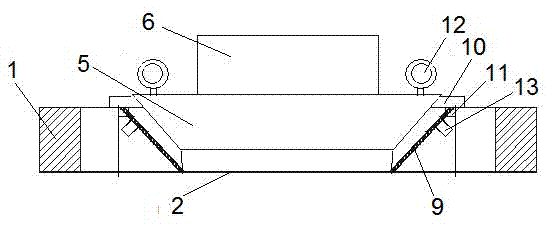

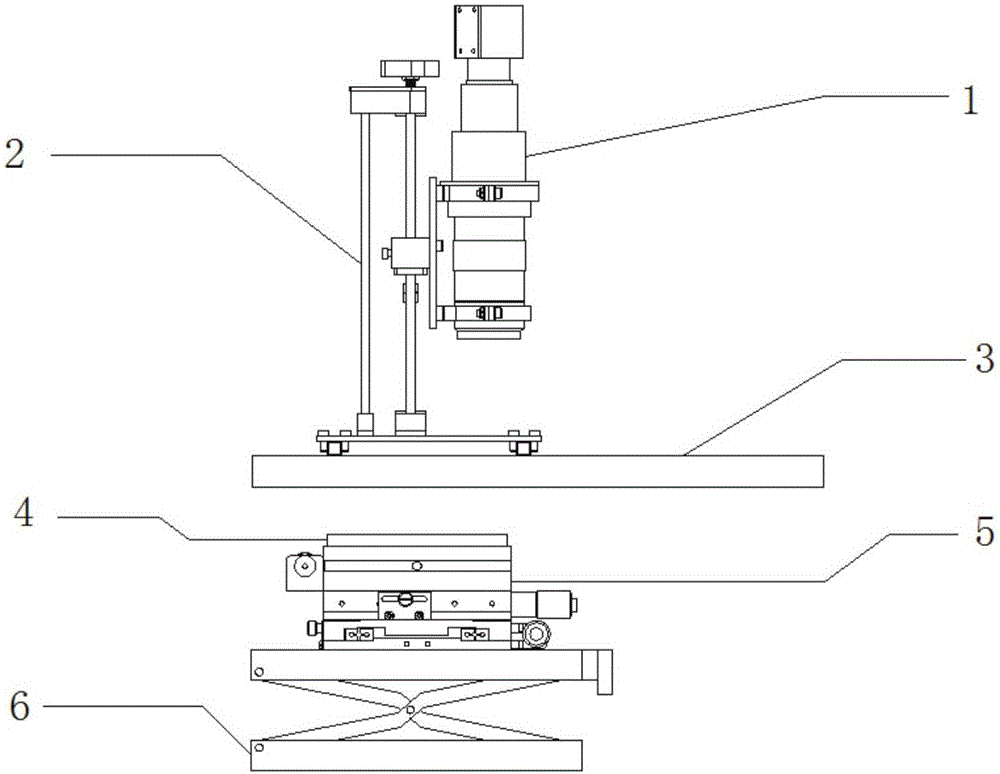

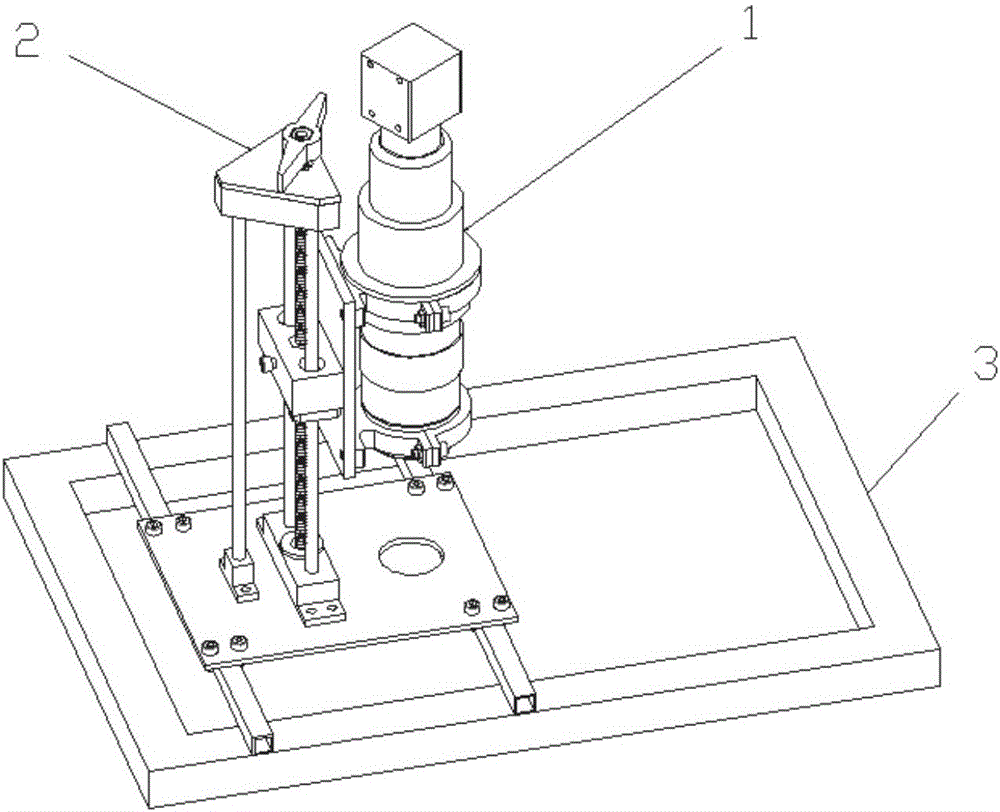

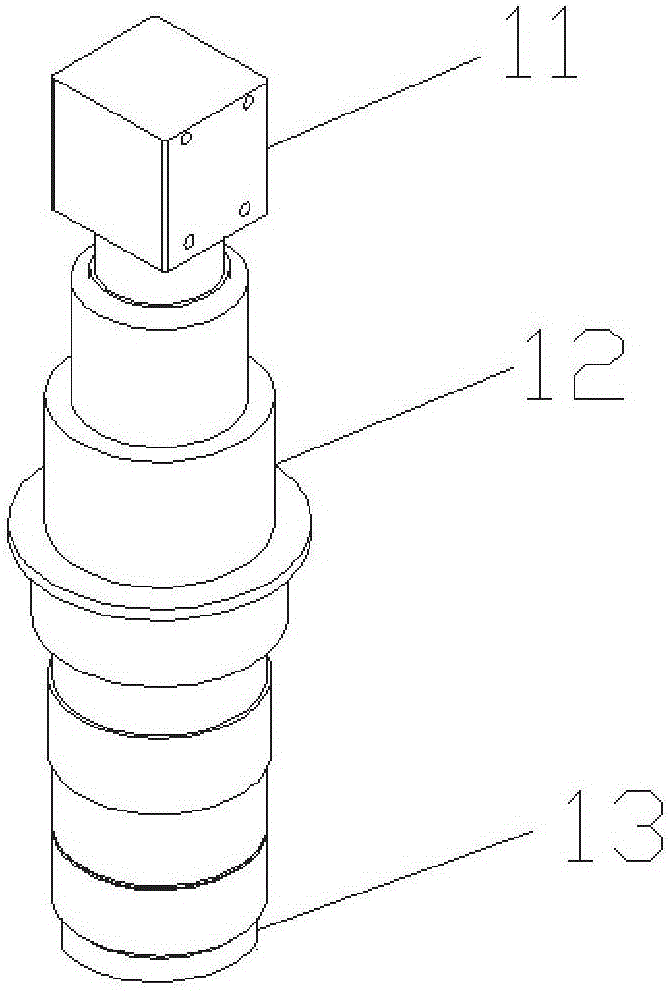

System and method for aligning silk-screen printing

InactiveCN104999776AEasy to install and removeSimple structureScreen printersSemiconductor/solid-state device manufacturingMicro motionPrinting press

