Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Dyeing speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural plant hair dye

InactiveCN1923164AStrong penetrating powerAchieve the effect of dyed black hairCosmetic preparationsHair cosmeticsCelluloseSide effect

The invention relates to a hair dye, especially a natural plant hair dye. Wherein, it is formed by mixed A and B solutions; A agent is formed by agent and metal chelant, while the agent can be guar gum, polyquaternary ammonium salt or glycol cellulose, and the chelant can be soluble ferric salt or ferrous salt; B agent contains pomegranate bark extractive and glycol cellulose; while it also can contain logwood extractive as color agent. The invention has short dye time, uniform dye and washing resistance, nearly without side effects.

Owner:SHANGHAI BAIMAO +1

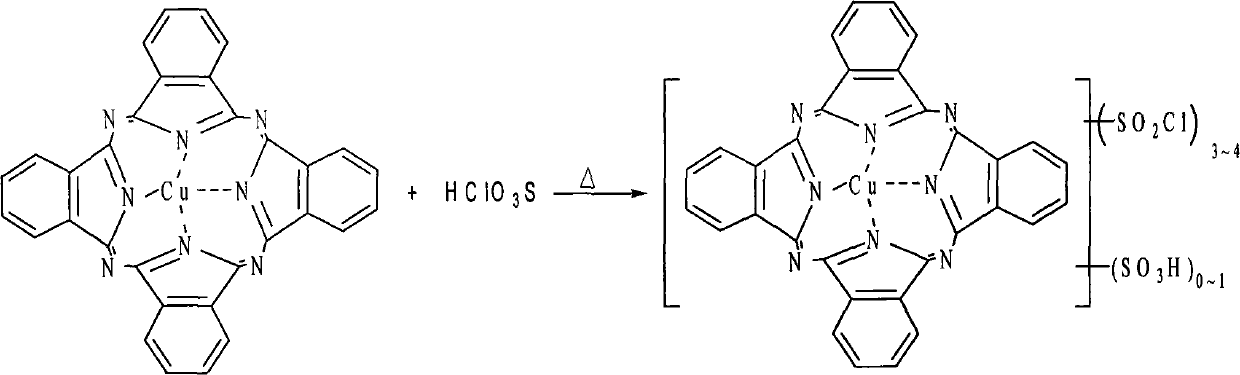

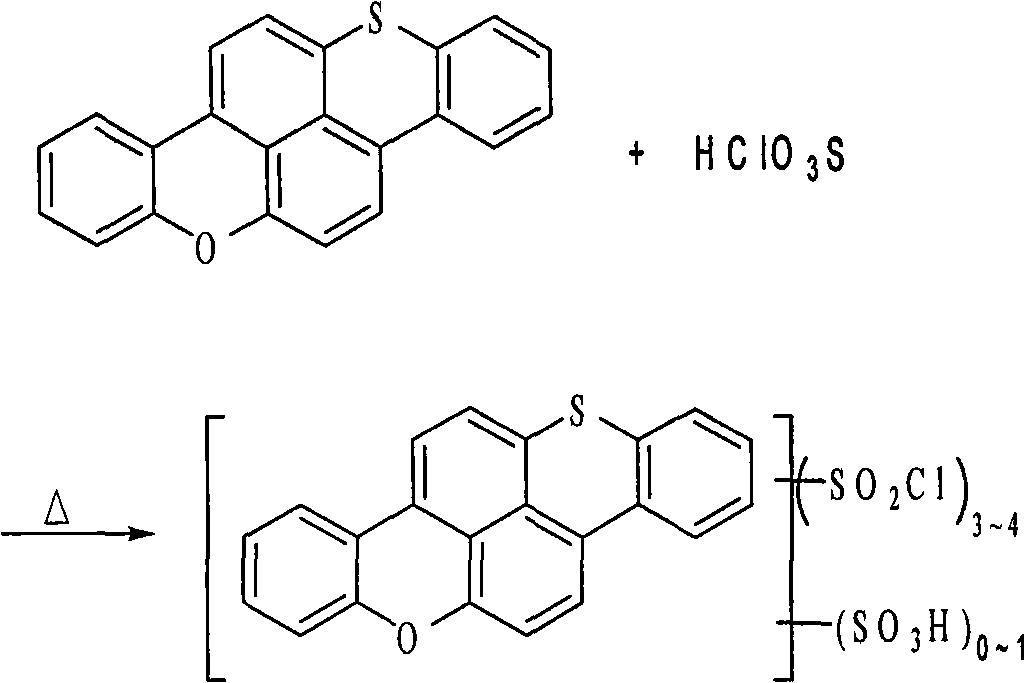

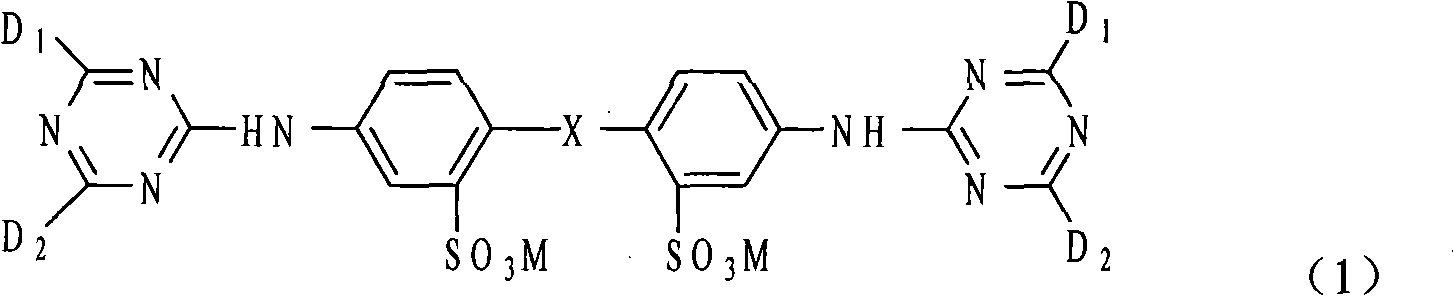

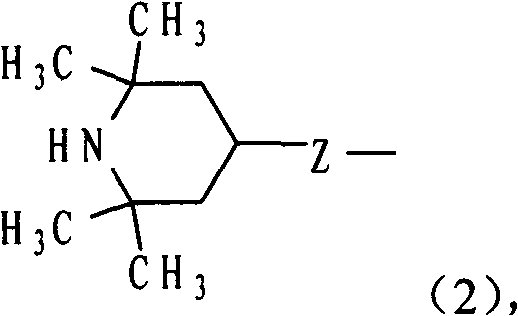

Sunproof water-soluble dye, method for preparing same and application thereof

InactiveCN101864188AImprove light fastnessHigh coloring rateInksPaper/cardboardSolubilityPhthalocyanine dye

The invention relates to sunproof water-soluble dye having the general formula (1), a method for preparing the same and application thereof. The sunproof water-soluble dye imports the group of hindered amine 4-Z-2,2,6,6-tetramethylpiperidine and the water-soluble group of sulfonic groups based on the common water-insoluble dye, so that under a condition of ensuring good water solubility of the dye, the light stability of the dye is improved, and the sunproof property of the dye is also improved. In a general formula(1), A represents a dye matrix selected from a group formed by dioxazine dye, anthraquinone dye and phthalocyanine dye which are water-insoluble; R1 represents a general formula(2): -(SO2-R)m(2); R2 represents a general formula(3): -(SO3H)n(3); in the general formula(2) and the general formula(3), m and n are both a natural number, preferably m is a natural number between 1 and 16, and n is a natural number between 0 and 2.

Owner:上海汇友精密化学品有限公司

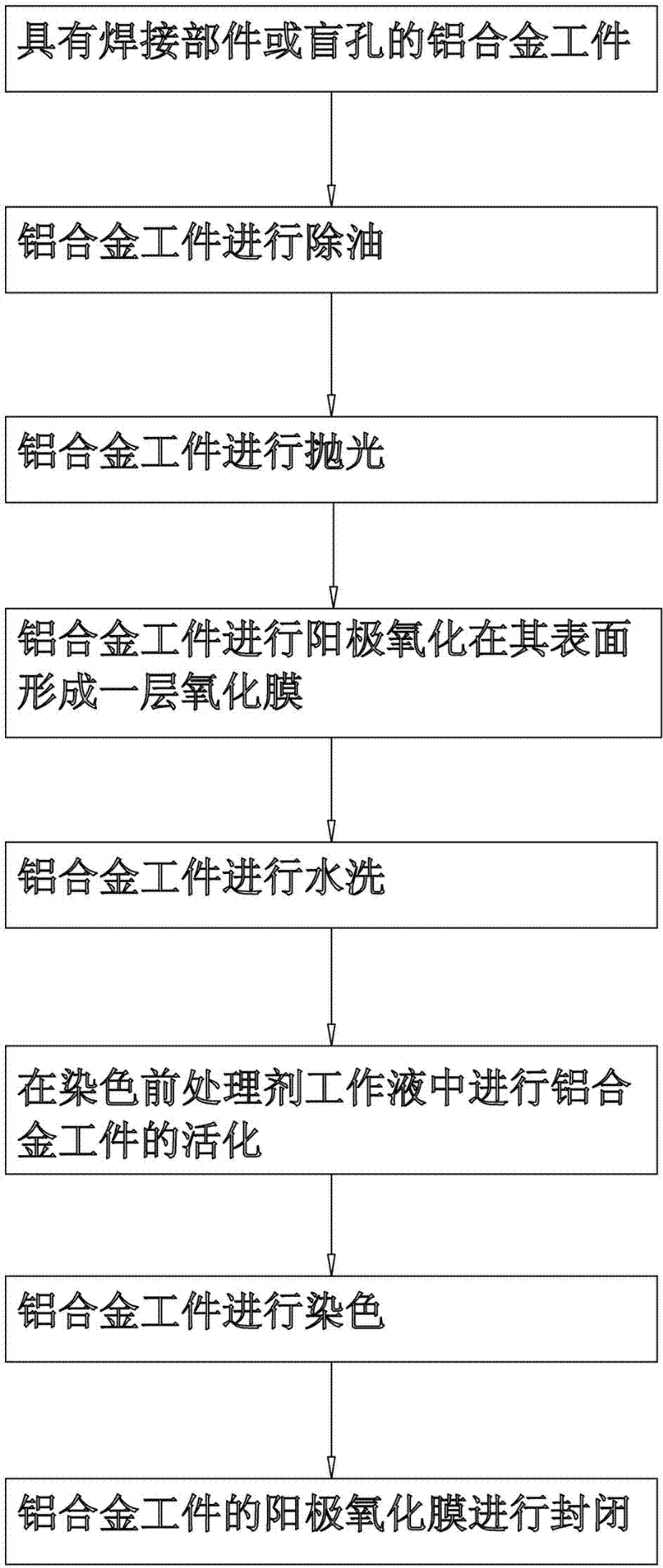

Pre-dyeing treatment agent for surface of blind hole workpiece in aluminum alloy welding area and application technology thereof

ActiveCN102534722APrevent poor dyeingImprove dyeing effectSurface reaction electrolytic coatingOrganic acidSURFACTANT BLEND

The invention discloses a pre-dyeing treatment agent for a surface of a blind hole workpiece in an aluminum alloy welding area and an application technology thereof. The pre-dyeing treatment agent comprises the following raw materials by mass percent: 70-85% of organic acids, 13-28% of organic acid salts and 0.5-2% of anionic surfactants. By utilizing a working solution of the pre-dyeing treatment agent to perform pre-dyeing treatment on an aluminum alloy workpiece with a welded blind hole structure, the dyeing quality of the workpiece is greatly increased, the dyeing speed is increased, the dyeing time is reduced and the dyeing reject ratio is greatly reduced. By utilizing the working solution of the pre-dyeing treatment agent to treat the aluminum alloy workpiece with the welded blind hole structure, the environmental pollution is avoided, the dyeing yield is greatly increased and is above 98%, the color quality of products is stable, the time is greatly saved and the production efficiency is increased, so that the defects and the inferior treating effect of the prior art are overcome.

Owner:ZHUHAI ALLMELUX CHEM +1

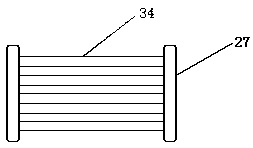

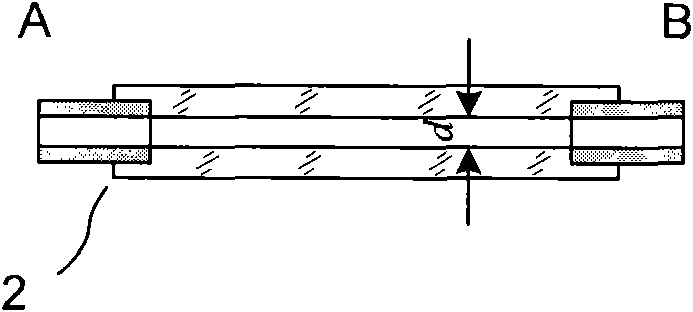

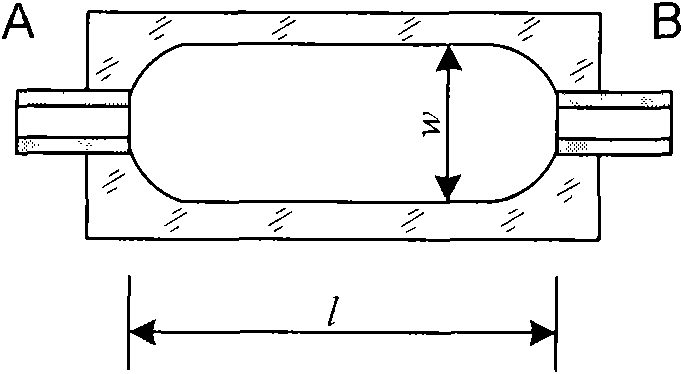

Wooden sheet dyeing method for performing pretreatment by using cold plasma

InactiveCN102350717AGood light fastnessMeet the requirements of energy saving and emission reductionWood treatment detailsProduct gasEngineering

The invention discloses a wooden sheet dyeing method for performing pretreatment by using cold plasma. The process comprises the following steps of: adjusting the water content of a wooden sheet to be 2-12 percent; placing on a feed conveying belt of a cold plasma treatment system; adjusting a space between two electrode rollers to keep the gap between the surface of the wooden sheet and an electrode at 0.5-1.5mm; starting a power supply; adjusting treatment power to be 1-6kW to produce cold plasma through dielectric barrier discharge of working gas between two electrodes; passing the wooden sheet through four pairs of discharge electrode rollers at a speed of 2-20m / min to simultaneously treat two surfaces of the wooden sheet, wherein the working gas between the two pairs of front electrode rollers is air and the working gas between the two pairs of rear electrode rollers is ammonia gas; and immersing the pretreated wooden sheet in direct dye solution for dyeing, and then washing and drying to obtain a dyed wooden sheet. The wooden sheet pretreated by cold plasma has high dyeing speed, high dye uptake and superior light resistance. In addition, the method has the advantages of energy conservation, environmental friendliness, easiness and convenience in operation, high efficiency and capability of continuous working.

