Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1418results about How to "Increase printing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

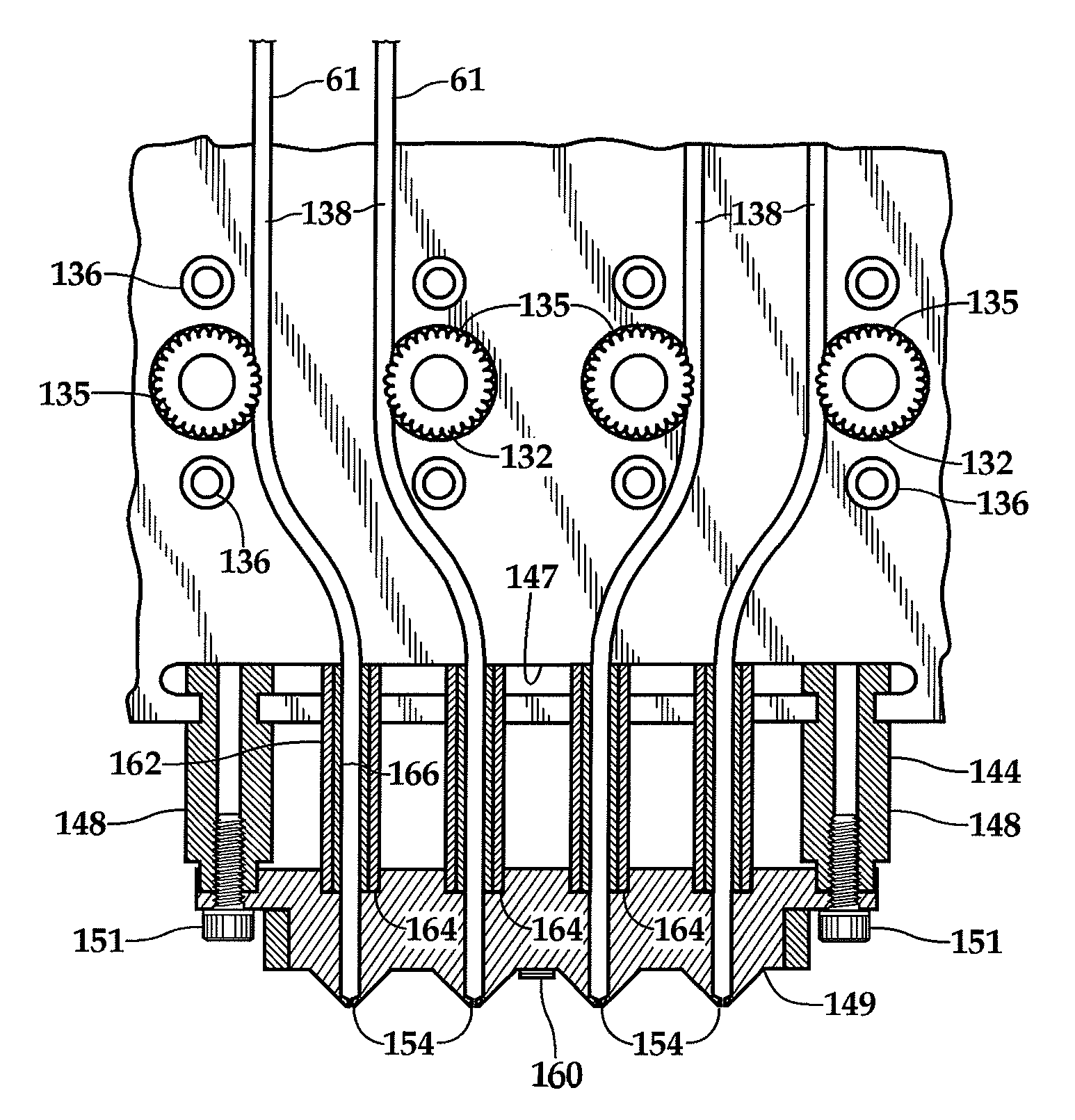

3D printer and printhead unit with multiple filaments

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

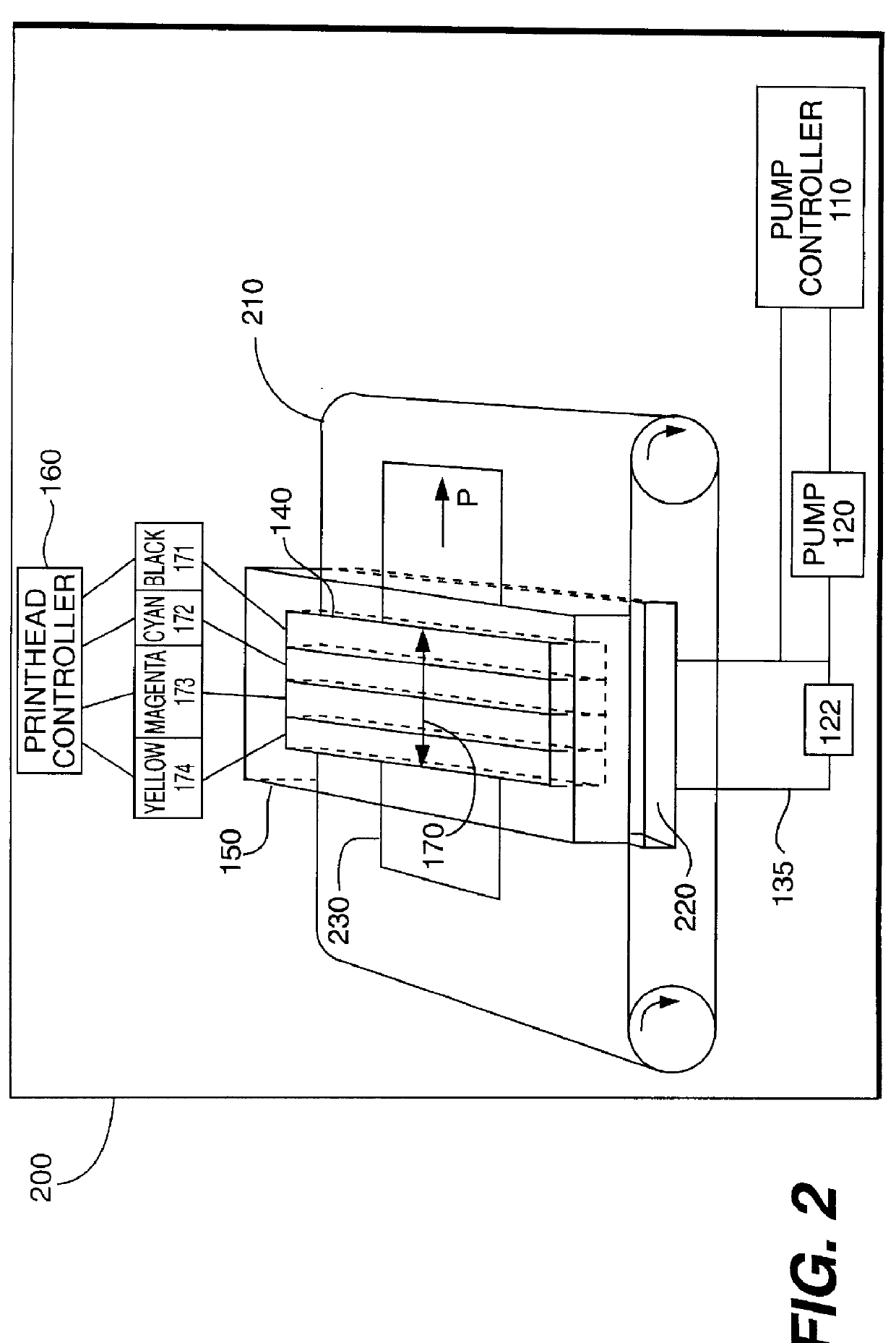

Method and apparatus for reducing intercolor bleeding in ink jet printing

In an ink jet printing process, a desired vacuum is applied to the back side of a print substrate with proper feedback and control. The optimum vacuum exerts a suction force on ink dispersed on the front side of the print substrate to accelerate penetration of the ink into the print substrate and to reduce smear and intercolor bleeding. In addition, the vacuum may be applied in the ink jet printing process in combination with various other techniques including heating of the print substrate at any stage of printing process including before, during, after, and combinations thereof and delaying the time between ink dispersing of two different inks as in the checkerboard printing method. The employment of proper vacuum, inks, and printheads including partial-width or full-width array printheads allows a fast speed multi-color ink jet printing process to be carried out on a print substrate to give high resolution (e.g., 600 spi) multi-color images with good print quality.

Owner:XEROX CORP

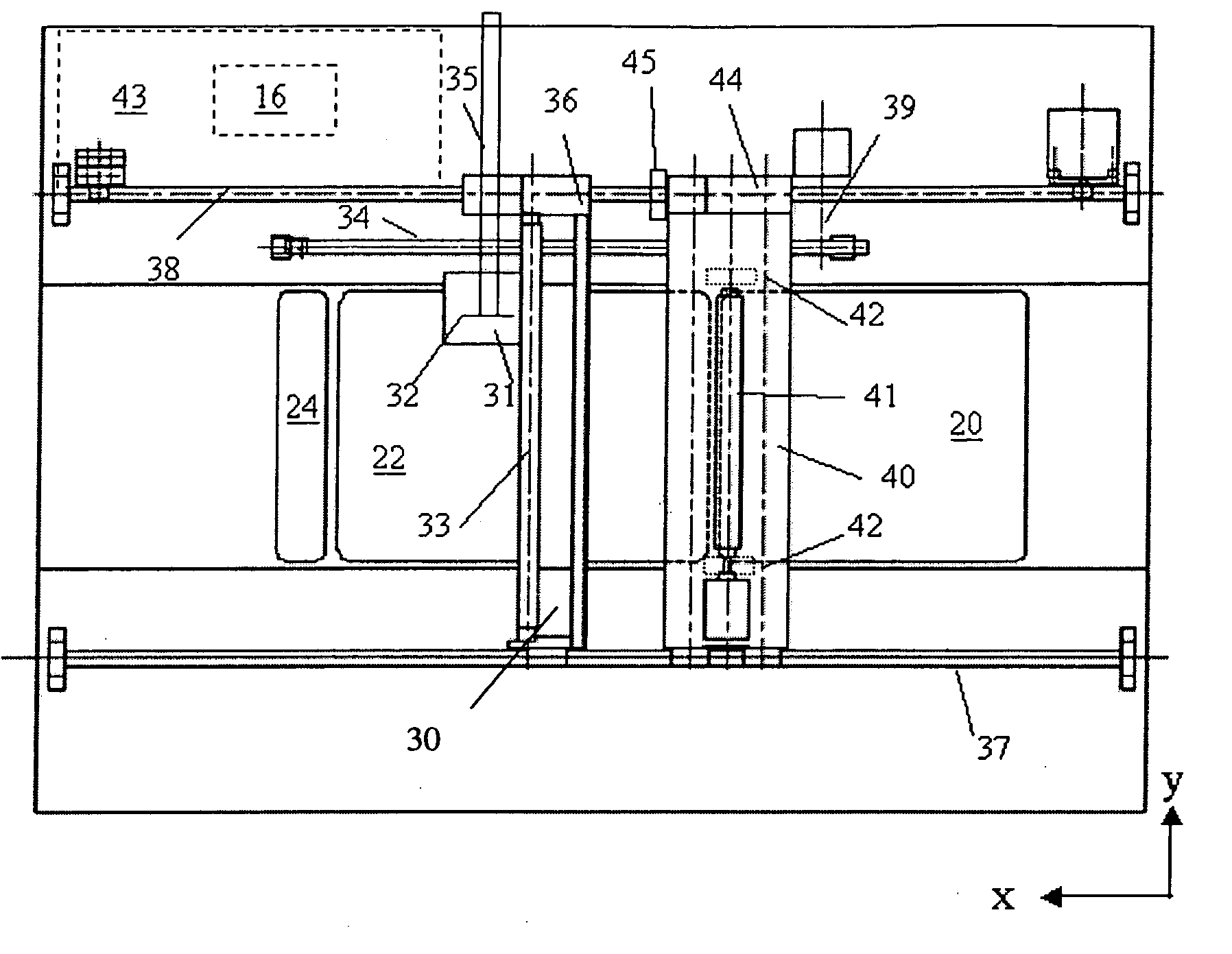

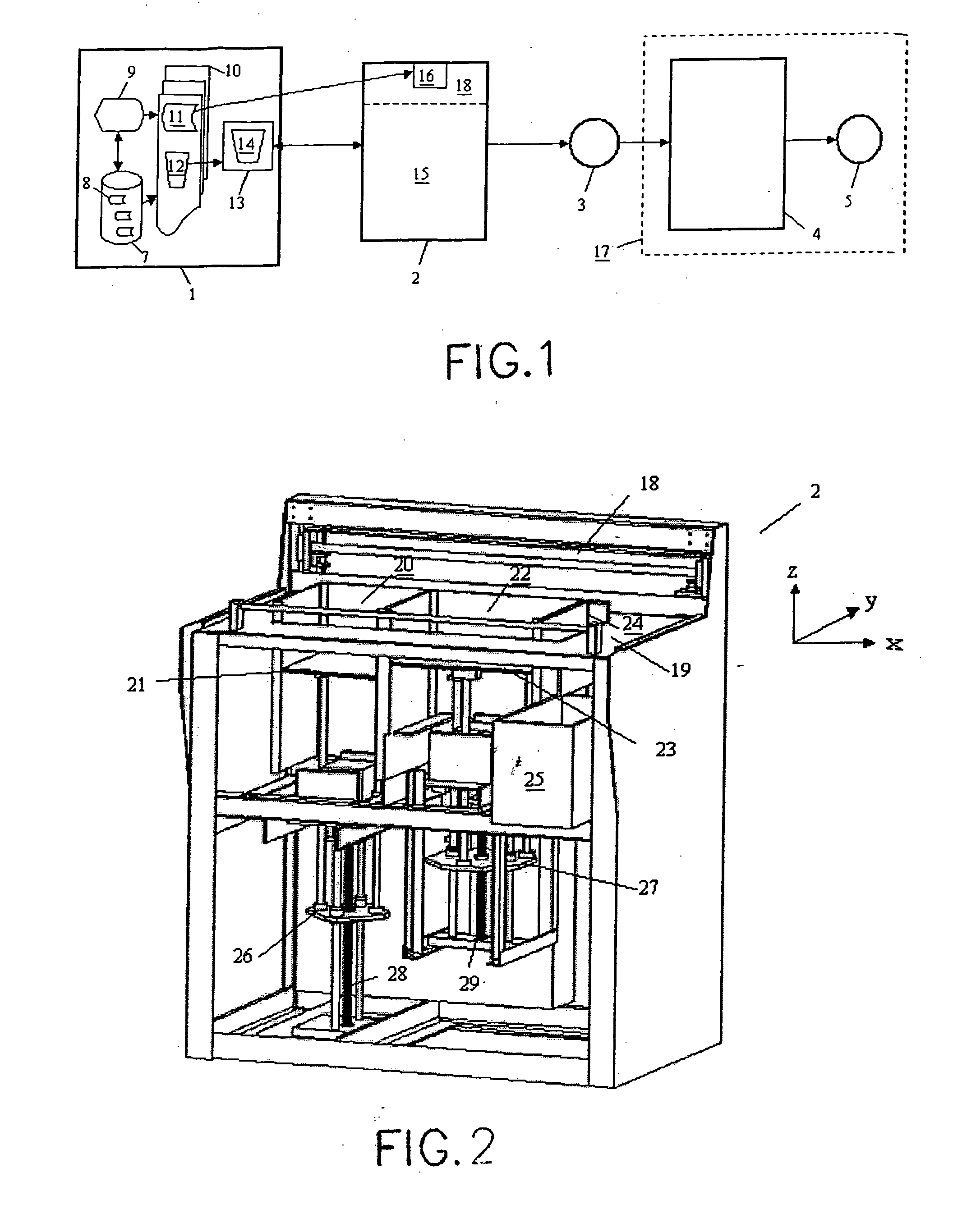

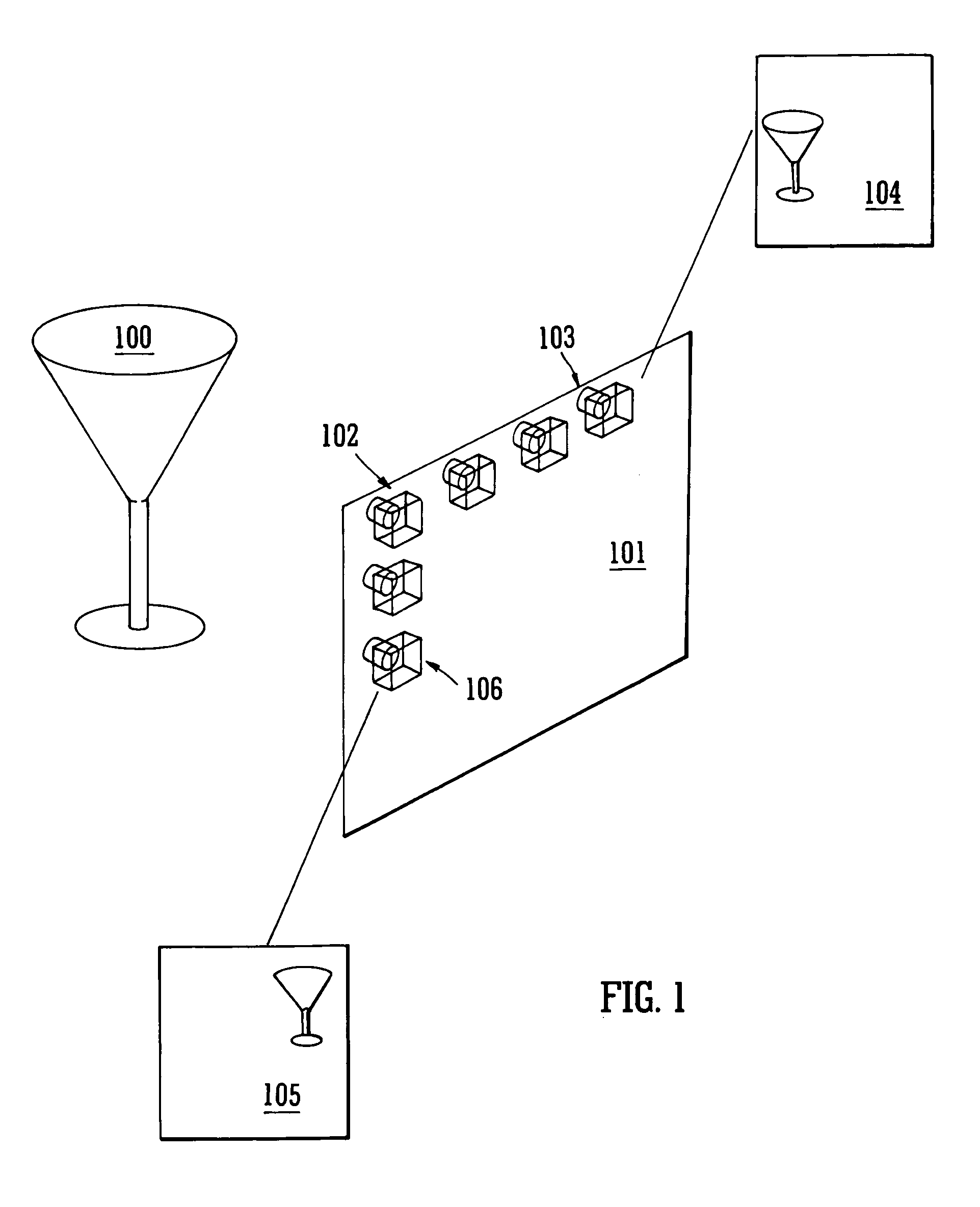

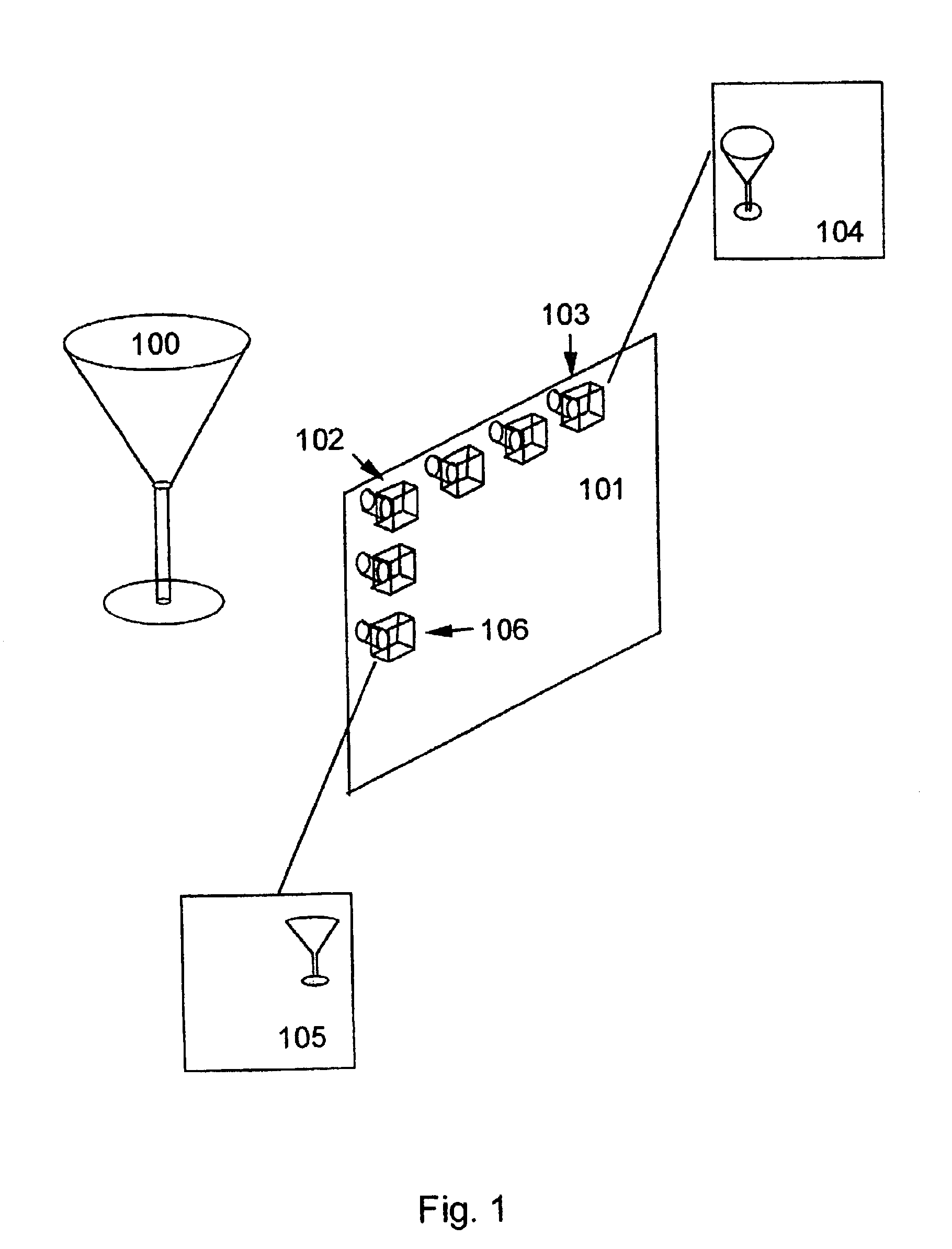

Method and apparatus for rapid prototyping using computer-printer aided to object realization

InactiveUS20050225007A1Shorten the timeIncrease printing speedConfectionerySweetmeatsComputer printingObject store

This invention applies a new computer and printer integrated technology to aid forming physical objects rapidly, and the method and apparatus are disclosed to satisfy the market requirements for a quick, reliable, safe, and inexpensive operation. The invention coverts a virtual object stored in the storage device of computer through software that slices the virtual object into many layers. The cross-section of the first layer is sent to a printer or a plotter, and the contour domain is printed or plotted by the printer or plotter. The fluid (not limited to binder) in the printer head is coated onto a layer of uniform distributed porous material which allows the powder and fluid to combine with each other; however, the combining process can be either a natural or an artificial process to enhance the binding force between the fluid and powder. After the first layer is finished, the second layer of powder is uniformly distributed on the first layer, and the contour printing process is repeated. As the printing process is repeated until all slicing layers of the model are finished, the object is stacked layer by layer sequentially. The physical object can be obtained after all the unglued powders are removed. The above-mentioned printing process not only produces monochrome objects, but also produces color objects. The machine includes components of a printer or plotter and its interface card, and x-z axis traversal driven mechanism. The operation platforms include a material supply chamber, a constructing chamber at which powder material is combined with solution, and a recycling hole. A slicing algorithm control software is used to calculate the cross-sectional contour, and the manufacture process is controlled by software and hardware interfaces.