The invention relates to the technical field of silk-screen printing equipment, particularly to a system and method for aligning silk-screen printing. A silk screen plate and a lifting table are arranged on a silk-screen printing machine, a fixture is arranged on the silk screen plate, an XYR micro-motion platform is arranged on the lifting table, a vacuum chuck is arranged on the XYR micro-motion platform, the vacuum chuck is used for adsorbing a printing stock, and the printing stock corresponds to a position under the silk screen plate; a first positioning mark is arranged on the silk screen plate, and a second corresponding positioning mark is arranged on the print stock; the fixture is used for regulating the height and the two-dimension plane coordinates, which are relative to those of the silk screen plate, of an imaging and amplifying camera, the XYR micro-motion platform is used for regulating the two-dimension plane coordinates of the print stock and rotating the print stock, the lifting table is used for regulating the height of the printing stock, the first positioning mark on the silk screen plate and the second corresponding positioning mark on the print stock are collected by the imaging and amplifying camera, and the position and the direction of the printing stock are regulated through the XYR micro-motion platform and the lifting table, so that the first positioning mark and the second positioning mark are accurately aligned, and the effect that a blanking region of the printing stock and a pattern on the silk screen plate are accurately aligned is achieved.

Owner:XIAMEN UNIV

3D printing machine and 3D printing method

ActiveCN105172143AImprove printing efficiencyAchieve fixation3D object support structuresManufacturing data aquisition/processingHost materialEngineering

The invention discloses a 3D printing machine which comprises a printing chamber. A printing assembly and a bearing platform are arranged in the printing chamber. The printing assembly is arranged above the bearing platform. The printing assembly comprises a printing support, a printing head assembly and a curing lamp assembly, wherein the printing head assembly and the curing lamp assembly are connected to the printing support. The printing support moves in the printing direction. In the printing direction, the printing head assembly is located in front of the curing lamp assembly. The printing head assembly comprises a main printing head body of a printing model body and an auxiliary printing head body of a printing supporting material. The model main material is photosensitive resin. The printing temperature in the printing chamber is lower than the solidification temperature of the supporting material. The supporting material is solidified at the printing temperature. The invention further discloses a 3D printing method. By means of the 3D printing machine and the 3D printing method, the supporting material is removed easily.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

