Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

562results about How to "Shorten molding cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:常州福源科技新材料有限公司

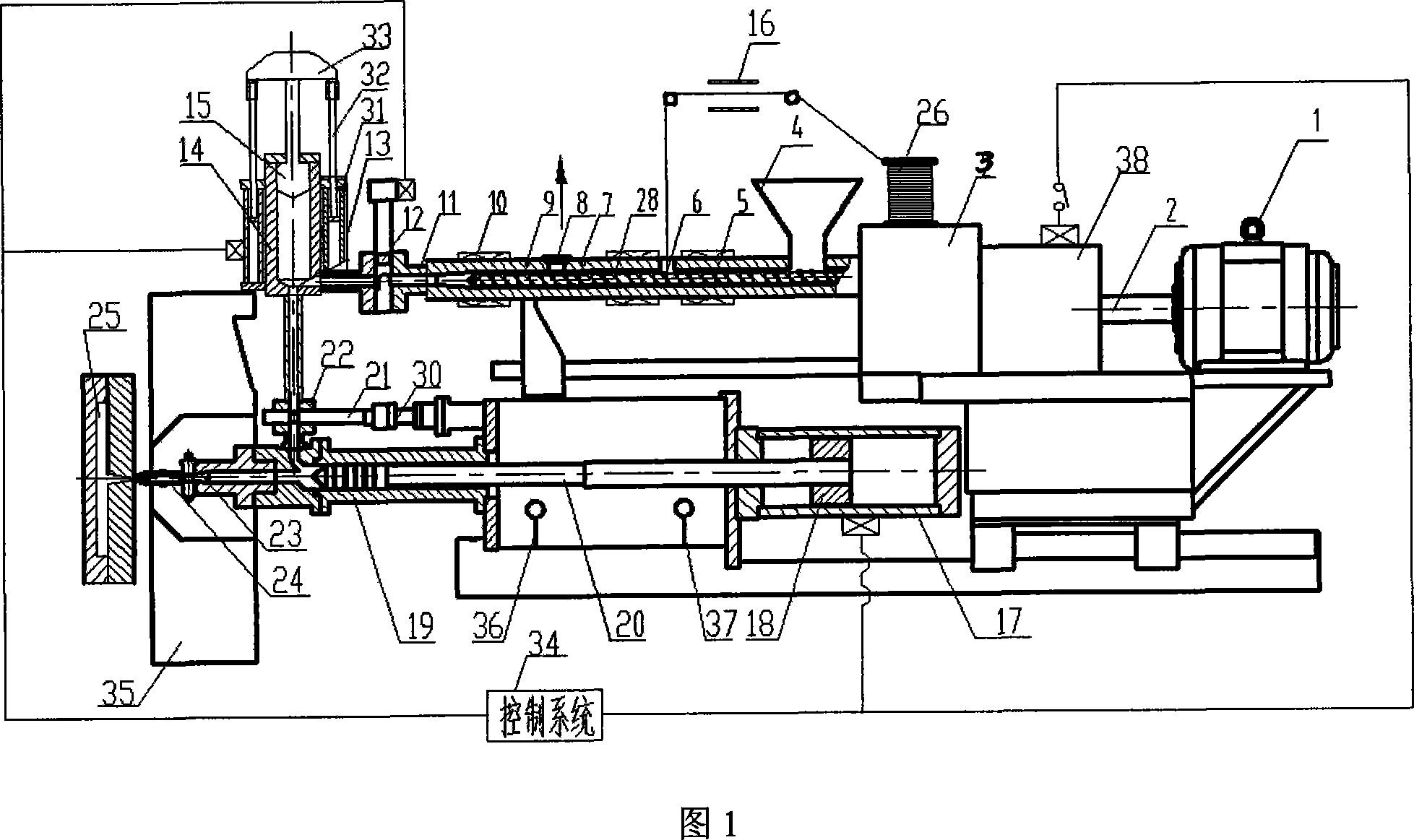

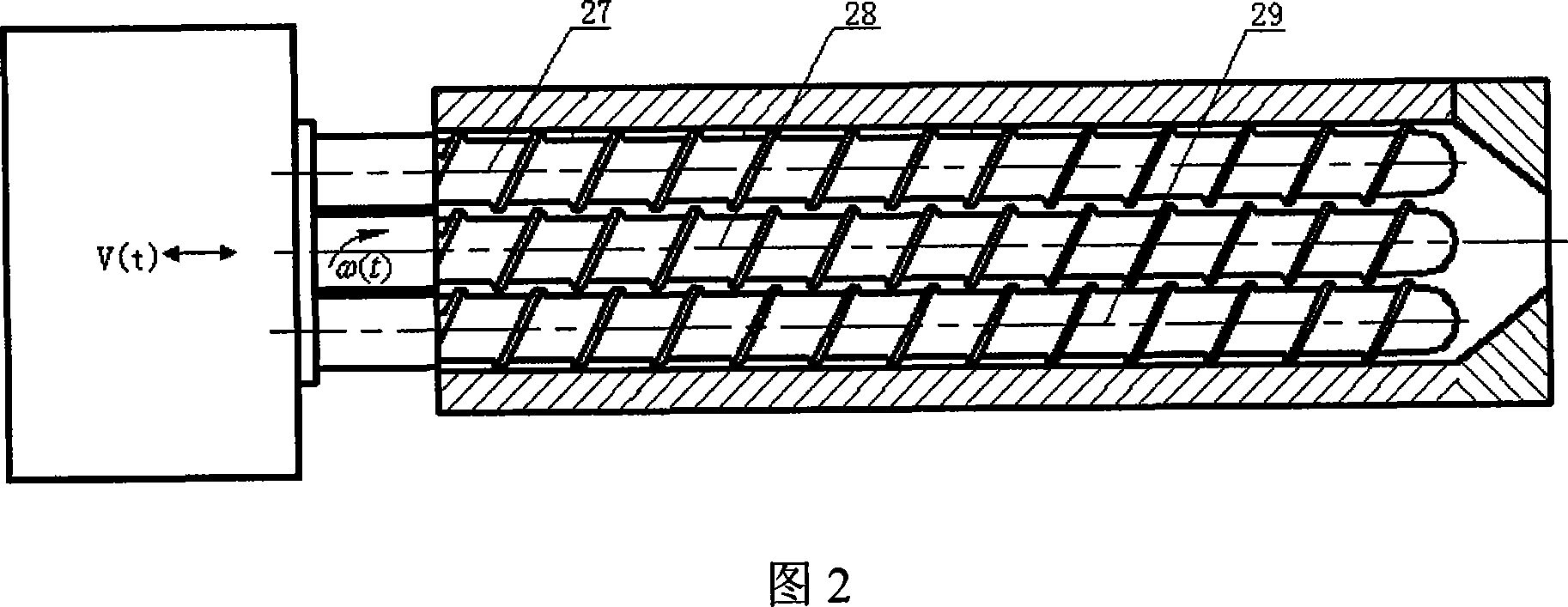

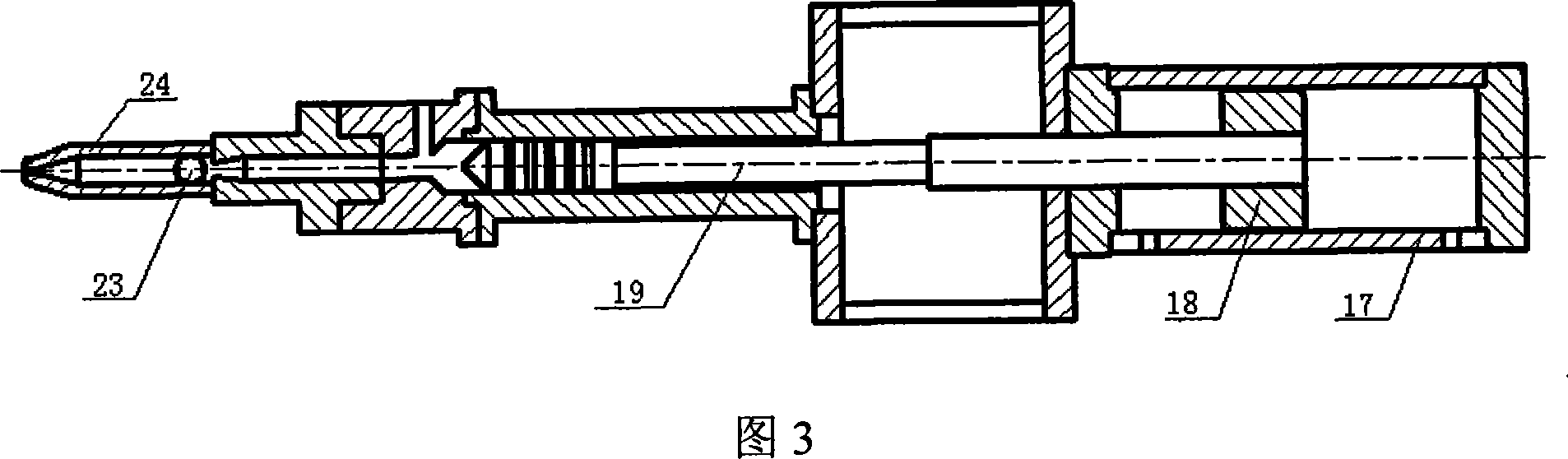

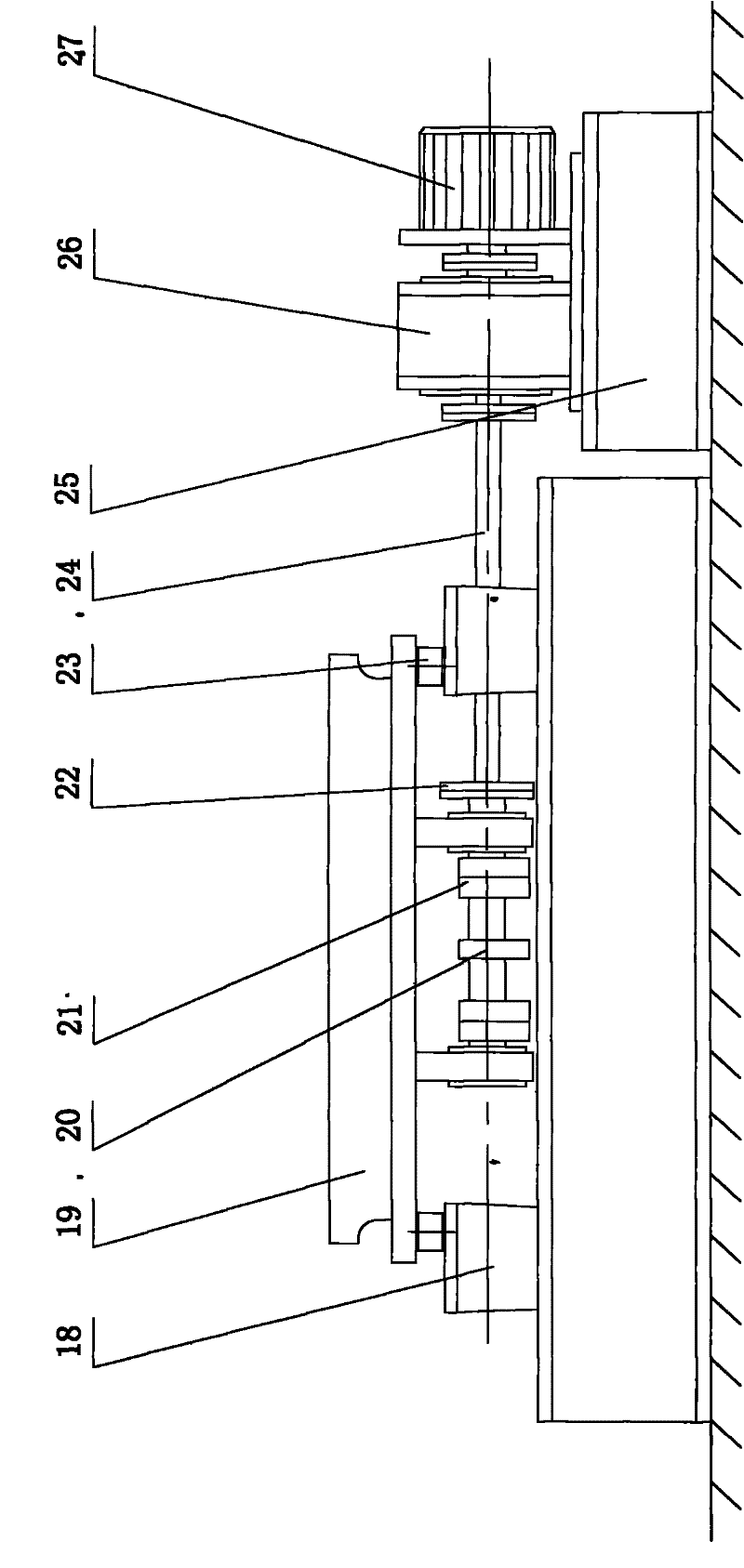

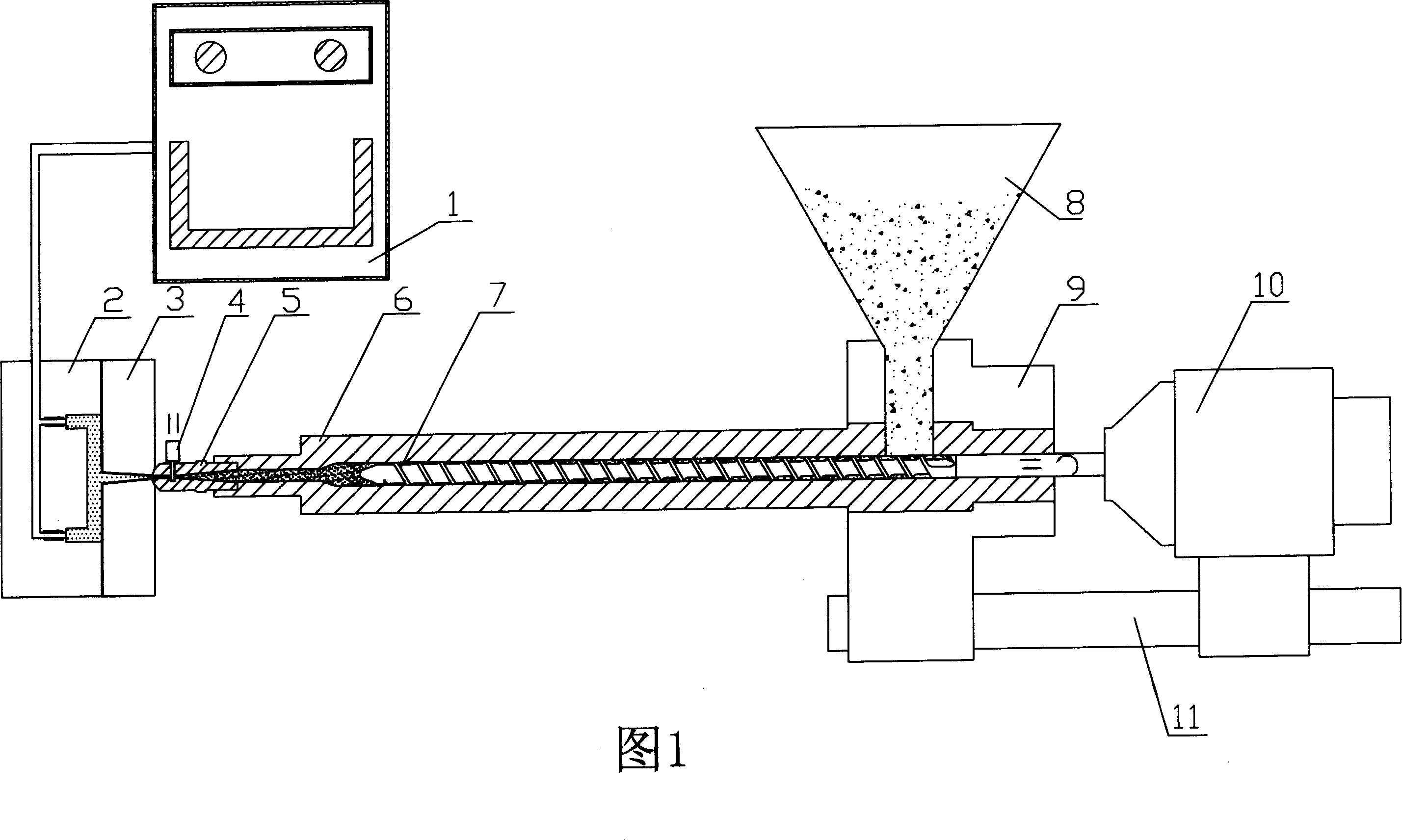

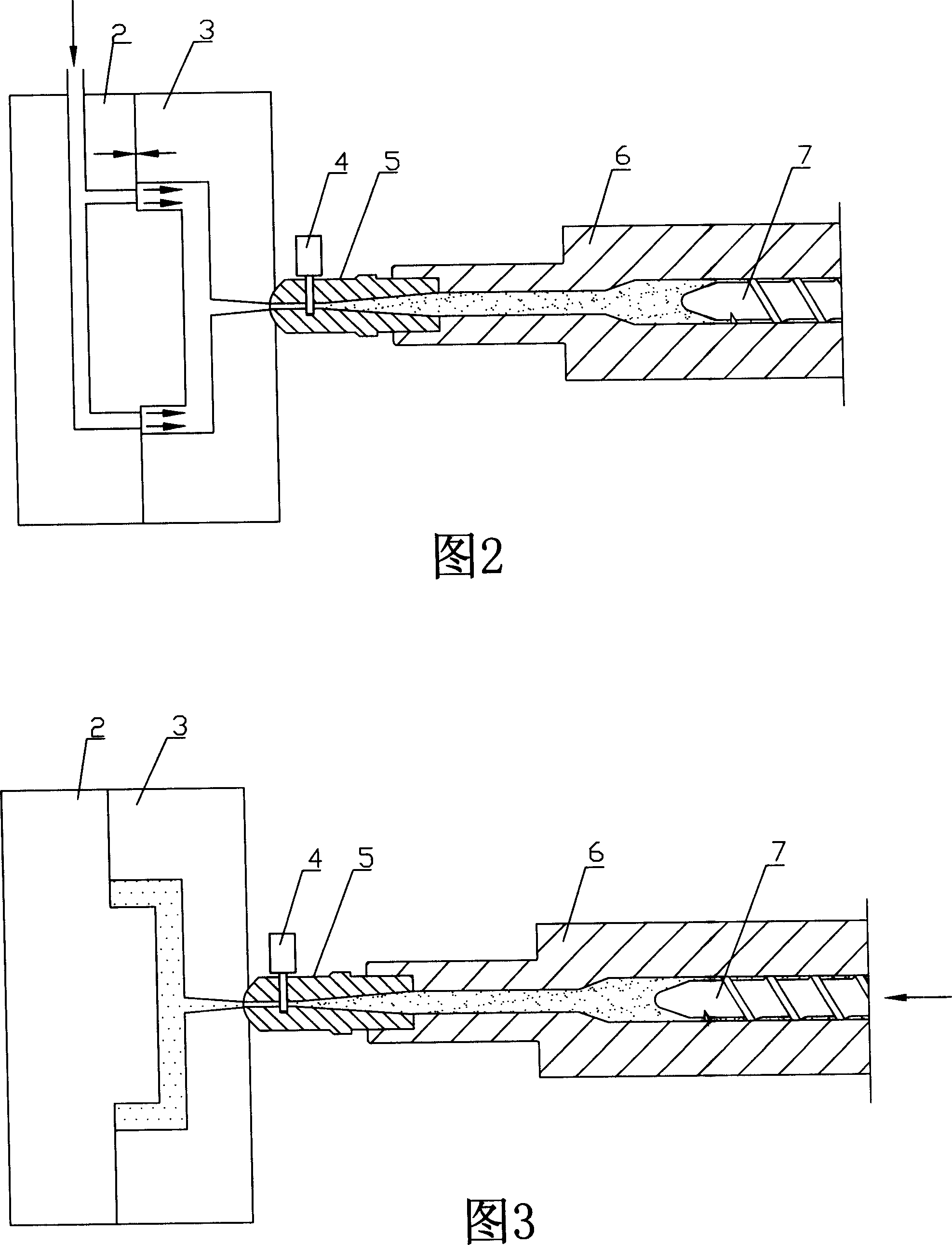

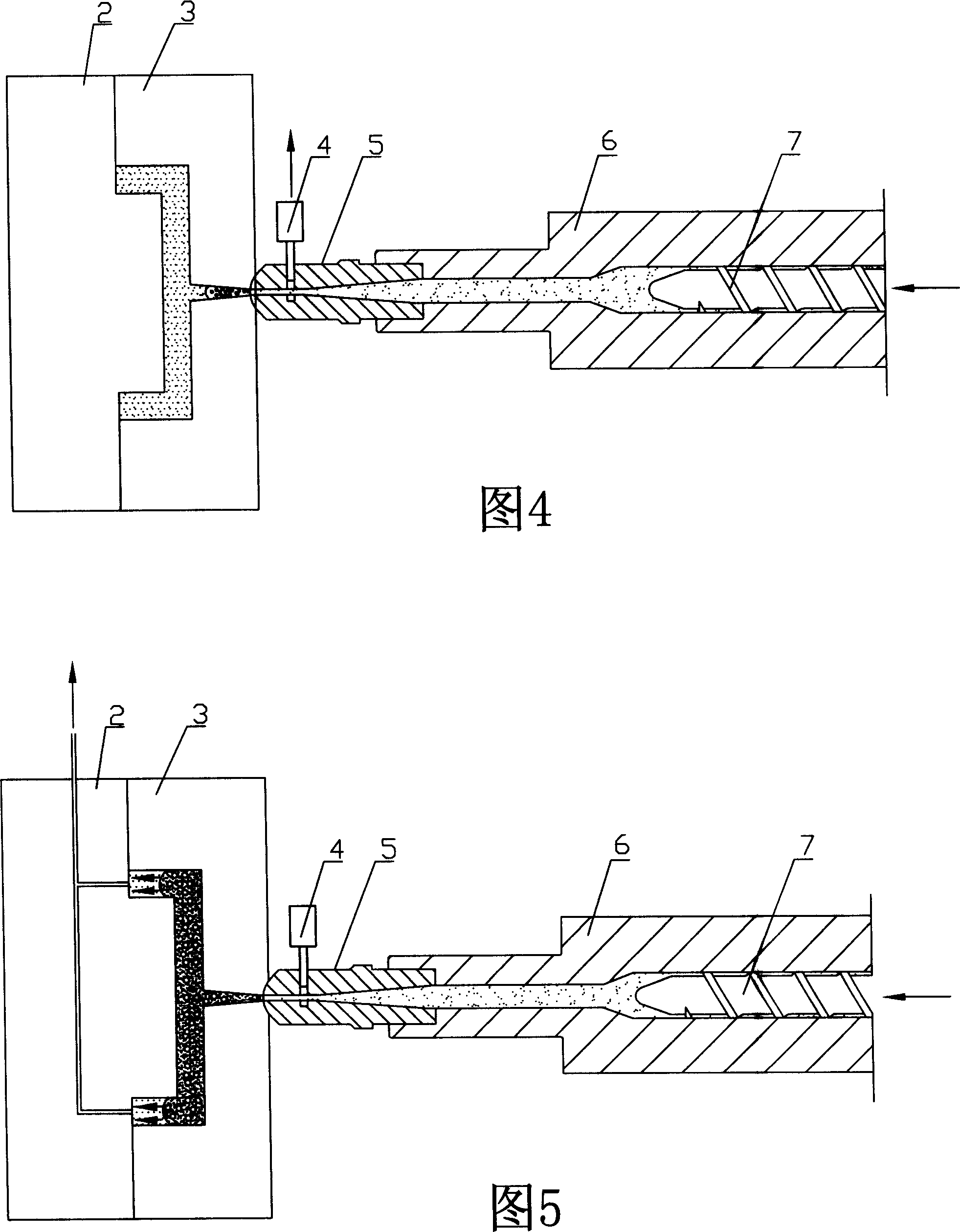

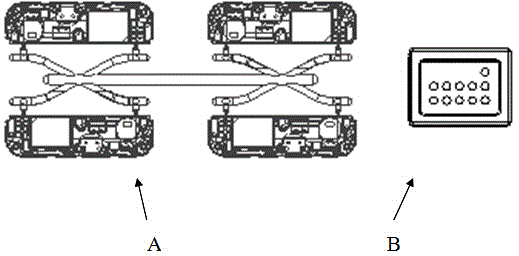

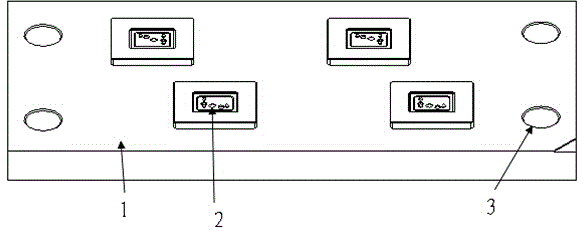

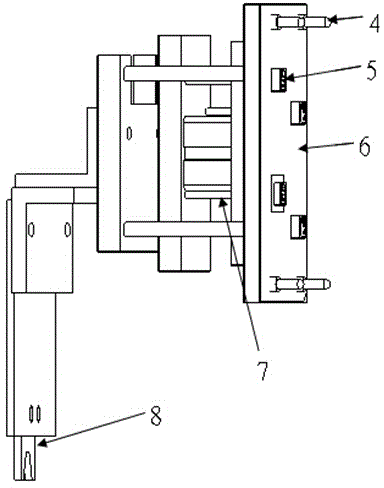

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

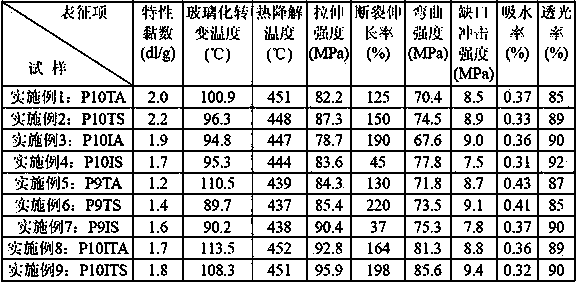

Semi-aromatic transparent polyamide material and preparation method thereof

The invention discloses a semi-aromatic transparent polyamide material and a preparation method thereof, belonging to the field of high-molecular materials. The material consists of a random copolymer of semi-aromatic amide salt and aliphatic amide salt and necessary auxiliaries; the intrinsic viscosity is 1.0-2.2dl / g, and the degree of crystallinity is less than 15%; the semi-aromatic amide salt is selected from amide salt 9T, amide salt 9I, amide salt 10T and amide salt 10I; and the aliphatic amide salt is selected from amide salt 610 and amide salt 1010. The preparation method comprises the following steps: adding the semi-aromatic amide salt, aliphatic amide salt and auxiliaries into a polymerization kettle; adding water which is 0.3-1.0 times the total mass of the semi-aromatic amide salt and aliphatic amide salt; in a protective gas atmosphere, stirring and heating to 160-210 DEG C within 