Owner:NANJING FORESTRY UNIV

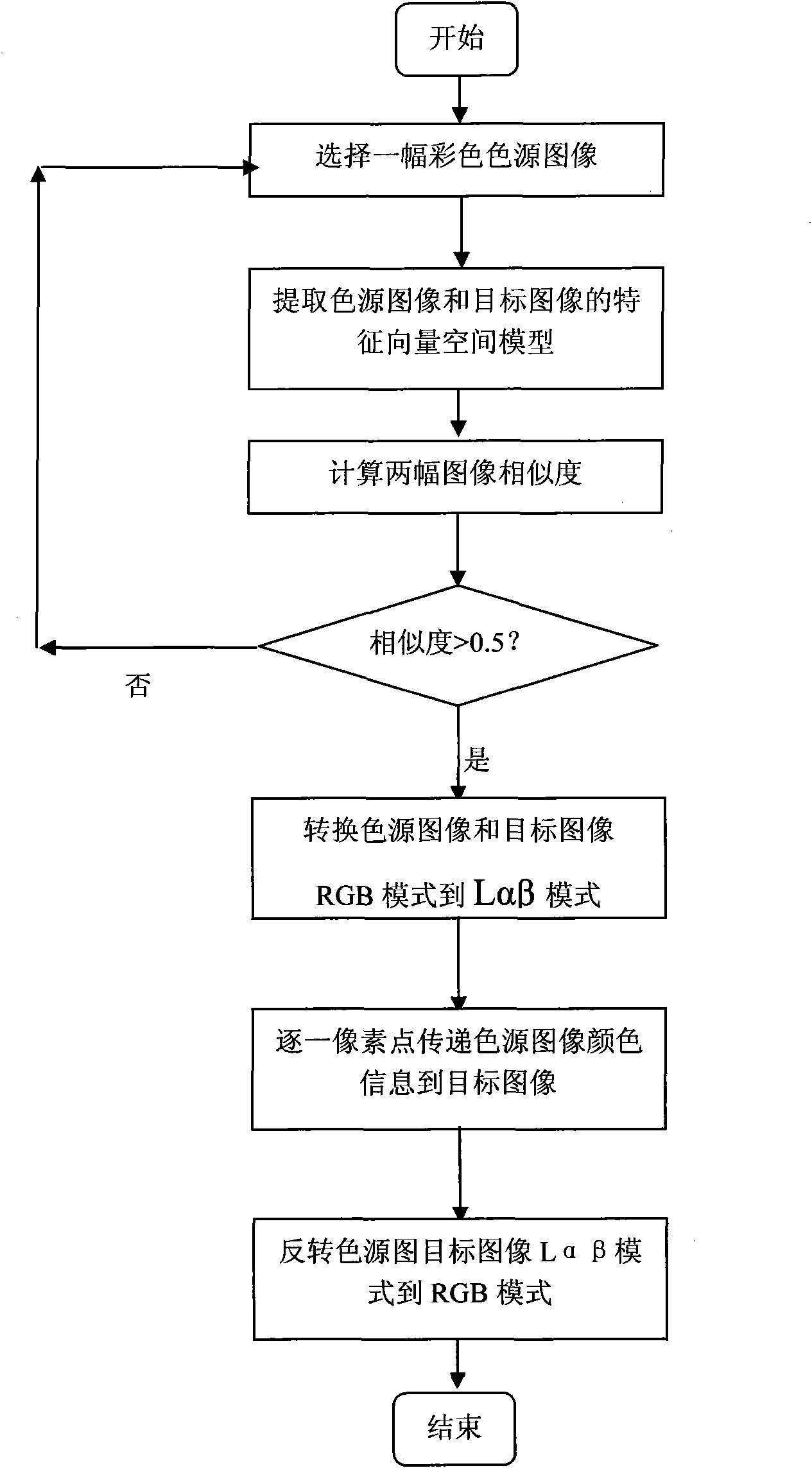

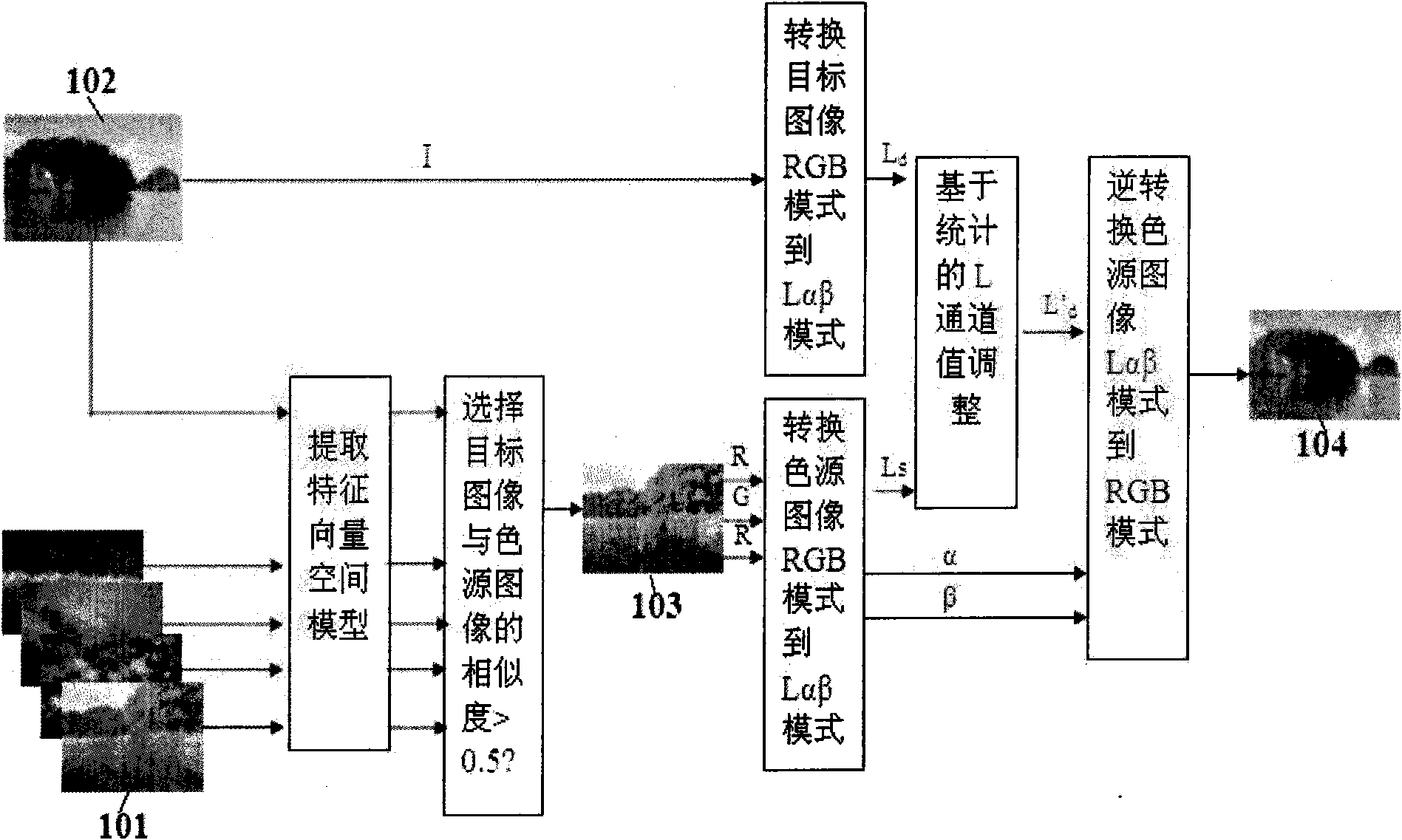

Method for staining digital image

InactiveCN101667299AGood colorObjectiveFilling planer surface with attributesDigital imageOptimal matching

The invention discloses a method for staining a digital image, comprising the following steps: selecting a color image with the content similar to a black and white image as a color source; respectively extracting characteristic vector space models of the two images; judging the similarity of a target image and the color source image; converting an RGB expression mode of the image to an L alpha beta mode; transmitting color information; and converting an L alpha beta expression mode of the image to an RGB mode so as to form the strained target image. The method has the color source from a color image with similar content, is automatically completed by utilizing brightness information according to an optimal matching algorithm, has objectivity and retains original information of the stainedimage with adding information, i.e. the color of the color source and the like, thereby enhancing the visual effect, the reality sense and the staining success rate; and in addition, the whole colorobtaining and providing process has completely automatic processing, thereby being convenient and fast and only needing normal visual perception capability without needing any professional skills, i.e. drawing, coloring and the like.

Owner:DALIAN MARITIME UNIVERSITY

Mercerized fiber dyed yarn and fabricating method

InactiveCN1600915ADyeing speed is fastHigh glossMercerising of yarns/threads/filamentsYarnYarnEngineering

Owner:WUXI NATURAL GREEN FIBER TECH

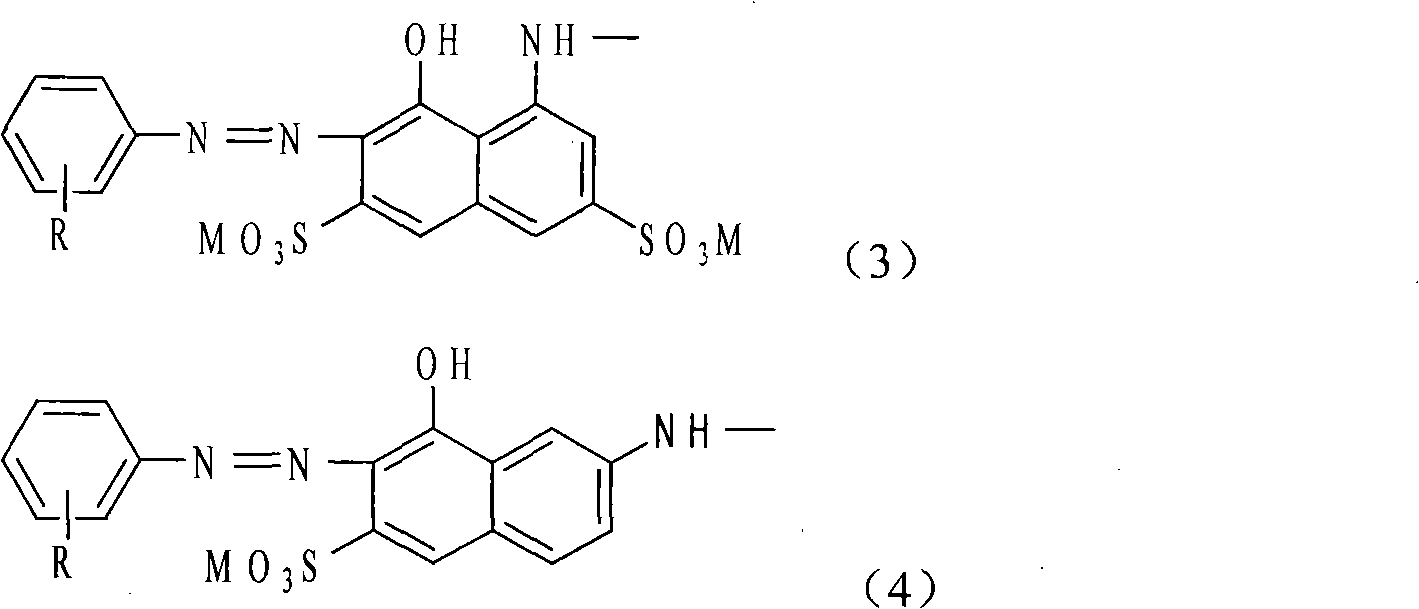

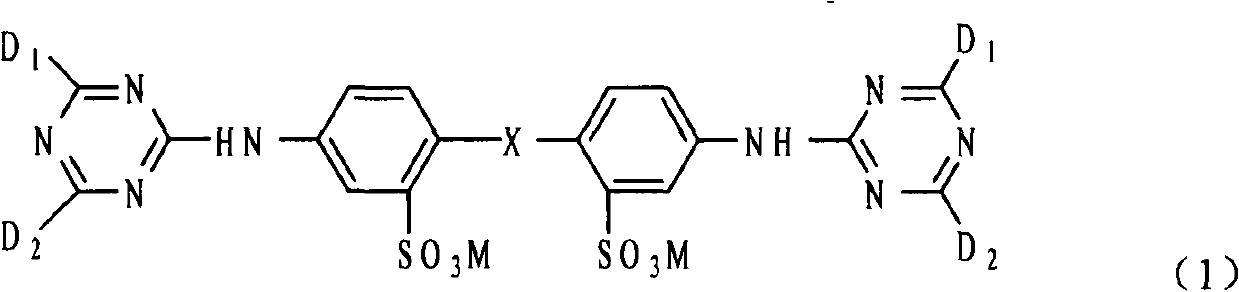

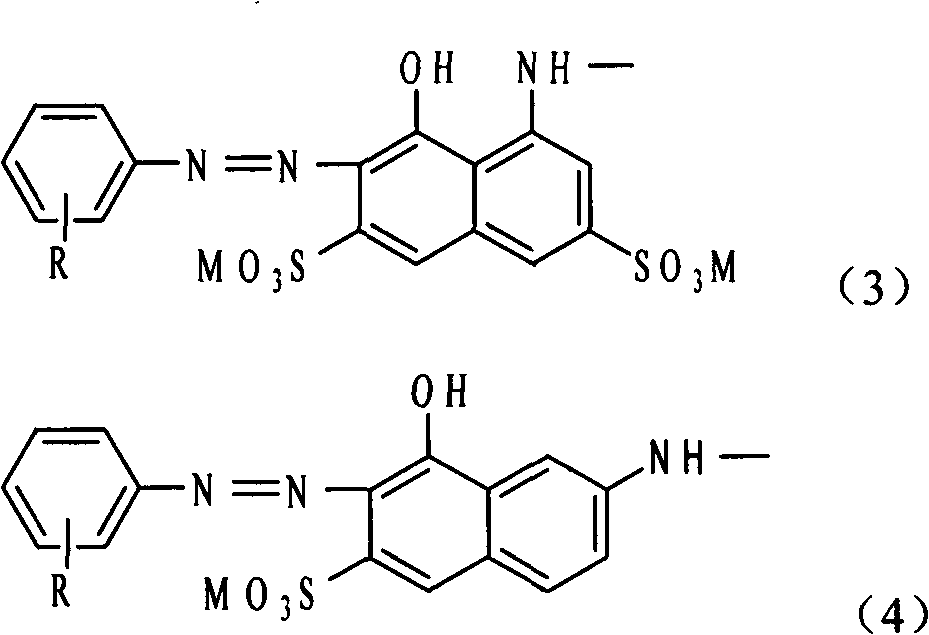

Weather-resistant azo-dyes, preparation and use thereof

InactiveCN101280118ADyeing speed is fastHigh dyeing rateAzo dye preparationMonoazo dyesEnergy transferHindered amine light stabilizers

The invention relates to a weather-resistant azo dye with the following general formula (I) and the preparation method and application. The invention introduces chlorinated triazine groups based on common azo dyes and then after a series of condensation reactions, a novel azo dye is obtained. The azo dye contains multiple chromogenic groups, wherein, hindered amine can absorb the infrared; DSD acid (that is, 4,4'-diaminostilbene-2,2'-disulfonic acid) can absorb the ultraviolet rays; therefore, the azo dye has good light-resistant and weather-resistant properties and can be used alone or with other dyes; the azo dye can be used in textiles, paper, leather, wood, ink-jet printing ink and other aspects, which is also a good energy transfer agent. As a result of a variety of functional groups, the azo dye of the invention has better weather-resistant performance than common azo dyes.

