Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "High tracking index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

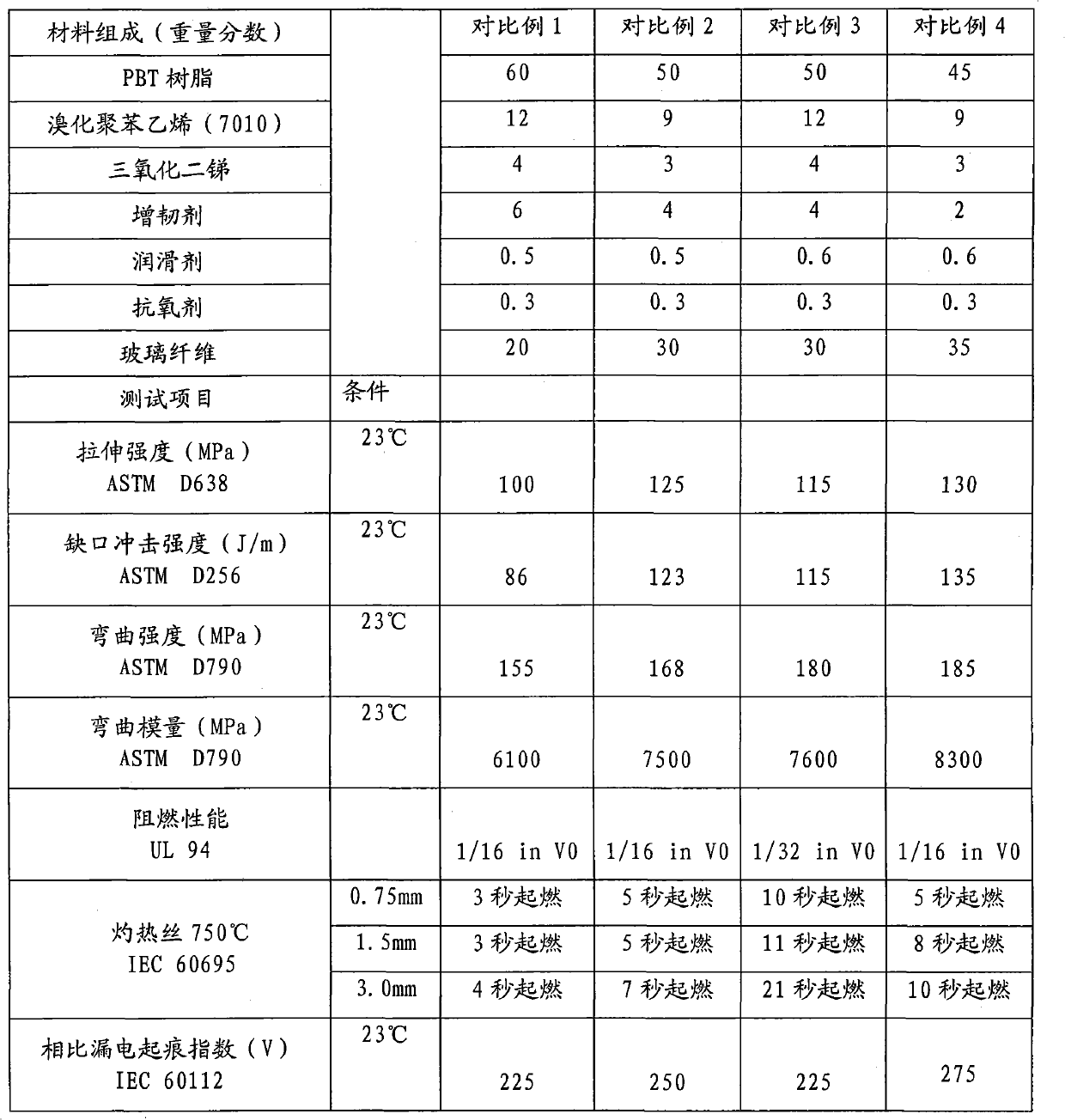

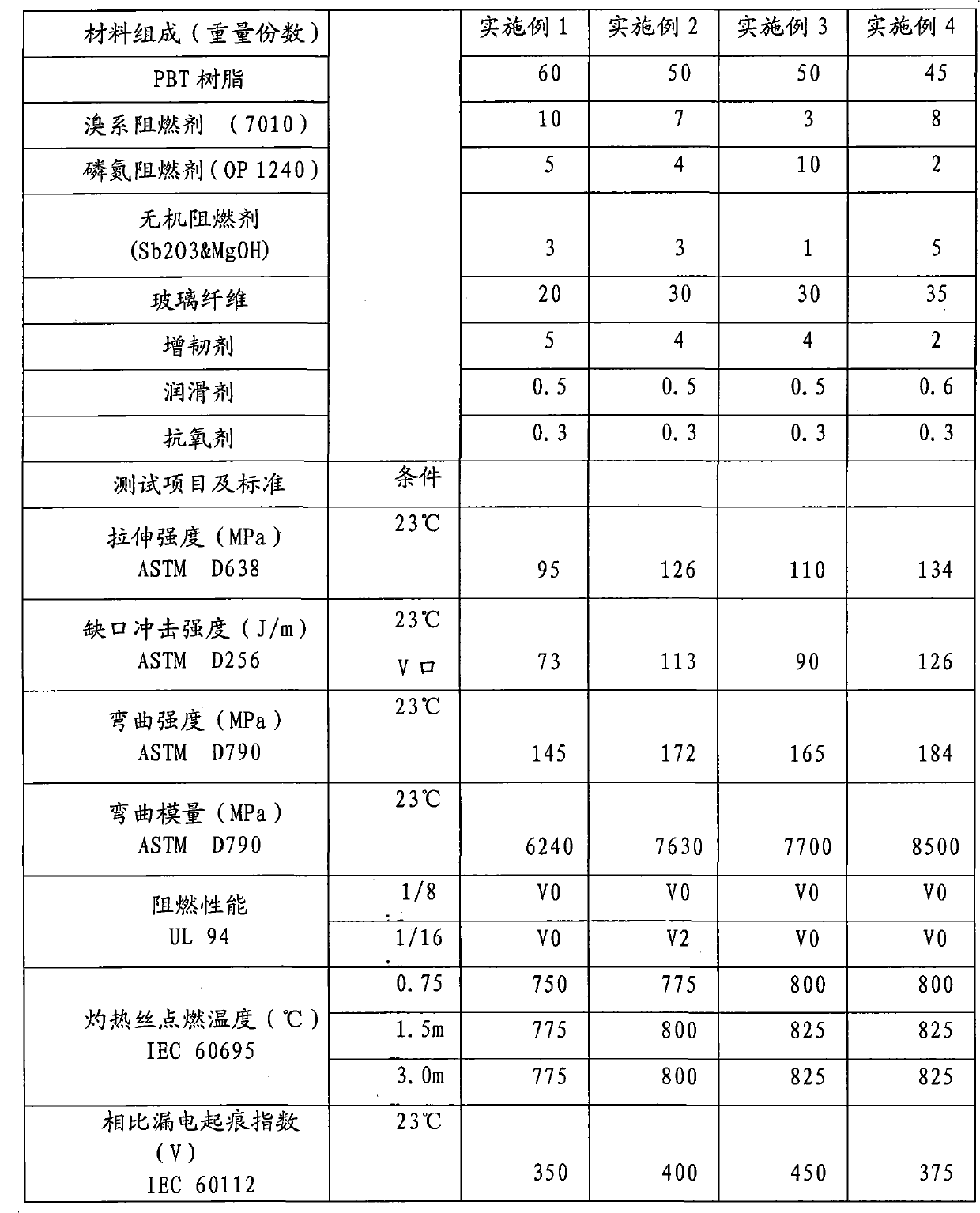

Flame-retardant enhanced PBT material and preparation method thereof

InactiveCN101817972ARaise the ignition temperatureHigh tracking indexComparative Tracking IndexAntioxidant

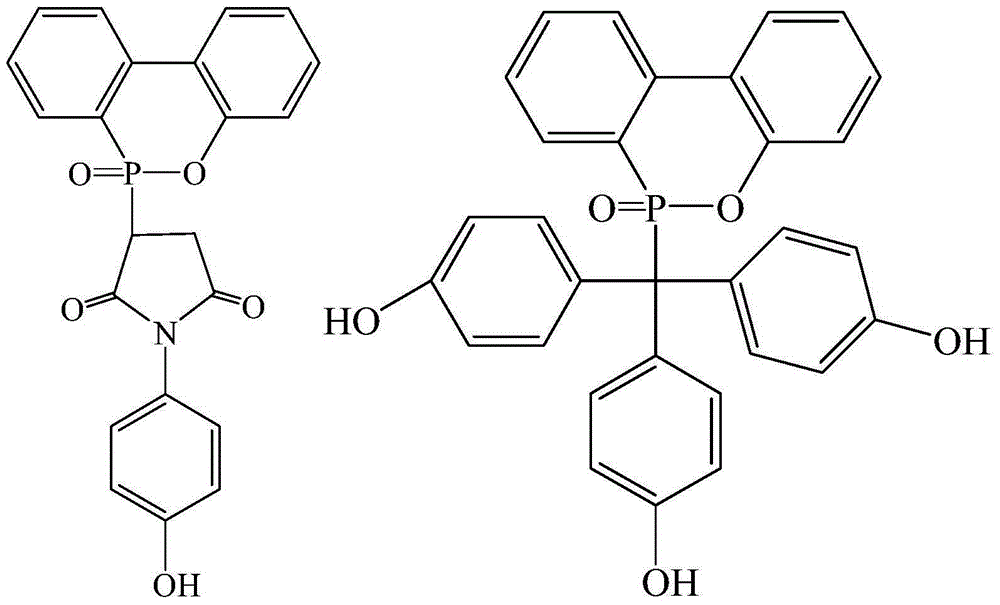

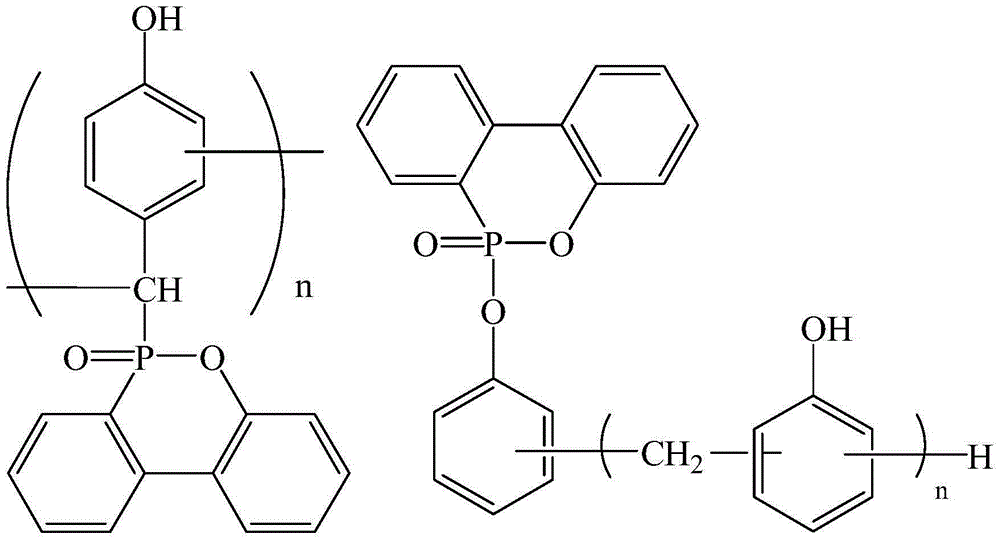

The invention discloses a flame-retardant enhanced PBT material and a preparation method thereof. The flame-retardant enhanced PBT material comprises the following components in percentage by weight: 45 to 60 percent of PBT resin, 3 to 10 percent of brominated flame retardant, 1 to 10 percent of phosphorus-nitrogen flame retardant, 1 to 5 percent of inorganic flame retardant, 2 to 5 percent of toughening agent, 20 to 35 percent of glass fiber, 0.3 to 1 percent of lubricating agent, and 0.1 to 0.6 percent of antioxidant. The flame-retardant enhanced PBT material has high ignition temperature of glowing filament, high comparative tracking index, and better mechanical property, and can be widely applied to the field of unattended electronic and electric products.

