Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Improve sun resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

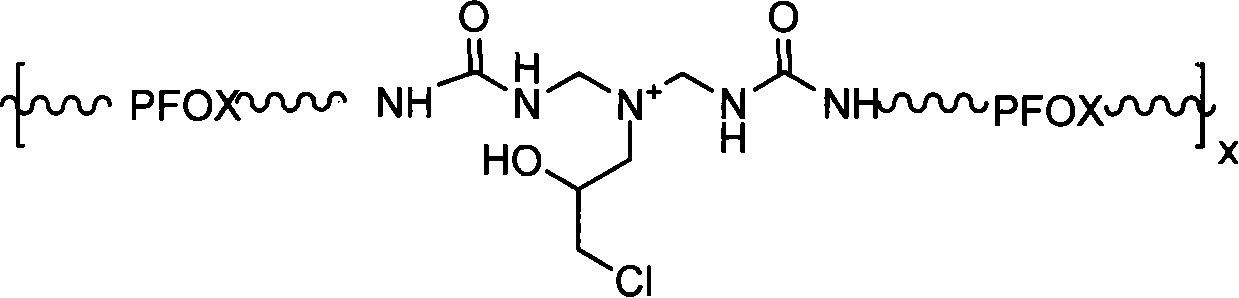

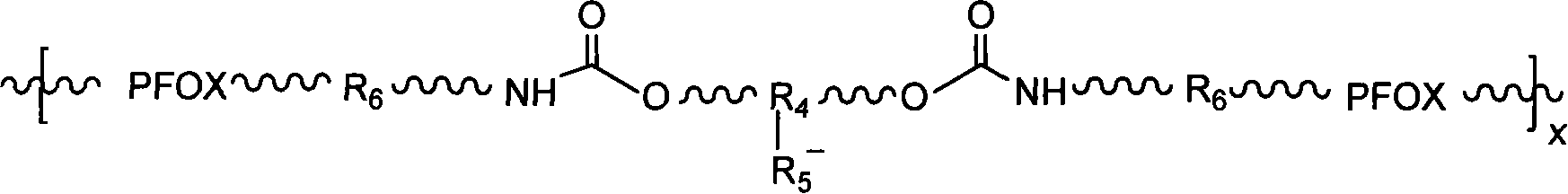

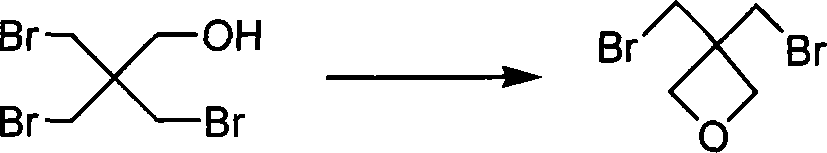

Fluorine-containing aqueous polyurethane and preparation method and application thereof

InactiveCN101041709AIncreased durabilityImprove waterproof performanceAntifouling/underwater paintsOther chemical processesGreen environmentFluorine containing

The invention discloses a making method and application of aqueous fluorine polyurethane, which contains cationic and anionic aqueous fluorine polyurethane with the making procedure comprises the following steps: (1) synthesizing bromoepoxybutane; (2) making fluoepoxybutane; (3) preparing fluorine polyether; (4) synthesizing aqueous polyurethane. The invention can be high-property green environment-protective water repellency, waterproof and stainproof paint, which possesses wide market prospect.

Owner:DONGHUA UNIV

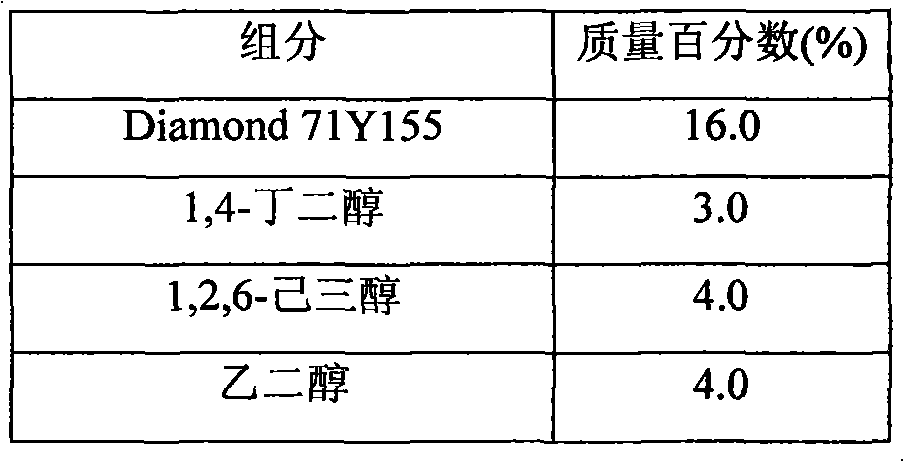

Water-based pigment type ink for absorbent base material spray ink printing, preparation and printing methods thereof

ActiveCN101993633AImprove versatilityGood printing fluencyInksPrinting after-treatmentWater basedEmulsion

The invention relates to a water-based pigment type ink for absorbent base material spray ink printing and a preparation method and a printing method thereof. The ink comprises the following components in percentage by mass: 2 to 15 percent of pigment, 0.1 to 3.0 percent of surfactant, 2 to 20 percent of water-soluble cosolvent, 0.1 to 10 percent of film-forming aid, 5 to 35 percent of polyacrylate emulsion and 1 to 12 percent of dispersing agent and deionized water. The preparation method comprises the following steps of: (1) adding the dispersing agent and partial water-soluble cosolvent into the deionized water, emulsifying, adding the pigment, dispersing, grinding and obtaining dispersion of the pigment; and (2) stirring and uniformly mixing the surfactant, the film-forming aid and the residual water-soluble cosolvent, adding water-based polyacrylate emulsion, stirring, adding the dispersion of the pigment, stirring, filtering and obtaining the ink. The ink does not produce toxic volatile matters, is high in universality, makes printing smooth and achieves high picture precision. Meanwhile, the printed picture has excellent sunshine resistance, washing resistance, friction resistance and high fastness, and is suitable for indoor and outdoor use.

Owner:上海英威喷墨科技有限公司 +1

Solvent type disperse dye ink-jet printing ink and preparation method thereof

The invention provides a solvent type disperse dye ink-jet printing ink and a preparation method thereof. The ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dye, 1 to 15 percent of dispersant, 0.5 to 15 percent of resin and 60 to 95 percent of organic solvent. The preparation method comprises the following steps of: adding 1 to 15 percent of dispersant and 0 to 10 percent of resin into the organic solvent, and emulsifying the mixture for 20 to 60min, adding 1 to 8 percent of dye into the mixture, grinding the mixture for 8 to 40h, and obtaining a disperse dye color paste; and adding 10 to 80 percent of disperse dye color paste and 0 to 10 percent of resin into the organic solvent, and filtering the mixture with a millipore filter between 0.2 and 2 mu m to obtain the solvent type disperse dye ink-jet printing ink. The ink has the advantages of good printing smoothness, bright lustre of patterns, and excellent sunlight fastness, washing fastness and rub resistance, and can be widely applied to multiple kinds of wide, high-speed and solvent type digital printing equipment; and the preparation method is simple and practical.

Owner:DONGHUA UNIV +1

Preparation method for transference resistance leather dye

InactiveCN102746714ADye performance is stableExcellent migration resistanceOrganic dyesDyeing processIsocyanate compoundDyeing

The present invention discloses a preparation method for a transference resistance leather dye, wherein an active group-containing dye, an anti-yellowing isocyanate compound, a hydroxyl group-containing polymer, a compound containing a hydroxyl group and a hydrophilic functional group, a chain extender, and the like are subjected to polymerization to obtain a product of the present invention. The dye prepared by the method of the present invention has the following advantages that: performance is stable, and transference resistance of products dyed by the dye is excellent. The method of the present invention has advantages of simple synthetic route, molecular weight adjusting, easy functionality control, and the like. The dye prepared by the method of the present invention can be used for leather dyeing, and colorant components in leather coating and synthetic leather coating.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

