Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1557 results about "Melamine formaldehyde resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

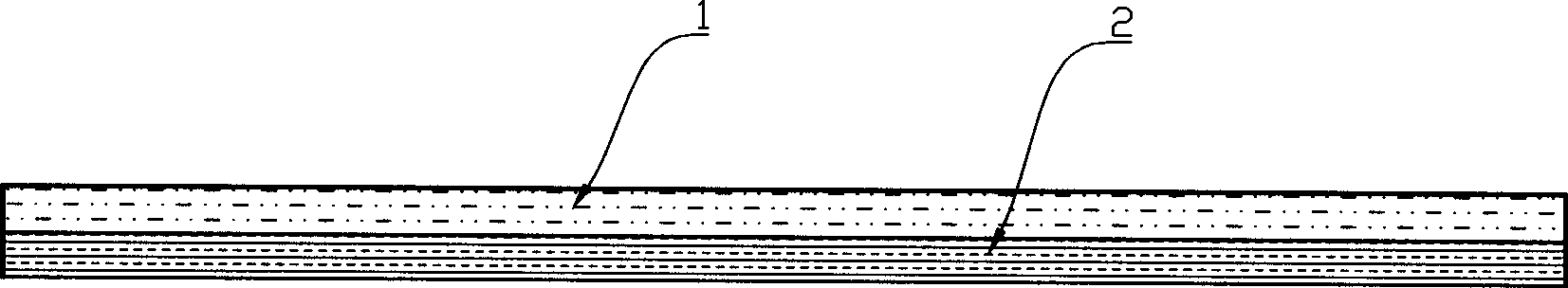

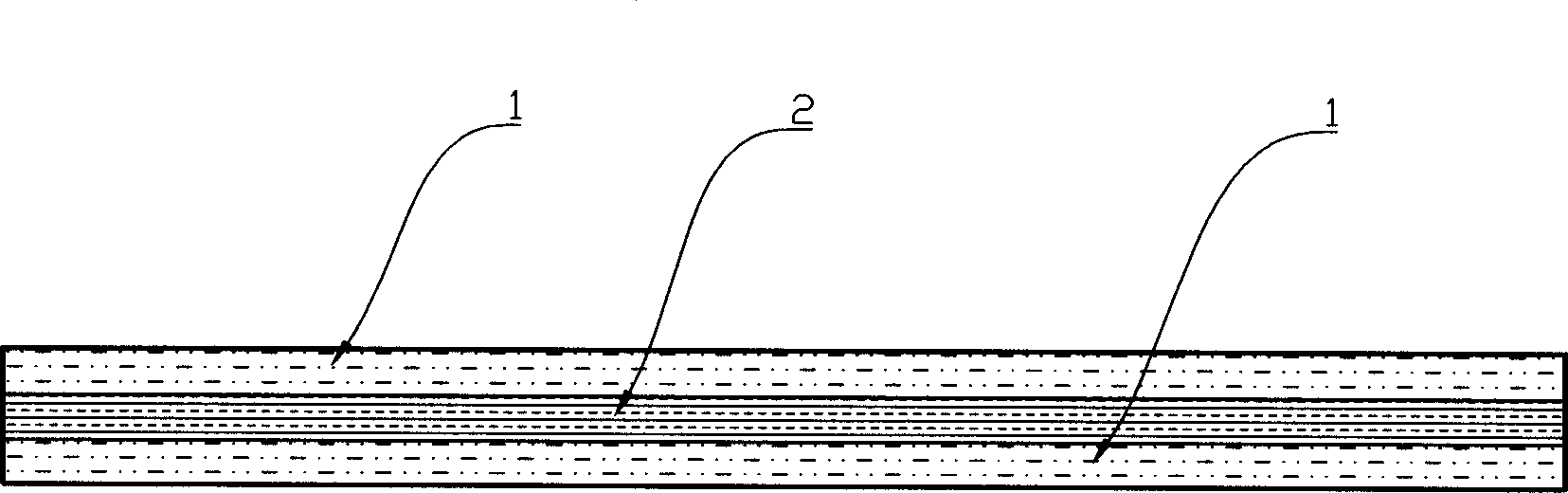

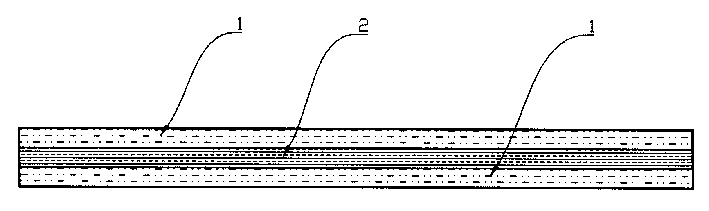

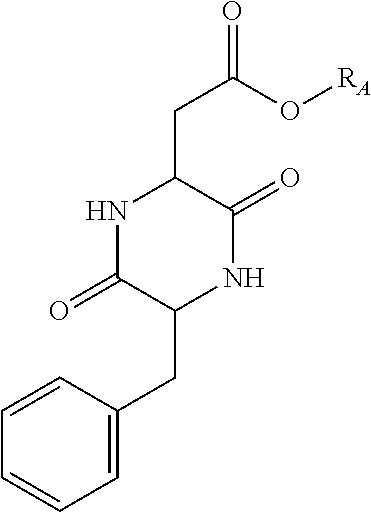

Dicing/die bonding sheet

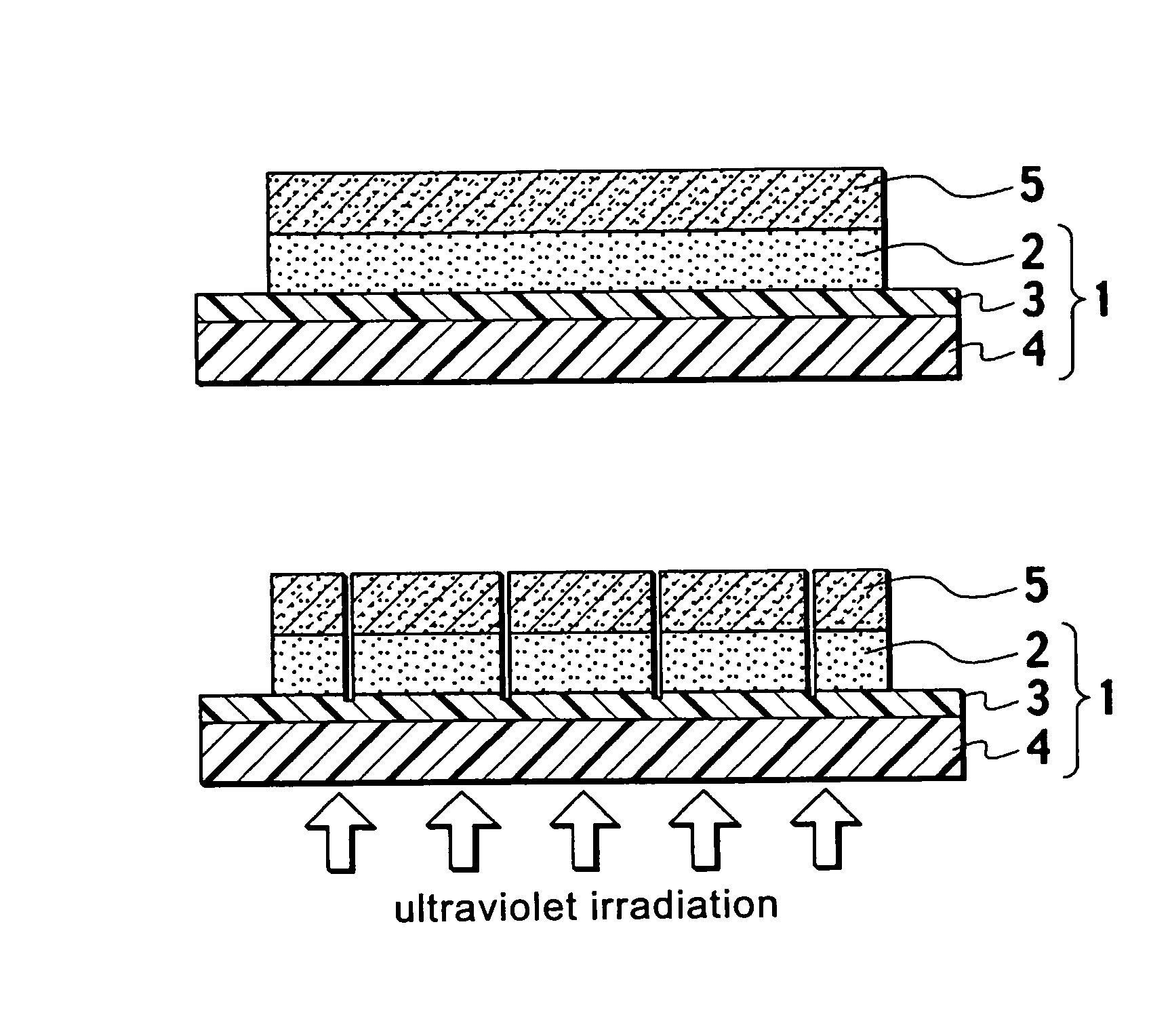

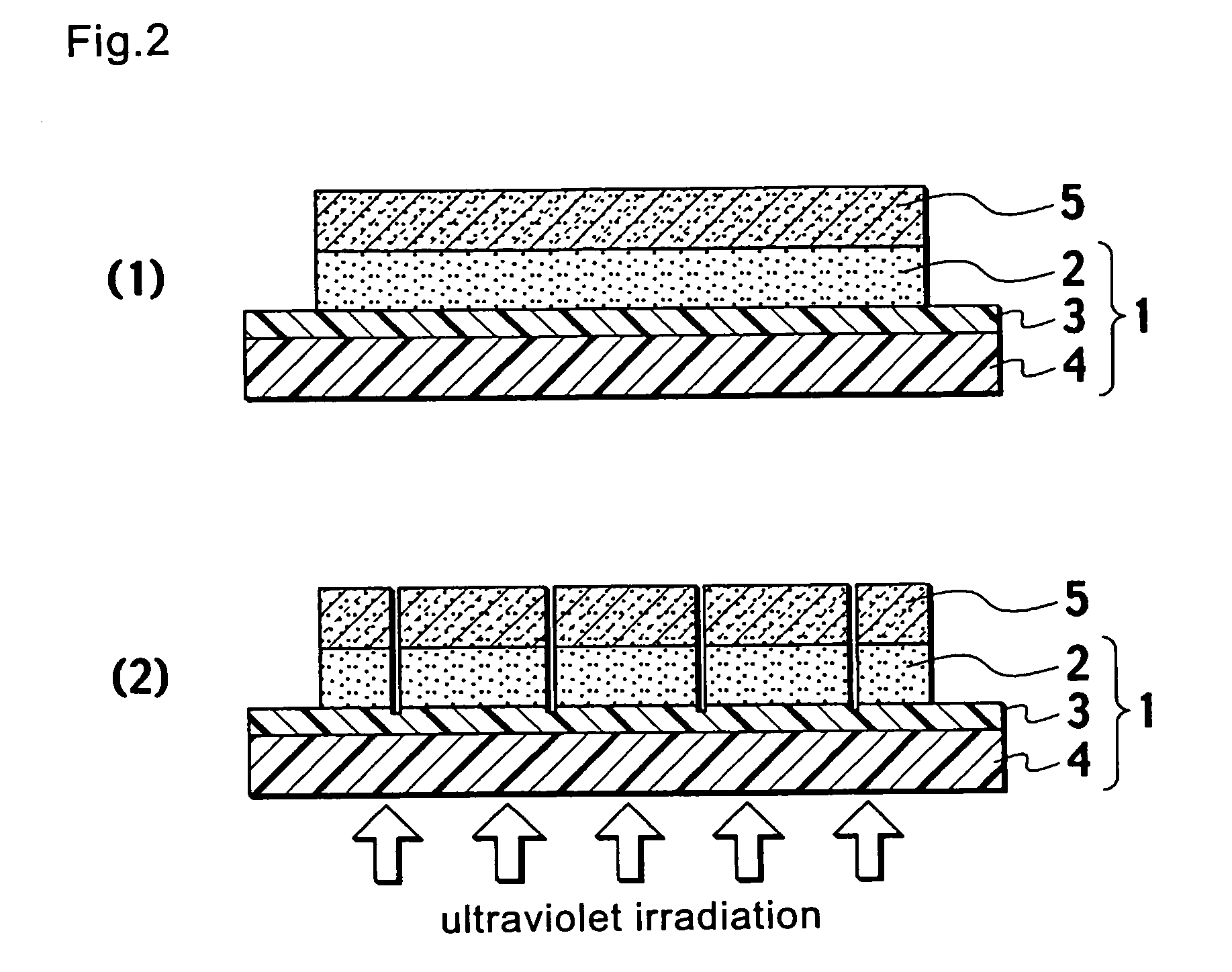

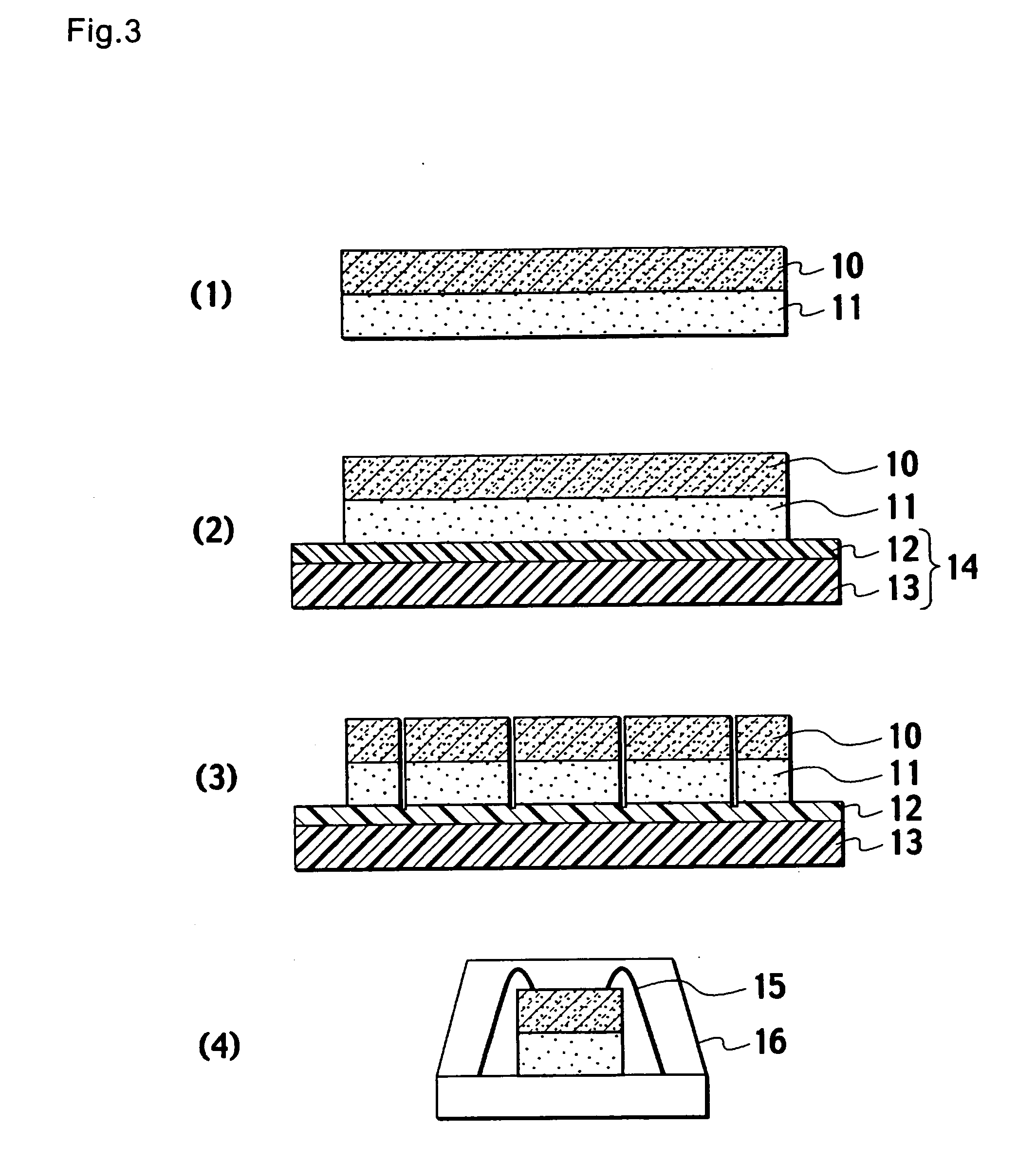

ActiveUS20070026572A1Satisfactory adhesivenessEasy to separatePolyureas/polyurethane adhesivesSynthetic resin layered productsEpoxyDicing tape

The present invention provides a dicing / die bonding sheet which can be used as a dicing tape during dicing, enables ready separation of the semiconductor element and the adhesive layer from the pressure-sensitive adhesive layer during pickup, and in which the adhesive layer has satisfactory adhesiveness as a die bonding material. A dicing / die bonding sheet in which the pressure-sensitive adhesive layer comprises a compound (A), containing intramolecular, radiation curable carbon-carbon double bonds with an iodine value of 0.5 to 20, and at least one compound (B) selected from a group consisting of polyisocyanates, melamine-formaldehyde resins, and epoxy resins, and the adhesive layer comprises an epoxy resin (a), a phenolic resin (b) with a hydroxyl equivalent of at least 150 g / eq., an epoxy group-containing acrylic copolymer (c), comprising from 0.5 to 6% by weight of glycidyl acrylate or glycidyl methacrylate, and with a weight average molecular weight of at least 100,000, a filler (d), and a curing accelerator (e).

Owner:RESONAC CORP +1

Microencapsulation expansion type flame retardant and application in epoxy resin composite material thereof

The invention discloses a microencapsulation expansion type flame retardant and application in an epoxy resin composite material thereof. The microencapsulation expansion type flame retardant uses ammonium polyphosphate as a capsule core and uses a thermosetting resin melamine-formaldehyde resin as a capsule material. The microencapsulation expansion type flame retardant epoxy resin composite material consists of the epoxy resin, a curing agent, a curing accelerator, the microencapsulation expansion type flame retardant and a flame-retardant carbon-forming accelerator. The microencapsulation expansion type flame retardant and the application are economic, simple and convenient; the flame retardant has good flame-retardant synergistic effects; and under the condition of little flame retardant addition, the composite material can pass V-0 level of UL-94 test, and the oxygen index reaches over 30.0 percent.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

A kind of warm mix asphalt additive and preparation method thereof

InactiveCN102268189ALower mixing temperatureClimate change adaptationBuilding insulationsMelamine formaldehydeReaction temperature

A warm-mix asphalt additive machine preparation method, the additive is formed by reacting the following components in parts by weight: 4-15 parts of alkoxysilane, 1-8 parts of polyether, 0-1 part of melamine formaldehyde resin, and 0 parts of acid catalyst -1 part, 0-1 part of alkali catalyst, 2-10 parts of deionized water, 30-100 parts of solvent; the preparation method comprises the following steps: (1) adding a quantitative amount of solvent and Alkoxysilane, heated to 80°C; (2) Add a mixture of acid catalyst, base catalyst, and deionized water, and react at a constant temperature of 80°C for 90 minutes; (3) Heat up to 100°C, condense and reflux for 120 minutes, and collect about 55ml of distillate; ( 4) Add an acid catalyst and a certain amount of polyether into the flask, heat up the esterification reaction for 180 minutes; (5) evacuate, condense and reflux for 30 minutes, cool down to room temperature, add a certain amount of melamine formaldehyde resin and stir evenly, add an appropriate amount of alkali catalyst to adjust the pH = 8 or so, the finished product is obtained.