Owner:SHENZHEN KEJU NEW MATERIAL

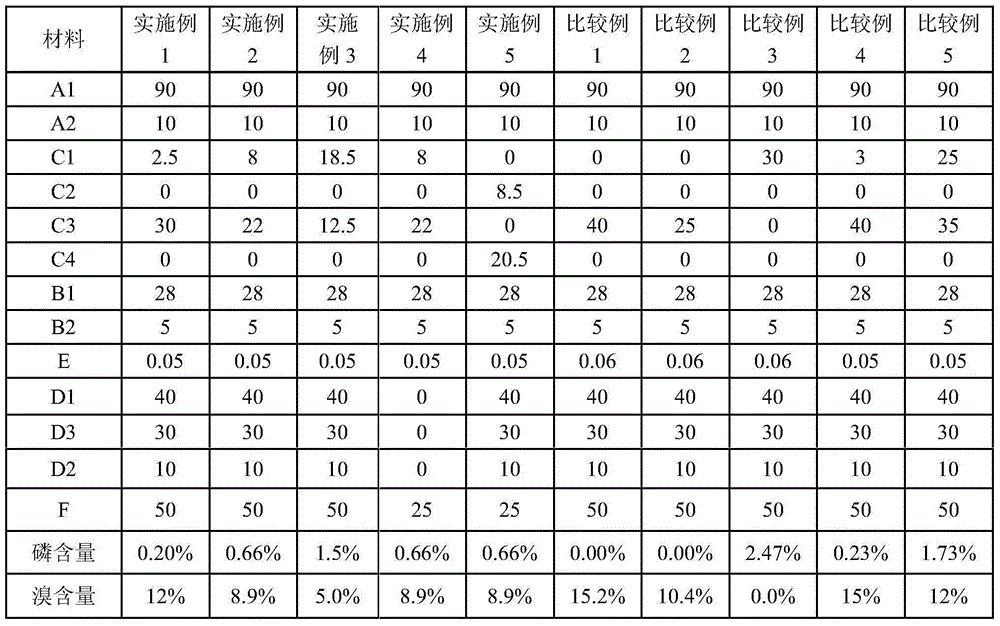

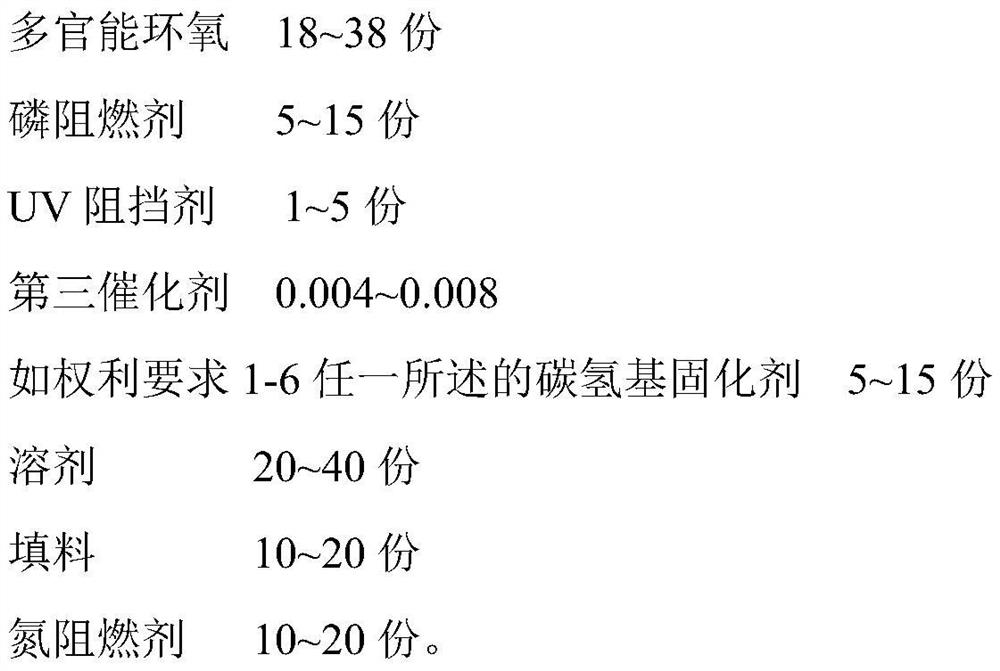

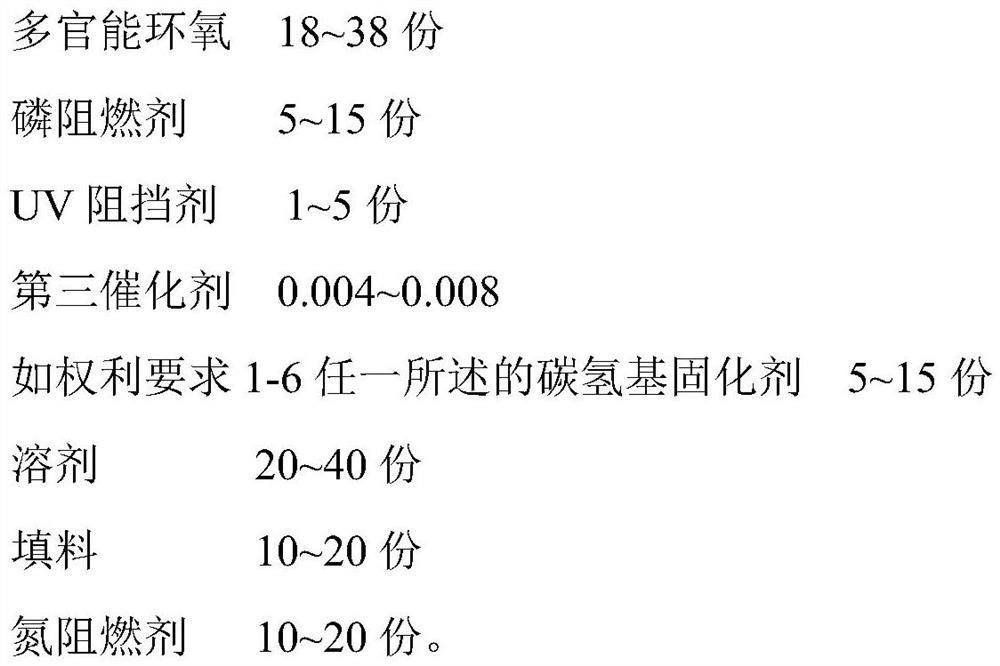

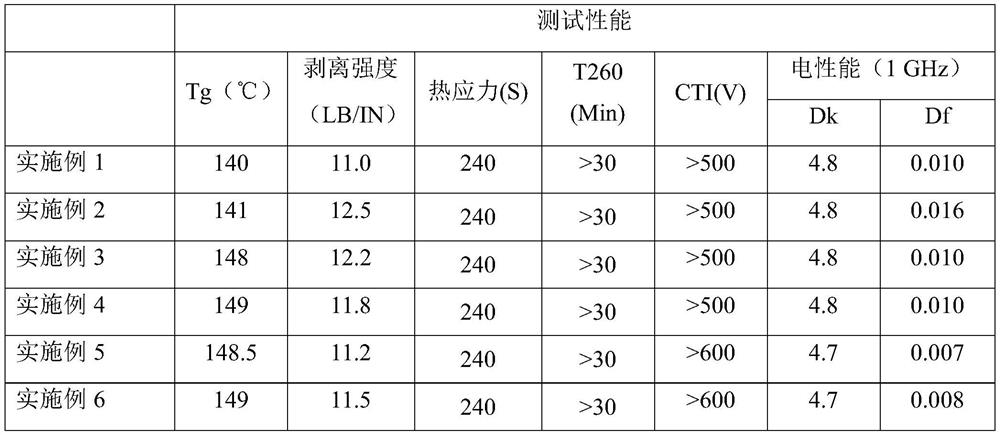

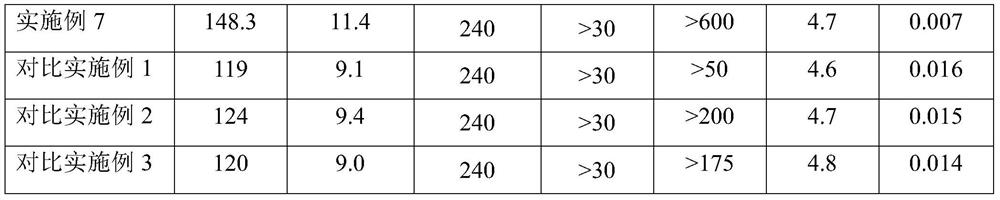

Epoxy resin composition for copper-clad plate and application thereof

ActiveCN105175994AImproved tracking indexCost controlPrinted circuit aspectsSynthetic resin layered productsEpoxyPolymer science

Owner:GUANGDONG SHENGYI SCI TECH

Epoxy resin composition for copper-clad plate and application thereof

ActiveCN105175995AImproved tracking indexEffective cost controlSynthetic resin layered productsPrinted circuit aspectsPolymer scienceHalogen

The present invention relates to an epoxy resin composition for copper-clad plate and application thereof. The epoxy resin composition can be used for preparing a prepreg and a copper clad laminate. The composition uses brominated bisphenol A and phenolic aldehyde containig phosphorus as a bromine source and a phosphorus source respectively; and the ratio of the two in the epoxy resin is adjusted to control the bromine content at 5-12%, phosphorus content at 0.2-1.5%; and the flame resistance reaches up to grade UL94 V-0. The prepreg and laminate produced by the epoxy resin composition not only has reduced halogen content and improved heat resistance, but also gains improved pressure resistance of substrate, low moisture absorption, good adhesion, reactivity and workability, realizes comparative tracking index higher than 600V, and greatly reduces the cost of production.

Owner:GUANGDONG SHENGYI SCI TECH

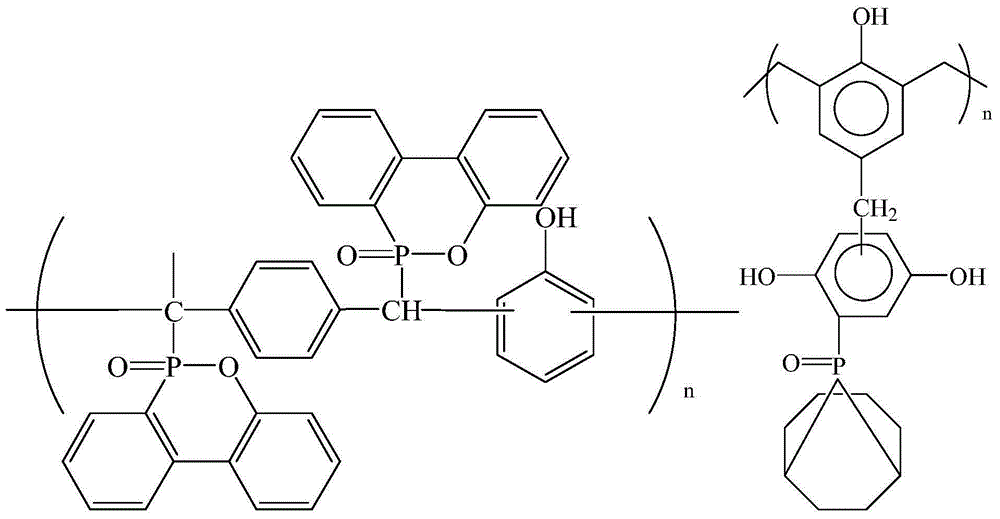

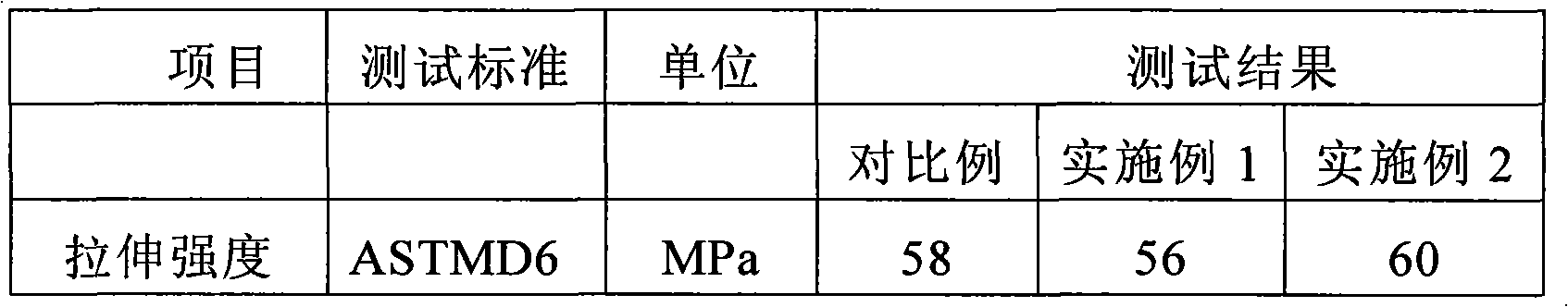

Halogen-free flame-retardant polycarbonate/styrene base resin composition and preparation method thereof

The invention relates to a halogen-free flame-retardant polycarbonate / styrene base resin composition and a preparation method thereof, and the composition comprises the following components in parts by weight: 650-900 parts of polycarbonate, 0.1-250 parts of styrene base resin, 20-100 parts of toughening compatibilizer, 10-100 parts of metal inorganic compound, 5-50 parts of organic silicon, 70-150 parts of complex flame retardant, 1-10 parts of antioxidant A, 1-15 parts of antioxidant B and 0-20 parts of other auxiliary materials. The preparation method comprises the following steps: mixing raw materials in a high-speed mixing machine, then introducing into a twin-screw extruder, adding the complex flame retardant in the lateral line feeding way, performing extrusion and granulation and finally getting the product. Compared with the prior art, the halogen-free flame-retardant polycarbonate / styrene base resin composition has the advantages of high comparative tracking index (CTI), high glow-wire ignition temperature (GWIT), halogen-free flame retardance, environment friendliness and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Epoxy resin composition for copper-clad board and application thereof

InactiveCN105086365AImproved tracking indexEffective cost controlPrinted circuit aspectsSynthetic resin layered productsEpoxyPolystyrene

The invention relates to an epoxy resin composition for a copper-clad board and an application thereof. The epoxy resin composition comprises flame retardant additives containing phosphorus and flame retardant additives containing bromine and can be used for preparing prepreg and copper-clad laminated boards. According to the epoxy resin composition for the copper-clad board and the application thereof, brominated polystyrene, decabromodiphenyl ethane and the like are adopted to serve as sources of the bromine, phosphazene, melamine polyphosphate, aluminum metaphosphate or melamine cyanurate and the like serve as sources of the phosphorus, the proportion of the flame retardant additives containing the phosphorus and the flame retardant additives containing the bromine of the composition is adjusted to make the bromine content controlled between 5% and 12% and make the phosphorus content controlled between 0.2% and 1.5%, and the flame retardancy of the composition can reach grade UL94 V-0; compared with a pure-bromine flame-retardant copper-clad board, the heat resistance is higher, and a higher CTI value can be reached; compared with a pure-phosphorus flame-retardant copper-clad board, the rate of moisture absorption is lower, and the adhesive property and the technological operability which are needed for printing circuit substrates can be provided; compared with a traditional board which has a high CTI and adopts a large amount of aluminum hydroxide, by means of the epoxy resin composition for the copper-clad board, the CTI can reach to be above 600 V by utilizing a small amount of the aluminum hydroxide or not utilizing the aluminum hydroxide at all.

Owner:GUANGDONG SHENGYI SCI TECH

Polyamide composite material with high glowing filament temperature and preparation method and application thereof

The invention discloses a polyamide composite material with high glowing filament temperature. A raw material formula of the polyamide composite material comprises, by weight, polyamide 40%-70%, halogen-free flame retardant 5%-15%, lubricating agent 0.1%-3%, antioxidant 0.1%-1% and reinforced modifying agent 10%-30%. The halogen-free flame retardant is cyanuric acid melamine. The invention further discloses a preparation method and application of the polyamide composite material with the high glowing filament temperature. The polyamide composite material with the high glowing filament temperature is light in color, light in specific gravity and wide in application range, can be dyed with various colors and has comparative tracking index larger than 500V, and the glowing filament combustion index is 960 DEG C. The polyamide composite material with the high glowing filament temperature can be prepared by means of a conventional device and a conventional method, a manufacture device is not required to be modified, and industrial production is easily performed.

Owner:上海耐特复合材料制品有限公司

High-performance reinforced flame-retardant PBT material and preparation method thereof

The invention relates to the field of modified engineering plastics, and discloses a high-performance reinforced flame-retardant PBT material and a preparation method thereof. The high-performance reinforced flame-retardant PBT material of the invention comprises (by weight): 50 to 65 parts of PBT resin, 5 to 15 parts of PET resin, 10 to 20 parts of a flame retardant, 1 to 5 parts of a flame retardant synergist, 20 to 30 parts of a filler, 1 to 2 parts of a toughening agent, 0.1 to 0.8 part of an antioxidant, 0.9 to 1.2 parts of a lubricant, 0.1 to 0.3 part of a nucleating agent, and 0.5 to 1.5 parts of a plasticizer. The high-performance reinforced flame-retardant PBT material achieves a high glow-wire initiation temperature and a high tracking index through the combination of the flame retardant and the synergist, and combustion performance and mechanical property of the PBT material are improved by using low-cost talcum powder as the nucleating agent.

Owner:横店集团得邦工程塑料有限公司

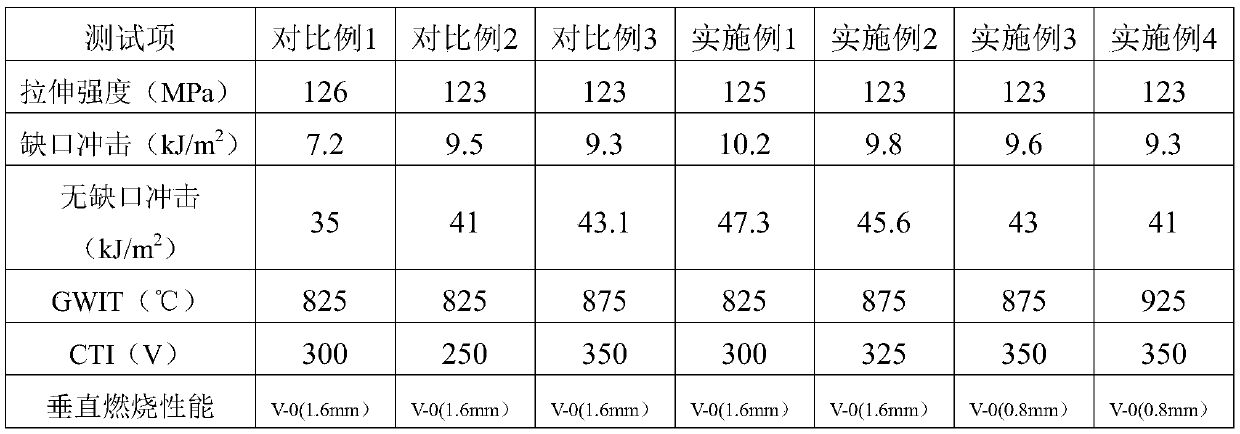

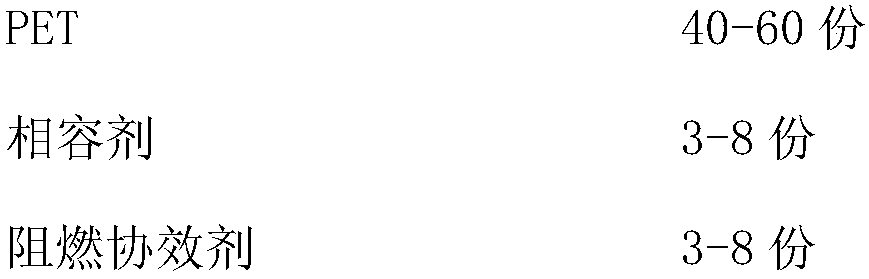

High-GWIT high-CTI thin-wall flame-retardant glass-fiber reinforced low-warpage PET composite material and preparation method thereof

InactiveCN108164935AGood synergySatisfy flame retardancyPolyethylene terephthalate glycolPolyethylene terephthalate