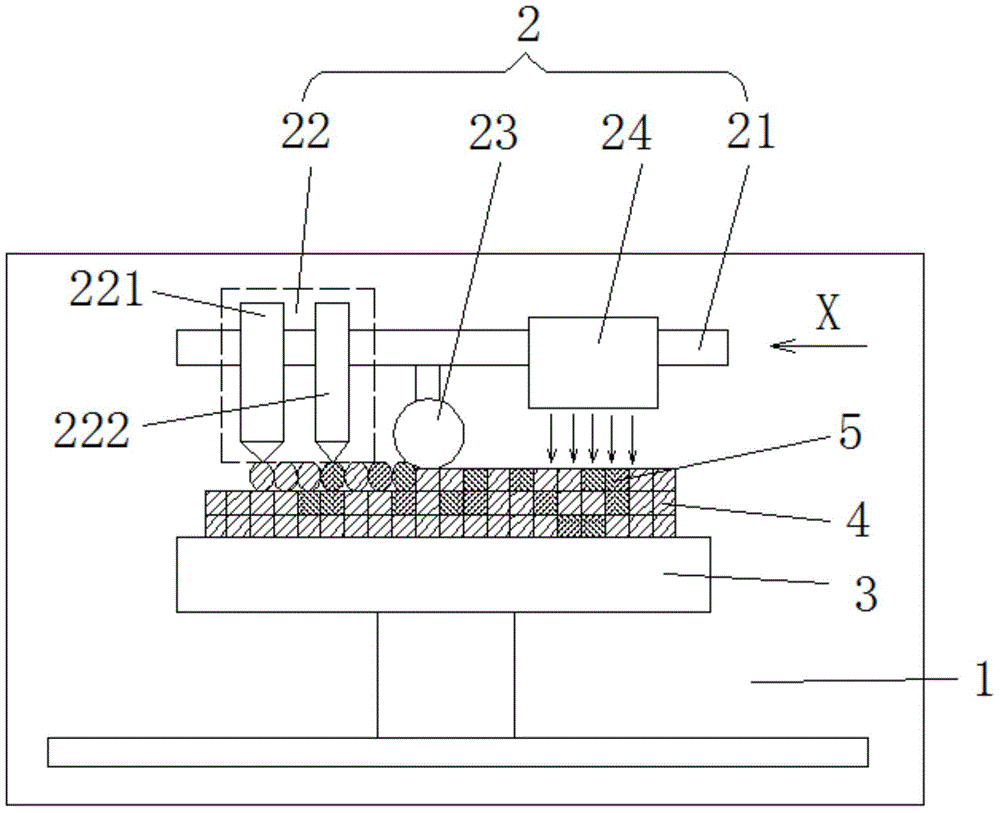

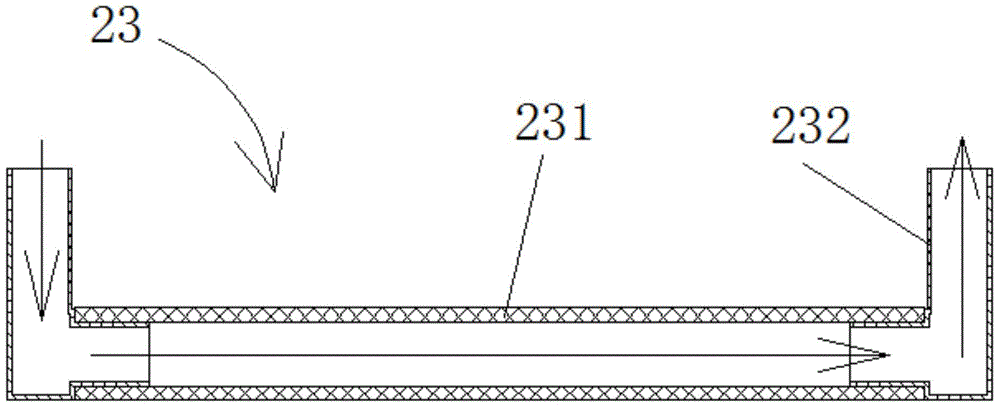

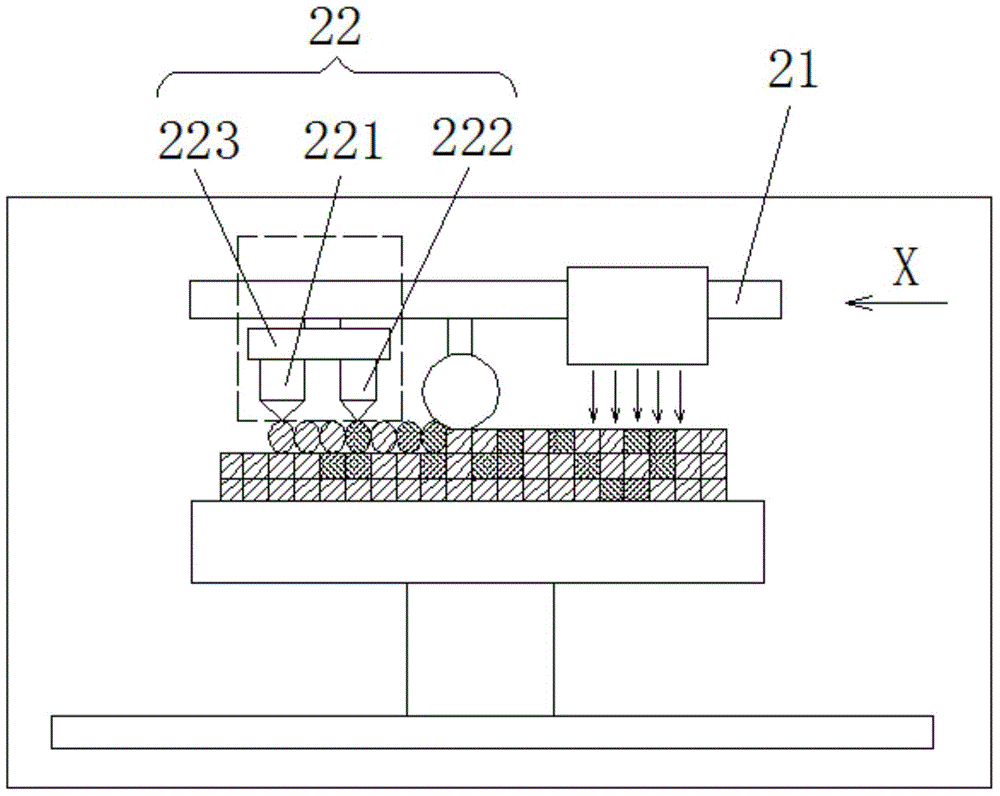

3D printing equipment with high-efficiency print head

ActiveCN104085035AImprove printing efficiencyFoundry mouldsCeramic shaping apparatusSpray nozzleEngineering

The invention discloses 3D printing equipment with a high-efficiency print head in the field of powder material forming production device. The 3D printing equipment comprises a powder spreading unit, a printing unit and a working box lifting unit, wherein the powder spreading unit comprises a feeding hopper; the feeding hopper is mounted above a powder spreader; the two ends of the powder spreader are mounted on first linear guide rails; a first driving mechanism for driving the powder spreader to move along the first linear guide rails is installed on the powder spreader; the printing unit comprises a print head; the print head is installed on second linear guide rails; the print head is in transmission connection with a second driving mechanism for driving the print head to move along the second linear guide rails; the working box lifting unit comprises a working box; a lifting platform is arranged inside the working box; the powder spreader and the print head are arranged above the lifting platform; the moving areas of the powder spreader and the print head cover the whole lifting platform; a plurality of spray nozzles capable of being independently controlled are formed in the print head. The 3D printing equipment is high in printing efficiency and is applicable to production of a metal casting sand mould.