1-2 hours, and performing constant-temperature pre-polymerization for 1-3 hours; heating to 240-300 DEG C, increasing pressure to 1-3MPa, and maintaining the pressure for reaction for 1-3 hours; slowly degassing to normal pressure within 1-4 hours; continuously stirring at constant temperature for 1-4 hours; and discharging after the reaction.

Owner:ZHENGZHOU UNIV

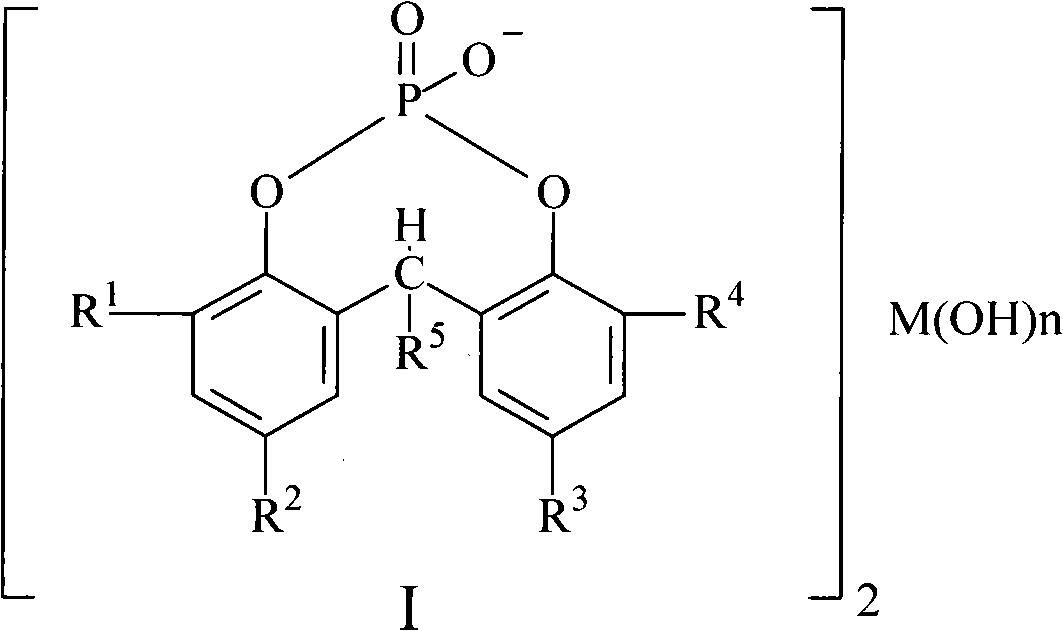

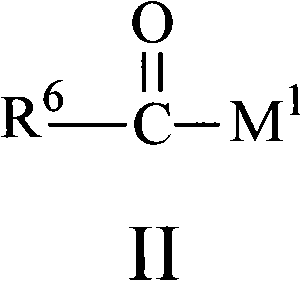

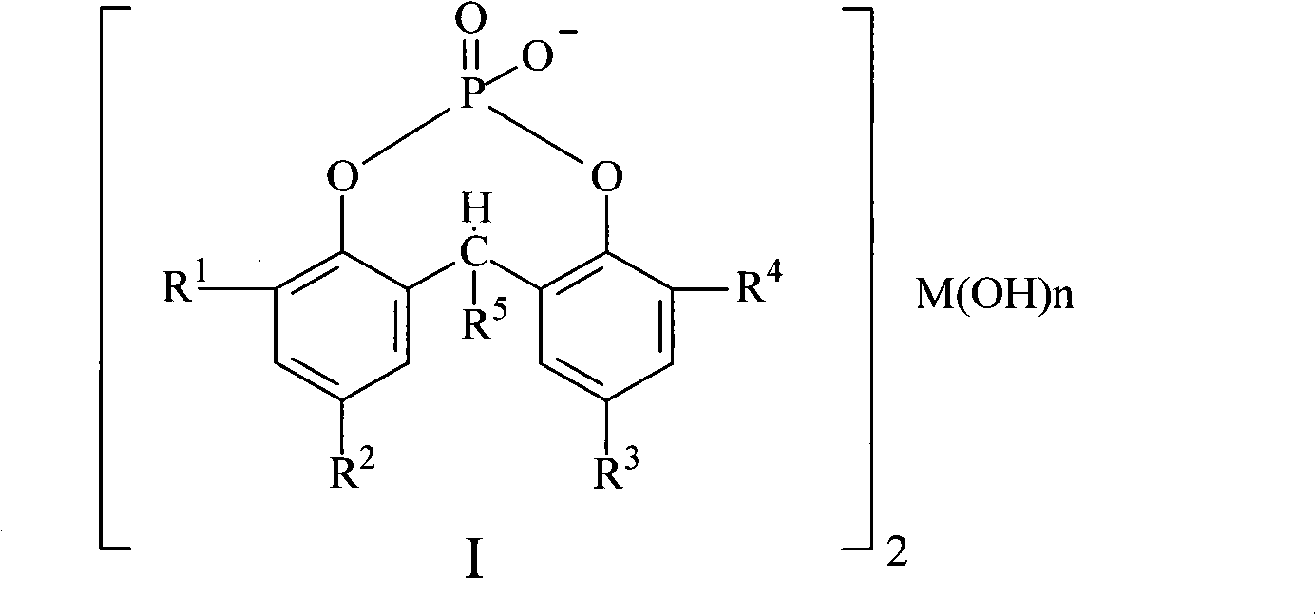

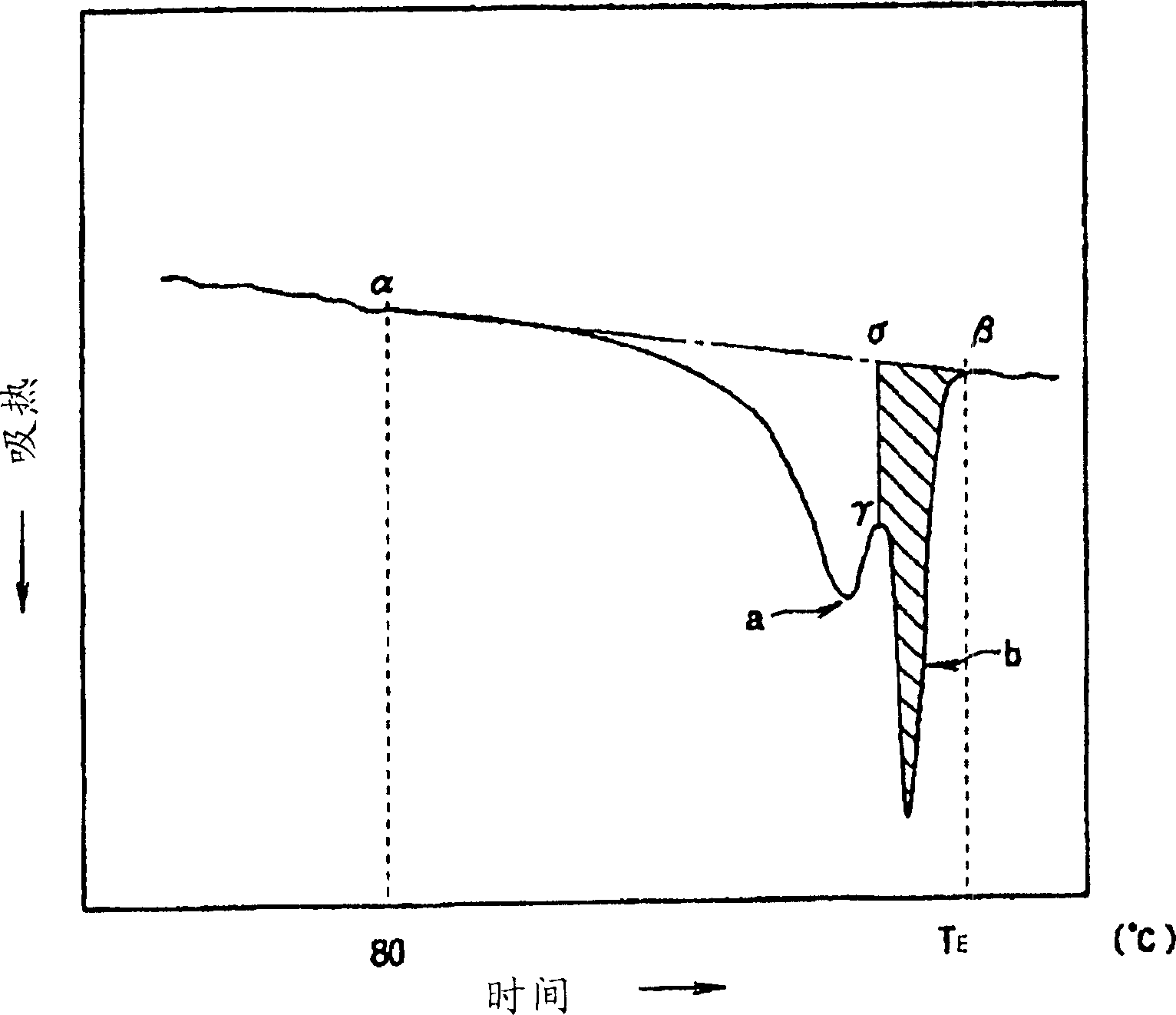

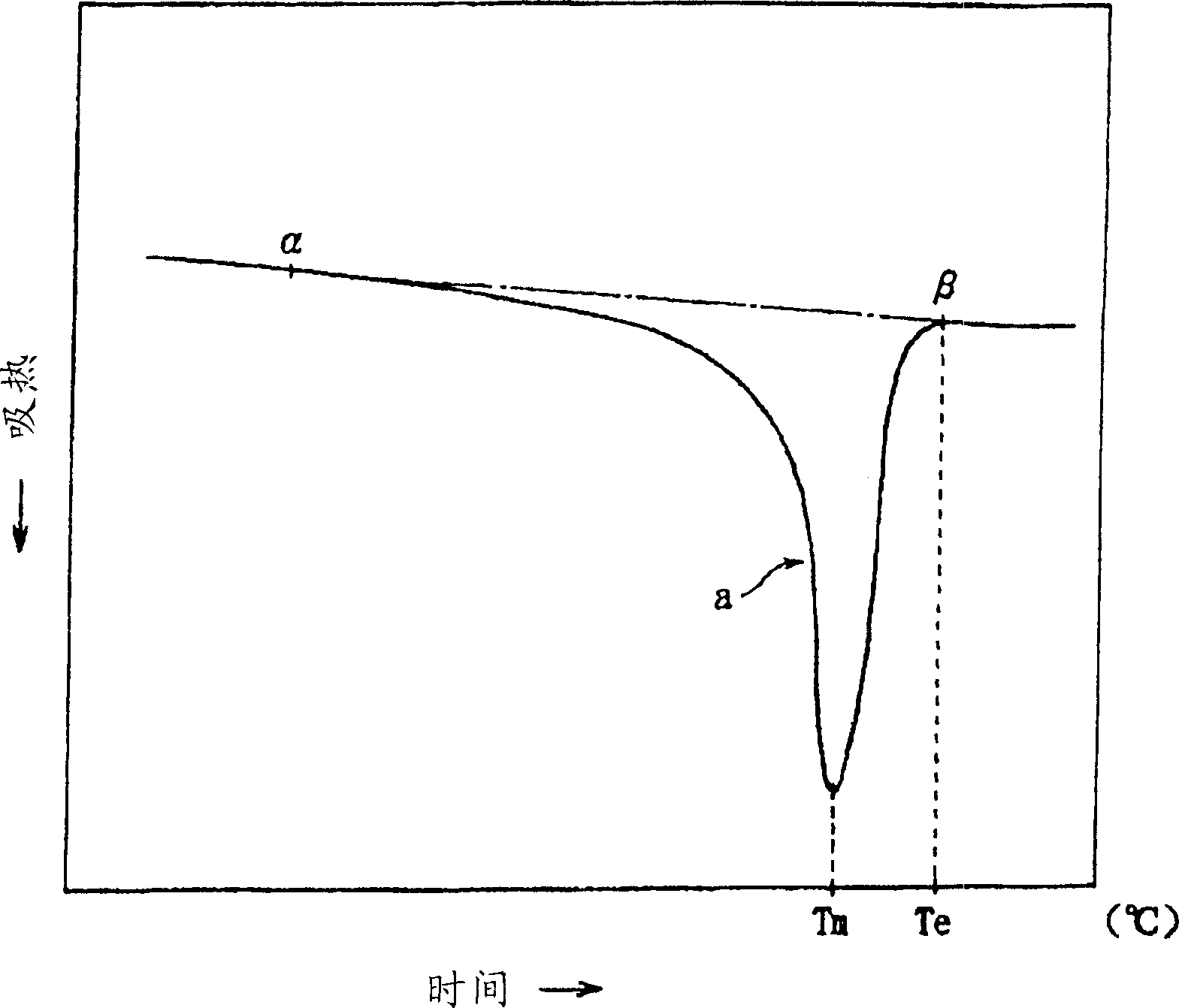

Polypropylene transparent nucleater

The invention discloses a polypropylene transparent nucleating agent, which consists of one or two compounds in category A accounting for 90 to 10 percent by weight and one or two compounds in category B accounting for 10 to 90 percent by weight. The compound(s) in category A is (are) multivalent metal salt(s) substituting for diaryl phosphoric acid; and the compound(s) in category B is (are) alkali metal salt(s) of monobasic fatty acid. The polypropylene transparent nucleating agent disclosed by the invention overwhelms the defects of organic phosphates in use, such as too high melting point, limited compatibleness with resin, poor dispersibility, causing flaws on the surfaces of products easily and so on. By adopting the invention, the polypropylene transparent nucleating agent improves the rigidity, the tensile strength, the creep resistance, the heat distortion temperature of polypropylene and so on, brings high transparency to polypropylene, and reducing the forming cycle. Products got by adopting the invention are of high quality.

