Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Raise the ignition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

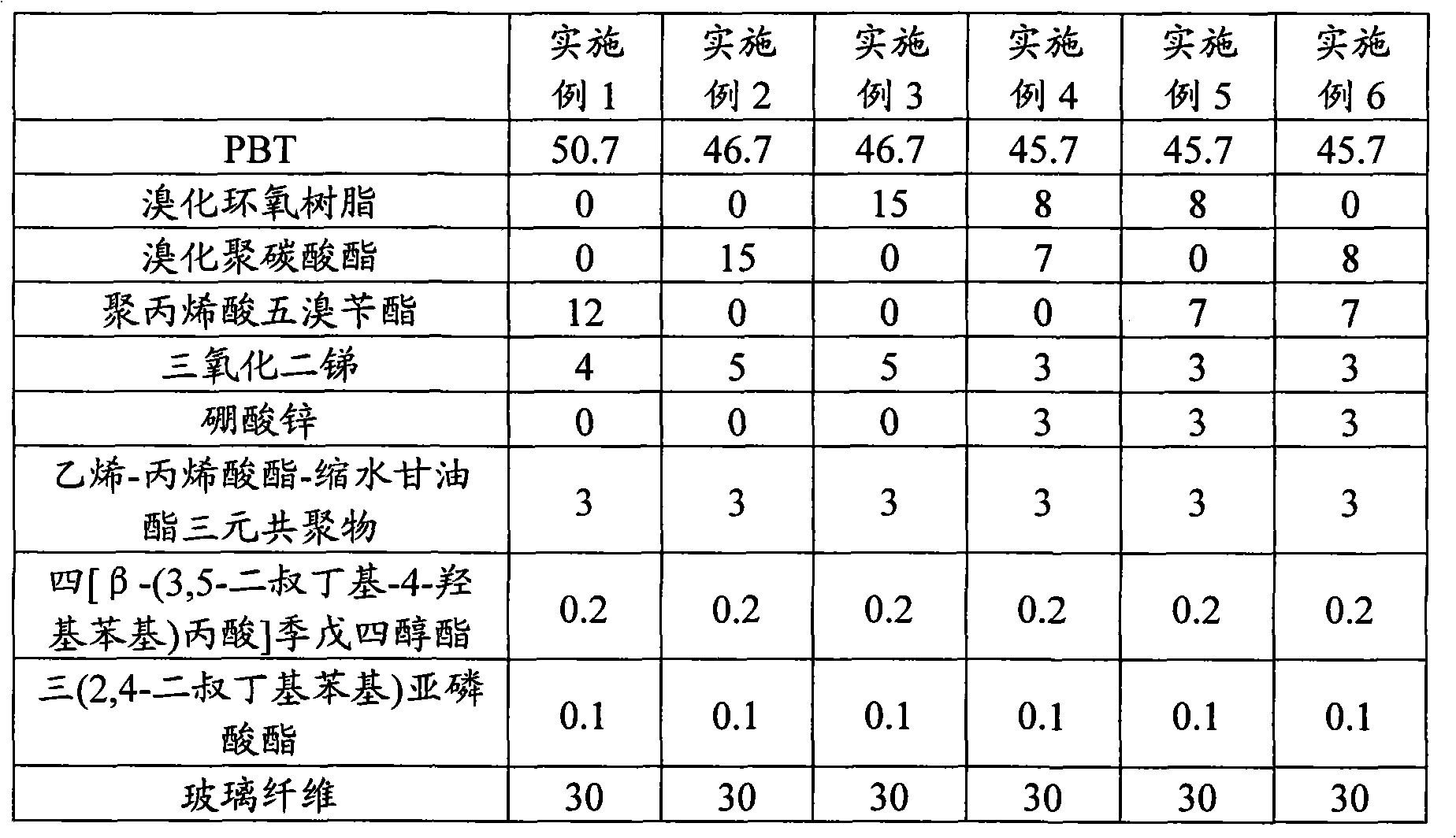

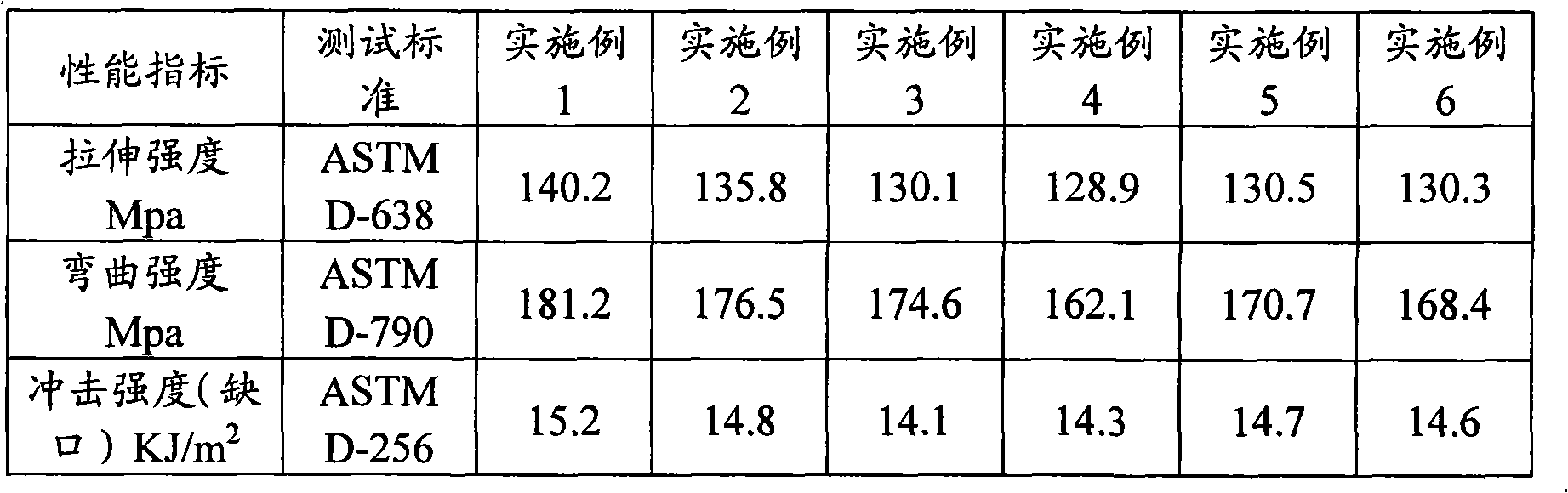

Flame-retardant enhanced PBT material and preparation method thereof

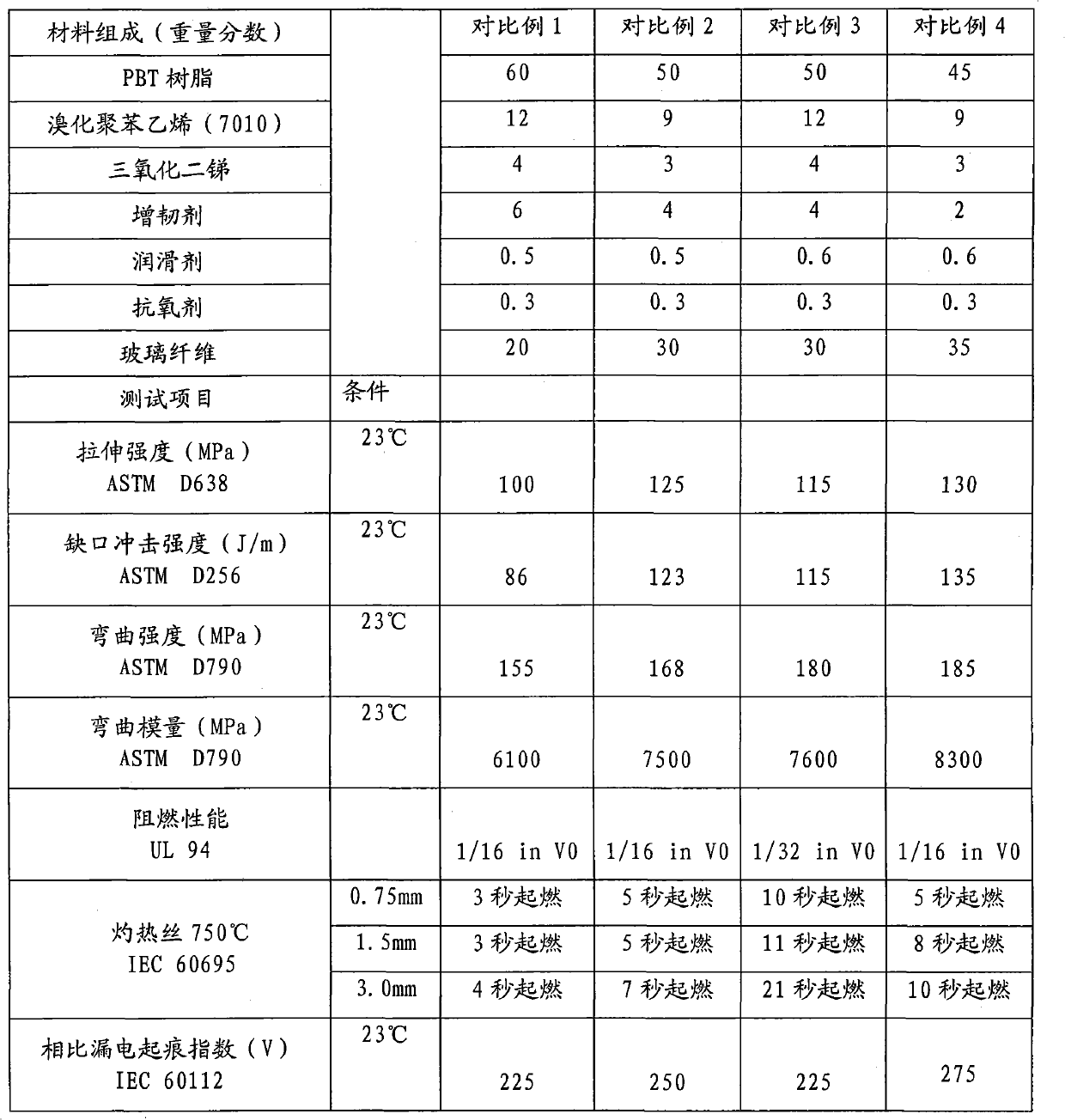

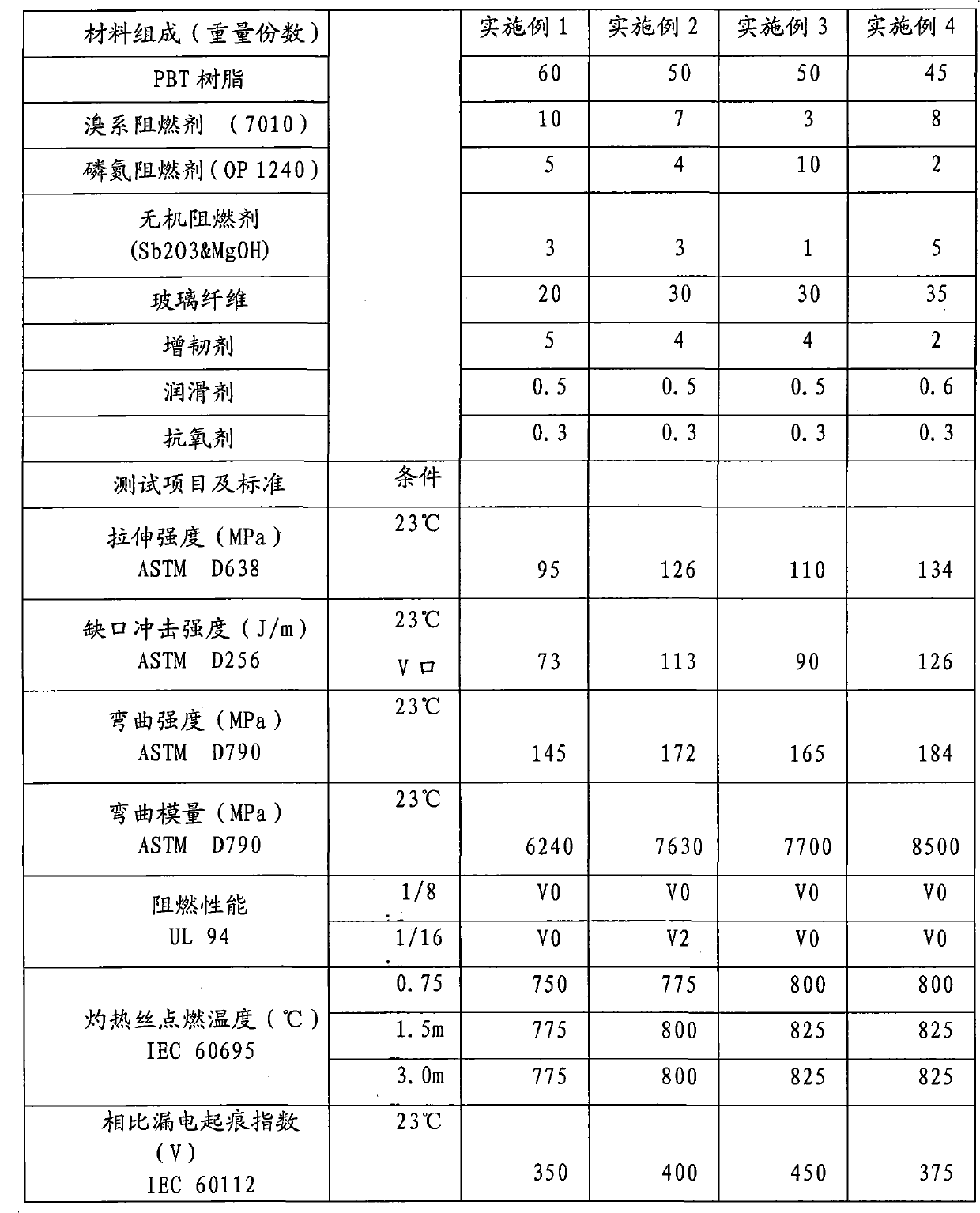

InactiveCN101817972ARaise the ignition temperatureHigh tracking indexComparative Tracking IndexAntioxidant

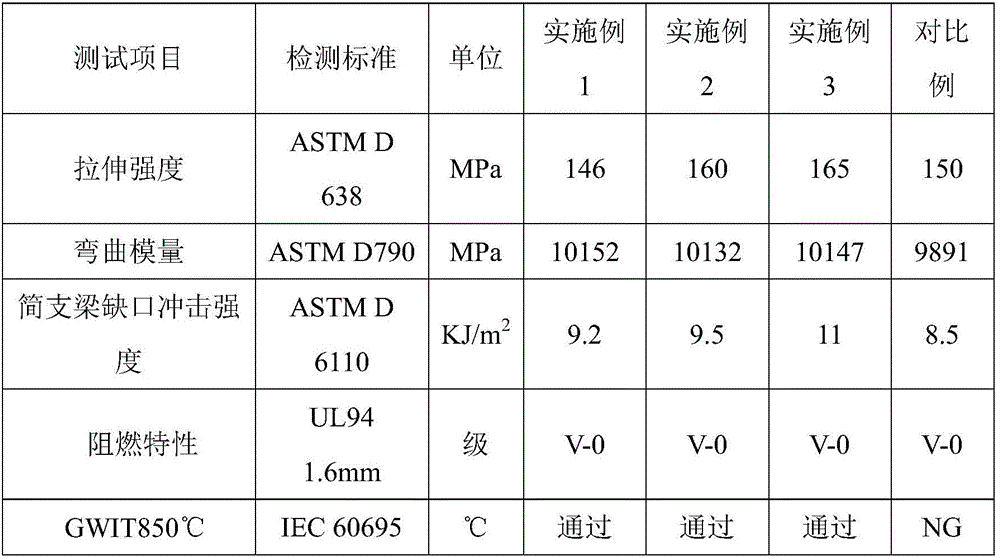

The invention discloses a flame-retardant enhanced PBT material and a preparation method thereof. The flame-retardant enhanced PBT material comprises the following components in percentage by weight: 45 to 60 percent of PBT resin, 3 to 10 percent of brominated flame retardant, 1 to 10 percent of phosphorus-nitrogen flame retardant, 1 to 5 percent of inorganic flame retardant, 2 to 5 percent of toughening agent, 20 to 35 percent of glass fiber, 0.3 to 1 percent of lubricating agent, and 0.1 to 0.6 percent of antioxidant. The flame-retardant enhanced PBT material has high ignition temperature of glowing filament, high comparative tracking index, and better mechanical property, and can be widely applied to the field of unattended electronic and electric products.

