Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

361results about How to "Shrink evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

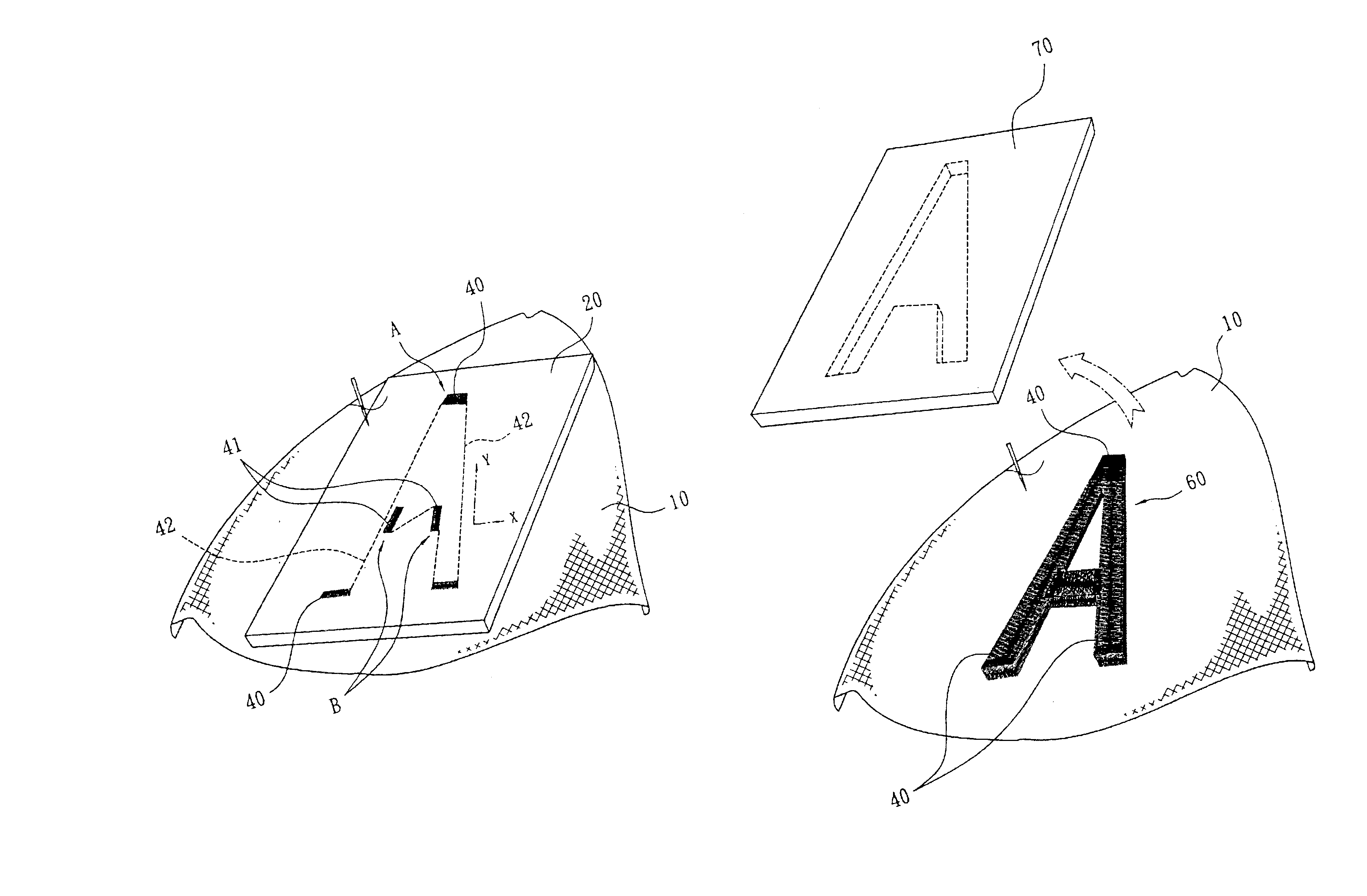

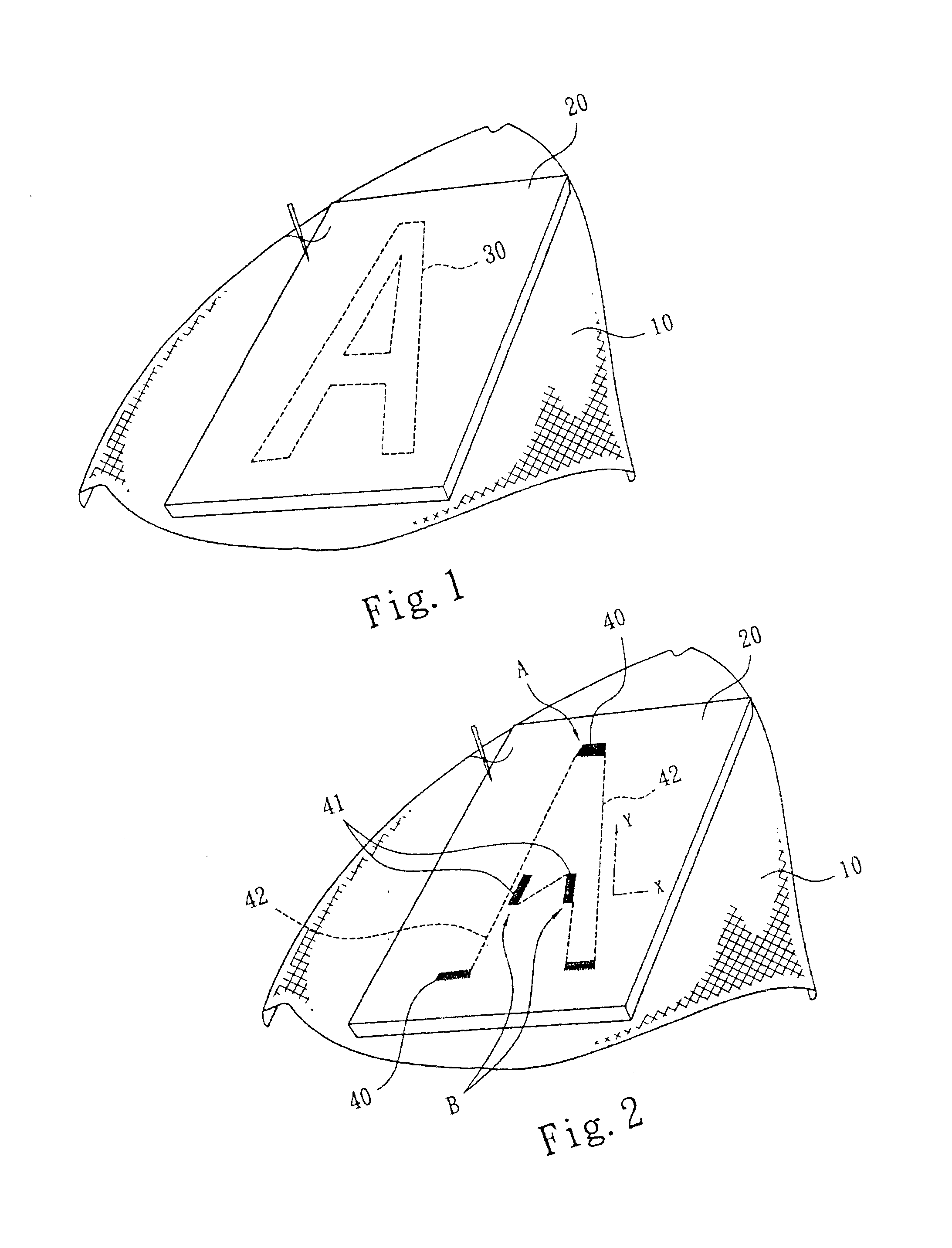

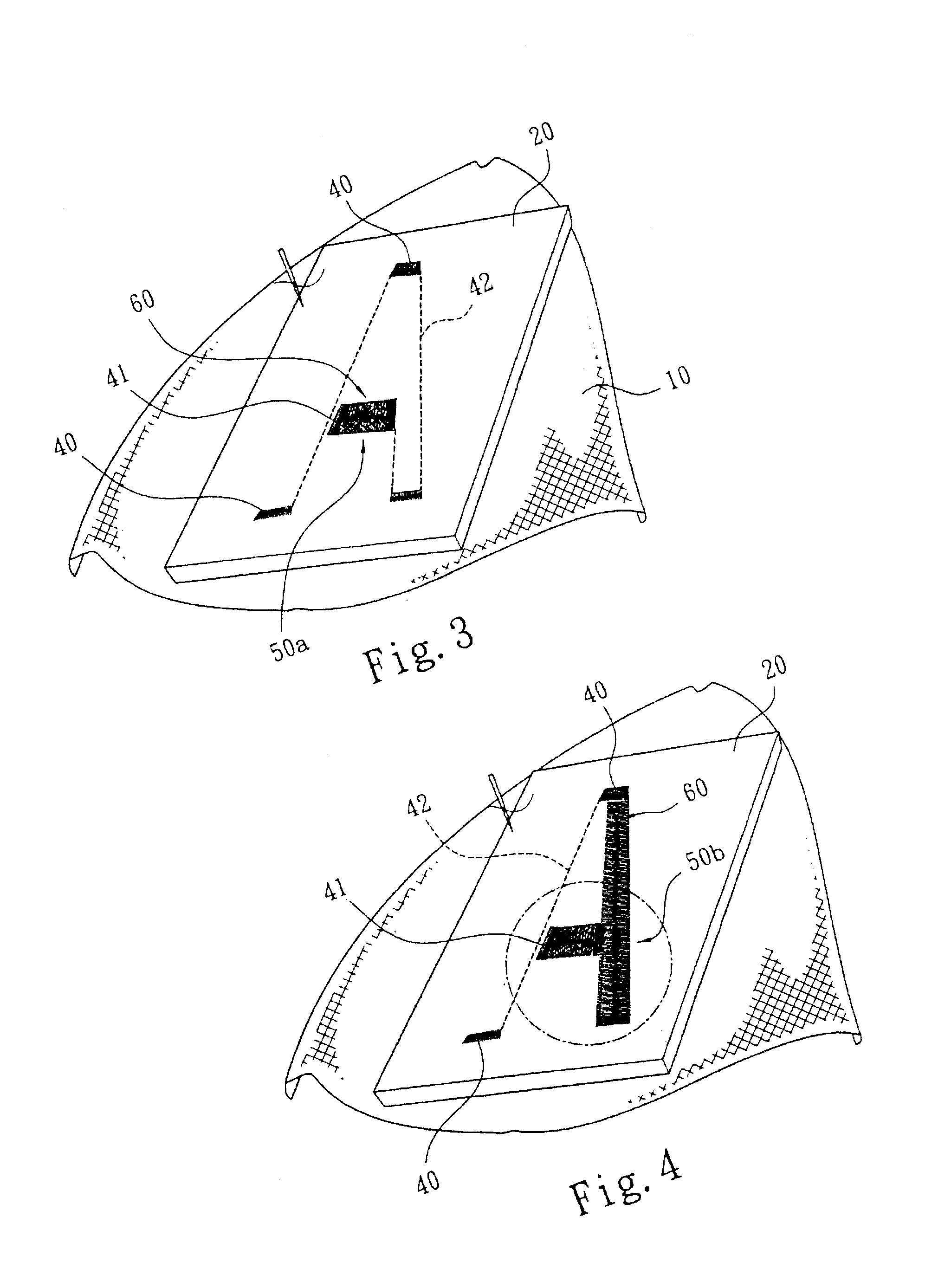

Raised embroidery process

Owner:WANG TAI KUANG

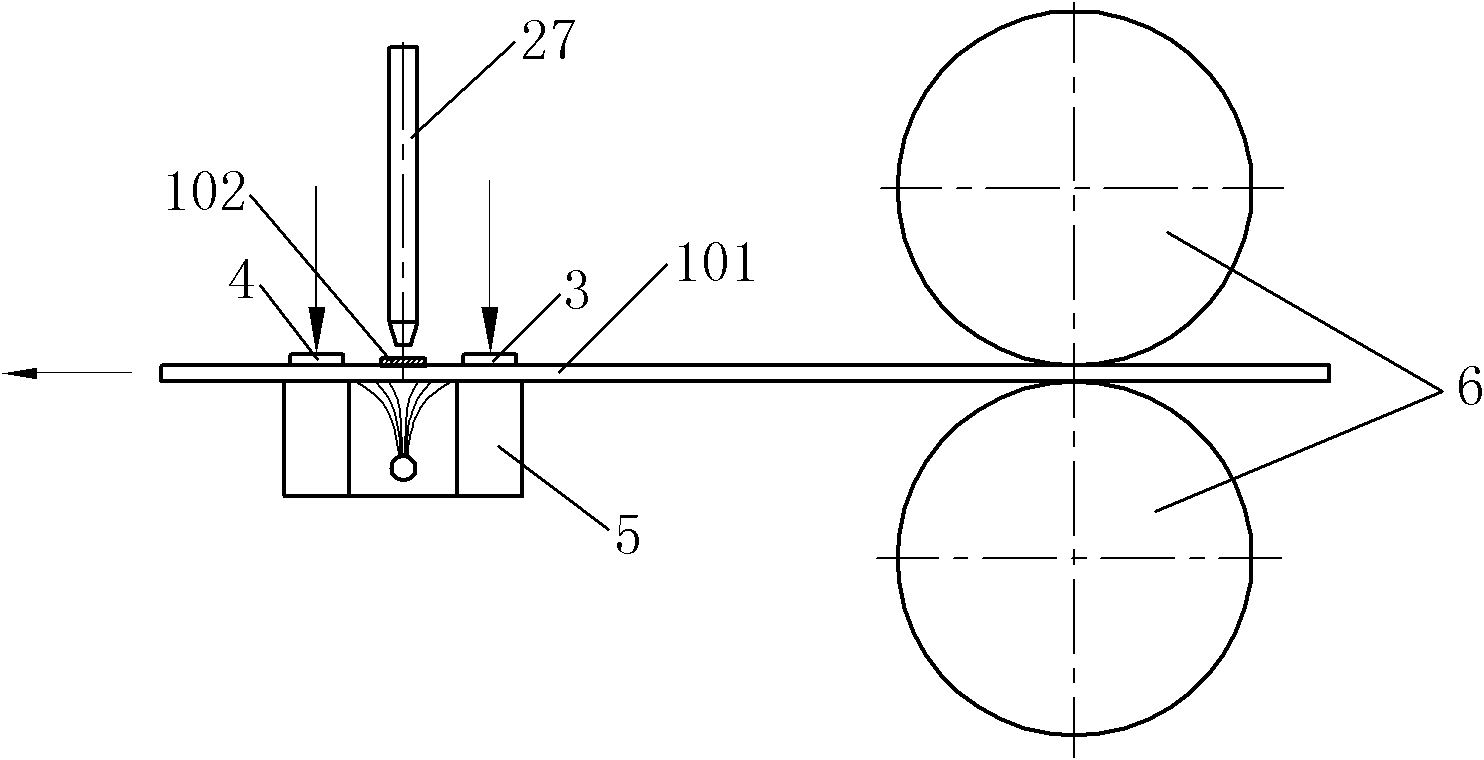

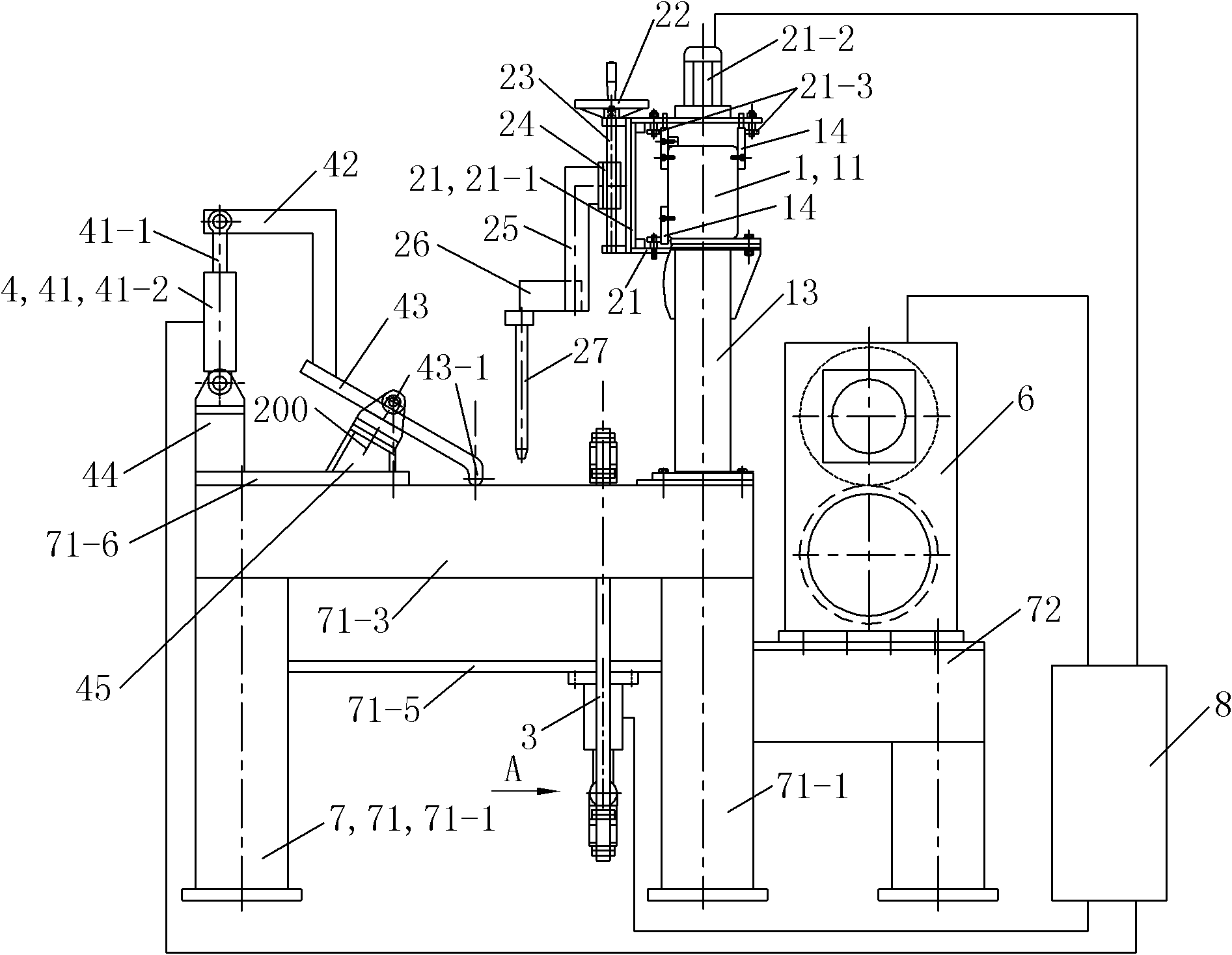

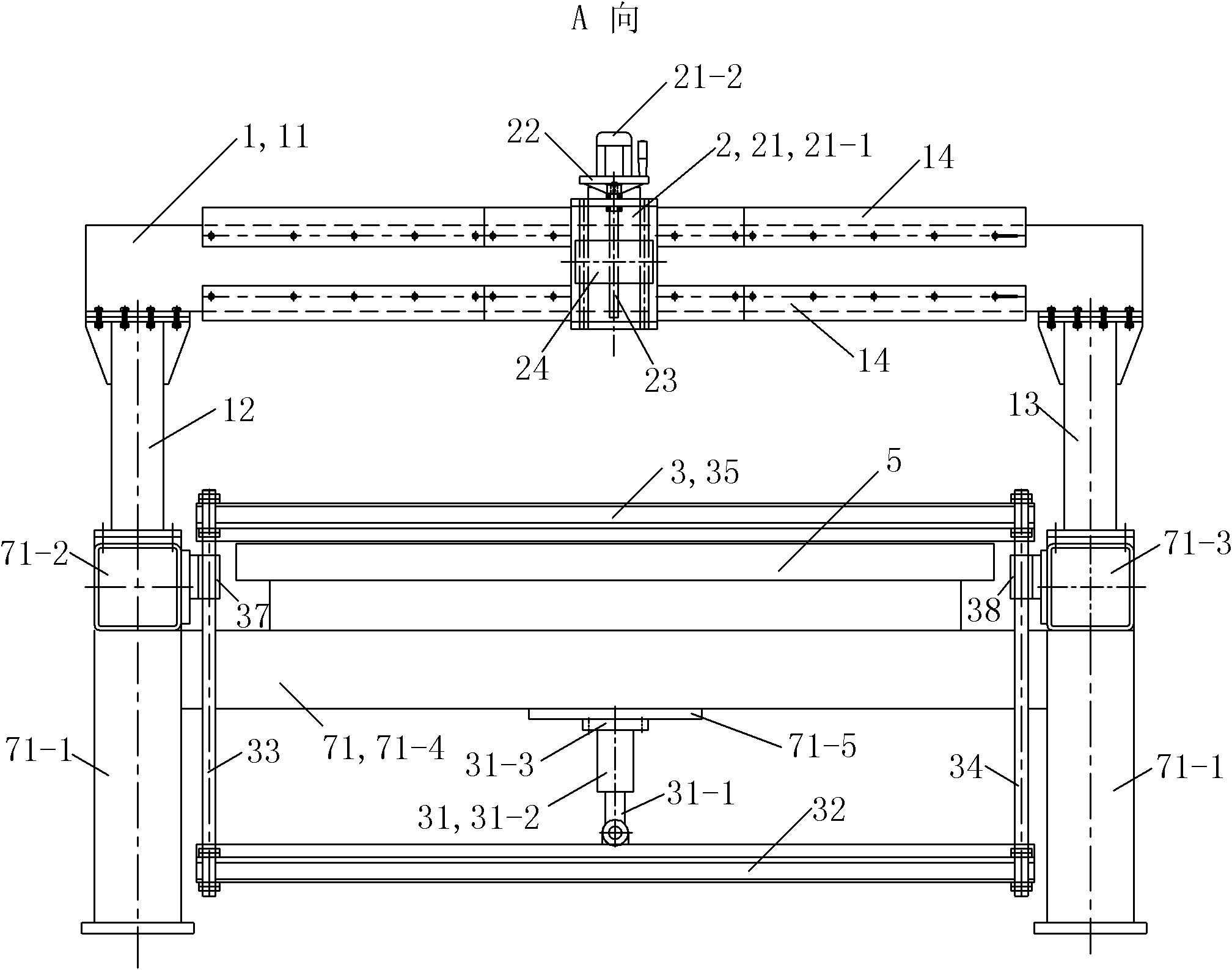

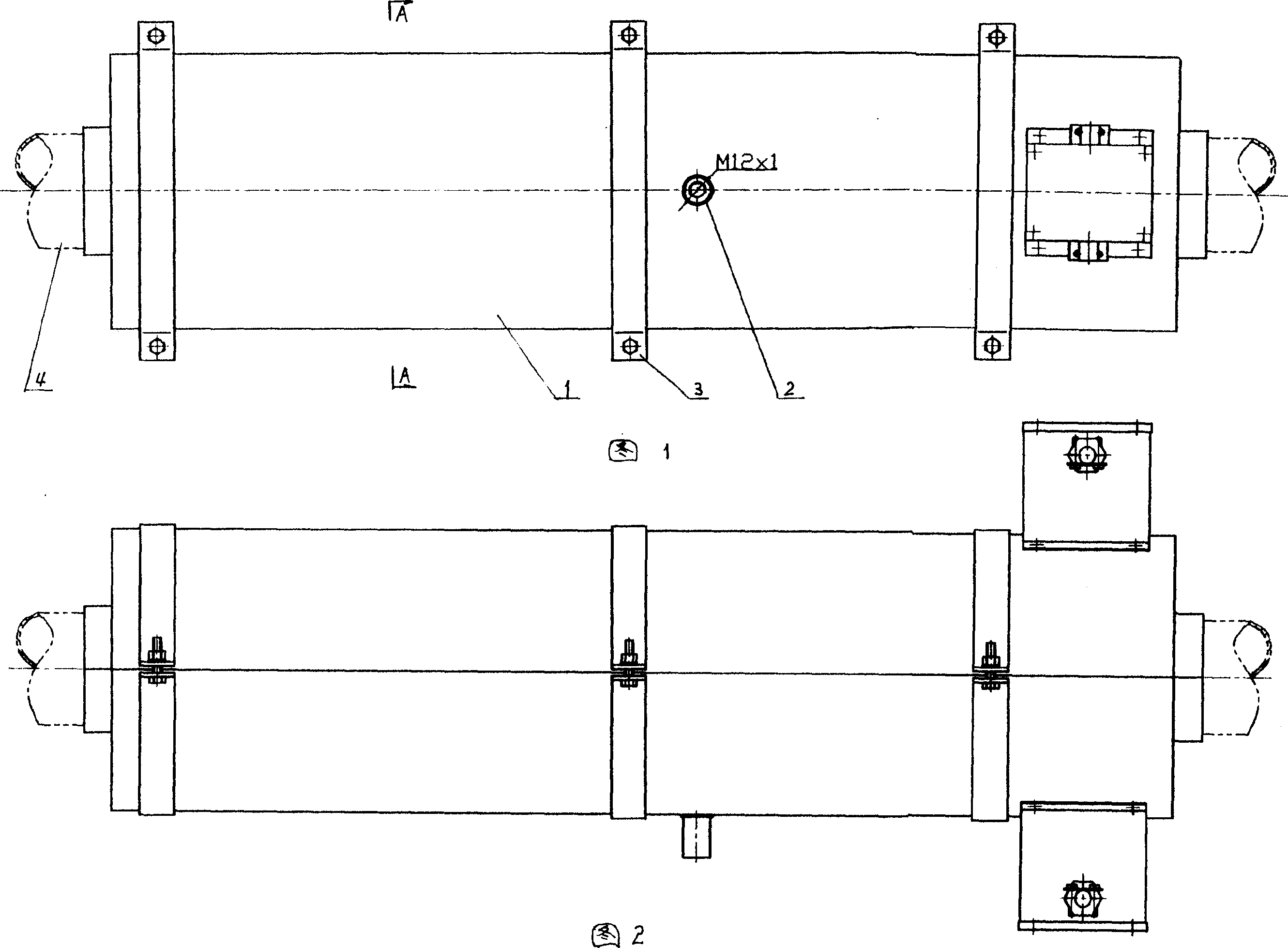

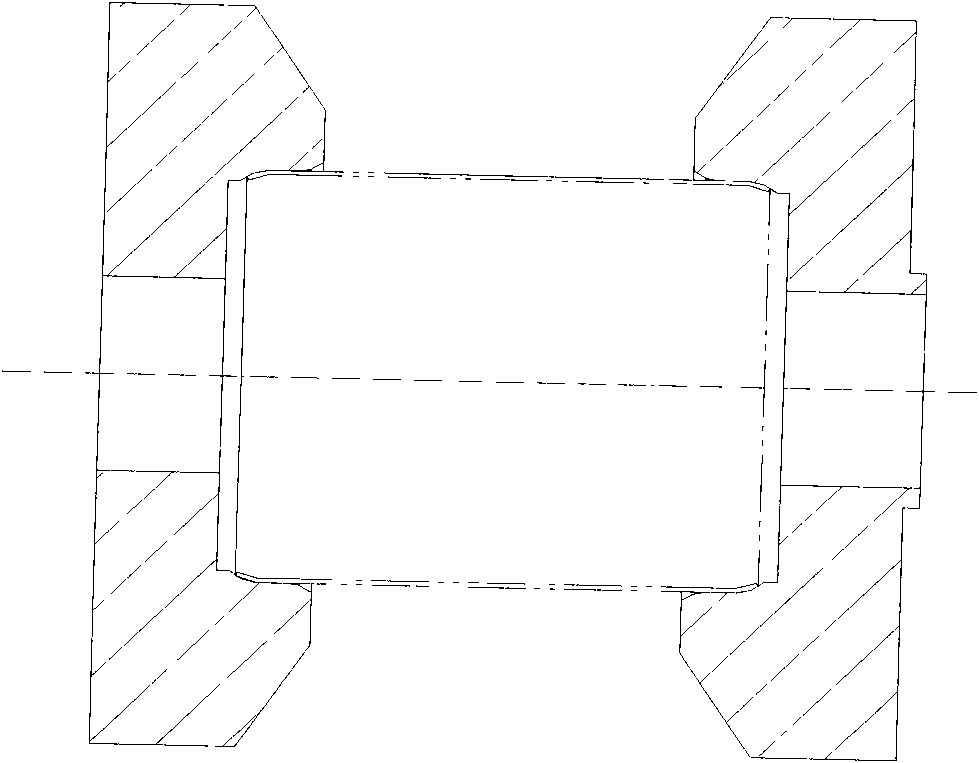

Method and equipment for manufacturing surfacing composite wear-resistant steel plate

ActiveCN102107315AImprove flatnessShrink flatWelding/cutting media/materialsSoldering mediaSheet steelWear resistant

The invention discloses a method for manufacturing a surfacing composite wear-resistant steel plate, which comprises the following steps of: tiling a steel base plate on a water-cooled platform, and compacting the steel base plate by employing front and rear side compaction devices respectively; after a weld pass is welded, opening the front and rear side compaction devices, and conveying the steel base plate for a certain distance forward through a pinch roll device; and repeating the steps for surfacing, until a flat surfacing composite wear-resistant steel plate with a high-chromium alloy wear-resistant layer is obtained on the whole steel base plate. A piece of equipment for manufacturing the surfacing composite wear-resistant steel plate applied to the method for manufacturing the surfacing composite wear-resistant steel plate comprises a portal frame, a welding device, a rear side compaction device, a front side compaction device, a water-cooled platform, a pinch roll device and a frame, wherein the rear side compaction device is arranged on the rear side of the welding device; and the front side compaction device is arranged on the front side of a welding gun of the welding device. The composite wear-resistant steel plate welded through the manufacturing method is small in deformation and high in welding quality and is not limited to specifications.

Owner:CHANGZHOU FUTONG WELDING

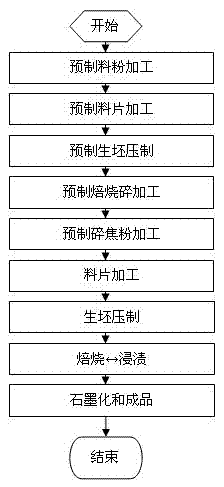

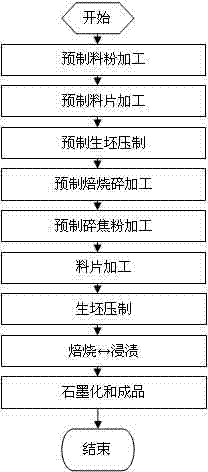