Owner:NAT CHENG KUNG UNIV

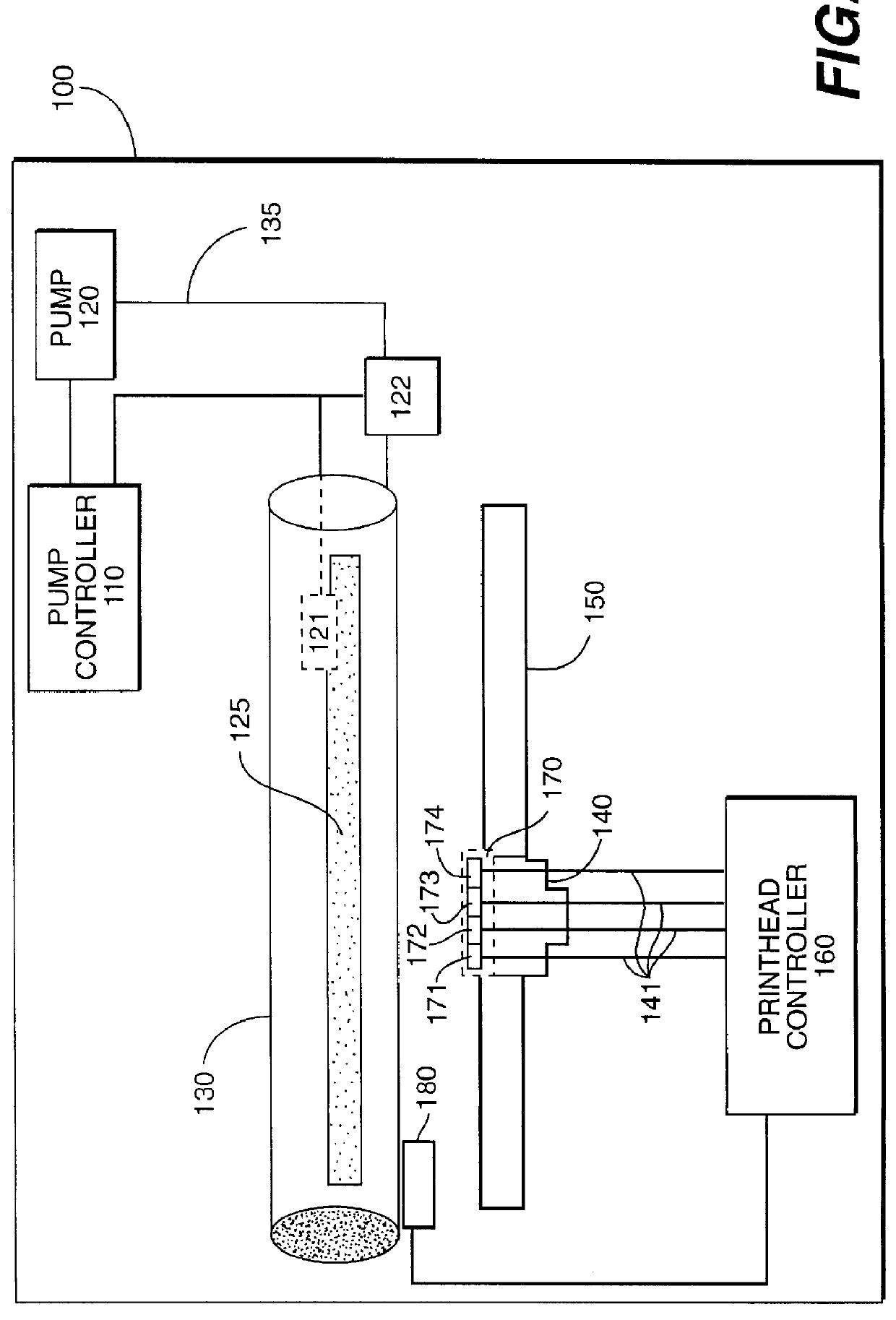

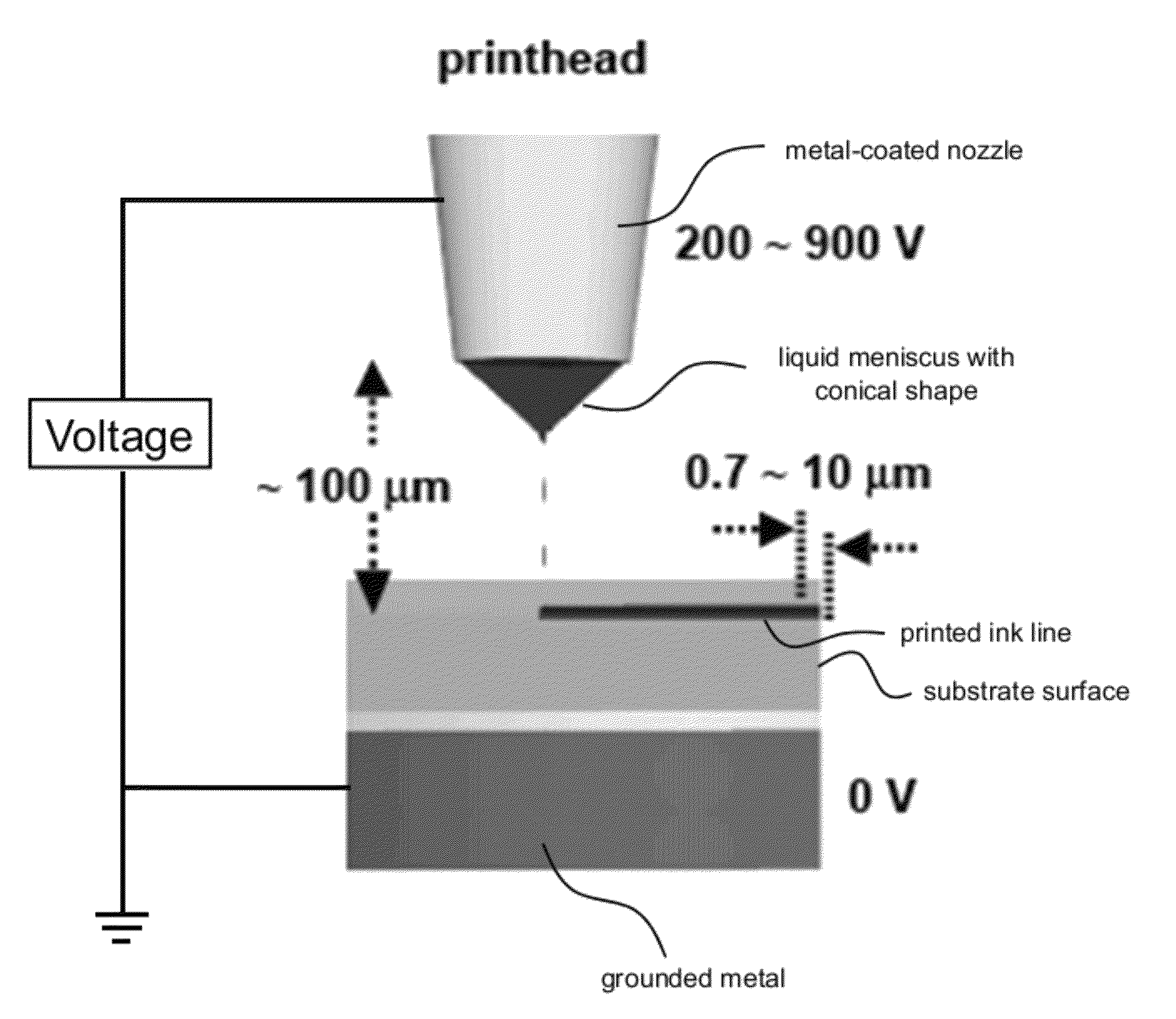

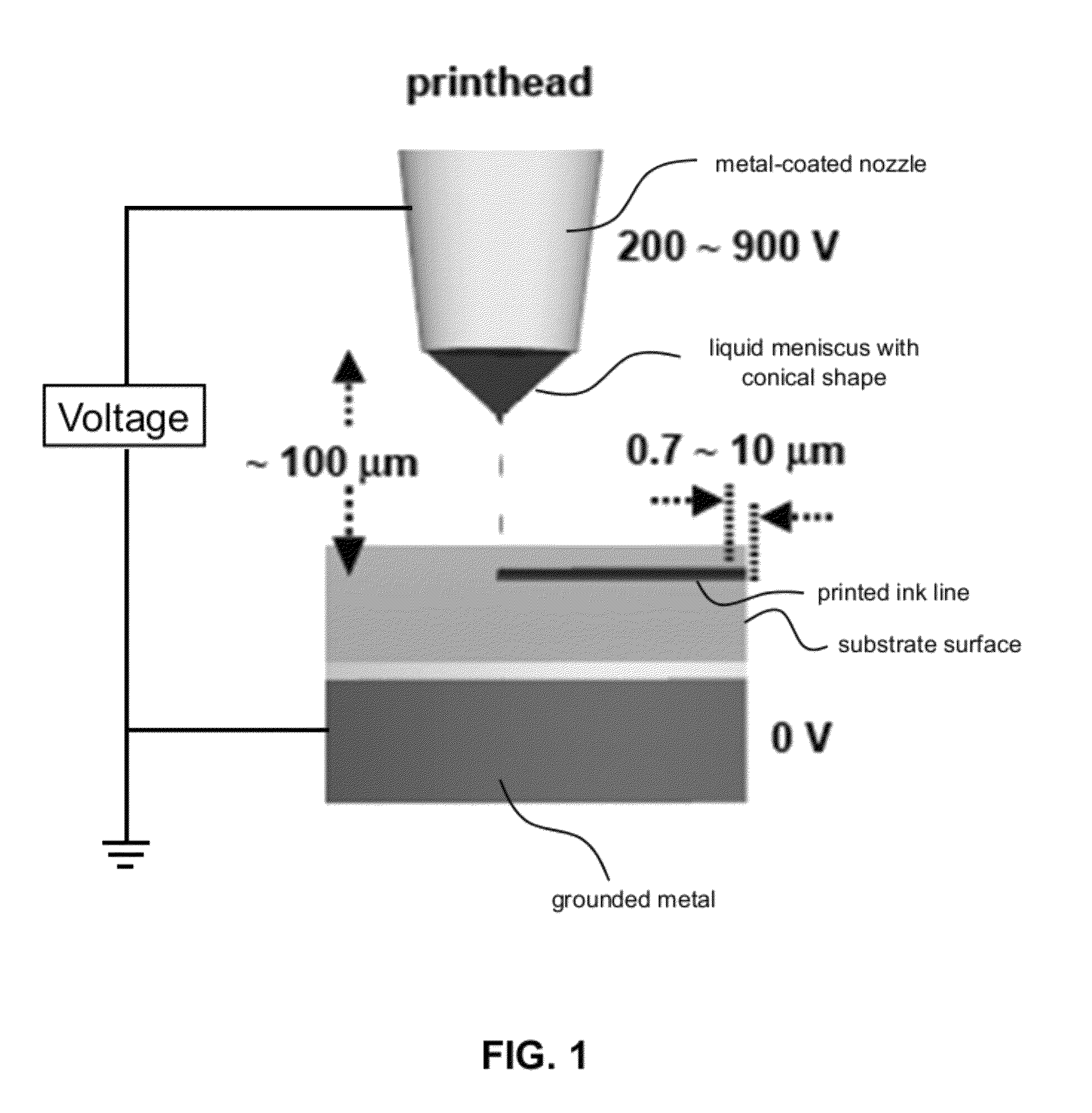

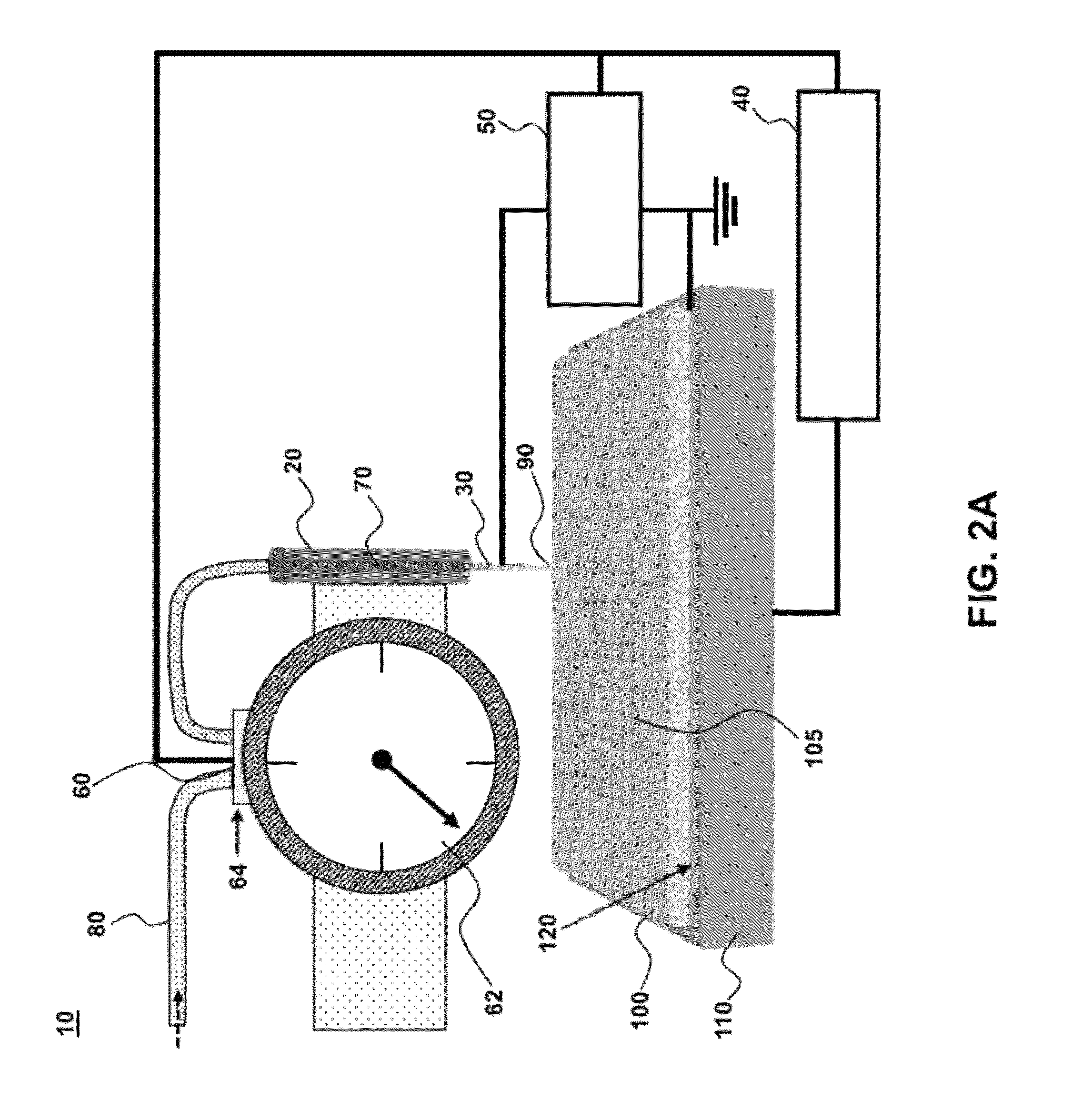

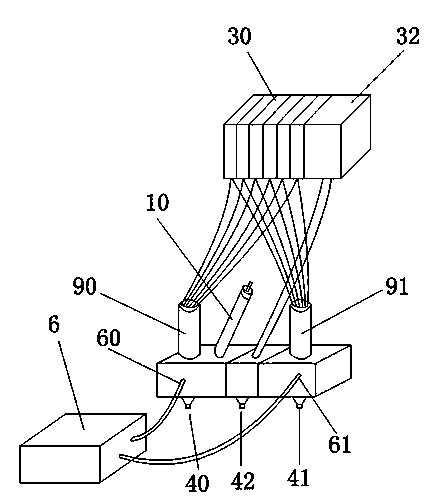

High resolution sensing and control of electrohydrodynamic jet printing

ActiveUS8562095B2Improve printing effectEasy to printOther printing apparatusElectricityImage resolution

Provided are various methods and devices for electrohydrodynamic (E-jet) printing. The methods relate to sensing of an output current during printing to provide control of a process parameter during printing. The sensing and control provides E-jet printing having improved print resolution and precision compared to conventional open-loop methods. Also provided are various pulsing schemes to provide high frequency E-jet printing, thereby reducing build times by two to three orders of magnitude. A desk-top sized E-jet printer having a sensor for real-time sensing of an electrical parameter and feedback control of the printing is provided.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