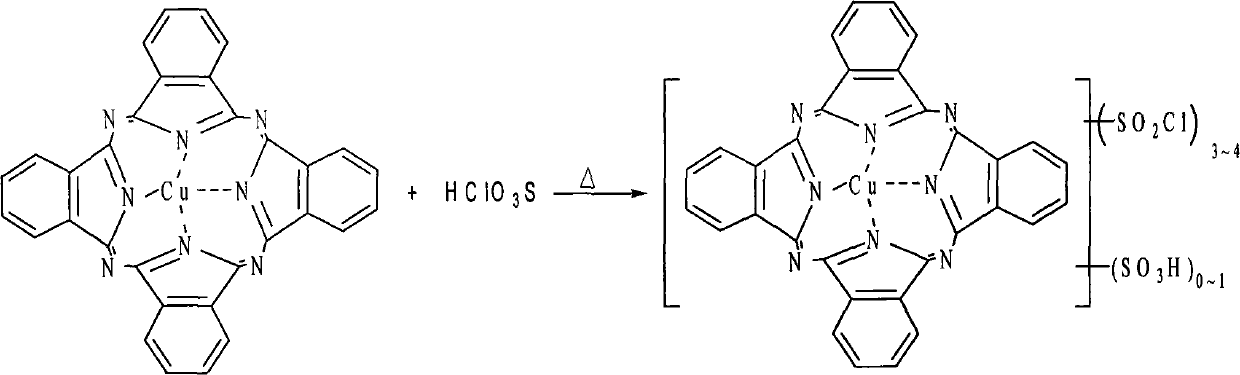

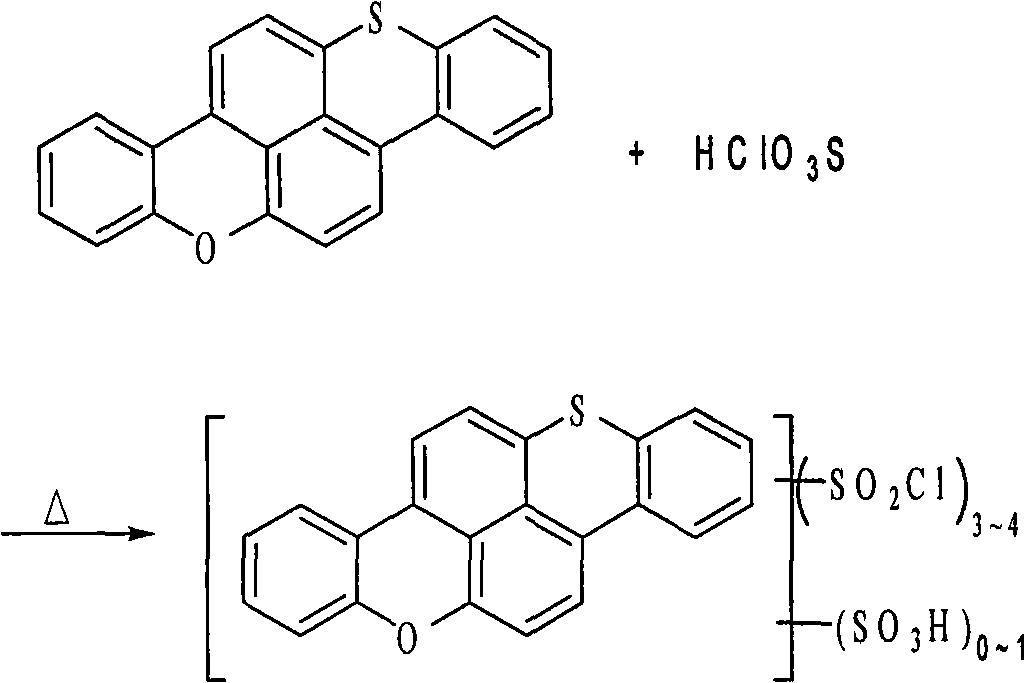

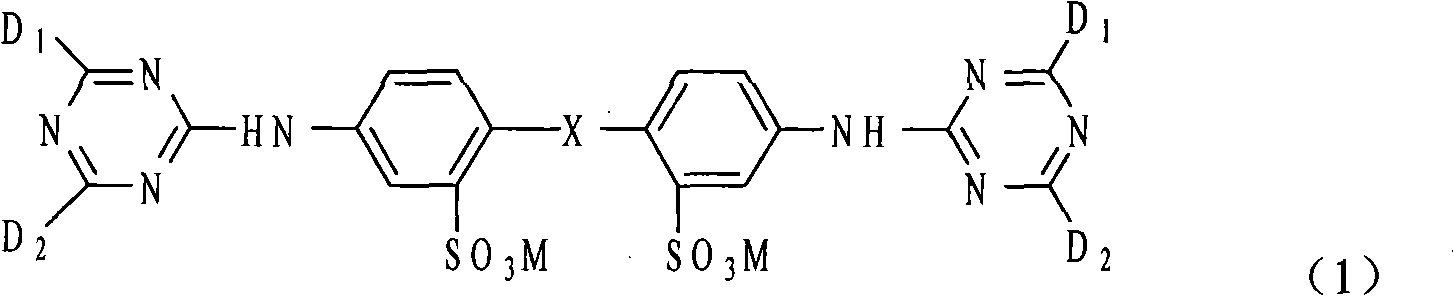

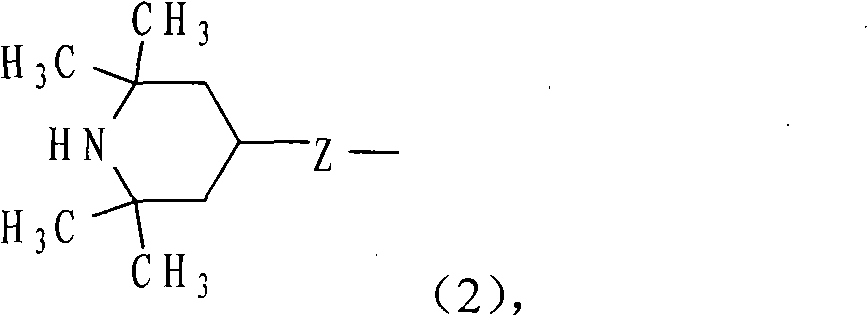

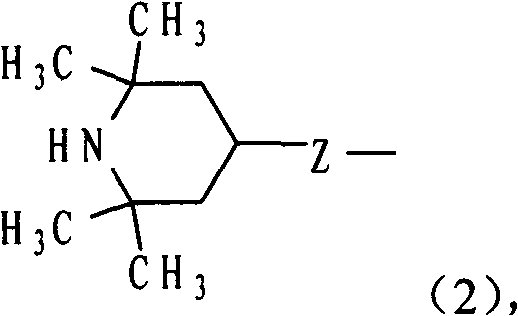

Sunproof water-soluble dye, method for preparing same and application thereof

InactiveCN101864188AImprove light fastnessHigh coloring rateInksPaper/cardboardSolubilityPhthalocyanine dye

The invention relates to sunproof water-soluble dye having the general formula (1), a method for preparing the same and application thereof. The sunproof water-soluble dye imports the group of hindered amine 4-Z-2,2,6,6-tetramethylpiperidine and the water-soluble group of sulfonic groups based on the common water-insoluble dye, so that under a condition of ensuring good water solubility of the dye, the light stability of the dye is improved, and the sunproof property of the dye is also improved. In a general formula(1), A represents a dye matrix selected from a group formed by dioxazine dye, anthraquinone dye and phthalocyanine dye which are water-insoluble; R1 represents a general formula(2): -(SO2-R)m(2); R2 represents a general formula(3): -(SO3H)n(3); in the general formula(2) and the general formula(3), m and n are both a natural number, preferably m is a natural number between 1 and 16, and n is a natural number between 0 and 2.

Owner:上海汇友精密化学品有限公司

Preparation method of cold black suiting

InactiveCN102618992AAvoid damageImprove insulation effectFibre treatmentDyeing processColour fastnessPolyester

The invention relates to a preparation method of cold black suiting. In the suiting, 52% of polyester fiber and 48% of polyester fiber by weight are used as raw materials; and the suiting is prepared by top dyeing and recombing, spinning, weaving and after-treatment. The method comprises the following steps of: before dyeing wool, performing pretreatment on wool; adjusting the pH value with alkali to adjust the wool to a neutral state; dyeing, wherein the dye adopts a Nylosan dyeing agent produced by the Clariant cooperation, the dyeing is started at 40 DEG C, and the temperature is increased to 100 DEGE C and kept for 60 minutes before after-treatment; performing cold black auxiliary treatment on the dyed wool, wherein the cold black auxiliary is the CWF cold black auxiliary produced by the Clariant cooperation; performing a dip dyeing technology, heating to 100 DEG C, and treating for 45-55 minutes at the temperature; and cleaning with an efficient cleaning agent ND-9 produced by the Nigeria Mita Auxiliaries Co., Ltd., Jiangyin. Through the invention, the prepared cold black suiting has good color fastness and low ultraviolet transmittance and is cool and suitable for summer.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

Latex-type waterborne pigment oil ink for inkjet printing of non-absorbed substrate as well as preparation method and applications thereof

ActiveCN101899237AGood printing fluencyHigh precisionInksOther printing apparatusWater basedWater soluble

The invention relates to latex-type waterborne pigment oil ink for the inkjet printing of a non-absorbed substrate, which is prepared from the following components in percentage by weight: 1-15 percent of pigment dispersant, 0.01-2.0 percent of surface active agent, 10-40 percent of water-soluble co-solvent, 0.1-30 percent of water-based polymer emulsion and the balance of deionized water. The preparation method comprises the following steps of: stirring and mixing the surface active agent, the water-soluble co-solvent and the deionized water under a normal temperature; then, slowly adding the waterborne polymer emulsion, continuously stirring; and finally, adding the pigment dispersant, fully mixing the contents to form an even dispersing system and filtering the even dispersing system to obtain latex-type waterborne pigment oil ink. The latex-type waterborne pigment oil ink for the inkjet printing has wide range of suitable substrates, is environment-friendly in the oil ink preparation process and the printing process and has good printing smoothness and high accuracy; and printed images on the non-absorbed substrate have excellent resistance to rubbing, scraping, sunshine and water and are suitable for outdoor use.

Owner:上海英威喷墨科技有限公司 +1

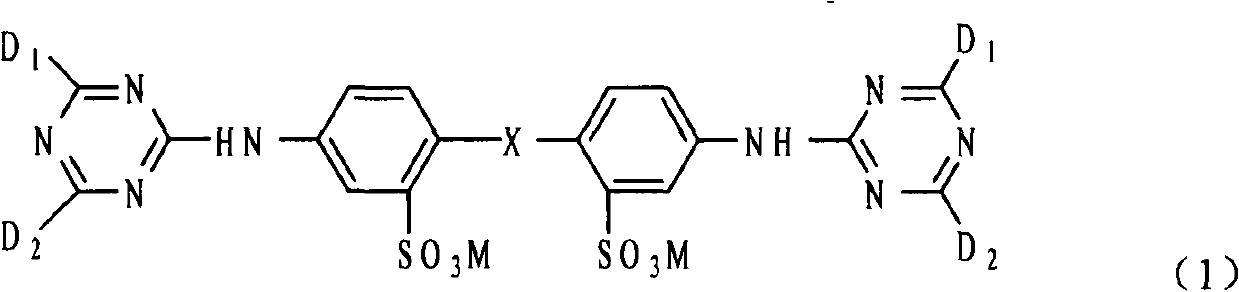

Weather-resistant azo-dyes, preparation and use thereof

InactiveCN101280118ADyeing speed is fastHigh dyeing rateAzo dye preparationMonoazo dyesEnergy transferHindered amine light stabilizers

The invention relates to a weather-resistant azo dye with the following general formula (I) and the preparation method and application. The invention introduces chlorinated triazine groups based on common azo dyes and then after a series of condensation reactions, a novel azo dye is obtained. The azo dye contains multiple chromogenic groups, wherein, hindered amine can absorb the infrared; DSD acid (that is, 4,4'-diaminostilbene-2,2'-disulfonic acid) can absorb the ultraviolet rays; therefore, the azo dye has good light-resistant and weather-resistant properties and can be used alone or with other dyes; the azo dye can be used in textiles, paper, leather, wood, ink-jet printing ink and other aspects, which is also a good energy transfer agent. As a result of a variety of functional groups, the azo dye of the invention has better weather-resistant performance than common azo dyes.

