Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

416results about How to "Reduce printing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

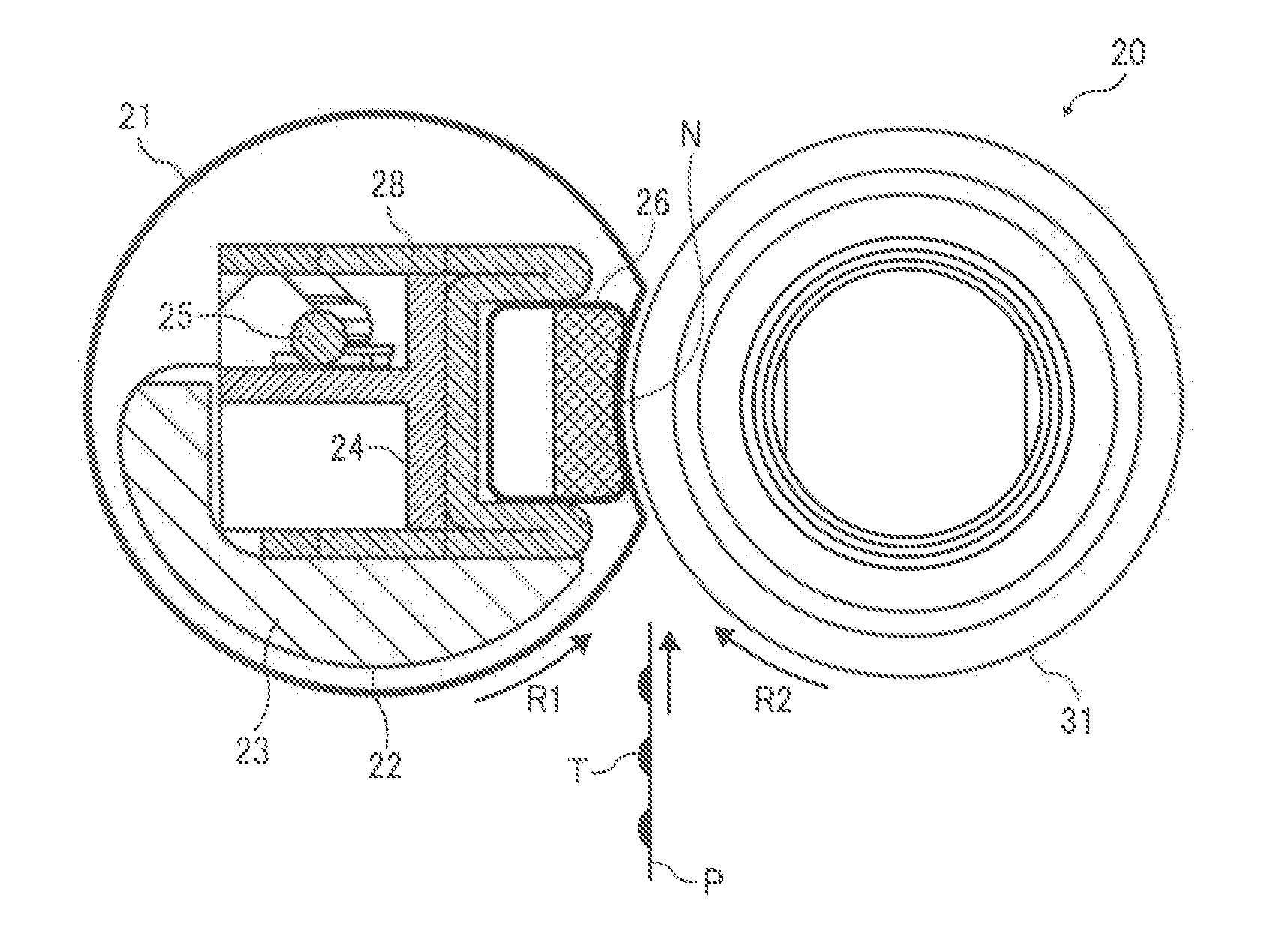

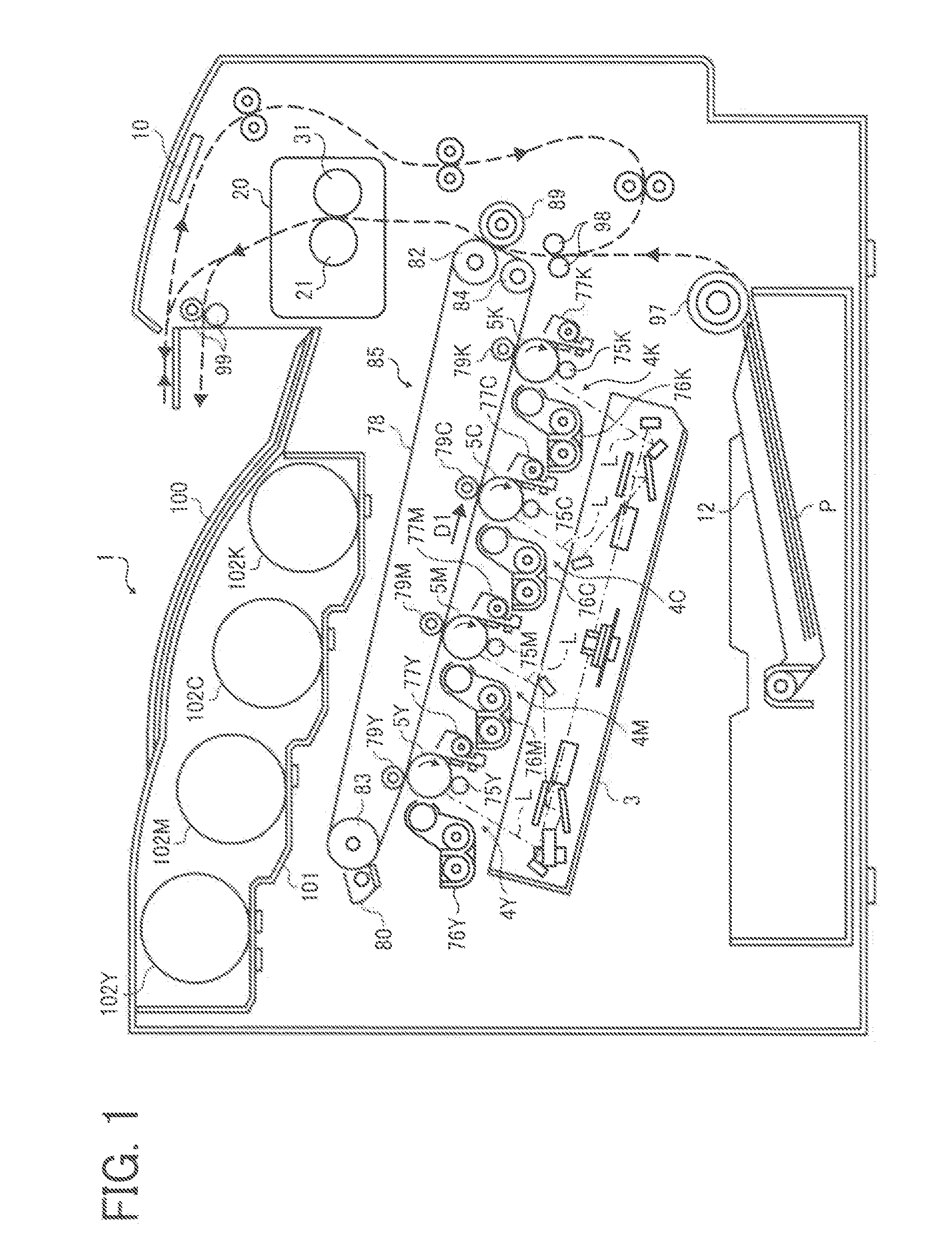

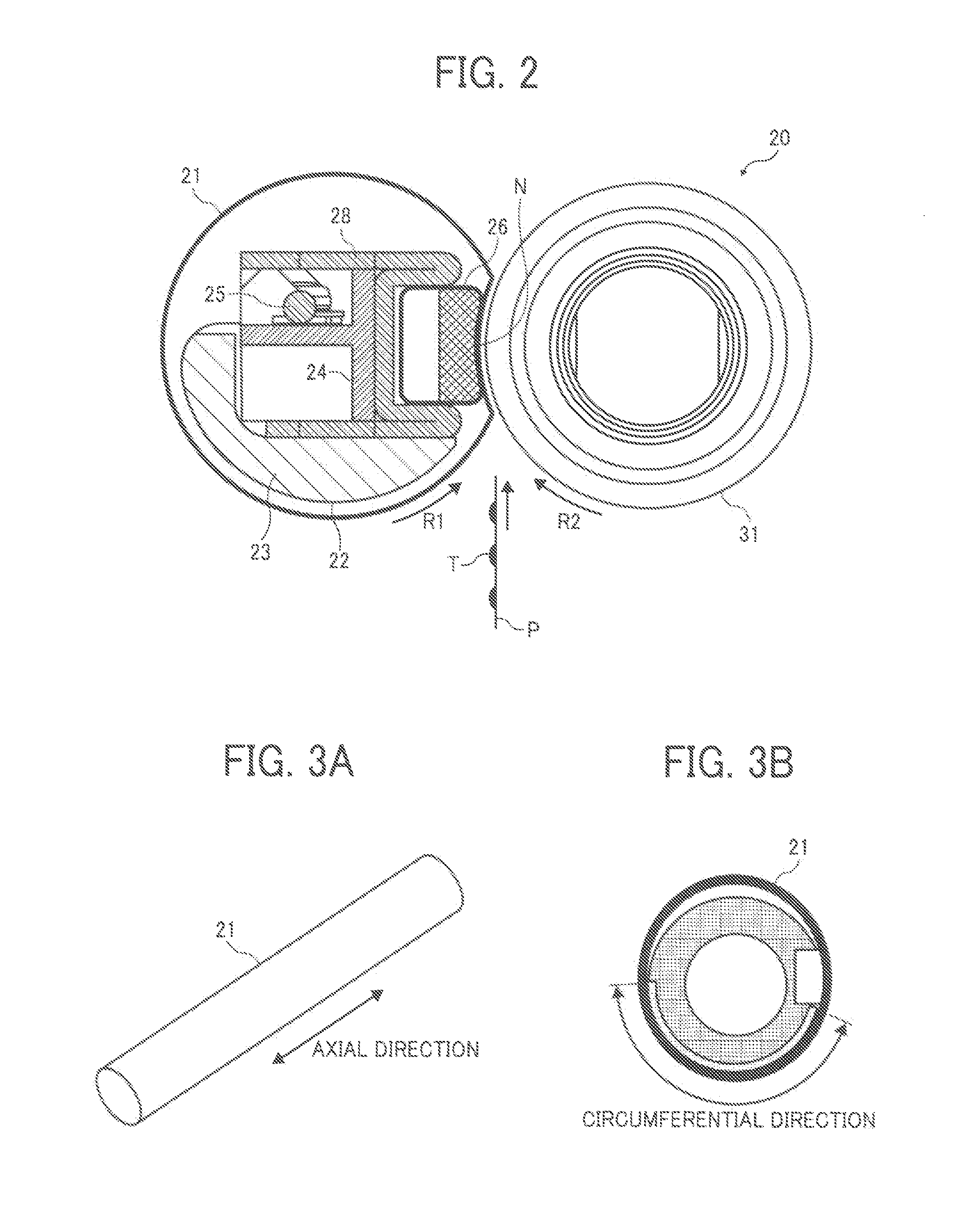

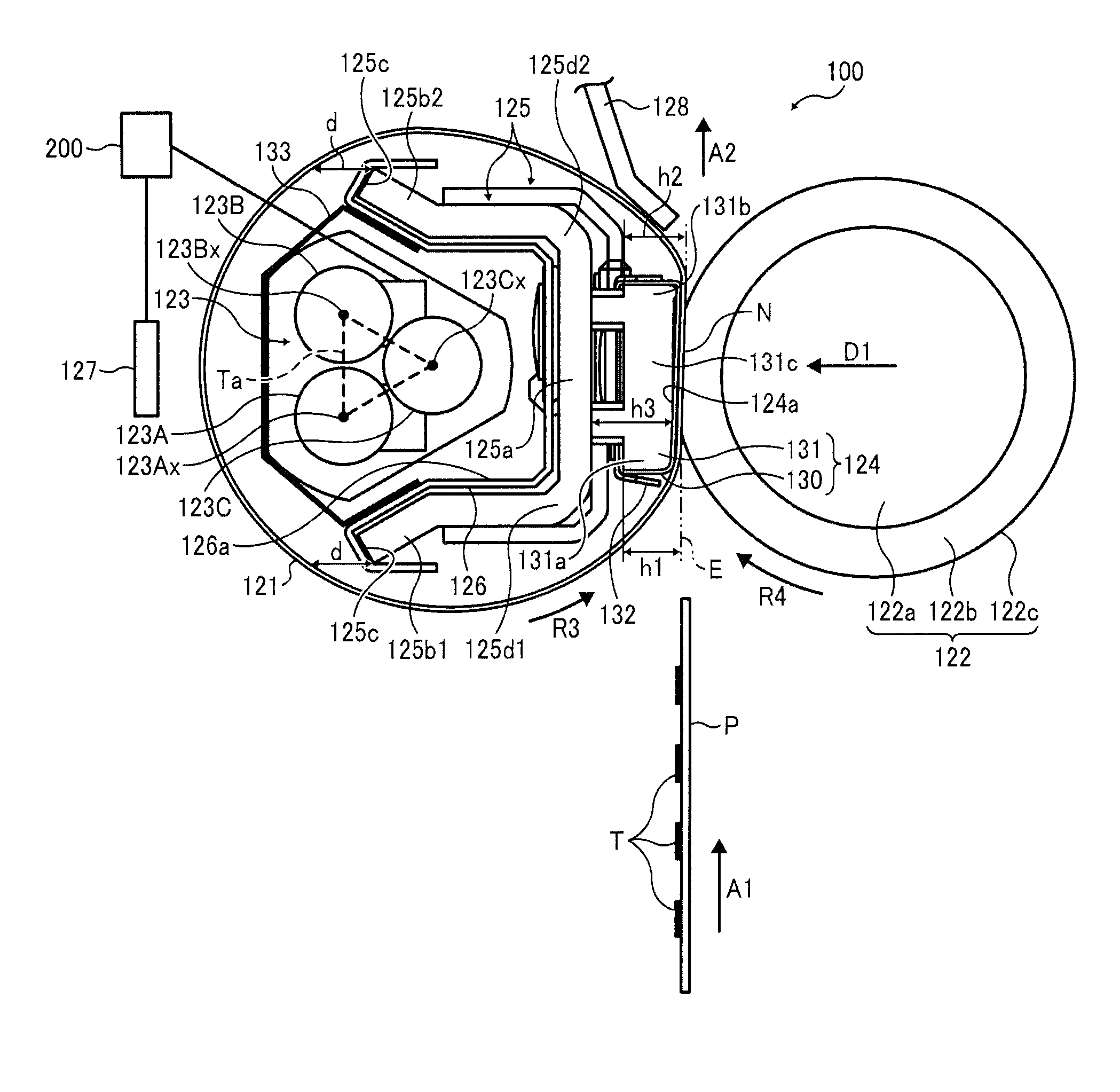

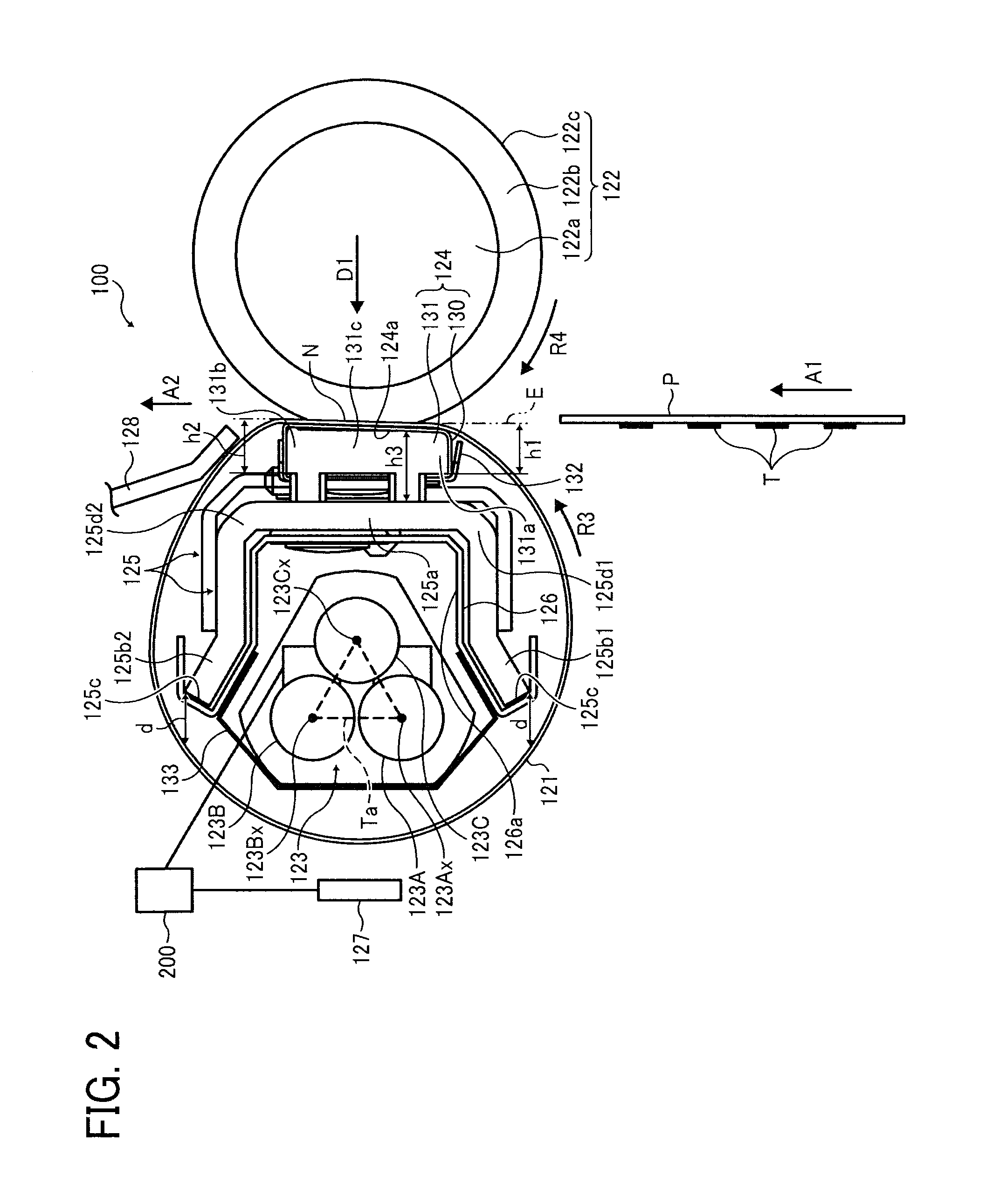

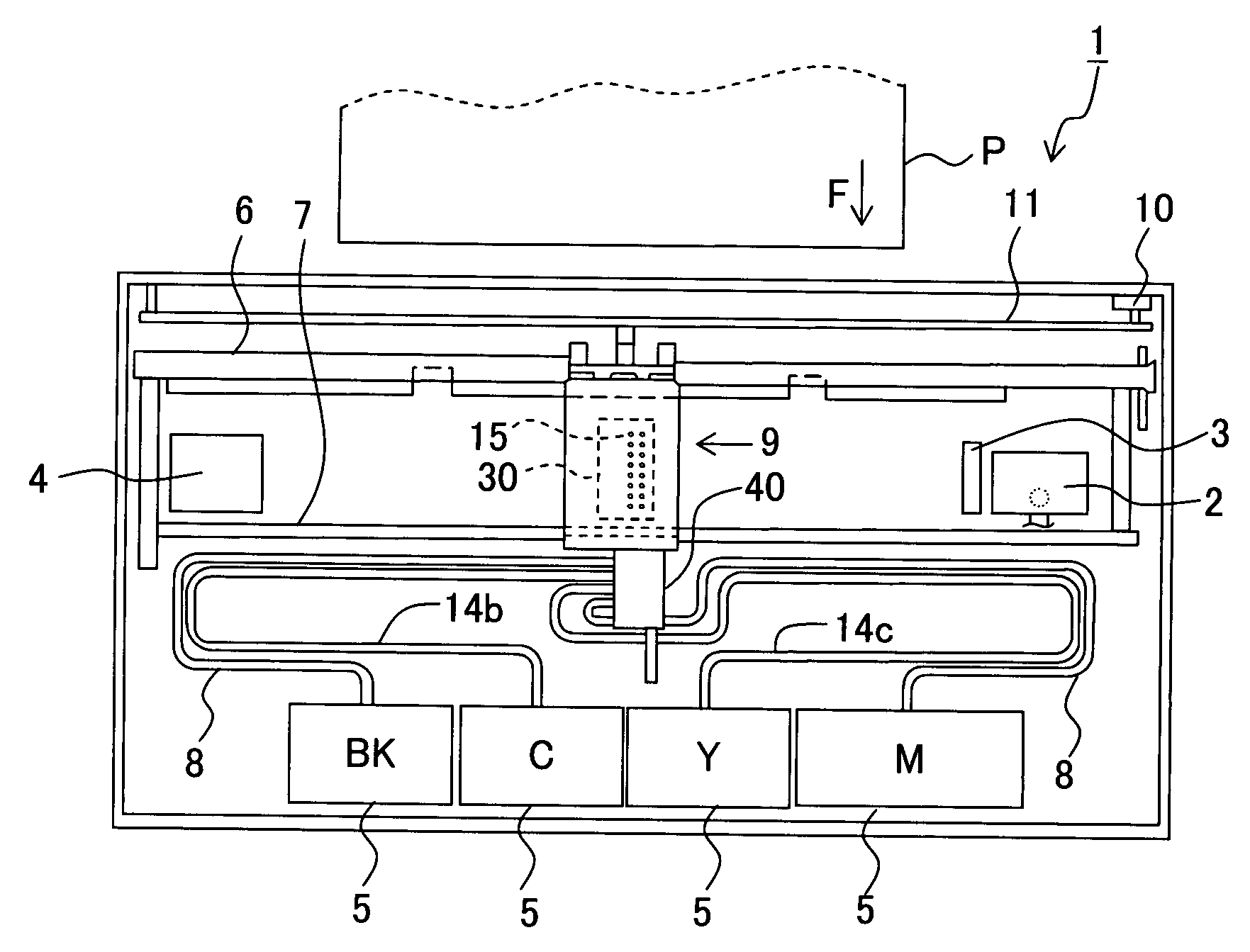

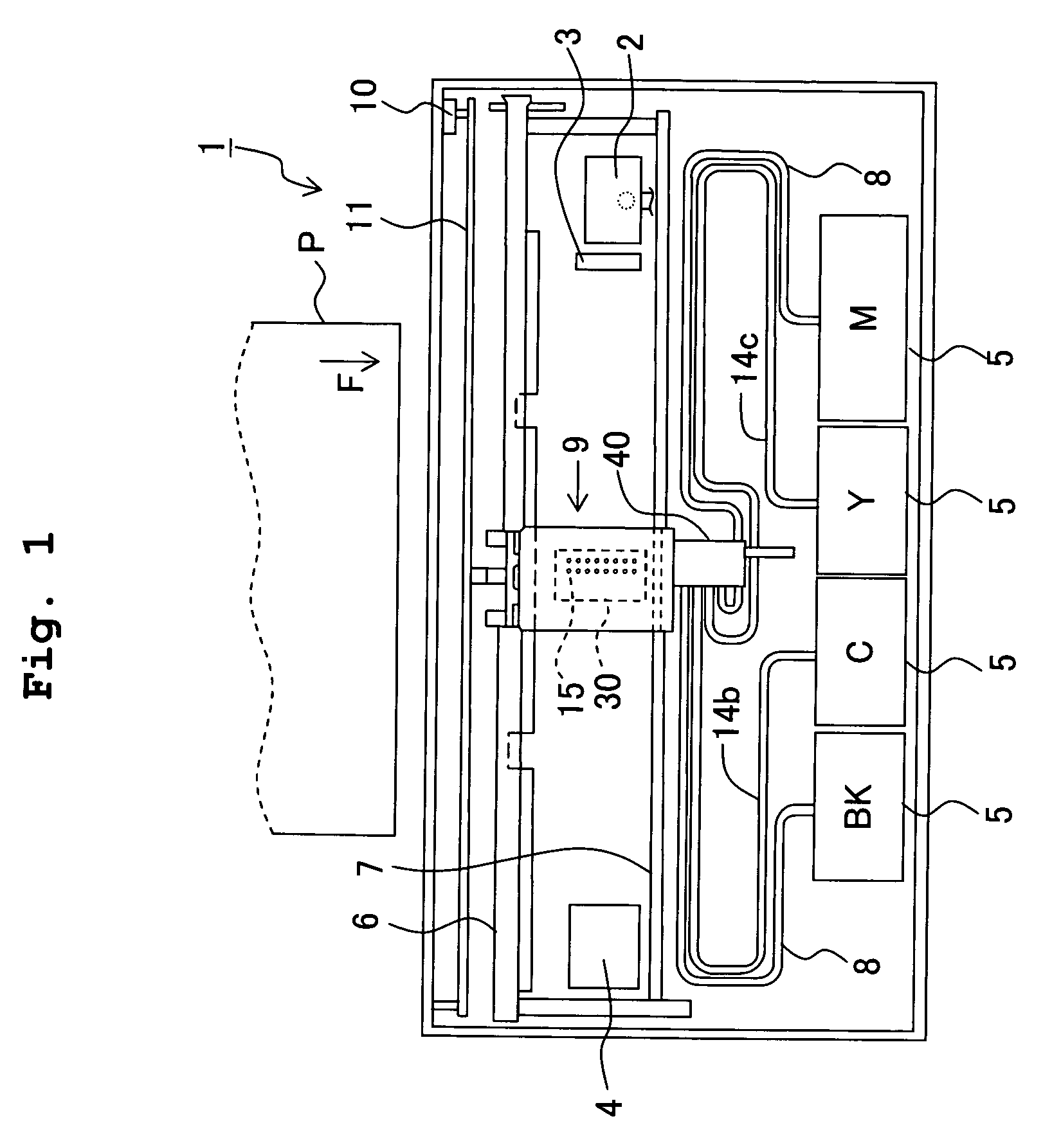

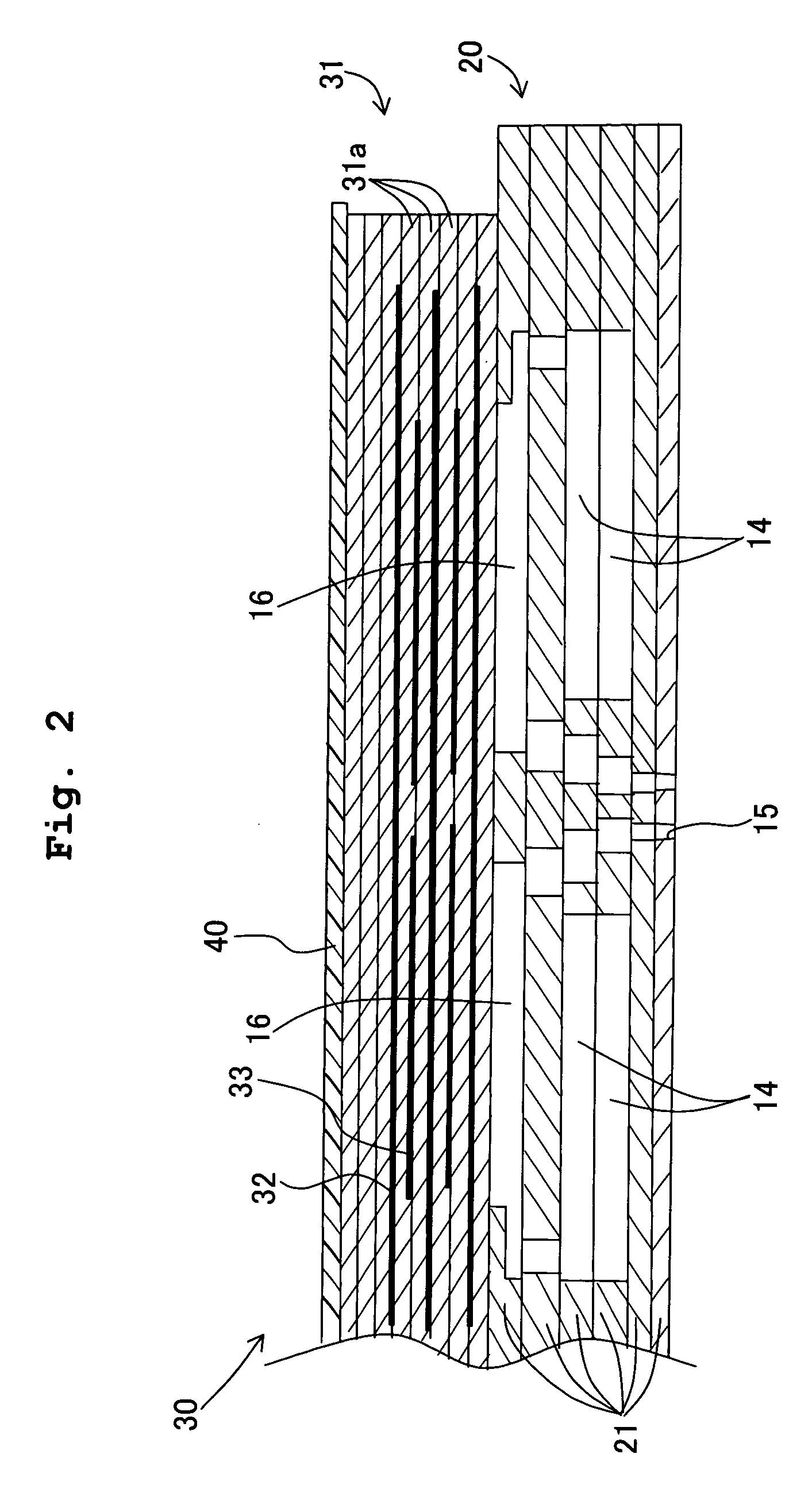

Fixing device and image forming apparatus incorporating same

ActiveUS20110129268A1Reduce wearShorten warm-up timeElectrographic process apparatusEngineeringHeat generation

A fixing device includes a pressing member pressed against a fixing member to form a nip between the pressing member and the fixing member through which a recording medium bearing a toner image passes. A heater support provided inside the fixing member supports a laminated heater. The laminated heater is provided between the fixing member and the heater support and includes a flexible, first heat generation sheet that includes an insulating base layer, at least one resistant heat generation layer provided on the base layer to generate heat, and at least one electrode layer provided on the base layer to supply power to the at least one resistant heat generation layer.

