High-GWIT high-CTI thin-wall flame-retardant glass-fiber reinforced low-warpage PET composite material and preparation method thereof

A low-warp, thin-wall technology, applied in the field of PET composite materials, can solve the problems of product warpage, GWIT and CTI can not be taken into account at the same time, to achieve the effect of reducing formulation cost, improving GWIT performance, and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

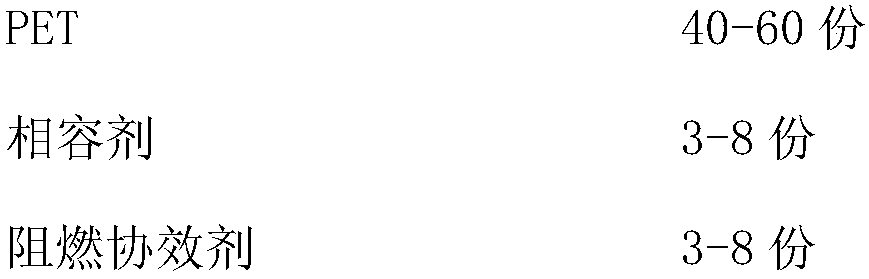

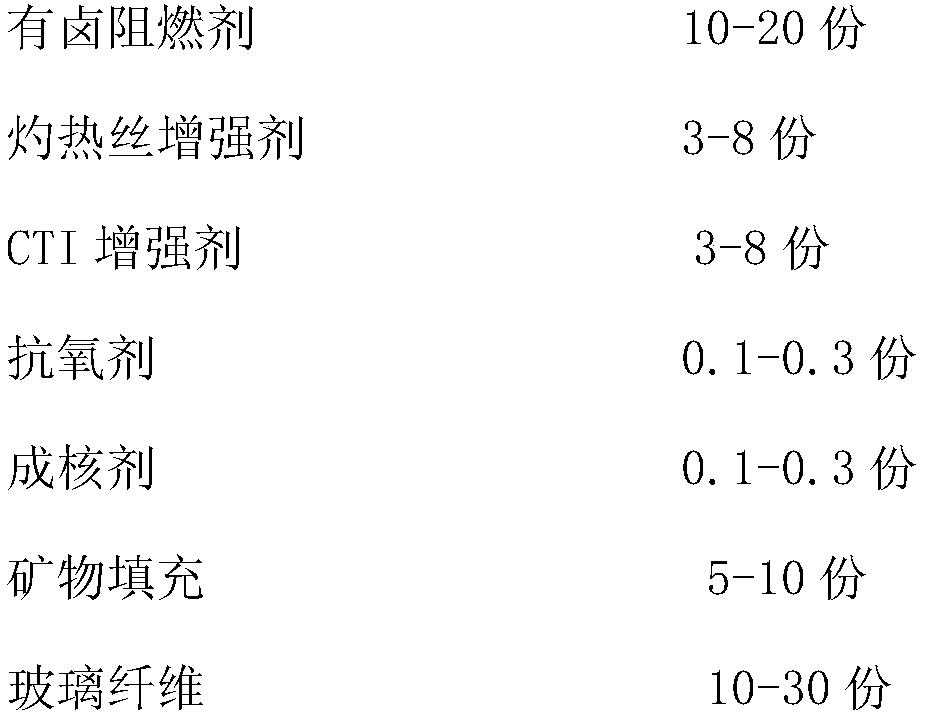

Method used

Image

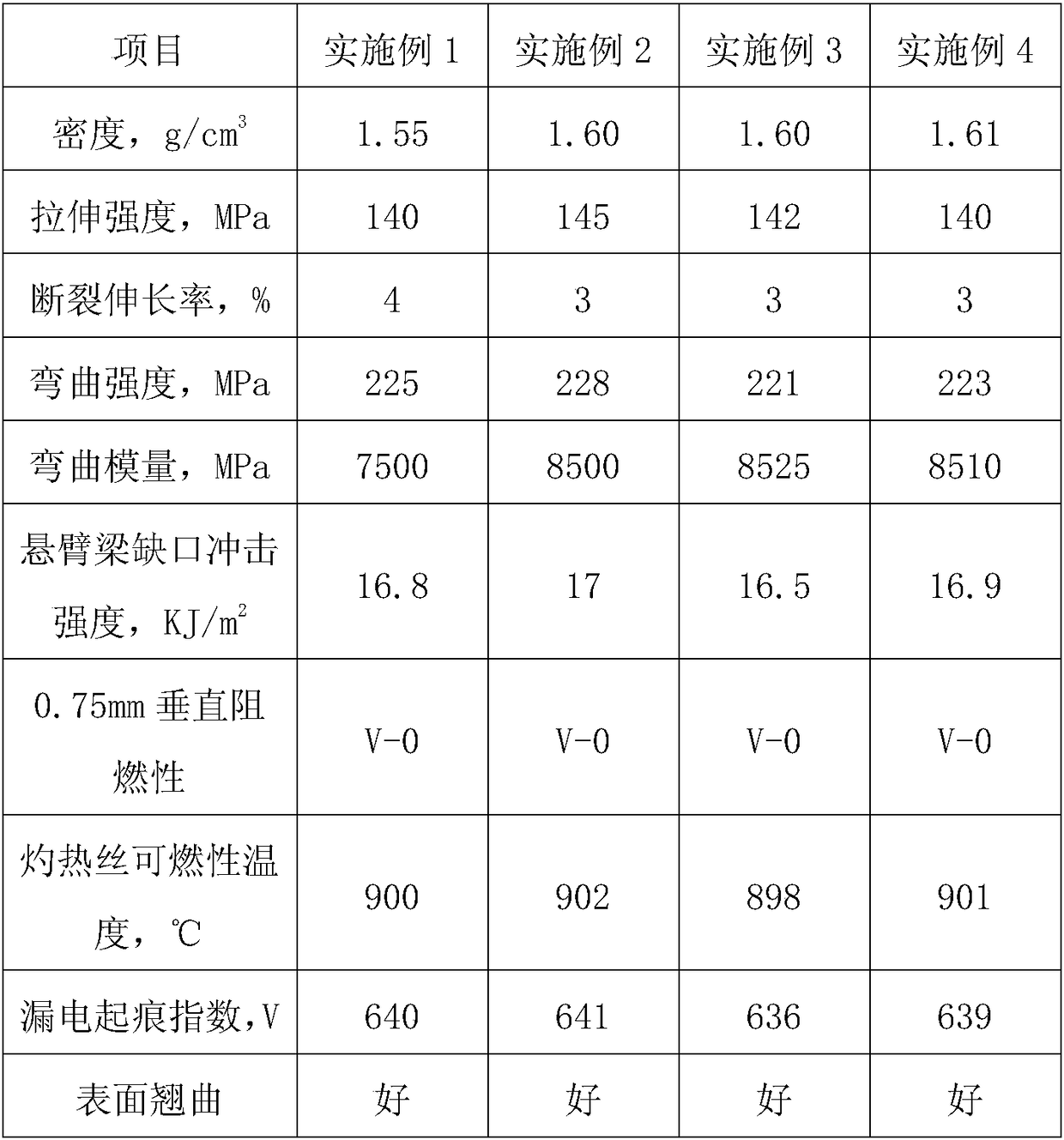

Examples

Embodiment 1

[0026] Take 45.7kg of PET resin (standard brand: Xinjiang Tunhe TH105), 2kg of compatibilizer ethylene-vinyl acetate copolymer (manufacturer: Arkema, France) and 1kg of ethylene butyl acrylate (manufacturer: DuPont), flame retardant synergist Antimony trioxide (manufacturer: Hunan Anhua) 1kg, zinc stearate (manufacturer: Shenzhen Lituo) 2kg, zinc carbonate 1kg, halogenated flame retardant decabromodiphenylethane (manufacturer: Taizhou Baili) 15kg, Glow wire enhancer (manufacturer: Shenzhen Ruihong, nitrogen and phosphorus mixture RHPP-085-3A-3h) 6kg, CTI enhancer (manufacturer: Guangdong Chendong Chemical, phosphate PK-5001) 6kg, nucleating agent P250 (Bruce Geman) 100g, 1500 mesh talc grains 5kg, antioxidant 1010 (Yabao) 100g and antioxidant 168 (Yabao) 100g, glass fiber (alkali-free long fiber, single filament diameter is 12μm, manufacturer: Jushi Chemical Fiber) 15kg, add it into a high-speed mixer, stir and disperse evenly, discharge the material, add it into a twin-screw ...

Embodiment 2

