Rapid dyeing device for textile production

A rapid dyeing and textile technology, applied in textiles and papermaking, textile material processing, and textile material processing equipment configuration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

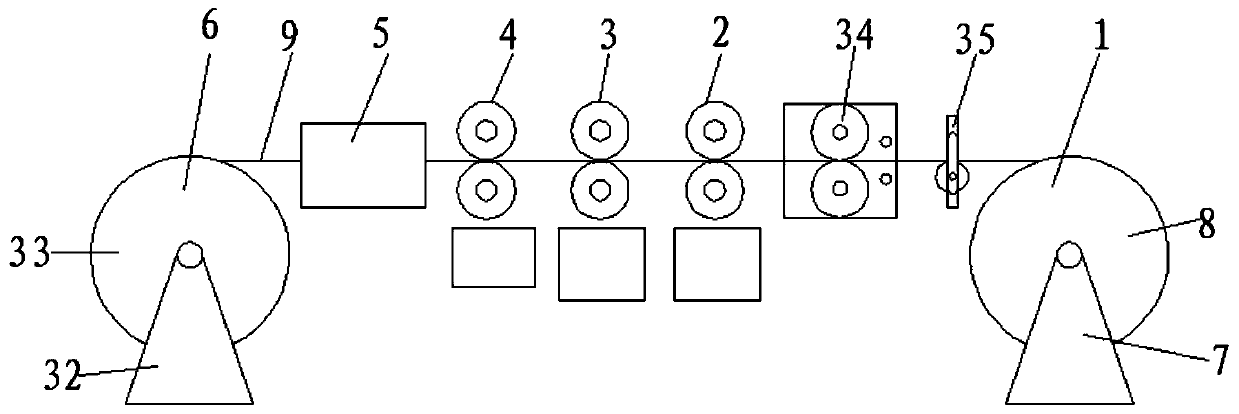

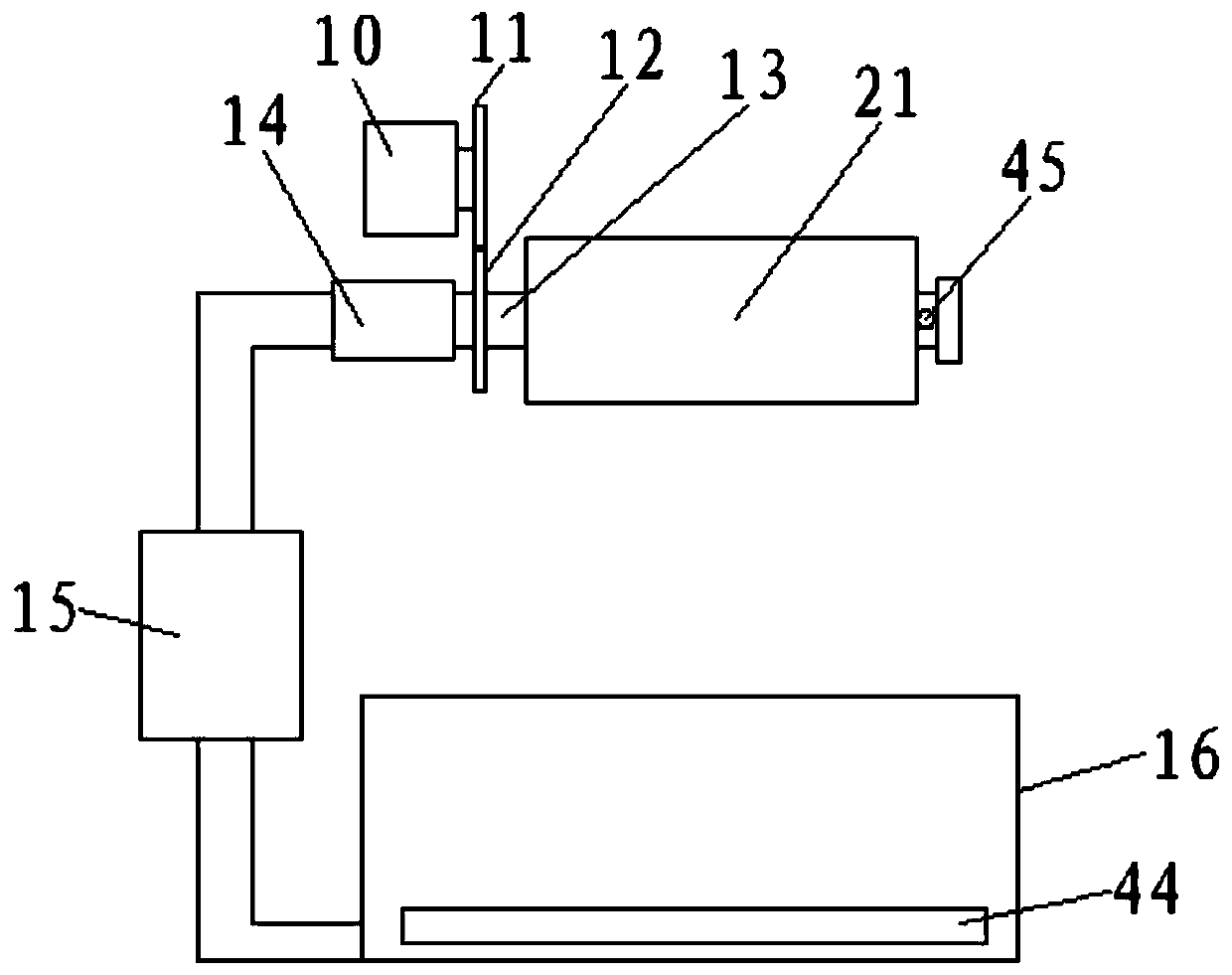

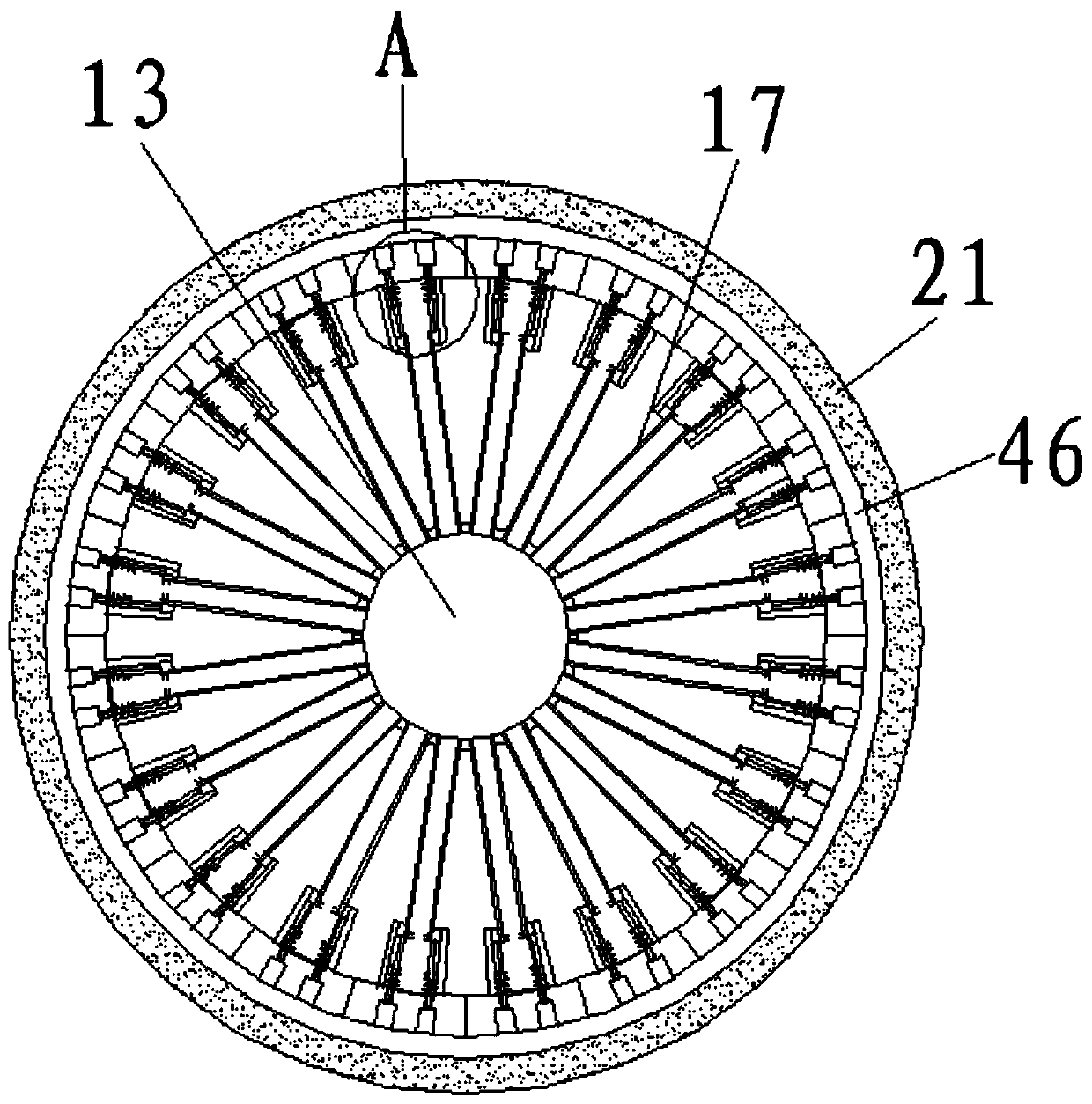

[0034] See Figure 1-9 , According to an embodiment of the present invention, a rapid dyeing device for textile production includes a cloth rolling mechanism 1, a first dyeing mechanism 2, a second dyeing mechanism 3, a scraping mechanism 4, a drying mechanism 5 and a winding mechanism 6 , The cloth rolling mechanism 1 includes a first base 7, a cloth rolling drum 8 is connected between the first bases 7 through a first movable shaft, and a cloth 9 is crimped on the cloth rolling drum 8. Pass through the first dyeing mechanism 2, the second dyeing mechanism 3, the scraping mechanism 4, and the drying mechanism 5 in sequence, and are crimped by the winding mechanism 6, the first dyeing mechanism 2 and the second dyeing mechanism 3 each includes two motors 10, the output end of the motor 10 is provided with a first gear 11, one side of the first gear 11 is meshed with a second gear 12, and the second gear 12 is fixed sleeve Set on the middle tube 13, the middle tube 13 is a tube...

Embodiment 2

[0037] See Figure 1-9 For the first dyeing mechanism 2, a dust removing mechanism 34 and a pulling mechanism 35 are provided between the first dyeing mechanism 2 and the cloth rolling mechanism 1. The dust removal mechanism 34 includes a housing, two ends of the housing are provided with cloth channels, two active rotating rollers 36 are arranged between the housings, and a cleaning brush is fixed on the active rotating roller 36. 37. One side of the cleaning brush 37 is located on the housing with a plurality of dust suction ports 38, and the dust suction ports 38 are connected with the input end of the vacuum cleaner 39. The lifting mechanism 35 includes two side plate racks 40. The side plate racks 40 are provided with notches. A passive roller 41 is arranged between the notches. The two ends of the passive roller 41 are located A first bearing is sleeved between the side plate frames 40, a bracket 42 is fixed on the first bearing, a screw rod 43 is connected to the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com