Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Good printing fluency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based pigment ink for quality improvement

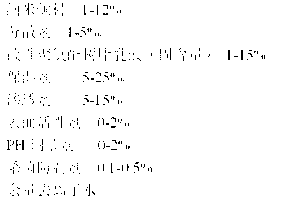

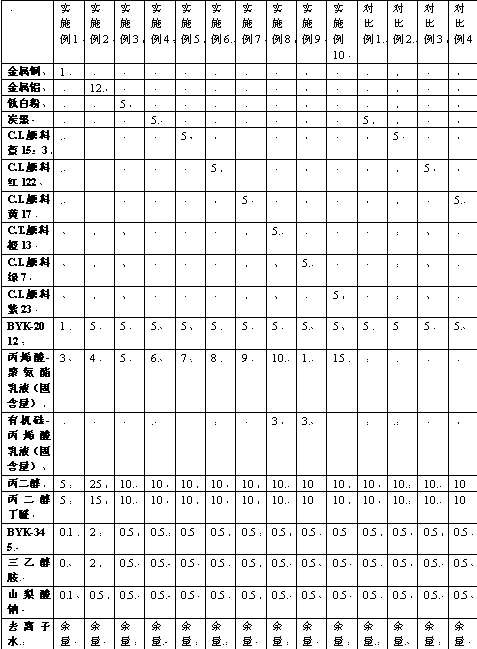

A water-based pigment jet ink comprises 1-12wt% of a nanopigment, 1-5wt% of a dispersant, 1-15wt% of a modified polyurethane resin emulsion (solid content), 5-25wt% of a humectant, 5-15wt% of an osmotic agent, 0-2wt% of a surfactant, 0-2wt% of a PH adjusting agent, 0.1-0.5wt% of a sterilization antiseptic, and the balance deionized water. The ink has the advantages of excellent preservation stability and printing smoothness, particle nanometer level, complete chromatogram, substantially increased comprehensive properties comprising the light resistance, the water resistance, the chemical resistance, the scratch resistance, high brightness, the high and low temperature resistances, the ageing resistance and the like, and application range enlargement.

Owner:深圳市凌普鑫科技有限公司

Ultraviolet-curing water-based inkjet ink

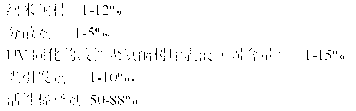

The invention discloses ultraviolet-curing water-based inkjet ink. The ultraviolet-curing water-based inkjet ink at least comprises the following components in percentage by weight: 1%-12% of nanometer pigment / water-soluble pigment, 1%-5% of dispersing agent, 1%-15% of UV (Ultraviolet)-curing modified polyurethane resin emulsion (solid content), 1%-10% of photoinitiators, 20%-50% of reactive diluents, 5%-25% of humectants, 5%-15% of penetrating agents, 0%-2% of surfactants, 0%-2% of pH regulators, 0.1%-0.5% of sterilization preservative, and the balance of deionized water. The ultraviolet-curing water-based inkjet ink is characterized in that the ink has excellent storage stability and printing fluency; the ink has excellent performances including water resistance, light resistance, solvent resistance, scratch resistance, ageing resistance, high-low temperature resistance, high brightness, good adhesive strength and quick curing speed, is suitable for various printers to print various uncoated and nonprinting coating media, hydrophobic and oily media, and is wide in application area.

Owner:NANJING CHEMBRIDGE TECH MATERIAL

Water-based pigment type ink for absorbent base material spray ink printing, preparation and printing methods thereof

ActiveCN101993633AImprove versatilityGood printing fluencyInksPrinting after-treatmentWater basedEmulsion

The invention relates to a water-based pigment type ink for absorbent base material spray ink printing and a preparation method and a printing method thereof. The ink comprises the following components in percentage by mass: 2 to 15 percent of pigment, 0.1 to 3.0 percent of surfactant, 2 to 20 percent of water-soluble cosolvent, 0.1 to 10 percent of film-forming aid, 5 to 35 percent of polyacrylate emulsion and 1 to 12 percent of dispersing agent and deionized water. The preparation method comprises the following steps of: (1) adding the dispersing agent and partial water-soluble cosolvent into the deionized water, emulsifying, adding the pigment, dispersing, grinding and obtaining dispersion of the pigment; and (2) stirring and uniformly mixing the surfactant, the film-forming aid and the residual water-soluble cosolvent, adding water-based polyacrylate emulsion, stirring, adding the dispersion of the pigment, stirring, filtering and obtaining the ink. The ink does not produce toxic volatile matters, is high in universality, makes printing smooth and achieves high picture precision. Meanwhile, the printed picture has excellent sunshine resistance, washing resistance, friction resistance and high fastness, and is suitable for indoor and outdoor use.

Owner:上海英威喷墨科技有限公司 +1

Solvent type disperse dye ink-jet printing ink and preparation method thereof

The invention provides a solvent type disperse dye ink-jet printing ink and a preparation method thereof. The ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dye, 1 to 15 percent of dispersant, 0.5 to 15 percent of resin and 60 to 95 percent of organic solvent. The preparation method comprises the following steps of: adding 1 to 15 percent of dispersant and 0 to 10 percent of resin into the organic solvent, and emulsifying the mixture for 20 to 60min, adding 1 to 8 percent of dye into the mixture, grinding the mixture for 8 to 40h, and obtaining a disperse dye color paste; and adding 10 to 80 percent of disperse dye color paste and 0 to 10 percent of resin into the organic solvent, and filtering the mixture with a millipore filter between 0.2 and 2 mu m to obtain the solvent type disperse dye ink-jet printing ink. The ink has the advantages of good printing smoothness, bright lustre of patterns, and excellent sunlight fastness, washing fastness and rub resistance, and can be widely applied to multiple kinds of wide, high-speed and solvent type digital printing equipment; and the preparation method is simple and practical.

