Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

357results about How to "High coloring rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

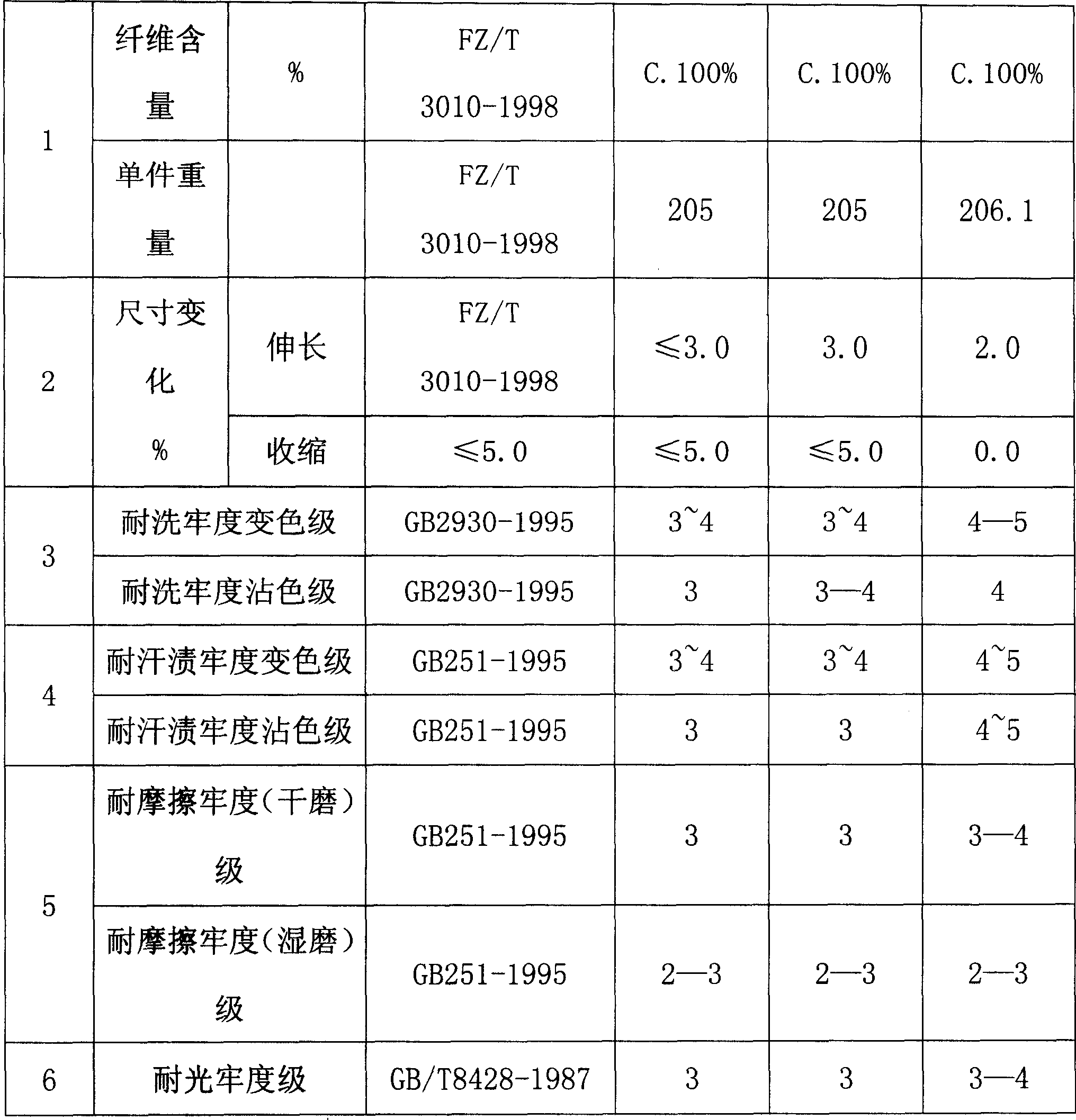

Environment-friendly dark blue and black series compound disperse dye and production method thereof

InactiveCN101792615AHigh coloring rateExcellent promotion rateOrganic dyesDyeing processDisperse dyePerspiration