Owner:杭州市城市建设科学研究院

Preparation method and application of aromatic microcapsule finishing agent with double-layer wall materials

ActiveCN102127864ADense wall membraneFacilitated releaseMicroballoon preparationVegetal fibresFiberMelamine formaldehyde resin

The invention discloses a preparation method and an application of an aromatic microcapsule finishing agent with double-layer wall materials. The method is characterized by preparing the aromatic microcapsule through covering the lavender essence oil capsule core material with the melamine-formaldehyde resin cyst wall and mixing the aromatic microcapsule with an adhesive (VAE) vinyl acetate-ethylene solution as the external wall material, thus generating the aromatic microcapsule finishing agent with double-layer wall materials. Aroma after-finishing on is carried out on the cotton fabrics by adopting the finishing agent and a padding method and the aromatic microcapsule is firmly fixed on the fibers of the cotton fabrics via own external wall with good adhesiveness, so the cotton fabrics have lasting aroma.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

Preparation method for melamine formaldehyde resin closed-cell foam

InactiveCN102898778AHigh closed cell rateImprove water resistanceThermal insulationMelamine formaldehyde resin

The present invention discloses a preparation method for melamine formaldehyde resin closed-cell foam. The preparation method comprises the following steps: introducing a modifier to a melamine formaldehyde resin synthesis process to carry out copolymerization, and carrying out a dehydration treatment on the synthesized resin to obtain a modified melamine formaldehyde solid resin with a solid content of more than 85%; adding a viscosity adjusting agent, dissolving the solid resin, respectively adding a curing agent, a foam stabilizer, an emulsifier and a foaming agent, and uniformly stirring; placing the resulting mixture in an oven or a microwave oven to carry out foaming to achieve a predetermined density; and placing the resulting material in the oven or the microwave oven to carry out aging to obtain the melamine formaldehyde foam with a closed-cell rate of more than 90%. The melamine formaldehyde resin closed-cell foam produced by the preparation method has excellent mechanical strength and flame retardant property, and can be applicable for building exterior wall thermal insulation.

Owner:NANTONG ZIXIN IND

High temperature resistant type phase-change material micro-capsule and preparation thereof

InactiveCN101376800AImprove thermal stabilityLow thermal weight lossHeat-exchange elementsMicroballoon preparationMelamine formaldehydeHeat resistance

The invention relates to a high-temperature resistant phase-change material microcapsule and a preparation method thereof which belong to the technical field of compound materials. The invention needs to solve the technical problem of providing a high-temperature resistant phase-change material microcapsule in the field of melt spinning; the components thereof counted according to weight portions include 100 portions of core phase-change material, 7 to 12 portions of dispersant, 2 to 5 portions of emulsifying agent as well as a wall material prepared by 0.3 to 0.6 portion of modified monomer and 30 to 50 portions of melamine resin. The preparation method of the high-temperature resistant phase-change material microcapsule includes the emulsification of the core, the preparation of the prepolymer of the wall material, the preparation of the microcapsule and the removing of free formaldehyde. The high-temperature resistant phase-change material microcapsule has higher heat stability, heat-resistance as well as uniform grain sizes and can meet the requirements of spinning fibers. The preparation technique is simple, is conveniently operated, can save energies and is environmental friendly; the product is easy for industrialization production and has a better market prospect.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