Owner:DONGHUA UNIV +1

Water-based pigment digital ink-jet textile printing ink and preparation and use methods thereof

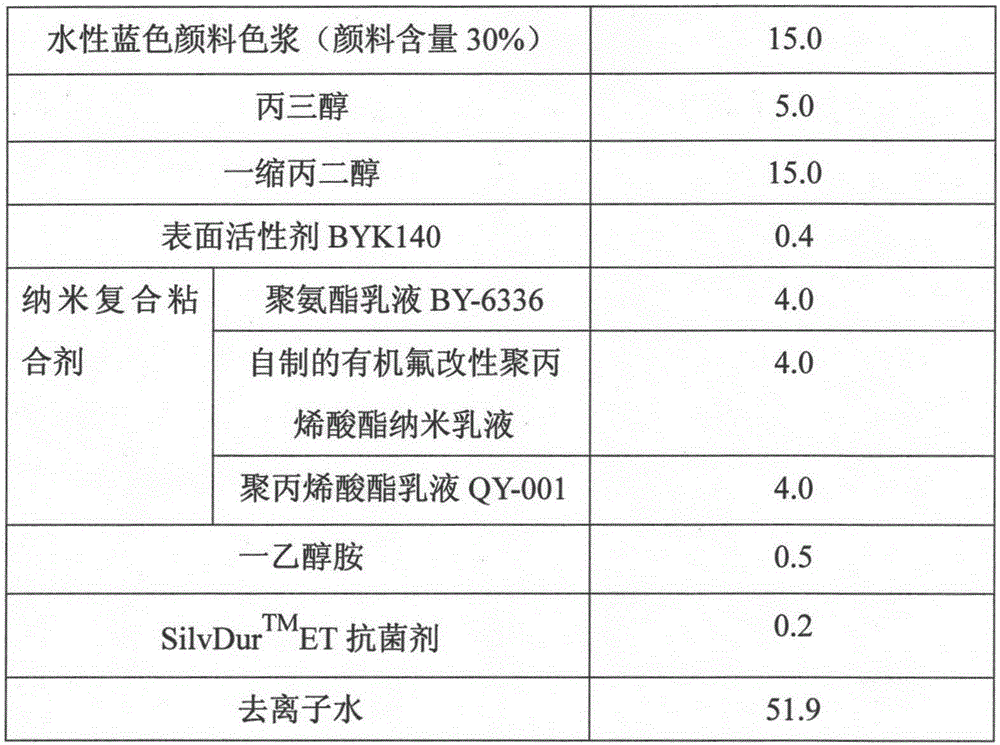

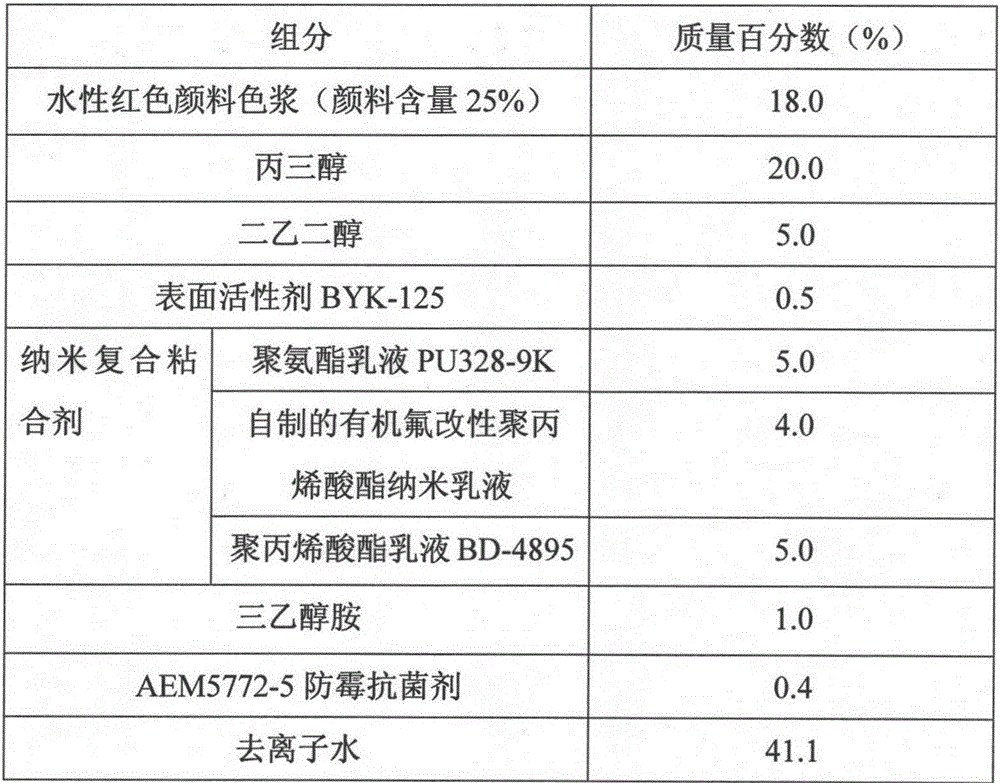

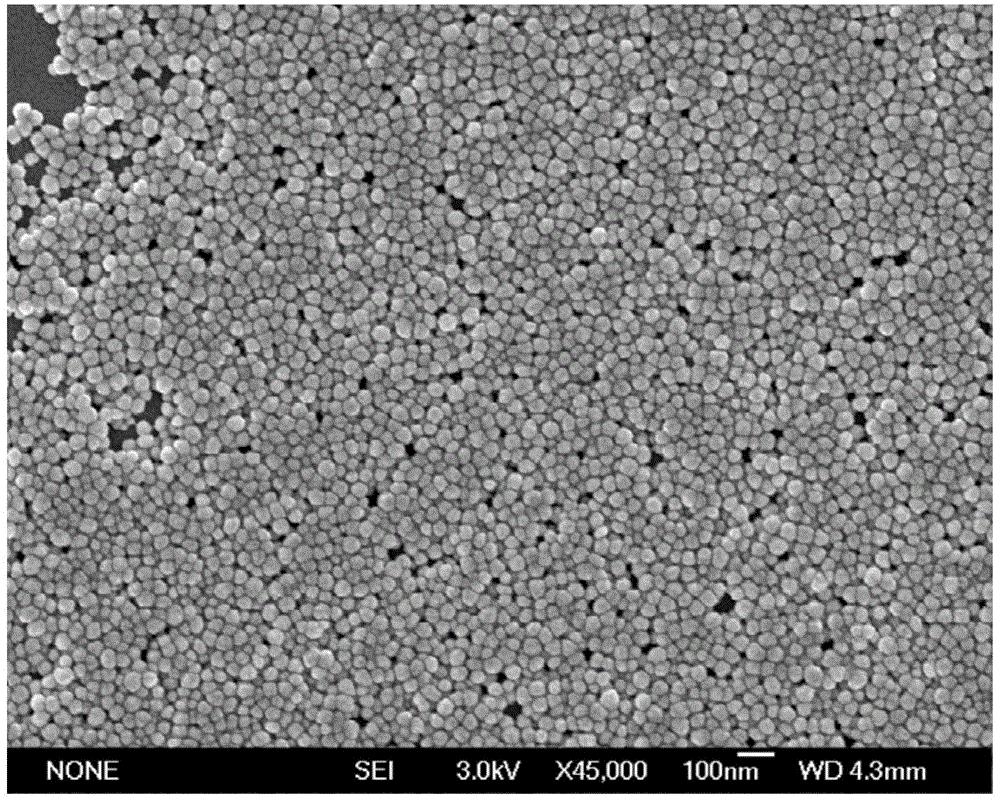

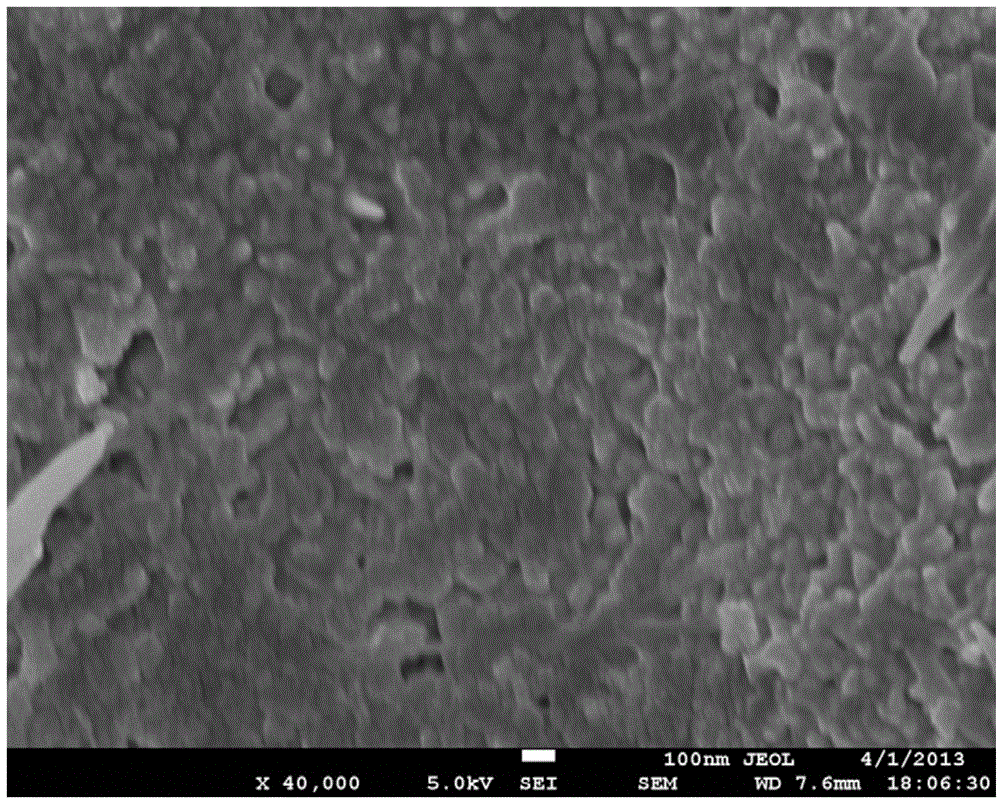

ActiveCN106567267AImprove washing fastnessImprove hydrophobicityDuplicating/marking methodsInksWater basedTextile printer

The invention provides a water-based pigment digital ink-jet textile printing ink and preparation and use methods thereof. The water-based pigment digital ink-jet textile printing ink is characterized by containing a pigment color paste, a nano composite adhesive and deionized water, wherein the nano composite adhesive comprises a polyurethane emulsion, an organic fluorine modified polyacrylate nano emulsion and another polyacrylate emulsion. With use of the nano composite adhesive, the problem of low water washing fastness of a water-based pigment ink-jet printing ink on a printing fabric is solved emphatically, and a new solution is provided for industrialized application of the water-based pigment ink-jet printing ink in the field of fabric digital ink-jet printing.