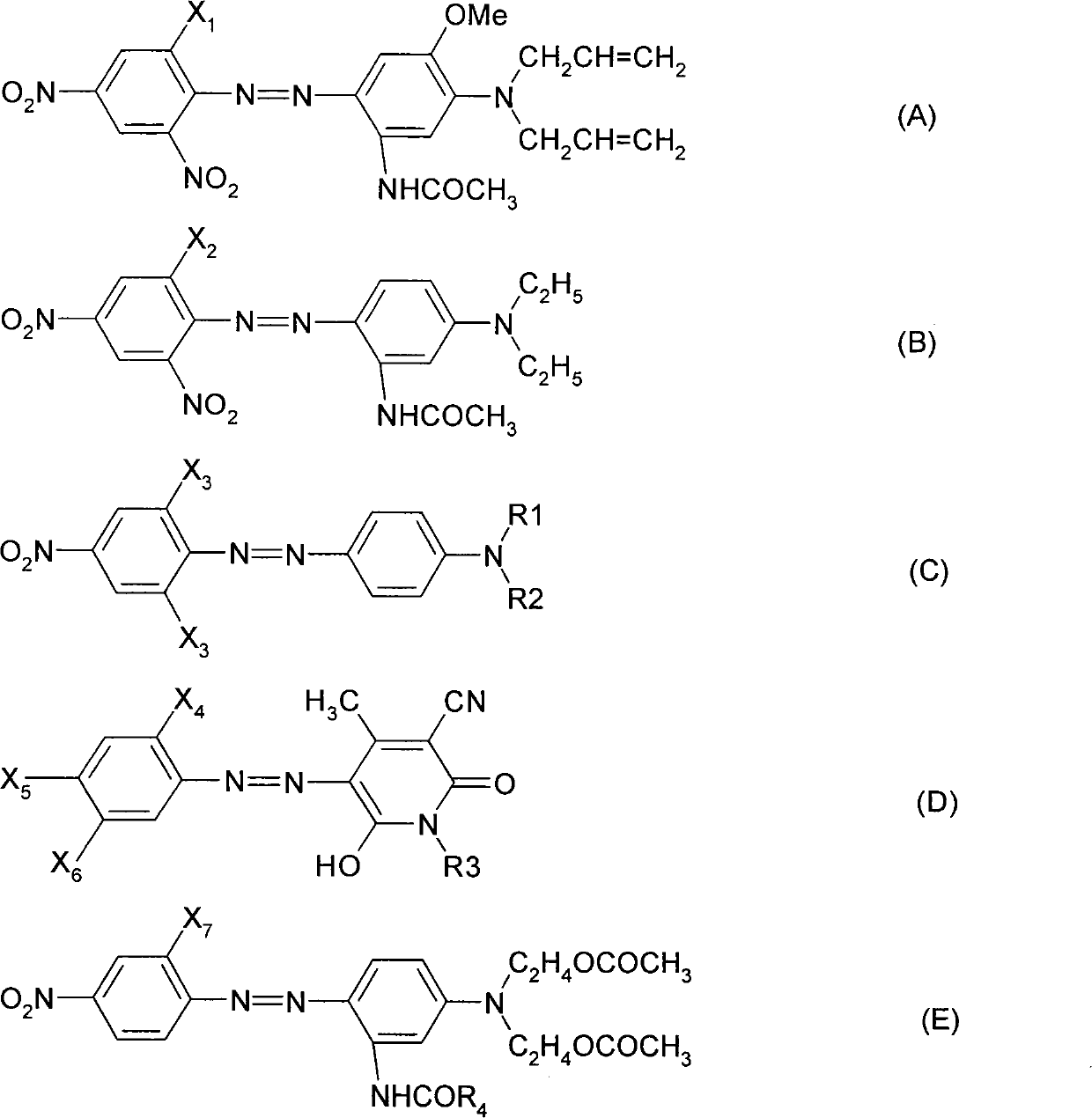

A dark blue and black series disperse dye compound is formed by compounding three or four of a monomeric dye A, a monomeric dye B, a monomeric dye C, a monomeric dye D or a monomeric dye E, wherein the mass percents of the monomeric dye A, the monomeric dye B, monomeric dye C, the monomeric dye D and the monomeric dye E are respectively 18-45%, 15-50%, 0-50%, 0-20% and 0-45%. When the commercial disperse dye produced by the disperse dye compound of the invention is used for dying hydrophobic polyester fibers, polyurethane fibers, polyamide fibers, acetate fibers and the like, the dark blue or black dyed fabrics with beautiful color shade, good dispersibility, high upgrading force and excellent sun proofness, washability, friction resistance, perspiration resistance and the like can be obtained by adjusting the ratio of different dyes.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

Novel unit module for solar-powered self-driven electronic paper apparatus and method for preparing same

InactiveCN101726956AHigh coloring rateIncrease contrastLight-sensitive devicesSolid-state devicesCapacitanceElectrical battery

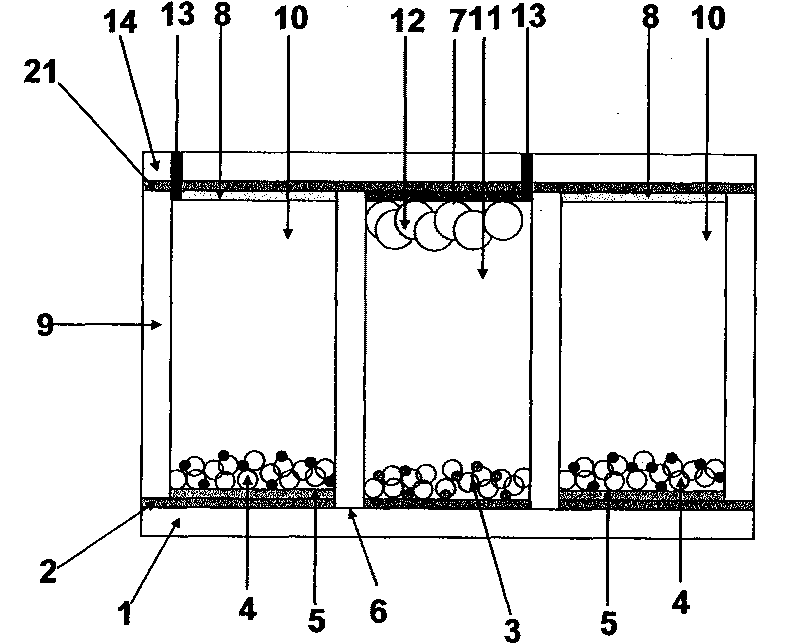

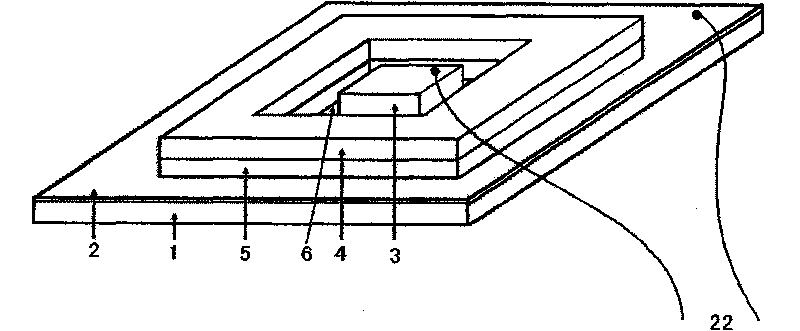

The invention relates to the technical field of electronic paper apparatuses, in particular to a unit module for a self-driven organic-inorganic electro-chromic electronic paper apparatus. The unit module is characterized in that the unit module has the following structure: a lower conductive film of cathode conductive glass is provided with a square etching region; the lower conductive film outside the square etching region is provided with an energy storage film layer and a solar cell light anode in turn; the lower conductive film inside the square etching region is provided with an electro-chromic cathode; an encapsulating material is arranged in the etching region and around the lower conductive film; the anode conductive glass and cathode conductive glass are longitudinally symmetrically arranged on the encapsulating material so as to be solidified into zigzag inner and outer cavities; an electro-chromic capacitance layer and a large-grain TiO2 reflecting layer are arranged in turn below an upper conductive film of the inner cavity; a Pt film counter electrode is arranged below the upper conductive film of the outer cavity; and the inner and outer cavities are respectively provided with electro-chromic electrolyte and solar cell electrolyte. Compared with the prior art, the novel unit module has the advantages of simple technique and low cost.

Owner:EAST CHINA NORMAL UNIV

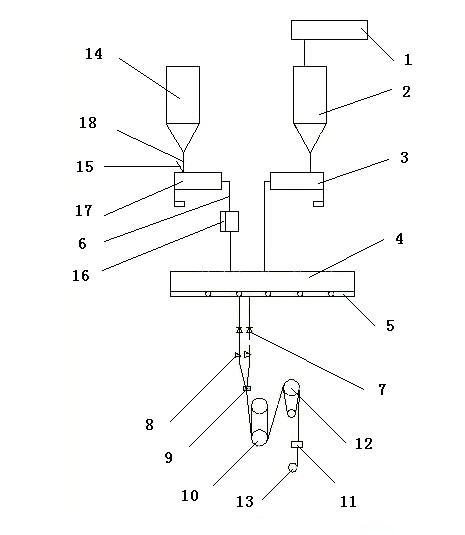

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

Method for producing advanced triple-wire double-calcination pure cotton fabrics

InactiveCN101718022AIncrease reflective areaShinyMercerising of yarns/threads/filamentsSingeingLiquid ammoniaDyeing

The invention provides a method for producing advanced triple-wire double-calcination pure cotton fabrics, comprising the working procedures of yarn dyeing, weaving, fabrics singeing, desizing, alkali mercerization, tenter setting and preshrinking. The method is characterized in that before being dyed, grey yarns are mercerized and singed, and a liquid ammonia working procedure is added between alkali mercerization and tenter setting, thereby forming the whole processing steps sequentially including yarn mercerization, yarn singeing, yarn dyeing, weaving, fabrics singeing, desizing, alkali mercerization, liquid ammonia, tentering and preshrinking. Compared with the traditional mercerized pure cotton fabrics, the triple-mercerization pure cotton fabrics obtained by the method have the advantages of higher lustre and high tinctorial yieldof yarns, fresher color of fabrics, good moisture absorption and ventilation, soft handle and high resilience, and the triple-wire double-calcination pure cotton fabrics are softer after being washed and maintain other excellent performances thereof.