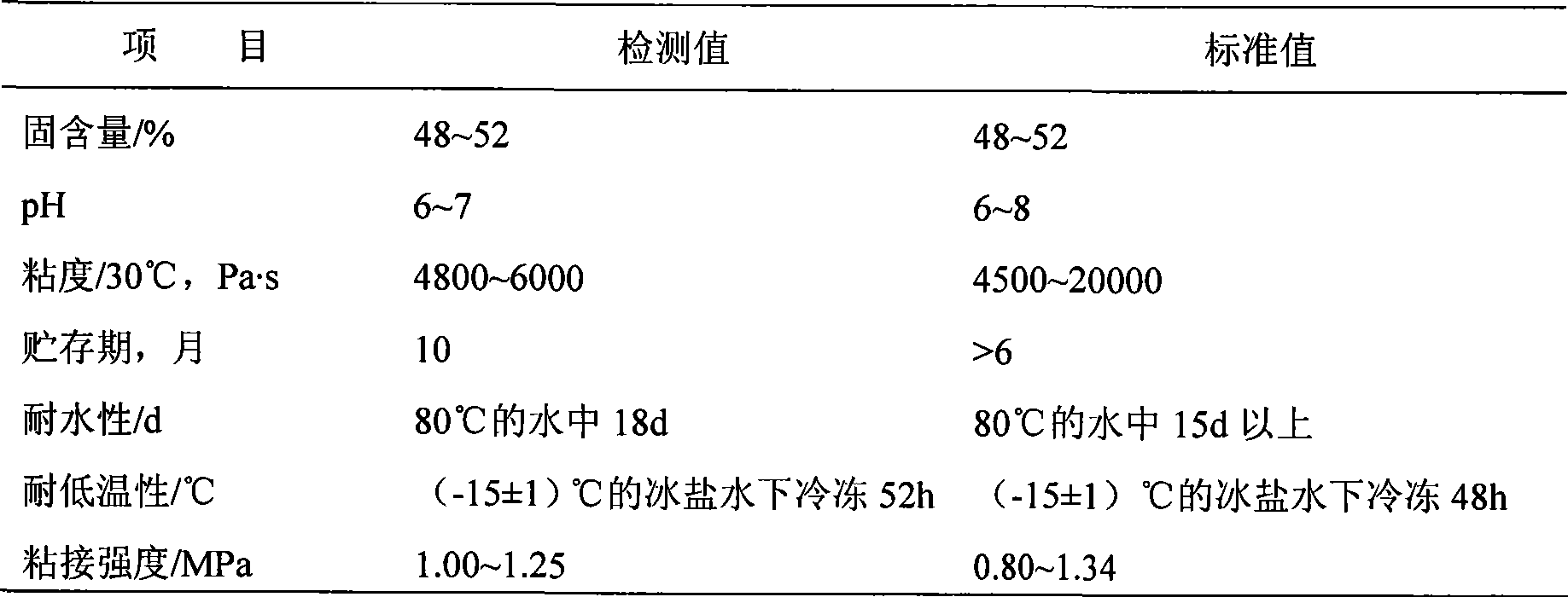

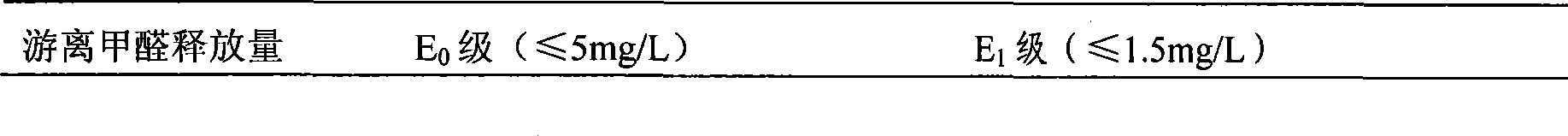

Modified starch based adhesion agent for lumber and preparation method

InactiveCN101508876AReduce releaseGood value for moneyAldehyde/ketone condensation polymer adhesivesGraft polymer adhesivesPolymer scienceEmulsion

The invention provides an adhesive for modified starch-based wood and a preparation method thereof. Starch and polyvinyl alcohol are taken as raw materials of the adhesive, the main agent of the adhesive is obtained by pretreating the starch via pasting, oxidizing, and the like, and grafting with the polyvinyl alcohol, the main agent is modified by adding in waterborne SBS emulsion or melamine-formaldehyde resin, so that the formaldehyde-free environment-friendly adhesive is prepared. The adhesive strength, the water resistance property, and the like of the adhesive meet requirement of national standard GB / T5849-2006, and release amount of free formaldehyde meet E0 level standard. The invention has the advantages of convenient use and moderate cost, and is applicable to manufacture of plyboards and furnitures.

Owner:CHANGCHUN UNIV OF TECH

Method for preparing microcapsule red phosphorus inflaming retarding polylactic acid

ActiveCN101696319ALow costThe preparation process is simple and environmentally friendlyPigment treatment with macromolecular organic compoundsPigment physical treatmentMelamine formaldehyde resinMoisture

The invention belongs to the technical field of inflaming retarding modification of high polymer materials, and specifically relates to a method for preparing microcapsule red phosphorus inflaming retarding polylactic acid. The method comprises the following steps of: pre-treating red phosphorus, and preparing melamine formaldehyde resin prepolymer solution; adding the pretreated red phosphorus, distilled water which is 2 to 20 times of the quantity of the red phosphorus and a dispersing agent which is 0.5 to 2 percent of the quantity of the red phosphorus into a reaction vessel; stirring the mixture and heating the mixture to a temperature of between 60 and 90 DEG C to obtain a red phosphorus suspension; then adding metal salt solution into the suspension; adjusting the pH value of the system by using ammonia water; keeping the temperature and stirring the mixture; adding the mixture into the melamine formaldehyde resin prepolymer solution so that the resin content in the solution is 22 to 94 percent of quantity of the red phosphorus; adjusting the pH value of the system to between 4 and 5 by using glacial acetic acid, keeping the temperature and stirring the mixture; after the reaction is finished, cooling and filtering the suspension, washing the suspension to be neutral, and drying the suspension to obtain inorganic-organic double-layer coated microcapsule red phosphorus; grinding the obtained microcapsule red phosphorus, and drying polylactic acid to remove the moisture; and adding the obtained microcapsule red phosphorus and the polylactic acid into a drying container, mixing the obtained microcapsule red phosphorus and the polylactic acid evenly, and melting and blending the mixture to obtain the required product. In the product, the polylactic acid accounts for 65 to 75 percent and the microcapsule red phosphorus accounts for 25 to 35 percent. The method has a low cost and a simple and environment-friendly preparation process.

Owner:TONGJI UNIV

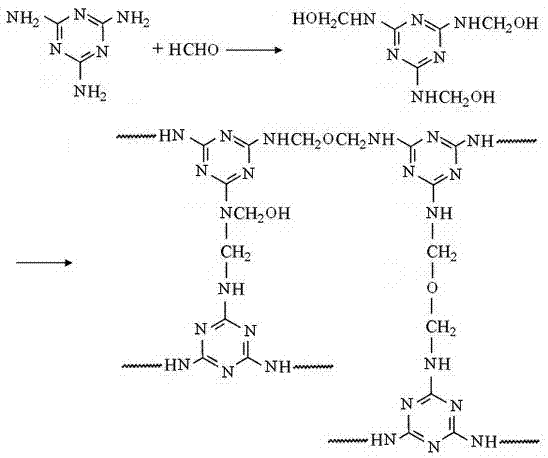

Method of preparing melamine formaldehyde resin/polyvinyl alcohol flame-proof fiber

InactiveCN101016658AImprove spinnabilityIncrease productivityFlame-proof filament manufactureWet spinning methodsFiberLimiting oxygen index

The invention discloses a method for producing melamine formaldehyde resin / polyvinyl alcohol flameproof fiber. The invention is characterized in that composing melamine and formaldehyde at the mole ratio as 1:1.2-1:6 and 50-100Deg. C into melamine formaldehyde resin water solution, to be mixed with the polyvinyl alcohol water solution at the solid content ratio as 2:8-8:2 to obtain spinning original liquid, then spinning and shaping the original liquid via general wet method, and treating solidifying bath via acid sodium sulfate saturated water solution, and the primary fiber is drawn, shaped via wet and heat method, washed, coiled, oiled, dried, and heated in dry condition to obtain the final melamine formaldehyde resin / polyvinyl alcohol flameproof fiber. The titer of said flameproof fiber is 10detex, while the strength is 1-3cN / dtex, the crack extended rate is 5-15%, the regain ratio is 5-10%, and the limit oxygen index is 30-45.

Owner:SICHUAN UNIV +1

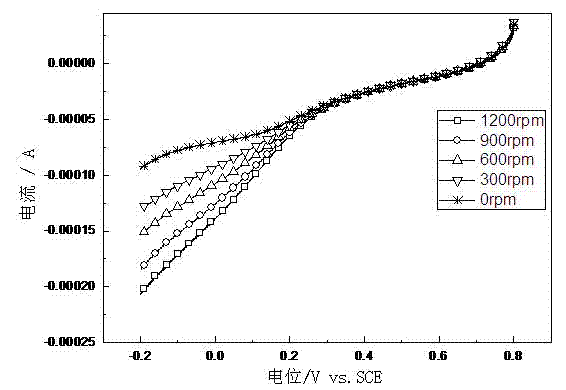

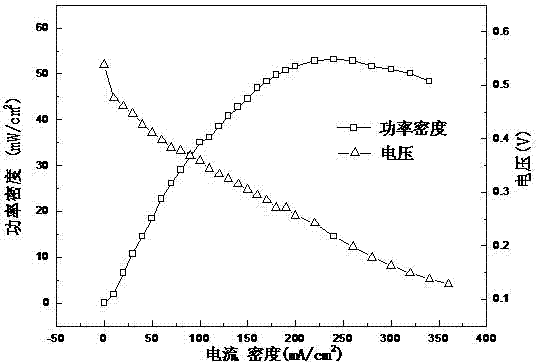

Spherical nitrogen-doped carbon-supported non-noble metal oxygen reduction catalyst and preparation method thereof

InactiveCN102247869ALow costExtended service lifePhysical/chemical process catalystsCell electrodesFuel cellsMelamine formaldehyde resin

The invention discloses a spherical nitrogen-doped carbon-supported non-noble metal oxygen reduction catalyst and a preparation method thereof, and aims to provide a nitrogen-doped non-noble metal oxygen reduction catalyst which has the advantages of simplicity, convenience, practicability, low cost and stable performance and a preparation method thereof. The technical key points are as follows: the catalyst comprises the following components: melamine formaldehyde resin prepolymer, non-noble metal salt and acid. The preparation method of the catalyst comprises the following steps of: (1) uniformly mixing the melamine formaldehyde resin prepolymer with pure water; (2) adding the non-noble metal salt and stirring; (3) adding the acid into the solution obtained by the step (2), curing and drying to obtain blocks; and (4) performing thermal treatment to obtain the spherical nitrogen-doped carbon-supported non-noble metal oxygen reduction catalyst. The invention belongs to the technical field of fuel cell material science.

Owner:GUANGZHOU UNIVERSITY

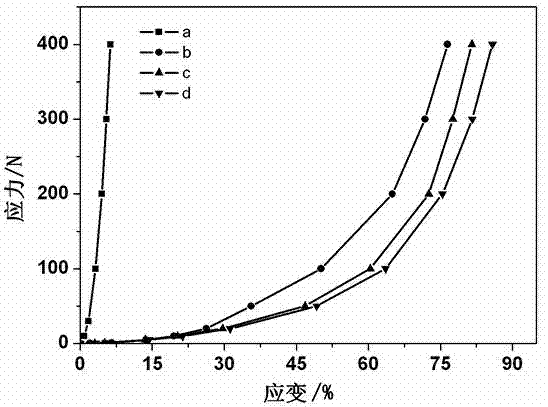

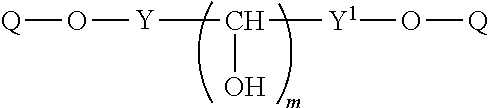

Toughening and modifying method for melamine formaldehyde resin

InactiveCN102875755AImprove brittlenessReduce manufacturing costPolymer scienceMelamine formaldehyde resin

The invention discloses a toughening and modifying method for melamine formaldehyde resin. According to the toughening and modifying method, a compound containing any one or two of polyhydroxy, polycarboxy and polyamino is adopted as the toughening agent to carry out polycondensation together with methylol melamine; a flexible chain polymer is introduced into the melamine formaldehyde resin, so that the degree of crosslinking of the resin is reduced, and the toughness is improved. The toughened melamine formaldehyde resin has the breaking elongation increased from 6.3% to 89.3%. With the adoption of the toughening and modifying method for melamine formaldehyde resin, the problems of the prior art that the melamine formaldehyde resin is high in fragility and poor in toughness, the resin is easy to fall, the preparation technology is complex and the like can be solved; and the toughening and modifying method has a wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gypsum base plastering mortar and gypsum base gravity flowing levelling mortar

A gypsum-based mortar for plastering is prepared from semi-hydrated gypsum, quartz sand, Ca(OH)2, powdered coal ash, slag, lime stone, hoolamite, volcanic dregs, haydite, polystyrene foam, expanded pearlite, zeolite, and ethene-vinyl acetate copolymer resin. Agypsum-based mortar for automatic leveling is prepared from semi- hydrated gypsum, quartz sand, Ca(OH)2, powdered coal ash, slag, lime stone, ethene-vinyl acetate copolymer resin, methyl hydroxyethyl (or hydroxypropyl) cellulose ether, sulfonated cyanuramide-formaldehyde resin and gluconate.