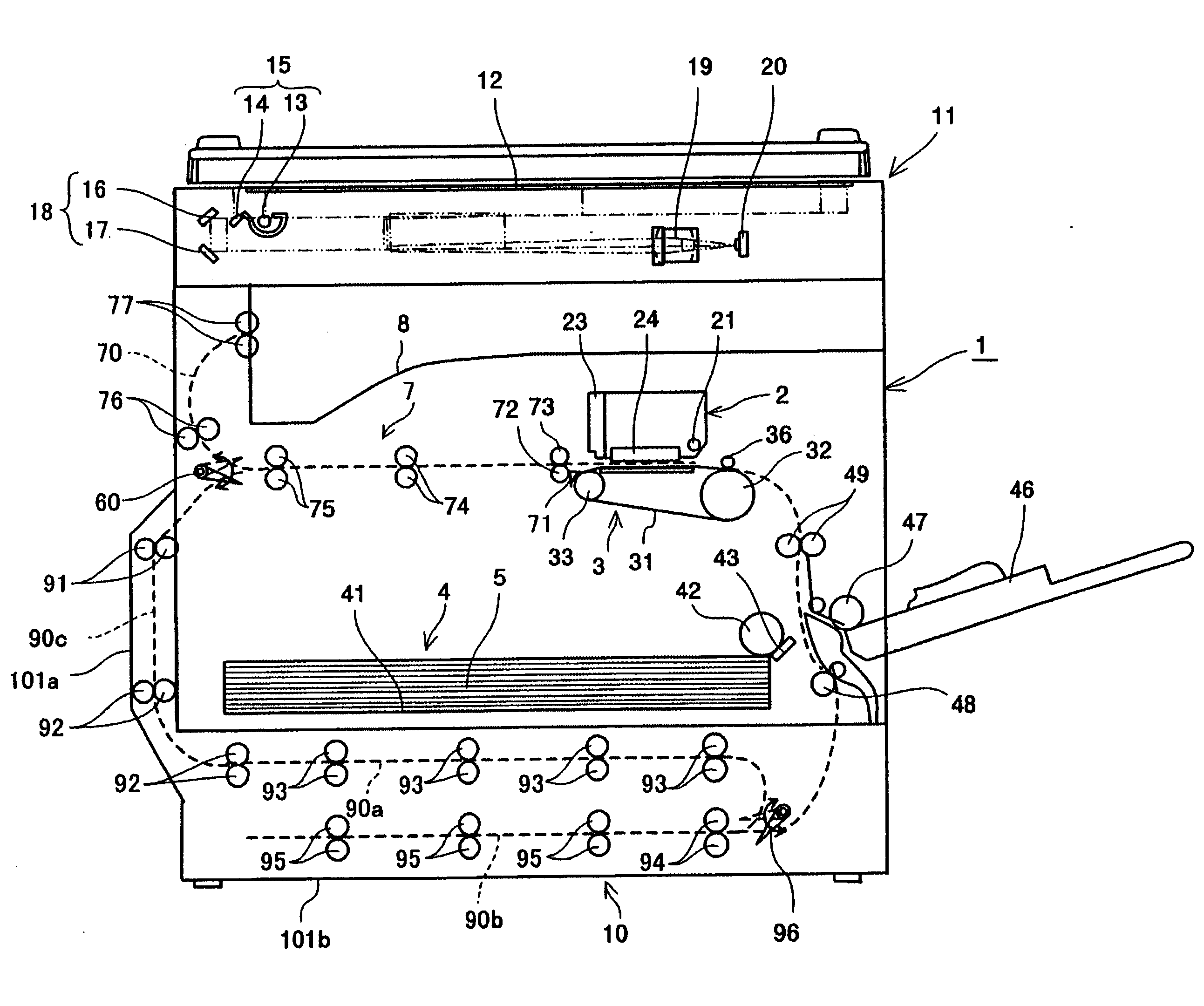

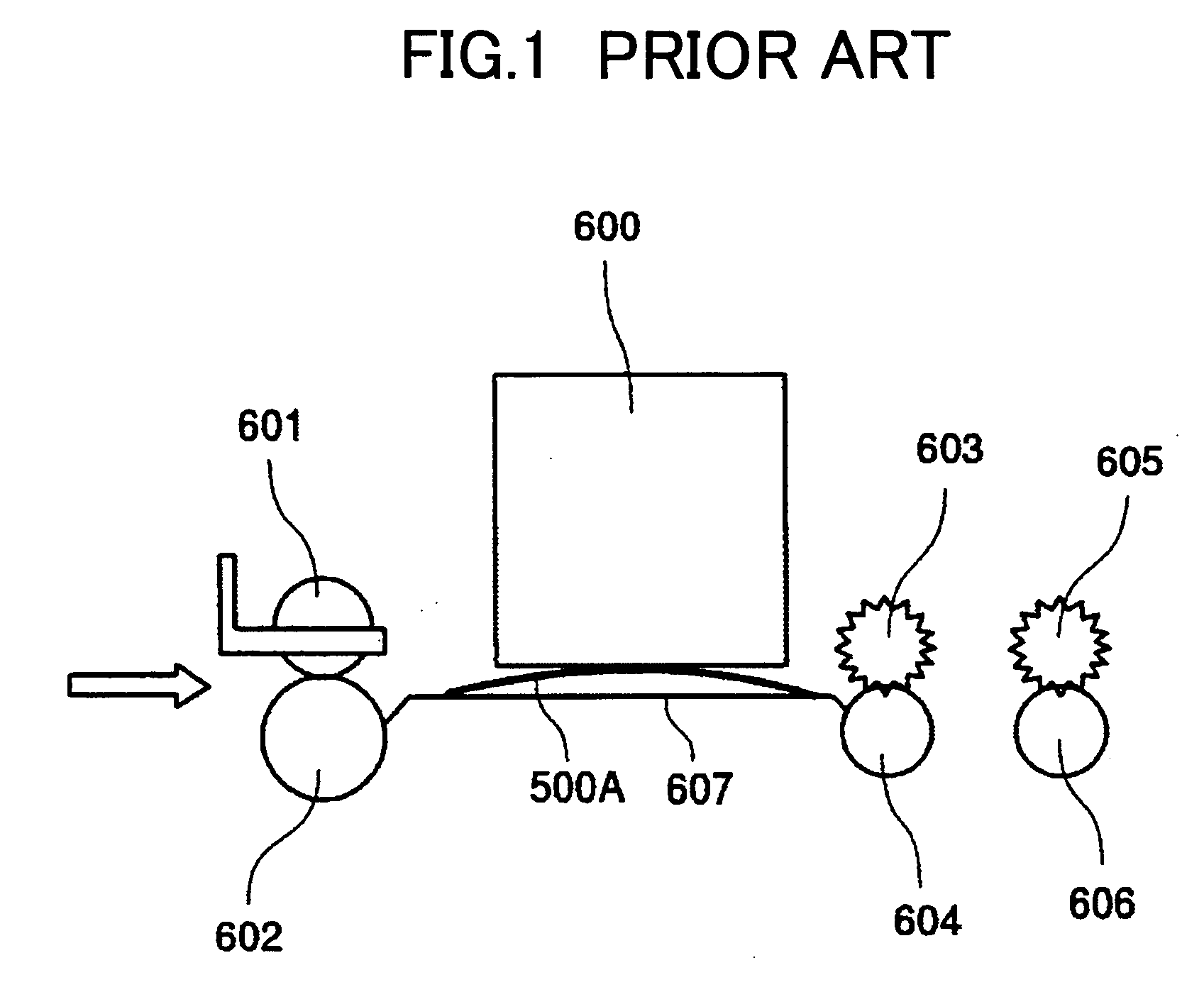

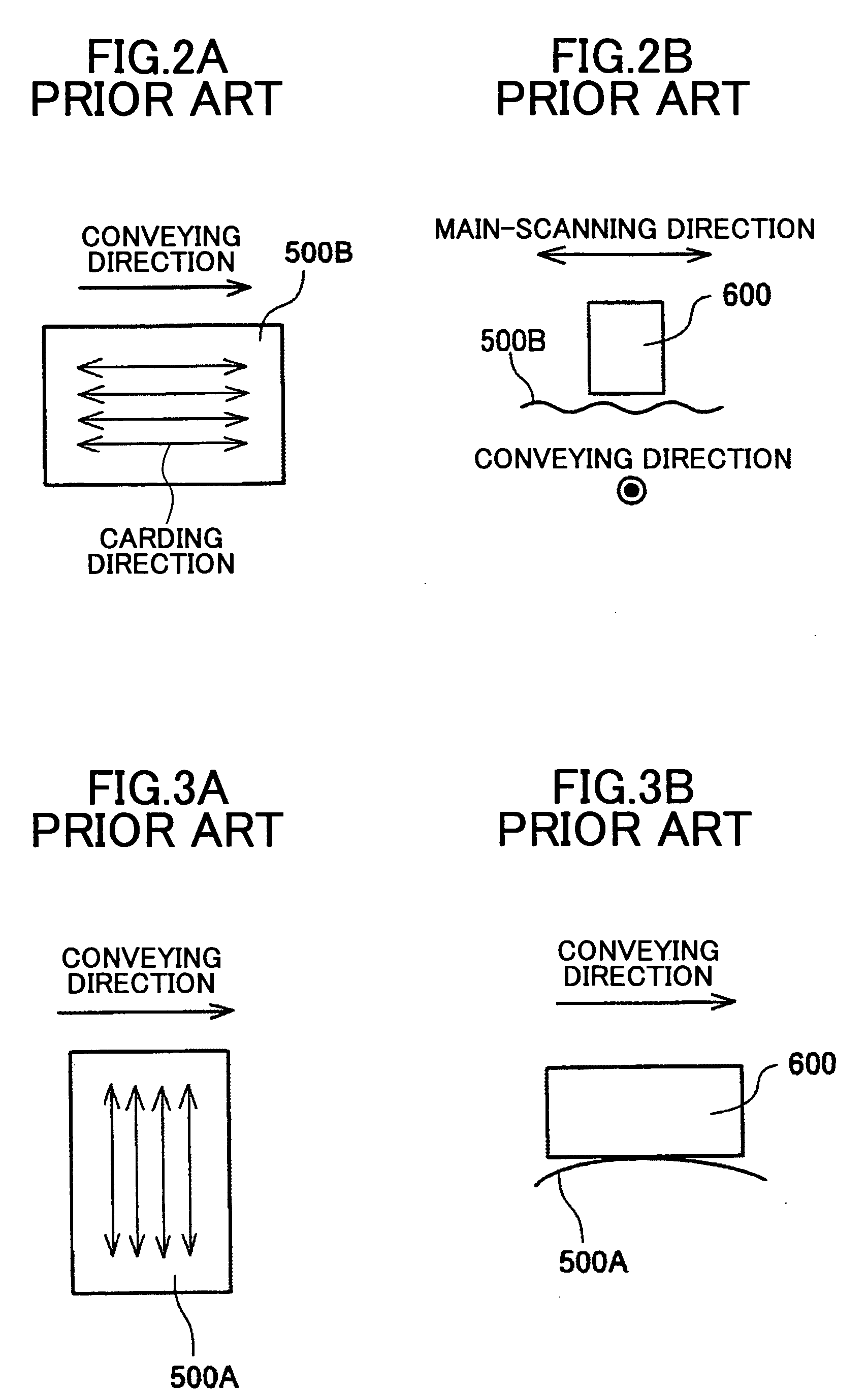

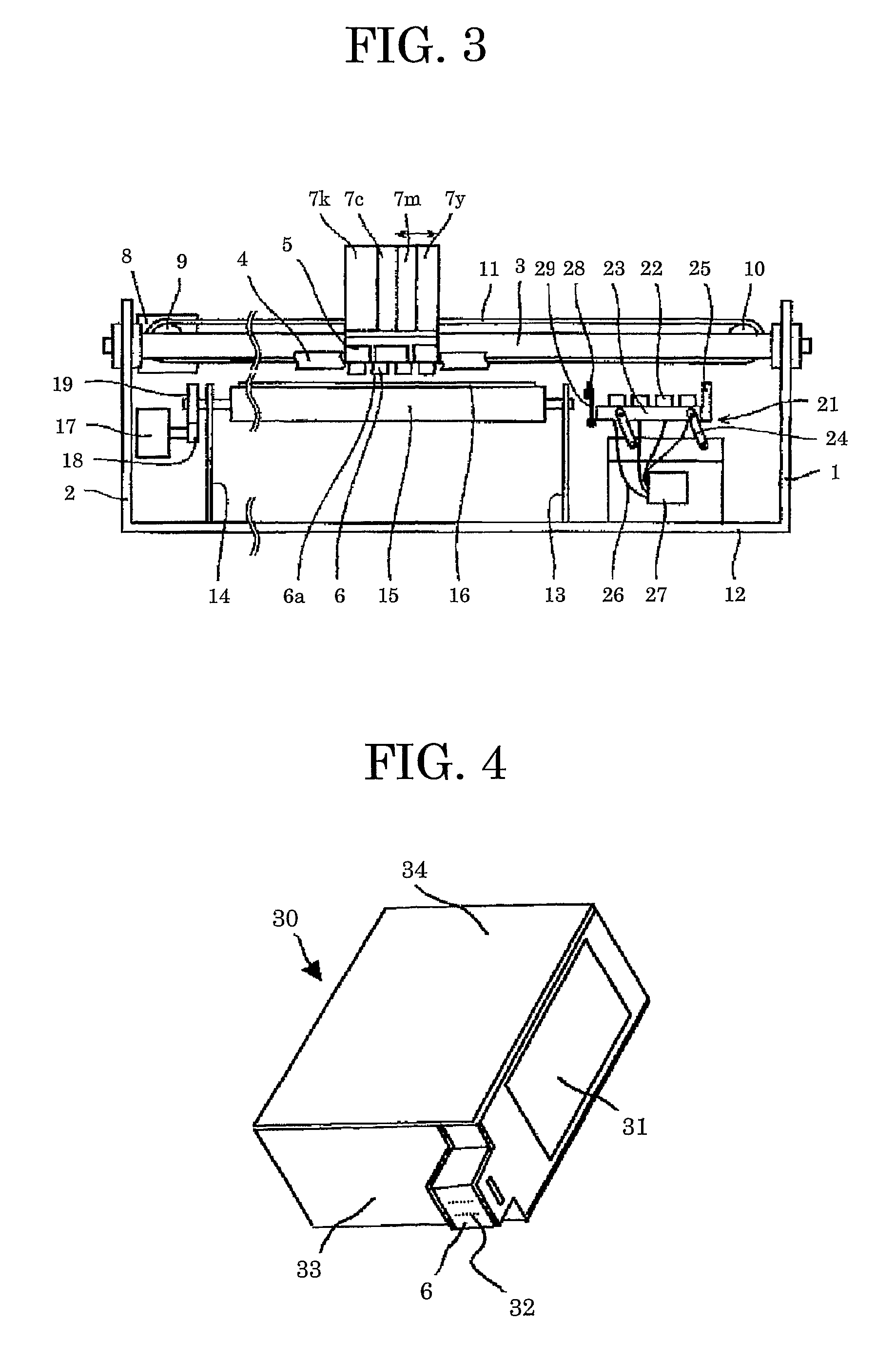

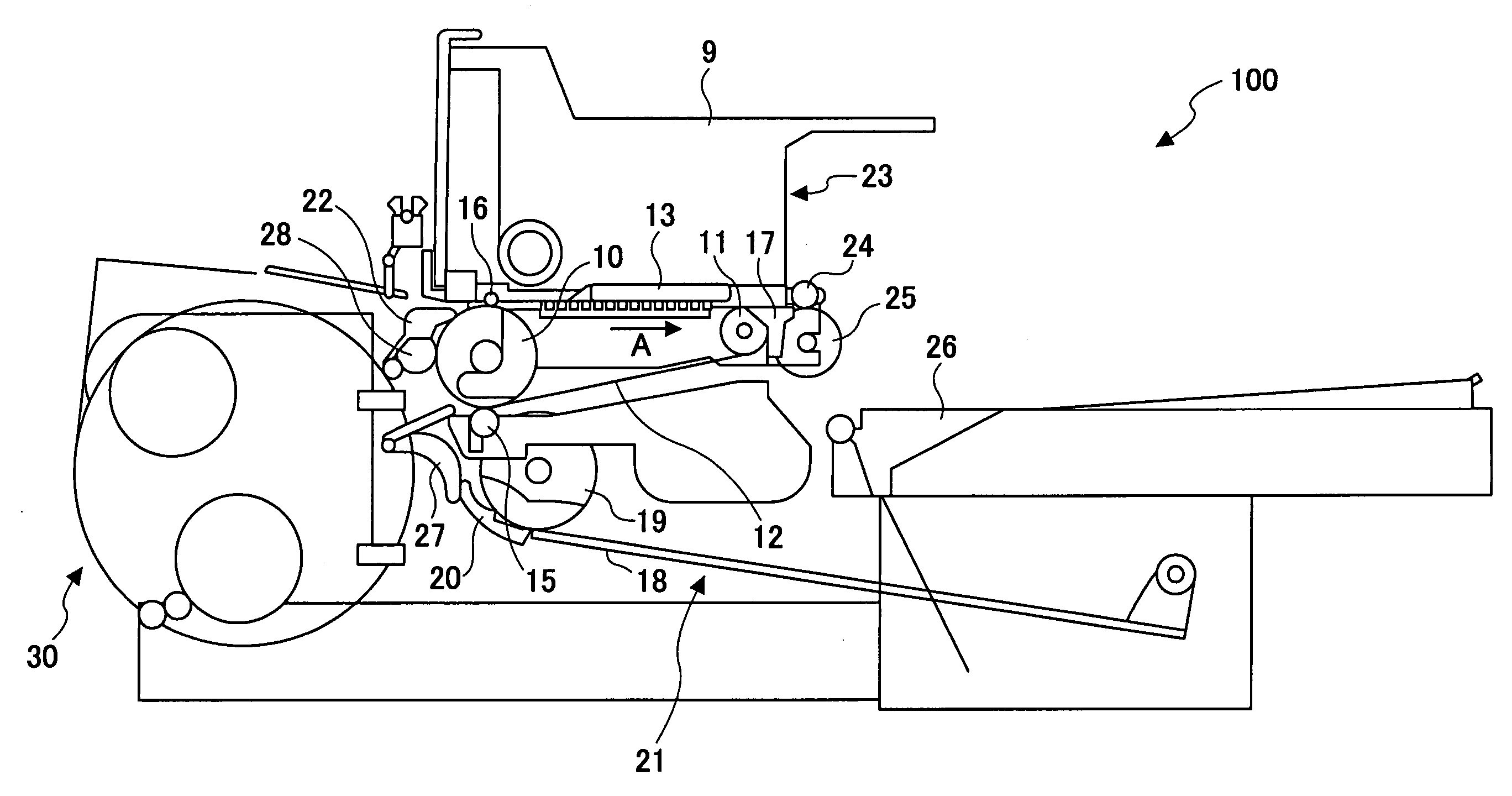

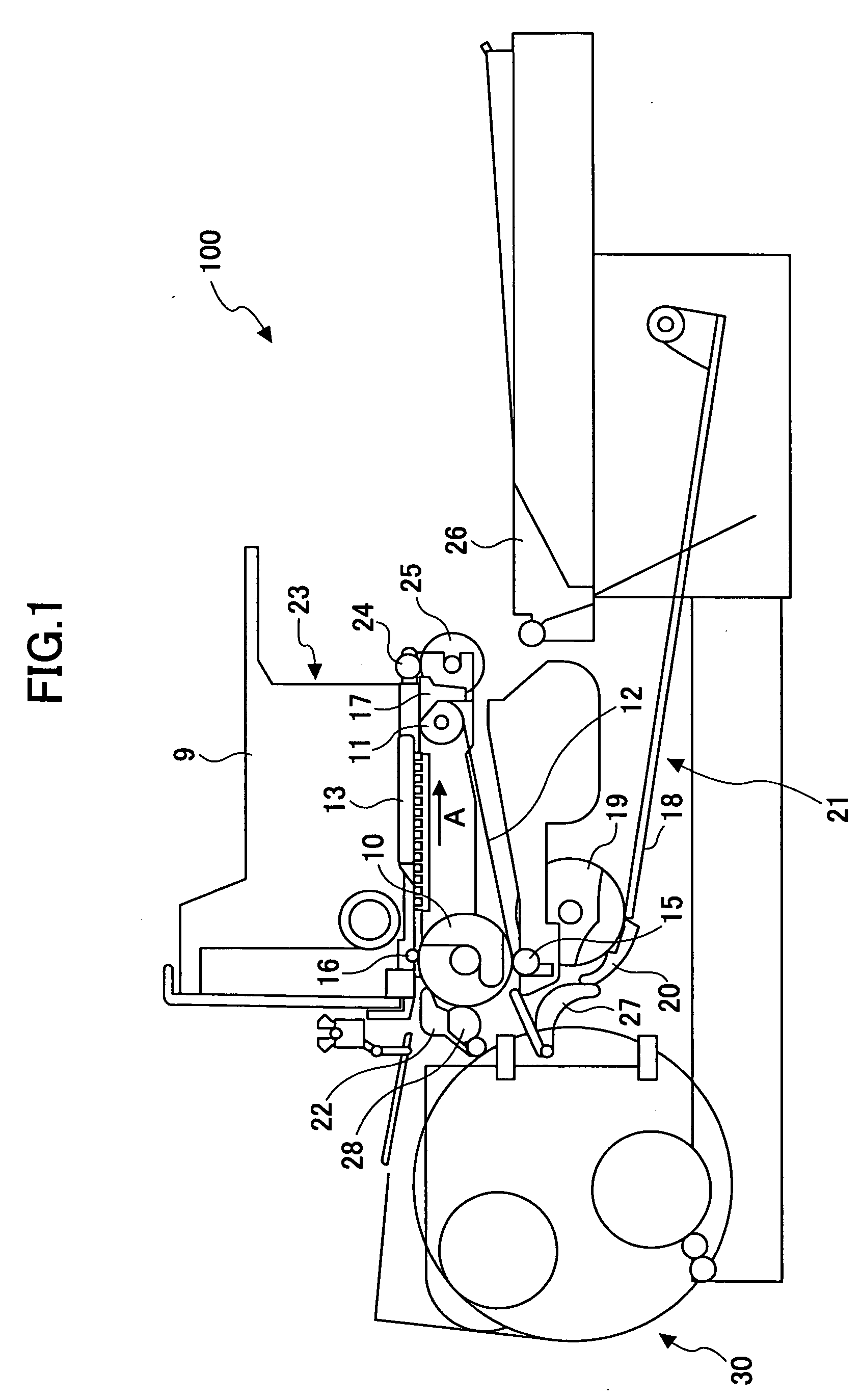

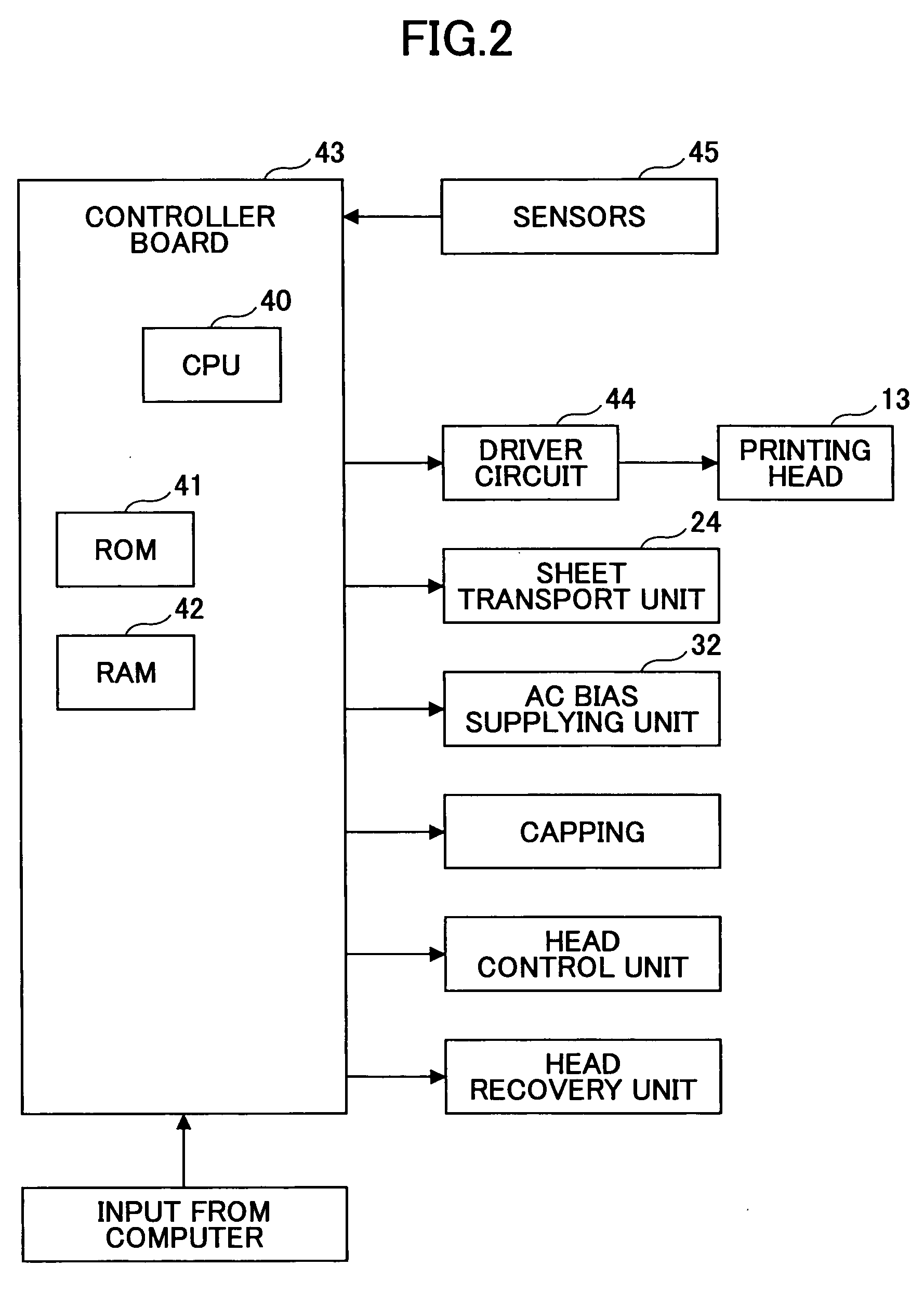

Image forming apparatus

InactiveUS20050194730A1Improve convenienceIncrease speedOther printing apparatusArticle feedersImage formationEngineering

An inkjet recording apparatus provides an improved printing speed and improved convenience of use. A recording head discharges droplets of a recording liquid onto a paper so as to form an image on the paper. A belt conveyance mechanism has a belt onto which the paper is electrostatically attached. The paper attached onto the belt is conveyed in a direction perpendicular to a carding direction of the paper.