Owner:JIANGSU TAIHU CHEM

Polyamide composition with high dimensional stability and preparation method thereof

InactiveCN101857723AReduce the degree of orderLow water absorptionHeat deflection temperaturePolyamide

The invention relates to a polyamide composition with high dimensional stability and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 60 to 90 of fatty polyamide composition, 2 to 10 of compatilizer, 1 to 10 of inorganic metal compound, 0 to 5 of polysiloxane with low molecular weight and 0 to 2 of auxiliary agent. The preparation method comprises the following steps of: premixing the raw materials in a high-speed mixer for 10 to 30min, controlling the temperature to be 40 to 60 DEG C, then adding premix into a double-screw extruder, conveying, melting, shearing, extruding, cooling and granulating so as to prepare a polyamide composition product with high dimensional stability. Compared with the prior art, the invention shows excellent dimensional stability and heat distortion temperature with high retention rate, is suitable for occasions with higher requirement to the dimensional stability, such as the panel of the air conditioner of an automobile, an instrument panel, a camera bracket, a sports apparatus and the like, and can be directly processed by injection molding or other forming methods.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

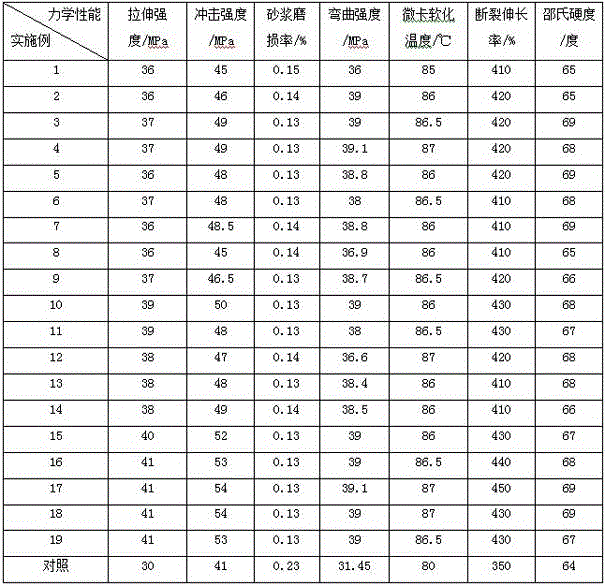

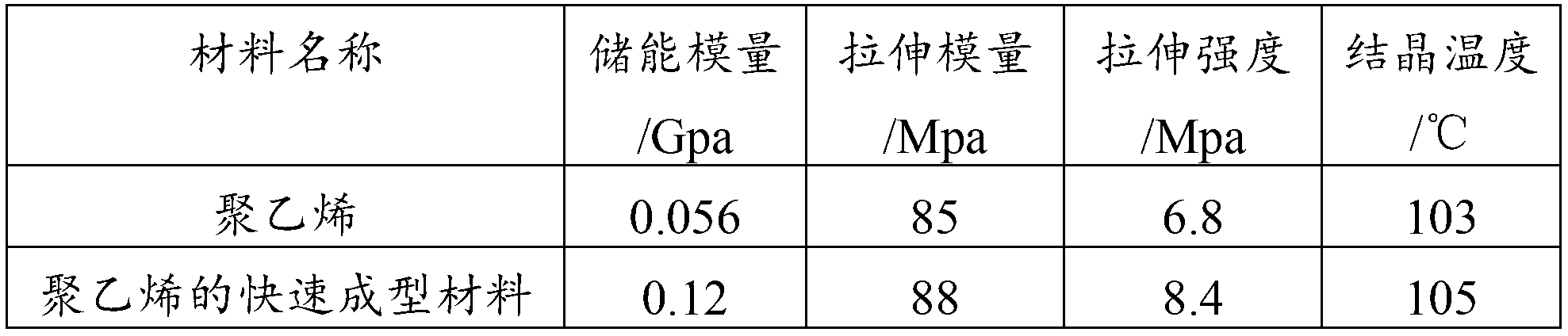

High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:漯河科莱堡科技有限公司

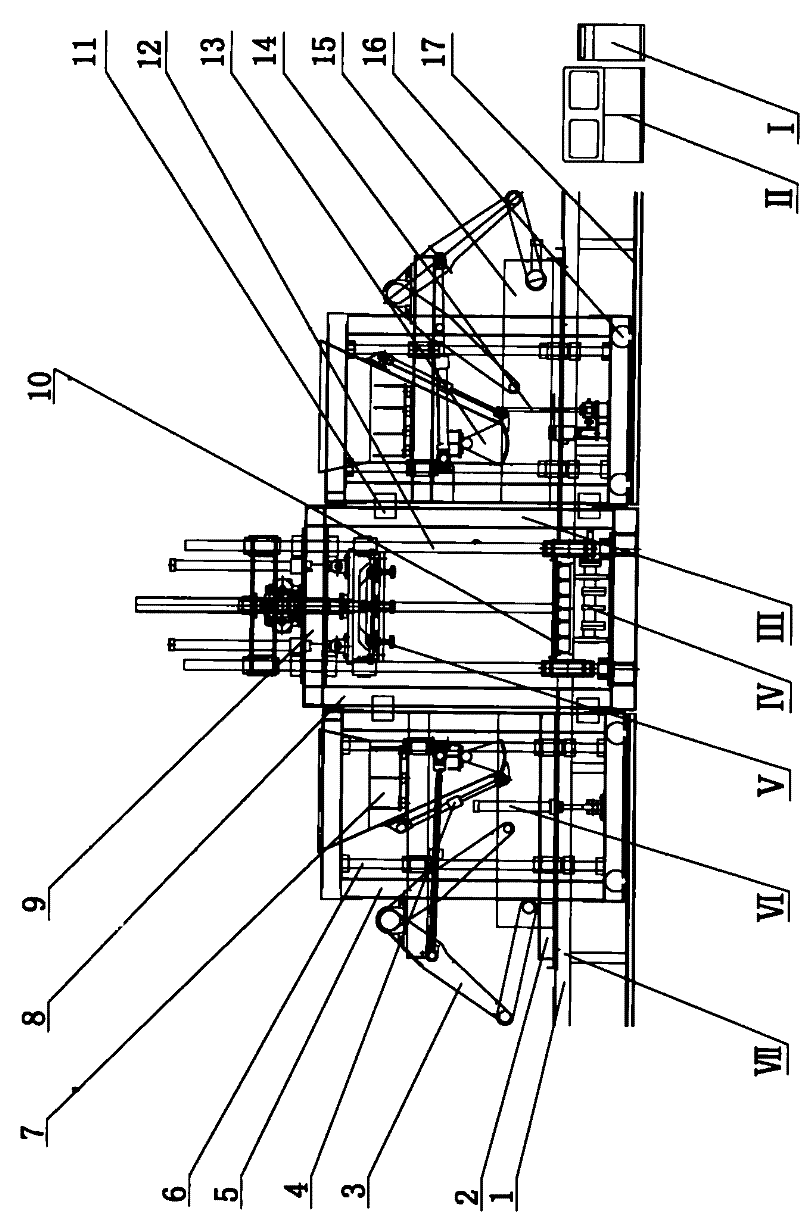

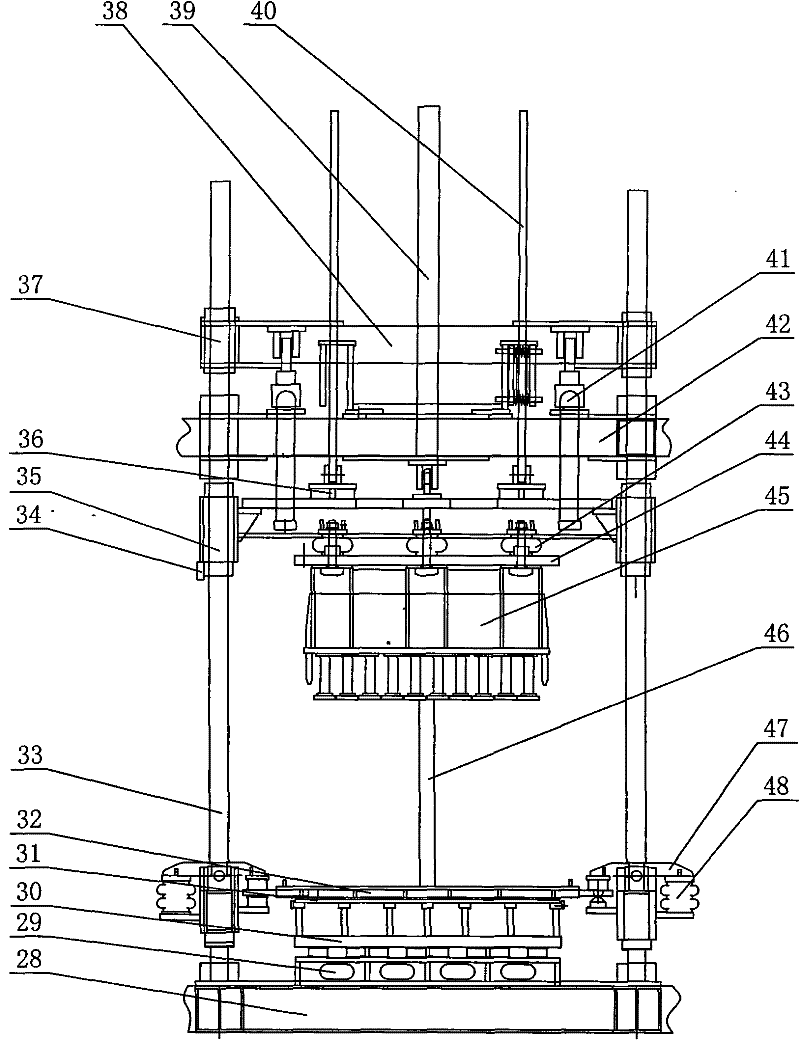

Automatic powerful vibration concrete block moulding machine

InactiveCN102452129AHigh strengthHigh precisionCeramic shaping plantsShaping press ramFiberVibration amplitude

The invention discloses an automatic powerful vibration concrete block moulding machine. The frame of the machine is welded into a frame structure, a powerful vibration excitation mechanism is arranged on a frame base, a support plate transfer mechanism is arranged upon a vibrating table, and a feeding mechanism and a compacting and moulding mechanism are arranged on a guide upright post. The machine adopts the drive control technical measures that after a frequency adjustment vibration motor is sequentially connected with a synchromesh gear case, a power transmission shaft and a vibration exciter, the vibrating table is driven to vibrate, the vibration motor is adjusted by a frequency automatic adjustment program control device to change the rotating speed of a vibration exciter and the like, and the machine solves the technical problems of four-axis synchronous efficient powerful excitation, stepless adjustment of vibration frequency, vibration amplitude, excitation force and the like; and the flexible connection parts such as a coupler, a vibration reduction block, an air spring and the like made by hard rubber fiber are adopted, so a multistage combined vibration isolation and vibration reduction measure is formed, and a damage impact force produced by vibration can be reduced. The machine is used for producing the concrete block, and has the characteristics of high degree of automation, large excitation force covering area, fast moulding period, high product strength grade and the like.

Owner:JILIN JIUSHENG MACHINING

Poly-l-butylene resin composition and its usage

InactiveCN1356353AShorten molding cycleIncrease production capacityRigid pipesTubular articlesWarm waterOlefin polymerization

Poly(1-butene) resin composition comprises 90-99.95 wt.% of a poly(1-butene) resin (A) which is obtained by copolymerizing 80-100 mol% of 1-butene with 0-20 mol% of a 2-10C α -olefin except 1-butene and has 0.01-50 g / 10 minutes MFR (190 deg.C) and 0.05-10 wt.% of a polypropylene resin (B) having 0.01-50 g / 10 minutes MFR (230 deg.C). This pipe and this joint for a pipe comprise the composition. According to this present invention a poly(1-butene) resin composition capable of preparing a pipe which shortens a curing time and reduces a molding cycle, namely has excellent productivity and excellent winding properties after extrusion molding, its pipe and a joint suitable for the pipe in which the pipe is suitable for a fluid transportation pipe such as a water supply pipe, a warm water supply pipe, etc., and the joint for a pipe is preferably useful as the joint for the pipe.