Owner:SHENZHEN KEJU NEW MATERIAL

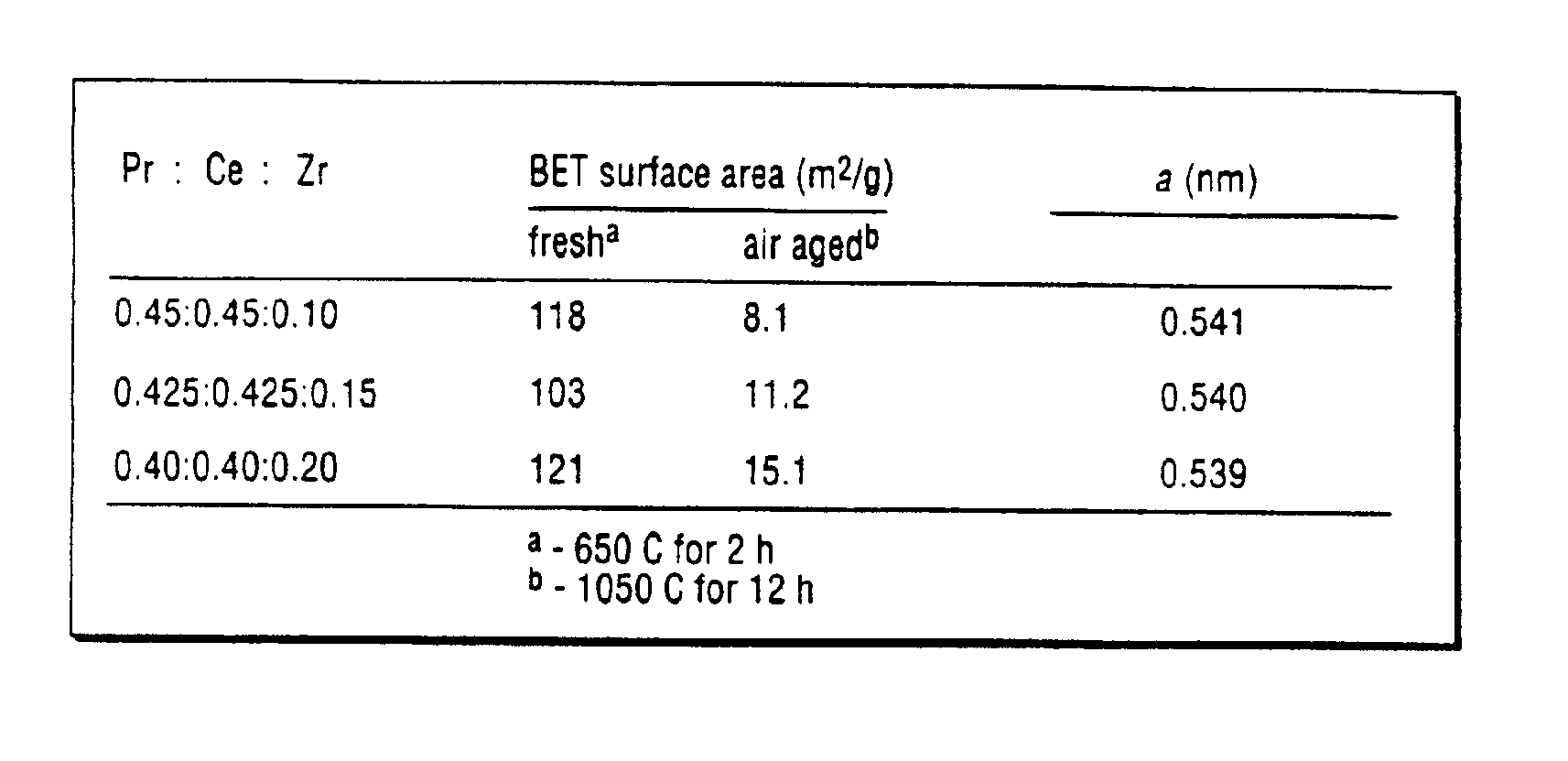

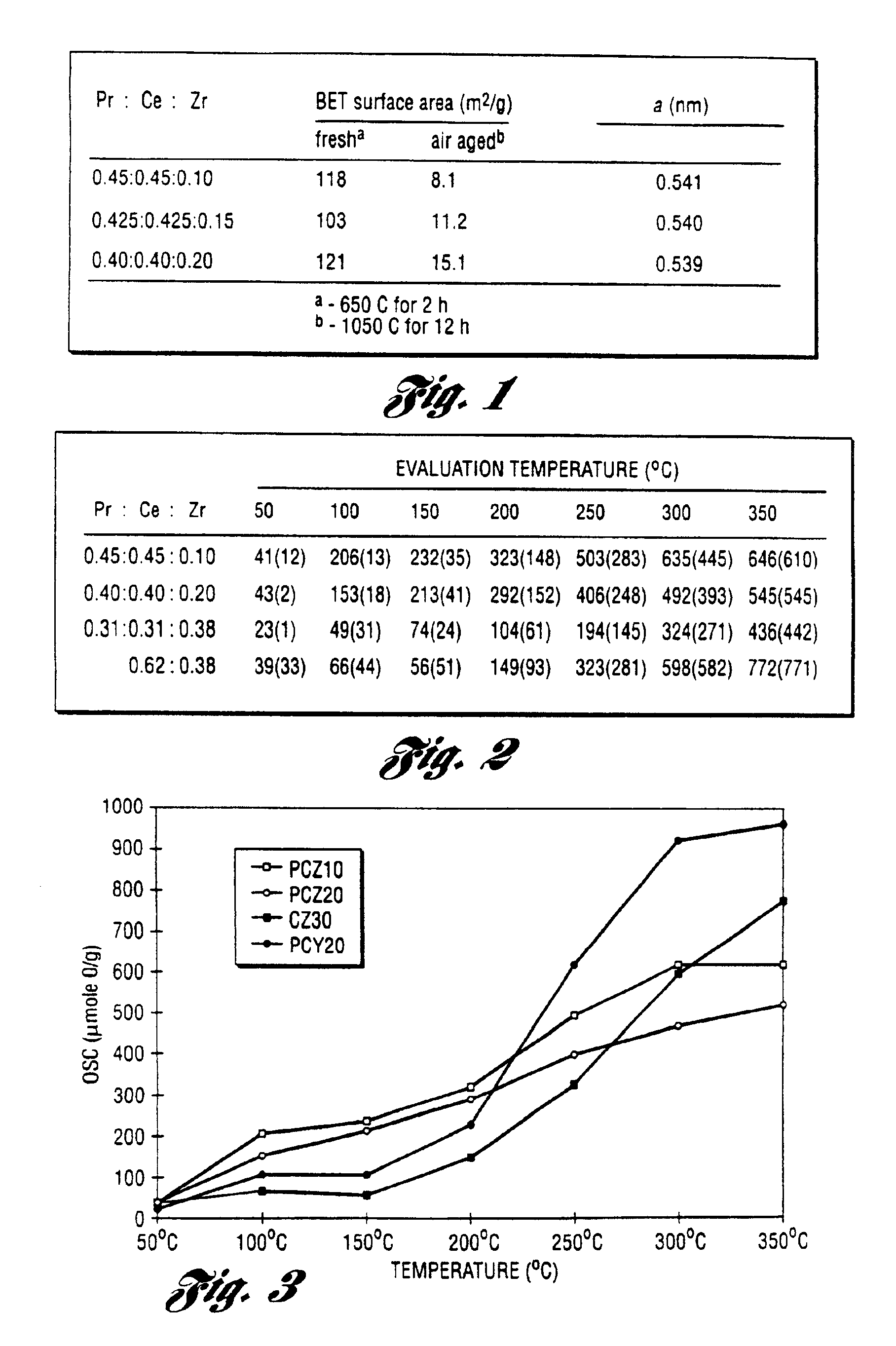

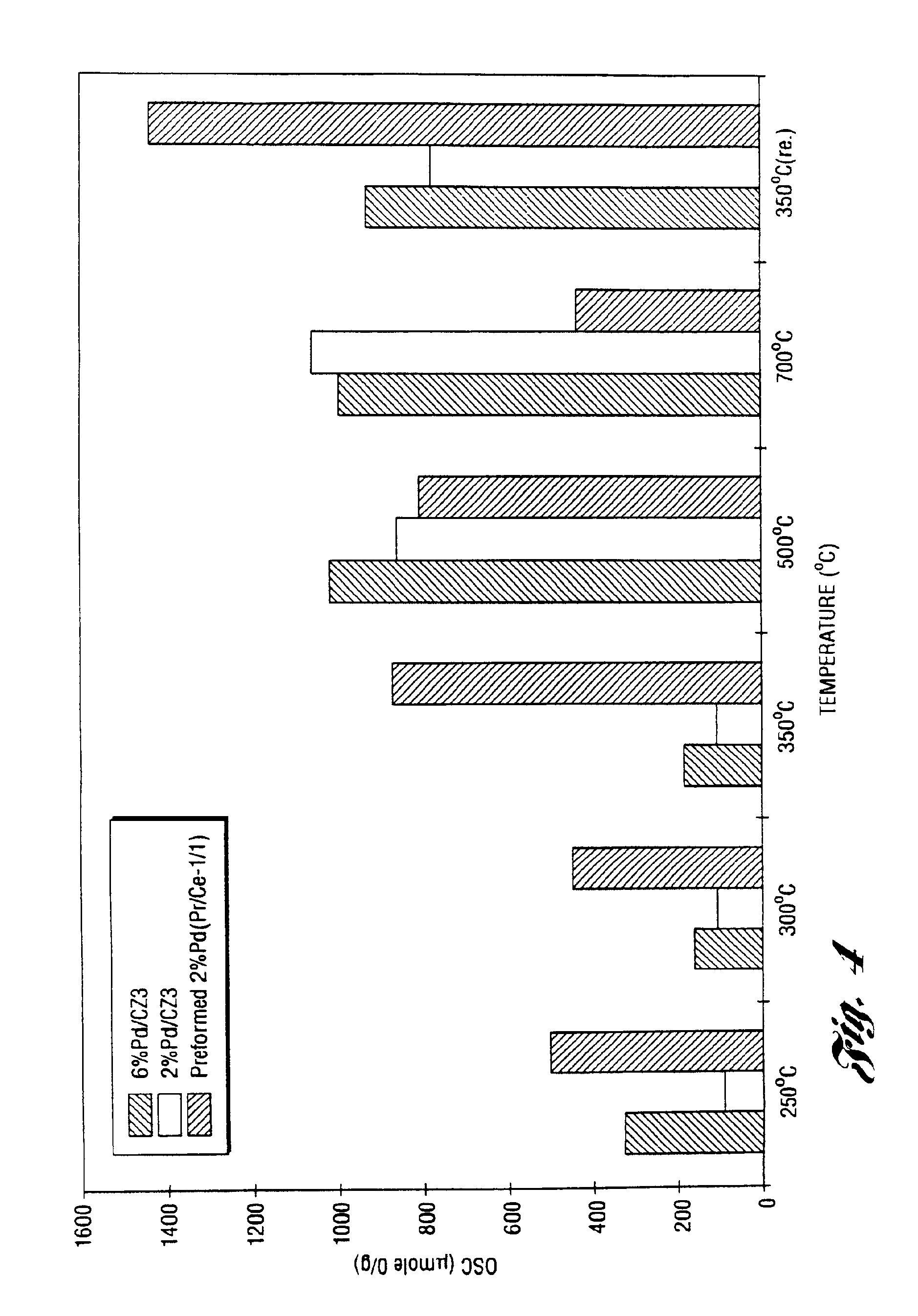

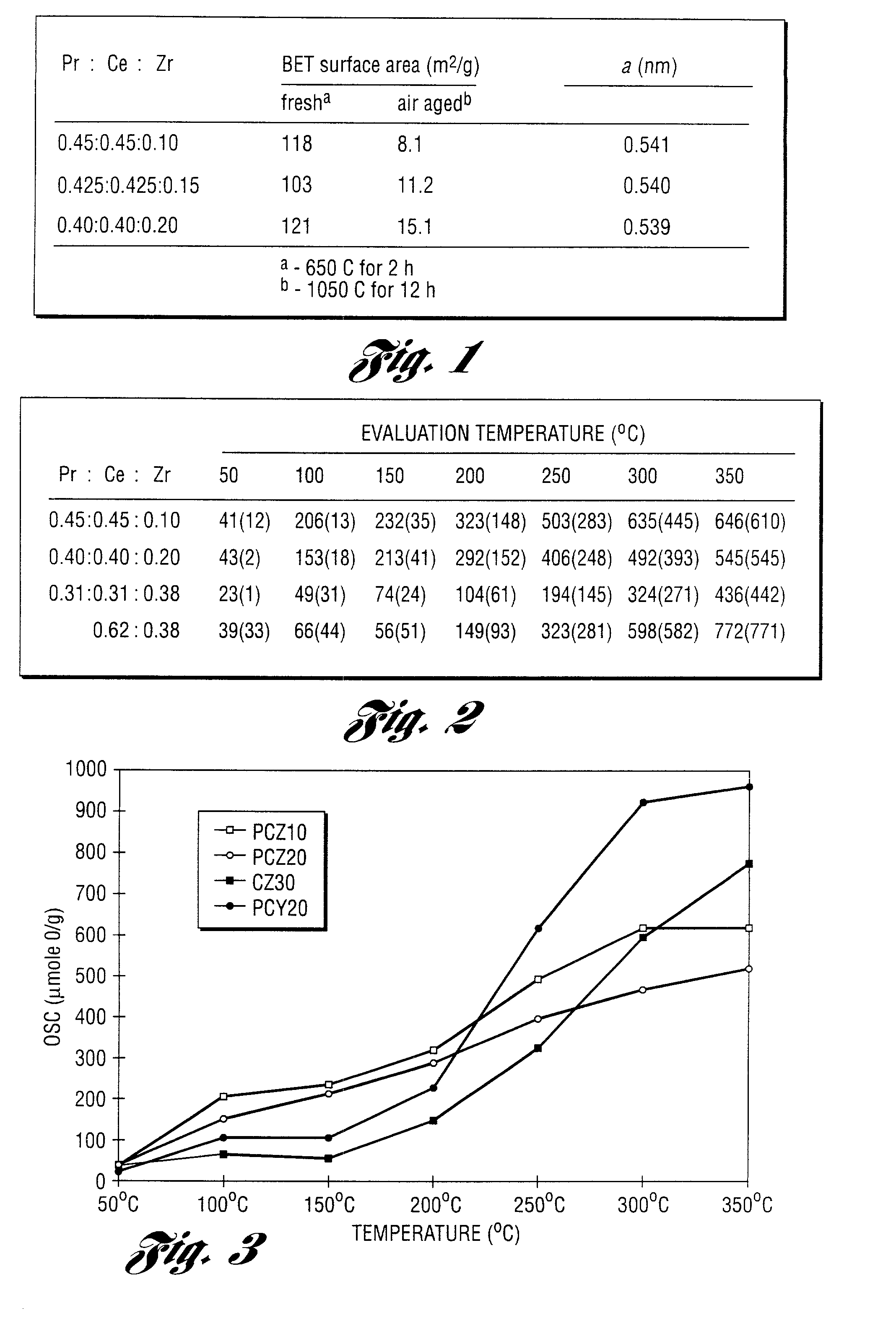

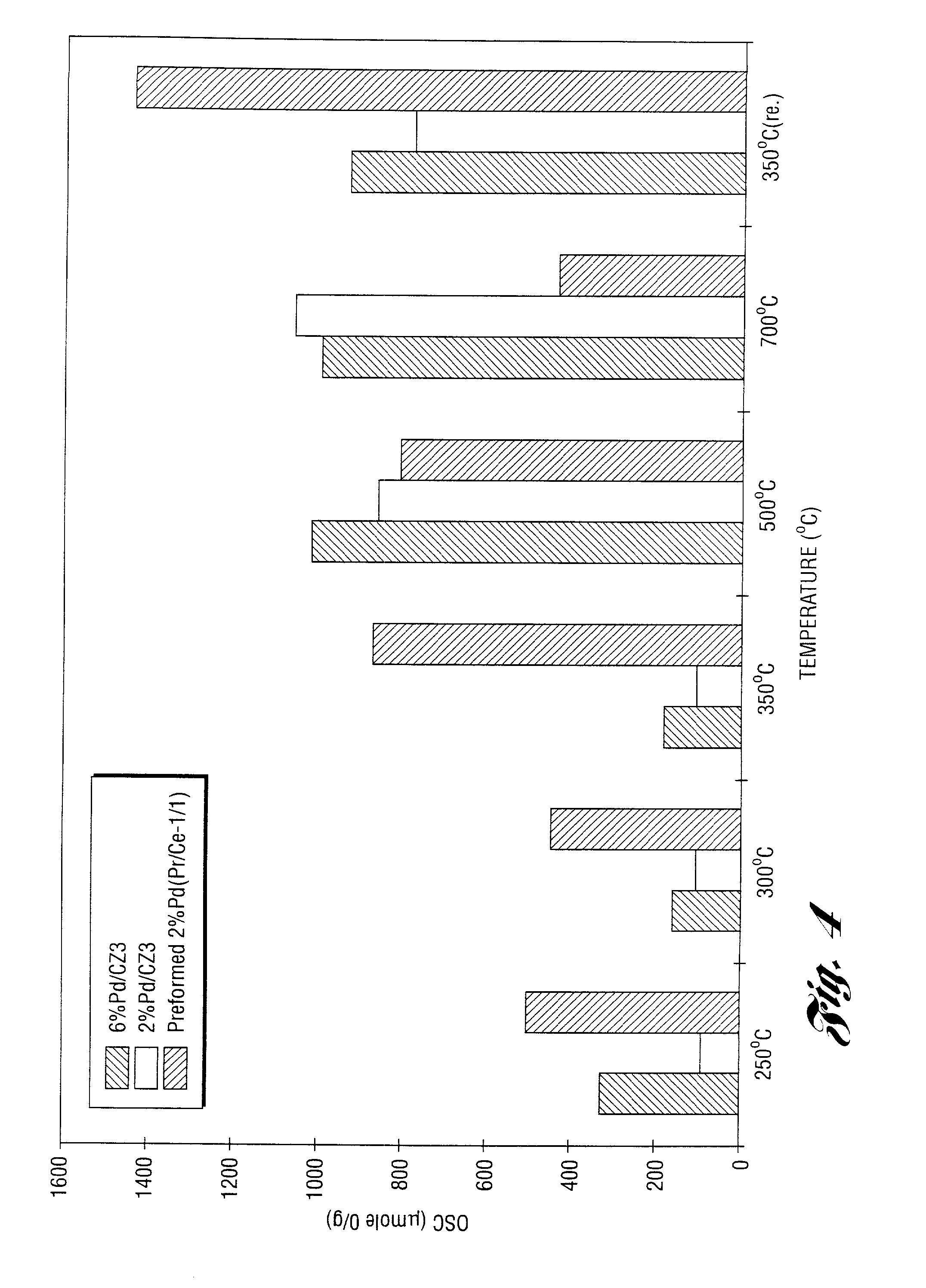

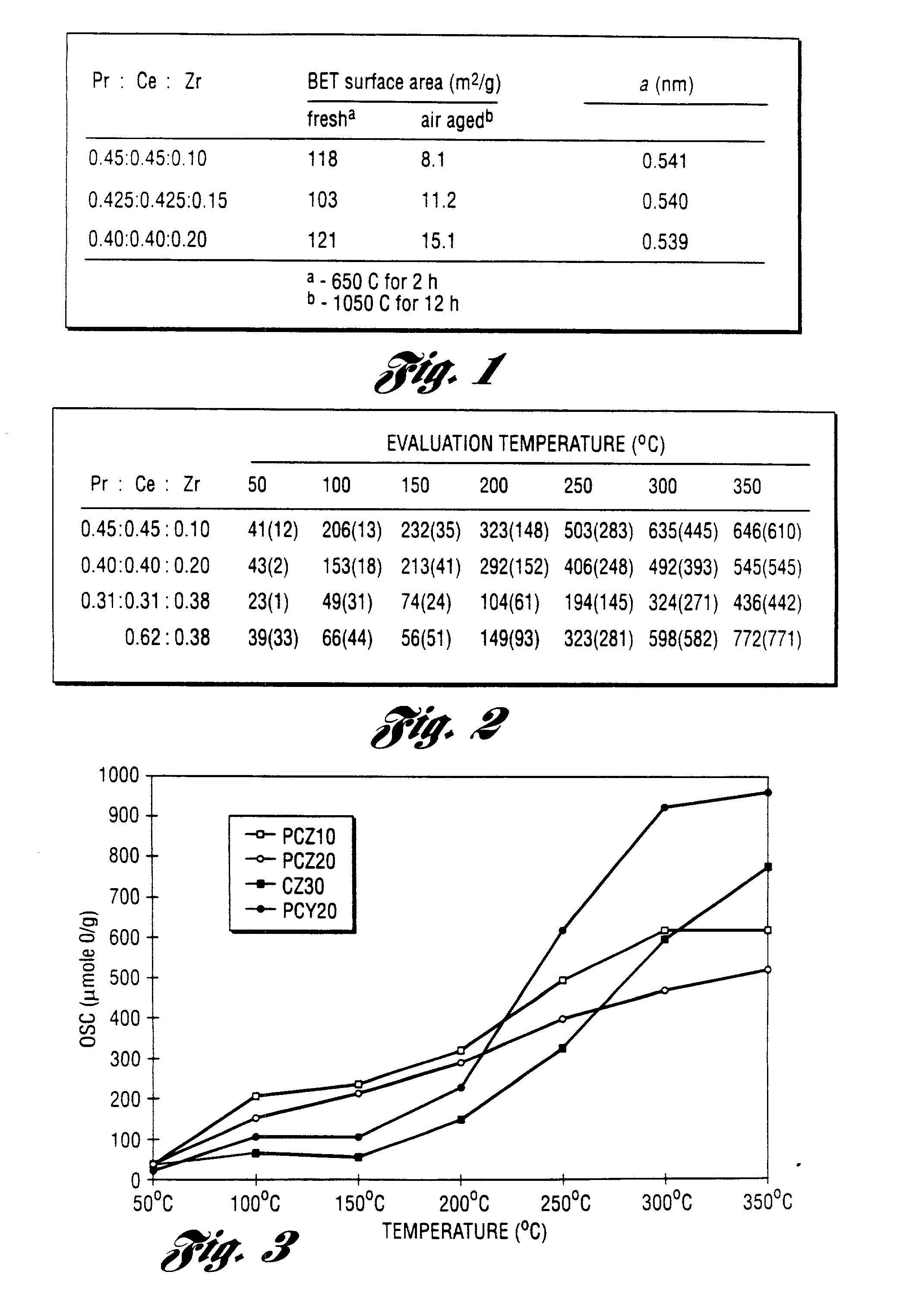

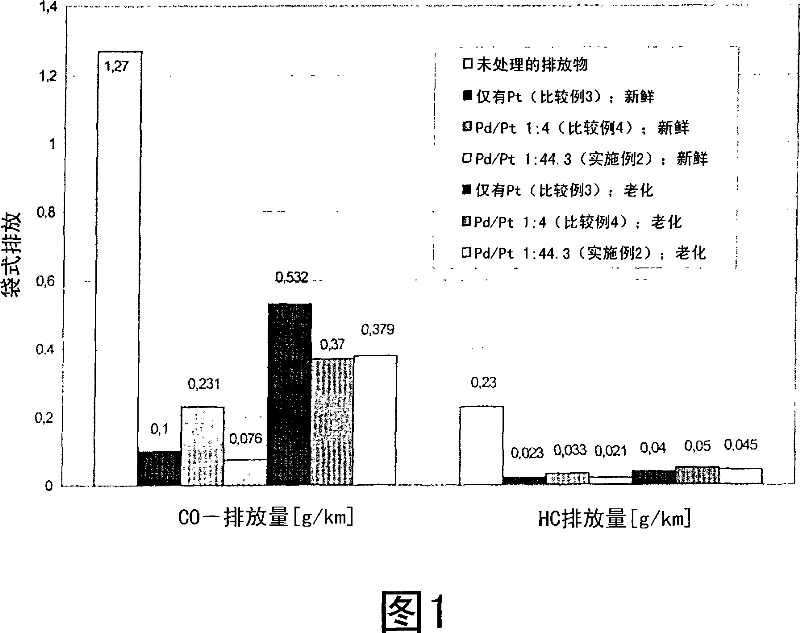

Exhaust gas catalyst and method of manufacturing same

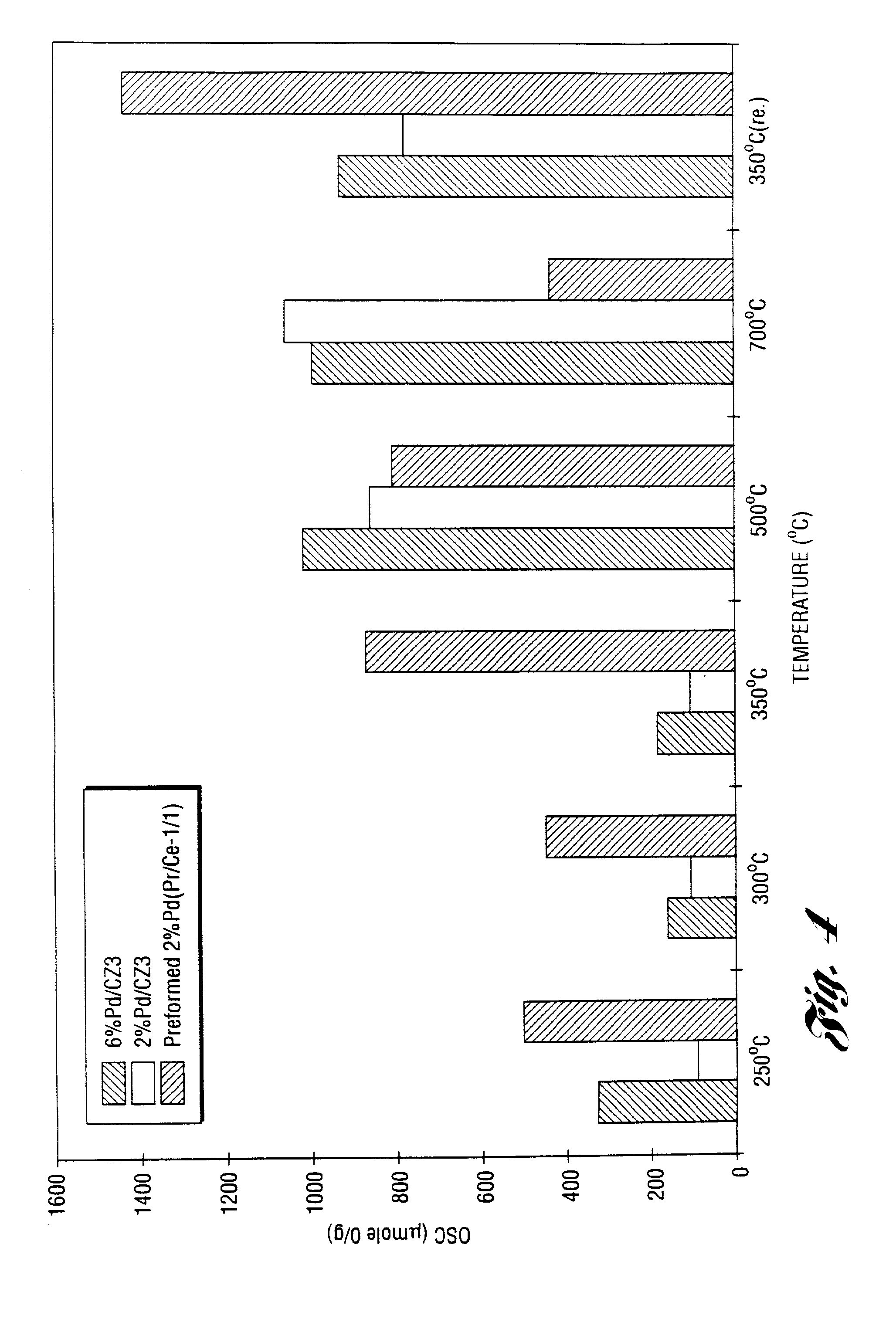

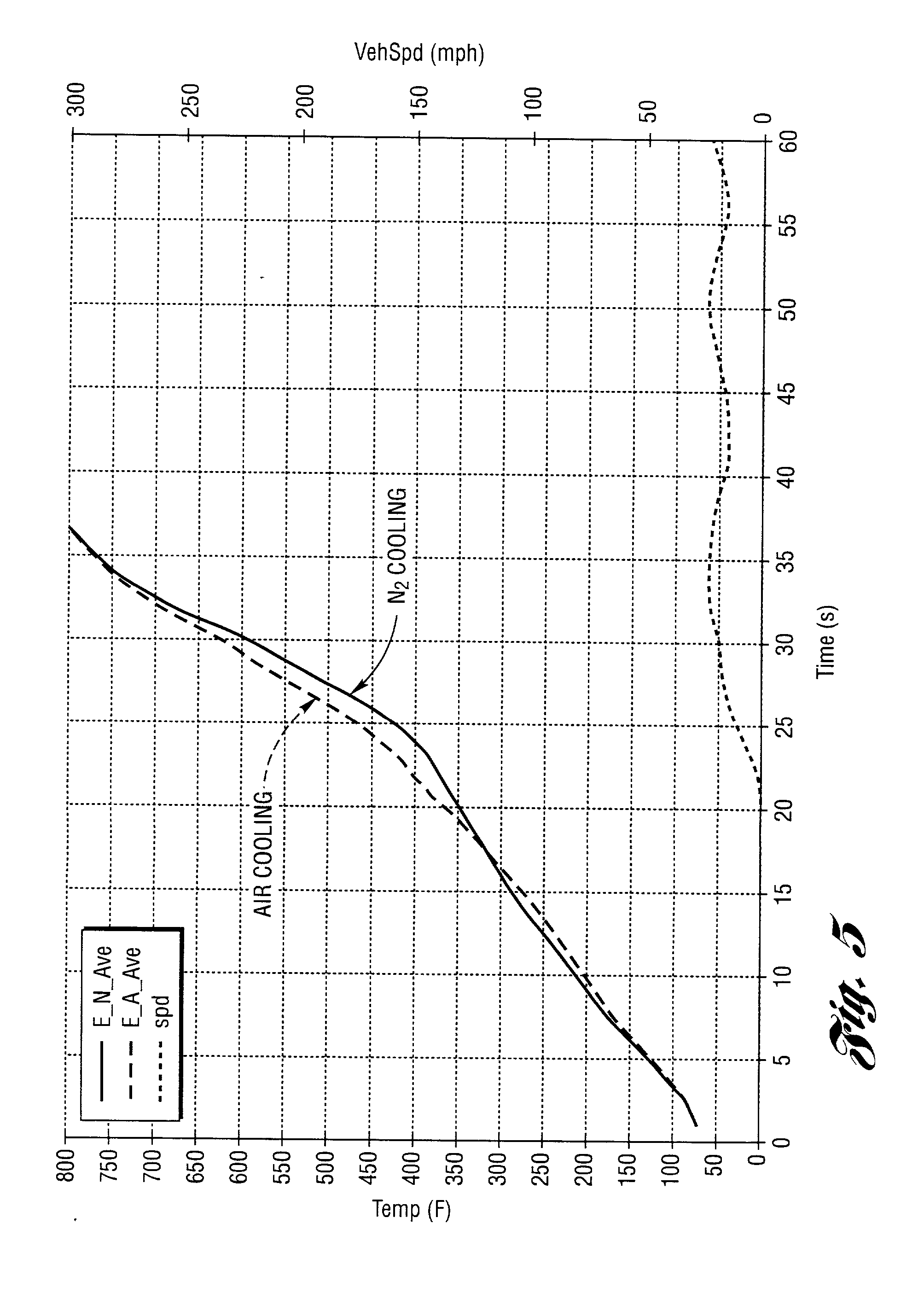

InactiveUS6893998B2Lower cold-start emissionCost effectiveInternal combustion piston enginesExhaust apparatusPlatinumCerium

An exhaust gas catalyst and method of manufacturing same. The invention provides for a cost-effective material which lowers the cold-start emissions from the exhaust of vehicles. The invention is a passive system which accelerates the light-off temperature of catalyst in a cost-effective fashion. The invention includes a method of manufacturing an exhaust gas catalyst capable of lowering cold-start emissions including the steps of providing an oxide mixture having praseodymium and cerium, doping about 0-10% weight zirconium and about 0-10% weight yttrium to the oxide mixture, adding about 0-2% weight metal including palladium, platinum, or rhodium to the oxide mixture, mixing gamma aluminum to the oxide mixture for washcoating and washcoating the oxide mixture onto a monolithic substrate.

Owner:FORD GLOBAL TECH LLC

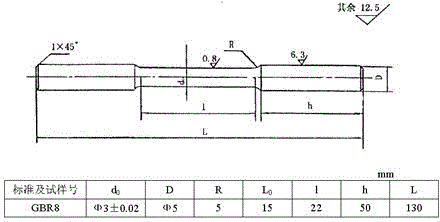

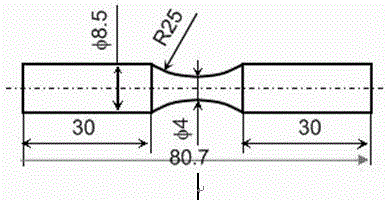

Low-cost high-strength anti-fatigue nonflammable wrought magnesium alloy and preparation method thereof

ActiveCN105779834AHigh strengthMeeting the Urgent Need for High-Performance MaterialsRare-earth elementChemical composition

The present invention discloses a low-cost high-strength anti-fatigue nonflammable wrought magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following chemical components in percentage by mass: 2.0-6.0% of Al, 1.5-4.0% of Ca, 0.2-0.8% of Mn, 0.1-0.8% of rare earth (RE), and the balance Mg and trace inevitable impurities, wherein the RE is one or more of cheap rare earth elements of La, Pr, Ce and Nd, and the content of the cheap rare earth is not zero simultaneously. The magnesium alloy provided by the present invention will meet the urgent need of users for high-performance materials, and the application of the magnesium alloy to magnesium alloy products, for example, load-bearing structural parts of aerospace, vehicles, rail trains and so on, structural parts of medical treatment, welfare and outdoor sport equipment, and parts (e.g., compressor scroll pans) having certain requirements for heat resistance and fatigue performance, is expanded.

Owner:BAOSHAN IRON & STEEL CO LTD

Organic-inorganic composite nanometer heat-insulating fire-retardant coating and preparation method thereof

ActiveCN104177965AImprove adhesionImprove anti-corrosion performanceFireproof paintsEpoxy resin coatingsEpoxyOrganic film

The invention discloses an organic-inorganic composite nanometer heat-insulating fire-retardant coating and a preparation method thereof. The organic-inorganic composite nanometer heat-insulating fire-retardant coating is prepared by mixing organic film-forming substance acrylic ester emulsions or styrene-acrylate emulsions, epoxide resin, organic intumescent fire-retardant system pentaerythritol, melamine and ammonium polyphosphate with inorganic fire retardant nanometer aluminum hydroxide, nanometer magnesium hydroxide, filler nanometer titanium dioxide, ceramic hollow microspheres, glass hollow microspheres and a part of auxiliary agents. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention not only has excellent facing property and fire-retardant property, but also achieves reflection effect on solar radiation and certain heat-insulating and heat-preserving property on a substrate, also has good adhesivity, mechanical property and hydrophobic effect, can be formed through spray coating or brush coating before being solidified, and is a novel water-based multifunctional fire-retardant material. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention can not only be used as a general building wall body fire-retardant coating, but also be suitable for the fire prevention of building and ornament materials, heat-insulating materials, steel structure supports, beam columns, metal roofs and the like.