Owner:上海汇友精密化学品有限公司

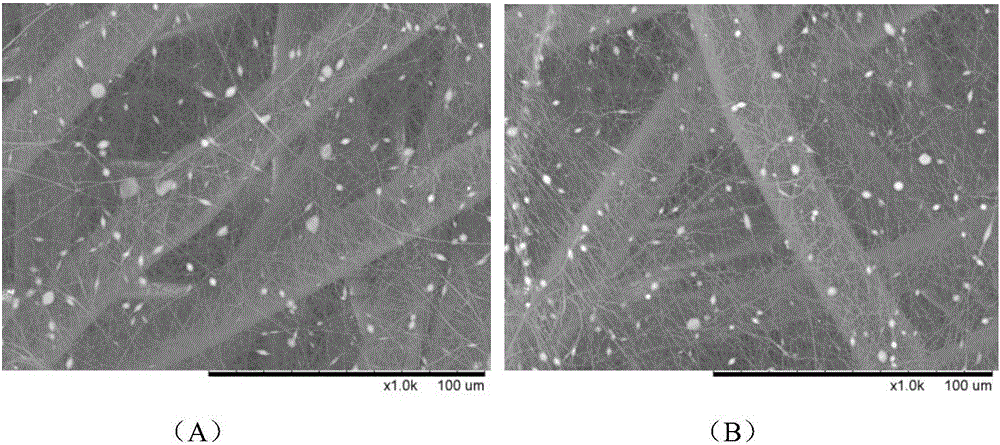

Preparation method of TiO2/PAN nanofiber membrane

InactiveCN108251970AEasy to operateLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsPolymer solutionHigh pressure

The invention discloses a preparation method of a TiO2 / PAN nanofiber membrane. The method comprises the specific preparation steps that polyacrylonitrile powder is dissolved to obtain a polymer solution; TiO2 nanocrystals are dispersed in the polymer solution to obtain a spinning solution; the spinning solution is sucked into a syringe, the syringe is fixed on an injection pump of electrospinningequipment, a spinneret is connected to a positive electrode of a high-voltage power supply at the same time, a receiving plate is connected to a negative electrode of the high-voltage power supply andcovered with aluminum foil, and electrospinning is conducted to obtain the TiO2 / PAN nanofiber membrane. The preparation method is easy to operate, short in process flow and suitable for wide popularization and application, and meanwhile further has excellent catalytic and mechanical properties and broad application prospects.

Owner:SUZHOU UNIV

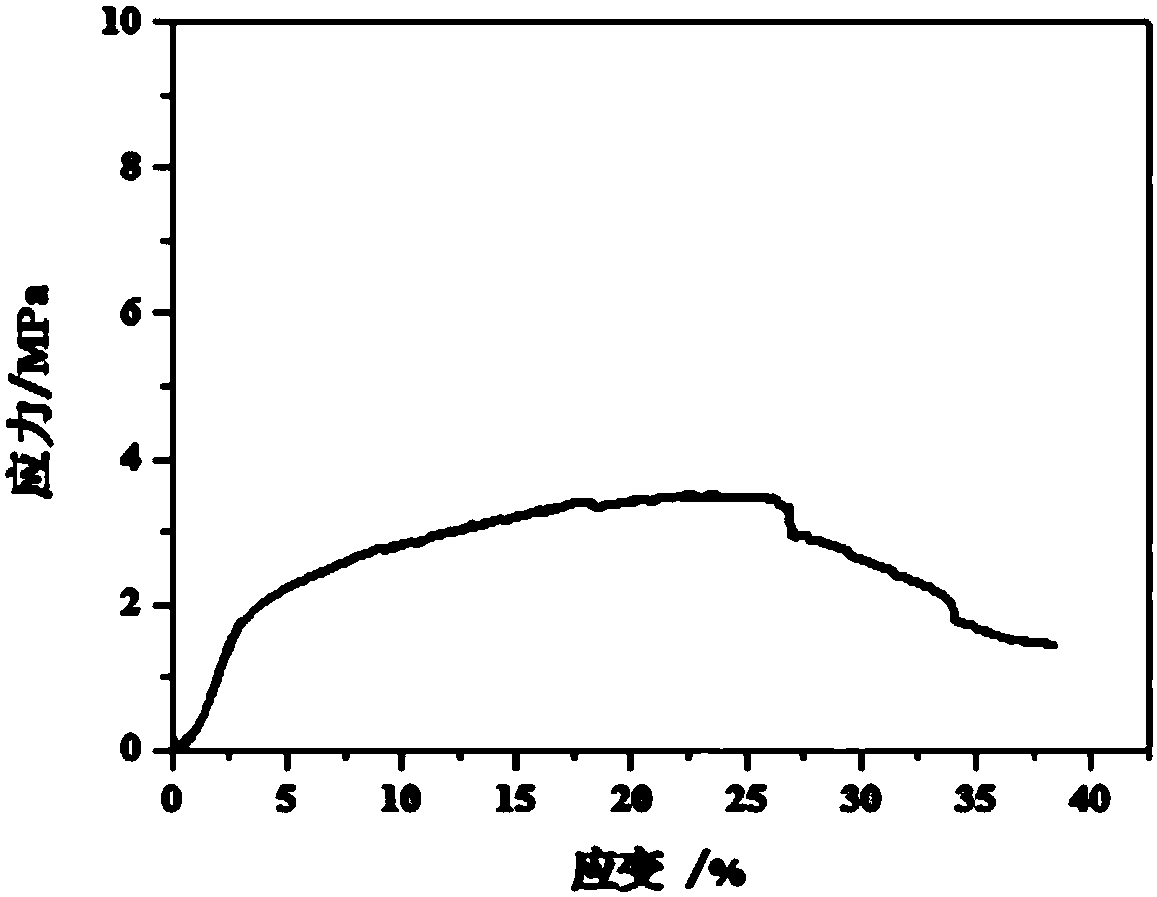

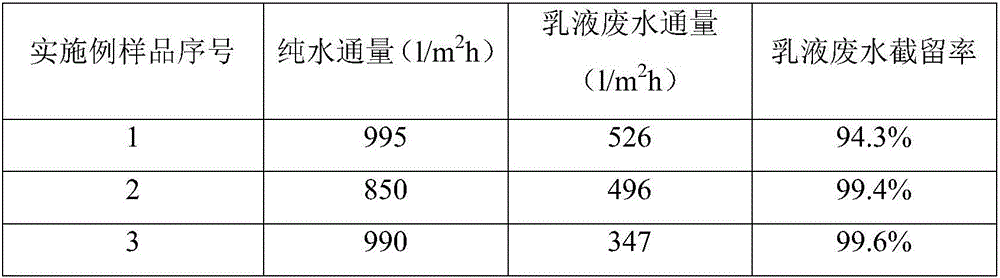

Nanofiber membrane capable of filtering out impurities and preparation method and application thereof

InactiveCN105803678AStable mechanical propertiesAvoid breakingElectro-spinningNon-woven fabricsParticulatesAir filter

The invention discloses a nanofiber membrane capable of filtering out impurities. The nanofiber membrane comprises a substrate and a nanofiber layer located on the receiving substrate; the diameter of the nanofiber layer ranges from 100 nm to 1000 nm, and the gram weight is 1-15 g / m<2>; the nanofiber layer is made of a high-molecular polymer material. In addition, the invention further discloses a preparation method of the nanofiber membrane, wherein a needle electrostatic spinning or linear electrostatic spinning or helical blade electrostatic spinning technology is adopted, electrostatic spinning process parameters and environmental conditions are adjusted, and the nanofiber membrane which filters out impurities in air and water efficiently can be prepared efficiently. Furthermore, the invention discloses application of the nanofiber membrane to air filtering products and water filtering products. The nanofiber membrane has the filtering efficiency of as high as 90% or above when used for filtering particles in air, air resistance is only 30-60 Pa, and the nanofiber membrane has the advantages of being high in flux and high in retention rate for pollution sources such as waste water.

Owner:スンナテクノロジーズシャンハイカンパニーリミテッド

Triazine type azo dye and preparation method thereof

InactiveCN103305023ADyeing speed is fastHigh dyeing rateStyryl dyesMethine/polymethine dyesWeather resistanceHindered amine light stabilizers

The invention relates to a triazine type azo dye with the general formula (I) shown in the specification and a preparation method of the azo dye. A novel azo dye is obtained by introducing a chloro-s-triazine group into a general monoazo dye and performing a series of condensation reaction. The azo dye comprises a plurality of color-development groups, wherein the contained hindered amine is capable of adsorbing infrared, the DSD acid (namely 4,4'-diamino stilbestrol-2,2'-disulfonic acid) is capable of adsorbing the ultraviolet in the sunlight, and the azo dye is provided with good illumination resistance and sunshine resistance, can be singly or together used with other dyes, and can be applied to the aspects of textile, paper, leather, wood, ink-jet printing ink, and oil ink. The azo dye is a good energy transfer. By containing a plurality of functional groups, the azo dye provided by the invention has more excellent weather resistance than that of a general azo dye.

Owner:上海汇友精密化学品有限公司

Manufacturing method for microfiber suedette for top-grade automobile interior trim

InactiveCN106012579AImprove sun resistanceAvoid emissionsSucessive textile treatmentsVehicle componentsWater basedThree level

The invention discloses a manufacturing method for microfiber suedette for top-grade automobile interior trim. The method includes the steps of material selection, fuzzing, processing before dyeing, dyeing, sanding and dipping in insolation-resistant auxiliaries, so that a finished product is obtained. Due to the fact that water-based PU resin which is high in insolation and extremely good in environmental protection is adopted, the insolation-resistant effect of the resin is improved, no organic solvent is contained, the microfiber suedette can be prevented from emitting poisonous gas, and the process is simple, concise, easy to operate and environmentally friendly and saves more energy. Through dipping of the insolation-resistant auxiliaries in the later period, the fiber insolation-resistant fastness is improved by three levels or more, the fiber insolation-resistant fastness of the finished microfiber suedette reaches the fifth level to the sixth level, and the requirement for automobile interior trim is met. Through continuous grinding of base cloth and a semi-finished product, the cloth cover is more fine and smooth, the writing effect is obvious, and the chamois leather feeling is higher. Large-scale production of the microfiber suedette can be achieved, and the price of the microfiber suedette is 50% lower than that of foreign products. The microfiber suedette for interior trim is low in cost, free of emission of poisonous gas, resistant to insolation, simple in manufacturing process, low in cost and capable of being produced on a large scale.

Owner:昌邑誉华纺织材料有限公司

Raw color matching yarn and preparation technology thereof

ActiveCN109112655AReduce pollution damageReduce manufacturing costSpinnerette packsPigment addition to spinning solutionYarnSkin color

The invention relates to a raw color matching yarn and a preparation technology thereof. The raw color matching yarn is characterized in that one beam of composite yarn which is formed by melt-spinning contains two or more types of raw color fiber with different colors; each raw color fiber is a single yarn in a single color. The preparation technology comprises the following steps of metering melts of different colors by different metering pumps, enabling the melts to enter distribution plates through different melt flow passages, and enabling the distribution plates to distribute the melts into different yarn spraying holes. The raw color matching yarn has the advantages that multiple types of raw color yarns of which the colors are difficult to distinguish by naked eyes are prepared into the composite yarn by melt-spinning, so as to obtain the single-color fiber with a uniform macrostructure, the appearance of strip dyeing or piece dyeing type single-color fiber is realized, and theexistence of multiple colors in the fiber cannot be distinguished under the near-distance observation condition; the layering feel is fine, and the vision style is particular.