Owner:LUTAI TEXTILE

Full biodegrade mulch master batch as well as preparation method and application thereof

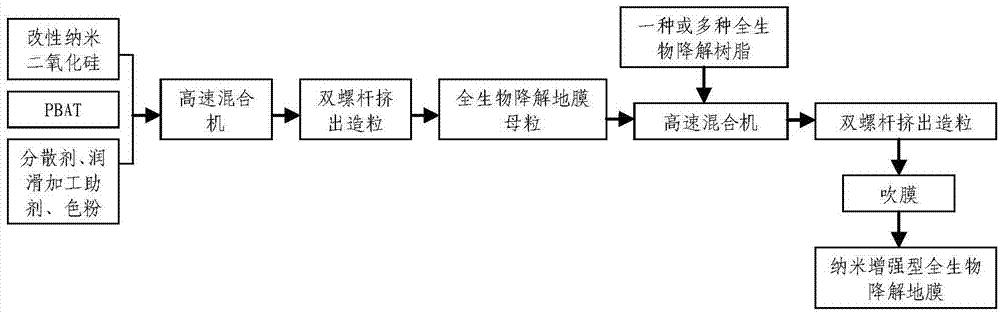

InactiveCN103756270AImprove mechanical propertiesGood compatibilityClimate change adaptationPlant protective coveringsUltimate tensile strengthSilicon dioxide

The invention discloses a full biodegrade mulch master batch which comprises the following components in percentage by weight: 70-80% of PBAT (Poly Butyleneadipate-co-Terephthalate), 10-30% of modified nano-silica, 4-7% of dispersing agent, 3-6% of lubrication machining additive and 0-5% of color powder. The invention further discloses a preparation method and an application of the master batch. A mulch product using the master batch has the following mechanical properties: the longitudinal tensile strength is more than or equal to 23MPa, the transverse tensile strength is more than or equal to 21MPa, the longitudinal elongation at break is more than 205%, the transverse elongation at break is more than 322%, and the right angle tear strengths in the longitudinal direction and the transverse direction are both more than 120N / mm.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

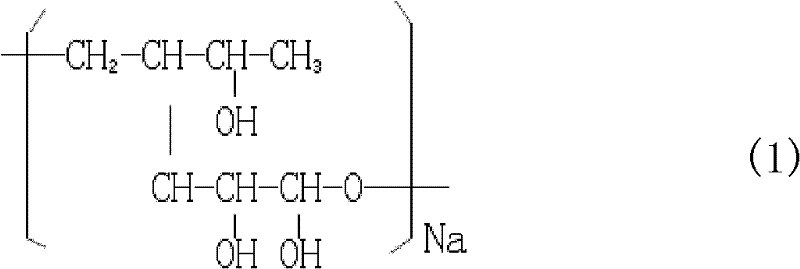

Sunproof water-soluble dye, method for preparing same and application thereof

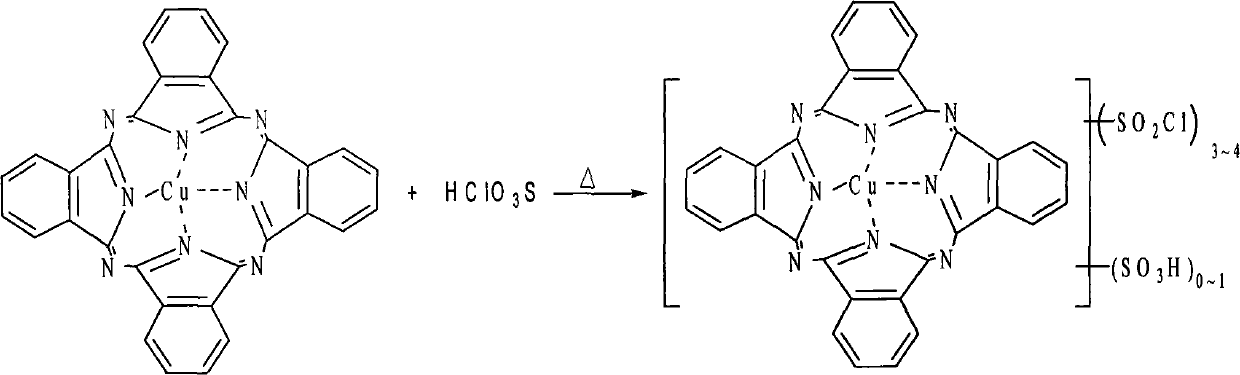

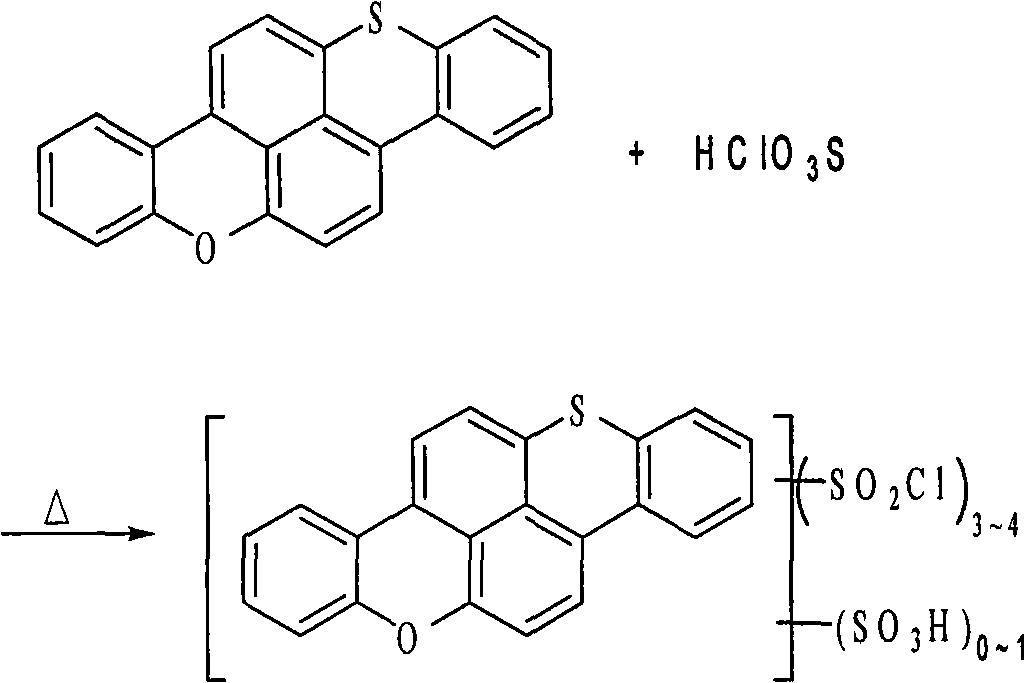

InactiveCN101864188AImprove light fastnessHigh coloring rateInksPaper/cardboardSolubilityPhthalocyanine dye

The invention relates to sunproof water-soluble dye having the general formula (1), a method for preparing the same and application thereof. The sunproof water-soluble dye imports the group of hindered amine 4-Z-2,2,6,6-tetramethylpiperidine and the water-soluble group of sulfonic groups based on the common water-insoluble dye, so that under a condition of ensuring good water solubility of the dye, the light stability of the dye is improved, and the sunproof property of the dye is also improved. In a general formula(1), A represents a dye matrix selected from a group formed by dioxazine dye, anthraquinone dye and phthalocyanine dye which are water-insoluble; R1 represents a general formula(2): -(SO2-R)m(2); R2 represents a general formula(3): -(SO3H)n(3); in the general formula(2) and the general formula(3), m and n are both a natural number, preferably m is a natural number between 1 and 16, and n is a natural number between 0 and 2.