Owner:山西省建筑科学研究院集团有限公司

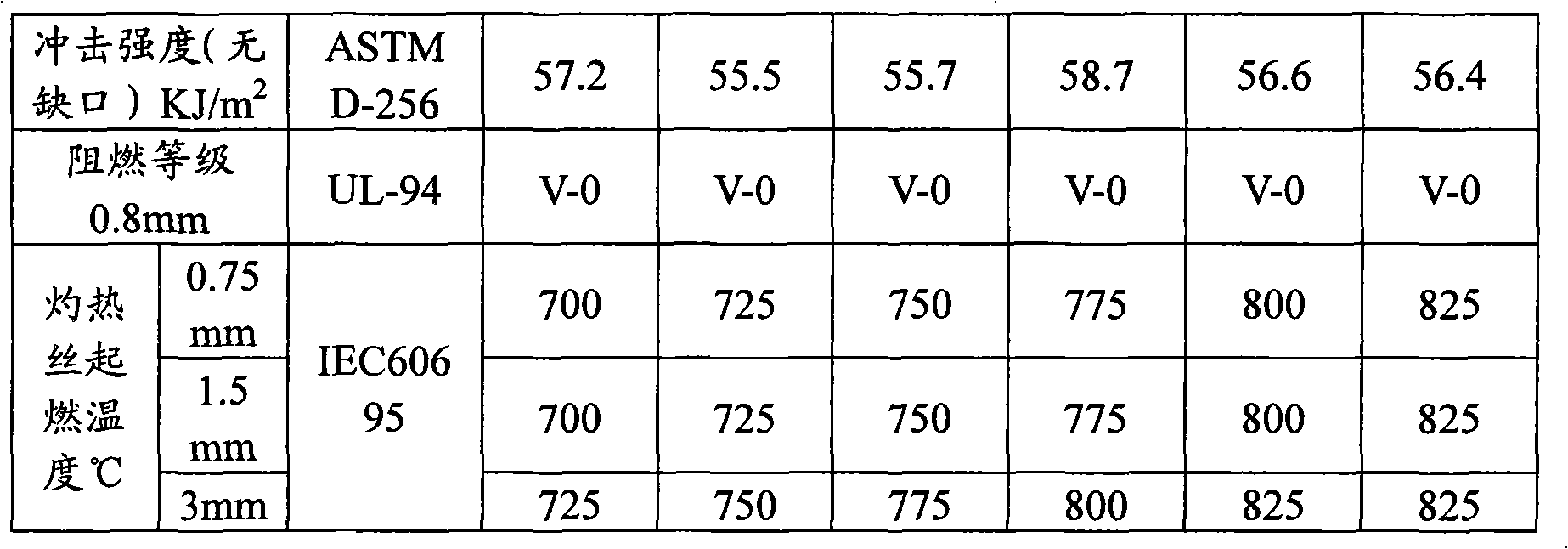

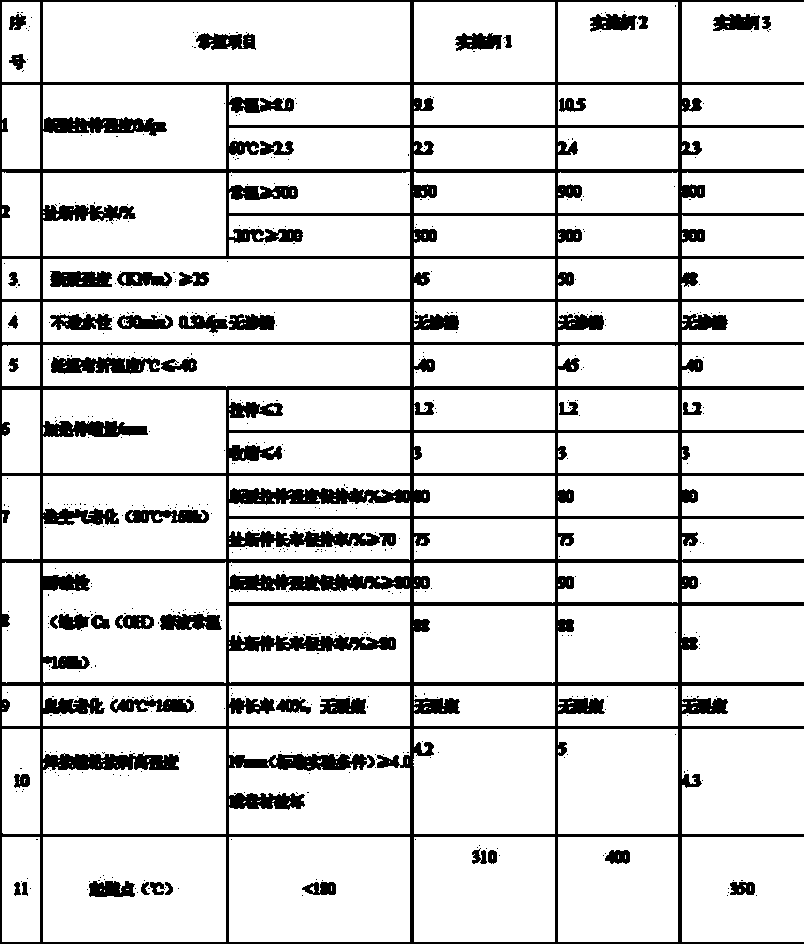

High glowing filament ignition temperature inflaming retarding reinforced poly(butylene terephthalate)

InactiveCN101928449ARaise the ignition temperatureImprove mechanical propertiesPolytetramethylene terephthalateGlass fiber

The invention discloses high glowing filament ignition temperature inflaming retarding reinforced poly(butylene terephthalate) which comprises the following raw materials in parts by weight: 25-68 parts of synergistic agent, 1-10 parts of toughening agent, 0-1 part of main antioxygen, 0-1 part of auxiliary antioxygen and 10-40 parts of glass fiber. The inflaming retarding reinforced poly(butylene terephthalate) has high glowing filament ignition temperature, higher mechanical property and lower material cost; and a preparation method is simple without using special equipment and is suitable for industrialized production.

Owner:中广核俊尔(上海)新材料有限公司 +1

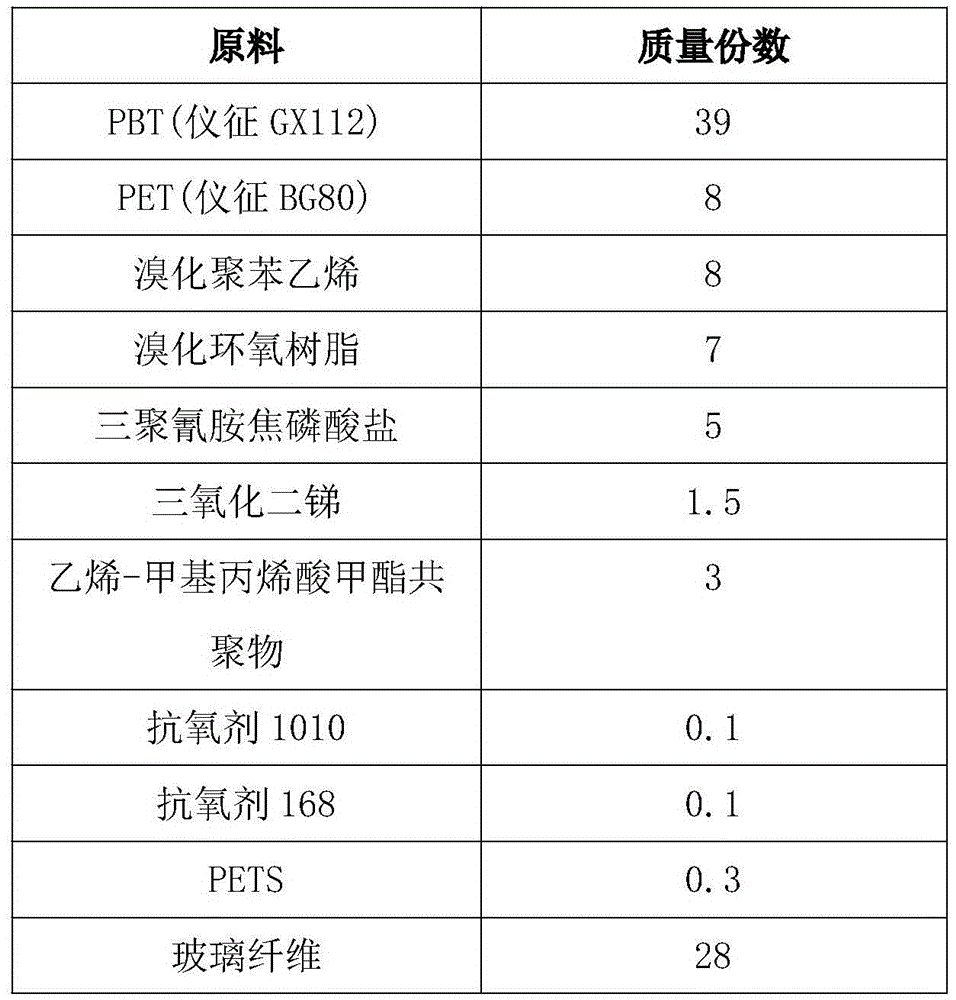

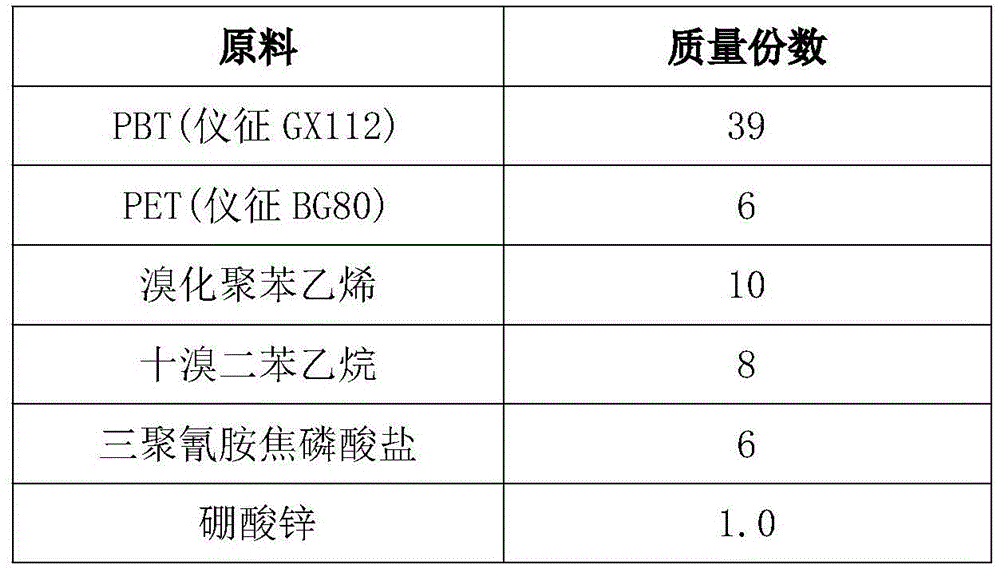

Flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) with high glow wires and high CTI (comparative tracking index) value and method for preparing flame-retardant glass fiber reinforced PBT

InactiveCN105647134ARaise the ignition temperatureImprove mechanical propertiesAntioxidantPolyethylene terephthalate

The invention discloses a flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) with high glow wires and a high CTI (comparative tracking index) value and a method for preparing the flame-retardant glass fiber reinforced PBT. The flame-retardant glass fiber reinforced PBT comprises, by weight, 38-45 parts of PBT, 5-8 parts of PET (polyethylene terephthalate), 15-18 parts of flame retardants A, 0.5-1.5 parts of flame retardants B, 5-8 parts of flame retardants C, 2-4 parts of toughening agents, 0.2-0.4 part of antioxidants, 0.3-0.6 part of lubricants and 25-30 parts of glass fibers. The flame-retardant glass fiber reinforced PBT and the method have the advantages that the glow wire ignition temperature (GWIT) of the flame-retardant glass fiber reinforced PBT can be increased and reaches 850 DEG C, and a comparative tracking index (CTI) of the flame-retardant glass fiber reinforced PBT can reach 400 V; the mechanical performance and the machining performance of the flame-retardant glass fiber reinforced PBT can be prevented from being damaged or only is damaged at low level.

Owner:贝克兰(厦门)新材料有限公司

Exhaust gas catalyst and method of manufacturing same

InactiveUS20020032123A1Lower cold-start emissionCost effectiveInternal combustion piston enginesExhaust apparatusPlatinumCerium

The present invention involves an exhaust gas catalyst and method of manufacturing same. The invention provides for a cost-effective material which lowers the cold-start emissions from the exhaust of vehicles. The invention is a passive system which accelerates the light-off temperature of catalyst in a cost-effective fashion. The invention includes a method of manufacturing an exhaust gas catalyst capable of lowering cold-start emissions including the steps of providing an oxide mixture having praseodymium and cerium, doping about 0-10% weight zirconium and about 0-10% weight yttrium to the oxide mixture, adding about 0-2% weight metal including palladium, platinum, or rhodium to the oxide mixture, mixing gamma aluminum to the oxide mixture for washcoating and washcoating the oxide mixture onto a monolithic substrate.

