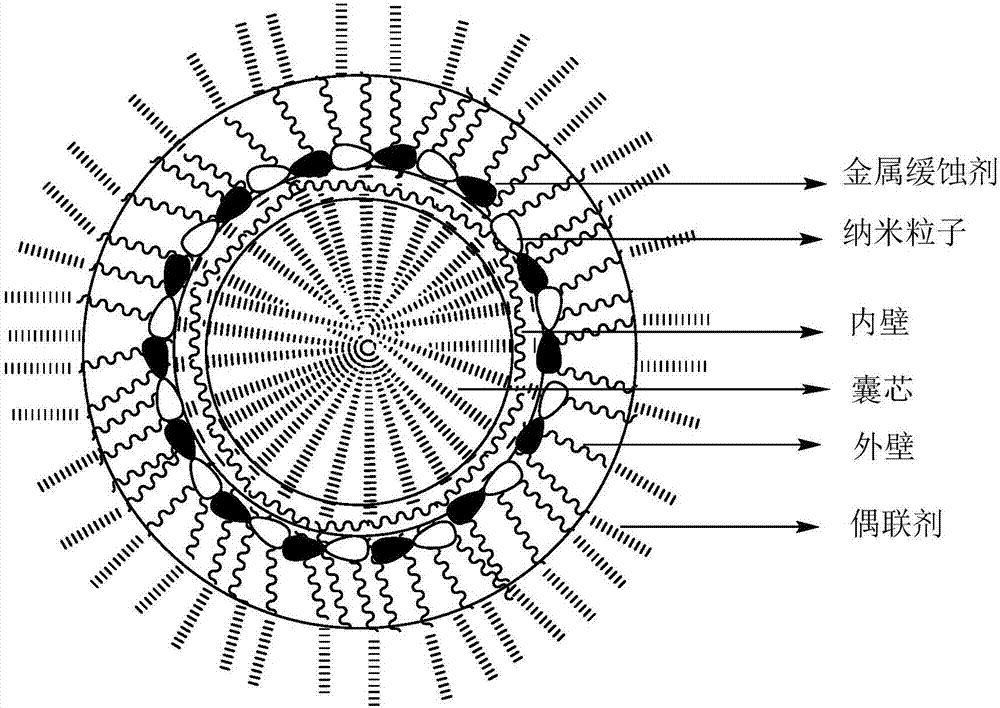

Self-repairing microcapsule used for metal anticorrosive paint and preparation method thereof

A technology of self-repairing microcapsules and metal anticorrosion, which is applied in the direction of anticorrosion coatings, microcapsule preparations, microsphere preparation, etc., and can solve the problems of limited repair efficiency of capsule core materials, poor matching performance of coating substrates, and no corrosion inhibition effect of steel materials. Achieve the effect of large fracture toughness ratio, high repair efficiency and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take myo-inositol and remove impurities and dry it in a vacuum drying oven for 1 hour, dry the cyclohexanone solvent with 4A molecular sieve to remove water, and then mix the dried myo-inositol and cyclohexanone at a ratio of 2:1 to obtain a dry mixed solvent for use;

[0048] equipped with N 2 Add 15g of diphenylmethane diisocyanate into the 500mL four-necked round bottom flask of inlet / outlet, dropping funnel, condenser, heating tank and agitator, and pour 6g of the above-mentioned dried mixed solvent into the dropping funnel; Adjust the temperature at 30°C, and add 1 drop of catalyst DBTDL to the flask under stirring, open the dropping funnel, drop the dry mixed solvent in the funnel into the flask within 30 minutes, and then raise the reaction temperature to 60°C , continue the reaction, and keep the reaction for 10h. Until the measured NCO content of the product aromatic isocyanate derivative reaches the calculated theoretical value, the solution is kept refrigera...