Owner:高君超

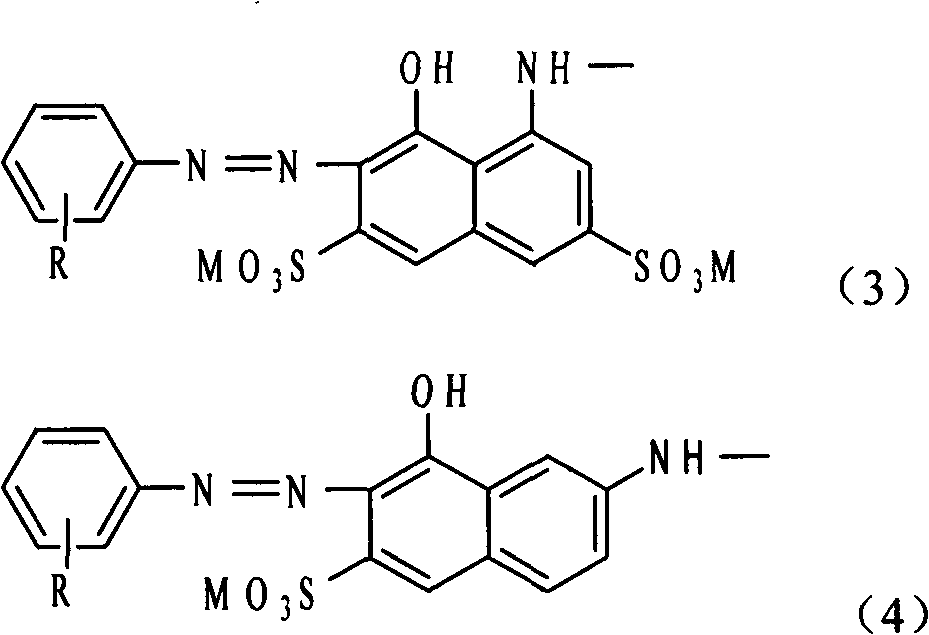

Novel reactive blue dye and preparation method thereof

ActiveCN104672949ABright colorDark colorOrganic chemistryOrganic compound preparationPolyamideCellulose fiber

The invention discloses a novel reactive blue dye and a preparation method of the novel reactive blue dye. The preparation method of the compound comprises the following steps: performing condensation on cyanuric chloride and 2-[2-(4-aminobenzenesul fonamide) ethyl sulfuryl] ethoxyl-sulphating compound and then performing secondary condensation on an obtained condensation compound and 2,4-diaminobenzenesulfonic acid; reducing the temperature of the condensate and performing diazotization; performing acid coupling on the condensate and H acid; then performing alkali coupling on the condensate and diazonium salt of sodium sulfamate or 2,5-disulfonic acid-phenylamine; spraying and drying to obtain a semi-finished product. The reactive blue dye has the characteristics of bright and deep color, high dissoluvability, high compatibility, high elevating power, high fixation rate, high firmness degree of all items and the like; the dye is suitable for coloring, printing and pad-dyeing of cellulosic fibers, protein fibers, viscose fibers and polyamide, and the color fasteness to sunlight and the fastness to rubbing of the novel reactive blue dye are 0.5-1 grade more than those of the general varieties.

Owner:TAIXING JINYUN DYESTUFF

Plant based light fastness improving agent and preparation method and application thereof

The invention provides a plant based light fastness improving agent and a preparation method and application thereof. The plant based light fastness improving agent is prepared form the following rawmaterials in parts by weight: 0.5-3 parts of scutellaria baicalensis extract, 1.5-3 parts of turmeric extract, 2-5 parts of sophora flower bud extract, 2-10 parts of mango leaf extract, 1-4 parts of pineapple leaf extract and 1-8 parts of cholla stem extract. The scutellaria baicalensis extract is a water extract of scutellaria roots; the turmeric extract is a water extract of a turmeric rhizome;the sophora flower bud extract is a water extract of an acacia flower; the cholla stem extract is a water extract of cholla stem roots; the pineapple leaf extract is an acetone extract of pineapple leaves; and the mango leaf extract is an extract of mango leaves in an ethanol water solution. The plant based light fastness improving agent penetrates into cotton fabrics under the action of ultrasonic wave, and fabrics with good light fastness are obtained.

Owner:LUOLAI LIFESTYLE TECH CO LTD +2

Ultraviolet-resistant luminescence textile fabric dye liquor

InactiveCN102330360AImprove sun resistanceImproves UV resistanceFibre treatmentDyeing processCelluloseFluorescence

The invention discloses an ultraviolet-resistant luminescence textile fabric dye solution. Each liter of dye solution is prepared from the following components by gram: 15-60 grams of luminescence pigment printing paste, 15-40 grams of anti-ultraviolet light agent, 5-25 grams of caster oil polyoxyethylene ether, 10-35 grams of undecyl imidazoline, 10-35 grams of hydroxymethyl cellulose, 10-20 grams of polyurethane, 4-30 grams of maleopimaricacid, and 10-100 grams of water.