Owner:MITSUI CHEM INC

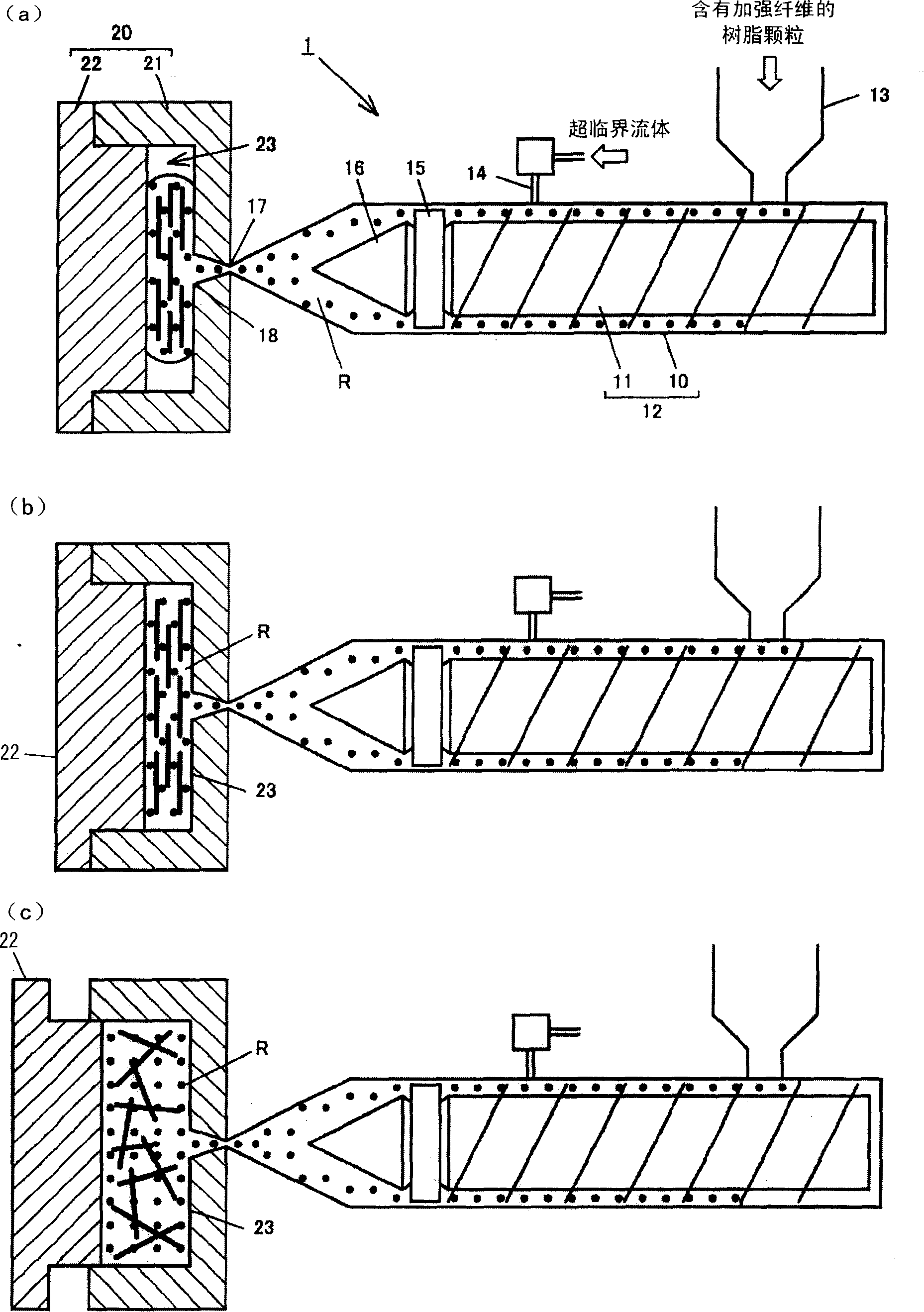

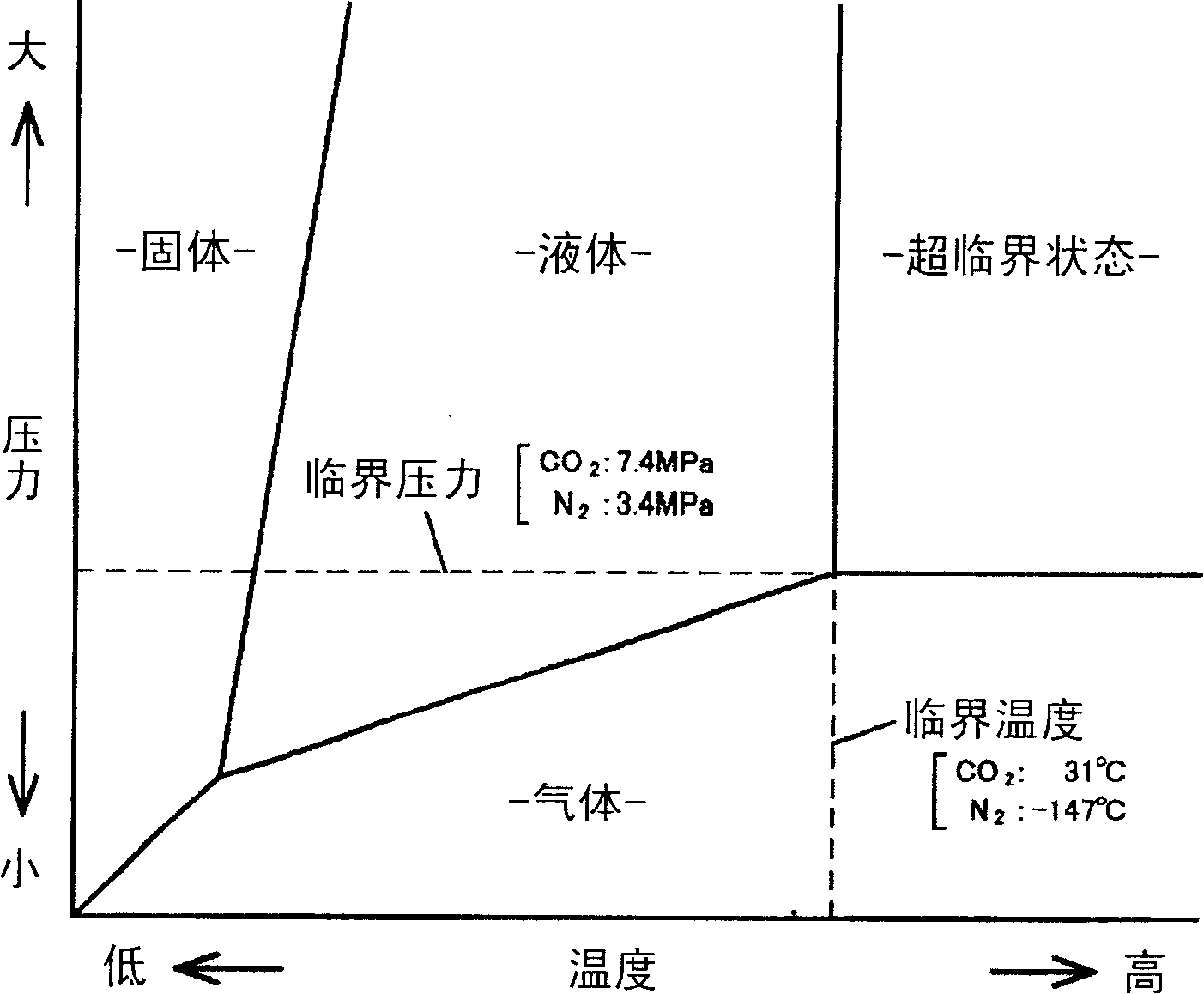

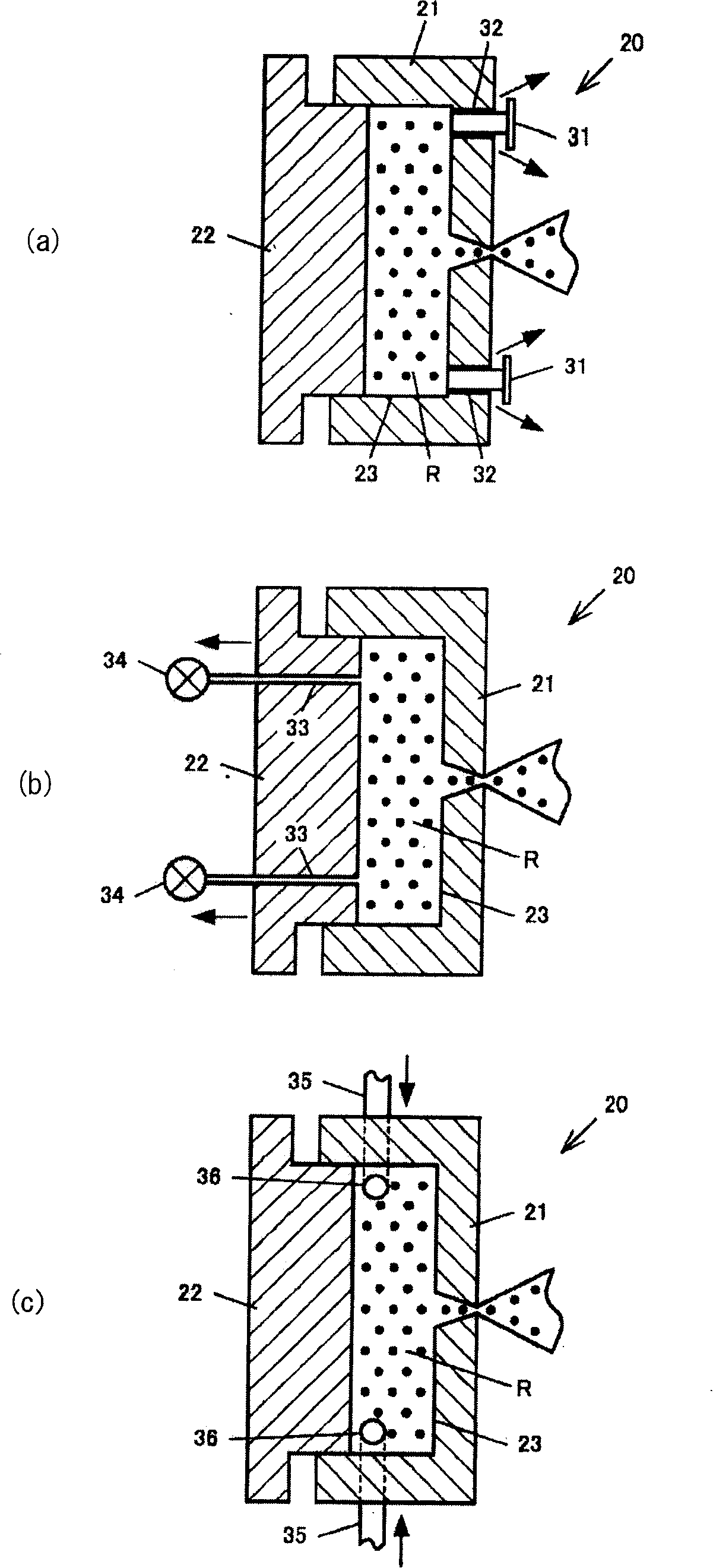

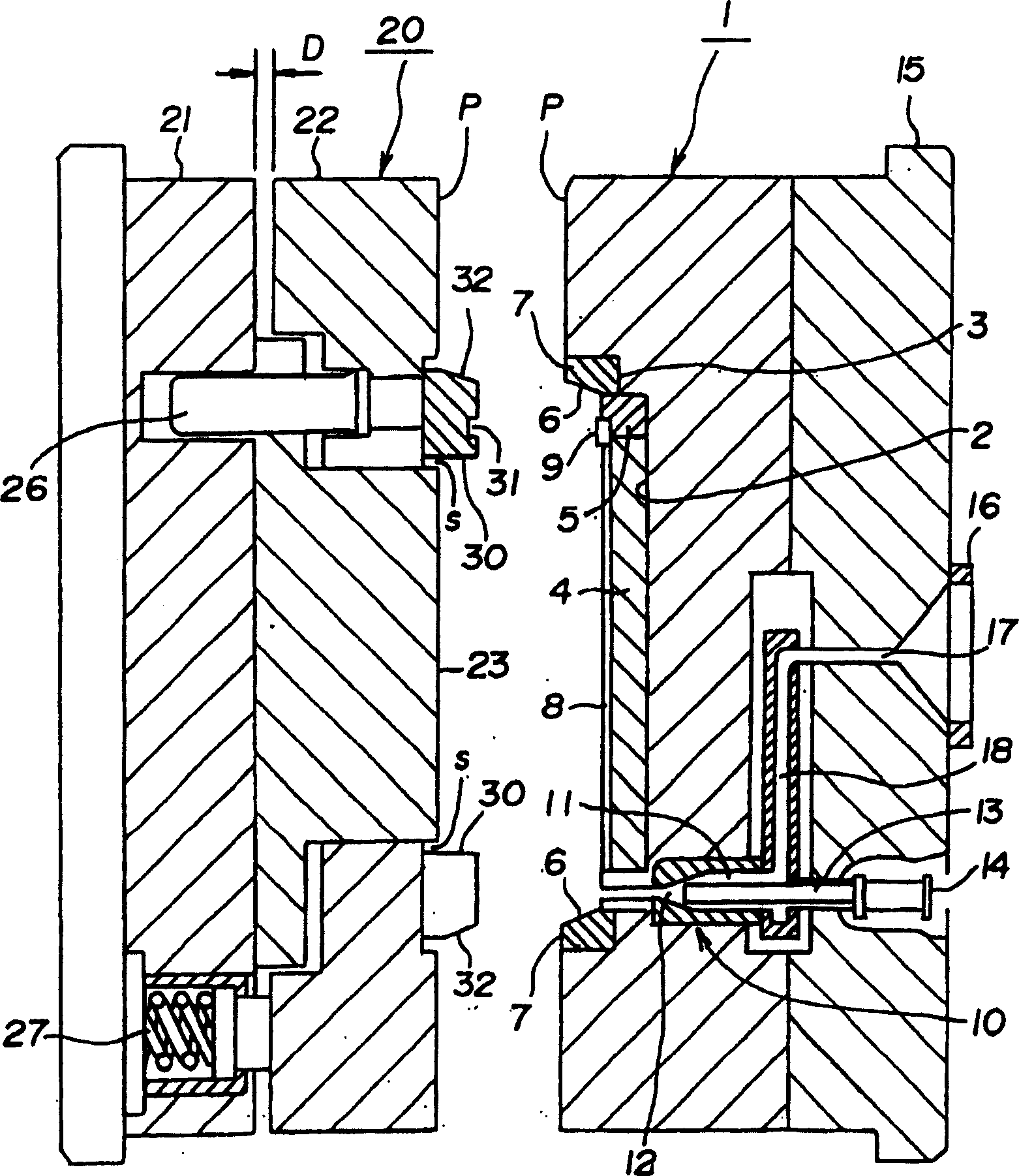

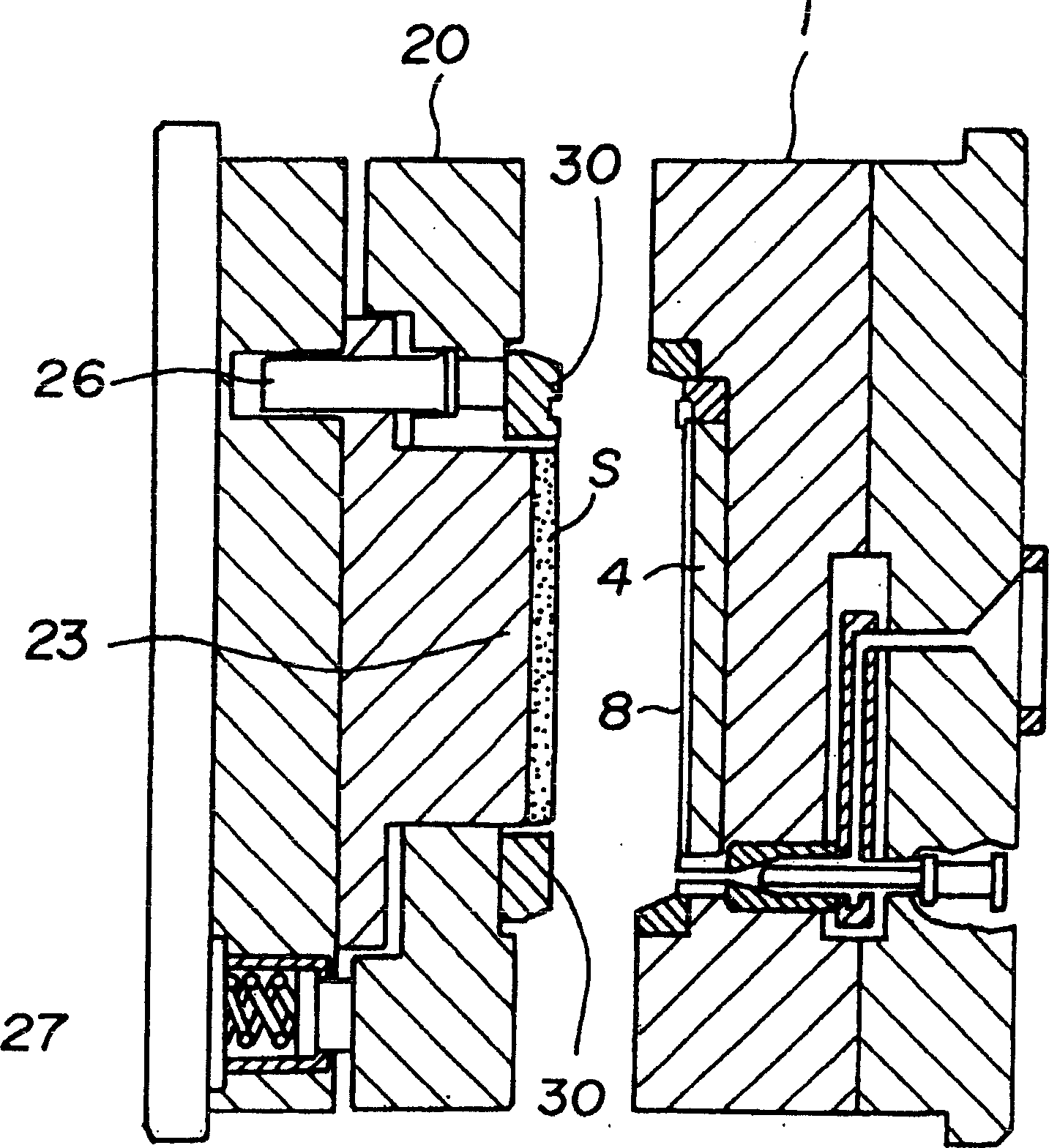

Molding method and apparatus for making resin molded article

In the molding method of the resin molding product in the invention, the foamable molten resin (R) containing reinforcing fiber and supercritical fluid is injected into a cavity (23) with a short shot mode, the foamable molten resin (R) is made self-foam and flow in the cavity (23), the dimension of the cavity (23) is increased by expanding the molds (21 and 22) to the preset position thereby expanding the foamable molten resin (R) in the cavity (23). During the expansion working procedure the expanding of the foamable molten resin (R) is assisted by the gas vent, vacuum suction, and partial pressure adding to the foamable molten resin (R) with a gas or a resin, or beforehand packing the reinforcing fiber in the foamable molten resin (R). The foamable molten resin molding product which has no bulky space, can sufficiently expand to increase the volume and has an excellent duplicating capacity can be manufactured when the invention is used.

Owner:MAZDA MOTOR CORP

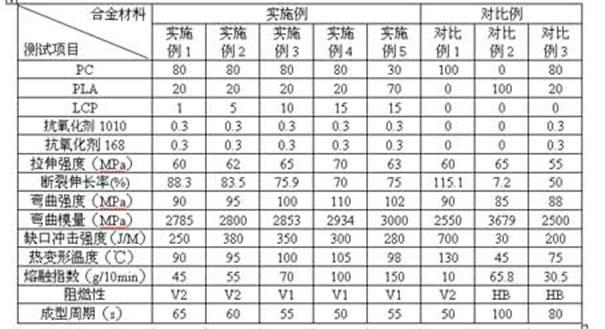

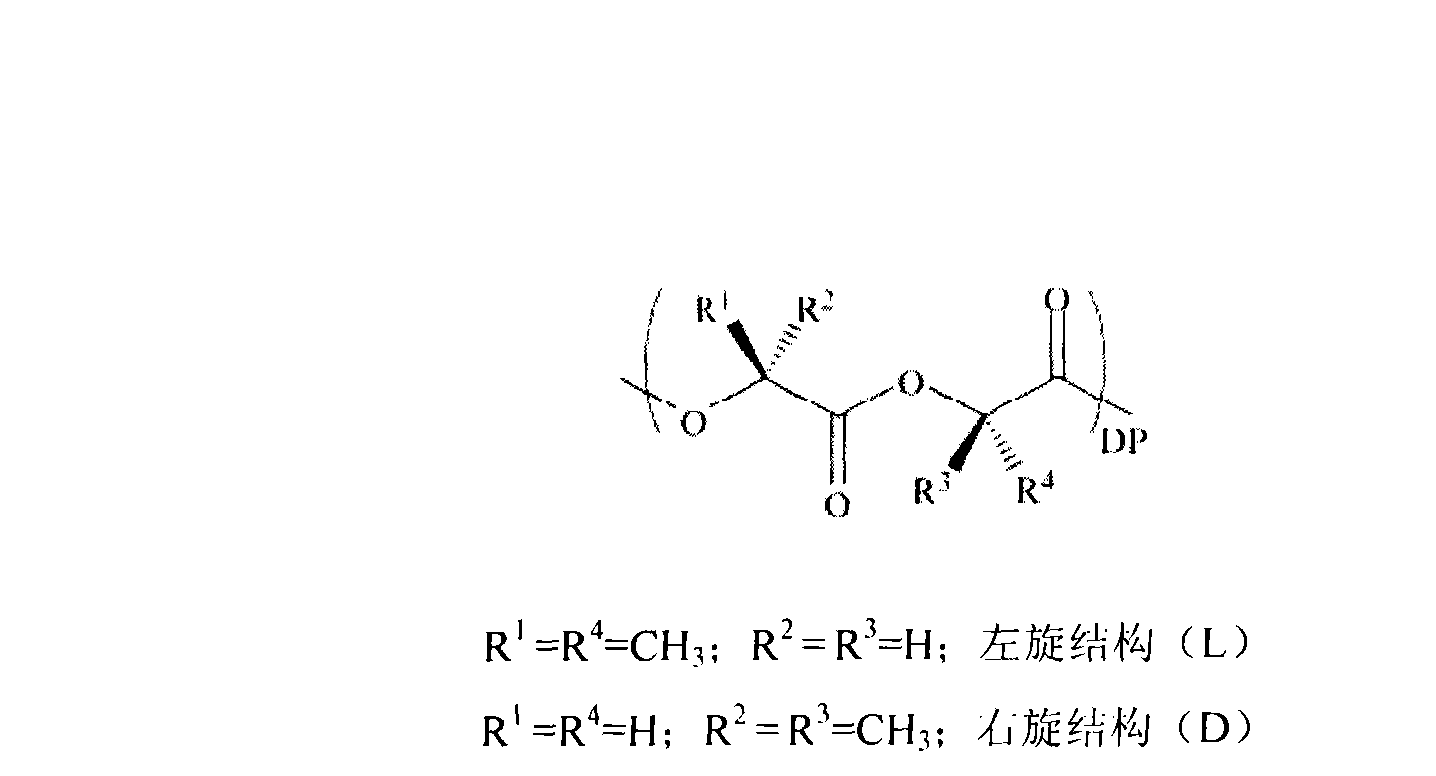

Polyactic acid/polycarbonate alloy material, and preparation method and application thereof

The invention discloses a polyactic acid / polycarbonate alloy material, and a preparation method and application thereof. The polyactic acid / polycarbonate alloy material comprises the following raw materials in part by weight: 10 to 90 parts of polycarbonate, 10 to 90 parts of polyactic acid, 1 to 20 parts of liquid crystal high polymer and 1 to 25 parts of flexibilizer. The polyactic acid / polycarbonate alloy material is prepared by adding the raw materials into a double-screw extruder to be melted and blended. The polyactic acid / polycarbonate alloy material provided by the invention has environmentally-friendly characteristics and excellent physical and mechanical properties, and greatly improves impact strength, bending modulus and heat distortion temperature. The liquid crystal high polymer is added to promote the quick crystallization of the polyactic acid, so that the prepared polyactic acid / polycarbonate alloy can be formed quickly, the forming cycle is reduced from 80 seconds to50 seconds, processing cost is reduced, flowability and fire resistance are improved, and the polyactic acid / polycarbonate alloy material is applicable in the fields of office automation (OA) equipment, communication equipment, automobile parts, domestic appliances and the like.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

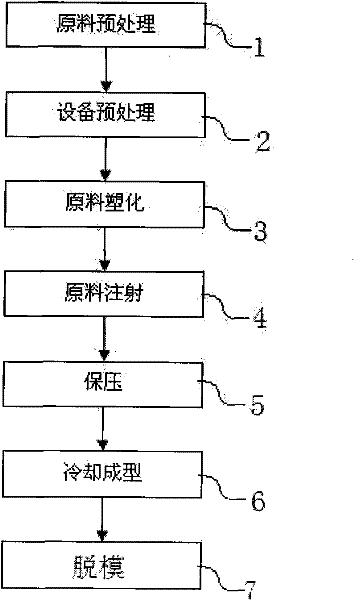

Injection molding technology for acrylonitrile butadiene styrene (ABS) plastic air conditioner shell

ActiveCN102407588AThe process steps are simpleEasy to implementCoatingsEngineeringInjection molding process

The invention discloses an injection molding technology for an acrylonitrile butadiene styrene (ABS) plastic air conditioner shell, and the technology comprises the following steps of: (1) pretreating raw materials; (2) pretreating an injection molding system and an injection molding mould; (3) plasticizing; (4) injecting; (5) maintaining the pressure; (6) molding by cooling; and (7) demoulding. The injection molding technology is simple in implementation steps, and can be used for effectively reducing the molding period and the production cost, and effectively improving the quality of finished products by virtue of the corresponding technological condition.

