Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

612 results about "Injection product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

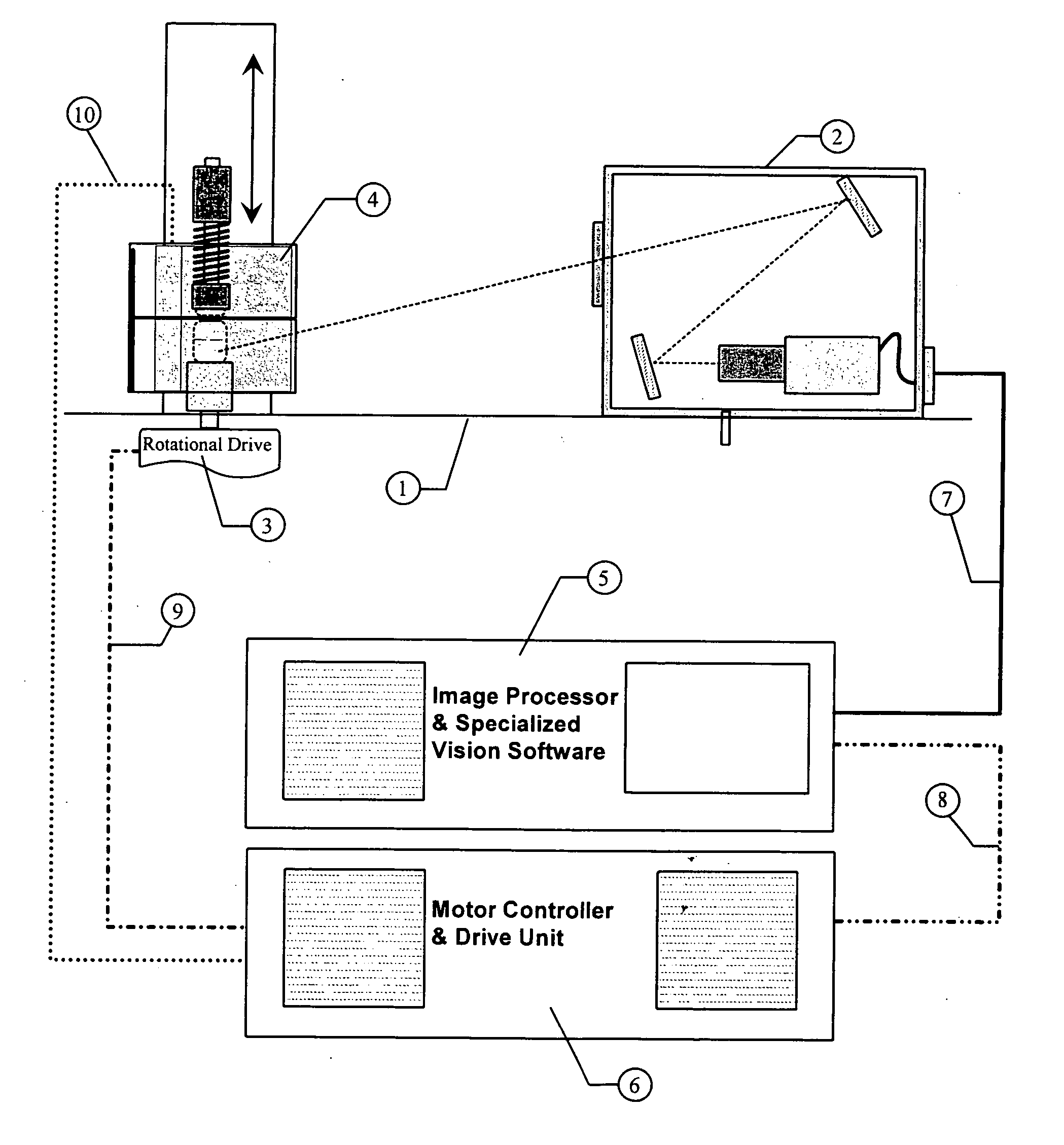

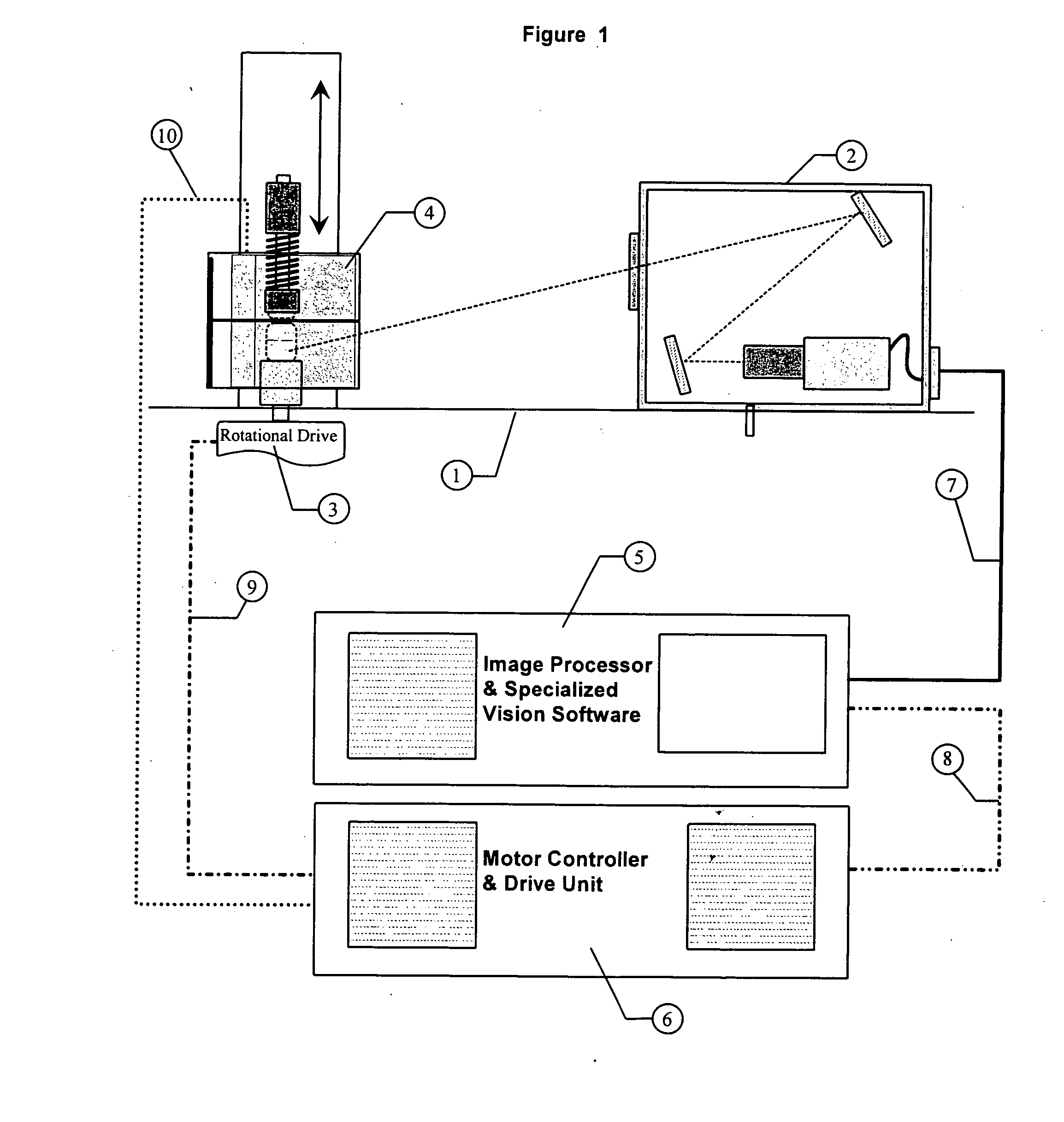

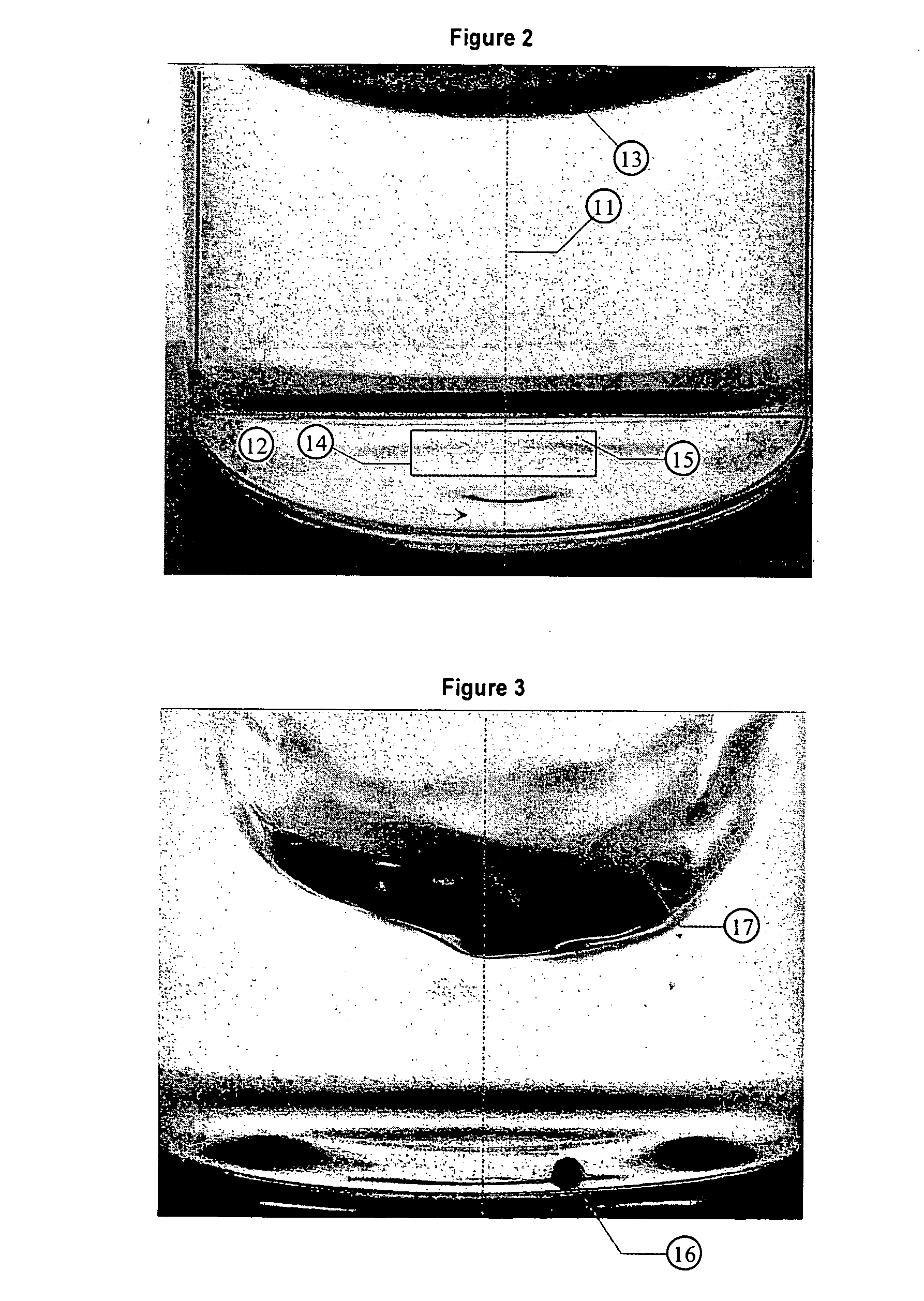

Small container fluid dynamics to produce optimized inspection conditions

ActiveUS20050248765A1Improve imaging characteristicReduce radiant energyOptically investigating flaws/contaminationIndividual particle analysisMeniscusEngineering

The generation of a desired non-linear resonance in the toroidal flow of liquid in a cylindrical injectable product is described. The resulting liquid flow pattern generated with an approximately smooth meniscus is down at the walls, across to the center of rotation, up on the center of rotation, across the meniscus to complete the pattern. The controlled flow pattern results in a predictable location for particle of varying mass and hydraulic shape. This predictability of location transforms the problem of particle detection from a chance occurrence to a deterministic task. The deterministic location of particle position is a contributor to the demonstrated capability to measure the size of visible particle range in a range from 33 μm to 1,000 μm with a median deviation of 1% and a maximum deviation from NIST dimensional accuracy of 3%.

Owner:BUDD GERALD WALTER +1

Injection moulding composition based on reclaiming ABS

InactiveCN101016401AImprove mechanical propertiesHas lasting effectCoatingsElastomerInjection product

The invention discloses a lifting property and effective ABS injection moulding component based on reclaiming, which is characterized by the following: The mass percent is: 50-95% reclaiming ABS, 5-40% elastic body flexibilizer, 0.1%-0.5% hyperoxide dissociate agent, 0.1%-0.5% complex light stabilizer, 0.1%-0.5% anti-oxidant, 1%-10% inorganic nanometer particle and 1%-5% inclusive agent, wherein the weight of inorganic nanometer particle is the guideline of mass percent of inclusive agent. This invention can not only modify mechanics property of rABS, but also can make rABS possess persisted property and be used to injection product.

Owner:ZHEJIANG UNIV

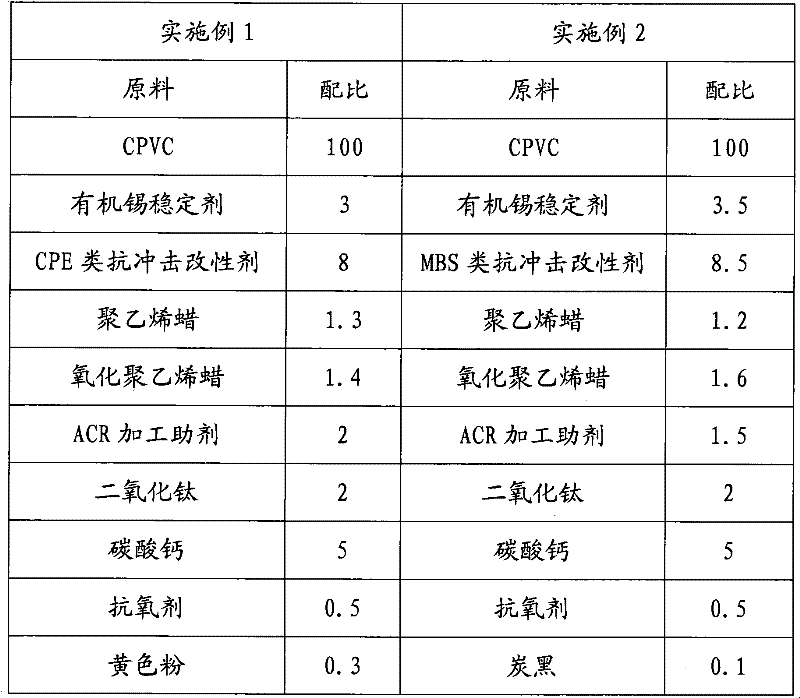

Preparation method of high-performance chlorinated polyvinyl chloride injection aggregate

The invention discloses a preparation method of chlorinated polyvinyl chloride (CPVC) injection aggregate which is characterized by high strength, high-temperature resistance, corrosion resistance and combustion supporting and a product of smooth surface. The chlorinated polyvinyl chloride injection aggregate comprises by weight: 100 parts of CPVC resin; 3-5 parts of stabilizer; 2-5 parts of lubricant and 5-12 parts of impact modifier; 0.5-5 parts of processing agent; 1-10 parts of filler; 0.1-2 parts of antioxidant. The invention also provides a preparation method of the chlorinated polyvinyl chloride injection aggregate. Specifically, each ingredient is subjected to a high-speed mixture to reach a temperature of 100-140 DEG C and dispersed well. Then the mixed ingredients are cooled to 40-60 DEG C. After extrusion and granulating, the chlorinated polyvinyl chloride injection aggregate can be obtained. With a Vicat softening temperature not below 103 DEG C, the high-performance chlorinated polyvinyl chloride injection aggregate provided in the invention has the advantages of high mechanical strength and toughness, excellent corrosion resistance and fire resistance. Thus, the injection aggregate can be widely used in manufacturing valves and parts for conveying high temperature soda acid in chemical industry and daily domestic hot water, and manufacturing other injection products with high intensity and high temperature resistance.