Production process of large isotropic and isostatic high purity graphite with fine particles

The invention discloses a production process of large isotropic and isostatic high purity graphite with fine particles, which comprises the following steps: processing prefabricated powder; processing prefabricated tablets; pressing prefabricated green bodies; processing prefabricated roasting scraps; processing prefabricated smashed coke powder; processing tablets; pressing green bodies; roasting and soaking; and graphitizing and finishing. A graphite product produced by the production process provided by the invention has a large size and has the diameter being more than phi 900; the strength, the density and the elasticity of the product are improved, and the mechanical behavior physical and chemical indicators of a final product is improved; and simultaneously, the produced graphite product has the characteristics of favorable isotropic performance, uniform and delicate structure, high volume density and the like.

Owner:雅安恒圣高纯石墨科技有限责任公司

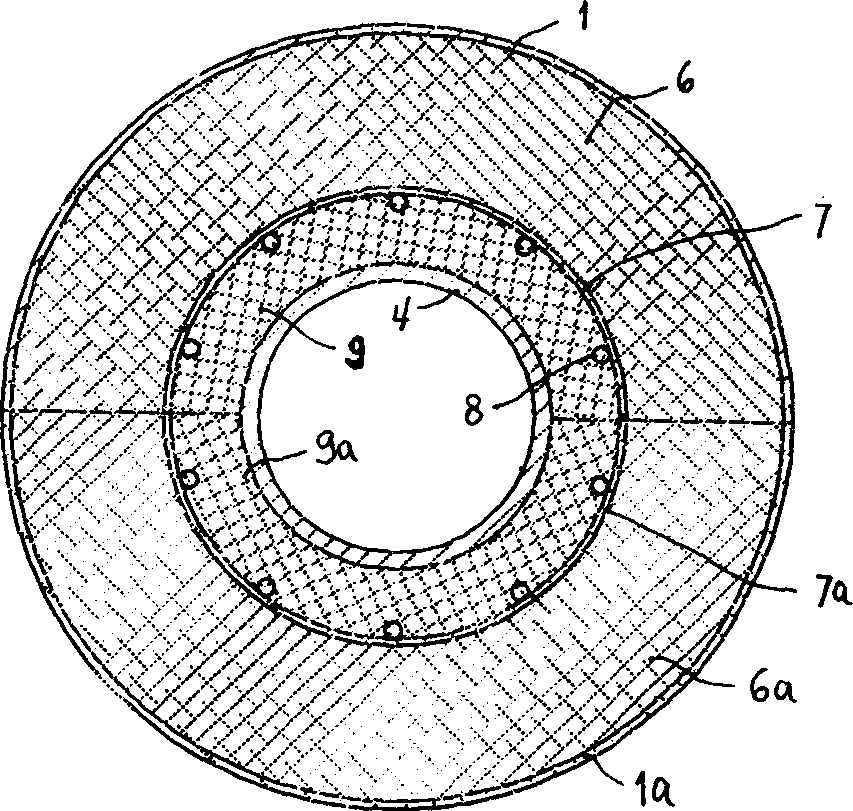

Electric heater for pipeline

InactiveCN1908499AImprove efficiencyIncrease heat conduction areaPipe heating/coolingPipeline systemsElectric heatingEngineering

An electric heater for pipeline is an electric heater used for heating the pipeline or the medium therein. A temperature control unit is composed of a SCM and a temperature sensor, also has two bush-shape metal endoconches. On the inwall side of the two metal endoconches is fixed with an electric heating pipe, also has two bush-shape molding heat-conducting layers made of heat conducting materials used in shrinking on the pipeline. The outerwall side of the molding heat-conducting layers is joint with the inwall side of two metal endoconches. Also provided are two bush-shape molding insulating layers joint with the outerwall side of the two metal endoconches, two bush-shape shell on the external surface of the two molding insulating layers. Also provided are the fixed links joining the heating module on the pipeline. The invention has the advantages of high thermal efficiency, convenient to assemble and disassemble and is widely used in a variety of pipeline heating occasions.