Owner:SHANGHAI PUDONG MEILING PLASTIC PROD

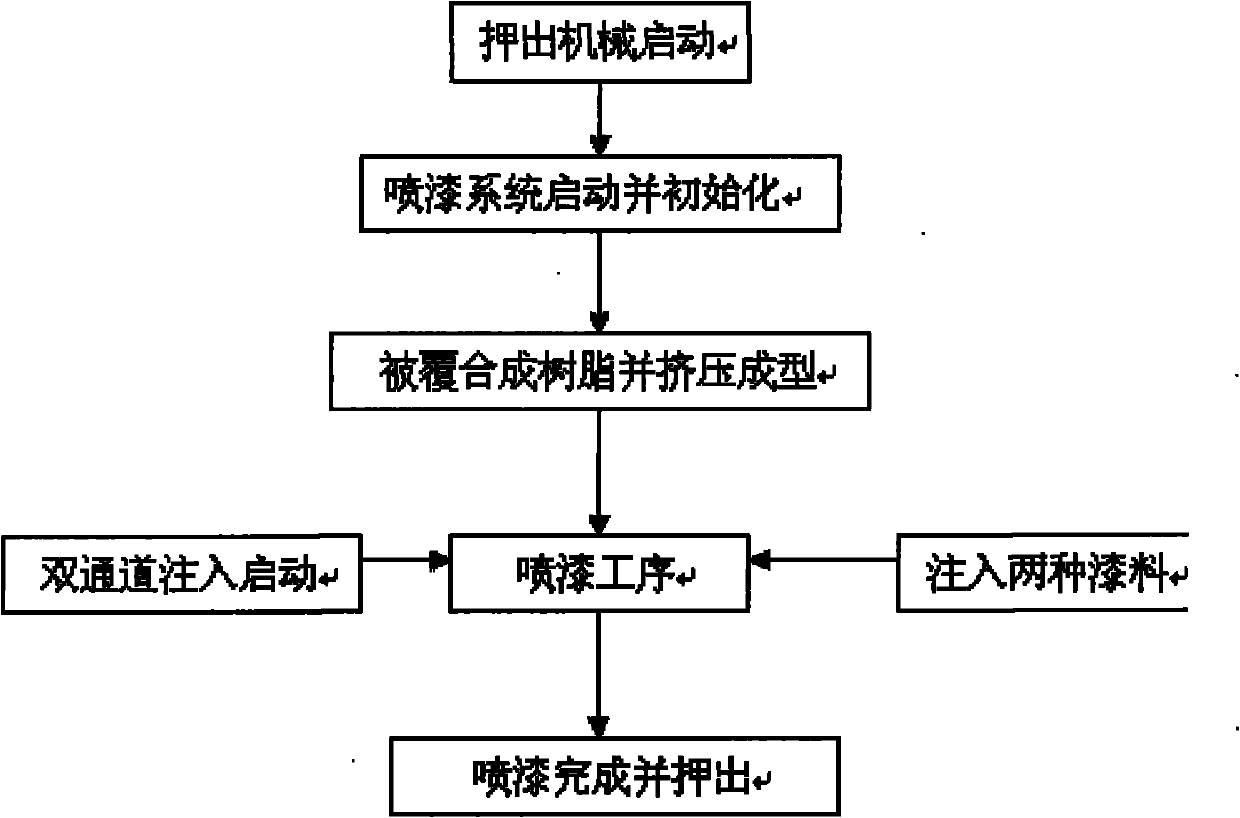

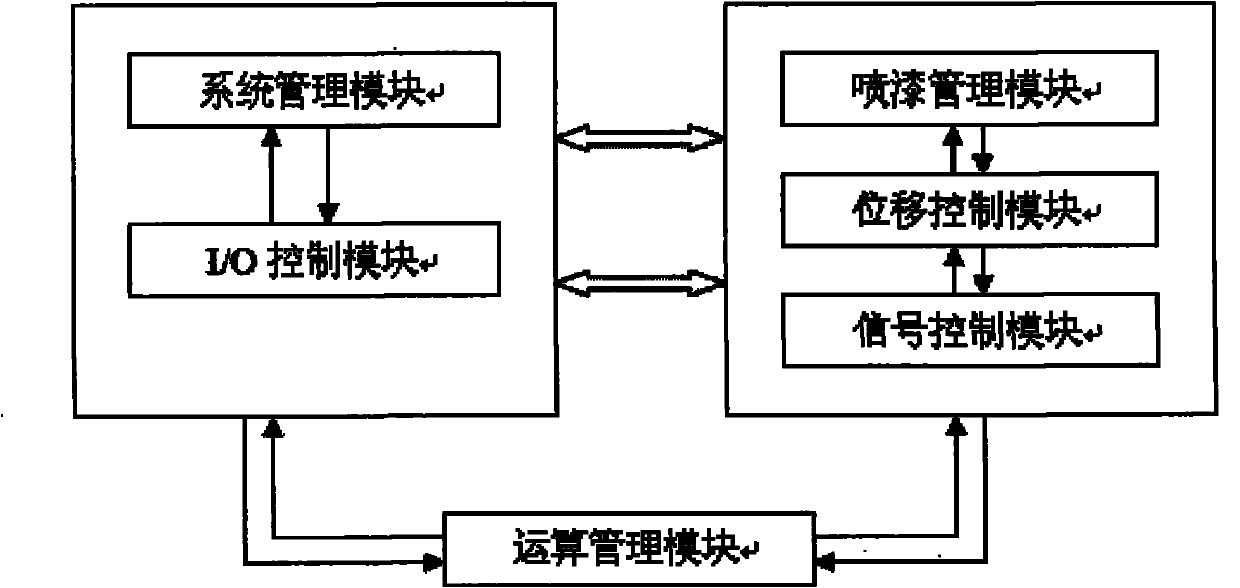

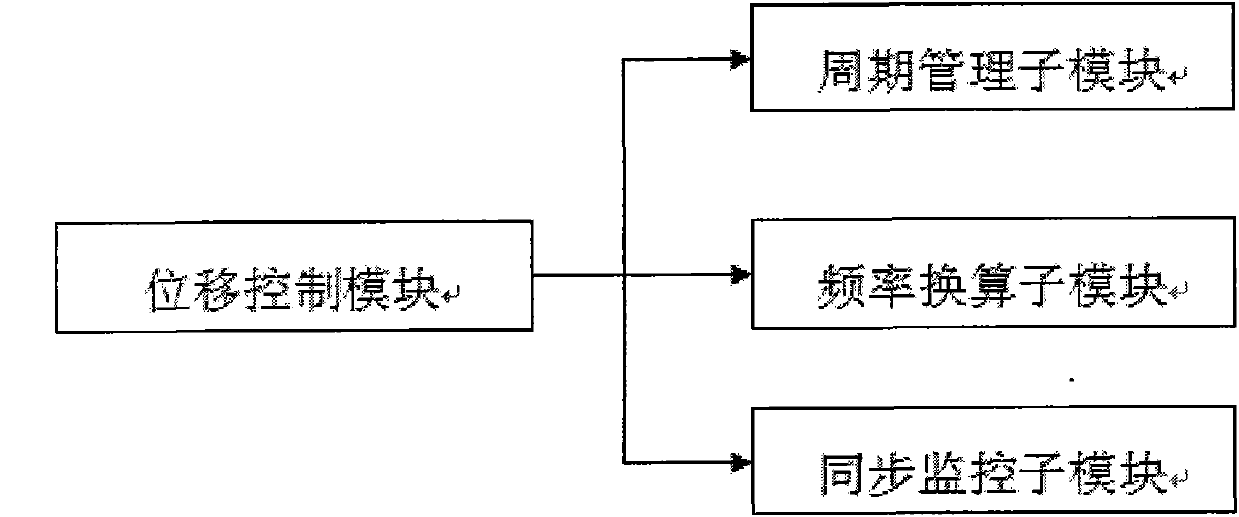

Automatic spraying process for precision hardware and spraying control method

InactiveCN102198434AImprove performanceEvenly distributed two colorsPretreated surfacesLiquid spraying apparatusProduction lineAutomatic control

The invention discloses an automatic spraying process for precision hardware and a spraying control method. The method comprises the following steps of: setting a product automatic spraying production line, sensor equipment, a core component precision gear pump, a spraying control system and an electrostatic generator device; and arranging a bilateral docking sensor and a multi-line configuration embedded control system; and realizing automatic control of a spraying process by matching an electric lift. A tunnel mode is adopted on the production line, one or more processing procedures are performed in each stage respectively, and the spraying process of a plurality of layers is completed once to form a composite coating on the surface of a structural piece according to a sequence from inner oil spraying to surface light spraying of a specific spraying process. A plurality of randomly set wave bands are itemized by using the spraying control system, wherein the operation speed of each wave band can be adjusted properly according to a complex workpiece so that the control process of the workpiece comprises multi-position spraying, multi-process spraying and multi-angle (360 DEG) spraying. The invention also discloses a spraying control system for implementing the method.

Owner:DONGGUAN GUANHUI HARDWARE

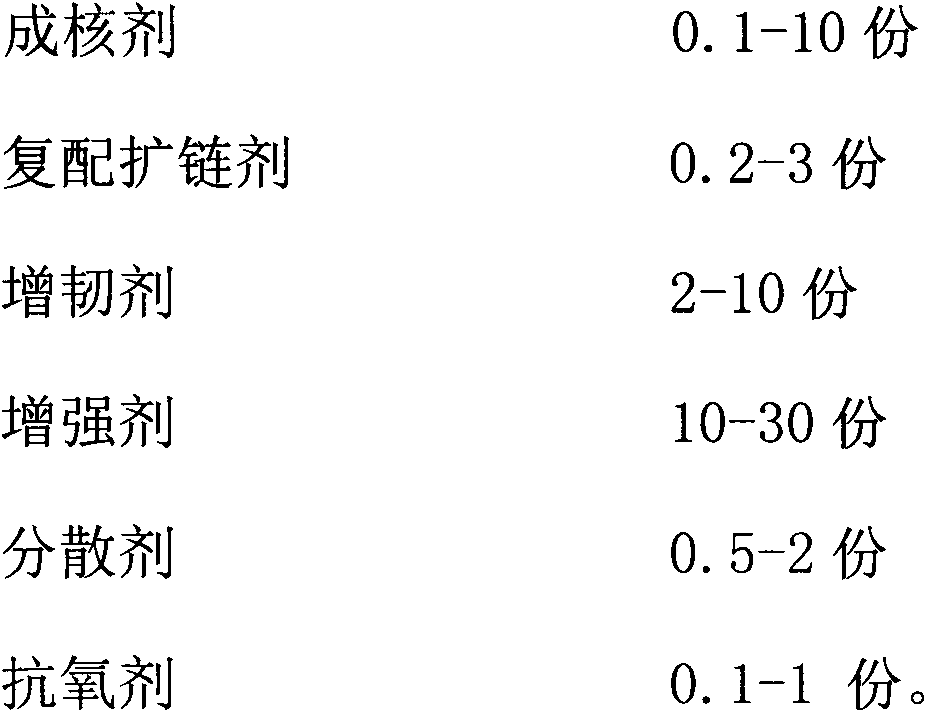

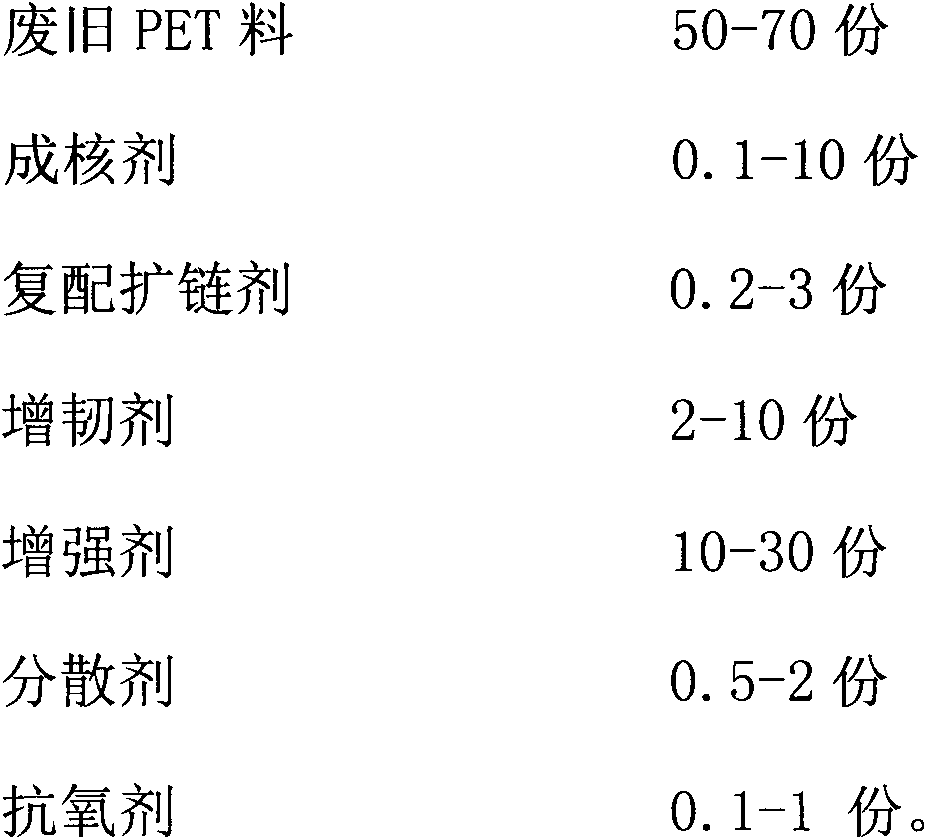

Waste PET (Polyester) heat-proof tackifying and reinforcing composite material and preparation process thereof

InactiveCN103146159AThe preparation process is simple and convenientGood mechanical propertiesPolyesterAntioxidant

The invention discloses a waste PET (Polyester) heat-proof tackifying and reinforcing composite material and a preparation process thereof. The preparation raw materials of the waste PET heat-proof tackifying and reinforcing composite material include a waste PET material, a nucleating agent, a compound chain extender, a toughening agent, a reinforcing agent, a dispersant and an antioxidant. When the waste PET heat-proof tackifying and reinforcing composite material is prepared, a first mixture formed by mixing the waste PET material and the toughening agent is added from a main feed port, the nucleating agent, the compound chain extender, the dispersant and the antioxidant are added from a powder side beside the main feed port in a feeding way, and the reinforcing agent is added from the feed port positioned at an extruder side, so that a small amount of powdery auxiliary agent and a main material can be uniformly mixed and the quality of a finished material is enhanced in such a unique charging way. The preparation process of the waste PET heat-proof tackifying and reinforcing composite material, which is disclosed by the invention, has the advantages of simple process and easiness for industrialization; and the waste PET heat-proof tackifying and reinforcing composite material disclosed by the invention has the advantages of high crystallization rate, high heat-proof temperature and excellent mechanical property.