Owner:RICOH KK

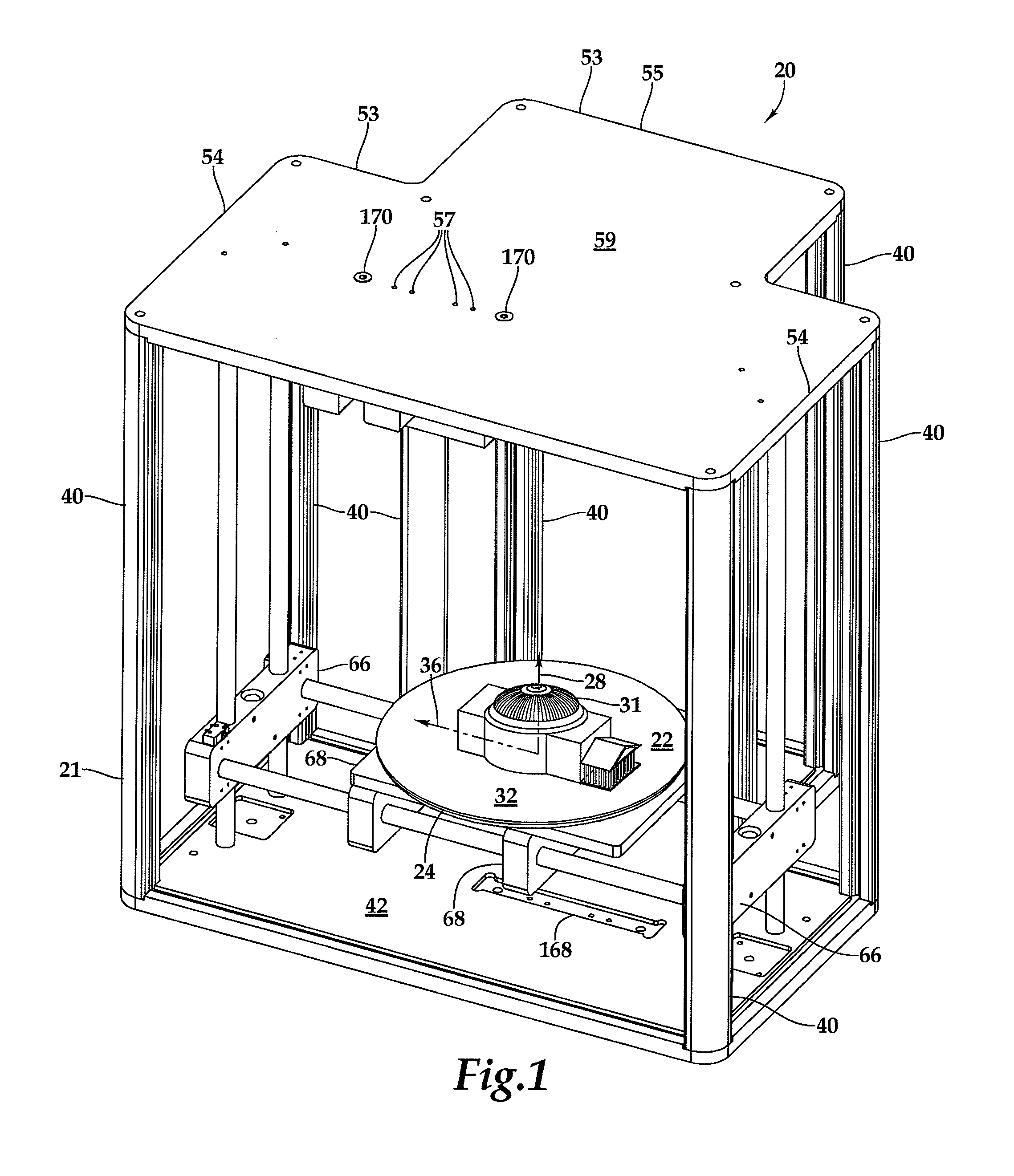

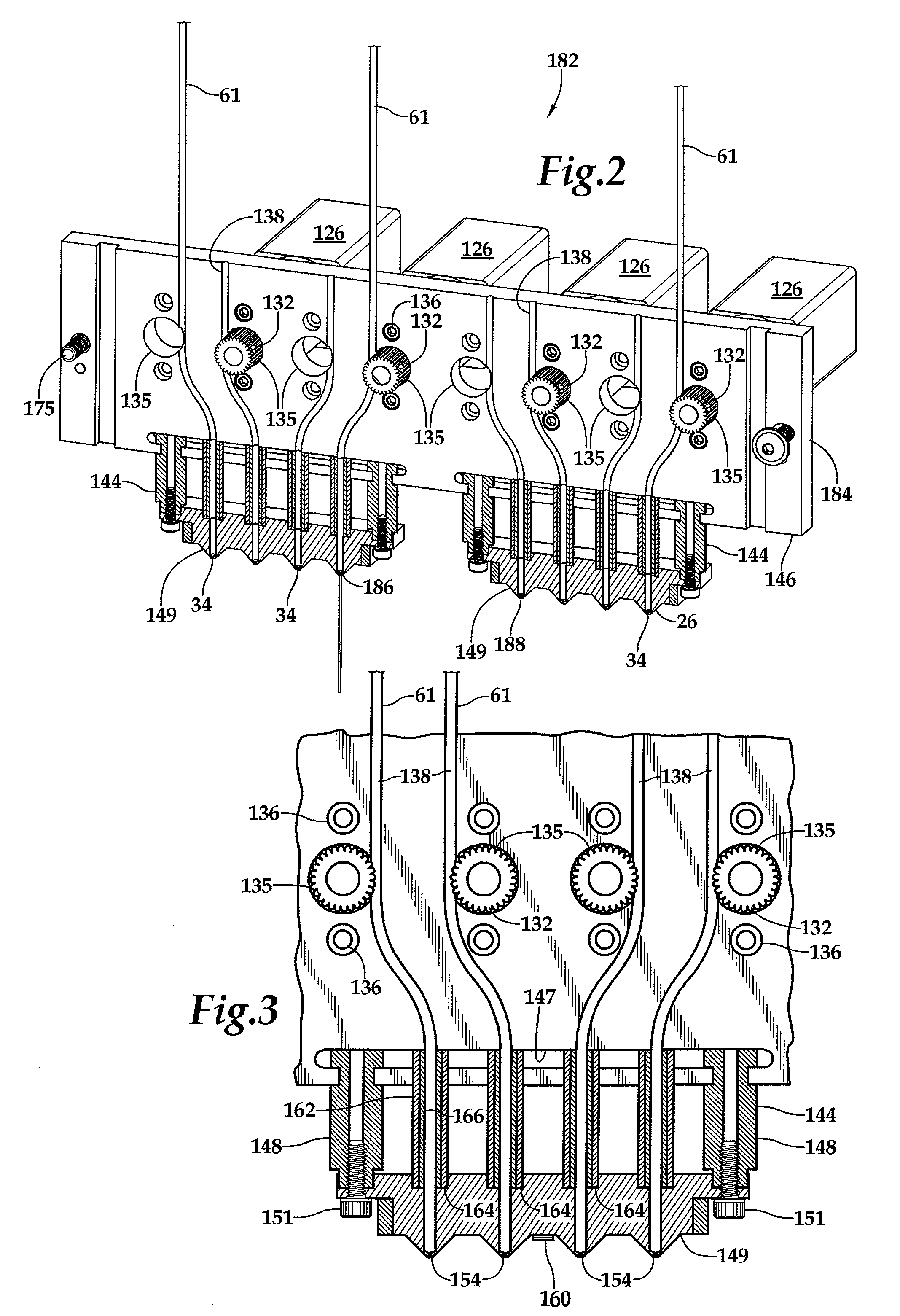

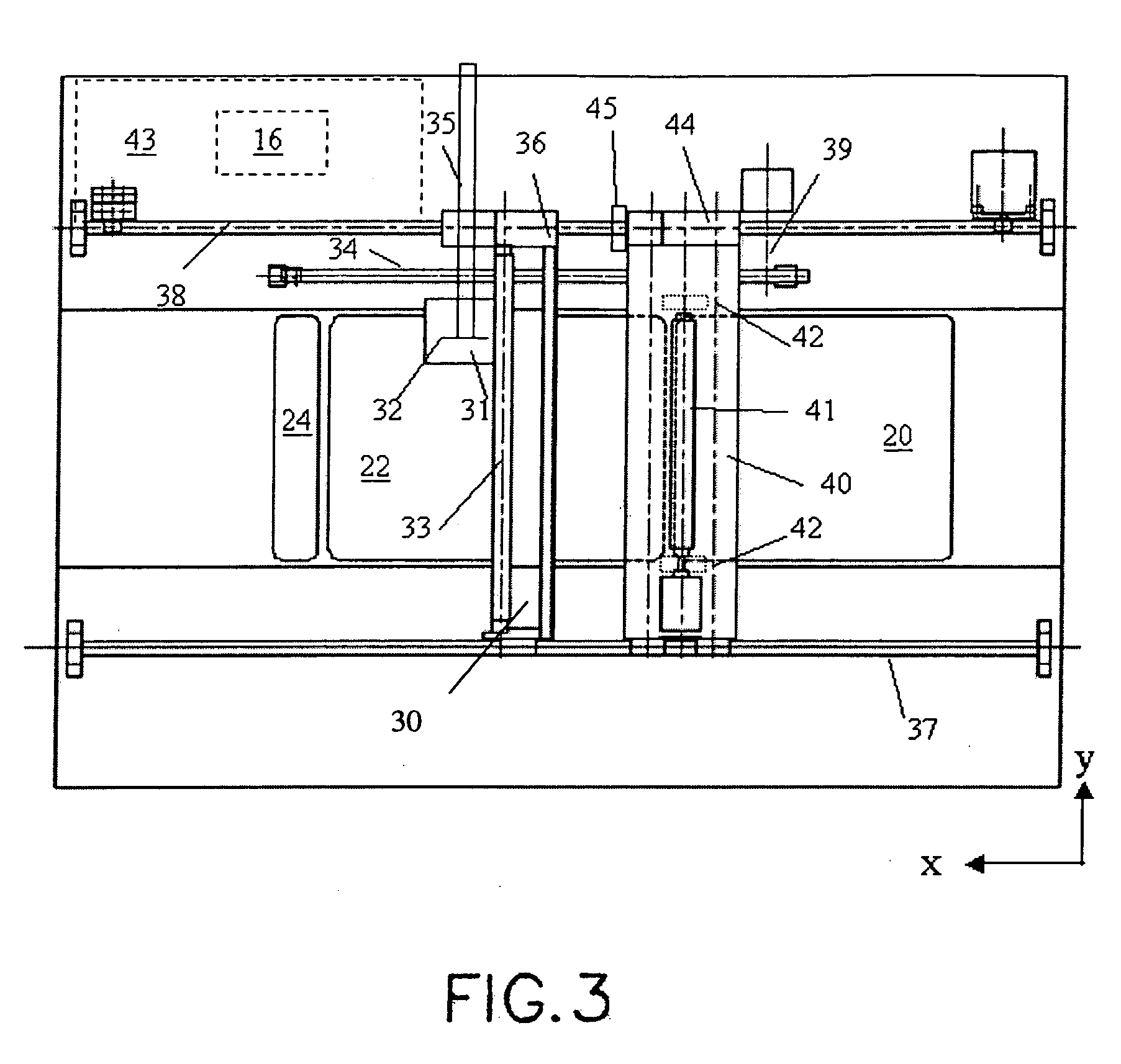

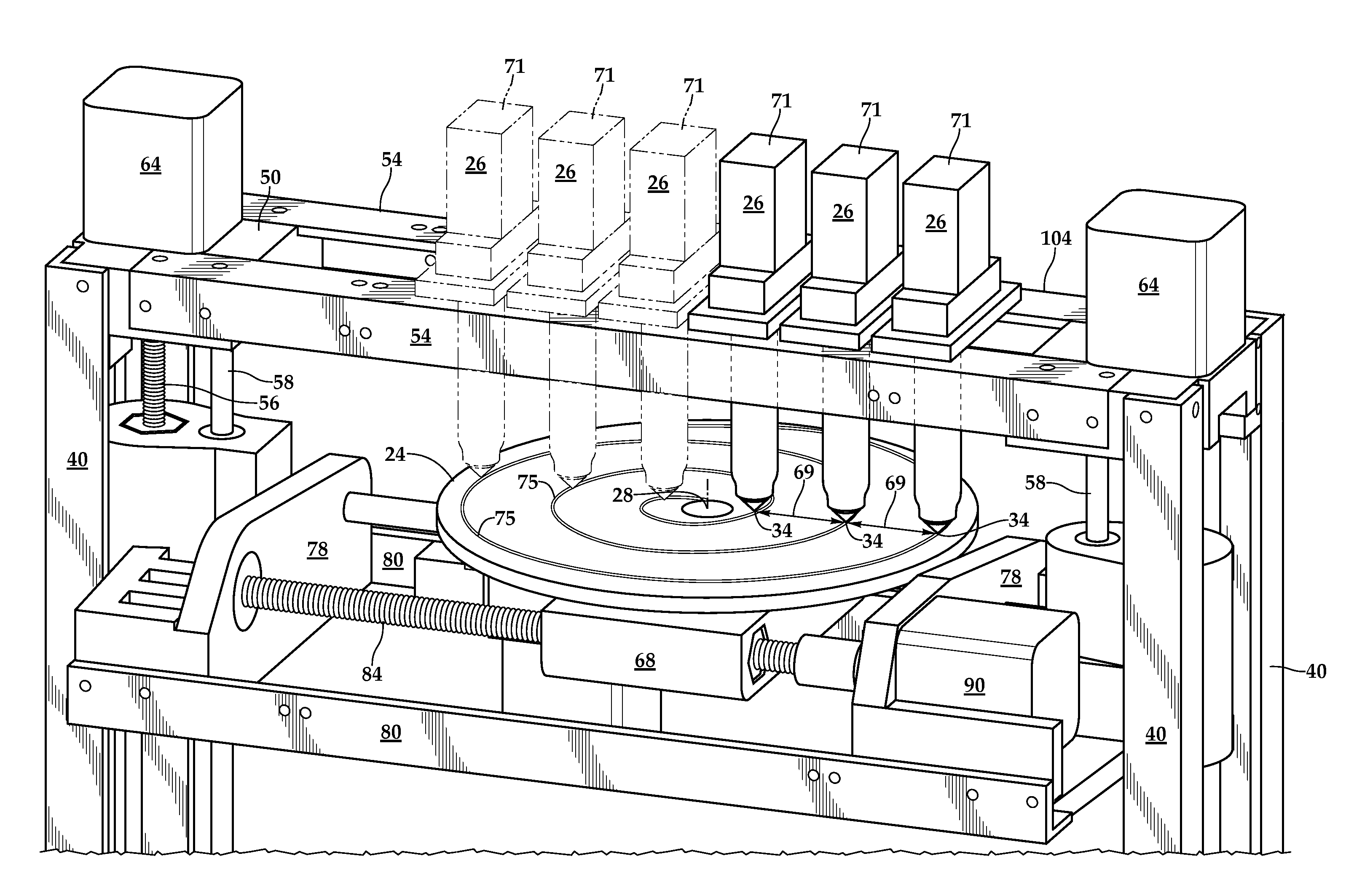

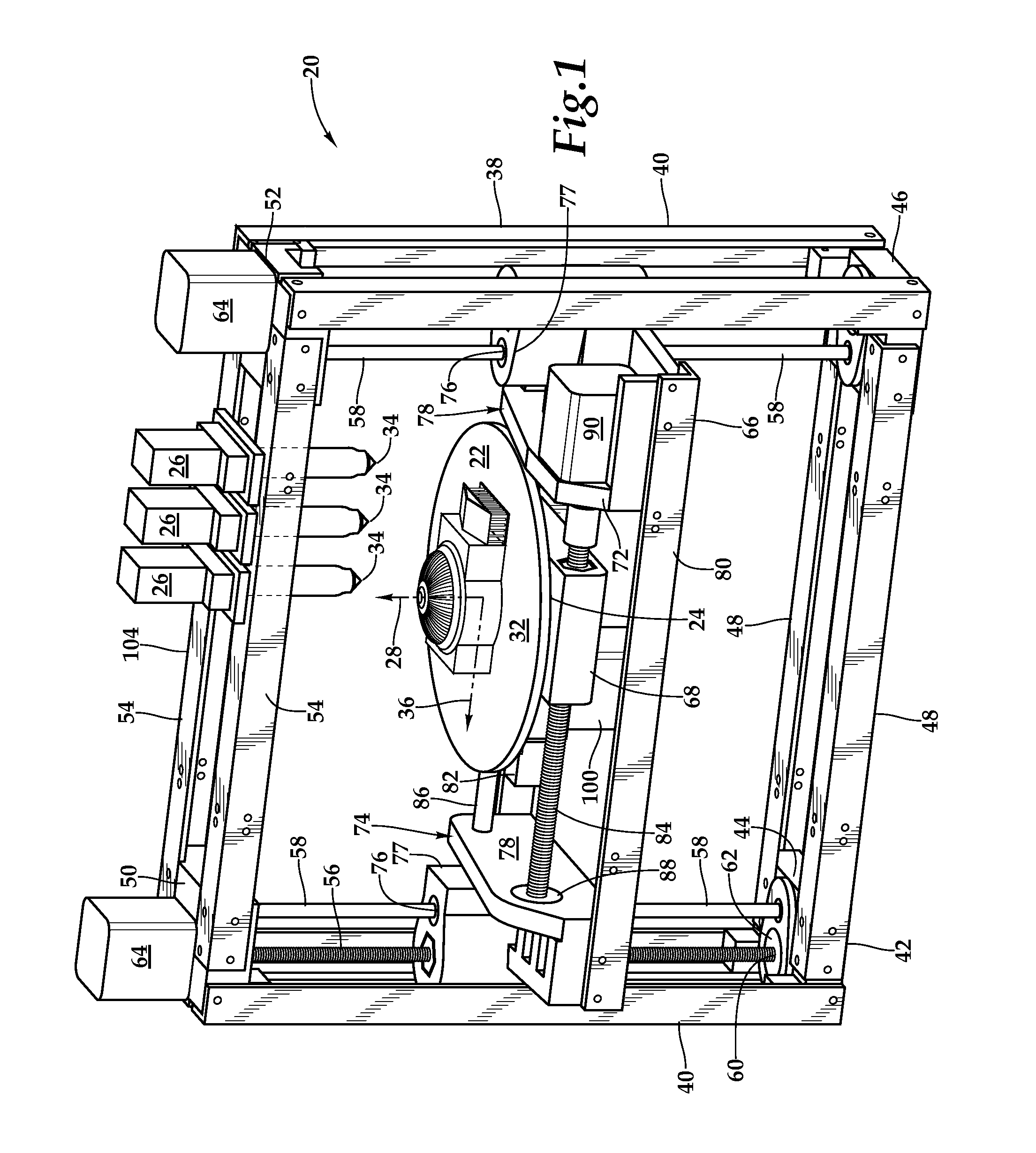

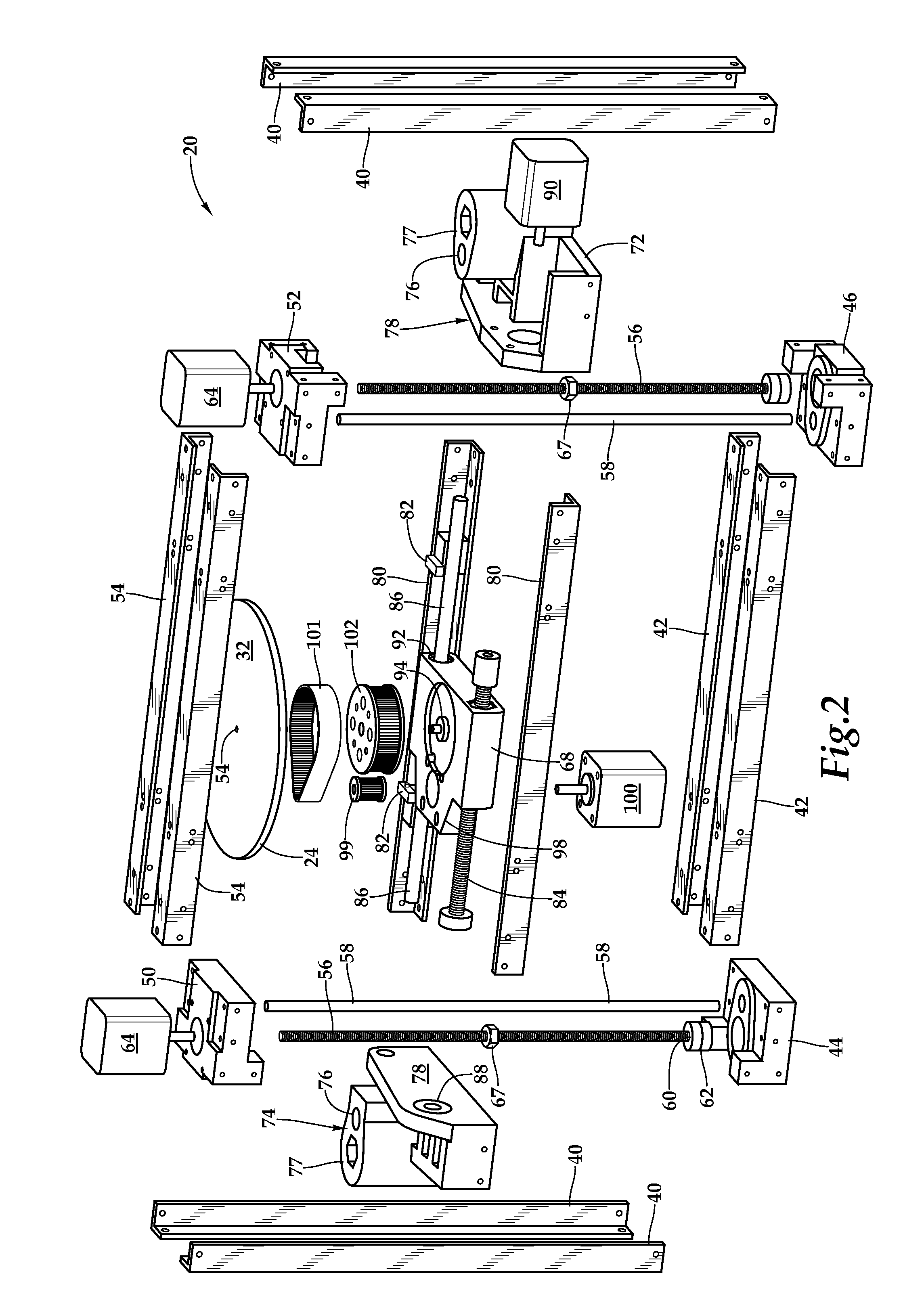

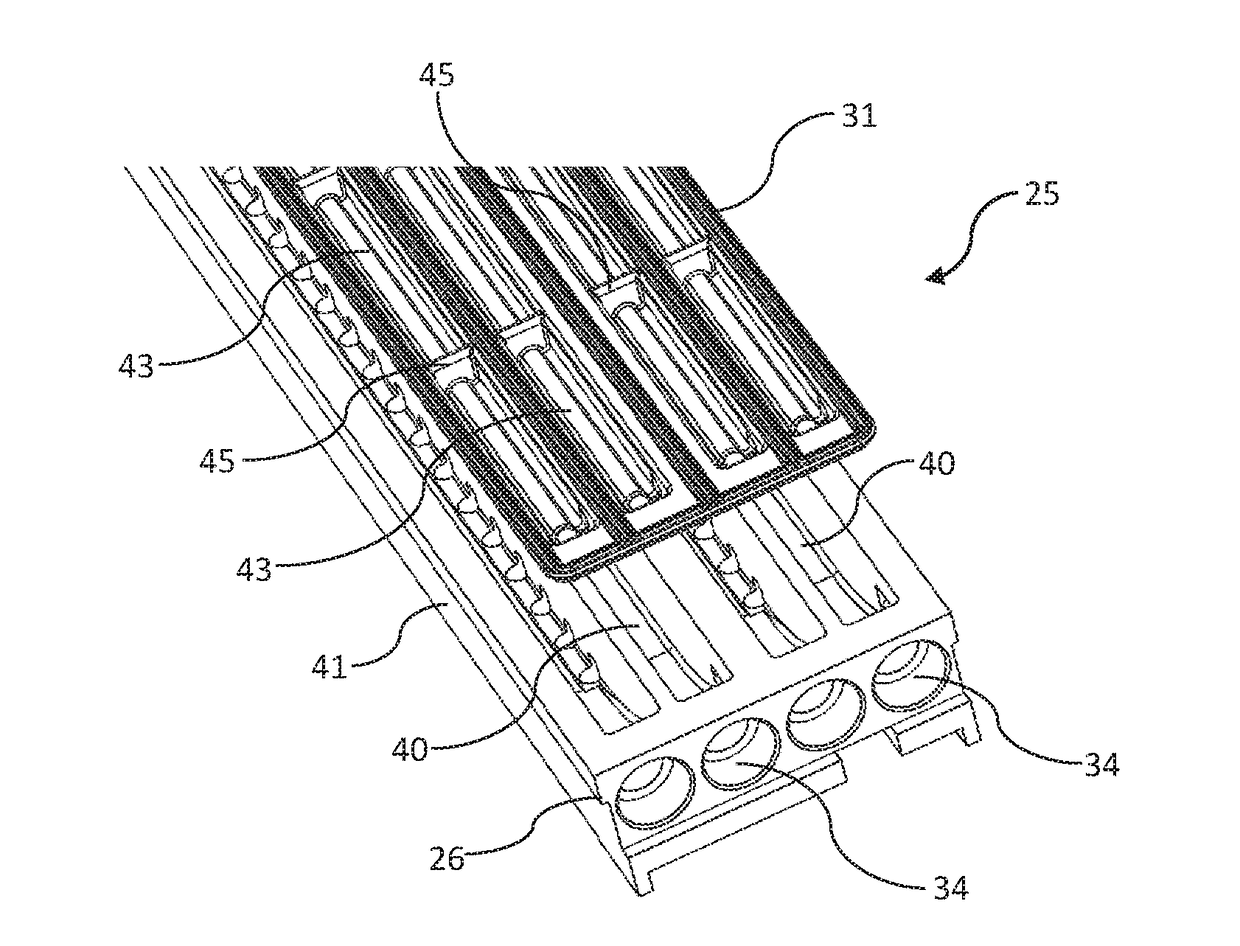

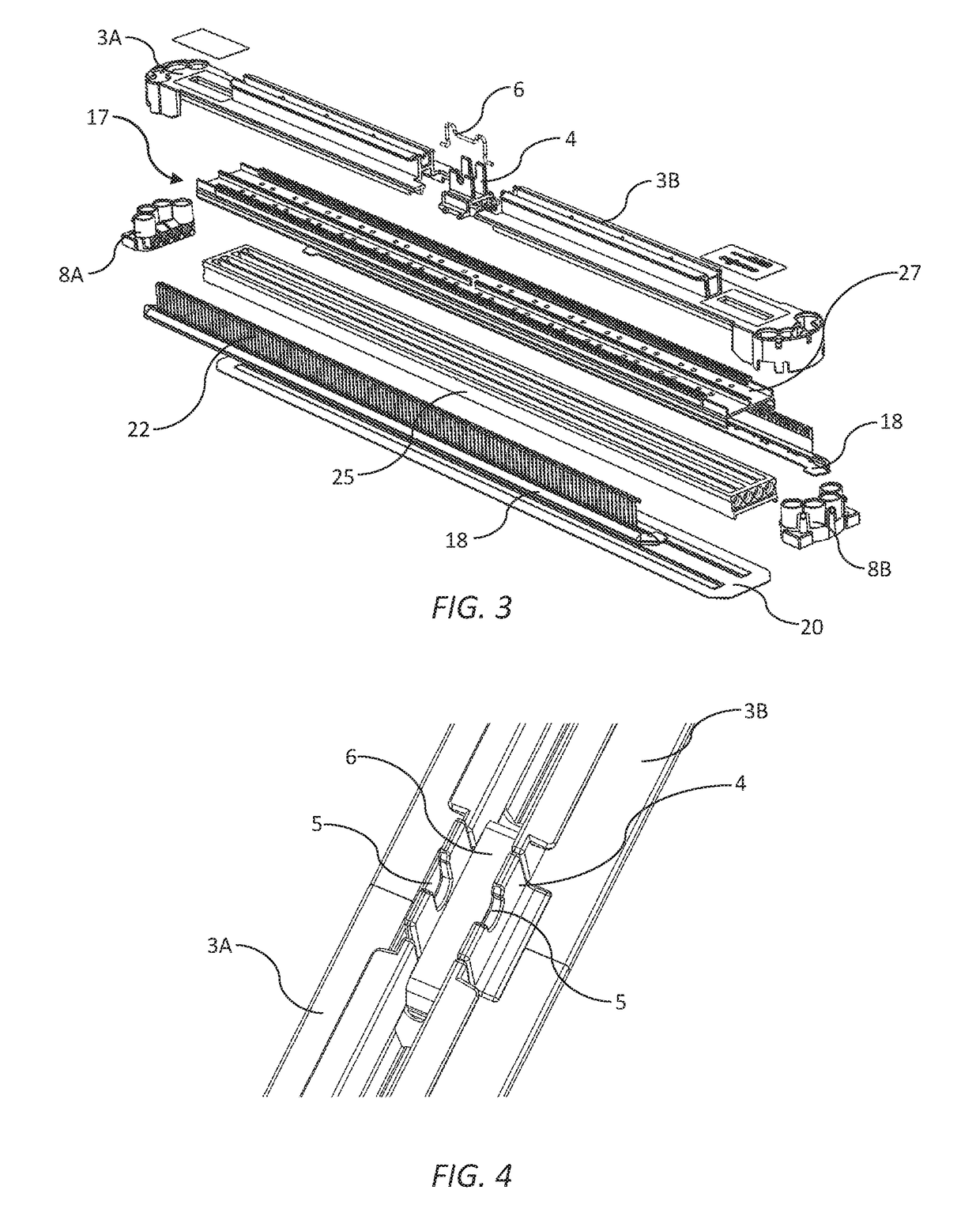

Fixed Printhead Fused Filament Fabrication Printer and Method

InactiveUS20140210137A1Increase printing speedEasily affixedConfectionerySweetmeatsCircular discLinear motion

A fused filament fabrication printer uses a plurality of fixed printing heads mounted to a structure over a build platform on which the model is built by constructing each layer of the model as the build platform is indexed through a multiplicity of successive print planes. The build platform may be in the form of a circular disk mounted for rotation about a z-axis and for linear motion along the z-axis between successive print planes, and for linear motion along a y-axis which is a selected radial direction perpendicular to the z-axis. Because the printheads are fixed, multiple printheads are easily affixed with respect to the build platform along the same radial line defining the y-axis transverse to the selected radial direction along which the build platform moves.

Owner:RADIANT FABTION

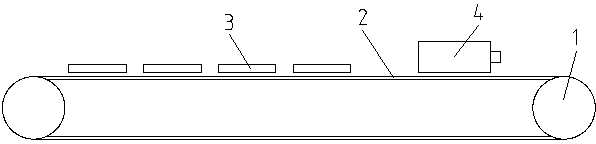

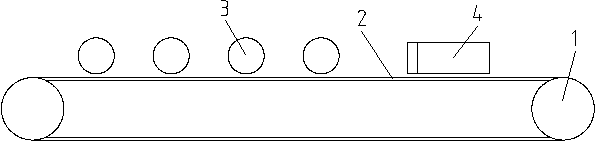

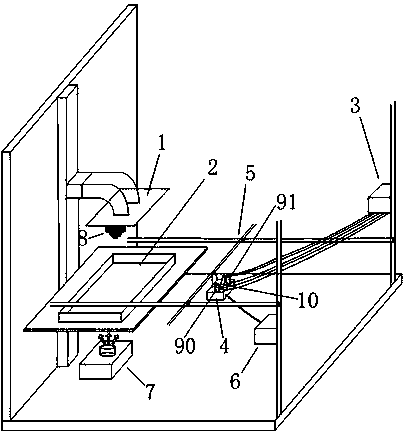

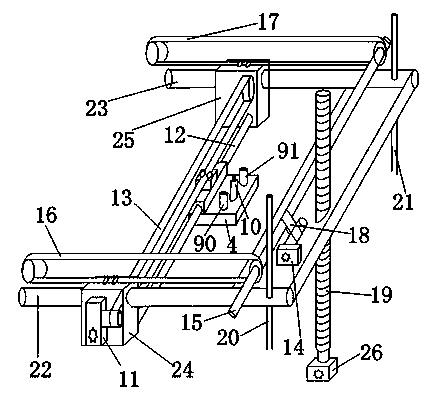

Screen printing and digital printing combined printing device and printing method thereof

ActiveCN103350561AReasonable structural designReliable performanceDuplicating/marking methodsRotary pressesDigital printingPrint-through

The invention relates to a screen printing and digital printing combined printing device and a printing method of the screen printing and digital printing combined printing device. At present, no printing method or printing method which is high in printing precision and printing speed exist. The printing device is characterized by comprising a machine frame, a rotating roller, a conveyer belt, a screen printing mechanism and a digital printing mechanism, the conveyer belt is installed on the rotating roller, the screen printing mechanism is installed on the machine frame, the digital printing mechanism is installed on the machine frame, and the screen printing mechanism is matched with the digital printing mechanism. The printing method is characterized in that shell fabric is driven to move through the conveyer belt, the shell fabric is printed through the screen printing mechanism and the digital printing mechanism, and if patterns needing to be printed on the shell fabric include large pieces of patterns, the patterns are printed through the screen printing mechanism; if the patterns needing to be printed on the shell fabric include high-precision patterns, the patterns are printed through the digital printing mechanism. The printing device and the printing method are reasonable in structural design, reliable in performance, high in printing precision and high in printing speed.

Owner:HANGZHOU HONGHUA DIGITAL TECH

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

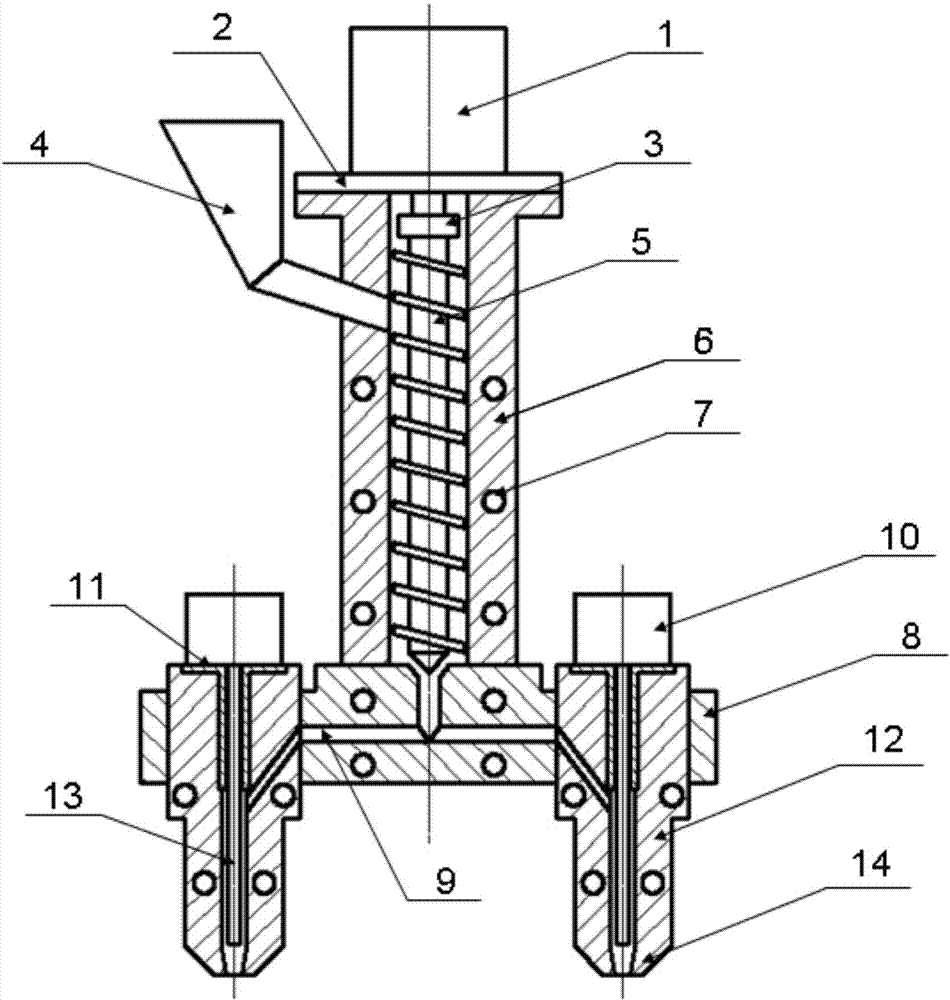

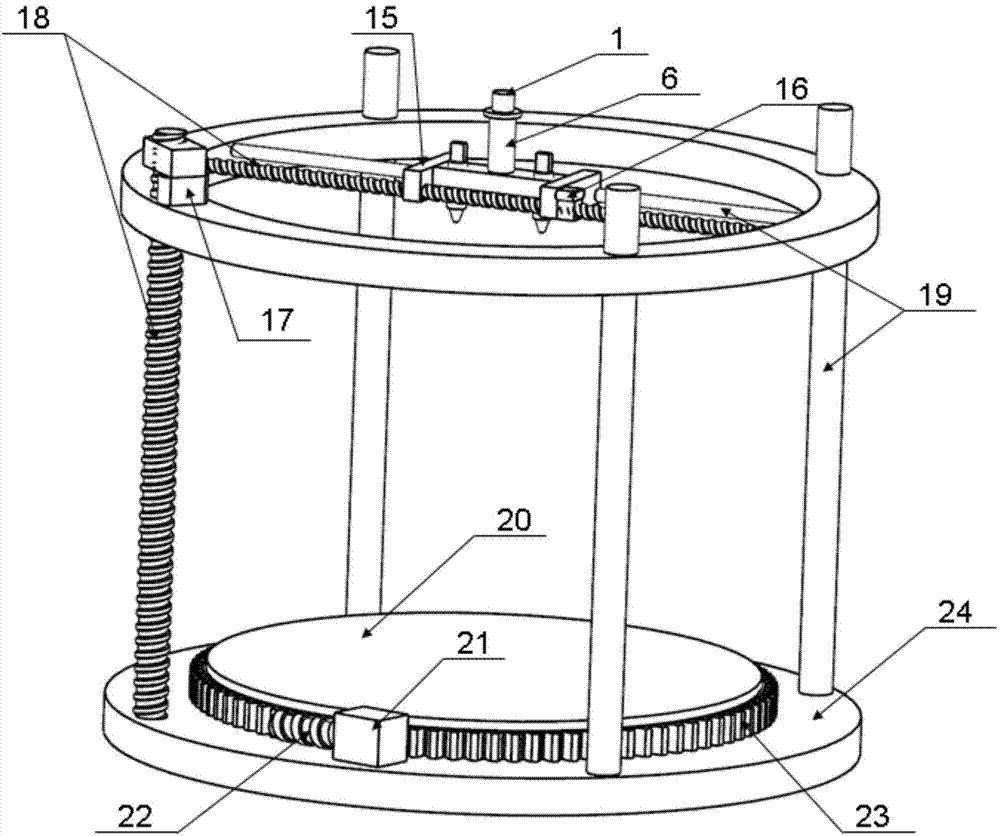

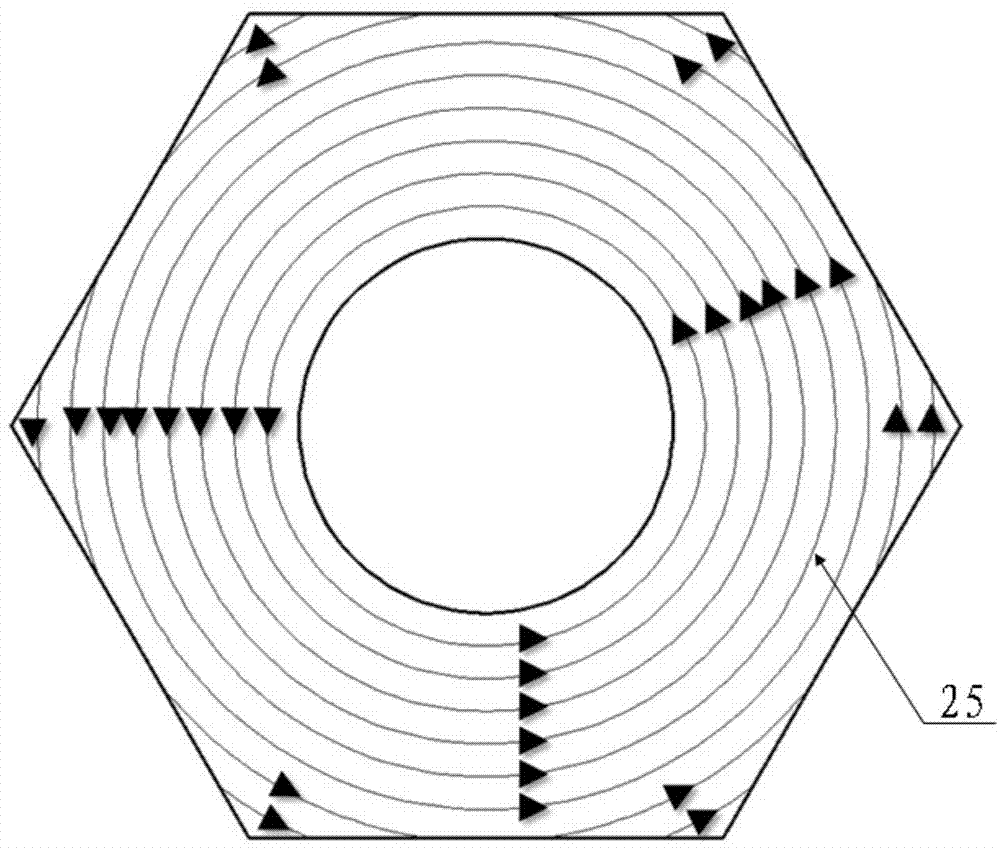

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

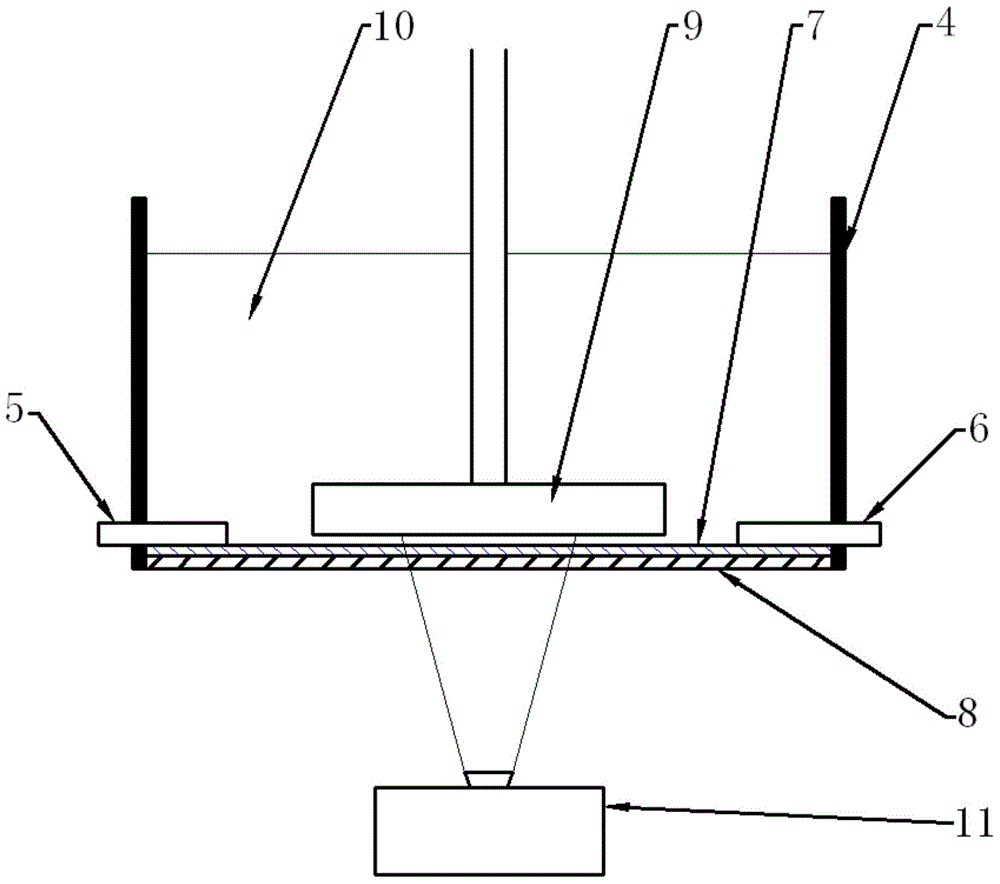

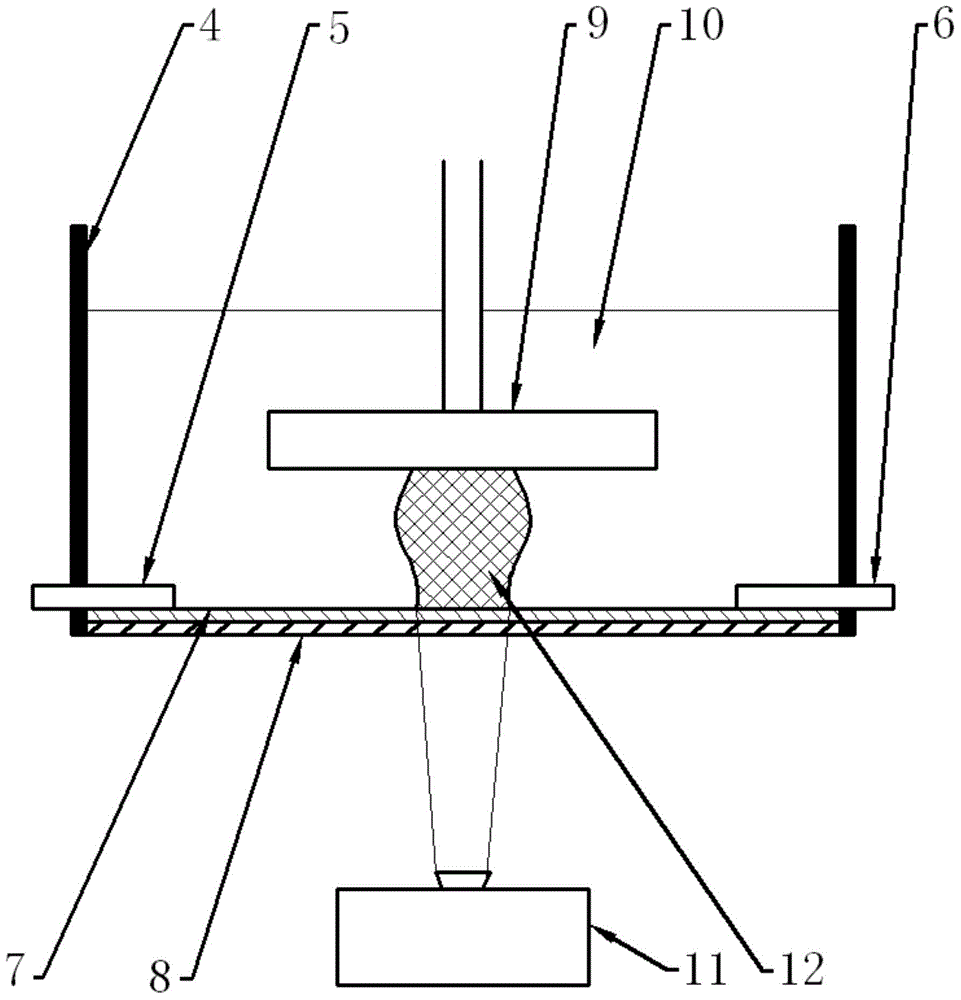

High-speed photocuring 3D printing device and printing method

ActiveCN105014974AInhibition of attachmentTroubleshoot disruptive technical issuesAdditive manufacturing apparatusEngineeringGlass sheet

The invention discloses a high-speed photocuring 3D printing device and method. The device comprises a liquid pool filled with liquid photosensitive resin, a printing platform and a radiation source. A transparent plate corresponding to the printing platform and the radiation source is arranged at the bottom of the liquid pool. The side, facing the printing platform, of the transparent plate is covered with a transparent anti-bonding coating. The device further comprises a liquid outlet and a liquid inlet which are formed in the side wall of the liquid pool, a pipeline connecting the liquid outlet and the liquid inlet, and a drive unit which is arranged on the pipeline and used for driving the liquid photosensitive resin to flow among the liquid outlet, the liquid inlet and the pipeline. A curing window is coated with the transparent anti-bonding coating, and therefore the problem that the curing photosensitive resin is bonded and attached to a glass plate due to excessively fast laser radiation is avoided. Pipelines promoting flowing of the liquid photosensitive resin are arranged on the two sides of a printing area, the mobility of the photosensitive resin near the printing area is improved, supplementing of the photosensitive resin is accelerated, and rapid printing of the SLA is achieved.