Owner:SHANGHAI DEWIN PLASTIC TECH

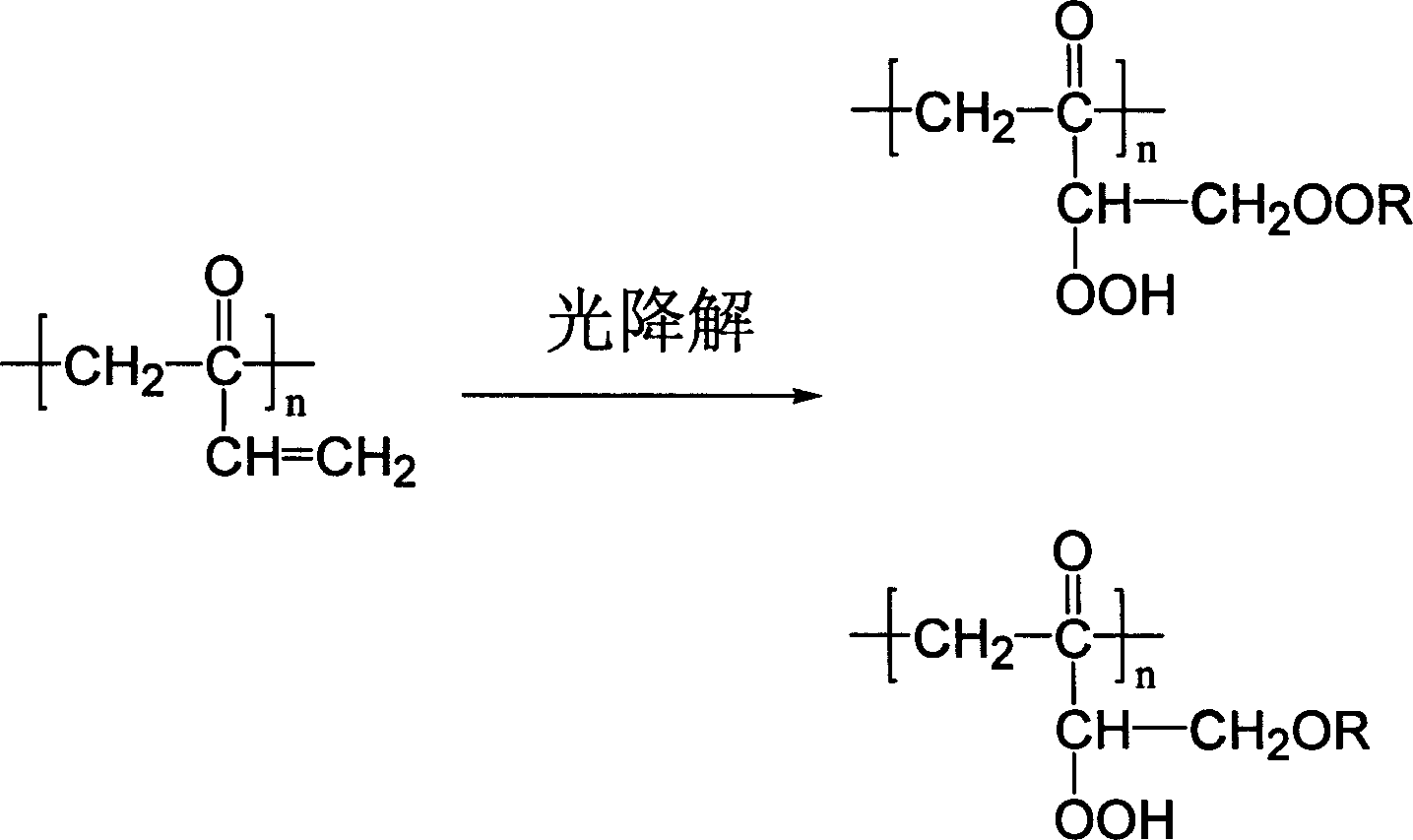

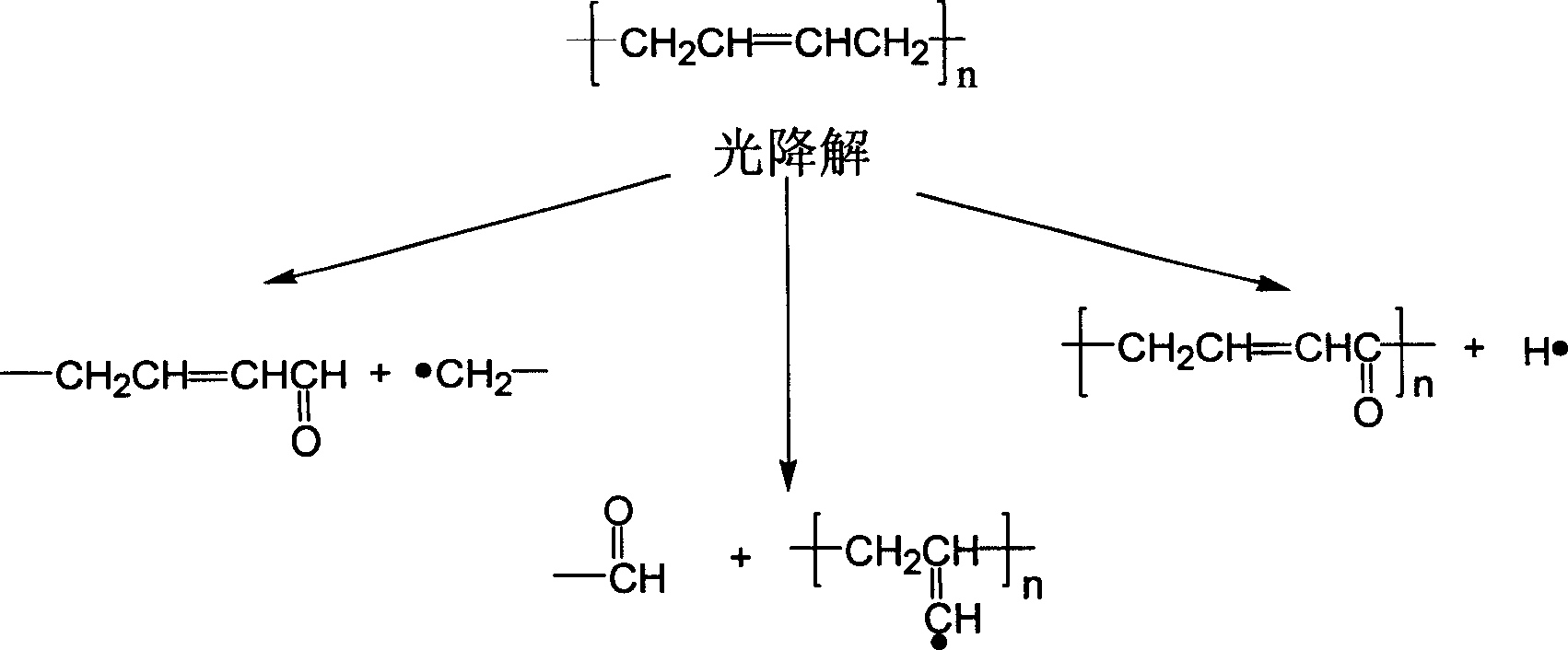

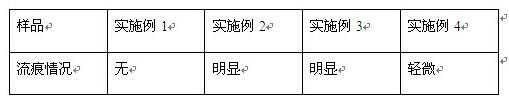

Biodegradable free-spraying aesthetic resin and preparation method thereof

The invention discloses a biodegradable free-spraying aesthetic resin and a preparation method thereof, and the composite raw materials comprises the following components by weight: 10-80 parts of polylactic acid resin, 20-70 parts of polymethyl methacrylate, 0-30 parts of impact modifiers, 0.1-0.8 parts of antioxidants, 0.1-2.0 parts of lubricants, 0-3.0 parts of metal pigments, and 0-3.0 parts of pearlescent pigments. The raw materials are dried in an oven at 60 DEG C for 5-8 hours; then metal pigments or pearlescent pigments treated by a coupling agent are added proportionally; the mixtureis premixed by a high-speed mixer, is processed by melt extrusion through a twin-screw extruder, and is cooled and granulated. Not only the obtained product has good metallic luster effect, but also its injection product has excellent mechanical properties and thermal properties, has beautiful appearance and no flowing marks, is biodegradable, is applicable to the manufacture of appearance parts of household appliance and office products which has high requirements on appearance.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

Automatic-cut waste material injection mould

InactiveCN1891432AReduce labor intensityHigh degree of automationInjection productInjection moulding

This invention discloses an injection molded die for automatically cutting scraps used in producing injection products including a fixed mold, a moving mold and a cutting unit, in which, said fixed mold is matched with the moving mold to form a cavity corresponding to the injection product and a runner conducting to the fixed mold or the moving mold, said cutting unit includes a cutting plate set close to the cavity and extending into the runner after molding a product to cut the scraps connected with the product along the edge of the cavity, said die can cut the scraps in the runner and separates them from the product by the cutting unit before the product is finished and taken out so as to avoid separating products from runners artificially to reduce production time and cost.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Fasudil salt injection for improving stability and preparation method thereof

InactiveCN102008433AExtended shelf lifeImprove stabilityOrganic active ingredientsInorganic non-active ingredientsInjection productOxygen content

The invention provides a fasudil salt injection for improving stability. The injection consists of the following components based on a weight ratio: the fasudil salt and medical sodium chloride are blended with water to 2,000ml according to a ratio of 100:1 to 1:100 to prepare 1,000 injections. The stability of the fasudil salt injection to light and heat is improved by reducing the oxygen content in the injection and introducing inert gas, so that the preserving period of injection products can be prolonged, and the injection has higher industrial application value. The invention provides a preparation method.