Owner:RICOH KK

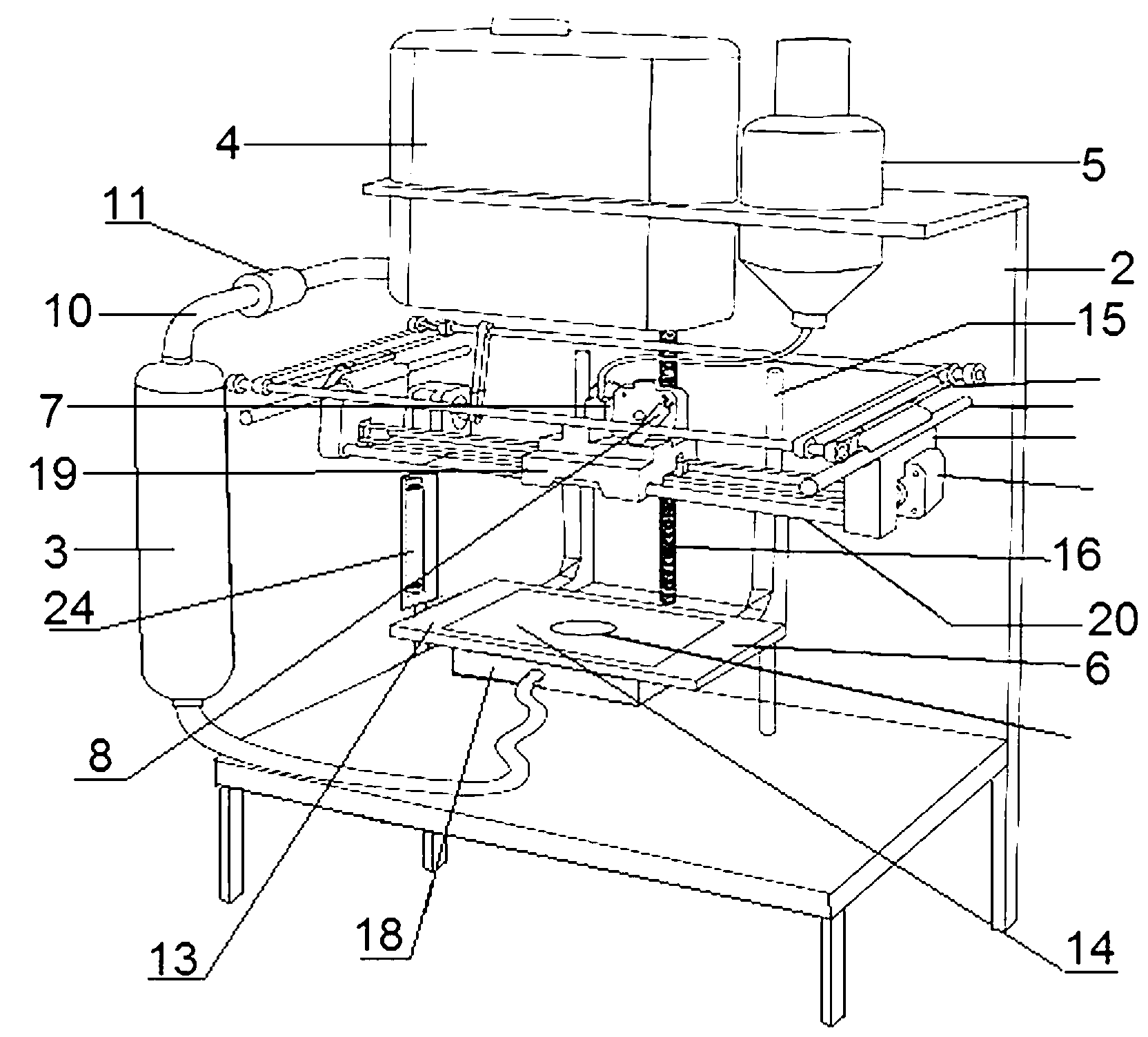

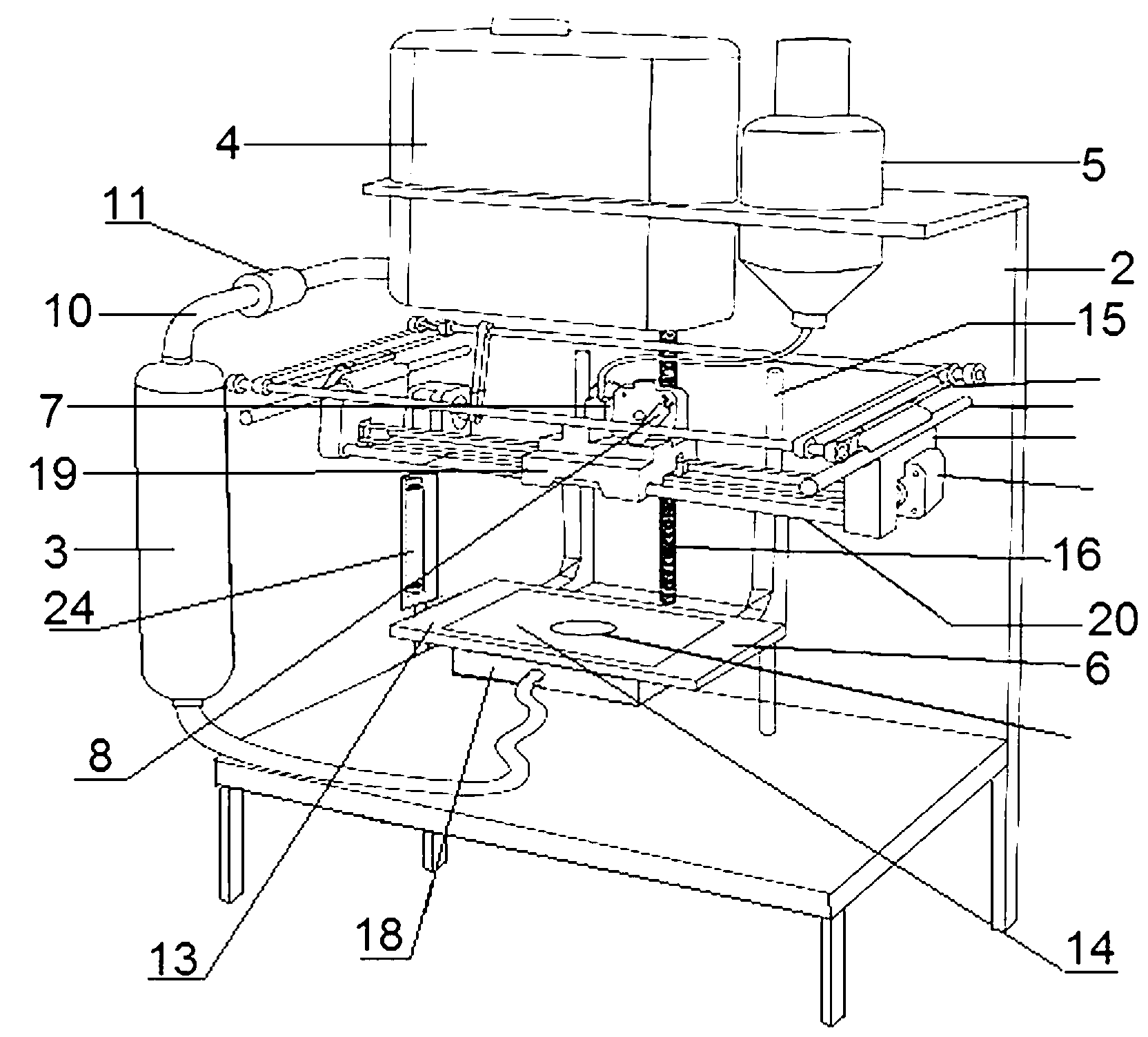

3D printing method and 3D printer

The invention discloses a 3D (three dimensional) printing method and a 3D printer. The method includes the steps of: making use of 3D modeling software in a computer to conduct modeling for an object needing printing; controlling the rise of a lifting platform by the computer; controlling a constant upper surface height of the liquid UV light cured resin in a liquid storage tank by the computer; carrying out printing from a first layer to the shell of a last layer in order, and in the shell printing process, letting the computer control descending of the lifting platform by one layer height in order through a Z-axle motor, making the liquid UV light cured resin in the liquid storage tank flow into the shell, and filling the shell; at the end of shell printing, controlling a wire extrusion device and making it stop extruding pasty UV light cured resin by the computer, and controlling an ultraviolet lamp in terms of irradiating the shell for a period of time by the computer so as to make the liquid UV light cured resin in the shell cured. With high printing efficiency, the 3D printing method and the 3D printer provided in the invention can ensure that the printed object has high density and is easy to damage while guaranteeing the printing efficiency.

Owner:温州启龙电子科技有限公司

Ink composition for ultraviolet curable ink jets, ink jet recording apparatus using the same, ink jet recording method using the same, and ink set

An ink composition for ultraviolet curable ink jets including monomer A represented by a general formula (I):CH2═CR1—COOR2—O—CH═CH—R3 (I)(in the formula, ‘R1’ represents a hydrogen atom or methyl group, ‘R2’ represents a divalent organic residue having a carbon number of 2 to 20, and ‘R3’ represents a hydrogen atom or a monovalent organic residue having a carbon number of 1 to 11), and a photopolymerization initiator containing an acylphosphine oxide-based photopolymerization initiator and a thioxanthone-based photopolymerization initiator, in which the total content of the acylphosphine oxide-based photopolymerization initiator and the thioxanthone-based photopolymerization initiator is 8% by mass to 16% by mass with respect to the total mass of the ink composition.

Owner:SEIKO EPSON CORP

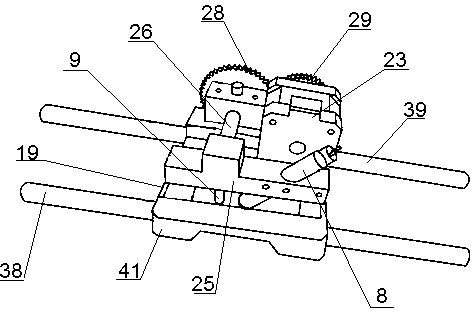

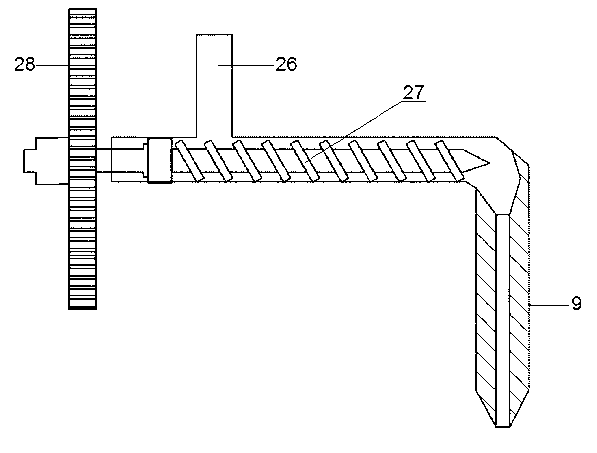

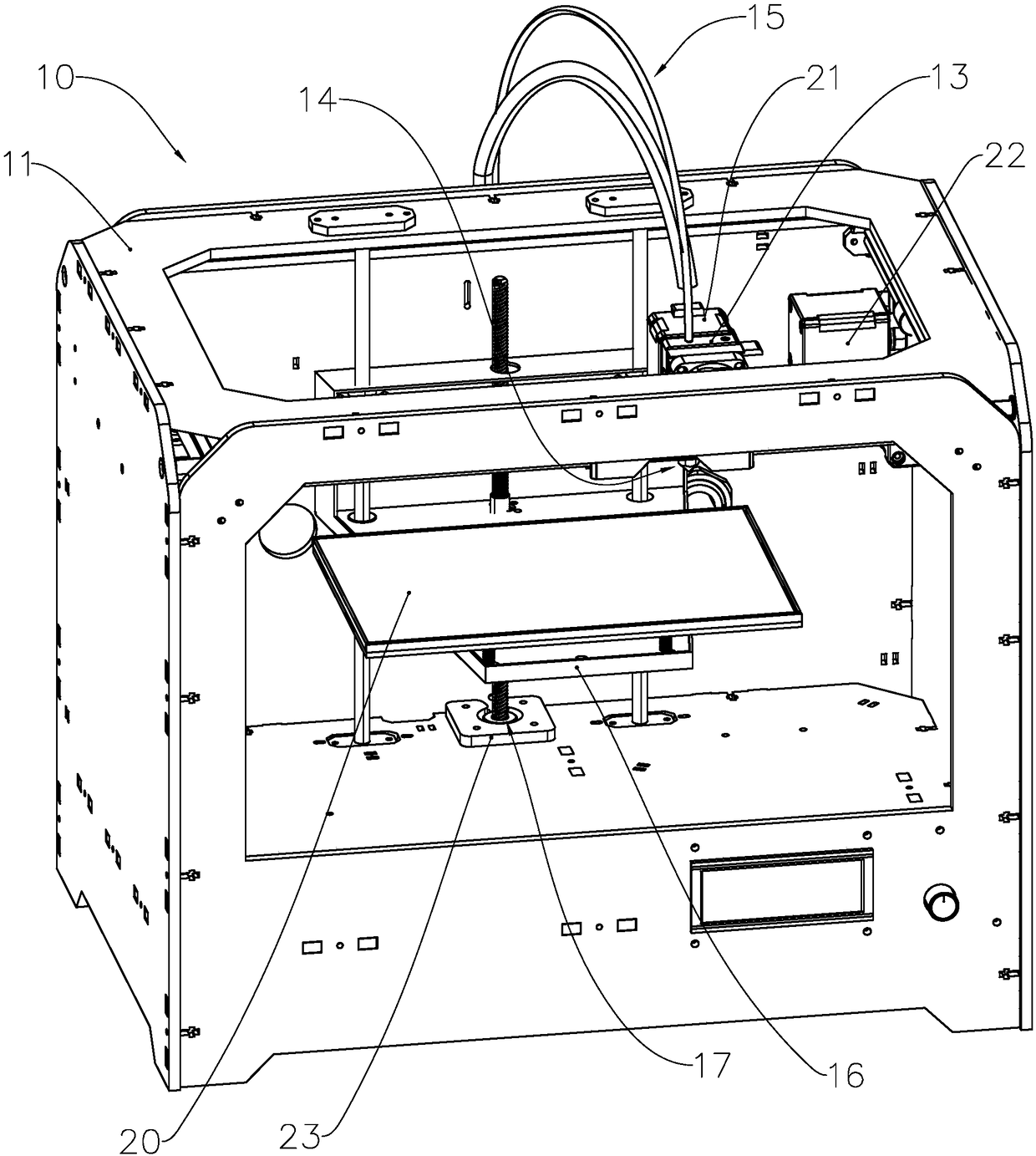

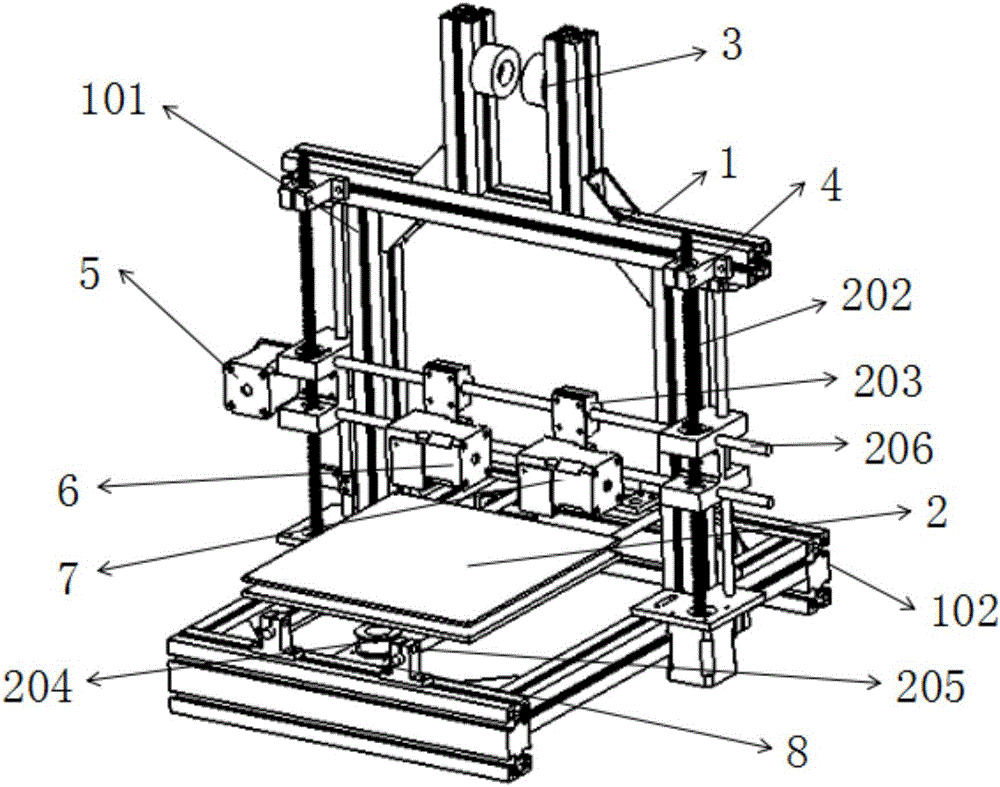

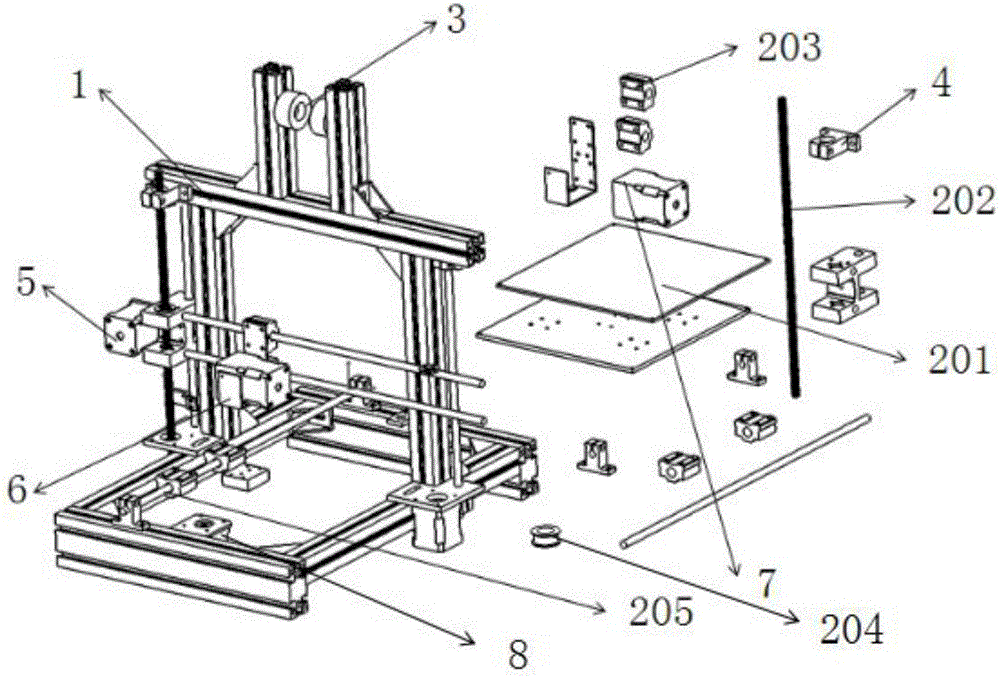

3D printer

The invention discloses a 3D (three dimensional) printer, which comprises a frame, a liquid storage pot with an upper end opening, as well as a first resin cylinder, a second resin cylinder, a lifting platform, a line extrusion device and an ultraviolet (UV) light point light source arranged on the frame. The first resin cylinder is loaded with liquid UV light cured resin, and the second resin cylinder is loaded with paste UV light cured resin. The lower part of the second resin cylinder is communicated with the line extrusion device that is provided with a nozzle, and the irradiation position of the UV light point source is located below the nozzle. The lifting platform includes a flat plate provided with a through hole in the middle part, the upper surface of the flat plate is provided with a metal net, and the flat plate is in sliding connection with two guide pillars on the frame. The lower part of the liquid storage pot is communicated with an upper end opened liquid storage box arranged on the flat plate lower surface through a duct. The 3D printer provided in the invention has high printing efficiency, and while ensuring the printing efficiency, it also can guarantee that the printed object has high density and is difficult to damage.

Owner:温州启龙电子科技有限公司

Fixing device capable of minimizing damage of endless rotary body and image forming apparatus incorporating same

ActiveUS20130209147A1Reduce capacityHeating fastElectrographic process apparatusImage formationRecording media

Owner:RICOH KK

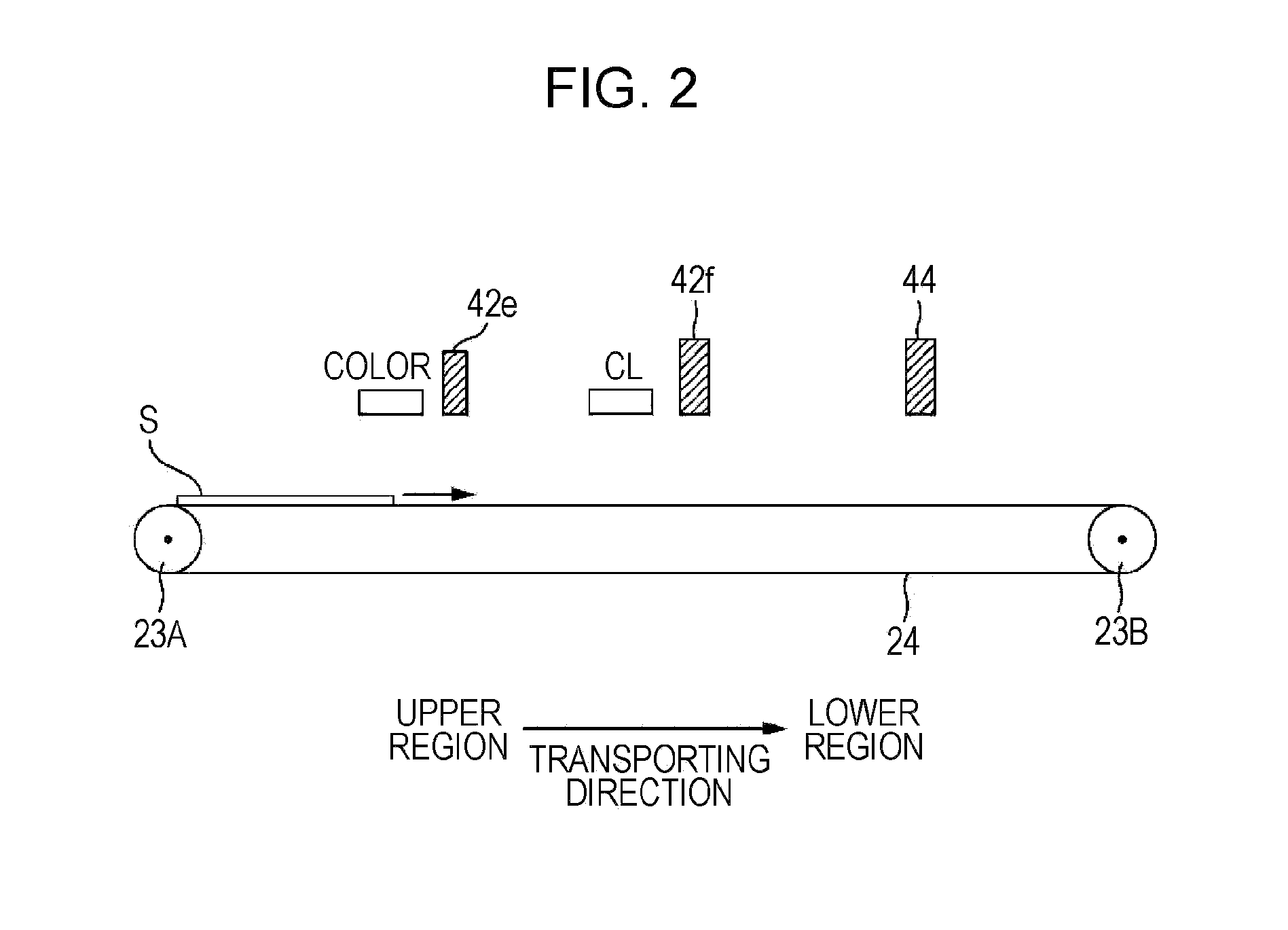

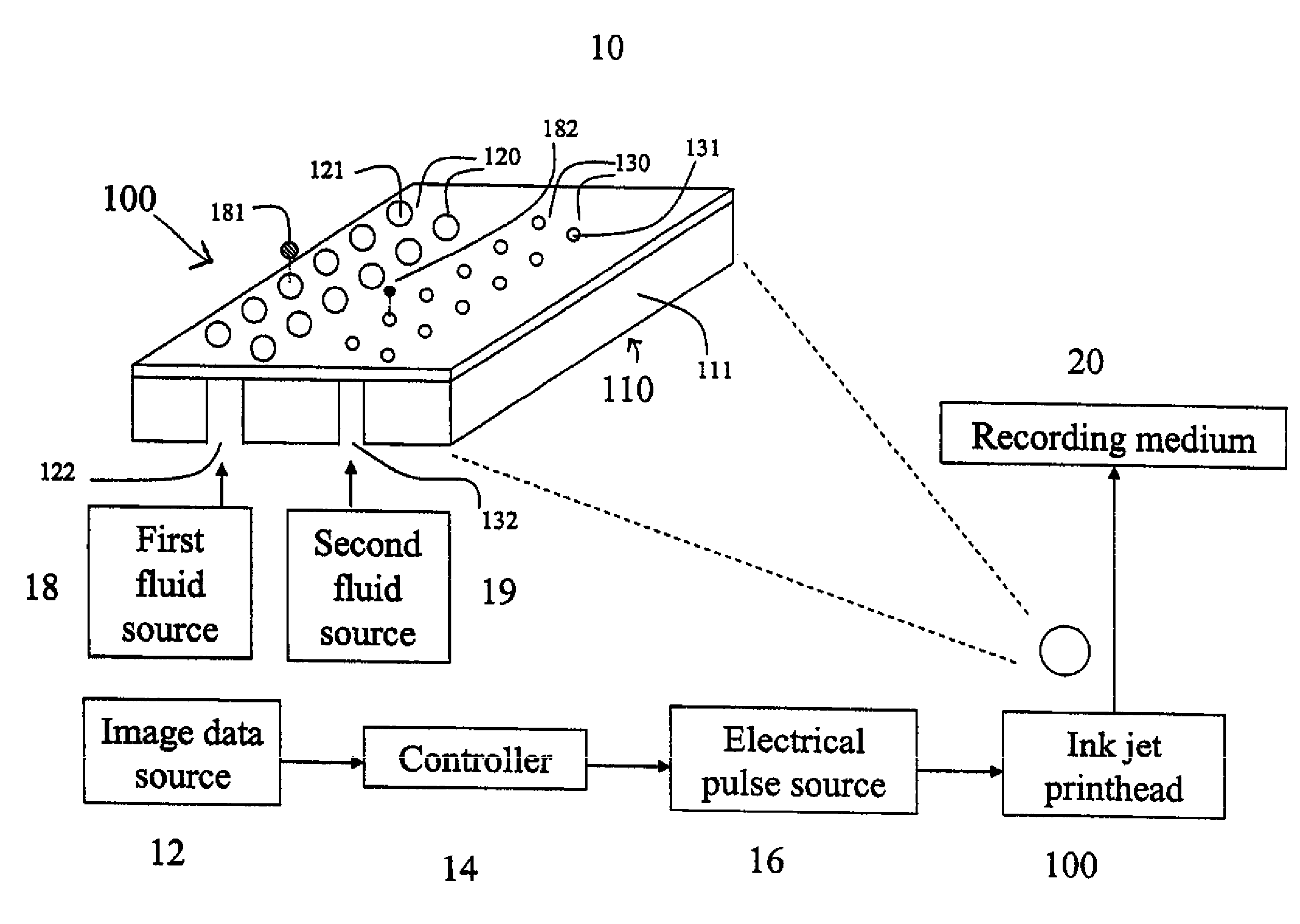

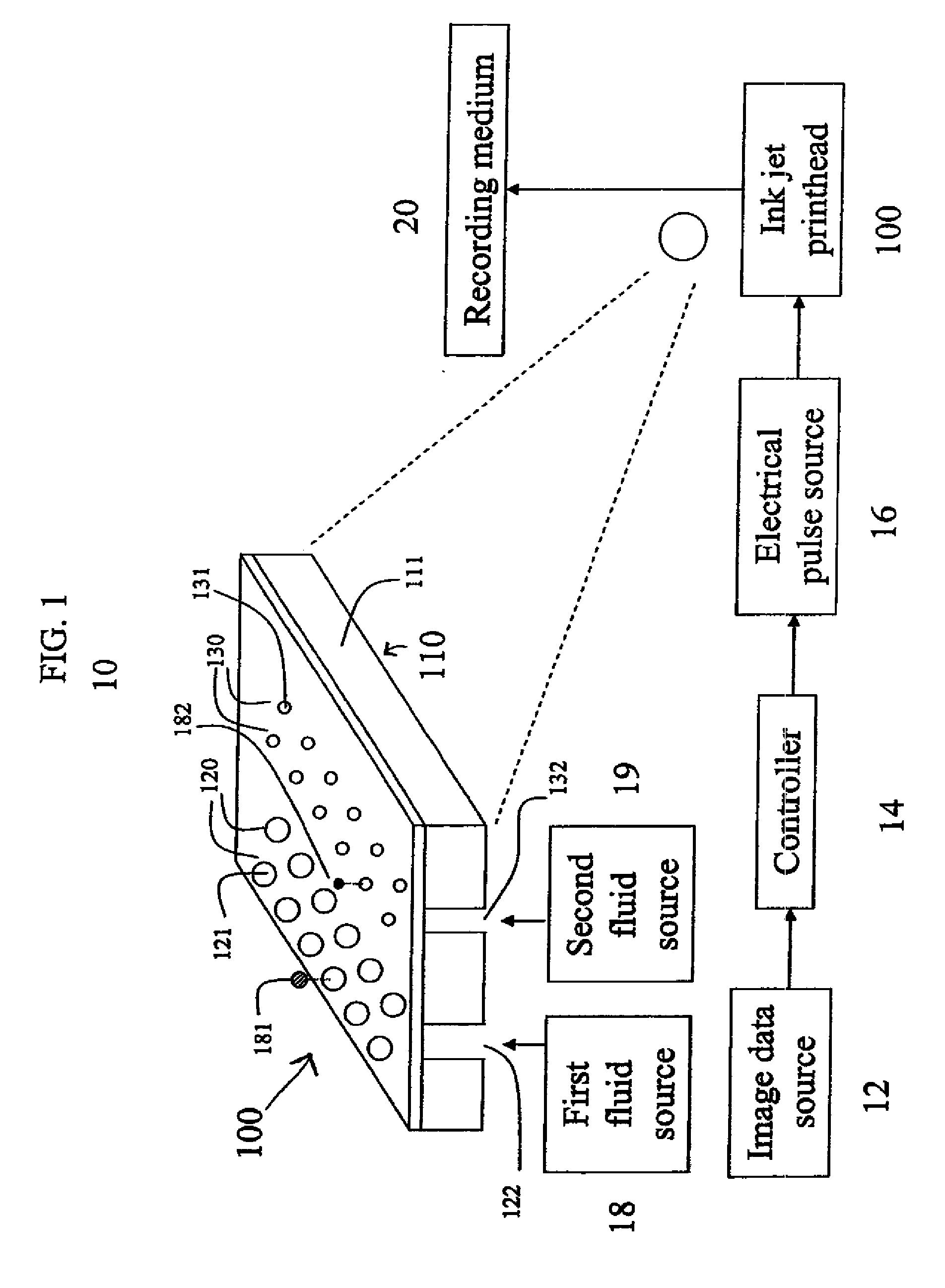

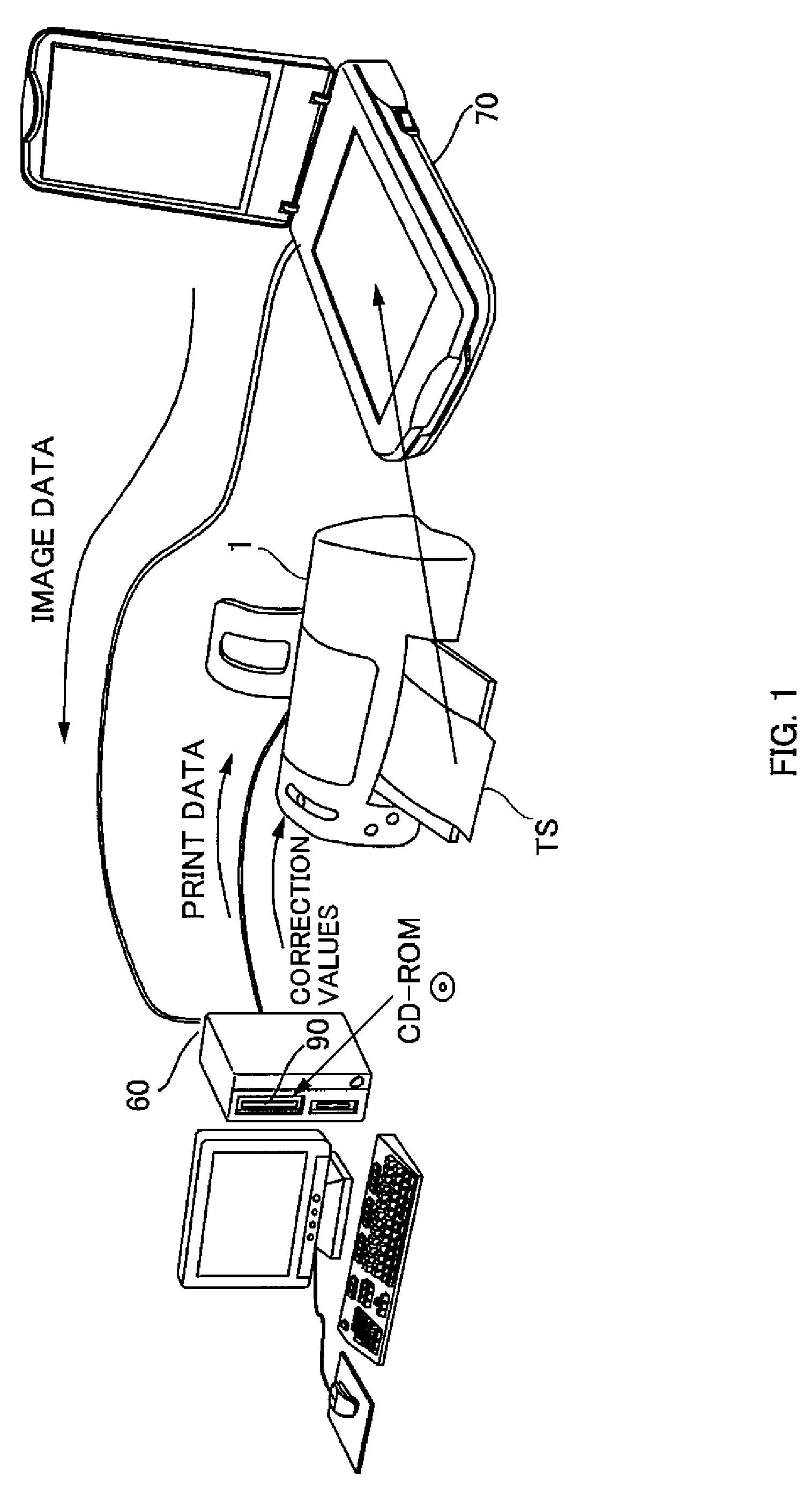

Inkjet printing system and method of printing

InactiveUS20090195579A1Reduce printing timeImprove image qualityDuplicating/marking methodsOther printing apparatusEngineeringDigital signal

A method of printing comprises providing a carriage-type inkjet printer having a printhead, with the printer being responsive to digital signals and capable of printing in a multi-pass printing mode, supplying the printer with pigment-based inks, supplying the printer with a receiver surface suitable for printing of photographic images, detecting a degree of texturing on the receiver surface, selecting a number of passes for the multi-pass printing mode based on the detected degree of texturing of the receiver surface, and passing the print head over the receiver surface in accordance with the selected number of passes.