Owner:江苏中再再生资源有限公司

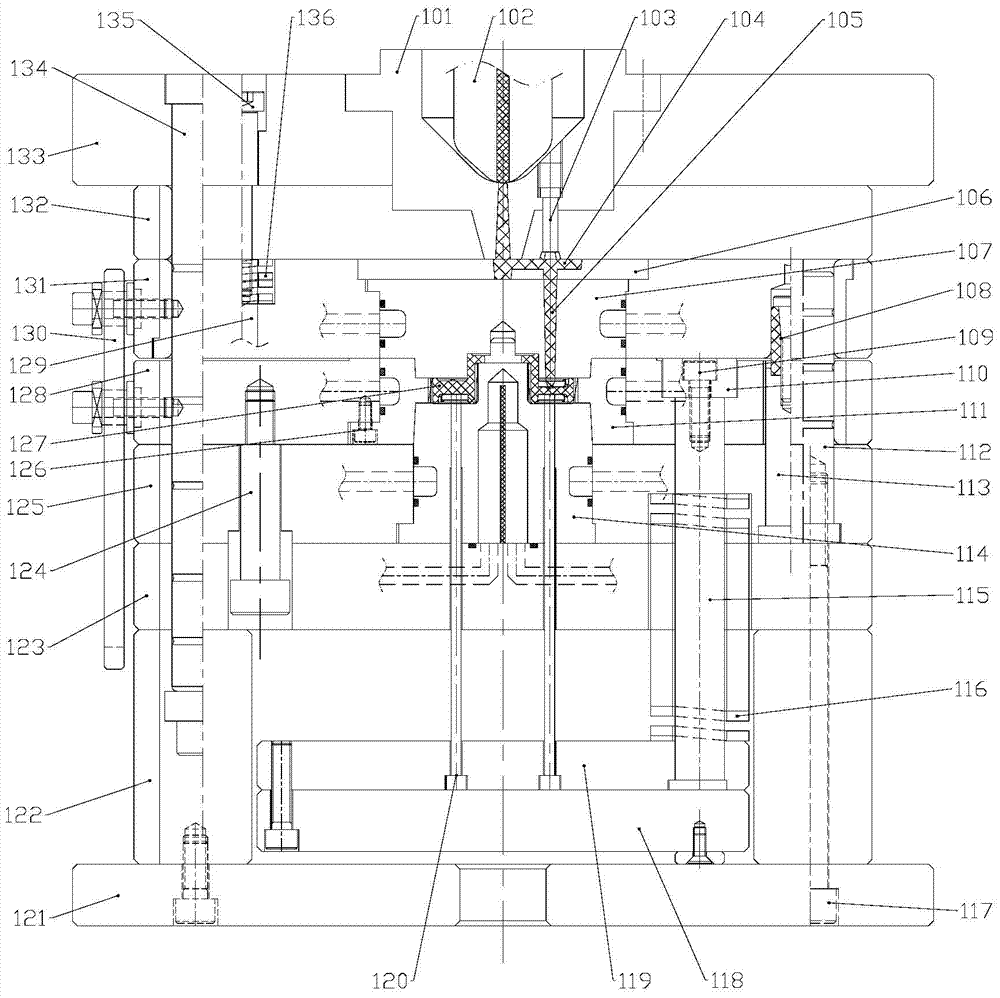

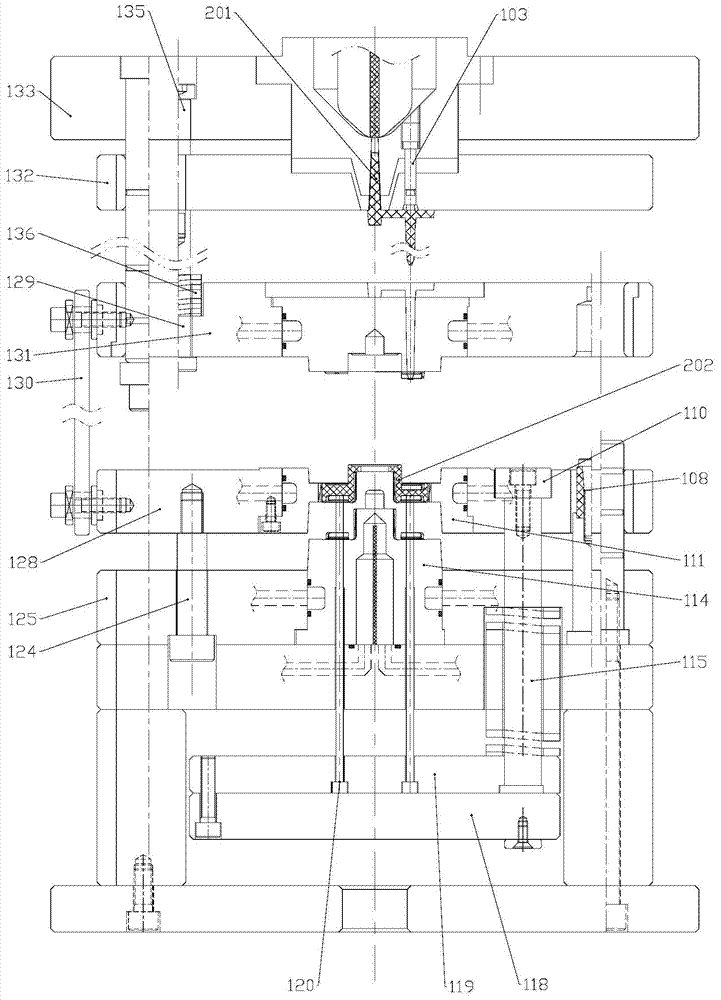

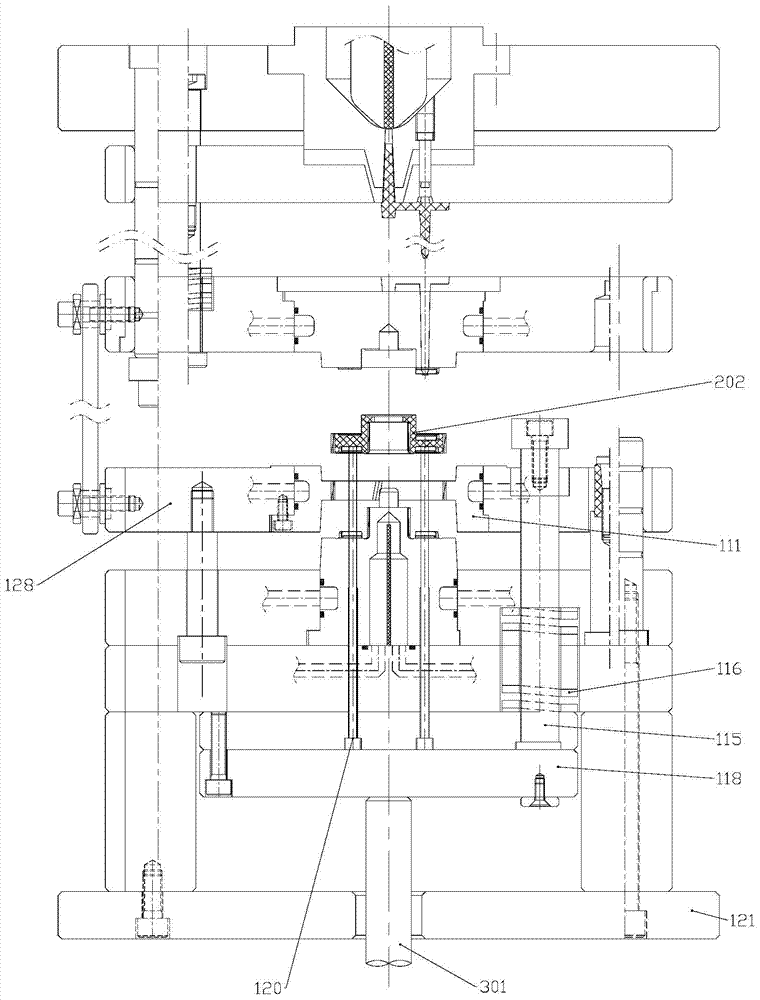

Demoulding structure for plastic helical gear injection molding

The invention relates to the field of mould making, in particular to a demoulding structure for plastic helical gear injection molding. The plastic helical gear mould comprises a fixing mould part, a moving mould part, and a demoulding component comprising a pulling plate fixed on a fixing mould cavity plate and a gear cavity plate, and an ejection structure arranged on the moving mould part, wherein a fixing mould cavity positioned in the fixing mould cavity plate, a gear cavity positioned in the gear cavity plate, and a moving mould cavity in the moving cavity plate mutually form step shapes, and sequentially and tightly connected in a sleeving manner to form a helical gear cavity. During the demoulding process, under the effect of the demoulding component, the injection molded plastic helical gear rotationally moves forwards in a spiral manner along the inner surface of the gear cavity to realize mold stripping, so that the finished plastic helical gear is obtained. The structure has the advantages that the mould is simple in structure, high in product accuracy and stable in production, and overcomes difficulties of easiness in deformation of the spiral plastic helical gear during the injection process, gear ring cooling, gear ring resetting performed to satisfy the requirements for gear position.

Owner:SHENZHEN HISYM IND

High speed injecting molding method by counter pressure method and chemical foaming method

The invention involves a counter-pressure chemical foaming high speed injection moulding shaping method. The invention provides a method which utilizes injection moulding shaping machine equipment, and dies, general gas energy, plastic raw materials and other system resources comprehensively, produces thick-wall plastic-foam product high speed and high effectively. The invention first closes the die and injects gas into die cavity, then injects molten material into die cavity, the welding fluid is full of die cavity after inner foaming, the molten material surface is closed to the metal wall-surface of die cavity, the molten material in die cavity is solidified and shaped after cooled, then opens the moving mold and static mold, the plastic products are prepared which surface is smooth and dense and inner is distributed with uniform foam. The invention can eliminate or reduce the converging cave and warping deformation of product surface, reduces injection moulding pressure, thereby reduces the lock-mode pressure of injection machine; reduces equipment operating costs, thereby improves the size accuracy and strength of products, can reduces 15% ~ 35% raw material consumption effectively, products have higher mechanical property and weight proportion.

Owner:DONGHUA MACHINERY

Flame-resistant PC (Polycarbonate)/PBT (Polybutylene Terephathalate)/PET (Polyethylene Terephathalate) alloy and preparation method thereof

The invention relates to a flame-resistant PC (Polycarbonate) / PBT (Polybutylene Terephathalate) / PET (Polyethylene Terephathalate) alloy and a preparation method thereof. The alloy is prepared from the following components in percentage by weight: 30-50 percent of PC, 10-30 percent of PBT, 10-20 percent of PET, 3-8 percent of toughening compatibilizer, 9-15 percent of flame retardant, 4-8 percent of flame-resistant synergistic agent, 0.4-1 percent of antioxidant and 0.4-1 percent of processing aids, wherein the flame retardant is one of bromine brominated epoxy resin, brominated polystyrene and decabromodiphenylethane, the toughening compatibilizer is an ethane-methyl acrylate copolymer and (or) an ethane-methyl acrylate-methacrylic acid glycidyl ester copolymer. The preparation method of the flame-resistant PC / PBT / PET alloy comprises the following steps of: drying raw materials; fully mixing; stirring for 10-20min at a room temperature; and melting, blending and extruding. The alloy phase has excellent comprehensive performance and high performance price ratio, reaches the flame-resistant level of UL94-V0 and can meet the special use requirements of a certain places.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

Low-warpage carbon-fiber-reinforced polyethylene terephthalate (PET)/polyester alloy and preparation process thereof

The invention discloses a low-warpage carbon-fiber-reinforced PET / polyester alloy and a preparation process thereof. The PET / polyester alloy comprises, by weight, 40-65% of PET, 7-30% of polyester, 0.5-1.5% of a polyester nucleating agent, 10-40% of carbon fibers, 3-10% of a compatilizer, 0.5-1% of an antioxidant and 0.5-1% of a lubricating agent. The preparation process comprises the steps of firstly, placing the PET, the polyester, the polyester nucleating agent, the compatilizer, the antioxidant and the lubricating agent into a highly mixing machine for mixing for 3-5min, then adding from a first section barrel of a double-screw extruder, adding the carbon fibers from a fourth section barrel of the double-screw extruder, controlling the revolving speed of the double-screw extruder to be 35-40Hz, and performing extruding granulating at the temperature of 240-250DEG C, so that the low-warpage carbon-fiber-reinforced PET / polyester alloy which is high in mechanical property, short in molding cycle and attractive in product appearance is obtained.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

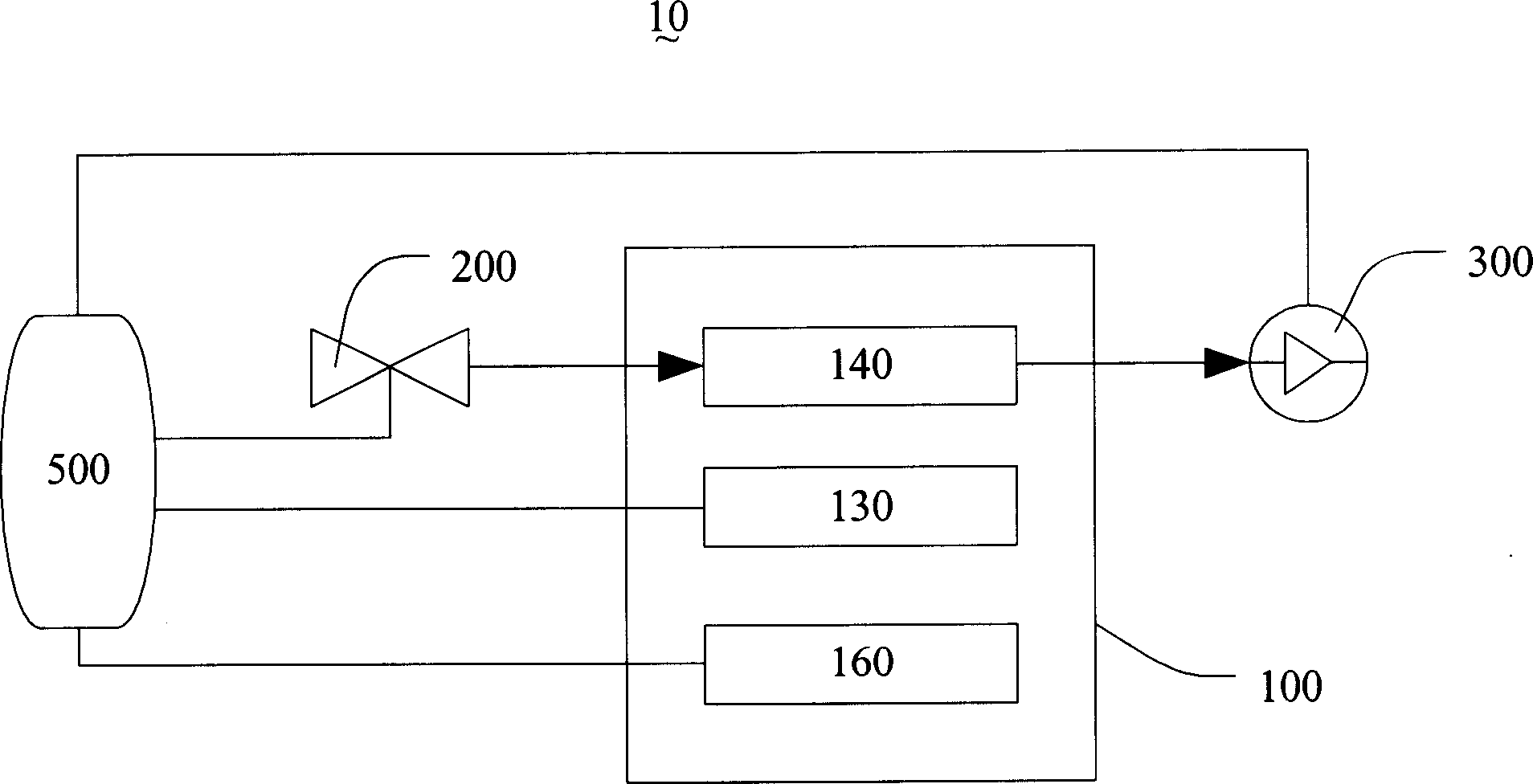

Jet forming system and method

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Rapid prototyping material and preparation method thereof