Owner:上海英威喷墨科技有限公司

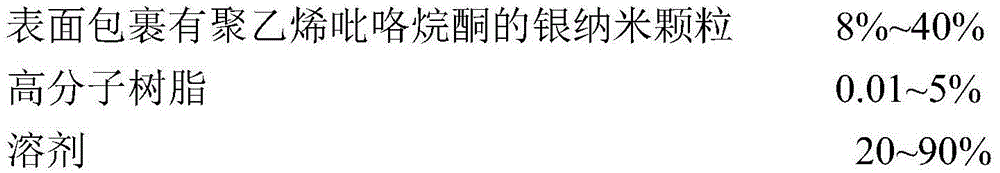

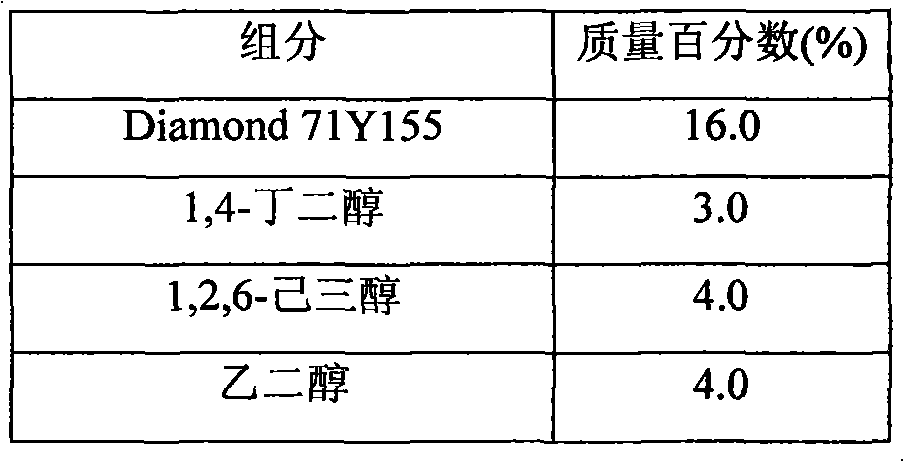

Ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof

The present invention relates to an ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof. According to the present invention, silver nanoparticles with polyvinylpyrrolidone wrapped on the surface, a polymer resin, a solvent, a surfactant, a preservative, an antifoaming agent and a humectant are uniformly mixed to obtain the ink-jet printing electric conduction ink; the ink-jet printing electric conduction ink can be printed on a printed circuit board so as to prepare the pattern of an electric conduction trace, a treatment liquid is coated on the printed circuit board having the electric conduction trace pattern, and the electric conduction trace pattern printed through the ink-jet printing electric conduction ink is subjected to chemical sintering through the treatment liquid at a room temperature so as to obtain the electric conduction trace having good electric conduction property; and the ink-jet printing electric conduction ink has characteristics of low cost, excellent printing suitability and excellent durability, and can be matched with the room temperature sintering method of the present invention so as to make the printed electric conduction pattern achieve the good electric conduction property at the room temperature.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Digital printing active red ink and preparation method thereof

The invention discloses digital printing active red ink. The digital printing active red ink is prepared from, by weight, 5-10% of reactive dye, 15-30% of humectant, 0.5-2% of surfactant, 0.2-0.5% of defoamer, 1-5% of pH buffer, 0.2-1% of bactericide, 1-5% of viscosity modifier, 5-10% of cosolvent and the balance deionized water. The digital printing active red ink is high in printing smoothness, high in dye uptake, stable in PH after being stored for a long time, good in filterability and high in storage stability, the service life of a sprayer can be prolonged, the color range is wide, the requirements of most users can be met, the dye uptake is high, and the wastewater treatment cost is reduced.

Owner:上海贝通色彩科技有限公司

Latex-type waterborne pigment oil ink for inkjet printing of non-absorbed substrate as well as preparation method and applications thereof

ActiveCN101899237AGood printing fluencyHigh precisionInksOther printing apparatusWater basedWater soluble

The invention relates to latex-type waterborne pigment oil ink for the inkjet printing of a non-absorbed substrate, which is prepared from the following components in percentage by weight: 1-15 percent of pigment dispersant, 0.01-2.0 percent of surface active agent, 10-40 percent of water-soluble co-solvent, 0.1-30 percent of water-based polymer emulsion and the balance of deionized water. The preparation method comprises the following steps of: stirring and mixing the surface active agent, the water-soluble co-solvent and the deionized water under a normal temperature; then, slowly adding the waterborne polymer emulsion, continuously stirring; and finally, adding the pigment dispersant, fully mixing the contents to form an even dispersing system and filtering the even dispersing system to obtain latex-type waterborne pigment oil ink. The latex-type waterborne pigment oil ink for the inkjet printing has wide range of suitable substrates, is environment-friendly in the oil ink preparation process and the printing process and has good printing smoothness and high accuracy; and printed images on the non-absorbed substrate have excellent resistance to rubbing, scraping, sunshine and water and are suitable for outdoor use.