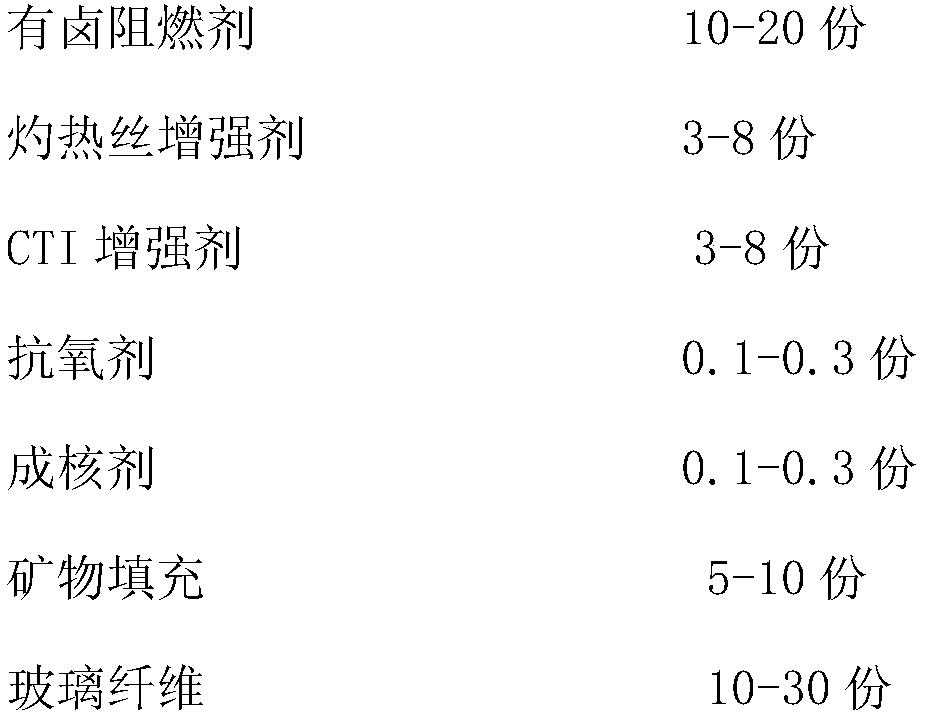

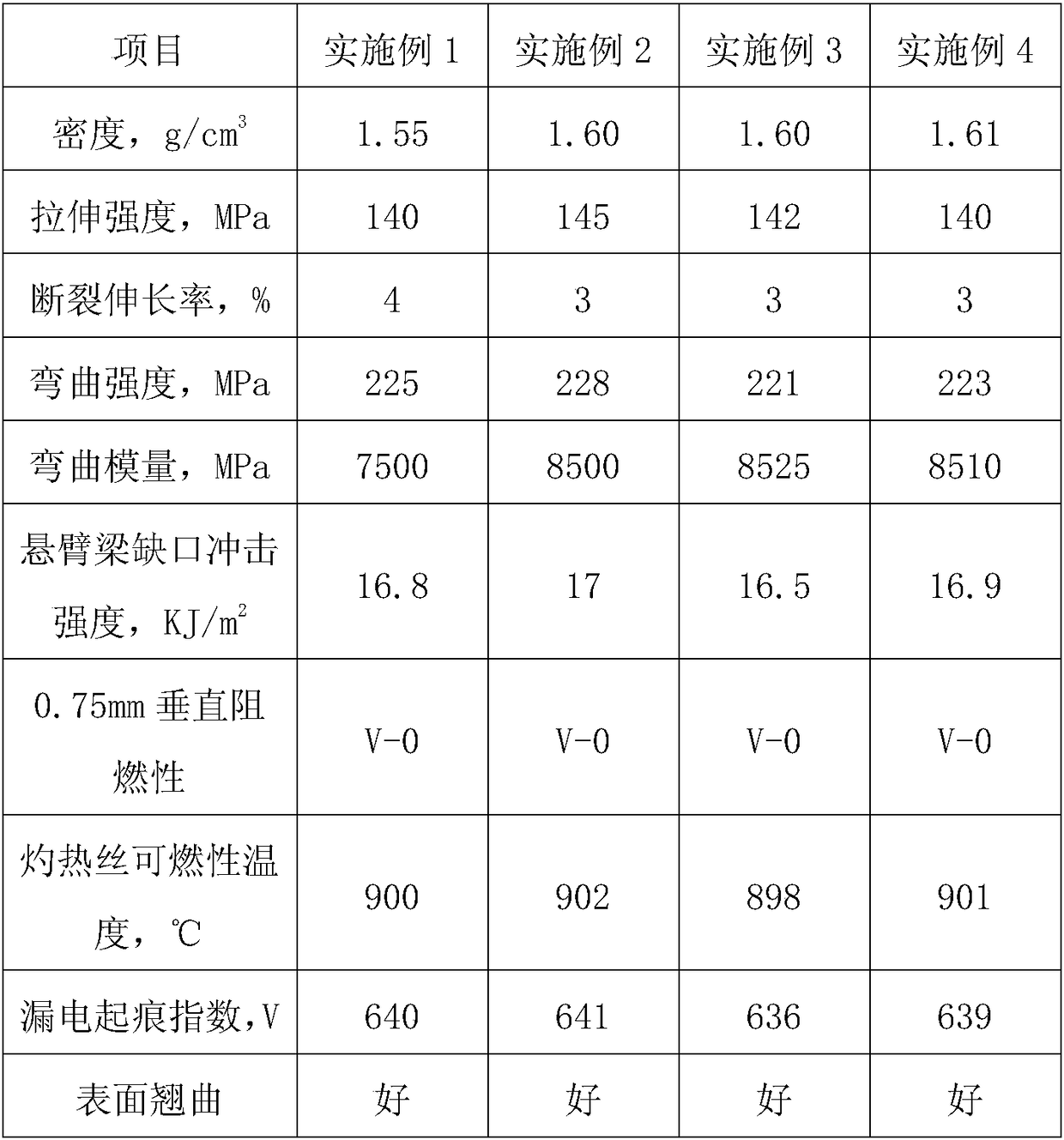

The invention discloses a high-glow-wire ignition temperature (GWIT) high-comparative tracking index (CTI) thin-wall flame-retardant glass-fiber reinforced low-warpage polyethylene terephthalate (PET)composite material and a preparation method thereof. The high-GWIT high-CTI thin-wall flame-retardant glass-fiber reinforced low-warpage PET material comprises the following raw materials in parts byweight: 40-60 parts of PET, 3-8 parts of a compatilizer, 3-8 parts of a flame-retardant synergist, 10-20 parts of a halogen-containing flame retardant, 3-8 parts of a glow-wire reinforcing agent, 3-8parts of a CTI enhancer, 0.1-0.3 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 5-10 parts of a mineral filler and 10-30 parts of glass fibers. According to the high-GWIT high-CTI flame-retardant glass-fiber reinforced low-warpage PET composite material, the GWIT of and the CTI of a glowing filament of the material are notably improved in the premise of not influencing the mechanicalproperties of the material and meeting the flame retardance; and with the addition of the nucleating agent and the mineral filler, the warping problem of a product is solved, the molding cycle of theproduct is reduced, and the formula cost is also reduced.

