Environment-friendly dark blue and black series compound disperse dye and production method thereof

A disperse dye and dark blue technology, which is applied in dyeing, organic dyes, textiles and papermaking, etc., can solve problems such as unsatisfactory printing and dyeing of textiles, human allergies, and production of harmful aromatic amines, and achieve excellent light fastness and high coloring rate , Excellent effect of lifting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

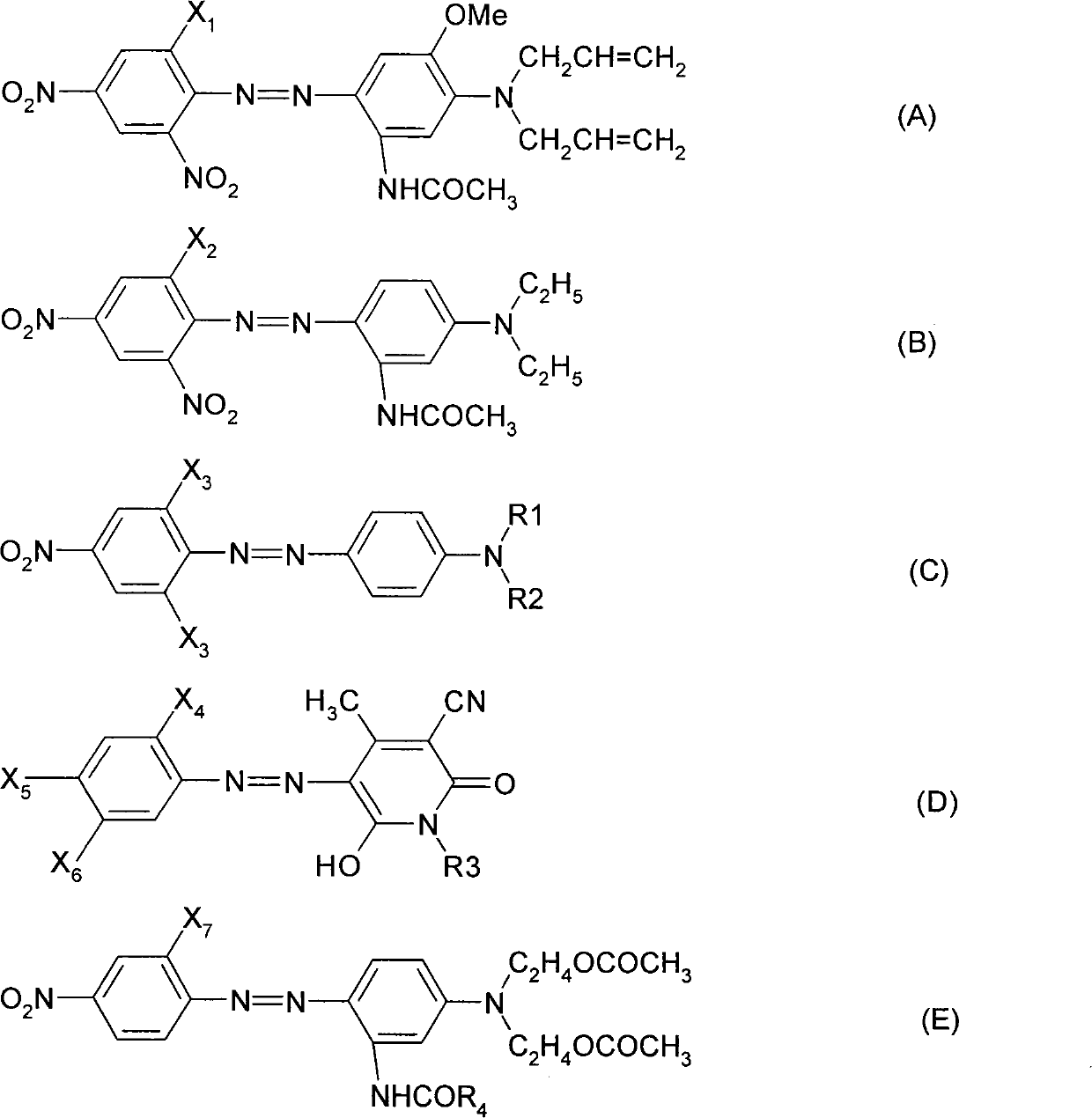

[0035] The monomer that quality is shown in the monomer A (disperse blue 3G) shown in 136 grams formula (1), the monomer B (disperse violet B) shown in 110 grams formula (2), the monomer shown in 200 grams formula (3) Monomer D (dispersion yellow 5G) shown in C (dispersion golden orange G), 43 grams of formula (4), with 1000 grams of water, 121 grams of sodium lignosulfonate, 390 grams of MF diffusion agent together in a sand mill Grind for 6 hours, and then spray dry to obtain the powdered disperse dye product. The above-mentioned dye products can be dyed according to conventional methods, for example, take 0.5 grams of the above-mentioned powdered dye products, disperse them in 500 ml of water, then absorb 40 ml of dye liquid and mix them with 60 ml of water, adjust the dyeing bath to pH 5 with acetic acid, and heat up to 70 At the same time, put 5 grams of polyester textile materials for dyeing, heat up from 70°C to 130°C, keep warm for 45 minutes, cool to 80°C for sampling...

Embodiment 2~16

[0038] According to the dye preparation method and dyeing method described in Example 1, the difference is that the disperse dye monomer with the structure shown in Table 1 is used, and the compounding is carried out according to the proportioning in Table 2. The fastness level data of the dyed fabrics dyed with polyester textile materials are shown in Table 3.

[0039] Table 1

[0040]

[0041] △for-COOC 2 h 4 OC 2 h 4 OCH 3

[0042] *for-SO 3 Ph

[0043] The dye monomer A, monomer B, monomer C, monomer D, and monomer E in Table 1 are all produced by Jiangsu Jihua Chemical Co., Ltd., Zhejiang Jihua Group Co., Ltd. and their subsidiaries, and their commodity names are as follows:

[0044]

[0045] Table 2 (the unit in the table is gram)

[0046]

[0047] table 3

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com