Owner:广东中润医药有限公司 +1

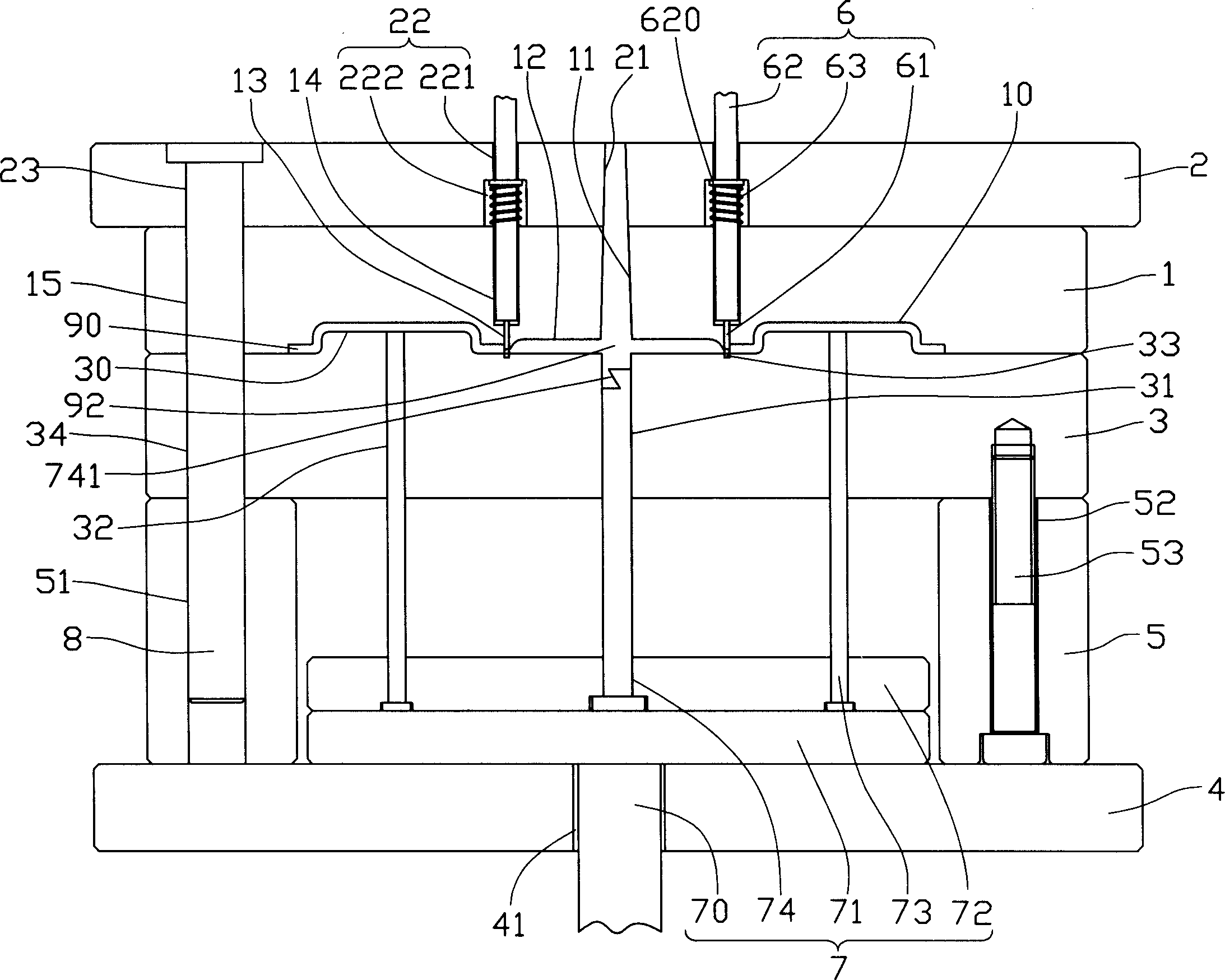

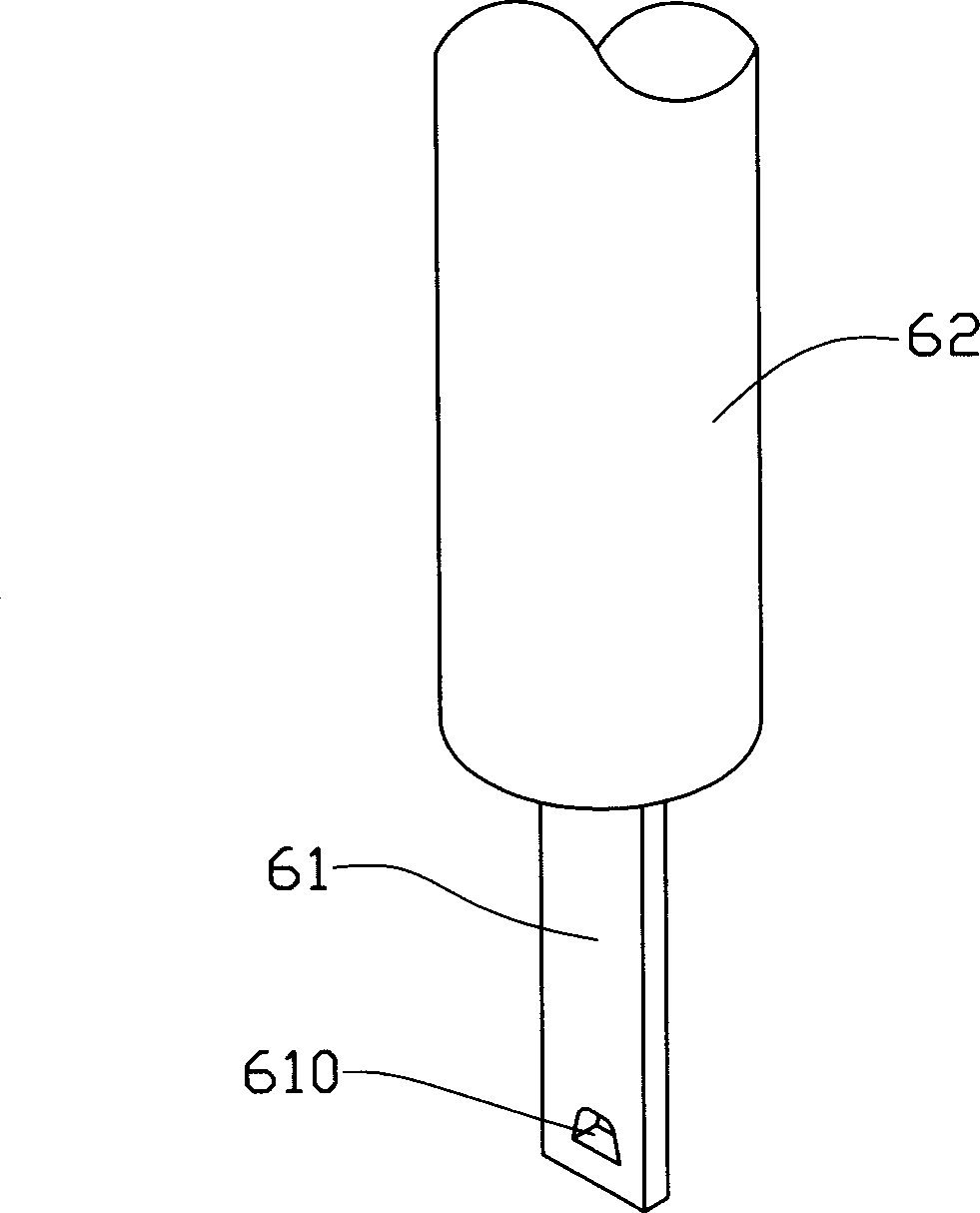

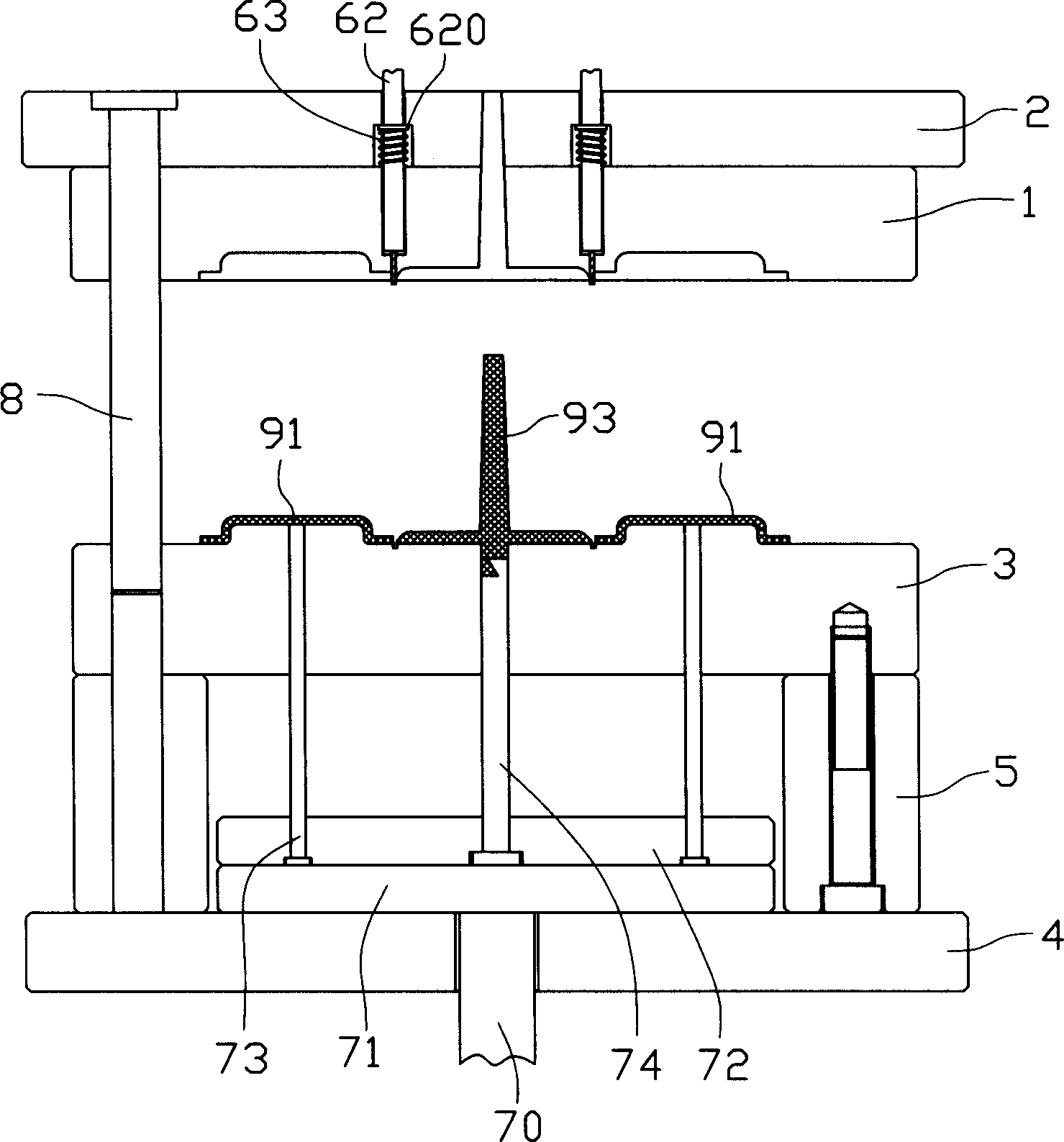

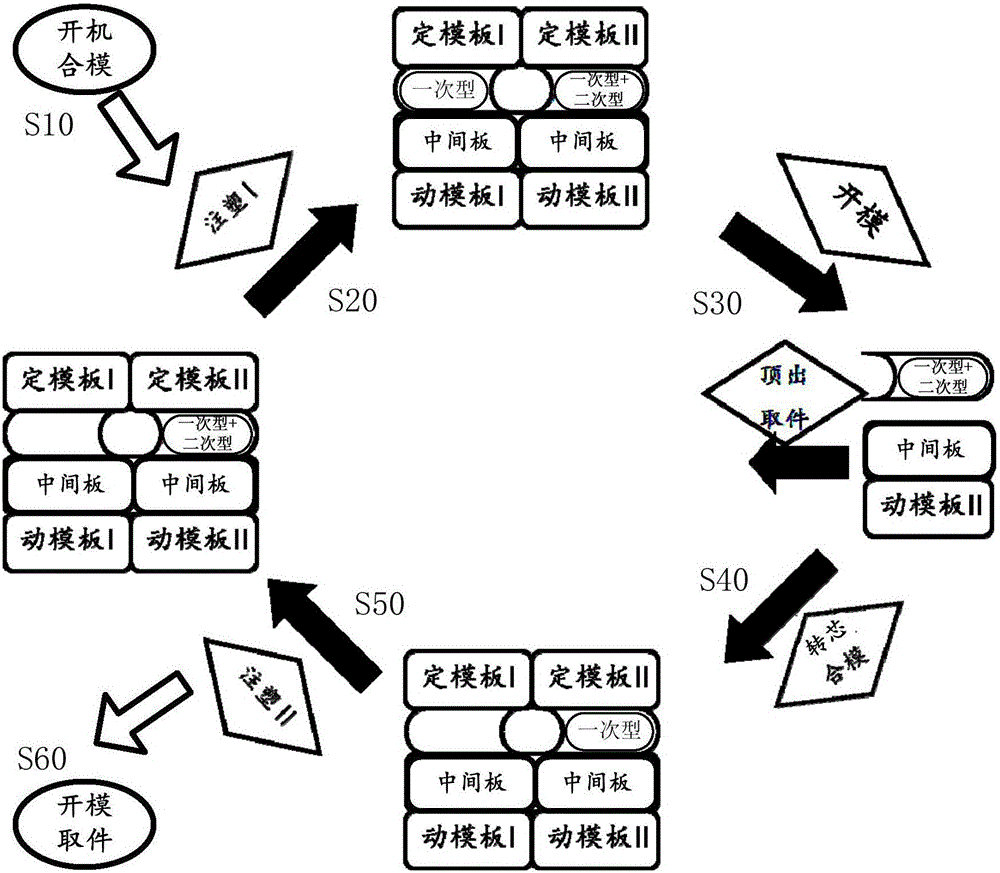

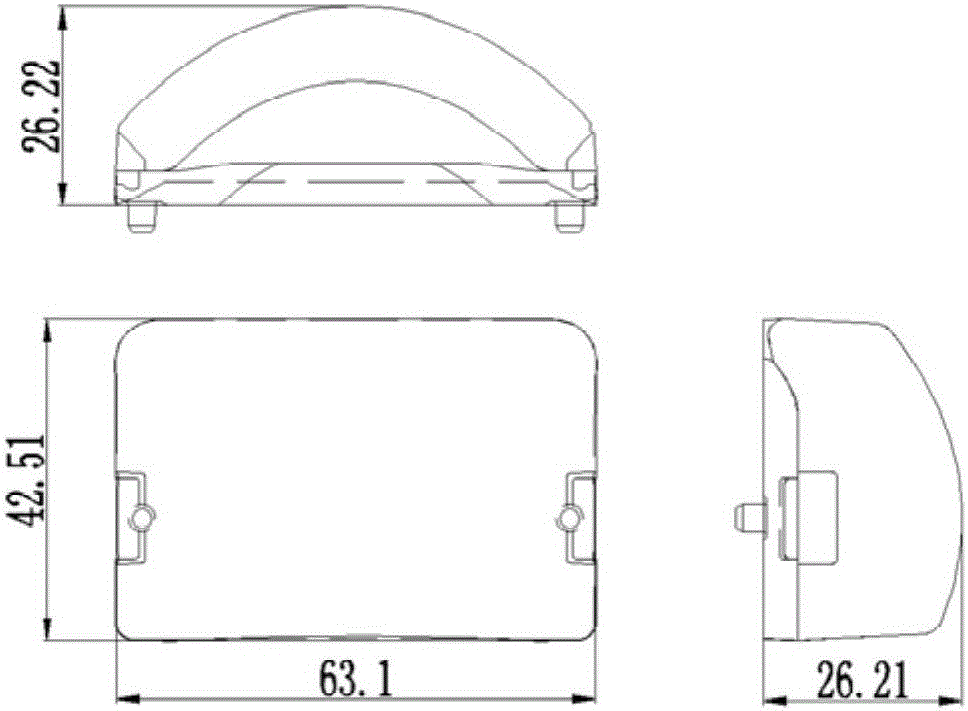

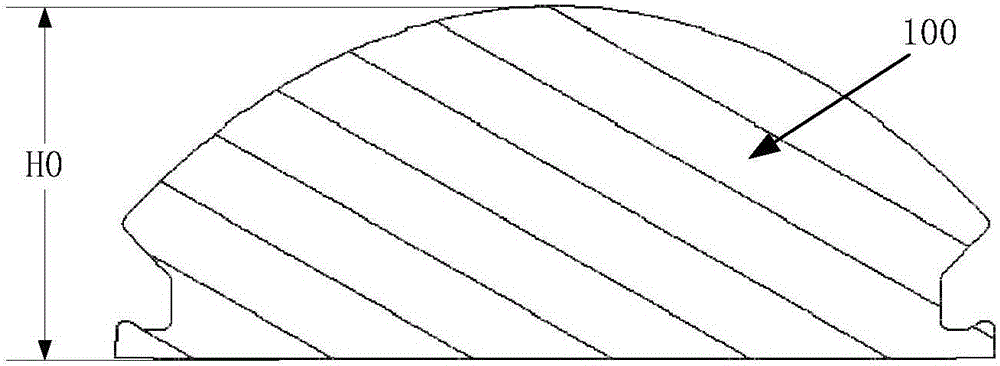

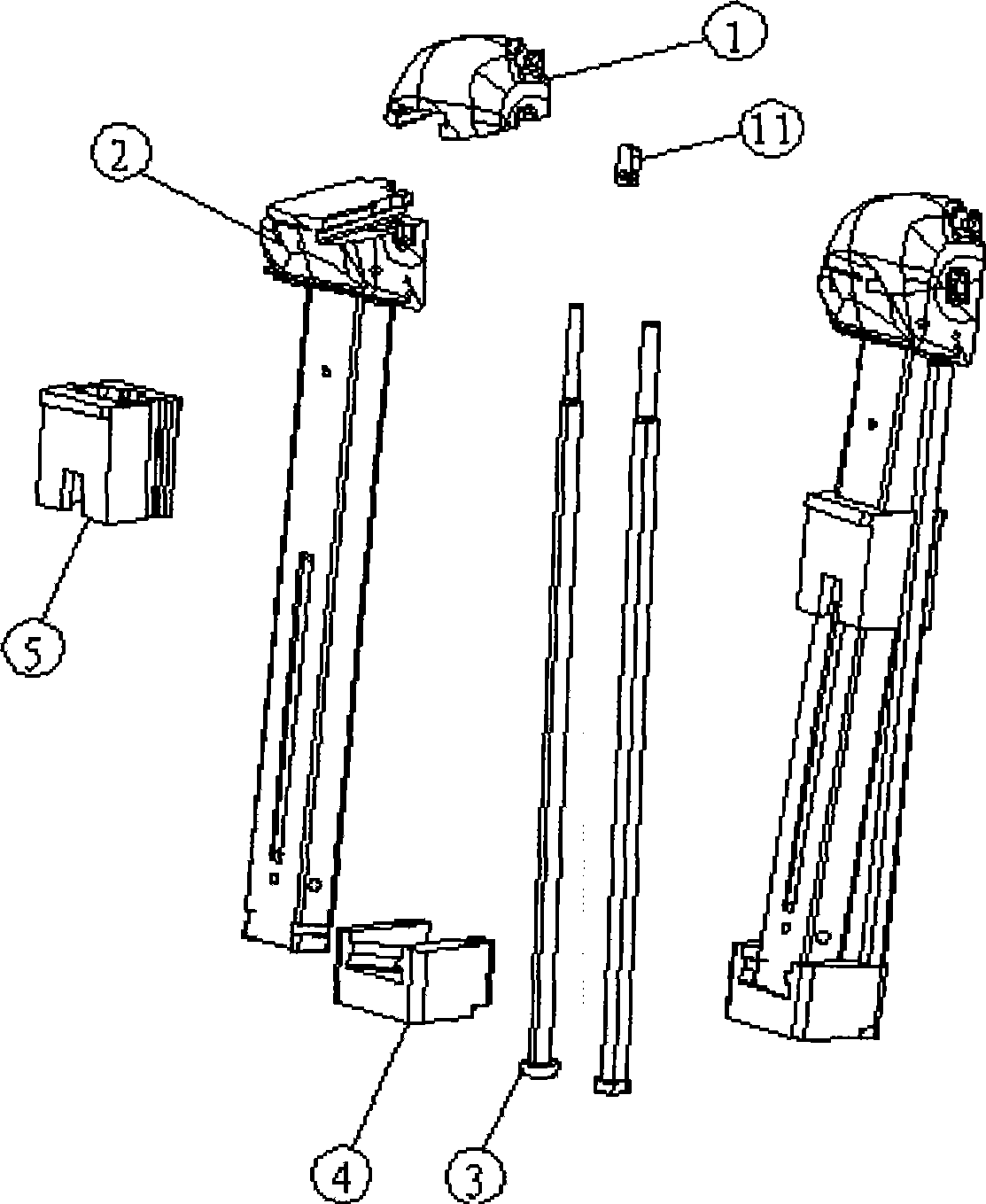

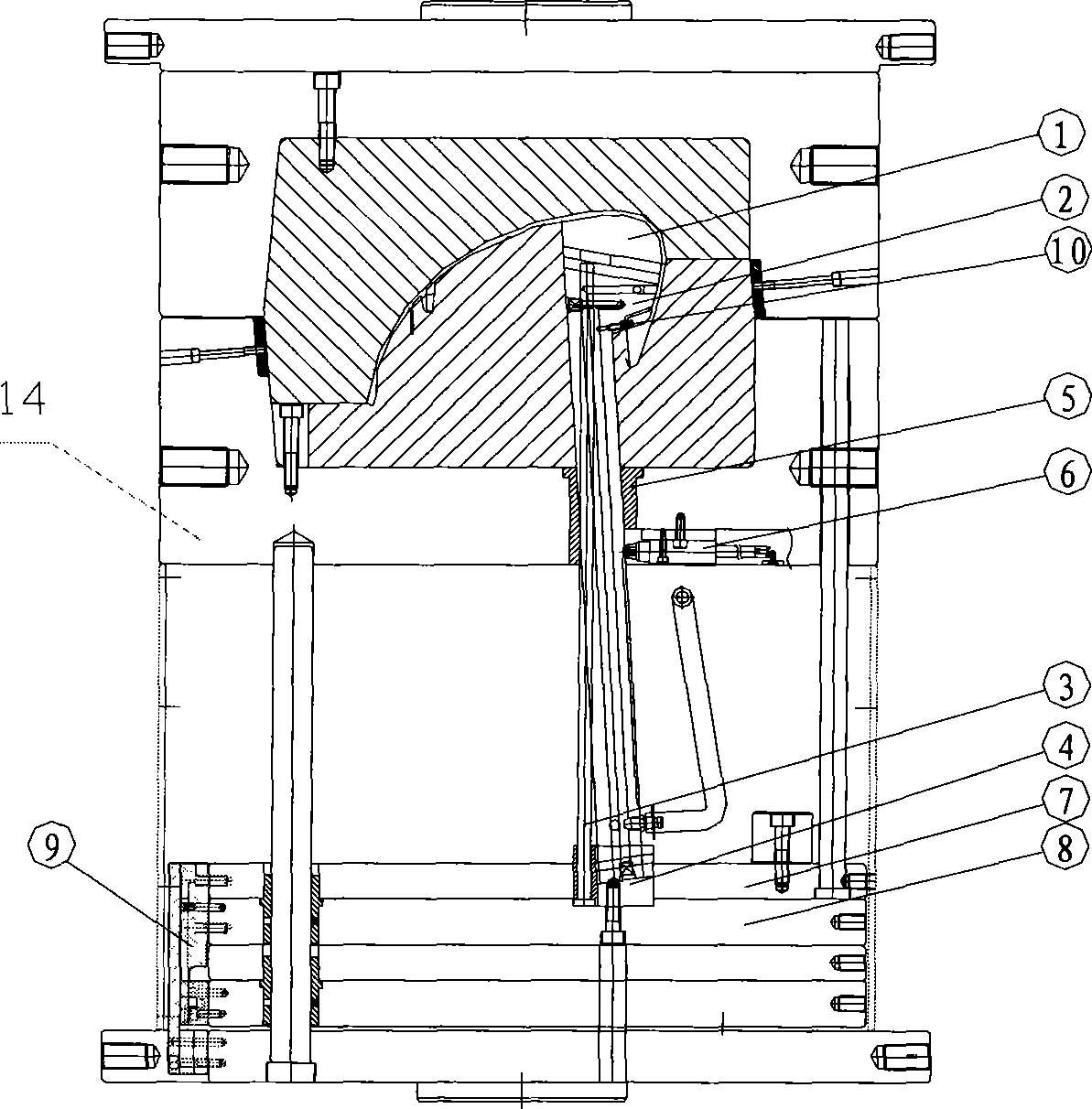

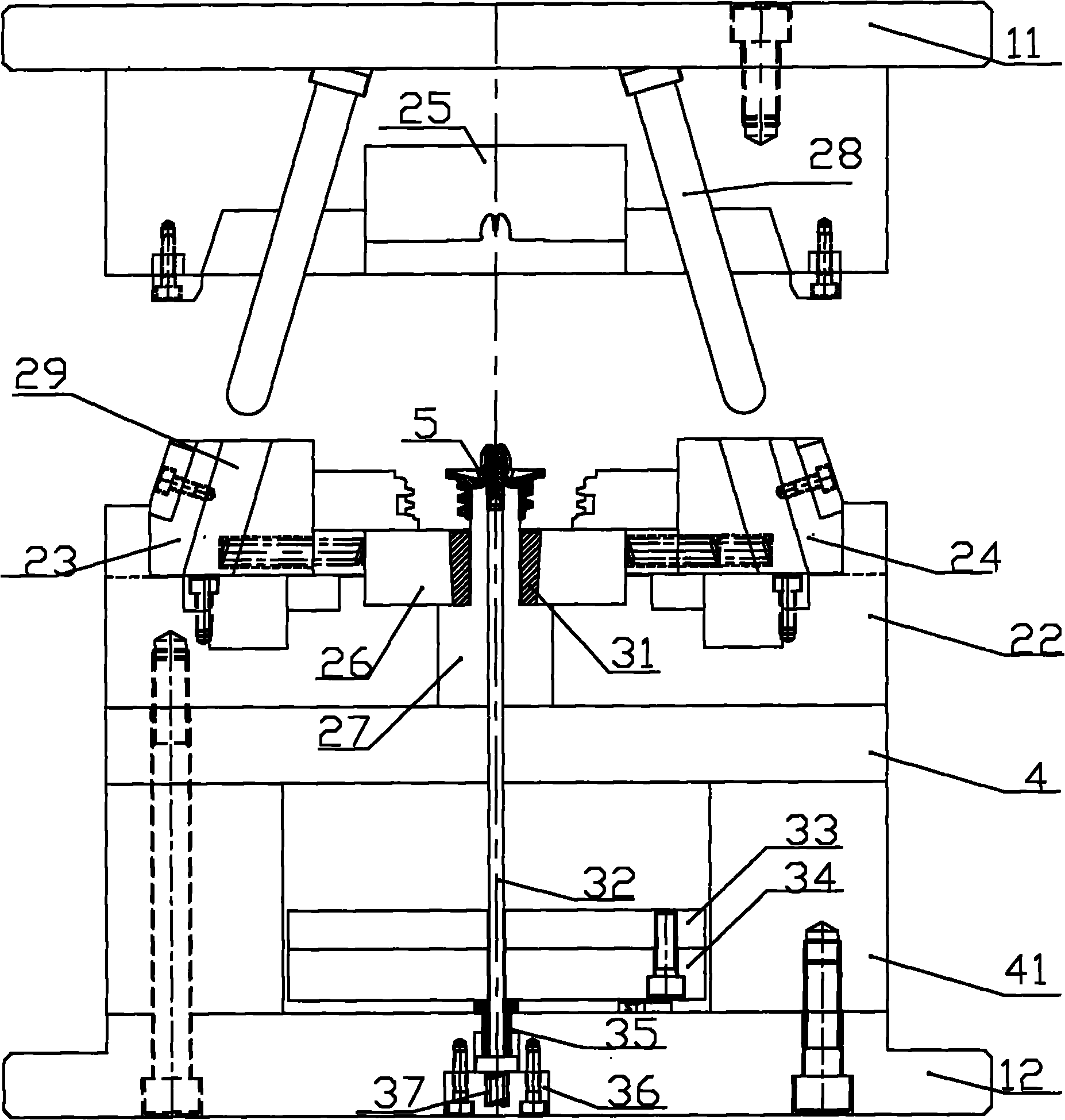

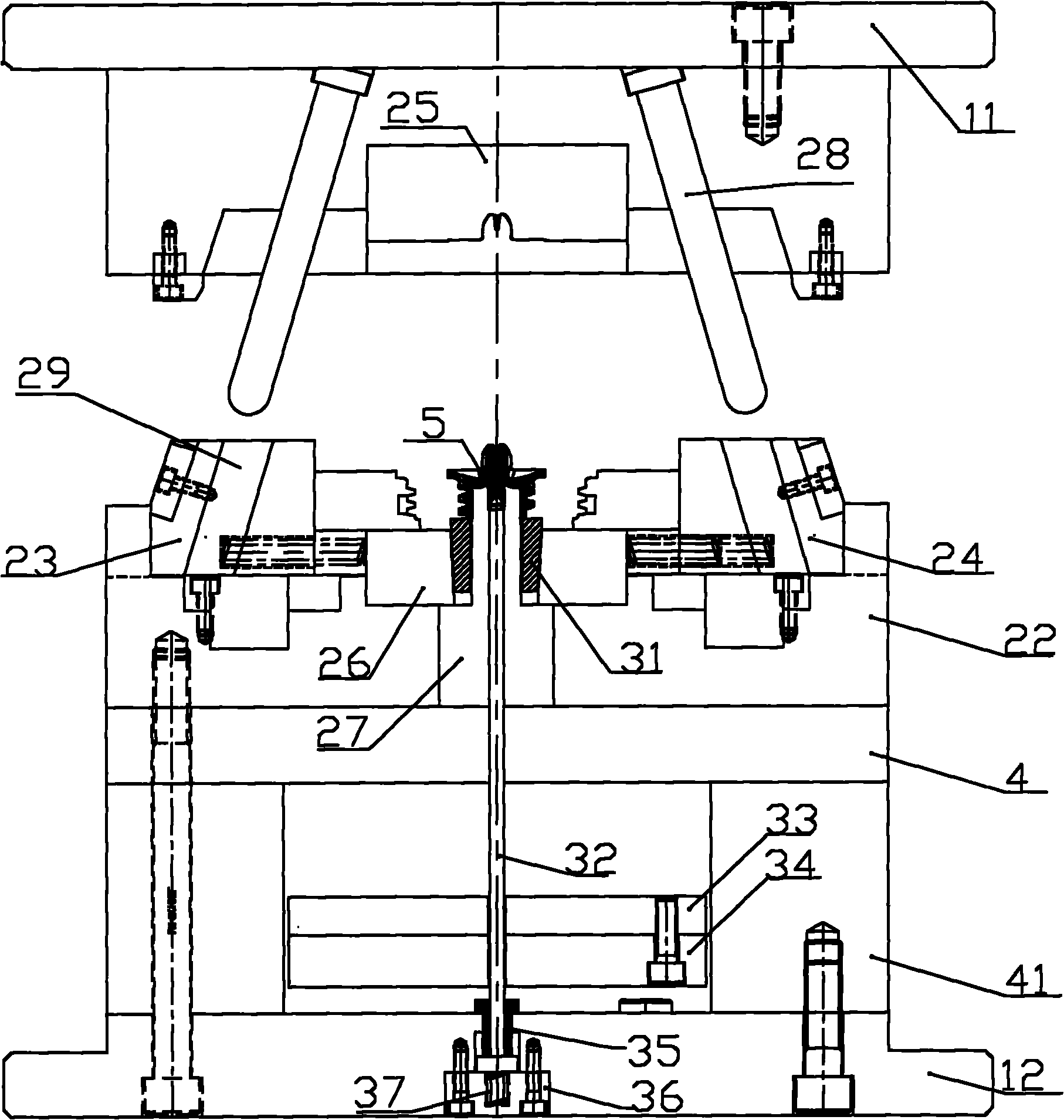

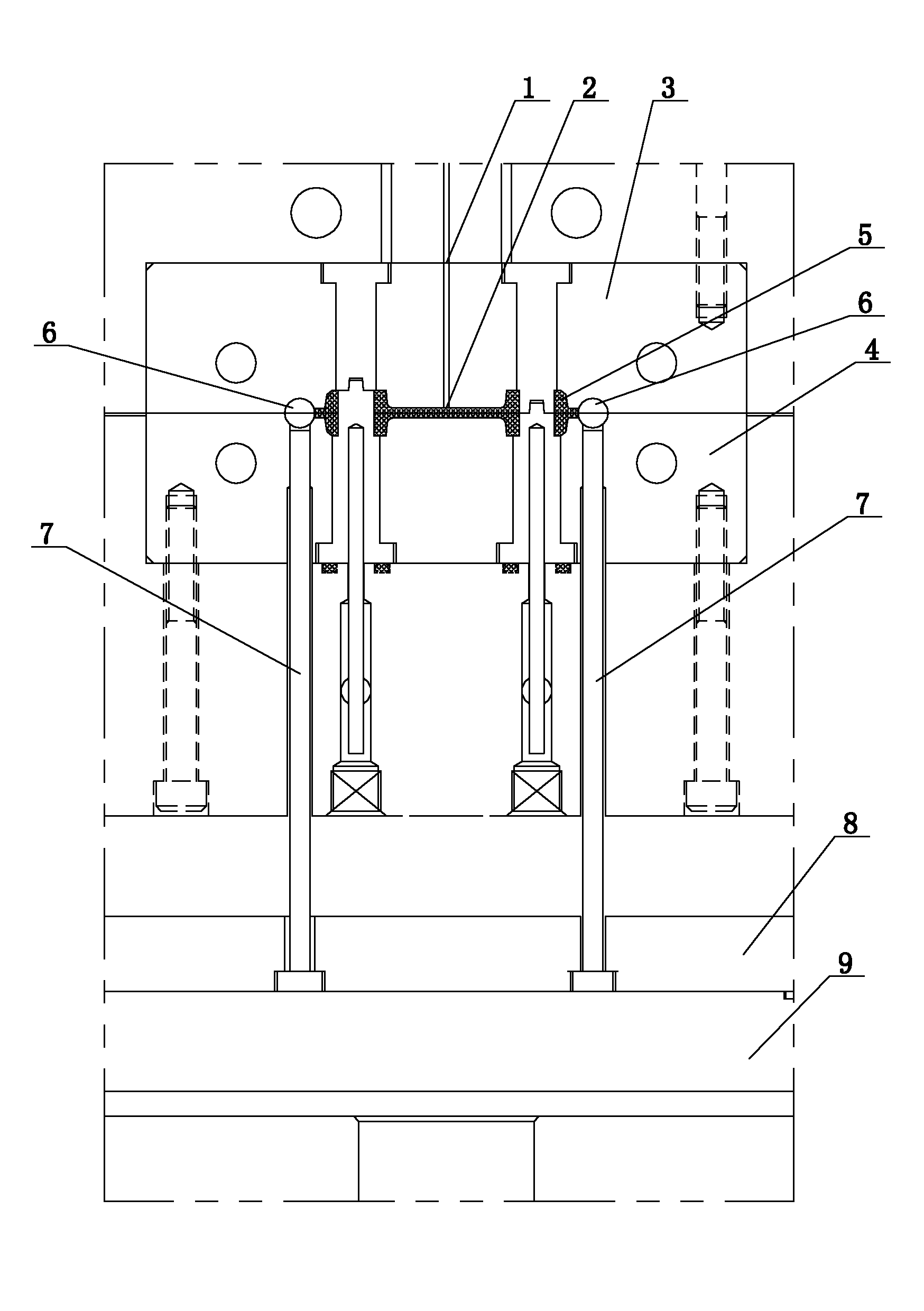

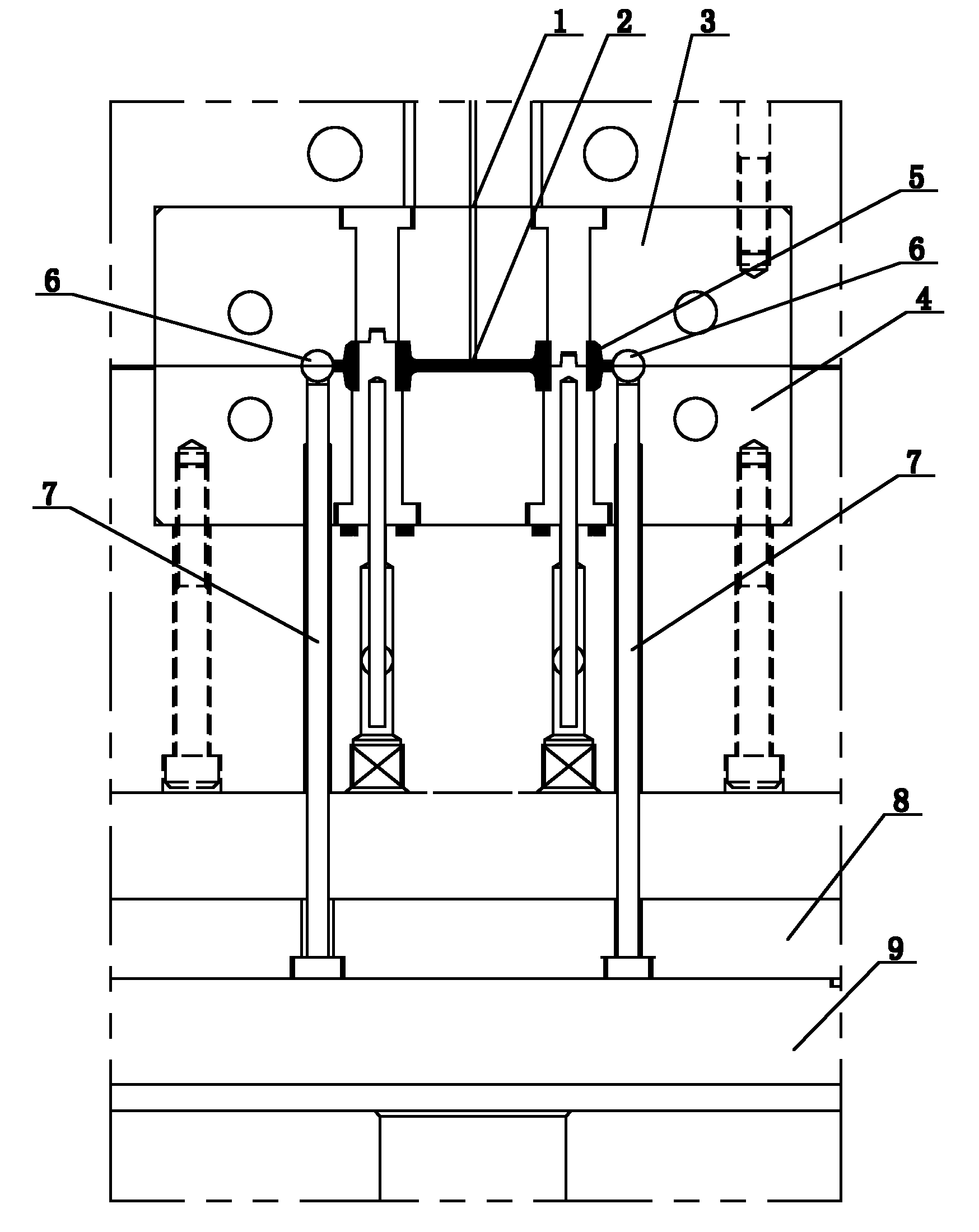

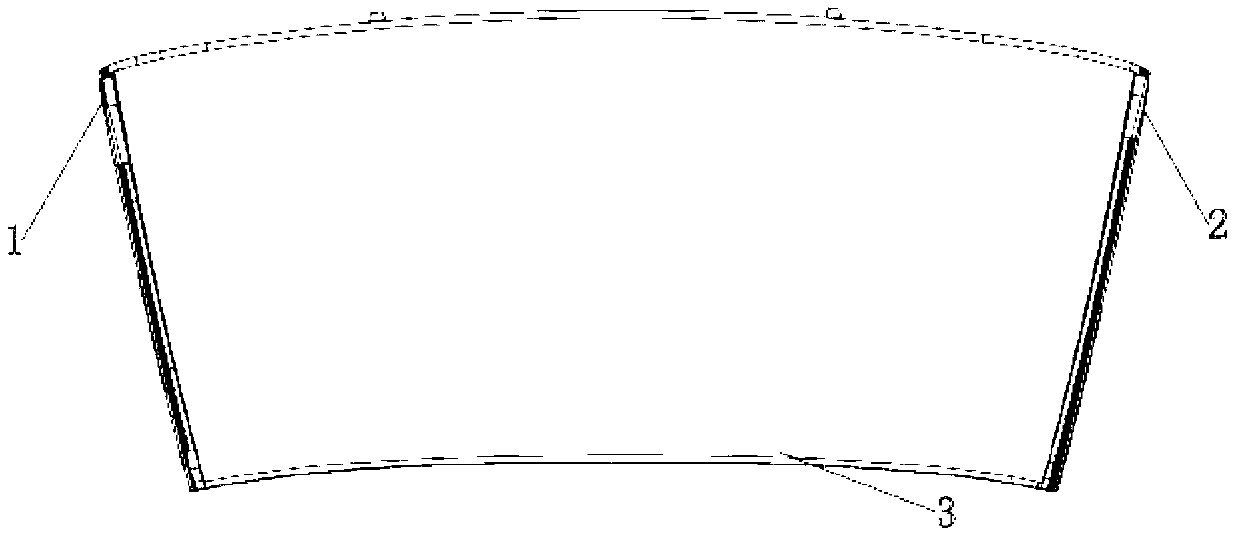

Thick wall plastic part surrounding type layered injection molding method and mold structure and lens product thereof

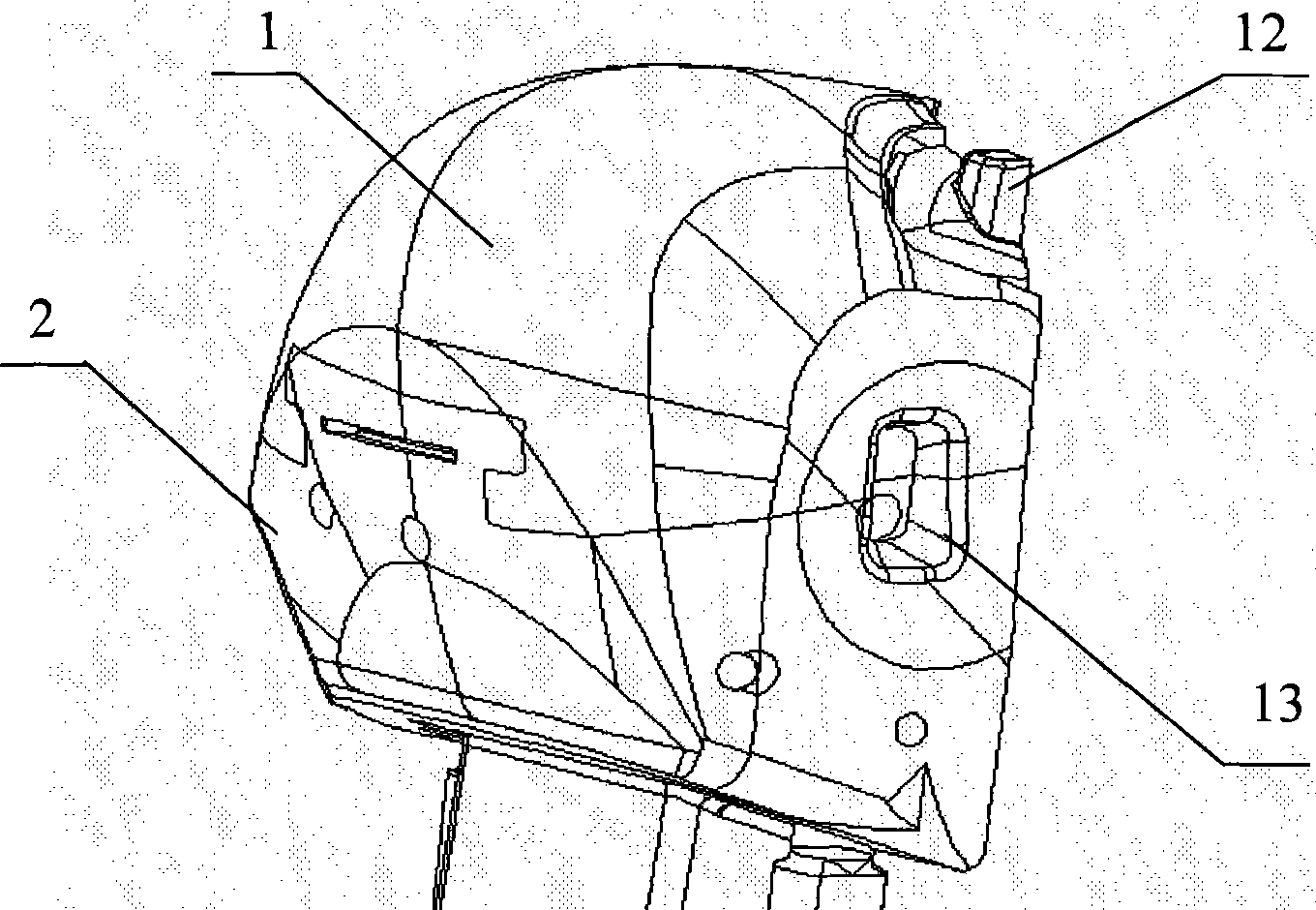

ActiveCN105818325AShrink evenlyMeet Optical Performance RequirementsVehicle headlampsRoad vehiclesInjection productEngineering

The invention discloses a thick wall plastic part surrounding type layered injection molding method and a mold structure and a lens product thereof, and relates to injection molding of plastic or plastic state matter and method and equipment of injection molding, in particular to a thick wall injection product surrounding type layered injection molding method, a special mold structure used for implementing the method and a car lamp lens product manufactured with the method. An intermediate plate is arranged between a fixed mold plate and a movable mold plate and is rotated to conduct core rotation operation, a middle cavity which is in the empty cavity state after piece taking operation is carried out is rotated to a first station, and die assembly is carried out to form a molding cavity of a primary mold of the product; the intermediate plate carrying the primary mold of the product is rotated to a second station, die assembly is carried out to form secondary mold forming cavities surrounding the two sides of the primary mold of the product, and therefore multi-layer injection molding is achieved; during injection molding of a second layer, shrinking supplementing is carried out on absorption shrinking occurring on a first layer, so that it is guaranteed that condensation shrinking of secondary molds of the product is even, and appearance filling is full; and the optical performance requirement of a headlamp lens is met, the production period is shortened, and the injection molding production efficiency is improved.