Owner:上海汇友精密化学品有限公司

Surfactant for woven fabric dye-bath retreat process and preparation method thereof

ActiveCN101709554AImprove Cloth EffectsHigh coloring rateDry-cleaning apparatus for textilesDyeing processChemistryWoven fabric

The invention discloses a surfactant for a woven fabric dye-bath retreat process and a preparation method thereof, wherein the surfactant comprises the following components in percentage by weight: 10-20 percent of sodium stearate, 20-30 percent of sodium dodecyl benzene sulfonate, 3-8 percent of polyoxyethylene nonyl phenyl ether, 30-40 percent of dispersing agent MF and the balance of water. The preparation method comprises the following steps of: adding water into the sodium stearate for dilution so as to prepare a solution with the concentration of 5-8 percent; then, adding the solution into a reaction kettle, and heating to the temperature of 70+ / -5 DEG C; sequentially adding the sodium dodecyl benzene sulfonate and the polyoxyethylene nonyl phenyl ether, fully stirring and mixing; and finally, cooling to the temperature of 35+ / -5 DEG C, adding the dispersing agent MF after foams naturally disappear, fully stirring and mixing to prepare the surfactant. The product can prevent the reattachment of slurry and impurities, and improve the dyeing quality.

Owner:石狮市万峰盛漂染织造有限公司

Sodium alga acid printing paste and preparation process thereof

The invention relates to sodium alga acid printing paste, comprising the following components in percent by weight: 60-90% of sodium alga acid, 5-15% of sodium hexametaphosphate and 5-25% of anhydrous sodium sulphate. The preparation method of the sodium alga acid printing paste comprises the following steps of: (1) weighing sodium alga acid, sodium hexametaphosphate and anhydrous sodium sulphate in the proportion of a formula; (2) smashing the sodium alga acid to 30-40 meshes; (3) placing smashed sodium alga acid, sodium hexametaphosphate and anhydrous sodium sulphate into a mixing tank to be stirred; and (4) stirring to be completely uniform, thus the sodium alga acid printing paste finished product is obtained. The sodium alga acid printing paste disclosed by the invention has the beneficial effects that (1) sodium carboxymethyl starch having adverse effects on colouring is removed, and anhydrous sodium sulphate which can activate active groups in dye and has high colouring rate is adopted; and (2) sodium hexametaphosphate can cause calcium ions or magnesium ions in water to enter into sodium hexametaphosphate molecules to be changed into stable soluble complex, thus permeability of the printing paste is improved, colour fastness is improved, and the dye can be saved.

Owner:青岛聚大洋藻业集团有限公司

Application of nanocarbon biological bacterial fertilizer in cultivation of Tangxin apples and preparation method thereof

The invention relates to the field of biological bacterial fertilizer, in particular to the application of a nanocarbon biological bacterial fertilizer in cultivation of Tangxin apples and a preparation method thereof. The raw materials of the nanocarbon biological bacterial fertilizer comprise actinomycetes which are actinomyces microflavus, nanocarbon material, organic fertilizer and inorganic nutrient element. As the nanocarbon material is added into the fertilizer of the invention, the activity of succinic acid and malic acid is increased, thus the root development of apples is strongly stimulated. The nanocarbon material can improve the antimicrobial capacity of the actinomyces microflavus and enhance the inhibitory effects on various plant pathogenic bacteria to enable the root system of apple trees to be strong. The number of hair roots can be increased by more than 50%, the length of the root system can be increased by more than 30% and the coloring rate of apples can be increased by 37-45%. The wax coat of apple skin is thickened, the apple skin is crisp, the palatability is good and the taste is sweet. The sugar content can be as high as 17-25%. After the fertilizer is applied, the condition of scurf (pellagra) of apples is improved and alleviated, little leaf of fruit trees is alleviated and the life of apple trees is prolonged.

Owner:甘朝生

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Technical method of pigment wash, dye, and general finish for ready-made clothes in pure cotton

InactiveCN101003952AIncrease profitImprove pass rateLiquid/gas/vapor article treatmentDyeing processFiberCellulose

The present invention relates to a pure cotton garment washing, dyeing and finishing process. Said process successively includes the following steps: preparing cotton yarn, weaving, placing pure cotton garment into garment dyeing machine, preparing scouring and bleaching solution according to technological formula, scouring and bleaching to predefined time, washing, neutralization, washing; using cationic modifying agent whose dose is 1-3% of garment weight to make cotton fiber undergo the process of cationic modification treatment to predefined time; thermostatical dyeing to predefined time, washing, soaping, washing; using cellulose whose dose is 2% of garment weight to make enzymatic washing (polishing treatment) to predefined time, under the alkaline condition stopping enzymatic active action; dewatering, drying and finalizing the design.

Owner:海城市宏泰纺织印染有限公司

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Salt-free dyeing process for natural silk fabric

InactiveCN104746365AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsFiberInorganic salts

The invention provides a salt-free dyeing process for natural silk fabric. The salt-free dyeing process comprises the following steps: pre-treatment, pre-setting, modified treatment, dyeing, soaping, fixation, after-treatment, drying, setting, calendaring and rolling. The fabric is subjected to modified treatment with a cationic modifying agent, so that the dyeing rate of the fabric is increased; and the difficulty in the subsequent dyeing step is reduced. In the dyeing procedure, inorganic salts such as anhydrous sodium sulphate or table salt are not used, so that the pollution is reduced. Due to the addition of the soaping and fixation processes, the dyeing fastness is good. Green environment-friendly aldehyde-free TCD-R is adopted in the fixation process; and the fiber is gradually dried after fixation, so that the fastness of the fiber is greatly improved. Due to the addition of the after-treatment process, the color fastness and the softness of the fabric are improved; the roughness sense of the fabric is relieved; and the fabric is fluffy and elastic.

Owner:太仓市宝明化纤有限公司

Composite moderate temperature type red disperse dyes

A medium-temp composite disperse red dye with high dye uptake, compatibility, dyeing uniformity and fastness contains proportionally dye monomer A, B and C and assistant.