Owner:FORD GLOBAL TECH LLC

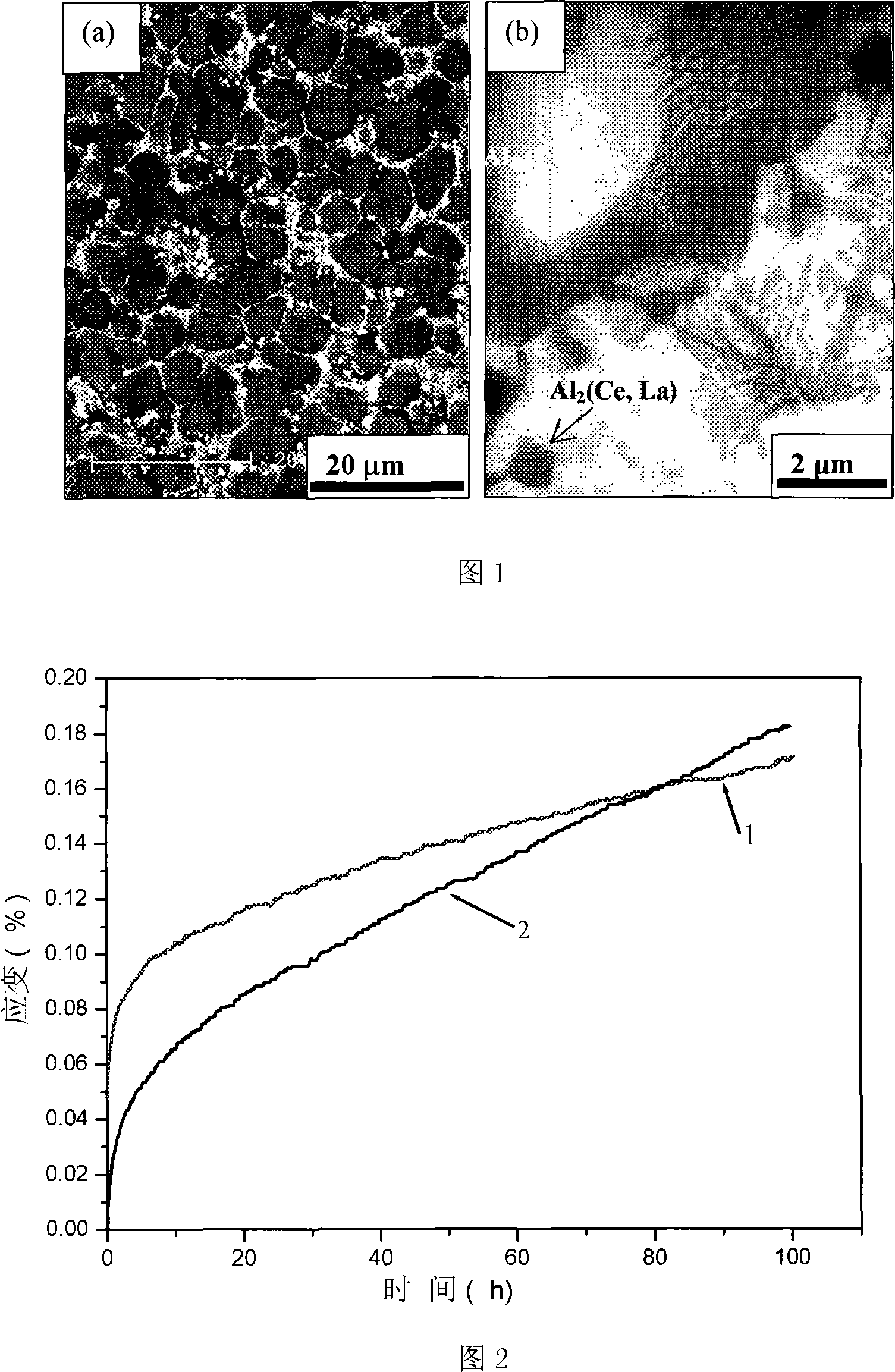

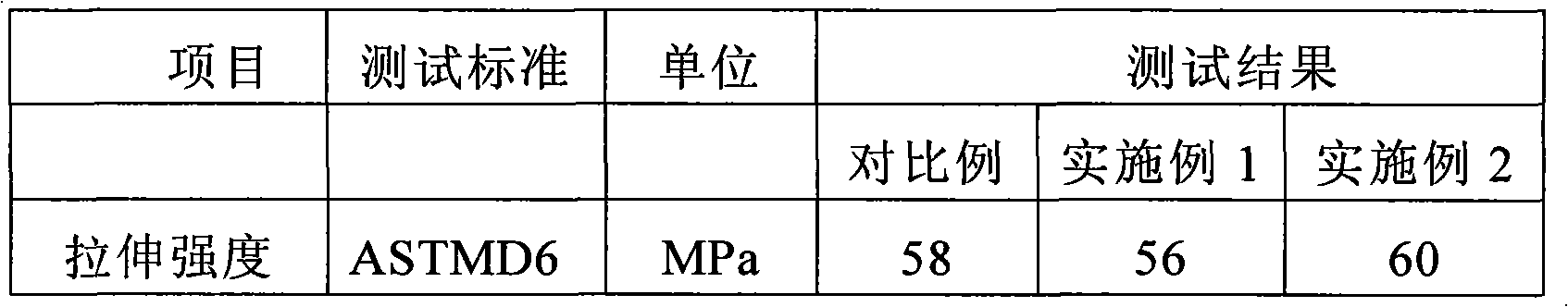

AE series thermo-stable die-casting magnesium alloy containing cerium and lanthanide

The invention relates to an AE series heat resistant casting magnesium alloy containing cerium and lanthanum, which comprises and has the weight percentage of each element of: Al:3%-5%, Ce:0.4%-2.6%, La:0.4%-2.6%, Mn:0.2%-0.6%, the rest being magnesium. The lanthanum cerium mischmetal used is produced by separating the Nd, Pr which is more valuable and selling from ordinary cerium rich mischmetal which leaves the cheap and abundant cerium lanthanum mischmetal. The invention has better mechanical performance in both normal and high temperature than AE44 and AZ91alloy, and the minimum creep rate under 200 DEG C, 70MPa is 1.82 multiplied by10-9s-1, 100 hour creeping elongation rate is 0.17%, all being better than an AE44 alloy.

Owner:白山市天安金属镁矿业有限公司

Halogen-free flame-retardant polycarbonate/styrene base resin composition and preparation method thereof

The invention relates to a halogen-free flame-retardant polycarbonate / styrene base resin composition and a preparation method thereof, and the composition comprises the following components in parts by weight: 650-900 parts of polycarbonate, 0.1-250 parts of styrene base resin, 20-100 parts of toughening compatibilizer, 10-100 parts of metal inorganic compound, 5-50 parts of organic silicon, 70-150 parts of complex flame retardant, 1-10 parts of antioxidant A, 1-15 parts of antioxidant B and 0-20 parts of other auxiliary materials. The preparation method comprises the following steps: mixing raw materials in a high-speed mixing machine, then introducing into a twin-screw extruder, adding the complex flame retardant in the lateral line feeding way, performing extrusion and granulation and finally getting the product. Compared with the prior art, the halogen-free flame-retardant polycarbonate / styrene base resin composition has the advantages of high comparative tracking index (CTI), high glow-wire ignition temperature (GWIT), halogen-free flame retardance, environment friendliness and the like.

Owner:HEFEI GENIUS NEW MATERIALS

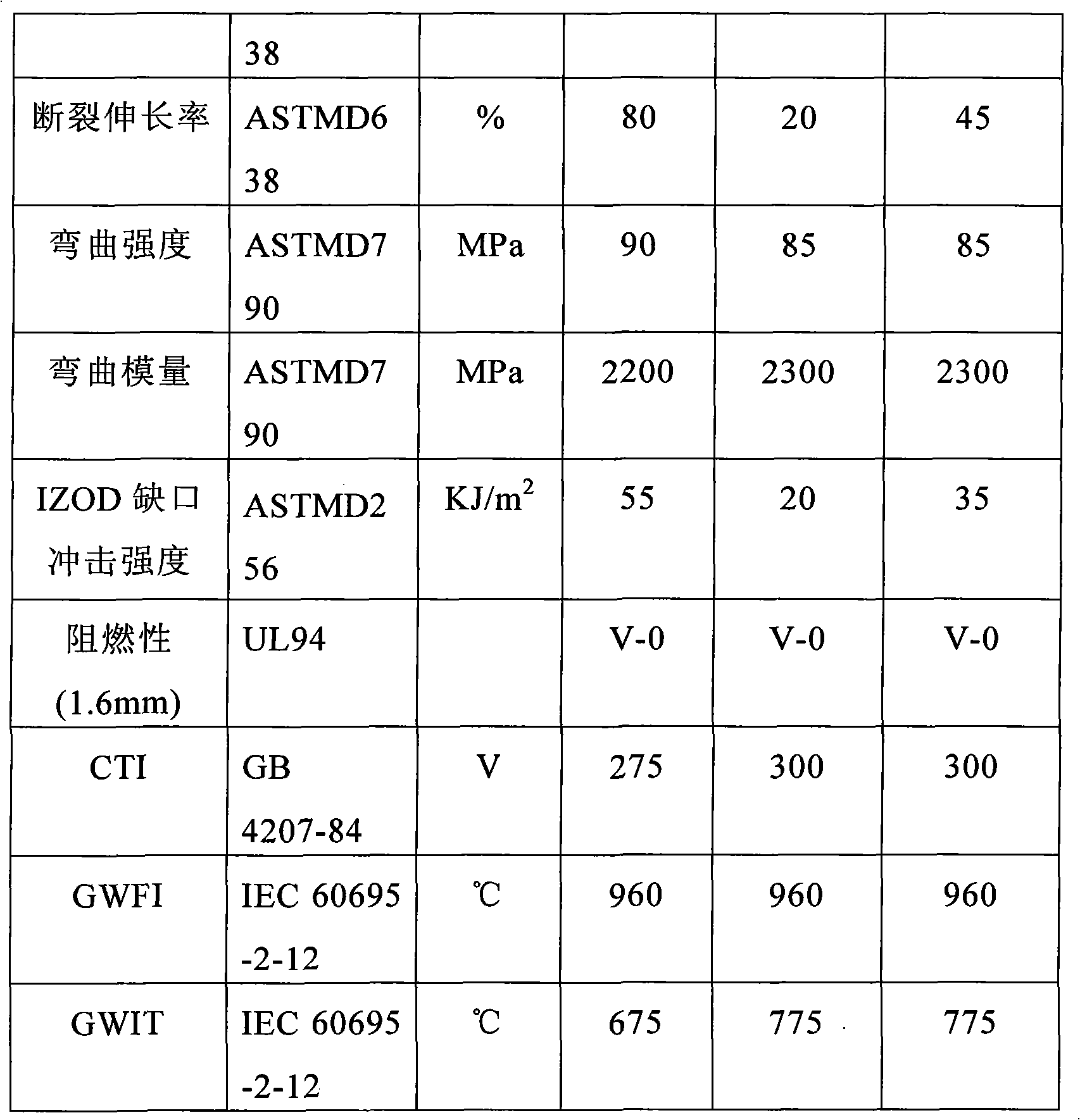

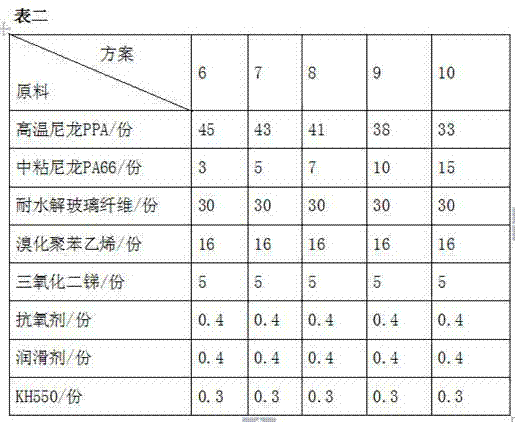

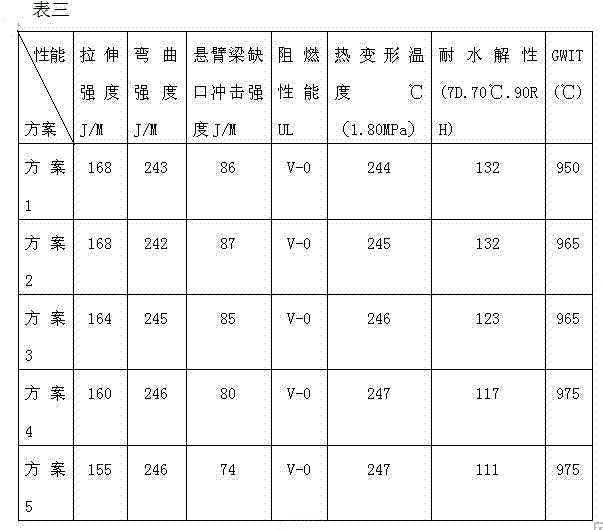

Flame-retardant reinforced high temperature nylon composite material and its preparation method

The invention discloses a flame-retardant reinforced high temperature nylon composite material. The composite material is prepared by blending the following raw materials, by weight, 25-65 parts of PPA, 3-15 parts of PA66, 15-50 parts of glass fiber, 15-22 parts of a bromine family flame retardant, 4-10 parts of a metal oxide flame retardant, 0.4-1 part of an antioxidant, 0.1-1 part of a lubricant and 0.1-1 part of a coupling agent. The invention also discloses a preparation method of the composite material. The method comprises the following steps: uniformly mixing the above raw materials except the glass fiber in a mixer, pouring the obtained mixture into a storage hopper under a feeding speed of 16-20hz, adding the mixture to an extruder, carrying out shearing blending, adding the glass fiber, carrying out melt extrusion, and granulating to obtain the composite material, wherein the extrusion speed is 320-400rpm, and the processing temperature is 280-310DEG C. The composite material has the advantages of high temperature resistance, high strength, good fluidity, good processing performance, good flame retardation property, and hydrolysis resistance.

Owner:DONGGUAN ZHONGYI NEW MATERIAL TECH CO LTD

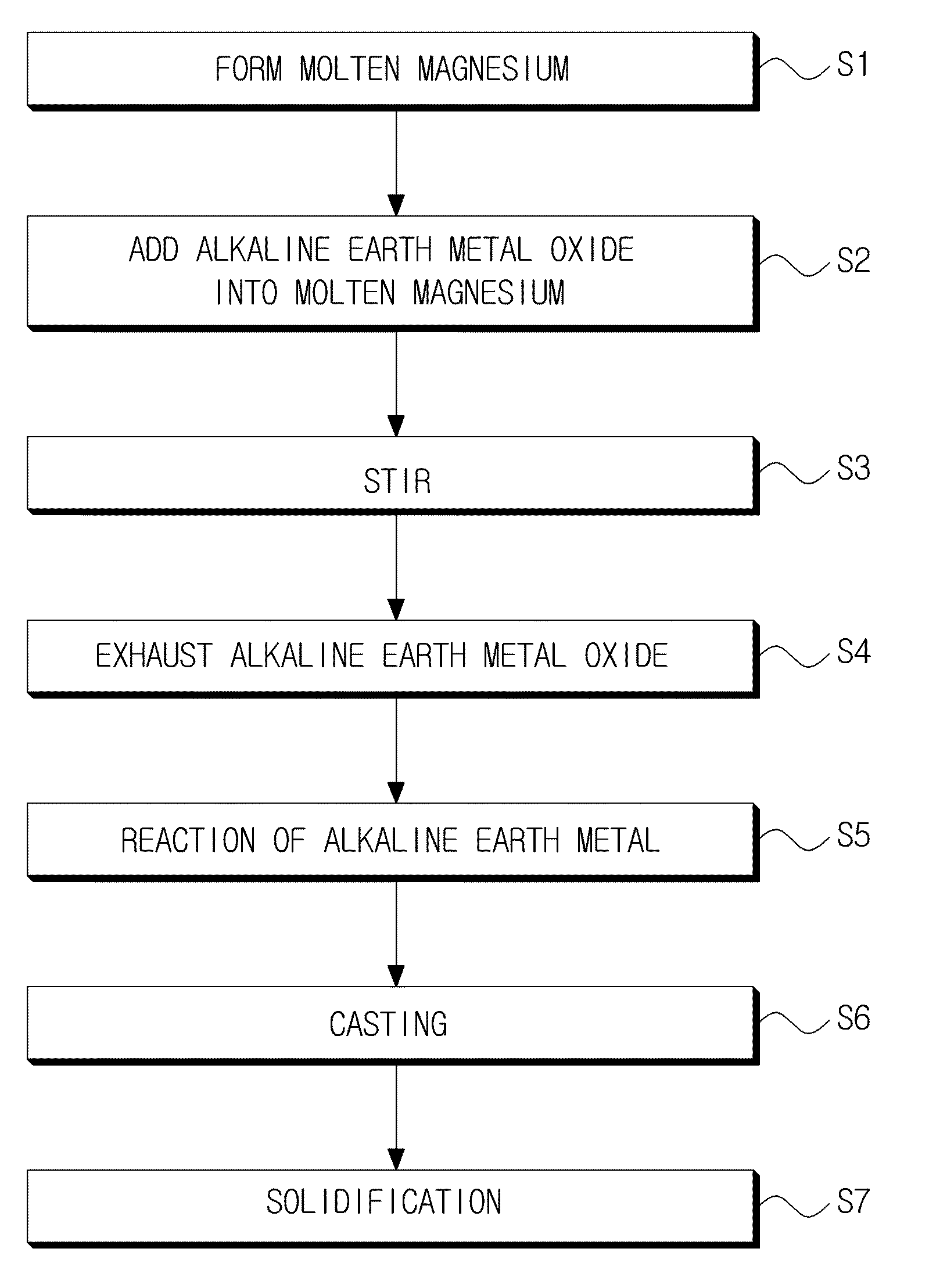

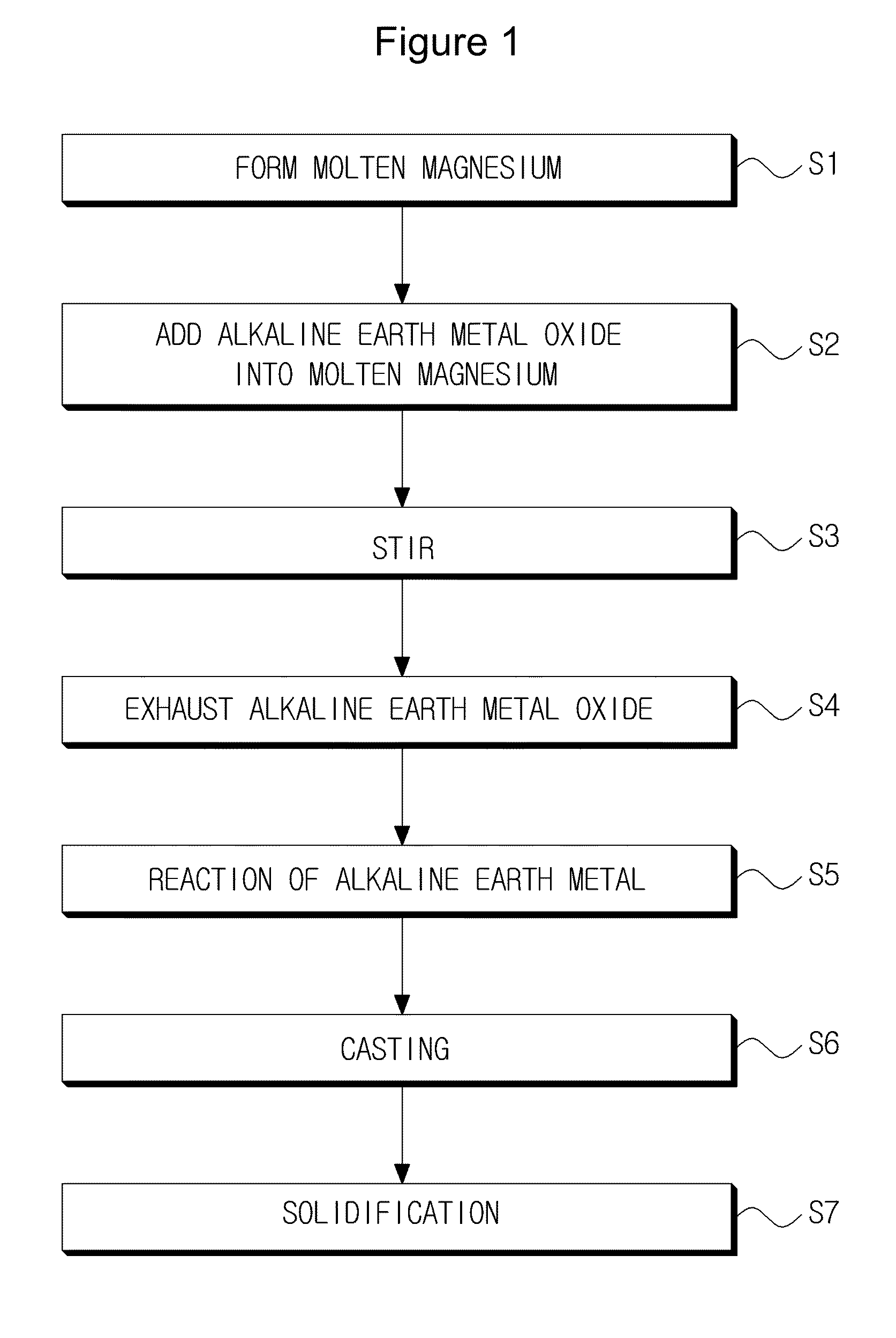

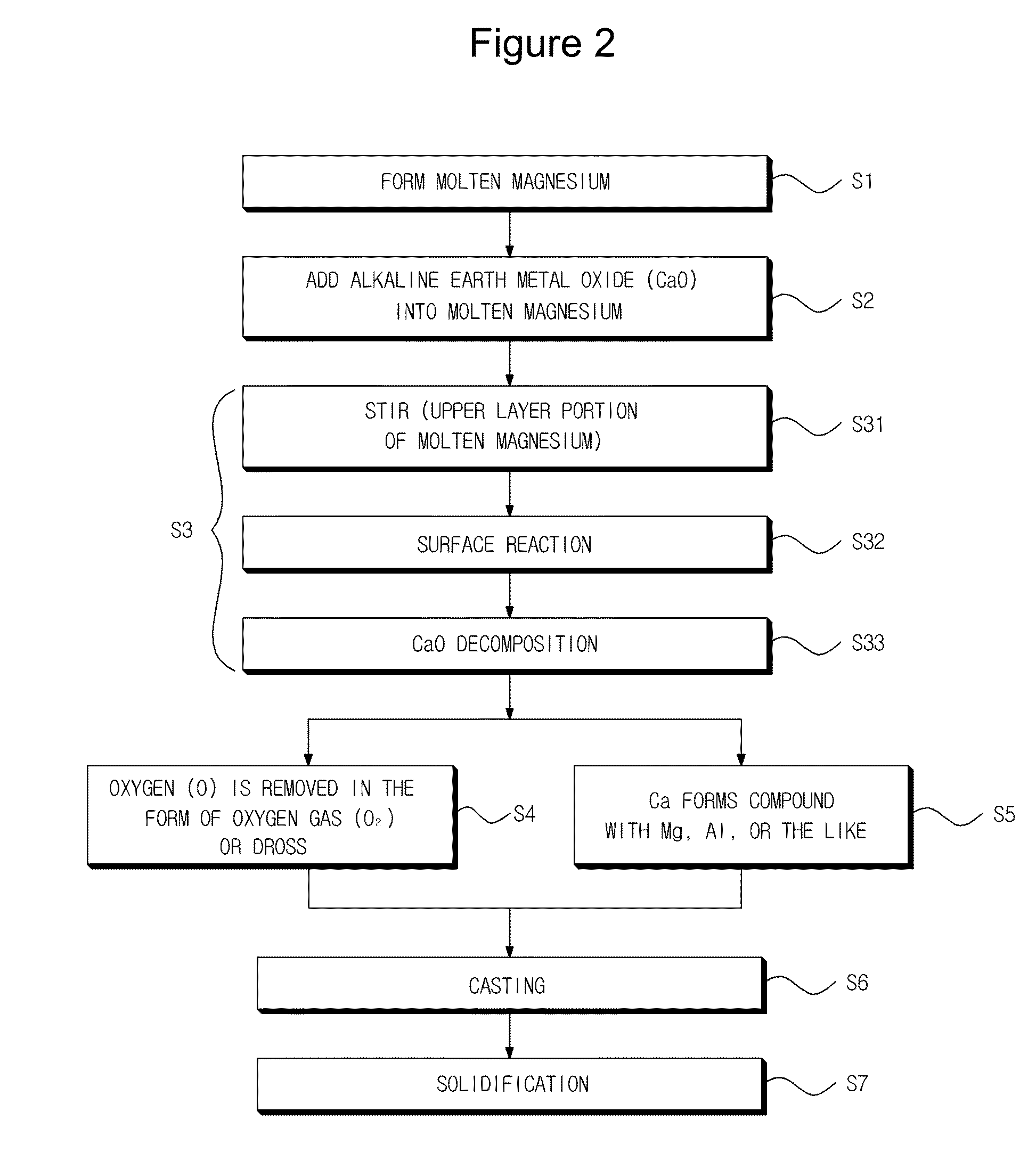

Magnesium-based alloy with superior fluidity and hot-tearing resistance and manufacturing method thereof

ActiveUS20110236249A1Reduce manufacturing costLow priceThin material handlingTarget weightAlkaline earth oxides

Provided are a magnesium-based alloy and a manufacturing method thereof. In the method, a magnesium alloy is melted into liquid phase, and an alkaline earth metal oxide is added into a molten magnesium alloy. The alkaline earth metal oxide is exhausted through surface reduction reaction between the melt and the alkaline earth metal oxide. Alkaline earth metal produced by the exhaustion reacts with Mg and / or other alloying elements in the magnesium alloy so that an intermetallic compound is formed. The magnesium prepared by the method is excellent in fluidity and hot-tearing resistance. To this end, the alkaline earth metal oxide added is CaO, and the added amount of CaO is 1.4 to 1.7 times the target weight of Ca to be contained in the final Mg alloy.