Owner:HASCO VISION TECHNOLOGY CO LTD

Composite inclined-roof stripper of injection mould

InactiveCN101422954ARealize automated productionReasonable structural designInjection productDegrees of freedom

The invention relates to an injection mold structure, in particular to an injection mold composite lifter demoulding mechanism, in which barbed demoulding exists in four degree-of-freedom-directions in six degree-of-freedom-spaces on the inner wall of an injection product and which realizes the automatic demoulding function of the product in a mode of composite lifter. The demoulding mechanism comprises an upper mold, a lower mold, a core plate and a travel switch. The lower mold is provided with a movable lifter insert and a lifter body. A runner is arranged between the upper ends of the movable lifter insert and the lifter body and forms a certain angle with the horizontal plane. The lifter body is provided with a lifter guide block in the middle and connected with a lifter sliding seat at the lower end. The composite lifter demoulding mechanism realizes three barbed surfaces on the inner wall of the product, the mold has automatic demoulding function with barbs in the demoulding direction and a cooling water channel as well as a gas-assisted molding air path is arranged on the lifer body.

Owner:NINGBO SUNNY MOLD

Compoisite material of polypropylene resin for case of household office electrical equipment and injection products thereof

The invention discloses a polypropylene resin composite, containing polypropylene resin 30-90 wt%, microball 5-70wt%, inorganic micron or nano particles 0-50 wt% and microfiber 0-50 wt%. The composite not only maintains original excellent properties of polypropylene but also has good molding property, balanced rigidity / flexibility, excellent surface quality of components made by injection molding, high surface hardness, property of uneasily scratching, and excellent molding processing property and lower molding shrinkage, able to make direct injection molding in original HIPS and ABS modules, thus replacing HIPS and ABS. It can be used in preparing the outer casing of home appliances and the cases office appliances, especially the front / back cases of TV sets, the outer casing of the remote controllers, etc as well as the cases of duplicating maclines, monitors, etc.