Owner:上海英威喷墨科技有限公司 +1

Water-based dye ink for jet printing of black and white images

InactiveCN102304306AGood printing adaptabilityHigh color reproductionInksWater basedConcentration gradient

The invention relates to a water-based dye ink for jet printing of black and white images, which is characterized by comprising the following components in percentage by weight: 0.72-5 wt% of black dye, 5-40 wt% of humectant, 1-10 wt% of viscosity modifier, 0.05-1 wt% of bactericide, 0-1 wt% of chelator, 0-1 wt% of pH buffer, 0-5% of surfactant and the balance of deionized water. When the water-based dye ink for jet printing of black and white images is applied to a desktop piezoelectric printer, different concentration gradients of several colors are regulated by the black dye; when being used for printing black and white images, the water-based dye ink for jet printing of black and white images has excellent color reproducibility which is obviously superior to that of the black and white images printed in a colored ink black and white mode; and besides, the water-based dye ink for jet printing of black and white images has excellent printing smoothness, printing stability and storage stability.

Owner:北京联创佳艺影像新材料技术有限公司

Water-based UV ink for inkjet printing and preparation method thereof

The invention relates to a water-based UV ink for inkjet printing and a preparation method thereof. The water-based UV ink for inkjet printing is prepared from the following components in parts by weight: 1-5 parts of pigment, 1-15 parts of dispersing agent, 5-30 parts of water, 5-20 parts of cosolvent, 30-65 parts of prepolymer, 0.1-5 parts of photoinitiator and 0.1-5 parts of other aids. The prepolymer is composed of one or more of water-based polyurethane acrylate, water-based epoxy acrylate and water-based polyester acrylate; the cosolvent is composed of one or more of ethanediol, propanediol, diethylene glycol, polyethyleneglycol, triglycol, amide, diethylene glycol butyl ether, triethylene glycol butyl ether, N-methylpyrrolidone and cyclohexyl pyrrolidone; and the other aids are a defoaming agent, a polymerization inhibitor and a surfactant. The water-based UV inkjet ink has the advantages of environment friendliness and high printing smoothness, and has favorable adhesive force and friction resistance after being cured on the printed material; and the product has high storage stability.

Owner:济南阿波罗文化用品有限公司

Water-based pigment ink for quality improvement

Owner:深圳市凌普鑫科技有限公司

UV crosslinked wide-color-gamut digital printing ink applicable to industrial piezoelectric nozzle and manufacturing method thereof

The invention discloses and provides UV crosslinked wide-color-gamut digital printing ink applicable to an industrial piezoelectric nozzle and a manufacturing method thereof to guarantee mill base stability and color saturation. The UV crosslinked wide-color-gamut digital printing ink comprises the following components of 5%-20% of color paste, 3%-10% of oligomers, 0.1%-1% of surfactants, 40%-60% of acrylic acid reaction type monomer solvent, 5%-15% of light initiators, and 0.5%-2% of polymerization inhibitors. The manufacturing method of the ink comprises the steps of pre-preparing of the oligomers, pre-dispersing, high-speed dispersing and the like. The UV crosslinked wide-color-gamut digital printing ink applicable to the industrial piezoelectric nozzle and the manufacturing method thereof are applicable to the technical field of UV crosslinked wide-color-gamut digital printing ink.

Owner:TRENDVISION TECH(ZHUHAI) CO LTD

Photocurable non-transparent material for 3D printing, preparation method thereof, 3D printing product and 3D printer

ActiveCN109232791AImprove qualityAvoid easy cloggingManufacturing irradiation arrangements3D object support structuresDiacrylate esterEngineering

The invention provides a photocurable non-transparent material for 3D printing, a preparation method thereof, a 3D printing product and a 3D printer. The photocurable non-transparent material for 3D printing comprises the following components in parts by weight: 30-70 parts of a first acrylate component, 20-60 parts of a second acrylate component, 0.5-5 parts of a photoinitiator, 0.5-8 parts of anauxiliary agent and 0-4 parts of a colorant, wherein the first acrylate component is a polar acrylate component; and the second acrylate component is selected from at least one of weakly polar and non-polar acrylate components. According to the photocurable non-transparent material for 3D printing provided by the invention, a 3D printing product can be made non-transparent without adding white pigments such as titanium dioxide, so that the photocurable non-transparent material for 3D printing has the characteristics of high stability, the smoothness in a 3D printing process is ensured, the 3Dprinting product has good quality, and the 3D printer containing the photocurable non-transparent material for 3D printing has good performance.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Water-based digital printing thermal dye sublimation jet ink

The invention discloses water-based digital printing thermal dye sublimation jet ink and belongs to the technical field of thermal dye sublimation ink. The thermal dye sublimation jet ink is preparedfrom components in percentage by mass as follows: 1%-10% of resin, 5%-50% of color paste, 10%-50% of a solvent, 0.1%-1% of an antibacterial preservative, 0.1%-1% of a pH regulator, 0.1%-3% of a wetting agent and 10%-50% of deionized water. The thermal dye sublimation jet ink has better printing smoothness and stability and high sharpness, the quick drying property is greatly improved, the printingeffect is good, and the applicability to an EPSON MT4114 nozzle is also improved.