Owner:成都市兴岷江电热电器有限责任公司

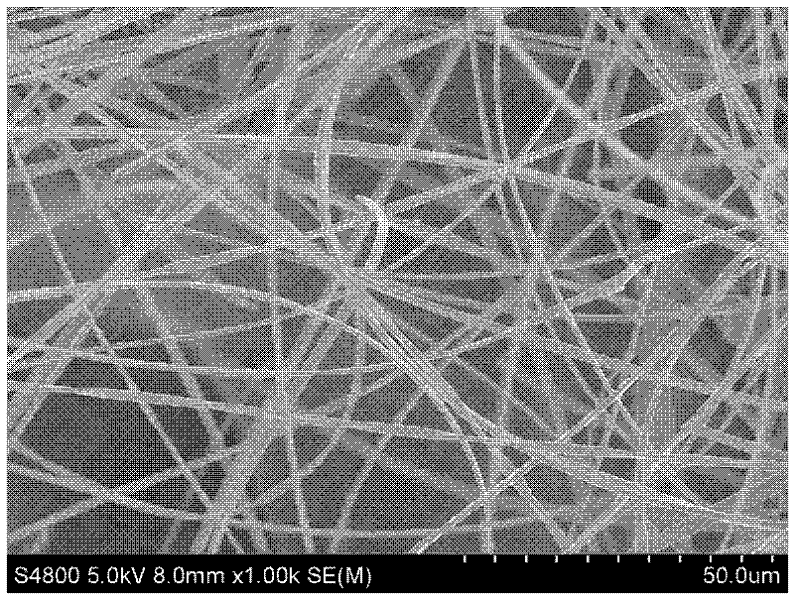

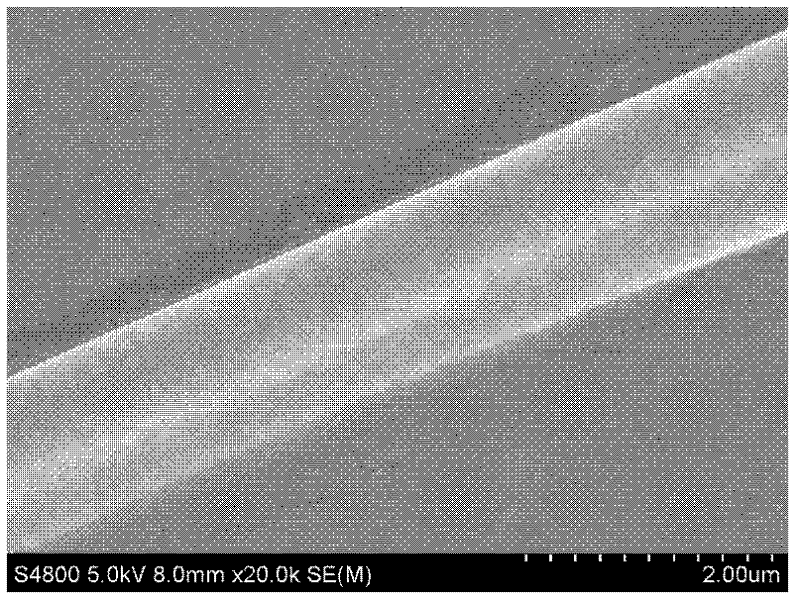

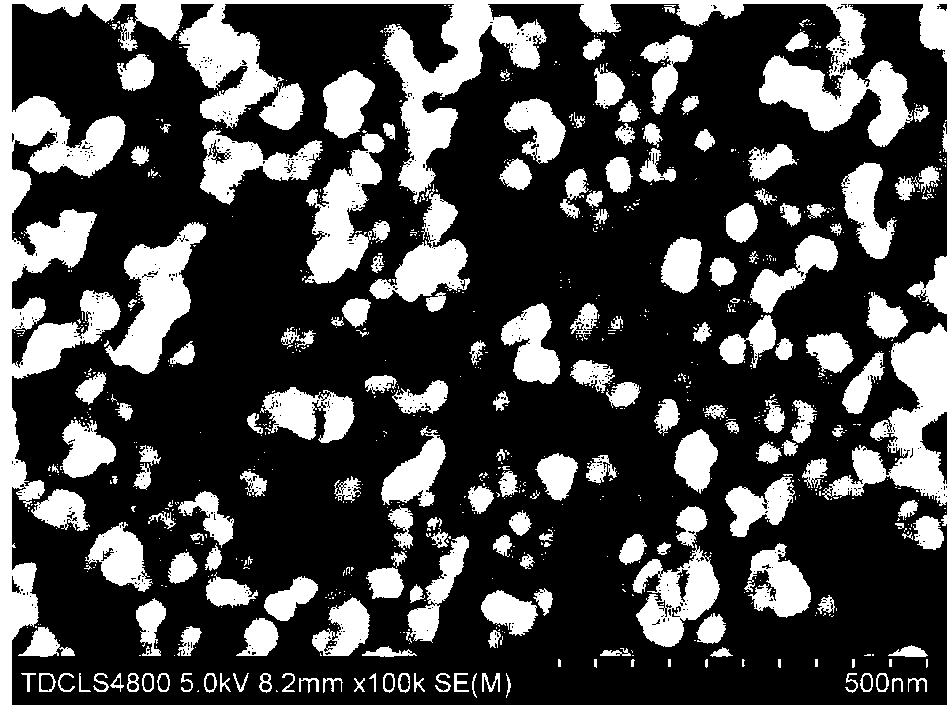

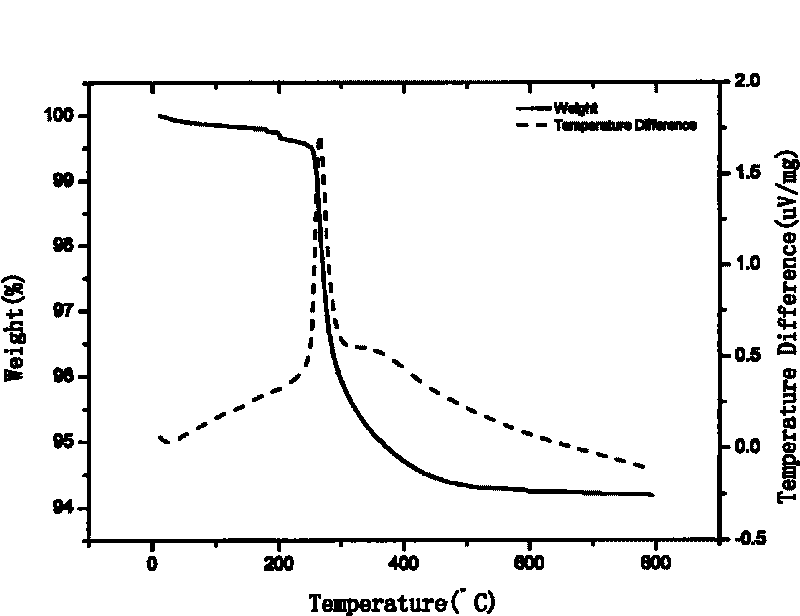

Flexible yttrium stable zirconium oxide ceramic fiber and preparation method thereof

The invention relates to a flexible yttrium stable zirconium oxide ceramic fiber and a preparation method thereof. The particle diameters of zirconium oxide particles constructing the ceramic fiber are 10-400 nanometers, the diameter of the ceramic fiber is 0.5-3 mum, and the fiber is uniform and continuous, is prevented from being broken easily and has high flexibility. A zirconium oxide gel fiber is prepared by combining a sol-gel method with an electrostatic spinning technology, and the yttrium stable zirconium oxide ceramic fiber is obtained by calcining the gel fiber. The obtained yttrium stable zirconium oxide ceramic fiber has high thermal stability and excellent mechanical property, can be taken as a high-temperature catalyst carrier, a high-temperature heat insulating material aswell as a battery membrane, and can be applied to high-temperature filtering and the like. A process disclosed by the invention has high operability, and is suitable for large-scale production.

Owner:SHANDONG UNIV

Glass fiber air filter paper with high dust holding capacity and production process thereof

ActiveCN103541279AGood mechanical strengthStable chemical propertiesWater-repelling agents additionSynthetic cellulose/non-cellulose material pulp/paperCorrosionAdhesive

The invention discloses glass fiber air filter paper with high dust holding capacity, which is prepared from alkali-free glass fiber chopped strands and alkali-free glass fiber cotton in the diameter of 0.3-0.4 mu m, as well as an adhesive, wherein the glass fiber air filter paper comprises 3-8 parts by weight of the alkali-free glass fiber chopped strands and 92-97 parts by weight of the alkali-free glass fiber cotton, and the adhesive is a water repellent containing fluorocarbon. The invention further discloses a production process of the glass fiber air filter paper with the high dust holding capacity, and the production process comprises the following steps: firstly beating and dispersing raw material to obtain pulp, then performing wet process forming on the pulp to obtain wet paper, removing water in the wet paper, then performing two-sided sizing on the dehydrated wet paper, and finally drying to obtain a product, wherein the beating degree during beating is 52-56 degrees SR, suction dehydration is performed in three stages, and drying treatment is performed in four stages. The glass fiber air filter paper disclosed by the invention has the advantages of smooth and uniform surface, large specific surface area and dust holding capacity, high mechanical strength and resistance to acid and alkali corrosion.

Owner:CHONGQING ZAISHENG TECH CORP

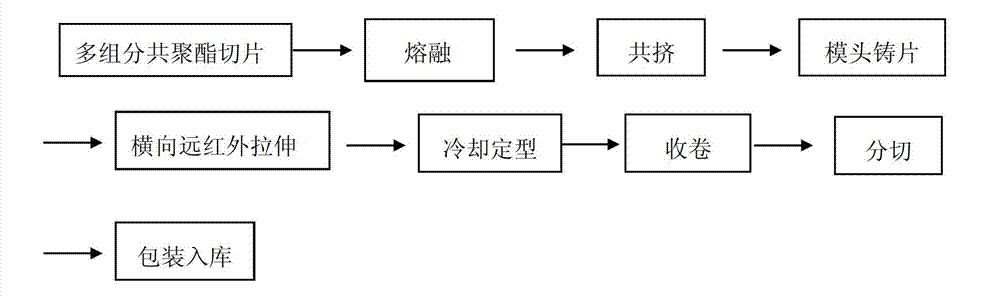

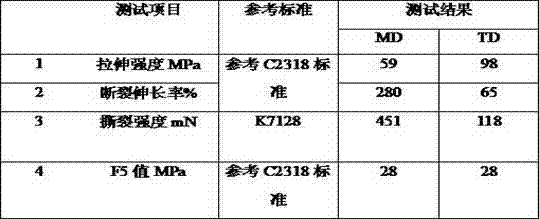

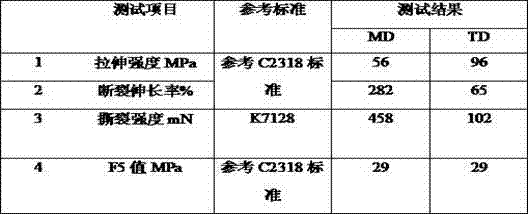

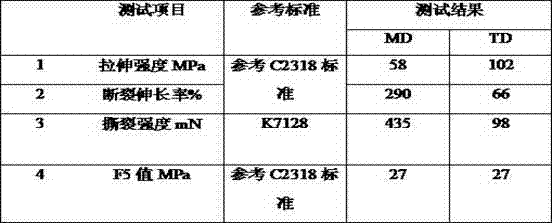

Preparation method of heat shrinkable polyester film

The invention discloses a preparation method of a heat shrinkable polyester film. The method comprises the following steps of: carrying out esterification and condensation polymerization reaction on multi-component dicarboxylic acid and multi-component dihydric alcohol in the presence of a catalyst, a stabilizing agent, an antistatic agent, a chain extender, an anti-caking agent or a modifying agent to prepare a multi-component polyester; carrying out melt extrusion, extension and pelleting on the multi-component polyester to prepare a multi-component polyester slice; and carrying out melted extrusion, die head casting, transverse far infrared drawing, cooling molding, rolling and cutting on the multi-component polyester slice to prepare the heat shrinkable polyester film. The heat shrinkable polyester film with high shrinkage percentage prepared by using the method is pretty high in strength and heat shrinkage performance, excellent in transparency, malleability, and toughness, good in glossiness, uniform in shrinkage, non-toxic, odorless, and easy to recycle, and a product of the film is suitable for labels for various containers and direct packaging of a food product, a beverage product, an electronic product, an electric product, a mechanical product, a hardware product and the like.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