Owner:EASTMAN KODAK CO

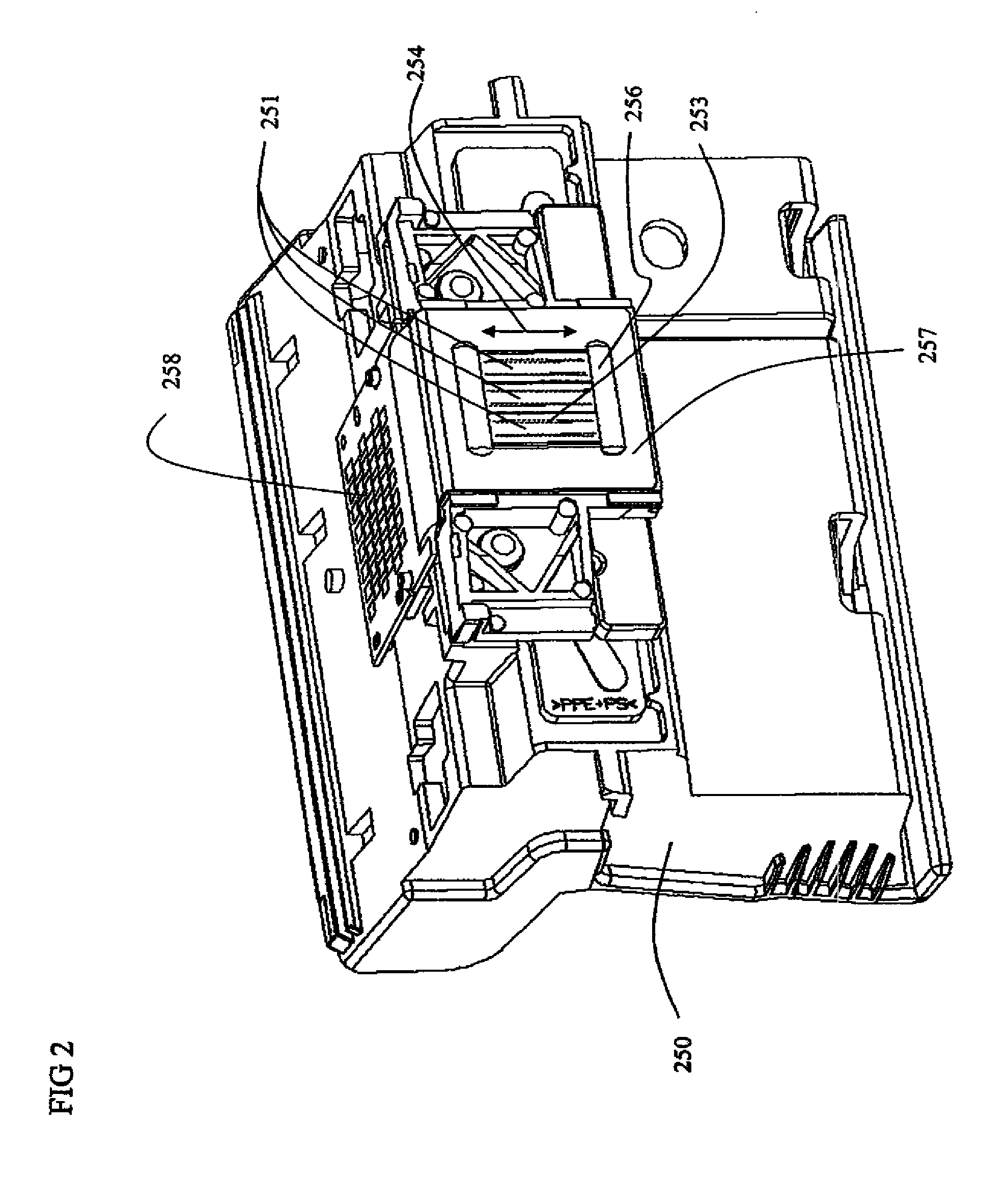

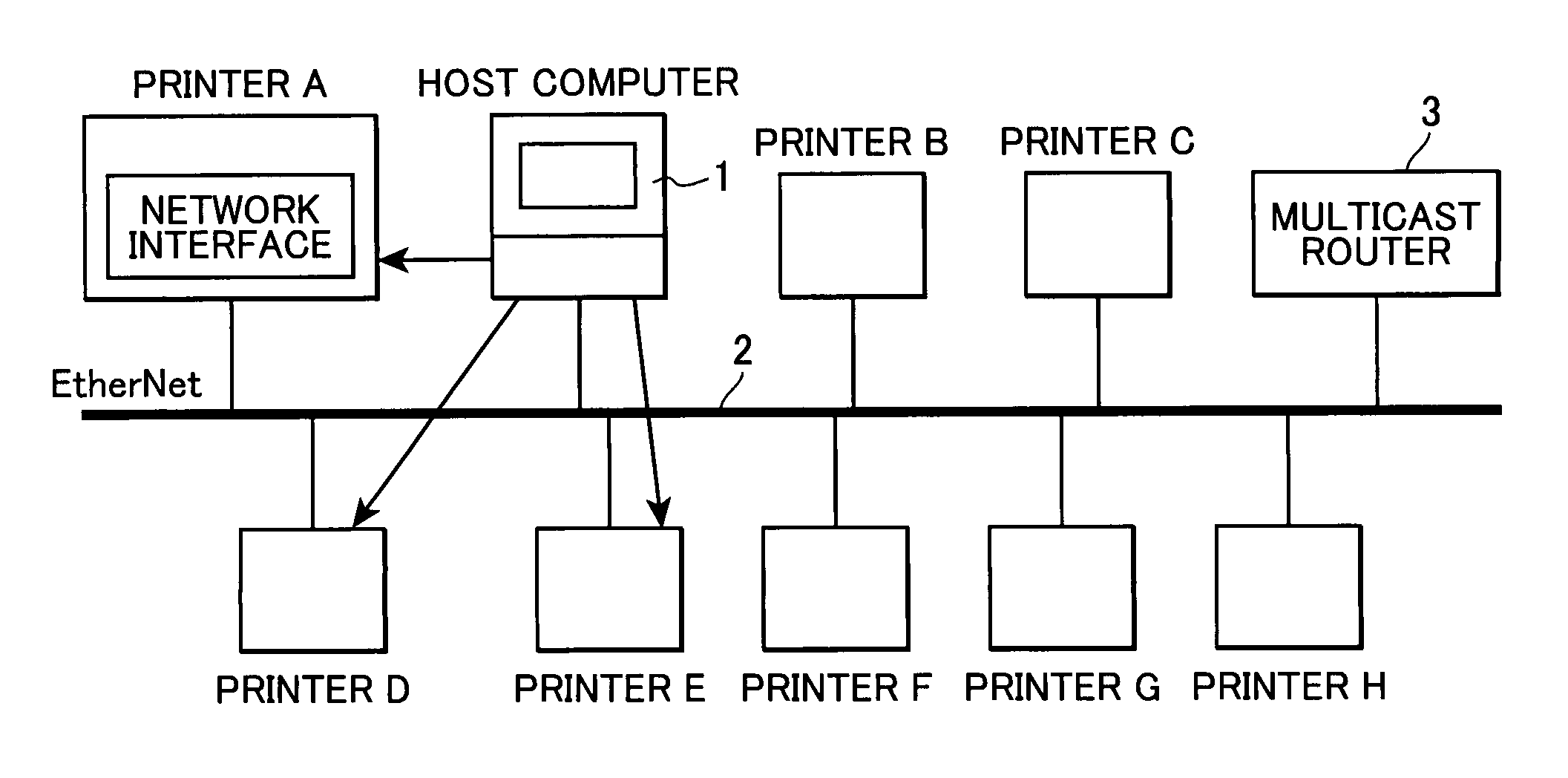

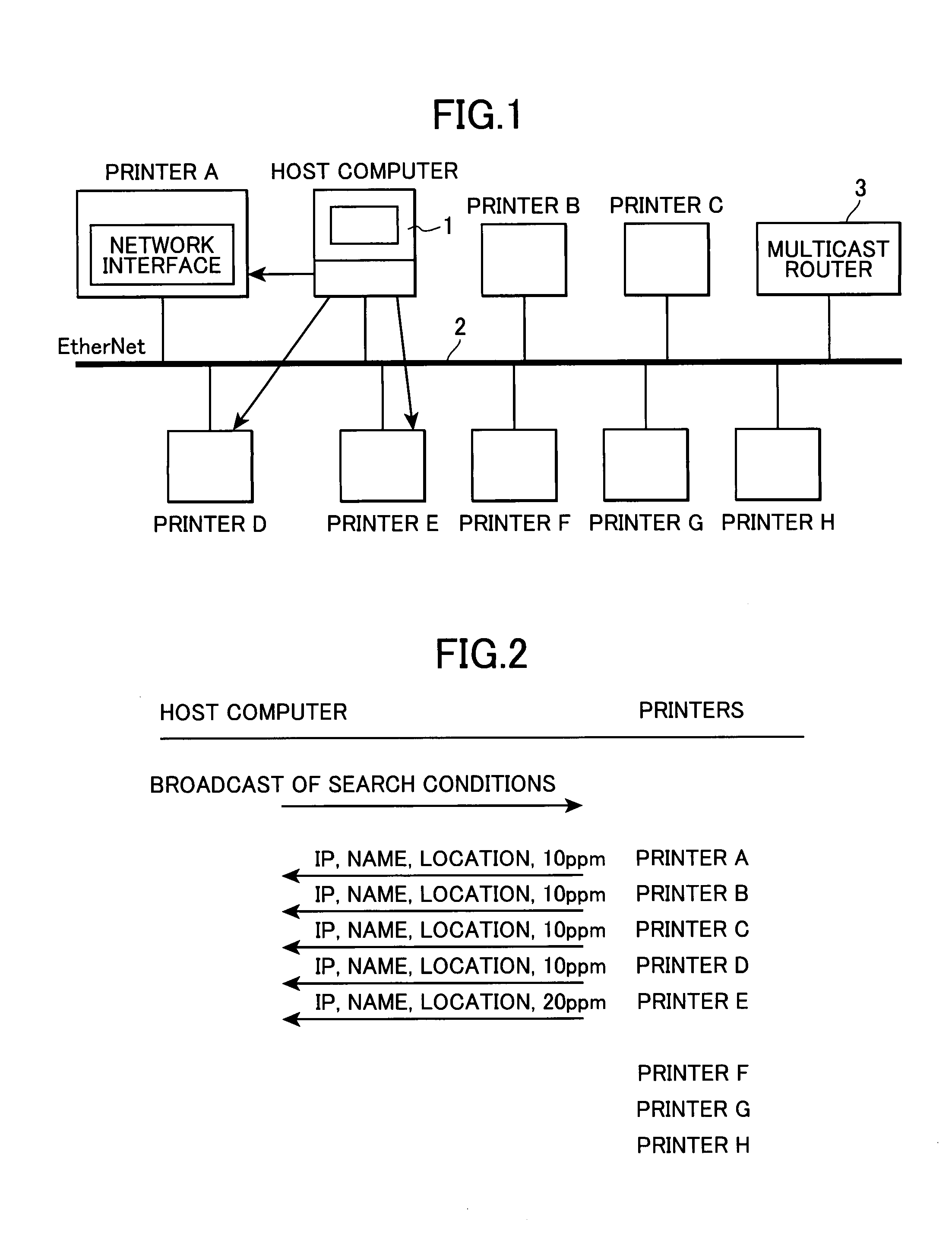

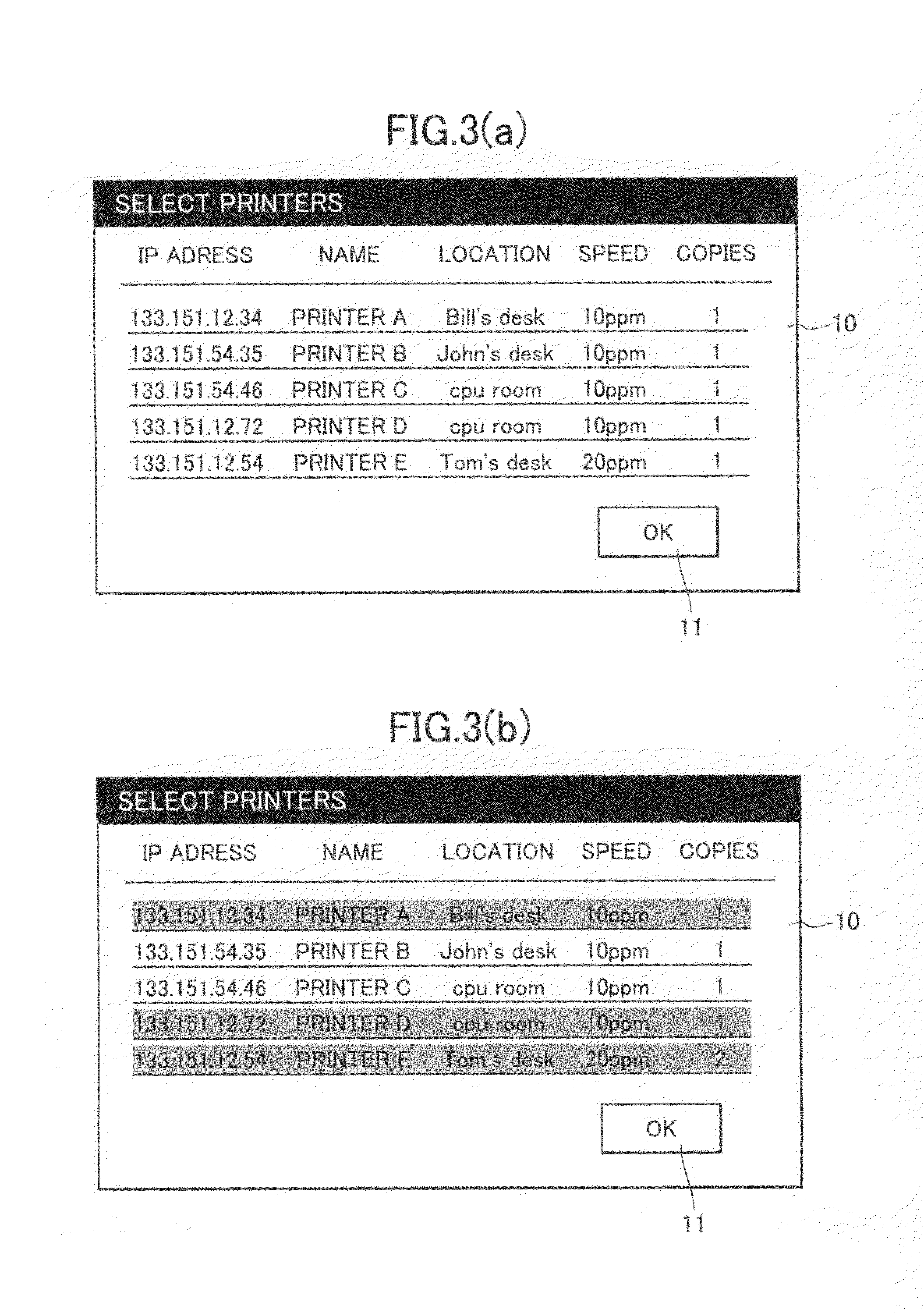

Device and method for using multicast to transmit print data to networked printers

InactiveUS7298508B2Easy to limitReduce printing timeVisual presentationDigital output to print unitsMulticast addressData conversion

A printer control device includes a joining unit, a transmission unit, and a control unit. The joining unit causes at least one network printer to join a predetermined multicast address. The transmission unit converts print data into packets and multicast transmits the packets to the predetermined multicast address. The control unit monitors transmission / reception status of the packets at the at least one network printer that has joined the multicast address. Based on monitoring results the control unit controls transmission of packets to, waiting for packets from, and retransmission of packets to the predetermined multicast address.

Owner:BROTHER KOGYO KK

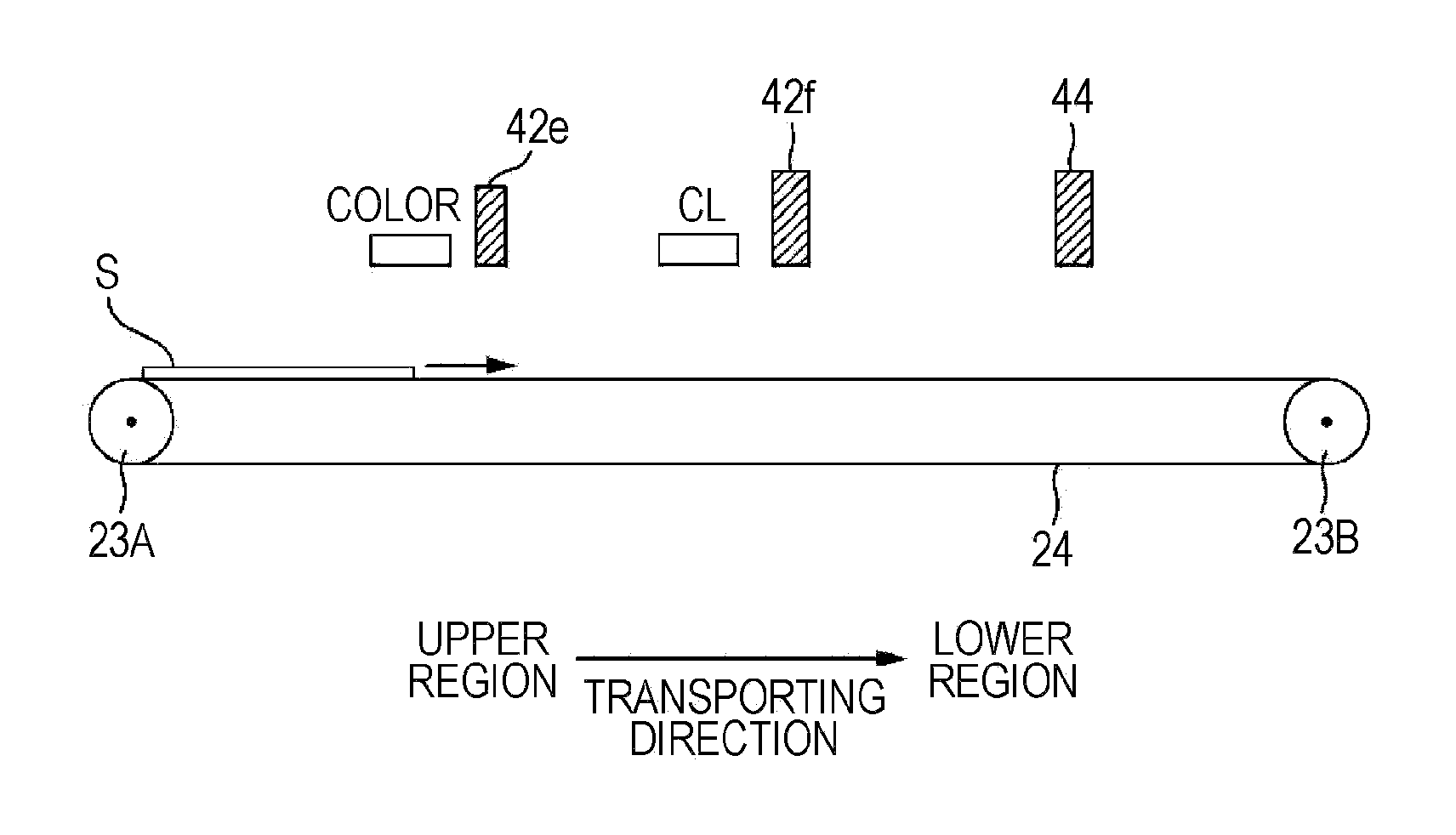

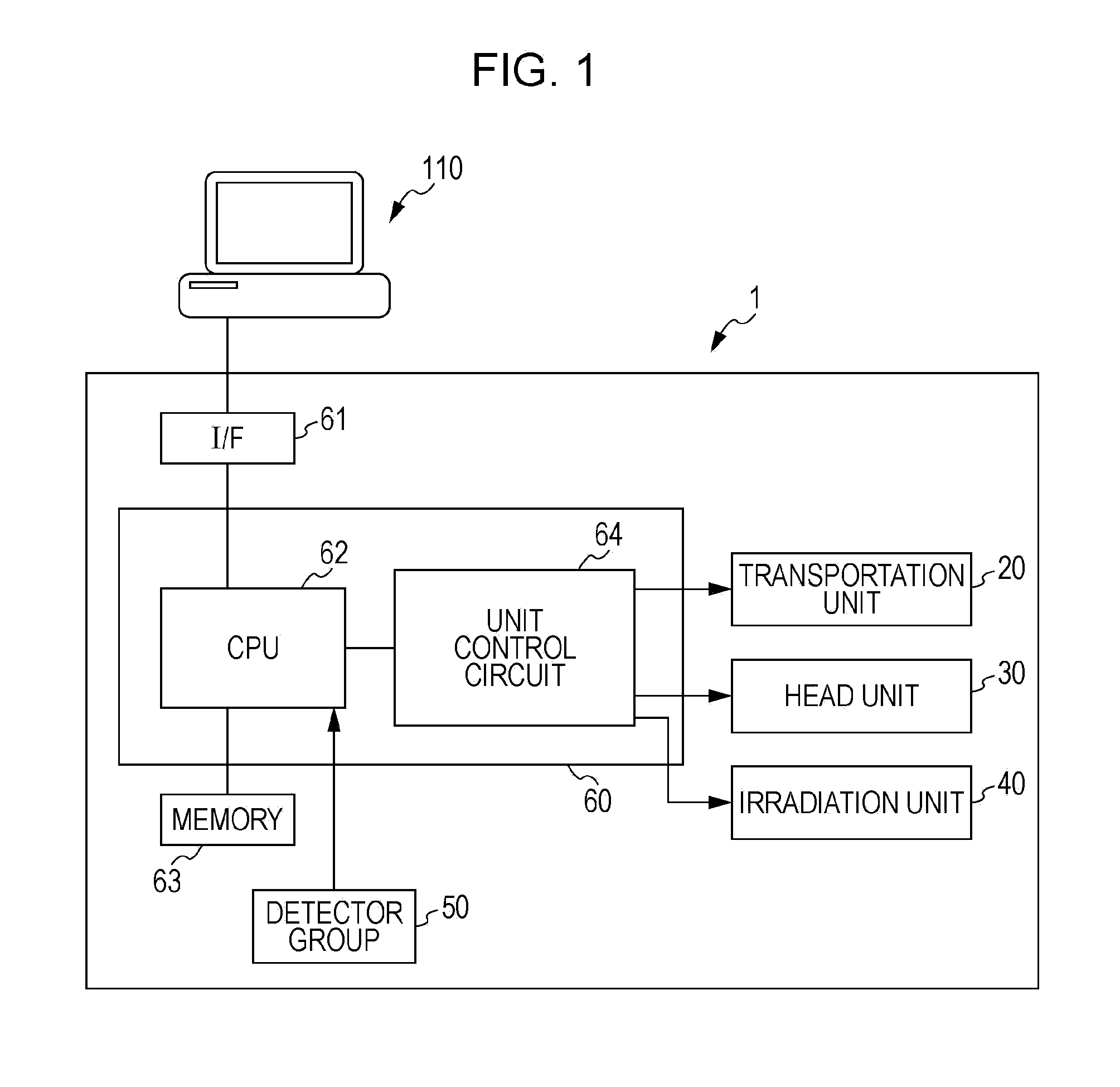

Liquid Discharging Apparatus and Control Method Therefor

InactiveUS20080049058A1Reduce printing timeTimely maintenanceOther printing apparatusLiquid dropWaste management

In a liquid discharging apparatus for discharging droplets from a liquid discharge nozzle to a discharge object to be discharged and in a method for controlling the liquid discharging apparatus, cleaning effects for the ink discharge nozzle and the adjacent areas can be enhanced, and the time required for a series of performance maintaining operations can be reduced. The apparatus includes a platen plate for supporting recording paper as the discharge object, defining a positional relationship between the discharge object and the liquid discharge head, and receiving the droplets discharged from the liquid discharge head. Ink droplets are preliminarily discharged from the ink discharge nozzle to the platen plate.