Owner:ZHUHAI HUACAI PRINTING SUPPLIES LTD

Water-based digital ink jet dispersed ink and preparation method and application thereof

ActiveCN102229761AGood printing fluencyGood moisturizing effectInksDyeing processDisperse dyeWater based

The invention discloses water-based digital ink jet dispersed ink and a preparation method and application thereof. The formula of the ink comprises 5 to 15 percent of dispersed dye and 1 to 8 percent of electric conductance regulator. The preparation method comprises the following steps of: mixing a dispersant, the dispersed dye, partial water-soluble organic solvent and partial deionized water,and grinding the mixture to obtain color paste; and then adding the electric conductance regulator, a surfactant, an additive, the rest water-soluble organic solvent and the reset deionized water into the color paste, and stirring and filtering to obtain the ink. The ink has good printing smoothness and nozzle moisturizing performance, can be adaptive to code spraying machines of various models, has the advantages of bright color, light resistance, washing resistance, abrasion resistance, strong firmness and the like when printed on chemical blended fabrics, and is suitable for spraying production date, batch number, bar code, pictorial trade mark, false-proof mark and Chinese character of textiles and printing blanket patterns and the like.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

High-pigment-concentration digital direct-injection textile coating material ink and preparation method thereof

InactiveCN110591448AGood flexibilityGood rubbing fastnessInksDyeing processGlycerolPolyethylene glycol

The invention discloses high-pigment-concentration digital direct-injection textile coating material ink, which is prepared from the following raw materials by weight: 400-500 parts of pigment color paste, 150-200 parts of a polymer resin, 150-200 parts of a solvent, 10-30 parts of a dispersing agent, 20-40 parts of a curing agent, 1-10 parts of a bactericide, 2-10 parts of a pH value regulator, and 50-250 parts of deionized water, wherein the resin is an aqueous polyurethane resin, the solvent comprises one or a plurality of materials selected from diethylene glycol, propylene glycol, polyethylene glycol, glycerol, triethylene glycol, ethylene glycol and glycerol, and the dispersing agent is a high-molecular-weight block copolymer solution containing a pigment affinity group. The invention further provides a preparation method. According to the present invention, the polyol chain segment in the aqueous polyurethane resin endows the resin with good flexibility, the isocyanate chain segment endows the resin with good rubbing fastness, the aqueous polyurethane is used in ink to provide good adhesion between the ink and the fabric, and the ink is endowed with proper viscosity by combining the excellent flexibility and the solvent, so that the ink has good printing fluency.

Owner:珠海佳印数码科技有限公司

Waterproof dye-based ink for ink-jet printing and preparation method thereof

ActiveCN104845452AImprove waterproof performanceImprove light fastnessInksPolymer scienceAcrylic resin

The invention provides waterproof dye-based ink for ink-jet printing and a preparation method thereof. The waterproof dye-based ink for ink-jet printing is characterized by containing the following components according to mass percent: 5-20 percent of water soluble dye, 0.3-0.6 percent of modified polyurethane resin, 10-40 percent of acrylic resin, 3-5 percent of humectant, 0.1-1 percent of non-ionic surface active agent, 5-10 percent of diethylene glycol, 0.1-0.5 percent of preservative, 0.1-1 percent of pH modifiers and 30-70 percent of water. The waterproof dye-based ink for ink-jet printing and the preparation method thereof belong to the technical field of printing supplies; the waterproof dye-based ink has good waterproof, light resistant, scratching resistant and stability properties, and is low in production cost and good in environment benefit.

Owner:ZHUHAI TUOJIA TECH

Transparent photocuring ink for 3D ink-jetting printing and preparation method thereof

ActiveCN107459871AExcellent application performanceExcellent printing effectAdditive manufacturing apparatusInksPhotoinitiatorEngineering

The invention provides transparent photocuring ink for 3D ink-jetting printing and a preparation method thereof. The transparent photocuring ink for 3D ink-jetting printing comprises acrylate monomers, sulfhydryl compounds, surfactants, photoinitiators and assistants. The transparent photocuring ink for 3D ink-jetting printing has the advantage of capability of inhibiting proneness to yellowing, muddiness and obscurity of printed products.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Ink-jet ink and application thereof

InactiveCN105803827AGood printing fluencyHigh color fastnessDyeing processEnvironmental chemistryInkjet printing

The invention discloses ink-jet ink and application thereof.The ink-jet ink is prepared from, by mass, 3.0%-25.0% of organic dye, 1.0%-2.0% of a surfactant, 0.1%-1.0% of a color fixing agent, 10.0%-20.0% of humectant, 1.0%-10.0% of alkali, 0.1%-0.5% of an antibacterial agent and the balance deionized water, wherein the pH is 7.0-8.0.The ink-jet ink is applied to cellulosic fiber inkjet printing, and a fabric can be directly printed without being starched; the printing fluency is good, the color fastness rate is high, the ink storage stability is good, and wastewater is easy to treat.