Owner:上海汇友精密化学品有限公司

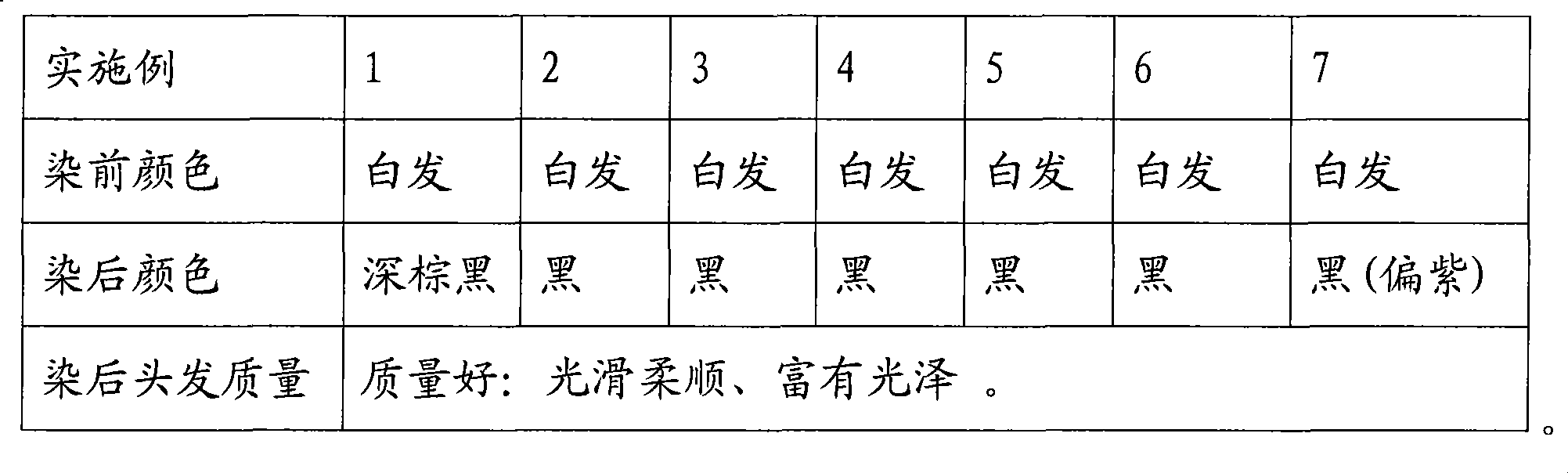

Quick-speed plant type black hair dye

ActiveCN1989940AImprove past problemsImprove dye uptakeCosmetic preparationsHair cosmeticsAdjuvantSide effect

The invention relates to the field of hair dyes; especially fast plant-based blacking hair agent. The invention discloses a fast plant-based blacking hair agent, the blacking hair agent consists of A, B two solution mixture, A agent consists of adjuvant and metallo-chelates, the adjuvant uses nitrogen ketone and the metallo-chelates uses soluble ferric salt or ferrous salt, and the A agent also can be added ethoxylated into itself cellulose as bodying agent; B agent contains gallnut extract, and B agent can be added isatis leaf extract and campeachy wood extract as color agent, silicone oil as amendment. The invention has some advantages of short dyed time, high dyed radio, uniform dyed and resistant wash, because of using natural plant extracts, the toxic and side effect is smaller.

Owner:SHANGHAI BAIMAO

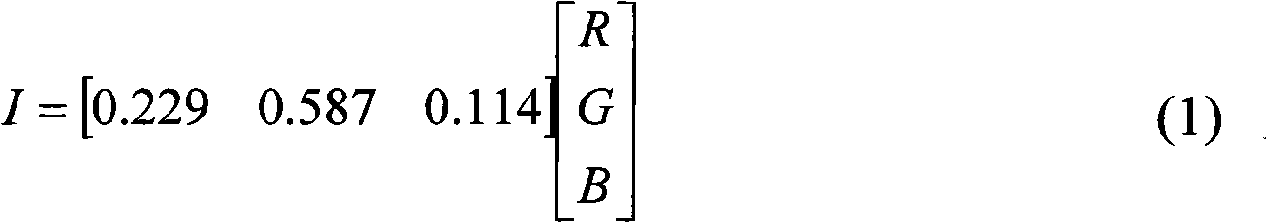

Triazine type azo dye and preparation method thereof

InactiveCN103305023ADyeing speed is fastHigh dyeing rateStyryl dyesMethine/polymethine dyesWeather resistanceHindered amine light stabilizers

The invention relates to a triazine type azo dye with the general formula (I) shown in the specification and a preparation method of the azo dye. A novel azo dye is obtained by introducing a chloro-s-triazine group into a general monoazo dye and performing a series of condensation reaction. The azo dye comprises a plurality of color-development groups, wherein the contained hindered amine is capable of adsorbing infrared, the DSD acid (namely 4,4'-diamino stilbestrol-2,2'-disulfonic acid) is capable of adsorbing the ultraviolet in the sunlight, and the azo dye is provided with good illumination resistance and sunshine resistance, can be singly or together used with other dyes, and can be applied to the aspects of textile, paper, leather, wood, ink-jet printing ink, and oil ink. The azo dye is a good energy transfer. By containing a plurality of functional groups, the azo dye provided by the invention has more excellent weather resistance than that of a general azo dye.

Owner:上海汇友精密化学品有限公司

Preparation method for colored eyeglass with colored coating

ActiveCN105319612ASolve for uniformitySolve the problem of coloringOptical elementsCase hardeningSolvent

The invention relates to a preparation method for colored eyeglass with colored coating. The preparation method comprises the following steps that (1) a pigment or dye is dissolved; (2) a hardening solution is prepared to harden basic glass primarily; and (3) secondary hardening is carried out to obtain a finished product, namely, the eyeglass which is hardened and solidified in the step (2) is hardened at the surface at the temperature of 110 DEG C for 2 hours, cooled, detected and form the finished product if qualified. According to the method, the dye or pigment is directly added to the hardening solution, the solution is in the color to be dyed, the basic eyeglass is immersed in the hardening solution and hardened to form the colored eyeglass, the dye added into the hardening solution is controlled to achieve different colors and darkness, the method is fully automatic and does not need manual operation, the labor intensity as well as stimulation to a solvent are reduced, the dyeing speed is very high, and the efficiency is very high.

Owner:ZENNI OPTICAL

Cloth dyeing technology

InactiveCN107904821ARealize automatic hangingDyeing speed is fastDyeing processTextile treatment carriersEngineeringDyeing

The invention relates to the field of cloth dyeing and printing, in particular to a cloth dyeing technology. The cloth dyeing technology comprises the following steps that 1, a dye is prepared for use; 2, a dye vat used for containing the dye, a soaking mechanism used for soaking cloth, a drawing mechanism used for drawing the cloth to move and a drying rack used for drying the cloth are prepared,wherein the soaking mechanism comprises a rotating unit, a swinging unit and a support clamping unit; 3, after the cloth is connected with the drawing mechanism, the cloth is thrown into the dye vatto be soaked for a period of time, and the cloth is soaked under cooperation of the rotating unit, the swinging unit and the support clamping unit; 4, the drawing mechanism draws the cloth to move, and the cloth is wrung and rolled out under cooperation of the rotating unit, the swinging unit and the support clamping unit; 5, the drawing mechanism draws the cloth to continue moving, and the clothis hung on the drying rack for drying. By means of the technical scheme, the cloth can be prevented from wrinkling in the dyeing and squeezing process, and meanwhile the cloth can be rolled out.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