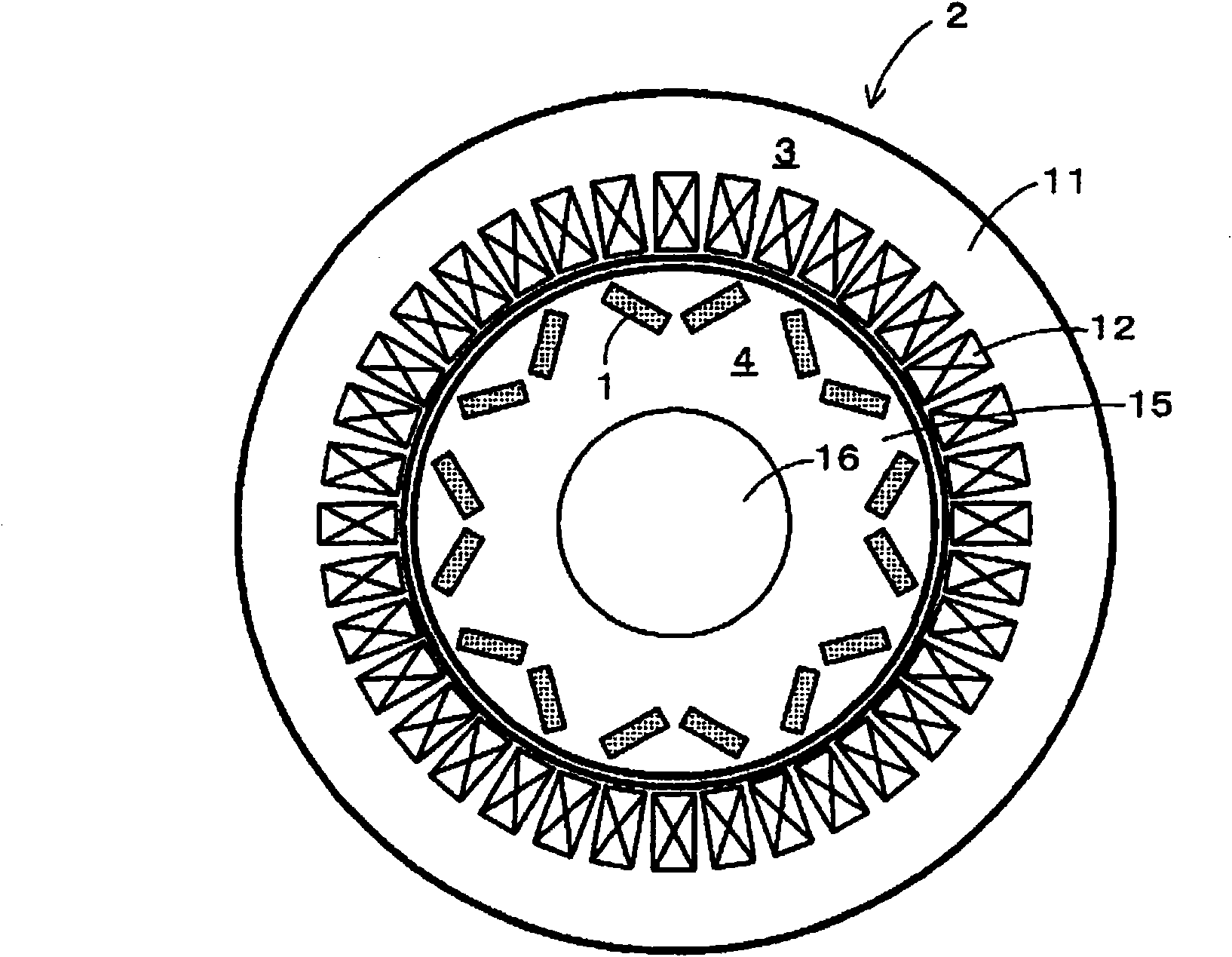

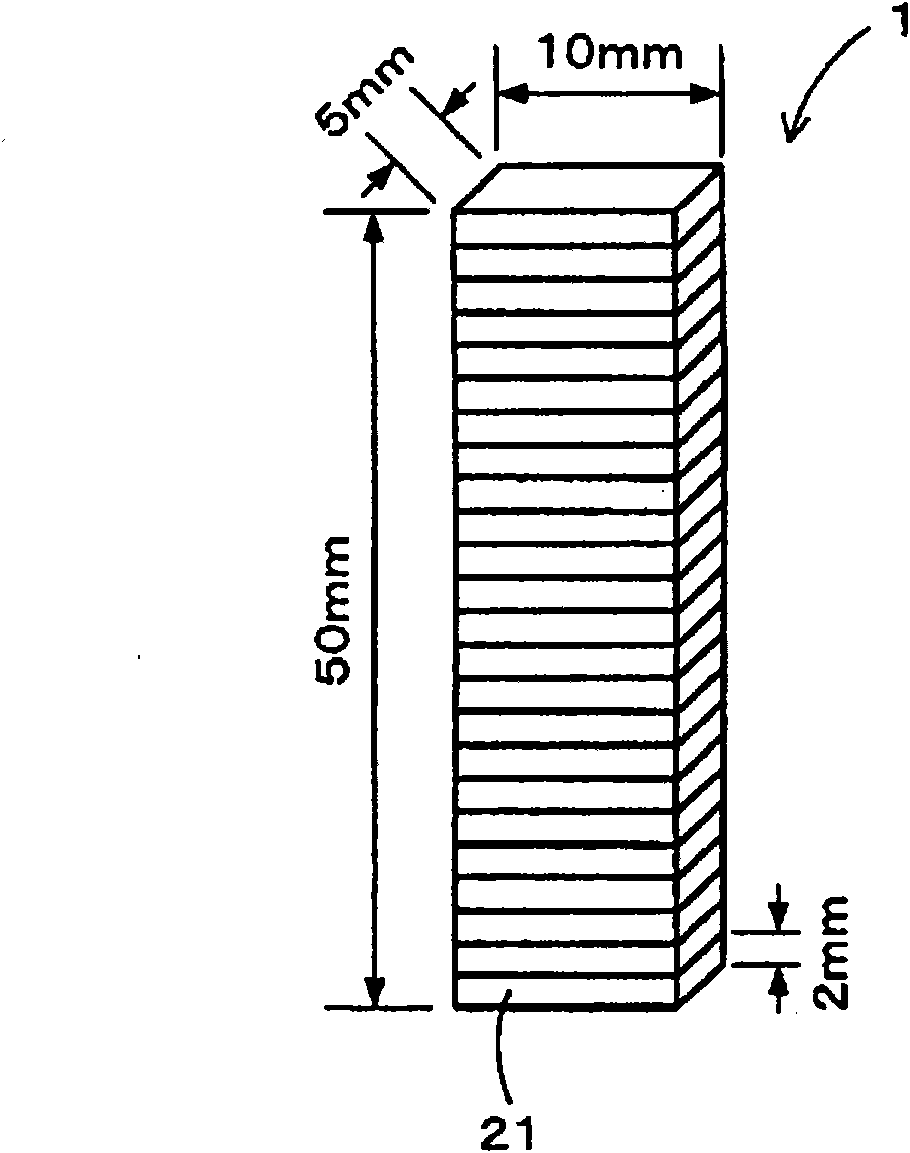

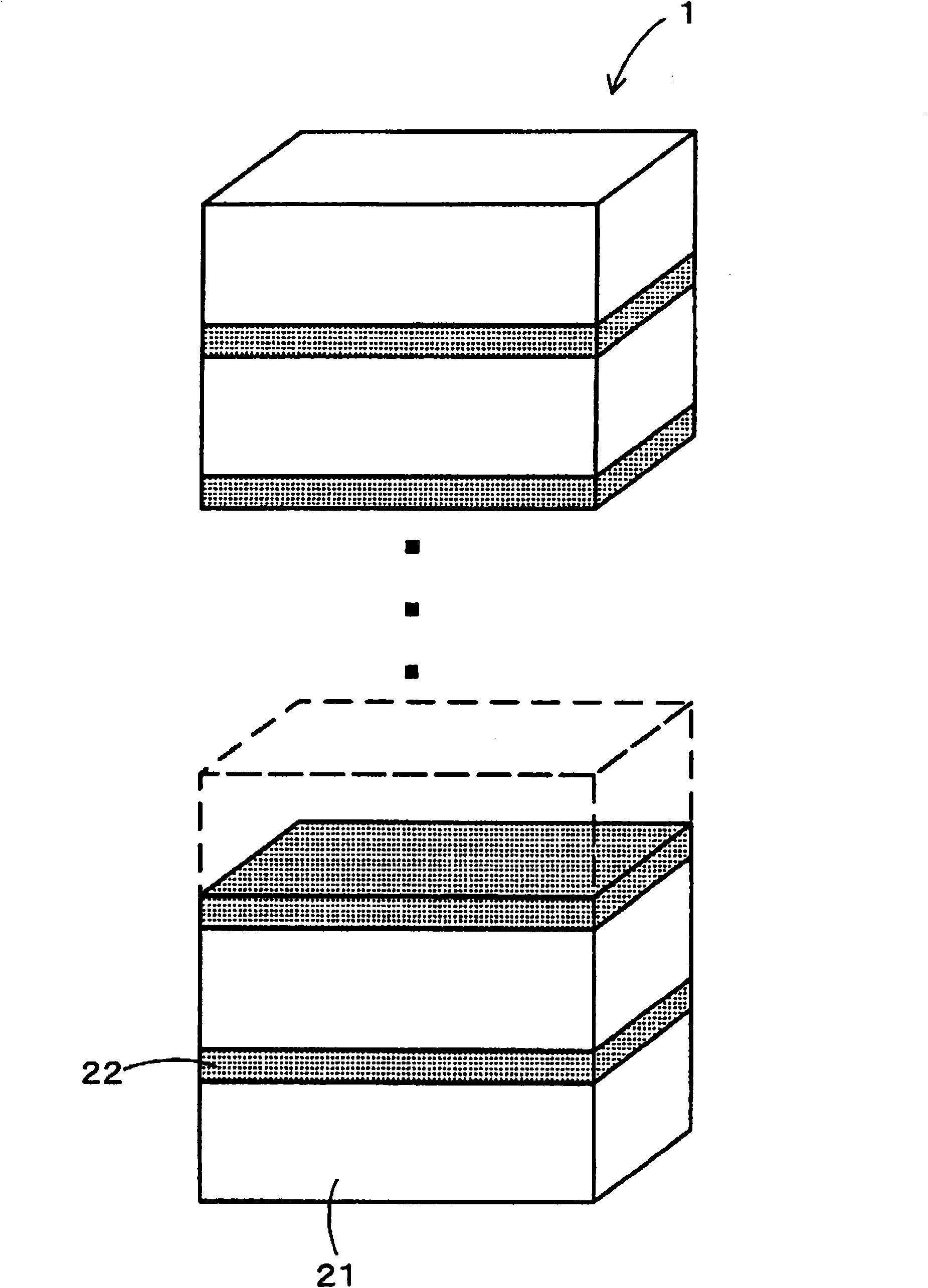

Permanent magnet for motor, and method for manufacturing the permanent magnet for motor

InactiveCN101978577AEasy to manufactureReduce eddy currentMagnetic circuit rotating partsSynchronous machinesPermanent magnet motorSizing

Provided is a permanent magnet to be buried in a permanent magnet motor. The permanent magnet is constituted to comprise a plurality of sheet magnets to be laminated, and insulating layers arranged between the laminated sheet magnets. This constitution can provide a miniature motor of a high output, which can prevent the temperature rise of the permanent magnet and the reduction of a coercive force. Moreover, the conventional correcting work required after a sintering step can be eliminated to simplify the manufacturing process thereby molding the permanent magnet in a high sizing precision.

Owner:NITTO DENKO CORP +1

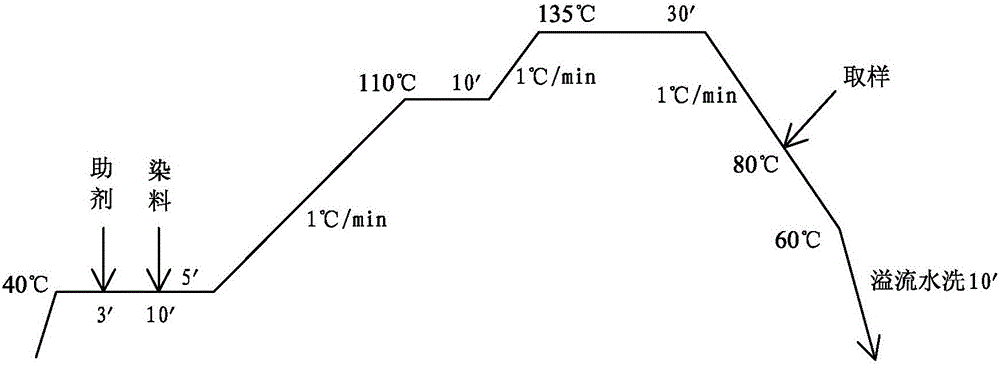

Dyeing and finishing process for improving color fastness to light of light-colored fabric of FDY (Fully Drawn Yarn) polyester filament yarn warp and weft four-way elastic textile

ActiveCN105696385AShrink evenlyNot prone to wrinklesGrip property fibresDyeing processAcetic acidDisperse dye

The invention discloses a dyeing and finishing process for improving the color fastness to light of a light-colored fabric of an FDY (Fully Drawn Yarn) polyester filament yarn warp and weft four-way elastic textile. The dyeing and finishing process comprises a dyeing process; a formula of a dyeing auxiliary adopted in the dyeing process comprises the following components: 0.5g / L to 1g / L of high-efficiency dispersant, 2g / L to 3g / L of chelating dispersant, 0.3g / L to 0.5g / L of 99 percent glacial acetic acid, X percent (o.w.f.) (on Weight the Fabric) of disperse yellow AM-2R, Y percent (o.w.f.) of disperse red AM-SLR and Z percent (o.w.f.) of disperse blue AM-SLR, wherein the sum of X, Y and Z is not more than 0.5, and a bath ratio is 1: (3 to 4). According to the dyeing and finishing process, the light-colored fabric of the FDY polyester filament yarn warp and weft four-way elastic textile which does not contain a fluorescent whitening agent and is obtained by being dyed by a disperse dye with color fastness to high sunlight is used as greige cloth; the color fastness to light which is up to a rating of 5 to 6 is realized through the specific dyeing and finishing process.

Owner:杭州天宇印染有限公司

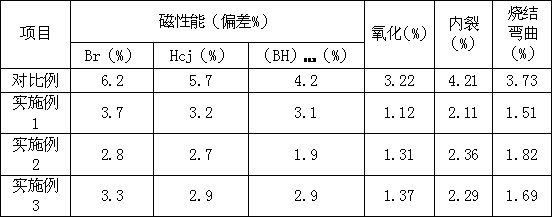

Partial pressure sintering method for sintering neodymium-iron-boron magnet

ActiveCN103000363AEnsure consistencyGuaranteed uniformityInductances/transformers/magnets manufactureMagnetic materialsMetallurgyVacuum pump

The invention relates to a partial pressure sintering method for sintering a neodymium-iron-boron magnet. Certain inert gases Ar are filled into various deflation sections in the sintering process, the pressure of the Ar gases inside a furnace is regulated according to blank deflation velocity and vacuum pump system exhaust velocity through vacuum degree control, so that heating sintering is carried out by uniformly deflating under different partial pressures of the Ar gases, and negative pressure is still kept. The partial pressure sintering method disclosed by the invention ensures the consistency and uniformity of magnetic property and saves the sintering time.