Owner:SOUTH CHINA NORMAL UNIVERSITY

SEBS composite material used for 3D printing and preparation method thereof

The invention relates to a SEBS composite material used for 3D printing and a preparation method thereof. The SEBS composite material comprises the following raw materials by mass percentage: 20-30 parts of polypropylene, 10-30 parts of a thermoplastic elastomer SEBS, 10-20 parts of polystyrene, 10-40 parts of mineral oil, 0-3 parts of an anti-oxidant, and 0-3 parts of a fire retardant. The above raw materials are mixed through a high-speed kneader, a double screw extruder is used for extrusion and wire drawing. Compared with the prior, the material has the characteristic of low hardness, the weatherability and hear resistance of the material are improved, and the material is excellent on fluency and bonding property between material layers.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Flexible material suitable for 3D printed chest and abdomen fixing belt and preparation method of flexible material

InactiveCN107446339AReduce hardnessImprove toughnessAdditive manufacturing apparatusEngineeringBond properties

The invention relates to a flexible material suitable for a 3D printed chest and abdomen fixing belt and a preparation method of the flexible material. The flexible material is prepared by the following components and raw materials in parts by weight: 10-30 parts of polypropylene, 20-40 parts of thermoplastic polyurethane (TPU) elastomer rubber, 0-50 parts of mineral oil, 0-3 parts of an antioxidant and 0-3 parts of a coupling reagent ST-5; after the raw materials are mixed by a high-speed kneading machine, extrusion and wire drawing are performed by utilizing a single screw extruder. Compared with the prior art, the flexible material prepared by the preparation method provided by the invention has low hardness, high toughness and other excellent mechanical properties, the weather resistance and the heat resistance of the material are also improved, moreover, the flexible material is excellent in performance in print fluency and material interlayer bonding property.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Low-conductivity and high-temperature direct injection disperse dye ink and preparation method thereof

ActiveCN107675522AImprove light fastnessGood acid and alkali resistanceInksDyeing processDispersion stabilityDisperse dye

The invention discloses low-conductivity and high-temperature direct injection disperse dye ink and a preparation method thereof. The low-conductivity and high-temperature direct injection disperse dye ink is prepared from the following raw materials in parts by mass: 10 to 40 parts of high-temperature disperse dye, 10 to 40 parts of dispersing agent, 10 to 50 parts of organic solvent, 10 to 60 parts of water, 0.05 to 0.5 part of preservative and 0.01 to 0.05 part of defoaming agent, wherein the dispersing agent is a compound product of a special dispersing agent and a nonionic dispersant, andthe weight ratio of the special dispersing agent to the nonionic dispersant is (60 to 95) to (5 to 40). The preparation method comprises the following steps: mixing the high-temperature disperse dye,the dispersing agent, the water, the preservative and the defoaming agent to form a mixture; sanding and dispersing; carrying out nanofiltration on a sanded mixture; adding the organic solvent into obtained color paste, thus obtaining the high-temperature direct injection disperse dye ink. The low-conductivity and high-temperature direct injection disperse dye ink disclosed by the invention has the characteristics of high saturation, bright color and less salt precipitation; the conductivity is low and the service life of a spray head is prolonged; the ink has good dispersion stability and long storage time.

Owner:ZHEJIANG SHANYU TECH CO LTD

Waterborne active direct-jet printing ink applicable to Kyocera inkjet print head

ActiveCN107904987AGood standbyStable printing performanceDyeing processDigital printingPropylene glycol

The invention provides waterborne active direct-jet printing ink applicable to a Kyocera inkjet print head. The waterborne active direct-jet printing ink comprises, by weight percentage, 4-20% of salt-free active dye, 30-45% of ethylene glycol, 3-8% of propylene glycol, 0.5-1.5% of urea, 0-0.2% of pH regulator, 0.5-5% of penetrating agent, 0.05-2% of wetting agent, 0.1-0.3% of sterilizing agent, 0.05-0.5% of chelating agent and the balance deionized water. The waterborne active direct-jet printing ink which passes REACH and Intertek certification is good in smoothness and standby performance,stable in printing performance, capable of avoiding filamentous ink trailing and inclined jet, good in color stability and reducibility, capable of resisting water, scratching, sunlight and the like,capable of satisfying digital printing requirements, environmentally friendly, nontoxic, good in compatibility with the Kyocera inkjet print head and universally applicable to active direct-jet printing equipment using the Kyocera inkjet print head.

Owner:珠海东昌色彩科技有限公司

Preparation method of PP/SEBS suitable for rapid molding

InactiveCN107964205AReduce hardnessGood surface textureAdditive manufacturing apparatusThermoplastic elastomerHardness

The invention relates to a PP / SEBS composite material suitable for rapid molding, and a preparation method thereof. The PP / SEBS composite material is prepared from, by mass, 25-40 parts of polypropylene, 10-30 parts of thermoplastic elastomer SEBS, 10-40 parts of mineral oil, 0-2 parts of an antioxidant and 0-2 parts of a fire retardant. Above raw materials are mixed by a high-speed mixer, and theobtained mixture undergoes extrusion wire-drawing by a twin-screw extruder. Compared with materials in the prior art, the material prepared in the invention has the characteristics of low hardness, improved resistance to weather and heat, excellent printing smoothness and excellent interlayer cohesiveness.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Water-based digital ink jet dispersed ink and preparation method and application thereof

ActiveCN102229761BGood printing fluencyGood moisturizing effectInksDyeing processDisperse dyeWater based

The invention discloses water-based digital ink jet dispersed ink and a preparation method and application thereof. The formula of the ink comprises 5 to 15 percent of dispersed dye and 1 to 8 percent of electric conductance regulator. The preparation method comprises the following steps of: mixing a dispersant, the dispersed dye, partial water-soluble organic solvent and partial deionized water,and grinding the mixture to obtain color paste; and then adding the electric conductance regulator, a surfactant, an additive, the rest water-soluble organic solvent and the reset deionized water into the color paste, and stirring and filtering to obtain the ink. The ink has good printing smoothness and nozzle moisturizing performance, can be adaptive to code spraying machines of various models, has the advantages of bright color, light resistance, washing resistance, abrasion resistance, strong firmness and the like when printed on chemical blended fabrics, and is suitable for spraying production date, batch number, bar code, pictorial trade mark, false-proof mark and Chinese character of textiles and printing blanket patterns and the like.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