Owner:NANJING HONGRUI PLASTIC PROD

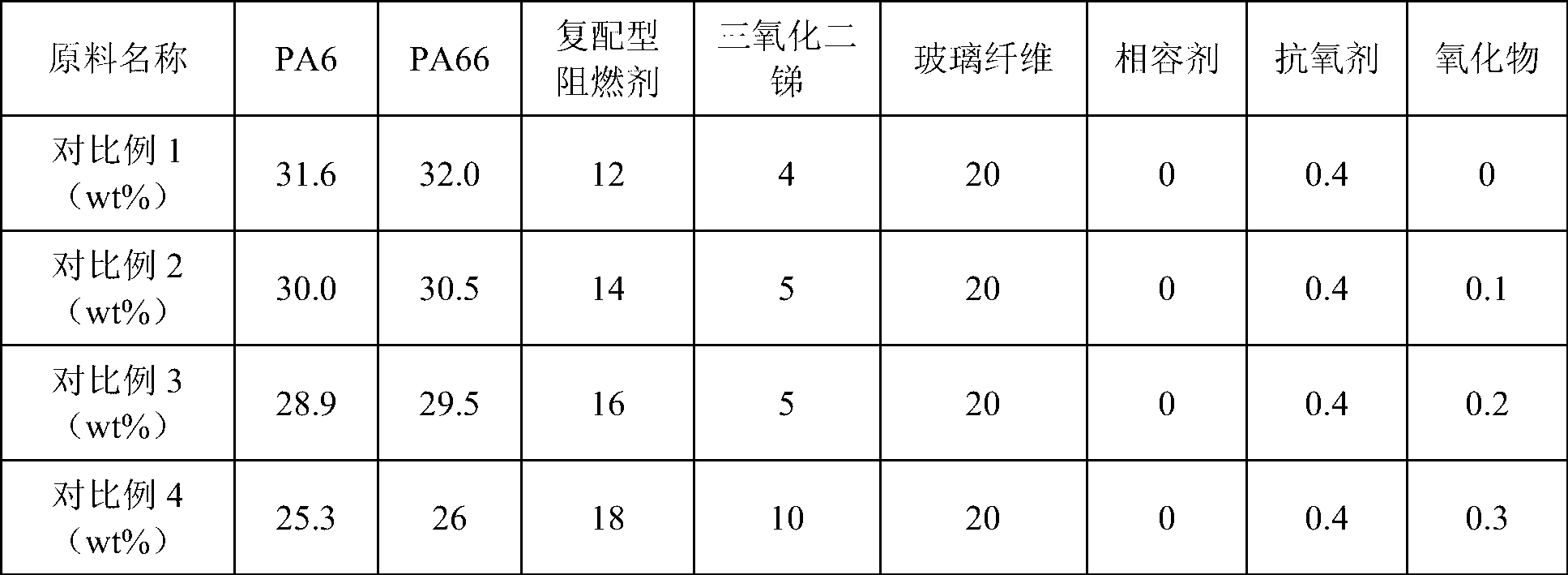

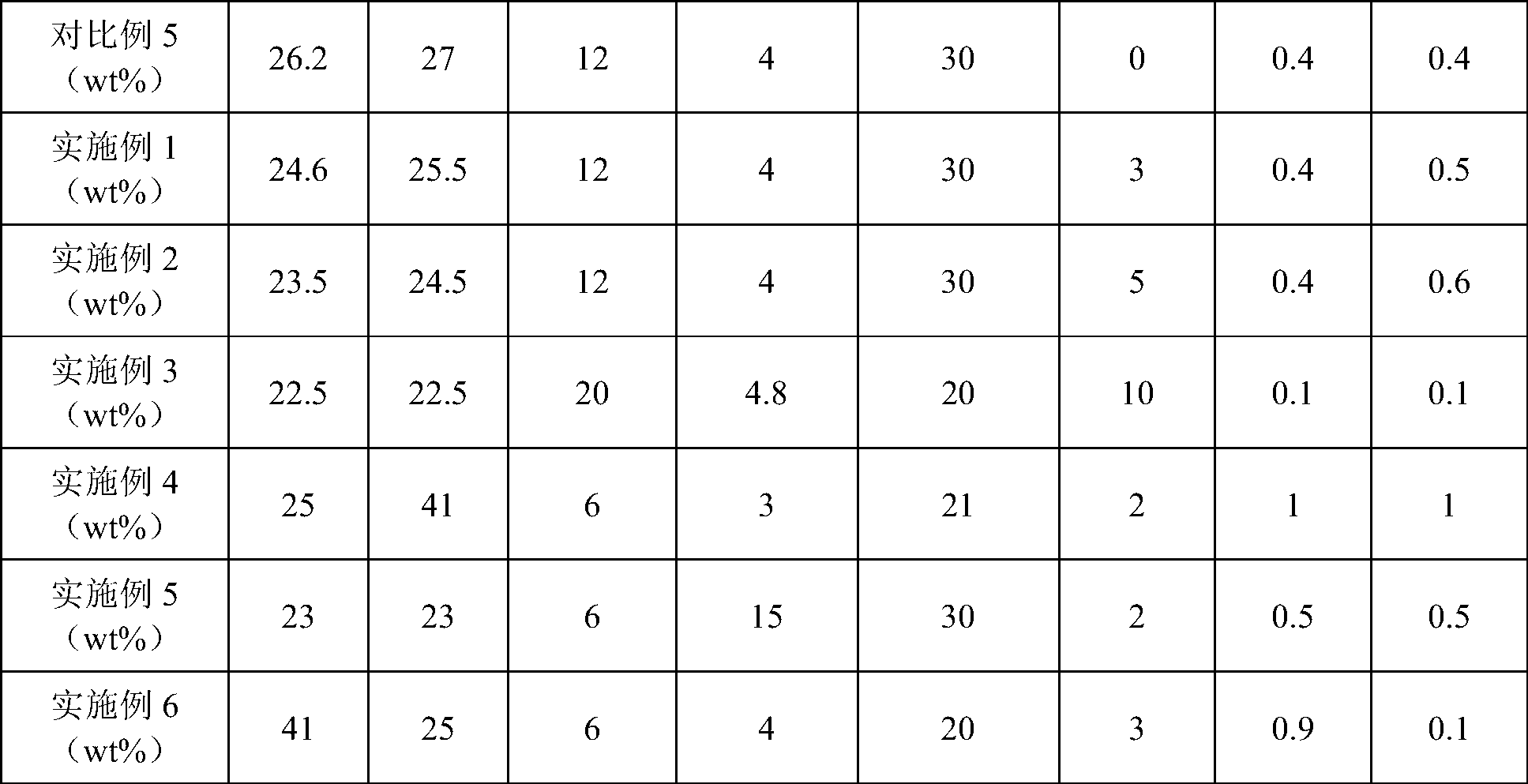

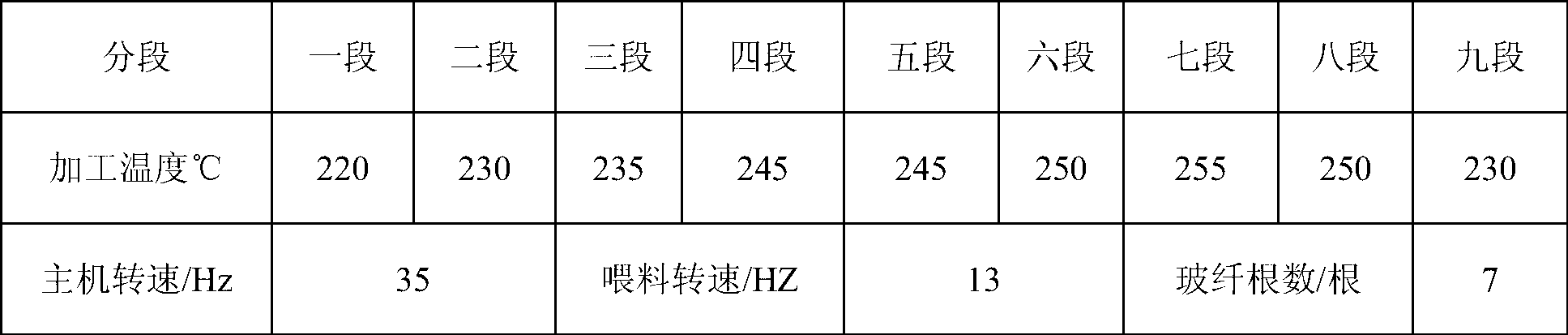

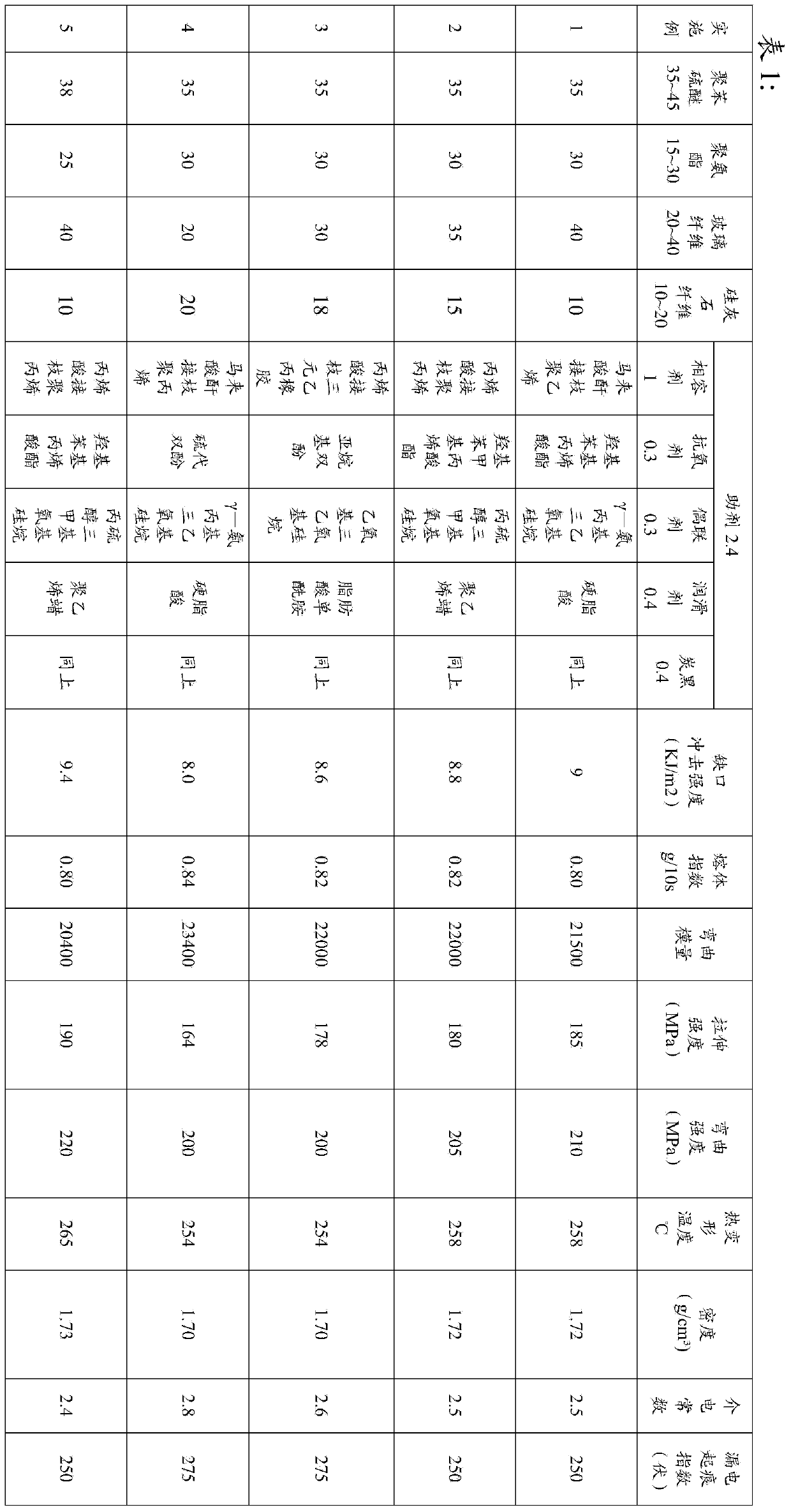

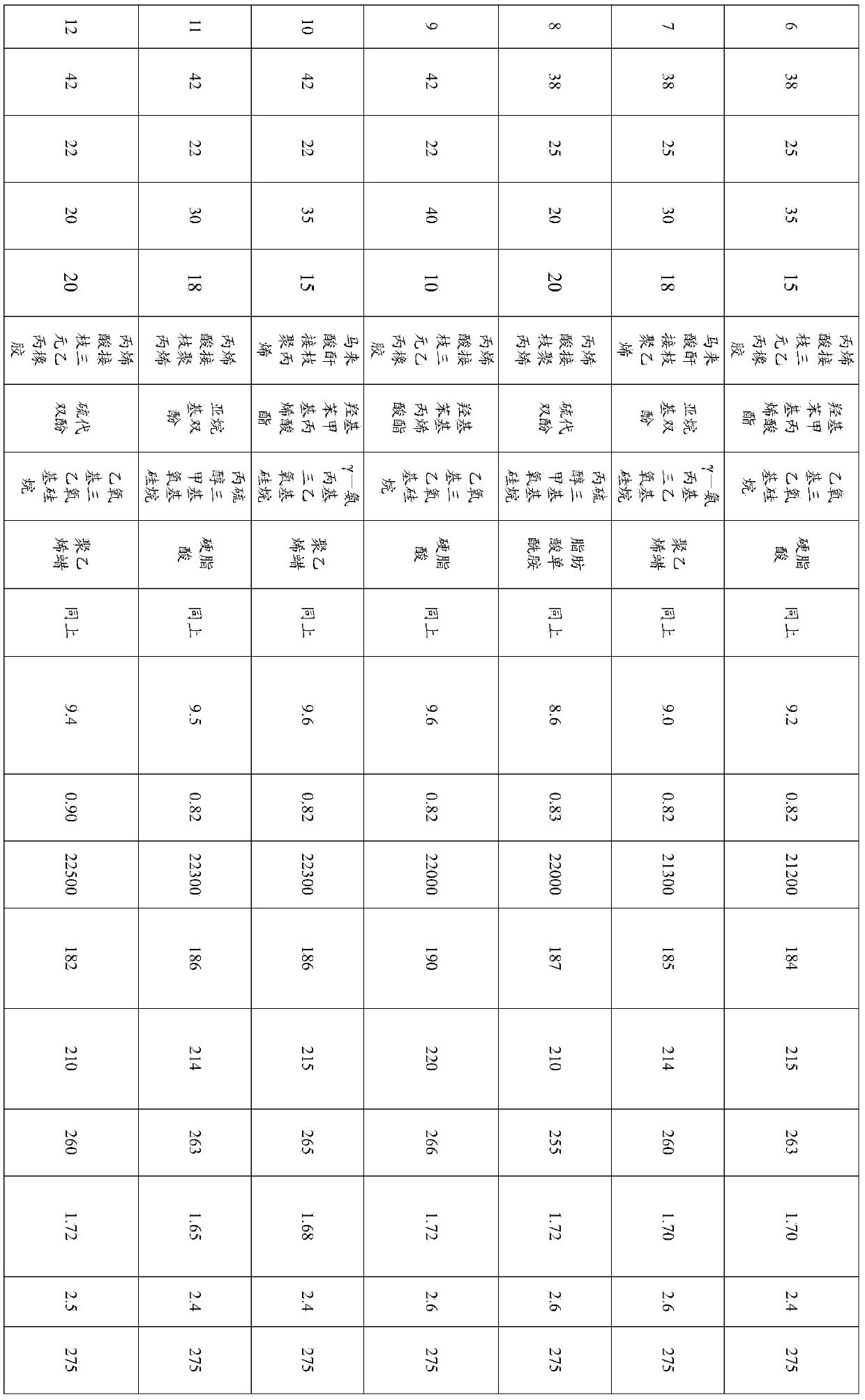

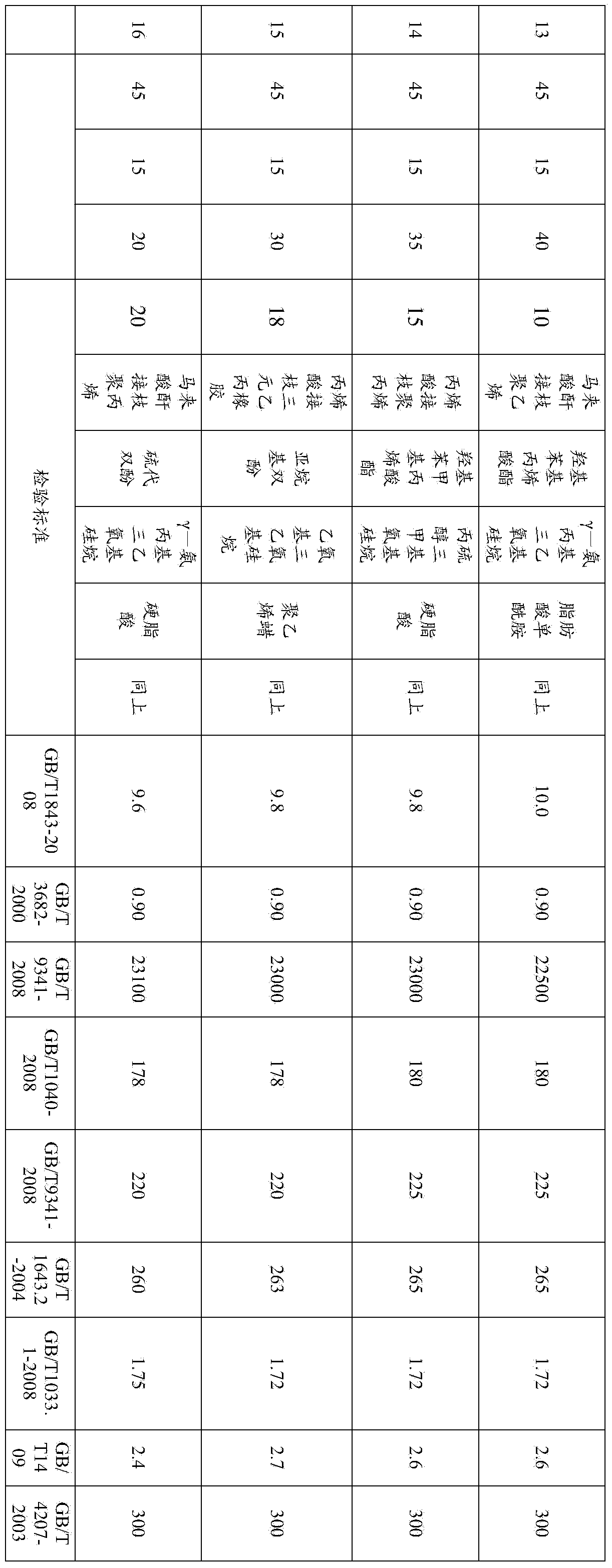

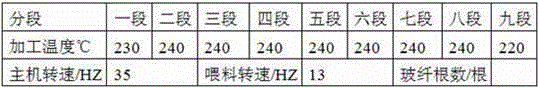

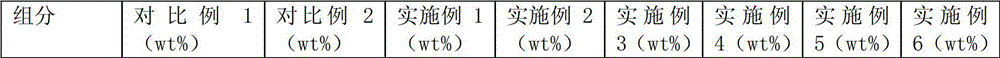

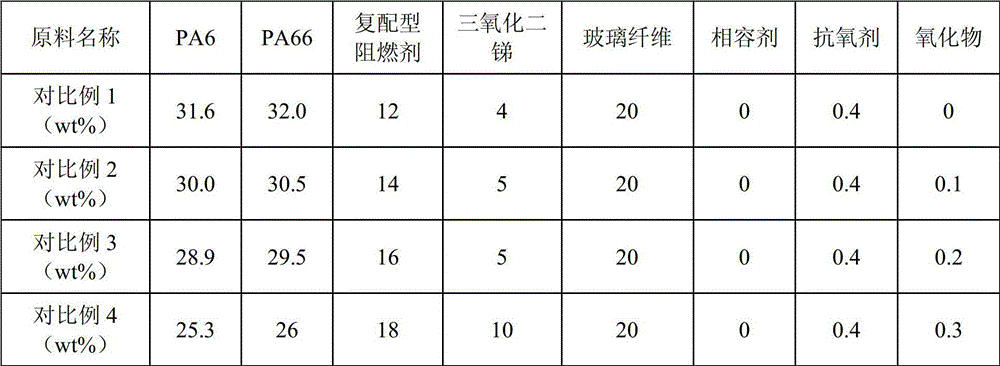

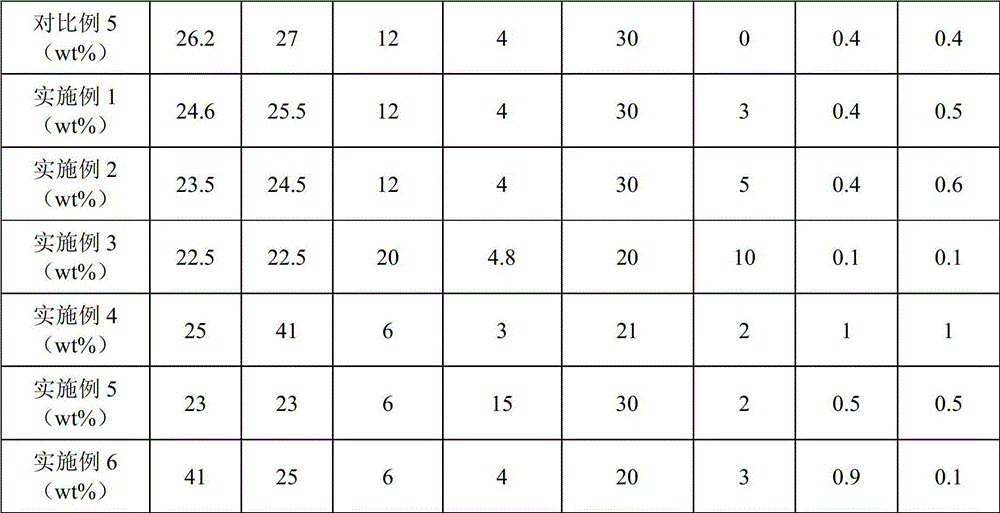

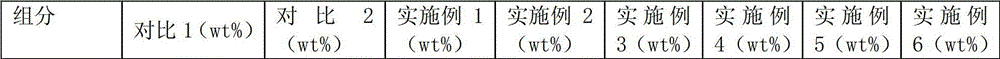

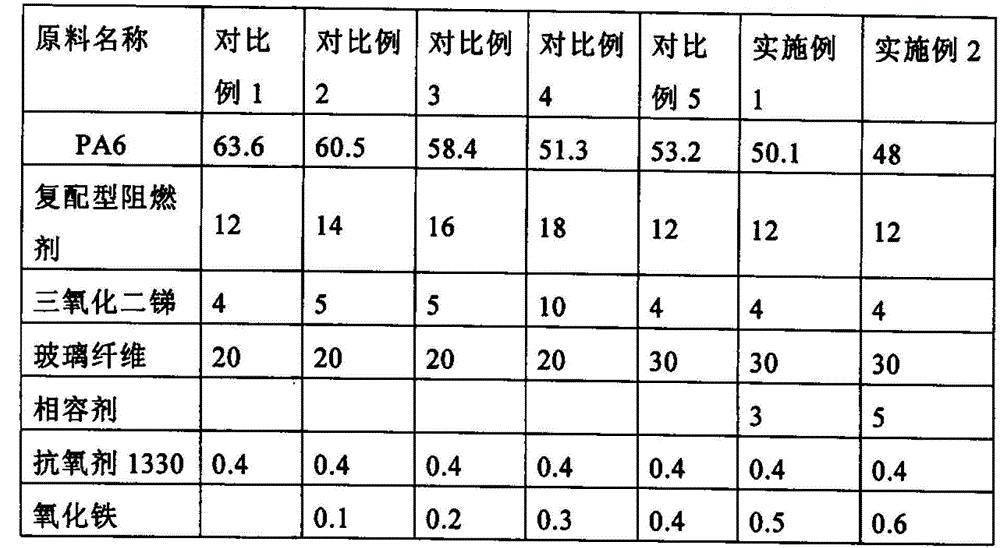

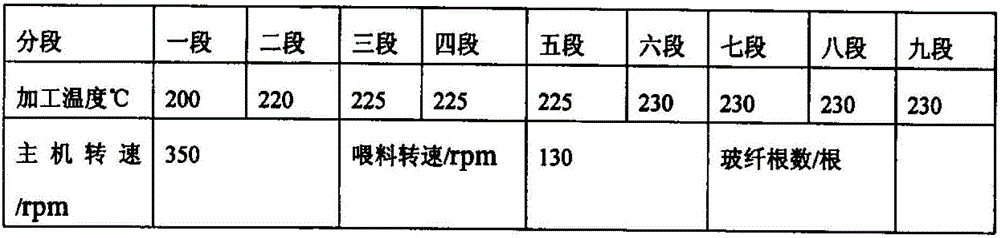

Flame-retardant glass fiber-reinforced PA6/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced PA6 / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 22.5 to 41% of PA6, 22.5 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 255 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high glow wire temperature, a high tracking index, environment-friendliness and balanced comprehensive properties and can be extensively used for low-voltage electronic capacitor shells, load break switches, carbon brush supports and molded case circuit breakers.

Owner:SHANGHAI SUNNY

Polyurethane co-mixed modified polyphenylene sulfide composite material and preparation method thereof

The invention discloses a polyurethane co-mixed modified polyphenylene sulfide composite material which comprises polyphenylene sulfide, polyurethane, glass fibers, wollastonite fibers and an assistant, wherein the assistant comprises a compatilizer, an antioxidant, a coupling agent, a lubricant and carbon black. The invention further discloses a method for preparing the polyurethane co-mixed modified polyphenylene sulfide composite material. The method comprises the following steps: (1) stirring and mixing the polyphenylene sulfide, the polyurethane, the glass fibers, the wollastonite fibers, the compatilizer, the antioxidant, the coupling agent, the lubricant and the carbon black to obtain a mixed material; (2) adding the mixed material into an extruder and extruding to obtain the strip-like composite material. The polyurethane co-mixed modified polyphenylene sulfide composite material disclosed by the invention not only has the characteristics of high strength, low creep, good mobility, easiness in processing and the like, but also has the characteristics of high toughness, low density, small dielectric constant, high comparative tracking index and the like.

Owner:GUANGZHOU GAOBAER PLASTIC

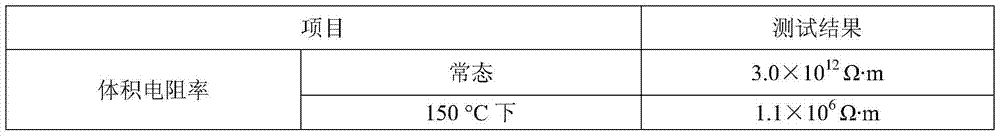

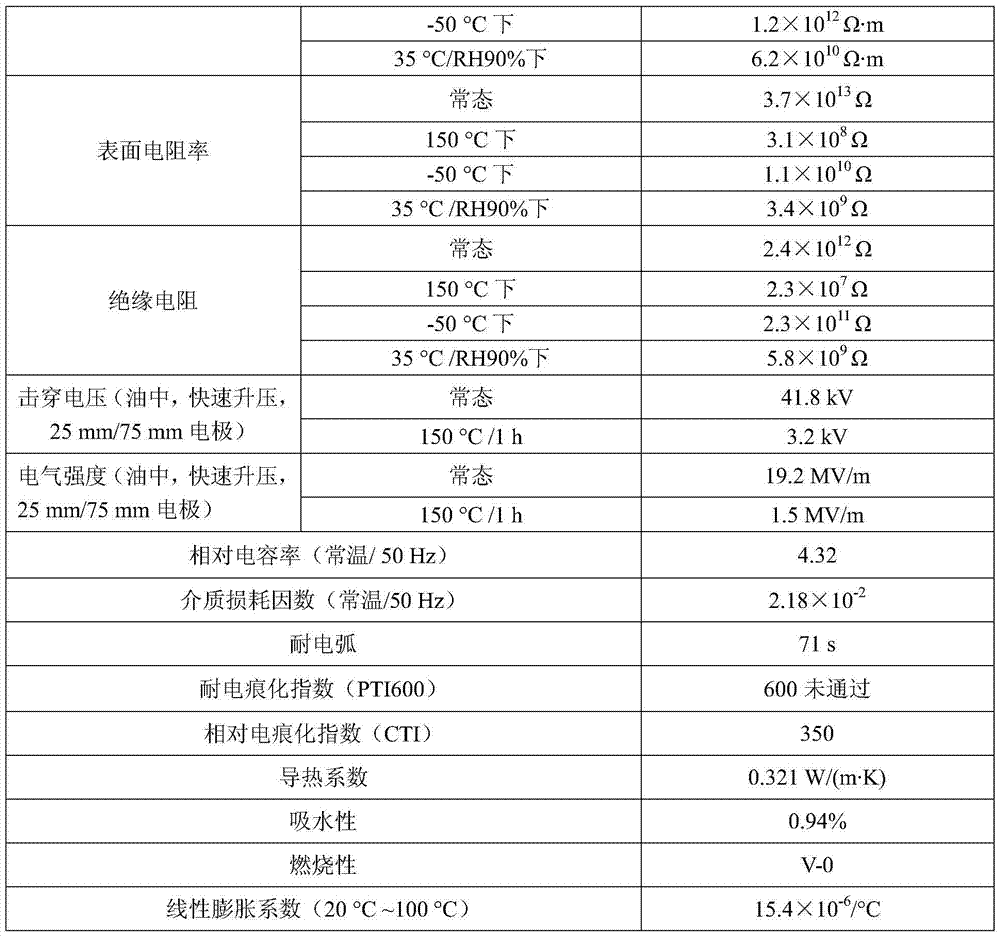

Thermosetting plastic and its preparation method and power lithium battery pack assembly casing prepared from thermosetting plastic

InactiveCN107083035AResistance to spark dischargeGood arc resistanceCell component detailsVehicle frameThermal deformation

The invention relates to thermosetting plastic and its preparation method and a power lithium battery pack assembly casing prepared from the thermosetting plastic. The thermosetting plastic comprises a base, fillers, a reinforcing material and aids. The base is prepared from thermosetting resins such as unsaturated polyester resin and vinyl ester resin. The fillers are inorganic non-metallic fillers such as wollastonite and barite. The preparation method comprises (1), dispersion, (2) stirring mixing, kneading and dipping, and (3) curing molding. The assembly casing comprises two or more single boxes connected with each other. The single box forms an integral structure through injection molding. The boxes are provided with connection holes or connection tabs connected to a vehicle frame. The main characteristics of the thermosetting plastic comprise that 1, a thermal deformation temperature is more than 250 DEG C higher than that of the reaction temperature of the lithium compound, 2, the thermosetting plastic is flame retardant, resists a high temperature and does not collapse after burning, 3, the spark discharge caused by battery short circuit is effective resisted, 4, insulation and thermal conductivity are obtained and a battery design is convenient, and 5, weight is light, electrombile weight reduction is promoted and noise is reduced.