Owner:宁波永久磁业有限公司

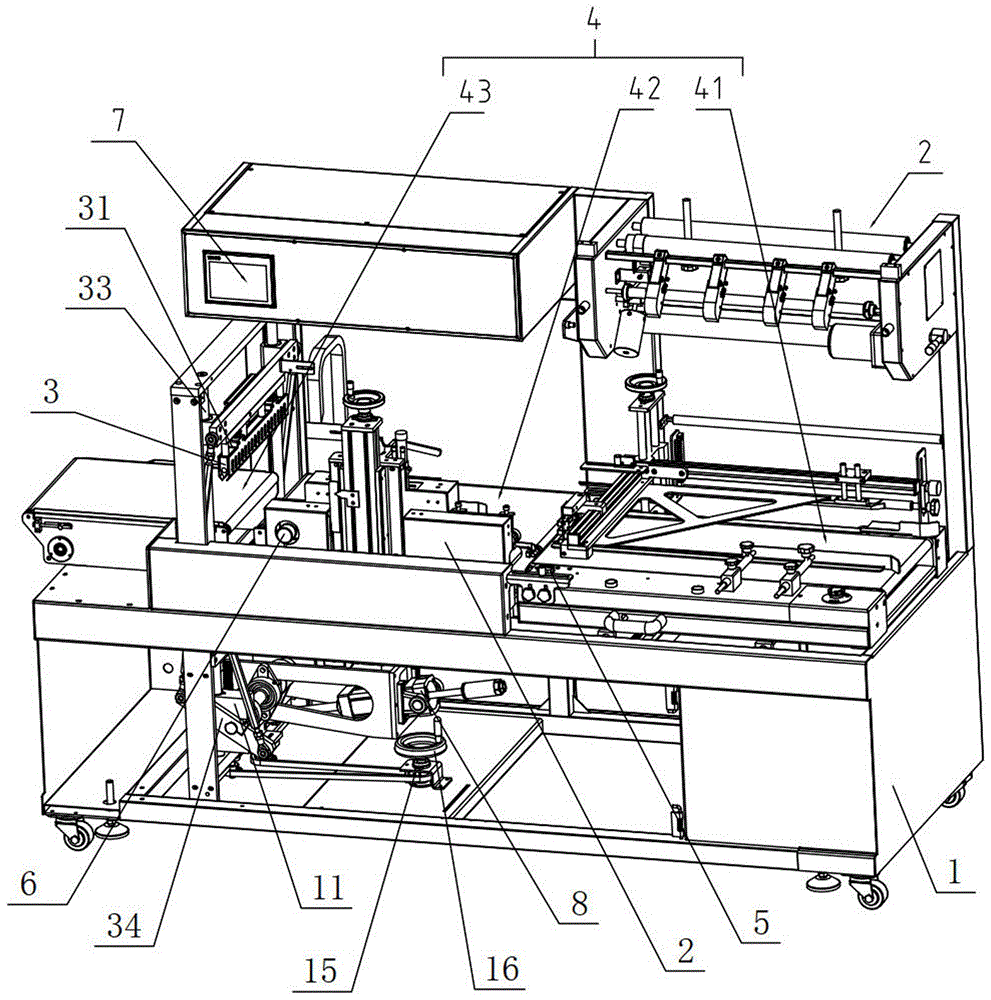

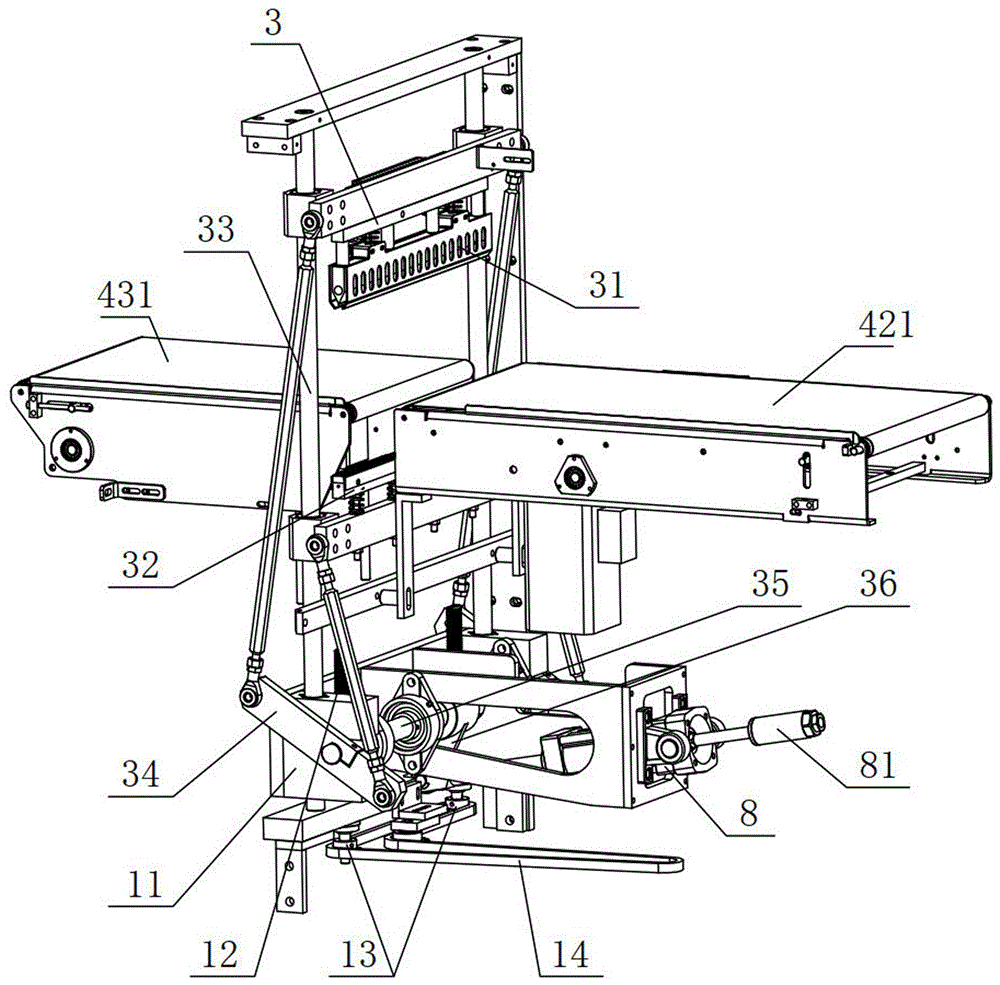

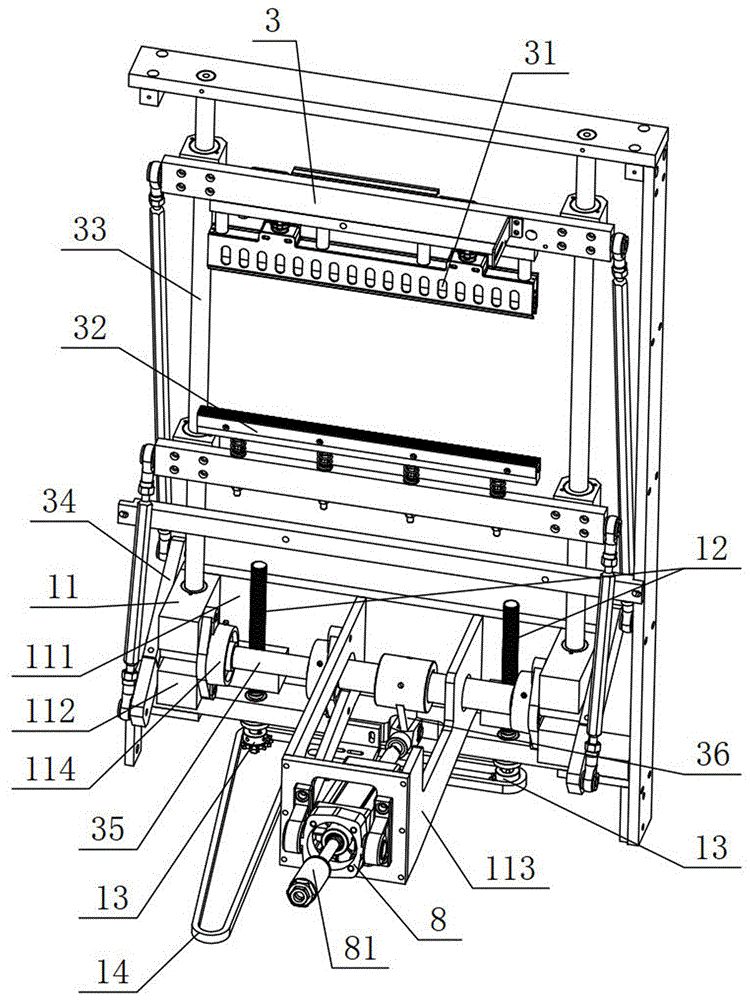

Full-automatic film seal-cutting packaging machine

ActiveCN106586137AShrink evenlyImprove packaging qualityPackaging automatic controlElectric machineryThin membrane

The invention discloses a full-automatic film seal-cutting packaging machine. The full-automatic film seal-cutting packaging machine is characterized by comprising a machine frame, a film conveying and sleeving device, a seal-cutting device and a conveying device; the conveying device comprises a first conveying mechanism, a second conveying mechanism and a third conveying mechanism; the seal-cutting device comprises an upper seal-cutting piece, a lower seal-cutting piece, a vertical rod and a swing piece; when the swing piece is driven to rotate in the forward direction or in the backward direction, the upper seal-cutting piece and the lower seal-cutting piece are driven to get close to or get away from each other; the swing piece is arranged movably in the vertical direction, so that the seal-cutting position when the upper seal-cutting piece and the lower seal-cutting piece are folded and the relative height of the working plane of the conveying device are adjusted; the machine frame is provided with an encoder and a programmable controller; the encoder is used for monitoring the stir quantity in real time and feeding the stir quantity back to the programmable controller; and the driving distance of a second motor is the new film packaging length of a packaged product. By the adoption of the full-automatic film seal-cutting packaging machine, the front film allowance length and the rear film allowance length of the product can be kept consistent, the height of a longitudinal seal-cutting mechanism can be easily adjusted according to to-be-packaged objects of different specifications, and the packaging quality is improved.

Owner:ZHEJIANG DINGYE MACHINERY

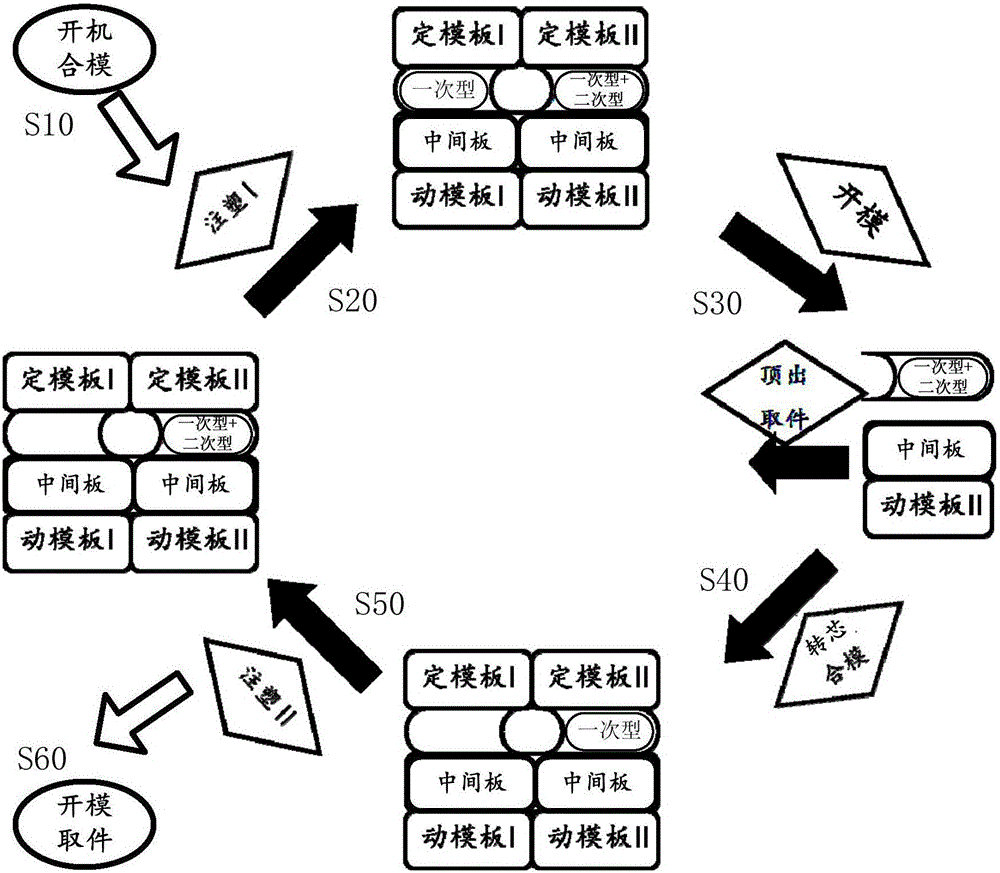

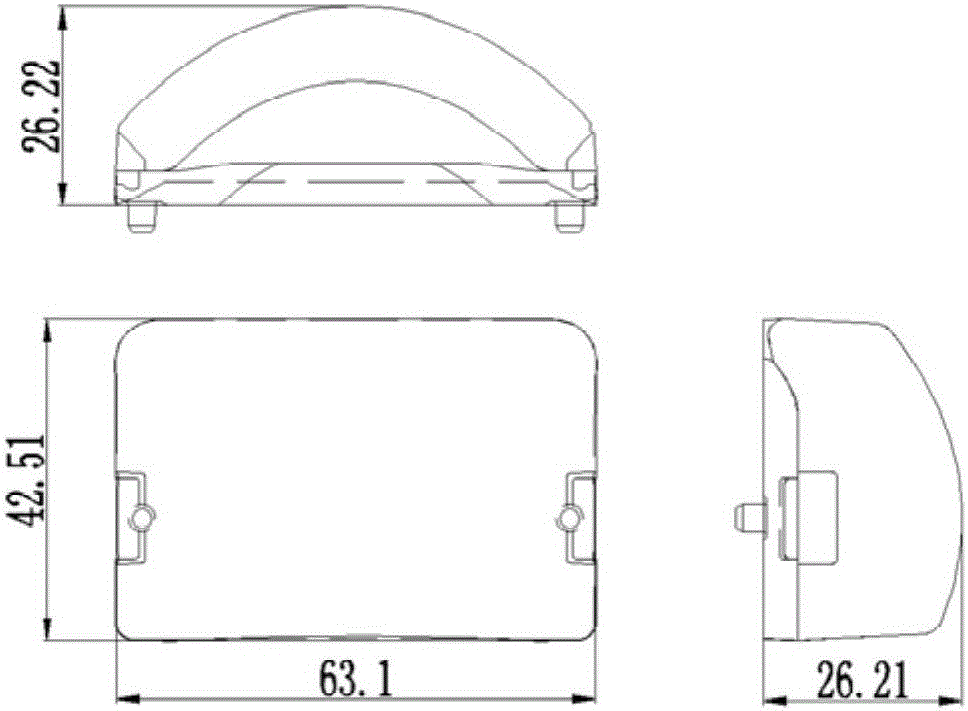

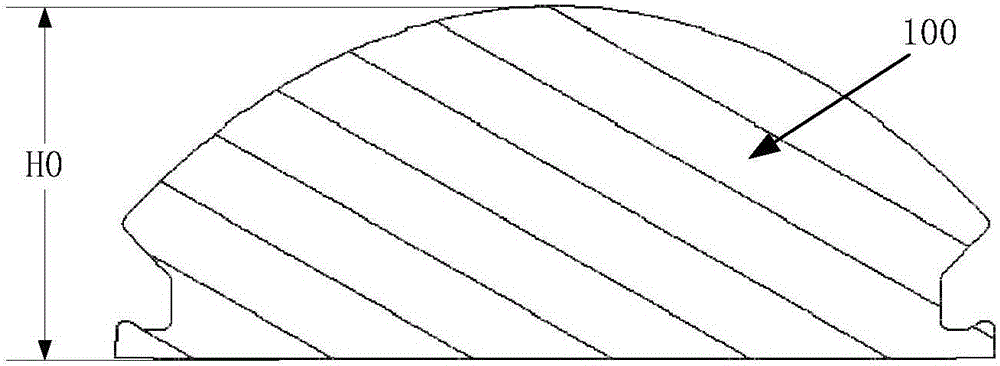

Thick wall plastic part surrounding type layered injection molding method and mold structure and lens product thereof

ActiveCN105818325AShrink evenlyMeet Optical Performance RequirementsVehicle headlampsRoad vehiclesInjection productEngineering

The invention discloses a thick wall plastic part surrounding type layered injection molding method and a mold structure and a lens product thereof, and relates to injection molding of plastic or plastic state matter and method and equipment of injection molding, in particular to a thick wall injection product surrounding type layered injection molding method, a special mold structure used for implementing the method and a car lamp lens product manufactured with the method. An intermediate plate is arranged between a fixed mold plate and a movable mold plate and is rotated to conduct core rotation operation, a middle cavity which is in the empty cavity state after piece taking operation is carried out is rotated to a first station, and die assembly is carried out to form a molding cavity of a primary mold of the product; the intermediate plate carrying the primary mold of the product is rotated to a second station, die assembly is carried out to form secondary mold forming cavities surrounding the two sides of the primary mold of the product, and therefore multi-layer injection molding is achieved; during injection molding of a second layer, shrinking supplementing is carried out on absorption shrinking occurring on a first layer, so that it is guaranteed that condensation shrinking of secondary molds of the product is even, and appearance filling is full; and the optical performance requirement of a headlamp lens is met, the production period is shortened, and the injection molding production efficiency is improved.

Owner:HASCO VISION TECHNOLOGY CO LTD

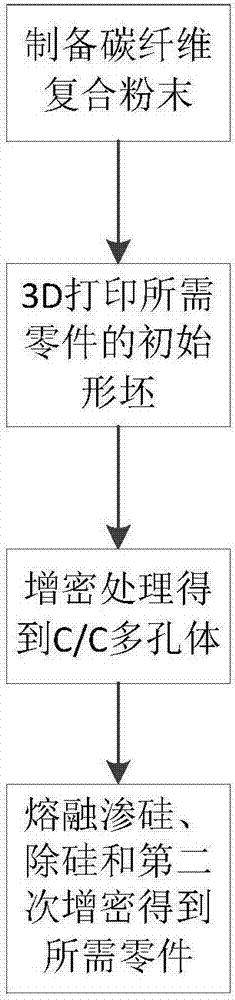

Method for preparing C/C-SiC composite part and product prepared through method

ActiveCN106927846AEvenly distributedAvoid damageAdditive manufacturing apparatusFiberSolvent evaporation

The invention belongs to the field of composites, and discloses a method for preparing a C / C-SiC composite part and a product prepared through the method. The method comprises the following steps that firstly, carbon fiber / phenolic resin composite powder is prepared by using a solvent evaporation method; secondly, according to a three-dimensional model of the part, the carbon fiber composite powder is molded into an initial molded blank by means of the 3D printing technology; thirdly, the initial molded blank is subjected primary densification and a C / C porous body is obtained; fourthly, the C / C porous body is subjected to a molten silicon infiltration reaction, high-temperature desilication and secondary densificaiton, and the final C / C-SiC part is obtained. By means of the method, the C / C-SiC composite part with a complex structure can be shaped in a near-net mode, the method is short in production period and low in cost, and the C / C-SiC composite part obtained through the method is low in residual silicon content and has excellent performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Low-density high-performance alumina-based ceramic fiber and preparation method thereof

ActiveCN106609404AImprove spinnabilityImprove performanceInorganic material artificial filamentsFiberAviation

The invention relates to a preparation method for a low-density high-performance alumina-based ceramic fiber. The method comprises the following steps: preparing spinnable alumina-based fiber precursor sol from an inorganic aluminum salt, a boron-containing additive, a silicone-containing additive and the like by using a sol-gel process; carrying out dry-process spinning so as to obtain alumina-based continuous green fibrous filaments; and subjecting the filaments to drying and sintering so as to obtain the alumina-based continuous ceramic fiber. The sol fiber prepared in the invention has good stability; preparation process is simple; the filaments can be formed without a high-molecular auxiliary agent; and the sintered fiber has low density and high strength and can be applied to high-tech fields like aviation and aerospace.