Owner:BEIJING SOULLEADER TECH DEV

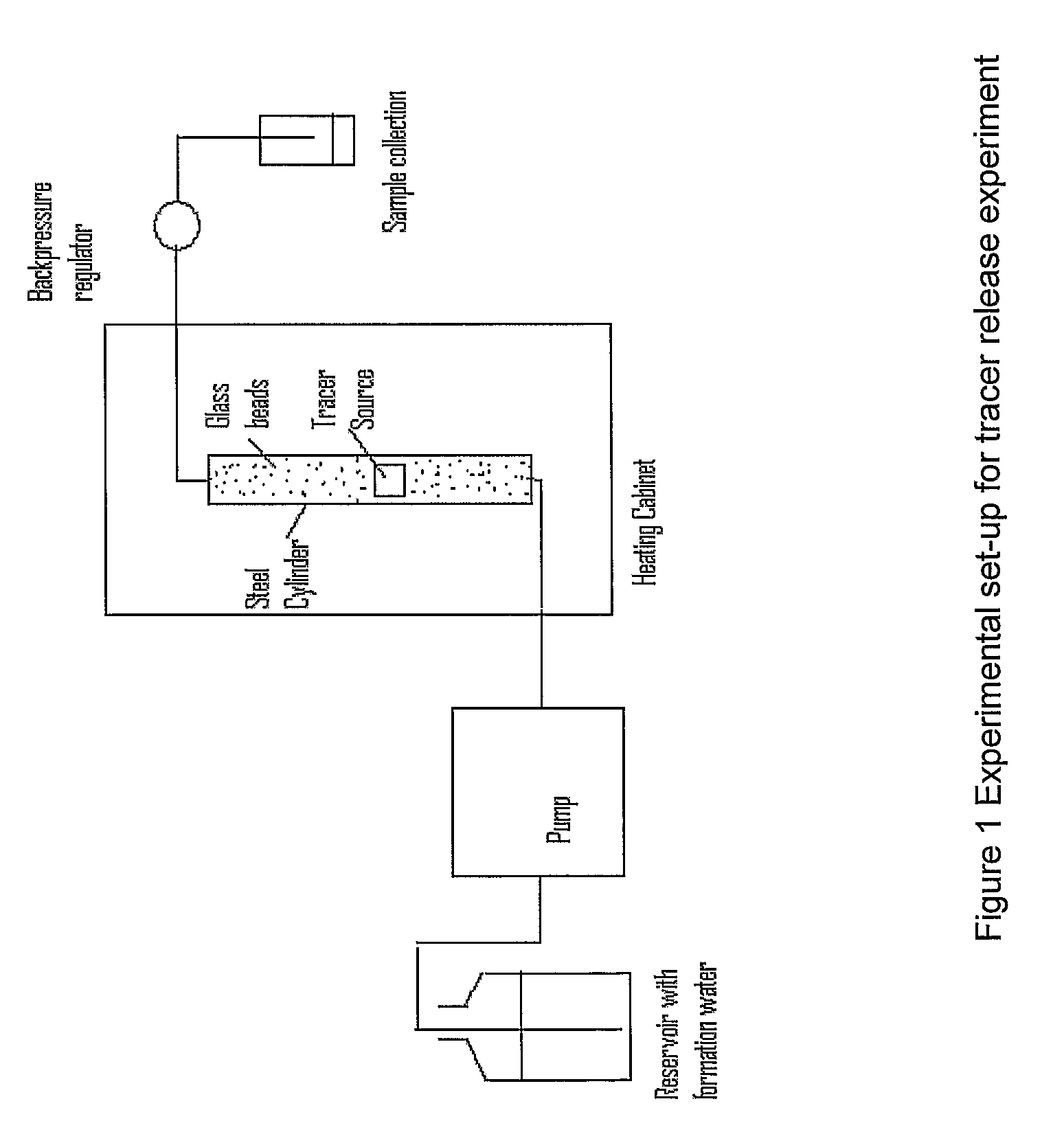

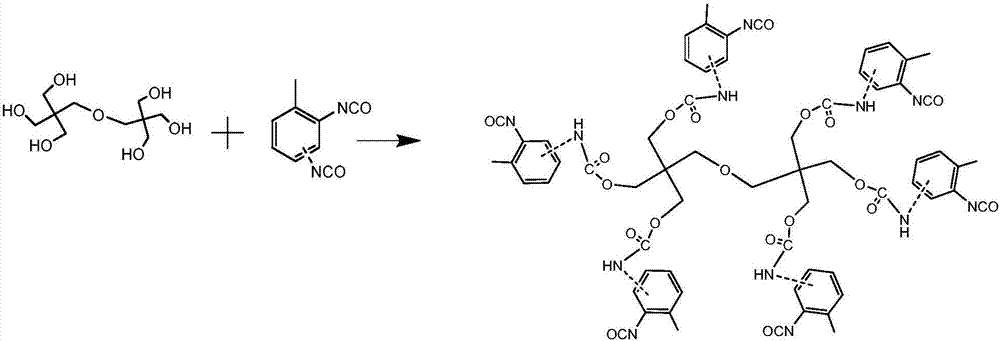

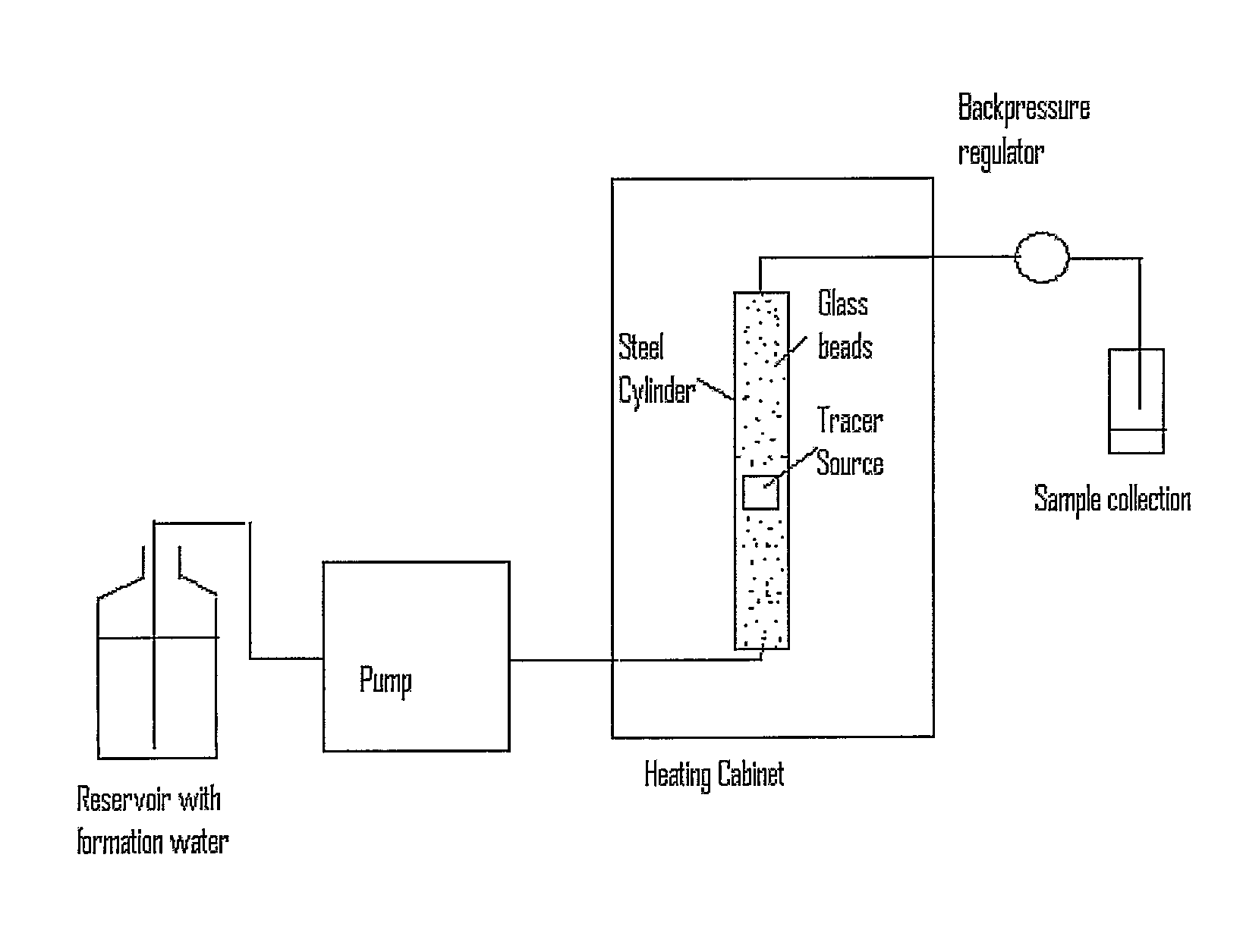

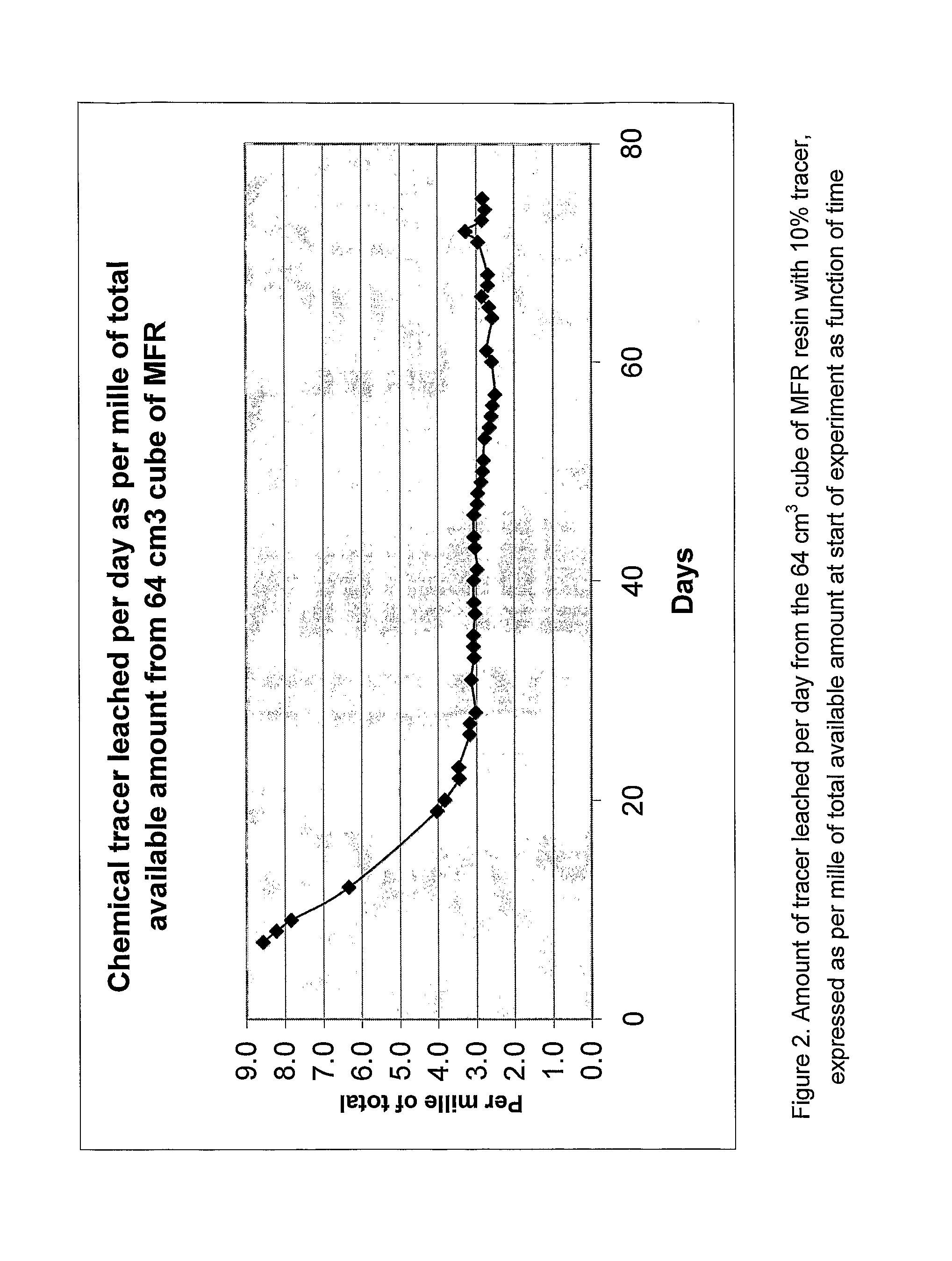

System for delivery of a tracer in fluid transport systems and use thereof

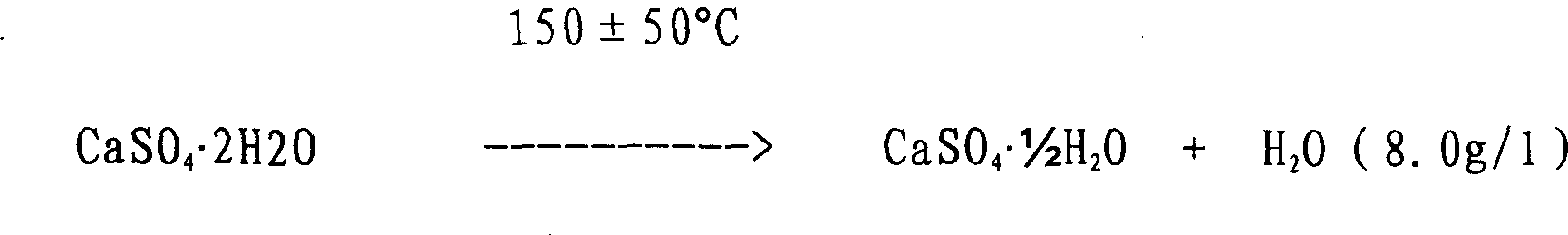

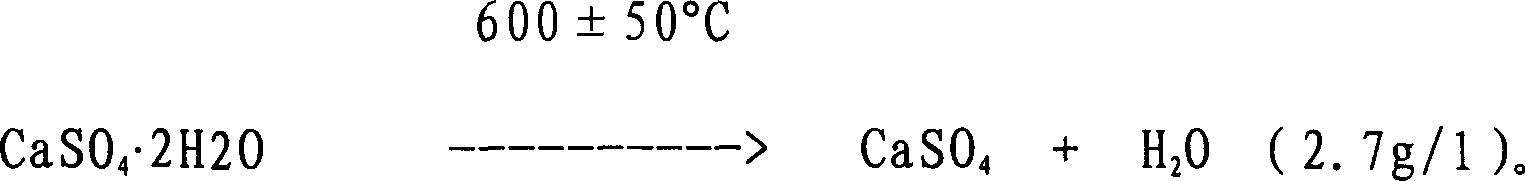

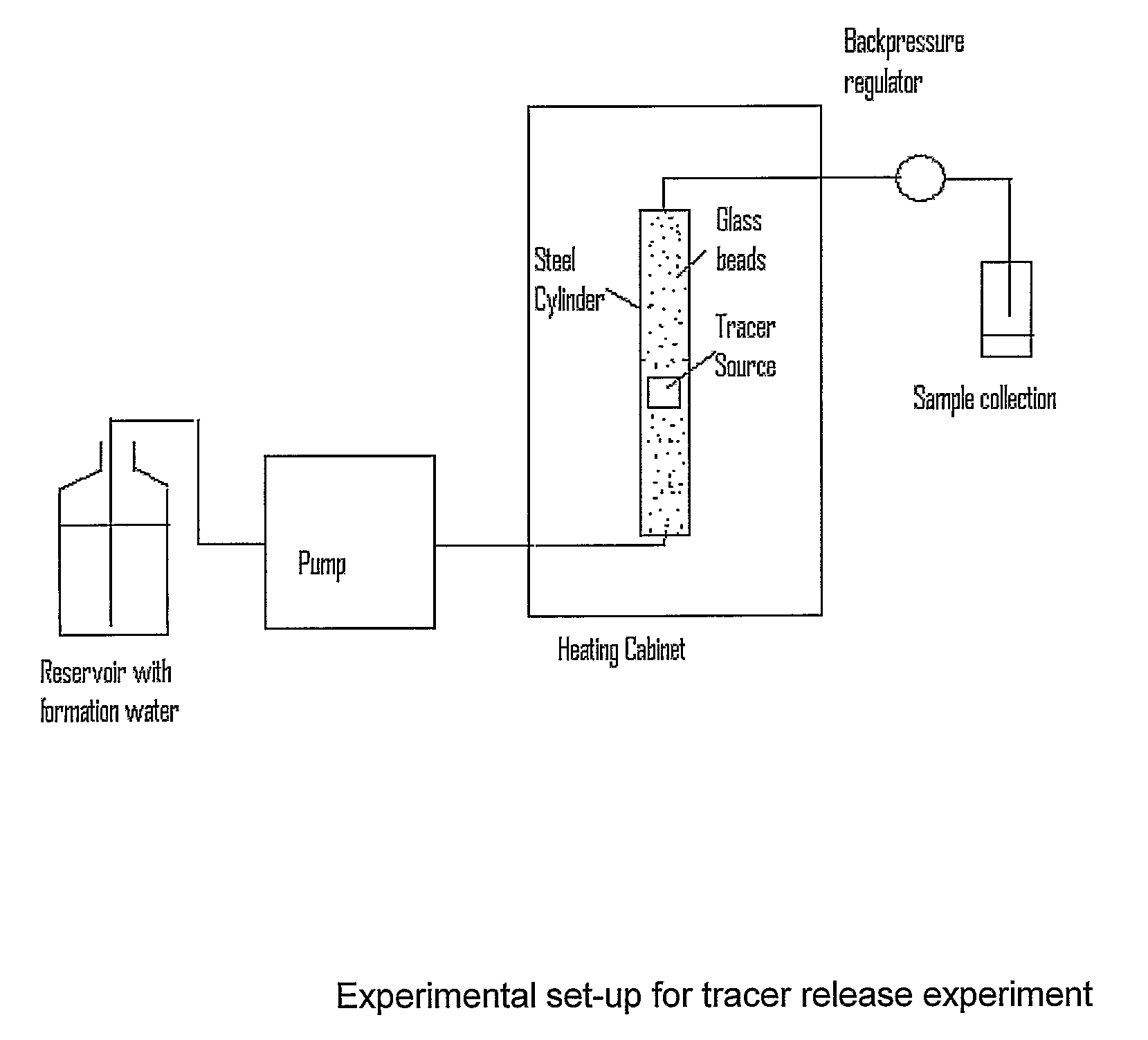

The present application describes a specific tracer delivery system that has been tested. The claimed system is composed of melamine formaldehyde resin (MFR) doped with various tracer materials. The MFR is used to slowly release tracer compounds into a liquid system. The MFR / tracer mixture is applied as part of a monitoring system where tracer is delivered from the MFR / tracer mixture at a specific location up-stream and detected at some location downstream, thereby verifying fluid flow from that specific location up-stream. The MFR can be doped with different types of tracers, thereby allowing placement of different tracers at several different positions upstream. Production from the various labelled zones can be verified through the analysis of one sample downstream.

Owner:RESMAN AS

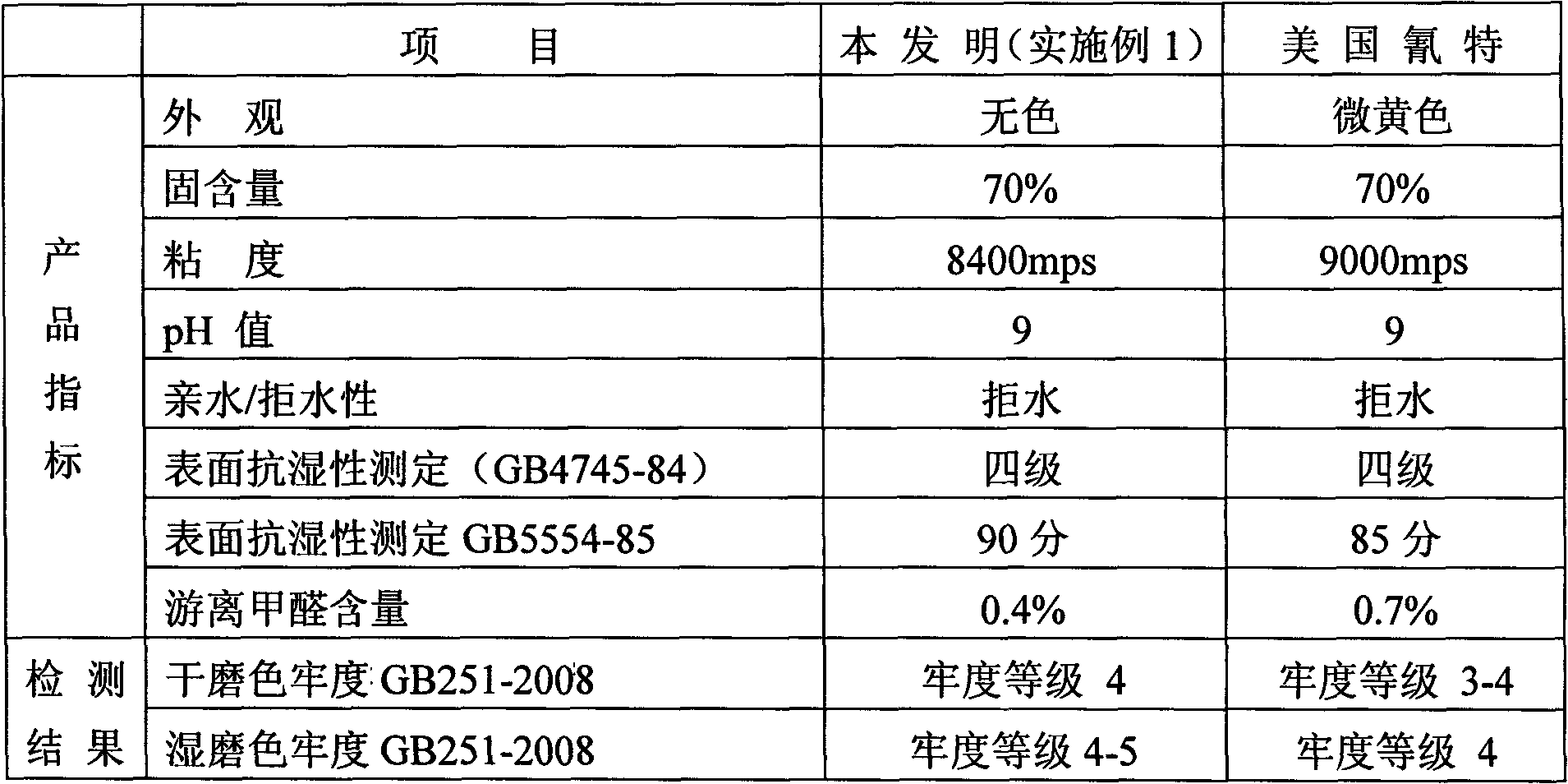

Method for synthesizing methylated melamine formaldehyde resin cross-linking agent with low free formaldehyde content

InactiveCN101817914ALong storage timeImprove performanceDyeing processCross-linkReaction temperature

The invention relates to a method for synthesizing a methylated melamine formaldehyde resin cross-linking agent with low free formaldehyde content. The technical scheme comprises the following steps of: putting melamine, formaldehyde and methanol into a reactor kettle, adjusting pH value to between 7 and 10 by using alkali, slowly raising the temperature, controlling the reaction temperature to be between 70 and 90 DEG C and preserving the heat for 1 to 2 hours; cooling reaction liquid, adding acid to adjust the pH value to between 3 and 6, etherifying the reaction liquid, controlling the reaction temperature to be between 50 and 70 DEG C and performing a reaction for 1 to 2 hours; lowering the temperature, adding an alkali terminator to adjust the pH value to between 8 and 10 to obtain mixed liquor A; and adding a formaldehyde catcher into the mixed liquor A, stirring and dissolving the mixture, dewatering in vacuum and removing methanol and formaldehyde to prepare a crude methylated melamine formaldehyde resin cross-linking agent product with low free formaldehyde content. The cross-linking agent has a long shelf life and low free formaldehyde content.