Owner:上海金发科技股份有限公司 +1

Color masterbatch and preparation method thereof

InactiveCN102675709AImprove temperature resistanceImprove filtering effectPigment addition to spinning solutionMasterbatchInjection product

An object of the invention is to disclose a color masterbatch and a preparation method thereof. The color masterbatch comprises the following components of, by weight, 60%-70% of a thermoplastic resin, 5%-10% of an additive and 25%-30% of a pigment. The color masterbatch prepared by the above components has the characteristics of good temperature resistance, excellent dispersion property and high dimension stability of products, is widely applied for coloring plastic caps and other injection products, and realizes the object of the invention.

Owner:上海彩艳实业有限公司

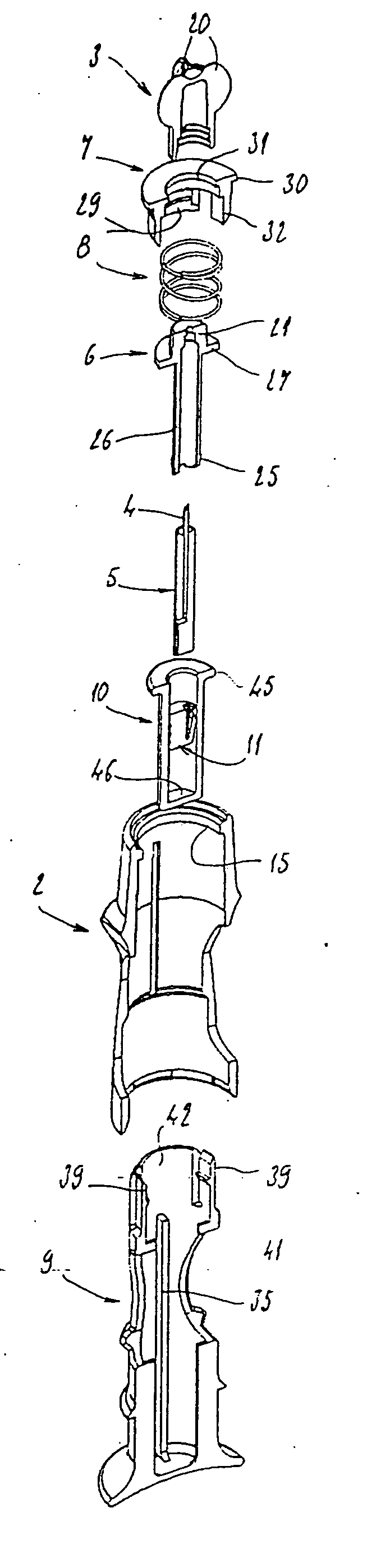

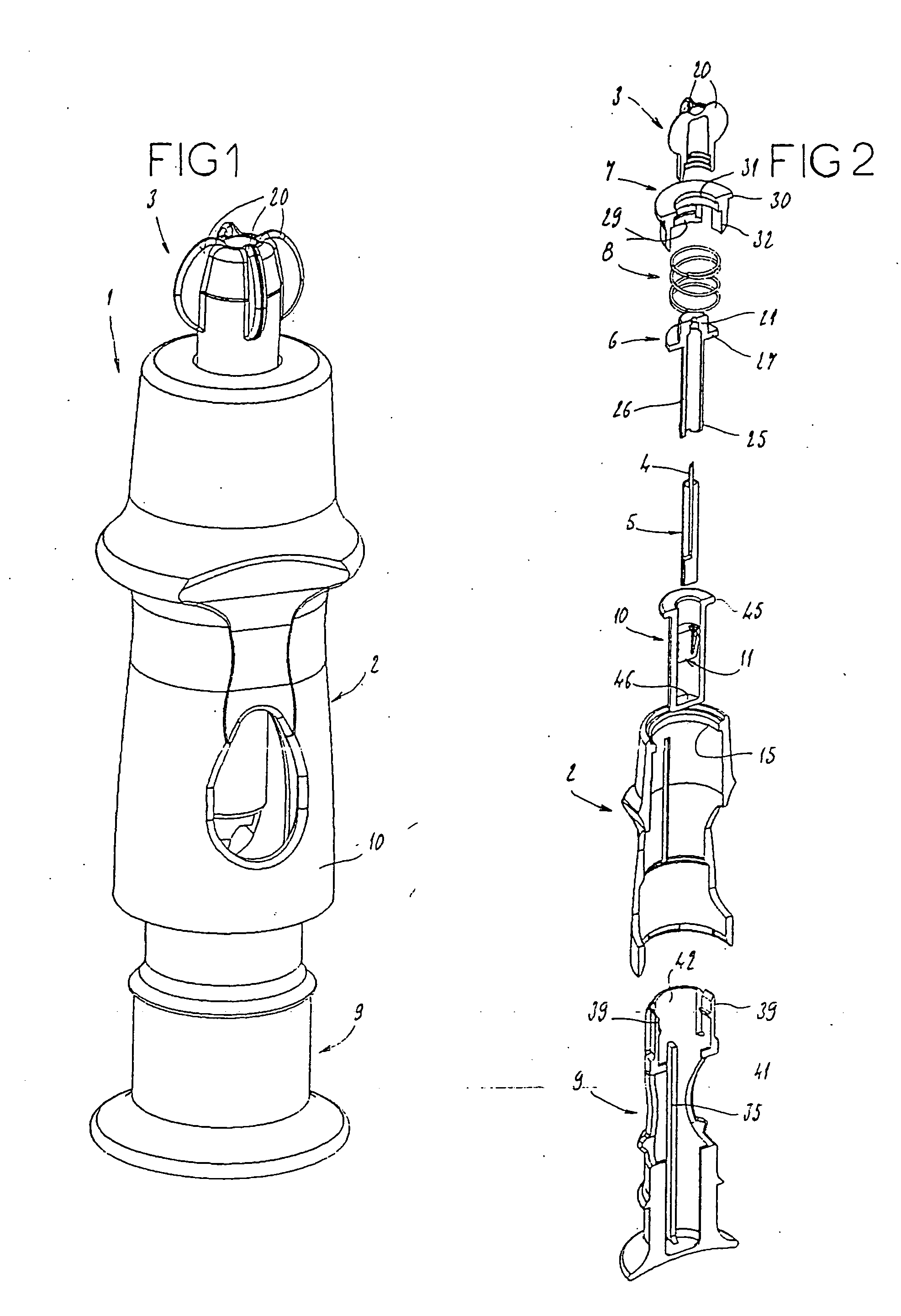

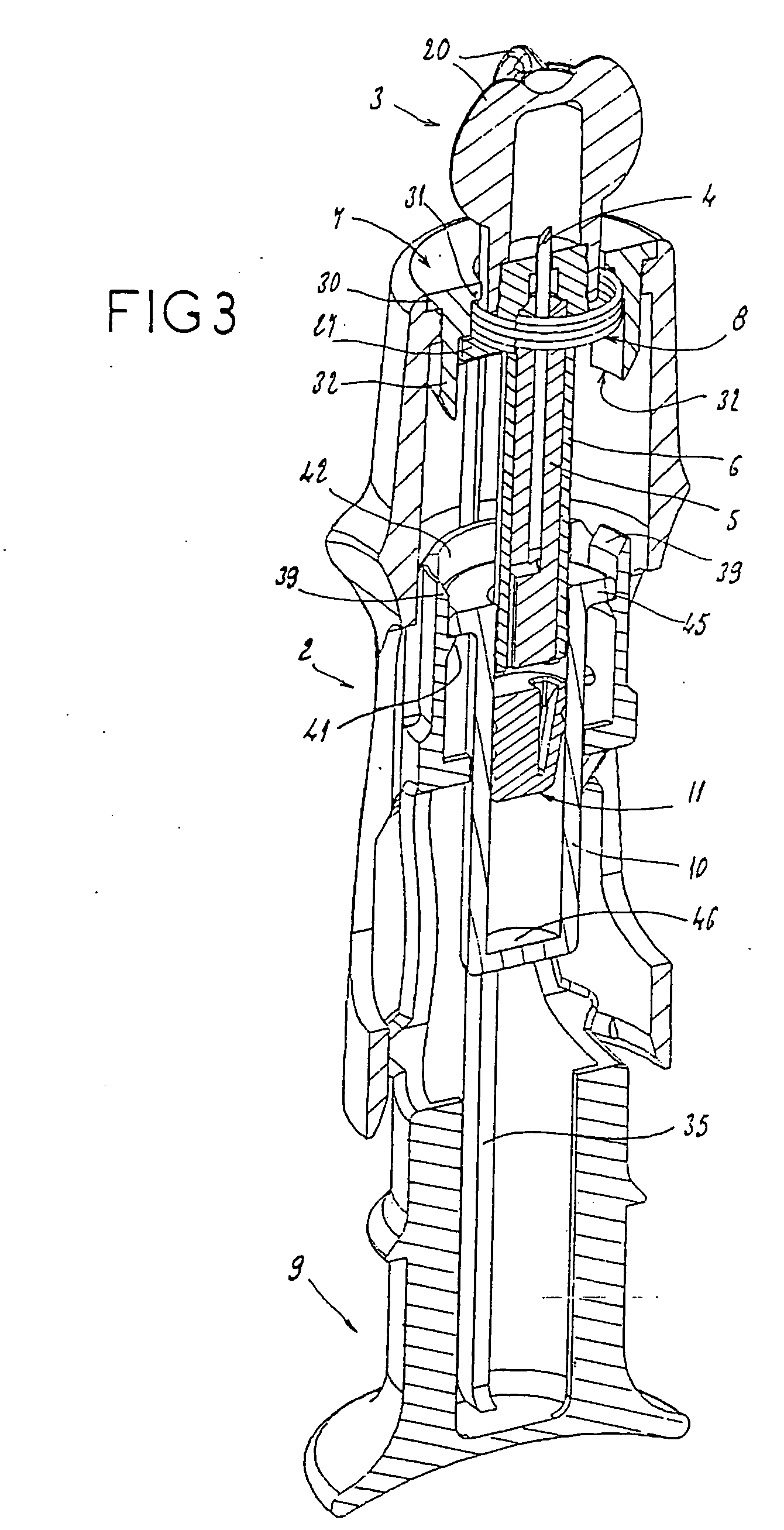

Device for injecting a product, in particular for medical use

ActiveUS20060111674A1Eliminate riskAmpoule syringesMedical devicesInjection productMedical treatment

This device comprises: a body housing a hollow injection needle and a container containing the injectable product; the needle is connected to the body but able to move relative to the latter between an injection position and a retracted position; a plunger that slides in the body and is displaceable relative to the latter to perform the injection; said container is able to move relative to the plunger between a position that enables the injection to be performed and a retracted position; means for keeping the needle and the plunger in injection position, which means can be released to free the needle and the plunger to move to said retracted position.