Owner:CENT SOUTH UNIV

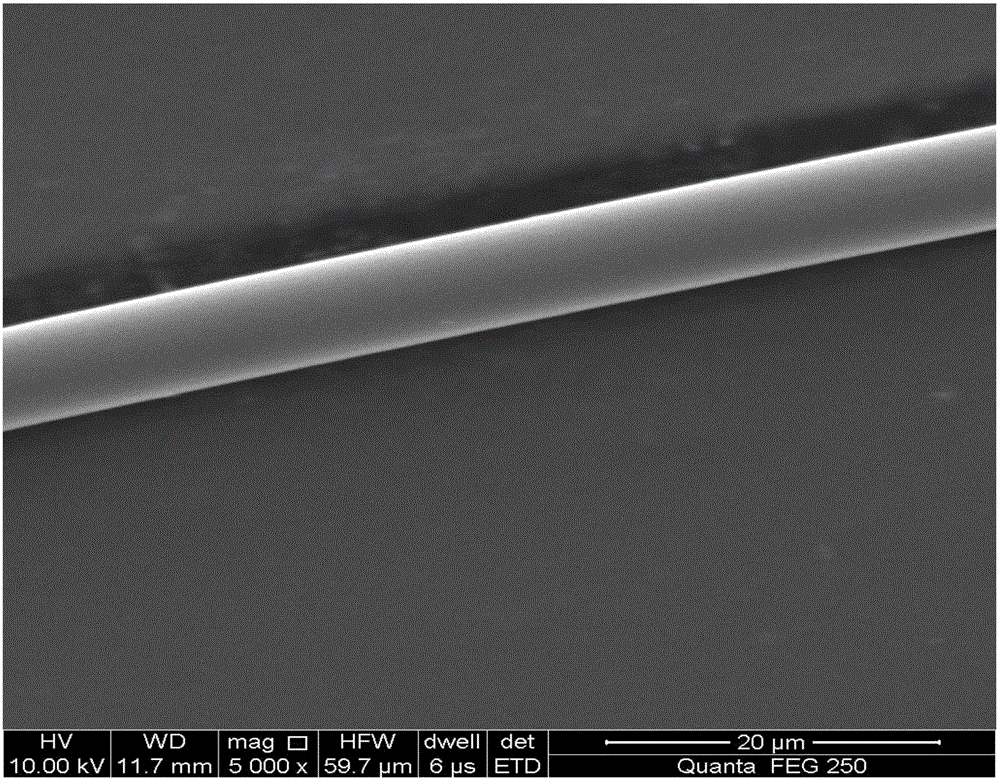

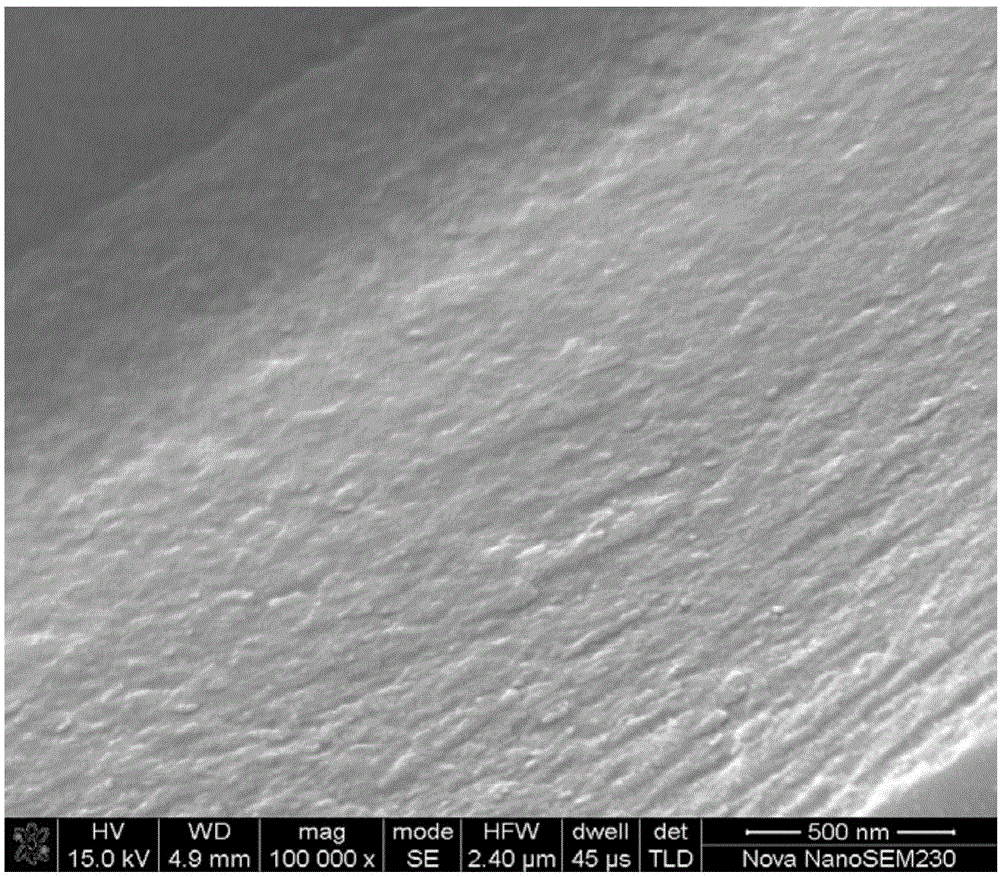

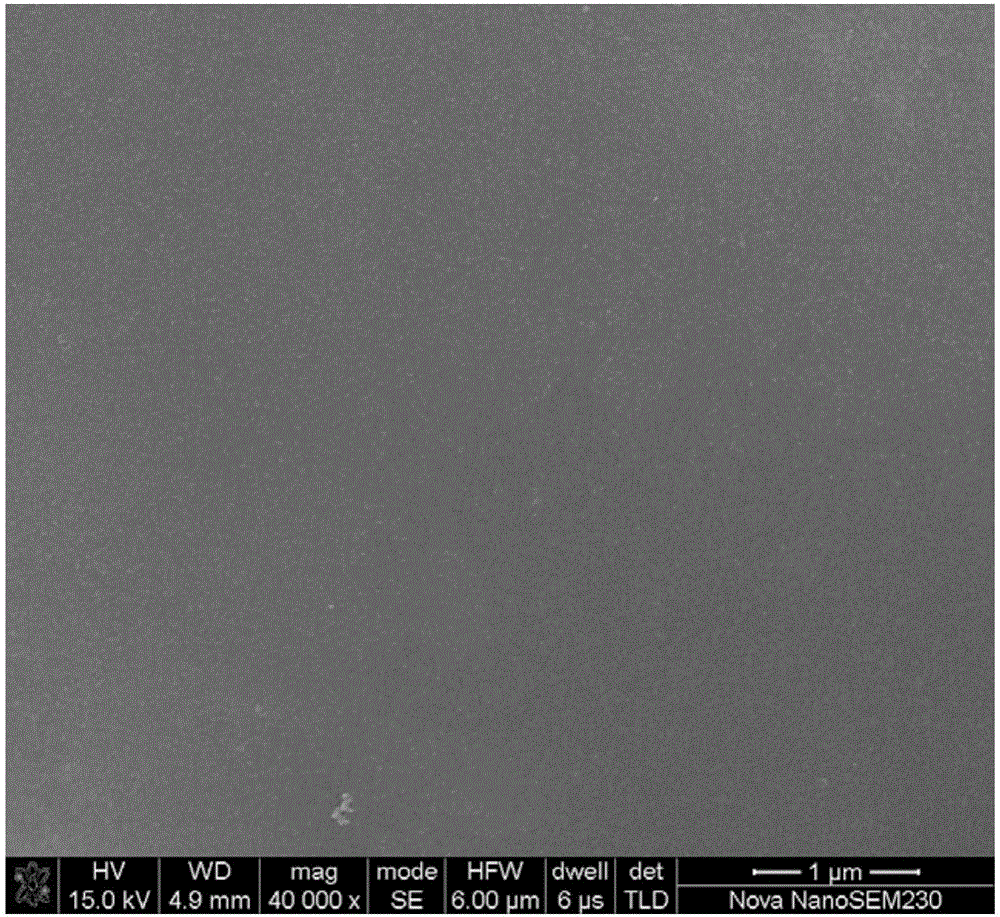

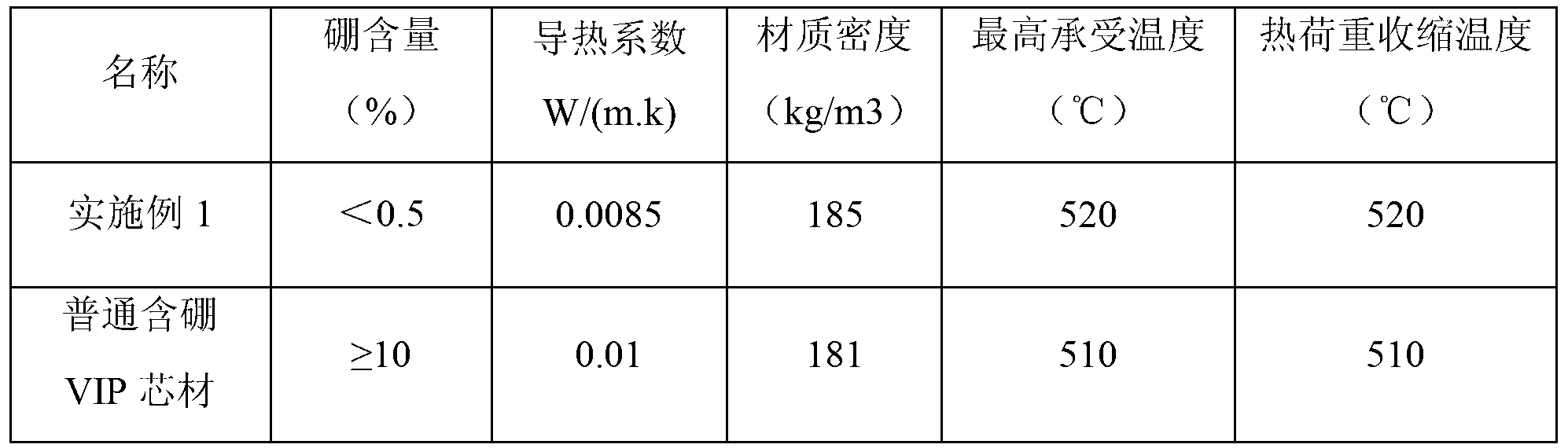

Novel glass fiber vacuum insulation panel core and preparation method

ActiveCN103244793ALower boron contentImprove insulation effectFibreboardThermal insulationAir filtrationGlass fiber

The invention discloses a novel glass fiber vacuum insulation panel core. The vacuum insulation panel core is made of low-boron glass cellucotton which has the boric mass percentage of less than 0.5% and the diameter of 0.5-1.0 micrometer. The invention further discloses a preparation method of the vacuum insulation panel core, which comprises the following steps of: (1) selecting the low-boron glass cellucotton, (2) beating and dispersing the selected low-boron glass cellucotton to obtain slurry, (3) diluting the slurry, (4) deslagging the slurry of Step (3) and preparing wet paper in a wet forming manner, (5) dehydrating the wet paper of Step (4); and (6) drying the wet paper of Step (5). The glass fiber air filtration paper has outstanding comprehensive performances; the preparation process is pollution-free; and the service life is long.

