High-performance reinforced flame-retardant PBT material and preparation method thereof

A high-performance, PBT resin technology, applied in the field of modified engineering plastics, can solve the problems of poor impact resistance, low tracking index, low glow wire ignition temperature, etc., and achieve high tracking index and impact resistance. superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

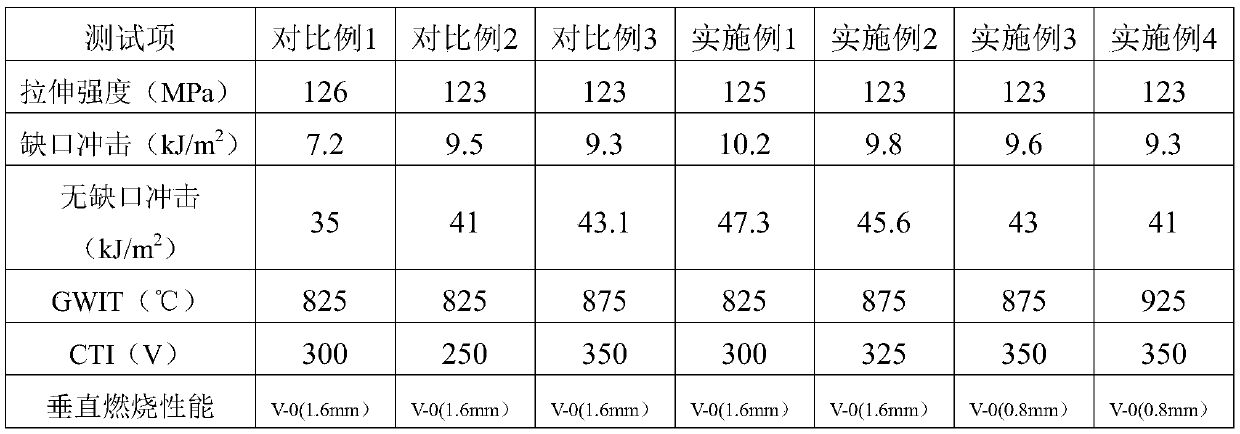

Examples

Embodiment 1

[0028] Weigh 50 parts by weight of PBT resin, 10 parts by weight of PET resin, 16 parts by weight of compound flame retardant (10 parts by weight of bromotriazine, 6 parts by weight of melamine cyanurate), flame retardant synergist (antimony trioxide ) 2 parts by weight, 1 part by weight of ethylene elastomer of acrylate and glycidyl ester difunctionalization, 0.6 part by weight of antioxidant, 0.9 part by weight of lubricant, 0.2 part by weight of nucleating agent, as described in the preparation method of the present invention Sequentially added to the high mixer and mixed evenly, added to the twin-screw extruder through the main feeding hopper, and at the same time, 25 parts by weight of glass fiber fillers that were surface-impregnated with silane coupling agents with epoxy groups or amino functional groups were passed through The glass fiber port is added, melted, kneaded, extruded, and granulated by a twin-screw extruder to obtain high-performance reinforced flame-retarda...

Embodiment 2

[0030] Weigh 50 parts by weight of PBT resin, 10 parts by weight of PET resin, 18 parts by weight of compound flame retardant (wherein 9 parts by weight of bromotriazine, 6 parts by weight of melamine cyanurate, magnesium hydroxide treated by silane chain coupling agent on the surface 2 parts by weight), flame retardant synergist (antimony trioxide) 2 parts by weight, acrylate and glycidyl ester bifunctional vinyl elastomer 1 part by weight, antioxidant 0.6 parts by weight, lubricant 0.9 parts by weight , 0.2 parts by weight of nucleating agent, according to the order described in the preparation method of the present invention, join in the high mixer and mix evenly, join in the twin-screw extruder through the main feeding hopper, and simultaneously use 25 parts by weight of epoxy group or amino The glass fiber filler with functional group silane coupling agent for surface infiltration treatment is added through the glass fiber port, melted, kneaded, extruded, and granulated by...

Embodiment 3

[0032] Weigh 50 parts by weight of PBT resin, 10 parts by weight of PET resin, 18 parts by weight of compound flame retardant (wherein 9 parts by weight of bromotriazine, 6 parts by weight of melamine cyanurate, the surface is processed by silane chain coupling agent Magnesium hydroxide 2 parts by weight), 3 parts by weight of flame retardant synergist (1 part by weight of antimony trioxide, 2 parts by weight of zirconium phosphate), 1 part by weight of acrylate and glycidyl ester bifunctional vinyl elastomer, antioxidant 0.6 parts by weight, 0.9 parts by weight of lubricant, 0.2 parts by weight of nucleating agent, according to the order described in the preparation method of the present invention, join in the high mixer and mix evenly, join in the twin-screw extruder through the main feeding hopper, and simultaneously 25 Parts by weight The glass fiber filler that uses the silane coupling agent of the epoxy group or the amino functional group to carry out the surface impregna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com