Owner:BECTON DICKINSON & CO

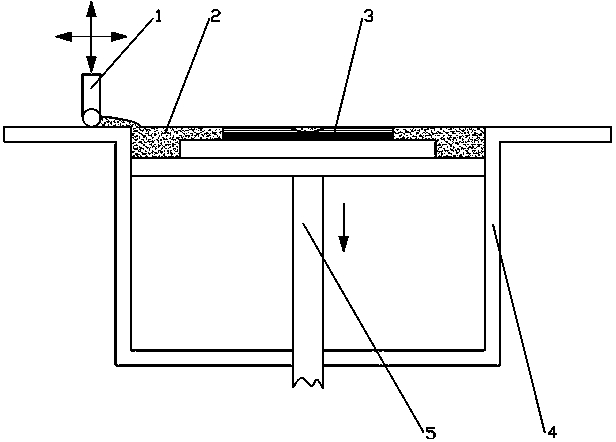

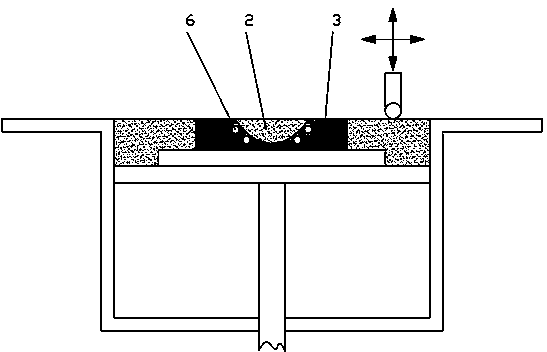

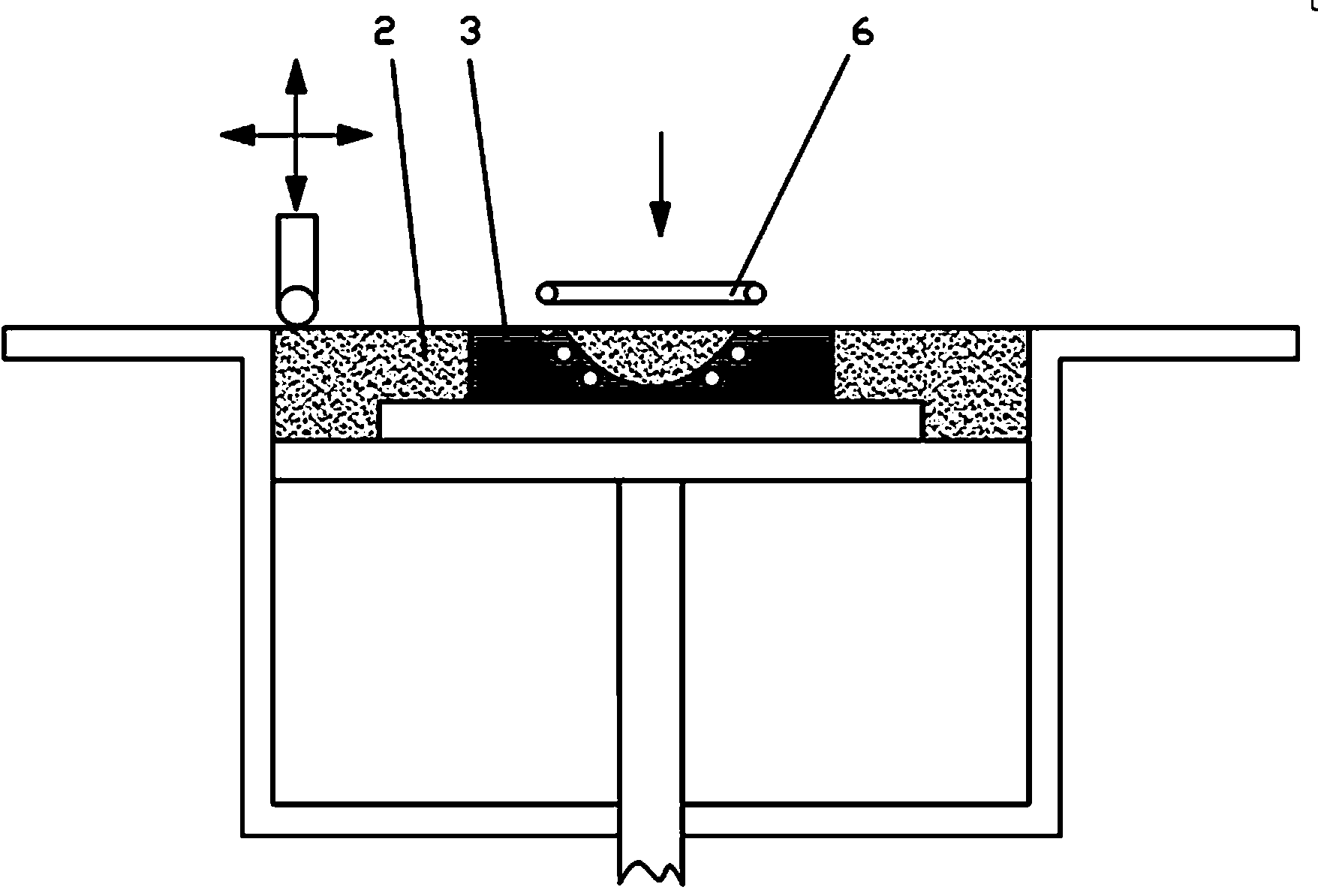

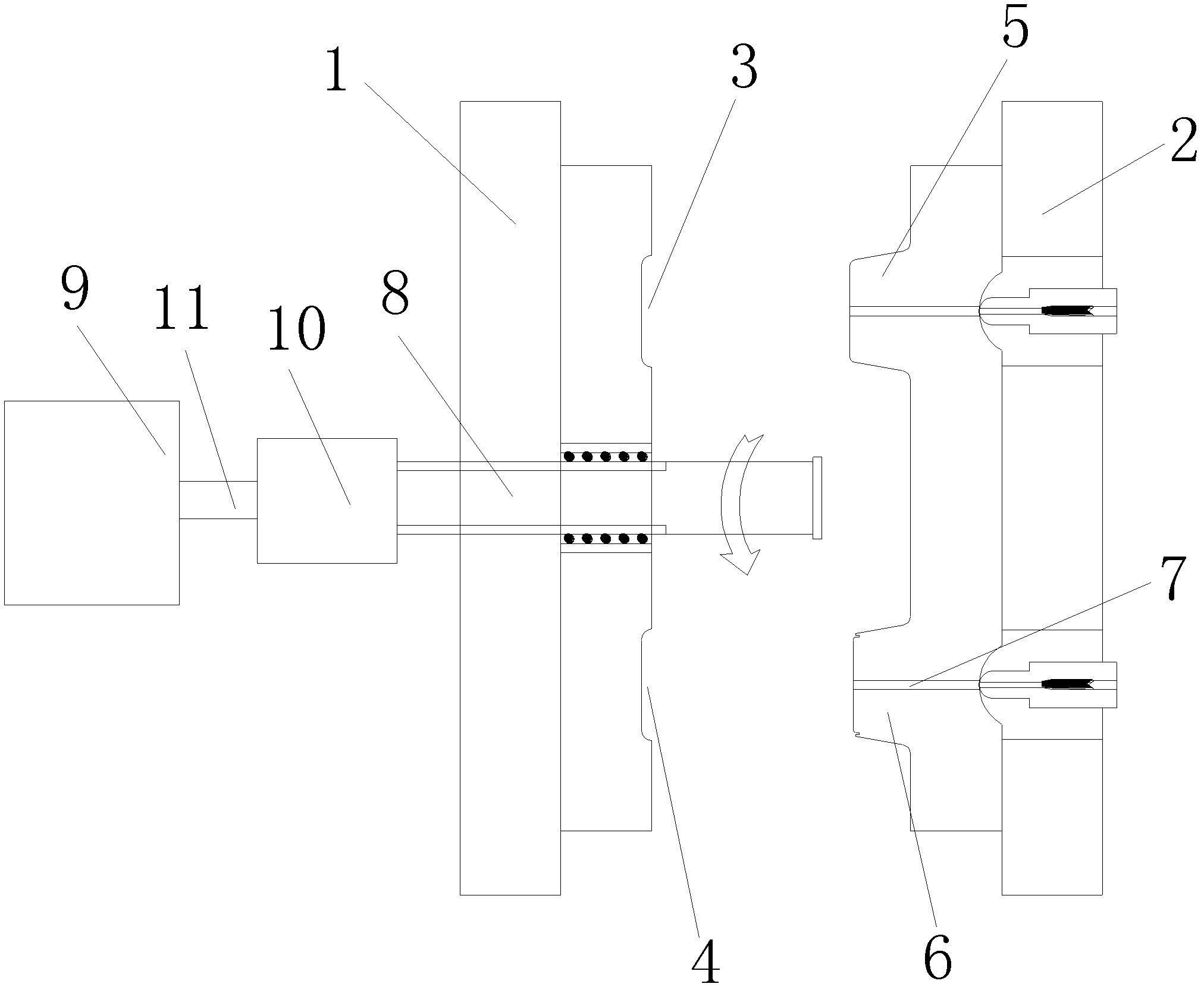

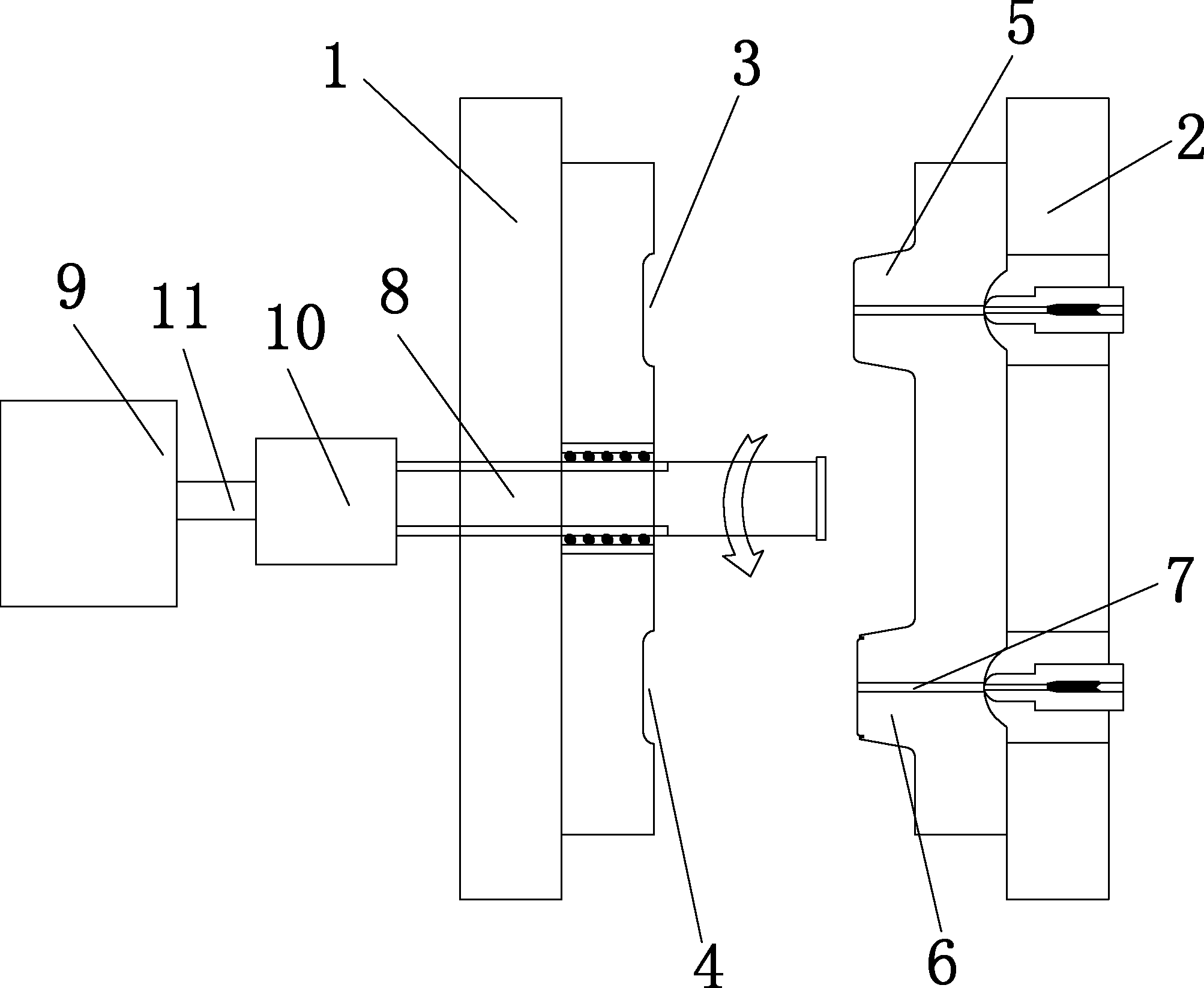

Manufacturing device and method for injection mold with conformal cooling pipeline

ActiveCN104001914AImprove liquidityImprove cooling effectIncreasing energy efficiencyMetallurgyInjection product

The invention discloses a manufacturing device and method for an injection mold with a conformal cooling pipeline. At first, a part of a mold cavity entity is machined by the adoption of an SLM technology based on a layered manufacturing principle, then a semicircular groove used for containing the conformal cooling pipeline is machined in a proper position inside the mold cavity entity, after metal powder in the groove is cleaned out, the conformal cooling pipeline is placed in the groove, metal powder in the first half of the pipeline is fused through the SLM technology finally, the conformal cooling pipeline can be embedded in the mold cavity entity accordingly, ultimately the method is repeated according to the depth of a mold cavity, and multiple layers of conformal cooling pipelines can be embedded in the mold cavity entity in a layered mode. Thus, the defect that conformal cooling pipelines of a mold are directly manufactured by the adoption of the SLM technology can be overcome, the cooling pipelines with the diameter less than 6 mm can be manufactured, meanwhile it is guaranteed that inner walls of the pipelines are smooth, cooling capacity of the mold and cooling evenness of plastic injection products can be effectively improved.

Owner:广东弗伦克智能科技有限公司

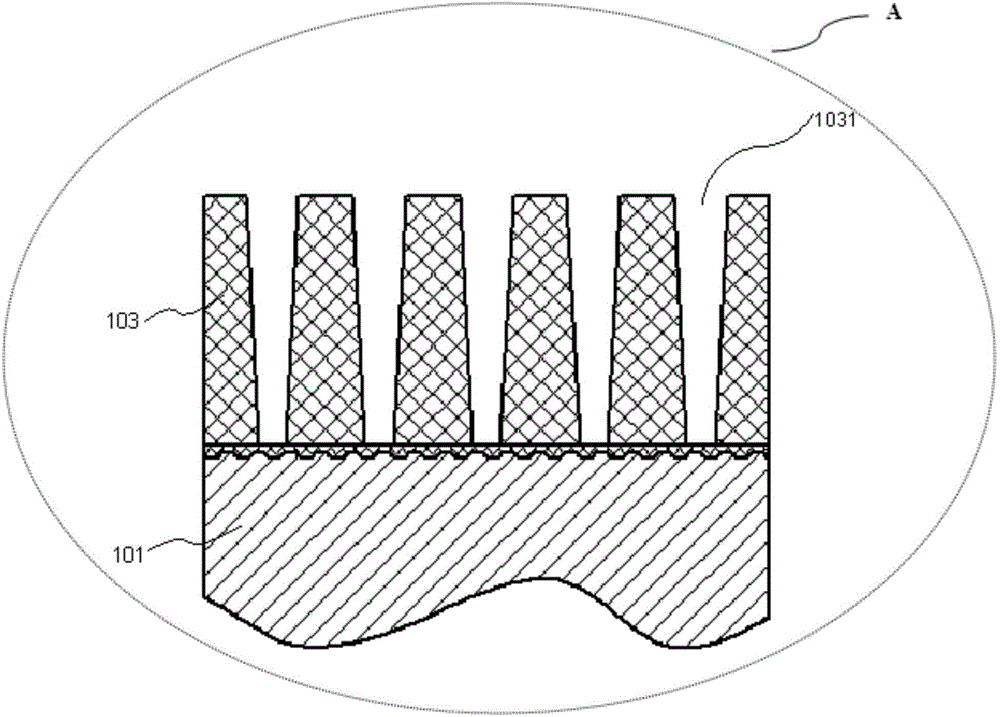

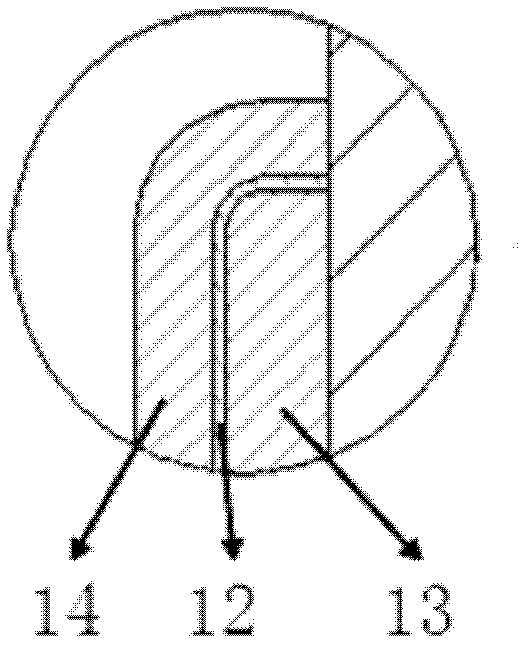

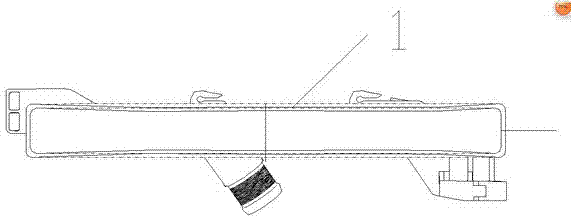

Injection mold core with air suction, discharge and rapid cooling functional structure

The invention provides an injection mold core with an air suction, discharge and rapid cooling functional structure. The injection mold core consists of a core body (1), a ventilated surface (2), an air suction and discharge channel (3) and a heat-conductive pin (4). In the injection mold core, the technical scheme that: the core body is made from a beryllium copper material with high heat conductivity; the ventilated surface which is made of porous ventilated steel is fixedly inlaid at the top of the core body; the air suction and discharge channel which is connected with a mold is reserved in the core body; and the heat-conductive pin which is directly inserted into a mold cooling water pipe is arranged at the bottom of the core body is adopted, so that the problems of low qualification rate, high cost and poor quality consistency of products in the molding of small-diameter deep-cavity injection products in the prior art are solved. The injection mold core with the air suction, discharge and rapid cooling functional structure provided by the invention fulfills the aims of improving the qualification rate, reducing the cost and ensuring the quality consistency of the products of the molding of the small-diameter deep-cavity injection products by increasing cooling rate and improving air suction and discharging conditions of the core body structurally.

Owner:NINGBO RUIYUAN MOLD & PLASTICS

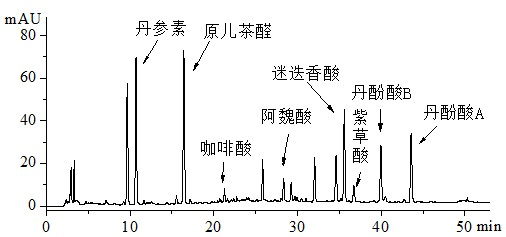

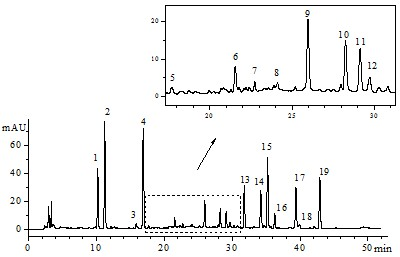

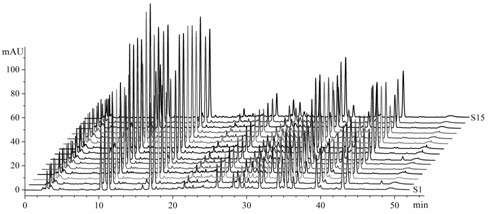

Danhong injection quality control method

ActiveCN102692462ASimple methodMethod stableComponent separationAdditive ingredientInjection product

The invention relates to a Danhong injection quality control method. According to the method, an efficient liquid chromatography is used for measuring fingerprint spectrums of Danhong injection products to be measured, and in addition, three kinds of algorithms including the included angle cosine algorithm, the relative coefficient algorithm and the ratio qualitative algorithm are adopted for calculating the qualitative similarity of fingerprint spectrums of the Danhong injection; and the P value and the M value are calculated, and the qualitative similarity of the fingerprint spectrums of the Danhong injection is obtained. Meanwhile, a content measuring method of eight effective ingredients of the Danhong injection is built. Finally, a high performance liquid chromatography (HPLC) is used for measuring, the conditions that the sodium danshensu and protocatechualdehyde content is greater than 350mug / mL, the qualitative similarity is greater than 0.95, the quantitative similarity P is between 0.80 and 1.20, and the M is between 0.90 and 1.10 are used as quality control standards for controlling the Danhong injection quality. The fingerprint spectrum qualitative and quantitative discrimination is combined with the multi-index quantitative analysis, and the reliability and the safety of the Danhong injection quality are further ensured.

Owner:ZHEJIANG UNIV +1

Prepn process of Qingkailing injection and injection powder and its quality control method

The present invention provides a improved preparation process of Qingkailing injection and powder for injection. The improved preparation process includes high speed centrifugal treatment in extracting cape jasmine, isatis root and honeysuckle, merging extractive liquid, ultrafiltering and other technological steps. It can produce Qingkailing injection product and powder product for injection with ever higher stability and ever longer effective period. The present invention also discloses the quality control method of baicalin, cholic acid, hyodeoxycholic acid, jasminoidin and chlorogenic acid in Qingkailing injection and powder for injectino as well as identification method of Qingkailing injection and power for injection.

Owner:GUIZHOU YIBAI PHARMA CO LTD

Method for enabling metal insert to be moulded through injection moulding and injection product containing metal insert

InactiveCN104786426ACombination structure is simpleReduce manufacturing costCoatingsManufacturing cost reductionSurface cleaning

The invention provides a method for enabling a metal insert to be moulded through injection moulding and an injection product containing the metal insert. The method comprises: performing pre-treatment to the metal insert having a pre-set shape to make the surface of the metal insert clean; performing anodic oxidation treatment to the metal insert after the pre-treatment to allow a film layer with a thickness of 1-8 mum to be formed on the surface of the metal insert, wherein holes with irregular shapes are formed in the film layer; performing adhesion treatment to the metal insert containing the holes by using an adhesion treatment agent; and carrying out injection moulding to the metal insert after the adhesion treatment to enable the metal insert to be directly combined with a plastic through flat surfaces. According to the invention, a combination structure of a metal and a plastic is effectively simplified; the manufacture cost is lowered; and the production efficiency and the yield are improved.

Owner:PERLOSGUANGZHOU ELECTRONICS COMPONENTS +1

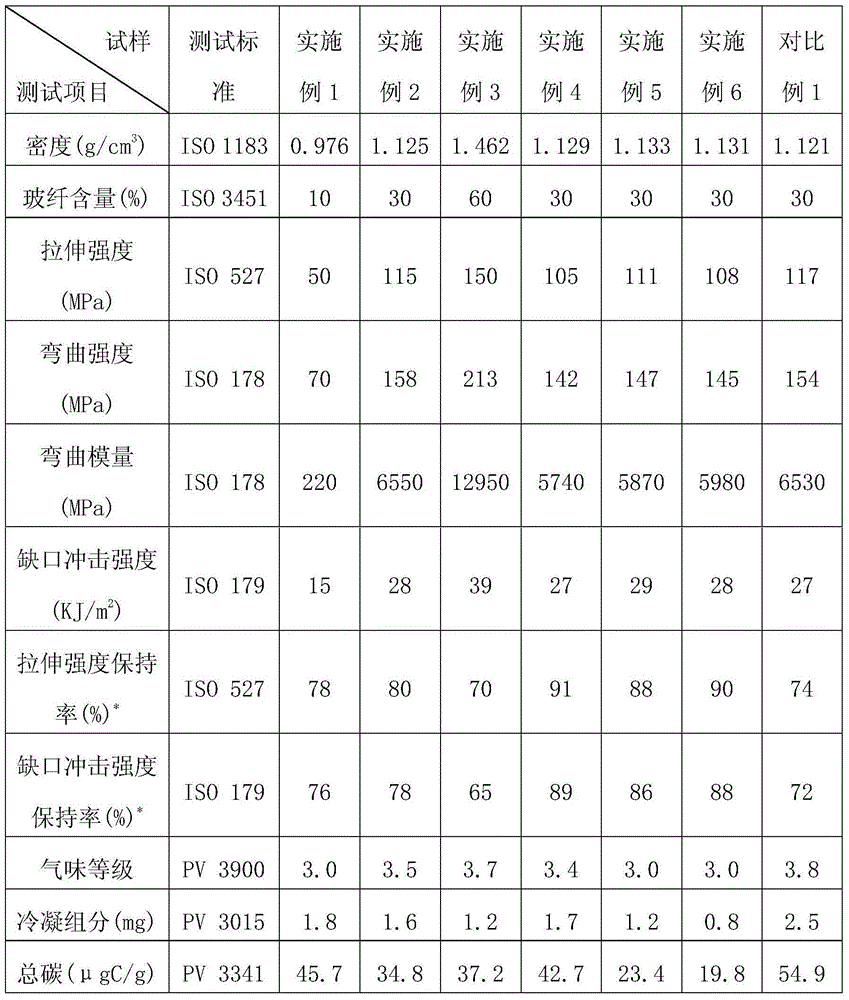

Low-emission long glass fiber reinforced polypropylene composite and preparation method thereof

InactiveCN104558830AReduce degradationImprove heat and oxygen aging timePolypropylene compositesGlass fiber

The invention discloses a low-emission long glass fiber reinforced polypropylene composite and a preparation method thereof. The low-emission long glass fiber reinforced polypropylene composite is concretely prepared from the following raw materials in percentage by weight: 28-88 percent of polypropylene, 10-60 percent of long glass fiber, 0.2-2 percent of an anionic layered compound, 1-6 percent of a compatibilizer, 0.2-2 percent of a heat stabilizer and 0.1-2 percent of a processing aid. Compared with prior art, according to the low-emission long glass fiber reinforced polypropylene composite disclosed by the invention, as the anionic layered compound is added in the raw material formula, on one hand, low-molecular volatiles generated during polypropylene composite processing can be adsorbed, acidic groups can also be fixed, degradation of the polypropylene is delayed, and the generation of the low-molecular volatile is reduced; on the other hand, the anionic layered compound and an antioxygen can have the synergistic effect, so that the heat-oxygen age stability time of a long glass fiber reinforced polypropylene material is prolonged; the preparation method is simple in method, safe in operation and uniform in dispersion of alkali-free continuous long glass fibers in the polypropylene and is capable of effectively preventing a glass fiber bundle from occurring on the surface of an injection product and greatly improving the quality of the polypropylene composite.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

Ejector mechanism and injection mold therewith

The invention relates to an ejector mechanism and an injection mold therewith. The ejector mechanism comprises a floating thimble and an ejector block, wherein the lower end part of the floating thimble is elastically connected with a rear plate, the ejector block is positioned below a mold cavity and can be slidably sleeved on the upper part of a male mold along the longitudinal direction; and the floating thimble penetrating a male mold core insert and the upper end part of the floating thimble extends into the mold cavity, the lower end part of the floating thimble is fixedly provided with a pulling-back sleeve, and a spring providing a downwards restoring force for the floating thimble is arranged between the pulling-back sleeve and the rear plate. The ejector block is connected with a drive part, the ejector block drives an injection product and the floating thimble to upwards move when the mold is opened until the periphery of the injection product is provided with an extending space, and the floating thimble is pulled out; the plasticity of the injection product is fully utilized, and the damage of the injection product caused by forced demolding is avoided.