Owner:MILIKUDO GLASS FIBER REINFORCED PLASTIC TAIZHOU

Flame-retardant glass fiber reinforced PA6 (polyamide 6)/PPO (P-Polyphenylene Oxide) alloy material and preparation method thereof

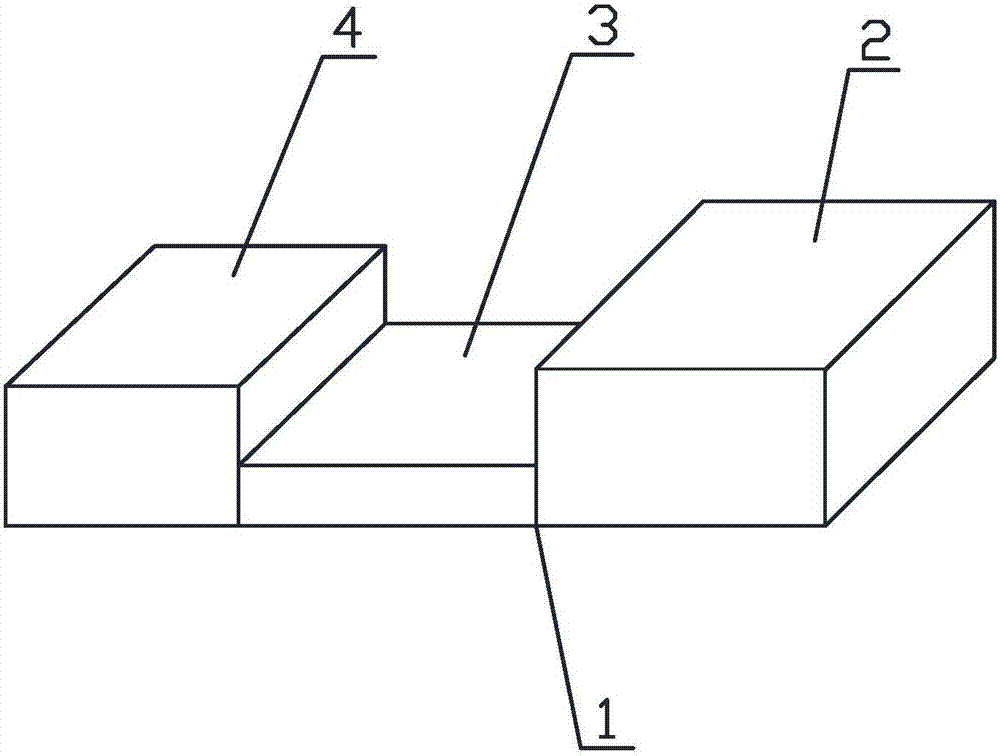

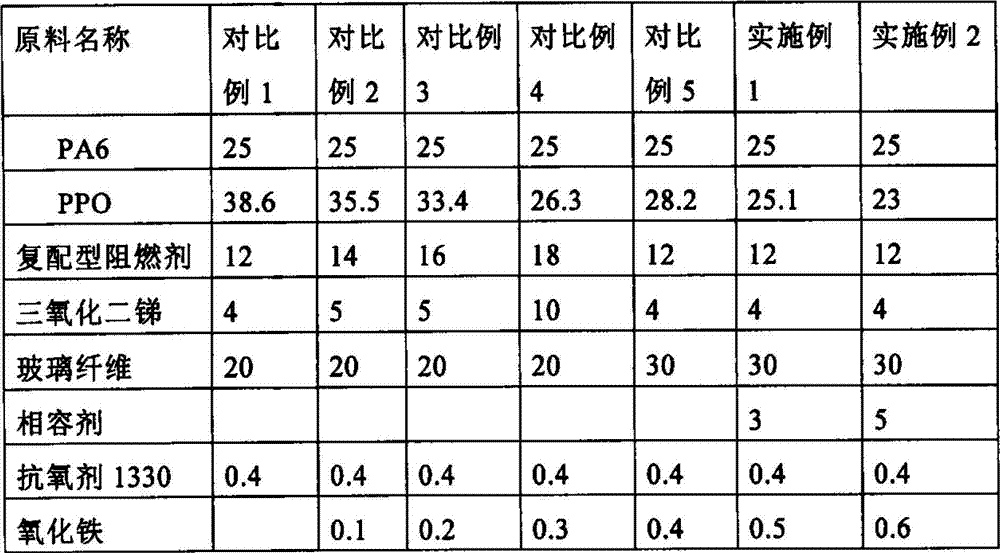

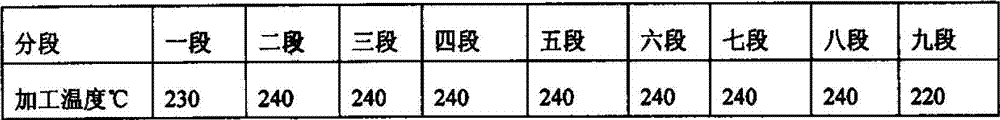

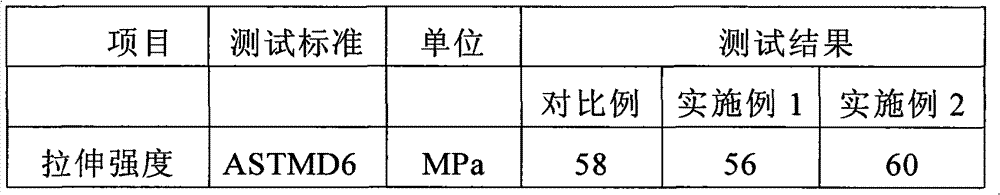

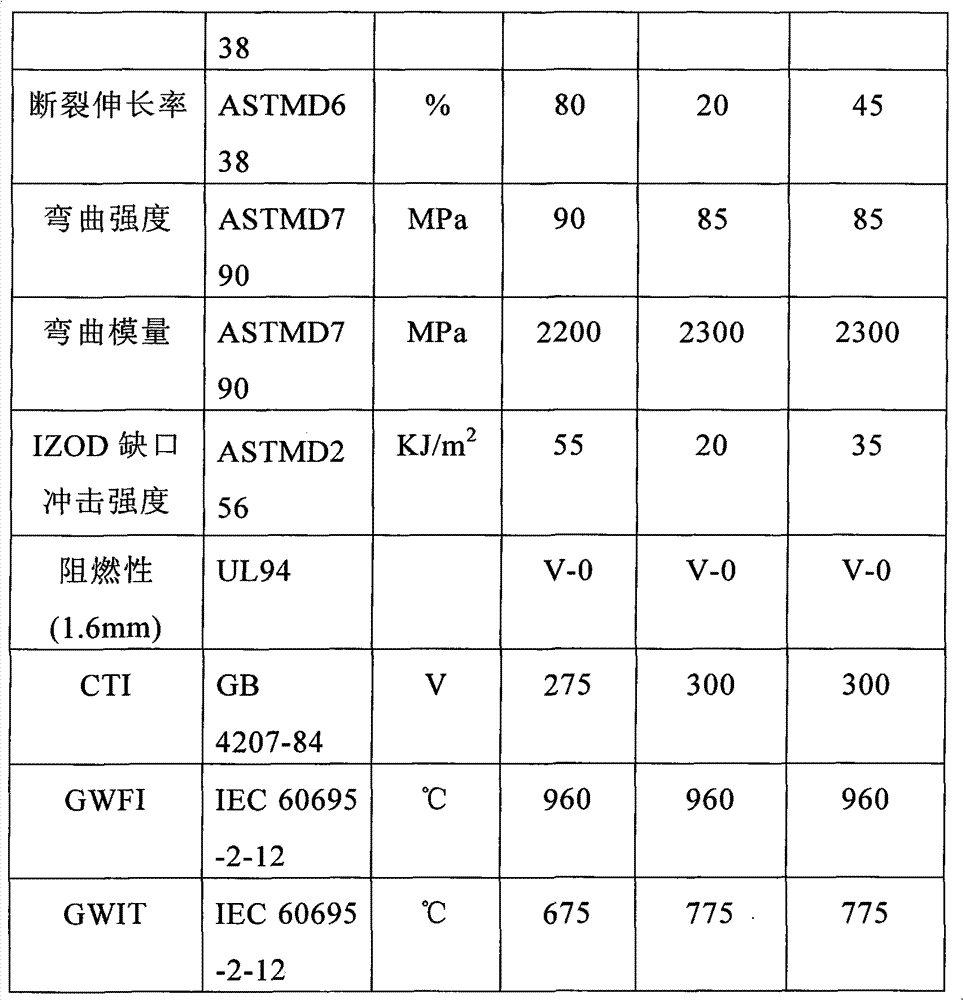

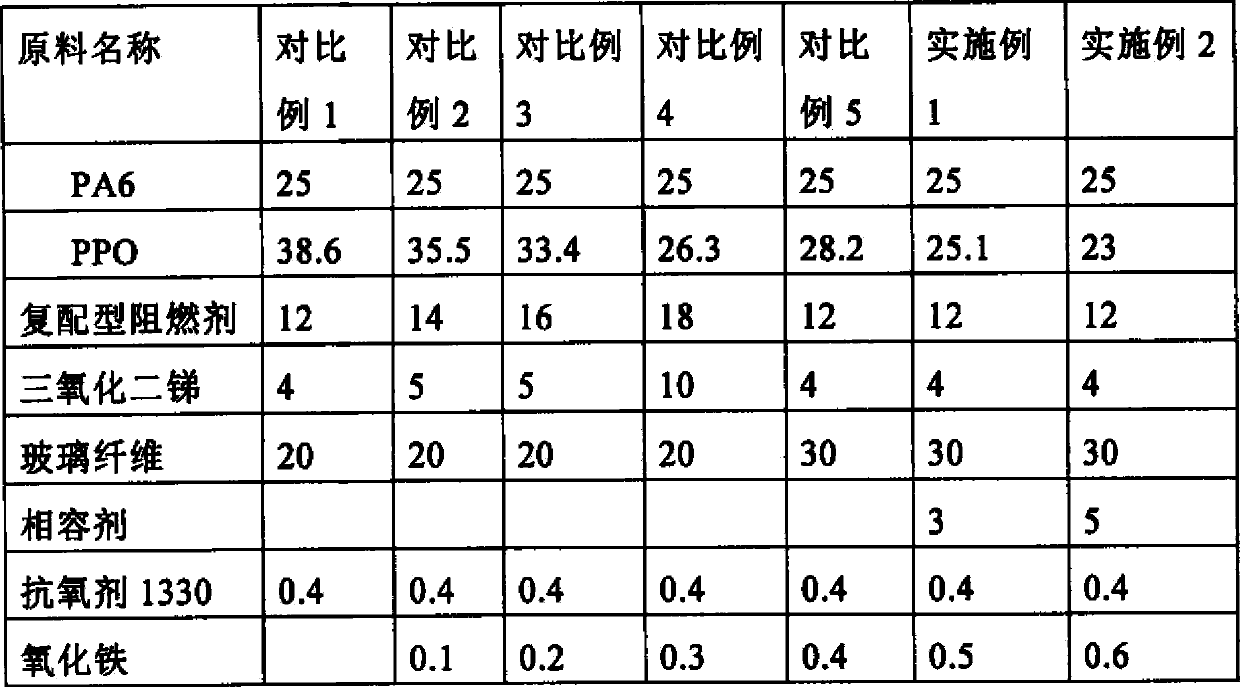

The invention relates to a flame-retardant glass fiber reinforced PA6 (polyamide 6) / PPO (P-Polyphenylene Oxide) alloy material and a preparation method thereof. The alloy material comprises the following components by weight percent: 23-41% of PA6, 22-41% of PPO, 6-20% of compound type flame retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxidizing material. The raw materials are put into a high mixing machine to be mixed for 2-5min and then are discharged, and then a doubles-screw extruder is used for extruding and pelletizing so as to obtain the flame-retardant glass fiber reinforced PA6 / PPO alloy material. Compared with the prior art, the flame-retardant glass fiber reinforced PA6 / PPO alloy material has the advantages that being high in temperature of a glowing filament, environment-friendly, balanced in comprehensive properties, high in CTI (Comparative Tracking lndex) and GWIT (Glow-Wire Flammability Index), and the like.