[0028] Take 40.7kg of PET resin (standard brand: Xinjiang Tunhe TH105), 2kg of compatibilizer ethylene-vinyl acetate copolymer (manufacturer: Arkema, France) and 1kg of ethylene butyl acrylate (manufacturer: DuPont), flame retardant synergist Antimony trioxide (manufacturer: Hunan Anhua) 1kg, zinc stearate (manufacturer: Shenzhen Lituo) 2kg, zinc carbonate 1kg, halogenated flame retardant decabromodiphenylethane (manufacturer: Taizhou Baili) 15kg, Glow wire enhancer (manufacturer: Shenzhen Ruihong, nitrogen and phosphorus mixture RHPP-085-3A-3h) 6kg, CTI enhancer (manufacturer: Guangdong Chendong Chemical, phosphate PK-5001) 6kg, nucleating agent P250 (Bruce Geman) 100g, 1500 mesh talc grains 5kg, antioxidant 1010 (Yabao) 100g and antioxidant 168 (Yabao) 100g, glass fiber (alkali-free long fiber, single filament diameter is 12μm, manufacturer: Jushi Chemical Fiber) 20kg, add it into a high-speed mixer, stir and disperse evenly, discharge the material, add it into a twin-screw ...

Embodiment 3

[0030] Take 43.7kg of PET resin (standard brand: Xinjiang Tunhe TH105), 2kg of compatibilizer ethylene-vinyl acetate copolymer (manufacturer: Arkema, France) and 1kg of ethylene butyl acrylate (manufacturer: DuPont), flame retardant synergist Antimony trioxide (manufacturer: Hunan Anhua) 1kg, zinc stearate (manufacturer: Shenzhen Lituo) 2kg, zinc carbonate 1kg, halogenated flame retardant decabromodiphenylethane (manufacturer: Taizhou Baili) 15kg, Glow wire enhancer (manufacturer: Shenzhen Ruihong, nitrogen and phosphorus mixture RHPP-085-3A-3h) 8kg, CTI enhancer (manufacturer: Guangdong Chendong Chemical, phosphate PK-5001) 6kg, nucleating agent P250 (Bruce Geman) 100g, 1500 mesh talc grains 5kg, antioxidant 1010 (Yabao) 100g and antioxidant 168 (Yabao) 100g, glass fiber (alkali-free long fiber, single filament diameter is 12μm, manufacturer: Jushi Chemical Fiber) 15kg, add it into a high-speed mixer, stir and disperse evenly, discharge the material, add it into a twin-screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com