Owner:SHENGMEI PRECISION INDAL KUSN

Mould structure of plastic injection product

InactiveCN102328389AHigh strengthMeet normal strength requirementsInjection productMaterials science

The invention provides a mould structure of a plastic injection product, which is used for enabling the strength of a filling position of a product at the end farthest away from a gate to be good and the strength of the whole product to be good so as to meet the normal strength requirement of the product. The mould structure of the plastic injection product comprises a runner, the gate, a front mould core and a back mould core, wherein the front mould core and the back mould core are mutually matched to form a diccavity; and the runner is communicated with the gate after penetrating through the front mould core. The mould structure of the plastic injection product is characterized in that the diccavity at the end farthest away from the gate is internally provided with cold material troughs which are specifically overflow cavities formed in a manner that the front mould core and the back mould core are mutually matched.

Owner:VANGUARD TECH WUXI

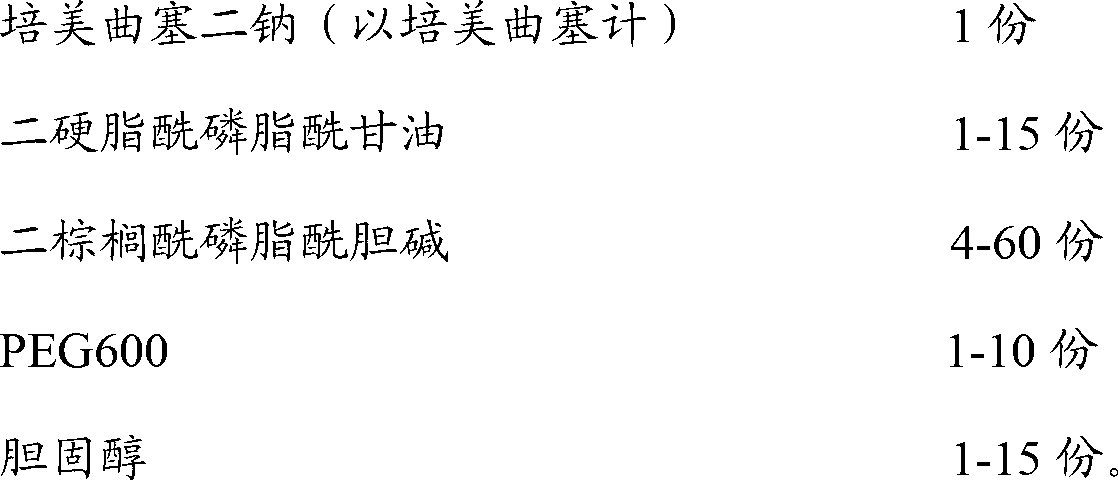

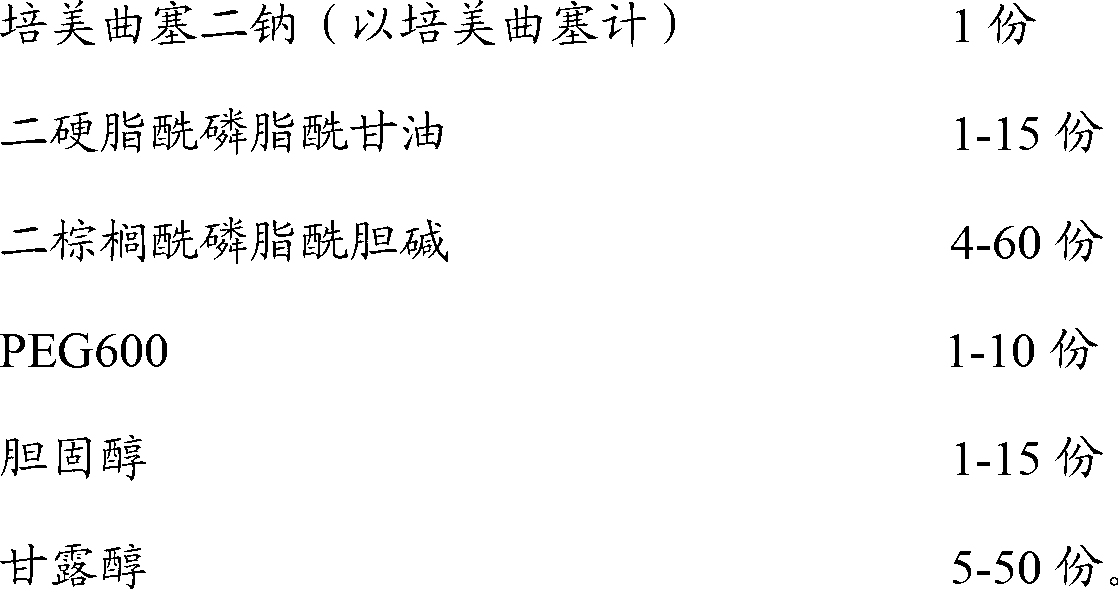

Pemetrexed disodium liposome injection

InactiveCN103040748AInhibit aggregationLarge particle sizeOrganic active ingredientsPharmaceutical non-active ingredientsSolubilityMedicine

The invention discloses pemetrexed disodium liposome injection which is mainly made of pemetrexed disodium and a preparation method thereof, distearoyl phosphatidyl glycerol, dipalmitoyl phosphatidyl choline, PEG600, cholesterol and mannitol. The liposome injection has the advantages that the particle size of liposome is small, the liposome is uniformly distributed, the encapsulation efficiency is high, the leakage rate is low, the stability is good, the solubility of the pemetrexed disodium and the quality of injection products are improved, the toxic and side effect is reduced, and the curative effect is improved.

Owner:海南路易丹尼生物科技有限公司

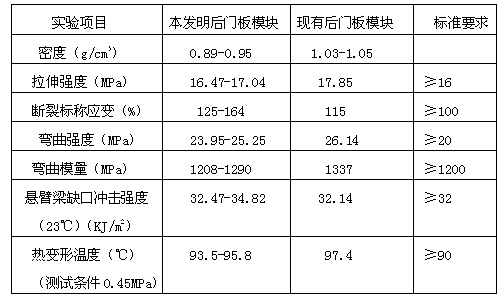

Low-density automobile back door plate module and preparation method thereof

The invention relates to a low-density automobile back door plate module and a preparation method thereof. The preparation method is used for reducing self weight of automobile back door plate modules and overcoming appearance defects of sink marks, warping deformation and the like. The low-density automobile back door plate module uses modified polypropylene particles and foaming masterbatches as raw materials and is produced through mixing injection molding, and the mass ratio of the modified polypropylene particles and the foaming masterbatches is 100: (1-4). According to the low-density automobile back door plate module and the preparation method thereof, the modified polypropylene particles and the foaming masterbatches are used as the raw materials, conventional injection processes are improved according to raw material characteristics and molding requirements, and a high-pressure high-speed injection process is used, so that the intensity of produced injection products is lower than that of ordinary polypropylene modules by 10%-15%, 10%-15% of a molding period can be shortened, the usage quantity of the raw materials is saved, and the molding period can be substantially shortened.

Owner:GREAT WALL MOTOR CO LTD

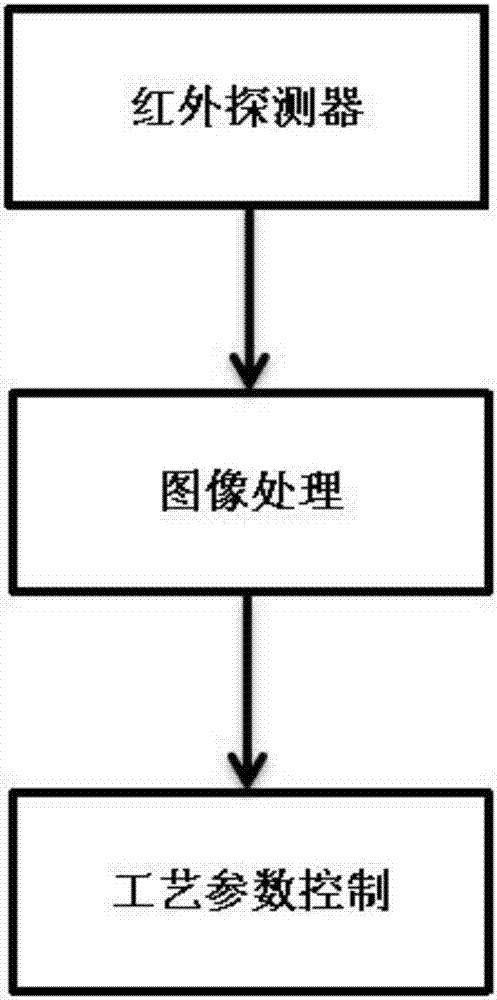

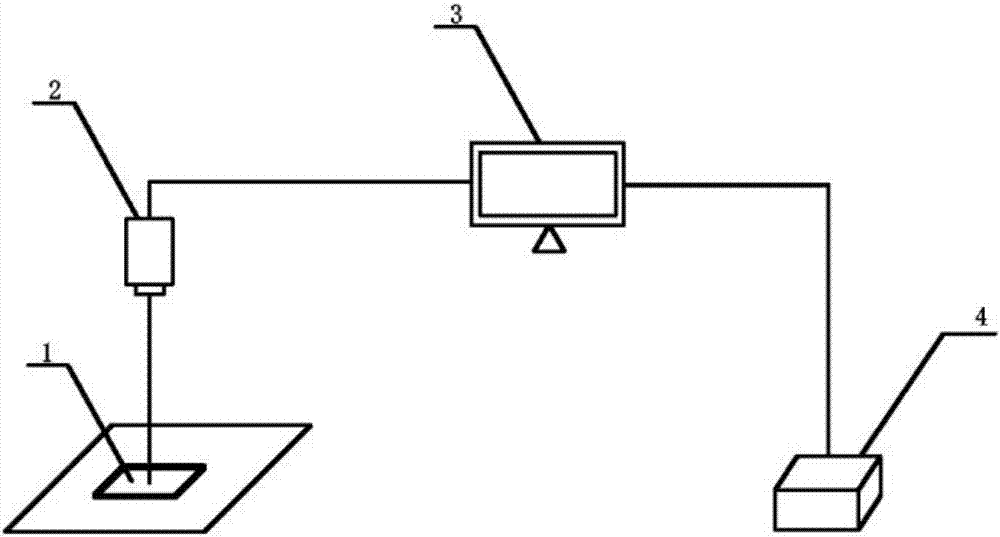

Online injection product quality detection device and method based on infrared imaging

InactiveCN106872509AQuickly process resultsThe processing result is accurateMaterial thermal analysisInjection productProcess engineering

The invention discloses an online injection product quality detection device and method based on infrared imaging. The device comprises an infrared detection and acquisition module, an image displaying and processing module and a process parameter regulation module which are in telecommunication connection in sequence. The method comprises the following steps: performing all-round detection and thermal image acquisition on injection products through the infrared detection and acquisition module in the injection molding process, and transmitting the acquired images to the image displaying and processing module through a wired network; inputting the processed image data into a knowledge base, wherein the knowledge base is capable of analyzing various quality indexes of the products according to the image information, such as internal histological morphology and structure of the product, density of the product, defect conditions of the products and the like; and transmitting the quality parameters to the process parameter regulation module so as to realize online regulation of injection molding process parameters. According to the device, the quality problems caused in the injection product production process can be monitored in real time, closed-loop control from the quality indexes to the process parameters is realized, and the quality of the injection products is improved.

Owner:SOUTH CHINA UNIV OF TECH

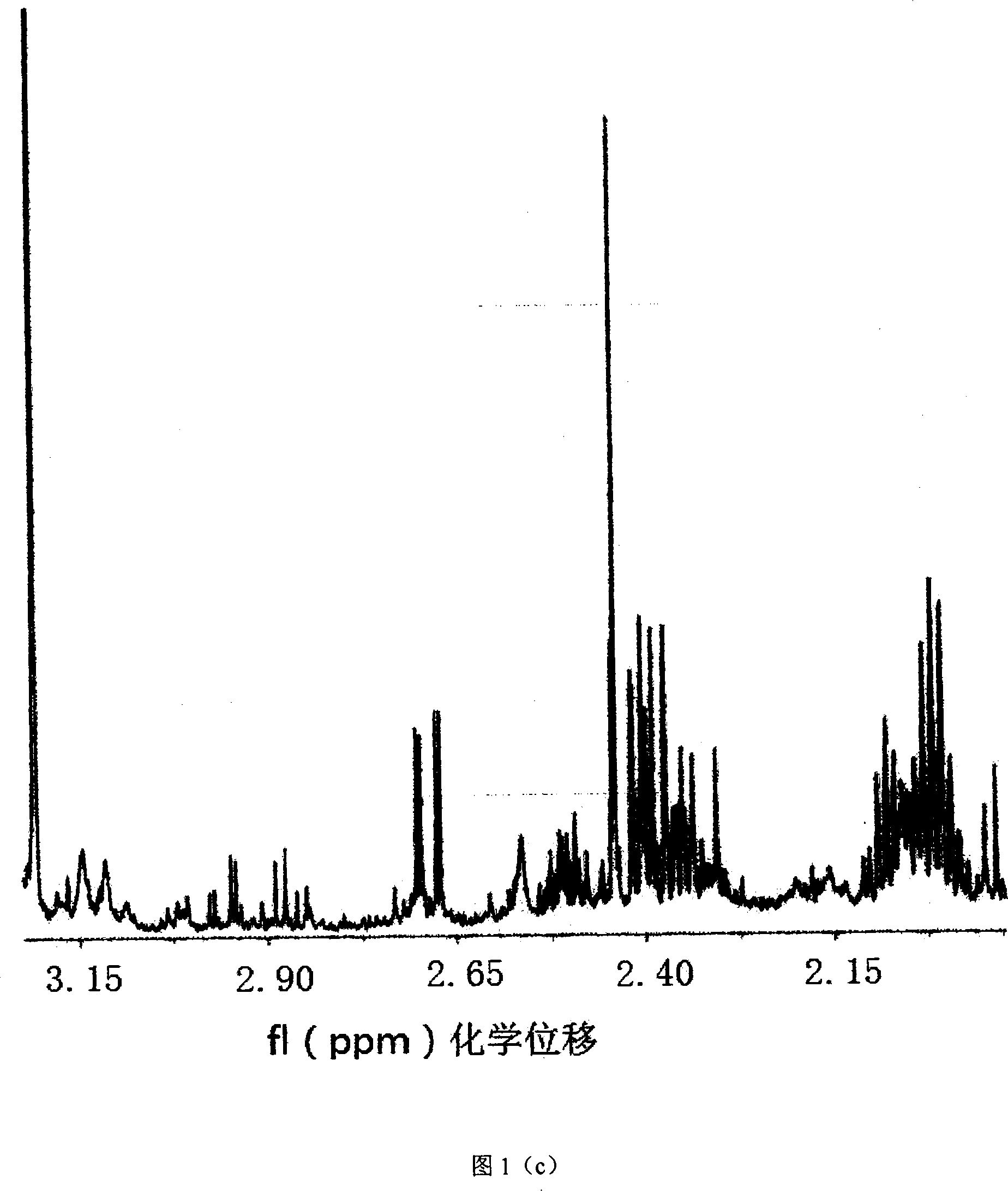

Nuclear magnetic resonance quality control method for ginseng and astragalus strengthening injection

ActiveCN103884731ASimple methodImprove stabilityAnalysis using nuclear magnetic resonanceHplc fingerprintAdditive ingredient

The invention provides a method of controlling the quality of amino acids, organic acids and sugars in a ginseng and astragalus strengthening injection by combining a proton nuclear magnetic resonance fingerprint with the content determination of a plurality of ingredients. A quality control method aiming at the amino acids, the organic acids and sugar compounds in the ginseng and astragalus strengthening injection is built by adopting a qualitative and quantitative nuclear magnetic resonance fingerprint technique, and can be combined with a high-performance liquid chromatography (HPLC) fingerprint in industrial production. Thus, total quantity control on the ginseng and astragalus strengthening injection product is achieved.

Owner:LI MIN PHARM FAB OF LIVZON PHARM GRP +1

Injectable implant and preparation method thereof

ActiveCN104055795AKeep buildSuppress generationSenses disorderPeptide/protein ingredientsPhosphateActive component

The invention relates to an injectable implant and a preparation method thereof. The implant is amnion microparticles mixed in a sodium chloride phosphate physiological solution with a pH of 7.0-7.5. The preparation method comprises the following steps of disinfection processing, decellularization processing, modification processing, and amnion microparticle preparation, and in particular, comprises: taking amnion microparticles as a component A and a sodium chloride phosphate physiological solution as a component B, performing vibration and well mixing according to a mass volume ratio of 20:1-100:1 to prepare an amnion microparticle suspension with a concentration of 20-100 mg / mL by high-speed microjet equipment, wherein the particle size of the amnion microparticles is 50-200 microns. The injectable implant of the invention maintains the natural three dimensional stereo structure and a lot of natural active components of human amnion, reduces immunological rejection reaction caused by raw material source after clinical application of cosmetic injection products, is suitable for injection into deep subcutaneous dermal layer to subcutaneous superficial layer to repair moderate to severe wrinkles or folds, and has good cosmetic repair effect.

Owner:SHAANXI RUISHENG BIOTECH

Liquid filling method for lithium battery

InactiveCN101047233ANo repeated injection phenomenonImprove labor productivityCell component detailsCapacitanceInjection product

A method for injecting electrolyte into lithium battery includes laying stainless steel support with liquid injection holes being arranged regularly towards to injection product into soaking box of injection liquid, covering and sealing said box then vacuuming said box to form negative pressure at internal of said battery, injecting electrolyte into said box and automatically sucking in electrolyte by said battery in said box under action of negative pressure.