Owner:EMK CO LTD +1

Ethylene-propylene-diene monomer rubber waterproof roll and production method thereof

The invention discloses an ethylene-propylene-diene monomer rubber waterproof roll. The ethylene-propylene-diene monomer rubber waterproof roll is prepared from the following raw materials in parts by weight: ethylene-propylene-diene monomer rubber, DOP (Dioctyl-Phthalate) thermal welding agent, carbon black, light calcium carbonate, stearic acid, zinc oxide, rubber accelerator, sulfur, processing oil, fire-retardant plasticizer, chlorinated polyethylene (CPE), white carbon black and rubber accelerator tetramethyl thiuram disulfide (TMTD). A production method of the ethylene-propylene-diene monomer rubber waterproof roll comprises the steps of banburying, filtering, compounding, thermal cracking, calendering, rolling, vulcanization and packaging. The ethylene-propylene-diene monomer rubber waterproof roll produced by the method has good ageing resistance, small possibility of cracking and good waterproof effect and has an inflaming retarding function, the initiation temperature exceeds 300 DEG C, and the ethylene-propylene-diene monomer rubber waterproof roll has no water-permeating phenomenon through permeable experiments.

Owner:WEIFANG ZHENGTAI WATERPROOF MATERIAL

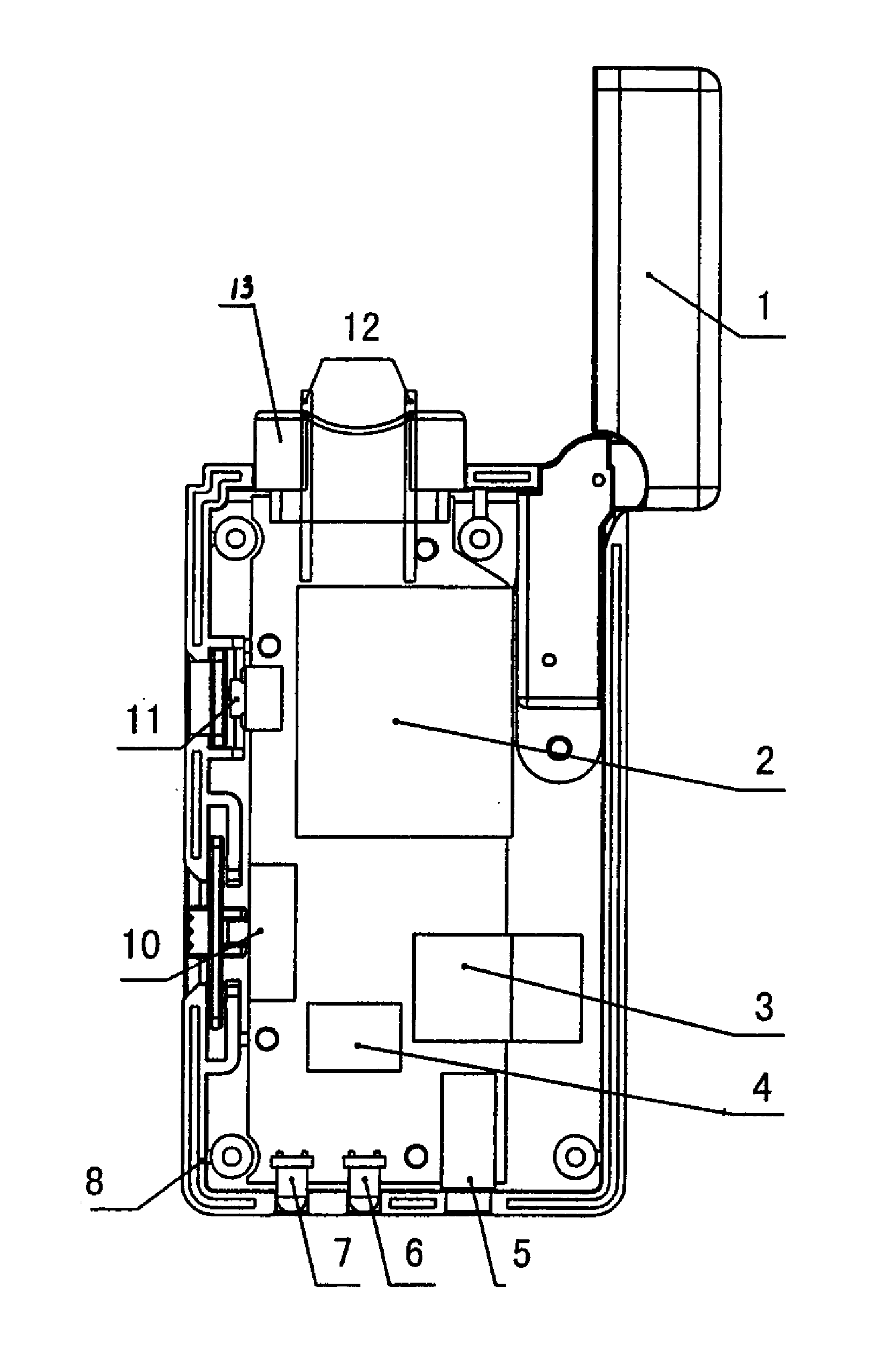

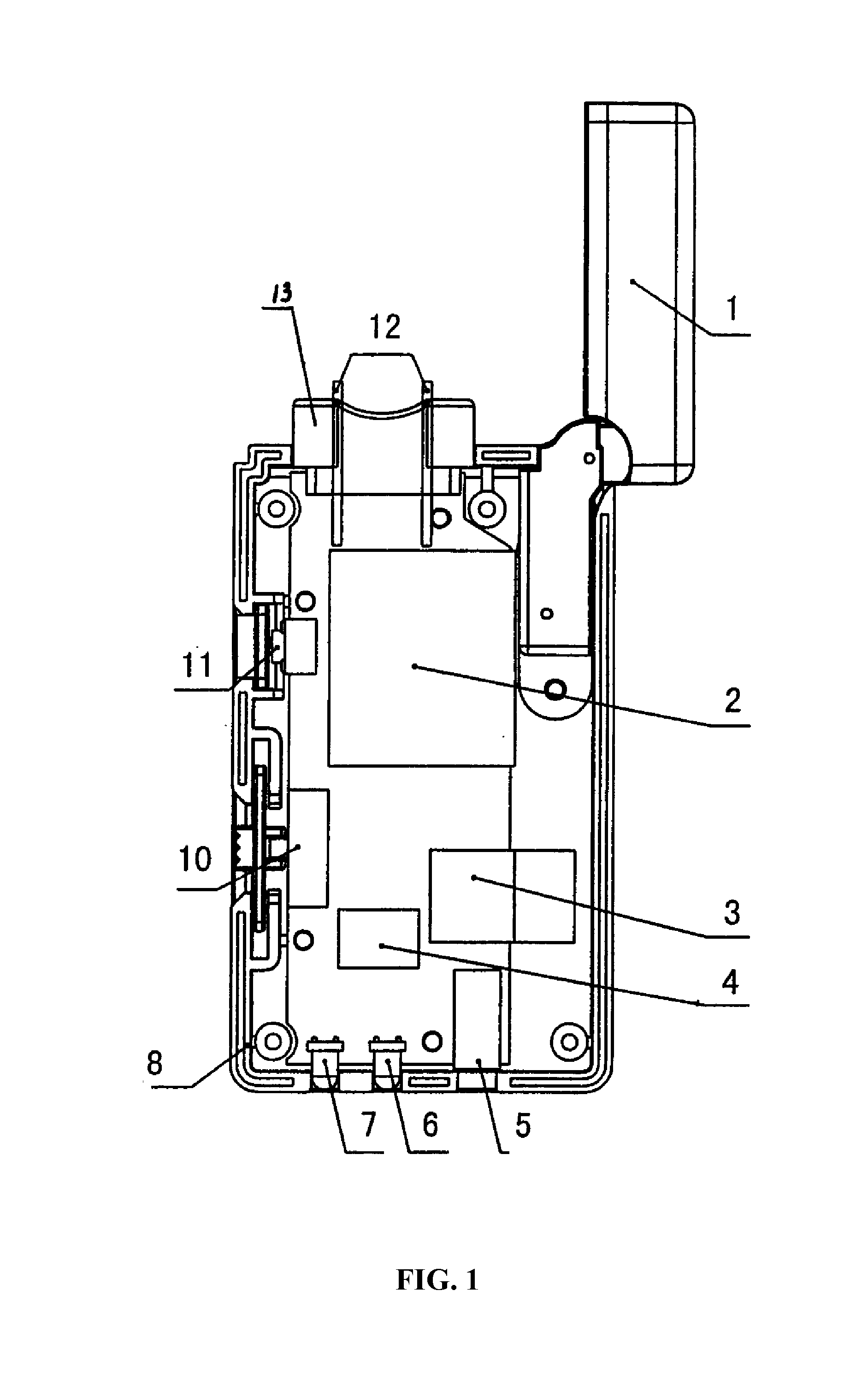

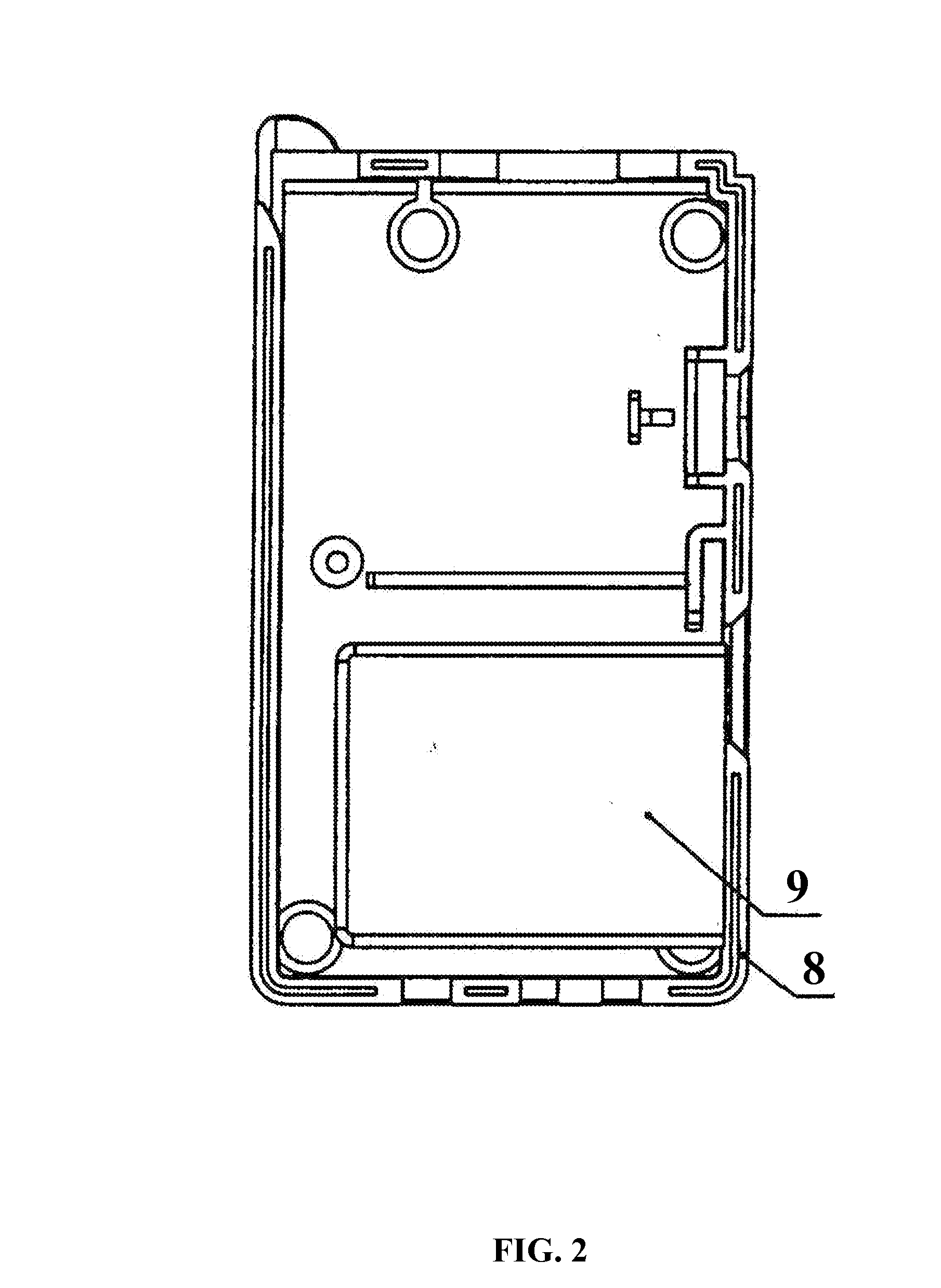

Lighter

InactiveUS20140076879A1Avoid explosionImprove the environmentIncandescent ignitionFuel lightersDetector circuitsToggle switch

A lighter, including: a casing, a turnable cap, a circuit board, a transformer, a power supply, switches, circuits, a power socket, an ignition chamber, and a pair of discharging needles. The circuit board is arranged inside the casing, and the discharging needles are disposed on the top of the ignition chamber. The circuits are disposed on the circuit board and include an oscillating circuit, a DC boost converter circuit, a lighting circuit, and a counterfeit money detector circuit. An ignition switch and a toggle switch are disposed on one side of the casing. The bottom of the casing is provided with a lighting lamp and a counterfeit money detector lamp.

Owner:YE YIN +1

Red phosphorus flame retardant enhanced PA66 and POK alloy material and preparation method thereof

The invention relates to the technical field of macromolecular composite materials, and discloses a red phosphorus flame retardant enhanced PA66 (nylon resin) and POK (polyketone) alloy material and a preparation method thereof. The red phosphorus flame retardant enhanced PA66 and POK alloy material is prepared from nylon resin, polyketone resin, red phosphorus master batch, a synergist, an antioxidant, a lubricating agent and glass fibers. The material is mainly prepared from the following components in percentage by weight: 5 to 50 percent of PA66, 15 to 25 percent of POK, 10 to 25 percent of the red phosphorus master batch, 20 to 35 percent of the glass fibers, 5 to 10 percent of the synergist, 0.2 to 0.5 percent of the antioxidant and 0.1 to 0.5 percent of the lubricating agent. The material is excellent in electrical property; the ignition temperature of a combustible heat wire of the material can be up to 850 DEG C; the material has high CTI value which is 600 V. The material is stable in processing, has excellent mechanical property and can be widely applied to the electrical and electronic industry.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

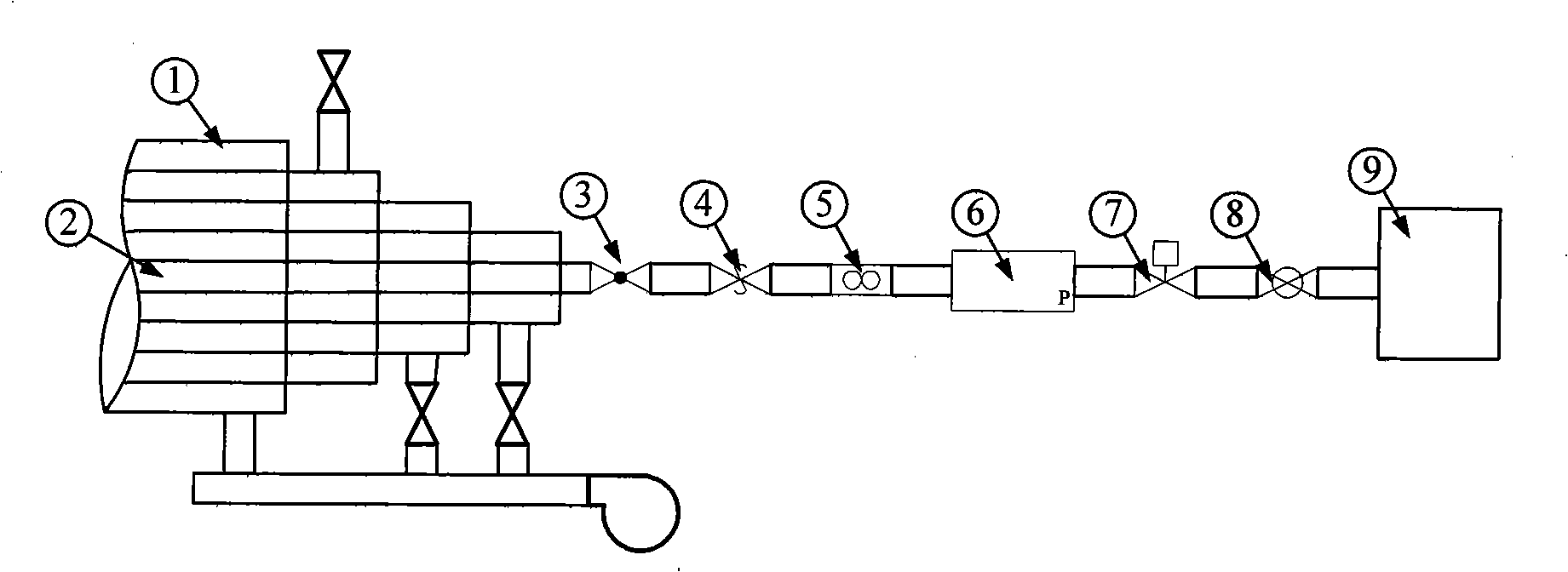

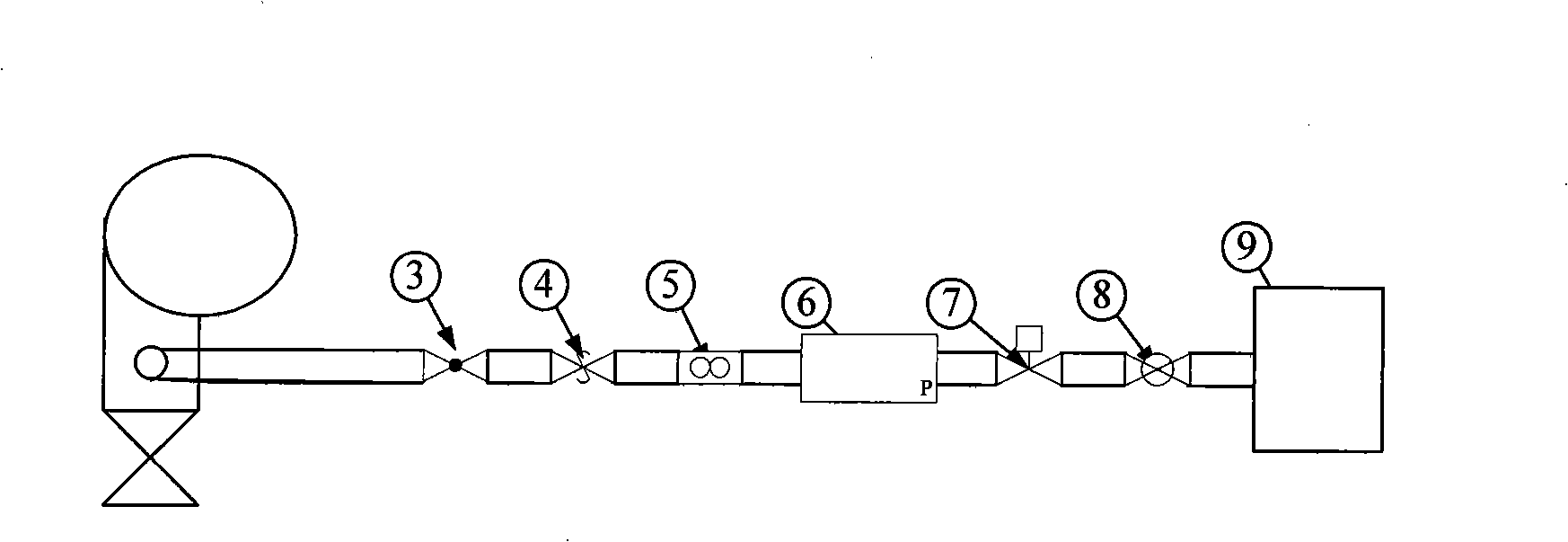

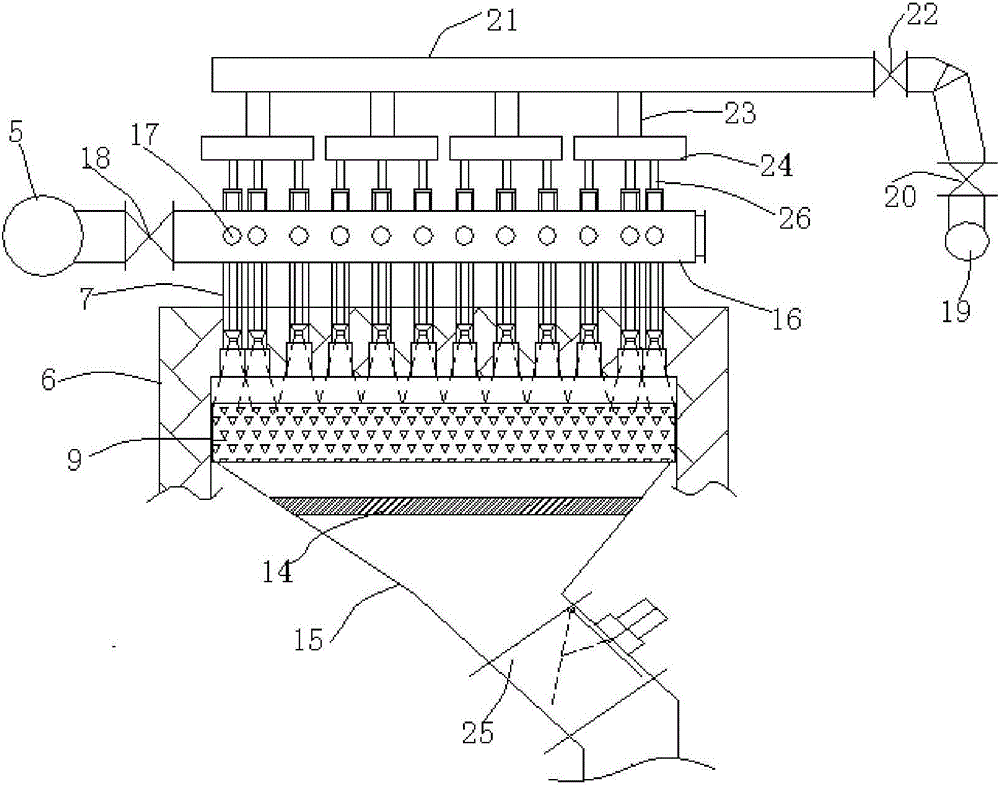

Oxygen-enriched combustion process for improving cement kiln clinker calcining temperature and apparatus thereof