Owner:苏州智能制造研究院有限公司

Ink-jet printing apparatus and method of printing seamless cans by using the same printing apparatus

ActiveUS20140028771A1Increase printing speedDuplicating/marking methodsTypewritersEngineeringElectrical and Electronics engineering

Owner:TOYO SEIKAN GRP HLDG LTD

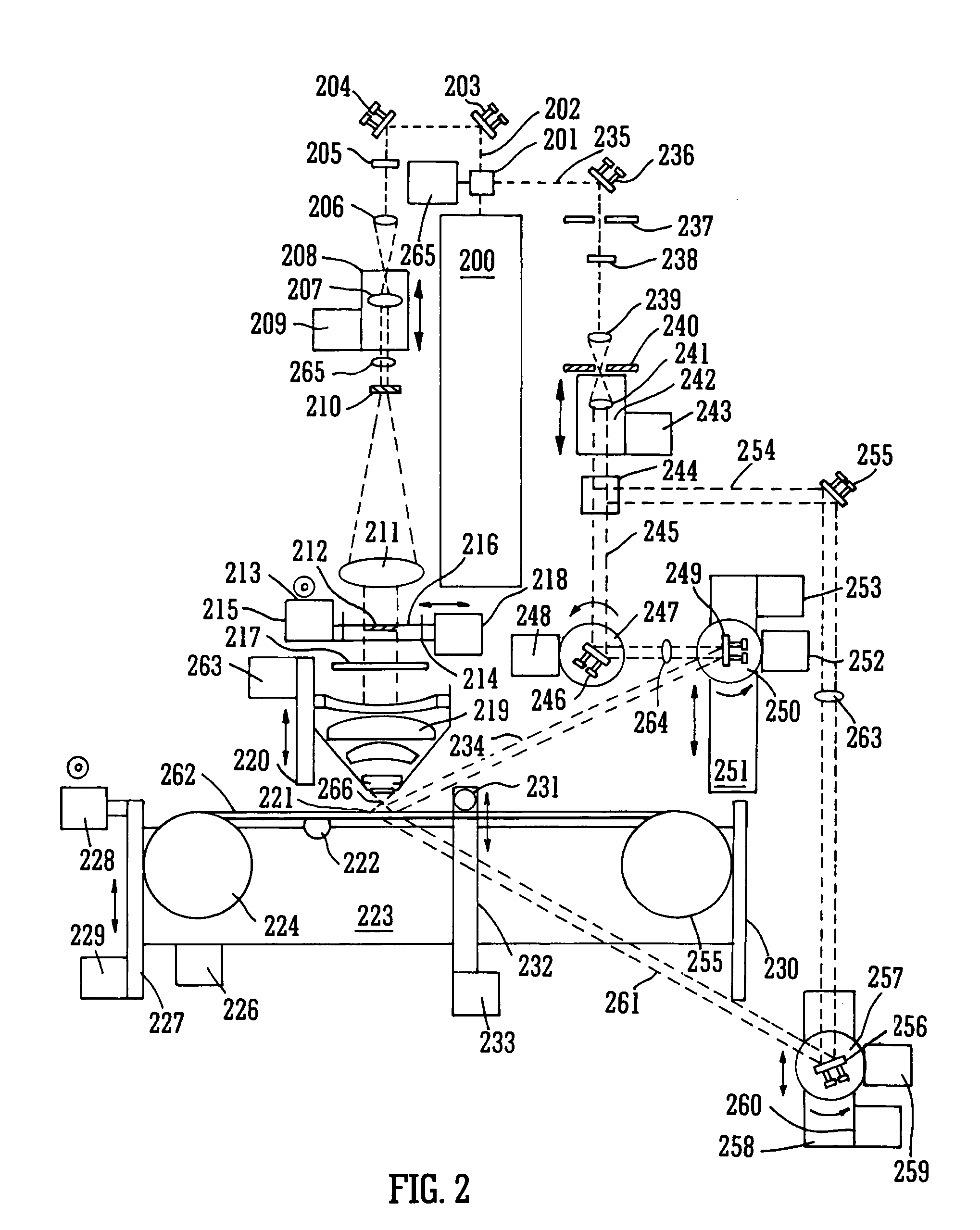

Holographic printer

InactiveUS7009742B2Increase printing speedGuaranteed uptimeHolographic light sources/light beam propertiesHolographic optical componentsCamera imageDigital data

Owner:XYZ IMAGING

Three-dimensional color printing device and method

ActiveCN105500700AImprove printing accuracyFast molding speedAdditive manufacturing apparatusAutomatic controlControl system

The invention discloses a three-dimensional color printing device and method. The three-dimensional color printing device comprises a print area, a feeding system, a nozzle group, a moving mechanism and an automatic control system, wherein the print area is provided with a forming plate and a forming work pool, and the forming plate is provided with a lifting mechanism which is used for drawing a workpiece curing layer; the feeding system comprises a support material feeding box and a solid material feeding box and is used for supplying print raw materials for the nozzle group; the nozzle group comprises at least one solid material nozzle and a support material nozzle, the solid material nozzle is connected with the solid material feeding box of the feeding system through a premixer, and the support material nozzle is connected with the support material feeding box of the feeding system; andthe moving mechanism is provided with motors and guide posts / rods on the X-axis direction, the Y-axis direction and the Z-axis direction and is used for driving the nozzle group for performing mobile printing on the three-dimensional direction. The three-dimensional color printing device has the characteristics of being high in print accuracy and smooth and clean in surface of formed products and can realize color printing and printing of different photosensitive materials.

Owner:QINGDAO ACADEMY OF INTELLIGENT IND

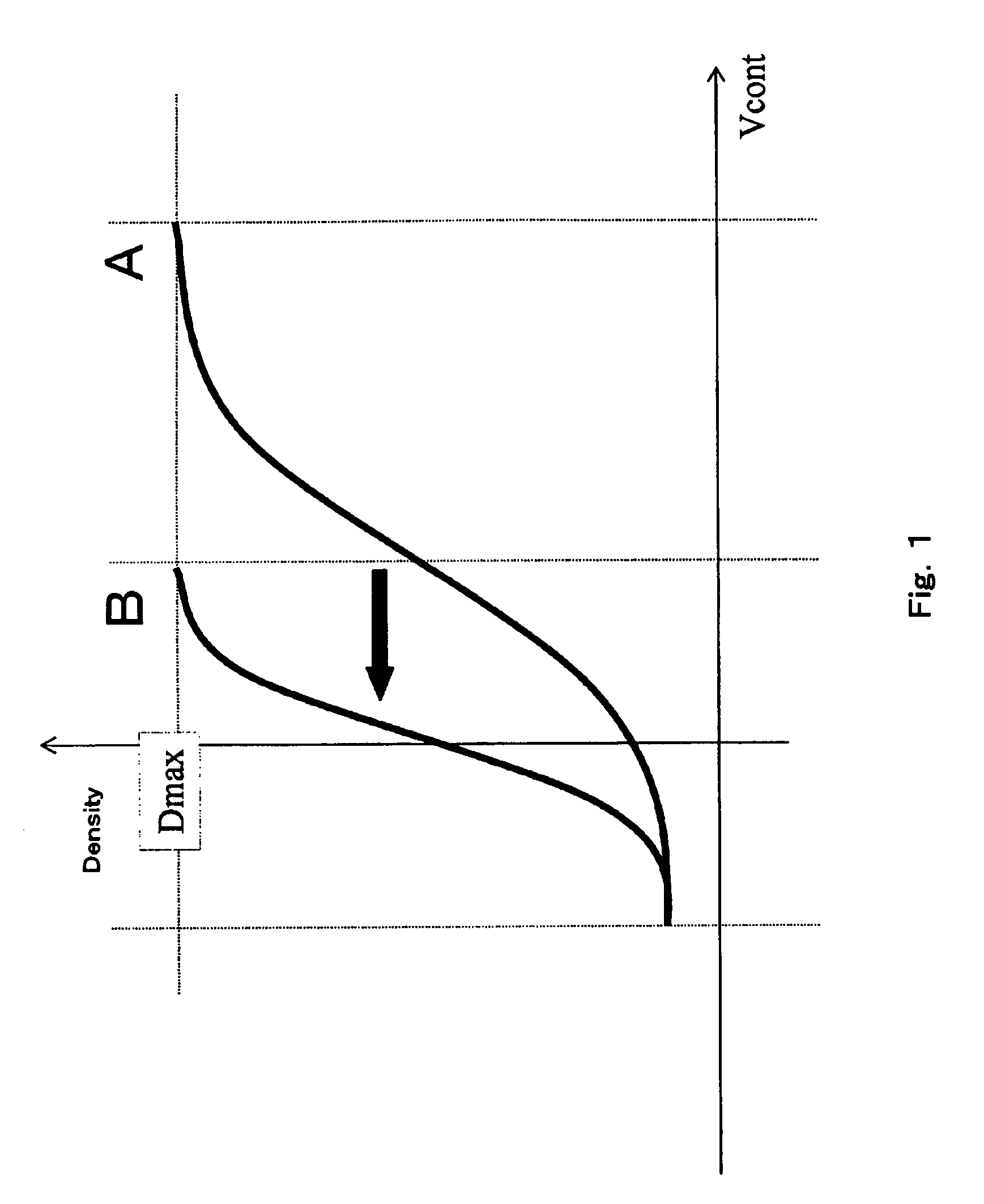

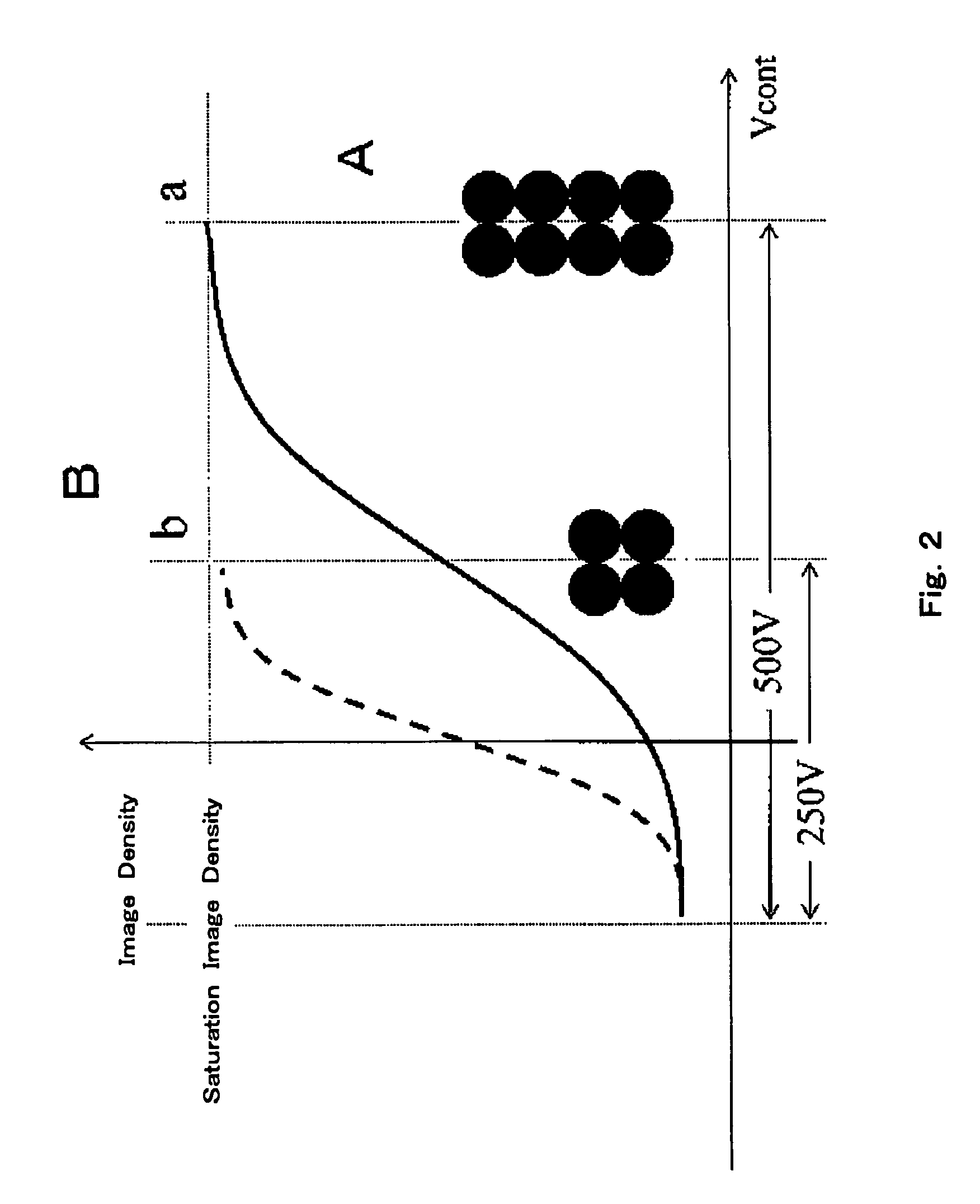

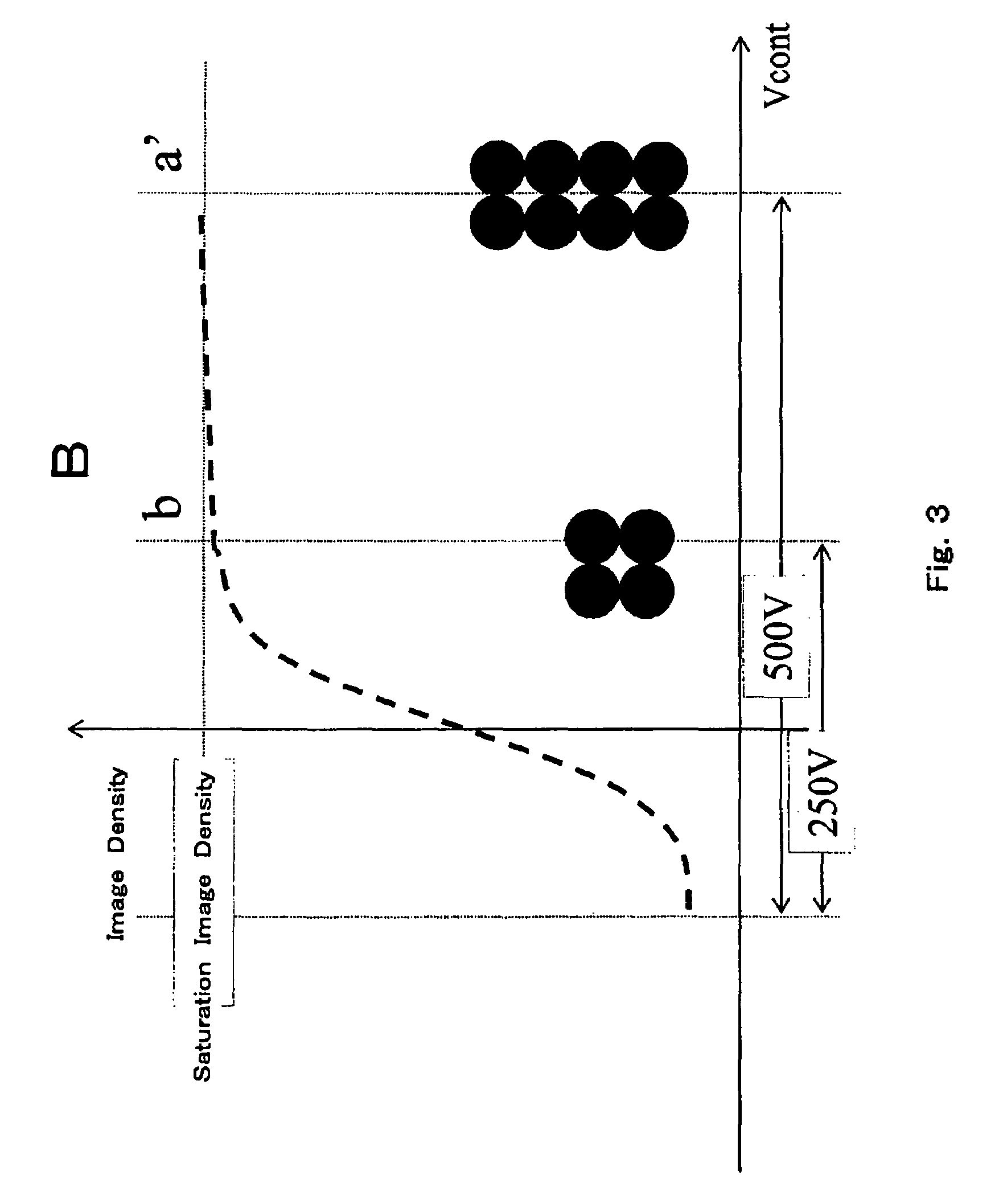

Two-component developer, replenishing developer, and image-forming method

InactiveUS7767370B2Small toner laid-on levelColor stableDevelopersElectrographic process apparatusImage formationLength wave

A two-component developer containing a magenta toner and a magnetic carrier, wherein the magenta toner has the characteristics: (i) when the concentration of the magenta toner in a solution of the magenta toner in chloroform is represented by Cm (mg / ml) and the absorbance of the solution at a wavelength of 538 nm is represented by A538, a relationship between Cm and A538 satisfies the relationship of 2.00<A538 / Cm<6.55; (ii) the lightness L* and chroma C* of the magenta toner determined in a powder state satisfy the relationships of 35≦̸L*≦̸45 and 60≦̸C*≦̸72; and (iii) the absolute value for the triboelectric charge quantity of the magenta toner measured by a two-component method using the magenta toner and the magnetic carrier is 50 mC / kg or more and 120 mC / kg or less.

Owner:CANON KK

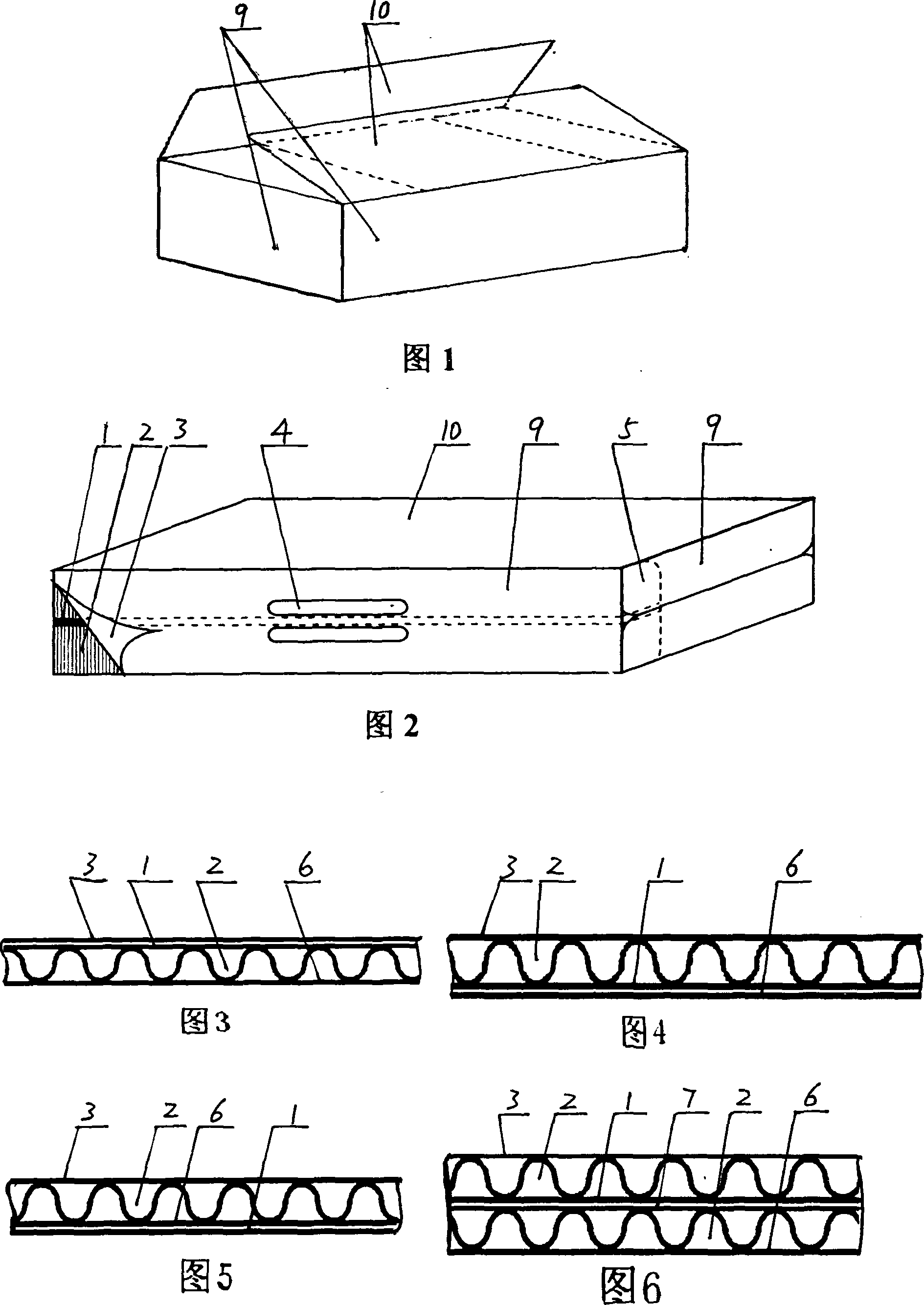

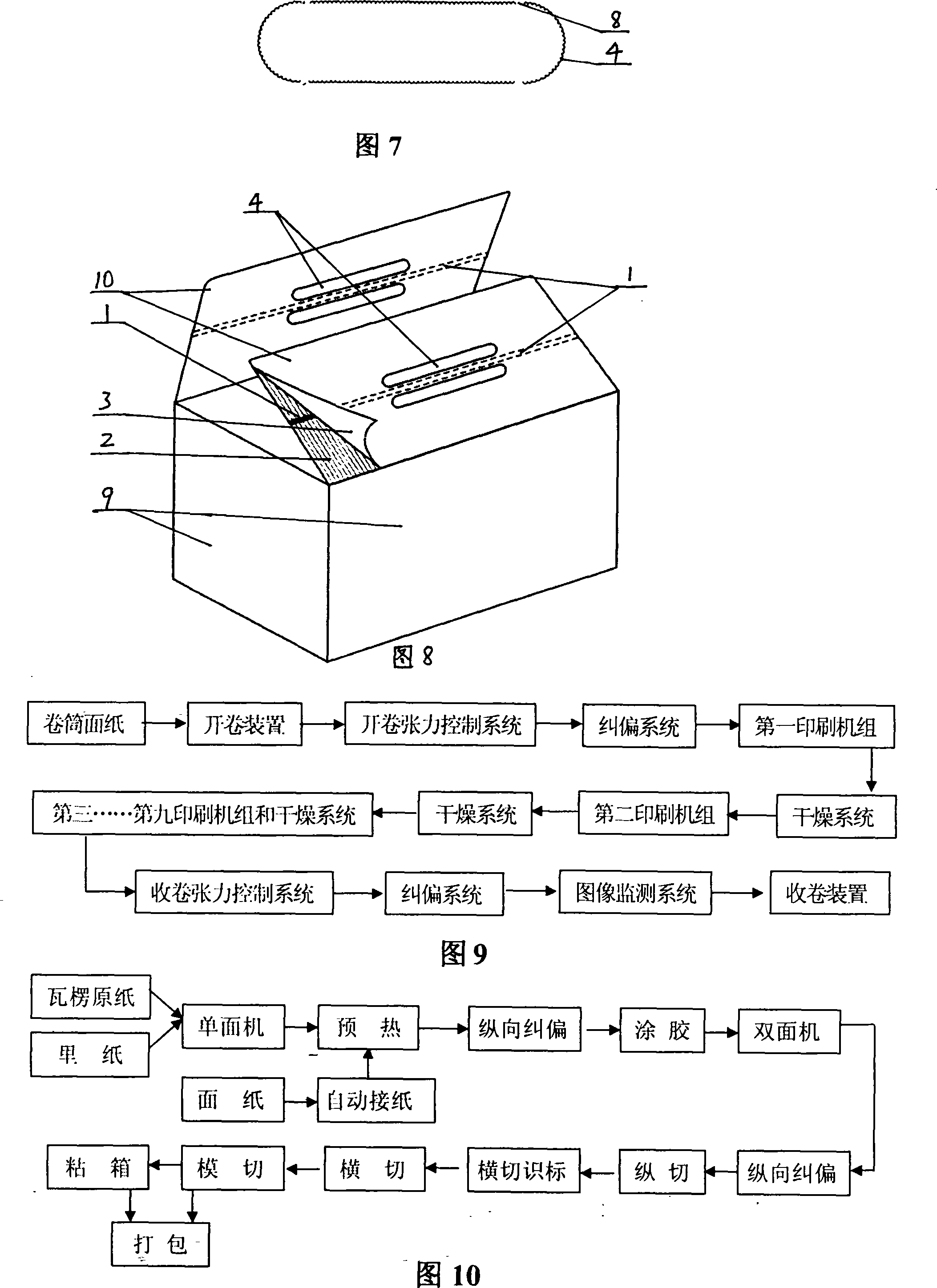

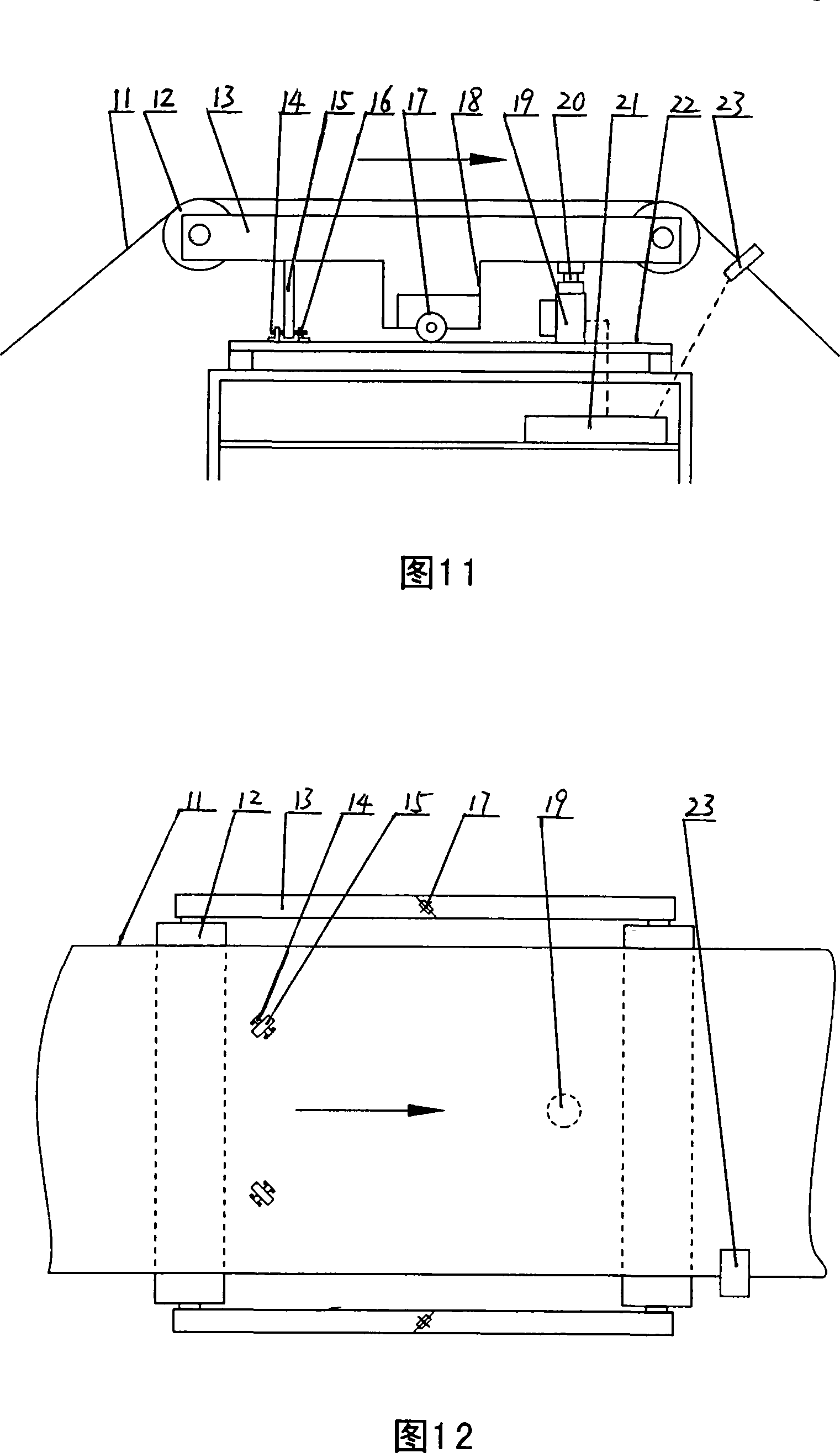

Flexible preprinting cardboard box, production method and production equipment thereof

The invention discloses a flexibly pre-printed paper box, a manufacture method and a manufacture equipment thereof; the paper box has a box body consisting of a printed sheet, corrugated paper, inner paper and in some cases core paper; color patterns on the printed sheet are flexibly printed on the printed sheet before the paper box is manufactured. The manufacture method consists of a manufacture method of flexibly printed paper sheet and a manufacture method of the paper box; firstly the color patterns are manufactured on the printed sheet with a rotary flexographic press; then bright oil is applied, and then the printed sheet, the corrugated paper and the inner paper are made into the paper box by adopting a corrugated paper manufacture device; some paper box also comprises the core paper. The manufacture device consists of the rotary flexoographic press, the corrugated paper manufacture equipment and a die-cutting machine. Adopting the method and the equipment of the invention, the manufactured paper box is green and environmental protective, nice in printed patterns, high in compressive strength, convenient in lifting and low in reject rate; compared with paper boxes which are printed with offset printing and directly with flexible plate of the same quality requirement, the paper box of the invention has lower cost.