Owner:WUJIANG ZHENGMING TEXTILE

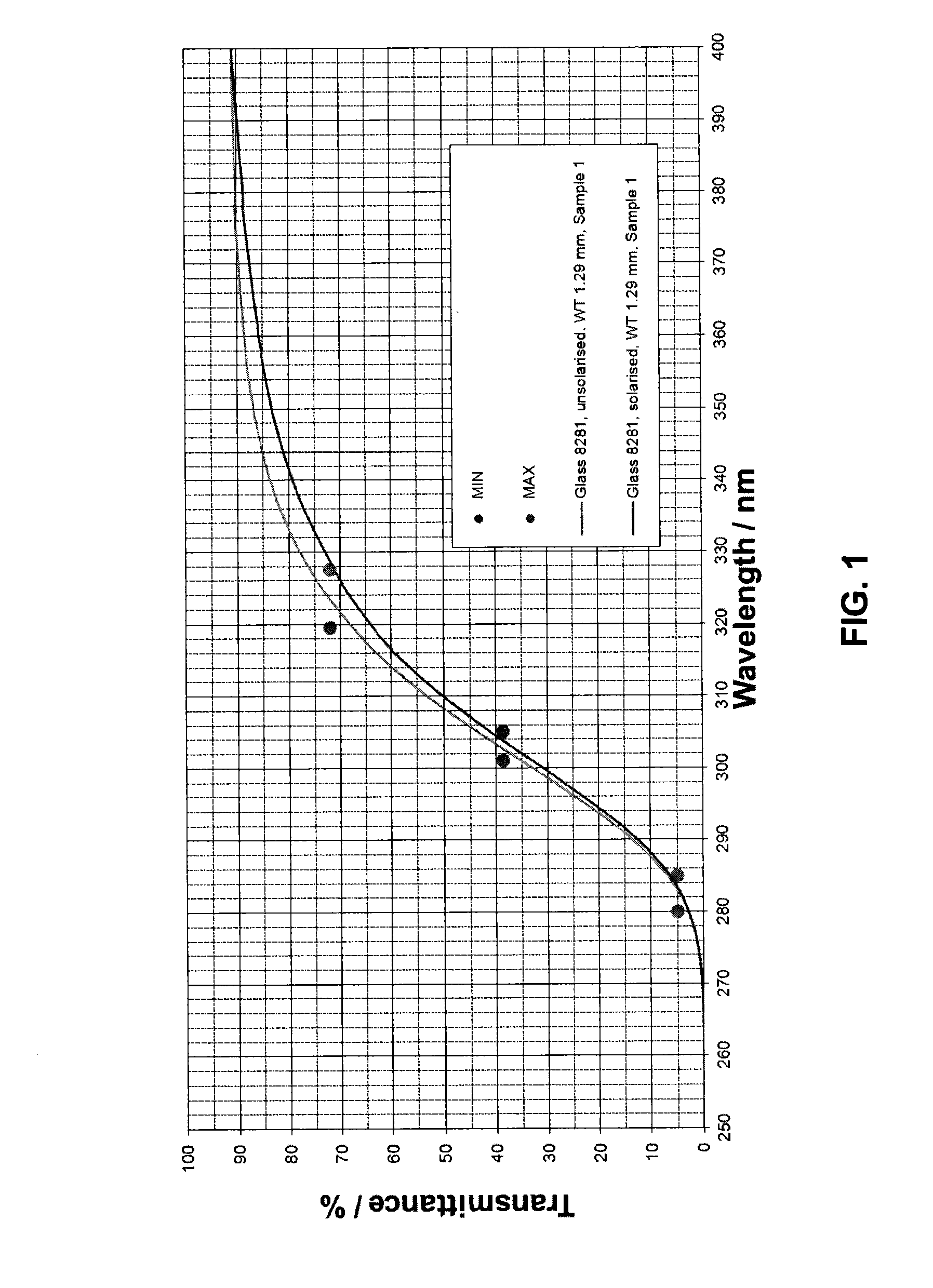

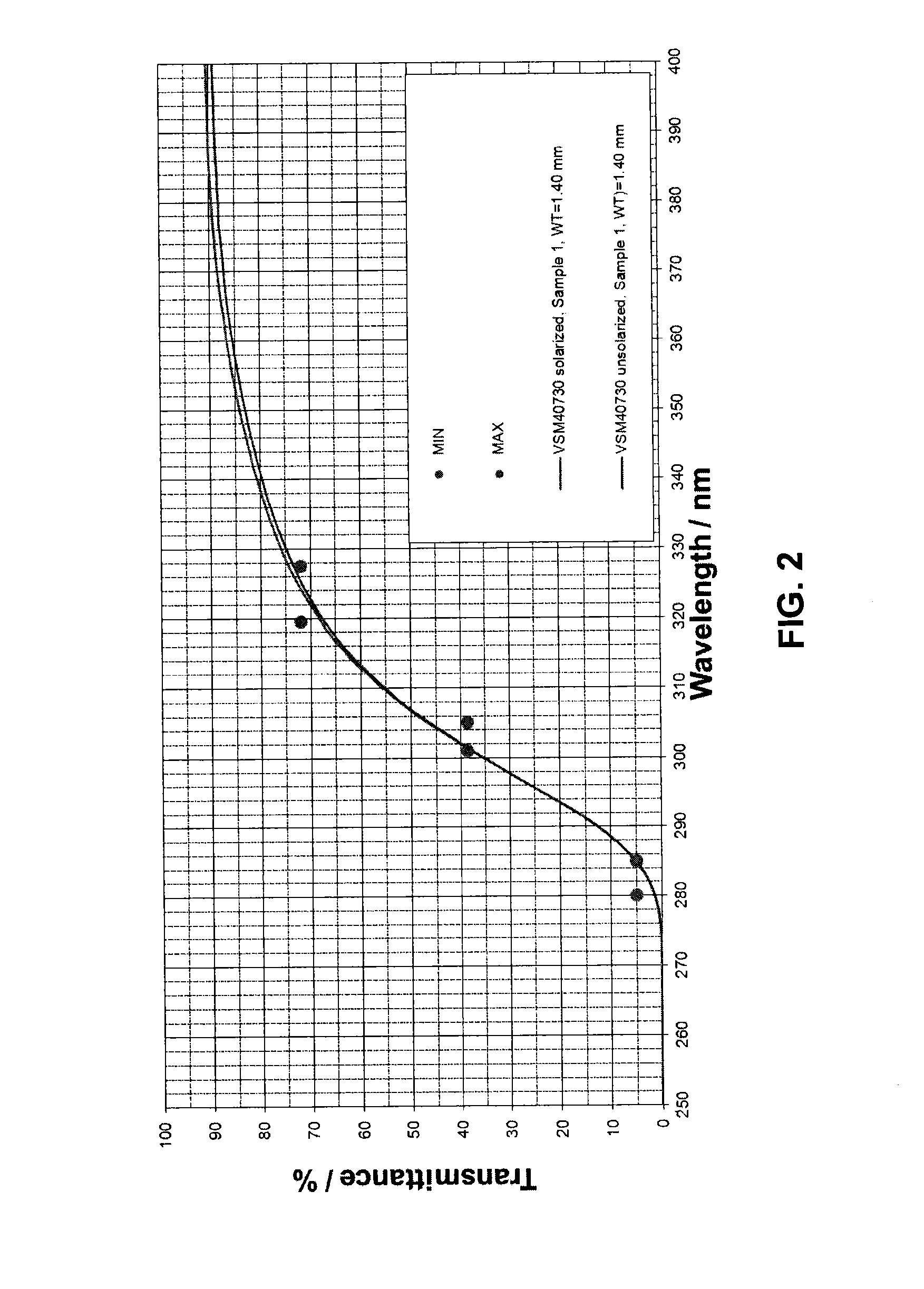

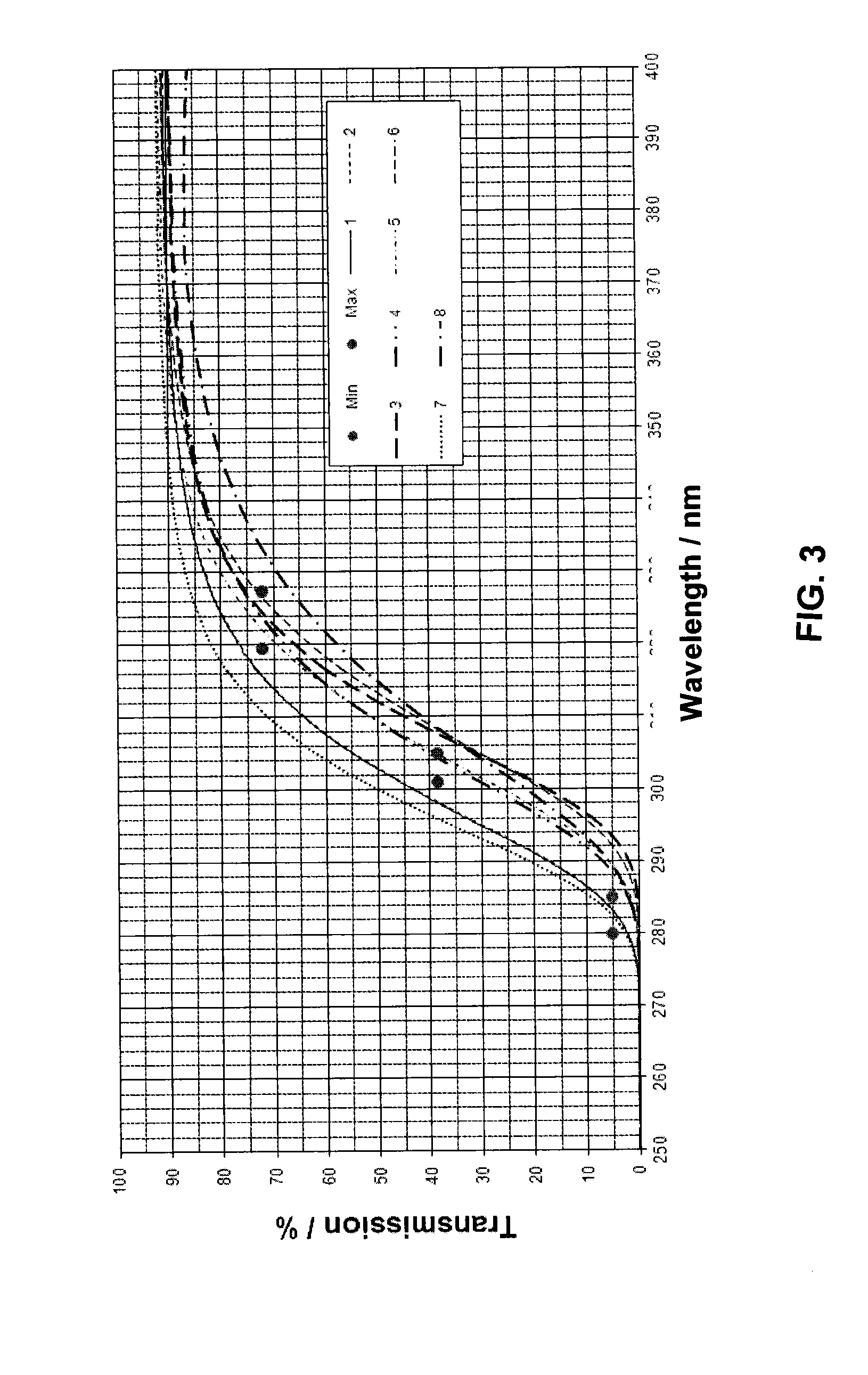

Solarization-resistant borosilicate glass and use thereof for production of glass tubes and lamps and in irradiation units

ActiveUS20140117294A1Improve sun resistanceReduction factorGlobesSpectral modifiersSilicate glassIrradiation

A borosilicate glass is provided that has high solarization resistance and a defined position of the UV edge. The borosilicate glass includes the following constituents, in percent by weight based on oxide, of:SiO2 65-85%;B2O3 7-20%;Al2O3 0-7%;Li2O 0-2%;Na2O 0-8%;K2O 0-12%;BaO 0-5%;CaO 0-2%;MgO 0-2%;ZnO 0-2%;TiO2 0.05-0.4%;MoO3 0.025-0.3%; andV2O5 0.001-0.01%.

Owner:SCHOTT AG

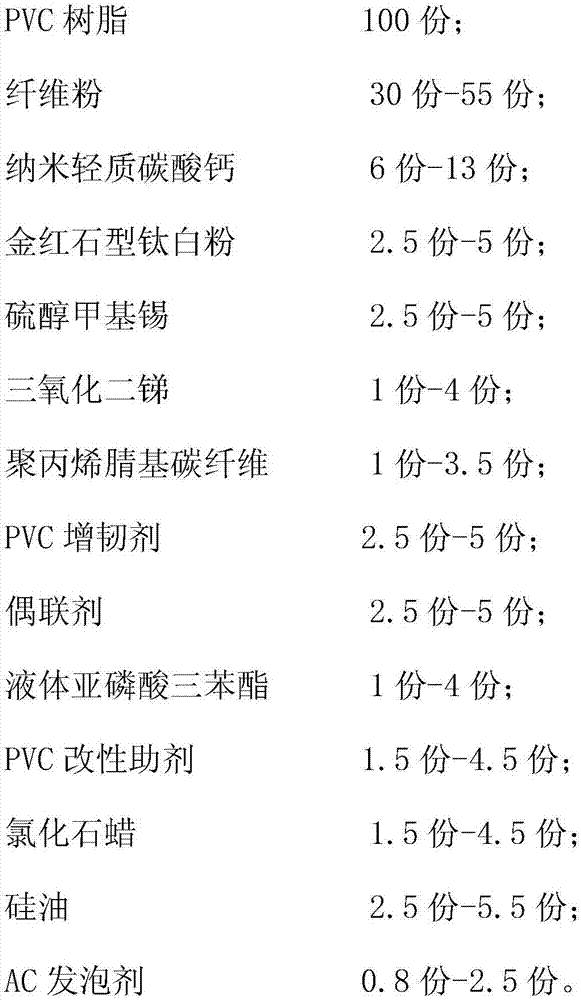

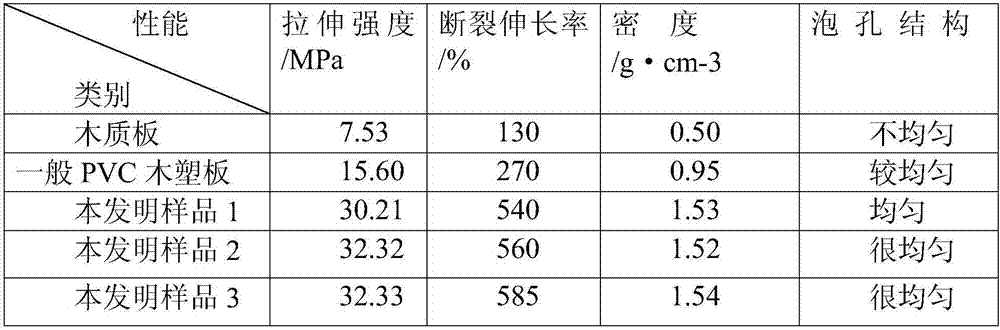

High-toughness flame-retardant foamed PVC wood-plastic board and preparation method thereof

InactiveCN107099103ADoes not affect curing speedDoes not affect molding speedCarbon fibersChlorinated paraffins

The invention discloses a high-toughness flame-retardant foamed PVC wood-plastic board. The high-toughness flame-retardant foamed PVC wood-plastic board comprises PVC resin, fiber powder, nanometer light calcium carbonate, rutile titanium dioxide, methyltin mercaptide, antimony trioxide, polyacrylonitrile-based carbon fibers, a PVC flexibilizer, a coupling agent, liquid triphenyl phosphite, a PVC modification aid, chlorinated paraffin, silicone oil and an AC foaming agent. The invention also discloses a preparation method for the PVC wood-plastic board. The preparation method for PVC wood-plastic board in the invention is simple in process and easy to operate; and the prepared PVC wood-plastic board has a plurality of advantages like good thermal stability, good ageing resistance, good anti-oxidizability, good impact resistance, good wear resistance, good insulating properties and good flame resistance.