InactiveCN101407381AQuality assuranceRaise the ignition temperatureTemperature resistanceCement kiln

The invention relates to an oxygen-enriched combustion technical method for improving heating power of a cement kiln and a device thereof. During the process of cement clinker calcination, the invention is characterized in that: 1) a pure oxygen (over 90 percent) feeding device is added at a coal dust combustion zone of the cement kiln so as to lead the combustion zone to form a local thermonuclear area, and with the gradual diffusion of high temperature at the thermonuclear area, the heating power of the whole cement kiln is further improved and stably controlled; and 2) an oxygen feeding device is added at a combustion area of the cement kiln so as to improve and stably control the oxygen content in combustion air within the range of 21.8-33 percent at the combustion area. In a coal supplying system and an air supplying system of the cement kiln, an oxygen-enriched combustion system is formed by arranging at least one high temperature resistance oxygen jet, a pipeline for transmitting oxygen, an oxygen generation device, an oxygen supply-quantity regulating device, a DCS control device and the like inside each independent combustion area of the cement kiln. The invention has the advantages of improving combustion efficiency of faulty coal and the heating power of the cement kiln, and stabilizing thermal regulation of the kiln so as to enhance the quality of the cement and prolong the service life of various heating equipment of the cement kiln.

Owner:昆明阳光基业股份有限公司

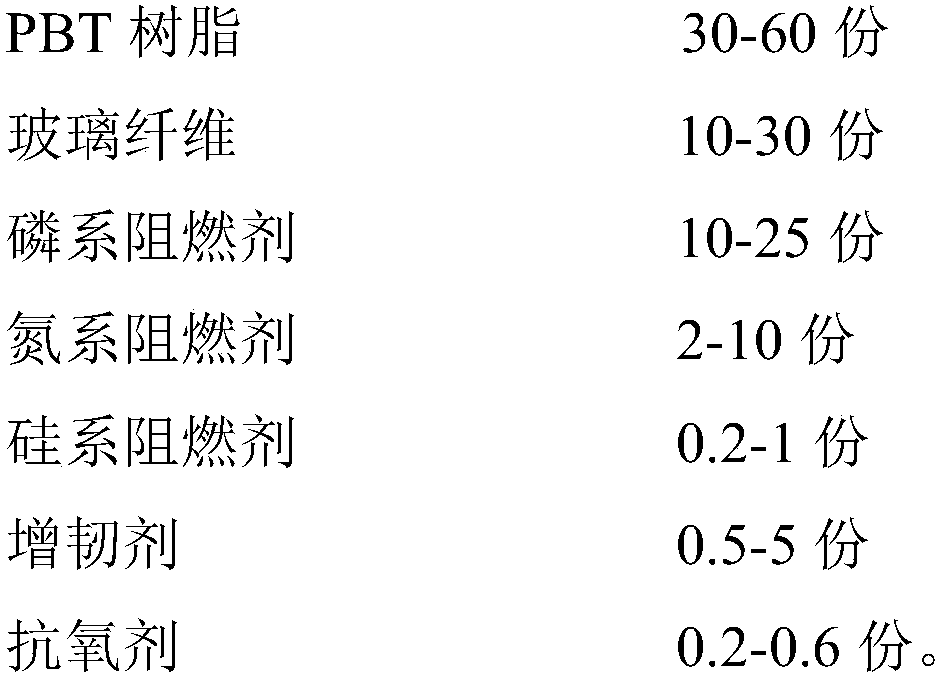

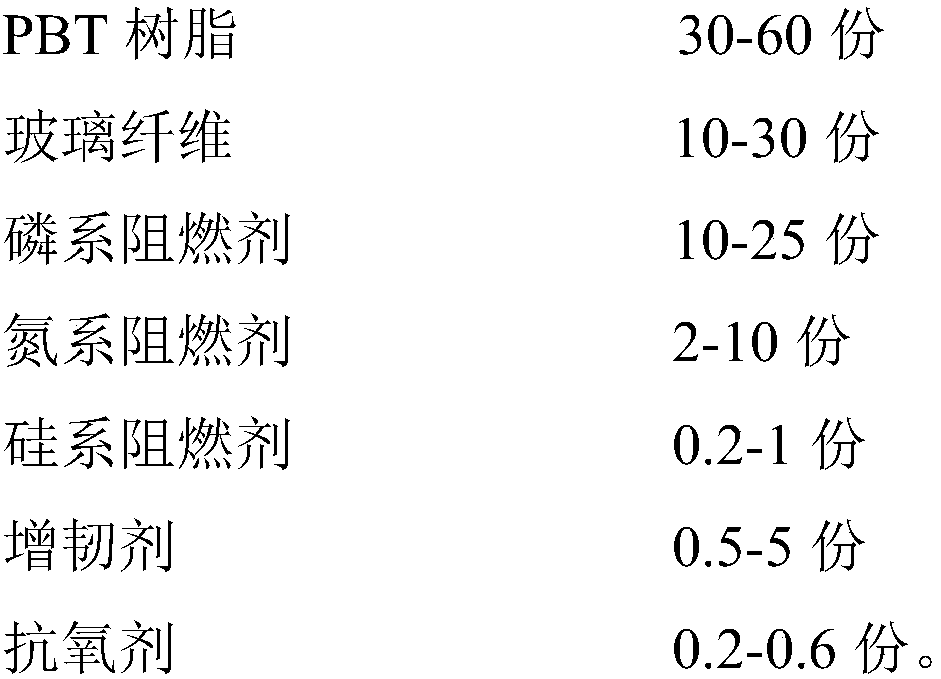

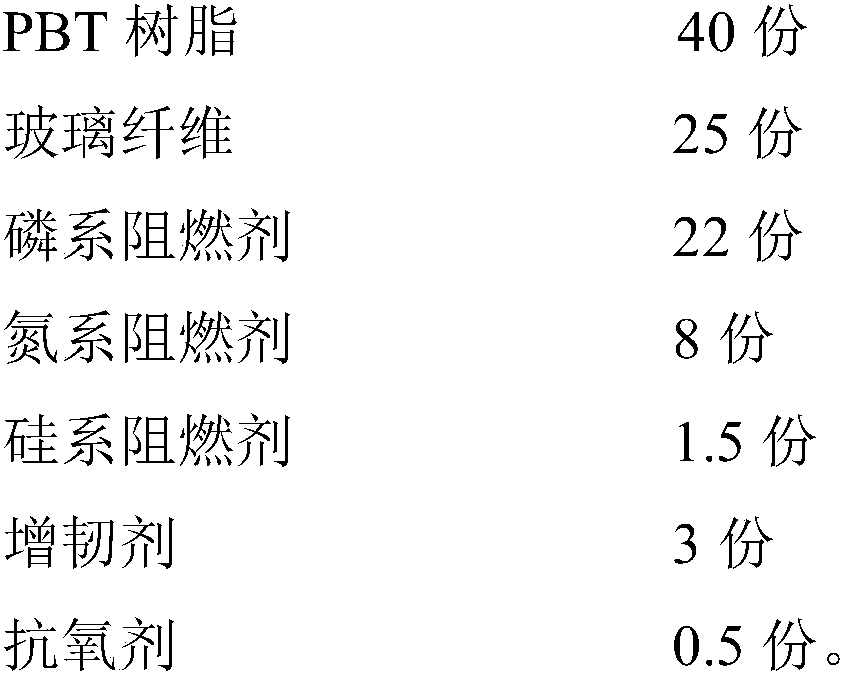

Halogen-free synergistic flame-retardant PBT material with high glow wire, and preparation method thereof

The invention discloses a halogen-free synergistic flame-retardant PBT material with a high glow wire. The PBT material comprises, by weight, 30-60 parts of PBT resin, 10-30 parts of glass fibers, 10-25 parts of a phosphorus-based flame retardant, 2-10 parts of a nitrogen-based flame retardant, 0.2-1 part of a silicon-based flame retardant, 0.5-5 parts of a toughener and 0.2-0.6 part of an antioxidant. The invention also discloses a preparation method of the halogen-free synergistic flame-retardant PBT material. The synergistic effects of the flame retardants are fully used, so the flame retardant performance of prepared PBT material reaches UL94 V0 (1.6 mm), the glow-wire ignition temperature reaches 800 DEG C, and the PBT material has excellent physical and mechanical properties, and issuitable for being applied to electrical and electronic fields.

Owner:杭州立心新材料有限公司

Exhaust gas catalyst and method of manufacturing same

InactiveUS20030004060A1Lower cold-start emissionCost effectiveInternal combustion piston enginesExhaust apparatusPlatinumCerium

The present invention involves an exhaust gas catalyst and method of manufacturing same. The invention provides for a cost-effective material which lowers the cold-start emissions from the exhaust of vehicles. The invention is a passive system which accelerates the light-off temperature of catalyst in a cost-effective fashion. The invention includes a method of manufacturing an exhaust gas catalyst capable of lowering cold-start emissions including the steps of providing an oxide mixture having praseodymium and cerium, doping about 0-10% weight zirconium and about 0-10% weight yttrium to the oxide mixture, adding about 0-2% weight metal including palladium, platinum, or rhodium to the oxide mixture, mixing gamma aluminum to the oxide mixture for washcoating and washcoating the oxide mixture onto a monolithic substrate.

Owner:FORD GLOBAL TECH LLC

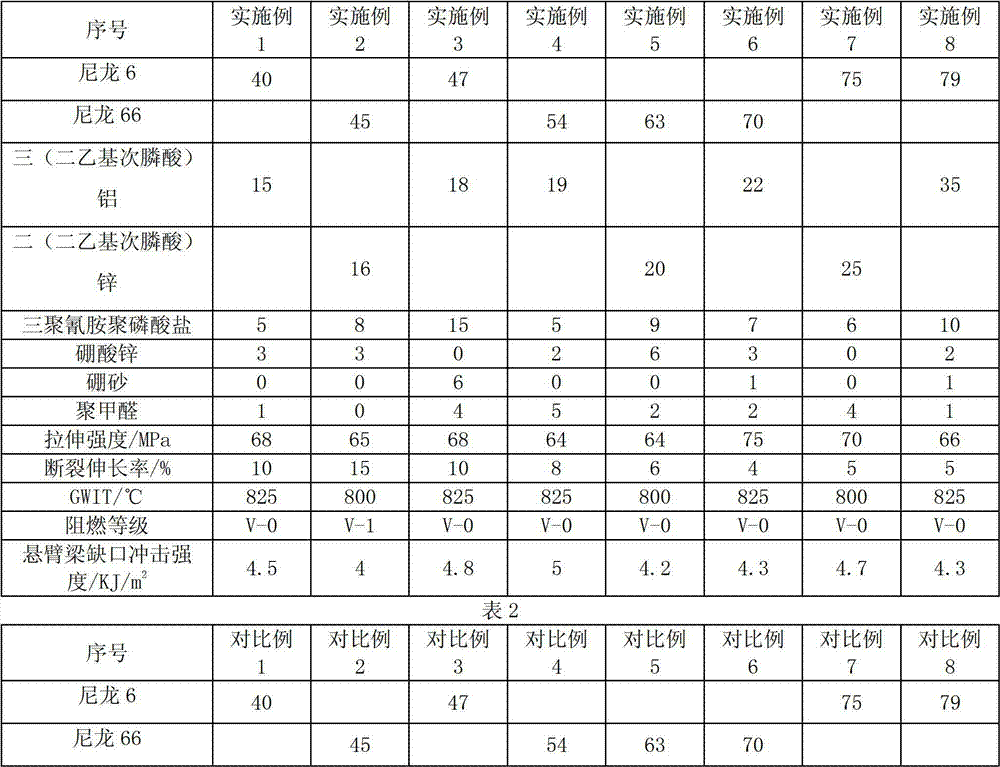

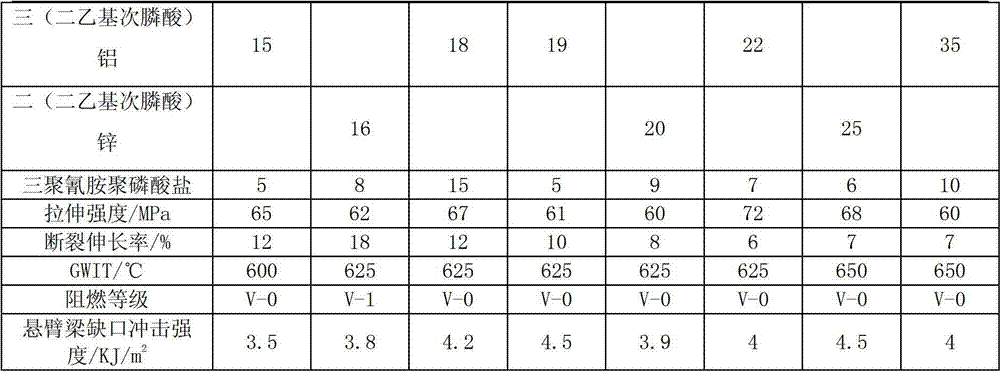

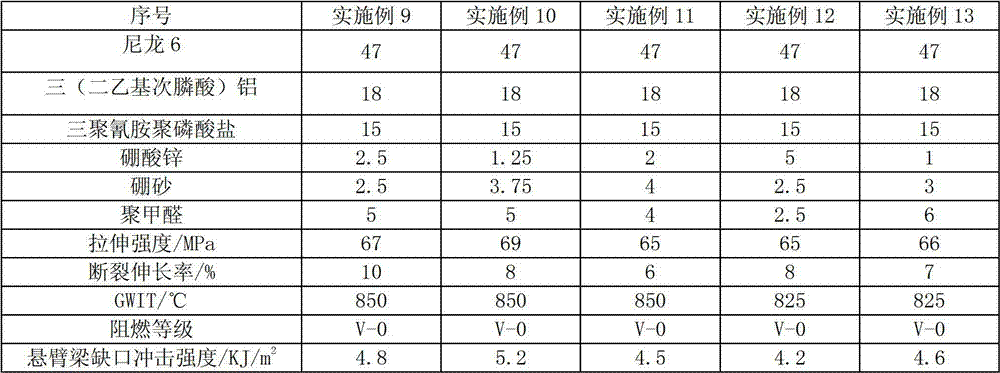

Polyamide composition, and preparation method and application thereof

ActiveCN103073878AImprove flame retardant performanceImprove tensile propertiesPolyamideMechanical property

The invention discloses a polyamide composition with high glow-wire ignition temperature, and a preparation method and application thereof. The composition comprises the following components by weight: (a) polyamide; (b) a phosphorus flame retardant; (c) a flame retardant synergistic agent; and (d) a flame retardant assistant of borate and / or polyformaldehyde. The invention also provides a preparation method and application of the polyamide composition. The polyamide composition provided by the invention has good flame retardant performance, good mechanical performance and high glow-wire ignition temperature.

Owner:TIANJIN KINGFA NEW MATERIAL +1

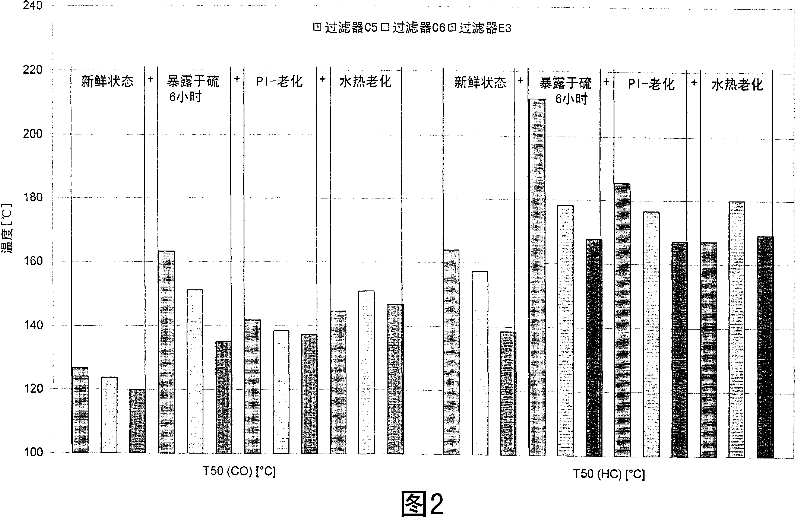

Catalytically coated particle filter and method for producing the same and its use

ActiveCN101043930ARaise the ignition temperatureGas treatmentInternal combustion piston enginesPtru catalystPhysical chemistry

Owner:UMICORE AG & CO KG

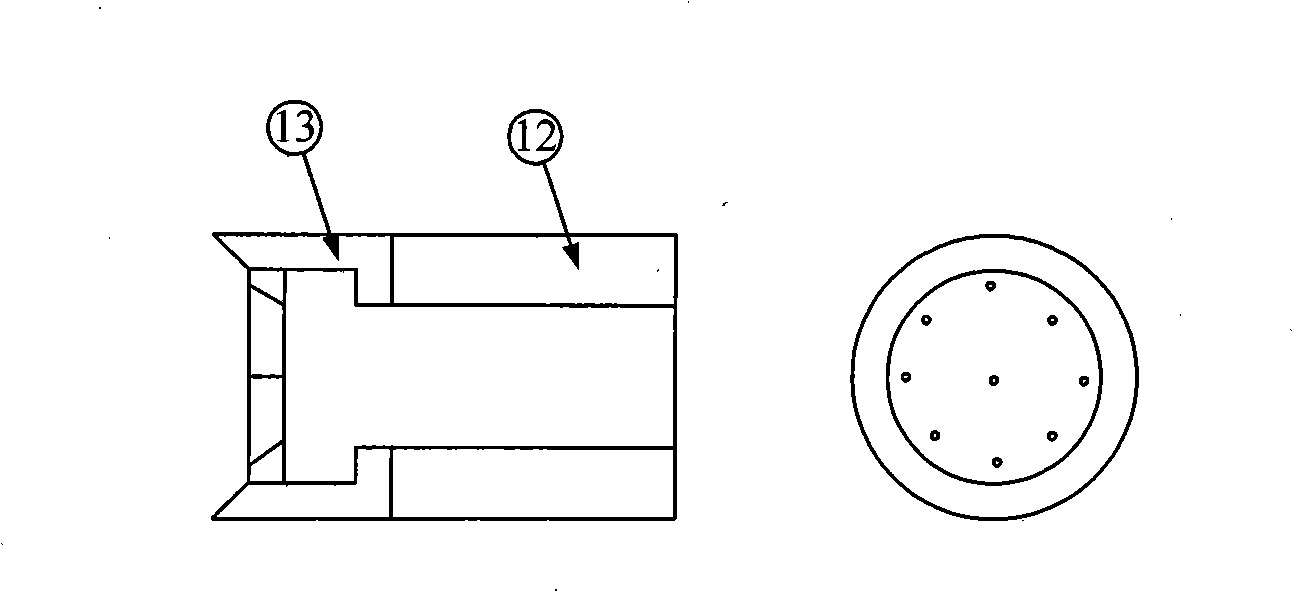

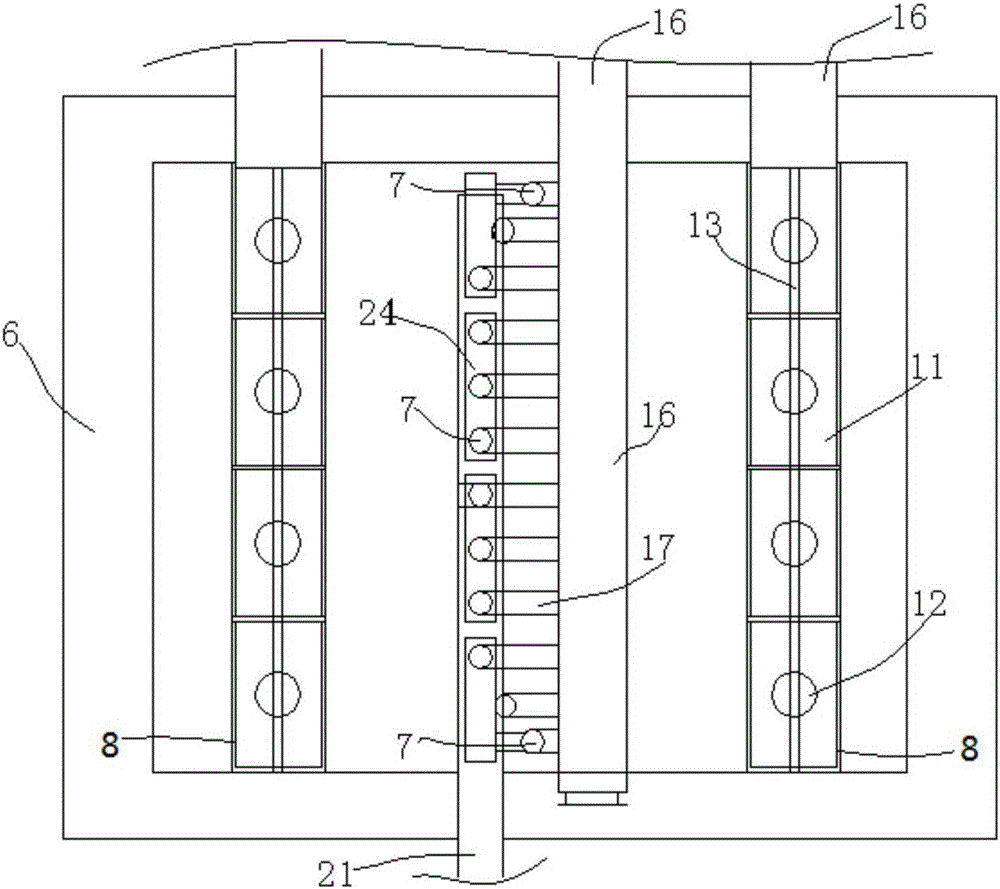

Igniting device and ignition method for sintering

ActiveCN106440811AImprove distributionBalanced sinter ignition qualityFuel lightersFurnace typesEngineeringEnergy conservation

The invention discloses an igniting device and an ignition method for sintering and belongs to the field of iron smelting of a blast furnace. The igniting device disclosed by the invention comprises an ignition furnace, a gas charging pipe and a hot air charging pipe; a row of burner nozzles are arranged on a part, at an ignition section of the ignition furnace, of the furnace top; the middle burner nozzles are arranged linearly; the burner nozzles close to the two sides of a sintering machine trolley are arranged in an arc shape; each burner nozzle communicates with the gas charging pipe and the hot air charging pipe respectively; the parts, at the front end and the rear end of the ignition section, of the furnace top are each provided with an isolation chamber; each isolation chamber communicates with the hot air charging pipe; an air box is arranged at the bottom of the ignition furnace, wherein a retarder is arranged inside the air tank under the burner nozzles. The igniting device disclosed by the invention has the advantages of optimizing distribution of an igniting fuel on an overall sintering material surface, balancing the ignition quality of sintering materials at all positions of a sintering machine, improving the quality of sintered ore products, also enhancing the ignition effect, reducing consumption of the igniting fuel and satisfying the production process requirements on energy conservation and environmental protection.