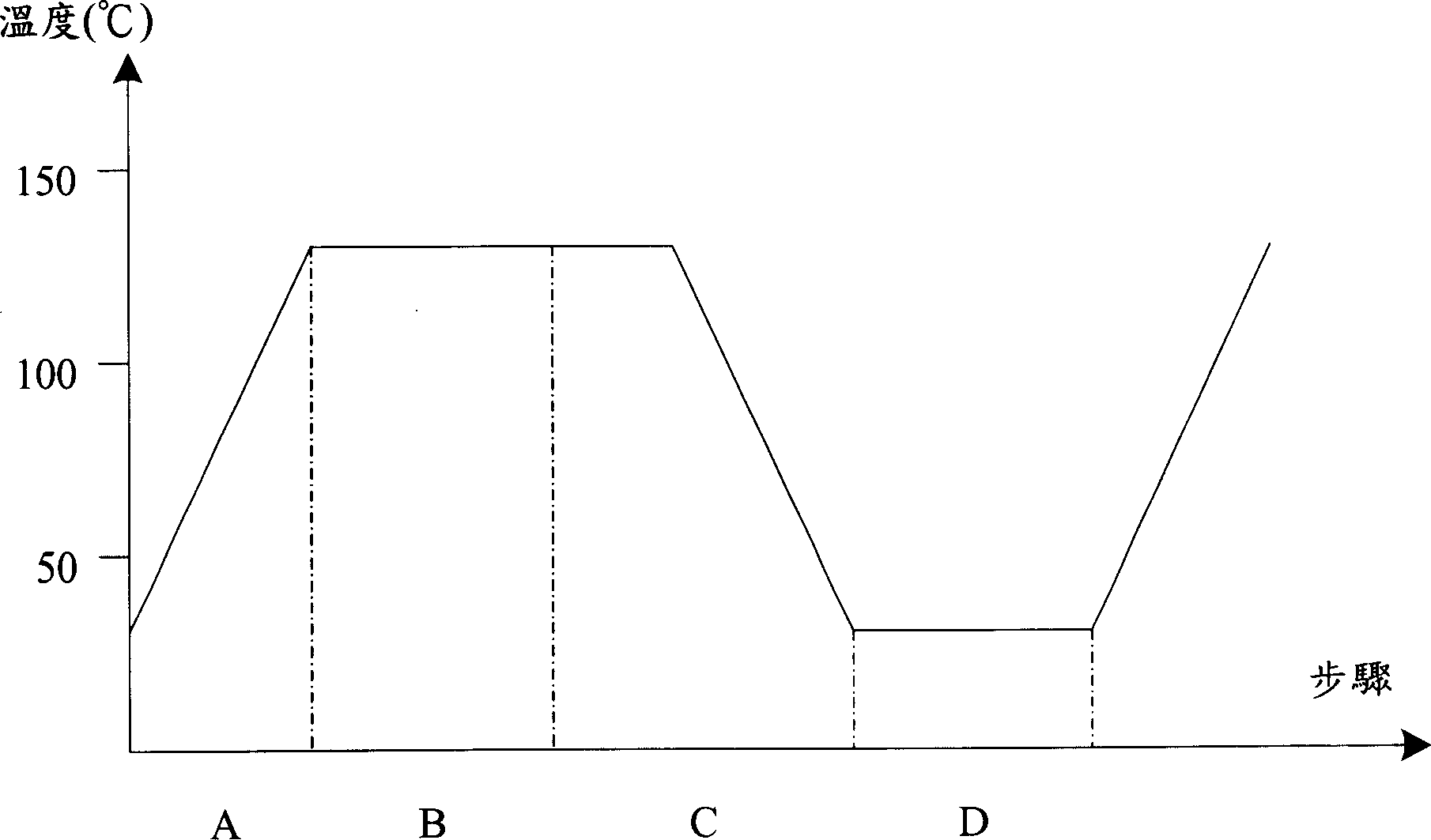

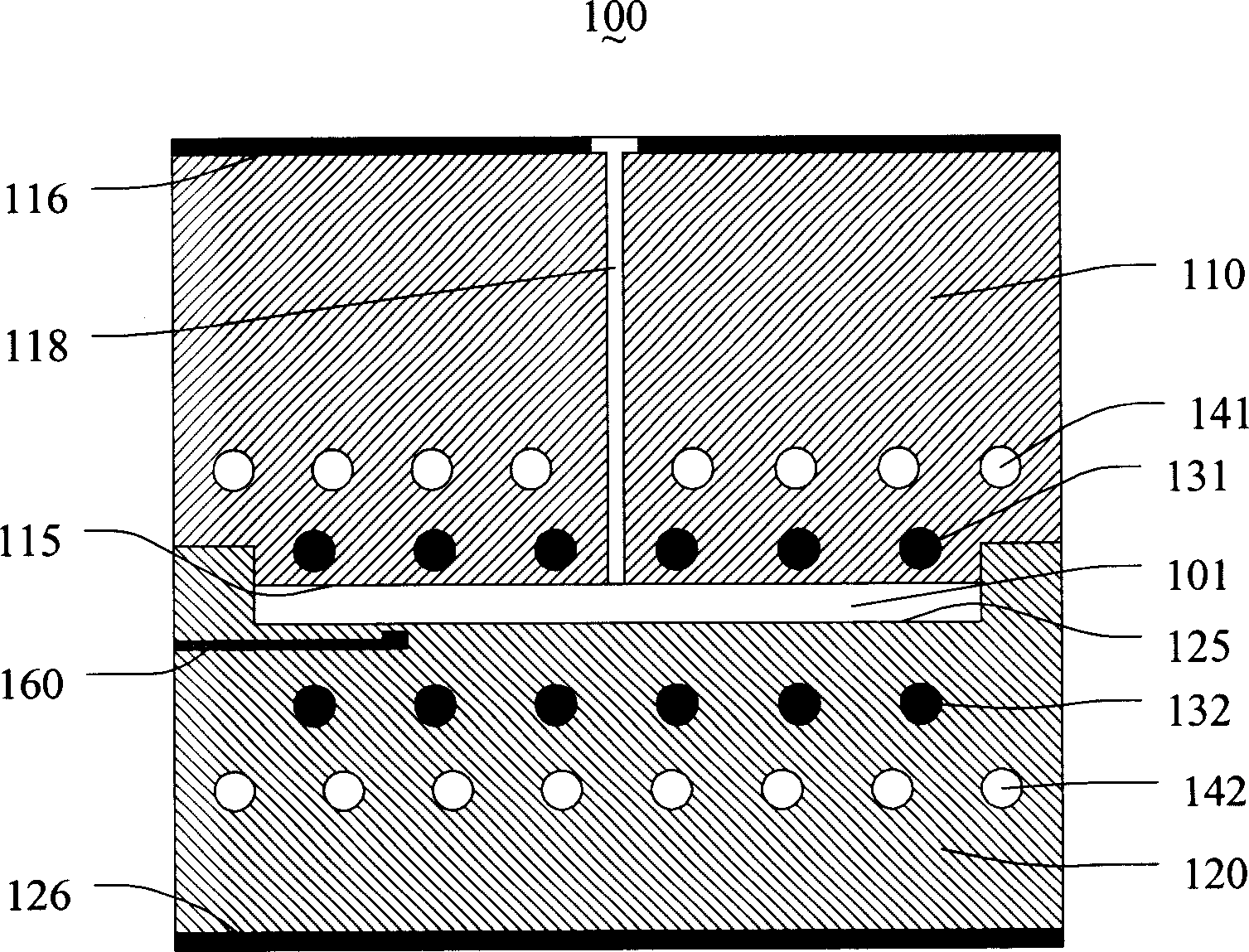

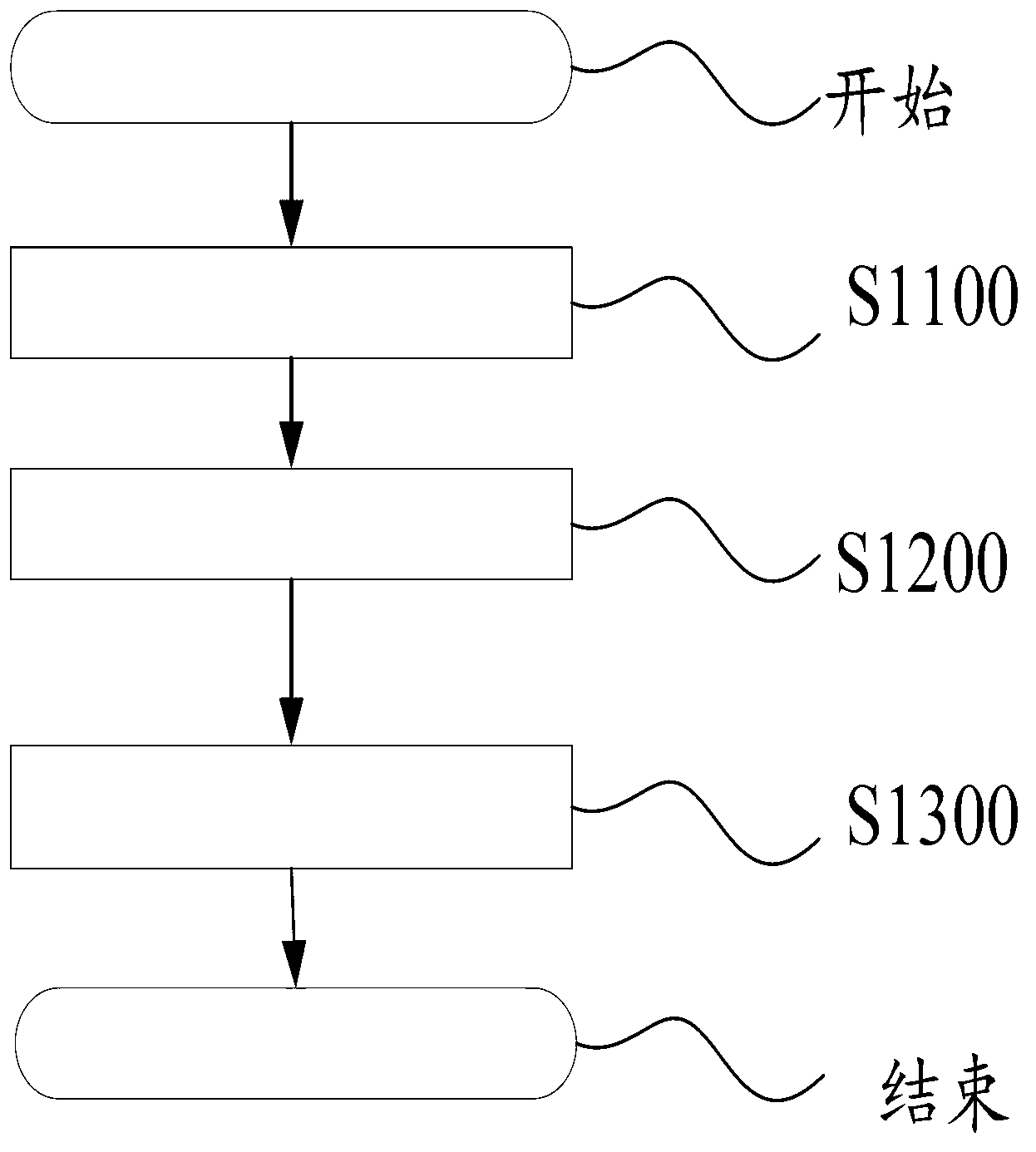

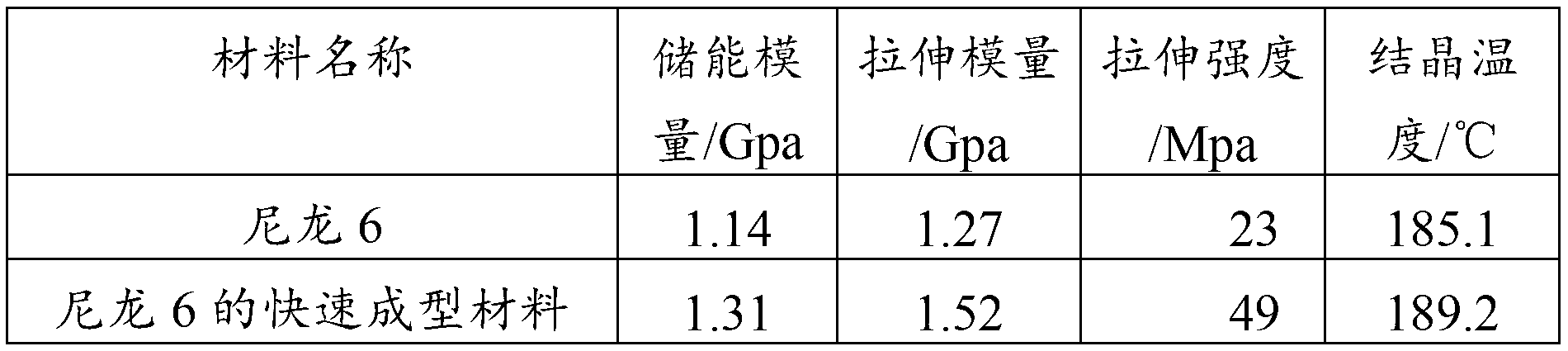

The invention discloses a preparation method of a rapid prototyping material. The preparation method comprises the steps of providing raw materials, wherein raw materials comprise the following ingredients in parts by weight: 85-97.5 parts of engineering plastics, 0.5-5 parts of nanocellulose and 2-10 parts of viscosity reducer; (S1100) weighing the raw materials: drying the raw materials for 4-10 hours at the temperature of 105 DEG C, and then, weighing the raw materials according to a weight ratio; (S1200) carrying out blending modification: carrying out three-dimensional stirring and blending on the weighed raw materials for 30-90 min; and (S1300) sieving: sieving the blended raw materials by using a sieve of 70-140 meshes. The invention further discloses the rapid prototyping material obtained through the preparation method. According to the rapid prototyping material disclosed by the invention, the preparation process is simple, and the industrialization is easy to realize; and the material is short in prototyping cycle, good in thermal stability and high in mechanical strength.

Owner:珠海市红旌发展有限公司

Fast shaping nylon 66 resin and its preparation method

The present invention discloses one kind of fast formed nylon-66 resin and its preparation process. The fast formed nylon-66 resin has main material including nylon-66 in 66 100 weight portions, and nucleater in 10-4-1 weight portions. It is prepared through vacuum drying nylon-66 powder and mixing nylon-66 powder and nucleater in a high speed kneading machine. Or, the nucleater is added during polymerizing nylon-66 for well mixing to obtain the fast formed nylon-66 resin. The present invention has simple preparation process suitable for industrial production, and the fast formed nylon-66 resin has short forming period and raised mechanical performance.

Owner:ZHENGZHOU UNIV

Method for producing polypropylene type resin foamed particle

The present invention relates to a method for producing expanded polypropylene resin particles, wherein favorable expanded particles that are not fused together can be obtained without inconsistencies caused by differences in the amount of dispersant adhering to the expanded particles that are obtained or the amount of dispersant which is added to prevent the resin particles from fusing together during a heat treatment step for ensuring the blowing agent impregnation of resin particles dispersed in an aqueous medium in a pressure tight vessel during the production of expanded polyolefin resin particles using a physical blowing agent, and it is also possible to more consistently produce expanded polyolefin resin particles which fuse together better when such expanded particles are molded, giving moldings with better mechanical strength. The method of the present invention is a method for obtaining expanded particles by allowing polypropylene resin particles impregnated with a physical blowing agent, which have been heated along with an aqueous medium and a dispersant, to be released and expanded at reduced pressure from the interior of a pressure-tight vessel, wherein the aforementioned aqueous medium has an electrical conductivity of from not less than 0.00 mS / m to not more than 20.00 mS / m.

Owner:JSP CORP

Production method of polypropylene cooling masterbatch

InactiveCN101798422AFast degradationReduce volatilityMonocomponent polyolefin artificial filamentMasterbatchPolymer science

The invention discloses a production method of polypropylene cooling masterbatch, including the following steps: (1) mixing: the following components by parts by weight are mixed for 10-20 minutes: 50-90 parts of polypropylene resin, 0.5-9.5 parts of dispersing agent, 0.1-0.6 part of surface modifier, 0.1-2.7 parts of lubricant and 0.2-0.8 part of liquidity regulator, and then the following components by parts by weight are sequentially added: 0.1-0.9 part of light stabilizer, 0.1-1.6 parts of antioxidant and 0.2-7 parts of molecular weight regulator, and mixing is carried out for 5-15 minutes; (2) pelletizing: the mixed material is subject to melt extrusion at 130-230 DEG C and then grain-sized dicing is carried out. The invention adopts compound peroxide as molecular weight regulator and adopts compound antioxidant, compound dispersing agent, compound light stabilizer and compound lubricant, and the produced polypropylene cooling masterbatch has the advantages of high initiator content, good dispersity and obvious cooling effect and modification effect.

Owner:郭学阳

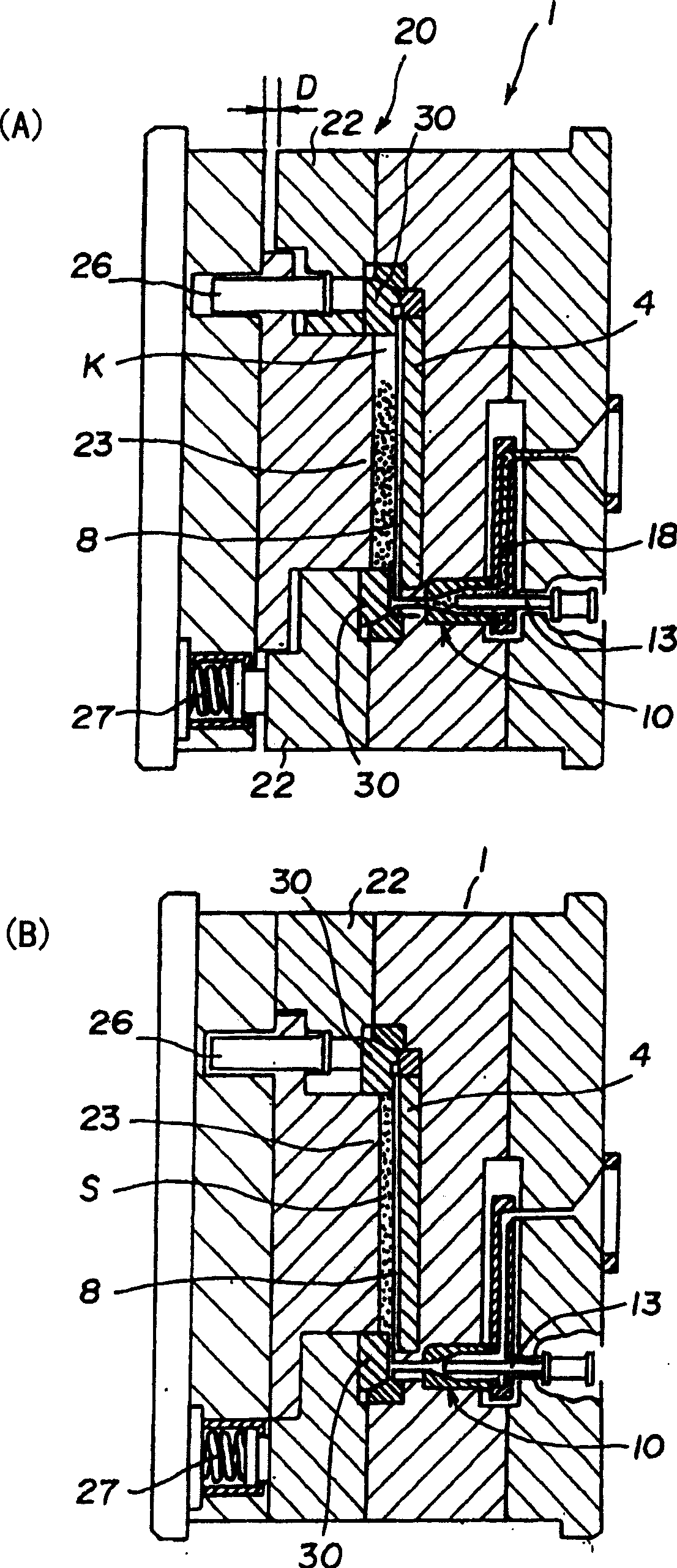

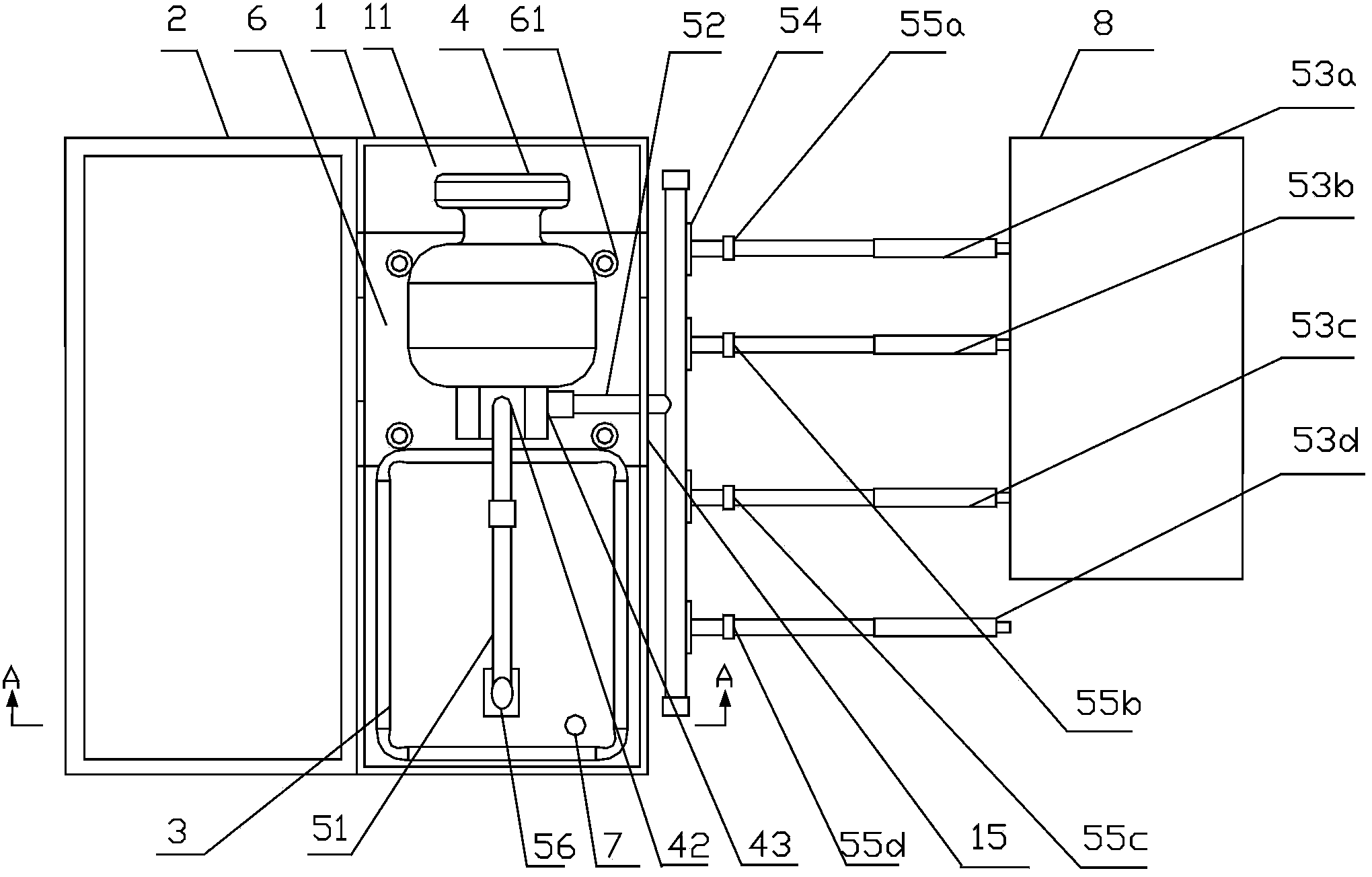

Shaping method of thick light guiding plate and its mould

InactiveCN1727169AShorten filling timeShorten molding cycleOptical articlesOptical light guidesLight guideCooling speed

The present invention provides a molding method capable of molding a thick-walled light guide plate of high quality by a short molding cycle. A predetermined amount of a molten resin is charged in the shaping space K constituted of the stamper (8) provided to the core (4) on the cavity side of a fixed mold, the core 23 on the core side of a movable mold and cores 30 and 30 on the peripheral wall side of the movable mold. Then, a valve gate is closed to compress the molten resin by the core 23 on the core side. Transfer properties are enhanced by compression and the molding cycle is shortened. At the time of compression, the temperature of the cores (30 and 30) on the peripheral wall side is made higher than the temperature of the core (4) on the cavity side and the core (23) on the core side. By this constitution, the cooling speed of the cores (30 and 30) on the peripheral wall side becomes slow to enhance a compression effect and the occurrence of a sink is suppressed.

Owner:JAPAN STEEL WORKS LTD +2

Flame-retardant glass fiber reinforced polypropylene composite material for manufacturing coil frame and preparation method thereof

The invention discloses a flame-retardant glass fiber reinforced polypropylene composite material for manufacturing a coil frame and a preparation method thereof. The composite material is mainly prepared from polypropylene, glass fiber, a fire retardant, a compatilizer, a nucleating agent, a dispersing agent and an antioxidant serving as raw materials. The preparation method comprises the following steps of: (1) uniformly mixing the polypropylene, the fire retardant, the compatilizer, the nucleating agent, the dispersing agent and the antioxidant; and (2) performing melt extrusion on the mixed raw materials obtained by the step (1) and the glass fiber in a melt extruder and pelleting to obtain a product. The invention provides the flame-retardant glass fiber reinforced polypropylene composite material for manufacturing the coil frame and the preparation method thereof.

Owner:ANHUI KEJU NEW MATERIALS

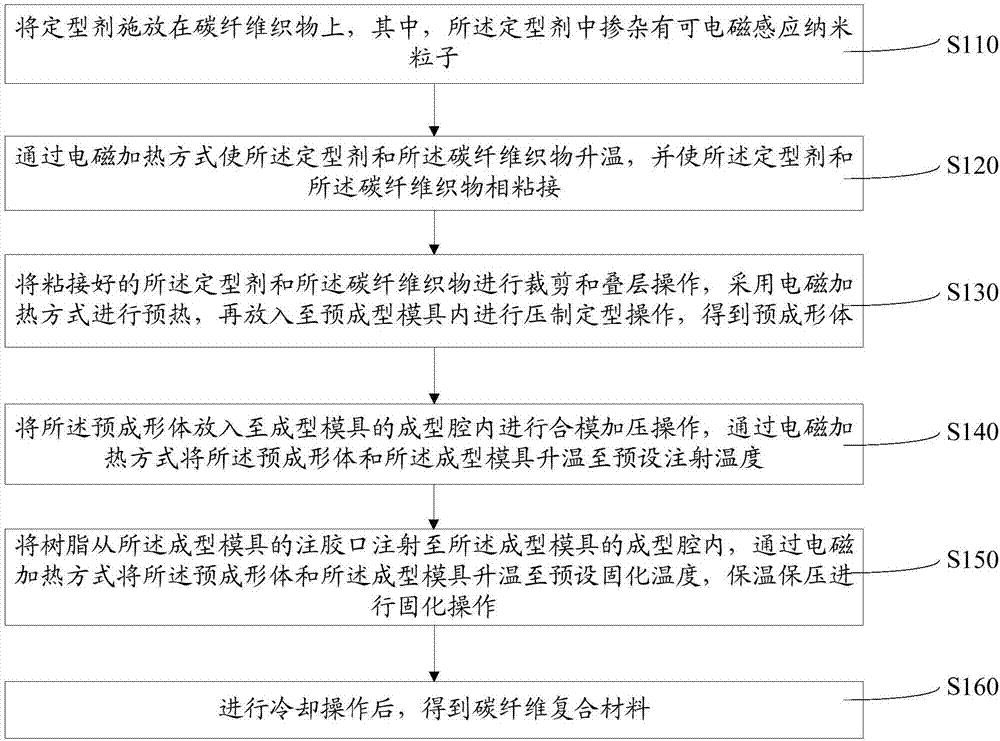

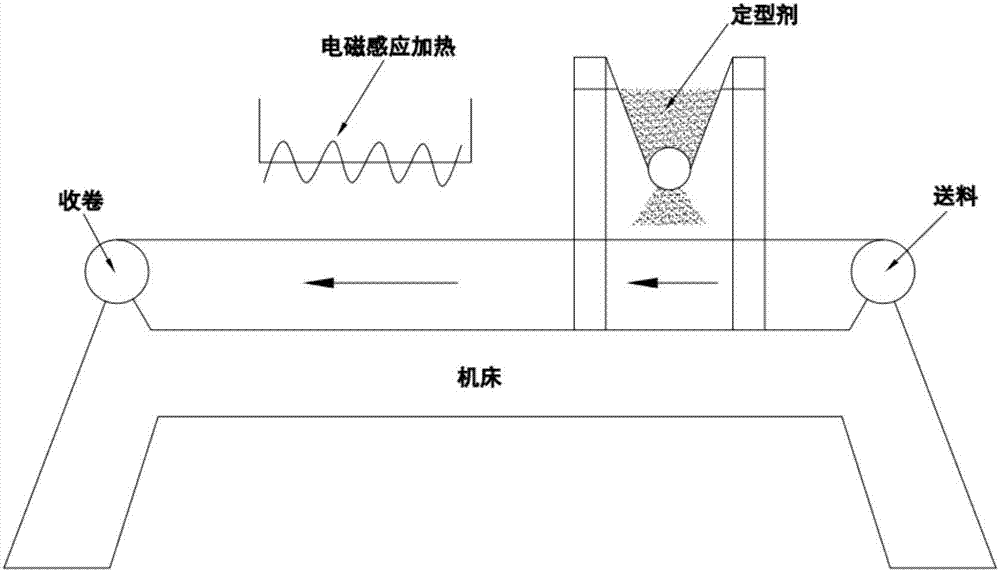

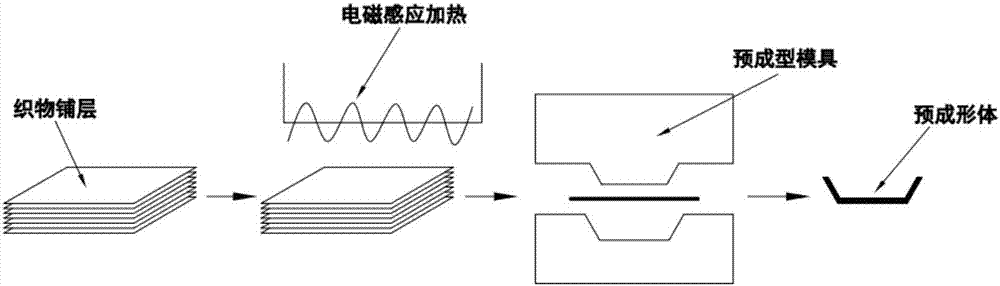

Manufacturing method for carbon fiber composite material

The invention discloses a manufacturing method for a carbon fiber composite material. The manufacturing method comprises the steps that a sizing agent is applied on carbon fiber fabrics, wherein electromagnetic-induction nano particles are doped in the sizing agent; the sizing agent and the carbon fiber fabrics are heated in an electromagnetic heating mode and are enabled to adhere to each other; the bonded sizing agent and carbon fiber fabrics are subjected to cutting and laminating operation, are preheated by adopting the electromagnetic heating mode and then are put into a pre-forming mold to be subjected to pressing shaping operation so as to obtain a pre-formed body; the pre-formed body is placed into a forming mold to be subjected to mold closing pressurization operation, and the pre-formed body and the forming mold are heated to a preset injection temperature in the electromagnetic heating mode; resin is injected into the forming mold, and the pre-formed body and the forming mold are heated to a preset curing temperature in the electromagnetic heating mode; and after curing molding cooling, demoulding is carried out to obtain the carbon fiber composite material. The method has the advantages that the rate of temperature increase by heating is high, the product manufacturing efficiency is high, and the energy consumption and the manufacturing cost are low.