Owner:程艳青

Active yellow dye and preparation and application thereof

The invention discloses an active yellow dye and preparation and application thereof. The active yellow dye has a structure shown in formula (I). The active yellow dye has the advantages that the structure of monomer compound is novel, the property is excellent, the color fixation rate is good, and the color fastness rate is high; the stability is realized, the washing-resistant, abrasion-resistant and sun exposure-resistant property are good, and the binding stability with fibers is good; during dyeing, the usage amount of water is reduced, the dying duration is short, the consumption of energy sources is decreased, and the usage amount of salt is reduced; a finished product has excellent colorful degree, the production cost is low, and the active yellow dye can be popularized and applied in a large scale way.

Owner:TAIXING JINYUN DYESTUFF

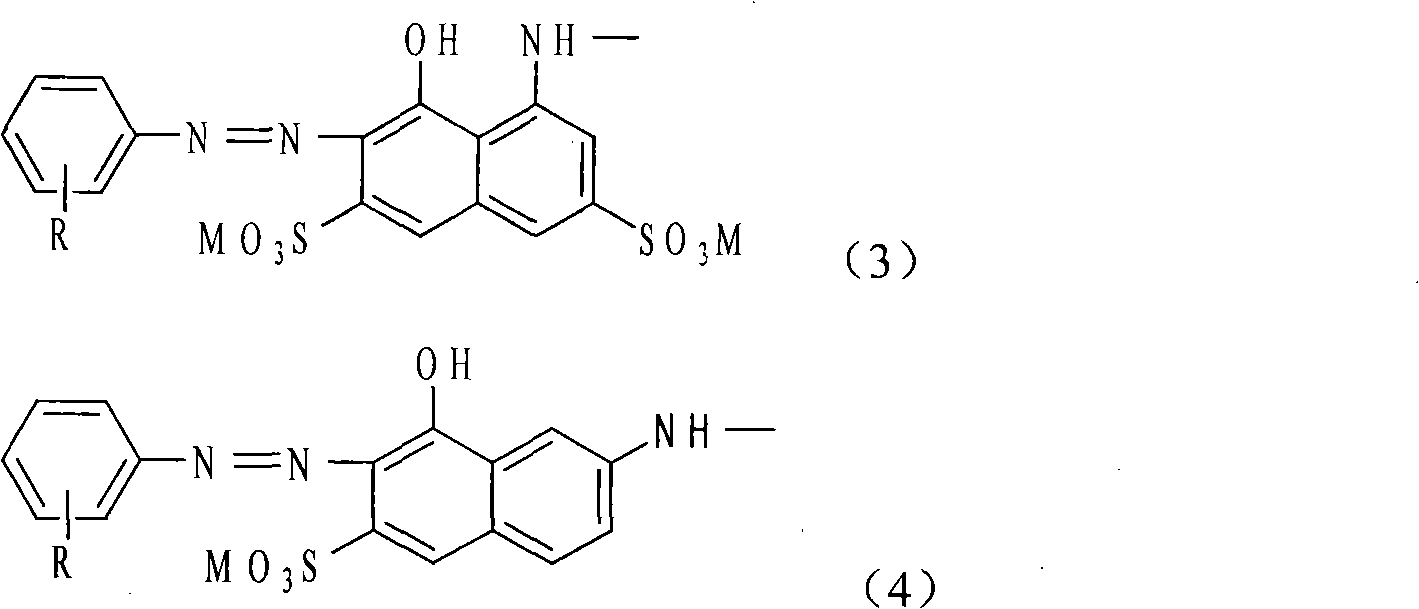

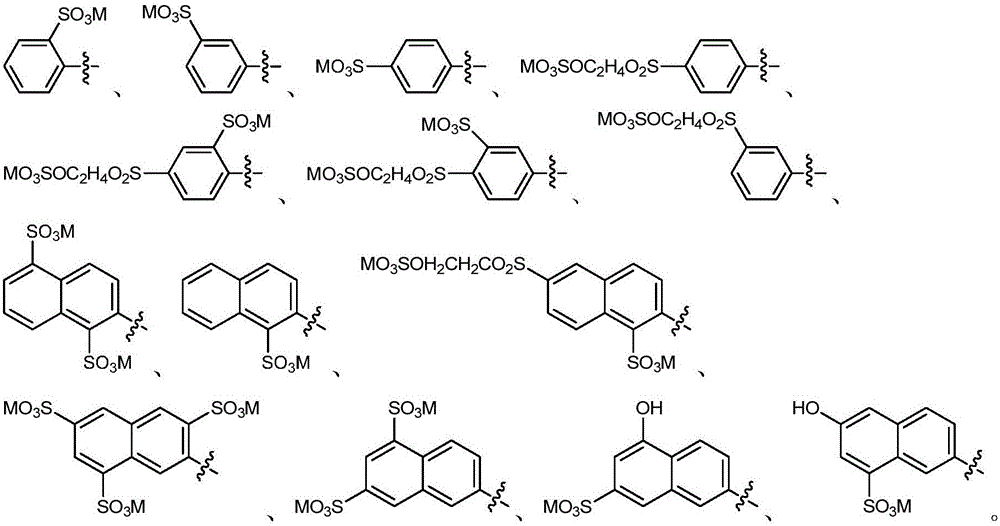

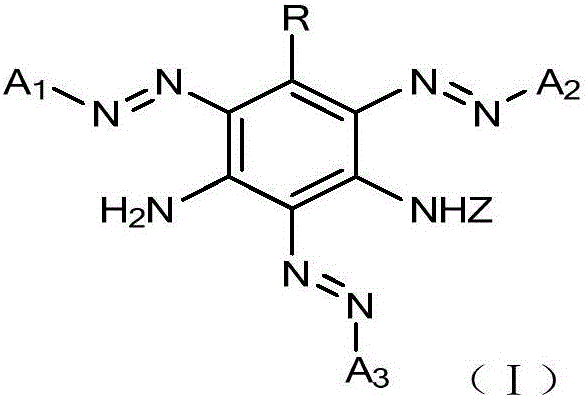

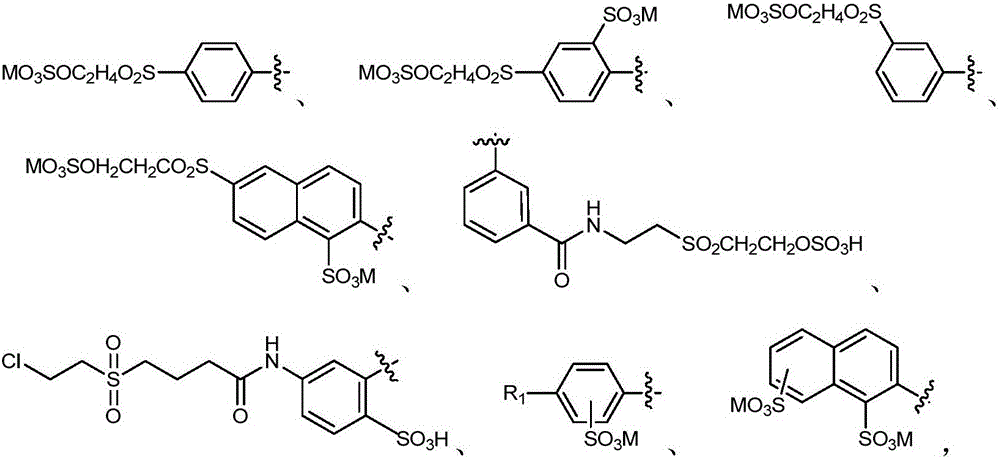

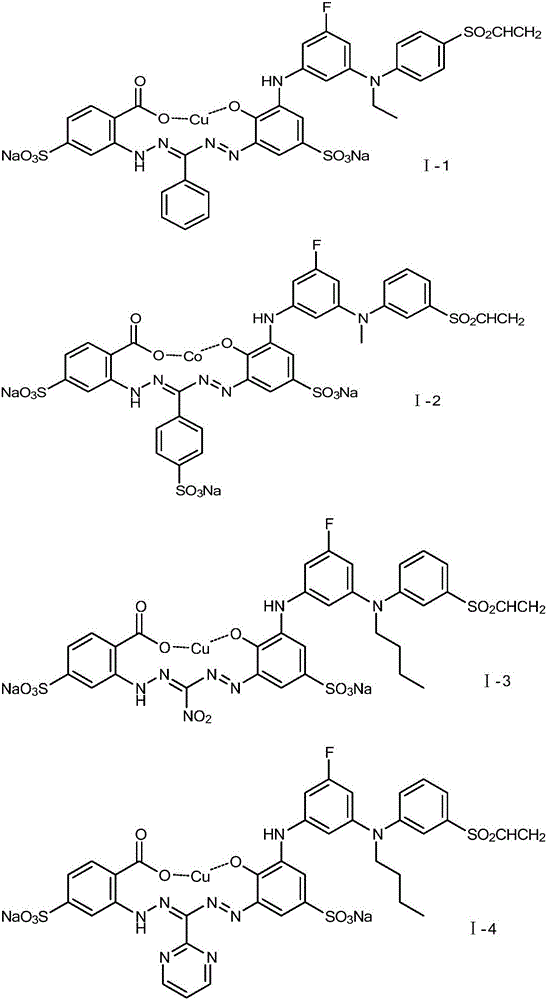

Active orange dye and preparation and application thereof

The invention discloses an active orange dye and preparation and application thereof. The active orange dye has a structure shown in formula (I), wherein R is hydrogen, C1-5 alkyl groups, C1-5 alkoxyl groups, C1-5 carboxyl groups, aldehyde groups, sulfo groups or amide groups; Z is hydrogen or AlkSO3M, and Alk is methylene or ethylene; A1, A2 or A3 is respectively selected from self-substituted phenyl group or substituted naphthyl; M is hydrogen or alkaline metal ion. The active orange dye has the advantages that the color fixation rate and color fastness are good, the stability is good after dyeing, the color is bright, and the active orange dye can be widely applied to dyeing technologies, such as dip dyeing, roll dyeing and ink jet printing of cotton, hemp and manmade cotton fiber products; the production cost is low, and the active orange dye can be popularized and applied in a large scale way.