Owner:宣汉正原微玻纤有限公司

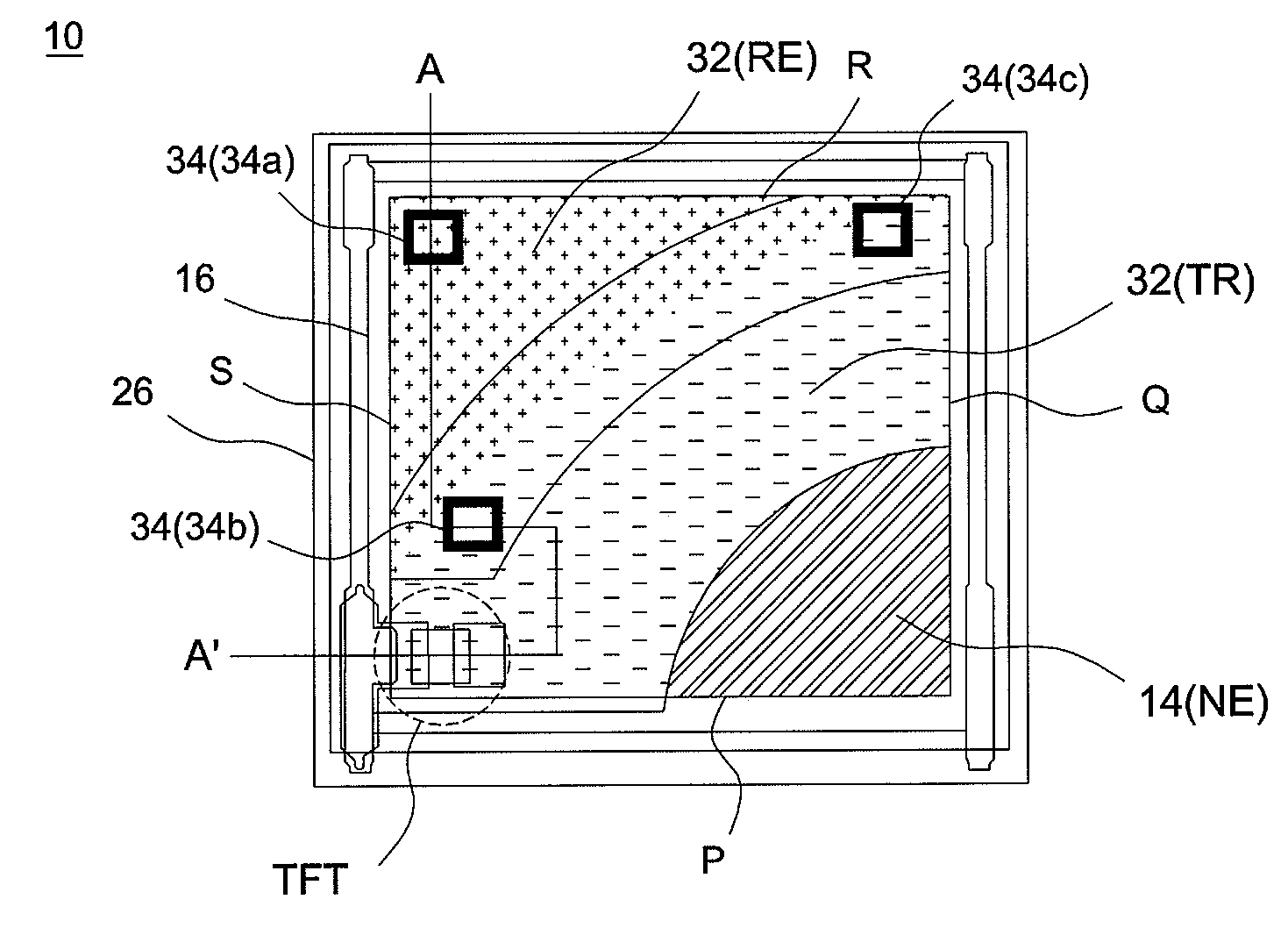

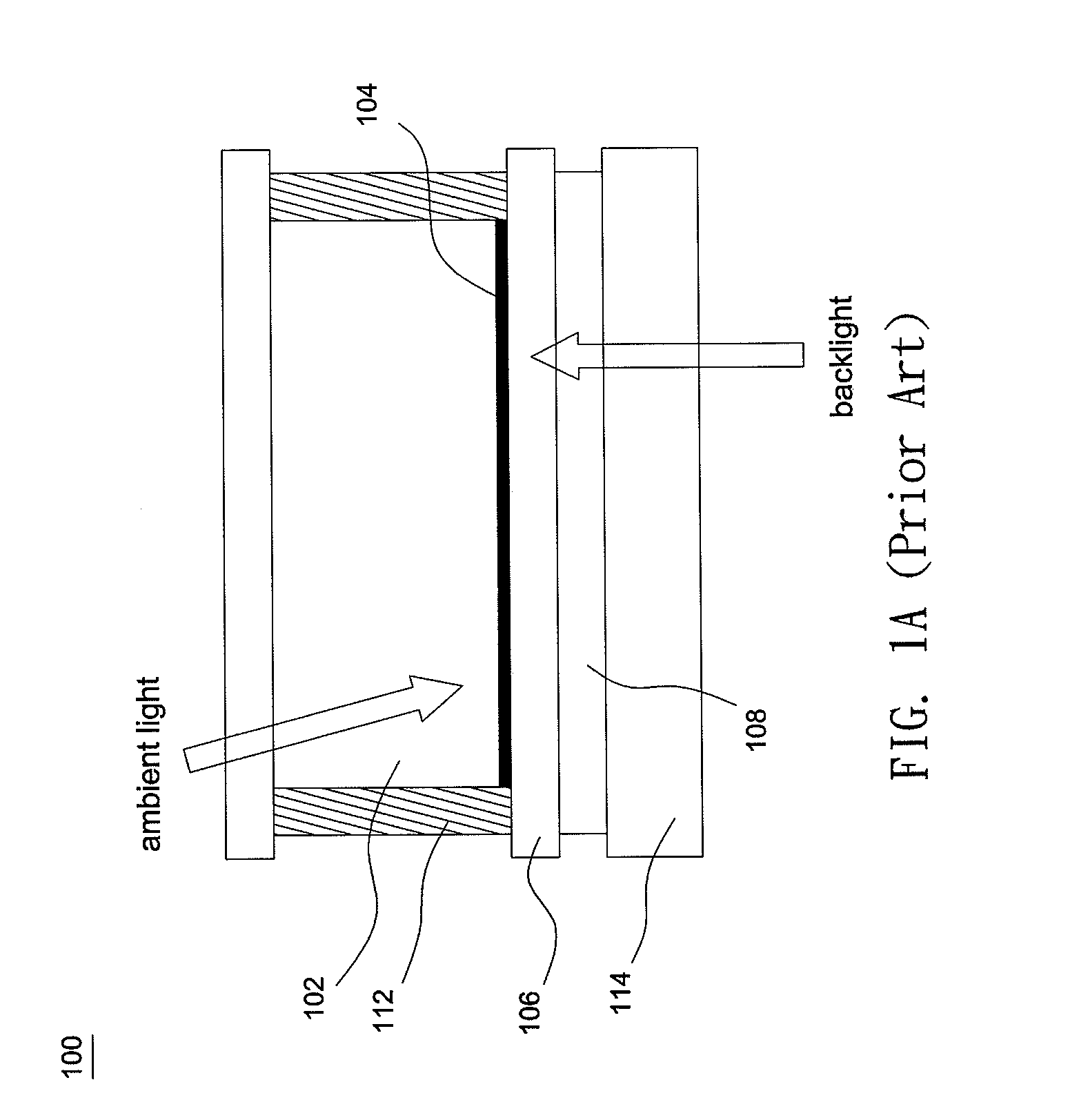

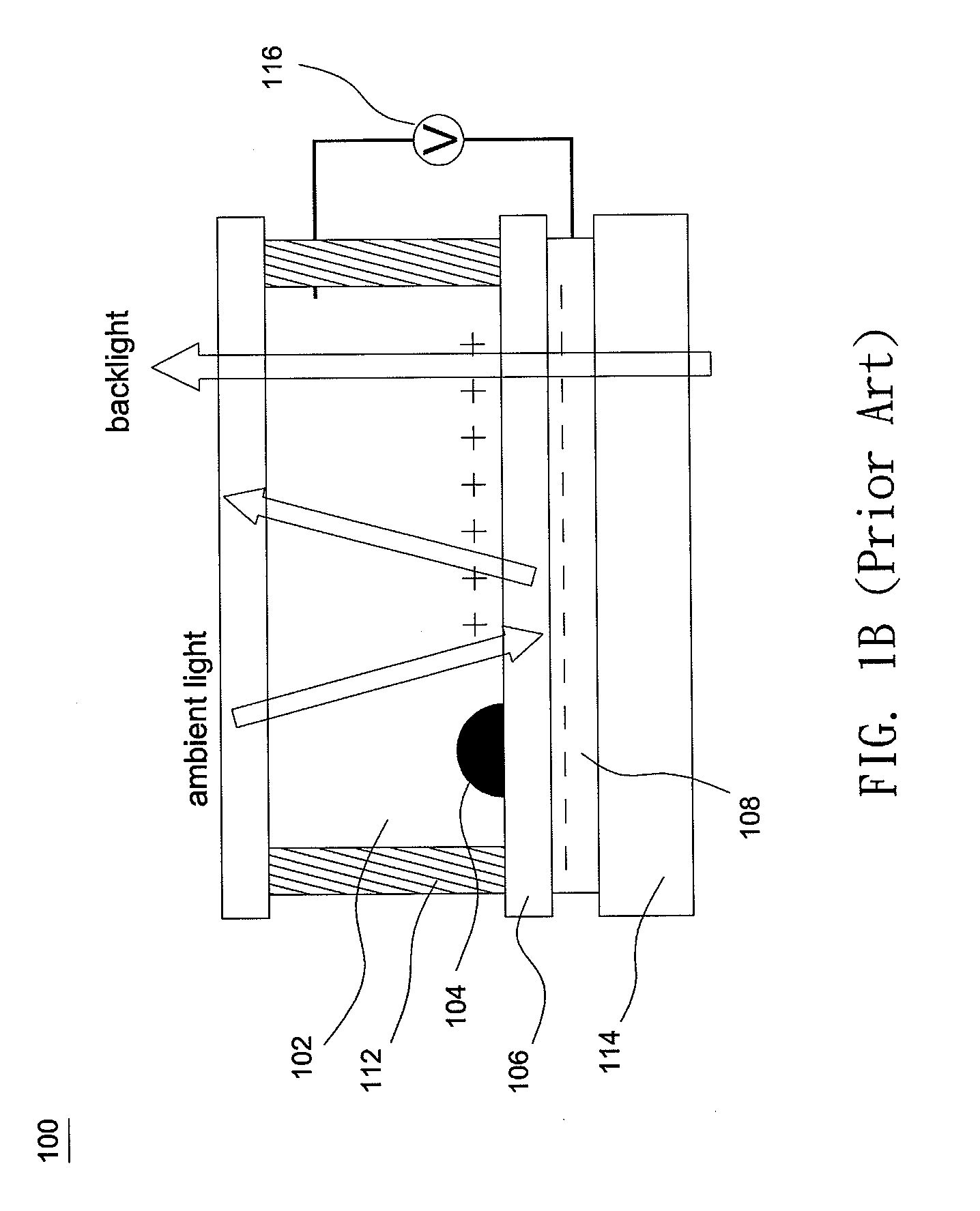

Electrowetting pixel structure

An electrowetting pixel structure includes a substrate, a hydrophobic dielectric layer, a non-polar liquid, a polar liquid, at least one electrode, and at least one contact hole. The hydrophobic dielectric layer is formed on the substrate, the non-polar liquid covers one surface of the hydrophobic dielectric layer, and the polar liquid is provided on the hydrophobic dielectric layer where the non-polar liquid and the polar liquid are immiscible. The electrode is formed on the substrate and divides the substrate into an electrode section and a non-electrode section. When a voltage is applied to the electrowetting pixel structure, the non-polar liquid contracts on the hydrophobic dielectric layer and is confined to an area substantially overlapping the non-electrode section. The contact hole is formed on the substrate at a position away from the non-electrode section of the electrowetting pixel structure.

Owner:WINTEK CORP +1

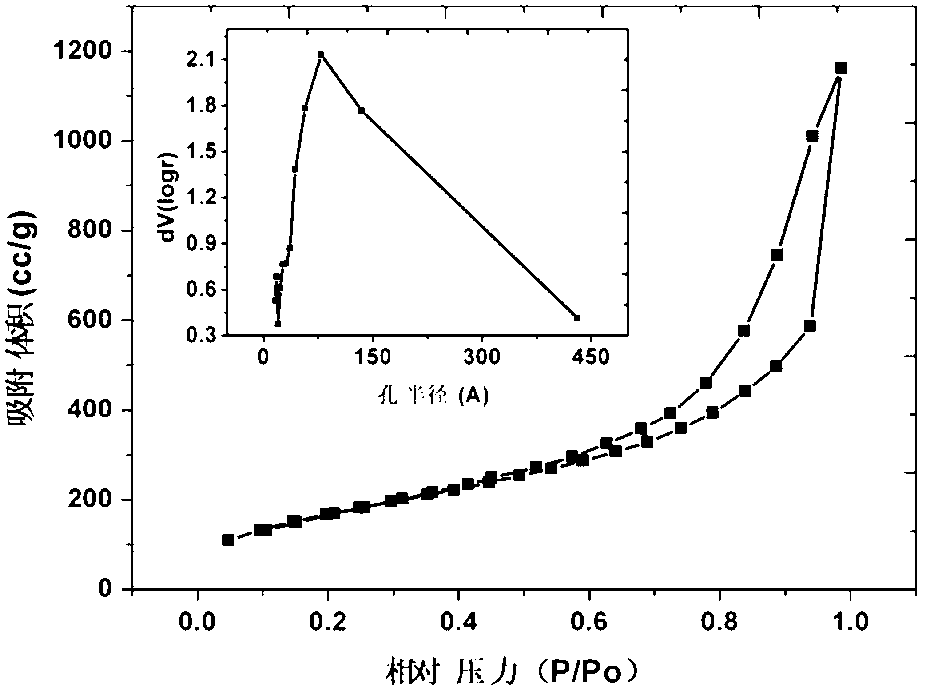

Preparation method of zirconium oxide aerogel

The invention provides a preparation method of zirconium oxide aerogel, which comprises the following steps of: dissolving alkoxide into anhydrous ethanol, and stirring and mixing to obtain an ethanol solution containing the alkoxide; dropwise adding concentrated nitric acid, then adding a mixed solution containing deionized water, formamide and epoxy propane, and continuously stirring for 20-60 minutes to obtain clear transparent sols; transferring the sols into a mould, and standing and ageing to obtain ZrO wet gels; respectively soaking the ZrO wet gels at 35-100 DEG C by using ageing liquids; and finally supercritically drying an object obtained by soaking with a drying medium solvent for 2-5 times to obtain a complete block-shaped ZrO aerogel. The method provided by the invention realizes the preparation of the block-shaped ZrO aerogel and solves the technical problem of preparing a low-density medium-intensity block-shaped zirconium oxide; and in addition, the block-shaped zirconium oxide aerogel has the density of 100-250 kg / m<3>, the normal-temperature heat conductivity of 0.018-0.031 w / mk and the compressive strength of 100-300 KPa.

Owner:蓝烟新材料科技有限公司

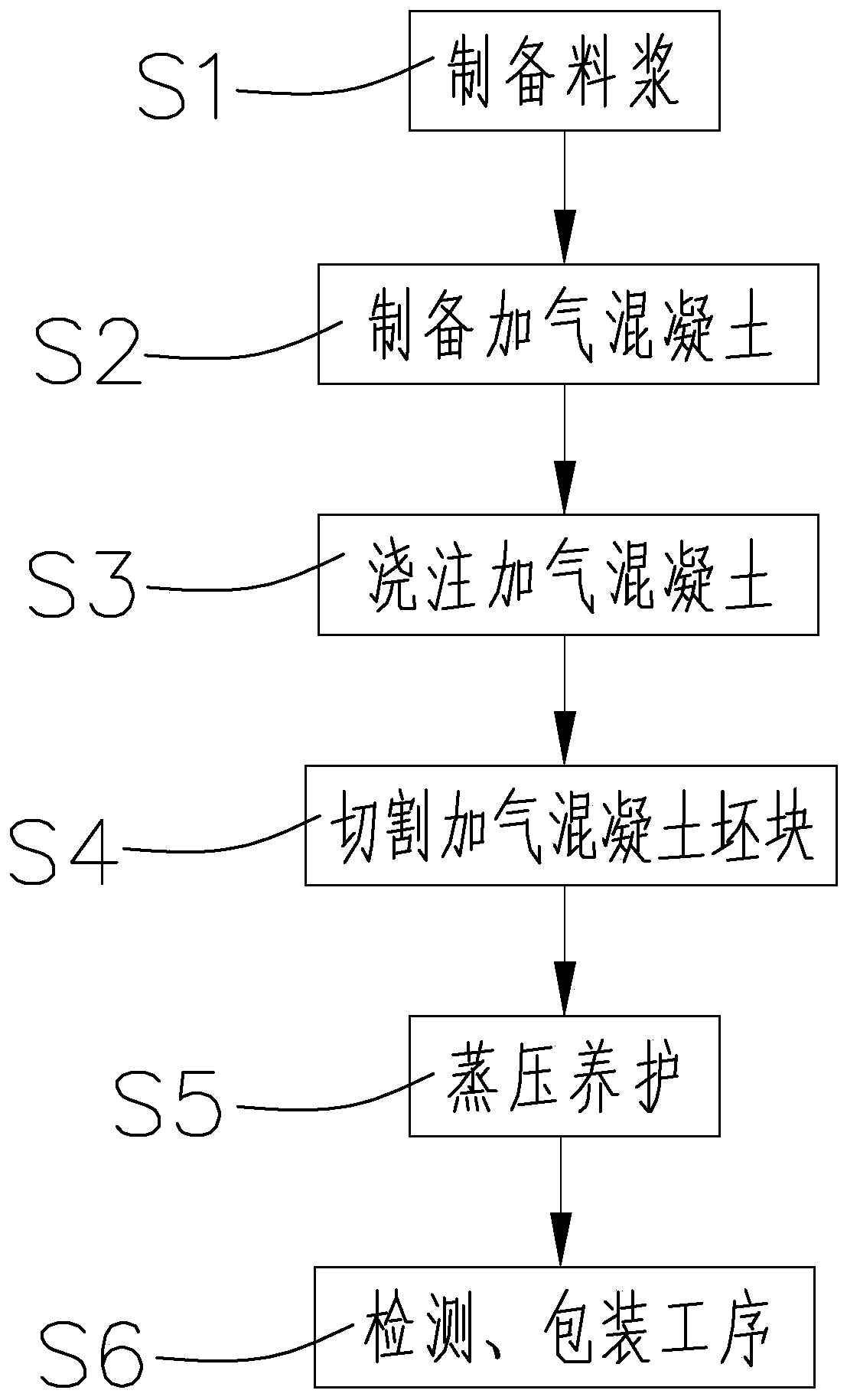

Autoclaved aerated concrete slab and manufacturing process thereof

PendingCN111574172AIncrease stiffnessHigh strengthFeeding arrangmentsCeramicwareFoaming agentMesh reinforcement

The invention relates to an autoclaved aerated concrete slab and a manufacturing process thereof. The autoclaved aerated concrete slab is prepared from the following raw materials in parts by weight:40-50 parts of quick lime; 40-44 parts of cement; 0.4-0.8 part of a foaming agent; 120-160 parts of mortar; and 50-80 parts of waste slurry. Reinforcing meshes parallel to the concrete slab are pre-buried in the concrete slab. The manufacturing process of the autoclaved aerated concrete slab comprises the steps of slurry preparation, aerated concrete preparation, aerated concrete pouring, aeratedconcrete briquette cutting, autoclaved curing, detection and packaging. The autoclaved aerated concrete slab obtained through autoclaved curing has good physical and chemical properties, and the comprehensive mechanical properties of the concrete slab are improved.

Owner:安徽铭科新材料科技有限公司

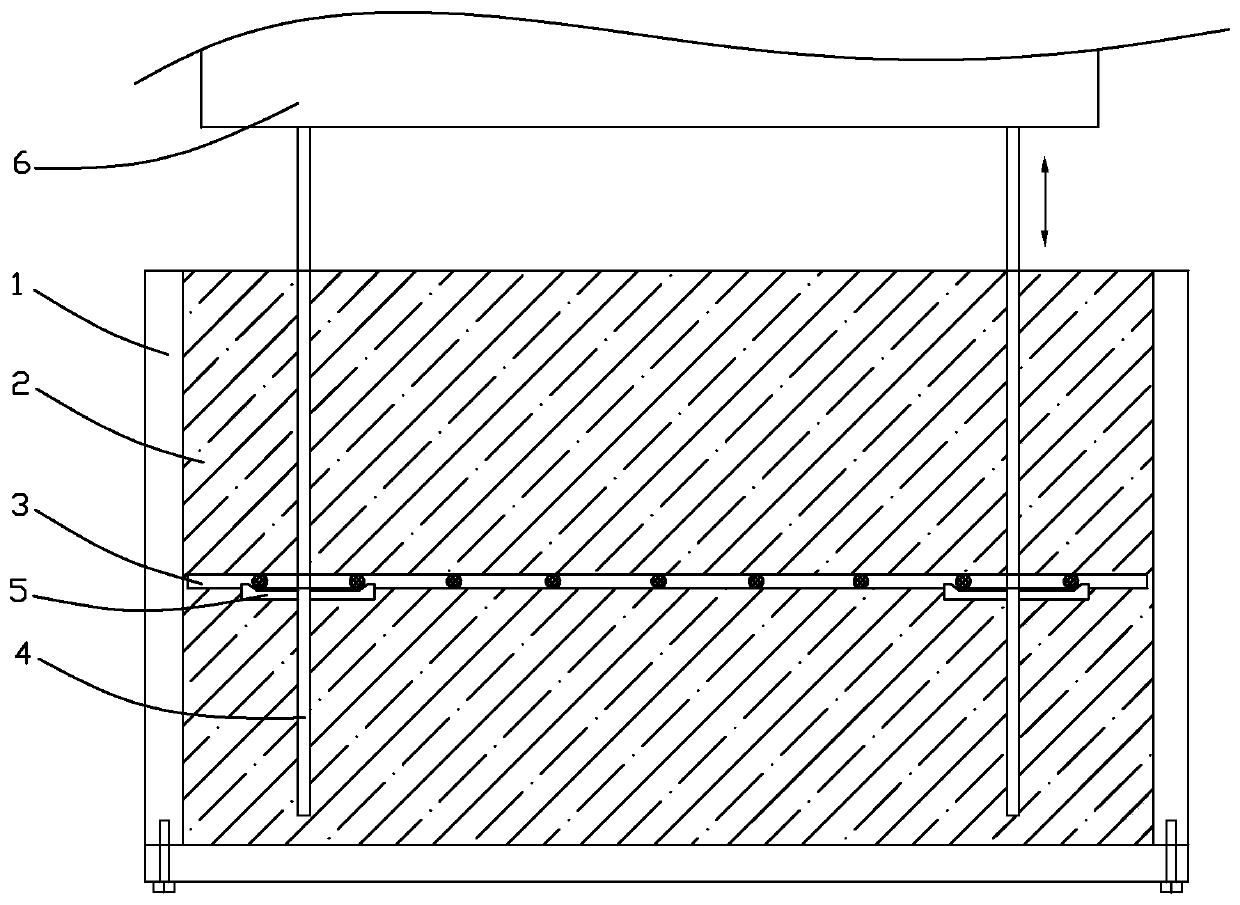

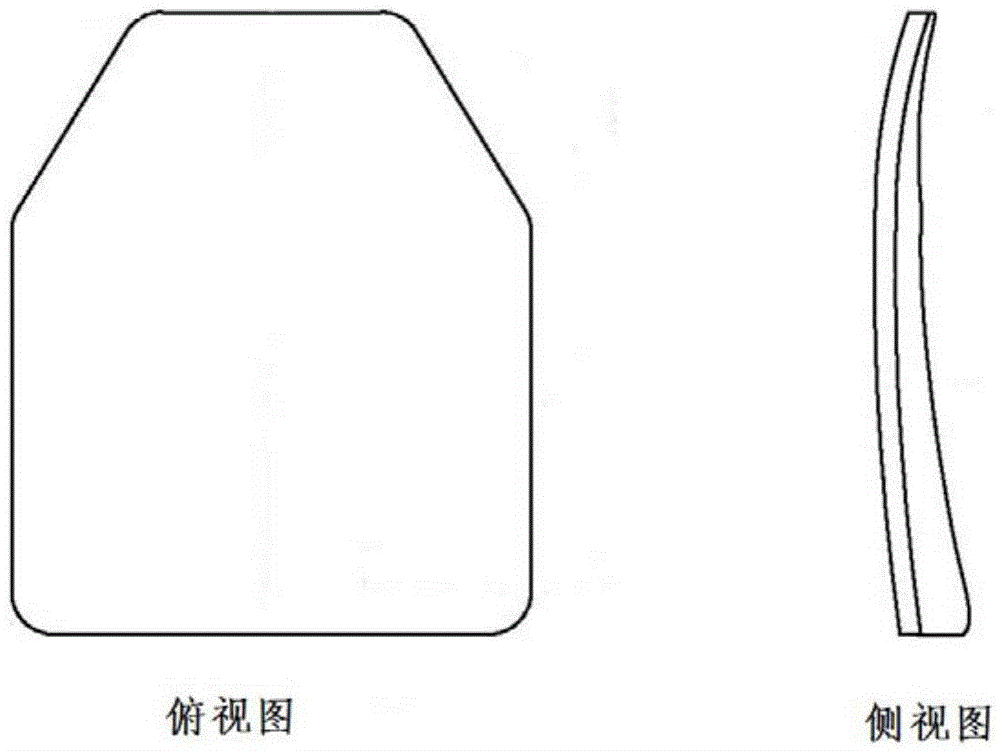

Boron carbide/silicon carbide ceramic entire board and preparation method and application thereof