Owner:SHANGHAI SUNNY

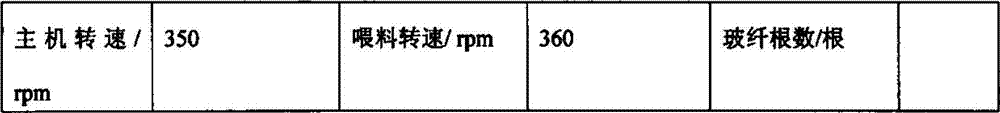

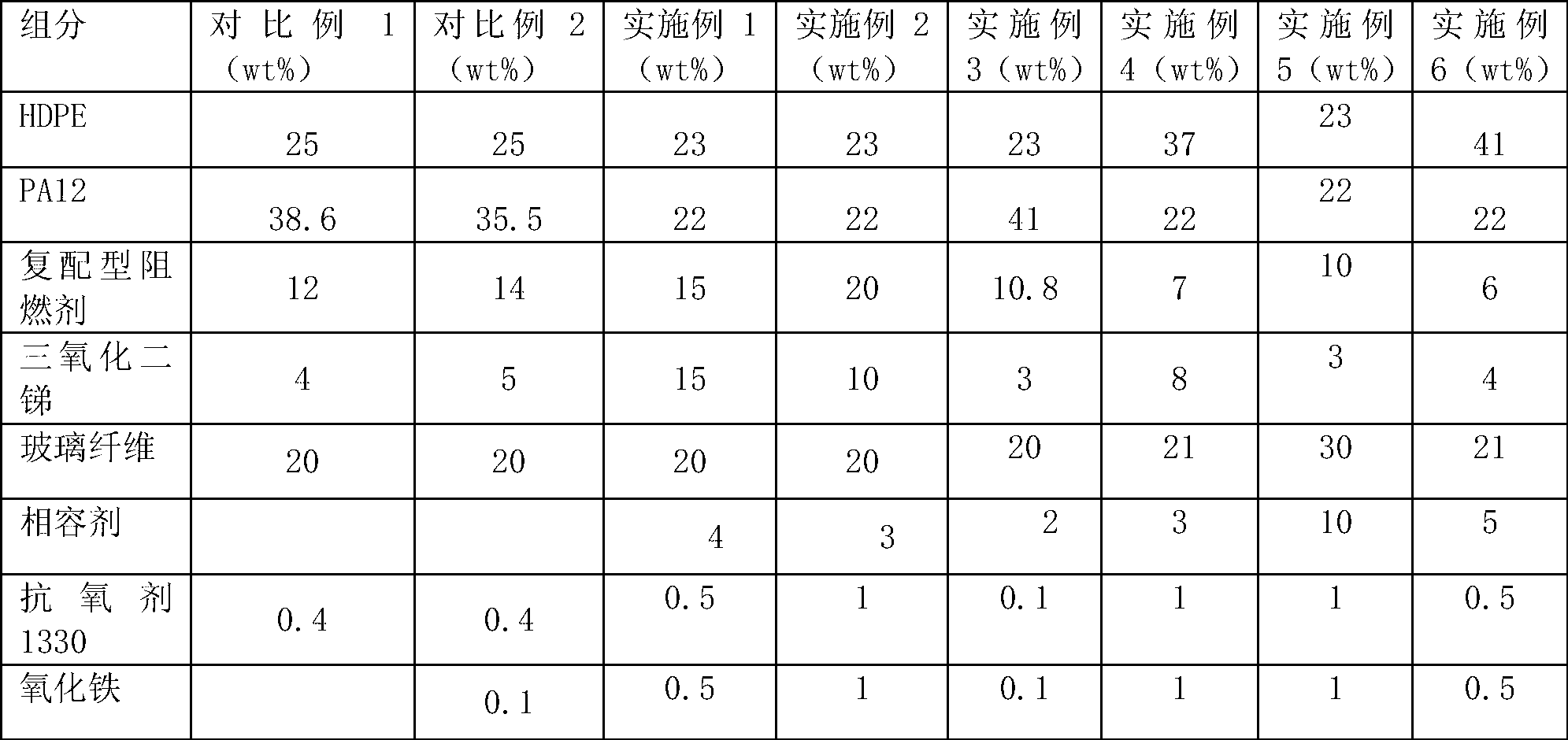

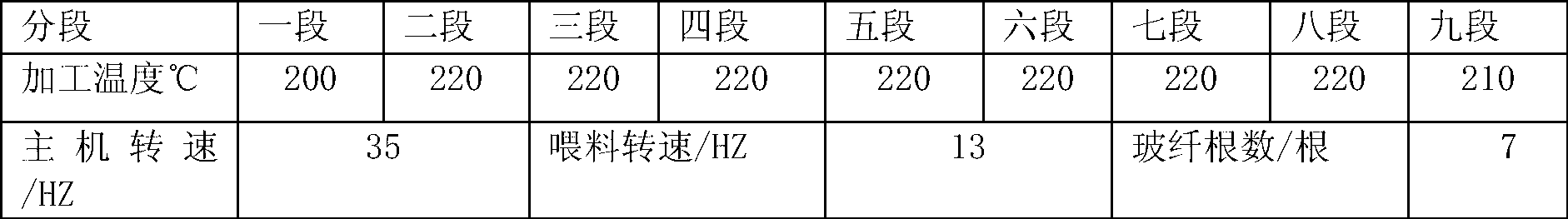

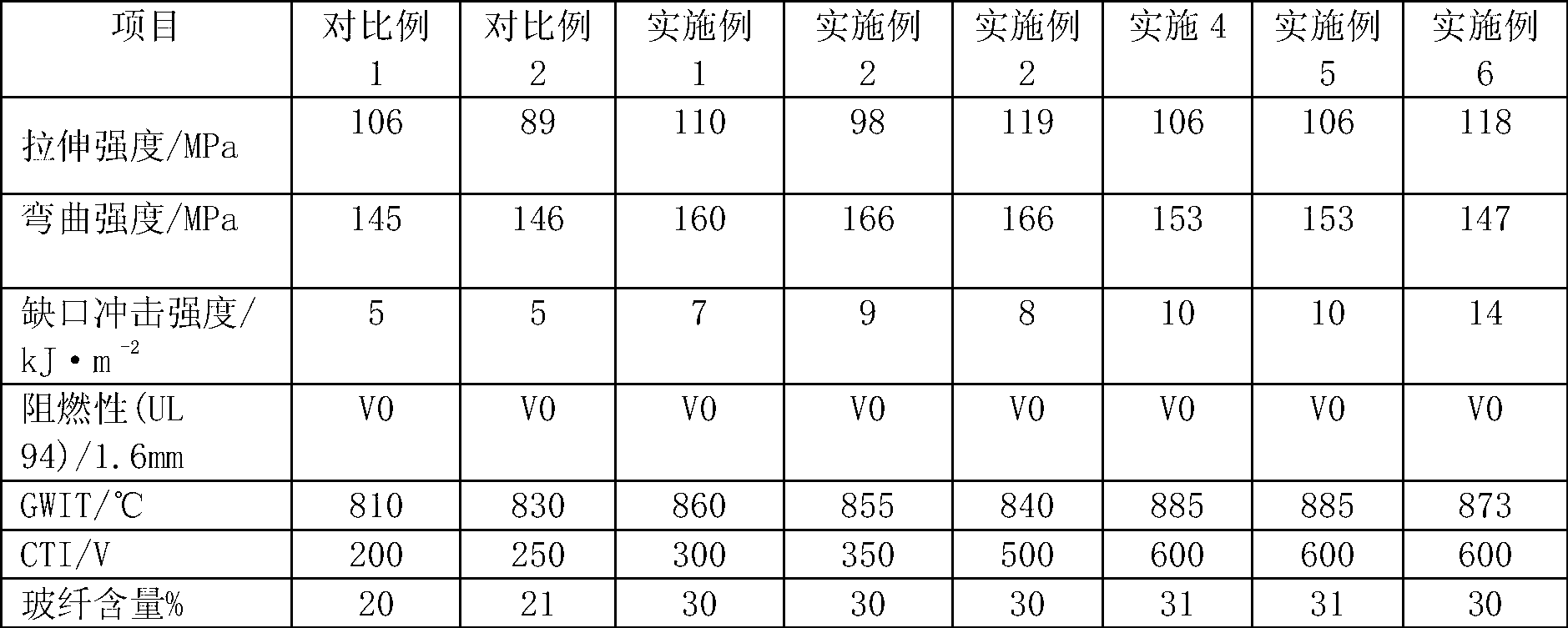

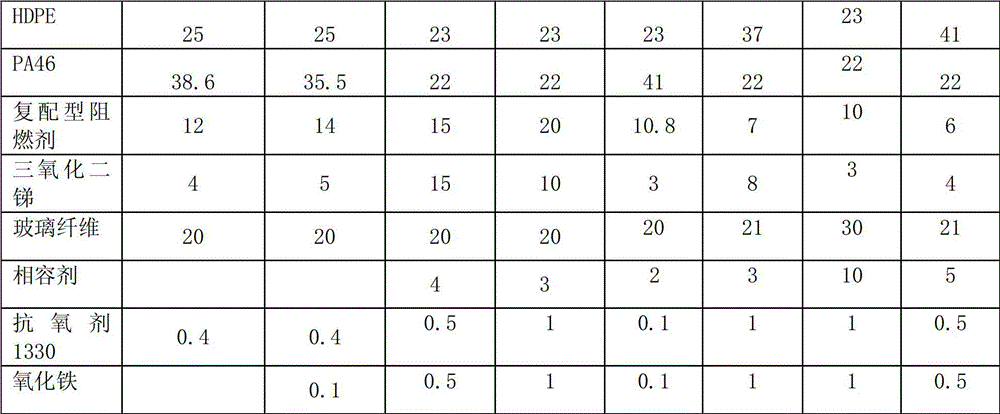

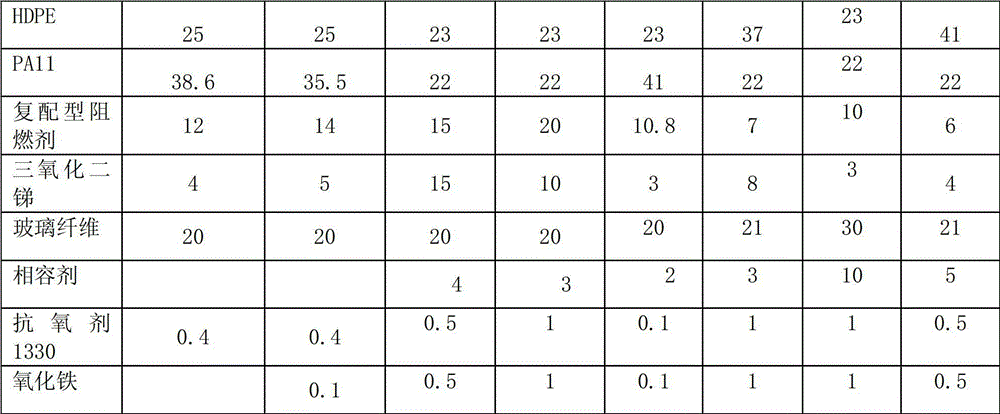

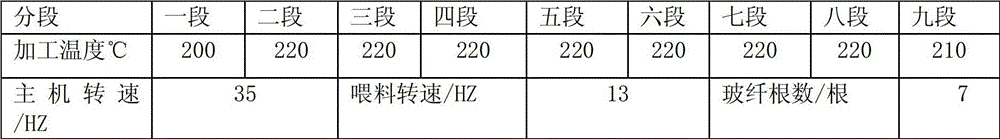

Flame-retardant glass fiber-reinforced HDPE/PA12 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA12 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA12, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 200 to 220 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

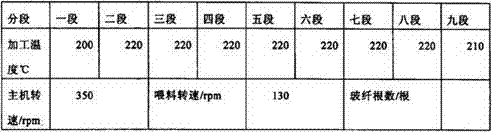

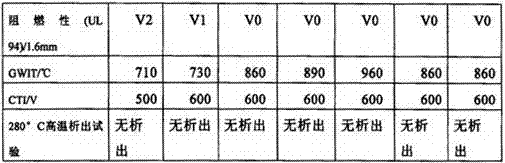

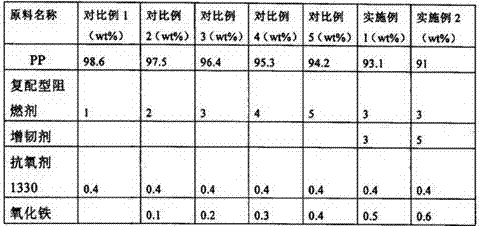

Environment-friendly flame-resistant PP material and preparation method thereof

InactiveCN107446229AAvoid decompositionImprove impact performanceAntioxidantComparative Tracking Index

The invention relates to an environment-friendly flame-resistant PP material and a preparation method thereof. The material is prepared from the following components in parts by weight: 90 to 96 parts of PP, 1 to 5 parts of a compounded flame retardant, 2 to 10 parts of a flexibilizer, 0.1 to 1 part of an antioxidant, and 0.1 to 1 part of an oxide. The preparation method comprises the following steps: mixing the raw materials into a high temperature mixer for 2 to 5 minutes, discharging, then using a double screw extruder for extrusion pelletization, and ensuring that the processing temperature is 200 to 220 DEG C and the revolution of a screw is 300 to 400 rpm, so as to obtain the environment-friendly flame-resistant PP material. Compared with the prior art, the environment-friendly flame-resistant PP material has the advantages that the glowing filament temperature (GWIT) is high, the comparative tracking index (CPI) is high, and the material is environmentally friendly and balanced in comprehensive performance, and can be widely applied to fields of wall switches, sockets, pipes, molded case circuit breakers, motor components, plates and the like.

Owner:RONGCHENG PIPE IND

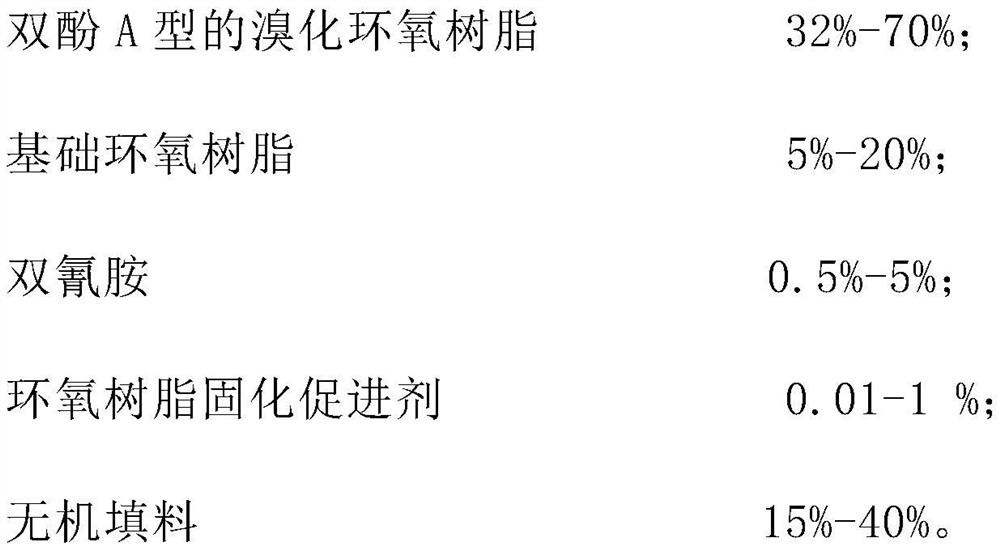

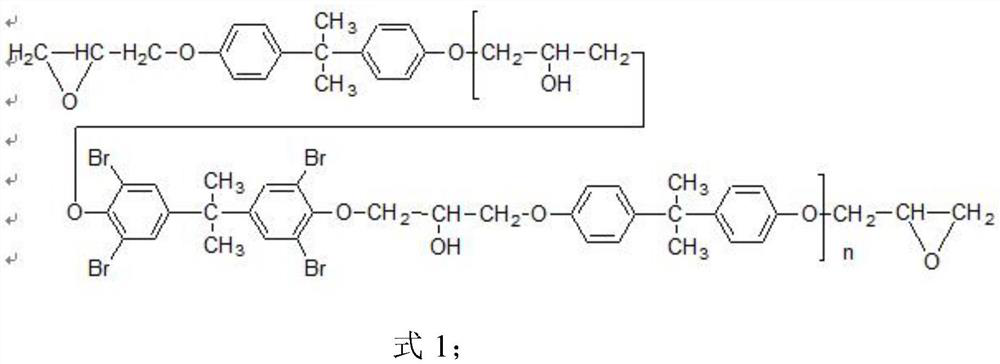

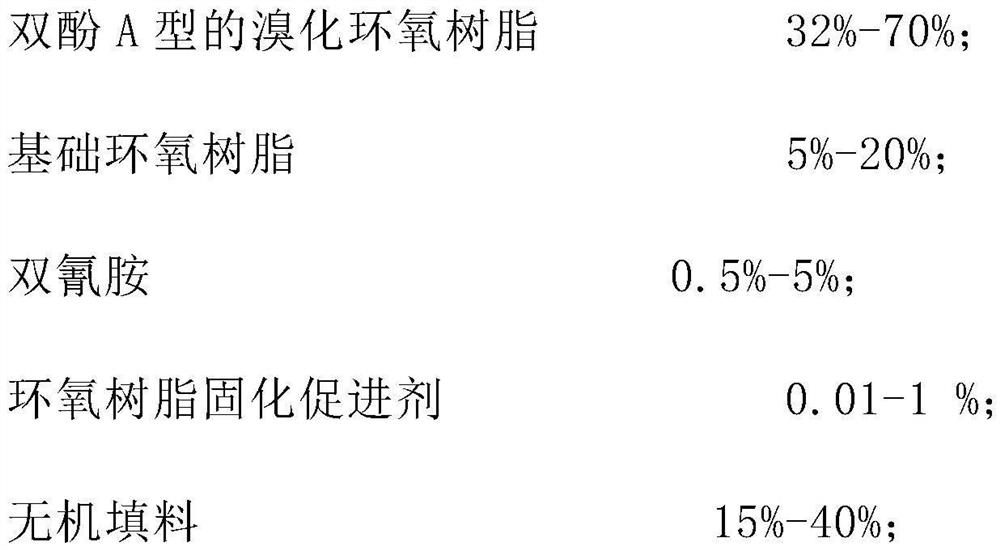

Epoxy resin adhesive with high comparative tracking index and preparation method thereof

PendingCN112625632AHigh tracking indexGood toughness strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceComparative Tracking Index

The invention discloses an epoxy resin adhesive with high comparative tracking index, which is characterized in that the percentages of the solid weights of the components (without a solvent) with respect to the total solid weight of the composition are as follows: 32%-70% of bisphenol A brominated epoxy resin; 5%-20% of basic epoxy resin; 0.5%-5% of dicyandiamide; 0.01-1% of an epoxy resin curing accelerator; and 15%-40% of inorganic filler. The invention also discloses a preparation method of the epoxy resin adhesive. A copper-clad plate prepared from the resin adhesive provided by the invention has a high tracking index (CTI is greater than or equal to 600V), and also has good toughness and peel strength and good flame retardancy.