Owner:MAANSHAN IRON & STEEL CO LTD

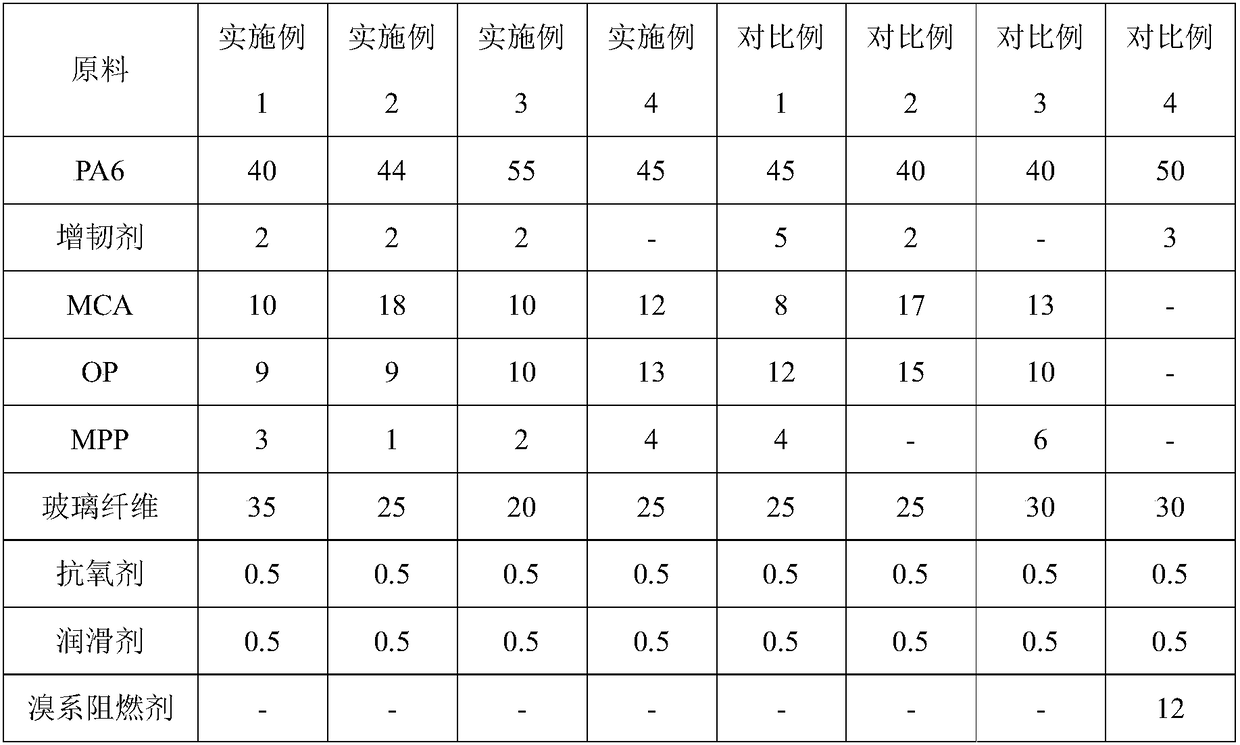

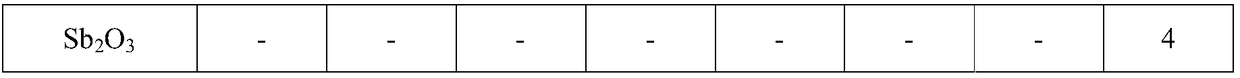

Halogen-free flame-retardant glass fiber-reinforced PA6 composite material with high-ignition-temperature glow wire and high CTI value and preparation method of halogen-free flame-retardant glass fiber-reinforced PA6 composite material with high-ignition-temperature glow wire and high CTI value

The invention discloses a halogen-free flame-retardant glass fiber-reinforced PA6 composite material with a high-ignition-temperature glow wire and a high CTI value and a preparation method of the PA6composite material. The PA6 composite material is composed of the following raw materials of: in parts by mass, 40-55 parts of PA6 resin, 0-5 parts of a toughening agent, 10-18 parts of melamine cyanurate flame retardant, 9-13 parts of aluminum hypophosphite flame retardant, 1-4 parts of melamine polyphosphate flame retardant, 20-35 parts of glass fiber, 0.3-0.5 part of an antioxidant and 0.3-1 part of a lubricant. Meanwhile, the invention discloses the preparation method of the halogen-free flame-retardant glass fiber-reinforced PA6 composite material with the high-ignition-temperature glowwire and the high CTI value. The halogen-free flame-retardant glass fiber-reinforced PA6 composite material with the high-ignition-temperature glow wire and the high CTI value has excellent flame retardant performance, high ignition temperature of the glow wire and high anti-tracking performance, and meanwhile the prepared composite material has excellent comprehensive mechanical properties and asimple preparation process, and is worthy of popularization and application.

Owner:GUANGDONG JUSHI CHEM CO LTD

Halogen-free flame retardant polyamide material and preparation method thereof

The invention discloses a halogen-free flame retardant polyamide material which is mainly prepared from the following components in parts by weight: 40-72 parts of polyamide, 8-15 parts of a halogen-free flame retardant, 3-9 parts of a flame retardant synergist, 0.5-2 parts of a processing aid and 0-40 parts of a reinforcing modifier, wherein the halogen-free flame retardant is hypophosphite and the flame retardant synergist is silicon stannate with the silicon content being 30-60%. By adding the flame retardant synergist silicon stannate to reduce the use level of the halogen-free flame retardant hypophosphite, the flame retardant performance and the mechanical property are more excellent than those of a flame retardant material without adding silicon stannate, so that the cost is lowered. For the flame retardant material without adding silicon stannate, in spite of high content of the halogen-free flame retardant hypophosphite, the GWIT (Glow Wire Ignition Temperature) still cannot reach 960 DEG C. By adding silicon stannate, the GWIT of the material is greatly enhanced and substantially reaches 960 DEG C.

Owner:SUZHOU CHUANGJIA PLASTIC

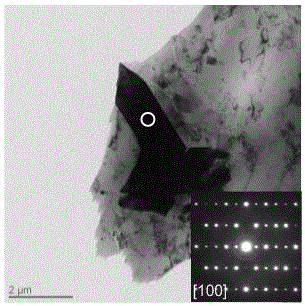

Pseudo-crystal reinforced high zinc magnesium alloy and method for manufacturing same

The invention discloses a quasi-crystalline reinforced high-zinc magnesium alloy and making method, which comprises the following parts: 2.50-5.00% Al, 6.00-20.00% Zn, 40-1.00% Y0., 0.40-1.20% Mn, 0.003-0.005% Ni, 0.03-0.05% Fe, 0.03-0.05% Cu and Mg. the cast shaped tissue is alpha-Mg+Tau (Mg32(Al, Zn)49)+phi (Al2Mg5Zn2)+, which is displayed in the alpha-Mg or tao-phase and phi-phase rim constituted by MgxZnuYtMnw magnesium-based four-phased composite tissues of quasi-crystalline with relative bulk at 1.50-4.00% in the high-zinc magnesium alloy material.

Owner:TAIYUAN UNIV OF TECH

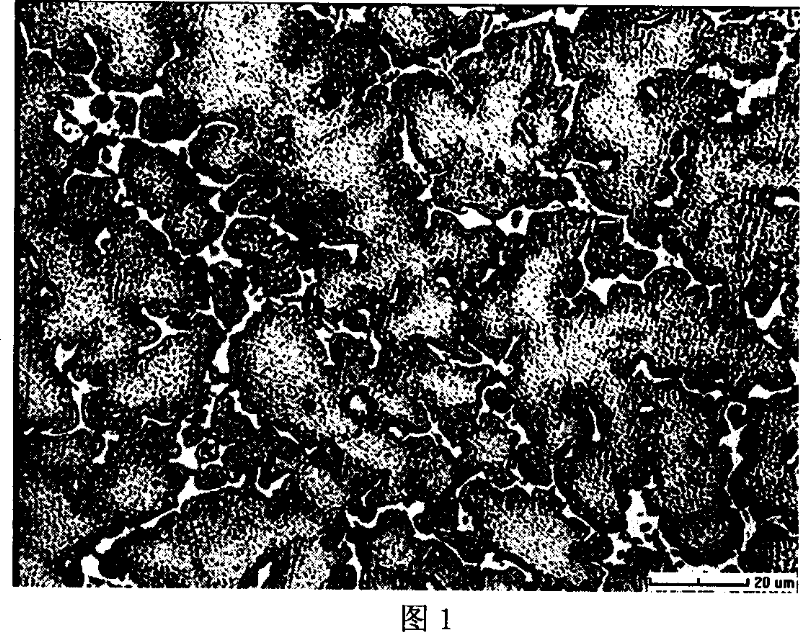

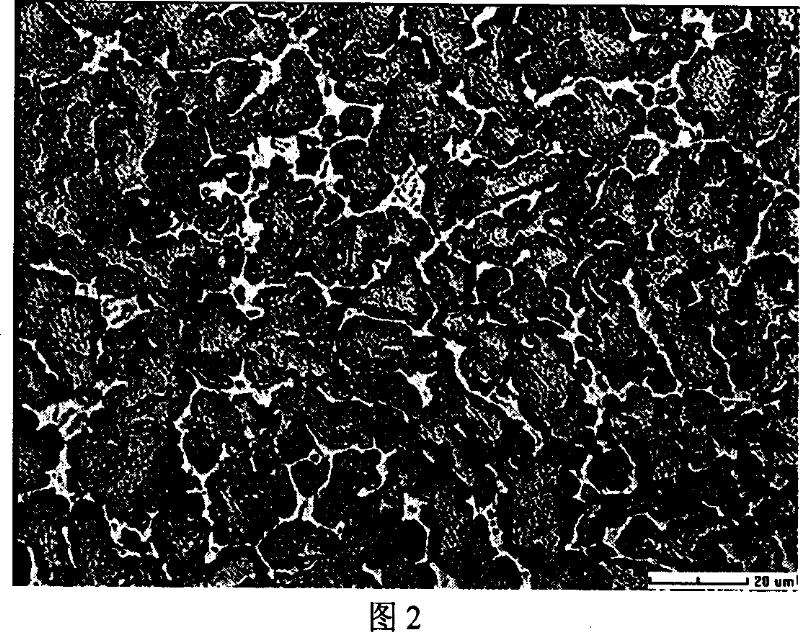

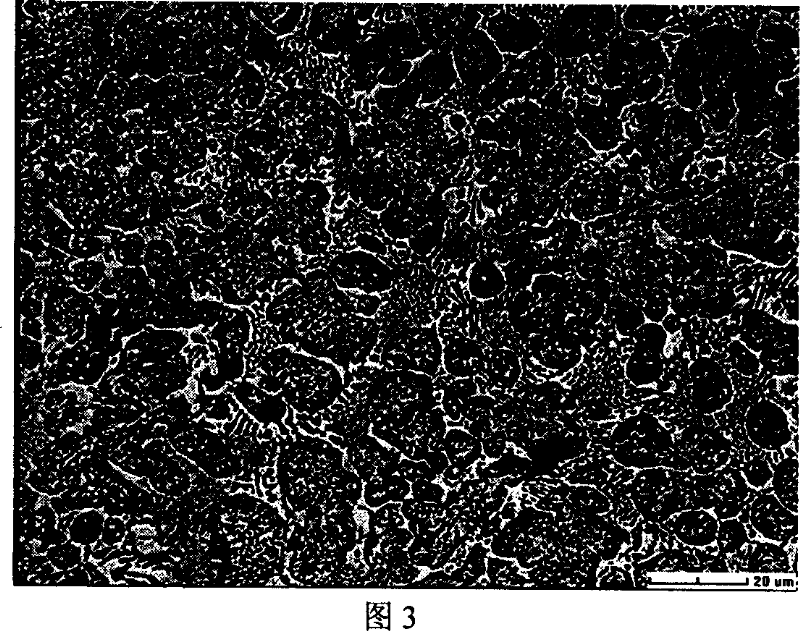

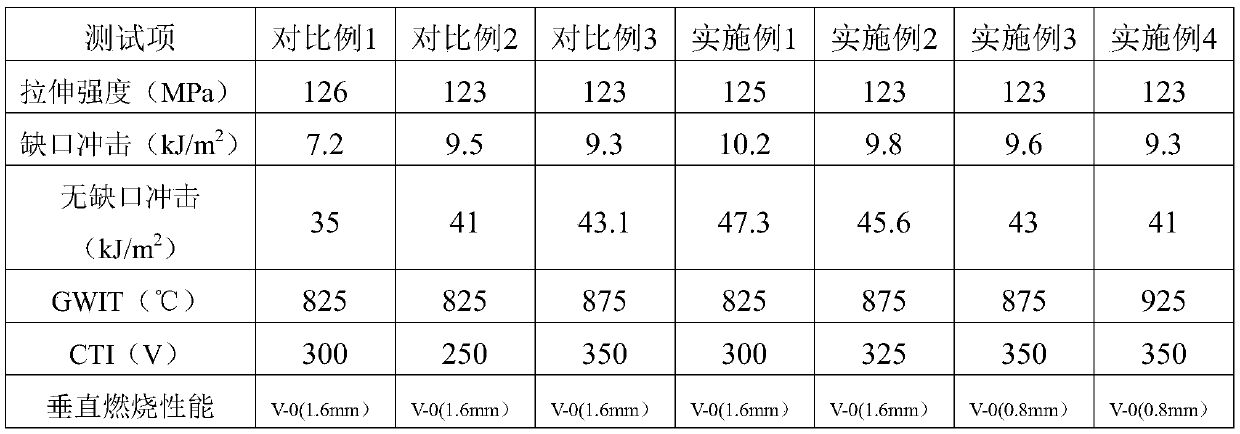

High-performance reinforced flame-retardant PBT material and preparation method thereof

The invention relates to the field of modified engineering plastics, and discloses a high-performance reinforced flame-retardant PBT material and a preparation method thereof. The high-performance reinforced flame-retardant PBT material of the invention comprises (by weight): 50 to 65 parts of PBT resin, 5 to 15 parts of PET resin, 10 to 20 parts of a flame retardant, 1 to 5 parts of a flame retardant synergist, 20 to 30 parts of a filler, 1 to 2 parts of a toughening agent, 0.1 to 0.8 part of an antioxidant, 0.9 to 1.2 parts of a lubricant, 0.1 to 0.3 part of a nucleating agent, and 0.5 to 1.5 parts of a plasticizer. The high-performance reinforced flame-retardant PBT material achieves a high glow-wire initiation temperature and a high tracking index through the combination of the flame retardant and the synergist, and combustion performance and mechanical property of the PBT material are improved by using low-cost talcum powder as the nucleating agent.

Owner:横店集团得邦工程塑料有限公司

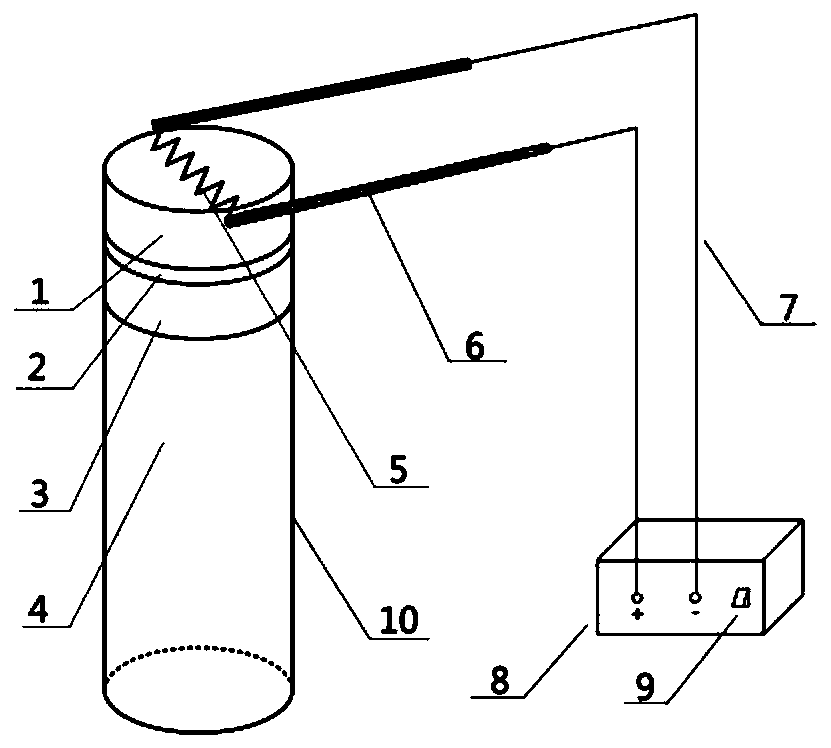

Ignition system for micron metal powder and liquid water mixture

ActiveCN109764355AGood ignition stabilityRaise the ignition temperatureFuel lightersBurn unitsLiquid water

The invention discloses an ignition system for a micron metal powder and liquid water mixture. The ignition system comprises a striking unit provided with heat by an oxidation reduction reaction, an ignition unit used for triggering the striking unit to burn, and a burning unit struck by the striking unit; the ignition unit is a control circuit including an electric heating wire; the burning unitis a gel system formed in the mode that micron metal powder is dispersed into water through gel, wherein an ignition reaction between the micron metal powder and the water is difficult; and the ignition unit comprises an ignition powder layer, a magnesium powder layer and an ignition gel layer, wherein the ignition powder layer is triggered by the electric heating wire and provided with the heat by the oxidation reduction reaction to uniformly heat the burning unit, the magnesium powder layer is used for blocking direct contact between the ignition powder layer and the burning unit and transmits heat generated by the ignition powder layer to the burning unit, and the ignition gel layer used for stably transmitting the heat of the magnesium powder layer to the burning unit so as to fully ignite the burning unit. The ignition system can achieve layered step-by-step ignition, the ignition temperature is high, and metal powder with any micron size and the water can be ignited stably.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