Owner:SONY CORP

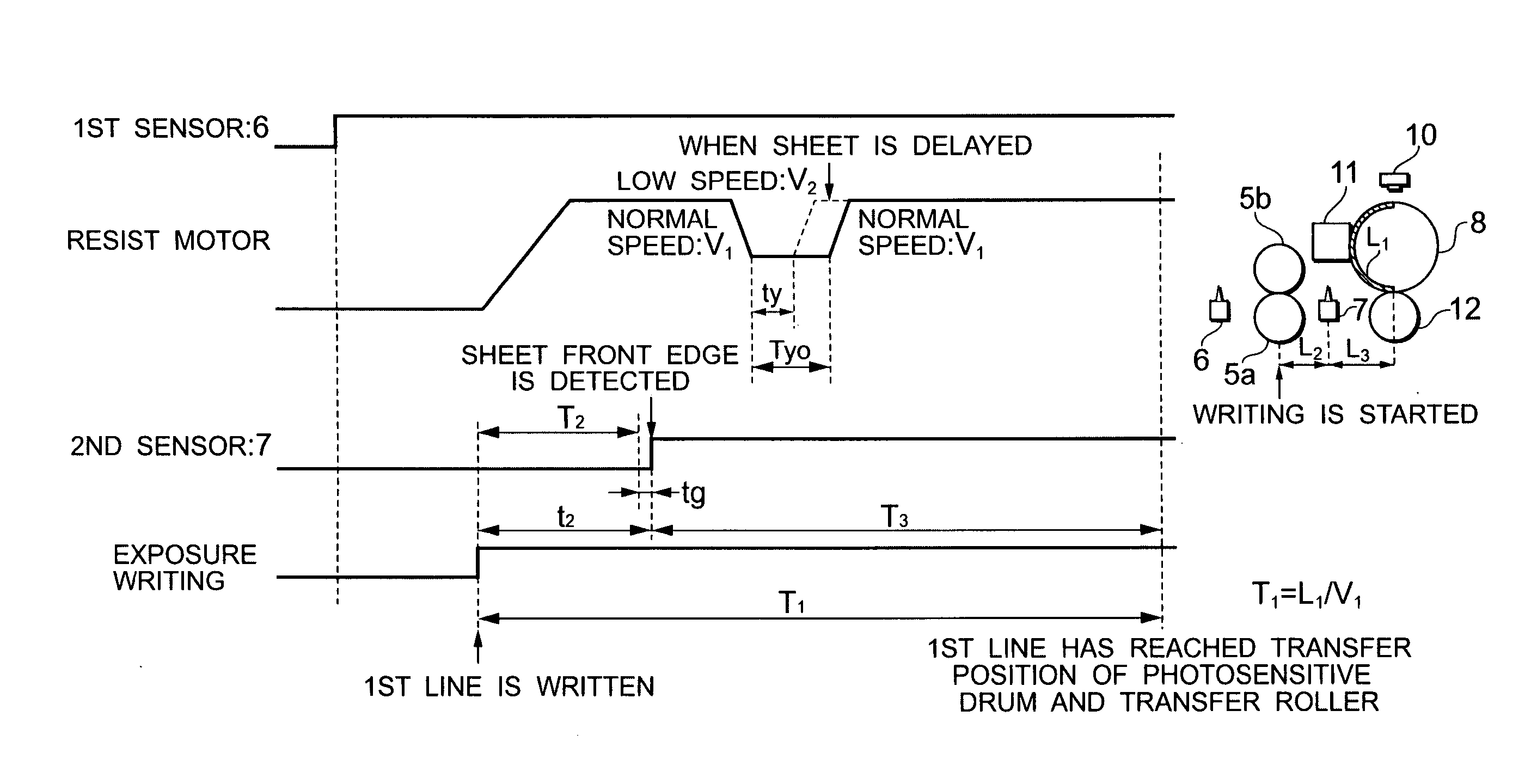

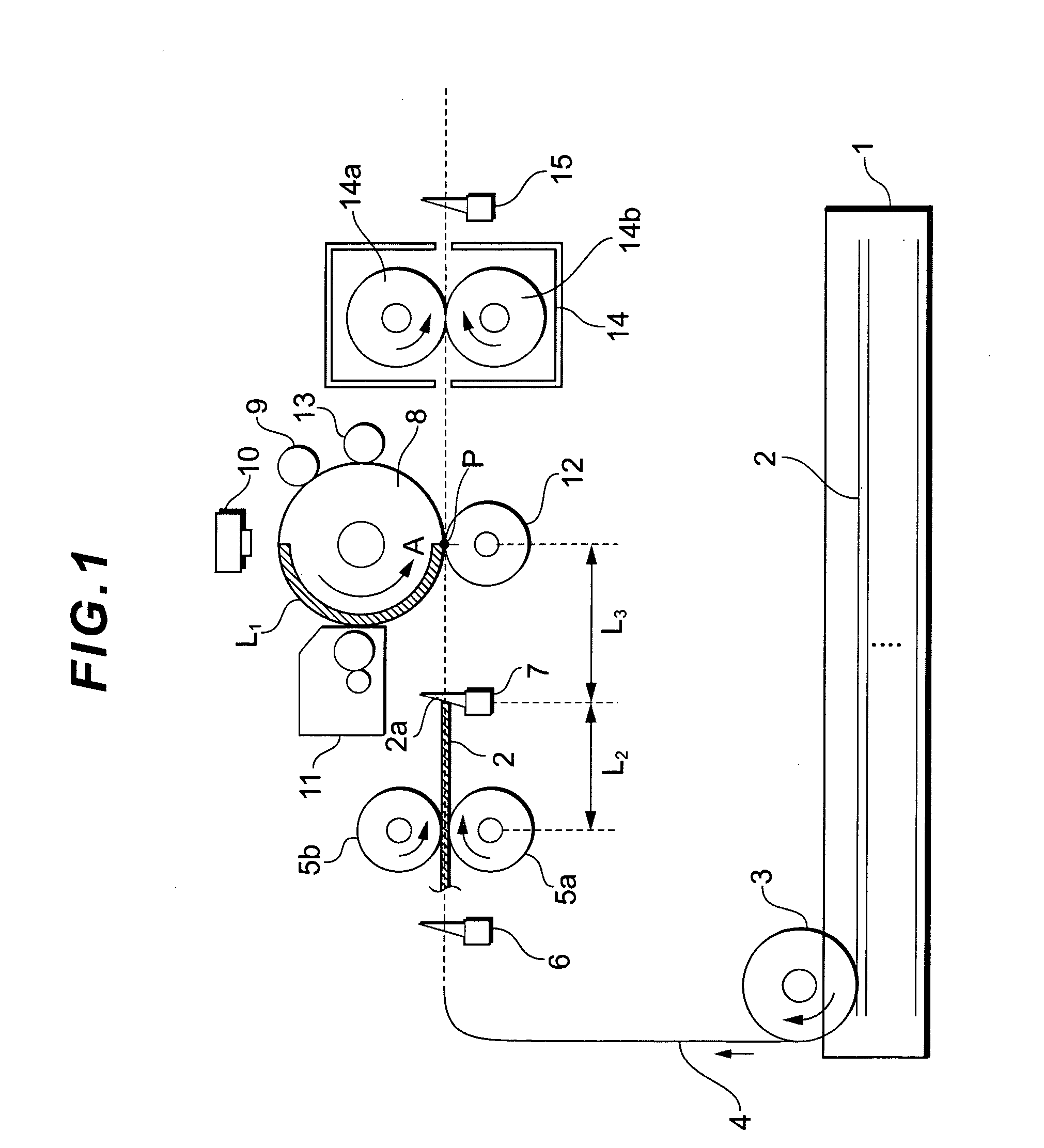

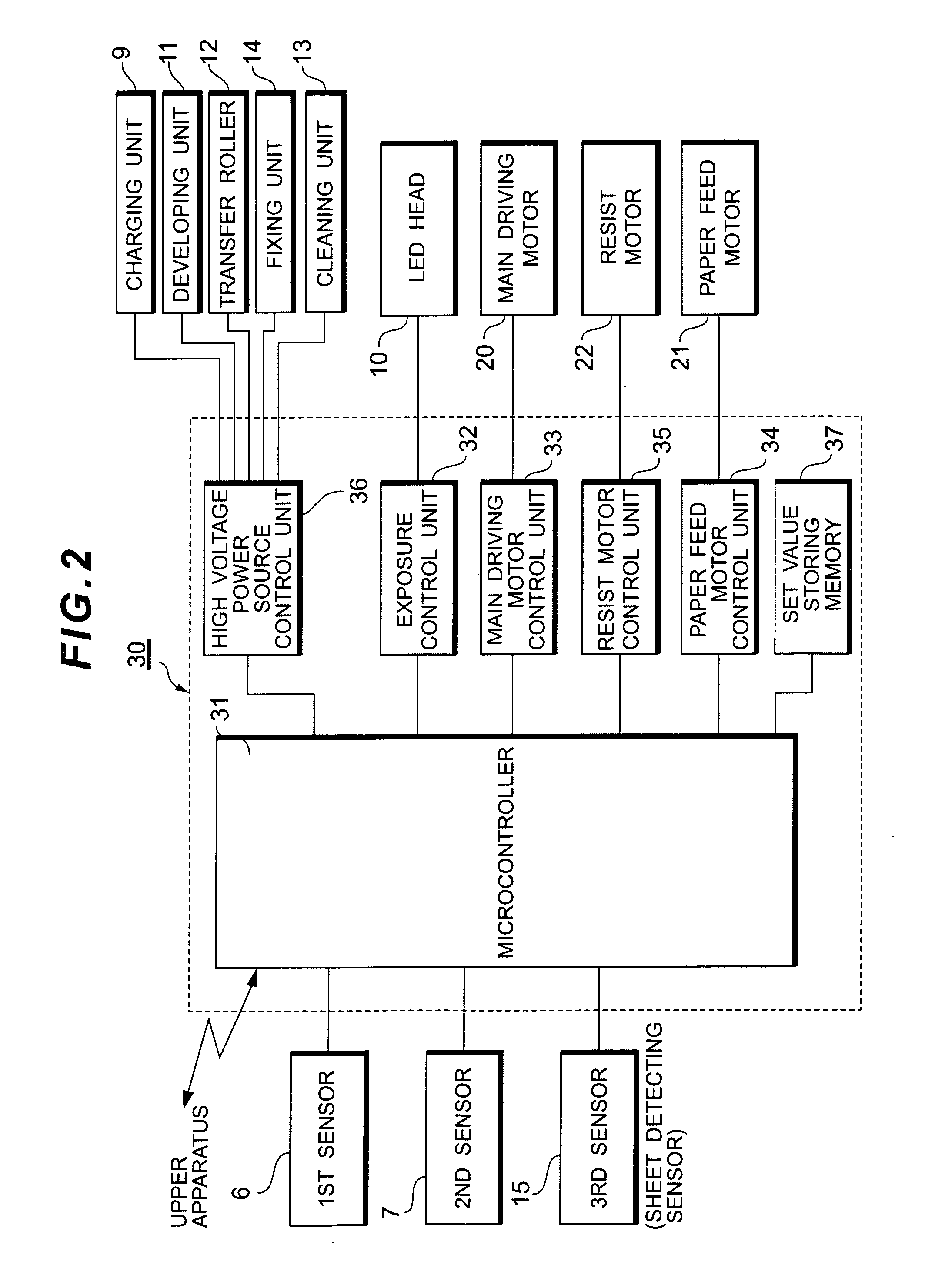

Image recording apparatus and its control method

ActiveUS20050254870A1High speedHigh-speed executionElectrographic process apparatusImage recordingTime of arrival

After a skew of a sheet as a recording medium is corrected by correcting a sheet curve, exposure writing on a photosensitive drum is started synchronously with re-driving of resist rollers. When a sheet front edge is detected by a sensor, sheet conveyance is continued while adjusting a sheet conveying speed when an exposure start position reaches a transfer position at a pressure contact point between the drum and a transfer roller, thereby adjusting the time of arrival at the transfer position. A time / distance interval between the preceding and subsequent sheets are shortened, a conveying path is shortened, and the whole apparatus is miniaturized. Print processing efficiency is raised and stable printing without a variation is executed. A transfer start position of the sheet is made to accurately coincide with the exposure start position of the drum, thereby realizing a high print processing speed.

Owner:OKI ELECTRIC IND CO LTD

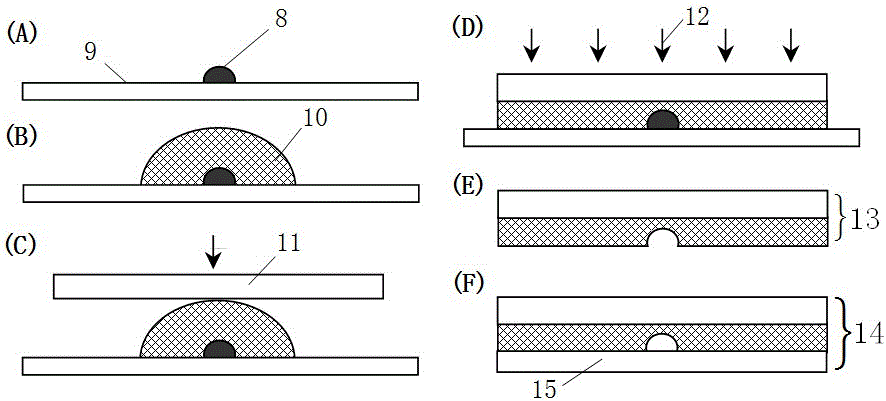

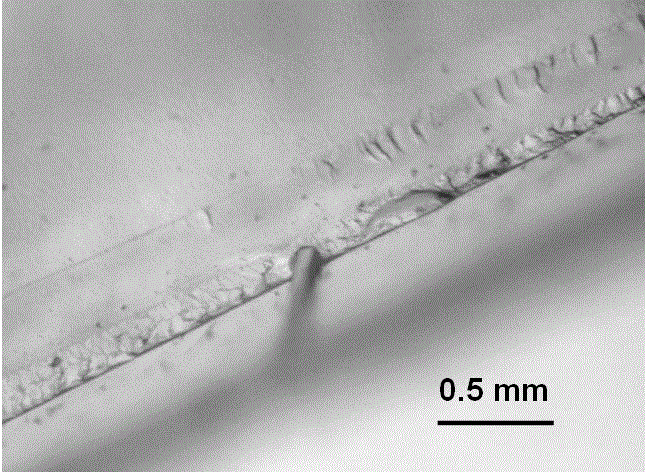

Preparation method for polymer micro-fluidic chips on basis of 3D hydrogel printing

ActiveCN105711017ALow costForming is simple and convenientAdditive manufacturing apparatusCross-linkEpoxy

The invention belongs to the technical field of micro-fluidic chips and particularly discloses a preparation method for the polymer micro-fluidic chips on the basis of 3D hydrogel printing. The preparation method comprises the steps of preparing hot and reversible carrageenan or agar hydrogel, and improving the mechanical strength of the hydrogel, lowering the viscosity of the molten hydrogel and increasing the gelatinization speed after the hydrogel is cooled by adjusting the concentration of the hydrogel and using cross-linking agents; designing structural units such as channel networks, solution holes and reactors of the micro-fluidic chips through software, outputting the design documents to a high-accuracy 3D hydrogel printer and printing the hydrogel on a bottom plate for obtaining male hydrogel molds; mixing macromolecular prepolymers and curing agents for obtaining mold casting solutions, pouring the solutions on the male molds, covering the male molds with cover plates, enabling the gaps between the cover plates and the male molds to be filled with mold casting solutions, releasing the molds for obtaining micro-fluidic chip substrates after curing and obtaining finished products of the micro-fluidic chips after the substrates and cover sheets are packaged. According to the method, the polymer micro-fluidic chips made of polymethyl methacrylate, polydimethylsiloxane or epoxy resin can be processed.

Owner:FUDAN UNIV

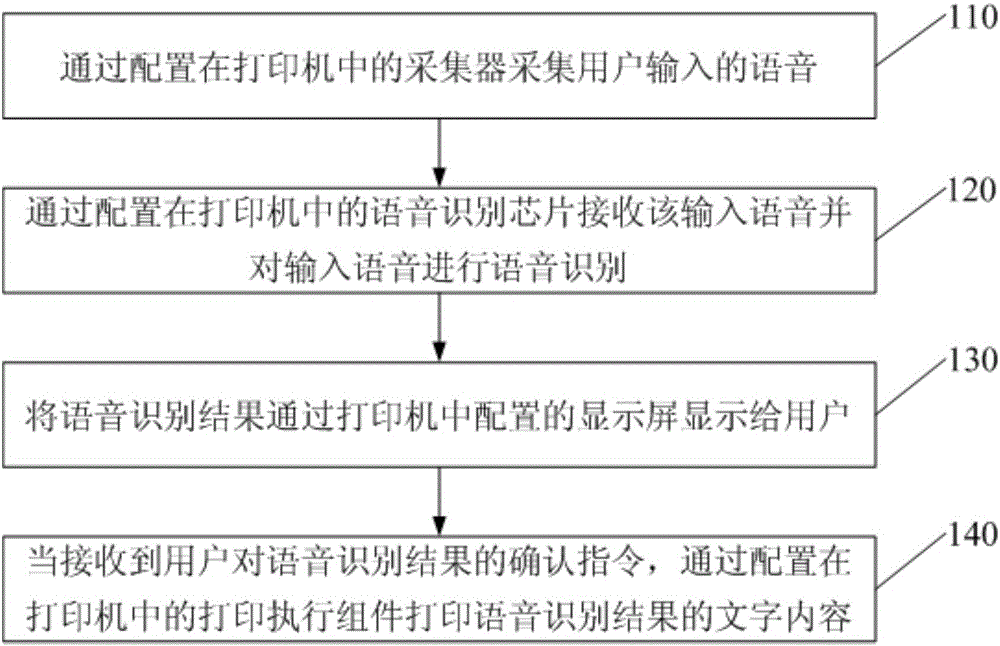

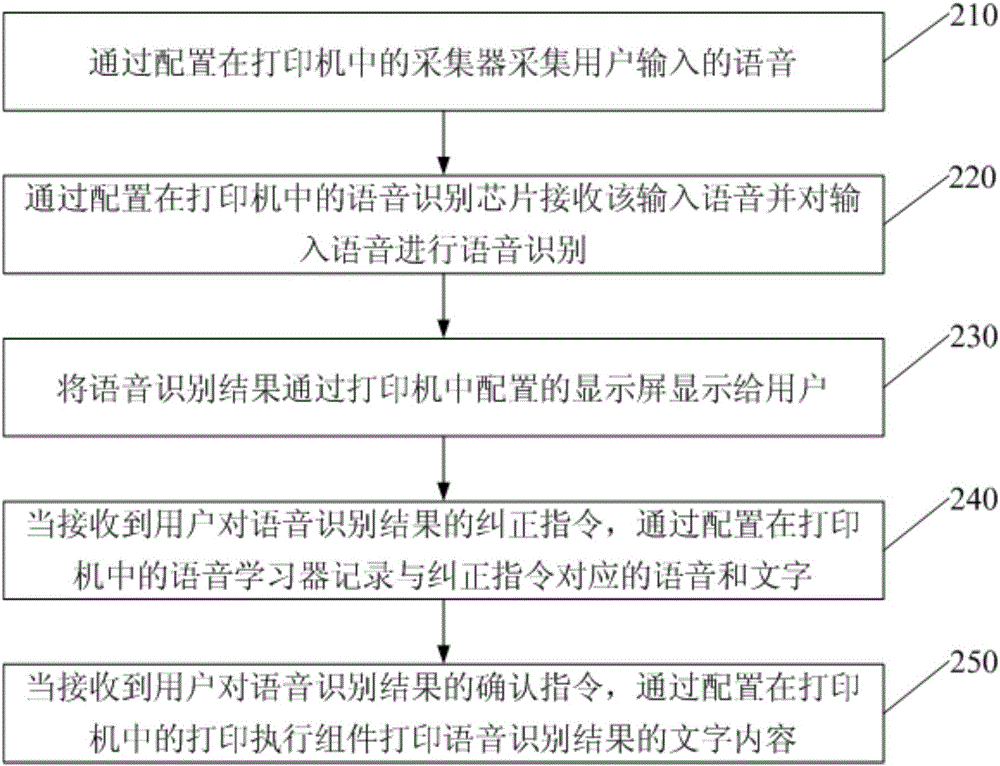

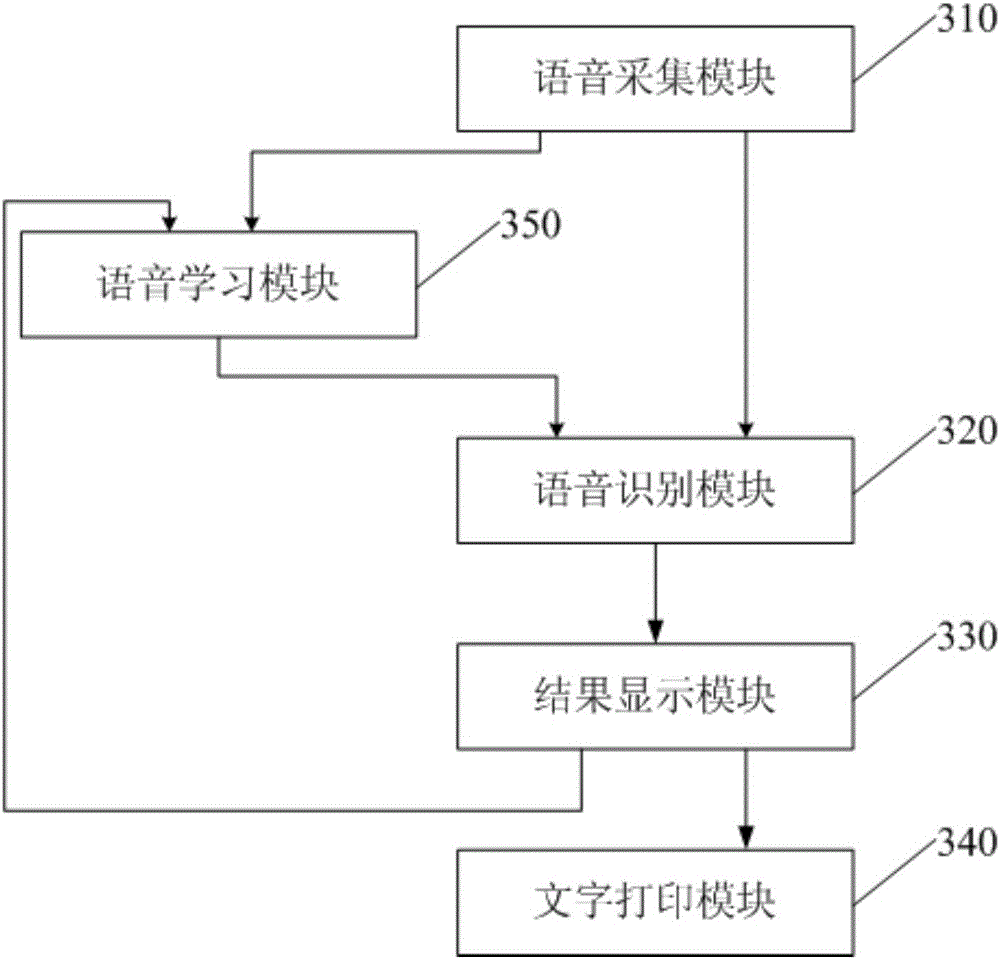

Printing method, printing device and printer based on voice input

ActiveCN105094717AImprove efficiencyImprove accuracySpeech recognitionDigital output to print unitsSpeech soundSubvocal recognition

The embodiment of the invention discloses a printing method, a printing device and a printer based on voice input. The printing method comprises following steps: collecting voice inputted by a user via a collector arranged in the printer; receiving inputted voice via a voice recognition chip arranged in the printer; displaying a voice recognition result to the user via a display screen arranged in the printer; and printing the text content of the voice recognition result via a printing execution assembly arranged in the printer when the user receives a confirmation instruction of the voice recognition result.The printing method, the printing device and the printer based on voice input have following beneficial effects: in intelligent combination of voice recognition technology and printing technology, the text content to be printed is inputted by voice so that high efficiency is obtained; the user determines whether the voice recognition result is correct or not by means of the display screen; printing errors are not easily made; printing time is saved; and during a printing process, no computer is needed so that cost is decreased.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

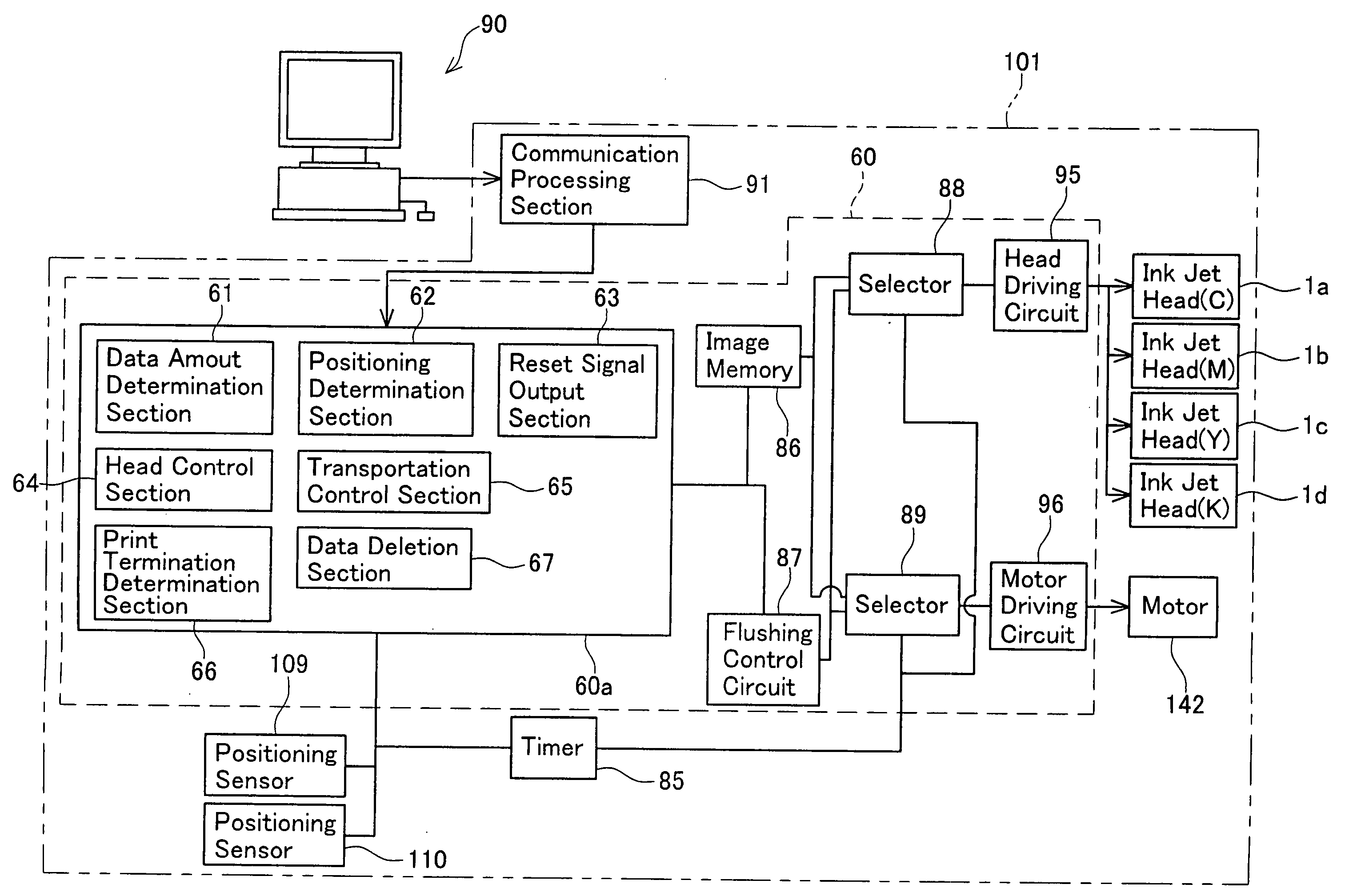

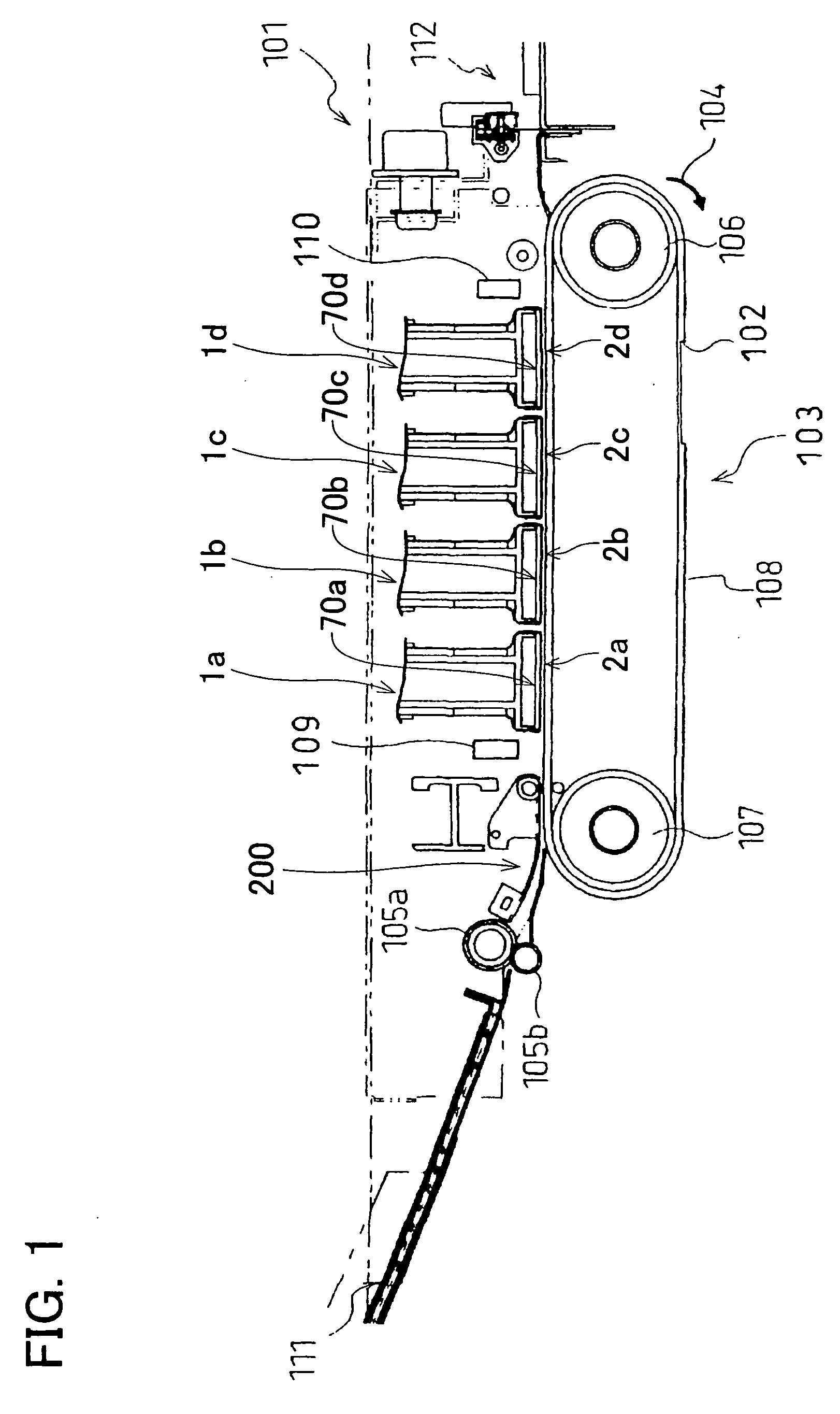

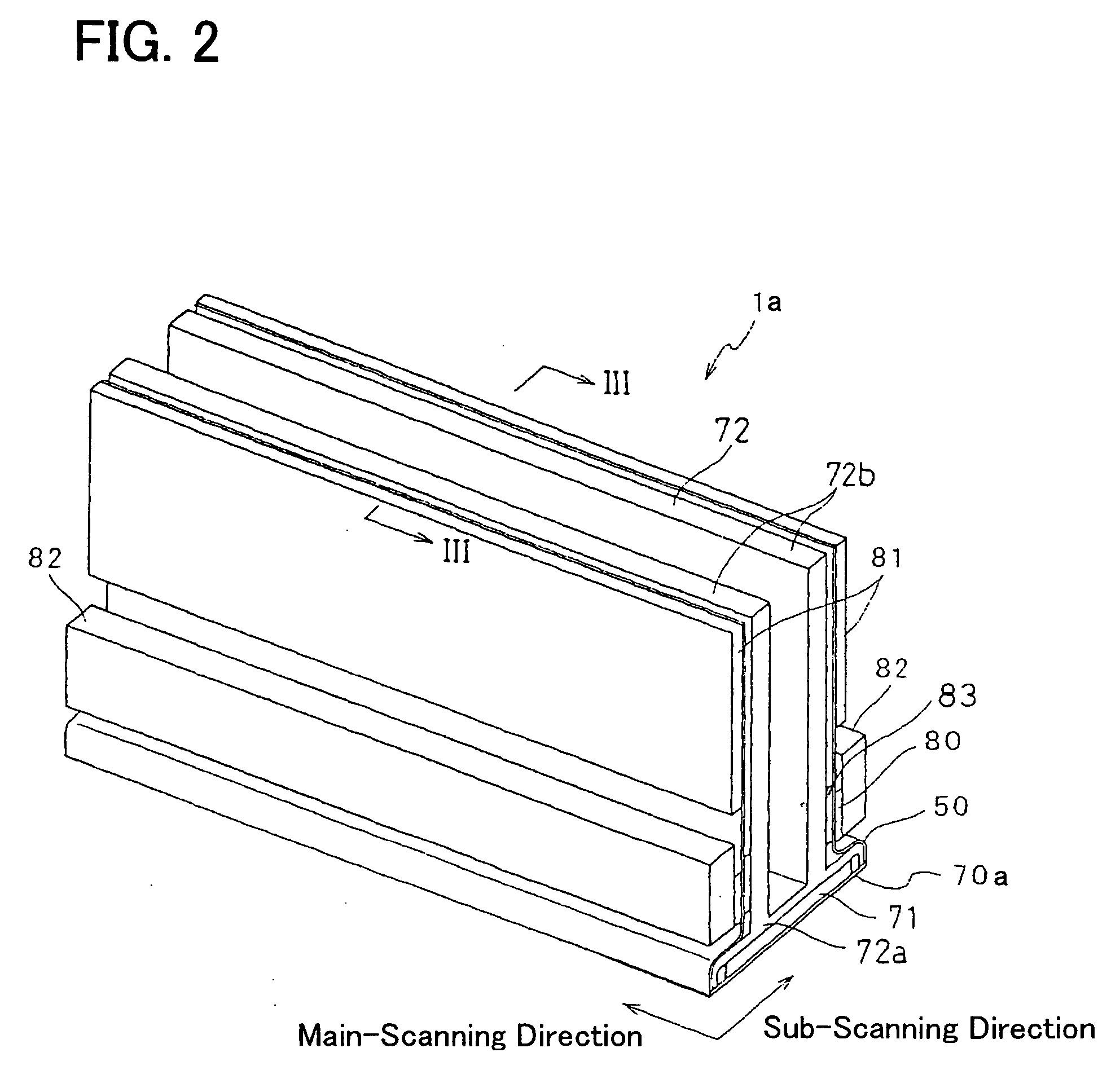

Ink jet printer, method for controlling an ink jet printer, and computer program product for an ink jet printer