Owner:JIANGSU YUANZHENG CHEM

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

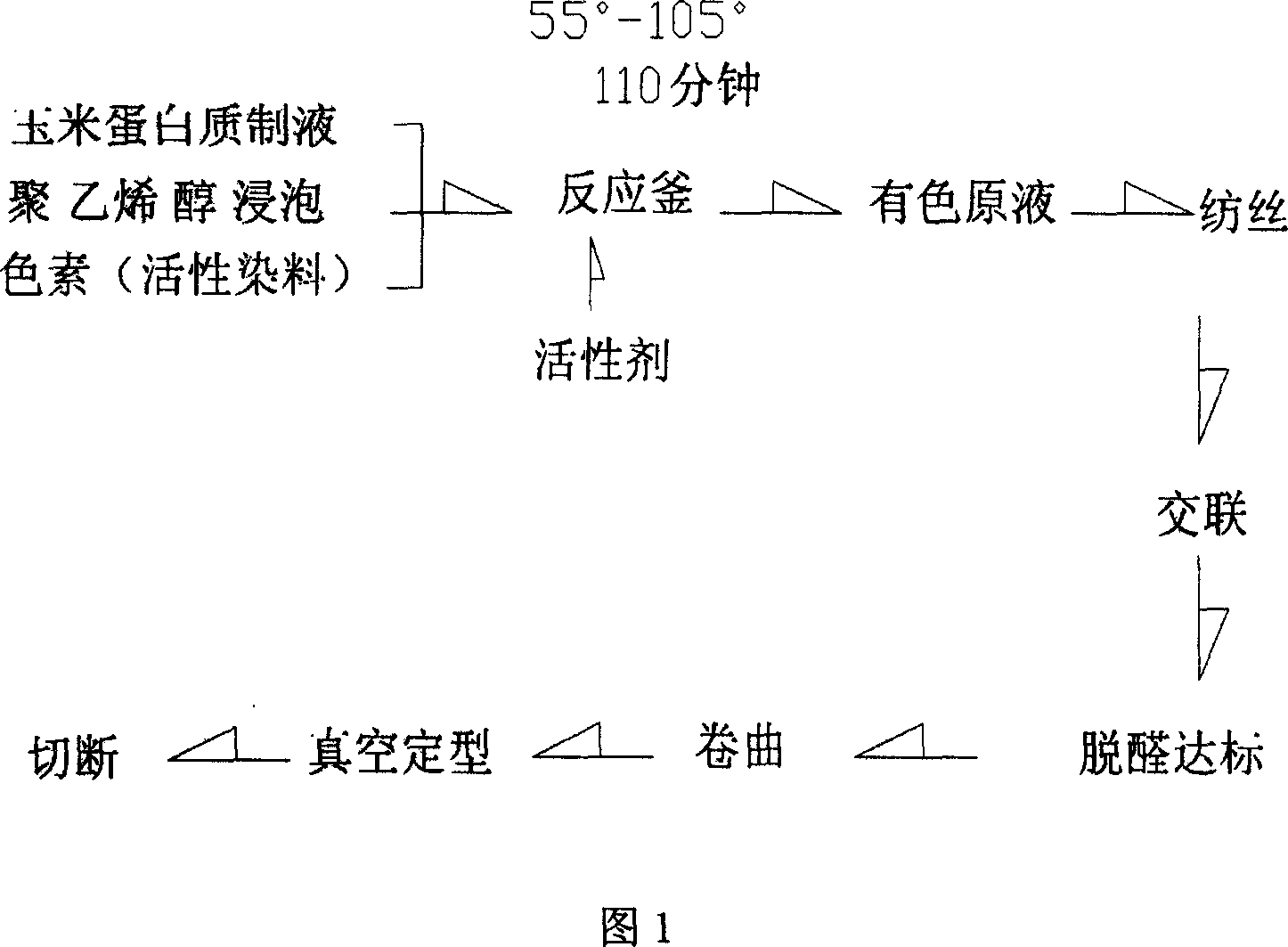

Maize protein colored textile fiber and method for producing same

InactiveCN1952225AHigh color fastnessNo pollution in the processMonocomponent protein artificial filamentDye addition to spinning solutionTextile fiberPhysical chemistry

The invention provides a colored fiber of corn protein and manufacture method. There is activated dye in corn protein. The manufacture method is that activated dye is added in the process for confecting spinning solution and plant protein colored fiber with the density of 0.7-3.0dtex is slubbed by wet spinning technology after ripening and polymerizing in reaction vessel. Because of activated dye added in confecting process, strike and fixation rates are improved. In detection method the cooler fiber has good fastness with five degree and enough light. There are no pollution and public disaster in the activated dye. The fiber is provided with good moisture conduction, light gravity, dry heat resistance and so on. It is knitted and tatted to various ultrathin or thickening apparel fabrics with high grade.

Owner:韩晓根 +1

Waterborne polyurethane spray paint for fabric and shoe materials and preparation method of waterborne polyurethane spray paint

InactiveCN107418418AGood dispersionLow viscosityPolyurea/polyurethane coatingsEmulsion paintsDispersion stabilityBiological activation

The invention discloses waterborne polyurethane spray paint for fabric and shoe materials and a preparation method of the waterborne polyurethane spray paint. The waterborne polyurethane spray paint is prepared from components such as waterborne polyurethane, water, toner and auxiliaries. The spray paint is good in dispersion stability, high in dyeing degree, good in brilliance, easy to process, free of sagging, free of bubbles, good in levelling, physical property and activation property, easy for secondary processing and free of polishing, can be bent for 130 thousand times or more, and is especially suitable for materials such as the fabric and the shoe materials.

Owner:HUNAN XINLIHUA NANO TECH

Paenibacillus mucilaginosus N6 and application thereof

InactiveCN105950505APromote growthPromote growth and developmentBiocidePlant growth regulatorsBacteroidesPaenibacillus mucilaginosus

The invention discloses paenibacillus mucilaginosus N6 and application thereof. The classified name of the strain is the paenibacillus mucilaginosus N6 which is collected in China Center for Type Culture Collection, and the collection number is CCTCC NO: M2015548. The paenibacillus mucilaginosus N6 can be grown under a plate cultivation condition of silicate bacteria culture media, and can dissociate potassium from minerals. Under the liquid oscillation culture condition, rapidly-available-potassium increment is compared with a contrast by a flame spectrophotometer and is found great. Bowl experiments show that growth and development of corn can be promoted obviously after the corn is inoculated with the paenibacillus mucilaginosus N6; experiments in orchards show that tinctorial yield of apples can be promoted obviously through application of N6 fermentation liquor. By the paenibacillus mucilaginosus N6, excellent strain resources are provided for improvement in corn growth and apple quality.