Owner:保定中士达包装有限公司

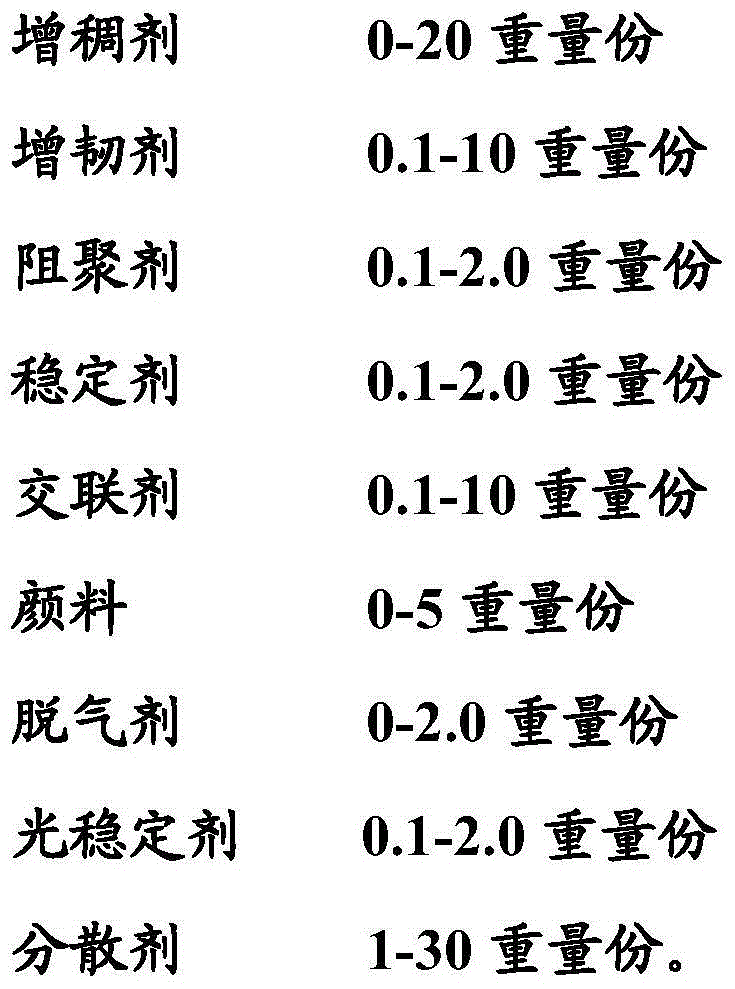

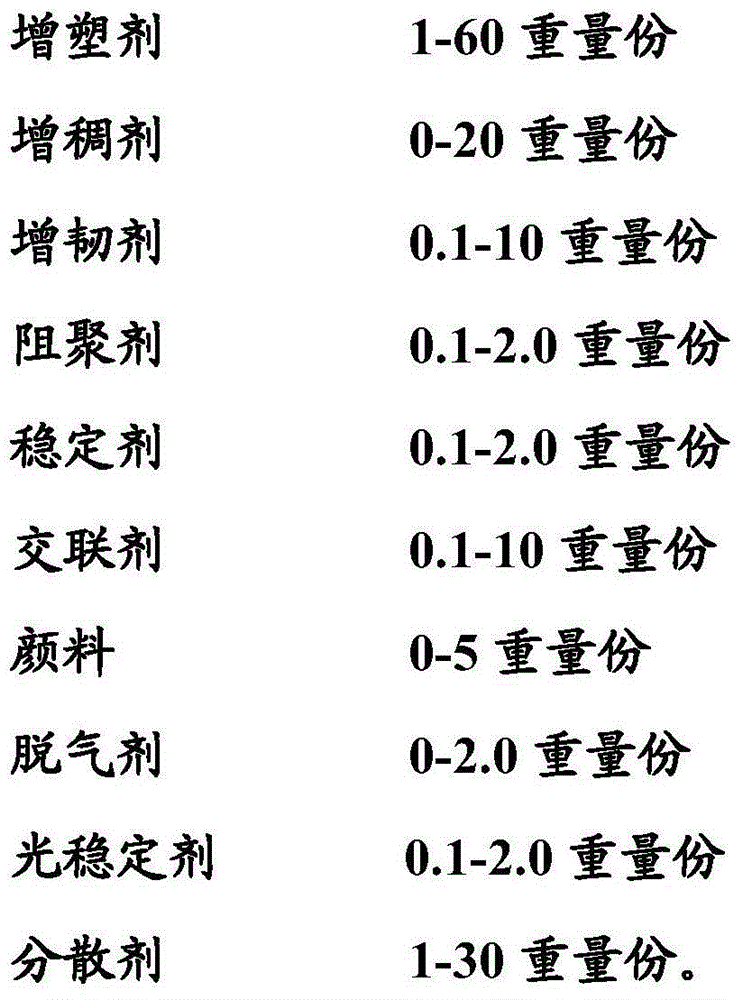

3D printing composition, preparation and application methods and product thereof

The invention discloses a 3D printing composition, its preparation and application methods and a product thereof. According to the material, cyanoacrylate and a powder material are used as main bodies; a solvent is added to adjust fluidity of the material; and simultaneously, certain amounts of a plasticizer, a thickener, a flexibilizer, a stabilizer, a cross-linking agent, a pigment, a degassing agent and the like are contained to raise stability of the material and mechanical property of a printing product. As the material is a liquid and solidification process of the material is controlled by controlling conditions such as environment humidity, temperature and the like during printing, an ink-jet printing head which has been developed comparatively mature at present can be used for printing. The composition provided by the invention has characteristics of high printing precision, fast forming speed and low cost. Meanwhile, a printing product has high mechanical strength. The composition is a novel green 3D printing material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

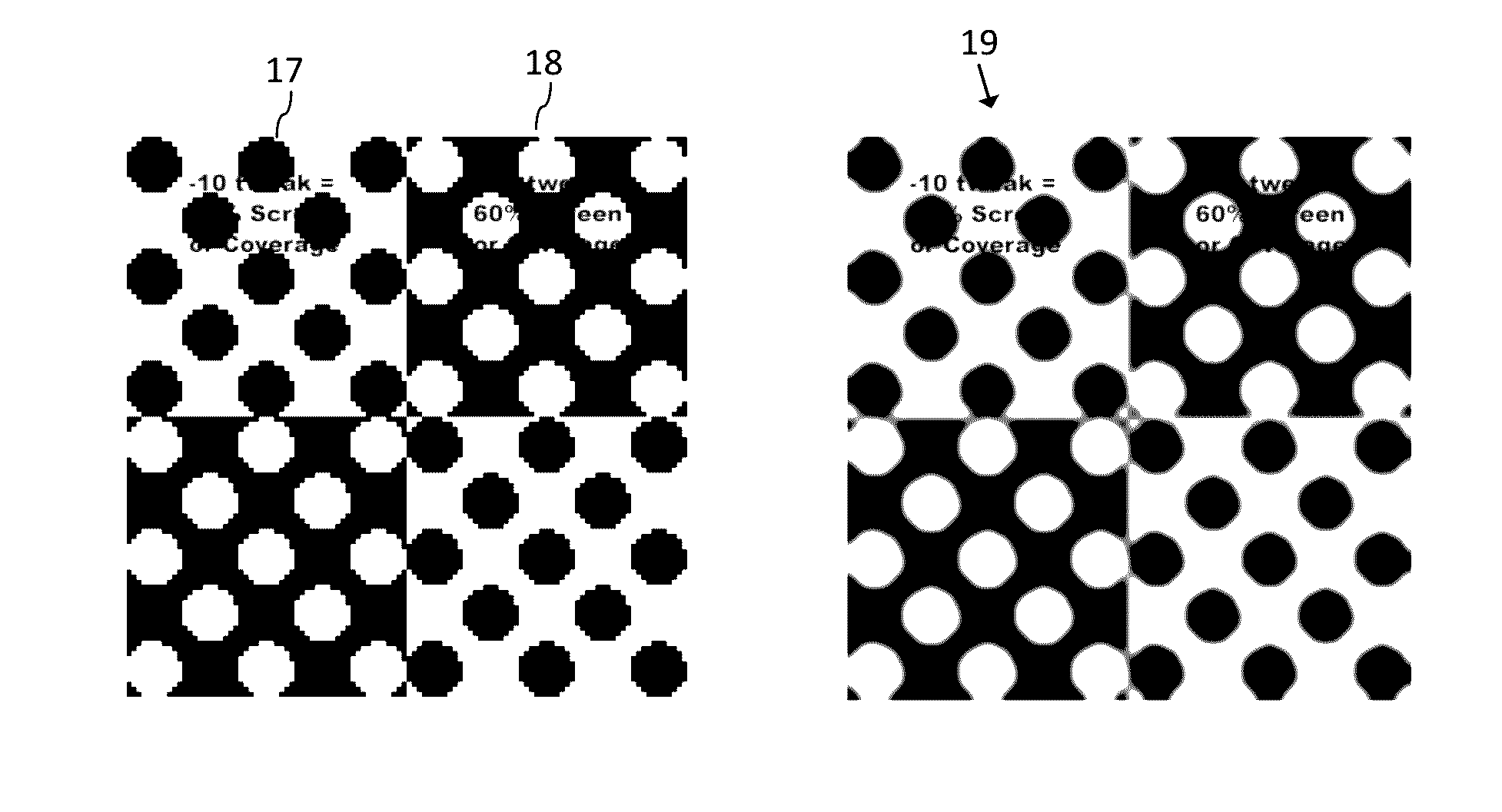

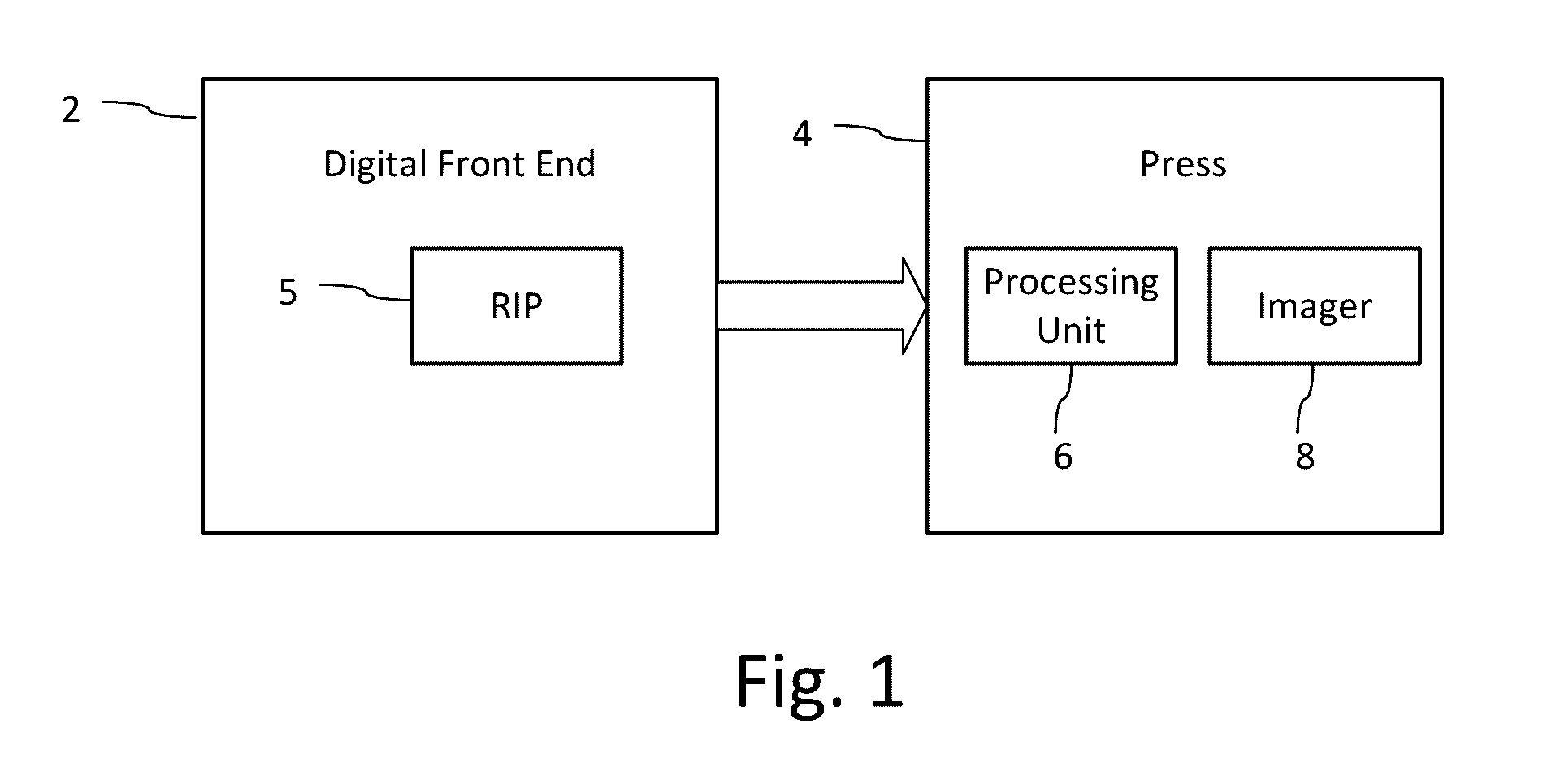

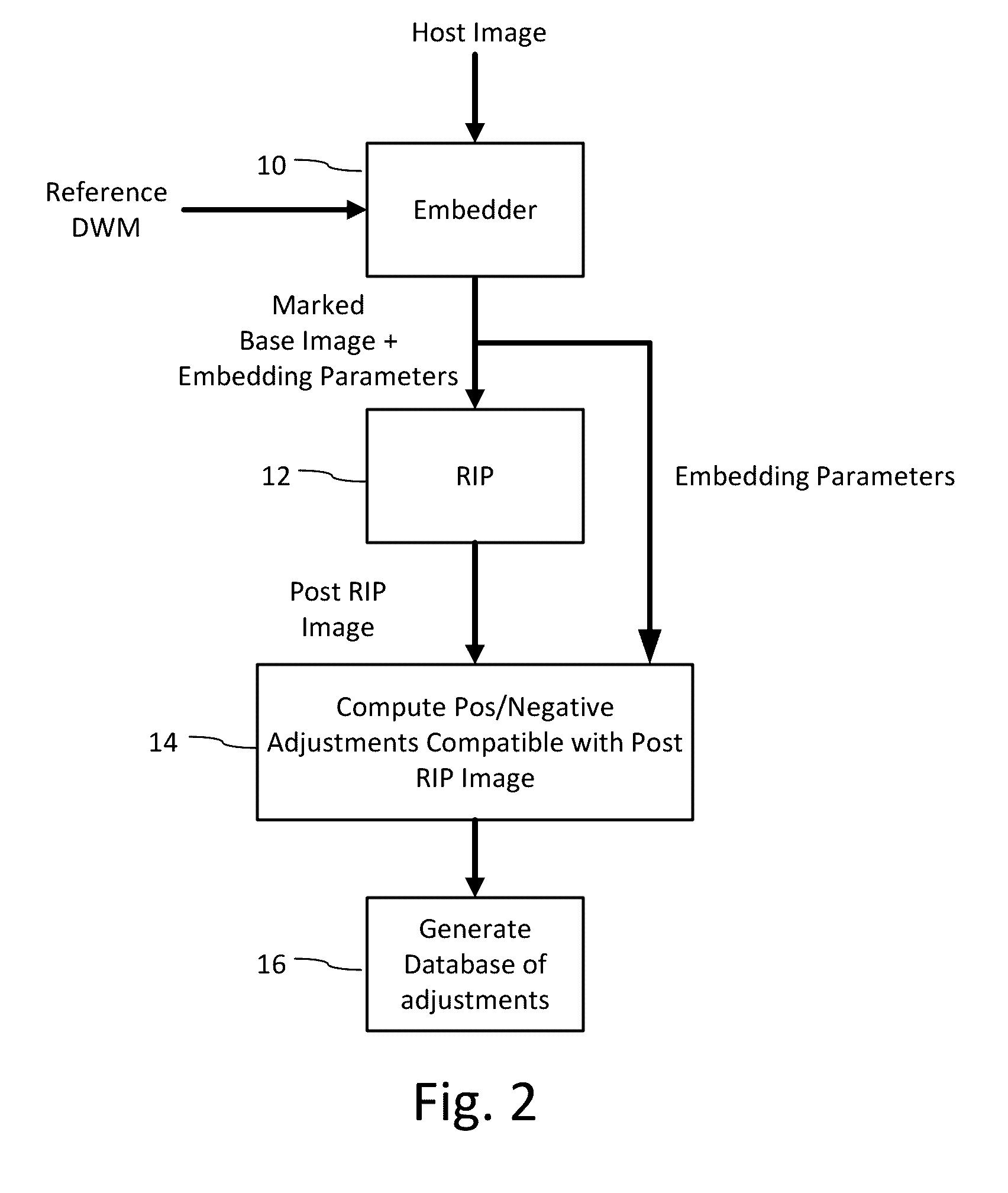

Serialized digital watermarking for variable data printing

ActiveUS20170024845A1Increased complexityEconomically viableImage watermarkingInput/output processes for data processingPrinting pressMachine-readable data

Digital watermarking is adapted for the variable data printing. A reference signal serves as a proxy for optimizing the embedding a watermark in a host image to be printed. Using the reference signal, embedding parameters are generated, which are a function of constraints such as visual quality and robustness of the machine readable data. Adjustments needed to embed a unique payload in each printed piece are generated using the embedding parameters. These adjustments are stored in a manner that enables them to be efficiently obtained and applied within the RIP or press during operation of the press. Various other methods, system configurations and applications are also detailed.

Owner:DIGIMARC CORP

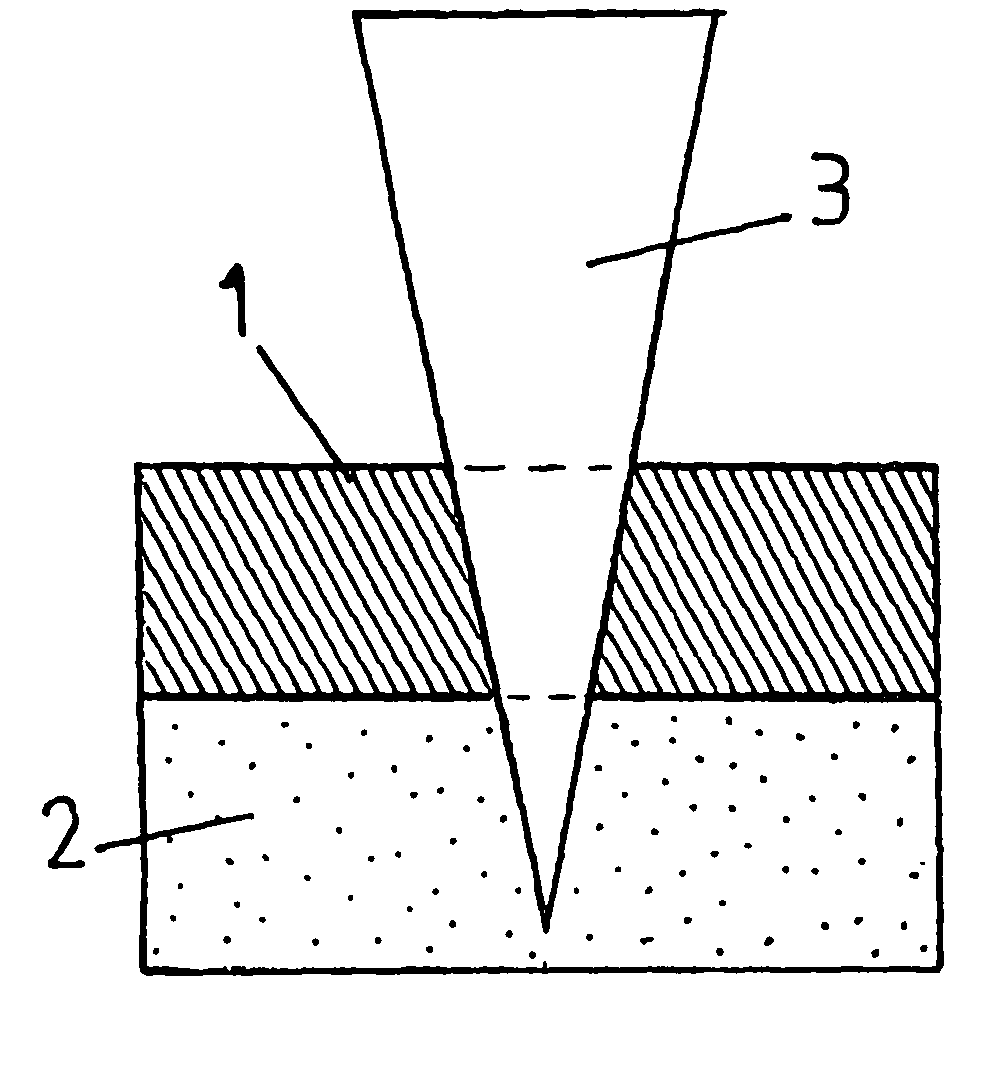

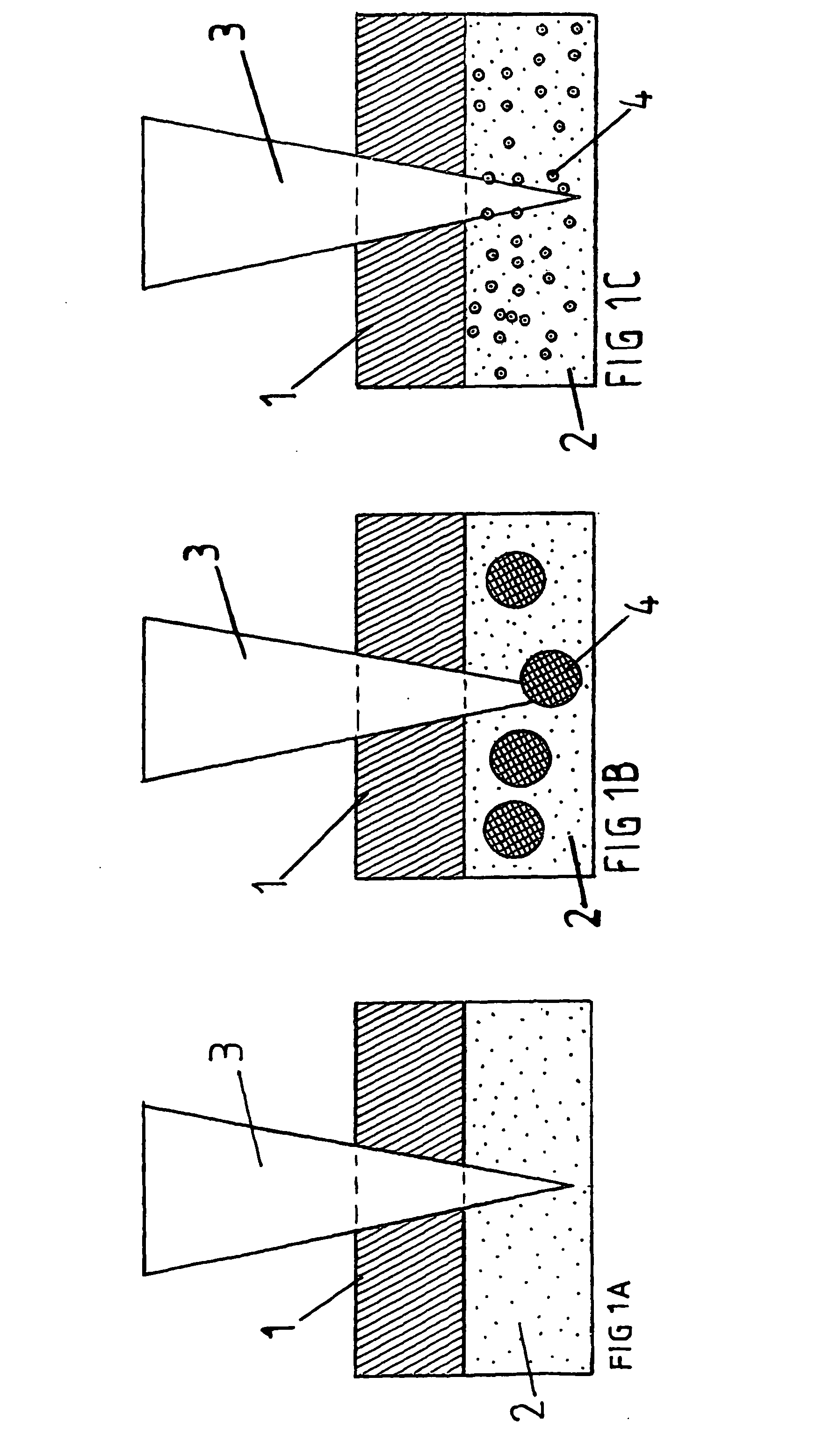

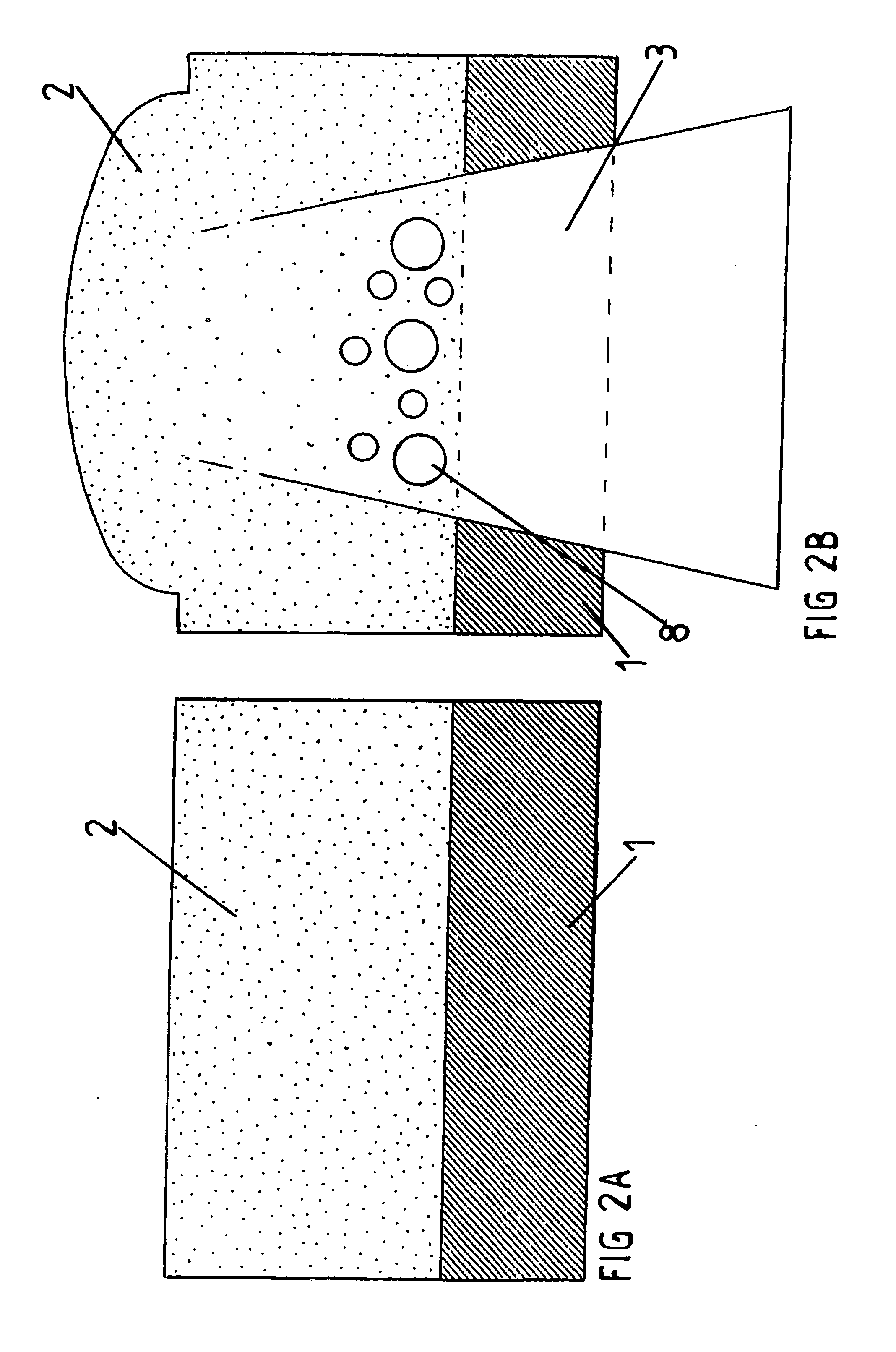

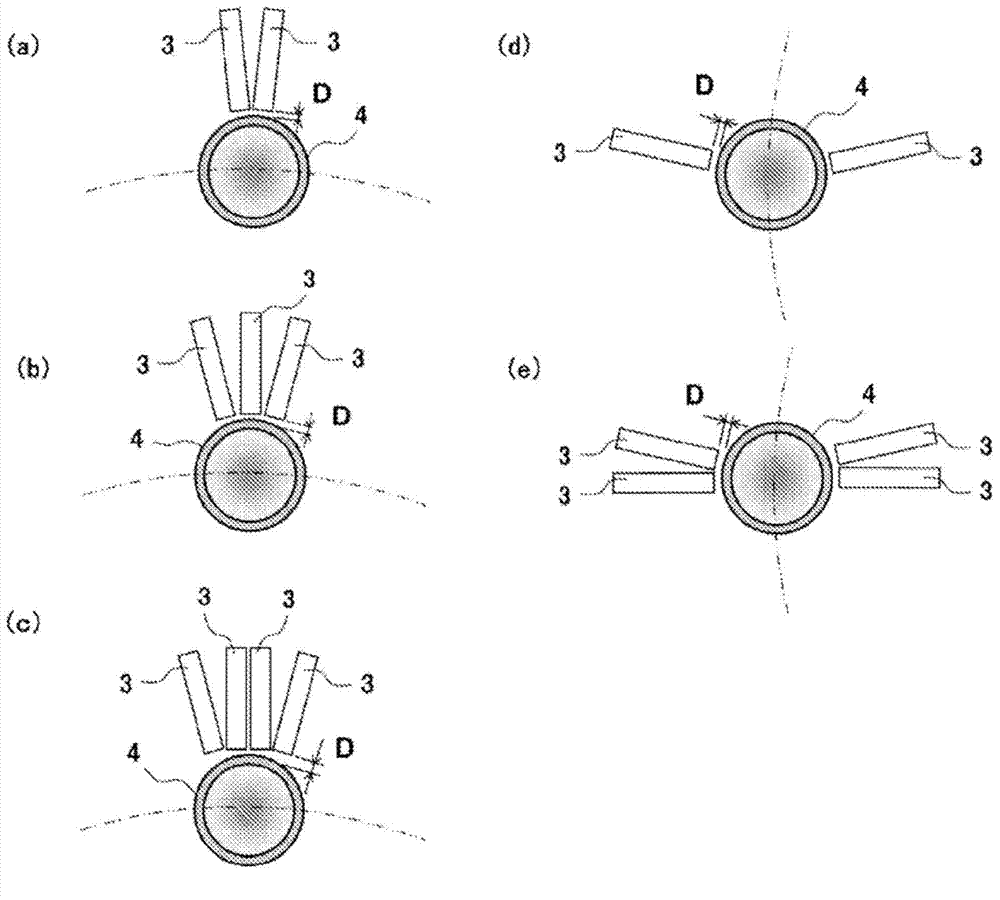

Quality printing method, printing machine, and corresponding printing substance

InactiveUS20050212888A1Improve printing qualityLess energyRecording apparatusInksElectrical and Electronics engineeringEnergy analysis

A printing process for the transfer of printing substance (2) from an ink carrier (1) to an imprinting material (6), in which, with the help of an energy-emitting apparatus, which, during a process period, emits energy in the form of electromagnetic waves (3), and the printing substance (2) undergoes a change in volume and / or position, wherein, with the help of absorption bodies (4), energy is transferred from the electromagnetic waves (3) into the printing substance (2). The invention also includes an apparatus for practicing the process of the invention and a printing substance containing absorption bodies.