InactiveUS20050285894A1Preventing unsightly printingReduce printing timeVisual presentationOther printing apparatusInk printerComputer program

Owner:BROTHER KOGYO KK

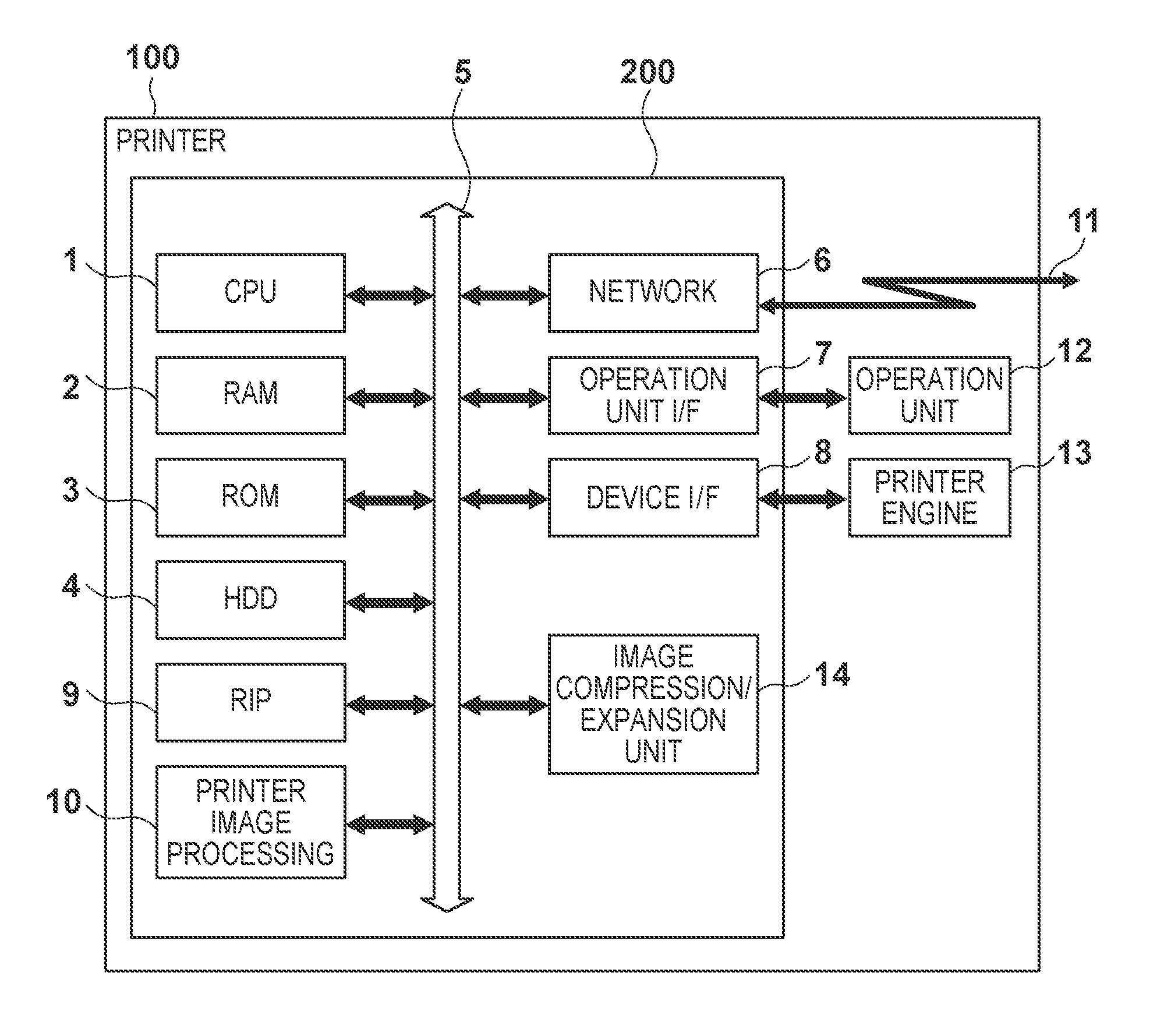

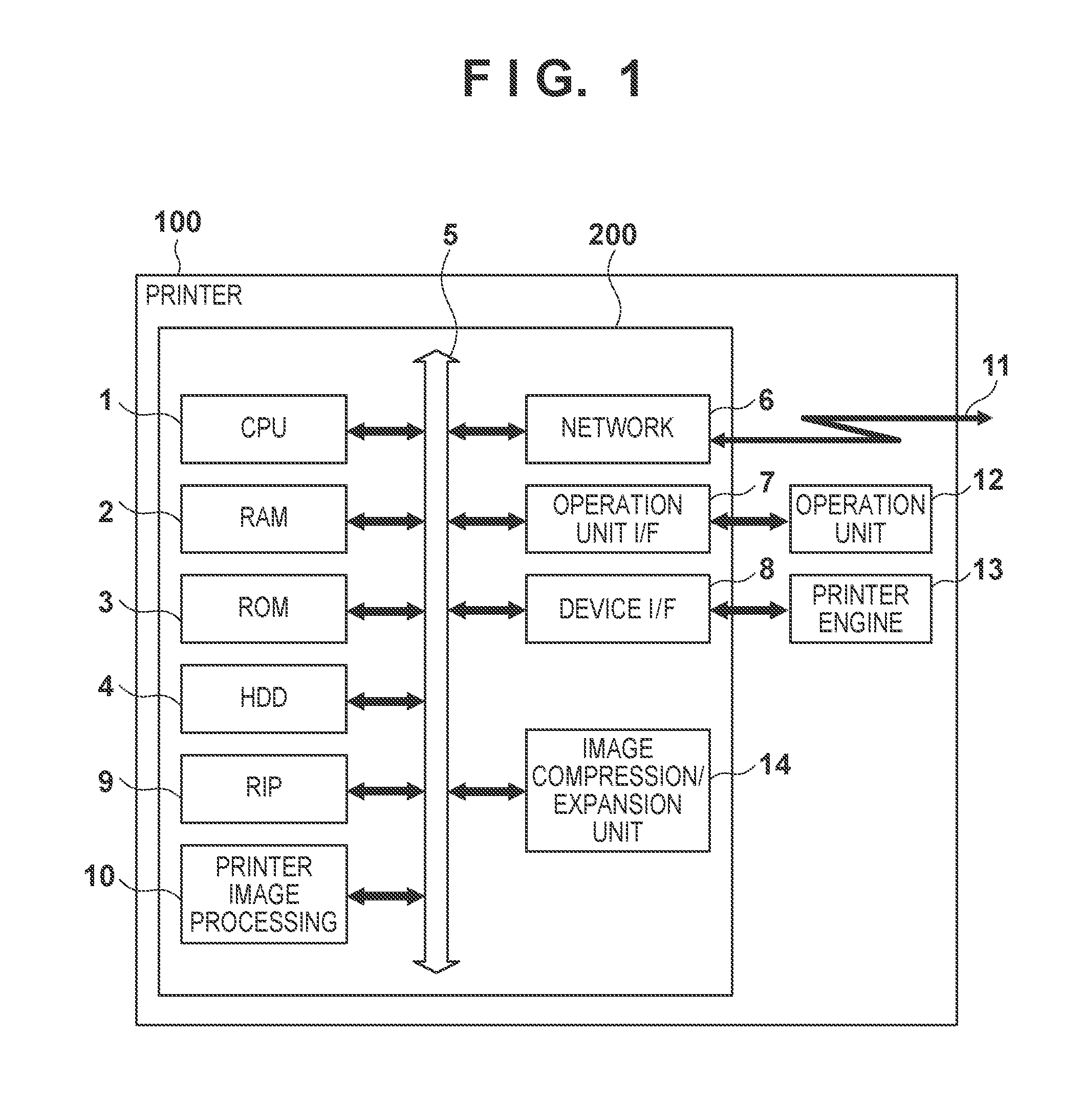

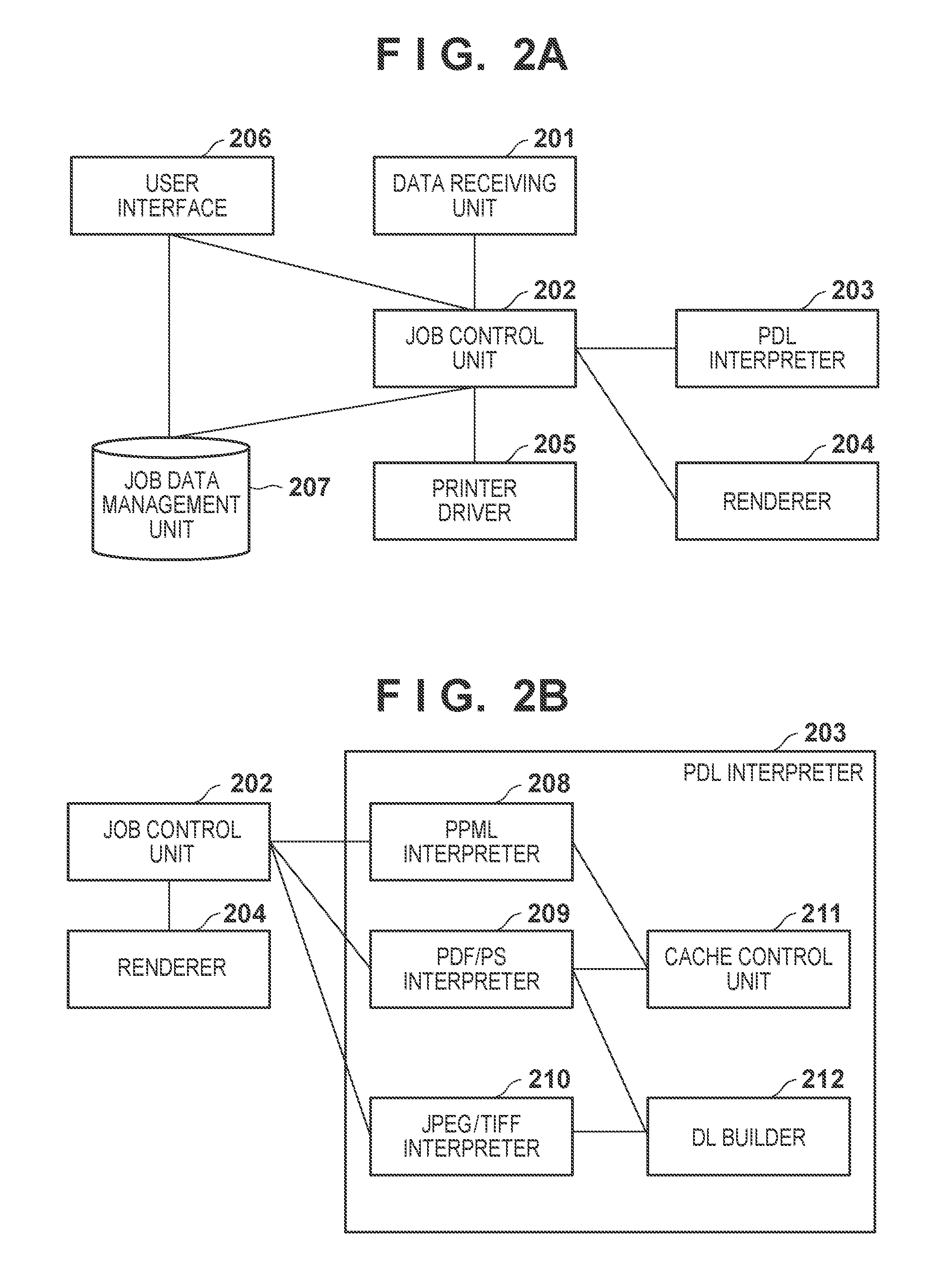

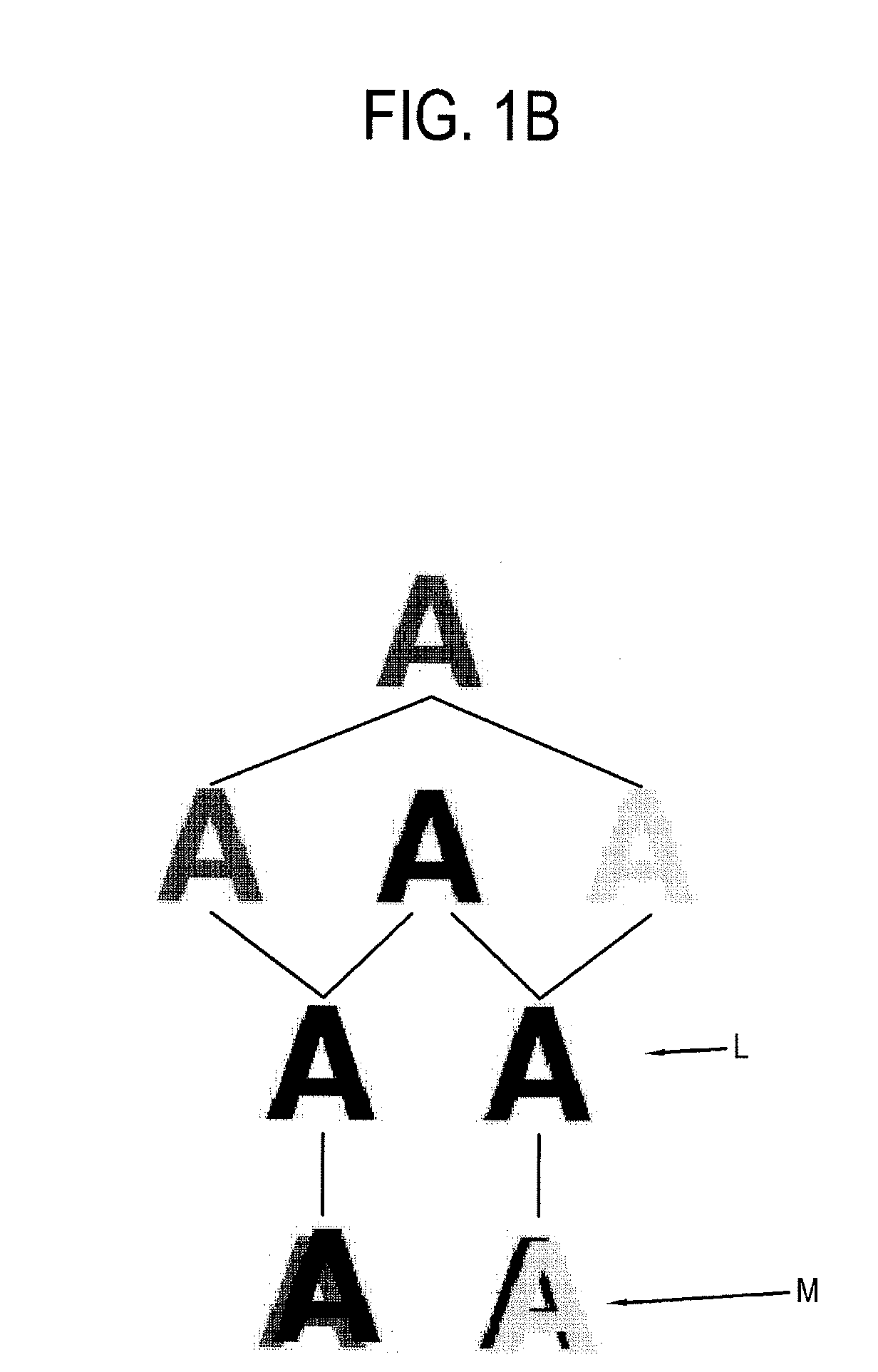

Print data processing apparatus and print data processing method

InactiveUS20120293832A1Processing time be shortenShorten effectVisual presentation using printersDigital output to print unitsData processing

A print data processing apparatus performs detection as to whether or not an identical resource is duplicated and described within print data. In a case where there is duplicated description, the duplicated resource is deleted from its second occurrence onward and the print objects are consolidated, the duplicated resources are deconstructed into individual resources and registered in a format that can be referenced in common from multiple print objects.

Owner:CANON KK

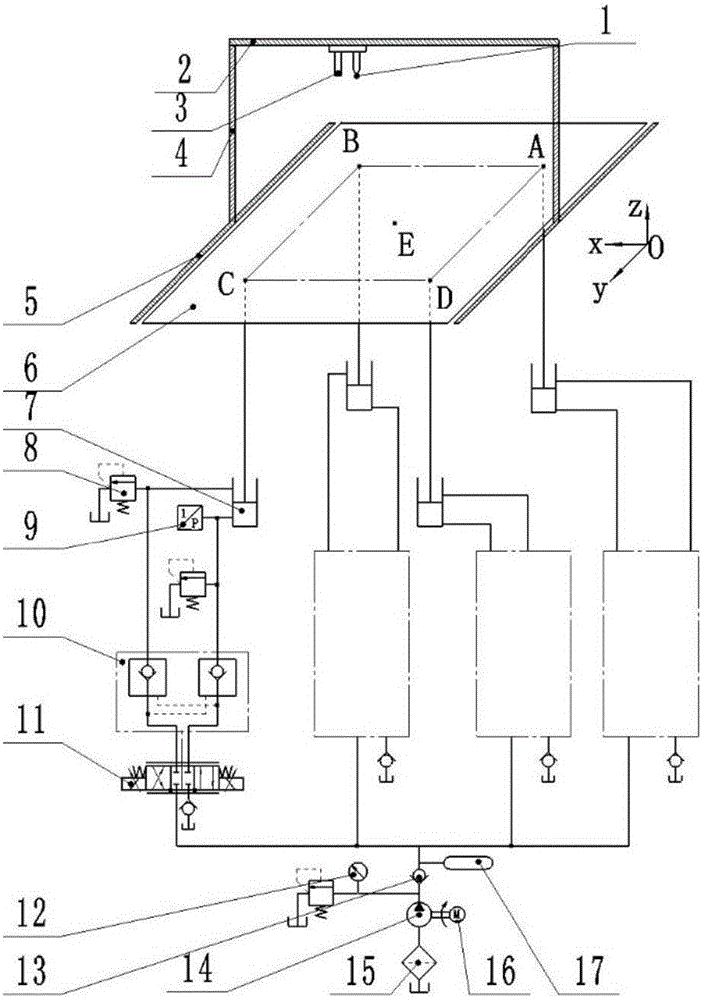

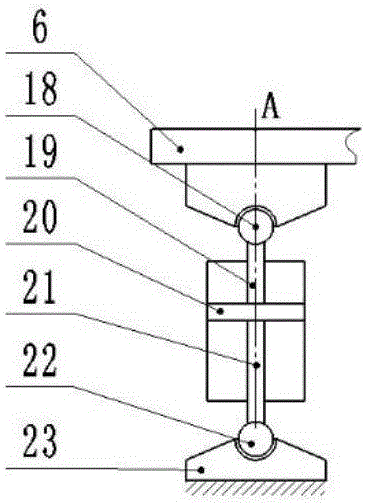

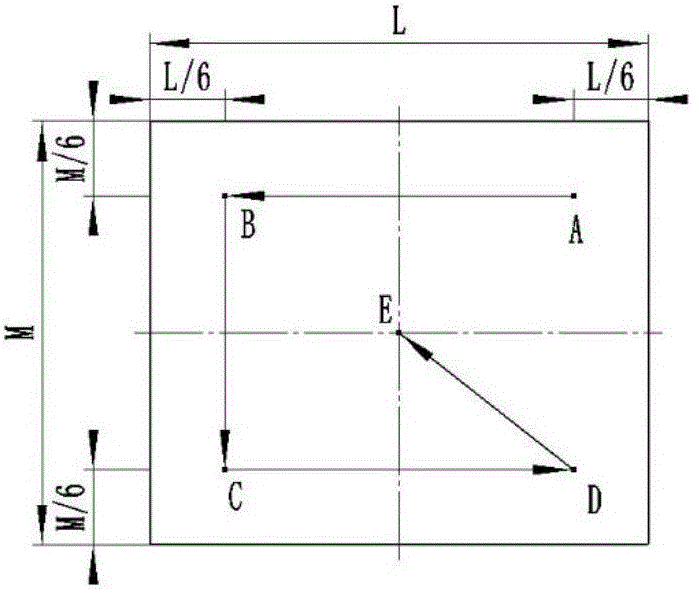

3D printer printing platform leveling method based on chasing method and hydraulic automatic leveling system

InactiveCN105904736ABest horizontal positionAccurate feedbackAdditive manufacturing apparatusServomotorsElectricityHydraulic cylinder

The invention discloses a 3D printer printing platform leveling method based on a chasing method and a hydraulic automatic leveling system. The 3D printer printing platform leveling method based on the chasing method and the hydraulic automatic leveling system are used for a large forming-breadth 3D printer. A printing head moves in the directions of an X axis, a Y axis and a Z axis; a distance measuring sensor and the printing head are installed on the same horizontal height, and the distance measuring sensor moves along with the printing head; a measured value of the distance measuring sensor is used for reflecting the relative positions of the printing head and a printing platform; the printing platform and a piston rod of a hydraulic cylinder are connected in the manner of a spherical hinge; the piston rod of the hydraulic cylinder is connected with a fixed supporting frame in the same manner of a spherical hinge; and the displacement of a valve element of a fluid electric proportional direction control valve controls lifting of a piston of the hydraulic cylinder to complete the automatic leveling process of the printing platform. The data output end of the distance measuring sensor is connected with the data input end of a controller, and the data output end of the controller is connected with the fluid electric proportional direction control valve. By means of cooperation of the hydraulic system and the controller, fast, accurate and automatic leveling of the printing platform is completed, the leveling workload of the platform is greatly reduced, and the printing precision is improved.

Owner:BEIJING HENGCHUANG ADVANCED MATERIALS & ADDITIVE MFG INST CO LTD

Liquid ejecting method and liquid ejecting apparatus

A liquid ejecting method includes detecting a faulty nozzle in which an ejection fault occurs when a liquid should be ejected, calculating corrected tone values by correcting tone values of pixels adjacent to pixels at which the liquid should be ejected from the faulty nozzle based on a correction amount, and a liquid ejecting apparatus ejecting the liquid to the adjacent pixels based on the corrected tone values.

Owner:SEIKO EPSON CORP

Image forming apparatus and computer readable recording medium

InactiveUS20090015865A1Printing time be sometimes not reduceSpeed-up copy processDigital output to print unitsImage basedImaging data