Owner:LIAONING FIXED STAR FINE CHEM

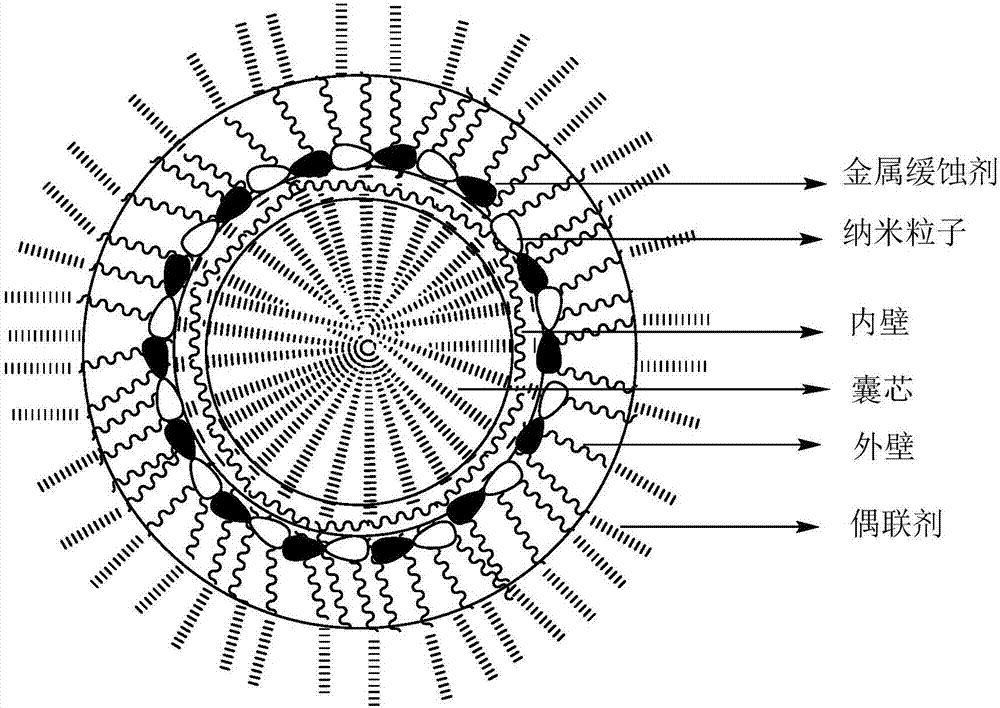

Self-repairing microcapsule used for metal anticorrosive paint and preparation method thereof

ActiveCN107312140AImprove repair efficiencyStable mechanical propertiesAnti-corrosive paintsMicroballoon preparationPetrochemicalMelamine formaldehyde resin

The invention relates to the technical field of self-repairing anticorrosive paints and particularly relates to a self-repairing microcapsule used for a metal anticorrosive paint and a preparation method of the self-repairing microcapsule. The self-repairing microcapsule sequentially comprises a capsule core material and double layers of wall materials from inside to outside, a corrosion-inhibiting material is loaded between the double layers of wall materials, a coupling reagent is adhered on an outer wall of the double layers of wall materials, wherein the capsule core material is a reactant of a polyhydroxyl or multiamino compound and isocyanate, an inner wall of the double layers of wall materials is polyurethane, the outer wall of the double layers of wall materials is melamine formaldehyde resin, and the corrosion-inhibiting material is a nanoparticle and a metal corrosion inhibitor. The microcapsule is high in repairing efficiency, stable in mechanical property and simple in process, is matched with a matrix, has extensive applications, and can be widely applied to the fields of metal anti-corrosion and self-repairing materials like the petrochemical engineering, the marine industry and the automobile industry.

Owner:SHENYANG RES INST OF CHEM IND +1

Preparation method of melamine/formaldehyde resin cladded melamine phosphatic microcapsules for fire retardant

InactiveCN102229712AReduce solubilityPrevent moisture absorption and agglomerationMicroballoon preparationMicrocapsule preparationPolymer sciencePolyolefin

The invention belongs to the technical field of materials, and specifically relates to a preparation method of melamine / formaldehyde resin cladded melamine phosphatic microcapsules for a fire retardant. The preparation method comprises the following concrete steps of: firstly adding 100g of MP and 0.1-3g of a dispersant into a solvent of 200-500ml, dispersing by stirring for 0.4-0.6 hours, adding a melamine / formaldehyde resin prepolymer into the system, dispersing by incessant stirring for 0.4-0.6 hours, heating up to 60-120 DEG C, reacting for 1-5 hours, filtering and drying to obtain a melamine / formaldehyde resin cladded MP microcapsule powder. The microcapsule coating is compact and uniform with good fluidity and greatly reduced water-solubility, can be used as a fire retardant for high-molecular materials such as polyolefin and nylon, and can be used in the flame retardation for materials such as timber, fabric, paintings and the like.

Owner:TONGJI UNIV

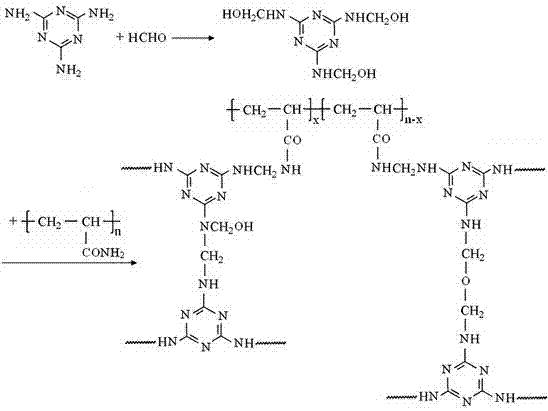

Composite modified soybean protein adhesive as well as production method and application thereof

InactiveCN101857792AImprove wettabilityNo pollution in the processProtein adhesivesWood veneer joiningCross-linkAlkaline water

The invention discloses a composite modified soybean protein adhesive as well as a production method and application thereof. The composite modified soybean protein adhesive comprises the following components: an alkaline water solution of surfactant, soybean protein products, a modifier, a cross-linking agent and fillers. In the invention, soybean protein molecules are modified by using a composite modifying method of degradation-crosslinking, the wetting property of the adhesive on wood surfaces is improved through degradation, and intermolecular cohesive forces of the solidified adhesive are improved through crosslinking. The composite modified soybean protein adhesive is water adhesive, which is nontoxic and pollution-free and has excellent glue joint strength and water resistant property, and can be used as the adhesive for processing man-made planks instead of traditional phenolic resin adhesives, urea-formaldehyde resin adhesives and melamine-formaldehyde resin adhesives.

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

System for Delivery of a Tracer in Fluid Transport Systems and Use Thereof

The present application proposes a specific tracer delivery system that has been tested. The claimed system is composed of melamine formaldehyde resin (MFR) doped with various tracer materials. The MFR is used to slowly release tracer compounds into a liquid system. The MFR / tracer mixture is applied as part of a monitoring system where tracer is delivered from the MFR / tracer mixture at a specific location up-stream and detected at some location downstream, thereby verifying fluid flow from that specific location up-stream. The MFR can be doped with different types of tracers, thereby allowing placement of different tracers at several different positions upstream. Production from the various labelled zones can be verified through the analysis of one sample downstream.

Owner:RESMAN AS

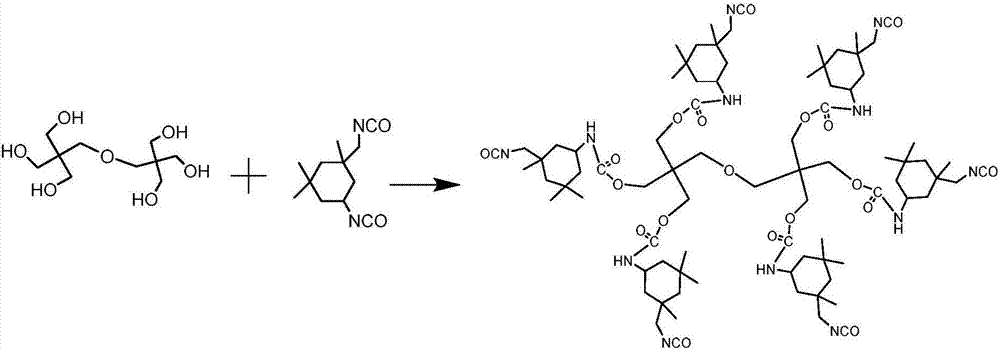

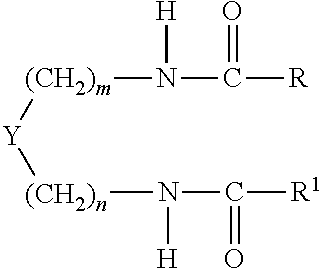

Two-component urethane resin adhesive for polymer lithium ion battery flexible package film

InactiveCN102329594ANot easy to peel offPeeling does not affectPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterStrong acids

The invention provides a two-component urethane resin adhesive for a polymer lithium ion battery flexible package film, and aims to provide an adhesive which has the advantages of high bonding strength, stripping resistance, excellent barrier property, impact resistance, high bonding compatibility with a nonmetallic film or an aluminum foil, resistance to swelling, dissolving, permeation and absorption of electrolyte organic solvents and high-volatility substances, resistance to strong acid and strong alkali and difficulty in breaking a molecular chain after becoming dry and hard. The two-component urethane resin adhesive consists of components, wherein a first component (A) is an emulsion waterborne Poly Urethane (PU) performed polymer which is obtained by compounding polyester and isocyanate / benzene ring-containing polyether in the mass ratio 75 / 25-55 / 45 and adding an aid for reacting; a second component (B) is a composition consisting of glycidyl ether epoxy resin with the epoxy resin 0.25-0.45 and a melamine-formaldehyde resin additional crosslinking agent; the weight ratio of the first component to the second component is 10 / 1-10 / 2; and a certain amount of additional crosslinking agent is added into a PU emulsion in a certain mass ratio.

Owner:刘继福

Method for modifying melamine foam

The invention relates to a method for modifying melamine foam, which comprises the following steps of: adding an emulsifier, a foaming agent, a curing agent and other aids into a base material, namely melamine formaldehyde resin synthesized by melamine and formaldehyde in a low molar ratio, adding melamine and one or more hydramine compounds, and uniformly emulsifying; heating and foaming at certain temperature for a certain period of time through microwaves in a microwave oven; and curing at high temperature, and processing and forming. In the process of foaming through the microwaves, the melamine or the melamine formaldehyde resin and the hydramine compounds can generate a compound capable of improving the performance of foam at high temperature under the action of the microwaves, and the foam is modified at the same time, so that the aim of improving the performance of the melamine foam is fulfilled.