Owner:LPKF LASER & ELECTRONICS

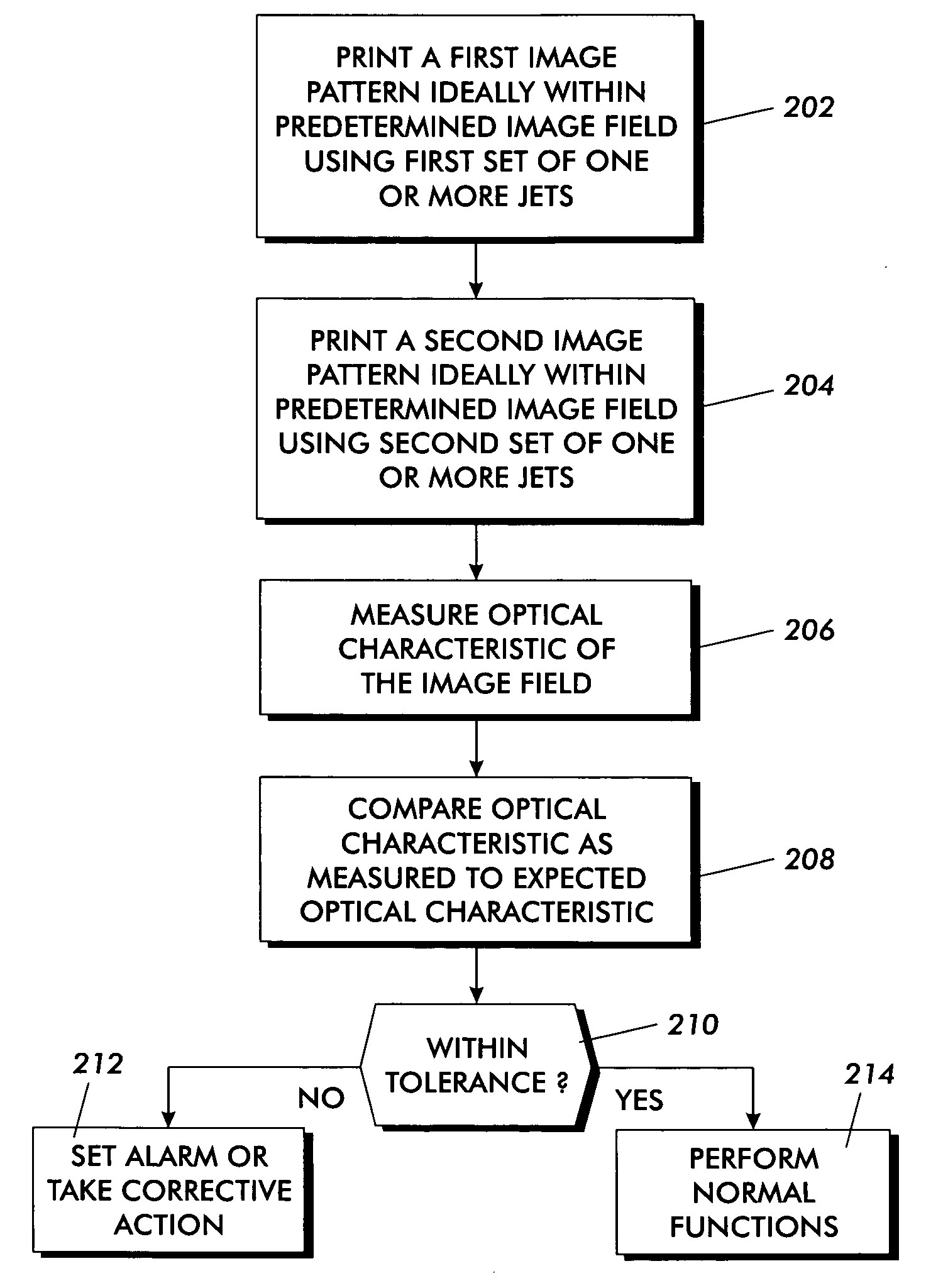

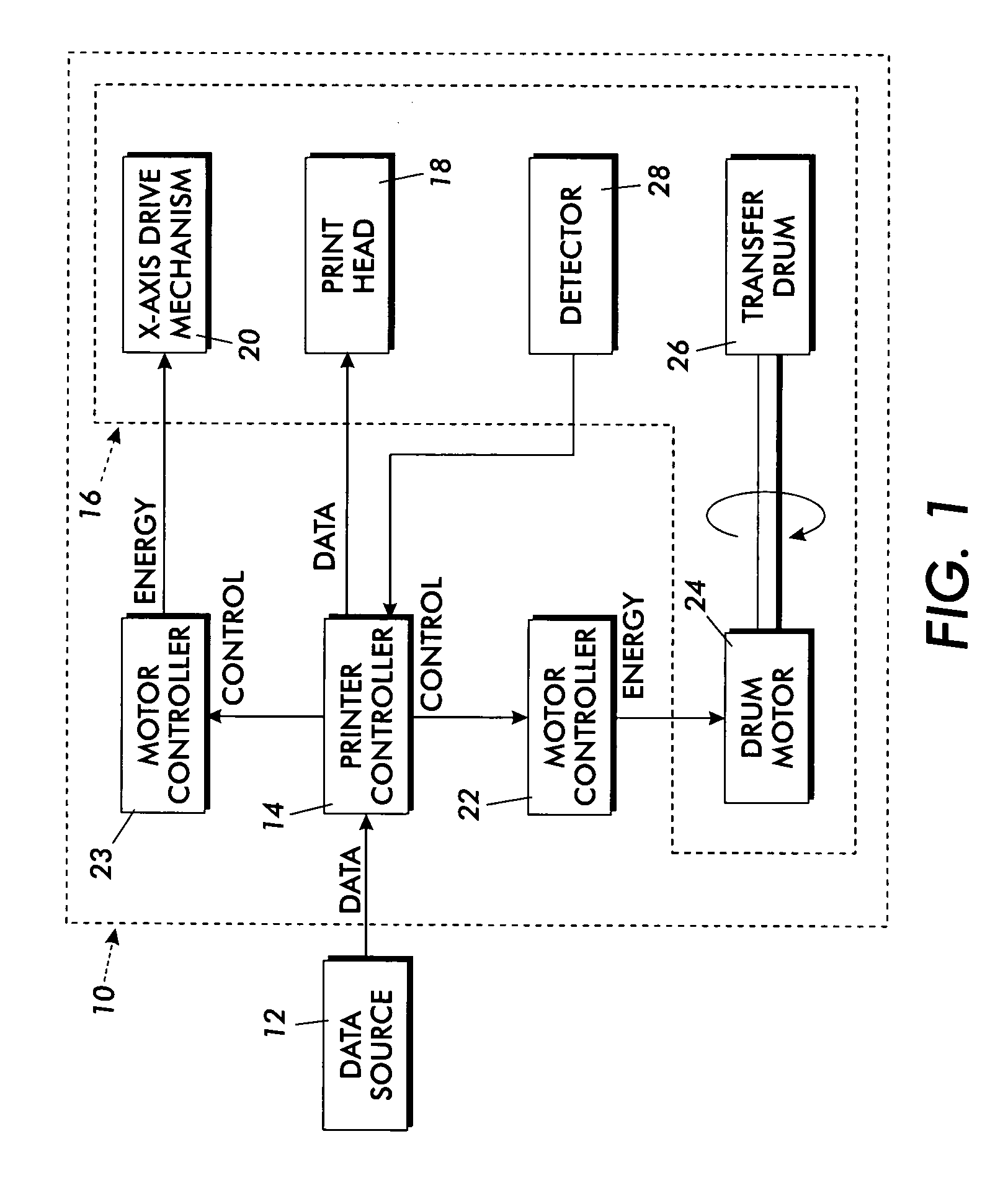

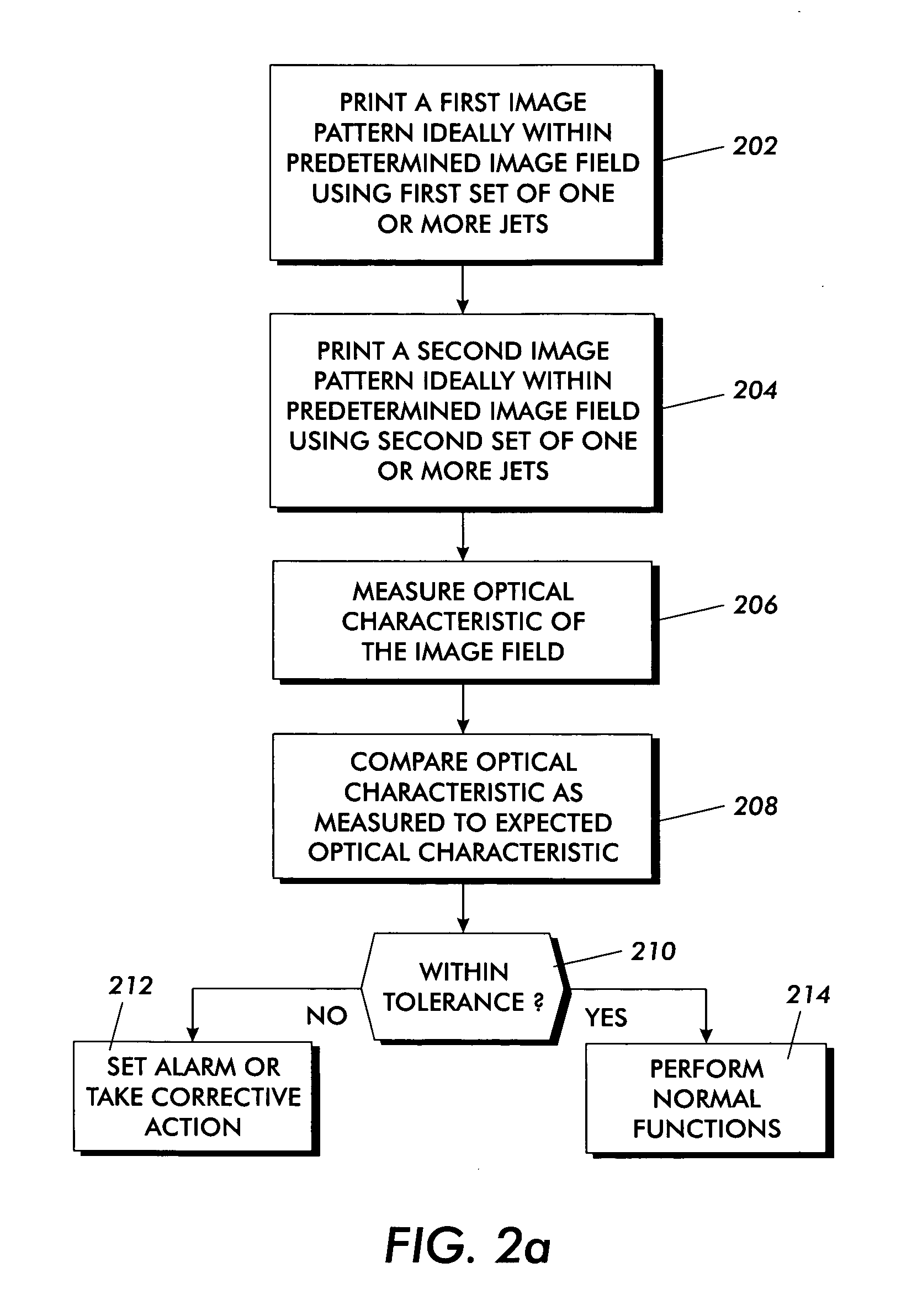

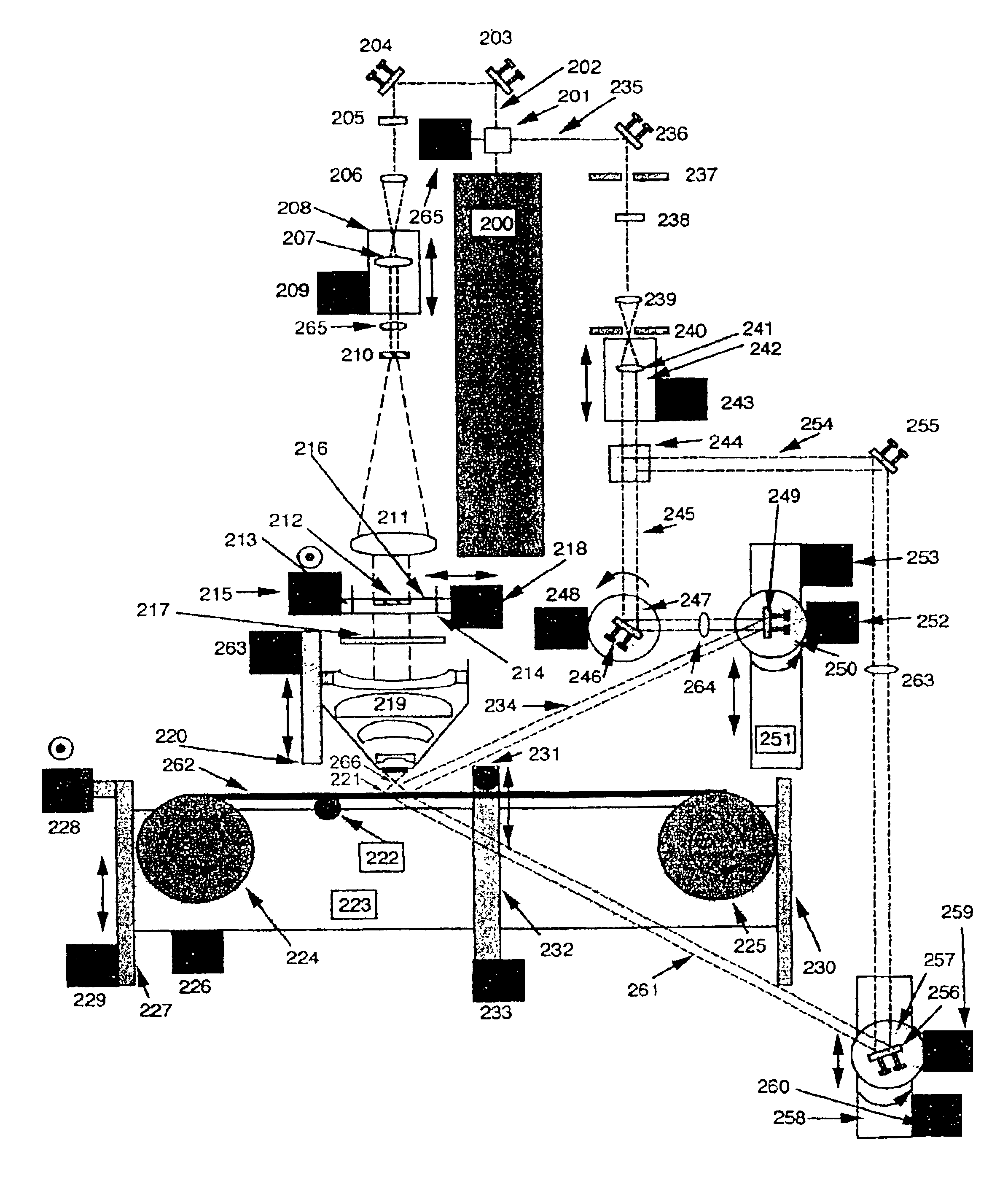

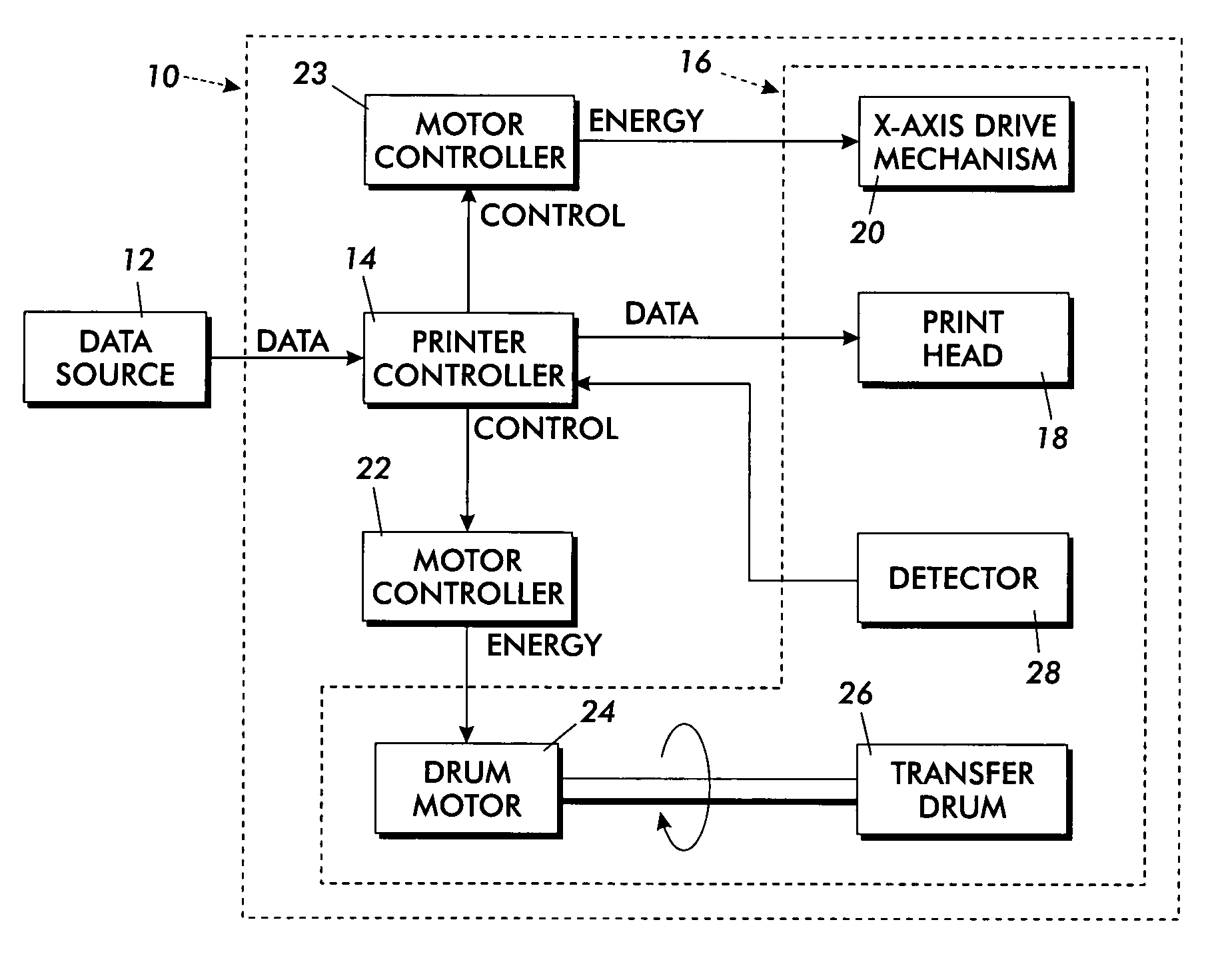

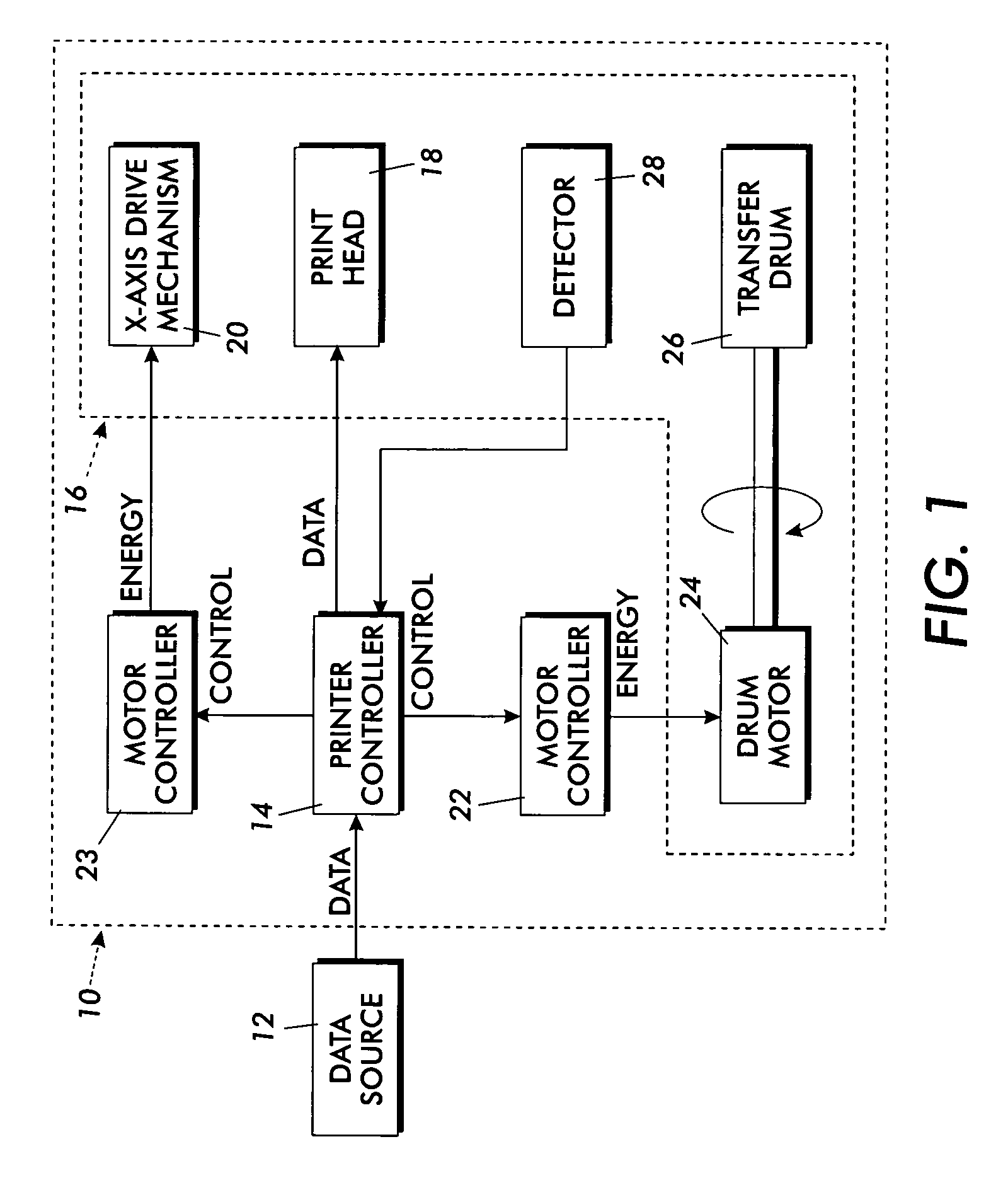

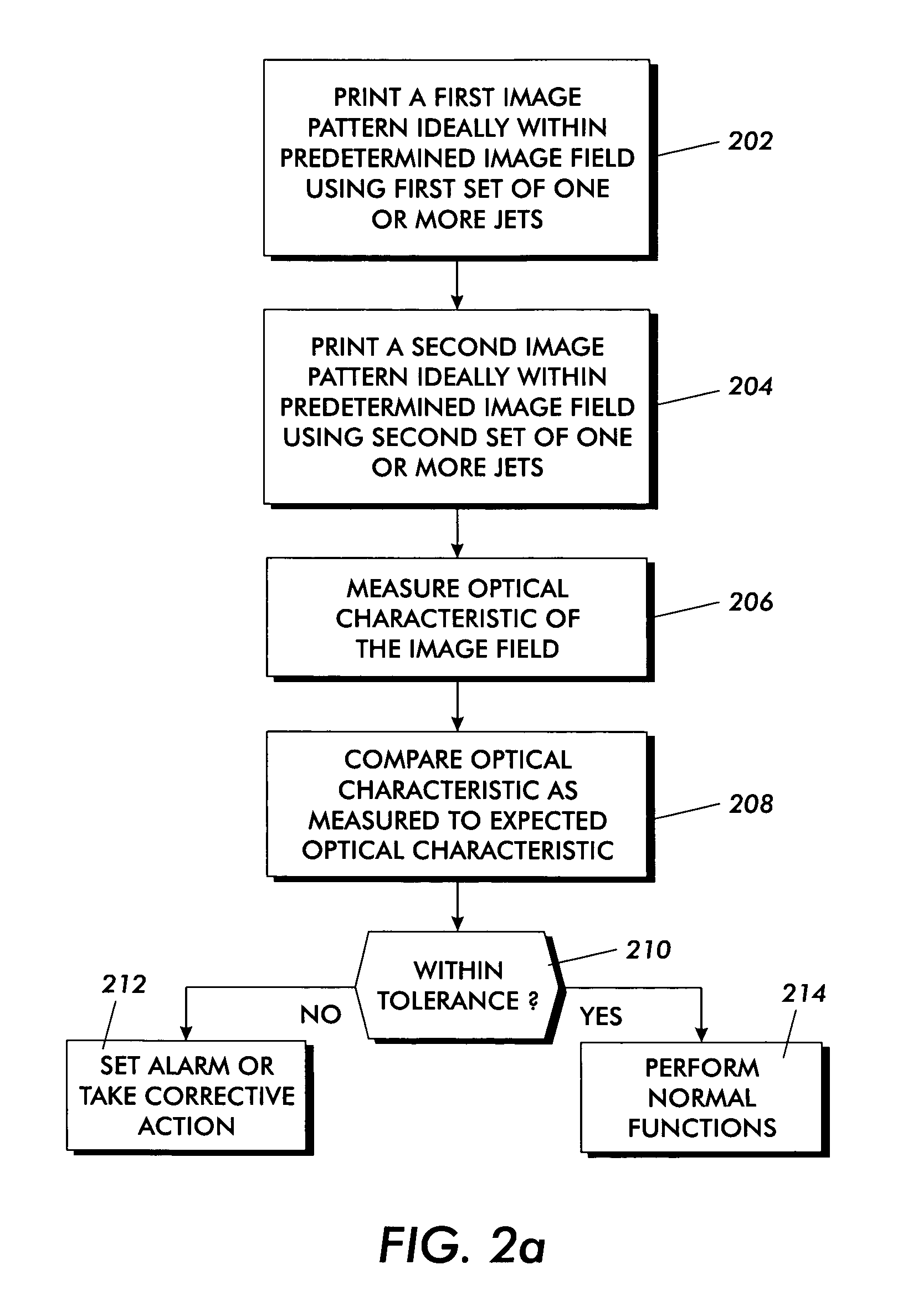

Printer jet detection method and apparatus

ActiveUS20050099439A1Increase printing speedReduce the amount requiredPower drive mechanismsOther printing apparatusOptical detectorsOptical detector

A method includes ejecting ink from a first set of one or more nozzles to form a first image pattern at least partially within an image field. The method likewise includes ejecting ink from a second set of one or more nozzles to form a second image pattern at least partially within the image field. The first image pattern and second image pattern form a composite pattern within the image field. Then, an optical detector obtains a measurement of an optical characteristic of the image field. The measurement may be compared with a reference optical characteristic for the composite pattern within the image field.