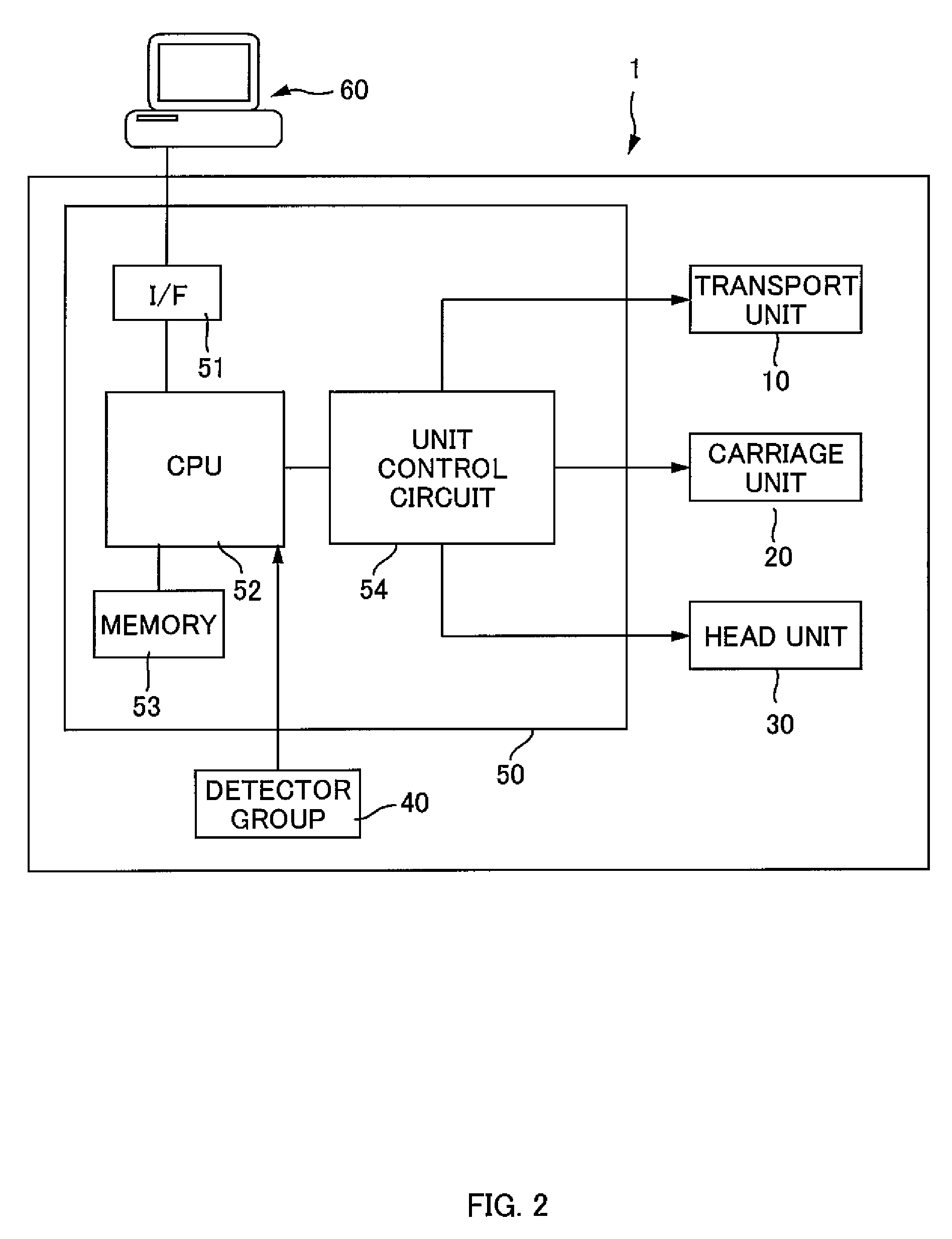

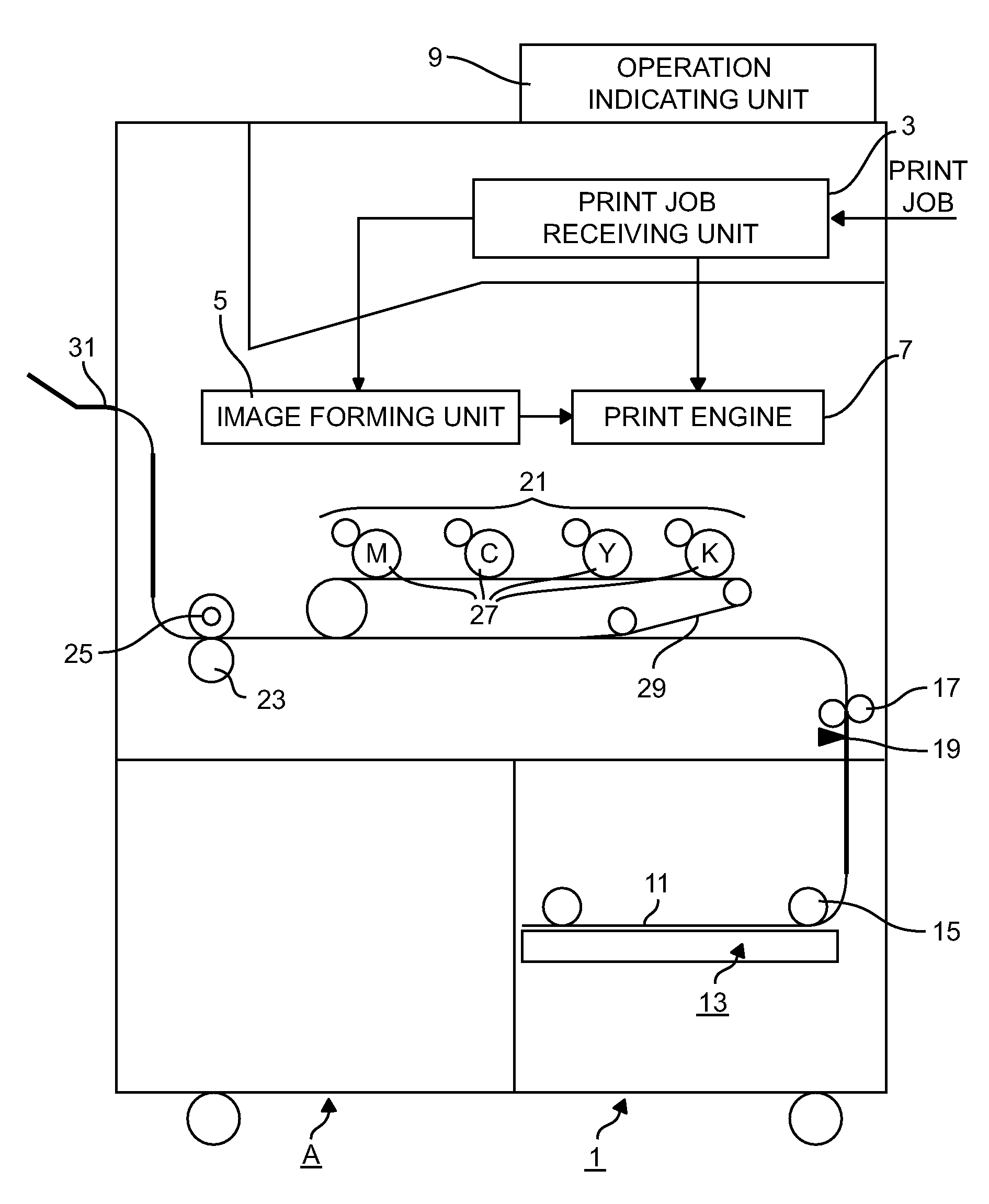

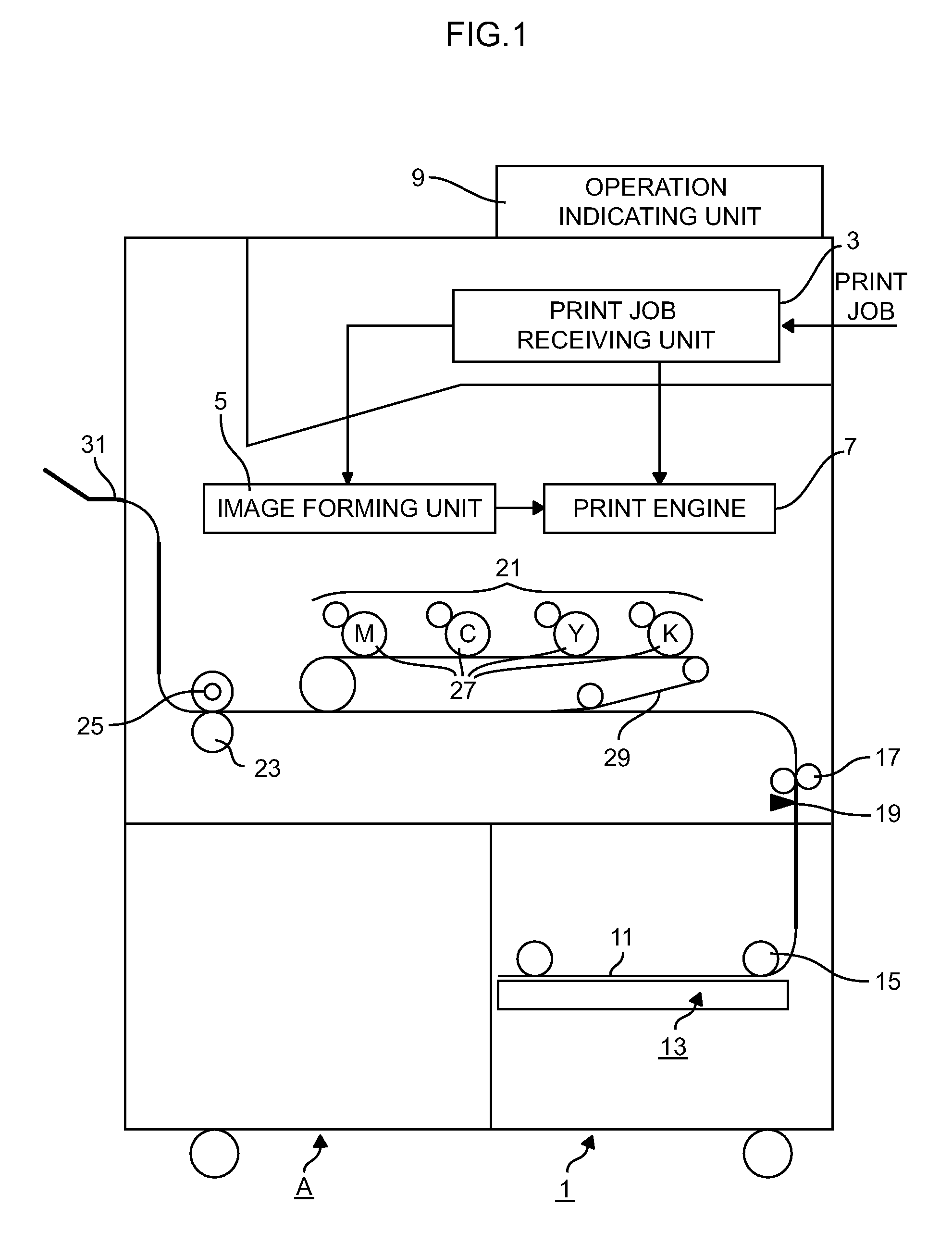

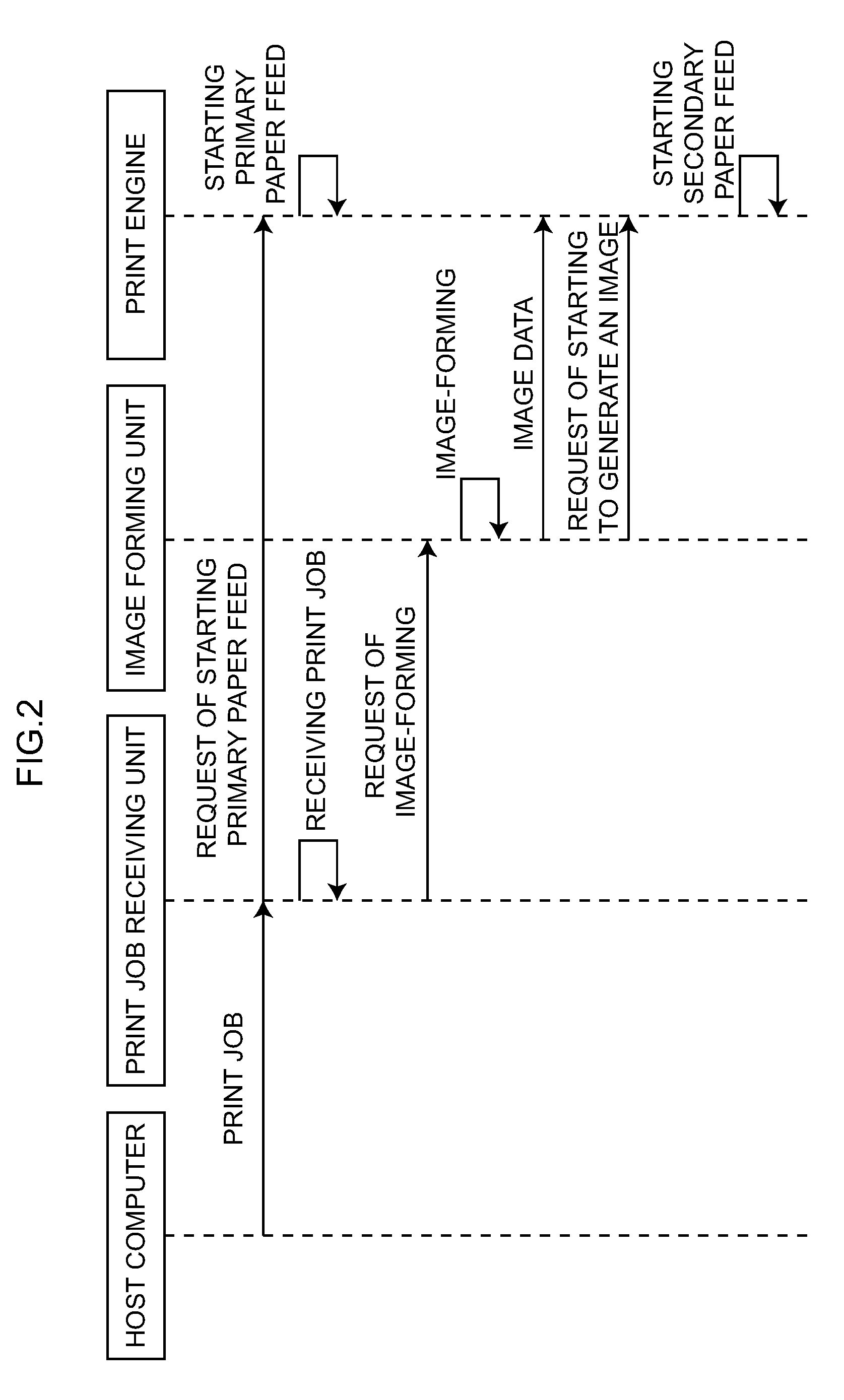

An image forming apparatus according to an aspect of the present invention includes (a) a print engine that performs secondary paper feed after primary paper feed, and generates an image based on image data and then transfers and fixes the image on a paper after the secondary paper feed, (b) a print job receiving unit that receives a print job and causes the print engine to start the primary paper feed and (c) an image forming unit that forms the image data based on the print job and outputs the image data to the print engine, and causes the print engine to start generating the image prior to the secondary paper feed after the primary paper feed.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

novel carpet RIP printing technology

The invention relates to a novel carpet RIP printing technology. The novel carpet RIP printing technology utilizes high-fastness eight-color dispersible ink or cationic ink and color matching software of RIP and comprises steps of spray printing design, color matching, ink-jet printing and drying color-development; and according to the novel carpet RIP printing technology, patterns are directly spray-printed on the surface of a carpet by a carpet ink-jet printing machine and the color is fixated. Through the novel carpet RIP printing technology, fixation fastness is high, after-treatment processes such as water washing and ageing are avoided after spray printing, small-batch and fast-response RIP printing production is really realized, and production batch is not limited. The novel carpet RIP printing technology solves the problem that the existing printing technology produces dye waste and discharges a large amount of printing and dyeing waste water thereby causing environmental pollution. The novel carpet RIP printing technology reduces enterprise burden and satisfies environmental protection requirements. The novel carpet RIP printing technology is suitable for printing production of carpets, tapestries and blanket fabric prepared from various vegetable fibers, chemical fibers and synthetic fibers.

Owner:NANYANG HAOHAI TECH CO LTD

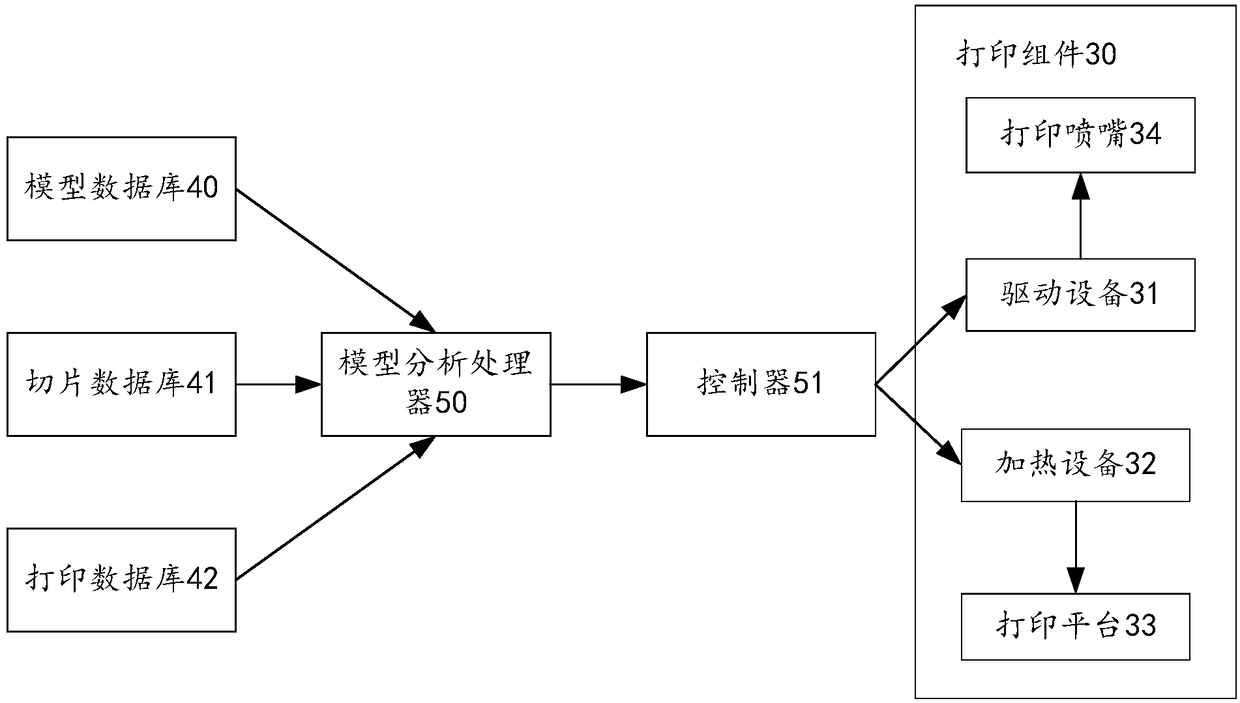

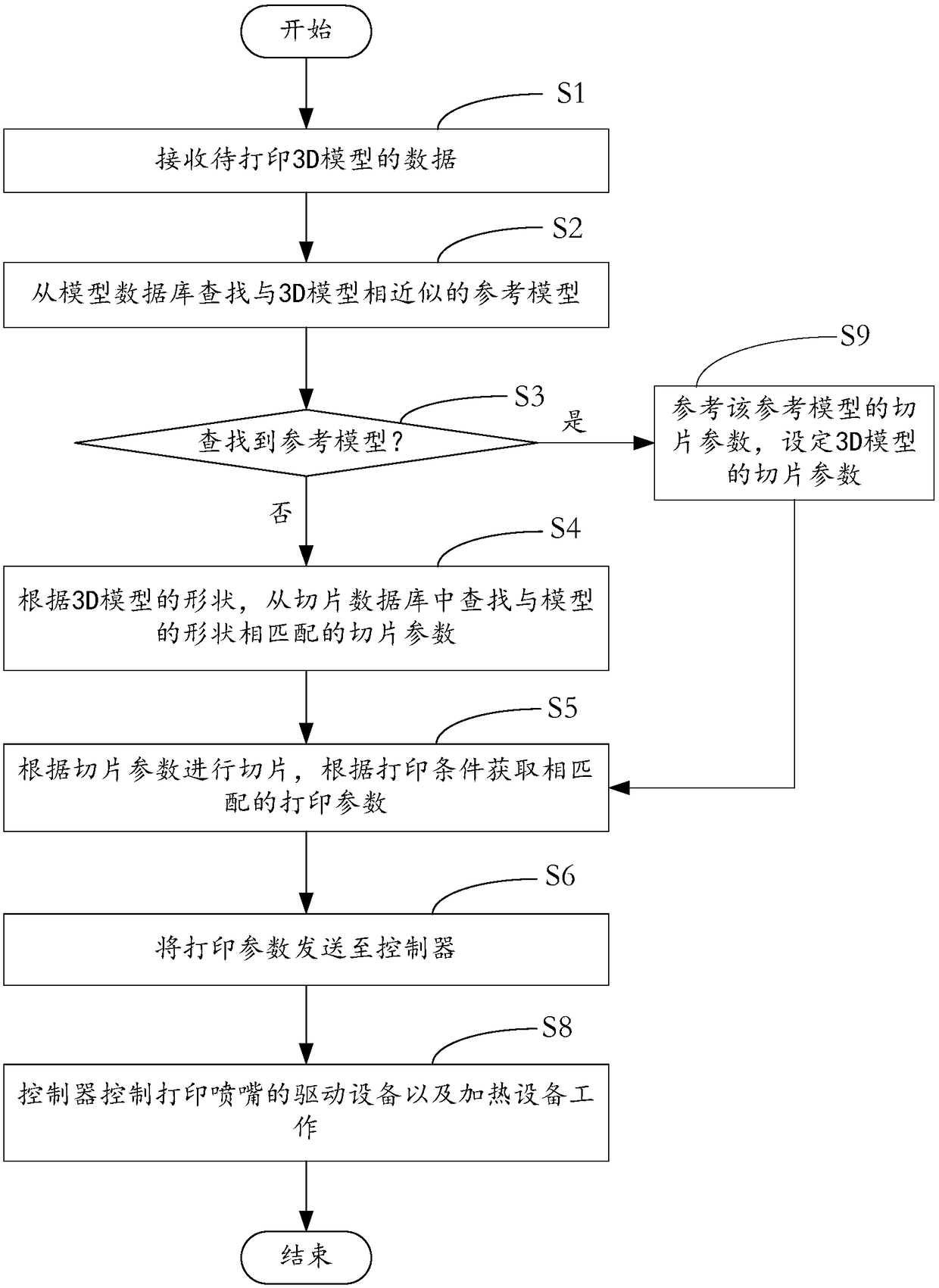

Intelligent 3D printing system and printing method thereof

ActiveCN108127913AAvoid wastingOptimal Printing ParametersAdditive manufacturing apparatus3D object support structuresEngineeringModelling analysis

The invention provides an intelligent 3D printing system and a printing method thereof. The system comprises a printing assembly, a controller and a model analysis processor, wherein the printing assembly is used for printing and spraying forming materials on a printing platform; the controller is used for outputting a control instruction to driving equipment of the printing assembly to control work of the printing assembly; the model analysis processor is used for receiving data of a 3D model to be printed, slicing the 3D model to form multiple slicing layers, obtaining printing conditions ofeach slicing layer, searching a printing database for printing parameters matched with the printing conditions, and outputting the printing parameters to the controller; and the printing database isa database arranged on a server or a local memorizer, and preset printing experience values or preferred data obtained through self-learning are stored in the printing database. The printing system isapplied to 3D printing in the method. By means of the intelligent 3D printing system and the printing method thereof, the printing quality of the 3D model can be improved, and forming materials are saved.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Liquid-droplet jetting apparatus

ActiveUS20070139487A1Good printing performanceReduce effect on jetting performanceOther printing apparatusPrintingInk printerEngineering

A liquid-droplet jetting apparatus such as an ink-jet printer makes a meniscus of an ink in a nozzle vibrate by applying a no-jetting drive pulse which does not jet the ink. An operation of outputting two no-jetting drive pulses in one cycle is repeated for 100 to 150, and then stopped for 100 to 150 cycles. A pulse width Tp of the no-jetting drive pulses, an interval Tw between two no-jetting drive pulses, and a time AL in which a pressure wave in an ink channel is propagated one way are set to be in a range 0.1 AL≦Tp≦0.2 AL, and 0.2 AL≦Tw≦4.5 AL. Accordingly, it is possible to prevent assuredly, thickening of a liquid such as an ink in the nozzle, and to reduce a generation of a defect in jetting of a liquid droplet.

Owner:BROTHER KOGYO KK

Printing apparatus, control method thereof, and storage medium storing program

ActiveUS20130140767A1Eliminate the problemEnhance the imageFunction indicatorsVisual presentation using printersMechanical engineering

Owner:CANON KK

Image forming apparatus and method of controlling the same

InactiveUS20080151302A1Shorten printing timeReduce printing timeDigital computer detailsVisual presentationStorage cellDocument recognition

Owner:S PRINTING SOLUTION CO LTD

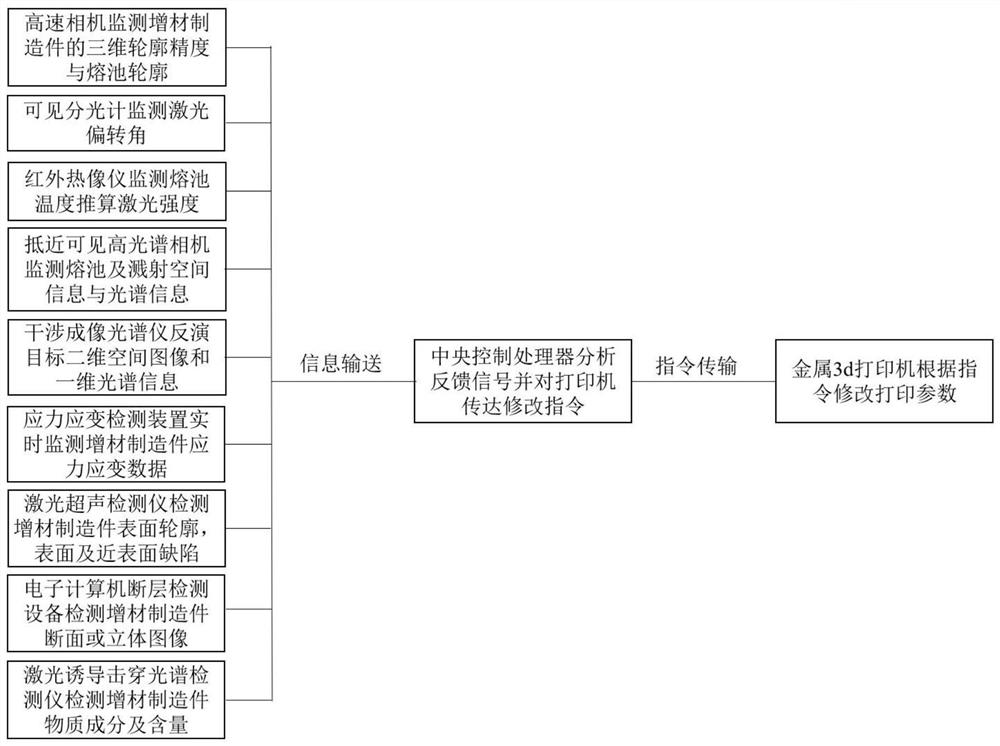

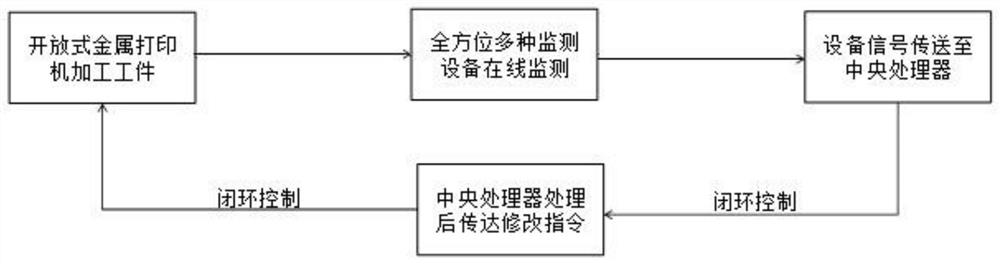

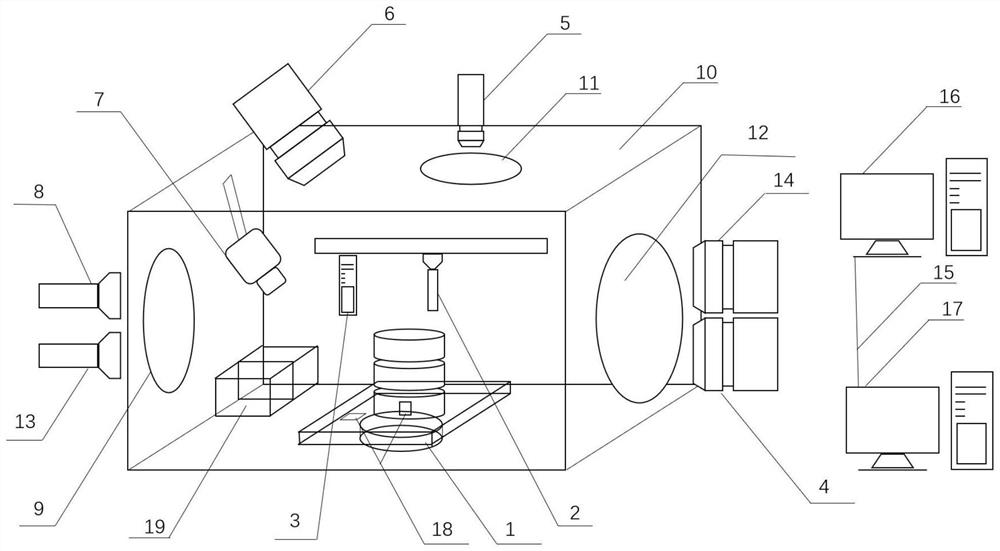

Online real-time monitoring system for multiple monitoring devices for metal additive manufacturing

InactiveCN111795977AImprove production efficiencyImprove detection accuracyAdditive manufacturing apparatusMaterial analysis using wave/particle radiationEngineeringLaser-induced breakdown spectroscopy

The invention provides an online real-time monitoring system for multiple monitoring devices for metal additive manufacturing, and the system comprises a high-speed camera detection module which detects the three-dimensional contour precision of an additive manufacturing part and the contour of a molten pool; a visible spectrometer detection module which is used for detecting the deflection angleof laser; a thermal infrared imager detection module which is used for detecting the temperature of the molten pool; an approaching visible hyperspectral camera detection module which detects spatialinformation and spectral information of the molten pool and sputtering; an interference imaging spectrometer detection module which is used for acquiring a two-dimensional space image and one-dimensional spectral information of the additive manufacturing part; a stress-strain detection module which is used for monitoring stress-strain data of the additive manufacturing part; a laser ultrasonic detection module which is matched with a rotary machining table to detect the surface and near-surface defects of the additive manufacturing part; an electronic computed tomography module which is matched with the rotary machining table to detect internal defects and internal geometric contours of the additive manufacturing part; a laser-induced breakdown spectroscopy detection module which is used for determining the material composition and content of the additive manufacturing part; and a central processing unit which finds out machining errors and metallurgical defects and then feeds back toa metal additive manufacturing machining end. According to the invention, the quality of finished products can be essentially improved.