Owner:NANJING FORESTRY UNIV

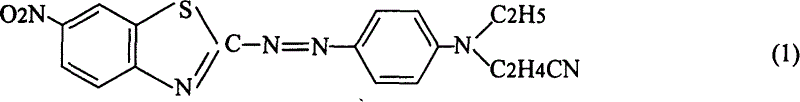

Dark blue to black disperse dye mixture

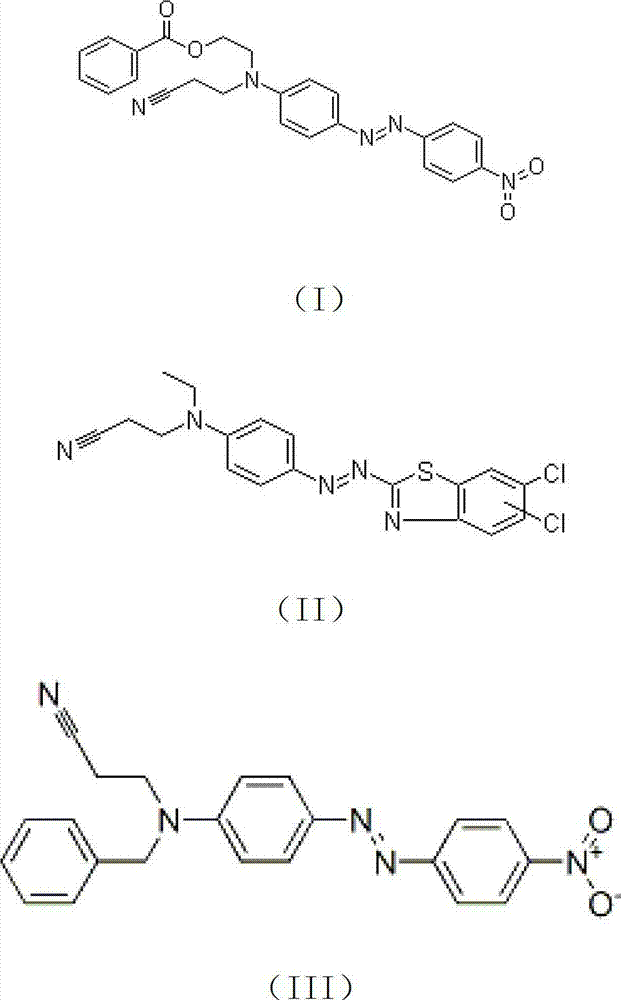

ActiveCN106479221ALight effectHigh color fastnessOrganic dyesDyeing processDisperse dyeStructural formula

The invention discloses a dark blue to black disperse dye mixture. The dark blue to black disperse dye mixture is composed of a component A shown in a structural formula (I), a component B shown in a structural formula (II), a component C shown in a structural formula (III), a component D shown in a structural formula (IV), a component E shown in a structural formula (V), and an auxiliary agent. The dye mixture comprises the following components by mass fraction: 2-30% of the component A, 15-45% of the component B, 1-10% of the component C, 1-10% of the component D, 2-15% of the component E, and the balance of the auxiliary agent. The cloth samples dyed by the dark blue to black disperse dye mixture is brilliant, and has the advantages of excellent fastness to washing, antifriction fastness, fastness to perspiration, fastness to light, and degree of dyeing.

Owner:HANGZHOU FLARIANT SPECIALTY

Polyamide fabric modifying, dyeing and finishing process

InactiveCN105019266AProcess temperature changeLow processing temperatureBiochemical fibre treatmentFibre typesPolyamideDyeing

The invention discloses a polyamide fabric modifying, dyeing and finishing process. The process comprises the steps of pretreatment, pre-setting, modification treatment, dyeing, soaping, color fixing, after treatment, drying, setting, calendering and rolling. Helicase and alpha-amylase are adopted for carrying out pretreatment, mixed liquor of nanometer titanium dioxide, gamma-(2, 3-epoxypropoxy) trimethoxypropylsilane and caprolactam is adopted for modifying performance of polyamide fabric fundamentally, and the dye-uptake rate of the fabric is increased; in the dyeing working procedure, a large number of alkaline substances and inorganic salts are not used, a leveling agent and a dispersing agent are added, and dyeing levelness is improved; meanwhile, as rosin powder is added to serve as a color fixing agent, the color fixing effect is enhanced, environmental pollution is avoided, and the requirement for environmental protection is met; moreover, montmorillonite is adopted for carrying out modifying and flame retarding on the fabric, and therefore the fire retarding property of the fabric is high; anti-yellowing reagents are used in the presetting and setting steps, and therefore the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

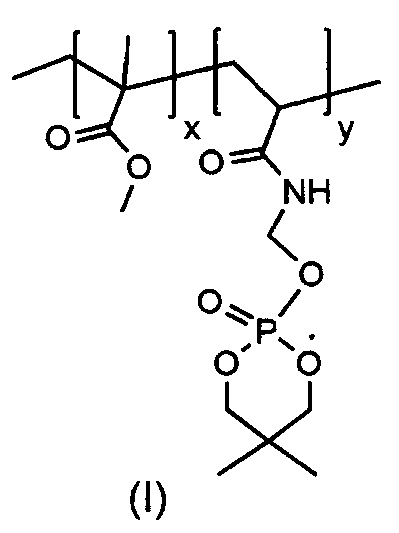

Highly-transparent flame-retardant modified organic glass and preparation method thereof

InactiveCN105315399AImprove flame retardant performanceMeet environmental protection requirementsCarvacryl acetateOxygen

The invention provides highly-transparent flame-retardant modified organic glass and a preparation method thereof. The highly-transparent flame-retardant modified organic glass comprises a polymer shown in a formula (I). According to the highly-transparent flame-retardant modified organic glass, a flame retardant is directly introduced into an organic glass molecular chain through a copolymerization reaction, the obtained flame-retardant organic glass has excellent flame resistance, transparency and colorability, and secondary pollution does not exist in the using process. The preparation method comprises the steps that methyl methacrylate is adopted as solvent; on the condition that a polymerization inhibitor exists, 2-oxo-2-chlorine-5,5-dimethyl-1,3,2-phospho heterocycle hexane and N-hydroxymethyl acrylamide are reacted to obtain mixed liquor of a phosphorus and nitrogen reaction type flame retardant shown in a formula (II) and vinyl acetate, under the action of an initiator, prepolymerization, low temperature polymerization in a mold and demoulding are conducted, and the highly-transparent flame-retardant modified organic glass is obtained. A methyl methacrylate monomer is adopted to serve as the solvent, solvent recovery does not exist in the preparation process, industrial three wastes are not produced, separation and purification are not needed for a product, operation is easy and convenient, and industrial production is easy.