Owner:XEROX CORP

Holographic printer

InactiveUS6930811B2Increase printing speedGuaranteed uptimeHolographic light sources/light beam propertiesHolographic optical componentsDigital dataParallax

A single method and apparatus for producing many of the most common types of hologram from digital data is disclosed. The data are generated entirely by a computer as a 3-D (animated) model or from multiple 2-D camera images taken of a real 3-D (moving) object or scene from a plurality of different camera positions. The data are digitally processed and displayed on a small high resolution spatial light modulator (SLM). A compact low energy pulsed laser, is used to record composite holograms. The present invention permits the creation of restricted or full parallax master transmission or reflection type composite holograms, known as H1 holograms, that can be copied using traditional methods. Alternatively the same invention and apparatus permits the direct writing of hologram without the need to pass through the intermediate stage of the H1 transmission hologram.

Owner:COMPHARE TRUST COMPANY OF CANADA

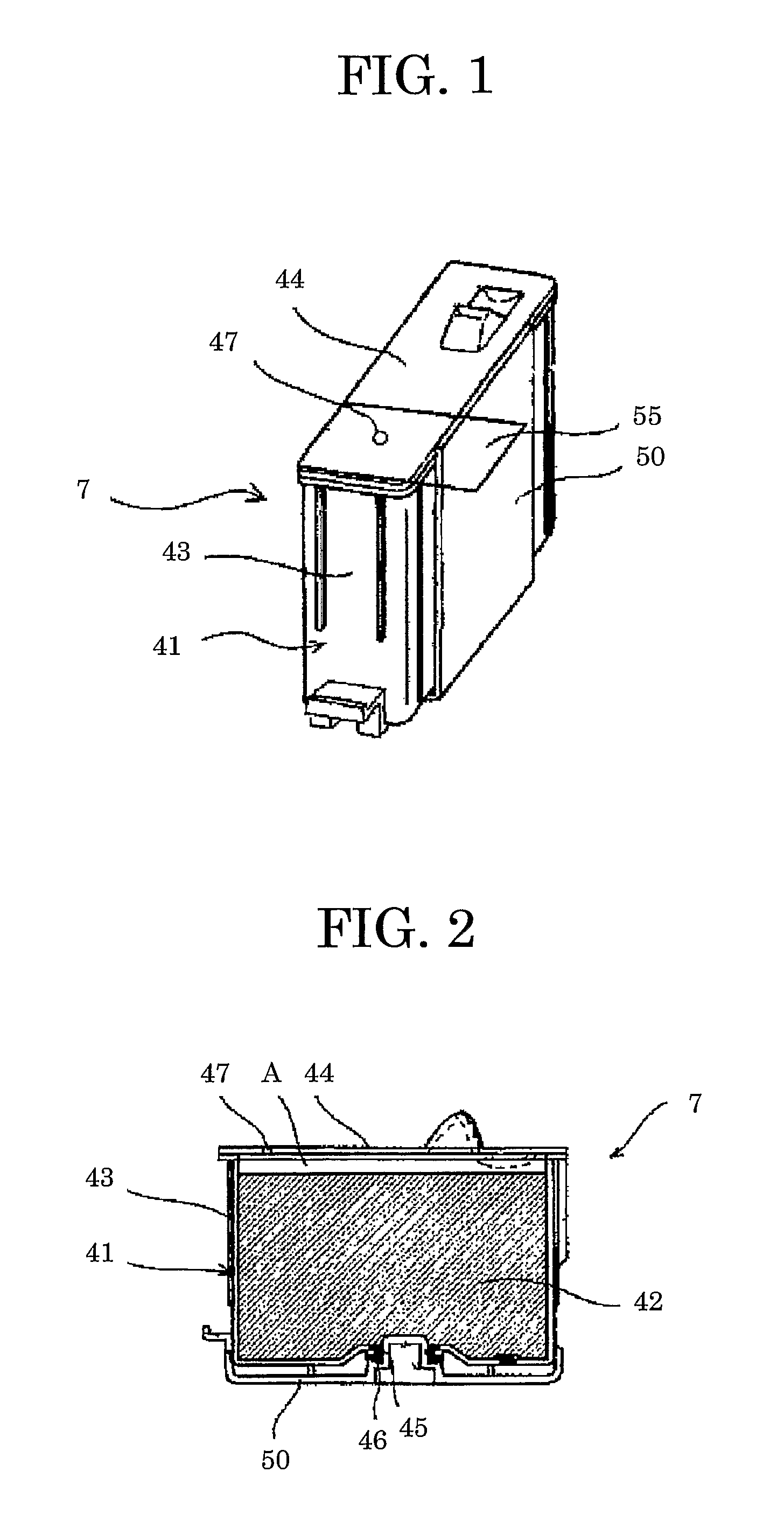

Recording ink, ink set, ink cartridge, ink record, inkjet recording apparatus and inkjet recording method

ActiveUS7977408B2Appropriate discharge stabilityGood colorOrganic chemistryMeasurement apparatus componentsEngineeringWater soluble

It is an object of the present invention to provide a recording ink which contains at least a pigment, a dispersant, a water-soluble solvent, a wetting agent and water, wherein the pigment contains at least one of diketopyrrolopyrrole red pigment and phthalocyanine green pigment in order to obtain a recording ink and ink set which excel in discharge stability with no head clogging during printing and can obtain high quality images with good color tone on the regular paper as well as on an exclusive recording paper; and ink cartridge, ink record, inkjet recording apparatus and inkjet recording method which utilize the recording ink and ink set respectively.

Owner:RICOH KK

Printer jet detection method and apparatus

ActiveUS7021732B2Reduce the amount requiredIncrease printing speedPower drive mechanismsOther printing apparatusComposite patternImage field

A method includes ejecting ink from a first set of one or more nozzles to form a first image pattern at least partially within an image field. The method likewise includes ejecting ink from a second set of one or more nozzles to form a second image pattern at least partially within the image field. The first image pattern and second image pattern form a composite pattern within the image field. Then, an optical detector obtains a measurement of an optical characteristic of the image field. The measurement may be compared with a reference optical characteristic for the composite pattern within the image field.

Owner:XEROX CORP

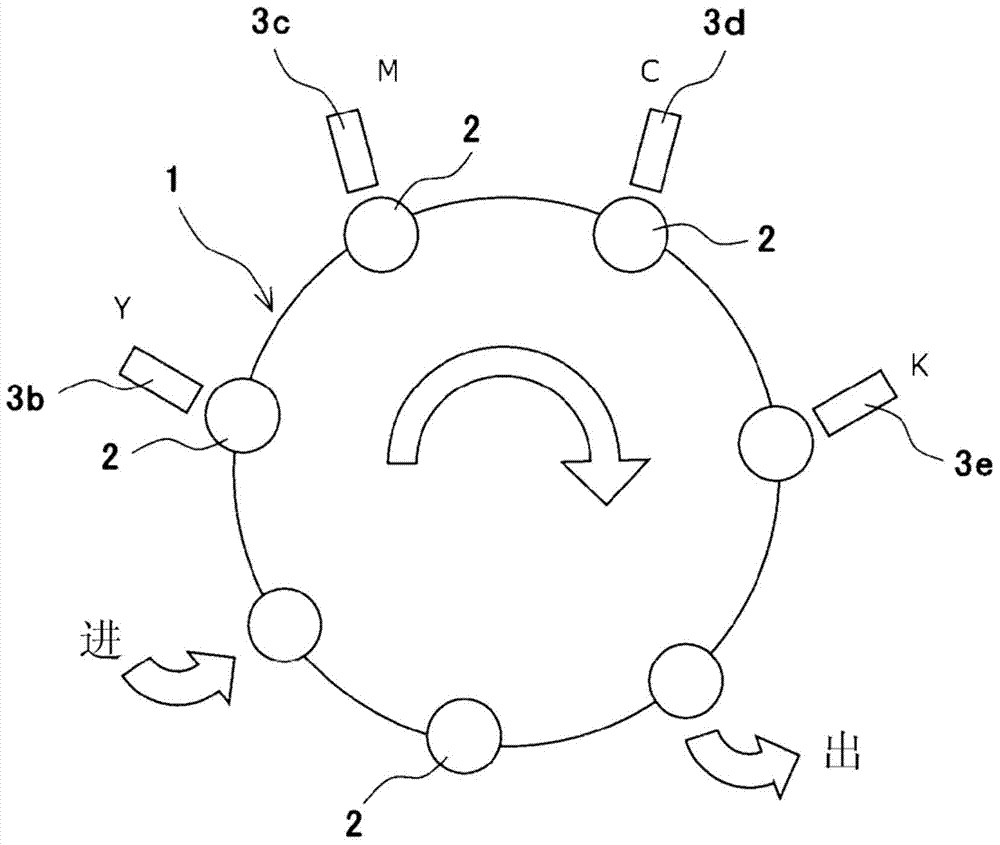

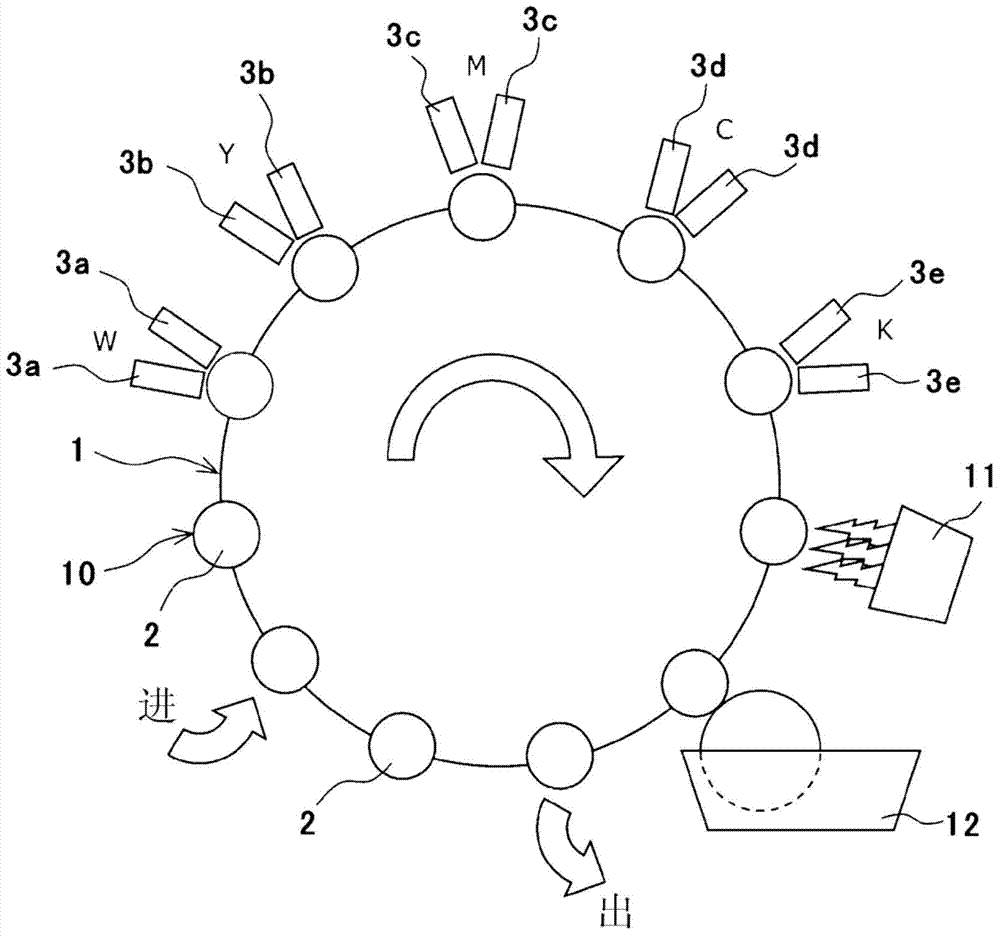

Ink-jet printer and method for printing seamless can using same

ActiveCN103492272AIncrease rotation speedIncrease printing speedDuplicating/marking methodsTypewritersProduction rateElectrical and Electronics engineering

Owner:TOYO SEIKAN GRP HLDG LTD

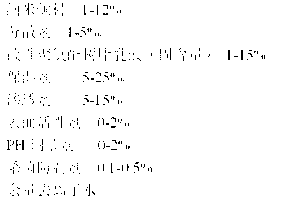

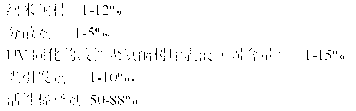

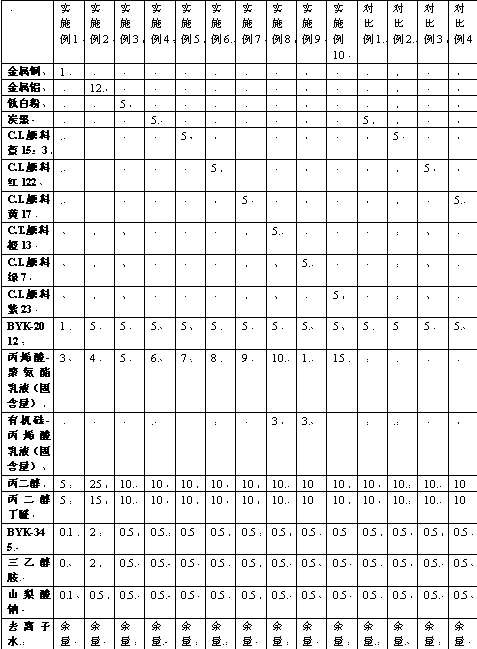

Water-based pigment ink for quality improvement

A water-based pigment jet ink comprises 1-12wt% of a nanopigment, 1-5wt% of a dispersant, 1-15wt% of a modified polyurethane resin emulsion (solid content), 5-25wt% of a humectant, 5-15wt% of an osmotic agent, 0-2wt% of a surfactant, 0-2wt% of a PH adjusting agent, 0.1-0.5wt% of a sterilization antiseptic, and the balance deionized water. The ink has the advantages of excellent preservation stability and printing smoothness, particle nanometer level, complete chromatogram, substantially increased comprehensive properties comprising the light resistance, the water resistance, the chemical resistance, the scratch resistance, high brightness, the high and low temperature resistances, the ageing resistance and the like, and application range enlargement.

Owner:深圳市凌普鑫科技有限公司

Human anatomic structure model and implant rapid forming method

ActiveCN105224759AHigh speedHigh precisionSpecial data processing applicationsAnatomical structuresStructure analysis

The present invention disclose a human anatomic structure model and implant rapid forming method. The method is characterized by comprising: firstly, obtaining three-dimensional digital models of an implant, an anatomic structure or parts and layers of the anatomic structure by software processing; secondly, performing inward or outward cavity, hollowing and thin wall processing on all or part of the models by the software to form an internal frame structure or add an internal tube cavity structure, thereby obtaining a printing model; thirdly, directly adding a supporting structure to a structure small in size and low in printing cost and performing printing; fourthly, performing 3D supporting structure analysis on a bulky, branch or netty structure, performing segmentation, printing the segmented model, and obtaining the model by assembling and bonding; and finally, further processing the model. According to the method provided by the present invention, the modeling precision can be improved, printing materials can be reduced, the costs and time are saved, and certain technological bottlenecks are avoided, so that the method is practical and easy to generalize.

Owner:佛山市三水区人民医院

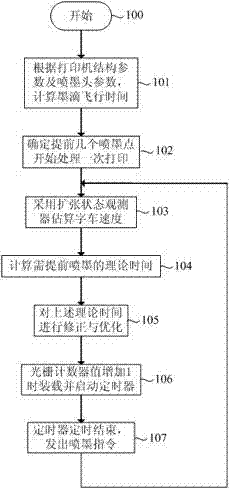

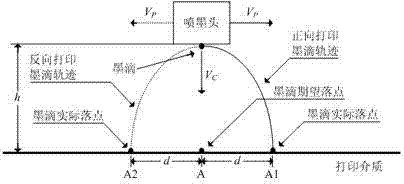

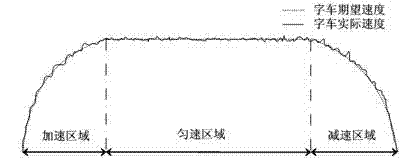

Ink droplet droppoint deviation compensation method in bidirectional printing of inkjet printer

The invention belongs to the technical field of inkjet printing, in particular to an ink droplet droppoint deviation compensation method in bidirectional printing of an inkjet printer. The invention is characterized in that: an adaptive compensation method is realized by seven steps; deviation of ink droplets in a character wheel constant speed area can be more precisely compensated, the printing speed is greatly improved, the printing quality is improved, a problem that printing cannot be carried out in a character wheel acceleration and deceleration area is solved, and the printing efficiency is improved while the cost is saved; and the method provides technical guarantee for high-speed high-precision printing.

Owner:XIDIAN UNIV

Image forming apparatus

InactiveUS20070109385A1Shorten the timeEliminate chargeTypewritersElectrographic process apparatusImage formationPaper sheet

Owner:RICOH KK

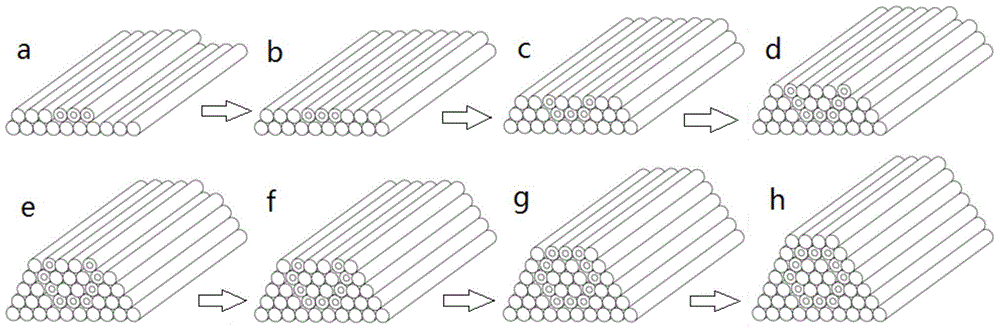

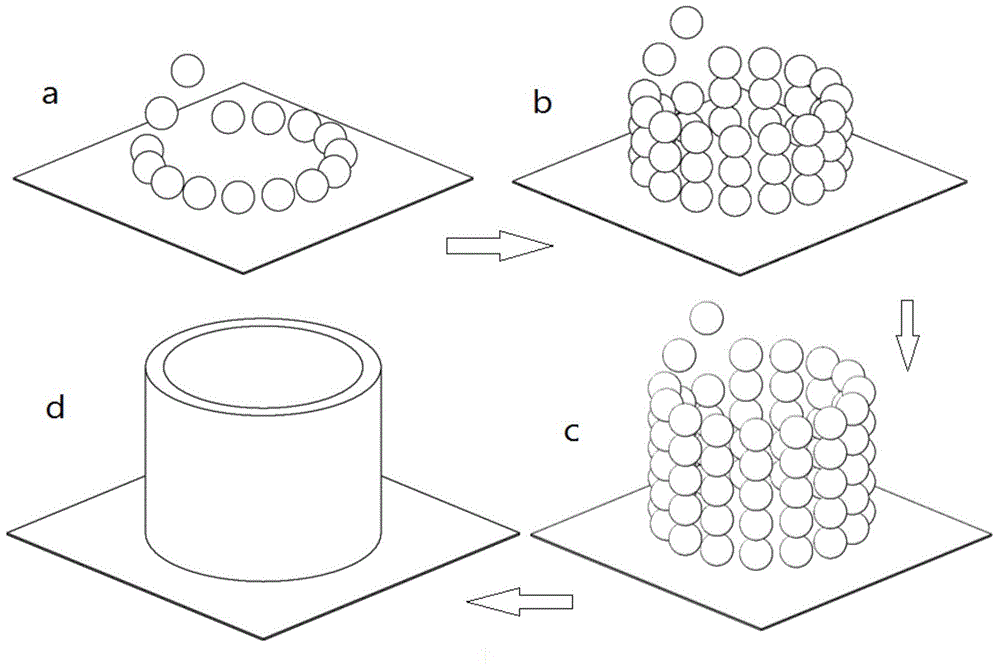

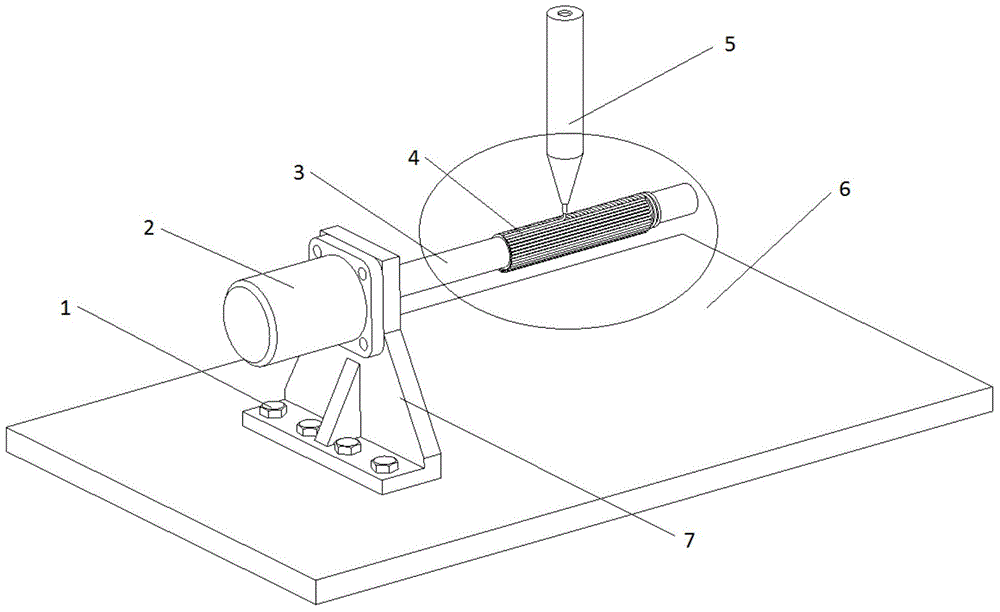

Blood vessel forming device and method for 3D bioprinting

InactiveCN104146794ALess affected by gravityThe overall impact is smallBlood vesselsBiological material testing proceduresBlood Vessel TissueBiomedical engineering

This invention discloses a blood vessel forming device and method for 3D bioprinting. The device and method are used for the bioengineering technology and aim to solve the problems that currently, when blood vessels are printed through the 3D bioprinting technologies, the blood vessels are poor in forming quality and small in forming length. According to the method, biological ink is printed on rotary rods with the surfaces coated with thermo-sensitive hydrogel through the 3D bioprinting technologies, and the needed biological blood vessels can be formed through further biological culture. According to the method, the rotary rods with different diameters and lengths can be prepared for printing the biological blood vessels with different sizes, blood vessel tissue which is uniform in thickness and accurate in printing size can be fast printed, the available 3D printing technologies are diverse, and the device and method are wide in practicability. We call the method a 3D rotational forming printing method (3Denvelop Bioprinting Method).

Owner:周惠兴

Inkjet printhead for full color pagewide printing

ActiveUS20180222198A1Increase distanceMinimize color mixingInking apparatusPower drive mechanismsEngineeringMechanical engineering

Owner:MEMJET TECH LTD

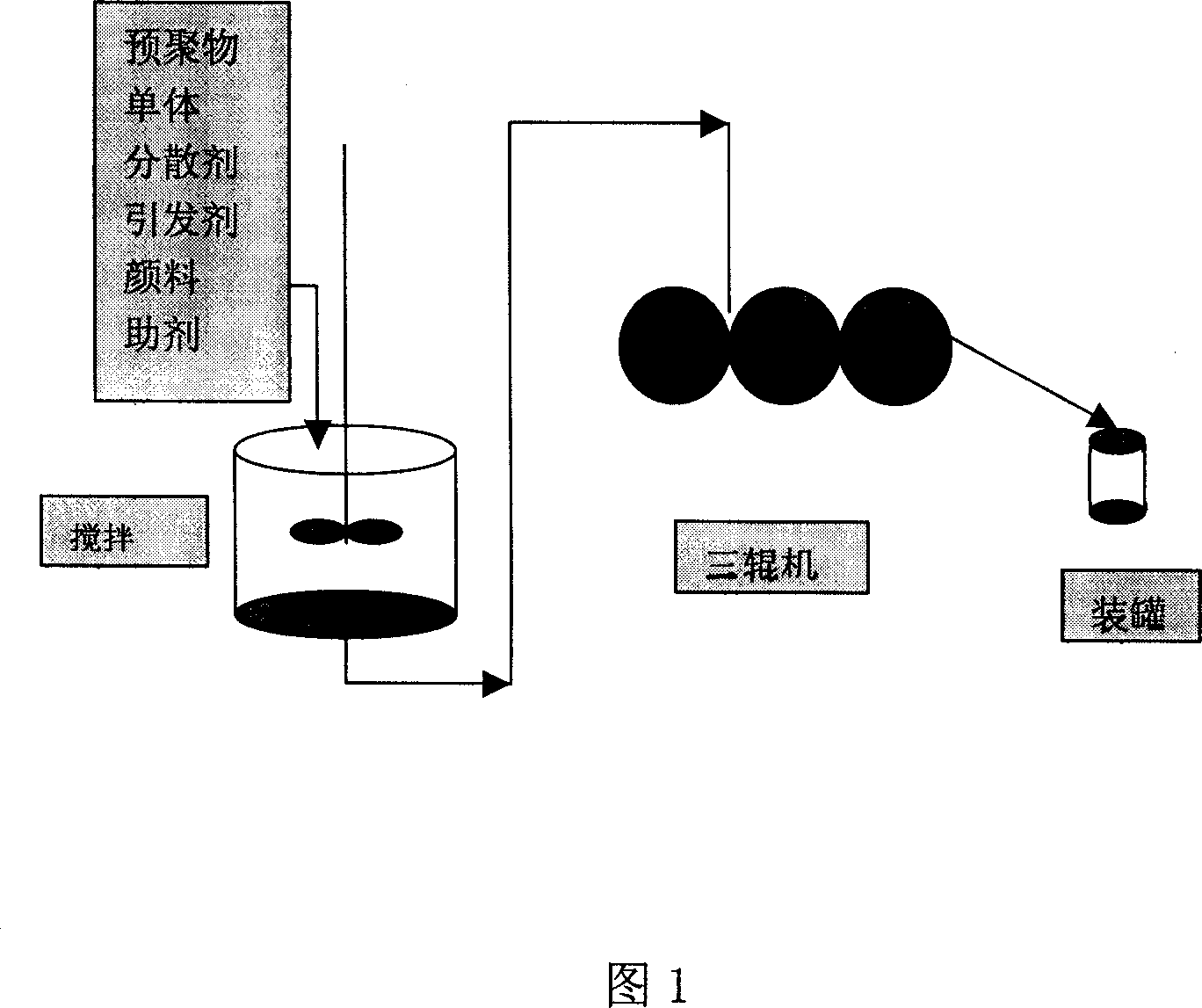

Environmental protection type tin printing ink solidified by ultraviolet light

This invention discloses environmentally friendly UV-curing tin plate ink, which comprises: acrylic acid prepolymer 50-70 wt.%, acrylic acid monomer 10-15 wt.%, initiator 5-10 wt.%, pigment 10-25 wt.%, dispersant and other additives 5-10 wt.%. The UV-curing tin plate ink is a color printing ink used on metal and cured by UV. The UV-curing tin plate ink has such advantages as low energy consumption, rapid curing, no VOC discharge, high efficiency, high safety and no pollution.

Owner:FOSHAN ROCKLINK CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com