Owner:岳阳珞佳智能科技有限公司

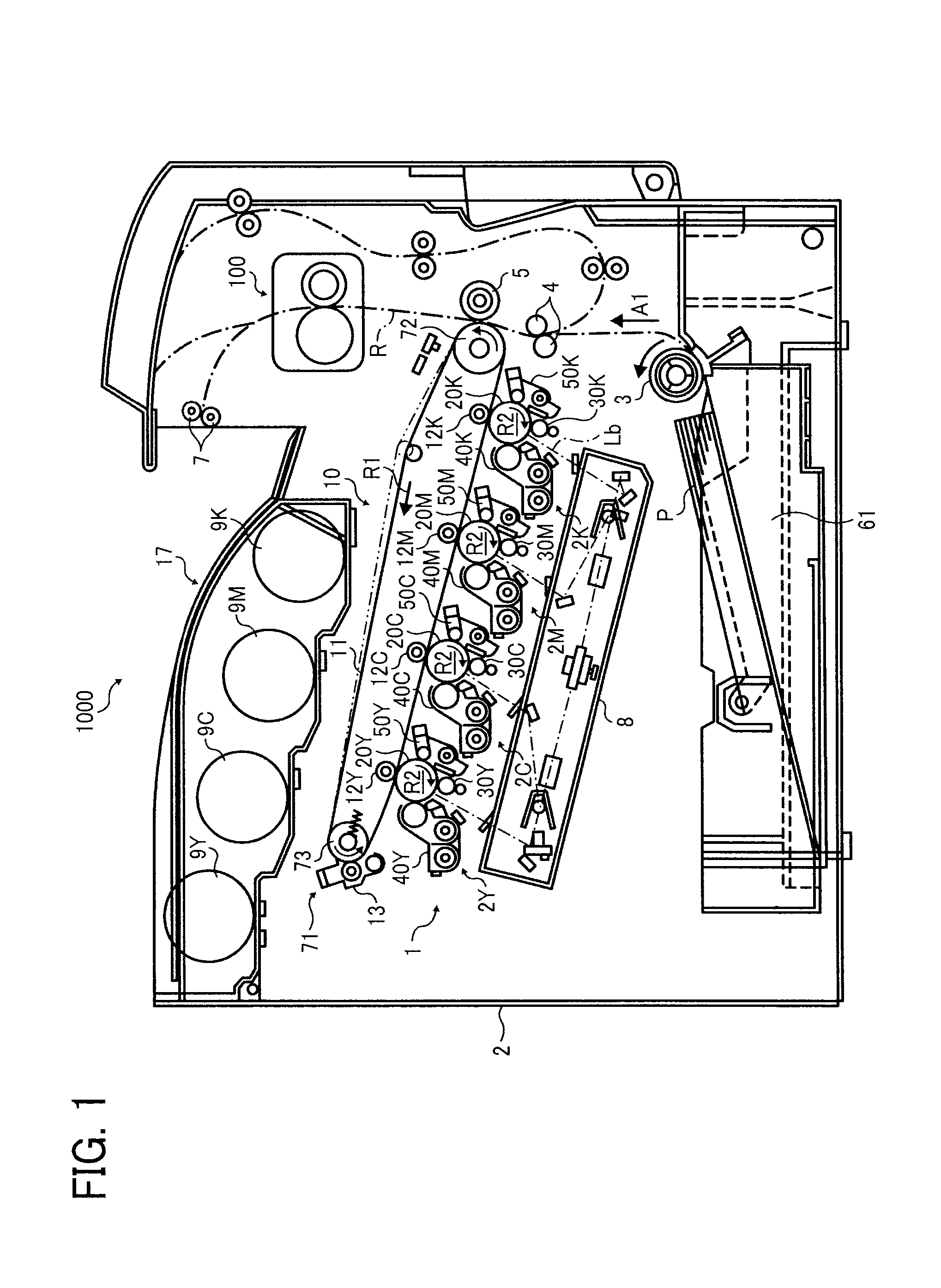

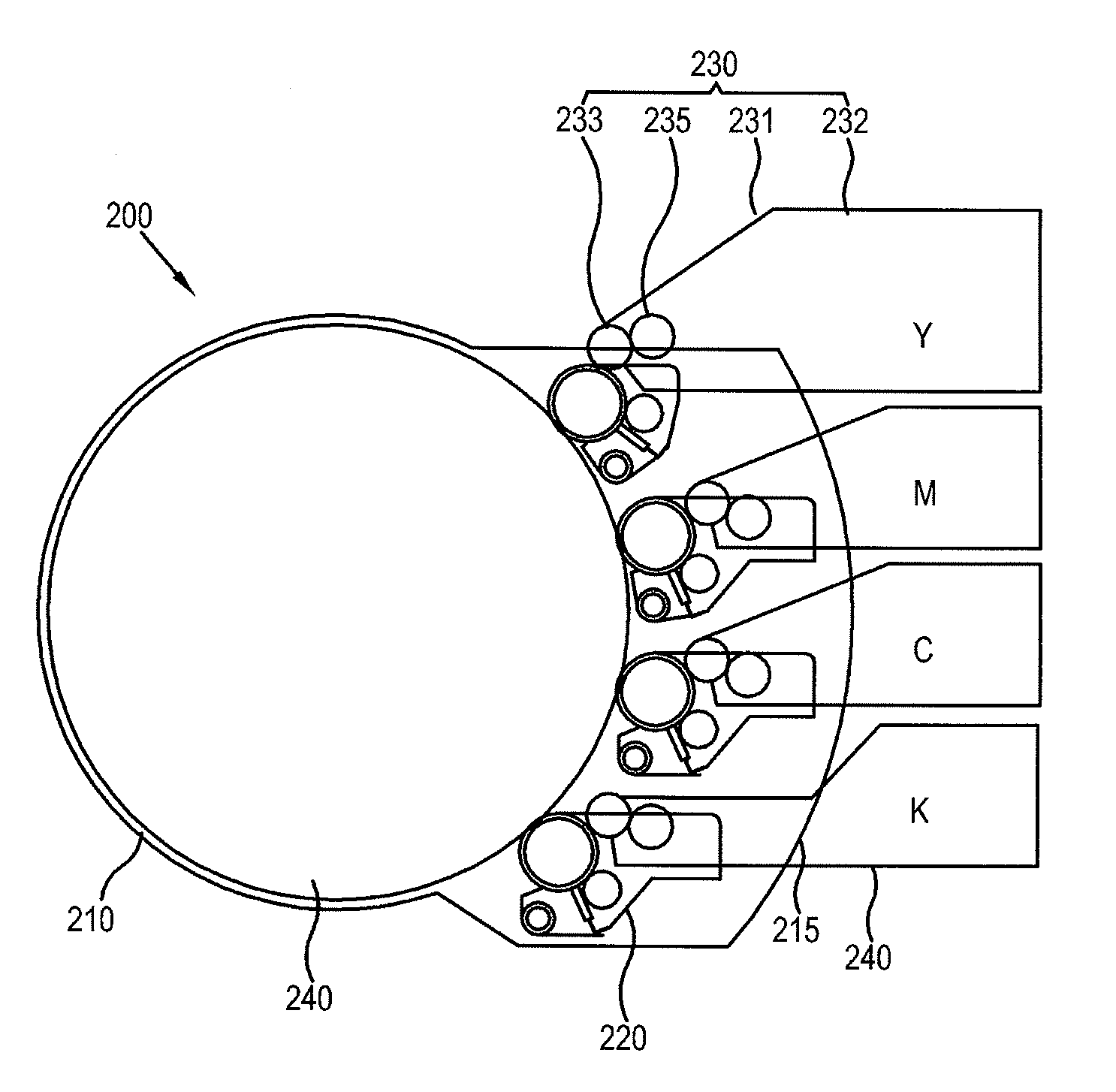

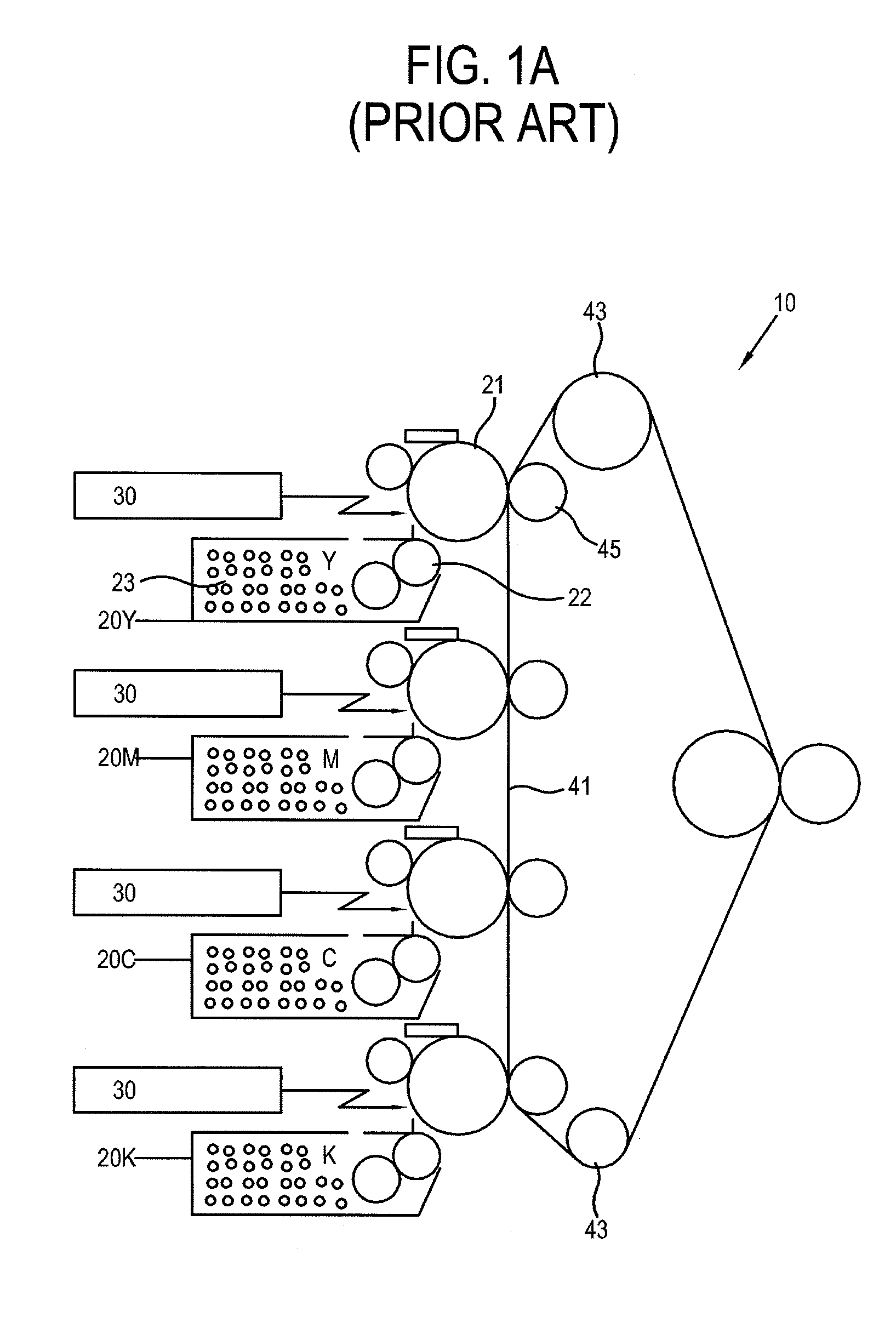

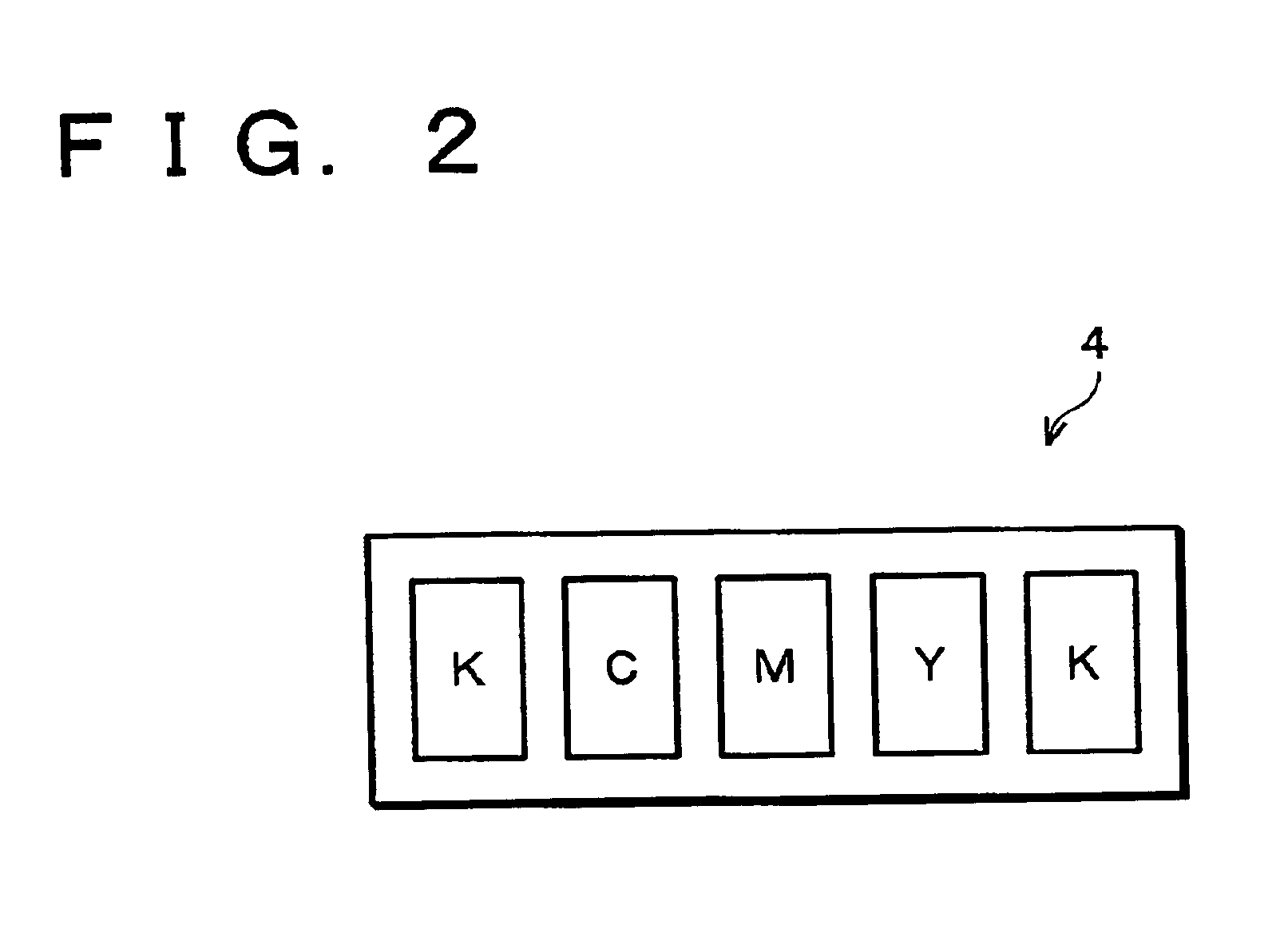

Developing-transferring module and image forming apparatus having the same

ActiveUS20080170881A1Minimizing alignment inferiorityReduce printing timeElectrographic process apparatusImage formationEngineering

A developing-transferring module includes a sub frame which is detachably mounted to a main frame, a plurality of photosensitive units which are disposed inside the sub frame with a predetermined interval and includes a photosensitive body to which a developer is attached, and a intermediate transferring unit which are provided inside the sub frame disposed opposite the plurality of photosensitive units so that the developer of the photosensitive units can be primarily transferred thereto and secondarily transfers the primarily transferred developer to a record medium of the main frame.

Owner:HEWLETT PACKARD DEV CO LP

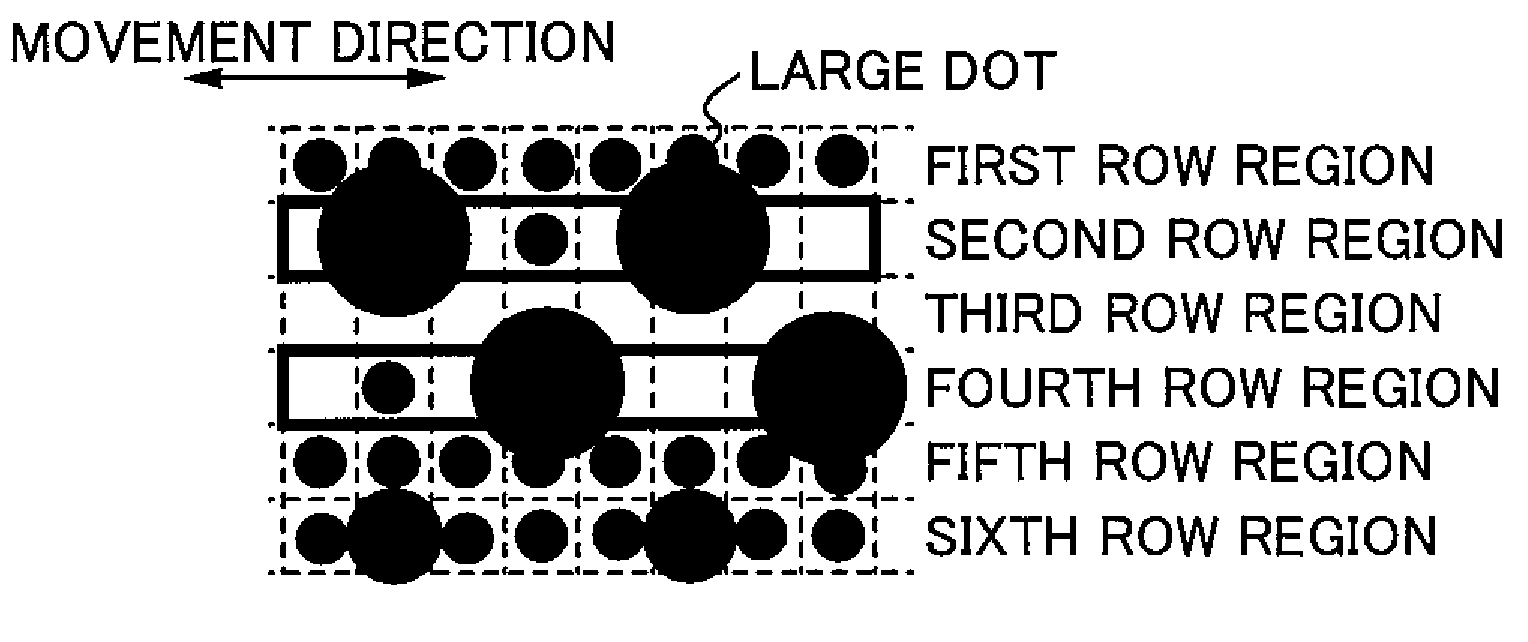

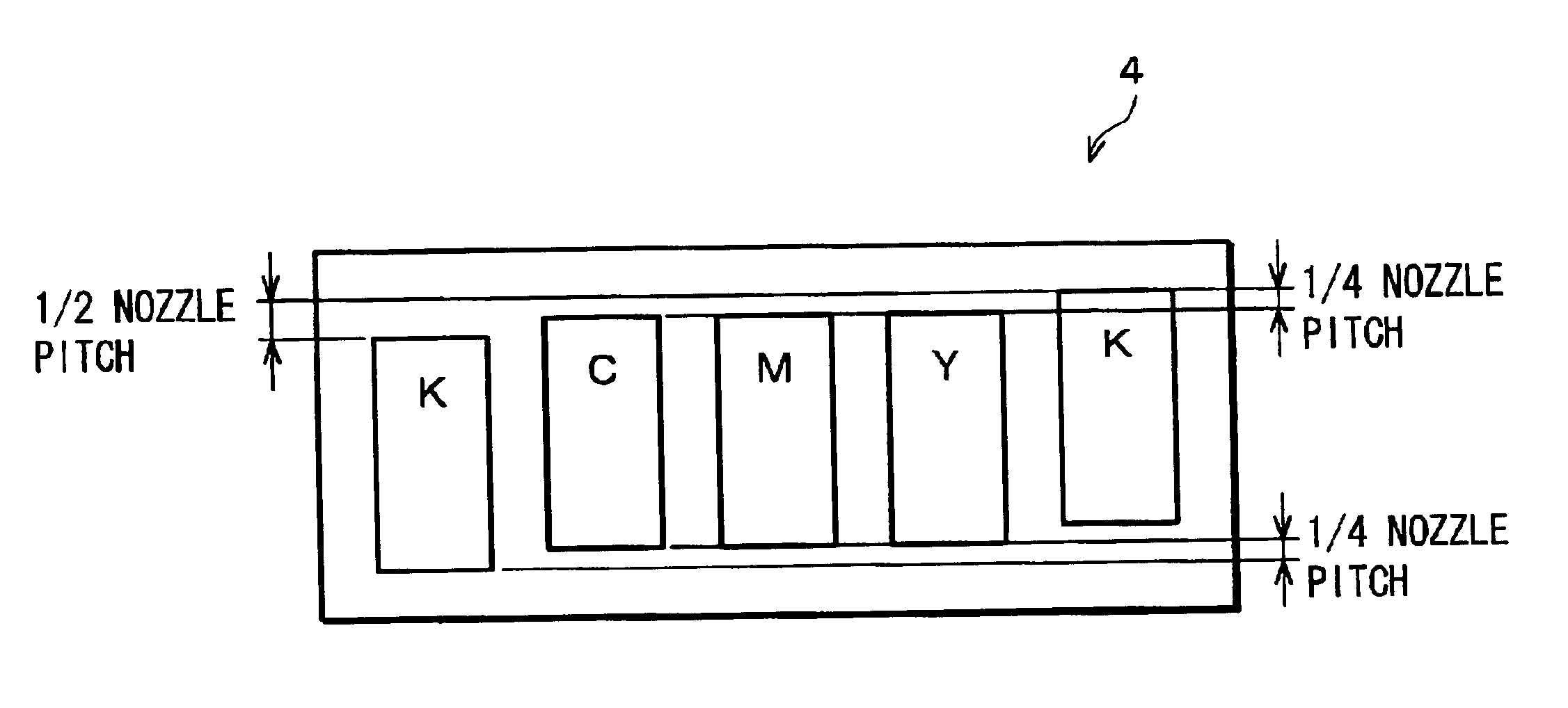

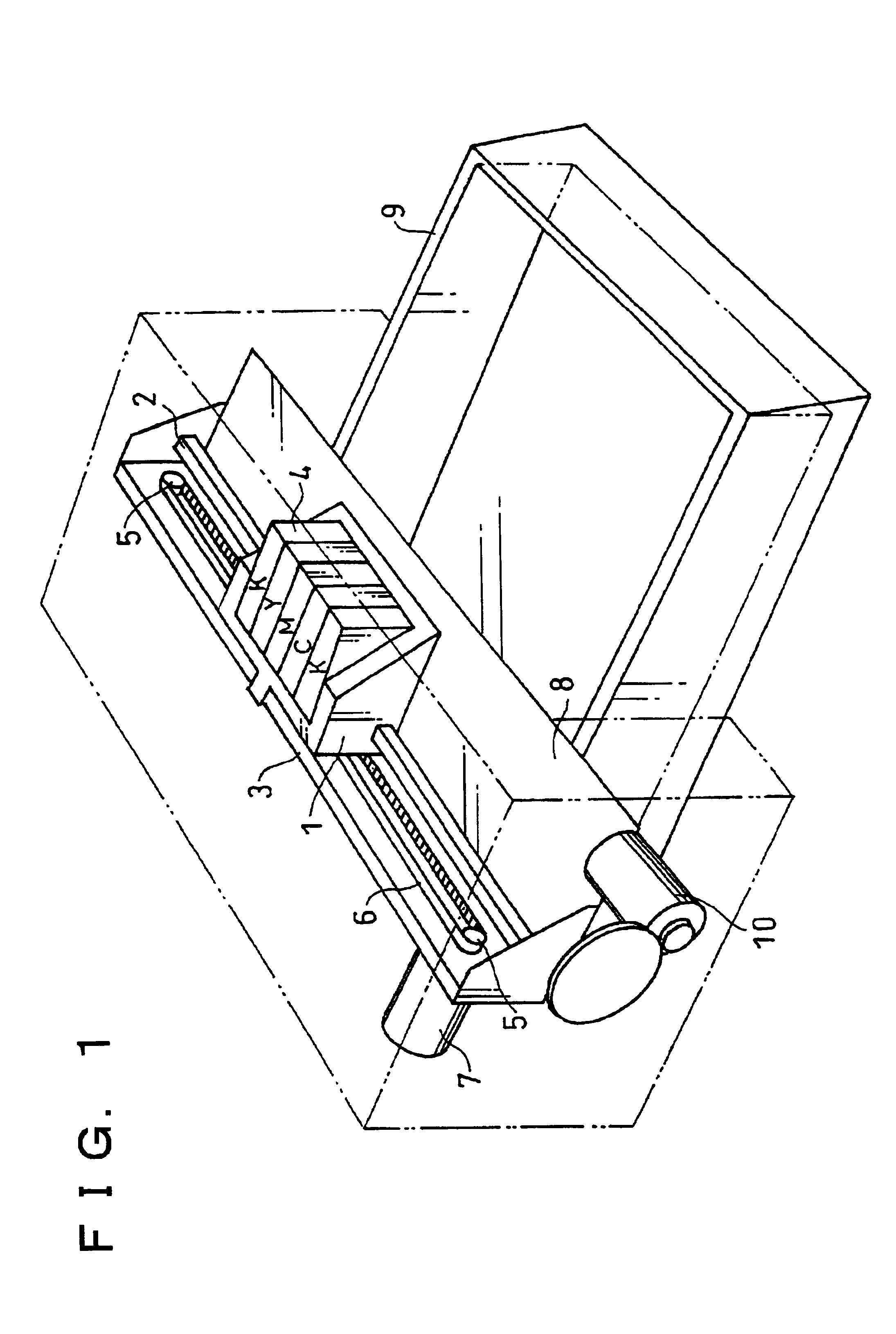

Image forming apparatus of ink-jet type and image forming method of ink-jet type

An image forming apparatus of an ink-jet type of the present invention is provided with an ink head section having a carriage that is composed of a plurality of ink head and scans so as to print. The ink head section is provided with black ink heads and a color ink head in such a manner that the black ink heads sandwich the color ink head. This eliminates the difference in blackness in printing, even if the carriage scans in two ways so as to print. Meanwhile, the ink heads are increased in number only by one, thereby limiting an increase in cost. In short, without a large increase in cost, it is possible to provide an image forming apparatus that forms a high-quality image, while printing time is shorted since the printing is carried out in two ways in a scanning direction.

Owner:SHARP KK

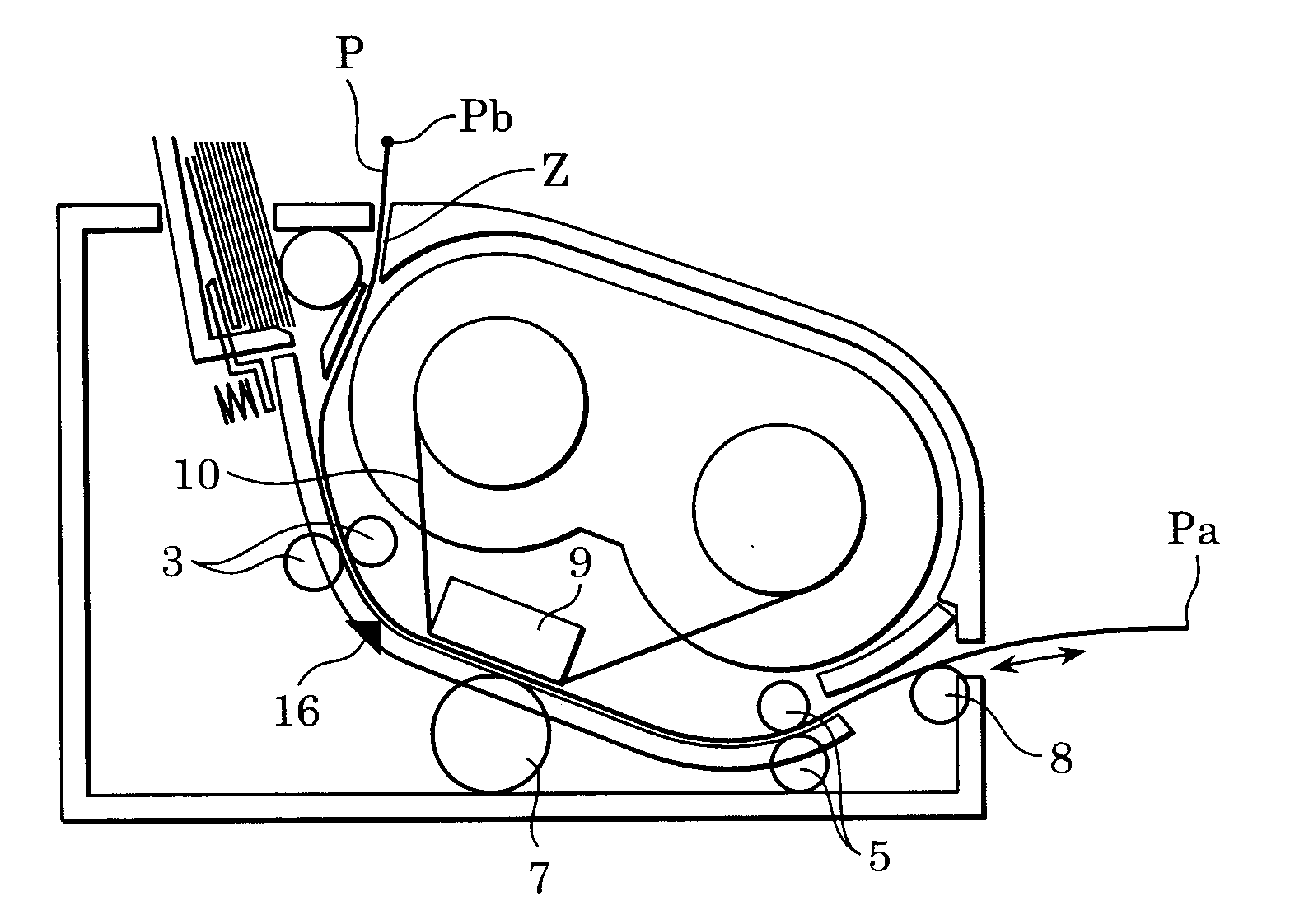

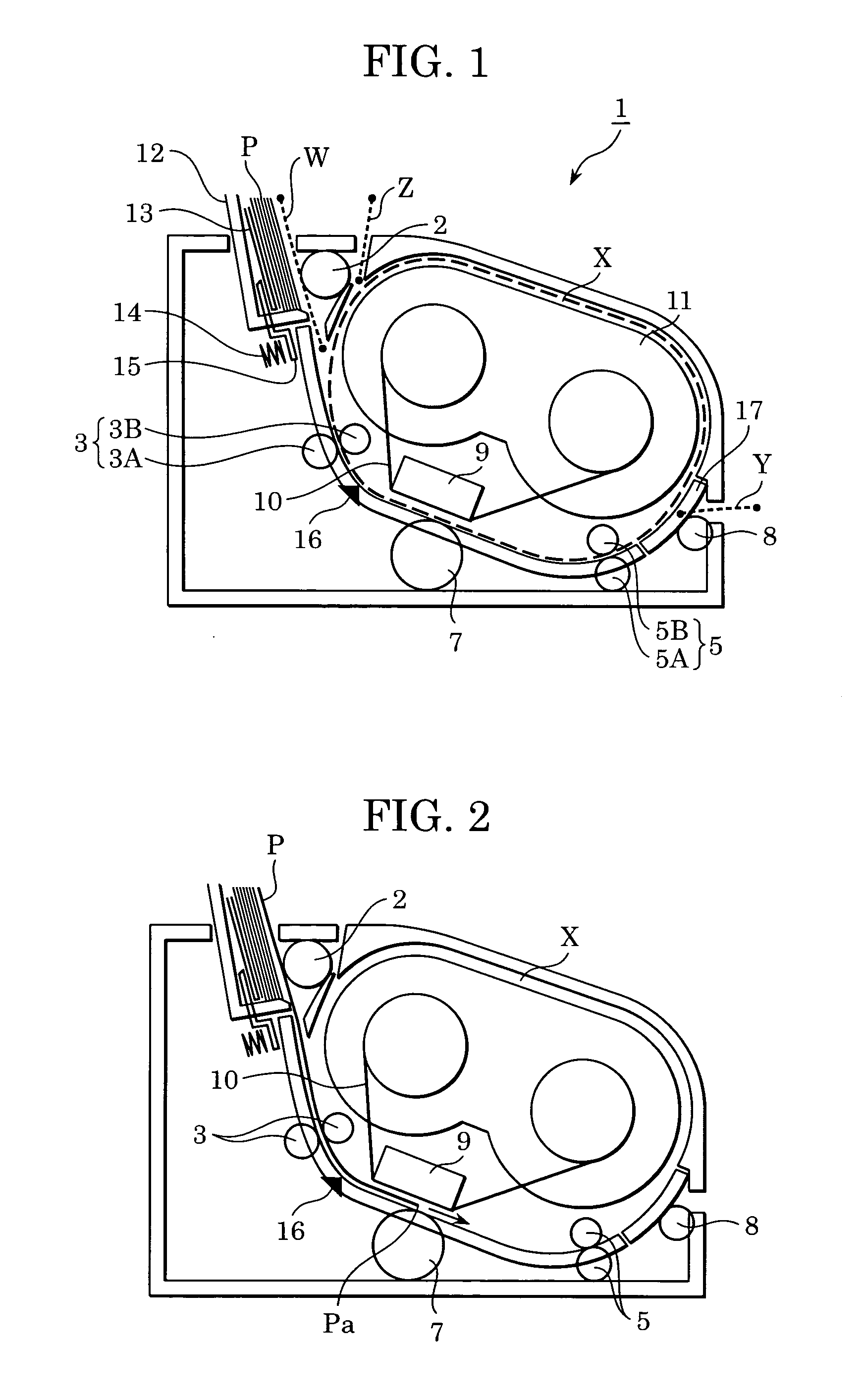

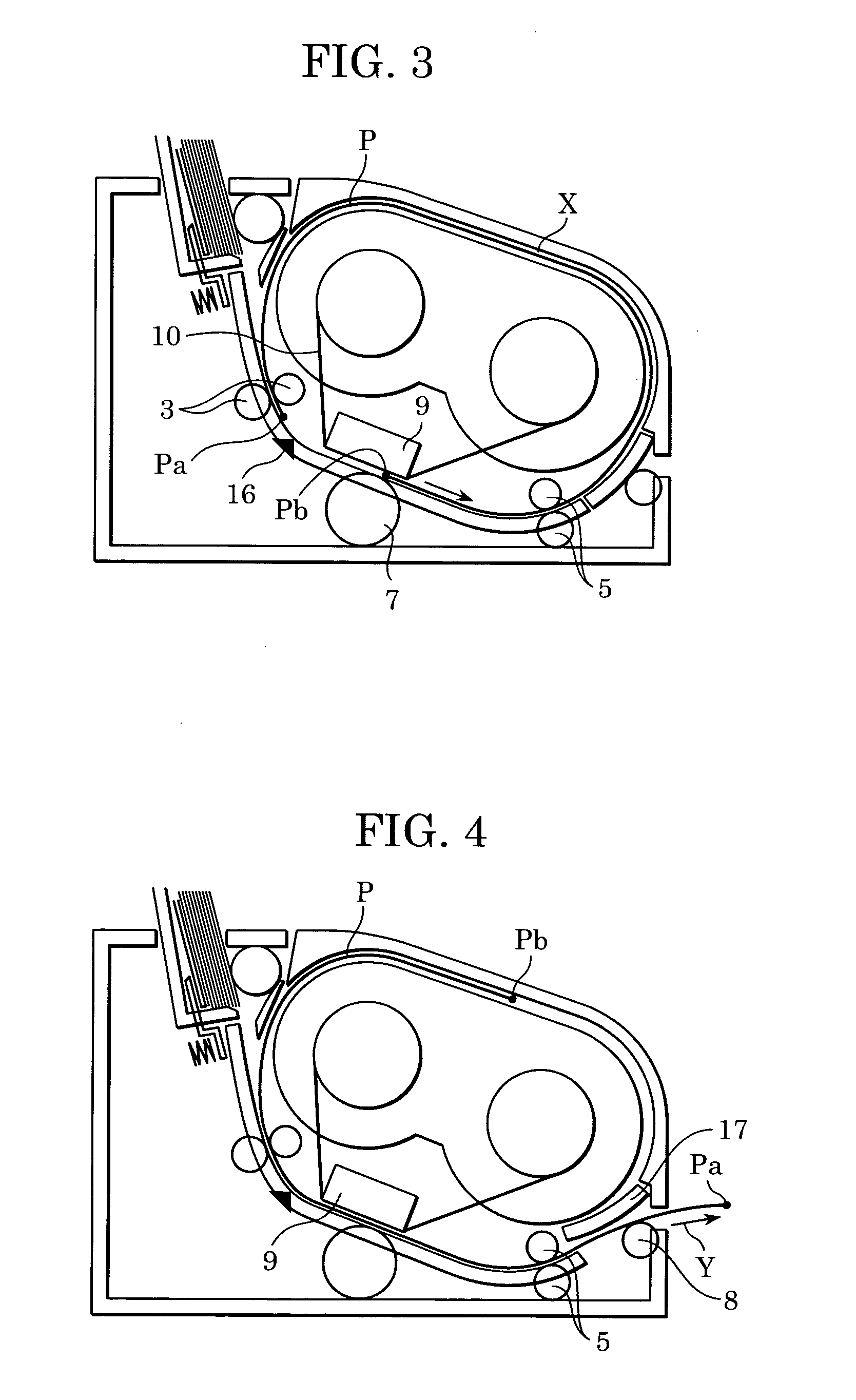

Printer and controlling method for printer

InactiveUS20050093959A1Without limiting sizeIncrease in sizeRecording apparatusOther printing apparatusElectrical and Electronics engineeringComputer printing

A printer and a method of controlling the printer. The printer includes a color ink ribbon and a thermal head for forming images on recording sheets and an accommodating portion accommodating the ink ribbon and the thermal head therein. The printer includes several paths for conveying the recording sheet including a circular path around the accommodating portion. Depending on the length of the recording sheet, the printer conveys the recording sheet along one of the several paths during a printing operation.