Embodiment 2

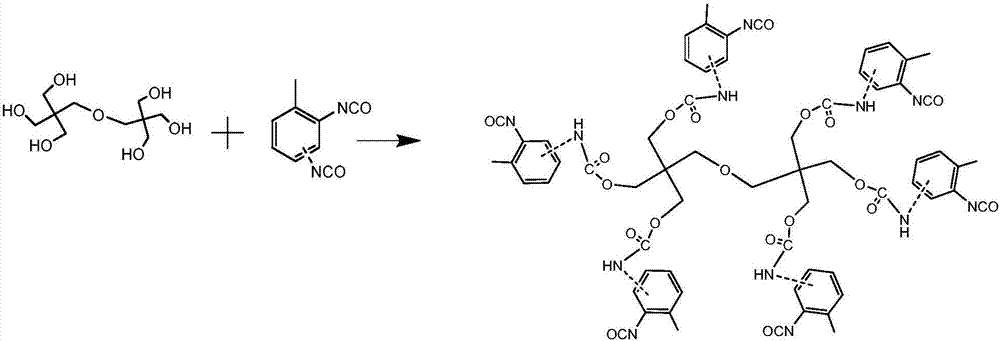

[0054] Take hexamethylolmelamine and remove impurities and dry it in a vacuum drying oven for 2 hours, use an appropriate amount of ethyl acetate solvent to dry and remove water with 4A molecular sieve; then mix the dried hexamethylolmelamine with ethyl acetate in a ratio of 3:1 to obtain dried Mixed solvent, ready to use;

[0055] equipped with N 2 Add 15g of 2,4-toluene diisocyanate into a 500mL four-necked round-bottomed flask with inlet / outlet, dropping funnel, condenser, heating tank and stirrer, and pour 7g of the above-mentioned dry mixed solvent into the dripping solution Funnel; adjust the temperature at 40°C, and add 1 drop of catalyst DBTDL to the flask under stirring, open the dropping funnel, and drop the mixture of hexamethylolmelamine and ethyl acetate in the funnel into the flask within 30 minutes , and then the reaction temperature was raised to 70° C., and the reaction was continued, and the reaction was kept for 9 hours. Until the measured NCO content of t...

Embodiment 3

[0061] Take polyether polyol and remove impurities and dry it in a vacuum drying oven for 3 hours. The solvent is dried with 4A molecular sieve to remove water; then the dried polyether polyol is mixed with toluene solvent in a ratio of 6:1 to obtain a dry mixed solvent for use;

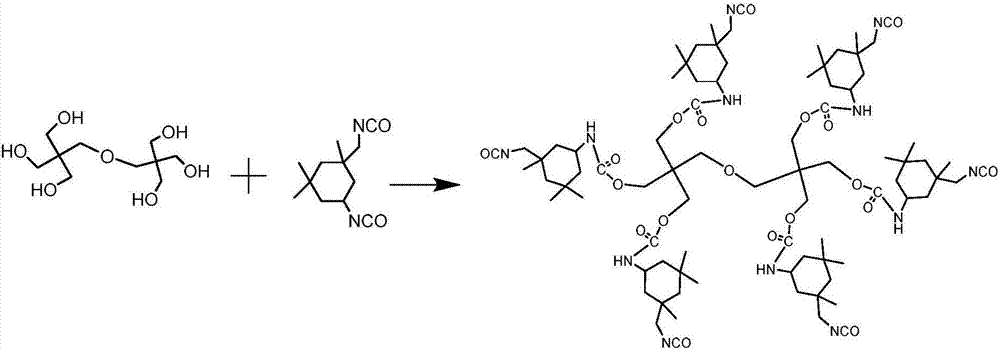

[0062] equipped with N 2 Add 10g of 1,4'-benzenediisocyanate and 4g of 2,6-toluene diisocyanate into a 500mL four-necked round bottom flask with inlet / outlet, dropping funnel, condenser, heating tank and stirrer, and mix the above Pour 12g of dry mixed solvent into the dropping funnel; adjust the temperature at 50°C, add 1 drop of catalyst DBTDL to the flask under stirring, open the dropping funnel, and drop the dried mixed solvent in the funnel within 30 minutes into the flask, then raise the reaction temperature to 70°C, continue the reaction, and keep the reaction for 9h. Until the measured NCO content of the product aromatic isocyanate derivative reaches the calculated theoretical value, the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com