Owner:黄国波

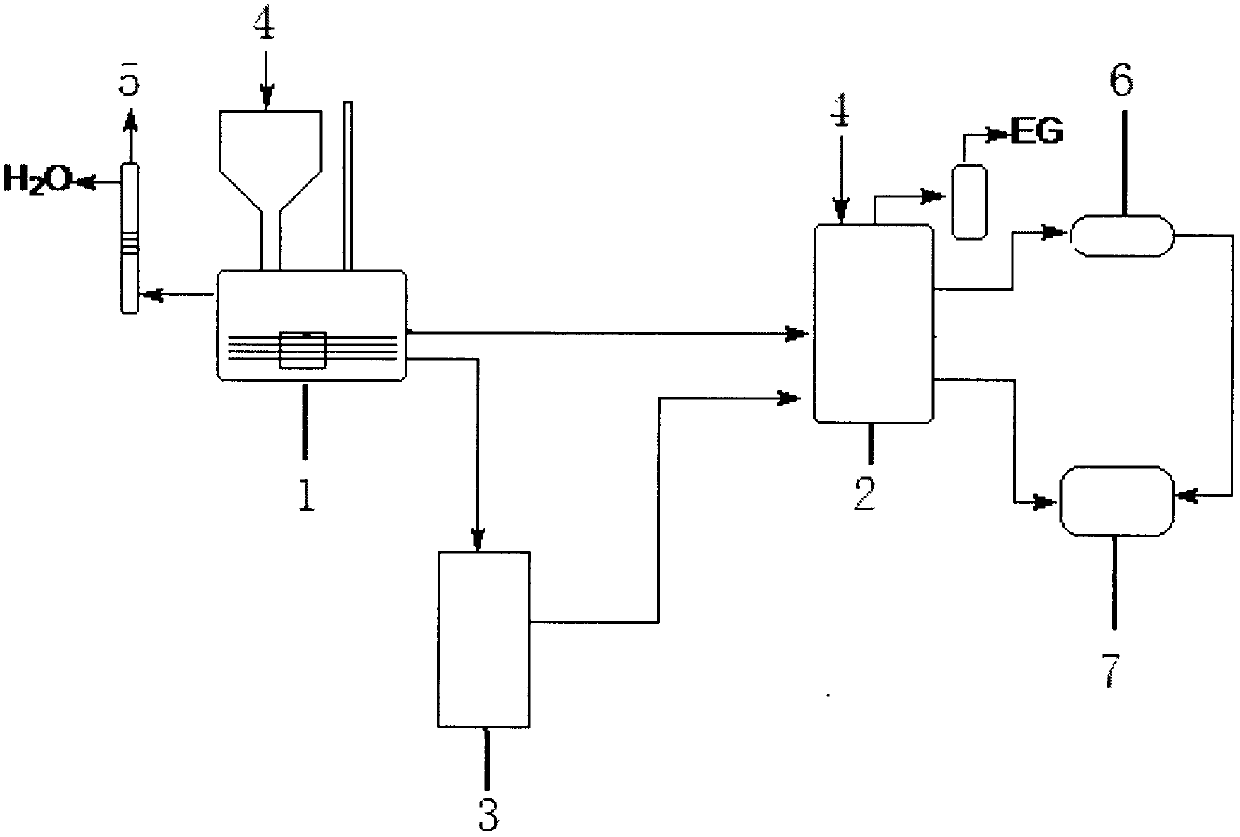

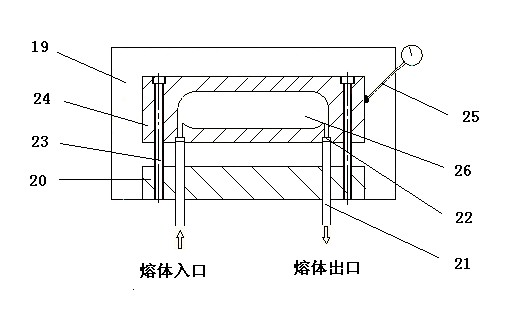

Normal-temperature chromophilous recycled polyester filament yarn and preparation method thereof

ActiveCN103122497AImprove technical levelImprove product performanceMonocomponent polyesters artificial filamentArtifical filament manufacturePorosityDepolymerization

The invention provides a normal-temperature chromophilous recycled polyester filament yarn and a preparation method thereof. A nano inorganic particle is modified by using a depolymerization product at a lower temperature, and thus the heat stability of an inorganic component is improved, and the porosity of a recycled polyester structure is enlarged; and meanwhile, through adding an additive capable of changing the degree of crystallinity and the crystallization rate of the recycled polyester and reducing the melting point, the structure and the performance of the recycled polyester are changed, and the dyeing property and the mechanical property of fibers are improved, so that the normal-temperature chromophilous recycled polyester filament yarn is prepared. The mechanical strength and the dyeing property of the normal-temperature chromophilous recycled polyester filament yarn are greatly improved in comparison with those of pure Dacron, and thus the creative industrialized production is achieved. The preparation method is simple, economic and environment-friendly, and is suitable for industrialized production.

Owner:SUZHOU SHENGHONG FIBER CO LTD

Sea-island fibre and preparation method thereof

ActiveCN102418169AWith memory functionLodging resistanceMelt spinning methodsConjugated synthetic polymer artificial filamentsColour fastnessPolymer science

The invention discloses a sea-island fibre and a preparation method thereof. A PTT (polytrimethylene terephthalate) slice is taken as an island component, a COPET (copolyester) slice is taken as a sea component, the two raw materials are respectively dried, extruded and molten, then the melts are fed into a spinning box and then are extruded out after being accurately metered by a metering pump, the island component is uniformly distributed into the sea component, the island component and the sea component are sprayed out from a same spinneret orifice, then cooling, moulding, oiling, drawing based on a silk guiding roller, winding and silk doubling are carried out to obtain a PTT sea-island fibre, the breaking strength of the fibre is 2.8-3.7cN / dtex, the breaking elongation is 57-62%, and the evenness uster value is less than 1.3%; and the filament number of the island component PTT is 0.05-0.20DPF. The sea-island fibre product not only has the characteristics of a common sea-island fibre but also has the characteristics of high elasticity, lodging resistance, high dyeing degree, high colour fastness, bright finished product colour, no wrinkling, easy care and memory function, thus the sea-island fibre is an ideal fibre used for a top-grade garment material and has great market potential.

Owner:SUZHOU LONGJIE SPECIAL FIBER

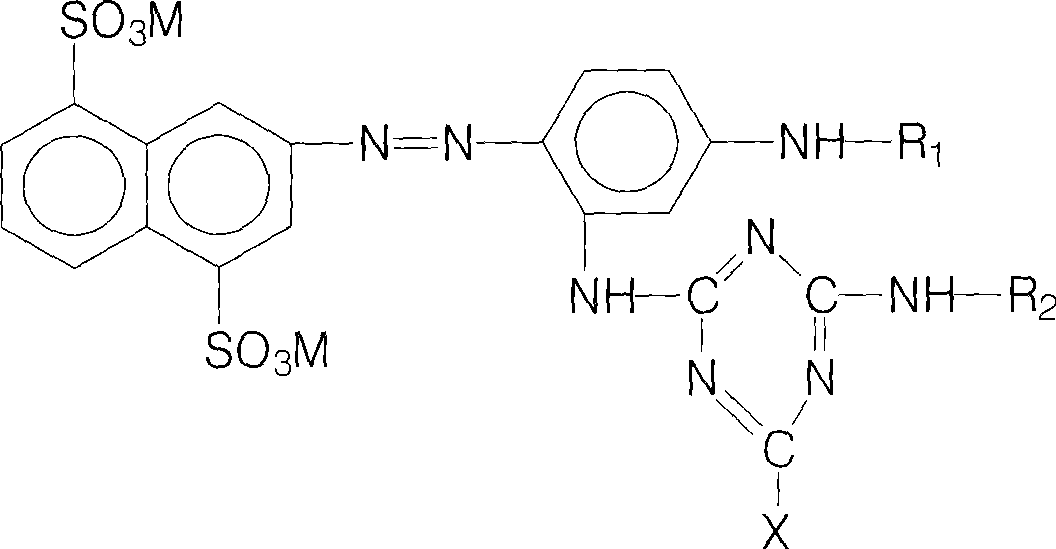

Yellow reactive dyes for wool and preparation method thereof

InactiveCN101418134ARaise the ratioOptimizationReactive dyesDyeing processYELLOW DYEOrganic chemistry

The invention discloses a yellow wool reactive dye. The general formula of the yellow wool reactive dye is as shown in (I). Moreover, the invention also relates to a method for preparing the yellow wool reactive dye. Compared with the acidic yellow dye in the prior art, the dye obviously improves the dyeing performance. Moreover, the preparation method is simple and reduces pollution.