Owner:江西省宏瑞兴科技股份有限公司

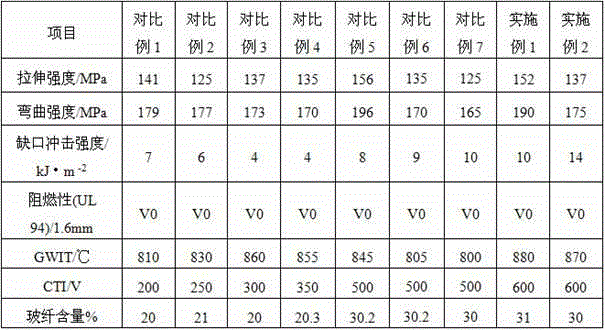

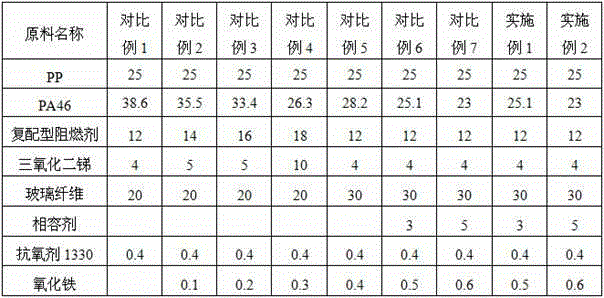

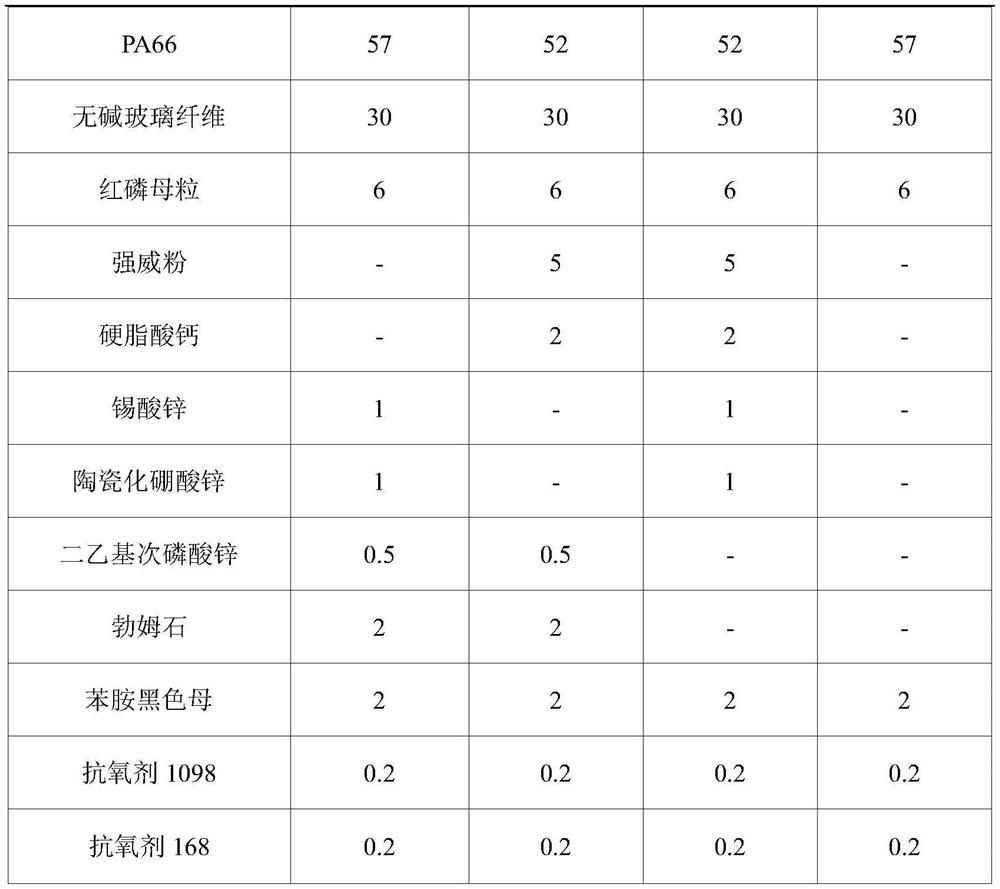

A kind of high cti value, high gwit value environmental protection flame retardant glass fiber reinforced pp/pa46 alloy material and preparation method thereof

Owner:SHANGHAI SUNNY

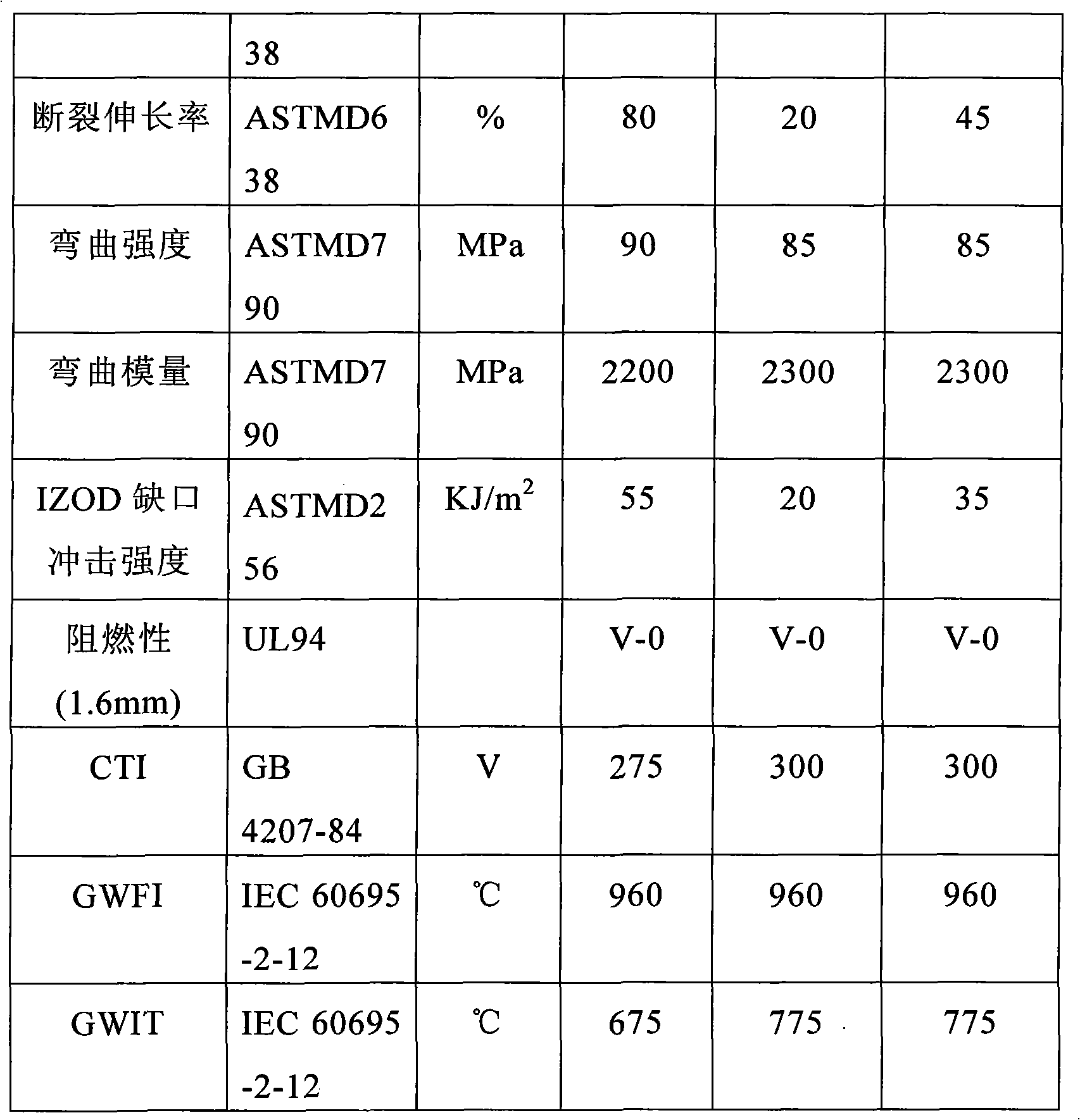

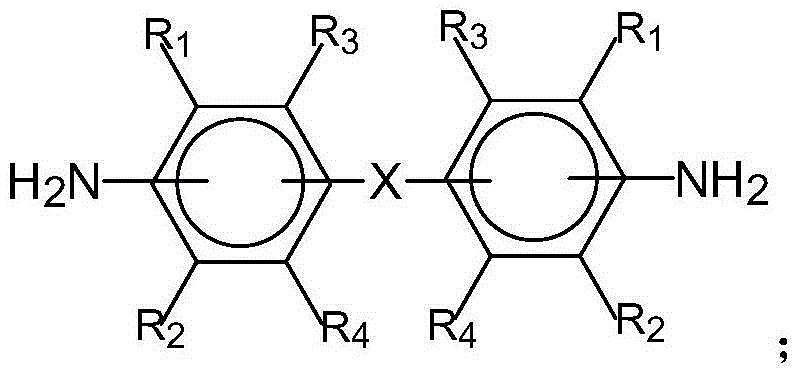

Curing agent and copper-clad plate

PendingCN112961297ARaw materials are easy to getLow costPrinted circuit detailsPolymer sciencePtru catalyst

The invention belongs to the field of new materials, and discloses a curing agent. The curing agent is obtained by reacting a hydrocarbon-based phenol intermediate and formaldehyde in the presence of a first catalyst, wherein the hydrocarbon-based phenol intermediate is obtained by reacting phenol and double-bond-containing olefin in the presence of a second catalyst, and the molar ratio of phenol to double-bond-containing olefin is (1.1-1.5): 1. The curing agent is low in cost. The invention further discloses a copper-clad plate.

Owner:建滔覆铜板(深圳)有限公司

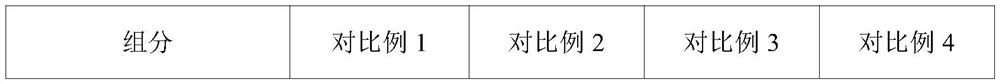

A kind of red phosphorus flame-retardant nylon composite material and its preparation method and the determination method of phosphorus precipitation amount in it

ActiveCN109929244BUniform performanceHigh flame retardant efficiencyAnalysis by thermal excitationMasterbatchFire retardant

The invention discloses a red phosphorus flame-retardant nylon composite material, which comprises the following components by weight: nylon resin: 40-80 parts; reinforcing component: 10-50 parts; red phosphorus flame retardant: 4-12 parts; Red phosphorus stabilizer: 0.5-8 parts; smoke suppressant: 0.5-5 parts; tracking index enhancer: 2-10 parts; masterbatch: 0.5-5 parts; antioxidant: 0.1-0.5 parts. The present invention also correspondingly provides a preparation method of the above-mentioned red phosphorus flame-retardant nylon composite material and a method for measuring phosphorus precipitation in the red phosphorus flame-retardant nylon composite material. The composition of the red phosphorus flame-retardant nylon composite material of the present invention is optimized, and each component interacts synergistically, and the performance of the obtained red phosphorus flame-retardant nylon composite material is more balanced. In addition to high flame-retardant efficiency, excellent mechanical At the same time, it also has the advantages of low smoke density, excellent anti-separation performance and high tracking index.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Flame-retardant glass fiber-reinforced HDPE/PA46 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA46 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA46, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

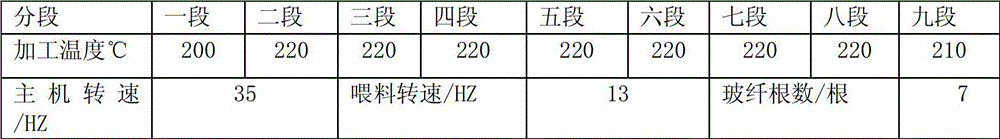

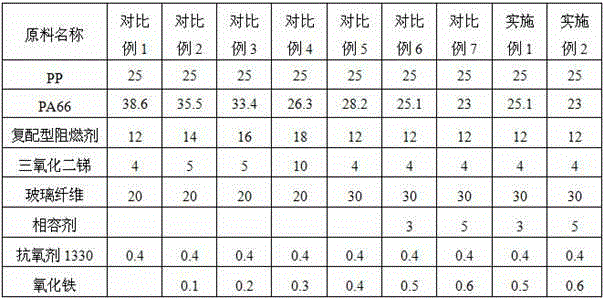

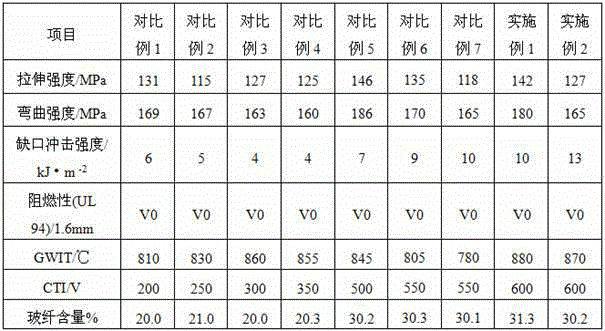

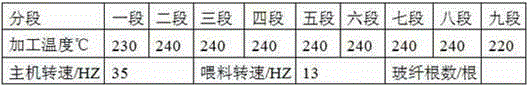

Environment-friendly flame retardant glass fiber reinforced polypropylene/ polyamide66 (PP/ PA66) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

The invention discloses an environment-friendly flame retardant glass fiber reinforced polypropylene / polyamide66 (PP / PA66) alloy material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 23-41% of PP, 22-41% of PA66, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PP / PA66 alloy material with high CTI value and high GWIT value. The environment-friendly flame retardant glass fiber reinforced PP / PA66 alloy material with high CTI value and high GWIT value has the advantages of being higher in GWIT and CTI, environment-friendly and balanced in combination properties, thus being widely applied to a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket and a moulded case circuit breaker.

Owner:SHANGHAI SUNNY

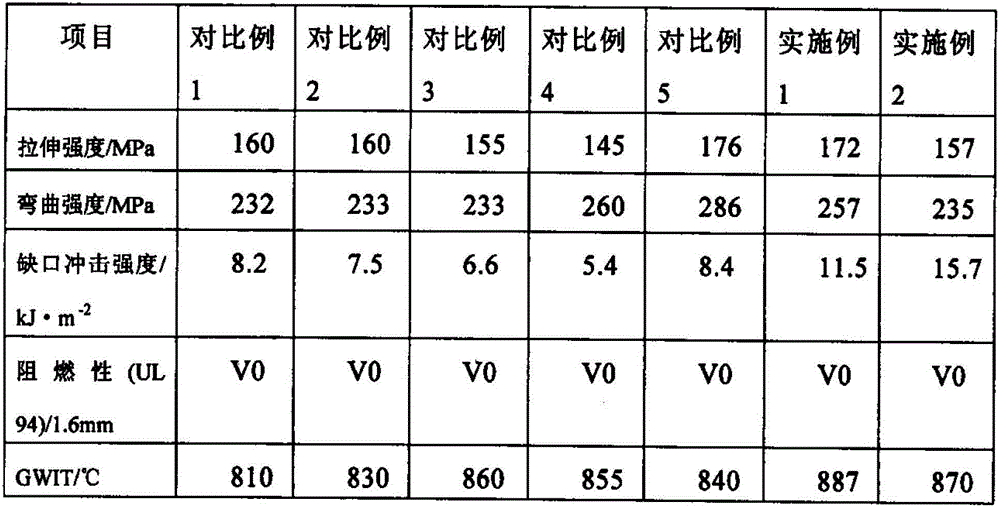

Halogen-free flame-retardant polycarbonate/styrene base resin composition and preparation method thereof

ActiveCN102108199BHigh tracking indexRaise the ignition temperaturePolymer scienceComparative Tracking Index

The invention relates to a halogen-free flame-retardant polycarbonate / styrene base resin composition and a preparation method thereof, and the composition comprises the following components in parts by weight: 650-900 parts of polycarbonate, 0.1-250 parts of styrene base resin, 20-100 parts of toughening compatibilizer, 10-100 parts of metal inorganic compound, 5-50 parts of organic silicon, 70-150 parts of complex flame retardant, 1-10 parts of antioxidant A, 1-15 parts of antioxidant B and 0-20 parts of other auxiliary materials. The preparation method comprises the following steps: mixing raw materials in a high-speed mixing machine, then introducing into a twin-screw extruder, adding the complex flame retardant in the lateral line feeding way, performing extrusion and granulation and finally getting the product. Compared with the prior art, the halogen-free flame-retardant polycarbonate / styrene base resin composition has the advantages of high comparative tracking index (CTI), high glow-wire ignition temperature (GWIT), halogen-free flame retardance, environment friendliness and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Flame-retardant glass fiber reinforced PA6 (polyamide 6)/PPO (P-Polyphenylene Oxide) alloy material and preparation method thereof

The invention relates to a flame-retardant glass fiber reinforced PA6 (polyamide 6) / PPO (P-Polyphenylene Oxide) alloy material and a preparation method thereof. The alloy material comprises the following components by weight percent: 23-41% of PA6, 22-41% of PPO, 6-20% of compound type flame retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxidizing material. The raw materials are put into a high mixing machine to be mixed for 2-5min and then are discharged, and then a doubles-screw extruder is used for extruding and pelletizing so as to obtain the flame-retardant glass fiber reinforced PA6 / PPO alloy material. Compared with the prior art, the flame-retardant glass fiber reinforced PA6 / PPO alloy material has the advantages that being high in temperature of a glowing filament, environment-friendly, balanced in comprehensive properties, high in CTI (Comparative Tracking lndex) and GWIT (Glow-Wire Flammability Index), and the like.

