Method for preparing microcapsule red phosphorus inflaming retarding polylactic acid

A technology of microencapsulated red phosphorus and polylactic acid is applied in the directions of dyeing physical treatment, fibrous filler, dyeing polymer organic compound treatment, etc. , the preparation process is simple and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

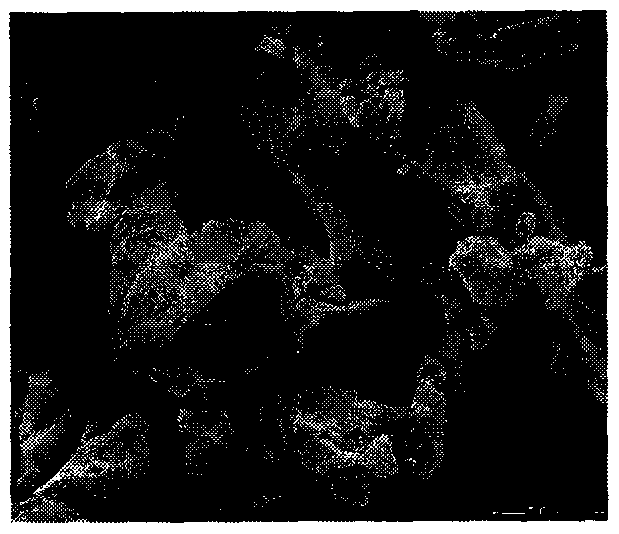

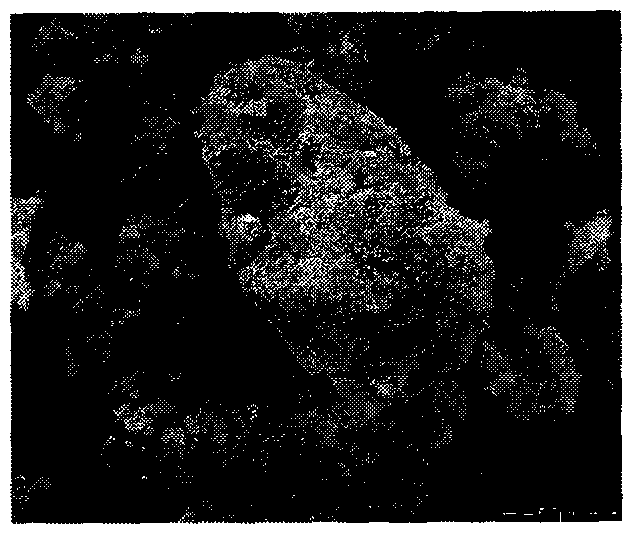

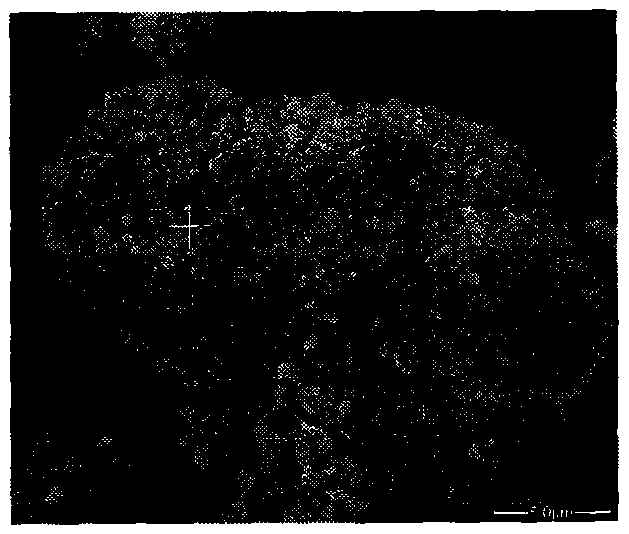

Image

Examples

Embodiment 1

[0039] (1) 25.0 grams of pretreated red phosphorus, 0.375 grams of sodium lauryl sulfate and 400 milliliters of distilled water are made into a suspension, and 137.0 grams of aluminum sulfate solution with a mass concentration of 10% are slowly added under magnetic stirring, and the system is heated After reaching 75°C, use 25% ammonia water to adjust the pH value to 8-9, stir and keep warm for 2 hours to obtain aluminum hydroxide-coated red phosphorus suspension.

[0040](2) Add 3.2 grams of melamine and 6.2 grams of 37% formaldehyde solution into the reaction vessel, adjust the pH value of the system to 8-9 with 25% ammonia water, stir and heat to 90°C, and keep it for 50 minutes to obtain colorless and transparent melamine formaldehyde resin prepolymer solution. Add all the above prepolymer solution into the aluminum hydroxide-coated red phosphorus suspension, adjust the pH value of the system to 4-5 with glacial acetic acid, and keep stirring for 2 hours. After the reacti...

Embodiment 2

[0045] (1) 30.0 grams of pretreated red phosphorus, 0.3 gram of sodium hexametaphosphate and 300 milliliters of distilled water are made into a suspension, slowly add 164.5 grams of aluminum sulfate solution with a mass concentration of 10% under magnetic stirring, and the system is heated to 90 ℃, adjust the pH value to 8-9 with 25% ammonia water, stir and keep warm for 5 hours to obtain aluminum hydroxide-coated red phosphorus suspension.

[0046] (2) Add 16.5 grams of melamine and 31.8 grams of 37% formaldehyde solution into the reaction vessel, adjust the pH value of the system to 8-9 with 25% ammonia water, stir and heat to 85°C, and keep warm for 1 hour to obtain colorless and transparent melamine formaldehyde resin prepolymer solution. Add all the above prepolymer solution into the aluminum hydroxide-coated red phosphorus suspension, adjust the pH value of the system to 4-5 with glacial acetic acid, and keep stirring for 1 hour. After the reaction, the suspension was c...

Embodiment 3

[0051] (1) 20.0 grams of pretreated red phosphorus, 0.4 grams of OP-10 and 250 milliliters of distilled water are made into a suspension, slowly add 78.0 grams of aluminum chloride solution with a mass concentration of 10% under magnetic stirring, and the system is heated to 60 After ℃, use 25% ammonia water to adjust the pH value to 8-9, stir and keep warm for 4 hours to obtain aluminum hydroxide-coated red phosphorus suspension.

[0052] (2) Add 7.2 grams of melamine and 13.8 grams of 37% formaldehyde solution into the reaction vessel, adjust the pH value of the system to 8-9 with 25% ammonia water, stir and heat to 80°C, and keep warm for 70 minutes to obtain a colorless and transparent melamine formaldehyde resin prepolymer solution. Add all the above prepolymer solution into the aluminum hydroxide-coated red phosphorus suspension, adjust the pH value of the system to 4-5 with glacial acetic acid, and keep stirring for 3 hours. After the reaction, the suspension was coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com