Owner:惠州市海龙新材料科技有限公司

Composite material of shell micro powder filling bio-based resin and method for preparing same

ActiveCN101633775AImprove mechanical propertiesImproved Vicat softening temperatureChemical LinkageUltrasonic cavitation

The invention provides a composite material of shell micro powder filling bio-based resin and a method for preparing the same. The composite material comprises the following component in percentage by mass: (1) 20 to 60 percent of shell micro powder, 40 to 80 percent of bio-based resin, 1.5 to 8 percent of coupling agent and 0.2 to 0.4 percent of anti-oxidant; and or 20 to 60 percent of shell micro powder, 40 to 80 percent of bio-based resin, 0.6 to 3 percent of isocyanate, 0.05 to 0.1 percent of organic tin or organic stannous catalyst, and 0.2 to 0.4 percent of anti-oxidant. The invention also discloses a method for preparing the composite material. The method has the advantages of utilizing the ultrasonic cavitation to grind and disperse the shell micro powder, simultaneously accelerating the grafting or chemical bonding of the coupling agent or isocyanate on the surface of the shell micro powder, greatly shortening the modification time of the shell micro powder and the forming period of the composite material, and improving the interface compatibility and the bonding strength of the shell micro powder and the bio-based resin. The composite material is widely applied in fields of the production and consumption of automobile interior parts, stationery, road blocks, sporting goods, food bags, refuse bags, disposable tablecloth, outdoor flower pots, canteens, knives and forks and the like.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

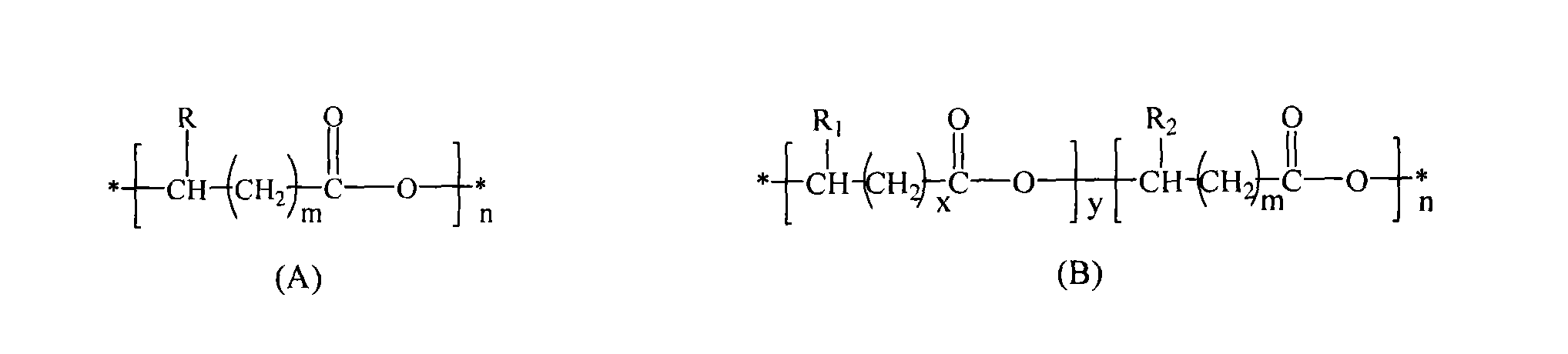

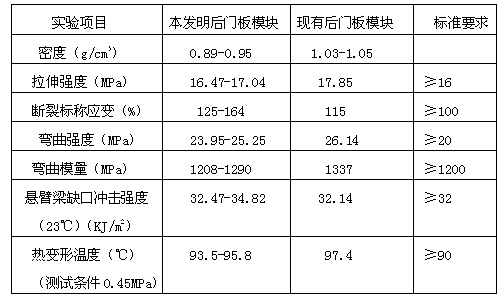

Low-density automobile back door plate module and preparation method thereof

The invention relates to a low-density automobile back door plate module and a preparation method thereof. The preparation method is used for reducing self weight of automobile back door plate modules and overcoming appearance defects of sink marks, warping deformation and the like. The low-density automobile back door plate module uses modified polypropylene particles and foaming masterbatches as raw materials and is produced through mixing injection molding, and the mass ratio of the modified polypropylene particles and the foaming masterbatches is 100: (1-4). According to the low-density automobile back door plate module and the preparation method thereof, the modified polypropylene particles and the foaming masterbatches are used as the raw materials, conventional injection processes are improved according to raw material characteristics and molding requirements, and a high-pressure high-speed injection process is used, so that the intensity of produced injection products is lower than that of ordinary polypropylene modules by 10%-15%, 10%-15% of a molding period can be shortened, the usage quantity of the raw materials is saved, and the molding period can be substantially shortened.

Owner:GREAT WALL MOTOR CO LTD

Mini-type iron piece automatic buried molding mechanism and molding method thereof

The invention relates to a mini-type iron piece automatic buried molding mechanism. The mechanism comprises a bearing jig and an insert jig, wherein the bearing jig is internally provided with bearing jig photoelectric inductors and bearing jig guide sleeves; the insert jig is provided with jig positioning columns and insert jig photoelectric inductors; the jig positioning columns and the bearing jig guide sleeves are mutually matched; the bearing jig photoelectric inductors and the insert jig photoelectric inductors are mutually induced; the insert jig is connected to a mechanical arm solenoid valve through an air cylinder; positioning pins in the insert jig and mold guide sleeves are matched and positioned; mold product positioning columns and a product are positioned; and weak magnets are matched with and adsorb iron pieces. The mechanism is simple in structure and stable and reliable in movement, is a mechanical type automatic mechanism and does not need subsequent manual operation, and therefore the labor intensity of workers is alleviated; and the production efficiency is greatly increased and automatic production is achieved.

Owner:上海英济电子塑胶有限公司

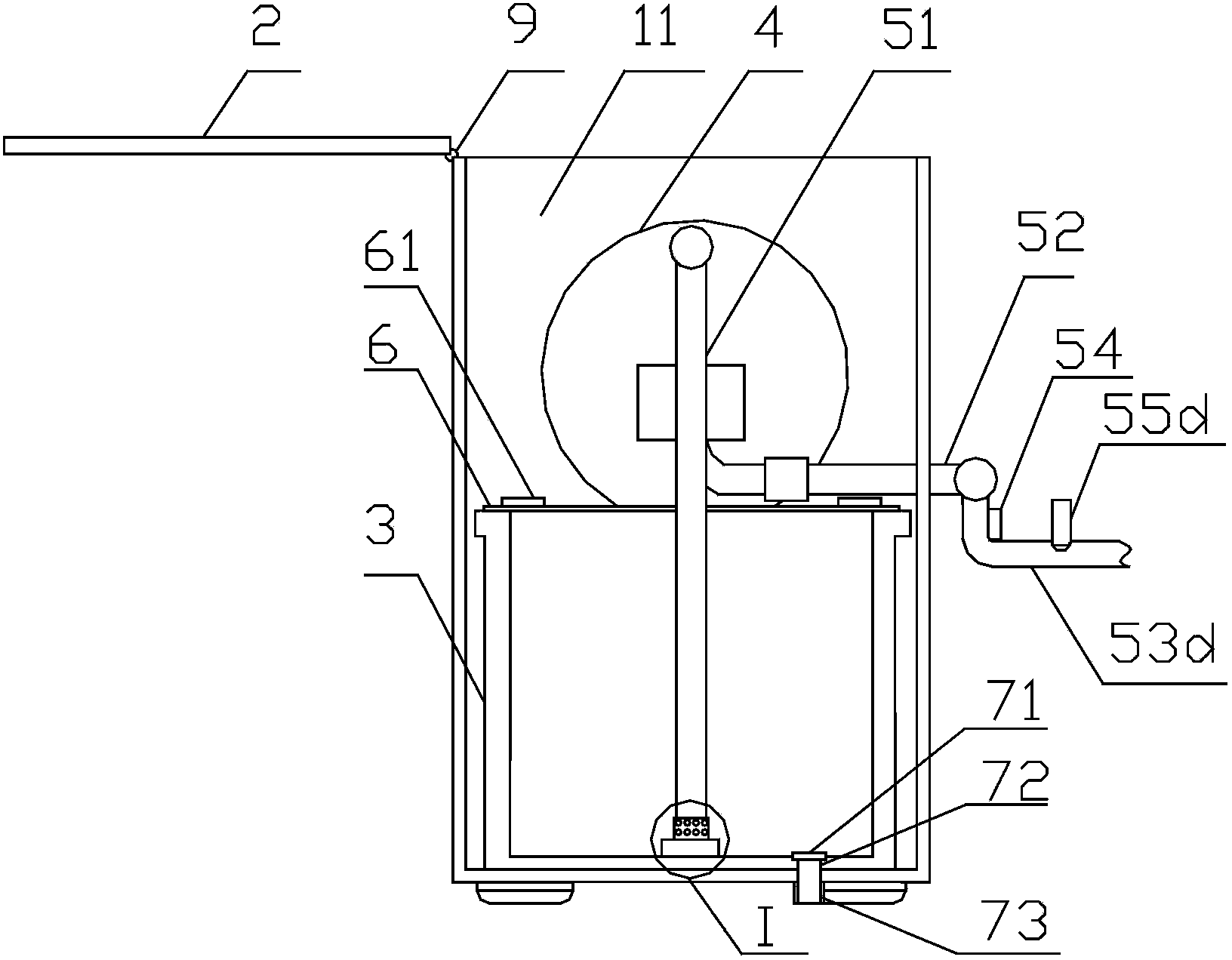

Cleaning device for die waterway

ActiveCN103406299AExtended service lifeFast heat conductionCleaning using liquidsEngineeringMechanical engineering

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

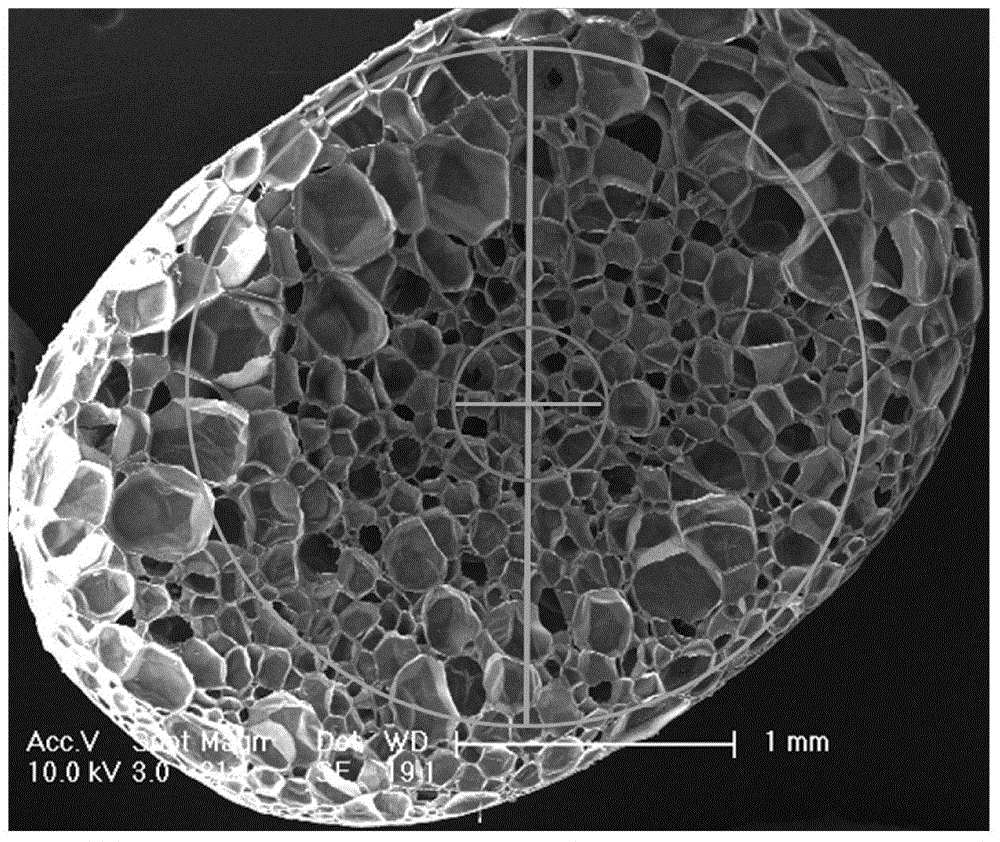

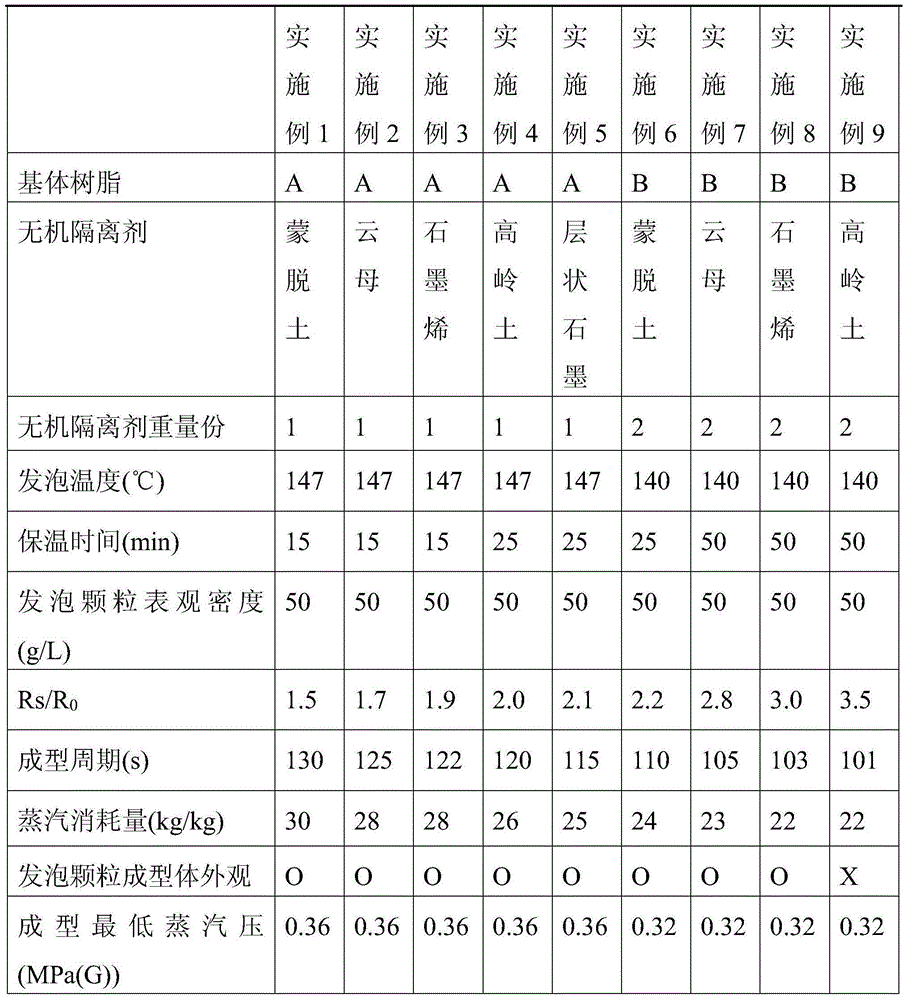

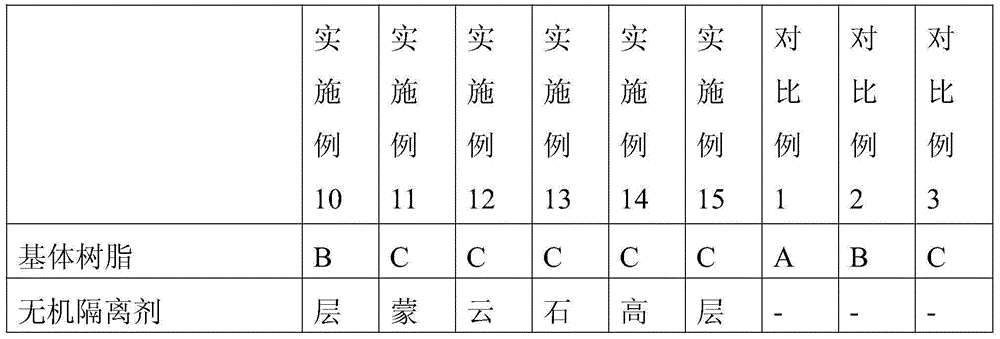

Polypropylene series resin composite foam particle, and preparation method and application thereof

The invention discloses a polypropylene series resin composite foam particle, and a preparation method and an application thereof, and belongs to the technical filed of foam materials. Technical problems of high molding pressure in a polypropylene series resin composite foam particle die, high preparation cost and long molding cycle in the prior art are solved. The foam particle is prepared through a dispersion medium release technology of blended resin particles, the cell diameters of the foam particle sequentially increase from inside to outside, and the average cell diameter Rs of a skin layer and the average cell diameter R0 of a core layer meet the following relationship: Rs / R0 is not smaller than 1 and not greater than 5; and the blended resin particles contain matrix resin and an inorganic separant, the mass fraction of the inorganic separant is 1-20%, the matrix resin is polypropylene series resin, and the inorganic separant is a layered inorganic substance. When the foam particle is used to prepare a foam body, the steam consumption is greatly reduced, the forming cycle is shortened, and the preparation cost is reduced; and the foam body obtained in the invention has smooth surface and excellent compliance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com