Owner:TAIXING JINYUN DYESTUFF

Raw material particles containing sludge and polyvinyl chloride for preparing electric wire and cable protective sleeve material and preparation method thereof

InactiveCN109370085ARealize resourcesRealize development and utilizationPlastic/resin/waxes insulatorsAluminateSludge

The invention discloses raw material particles containing sludge and polyvinyl chloride for preparing an electric wire and cable protective sleeve material and a preparation method thereof. The raw material particles are prepared from 100 parts of polyvinyl chloride (PVC), 20 to 60 parts of sludge fine powder, 0.2 to 1 part of indianite, 0.2 to 1 part of needle-shaped wollastonite, 1 to 10 parts of rutile type titanium dioxide, 10 to 30 parts of nano calcium carbonate, 5 to 20 parts of precipitated white carbon black, 10 to 30 parts of epoxidized soybean oil, 2 to 4 parts of a liquid calcium-zinc stabilizer, 4 to 10 parts of chlorinated paraffin, 0.8 to 1.6 parts of stearic acid, 1 to 5 parts of aluminate and 10 to 20 parts of dioctyl phthalate. The preparation method comprises the following steps: stirring at a high speed to prepare dispersed modified powder A; meanwhile, preparing a PVC-based modified organic carrier material B; then mixing the materials A and B while stirring at a high speed; and finally, granulating through double screw rods-single screw rod extrusion. The prepared particles can be used as a protective sleeve layer material of electric wires and cables. The environment-friendly particles prepared by the preparation method are easy to process and mold and the mechanical, electrical and anti-ageing properties of the prepared terminal protective sleeve material are excellent; and the particles can be used in fields including industrial or civilian electric wires and cables.

Owner:浙江工业大学温州科学技术研究院

Coating material for electrostatic spraying on polypropylene automobile bumper bar

InactiveCN107189645AImprove adaptabilityGood weather resistancePolyurea/polyurethane coatingsEpoxy resin coatingsButyl acetateFiltration

The invention discloses a coating material for electrostatic spraying on a polypropylene automobile bumper bar. The coating material is prepared from 8-15 parts by weight of polyurethane resin ester, 10-20 parts by weight of polyester resin, 18-28 parts by weight of modified functional resin, 5-10 parts by weight of ethyl acetate, 5-10 parts by weight of butyl acetate, 0.5-2 parts by weight of an auxiliary agent, 5-10 parts by weight of acrylic resin, 0.5-2 parts by weight of a resistance regulator and 30-40 parts by weight of colorant paste. The preparation method comprises the following steps: a. adding the polyurethane resin ester, the polyester resin, the modified functional resin, the ethyl acetate, the butyl acetate, the auxiliary agent, the acrylic resin and the resistance adjusting agent into a blending kettle and carrying out uniform stirring, b. according to the color of the automobile coating, adding 80-95% of the corresponding colorant paste into the above mixture, carrying out stirring, detecting the color of the coating film, and according to color difference, continuously adding different colorant paste to adjust the color so that the coating film color satisfies the standard, and c. carrying out detection, and when the coating film is qualified, carrying out filtration and packaging.

Owner:CHENZHOU TEIKYO CHEM TECH

Disperse yellow dye composition, its product and application thereof

The invention discloses a disperse yellow dye composition, its product and an application thereof. The disperse yellow dye composition comprises a component A, a component B and a component C. The component A is at least one selected from compounds represented by a following formula (I), and the component B is at least one selected from the compounds represented by a following formula (II), and the component C is at least one selected from the compounds represented by a following formula (III), based on the component A, the component B and the component C, the mass percentage of the componentA is 10 to 90%, the mass percentage of the component B is 5 to 85%, and the mass percentage of the component C is 5 to 60%. A disperse yellow dye preparation contains the disperse yellow dye composition and an adjuvant. The disperse yellow dye composition and the product can be used in the printing and dyeing of a hydrophobic fiber material, have good compatibility, good level-dyeing property, good pH dependence, excellent light fastness resistance, sublimation resistance, and washing fastness resistance.

Owner:ZHEJIANG LONGSHENG GROUP +1

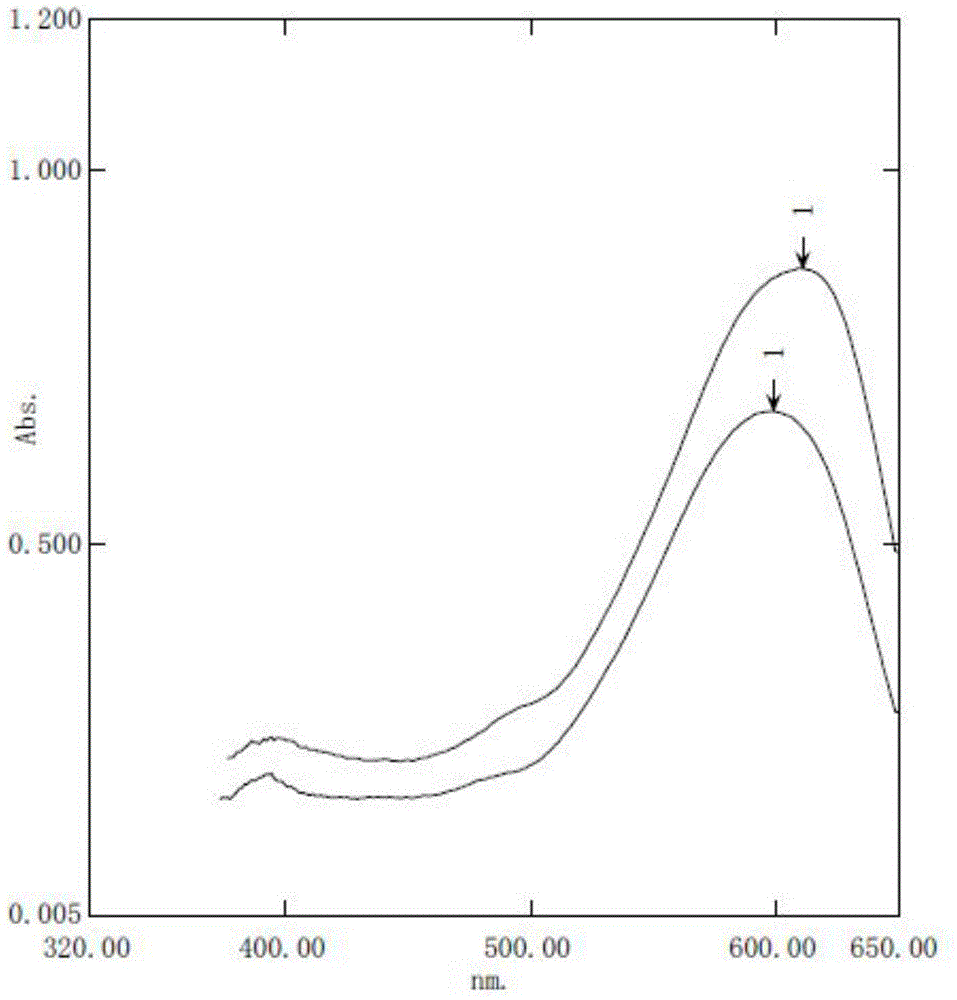

Photochromic water-based ink for textiles, and preparation method and application thereof