Owner:SICHUAN NEW ENERGY POWER CO LTD

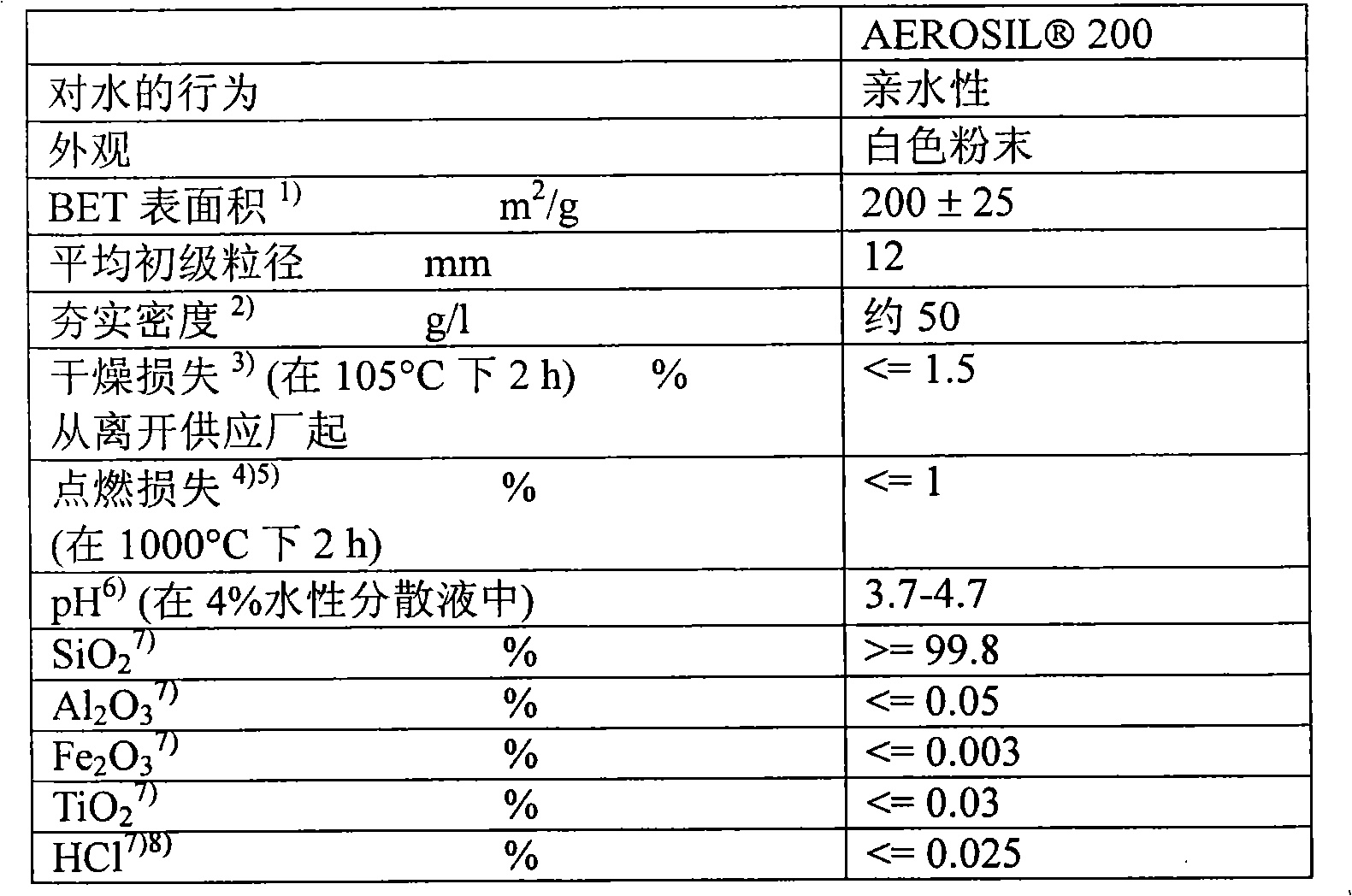

Adhesive and sealant systems

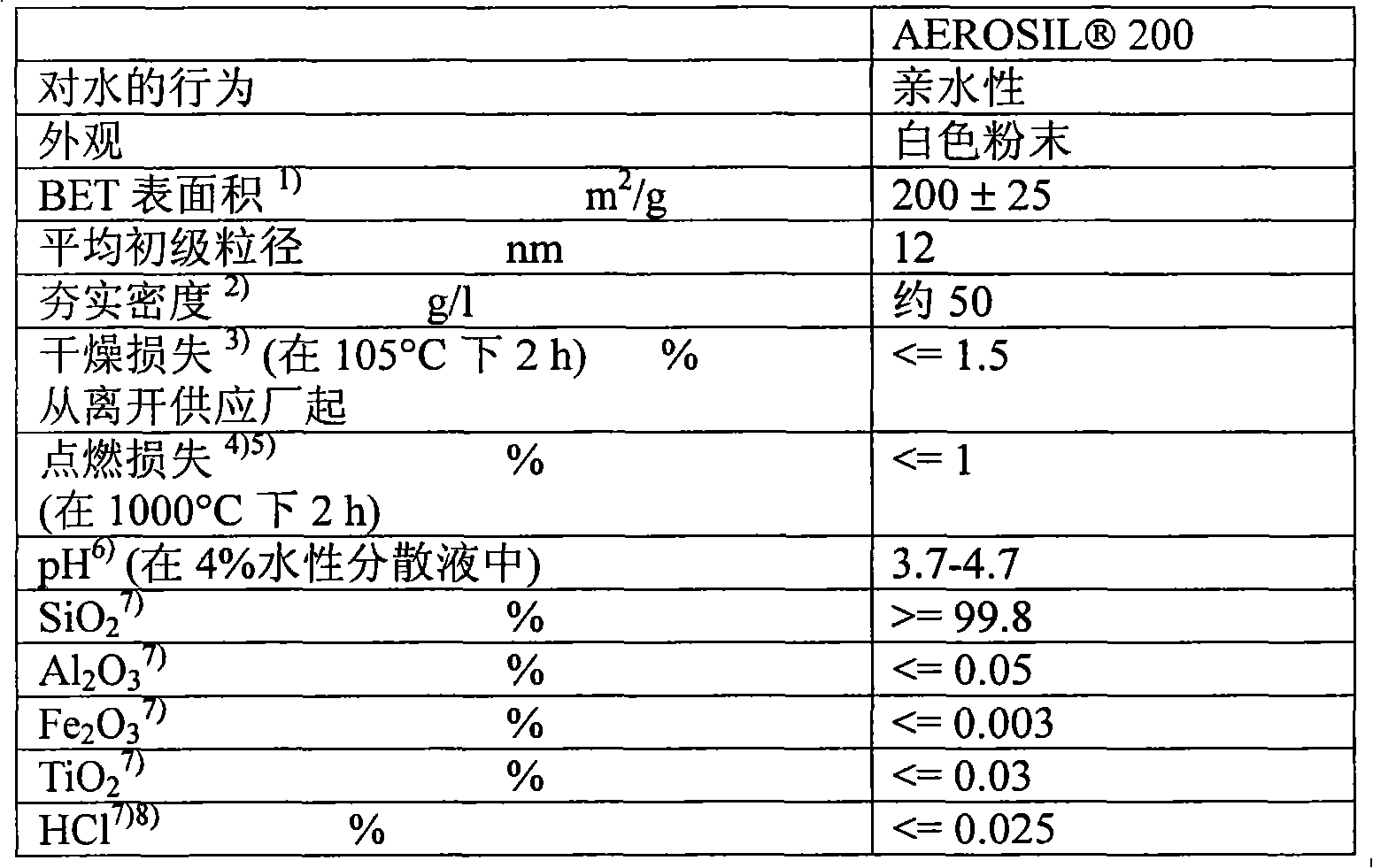

Adhesive and sealant systems Adhesive and sealant systems on the basis of unsaturated polyester resins, epoxy resins, polyurethane, silane-terminated polymers, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ethers, ethylene-vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulphide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles or polysulphones and containing 1% to 15% by weight of a hydrophilic fumed silica structurally modified by grinding.

Owner:EVONIK DEGUSSA GMBH

Method for manufacturing surface wear-resisting impregnated paper of laminate floor by dry-spraying Al2O3

ActiveCN102086616AImprove wettabilityImprove the wrapping effectNon-fibrous pulp additionPaper coatingRolling paperMelamine formaldehyde

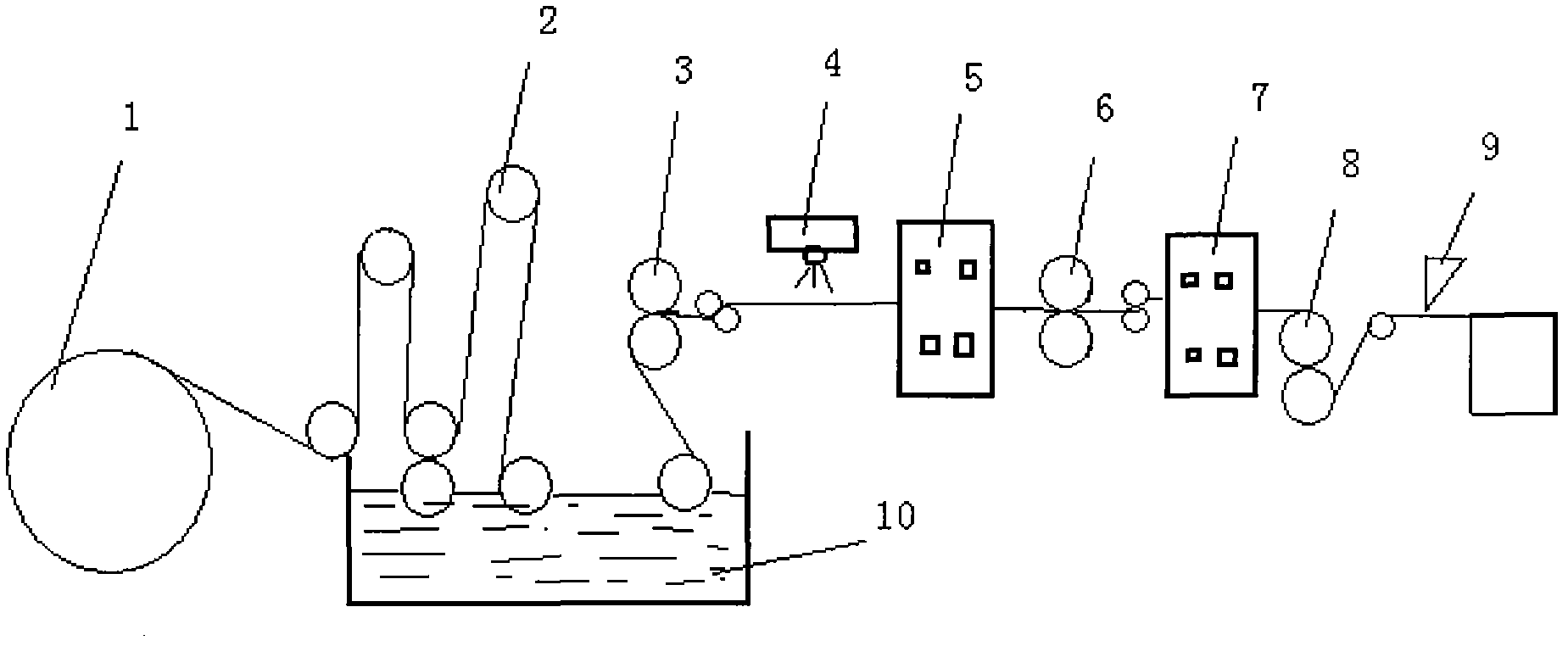

The invention relates to a method for manufacturing surface wear-resisting impregnated paper of a laminate floor by dry-spraying Al2O3. The method comprises the following steps: impregnating pure wood pulp roll paper with a melamine-formaldehyde (MF) resin liquid; uniformly spraying the Al2O3 on the surface of the impregnated paper by utilizing a dry sprayer; allowing the impregnated and sprayed paper to enter a first oven for drying at the temperature of 100-150 DEG C; roll-coating 300-500% (relative to the weight of the paper) of the MF resin liquid on the paper surface after preliminary drying; and allowing the roll-coated paper to enter a second oven for drying at the temperature of 100-150 DEG C, controlling the whole-course running speed of the paper at 10-12m / minute, cooling, adjusting the temperature of the oven and machine speed so as to reach 6.0-7.5% of volatile matters and 40-60% of pre-curing degree, cutting and packaging. By means of the method, the defects of the prior art are overcome, and the spray quantity of the Al2O3 can be adjusted by controlling the dry sprayer so as to obtain the surface wear-resisting impregnated paper with reliable quality according to different wear-resisting requirements; and the method has the advantages of reasonable process and obvious effect, and is simple in operation, thus effectively improving the product quality.