Owner:JIANGSU YINGTAI ELECTRONICS +1

Bicolor product injection mould

The invention discloses a bicolor product injection mould which comprises a male template and a female template and is characterized by further comprising a male die, two female dies and a rotary device, wherein the male die is arranged on the male template; the two female dies are arranged on the same side of the female template; a glue inlet runner is arranged on the two female dies respectively; one female die is provided with a positioning mechanism for placing a film into a cavity of the female die; and the rotary device can drive the male template to rotate for at least 180 degrees. Through the invention, the problems that the bicolor injection product has relatively single appearance effect, the pattern is located on the appearance surface of the bicolor injection product and easily drops and fades along with the increase of the service time and the product has short service life and relatively bad using effect in the prior art are solved; and the invention provides a bicolor product injection mould, wherein the structure is simple, the pattern is located in the bicolor injection product and does not drop or fade, and the using effect is better.

Owner:JINLI TRADE MARK KUSN

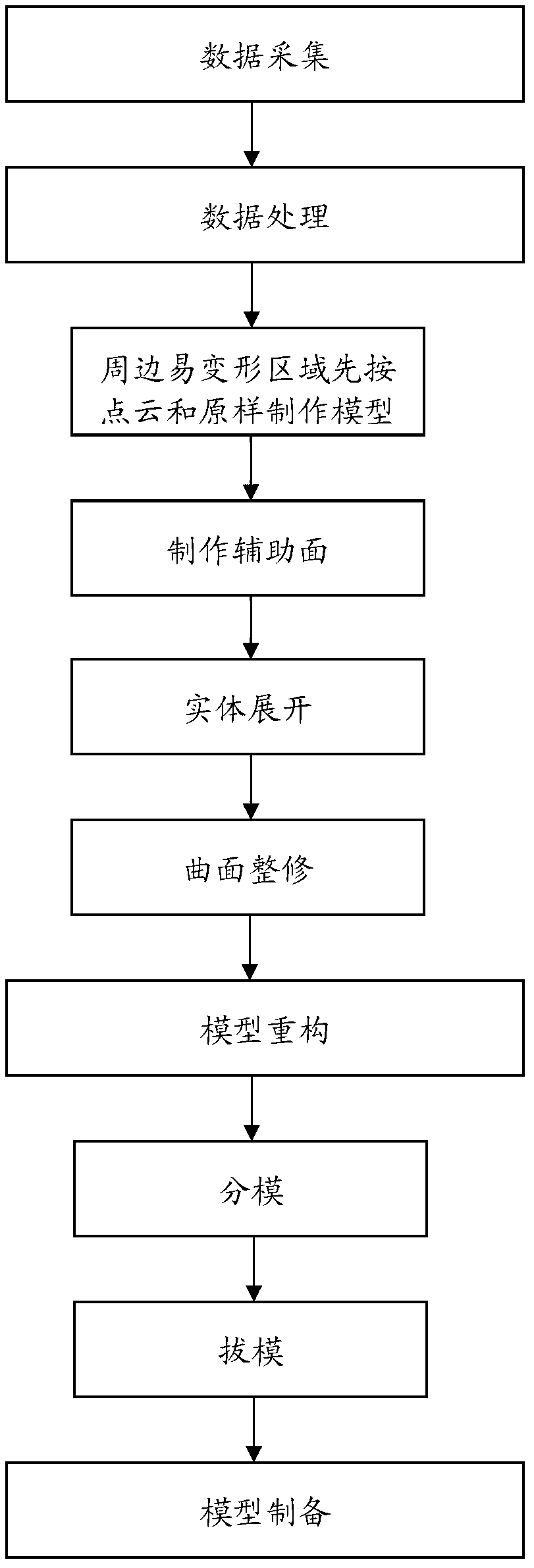

Method for manufacturing injection product model

The invention discloses a method for manufacturing an integrated injection product model. The method comprises the following steps of: (1) acquiring data, (2) processing the data, (3) reconstructing the model, and (4) manufacturing the model. The step (1) comprises the substeps of breaking off deep and shallow parts of a groove until the groove is deformed and then acquiring the data; the step (2) is used for treating an easily deforming region around the product in the following way: 1) manufacturing an original shape point cloud model on a deforming part of a soft edge of the periphery according to an original shape, 2) then producing an auxiliary surface, 3) unfolding an entity, and 4) finishing a curved surface and fitting scanning points on the break-off deforming parts; the step (3) comprises the following substeps: splitting the product model, then properly dragging the model until a final counter-deformation model of an integrated injection product meeting a precision requirement is obtained and eventually obtaining the product entity model according to the final counter-deformation model. According to the method, the model manufacturing cost can be reduced, the product manufacturing speed can be increased, the product handover time is shortened, and the product quality is improved.

Owner:XINYI AUTOMOBILE GLASS (SHENZHEN) CO LTD

Predeformation design method of plastic injection product

InactiveCN103699718AEasy to manufactureAvoid cumbersomeSpecial data processing applicationsInjection productProduct base

The invention belongs to the field of mould manufacturing, and discloses a predeformation design method of a plastic injection product. The method comprises the steps: 1) inputting used parameters while mold flow analysis is carried out on a mold flow analysis software, and carrying out injection molding flow simulation to obtain deformation data; 2) copying the deformation data of the product; 3) settling the deformation data, and calculating the predeformation of the product; 4) predeforming a 3D product based on a primary specification, so as to obtain a simulated 3D product; 5) designing a module for producing a product according to the predeformed simulated 3D product; and 6) manufacturing a mould and using the manufactured mould to carry out injection molding production, so as to obtain a finished product. According to the method, the tedious processes of repeatedly testing the moulds, modifying products, and repeatedly modifying the moulds over and over can be prevented, the materials and cost for repeatedly modifying the moulds can be saved, most importantly, the developing efficiency can be improved, and the developing period can be shortened.

Owner:锦丰科技(深圳)有限公司

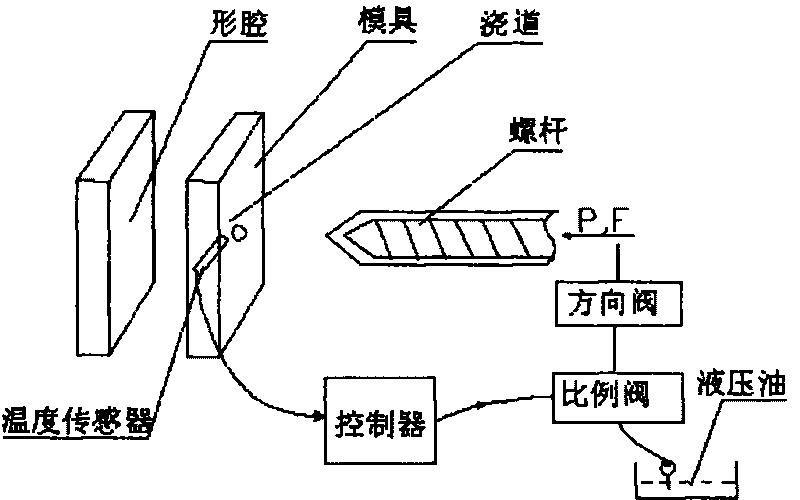

Technology for holding pressure control according to melting body temperature as injection molding machine

InactiveCN101698350AGood specific volume consistencyImprove qualityInjection productInjection molding machine

The invention discloses a technology for holding pressure control according to melting body temperature as an injection molding machine, comprising the following technical steps: A), installing a melting body temperature sensor on the mould cavity or pouring gate of an injection machine for measuring the melting body temperature; B), connecting the output signal of the melting body temperature sensor to an injection machine controller; C), writing the holding pressure control procedure in the injection machine controller as the holding pressure switch according to the melting body temperature; D), in the injection holding pressure process, the melting body temperature in the mould cavity is quickly increased firstly and slowly reduced then, after the temperature reaches the top point, the invention performs transfer holding pressure, holding pressure switch and holding pressure end control according to the set melting body temperature. The invention has the advantages of high injection product quality and repeat accuracy.

Owner:ZHEJIANG KEQIANG INTELLIGENT CONTROL SYST

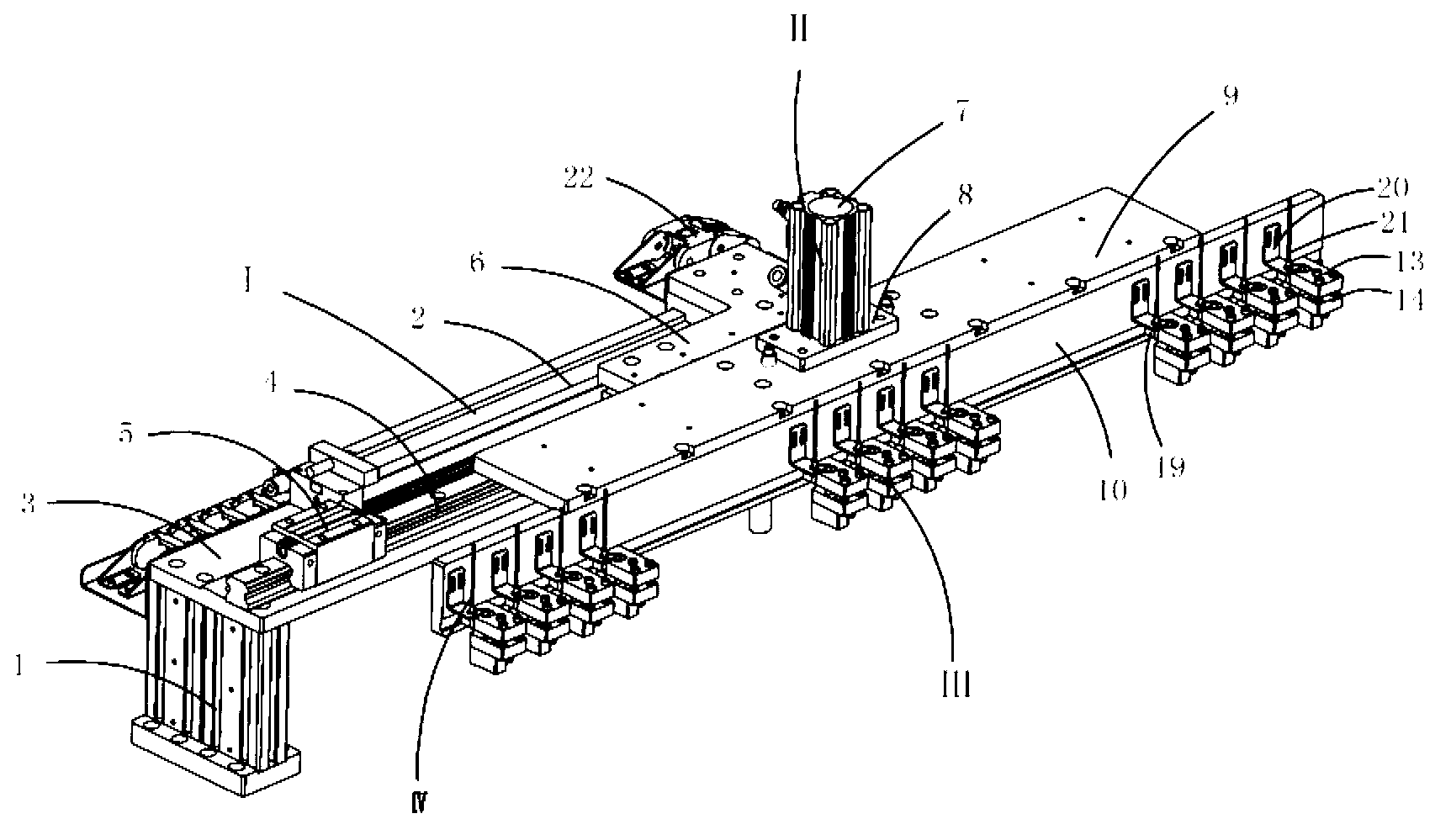

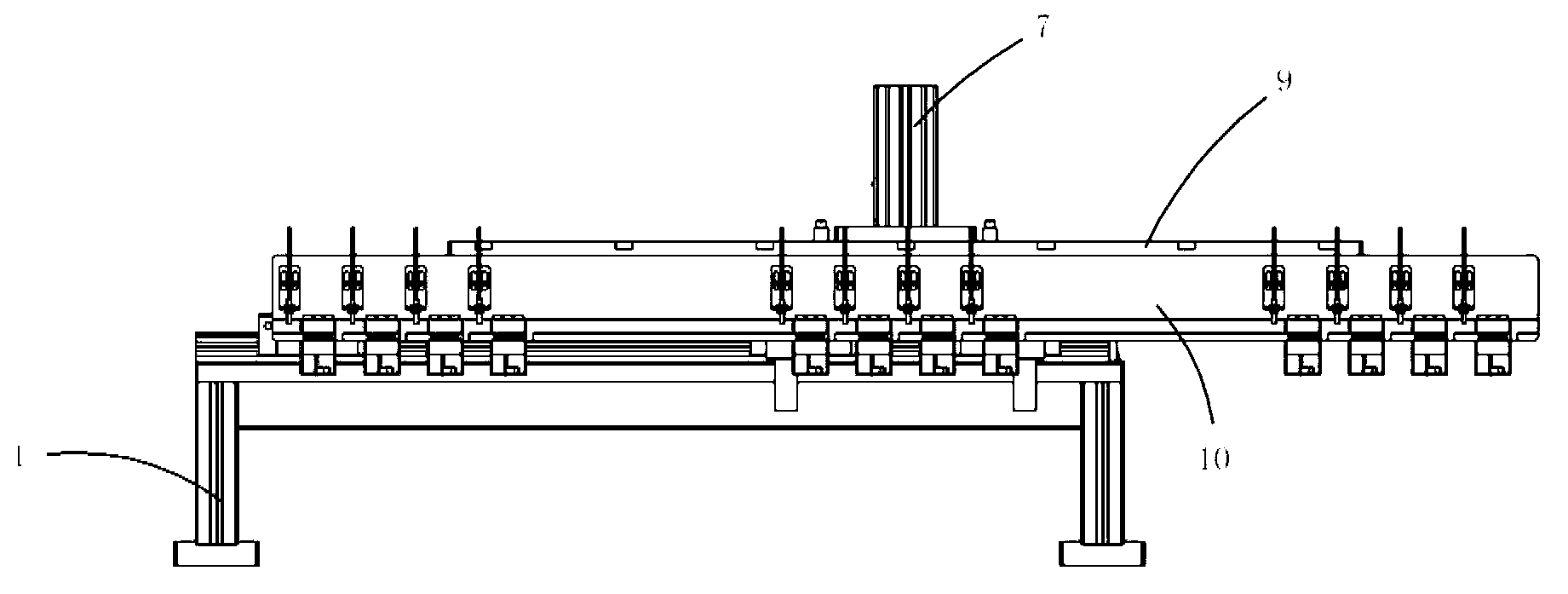

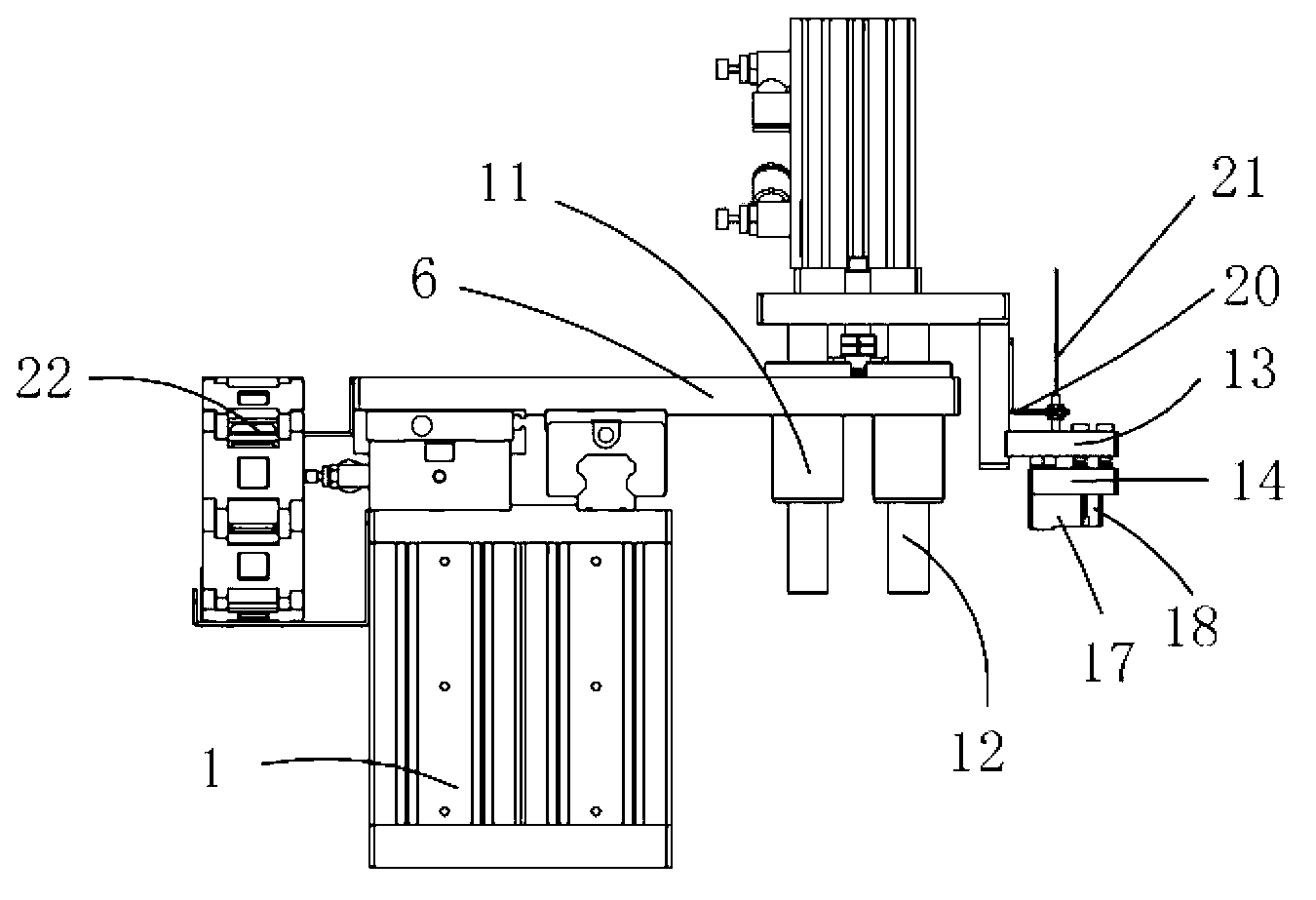

Automatic injection product carrying module

ActiveCN103193084AHigh precisionImprove crawl success rateConveyor partsMaintainabilityInjection product

The invention relates to an automatic injection product carrying module. During a coordinate movement process of four modules including a linear movement module, a lining module, a suction nozzle module and an optical fiber module, simultaneous moving of a plurality of platform articles is realized to form an assembly work line. The automatic injection product carrying module is high in stability, precision and integral moving efficiency, production efficiency is greatly improved, space is saved, maintainability is improved, and production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com