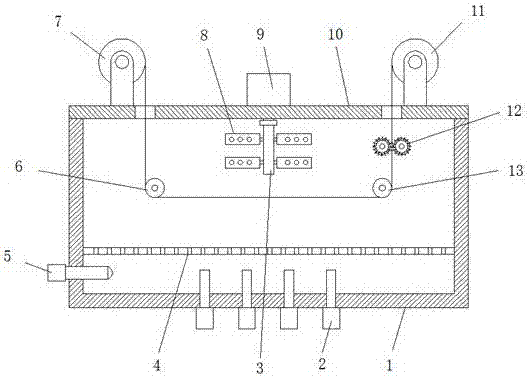

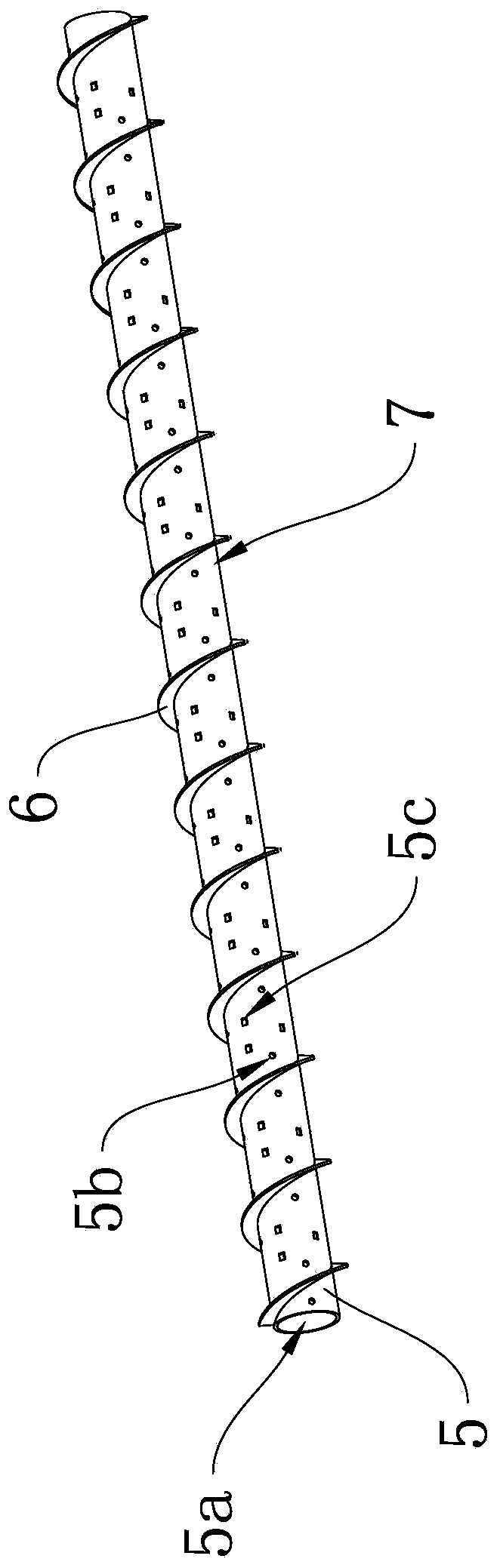

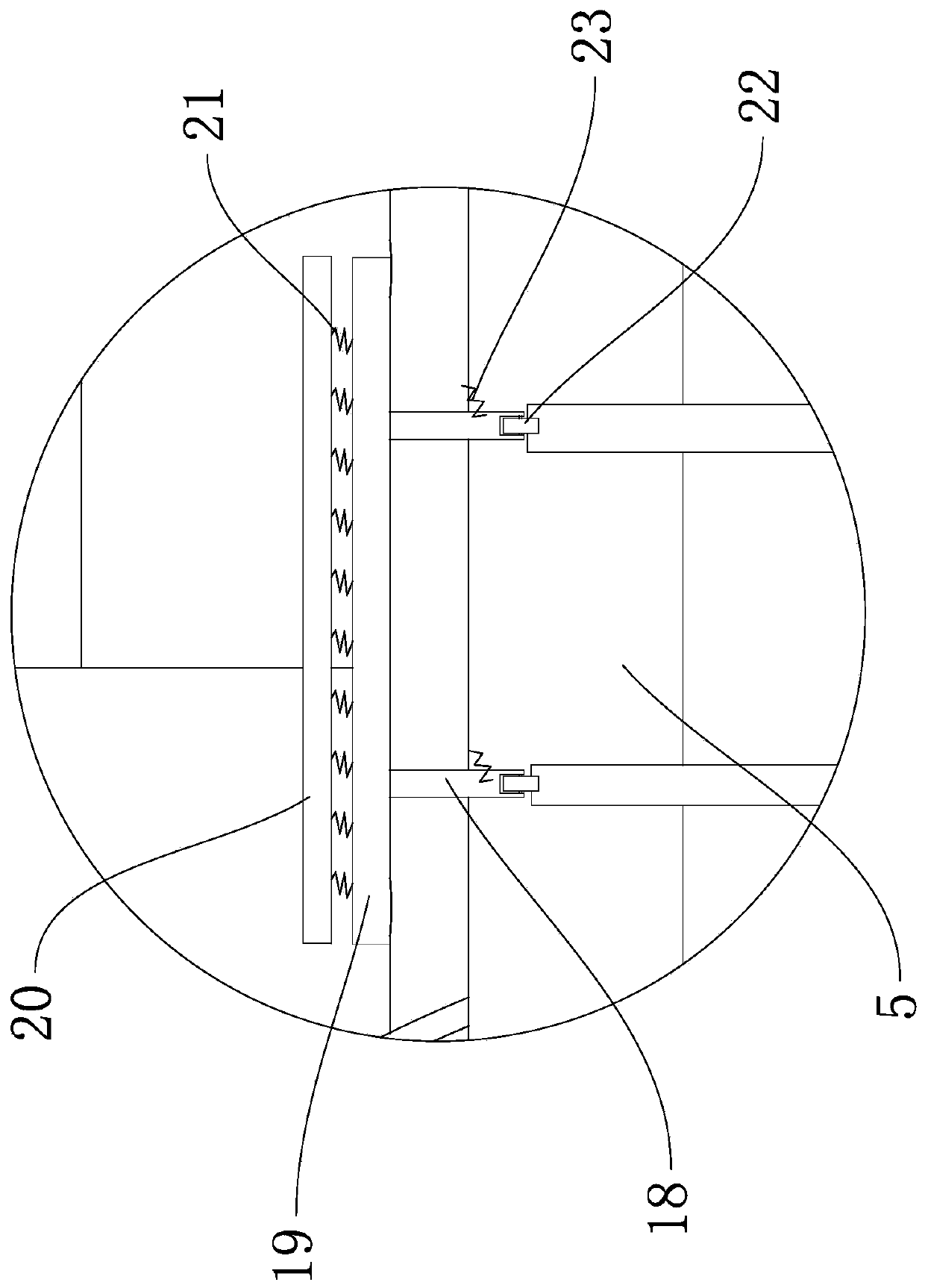

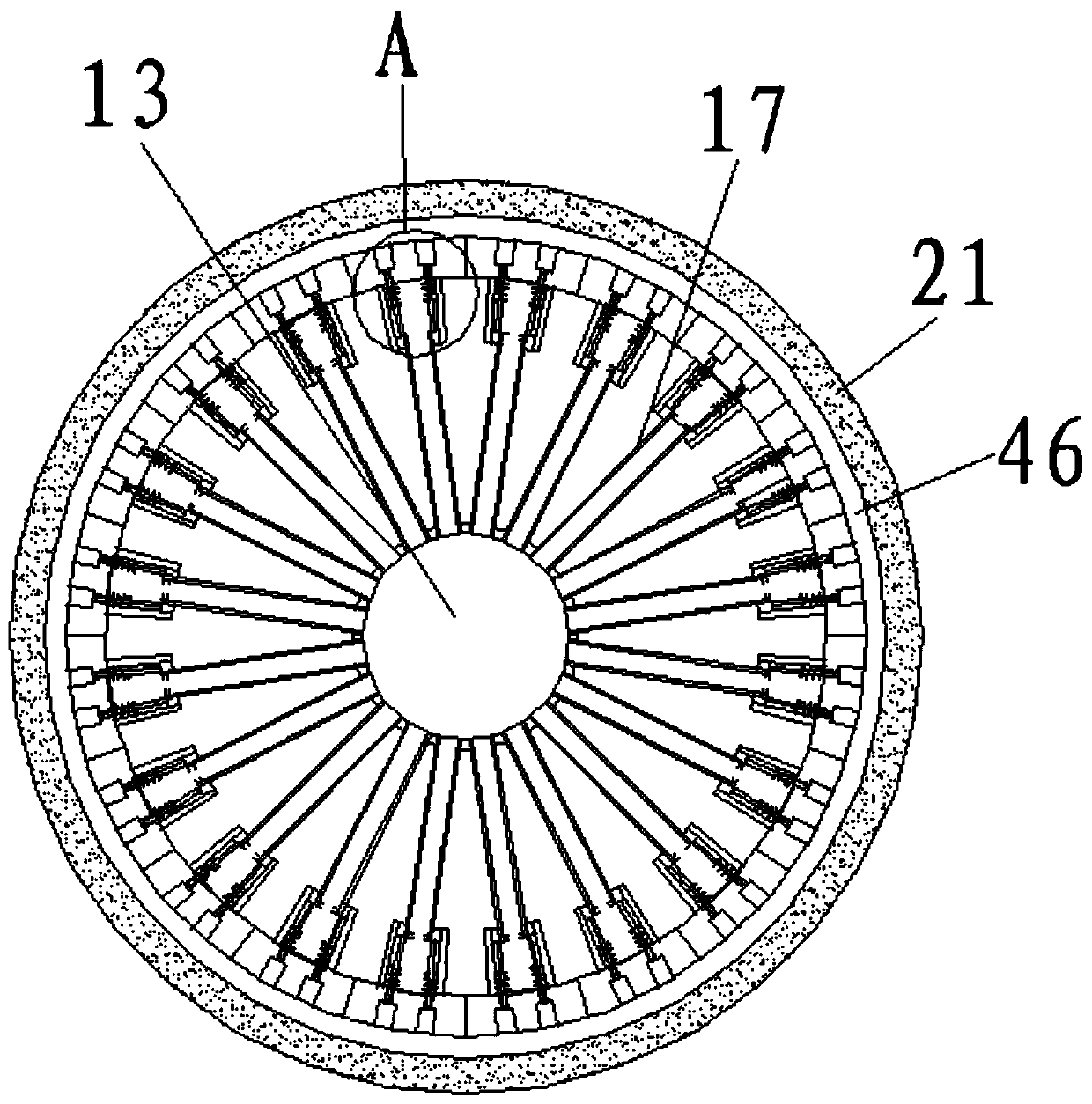

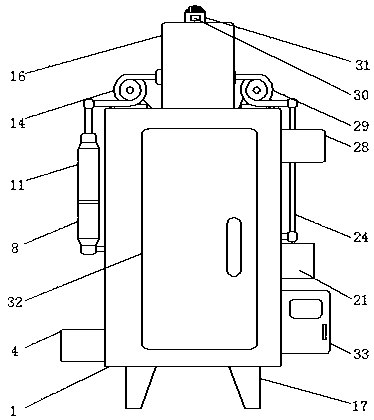

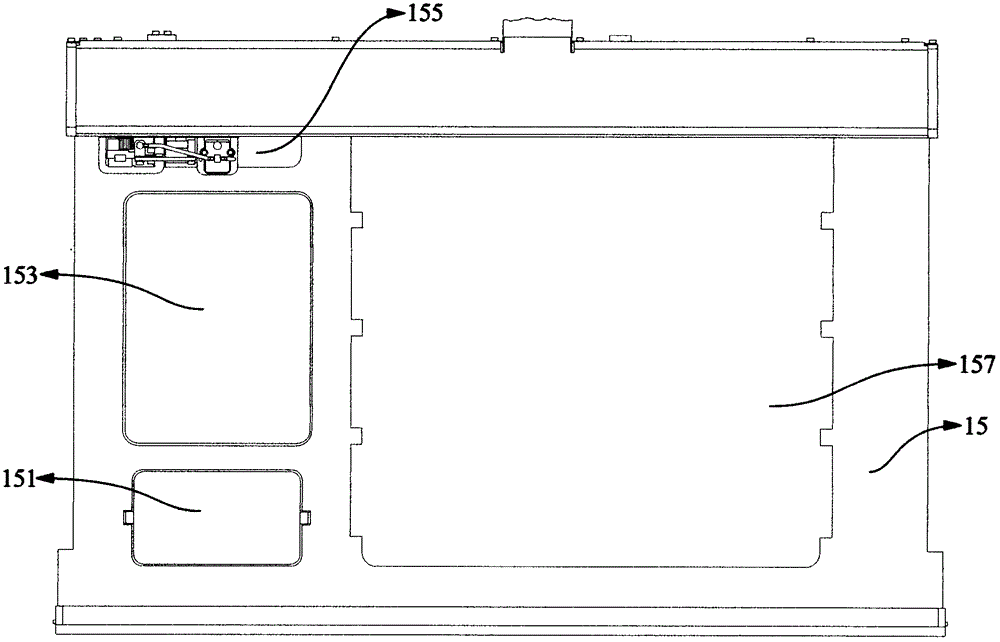

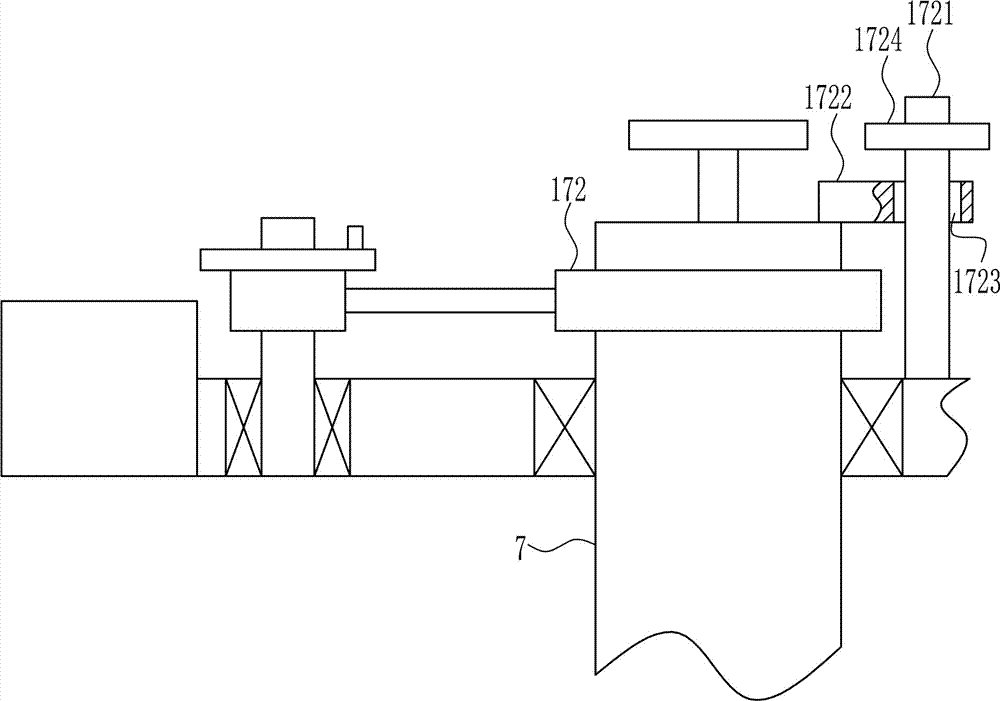

Polyester yarn dyeing production line

InactiveCN107419456AImprove uniformityDyeing speed is fastTextile treatment machine partsLiquid/gas/vapor textile treatmentProduction lineYarn

The invention discloses a polyester yarn dyeing production line, comprising a dyeing pool, the dyeing pool has a cuboid structure, a heater is installed at the bottom of the dyeing pool, a thermometer is installed on the inner wall of the dyeing pool, and a partition is installed inside the dyeing pool , the top of the partition is provided with a through hole, the first guide roller and the second guide roller are installed on the inner wall of the dyeing pool, the combing roller is installed on the inner wall of the dyeing pool, and the combing roller is provided with two groups , the combing roller is located directly above the second guide roller, combing is installed on the side of the combing roller, a cover is installed on the top of the dyeing pool, and a discharge roller and a receiving roller are installed above the cover. roller, and the discharge roller is positioned directly above the first guide roller, the receiving roller is positioned directly above the second guide roller, a motor is installed above the cover plate, and the output shaft of the motor is connected to a rotating shaft. The invention improves the dyeing uniformity of the polyester gauze and improves the dyeing quality.

Owner:JIANGSU HUIFENG TEXTILE

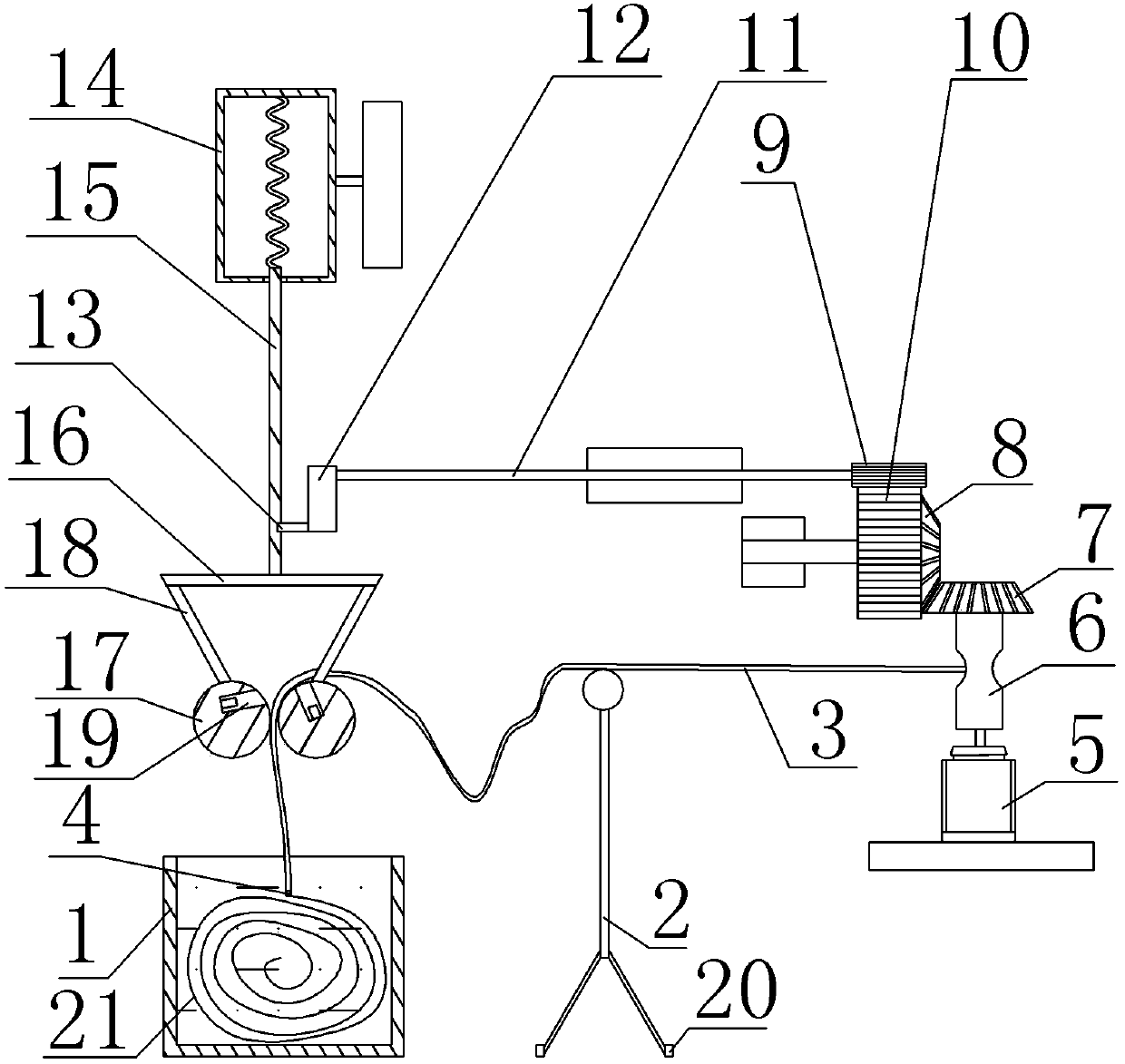

Natural plant dyeing agent and application method thereof

ActiveCN101390819AStrong penetrating powerDyeing speed is fastCosmetic preparationsHair cosmeticsFerrous saltsAdditive ingredient

The invention discloses a natural plant-type black hair dye and the application method thereof; the hair dye is prepared by natural plant raw materials including A agent, B agent and C agent. A agent is reducing agent which adopts cysteine or mercaptoacetic acid, or the combination of cysteine and mercaptoacetic acid, and is adjusted by sodium hydroxide to have the PH value of 8-12; B agent is chromogenic reagent which contains the main ingredients of water-soluble ferric salt, ferrous salt and azone, and used for improving the dye uptake rate and enhancing the washing endurance; C agent is pigment agent which is the extract of natural plants and prepared through the steps: the following ingredients by weight portion of containing the following ingredients, 7 portions of galla chinensis, 3 portions of mulberry, 4 portions of black sesame, 1-2 portions of angelica sinensis; the ingredients are crushed and mixed, and obtained through mixed immersion in water. The natural plant-type black hair dye has the advantages of adopting the natural plane extract as the main ingredients of the hair dye, natural and non-toxic extract, well hair infiltration, short dye uptake time, good washing endurance property, promoting the nutrition absorption of hair due to the Chinese traditional medicine nutritious ingredients and ensuring hair to be smooth.