Crosslinkable reactive disperse dye compound and preparation and application thereof

The invention relates to a crosslinkable active disperse dye compound as well as a preparation method and application thereof. A structural formula of the disperse dye compound is one or more as shown in the specification. The preparation method of the crosslinkable active disperse dye compound comprises the following steps: preparing coupling components, carrying out diazotization and coupling reaction, wherein amino of aminoaniline-containing compounds in the synthesized compound structure is substituted by an active group which is 3-chloro-2-hydroxypropyl, and the substituent group can be formed into a crosslinkable epoxy ethyl active group under an alkaline condition. The crosslinkable active disperse dye compound is applied to inkjet ink. The crosslinkable active disperse dye compound is capable of printing on polyester fibers and cotton fibers at the same time, and prepared into inkjet ink for being applied to printing of blended fabrics such as polyester cotton, so that the defect that the cotton-polyester blended fabric paint is poor in hand feeling during printing, poor in washing fastness, long in mixed dye printing process flow and severe in mutual-staining of dyes is solved.

Owner:DONGHUA UNIV

Inkjet ink applicable to photo printing and preparation method thereof

ActiveCN109810560AImprove coloring performanceGood for anti-smudge performanceInksBoiling pointSpray nozzle

The invention discloses inkjet ink applicable to photo printing and a preparation method thereof. The inkjet ink is prepared from the following raw materials in percentage by weight: 20 to 40 percentof dyestuff color paste, 2 to 10 percent of a high-boiling-point solvent, 10 to 30 percent of a medium-boiling-point solvent, 1 to 5 percent of a low-boiling-point solvent, 0.2 to 3 percent of a surfactant, 0.1 to 0.2 percent of fungicide and 20 to 40 percent of de-ionized water, wherein the high-boiling-point solvent is a solvent with the boiling point which is greater than or equal to 250 DEG C;the medium-boiling-point solvent is a solvent with the boiling point which is greater than 120 DEG C and less than 250 DEG C; the low-boiling-point solvent is a solvent with the boiling point which is greater than 70 DEG C and less than or equal to 120 DEG C. With the adoption of the manner, the inkjet ink disclosed by the invention is matched with other raw materials by adopting a specific ratioand the solvents with different melting points; all the raw materials are cooperatively matched and the product ink can have good printing smoothness and does not block a spraying nozzle; the ink hasgood color representation on photo paper, does not have a color blending phenomenon and is applicable to the photo printing.

Owner:深圳市墨库图文技术有限公司

Water-based pigment digital inkjet textile printing ink and its preparation and use method

ActiveCN106567267BImprove washing fastnessImprove hydrophobicityDuplicating/marking methodsInksTextile printerWater based

The invention provides a water-based pigment digital ink-jet textile printing ink and preparation and use methods thereof. The water-based pigment digital ink-jet textile printing ink is characterized by containing a pigment color paste, a nano composite adhesive and deionized water, wherein the nano composite adhesive comprises a polyurethane emulsion, an organic fluorine modified polyacrylate nano emulsion and another polyacrylate emulsion. With use of the nano composite adhesive, the problem of low water washing fastness of a water-based pigment ink-jet printing ink on a printing fabric is solved emphatically, and a new solution is provided for industrialized application of the water-based pigment ink-jet printing ink in the field of fabric digital ink-jet printing.

Owner:上海英威喷墨科技有限公司

Ultraviolet-curing water-based inkjet ink

The invention discloses ultraviolet-curing water-based inkjet ink. The ultraviolet-curing water-based inkjet ink at least comprises the following components in percentage by weight: 1%-12% of nanometer pigment / water-soluble pigment, 1%-5% of dispersing agent, 1%-15% of UV (Ultraviolet)-curing modified polyurethane resin emulsion (solid content), 1%-10% of photoinitiators, 20%-50% of reactive diluents, 5%-25% of humectants, 5%-15% of penetrating agents, 0%-2% of surfactants, 0%-2% of pH regulators, 0.1%-0.5% of sterilization preservative, and the balance of deionized water. The ultraviolet-curing water-based inkjet ink is characterized in that the ink has excellent storage stability and printing fluency; the ink has excellent performances including water resistance, light resistance, solvent resistance, scratch resistance, ageing resistance, high-low temperature resistance, high brightness, good adhesive strength and quick curing speed, is suitable for various printers to print various uncoated and nonprinting coating media, hydrophobic and oily media, and is wide in application area.

Owner:NANJING CHEMBRIDGE TECH MATERIAL

Low-hardness material used for 3D printing and preparation method thereof

InactiveCN106467650AReduce hardnessGood surface textureAdditive manufacturing apparatusThermoplastic elastomerHeat resistance

The invention relates to a low-hardness material used for 3D printing and a preparation method thereof. The low-hardness material comprises the following raw materials by mass percentage: 20-40 parts of polypropylene, 30-40 parts of a thermoplastic elastomer SEBS, 30-40 parts of mineral oil, and 0-3 parts of an anti-oxidant. The above raw materials are mixed through a high speed kneader, and a mixture is subjected to extrusion and wire drawing by using a double screw extruder to obtain the product. compared with the prior art, the produced material has the characteristic of low hardness, improves weatherability and heat resistance of the material, and has excellent performance on printing fluency and material layer interlayer bonding.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com