Owner:TIANJIN DEK CHEM

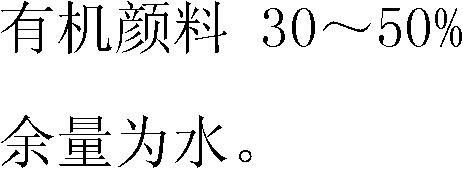

Multifunctional environment-friendly color paste

InactiveCN102358811AImprove water resistanceHigh coloring ratePaper/cardboardDyeing processPolyesterMelamine formaldehyde resin

The invention discloses a multifunctional environment-friendly color paste which is prepared by the following components by weight: a wetting agent 2 to 20%, a dispersing agent 1 to 20%, a stabilizing agent 1 to 10%, organic pigments 30 to 50%, and the balance being water, wherein, the wetting agent is dihydric alcohol, or trihydric alcohol or a composition of dihydric alcohol or trihydric alcohol and a polyhydroxy-carboxyl copolymer with a molecular weight of 8000 to 10000 or a sodium salt thereof, the dispersing agent is one selected from the group consisting of sodium methylnaphthalene sulfonate, ammonium methylnaphthalene sulfonate, sodium lignosulfonate, sulfonic acid sodium salt of melamine-formaldehyde resin copolymer and sodium salt or ammonium salt of acrylic acid-itaconic acid copolymer or a composition of two or more selected from the group, and the stabilizing agent is a silane coupling agent or a titanate coupling agent. The multifunctional environment-friendly color paste provided in the invention is applicable to coloring of aqueous building coatings and pigment printing and pulp coloring of cotton, polyester cotton and blended fabrics, has a wide application scope, enables a paint film to have high water resistance, and has a high degree of dyeing.

Owner:天津市宝坻区天海印染助剂厂

Alkali-resistant disperse dye composition and preparation method and application thereof

ActiveCN102924970AShort processPlay the effect of energy saving and emission reductionOrganic dyesDyeing processDisperse dyePhotochemistry

The invention discloses an alkali-resistant disperse dye composition and a preparation method and the use thereof. The composition is composed of five disperse dyes and a dispersing agent. A preparation method of the dyes is further provided. The preparation method includes the following steps: evenly mixing 6 components forming the dye composition to obtain a final product of the alkaline-resistant brown disperse dye composition. The dye composition is used for the field of printing of cloth fibers such as dacron double-faced pile and poly spun velour. The alkaline resistance of the brown dye composition is better than commonly used brown in market, pH value is wide in suitable range of 13.5-14, and the alkali-resistant disperse dye meets requirements for brown dye and has good market prospect.

Owner:上海贝通色彩科技有限公司

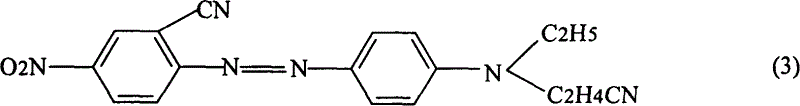

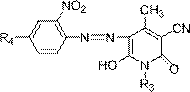

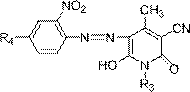

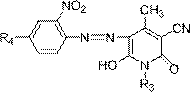

High washing fastness dispersed dark blue dye composition

ActiveCN103421347AImprove washing fastnessHigh coloring rateOrganic dyesDyeing processDisperse yellowMaterials science

The invention relates to a dye composition, in particular to a high washing fastness dispersed dark blue dye composition. The high washing fastness dispersed dark blue dye composition is composed of 35 % to 50 % of dispersed red, 20 % to 40 % of dispersed golden yellow, 10 % to 30 % of dispersed purple and 10 % to 30 % of dispersed yellow in a mixing mode, and the balance auxiliaries. The dispersed red is the combination of one or more kinds of compounds shown in a formula (1); the dispersed golden yellow is the combination of one or more kinds of compounds shown in a formula (2); the dispersed purple is the combination of one or more kinds of compounds shown in a formula (3), and the dispersed yellow is the combination of one or more kinds of compounds shown in a formula (4); when the high washing fastness dispersed dark blue dye composition is used for dyeing of spandex fabrics, the dyeing effect is good, the color fastness is good, and the quality of the spandex fabrics can be greatly improved.

Owner:HANGZHOU FLARIANT SPECIALTY

Degradable masterbatch and preparation method thereof

The invention provides degradable masterbatch and a preparation method thereof and belongs to the technical field of masterbatch manufacturing. The degradable masterbatch provided by the invention takes modified polylactic acid as a carrier, and the degradable masterbatch obtained by optimizing the proportioning of pigment and additives has the advantages of uniform coloring, low cost, easiness in process control and the like, thereby having wide industrial application prospect.

Owner:广州保亮得塑料科技有限公司

Anti-staining dyeing method of polyamide-cotton fabric

ActiveCN104790226ANylon jacquard has good anti-staining and leveling effectsHigh coloring rateDyeing processSodium carbonatePolyamide

The invention discloses an anti-staining dyeing method of cotton-polyamide fabric. The anti-staining dyeing method comprises the following steps: at the temperature of 40 DEG C, sequentially adding a dye and a dyeing auxiliary into fabric; after keeping the temperature for 10 minutes, adding sodium carbonate of 0.05-0.1g / L, controlling the PH value of a dye bath to be 8-9 and keeping the temperature for 30 minutes, and then adding sodium carbonate of 15-20g / L; raising the temperature to be 50 DEG C by the rate of 1DEG C / min, and keeping the temperature for 30 minutes so as to perform color fixation; raising the temperature to be 70 DEG C by the rate of 2DEG C / min, keeping the temperature for 15 minutes, and completing the dying process; reducing the temperature to be 45 DEG C to perform post processing, so as to obtain the dyed fabric. The used dye is an active dye, and the problem of the serious staining of vinyl-sulfone type active dyes on polyamide fabric is mainly solved. The anti-staining dyeing method disclosed by the invention has the advantages that the procedure operation is feasible, the utilization rate of the dyes is high, the color fastness of the dyed fabrics is good, and the like; the anti-staining dyeing method can be applied to the technical field of dying of polyamide-cotton blended fabric.

Owner:浙江劲光纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com