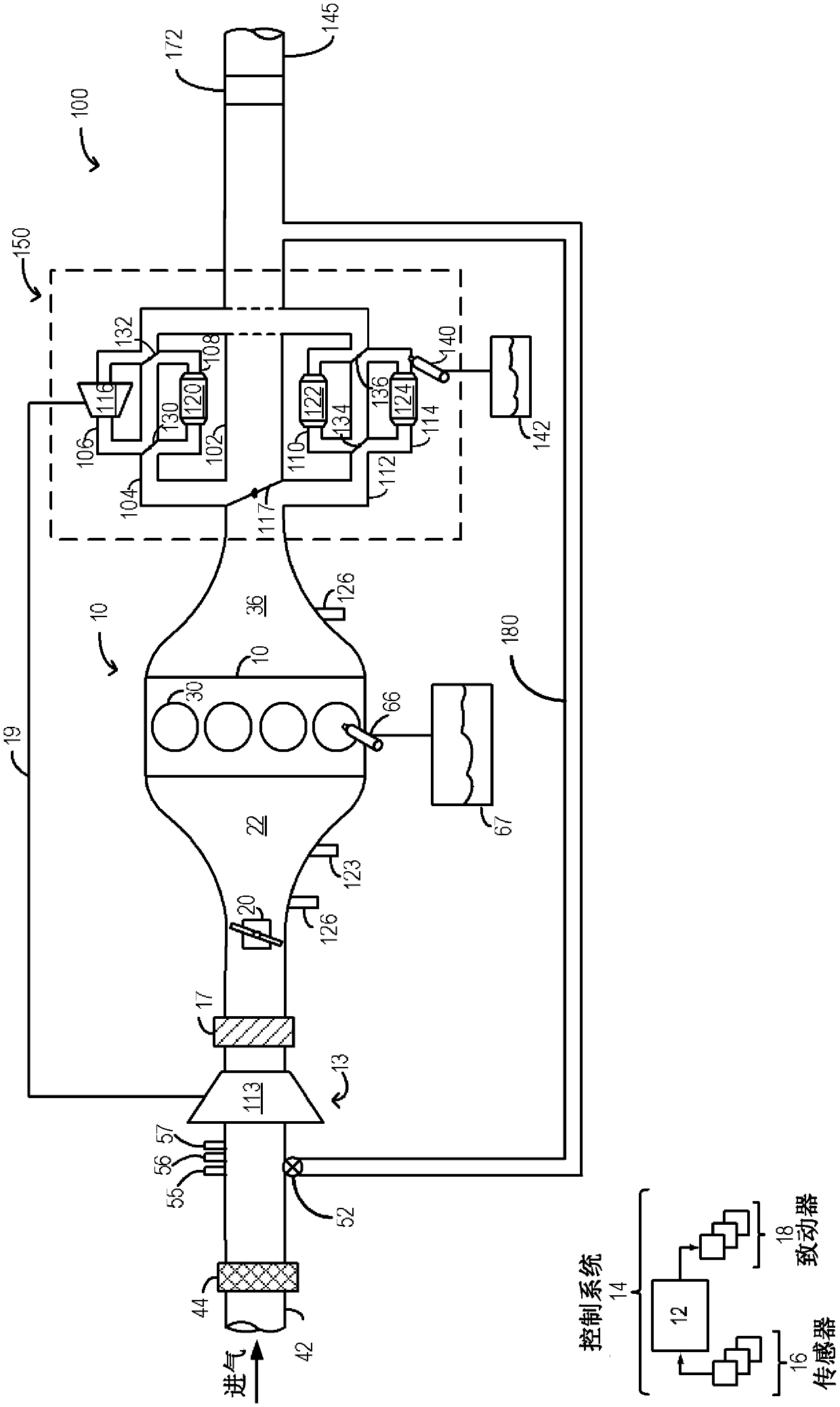

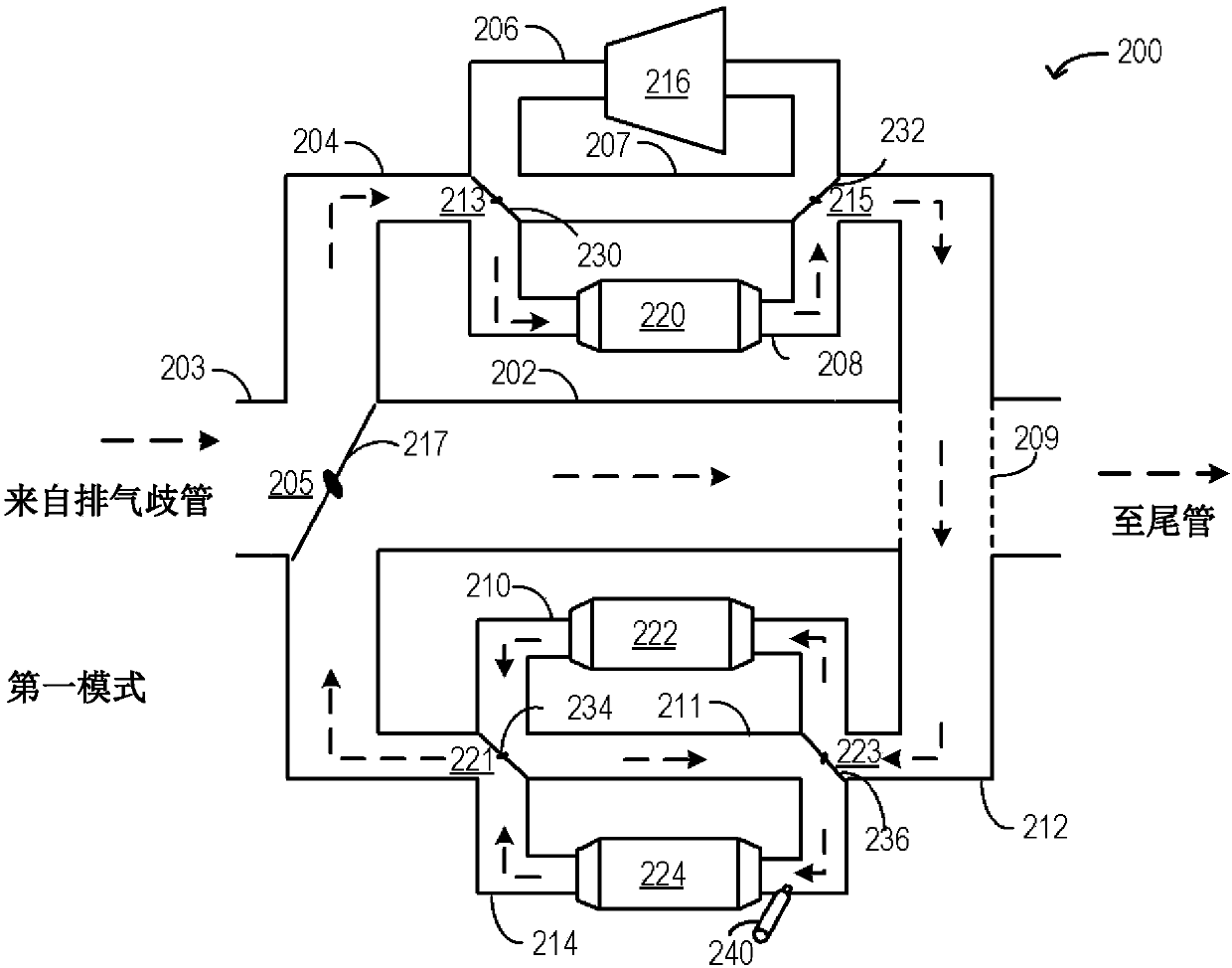

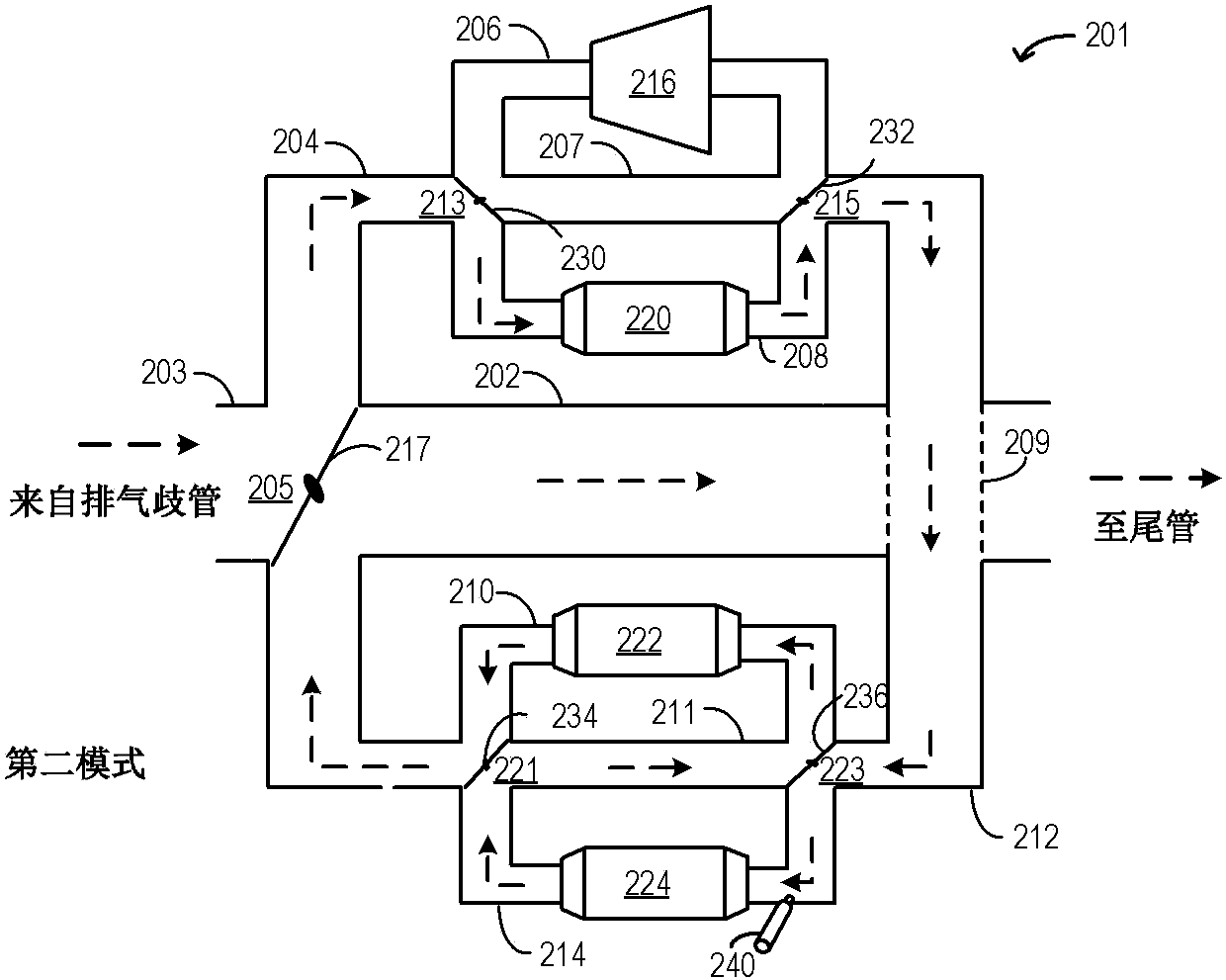

Method and system for exhaust aftertreatment

InactiveCN107654278ARaise the ignition temperatureAccelerates reaching light-off temperatureInternal combustion piston enginesExhaust apparatusAerospace engineering

Methods and systems are provided for reducing engine emissions using a branched exhaust system. In one example, a branched exhaust system may include a plurality of sub-branches each housing a distinct exhaust component, and an order of exhaust flow through each of the exhaust components may be adjusted based on engine operating conditions and temperature demand of the distinct components.

Owner:FORD GLOBAL TECH LLC

Environment-friendly type safety fireworks firecracker gun powder oxidant

InactiveCN101265146AHigh decomposition temperatureRaise the ignition temperatureExplosivesFirecrackerBarium nitrate

The invention discloses an environment-friendly safe gunpowder oxidizer of fireworks and firecrackers, and belongs to the chemical field. The environment-friendly safe gunpowder oxidizer is mixed and made by potassium hyperchlorate, strontium nitrate, barium nitrate and flame retardant material. The gunpowder oxidizer is characterized in simple prescription, good safety, no potassium chlorate, no sulfur, etc., and is widely used in the industries such as firecrackers, fireworks, etc., and is an ideal safe gunpowder oxidizer.

Owner:祁阳县梅溪镇第二鞭炮厂

High-density fiberboard with high fire resistance and preparation method of high-density fiberboard

ActiveCN113070969AStrong fire resistanceImprove fire and flame retardant performanceWood working apparatusFlat articlesHigh densityMagnesium stearate

The invention belongs to the technical field of fiberboard materials, particularly relates to a high-density fiberboard with high fire resistance and a preparation method of the high-density fiberboard. The problems that in the prior art, a fiberboard can release harmful substances such as formaldehyde, the fiberboard belongs to an inflammable material are solved, and the high-density fiberboard comprises the following raw materials of, in parts by weight, 30-50 parts of wood chips, 30-50 parts of straws, 10-20 parts of light silicon dioxide, 3-5 parts of an adhesive, 3-5 parts of a flame retardant, 1-3 parts of magnesium stearate, 2-4 parts of hexamethyldisiloxane and 2-5 parts of p-hydroxybenzenesulfonic acid. According to the high-density fiberboard with the high fire resistance and the preparation method of the high-density fiberboard, the high-density fiberboard is scientific in formula and rigorous in proportion, the obtained high-density fiberboard has excellent fire-resistant and flame-retardant performance, waterproof and moistureproof performance and physical and mechanical performance, the preparation method of the high-density fiberboard is simple, mild in preparation condition and easy for industrial production, and can be widely applied.

Owner:佳诺威集团股份有限公司

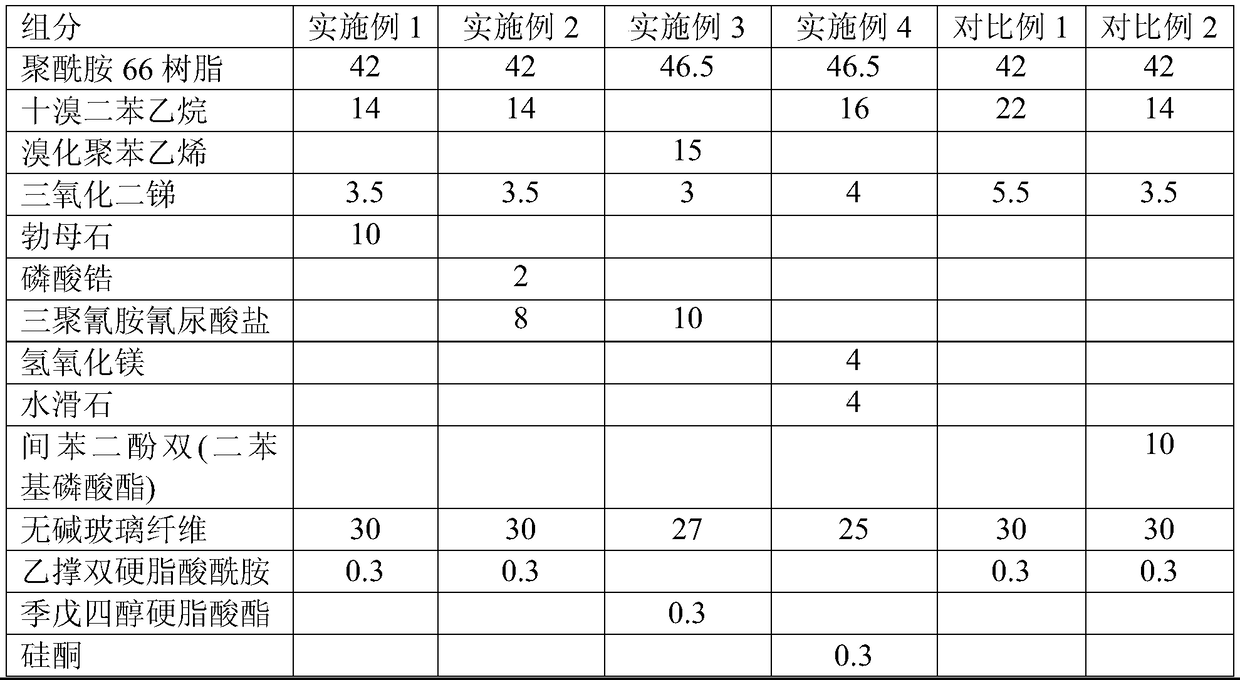

Enhanced flame-retardant nylon composition with high glow wire initiation temperature and preparation method thereof

The invention discloses anenhanced flame-retardant nylon composition with a high glow wire initiation temperature. The enhanced flame-retardant nylon composition is prepared from the following components in parts by mass: 35 to 53 parts of polyamide 66 resin, 15 to 25 parts of a composite flame retardant, 5 to 10 parts of a glow wire initiation temperature improvement agent, 25 to 30 parts of glass fibers, 0.2 to 1 part of an antioxidant and 0.3 to 1 part of a moistening agent. The enhanced flame-retardant nylon composition belongs to the technical field of high molecule materials. By adoptingthe enhanced flame-retardant nylon composition, the glow wire initiation temperature (GWIT) can be improved remarkably, and meanwhile superior temperature resistance, machining performance and coloring performance of the bromine-antimony flame retardant nylon composition are kept.

Owner:中山市华邦塑料有限公司

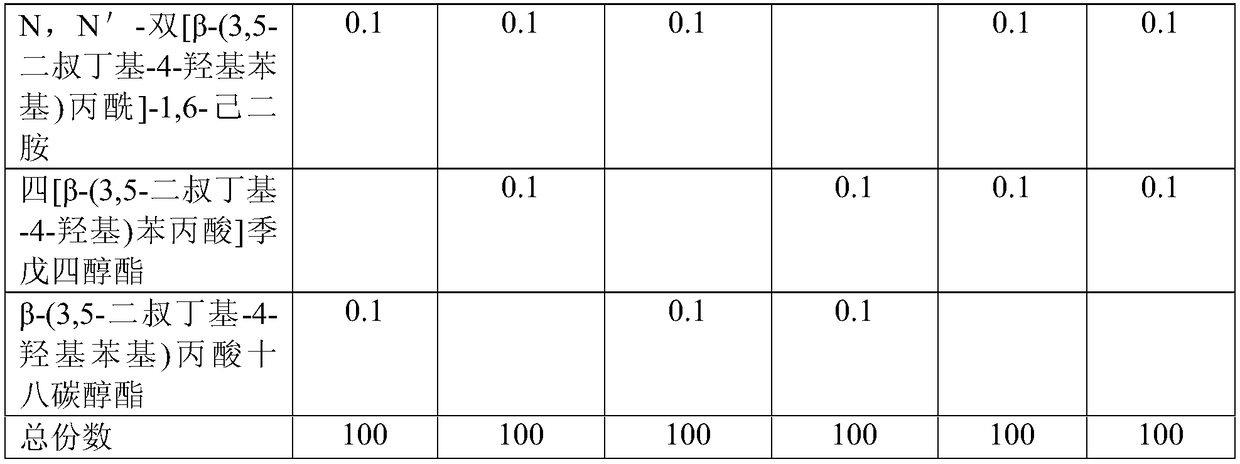

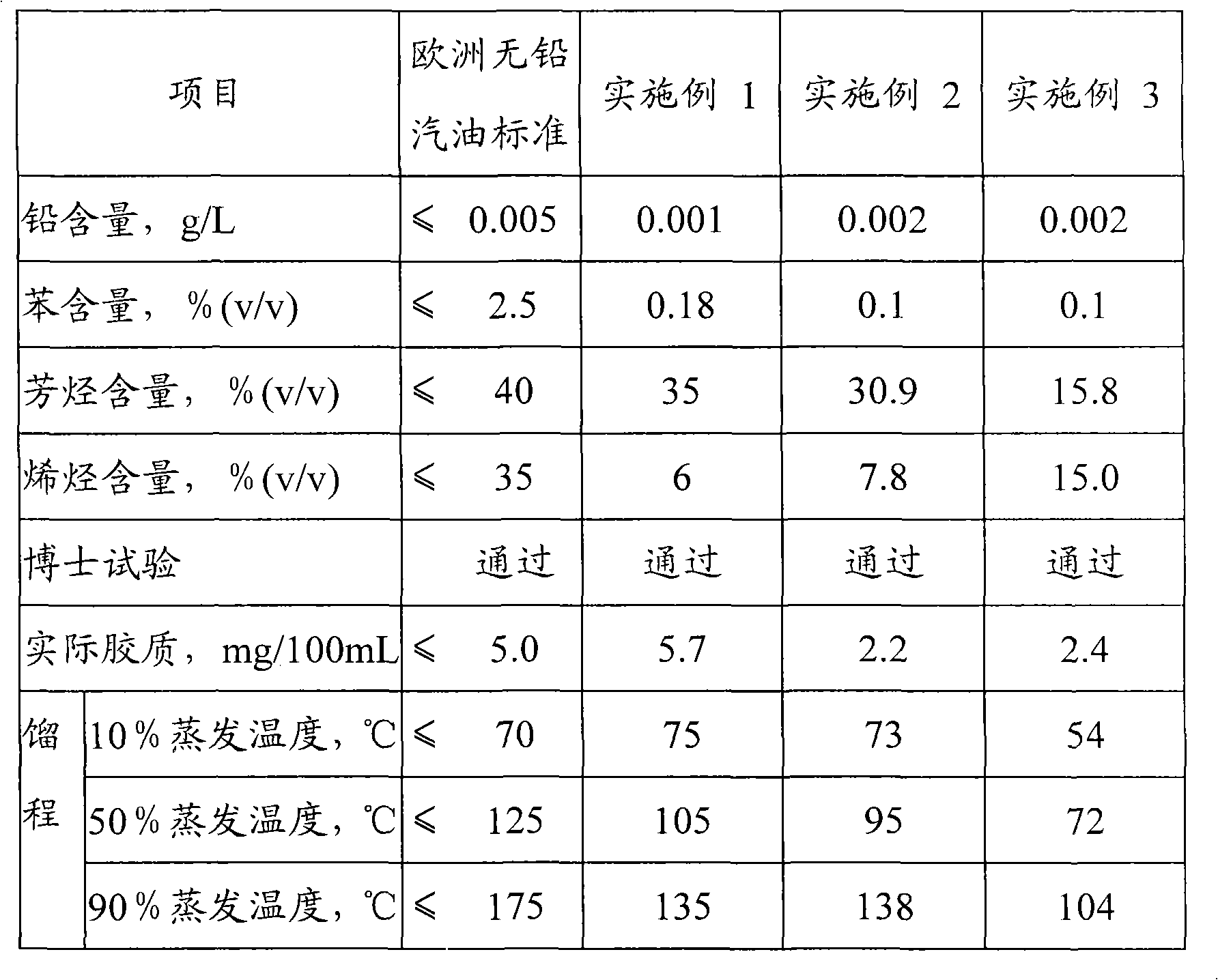

Environmentally-friendly alternative fuel composition and method for manufacturing same

InactiveCN101525554ALow costImprove fuel efficiencyLiquid carbonaceous fuelsAlternative fuelsDetonation

The invention relates to an environmentally-friendly alternative fuel composition and a method for manufacturing the same. The composition comprises: 40 to 60 weight portions of a mixture of alkanes, alkenes and naphthenic hydrocarbons, 15 to 20 weight portions of a mixture of aromatic hydrocarbons, 5 to 10 weight portions of a mixture of C5 hydrocarbons, 7 to 12 weight portions of a mixture of C9 hydrocarbons, 3 to 15 weight portions of toluene, 4 to 12 weight portions of methyl tert-butyl ether (MTBE) and 4 to 20 weight portions of C1 to C4 alcohol compounds. Compared with common gasoline, the environmentally-friendly alternative fuel composition can effectively reduce harmful gases such as carbon monoxide, organic hydrocarbons and nitrogen oxides in exhausted tail gases and consequently reduce air pollution greatly due to more sufficient burning, and well suppress detonation and improve the power of a motor, namely the thermal efficiency of the motor, due to a high octane number. In addition, due to a higher thermal value and higher combustion efficiency, the environmentally-friendly alternative fuel composition achieves a good energy-saving effect.

Owner:郑炳祚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com