Pre-dyeing treatment agent for surface of blind hole workpiece in aluminum alloy welding area and application technology thereof

A technology of pre-dyeing and welding area, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of operator's health damage, environmental pollution, and unguaranteed yield rate, so as to improve work efficiency. Efficiency, saving time and cost, improving the effect of dyeing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

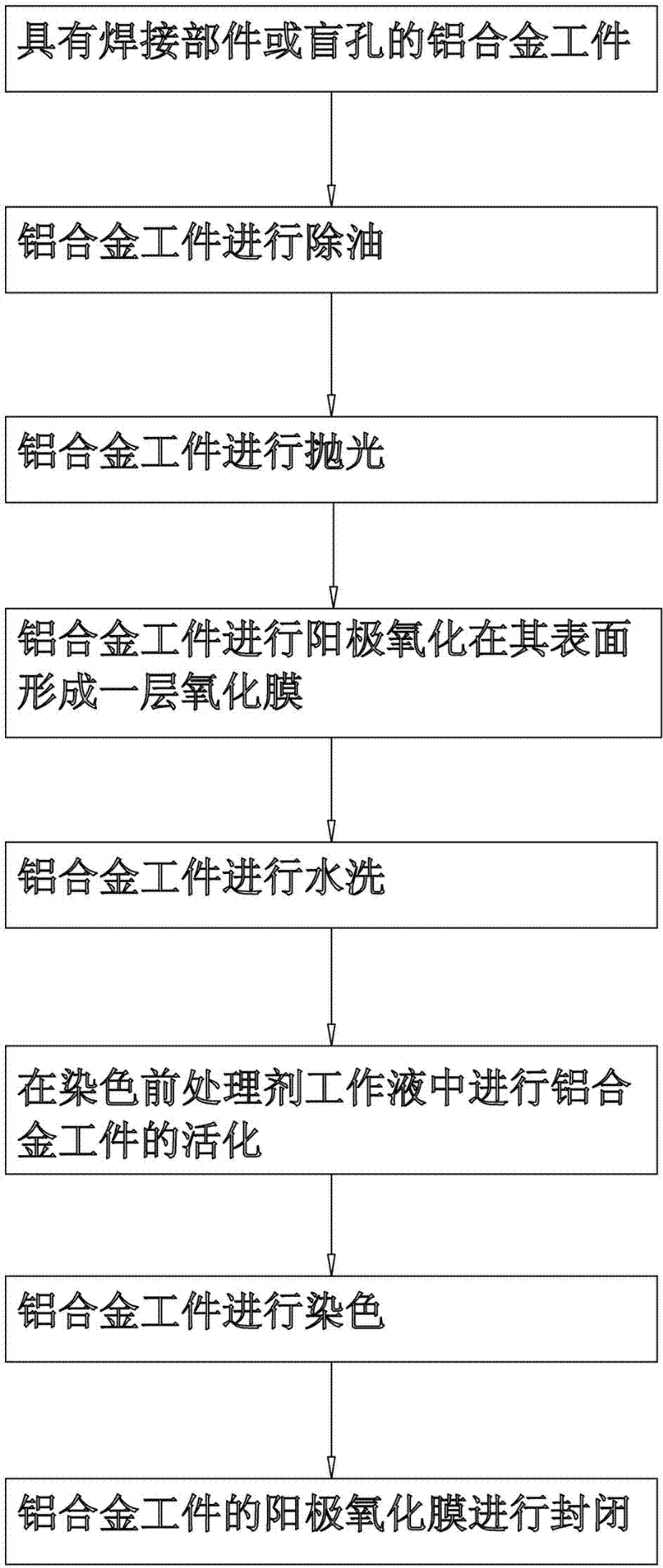

Method used

Image

Examples

Embodiment 1

[0021] Weigh 70% of citric acid, 28% of sodium citrate, and 2% of sodium dodecylbenzenesulfonate according to the total amount of dyeing pretreatment agent, and add the weighed organic acid and organic acid salt into the pulverizer to pulverize for 10- 15 minutes, then add the pulverized organic acid and organic acid salt into the mixer, then add the weighed anionic surfactant into the mixer, fully stir for 20-30 minutes at normal temperature and pressure, and then mix to form dyeing Pretreatment agent.

Embodiment 2

[0023] Weigh 75% of tartaric acid, 24% of potassium sodium tartrate, and 1% of sodium lauryl sulfate according to the total amount of dyeing pretreatment agent, add the weighed organic acid and organic acid salt into the pulverizer and pulverize for 10-15 minutes, and then Add the pulverized organic acid and organic acid salt into the mixer, then add the weighed anionic surfactant into the mixer, fully stir for 20-30 minutes at normal temperature and pressure, and then mix to form the dyeing pretreatment agent.

Embodiment 3

[0025] Weigh 80% of malonic acid, 18.5% of potassium hydrogen phthalate, and 1.5% of dioctyl sodium sulfosuccinate according to the total amount of pre-dyeing treatment agent, and add the weighed organic acid and organic acid salt to crush Pulverize in the machine for 10-15 minutes, then add the pulverized organic acid and organic acid salt into the mixer, then add the weighed anionic surfactant into the mixer, and fully stir for 20-30 minutes at normal temperature and pressure. That is, it is mixed to form a pretreatment agent for dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com