Owner:天津市瑞鸿装饰材料销售有限公司

Antibacterial fire-proofing board and manufacturing method thereof

InactiveCN1454776AWill not cause secondary pollutionNovel ideaSynthetic resin layered productsBiochemical engineeringMelamine formaldehyde resin

The present invention discloses an antibacterial fire-proofing plate and its production method, which comprises a fire-proofing layer using phenolic-resin impregnated paper as base material. The antibacterial layer is adhered on the single side of the fire-proofing layer or its two sides. The said antibacterial layer uses the melamine resin impregnated decorative paper with bacteriocide as base material, and the bacteriocide is silver ion and zinc ion, and on the surface of antibacterial layer decorative paper the pattern can be printed to be used as decorative layer. Its production method includes preparation of fire-proofing and antibacterial resin, impregnation of fire-proofing layer and antibacterial layer and drying, heating fire-proofing and antibacterial layer group blank and press-forming steps.

Owner:马青

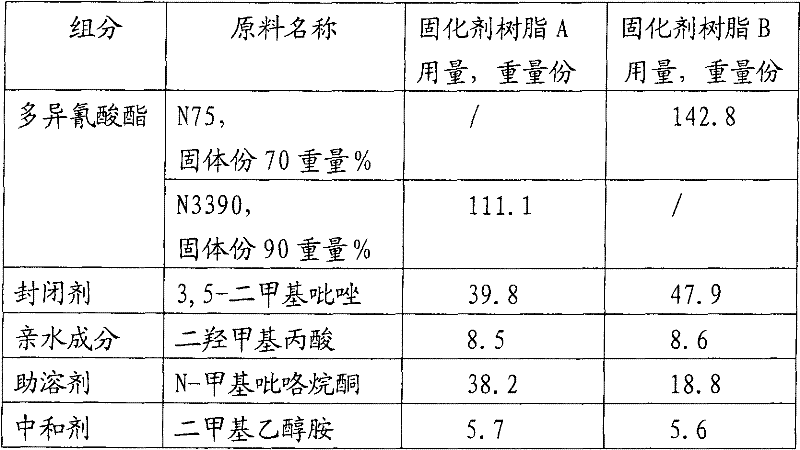

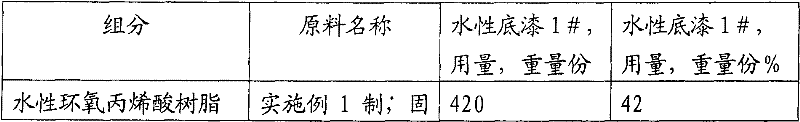

Aqueous primer used for bicycles

The invention relates to an aqueous primer used for bicycles, which comprises the following components in percentage by weight: 25-45% of aqueous epoxy acrylate resin, 2-10% of curing agent resin, 1-3% of neutralizing agent dimethylethanolamine, 2-10% of compound anticorrosive pigment, 5-20% of tinting pigment and filler, 0.1-0.5% of antifoaming agent, 0.1-0.5% of flatting agent and 20-40% of deionized water, wherein the sum of the content of all components is 100%. The aqueous epoxy acrylate resin accounts for 10-40% of the total mass of epoxy resin; the curing agent resin comprises aqueous closed-type polyurethane curing agent resin and amino curing agent resin, wherein the mass ratio of the aqueous closed-type polyurethane curing agent resin to the amino curing agent resin is 1:5-5:1; the aqueous closed-type polyurethane curing agent resin is decapsulated and solidified at the temperature of 130DEG C; the amino curing agent resin is carbinol or butylated amino melamine formaldehyderesin; and the compound anticorrosive pigment comprises modified zinc phosphate, zinc oxide and ion exchange type anticorrosive pigment. The aqueous primer disclosed by the invention is especially suitable for preventing rust and corrosion of structures, such as bicycles and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

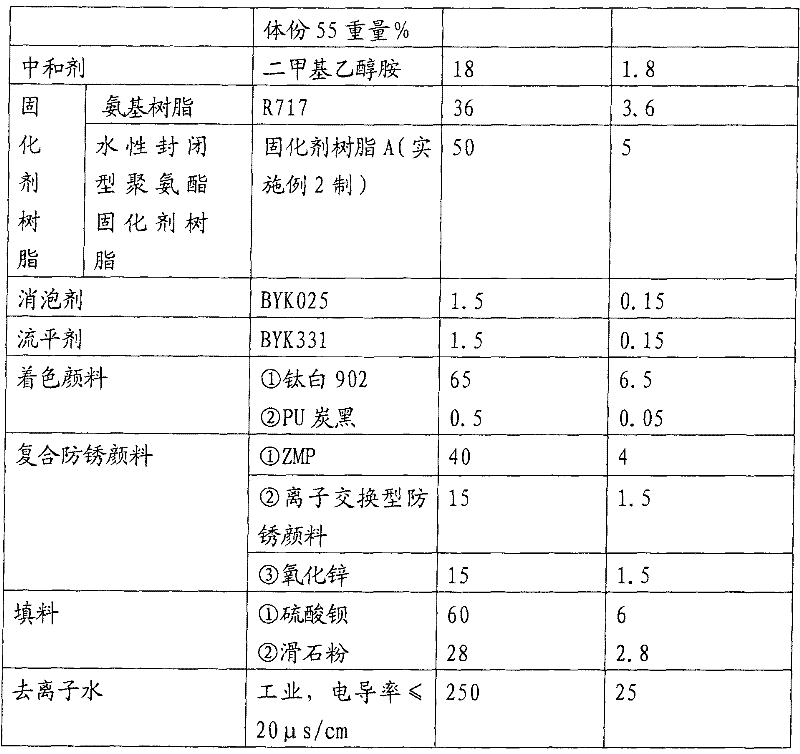

High-glowing filament anti-soaking separate-out-free halogen-free inflaming retarding polypropylene materials and preparation method thereof

The invention discloses high-glowing filament anti-soaking separate-out-free halogen-free inflaming retarding polypropylene materials which comprise the following components: by weight, 40-80 parts of polypropylene (PP) resins, 20-40 parts of compound halogen-free flame retarding agents, 0.5-5 parts of flame retardant synergists, 0-30 parts of inorganic fillers, 0.1-0.5 part of antioxidants, and 0.4-1 part of lubricating agents. The compound halogen-free flame retarding agents are composed of the following components: by weight, 30-50 parts of silane-wrapped organic or inorganic hypophosphite, 35-50 parts of melamine formaldehyde resin (MF)-wrapped halogen-free organic phosphate ester or the ramification thereof, and 15-40 parts of melamine cyanuric acid ester. The compound halogen-free flame retarding agents are easy to disperse in the process of processing, so that processing is convenient. The halogen-free inflaming retarding polypropylene materials prepared by the method have high-glow filaments, and have the advantages of being anti-soaking, separate-out-free and the like. In addition, the production process is simple, so that industrial production can be achieved.

Owner:聚石化学(苏州)有限公司

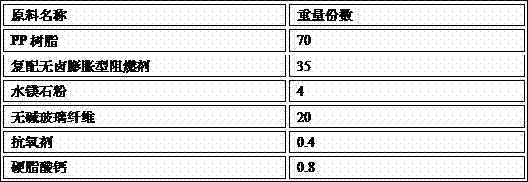

Aqueous fire-retardant water-resistant non-corrosive composition for topical application to products and articles

InactiveUS20160137853A1Maintain propertiesImprove flame retardant performanceFireproof paintsAntifouling/underwater paintsAdhesivePreservative

Disclosed is a fire-retardant, non-corrosive, water-resistant, insect-resistant, fungus-resistant composition comprising a first flame-retardant agent, water-resistant composition, a preservative composition, a second flame-retardant agent, a third flame-retardant agent, and a liquid melamine formaldehyde resin adhesive. The composition is to be used for topical application to articles using a spray device, where a layer of a desired thickness is applied.

Owner:LOPEZ RICHARD A +1

Aqueous fire-retardant non-corrosive composition for topical application to products and articles

Owner:LOPEZ RICHARD A +1

Resin solution for preparing melamine formaldehyde resin foam plastics and preparation method thereof

The invention discloses resin solution for preparing melamine formaldehyde resin foam plastics and a preparation method thereof. The preparation method for melamine formaldehyde resin solution comprises the following steps: adding weak-acid-strong-alkali salts into the resin solution, and evenly mixing to prepare the melamine formaldehyde resin solution, wherein the resin solution is a reaction product of melamine and formaldehyde. The melamine formaldehyde resin solution has good storage stability, and has shelf life of above 72 hours when preparing the melamine formaldehyde resin foam plastics so as to greatly facilitate preparing the melamine formaldehyde resin foam plastics. Experiments show that the melamine formaldehyde resin flexible foam plastics prepared from the melamine formaldehyde resin solution have good mechanical property, physiochemical performance and flame resistance.

Owner:SHANGHAI HAOHAI CHEM

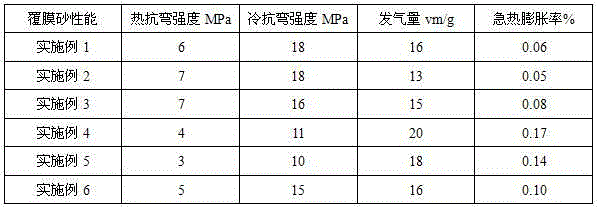

3D printing precoated sand and preparation method thereof

ActiveCN104923712AStrong adhesionImprove smoothnessFoundry mouldsFoundry coresMelamine formaldehydeMelamine formaldehyde resin

The invention relates to a precoated sand for a casting field, in particular to a 3D printing precoated sand. The 3D printing precoated sand comprises the following components: 5-8 wt% of cashew nut shells, 1-2 wt% of melamino-formaldehyde resins, 1-5 wt% of cashew nut shell liquid modified phenolic resins, 0.6-0.8 wt% of urotropin, 0.1-0.4 wt% of lubricant, 0.1-0.8 wt% of binding agents, 0.1-0.4 wt% of coupling agents, 0.5-1 wt% of dispersing agents, and the balance of crude sands. The prepared 3D printing precoated sand has high strength, high-temperature resistance, low gas generating amount and low expansion rate.

Owner:SHIYAN CHANGJIANG RIVER MOLDING MATERIAL

Antiperspirant compositions

InactiveUS20120076839A1Prevents and reduces localised sweatingFacilitate cognitionCosmetic preparationsToilet preparationsMedicineMelamine formaldehyde resin

Anhydrous antiperspirant compositions containing an encapsulated fragrance, in which the encapsulate shell comprises an aminoplast resin, and preferably a melamine / formaldehyde resin. The encapsulates have a weight average particle diameter in the range of 25 to 60 μm, a shell having a measured thickness in the range of from 1 to 10 μm and an average in the range of from 5 to 8 μm, a ratio of the shell thickness to the average particle diameter in the range of from 1:5 to 1:10 and a Hysitron hardness in the range of from 2 MPa to 50 MPa, particularly 15 to 25 MPa, enabling them do be advantageously employed in the anhydrous antiperspirant compositions.

Owner:CONOPCO INC D B A UNILEVER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com