Owner:吉林省御美天品科技开发有限公司

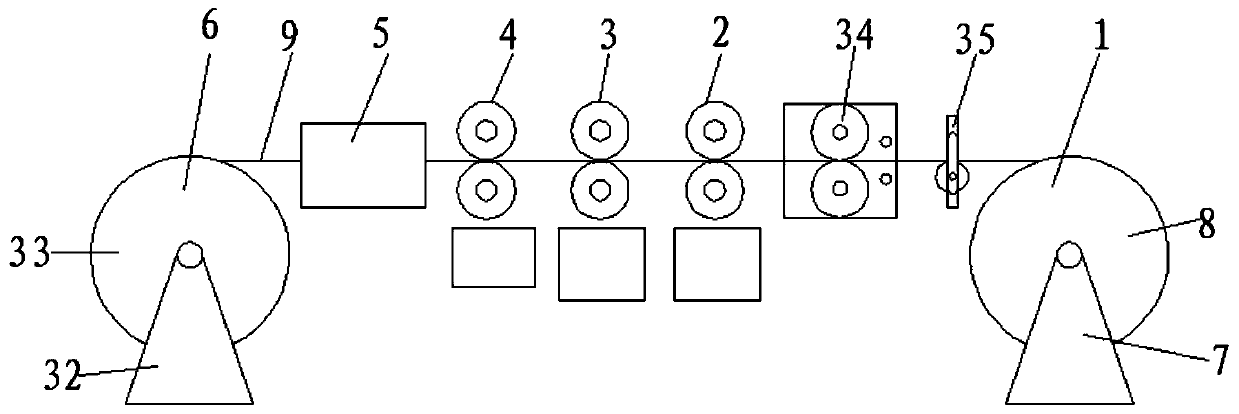

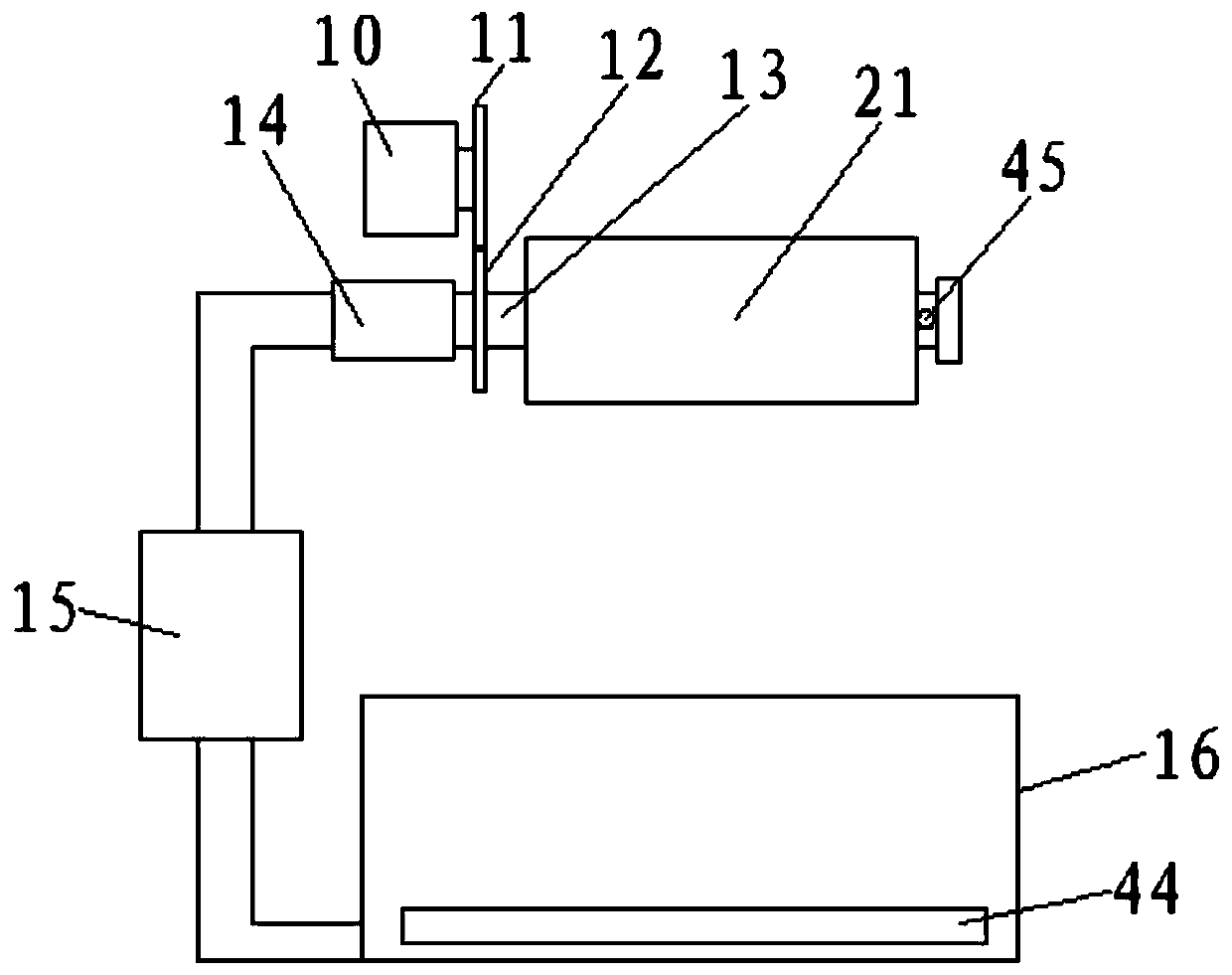

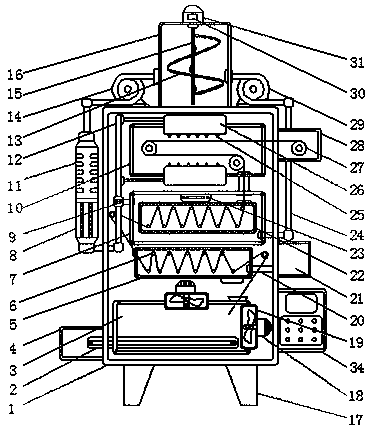

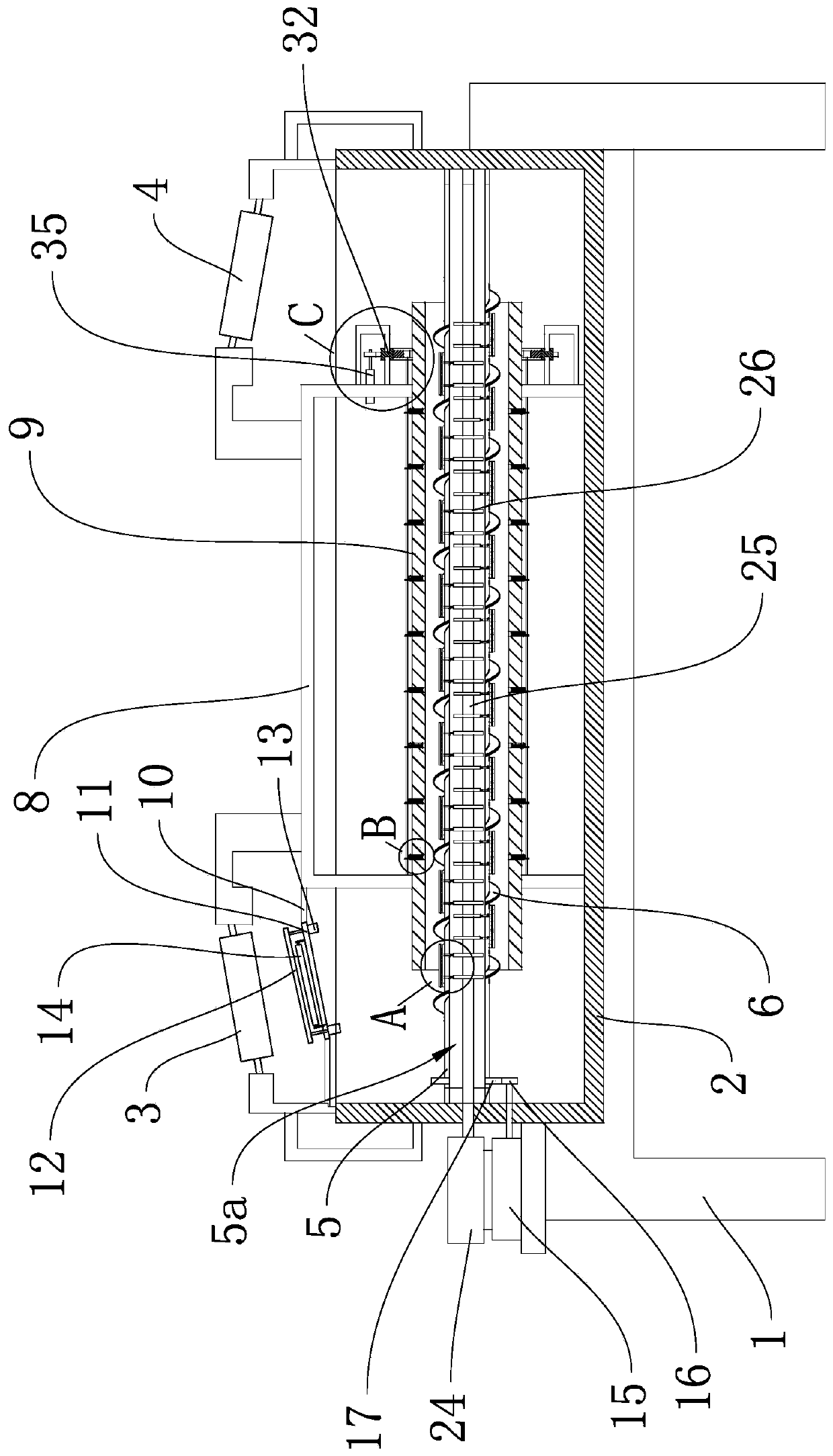

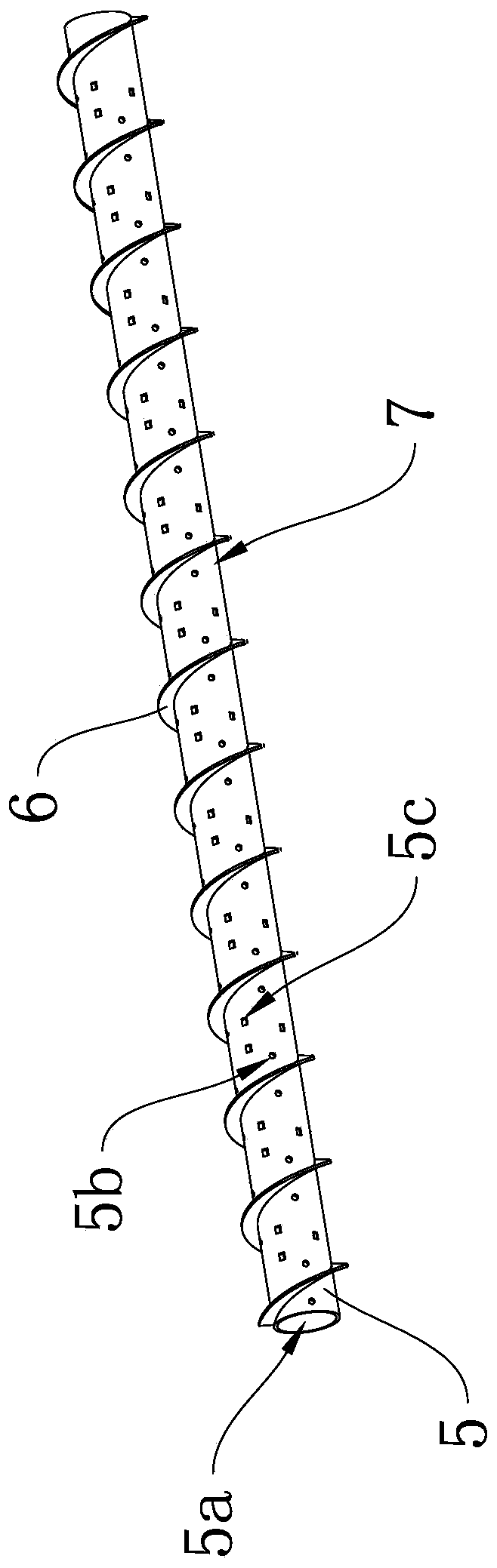

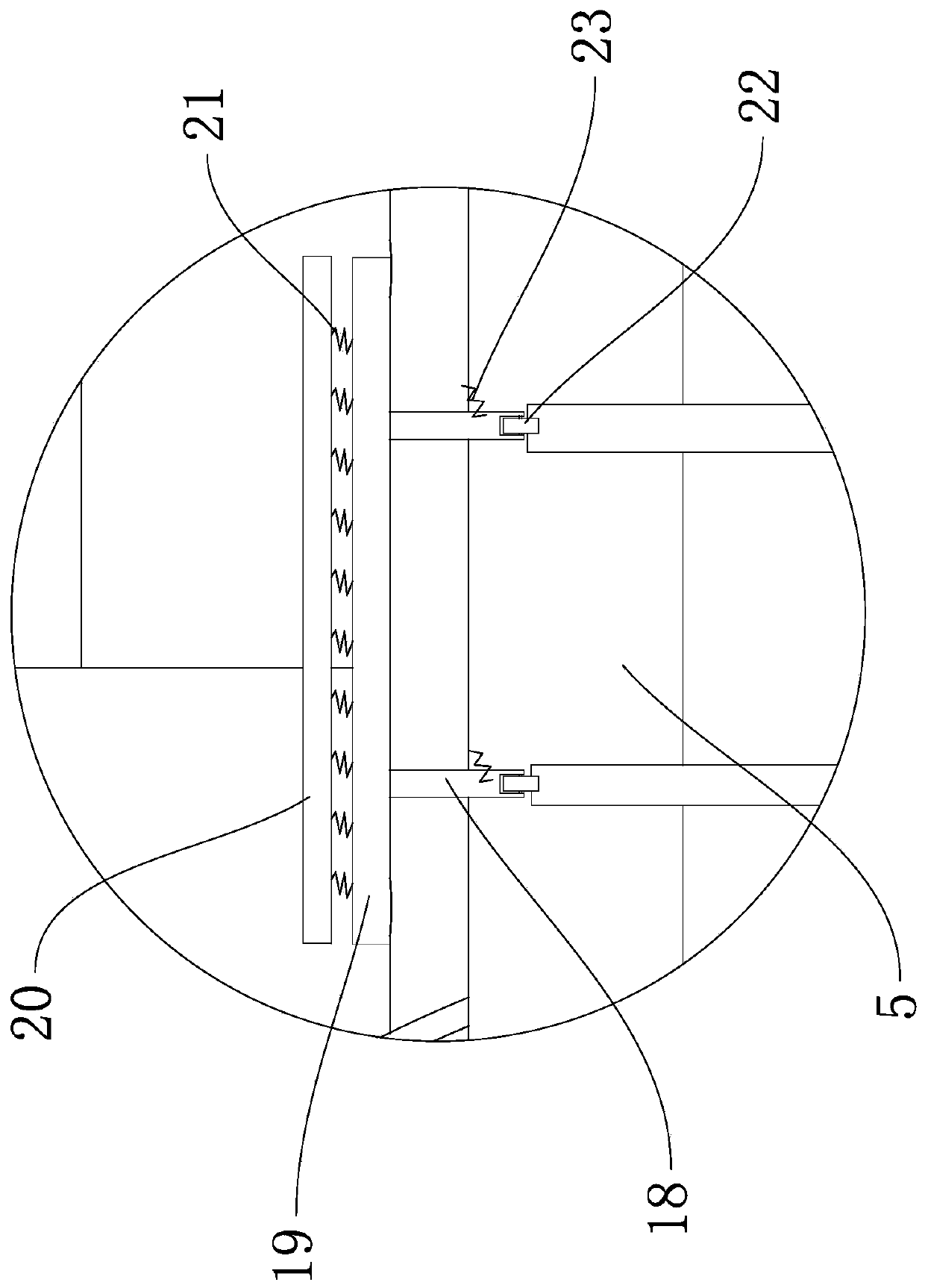

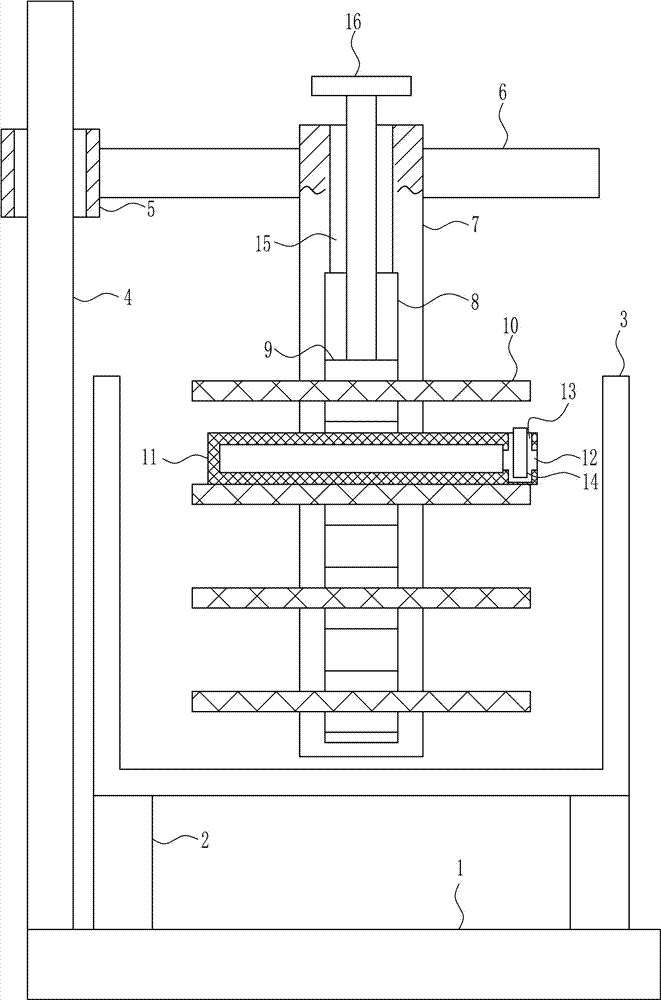

High-efficiency fabric dyeing device

ActiveCN109881409AImprove dyeing efficiencyConvenient for continuous dyeingTextile treatment machine arrangementsVibration treatmentWrinkleDyeing

The invention provides a high-efficiency fabric dyeing device, belongs to the technical field of machinery, and solves the technical problems that the existing dyeing efficiency is low, and a fabric easily wrinkles. The high-efficiency fabric dyeing device comprises a rack, wherein the rack is fixedly provided with a dyeing box internally provided with a dye, the rack is also provided with an unreeling cylinder and a reeling cylinder, the unreeling cylinder and the reeling cylinder are located at the two sides of the dyeing box, a fixing mechanism for preventing the fabric from falling off from the unreeling cylinder is arranged between the unreeling cylinder and the dyeing box, the dyeing box is internally and rotationally provided with a first rotating shaft, the surface of the first rotating shaft is provided with a spiral barrier strip, the barrier strip and the surface of the first rotating shaft form a channel for the fabric to pass through, the barrier strip is used for preventing the fabric from overlapping, the first rotating shaft is driven by a driving mechanism to rotate, and the first rotating shaft is provided with a hollow channel. The high-efficiency fabric dyeing device has the advantages that the dyeing efficiency is high, and the fabric does not easily wrinkle.