Owner:CANON KK

Color three dimensional curved surface ink jet printing equipment

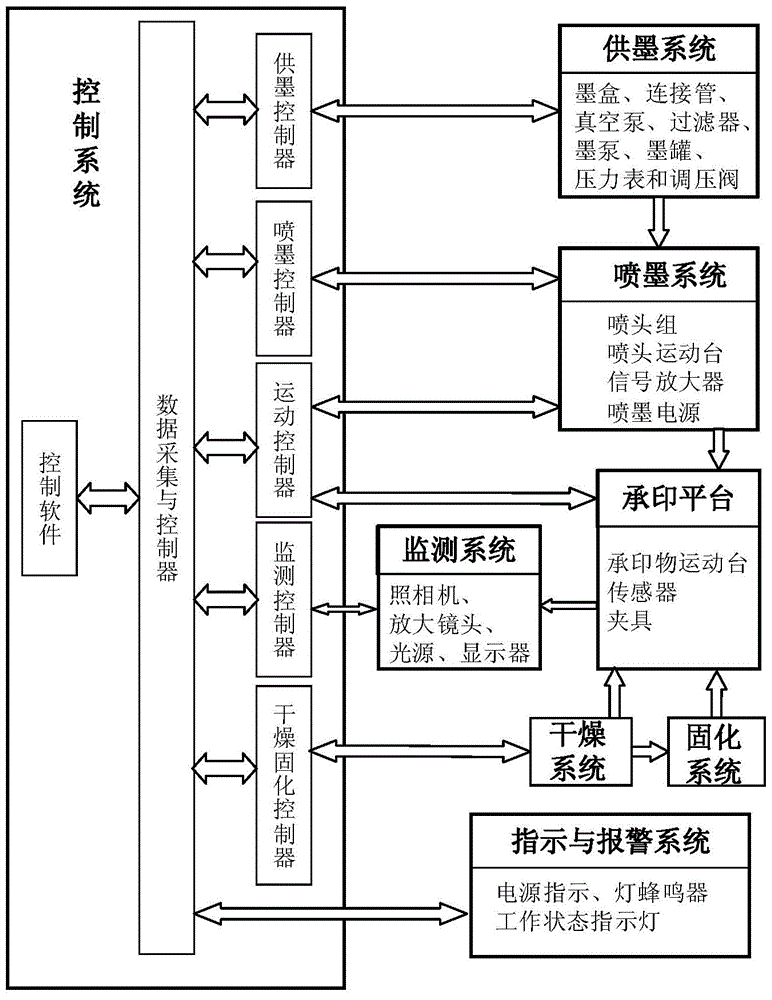

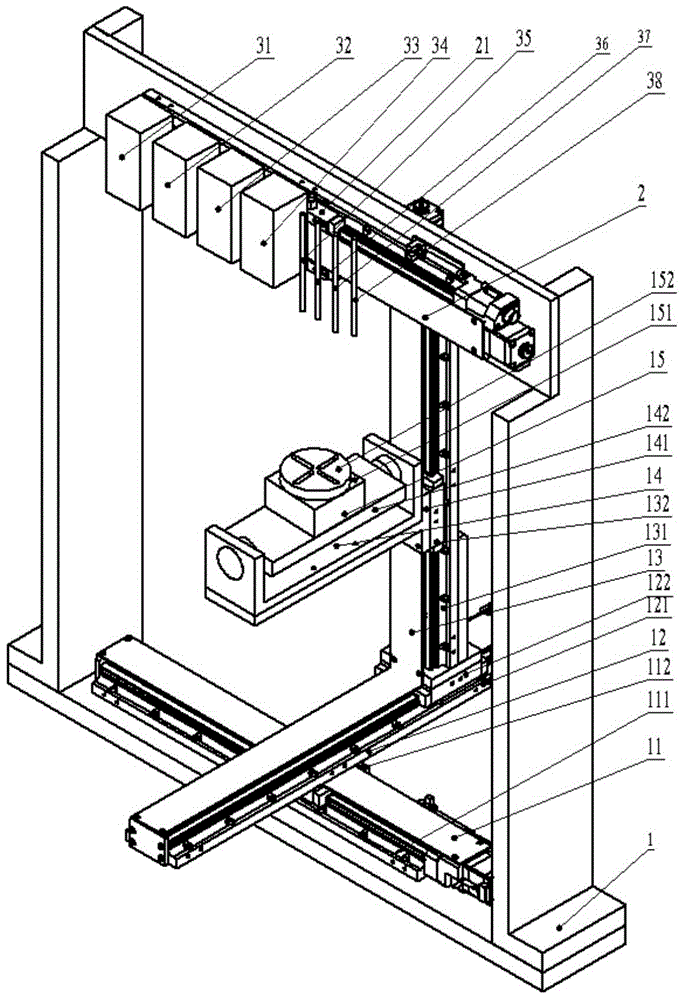

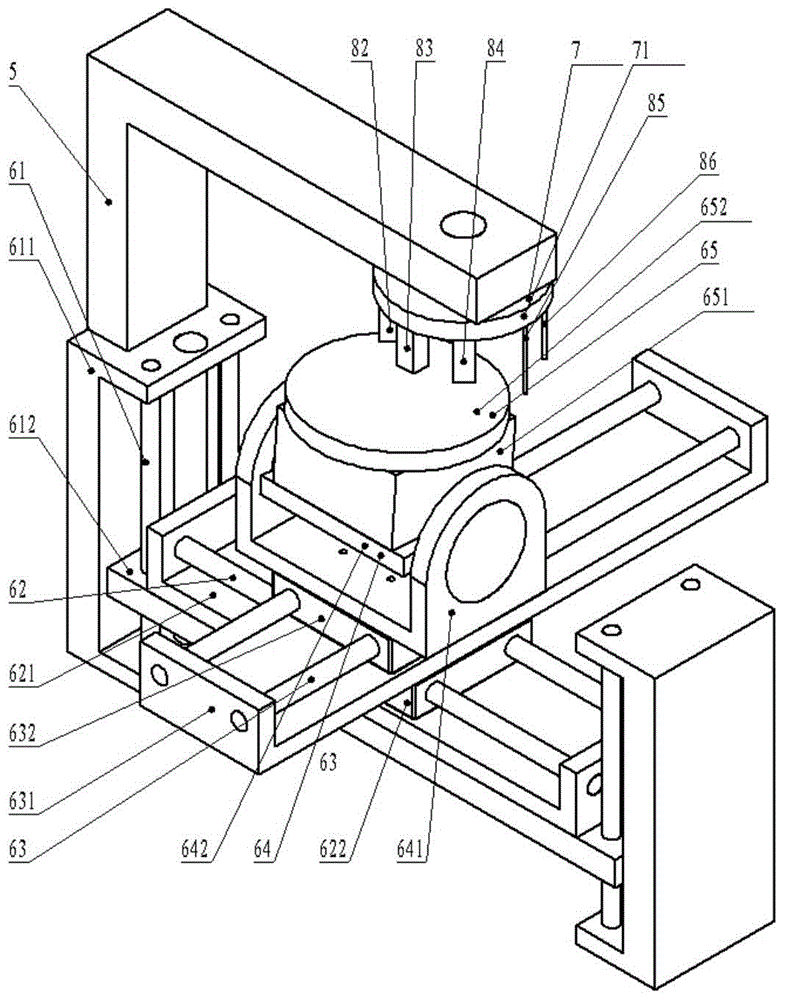

ActiveCN104553342AImprove printing accuracyIncrease printing speedDuplicating/marking methodsTypewritersControl systemMonitoring system

The invention discloses color three dimensional curved surface ink jet printing equipment which is used for color curved surface ink jet printing of three dimensional objects. The equipment mainly comprises a control system, an ink jet system, an ink supply system, a printing platform, a drying system, a curing system, a monitoring system and an indicating and alarming system. A nozzle is motionless during ink jetting, so that the ink jet printing accuracy can be effectively improved; CMYK (cyan, magenta, yellow and black) four-color ink jet printing is sequentially performed on the conventional curved surface part of a printed object with a conventional nozzle and on the complex curved surface part of the printed object with a capillary nozzle through the synchronous motion of the equipment and the curved surface of the printed object during the ink jetting process. The combined ink jet printing mode of the equipment can not only realize complex curved surface ink jet printing, but also improve the curved surface printing quality and increase the curved surface printing speed, shortens the printing time, and obtains high-quality color three dimensional ink jet printing effect of the printed object.

Owner:中国印刷科学技术研究所

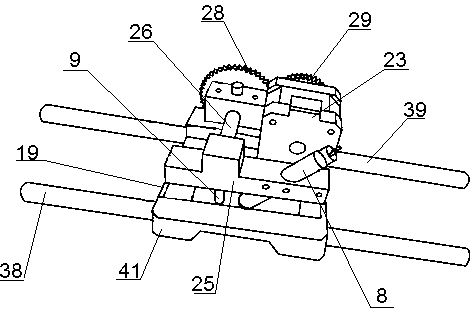

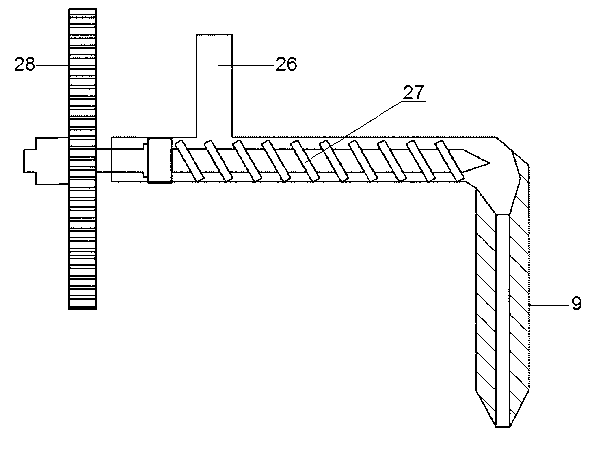

Double-sprayer and dual-mode 3D printer and operation method thereof

The invention discloses a double-sprayer and dual-mode 3D printer and an operation method thereof, and belongs to the technical field of 3D printing equipment. The printer comprises a bracket, a bottom platform device, a printed material fixing device, a driving motor I, a sprayer I, a sprayer II, a driving motor II and a central control unit, wherein the sprayer II is provide with two nozzles, and the two nozzles are respectively loaded with liquid A and liquid B in PU resin AB adhesive. The printer adopts a technology for constructing an object by replacing the mode of printing layer by layer through a mode of printing a casing and spraying the filler (PU resin AB adhesive), ensures that the strength of parts is improved, and reduces the part scrapping ratio. The weight mixing ratio of the liquid A to the liquid B in the PU resin AB adhesive is 1:1, as the liquid A and the liquid B can be cured in 1.5 to 2 minutes after being mixed, the curing speed is high, and the purpose of saving printing time is achieved. The printer adds new structure improvement design on traditional 3D printer equipment, and is low in improvement machining cost, and good in inheritability of manufacturing process and technical process.

Owner:CHANGCHUN UNIV OF TECH

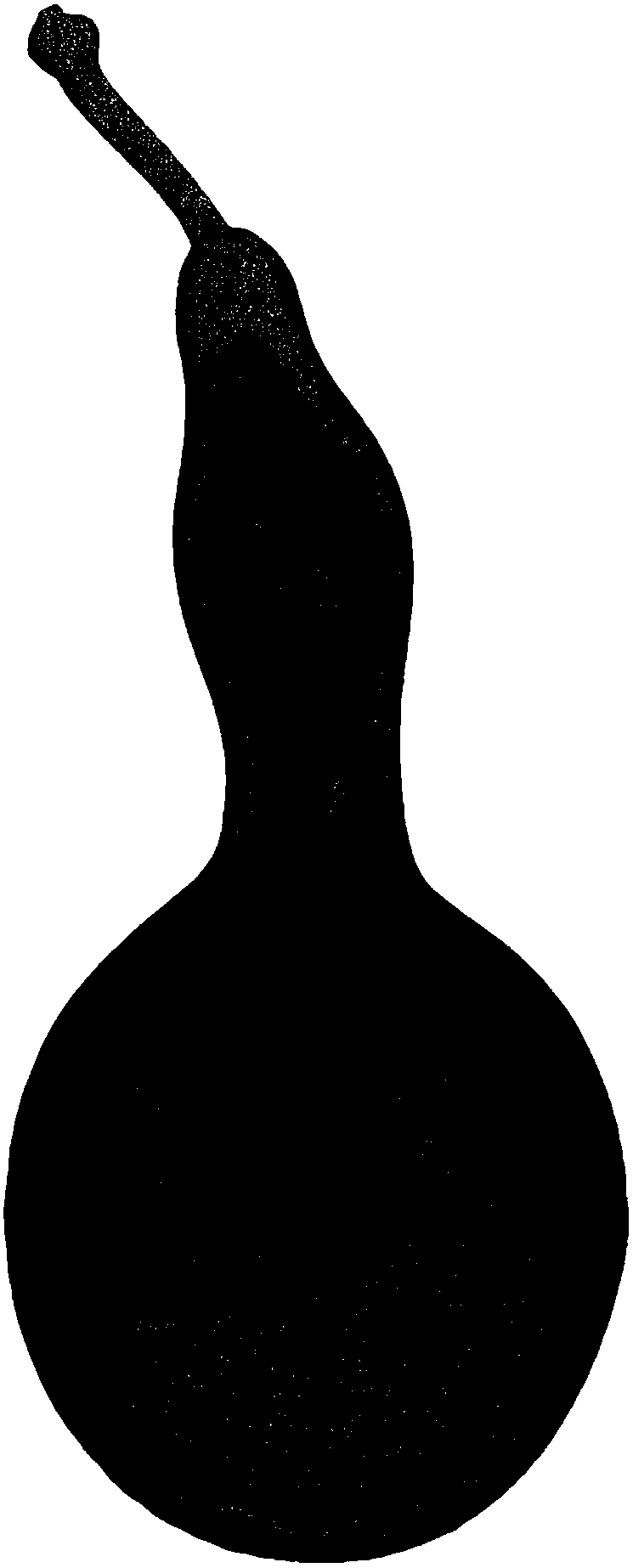

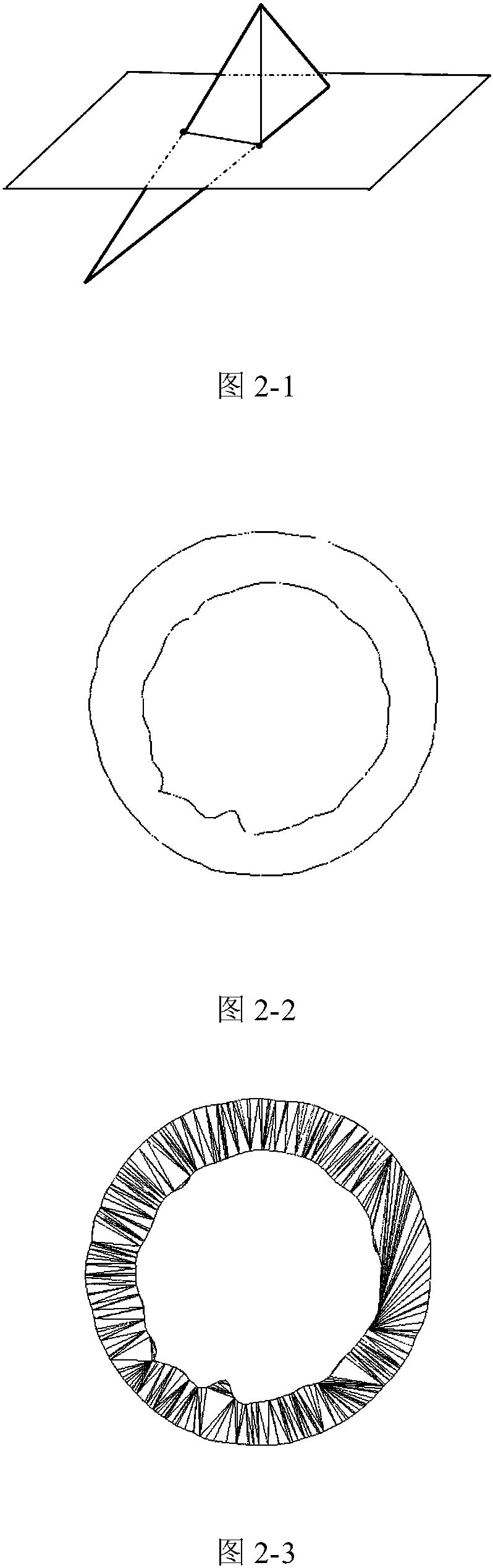

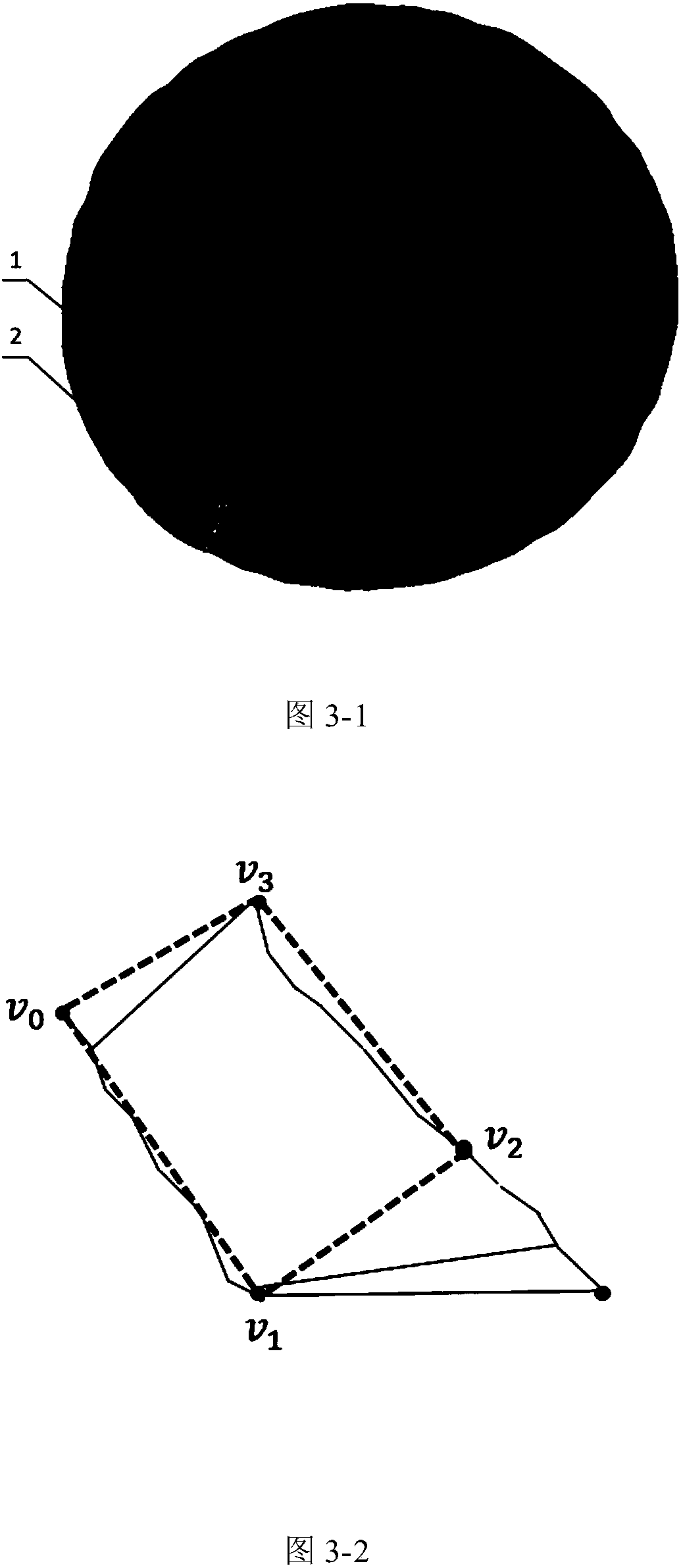

3D printing digital model sectioning and interface designing method, and application thereof

ActiveCN107610230AReduce printing timeSolve the problem that 3D printing cannot be done normallyAdditive manufacturing apparatusSpecial data processing applicationsComputer graphics (images)3d printer

Owner:CAPITAL NORMAL UNIVERSITY +1

Method for rapid multi-nozzle 3D printing of tumor tissue model using supporting bath

ActiveCN108587903AConvenient researchBuild fastAdditive manufacturing apparatusTissue/virus culture apparatusSterile environmentEngineering

The invention discloses a method for rapid multi-nozzle 3D printing of a tumor tissue model using supporting bath, and relates to the field of biological 3D printing. The method mixes alginate, photocurable gelatin and the like to encapsulate cells and prints rapidly in the supporting bath, and printing of different cells is achieved by rapidly switching nozzles. By printing a normal tissue and atumor tissue in a complete model, the structure of a tumor tissue in vivo is better restored. The closed property of the hydrogel support bath provides a better sterile environment, and at the same time, uncontrolled cell density and species space due to settlement are avoided during printing. The rapid switching of the nozzles reduces the printing time to a certain extent, the decreasing of the activity of the cells is effectively slowed down in the printing process, and the integrity of the printing structure is effectively ensured. The problem of gel curing is effectively solved by printingwith a concentric needle. The tumor model is built faster and can be better used for tumor treatment research.

Owner:JINAN UNIVERSITY

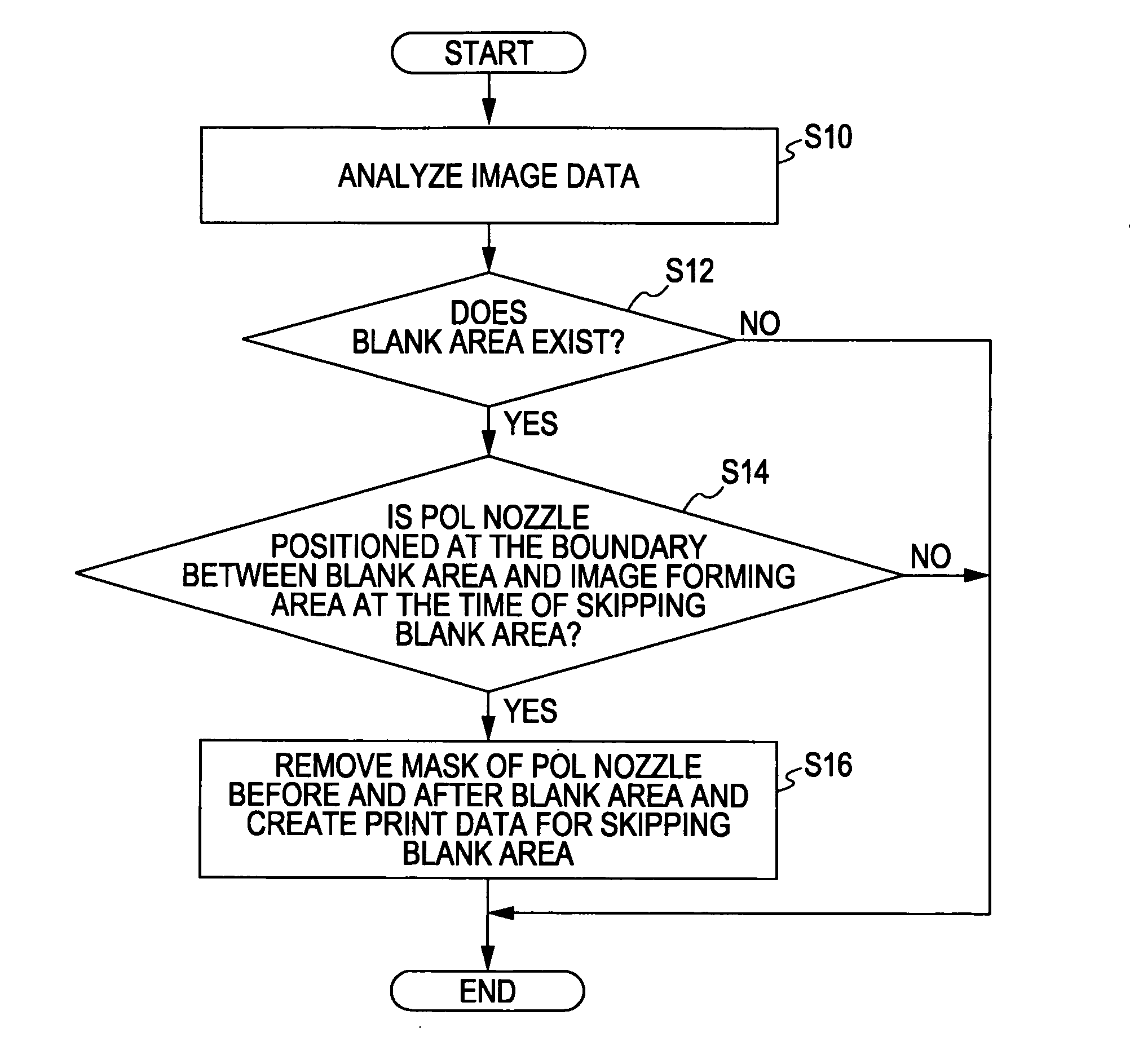

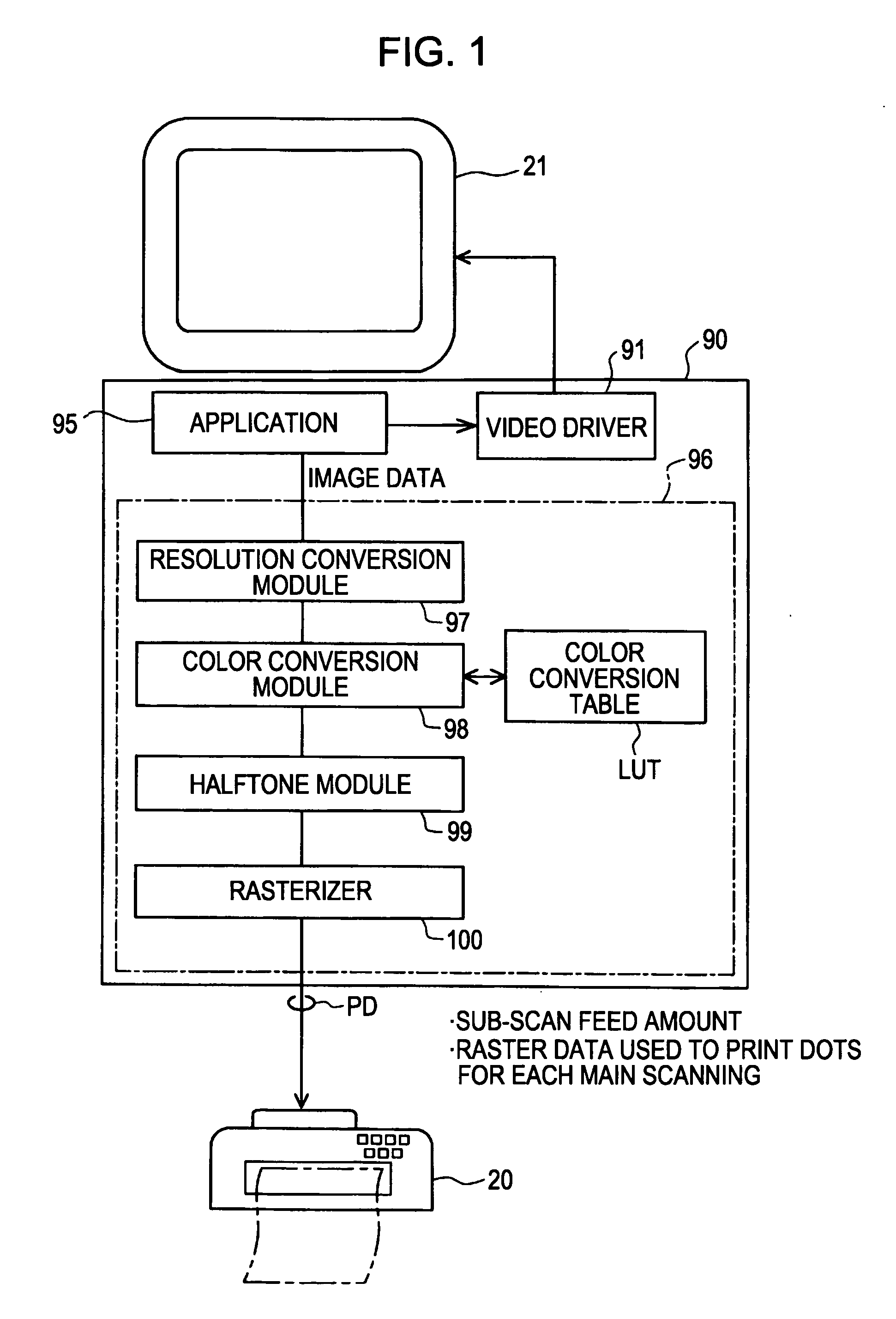

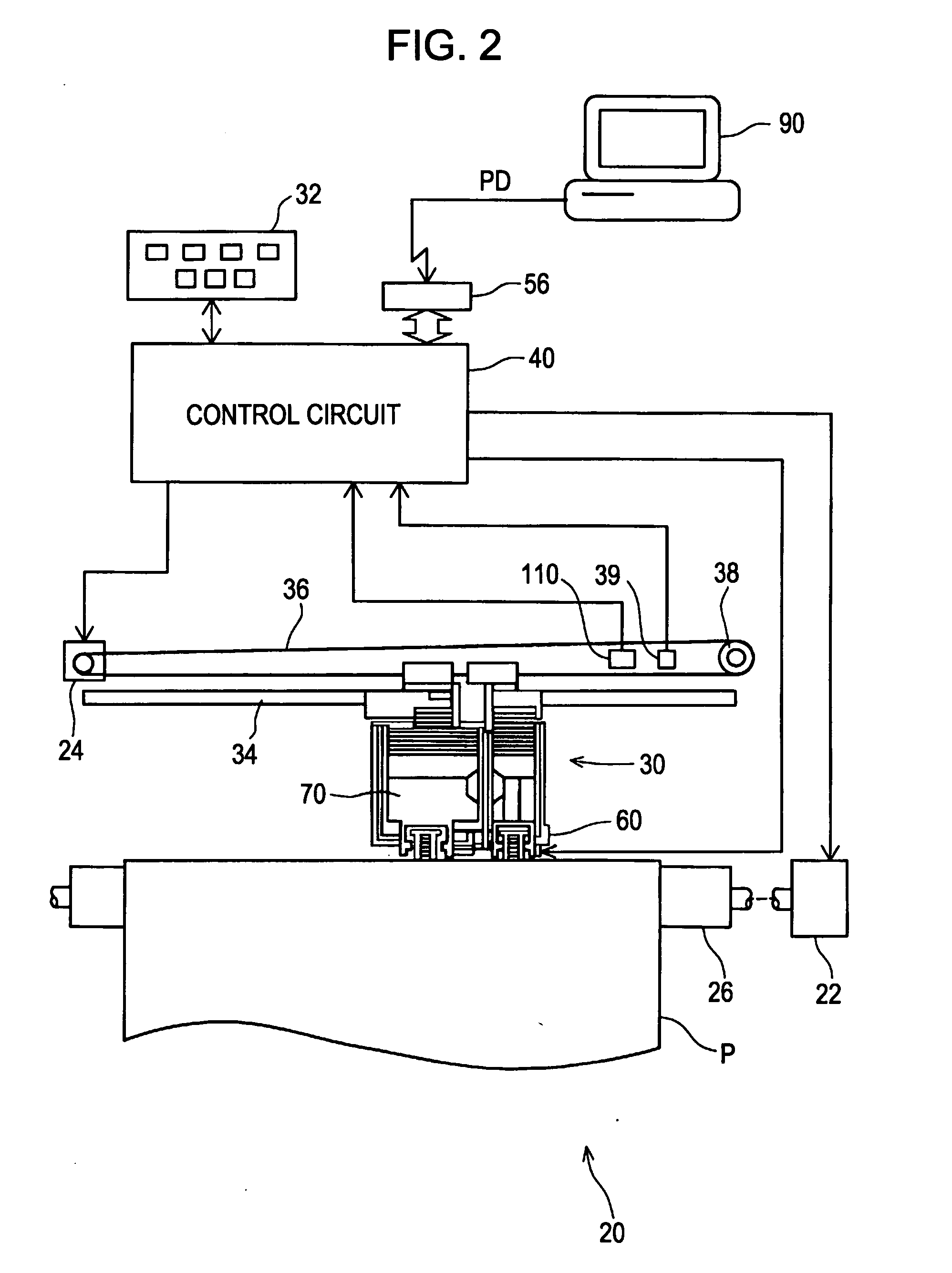

Liquid ejecting apparatus and liquid ejecting method

ActiveUS20090251499A1Shorten image forming process timePrevent image degradationVisual presentationOther printing apparatusLiquid jetImage formation

A liquid ejecting apparatus includes: a printing head that ejects liquid to form dots on a recording medium; a head driving section that performs a main scanning for the printing head; a transporting section that performs a sub-scanning for the recording medium; an image forming section that forms an image, a first dot formation area and a second dot formation area; an overlap control section that performs overlap control for intermittently forming dots on the first and second dot formation areas so as to make the second dot formation area overlap with the first dot formation area and fill spaces between the dots intermittently formed on the first dot formation area; and a cancellation section that cancel the overlap control when a blank area exists in an image and a nozzle forming at least one of the first dot formation area and the second dot formation area.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com