Owner:SHANGHAI SUNNY

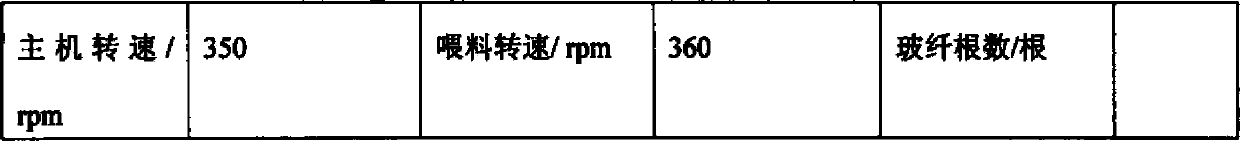

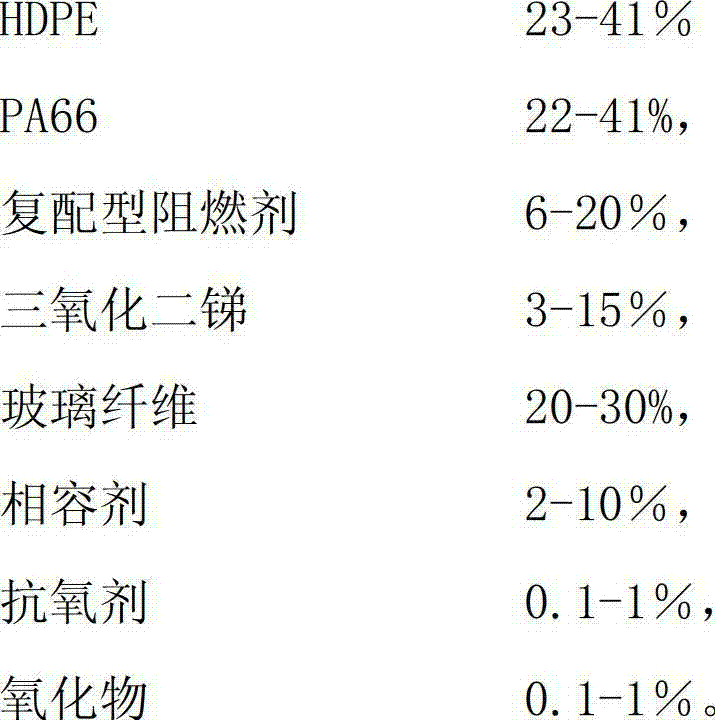

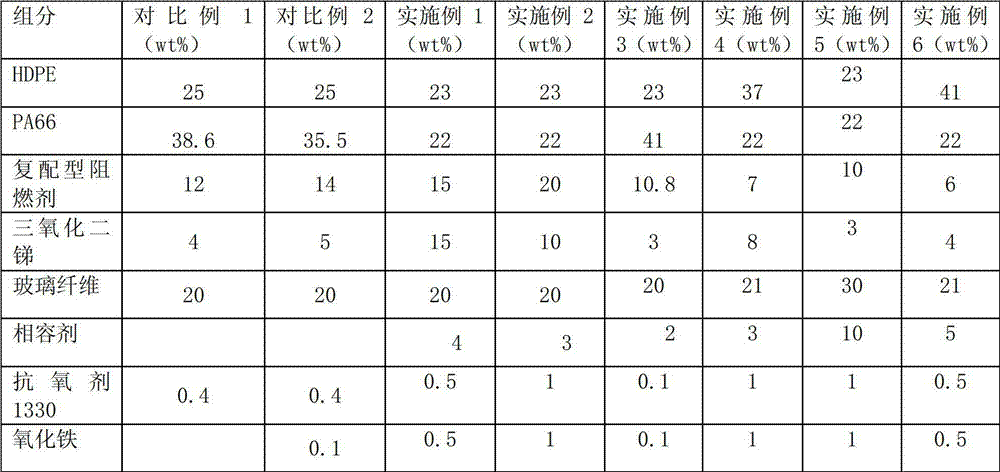

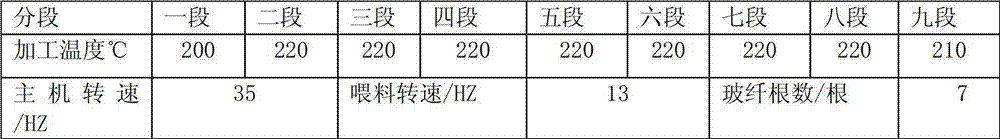

Flame-retardant glass fiber-reinforced HDPE/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

Copper-clad plate and preparation method thereof

PendingCN111849124AHigh glass transition temperatureGood high CTI valueSynthetic resin layered productsLaminationEpoxyVitrification

The invention discloses the raw material composition of a copper-clad plate and a preparation method of the copper-clad plate. The copper-clad plate is prepared from the following raw materials in parts by weight: 350-450 parts of brominated epoxy resin, 7-10 parts of dicyandiamide, 0.1-0.25 part of a curing accelerator, 70-90 parts of a solvent, 35-60 parts of an inorganic filler and 0.5-1 part of silane. The copper-clad plate prepared by the method has high glass-transition temperature and good machining performance, so the copper-clad plate has good reliability in the application aspect ofa circuit board; and the copper-clad plate has high tracking index, and can well meet the requirement of a PCB on the machining performance of the copper-clad plate.

Owner:重庆德凯实业股份有限公司

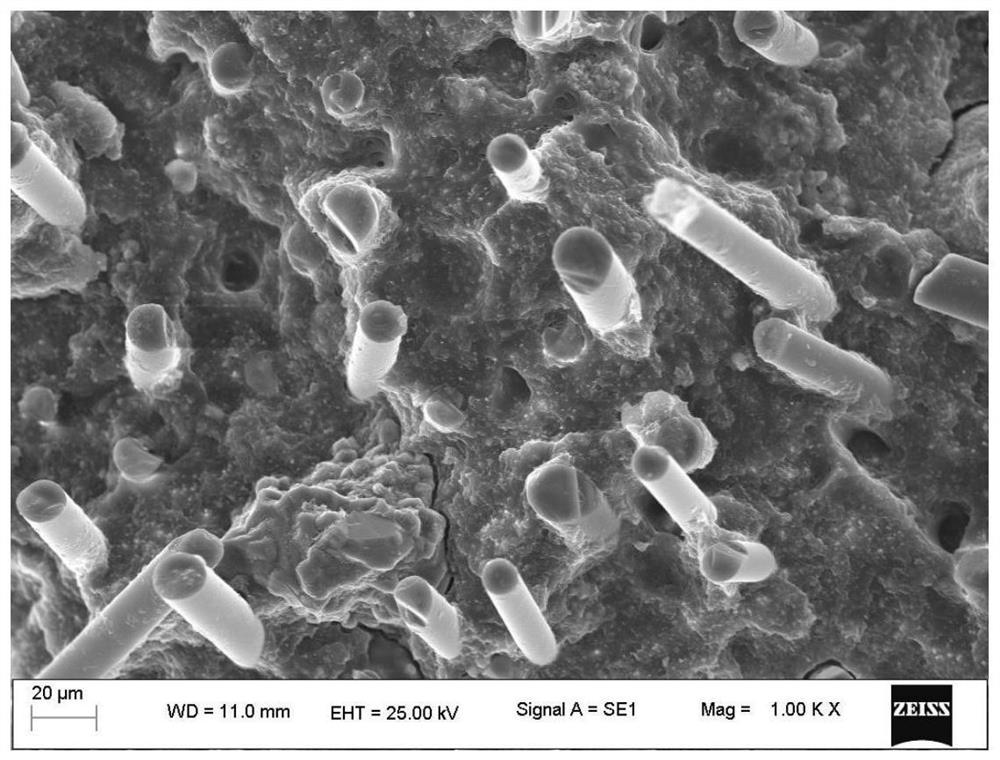

Preparation and Application of Flame Retardant Recyclable Insulation Modified Materials, Insulation Parts

ActiveCN104861644BImprove mechanical propertiesOvercome the disadvantage of being flammablePlastic/resin/waxes insulatorsPolyester coatingsGlass fiberElectricity

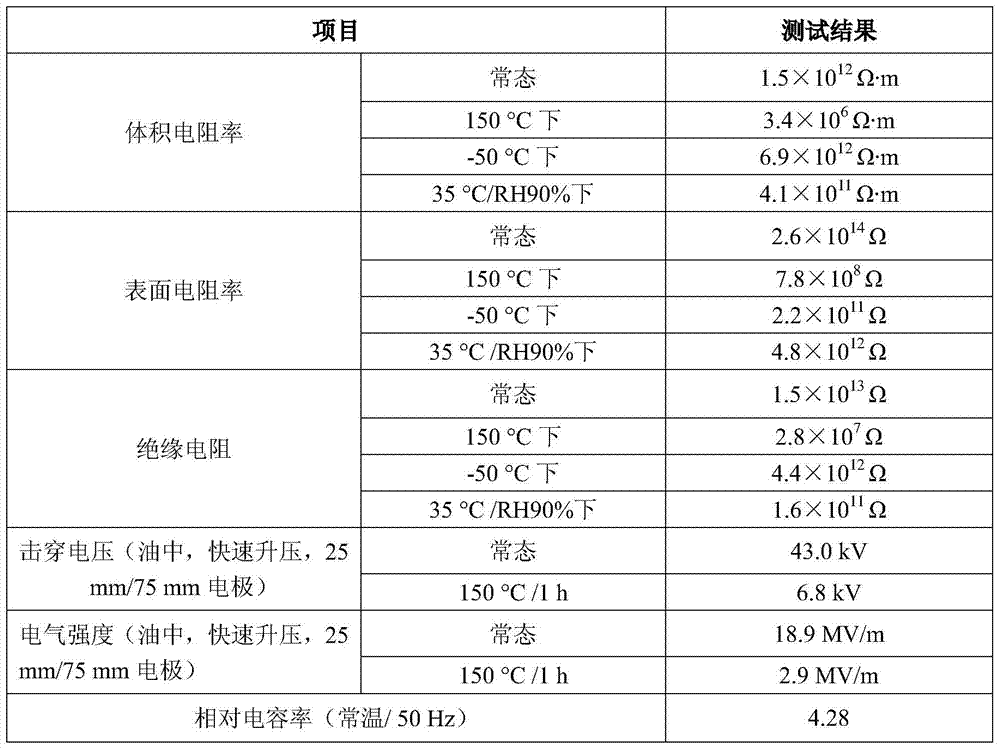

The invention relates to the technical field of the production of insulating parts applied to various cabinets under an indoor medium voltage (10-20KV), particularly to a recoverable flame-retardant insulating modified material which is superior in electrical properties, such as creepage trace, and is high in mechanical strength, and preparation and application of insulating parts. A polymer with favorable thermoplasticity and favorable electrical properties, namely polyamide (nylon 6 or nylon 66), is adopted as matrix resins, and glass fibers, a fire retardant and an auxiliary agent are added in the polyamide; a melt blending modification method is adopted, so that the organic compound insulating modified material is formed; an insulating part can be formed through injection molding; after the surface of the insulating part is coated with an appropriate coating and is processed by a solidification technology, a part with a better electrical insulation property can be prepared, so that the used safety of insulating parts is improved; in addition, the insulating parts produced from the novel insulating modified material disclosed by the invention are flame-retardant, recoverable, light in weight, and high in production efficiency.

Owner:JIANGSU NARI TURBOSTAR ELECTRIC +1

Flame-retardant glass fiber-reinforced PA6/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced PA6 / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 22.5 to 41% of PA6, 22.5 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 255 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high glow wire temperature, a high tracking index, environment-friendliness and balanced comprehensive properties and can be extensively used for low-voltage electronic capacitor shells, load break switches, carbon brush supports and molded case circuit breakers.

Owner:SHANGHAI SUNNY

Flame-retardant glass fiber-reinforced HDPE/PA11 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA11 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA11, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 200 to 220 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

Environment-friendly flame-retardant glass fiber reinforced PA6 (Polyamide 6) material and preparation method thereof

InactiveCN102952397BAvoid decompositionImprove impact performanceComparative Tracking IndexAntioxidant

The invention relates to an environment-friendly flame-retardant glass fiber reinforced PA6 (Polyamide 6) material and a preparation method thereof. The environment-friendly flame-retardant glass fiber reinforced PA6 material is prepared from the following components in parts by weight: 45-82 parts of PA6, 6-20 parts of compound flame retardant, 3-15 parts of antimony trioxide, 20-30 parts of glass fiber, 2-10 parts of compatilizer, 0.1-1 part of antioxidant and 0.1-1 part of oxide. The method comprises the following steps of: weighing raw materials according to a formula, and putting into a highly mixing machine for mixing for 2-5 minutes; and discharging, and extruding and pelletizing by using a double-screw extruder to obtain the environment-friendly flame-retardant glass fiber reinforced PA6 material. Compared with the prior art, the environment-friendly flame-retardant glass fiber reinforced PA6 material has the advantages of high glowing filament ignition temperature (GWIT), environment friendliness, balanced comprehensive performance, high CTI (Comparative Tracking Index) value, high GWIT value and the like.

Owner:SHANGHAI SUNNY

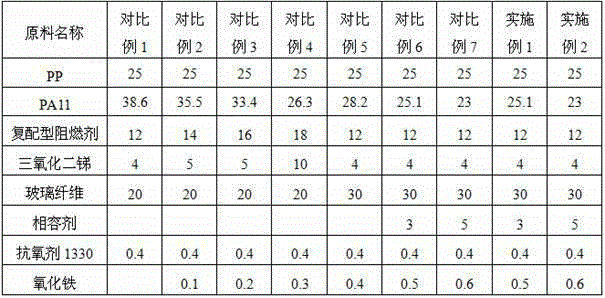

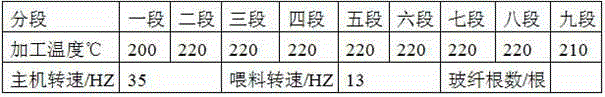

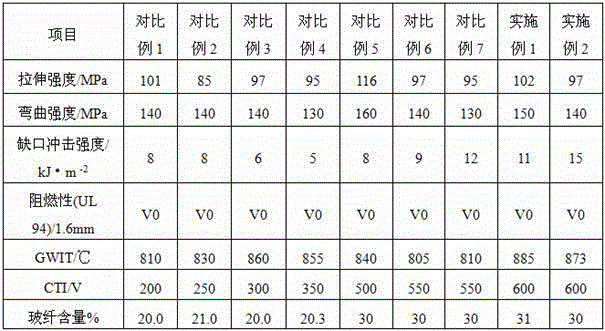

A kind of high cti value, high gwit value environmental protection flame retardant glass fiber reinforced pp/pa11 alloy material and preparation method thereof

The invention relates to an environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene) / PA (polyamide) 11 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value. The alloy material is prepared from the following raw materials in percentage by weight: 23-41% of PP, 22-41% of PA11, 6-20% of compound flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also provides a preparation method of the alloy material. The alloy material has high GWIT and high CTI, is environment-friendly, has balanced overall performances and can be widely applied to low-voltage electronic capacitor shells, load break switches, carbon brush brackets and moulded case circuit breakers.

Owner:SHANGHAI SUNNY

Epoxy resin copper-clad plate with high comparative tracking index suitable for PCB (Printed Circuit Board) manufacturing process and preparation method of epoxy resin copper-clad plate

PendingCN114311881AHigh tracking indexGood toughness strengthLamination ancillary operationsSynthetic resin layered productsEpoxyPolymer science

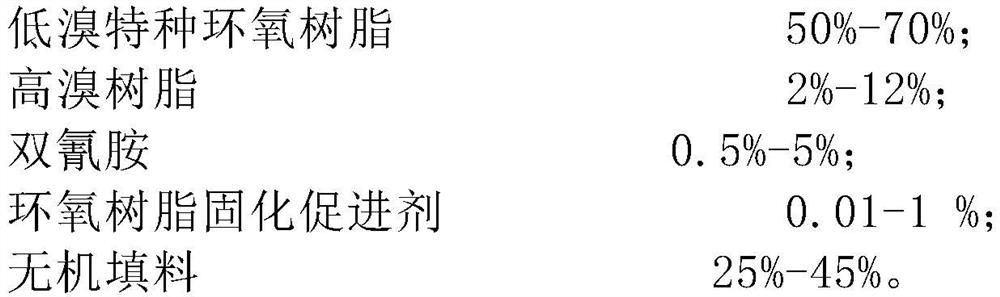

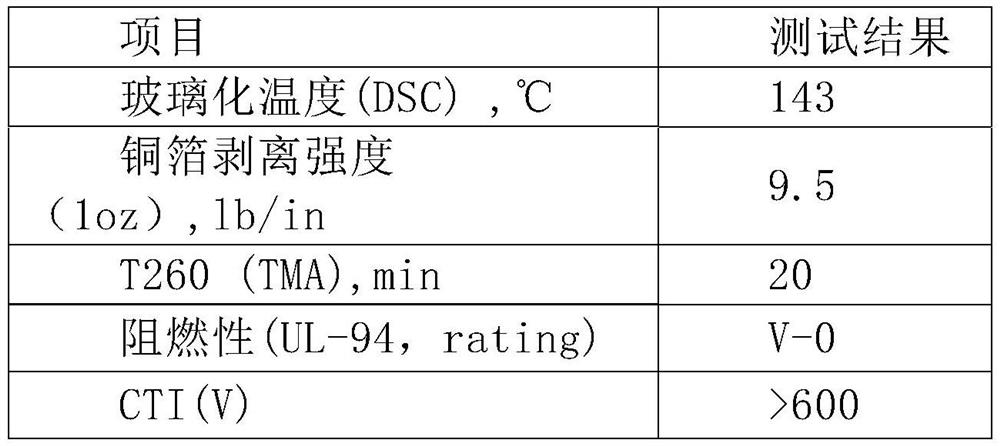

The invention discloses an epoxy resin copper-clad plate with high comparative tracking index suitable for a PCB (printed circuit board) manufacture procedure, the epoxy resin copper-clad plate is prepared from an adhesive, glass fiber cloth and copper foil, the adhesive is composed of 50-75% by weight of solid matter and the balance of organic solvent, and the glass fiber cloth and the copper foil are bonded to form the epoxy resin copper-clad plate. The solid matter is prepared from the following components in percentage by weight: 50 to 70 percent of low-bromine special epoxy resin; 2%-12% of high-bromine resin; 0.5%-5% of dicyandiamide; 0.01-1% of an epoxy resin curing accelerator; and 25%-45% of an inorganic filler. The invention also discloses a preparation method of the composition. The copper-clad laminate prepared by the invention has a high tracking index (CTI is greater than or equal to 600V), good toughness and peel strength and good flame retardance, and can be suitable for manufacturing a high-CTI printed circuit board.

Owner:江西省宏瑞兴科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com