Owner:QUZHOU UNIV

Date peel red pigment, and preparation and application thereof

The invention provides a date peel red pigment, and preparation and application thereof. The preparation and application comprise 1) preparation of the date peel red pigment; and 2) ecological hair dyeing of the date peel red pigment. The date peel red pigment has the advantages of simple preparation method, low cost, high extraction efficiency and high pigment purity. When being used for ecologically dyeing hair, the natural plant hair dye prepared from the date peel red pigment as the main raw material has the advantages of high dyeing speed, high dye-uptake rate, high gloss after dyeing, no stimulation or anaphylactic reaction to the human body, high safety, no toxicity and favorable effect.

Owner:CHANGZHOU UNIV

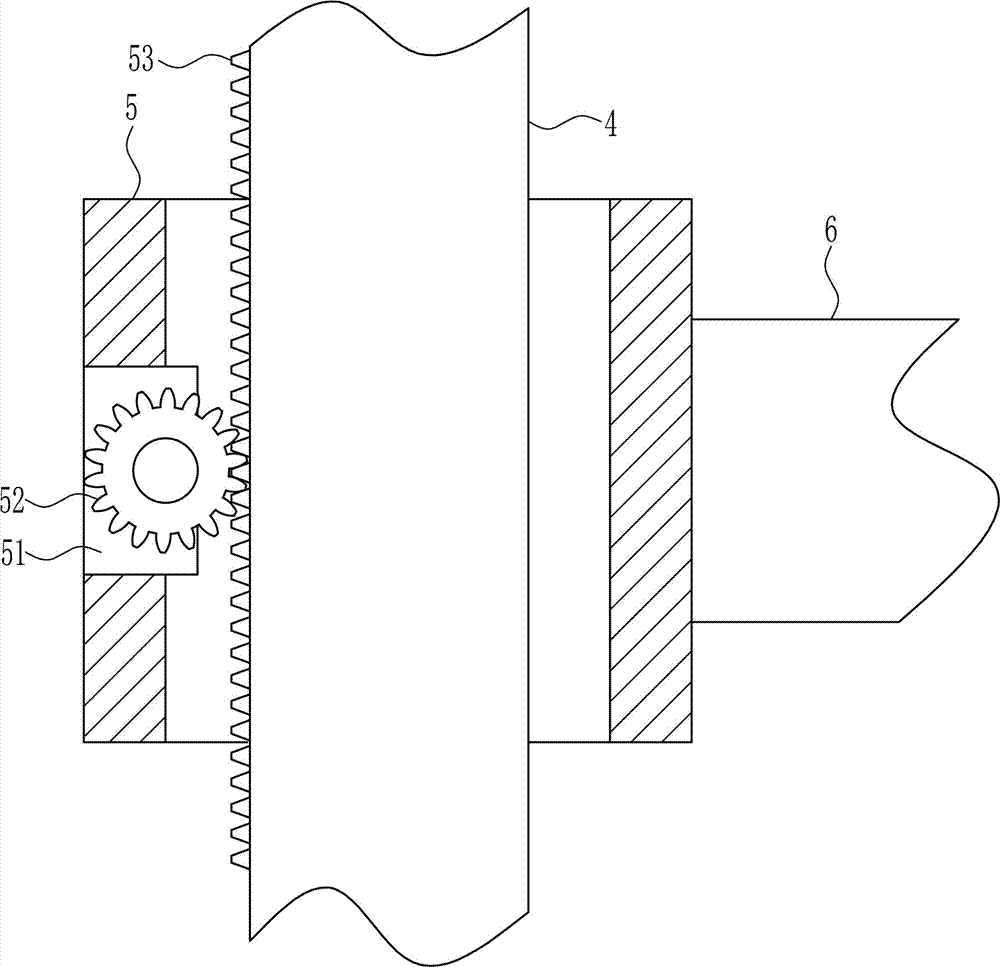

Rapid dyeing device for textile production

ActiveCN110923988ASave spaceDyeing speed is fastMechanical cleaningPressure cleaningPolymer scienceElectric machinery

The invention discloses a rapid dyeing device for textile production. The rapid dyeing device comprises a cloth rolling mechanism, a first dyeing mechanism, a second dyeing mechanism and a scraping mechanism, a drying mechanism and winding mechanism, wherein the cloth rolling mechanism comprises first bases; a cloth rolling cylinder is connected between the first bases through a first movable shaft; the cloth rolling cylinder is wound with cloth; the cloth sequentially penetrates through the first dyeing mechanism, the second dyeing mechanism, the scraping mechanism and the drying mechanism and is wound by the winding mechanism; each of the first dying mechanism and the second dyeing mechanism comprises two motors; the output end of each motor is provided with a first gear; one side of thefirst gear is meshed with a second gear; the second gear is fixedly arranged on a middle tube in a sleeving mode, and the middle tube is a tube sealed at one end; and one end of the middle tube is connected with a water pump through a rotary connecting piece. The rapid dyeing device has the beneficial effects that the dyeing speed is high, the dyeing quality can be ensured, and the required spacefor dye and dyeing can be effectively saved.

Owner:HANGZHOU XINLONG PRINTING AMD DYEING CO LTD

Dyeing process for superfine polyester denier fiber yarn

InactiveCN111172779AReduce dosageDyeing speed is fastLiquid/gas/vapor removalDyeing processDisperse dyeYarn

The invention discloses a dyeing process for a superfine polyester denier fiber yarn. The dyeing process comprises the following steps of (1) pre-shrinking, (2) slack winding, (3) caging, (4) deoilingpretreatment, (5) dyeing, (6) color fixation, (7) washing, and (8) drying. Furthermore, a carrier and phenyl ester are adopted as dyeing assistants for a yarn. According to the dyeing process for thesuperfine polyester denier fiber yarn, vacuum steaming is firstly adopted, then a low-bath-ratio dyeing process is adopted, and the yarn is dyed by using heterocyclic disperse dyes, so that the dyeing speed can be improved in the whole dyeing process and the amount of the dyes is reduced; and furthermore, a non-aqueous medium is adopted for color fixation, so that the color fastness can be greatly enhanced.

Owner:长江纺织(浙江)有限公司

Colored spun yarn dyeing device

PendingCN109423796APrevent precipitationUniform dyeingSucessive textile treatmentsTextile treatment machine arrangementsYarnColored

The invention discloses a colored spun yarn dyeing device which comprises a box body, a drying chamber, a first dyeing chamber and a dye tank. The bottom of the box body is provided with supporting legs, the bottom of the inside of the box body is provided with the drying chamber, the top and one side of the drying chamber are provided with fans extending into the drying chamber, the input ends ofthe fans are provided with first servo motors, the outer side wall, away from the first servo motor, of the box body is provided with a discharging port, the bottom of the drying chamber is providedwith a conveying belt extending to the discharging port, and a fixation chamber is installed in the portion, above the drying chamber, of the box body. The colored spun yarn dyeing device comprises the box body, the drying chamber, the first dyeing chamber and the dye tank, spiral stirring blades are installed in the dye tank and can stir dyes in advance, prevent dye sediment and the situation ofnonuniform dyeing, a filter can adsorb impurities in dyes and makes the dyeing quality of fabrics in dyeing improved, and the colored spun yarn dyeing device has strong practicability and is worthy ofpopularization and use.

Owner:江苏爱纺纺织有限公司

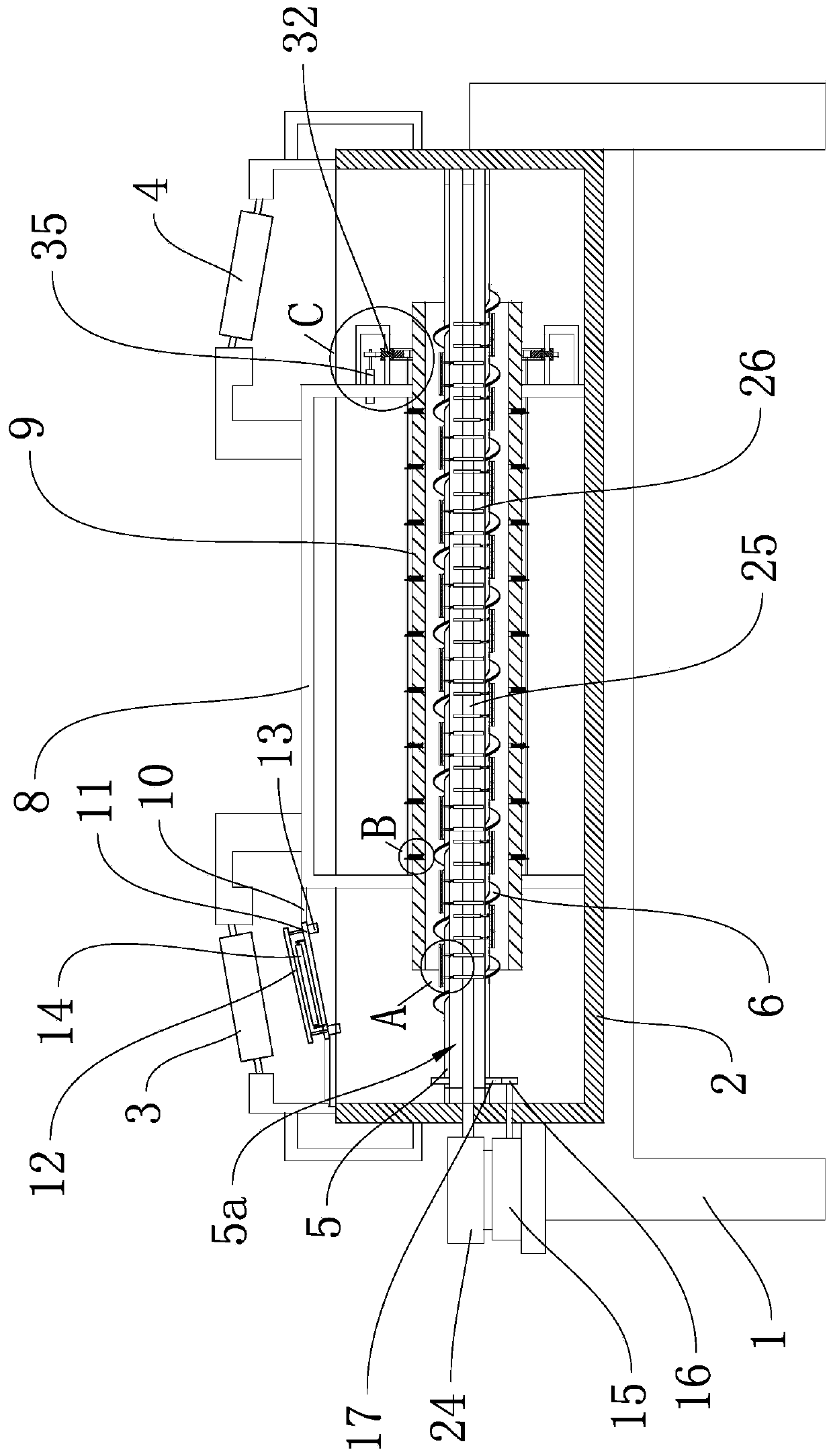

Cell morphology microscopic examination device and method based on staining technology

InactiveCN101762585AThe overall number will not decreaseGuaranteed statisticalPreparing sample for investigationInvestigating moving fluids/granular solidsStainingFlow cell

A cell morphology microscopic examination device based on the staining technology comprises a reaction bath, a measuring room, a liquid road unit and a micro-optical system. The device is characterized in that the liquid road unit comprises a cell sample interface and at least one reagent interface; the liquid road unit is at least communicated with one of the reaction bath and the measuring room; the reaction bath is communicated with the measuring room; and the measuring room is arranged in the micro-optical system. A cell morphology microscopic examination method based on the staining technology is characterized in that the liquid road unit is used to inject the cell sample and at least one agent in the reaction bath to mix together; after a certain time, the cell sample in the reaction bath is injected in the measuring room; and the flowing cell sample in the measuring room is imaged by the micro-optical system. The invention does not need the complicated mechanical smear device, the micro-optical system is fixed and the stained cell sample fast passes through the micro-optical system in an assembly-line mode, thus the fast cell morphology microscopic examination with high automation and compact structure can be realized.