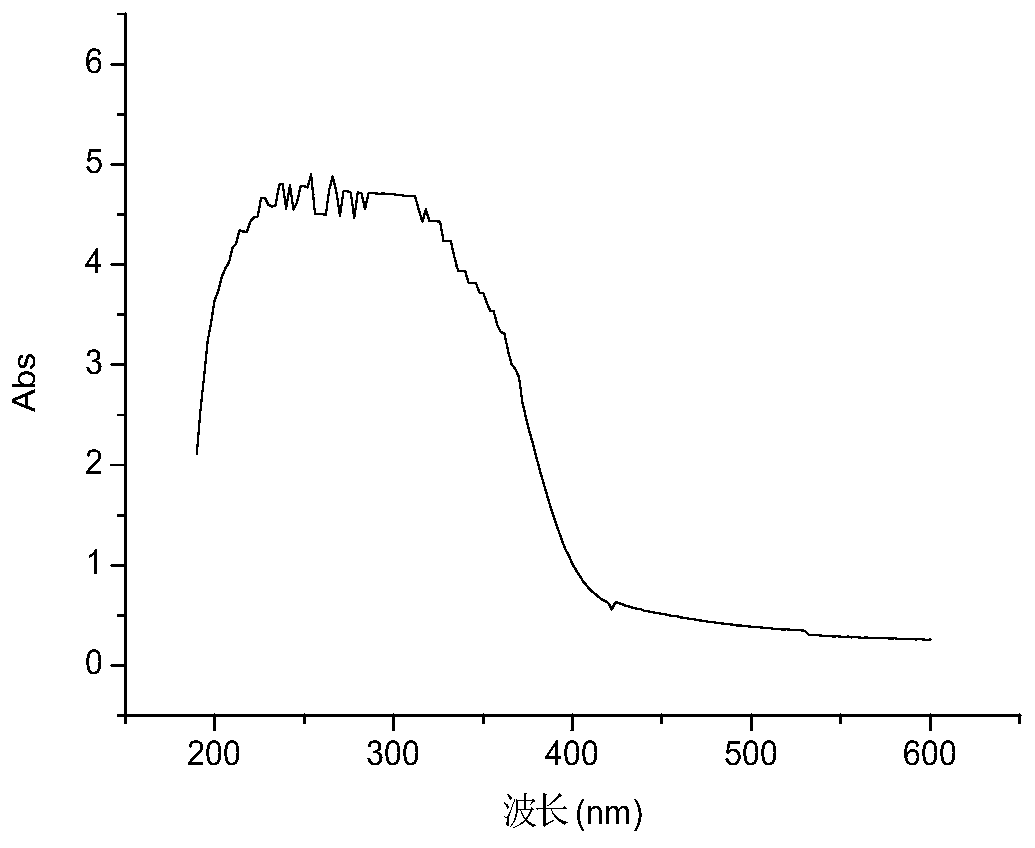

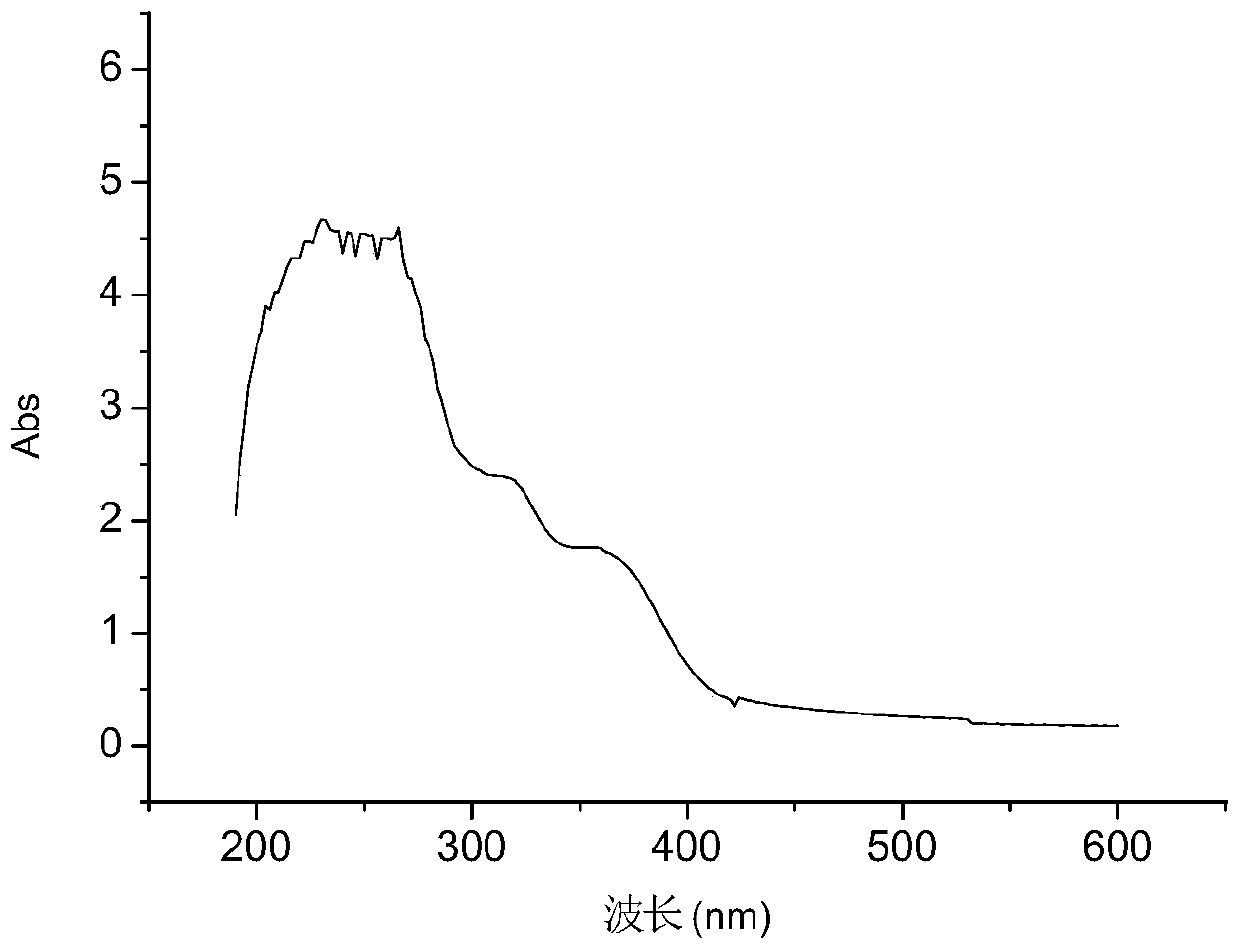

InactiveCN110951317AAbsorption reachedImprove sun resistanceInksDyeing processAdhesiveFilm-forming agent

The invention relates to a photochromic water-based ink for textiles, and a preparation method and an application thereof. The photochromic water-based ink is prepared from a weather-proof photochromic microcapsule powder, an adhesive, a cross-linking agent, a dispersing agent, a wax emulsion, a leveling agent, a film-forming agent, a penetrating agent, a pH regulator, an antifoaming agent, an antioxidant, a preservative, a thickener and deionized water. The photochromic water-based ink for textiles makes up the defects of a commercially available photochromic oily system, realizes zero TVOC emission, meets the requirements of ecological environmental protection, makes up the defects of a commercially available photochromic aqueous system, and has the characteristics of uniform dispersion,long storage time, good stability, excellent washability, high drying speed and good processing continuity.

Owner:上海驰纺材料科技有限公司

A photocatalysis antisolarization titanium dioxide marble paint and a preparing method for the same

InactiveCN108546474AImprove mechanical stabilityImproves UV resistanceCoatingsSodium PyrithioneCross-link

The invention discloses a photocatalysis antisolarization titanium dioxide marble paint. The photocatalysis antisolarization titanium dioxide marble paint comprises, by weight: 0.1-0.2 part of 2,4-dihydroxy benzophenone, 14-20 parts of photocatalysis sol, 70-80 parts of silicone acrylic emulsion, 2-3 parts of 2.2-Dimethylol propionic acid, 10-13 parts of marble powder, 0.7-1 part of azodicarbonamide, 0.8-1 part of Polyethyleneglycol monooleate, 1-2 parts of zinc pyrithione and 0.8-1 part of a cross-linking agent taic. The sol is added, the agglomeration can be effectively reduced by the marblepowder, the mechanics stability of the finished product paint film is improved, benzotriazol and titanium dioxide which have good anti ultraviolet effect are added, and the antisolarization propertycan be effectively improved.

Owner:佛山市嘉柏丽涂料有限公司

High-light-fastness acid dyestuff dyeing and finishing process

InactiveCN109853261AHigh sun resistanceHigh fastnessDry-cleaning apparatus for textilesDyeing processChemistryPolyester

The invention discloses a high-light-fastness acid dyestuff dyeing and finishing process. The process is characterized by comprising the following steps of S1, preparation of a gray cloth; S2, desizing; S3, preshaping; S4, alkali reduction; S5, dyeing; S6, heat shaping; S7, after-finishing. In the second step, a desizing mixed solution is prepared, and the desizing mixed solution is adopted for conducting desizing treatment on the gray cloth. In the third step, the preshaping temperature is 180-210 DEG C, the shaping time is 30-45 s, and the radial overfeed is 5-10%; in the fifth step, after the gray cloth treated in the fourth step is immersed in a dyeing solution, the temperature is increased to 80-90 DEG C, the constant temperature is kept for 20 min, heat preservation is conducted for45-60 min after the temperature continues to be increased to 125-135 DEG C, and then the gray cloth is cleaned with a cleaning solution. The process is suitable for dyeing pure polyester, ultra-fine polyester, polyester cotton and the like and has high sun resistance and high fastness, a dyed fabric can be used for a long time without fading or color losing, and the dyeing quality of the fabric isimproved.

Owner:浙江名毅新能源股份有限公司

Composite filling particle for preparing high-strength non-woven fabric and preparation method and application thereof

InactiveCN108774757AHigh tensile strengthEasy to useNon-woven fabricsArtifical filament manufactureCarbon fibersStearic acid

The invention discloses a composite filling particle for preparing a high-strength light-colored non-woven fabric and a preparation method thereof and an application field thereof. The composite filling particle is composed of the following raw materials by weight: 100 parts of biomass calcium carbonate shell powder, 1-5 parts of acicular wollastonite, 1 to 5 parts of chopped carbon fiber, 1 to 2parts of rutile type titanium dioxide, 10 to 25 parts of polypropylene, 0.1 to 0.5 parts of stearic acid, 0.2 to 0.5 part of a silane coupling agent and 0.5 to 2 parts of PE wax; the preparation method is as follows: first preparing dispersed powder A, then preparing modified powder B, and finally using a single-screw-assisted twin-screw plasticization process for extruding and granulating the polypropylene and the PE wax. The composite filling particle has excellent application performance, and a prepared end product non-woven fabric has high tensile strength and can be used in the field of an industrial or civil packaging material, a filter material and the like.

Owner:浙江工业大学温州科学技术研究院

Linen fiber reinforced polypropylene automobile interior part injection molding method

InactiveCN107129632AImprove toughnessImprove sun resistanceBiochemical fibre treatmentLight resistant fibresFiberCellulose

The invention provides a linen fiber reinforced polypropylene automobile interior part injection molding method. According to the invention, the surface and pores of a linen fiber are filled with porous nano-scale silicon dioxide, titanium dioxide and nano crystalline cellulose, so that the toughness and light fastness of the linen fiber are improved; meanwhile, the polypropylene compatibility is improved, so that the material after injection molding has improved strength, improved durability, light fastness, antibacterial property and wear resistance, and is easy to clean; and the linen fiber and polypropylene are subjected to injection molding to obtain strips, and the strips are subjected to re-injection molding, so that the anisotropy of the linen fiber is eliminated, thereby improving the dimensional stability of the injection molding product.

Owner:岳西县同兴尼龙橡胶制品有限公司

Treatment process of rattan used for rattan-weaved products

InactiveCN109986669AHigh hardnessAvoid insufficient immersionBiocidePlant growth regulatorsUltimate tensile strengthToughness

The invention discloses a treatment process of rattan used for rattan-weaved products. The process comprises the following steps: (1) raw material selection, (2) pretreatment, (3) cooking, (4) softening, (5) drying, and (6) mold prevention. The process provided by the invention firstly adopts the pretreatment and the cooking treatment to soften the rattan, then adopts a special softening agent tofurther soften the rattan, and adopts fresh ginger powder to prevent mold of the rattan, so that the rattan has better strength, toughness, sun resistance and flame-retardant effects; and the processis simple, the effects are obvious, the industrial production is easy to realize, and the process has good market prospects.

Owner:ANHUI JINYUAN HOUSEHOLD ARTS

Reactive blue dye and preparation and application thereof

ActiveCN106590026ANovel structureGood color fixation rateReactive dyesDyeing processFiberResource consumption

The invention discloses a reactive blue dye and preparation and application thereof. The structure of the reactive blue dye is shown in a formula (I) defined in the description. The reactive blue dye is novel in structure and excellent in performance, has the good fixation rate and color fastness, can effectively lower resource consumption, has the good stability after dyeing is performed, is bright in color, can be widely applied to dip dyeing, pad dyeing, inkjet printing and other dyeing technologies of cotton fiber products such as polyeseter, fiber and artificial cotton, is low in production cost and can achieve large-scale application and popularization.

Owner:TAIXING JINYUN DYESTUFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com