Owner:NINGXIA KOCEL MOLD

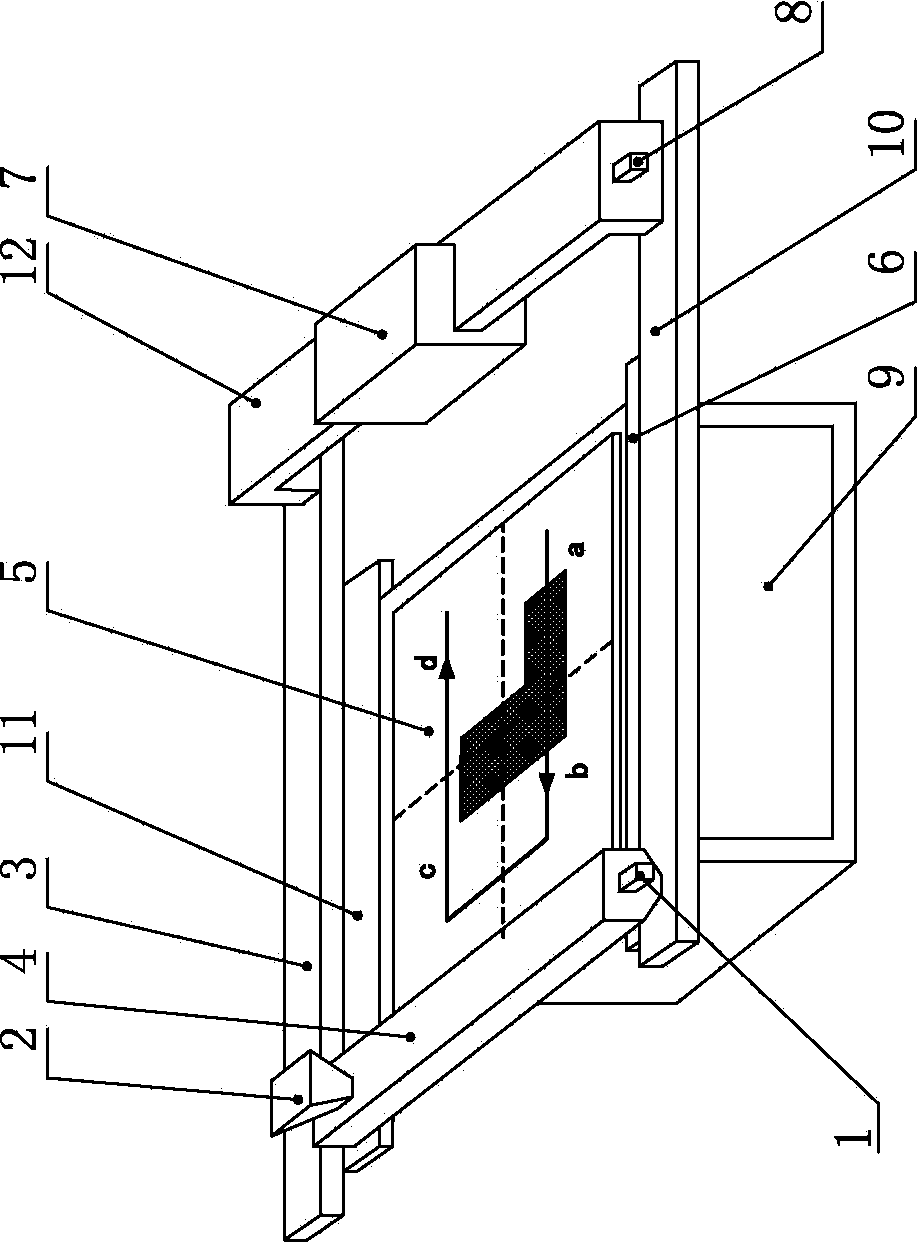

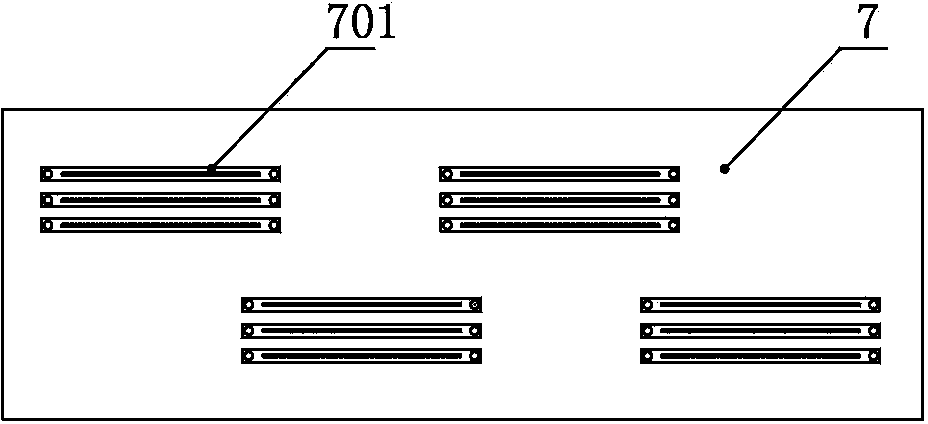

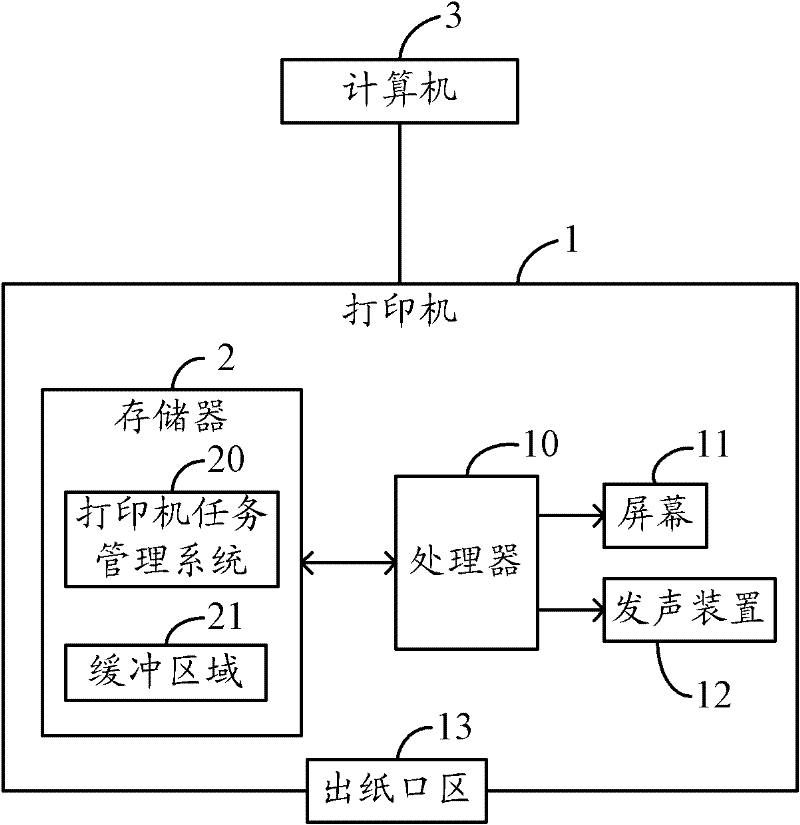

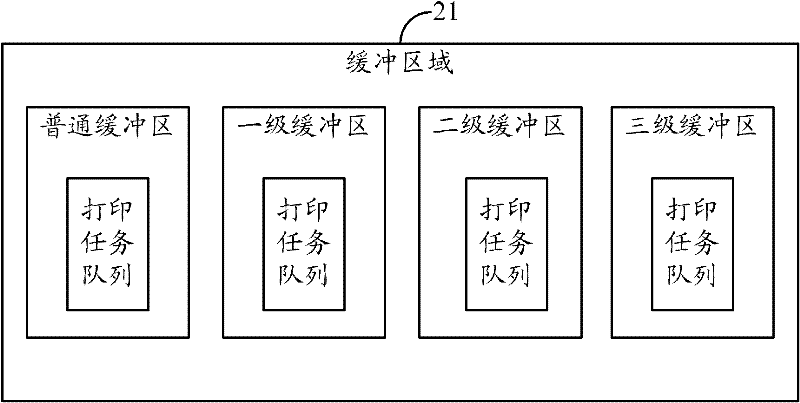

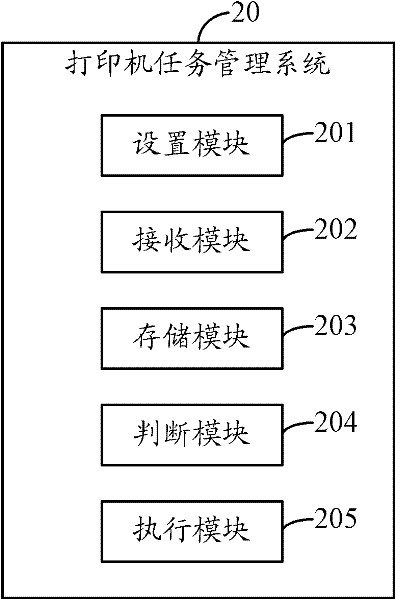

Printer task management system and method

InactiveCN102455880AAvoid Task ConflictsFlexible executionVisual presentationDigital output to print unitsTask managementOperating system

A printer task management method comprises the steps of: (a) storing printing tasks in corresponding buffer areas; (b) reading a printing task from a buffer region in which the printing task is stored and has a high priority, and executing the printing task; (c) when the execution of the present printing task is completed and a printing task which is not executed is still present, returning to the step (b); (d) when the execution of the present printing task is not finished yet and no printing task is present in a buffer area which is higher than the buffer area where the present printing task is present in priority, continuing the execution of the present printing task; and (e) when the execution of the present printing task is not finished yet and a printing task is present in the buffer area which is higher than the buffer area where the present printing task is present in priority, suspending the present printing task, and then reading the printing task from the buffer area which is higher than the buffer area where the present printing task is present in priority and executing the same. The invention also provides a printer task management system. With the system and the method provided in the invention, the printing tasks can be executed flexibly; as a result, the printing efficiency is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com