Owner:孔兵

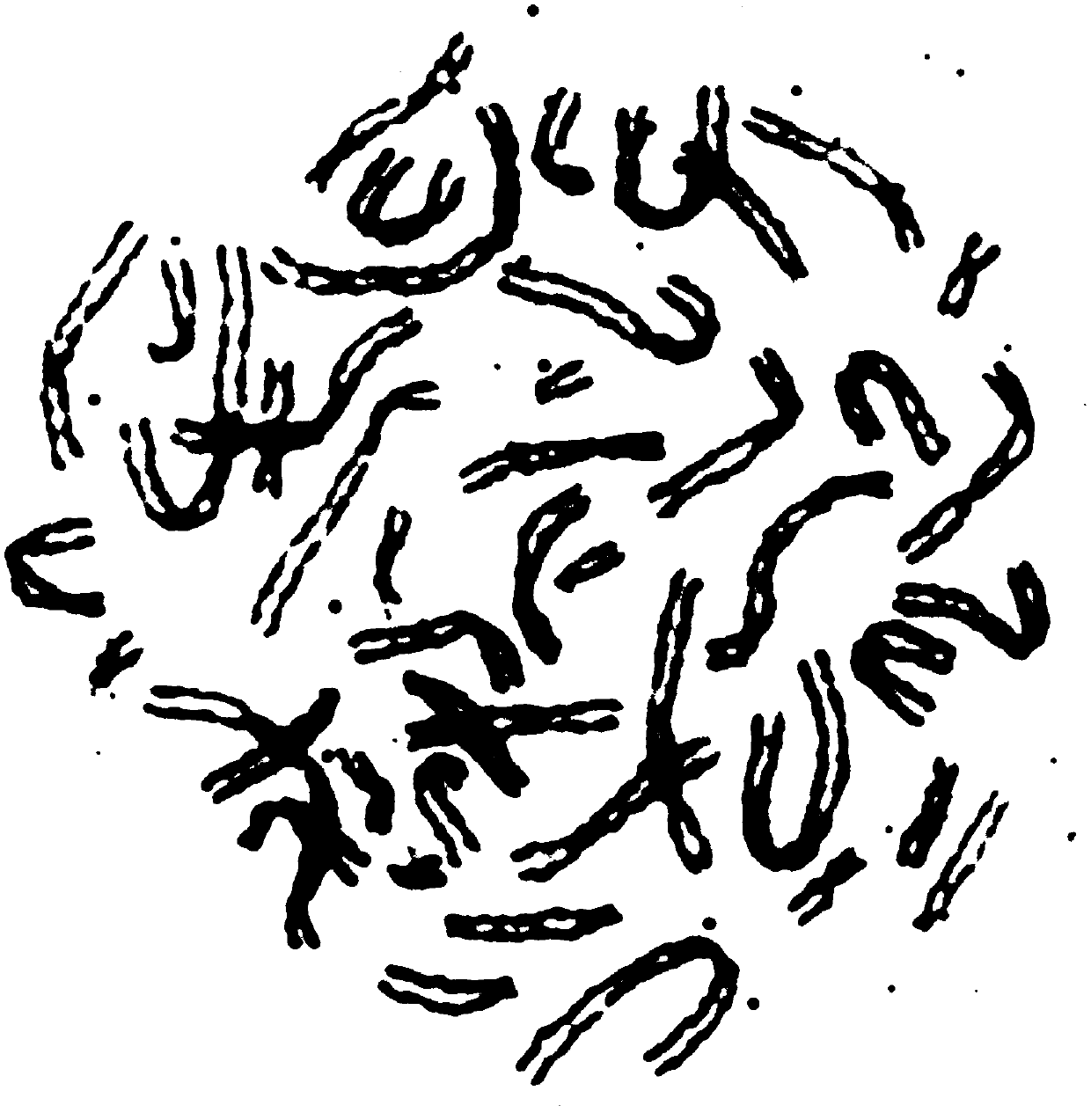

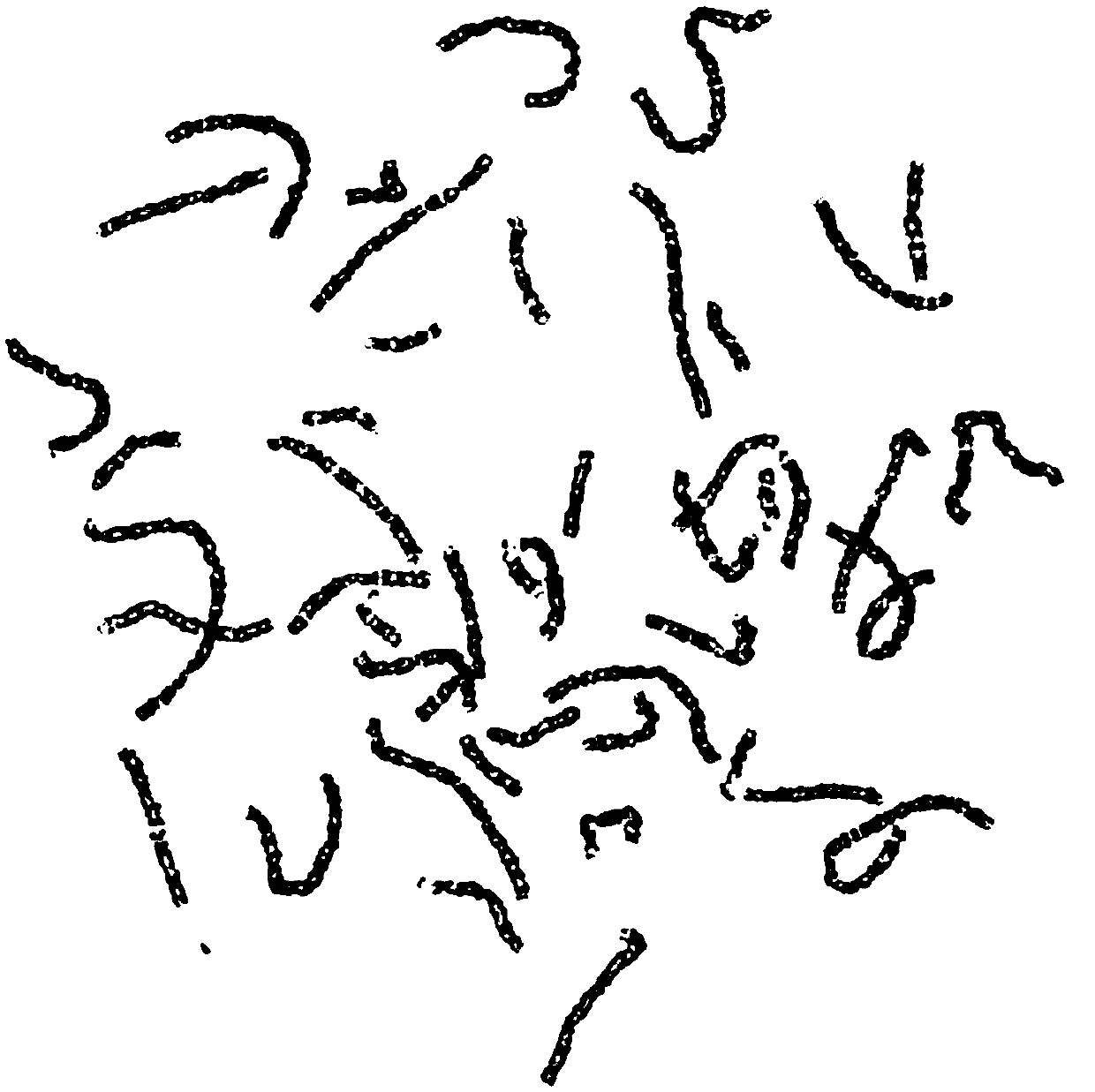

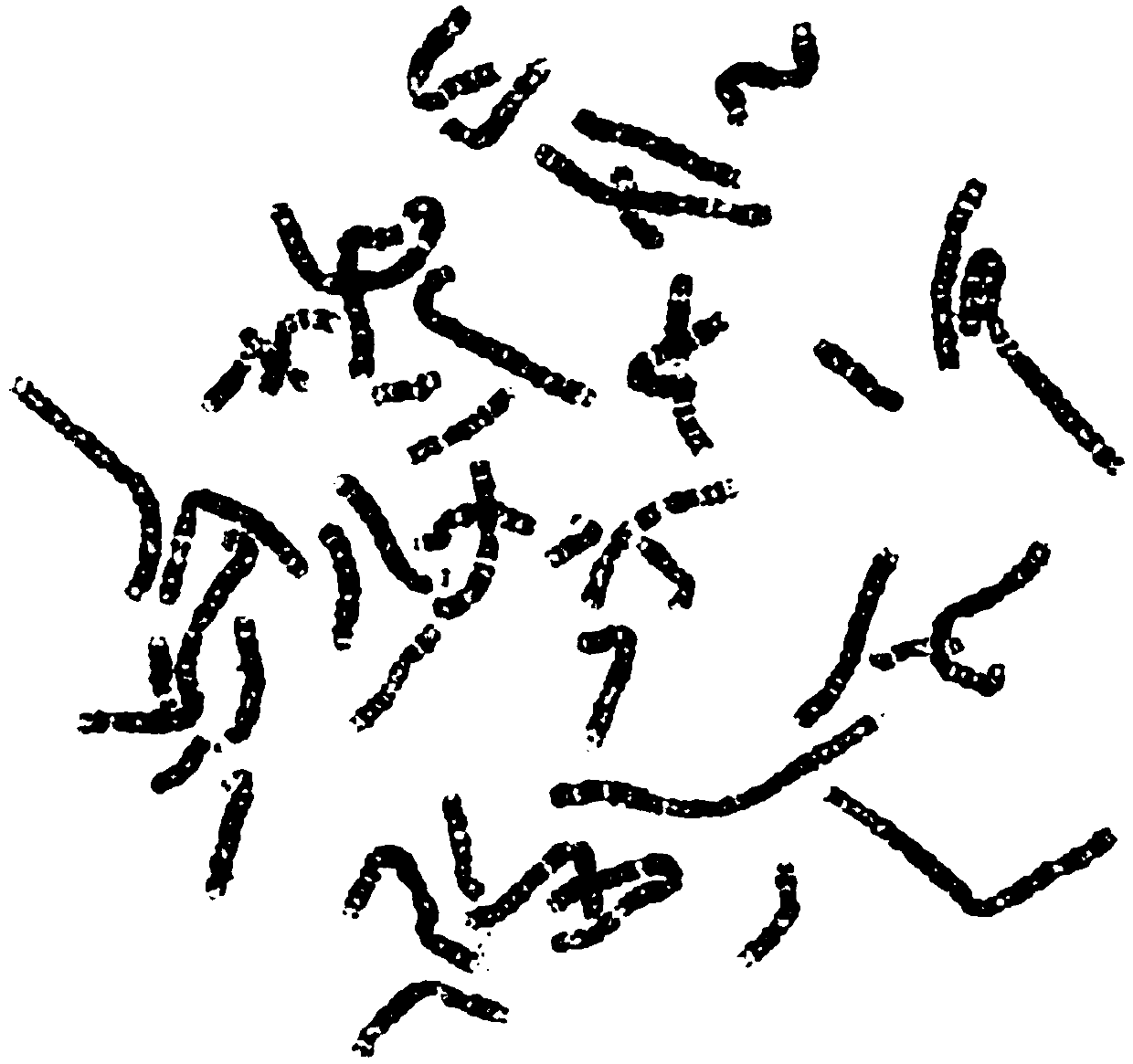

Dye liquid special for preparation of high-resolution chromosome by karyotype analysis

ActiveCN109540633AImprove dispersion characteristicsImprove dyeing qualityPreparing sample for investigationAlcoholKaryotype

The invention relates to a dye liquid special for preparation of high-resolution chromosome by karyotype analysis. The dye liquid is prepared by the following raw materials according to a proportion:1-3g of Giemsa dye power, 66-69ml of glycerinum, 66ml of methyl alcohol and 1-10 ml of dispersing agent. The dye particle is more refined and standard by grinding the dye particle, the dispersing characteristic of the dye particle is improved by addition of a dispersing agent, so that the uniformity and the clearness of dyeing are improved. By the novel dye liquid, the banding dyeing quality of the high-resolution chromosome is obviously improved, the banding belt dyeing effect of the high-resolution chromosome is clearer, the dyeing speed of human chromosome is rapid and controllable, and thebelt is clear. The dye liquid can be applied to large-scale clinic genetic laboratory.

Owner:BEIJING INST OF HUMAN GENETICS & REPRODUCTION MEDICINE LTD CHINA +3

Dyeing method of natural fiber

The invention discloses a dyeing method of a natural fiber. The dyeing method comprises the following particular steps of firstly, adding natural vegetable dye, liquid carbon dioxide and a color fixing agent into a supercritical carbon dioxide dyeing device, heating, and maintaining for a certain time; afterwards, adding the natural fiber into the supercritical carbon dioxide dyeing device, dyeingat and under certain temperature and pressure, and maintaining for a certain time; next, relieving the pressure, cooling to a normal temperature and depressurizing to normal pressure to obtain a preliminarily dyed natural fiber; treating the preliminarily dyed natural fiber, afterwards, adding into the supercritical carbon dioxide dyeing device, dyeing at and under certain temperature and pressure, maintaining for a certain time, and then relieving the pressure to obtain a finished-product dyed natural fiber. The dyeing method, through a two-step dyeing method, is used for realizing printingand dyeing the natural fiber by natural dye, and further, does not need pretreatment, and the dyeing method has advantages of good environmental protection effect, water resource conservation, good color fixation effect and the like.

Owner:JIANGSU NEW REBA TECH CO LTD

Black mulberry hair dye and preparation method thereof

InactiveCN103494753AStrong penetrating powerDyeing speed is fastCosmetic preparationsHair cosmeticsSulfite saltSemen

The invention relates to a walnut peel hair dye and a preparation method thereof. The walnut peel hair dye comprises a solvent A, a solvent B and a solvent C matched in use. The solvent A comprises the components in percentage by weight as follows: 3-8% of cysteine, 0-3% of hydroxyethyl cellulose and deionized water. The solvent B comprises the components in percentage by weight as follows: 2-20% of ferric salt, 2-20% of ferrite, 2-20% of azone, 0.5-3% of sodium sulfite and deionized water. The solvent C comprises the components in percentage by weight as follows: 10-20% of walnut peel, 3-10% of gallnut, 1-4% of mulberry, 2-6% of Semen sesami nigrum, 0.5-2% of Angelica sinensis and deionized water. The hair dye provided by the invention has the beneficial effects that natural plant extracts are used as main components of the hair dye which does not contain chemical substances such as aniline, strong oxidant and the like and is natural and free from toxicity, so that blue-black and purple black of hair after application of some hair dyes are avoided. In addition, nutritional components are added to promote hair to absorb nutrition, so that the hair is more gentle and agreeable.

Owner:济南益正生物科技有限公司

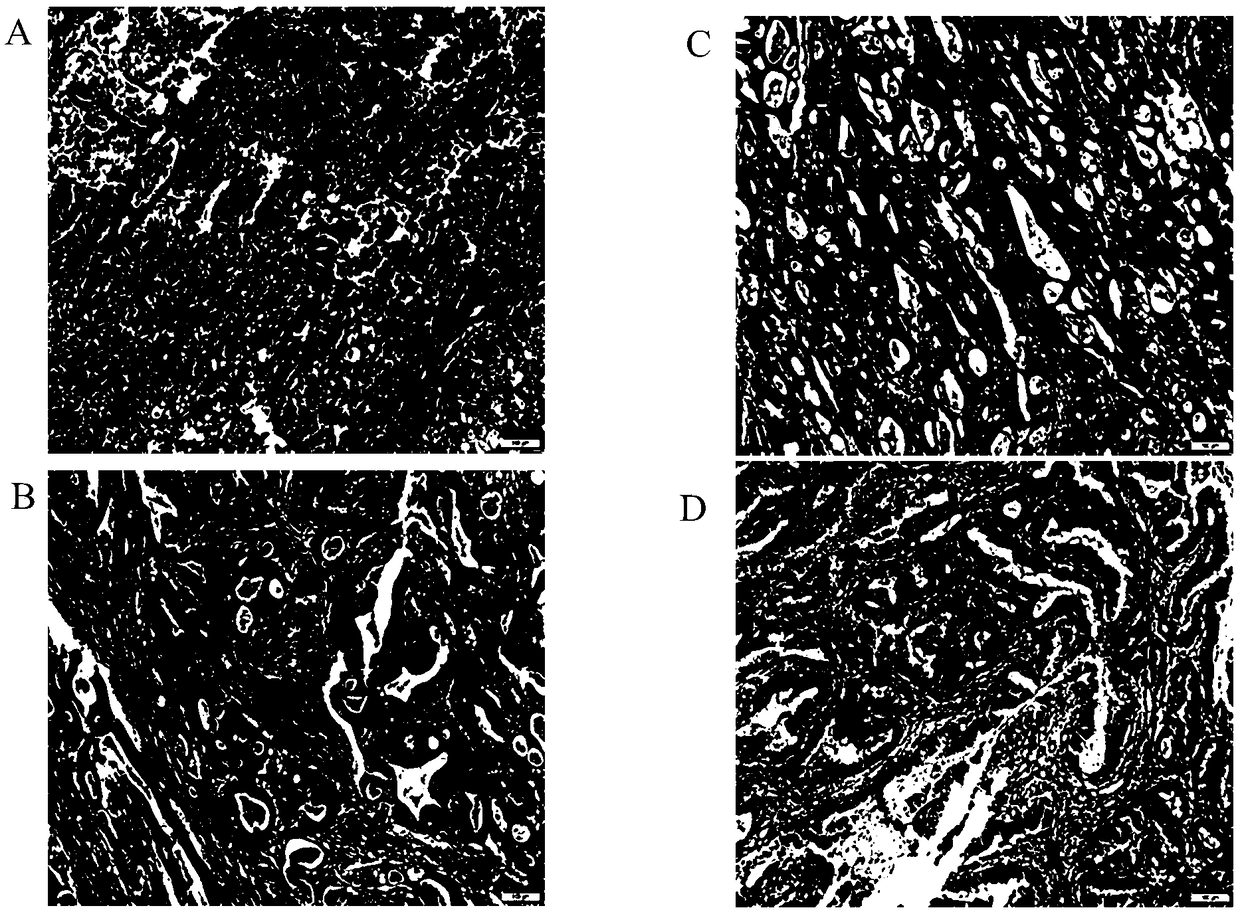

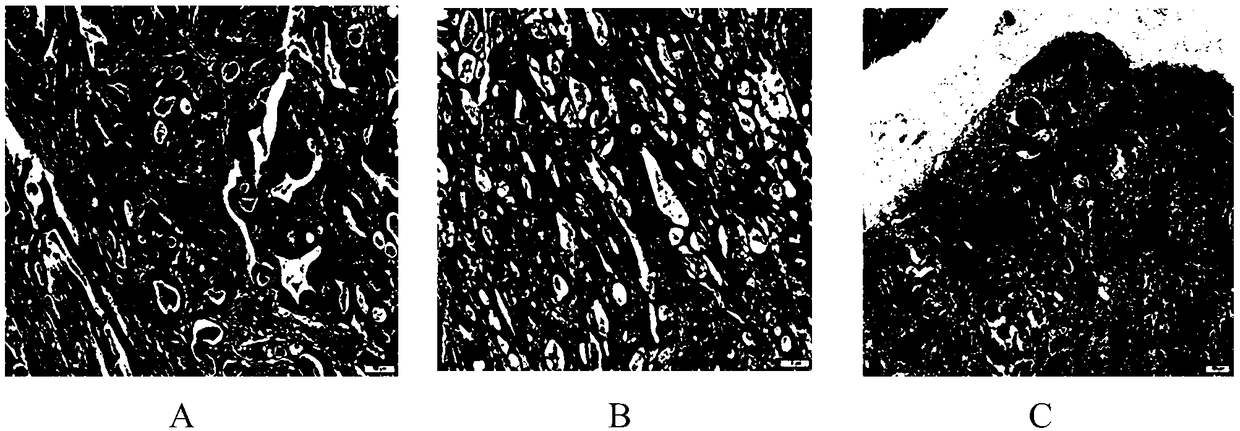

Improved HE staining method

ActiveCN108896376AEasy to controlDyeing speed is fastPreparing sample for investigationHematoxylin stainElectromagnetic shielding

The invention discloses an improved HE staining method. The method includes steps of dewaxing, rehydration and hematoxylin staining of sections under electromagnetic stirring at a temperature of 41-44DEG C. The method enables the dewaxing, rehydration and hematoxylin staining steps to be carried out at an elevated temperature and cooperates with the electromagnetic stirring, and so the staining speed is greatly accelerated. Furthermore, the stirring and temperature conditions in the steps are the same, and the steps can be sequentially carried out in the same constant temperature equipment, which is convenient for the operation and is more convenient for the staining quality control and the consistent staining effect.

Owner:SICHUAN MACCURA BIOTECH CO LTD

Preparation method of black aluminum alloy dye and aluminum alloy dyeing method thereof

ActiveCN111621165ADyeing speed is fastGood UV resistanceSurface reaction electrolytic coatingOrganic dyesSodium acetateUV resistance

The invention discloses a preparation method of a black aluminum alloy dye and an aluminum alloy dyeing method thereof. The preparation method comprises the following steps: (1) crushing a black dye and a dyeing assistant and carrying out uniform mixing to obtain a mixture; (2) dissolving the mixture obtained in the step (1) in water to obtain a mixed solution; and (3) adjusting the pH value of the mixed solution obtained in the step (2) to 5.0-6.5, and adding a pH stabilizer to obtain the black aluminum alloy dye, wherein the dyeing assistant in the step (1) is prepared from sodium acetate, anhydrous sodium sulphate and dextrin. According to the dyeing method, aluminum alloy having undergone anodic oxidation and water washing is soaked in the black aluminum alloy dye obtained through thepreparation method for dyeing. Compared with the prior art, the prepared black aluminum alloy dye is high in dyeing speed and good in UV resistance.

Owner:柏安美创新科技 (广州) 有限公司

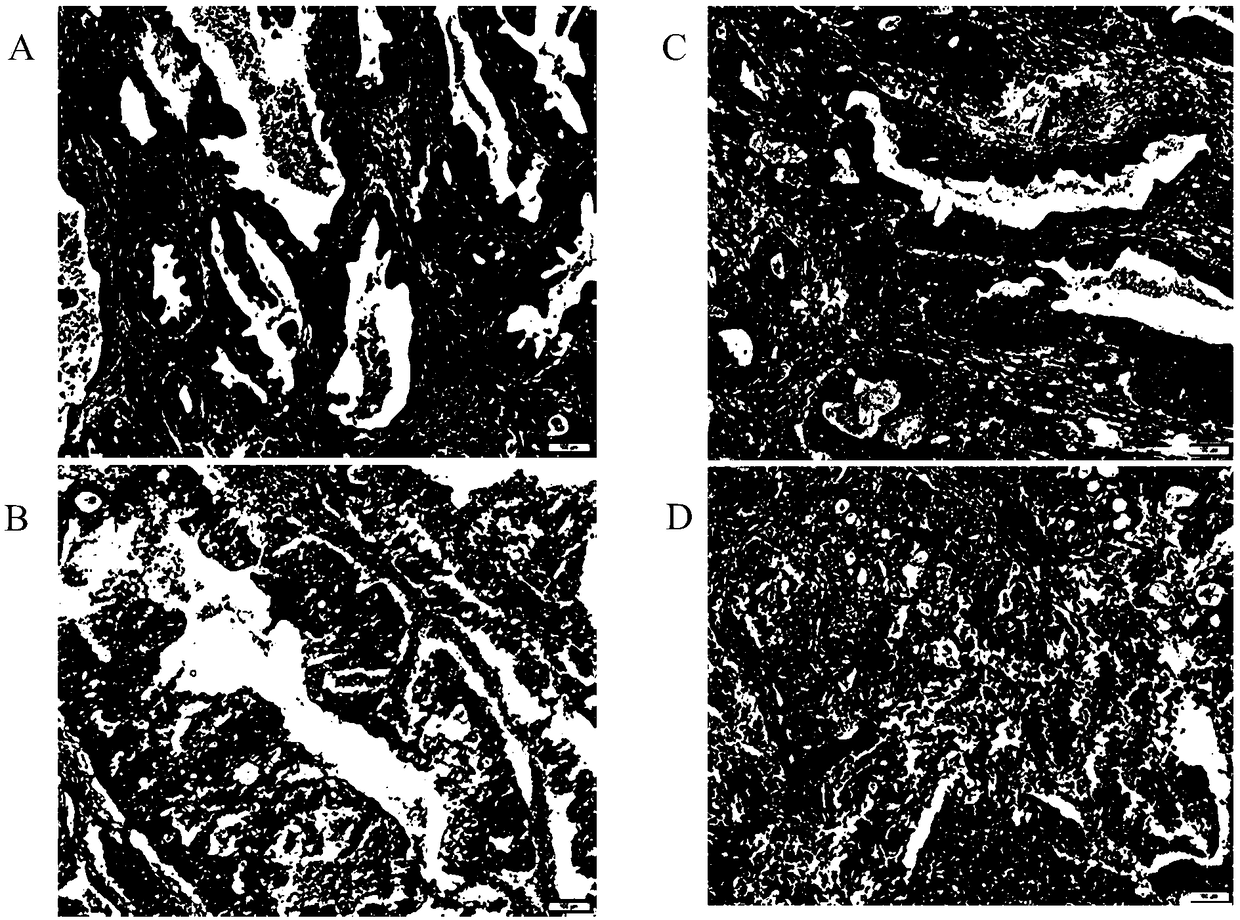

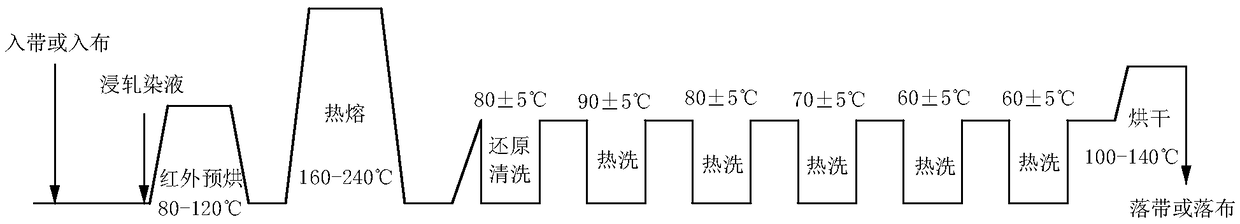

Continuous disperse dye pad-dyeing method for polyamide braids and fabrics

InactiveCN109098010ASimple dyeing processMaterial damage is smallDry-cleaning apparatus for textilesDyeing processTextile dyeingBraid

The invention relates to a continuous disperse dye pad-dyeing method for polyamide braids and fabrics and belongs to the technical field of textile dyeing and printing. According to the adopted technical scheme, the continuous disperse dye pad-dyeing method for polyamide braids and fabrics comprises the following steps that dyeing treatment is conducted on the polyamide braids or fabrics, whereina padding dispersion dye is adopted for the dyeing treatment, and then infrared preheating, hot-melting, baking and drying, reduced cleaning, washing and drying performed are performed after dyeing treatment. The continuous disperse dye pad-dyeing method has the advantages of being simple in process, stable in quality and high in production and processing efficiency, the influence on the physicaland mechanical properties of the polyamide braids or fabrics in the dyeing process is small, the influence of chemical assistants on the colors and color fastness of products after dyeing is small, and dyes have the higher capability of covering defects of fabrics.

Owner:CHENGDU HAIRONG TECHNICAL TEXTILES CO LTD

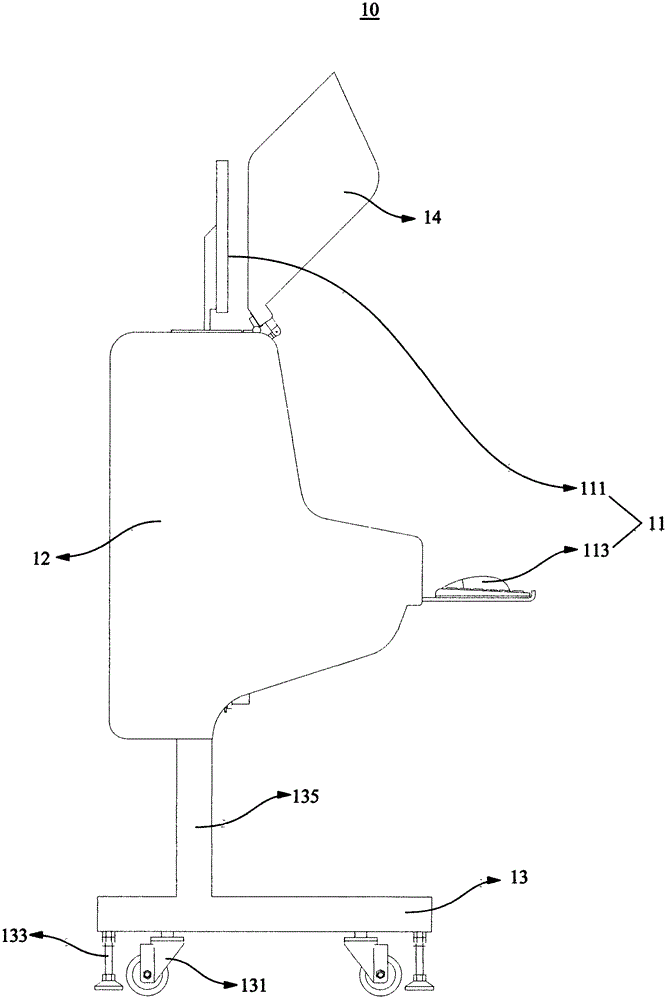

Staining instrument and control method for staining instrument

InactiveCN105890959AReasonable designShorten the motion pathPreparing sample for investigationEngineeringHead moving

The invention provides a staining instrument which is used for tissue slice immumohistochemical staining before a hospital morphology pathological test. The staining instrument comprises a workbench and a mobile mechanical head, wherein the mechanical head is located above the workbench; a suction nozzle area, a reagent area, a recycling area and a staining area are arranged on the workbench; a suction nozzle is arranged in the suction nozzle area; a reagent bottle containing a reagent is arranged in the reagent area; a test block is arranged in the staining area; the mechanical head moves to the suction nozzle area, effectively extracts a suction nozzle and then moves to the reagent area for absorbing the reagent; and then the mechanical head is used for dropwise adding the reagent into the staining area and putting the suction nozzle to the recycling area. The invention also provides a control method for the staining instrument. The control method is used for performing staining operation and comprises the following steps: S1) acquiring the suction nozzle from the suction nozzle area by a sucker of the mechanical head; S2) absorbing the reagent in the reagent area through the suction nozzle by the sucker; S3) dropwise adding the reagent in the suction nozzle onto the test block; S4) separating the suction nozzle from the sucker and placing the suction nozzle into the recycling area. The staining instrument and the control method thereof have the advantages of simpleness, high degree of automation, and the like.

Owner:王素蓉

Energy-saving and emission-reducing assistant for printing and dyeing and production method thereof

InactiveCN102021845ADyeing speed is fastUniform dyeing speedDyeing processDiacetone alcoholRare earth

The invention relates to an energy-saving and emission-reducing assistant for printing and dyeing, which comprises an assistant 1 and an assistant 2, wherein the assistant 1 comprises the following components in parts by weight: methylpyrrolidone, diacetone alcohol, salethyl, isopropyl salicylate and lauryl azone; and the assistant 2 comprises the following components in parts by weight: rare earth oxide, oxalic acid, water and ammonium carbonate. The production process of the assistant 1 comprises the steps of: adding the methylpyrrolidone in a reaction vessel, raising the temperature and then adding the diacetone alcohol, the salethyl,the isopropyl salicylate and the lauryl azone, reacting under the condition of preserving the temperature until the pH value is 6-6.5, and finally obtaining the assistant 1. The production process of the assistant 2 comprises the steps of: adding the oxalic acid and the water into the rare earth oxide La2O3, and then stirring with a high-speed stirring machine, adding the ammonium carbonate and the water, then stirring for 3-6min at a high speed, standing, and storing in a dark place.

Owner:陈家标

Processing technology of antibacterial ultraviolet-proof fabric

ActiveCN109972266AImprove dyeing efficiencyEasy to processSucessive textile treatmentsTextile treatment containersOrganic solventAntioxidant

The invention provides a processing technology of an antibacterial ultraviolet-proof fabric and belongs to the technical field of fabric processing. The processing technology of the antibacterial ultraviolet-proof fabric is characterized by comprising the following steps of S1, base cloth manufacturing, wherein a base cloth is woven by polyamide warp and dacron weft materials; S2, preparation of apadding solution, wherein an ultraviolet light absorber, a light stabilizer, an antioxidant, an antibacterial agent, a dispersion agent and an organic solvent are added to a stirrer, the stirring time is 12-24 minutes, the stirring speed is 260-320 r / h, and the padding solution is prepared; S3, base cloth dyeing, wherein a dyeing device is adopted for dyeing the base cloth in step S1, the paddingsolution in step S2 is put into the dyeing device, a dye is mixed with the padding solution, the temperature is controlled within 65-75 DEG C, and the dyeing time is 50-60 minutes; S4, cleaning; S5,drying; S6, cloth inspection; S7, warehousing. The processing technology has the advantages of being good in antibacterial effect, good in ultraviolet-proof performance and short in processing process.

Owner:嘉兴量创科技有限公司

Rapid cow leather dyeing equipment for leather processing plant

ActiveCN106868236AShort dyeing timeQuick stainLeather/skins/hides/pelt chemical treatment apparatusProcessing plantsWaste management

The invention relates to leather dyeing and processing equipment, in particular to rapid cow leather dyeing equipment for a leather processing plant. In order to solve the technical problems, the invention provides the rapid cow leather dyeing equipment for the leather processing plant, and the rapid cow leather dyeing equipment is relatively short in dyeing time and is relatively uniform in adsorption. The rapid cow leather dyeing equipment for the leather processing plant comprises a bottom plate, supporting columns, material boxes, a guide rail, a guide sleeve, a supporting plate, a connecting rod, a slide rail and the like, wherein the two supporting columns are mounted at the left side and the right side of the bottom plate in a welding mode; the material boxes are mounted at the upper ends of the supporting columns in a welding mode; the guide rail is mounted at the left side of the bottom plate in the welding mode; and the guide rail is connected on the guide rail in a sliding mode. The rapid cow leather dyeing equipment achieves the effects of being short in dyeing time and relatively uniform in dyeing; and a mode of arranging a filter box and cow leather on the connecting rod with a relatively great gap is adopted, so that a plurality of pieces of cow leather can be dyed once.

Owner:温州市依恋典鞋业有限公司

Hair dyeing box

The invention provides a hair dyeing box. The hair dyeing box comprises an upper cover, a lower cover, card wires and leather wings, wherein the upper cover and the lower cover are connected through a rotation shaft; notches for accommodating hairs are formed on the two sides of the upper cover and the two sides of the lower cover; the leather wings are adhered to a notch on one side; when the upper cover and the lower cover are folded, the leather wings shield the notches; the card wires are arranged on the inner surface of the upper cover and are densely distributed; and a cavity is reserved in the middle of the distributed surface. When the hair dyeing box is used for dyeing the hairs, extremely uniform dyeing effect can be achieved on the promise of saving a large number of hair dyes; head skin can be protected; and healthy hair dyeing is realized.

Owner:方郎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com