The invention discloses a boron carbide / silicon carbide ceramic entire board and a preparation method and application thereof. The method comprises the following steps: (1) mixing boron carbide powder, silicon carbide powder, carbon powder, a binder, a dispersant and water, and then, carrying out ball-milling and slurrying, so as to prepare slurry; (2) enabling the slurry prepared in the step (1) to be subjected to drying and granulating by adopting spray granulation and drying processes, so as to obtain granules; (3) carrying out compacting molding on the granules prepared in the step (2) by adopting a cold isostatic compacting process, so as to obtain a biscuit; (4) carrying out pressure-less sintering on the biscuit prepared in the step (3), and carrying out cooling, thereby obtaining the ceramic entire board. According to the boron carbide / silicon carbide ceramic entire board and the preparation method and application thereof, the boron carbide / silicon carbide biscuit, of which the density of all points are uniform, is obtained by adopting a cold isostatic compacting method and determining the pressure holding pressure and pressure holding time of each stage through repeated trials, and the biscuit is uniformly contracted proportionally during sintering, so that the original camber of the biscuit is completely reserved, and a pressure-less sintering process can be applied to the preparation of large-area and complicated-shape boron carbide / silicon carbide workpieces.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

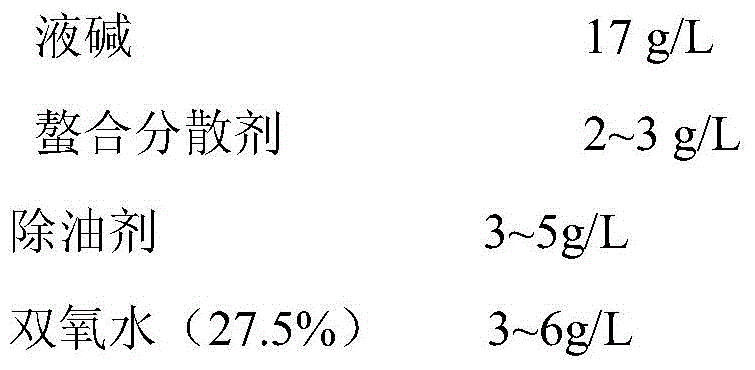

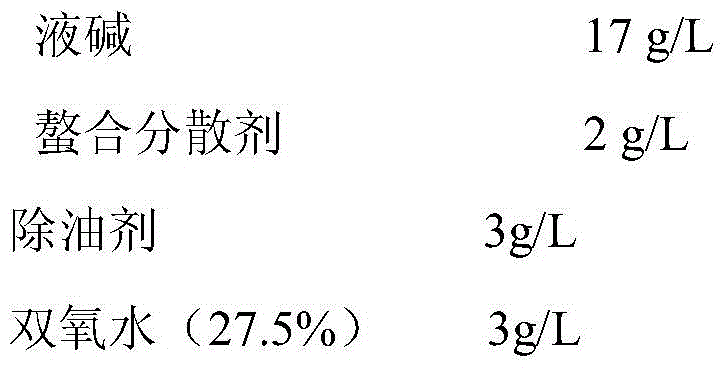

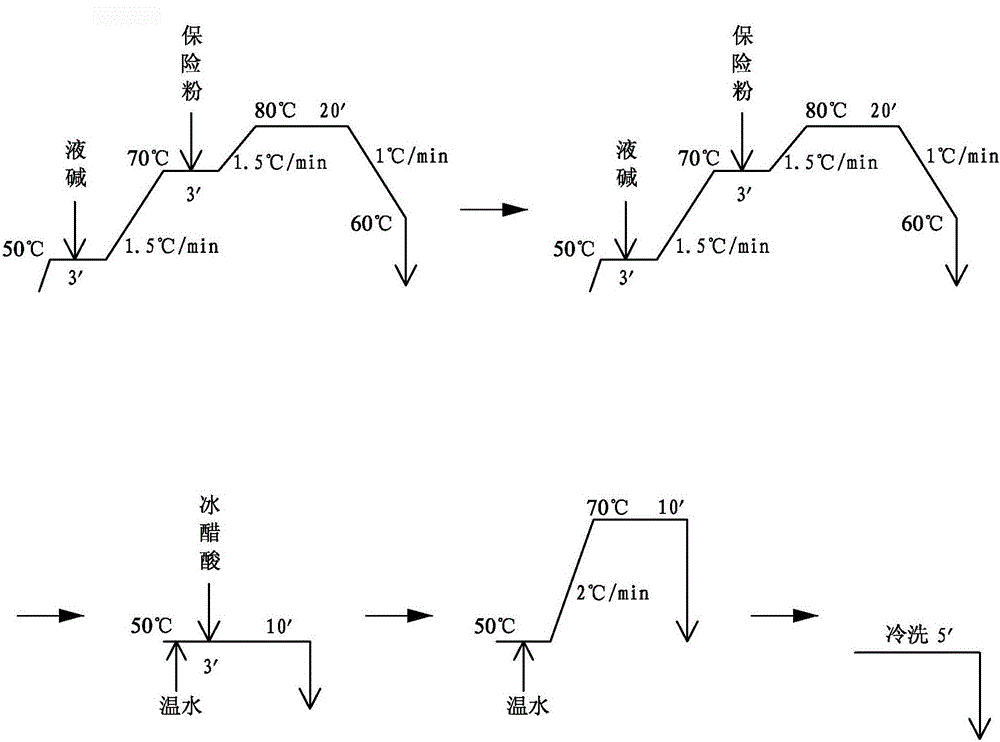

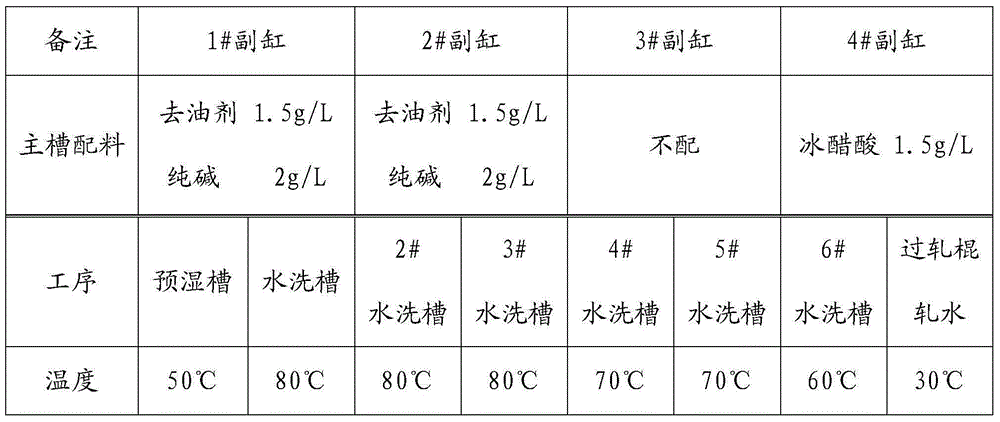

High-elastic and high-fluffy ultra-cotton-imitated fabric and production technology of same

InactiveCN104988633AFully degreasingShrink evenlyHeating/cooling textile fabricsWoven fabricsDyeingEngineering

A high-elastic and high-fluffy ultra-cotton-imitated fabric is formed by weaving ultra-cotton-imitated filaments and spandex filaments into a gray fabric with a single-face organization structure, and produced successively through weaving, open-width washing, initial shaping, dyeing, a post-treatment, drying, sanding and a shaping technology. The high-elastic and high-fluffy ultra-cotton-imitated fabric adopts a new technological process of conducting gray fabric shaping after the open-width washing, a rationally designed initial shaping technology and an improved dyeing technology, and solves problems in the prior art that a hand feeling, fluffiness and elasticity of the fabric are obviously weakened after the ultra-cotton-imitated elastic fabric is shaped by high-temperature heating. The fabric has good stretching resilience, can be stretched freely, is free of compression or tension, has the high fluffiness and a good texture, is equipped with functions of moisture absorption and sweat release, and has very excellent wearing comfort like cotton. Meanwhile, raw materials are cheap and no additional investments are added, but performances of the product far exceed the performances of common cotton-imitated elastic cloth. The high-elastic and high-fluffy ultra-cotton-imitated fabric has very high additional product values, promises a good market prospect and can generate good economic and social benefits.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

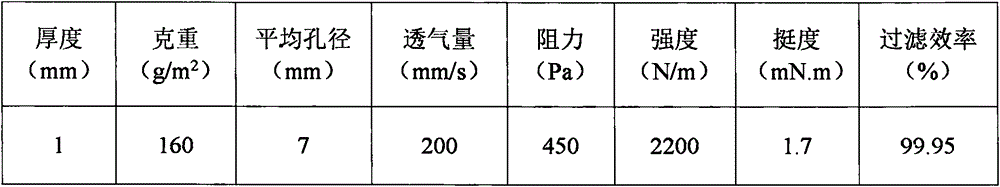

Three-layer composite filter paper and preparation method thereof

InactiveCN105970715AReasonable adjustment of filtration efficiencyReasonable adjustment of filter resistanceNon-fibrous pulp additionPaper/cardboardGlass fiberSlurry

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Dumping and sintering process for 3D printing ceramic body

The invention relates to a dumping and sintering process for a 3D printing ceramic body. The process comprises the steps that 1, the ceramic body with the 3D printing solid content being 20-95 wt.% is placed into a crucible, and raw material powder with the same component as the ceramic body is used for embedding and filling the ceramic body; 2, the crucible which contains the ceramic body is placed into a muffle furnace, and segmented dumping is carried out in an air atmosphere; 3, the temperature is raised to sintering temperature at the temperature rise rate of 1-3 DEG C per minute, and sintering time is 1-12 hours, wherein the densification temperature is 300-1,000 DEG C lower than the sintering temperature of the ceramic body. The raw material powder with the same component as the ceramic body is used for embedding and filling the ceramic body, the raw material powder needs to wrap the ceramic body, and holes and other hollow structures in the ceramic body need to be filled with the raw material powder so that the ceramic body can be heated uniformly and slowly to prevent sudden change of temperature, prevent internal stress from being generated inside the ceramic body and reduce the probability of collapse.

Owner:江苏先进无机材料研究院

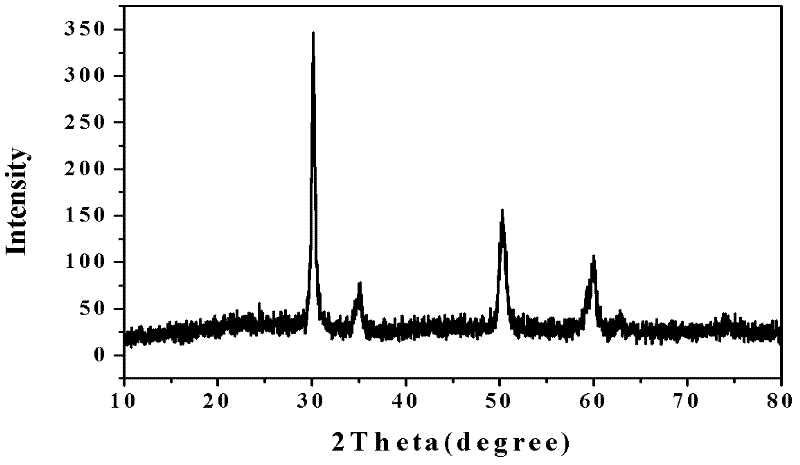

Aluminium-doped perovskite phase negative temperature coefficient thermal sensitive ceramic material

The invention relates to an aluminium-doped perovskite phase negative temperature coefficient thermal sensitive ceramic material. The aluminium-doped perovskite phase negative temperature coefficient thermal sensitive ceramic material is prepared from La2O3, MnO2 and Al2O3 by steps of preparing a perovskite phase LaMn1-xAlxO3 powder material by adopting an oxide solid-phase method, then doping Al2O3, forming and sintering at a high temperature. The electrical parameter range of the aluminium-doped perovskite phase negative temperature coefficient thermal sensitive ceramic material is B25 / 501817-3920K+ / 2%, rho25 DEG C 4.7-6.13*10<6>omega.cm+ / -3%. The aluminium-doped perovskite phase negative temperature coefficient thermal sensitive ceramic material has the advantages of wide adjustment range of electrical parameter and high repeatability. The aluminium-doped perovskite phase negative temperature coefficient thermal sensitive ceramic material is simple in a preparation technology and convenient to operate. The material formulation can be flexibly selected in a wide range according to the need. The aluminium-doped perovskite phase negative temperature coefficient thermal sensitive ceramic material is applied to thermistor elements for temperature measurement, control compensation and the like under different conditions.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

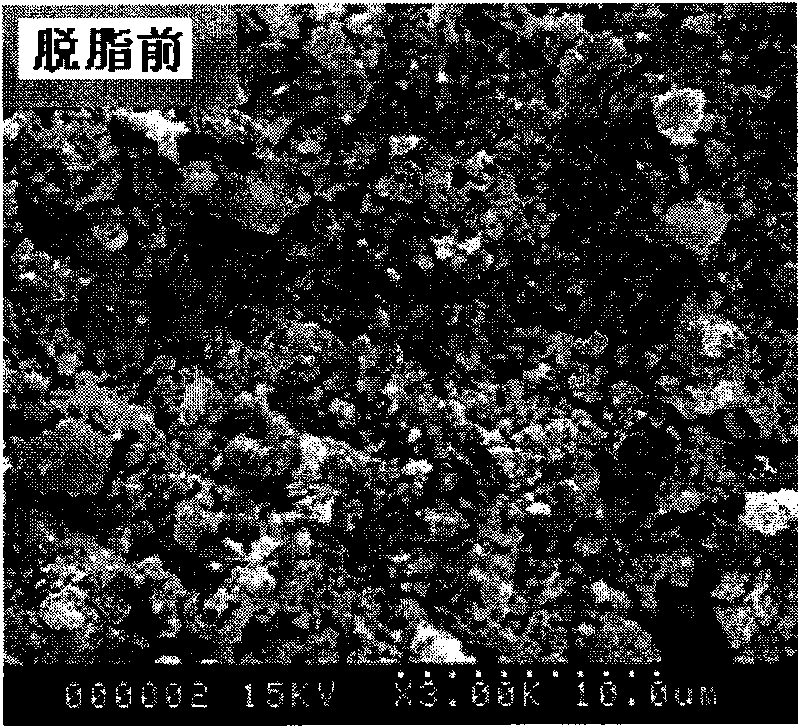

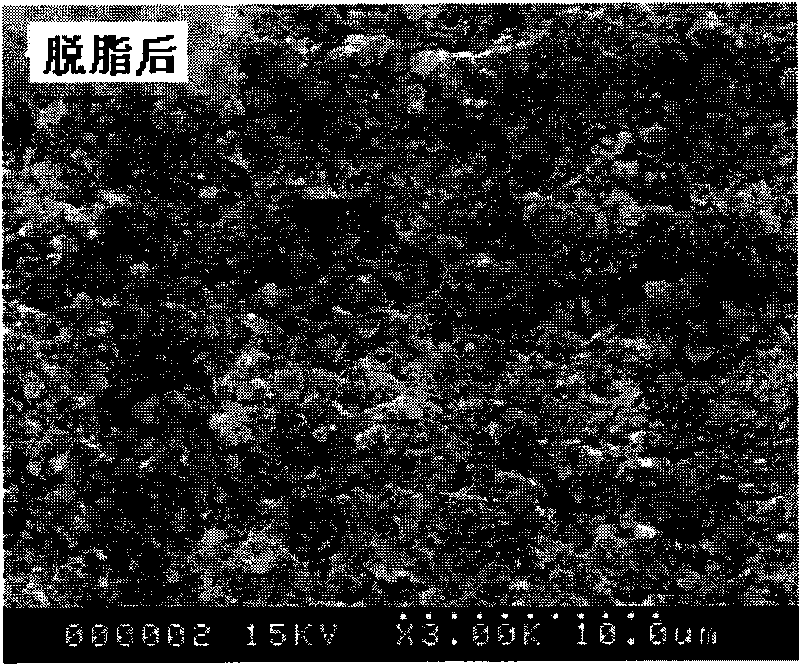

Degreasing method used for transparent alumina ceramic injection molding product

The invention relates to the field of the injection molding of transparent ceramics and ceramic powder, which discloses a degreasing method used for a transparent alumina ceramic injection molding product. The method comprises the following steps: firstly, injecting and molding a ceramic crude blank, wherein the assistant materials of the ceramic crude blank are alumina and an adhesive, and the adhesive comprises the following components by weight percent: 18-20% of polypropylene, 70-80% of paraffin and 1-12% of stearic acid; secondly, immersing the ceramic crude blank in an extraction solvent and extracting for 3-4h at the temperature of 45-60 DEG C, wherein the extraction solvent is prepared by mixing 20-30% of alcohol by volume and 70-80% of normal heptane by volume; then, discharging the extraction solvent and drying the ceramic crude blank in the air at room temperature; and finally, burying the ceramic crude blank in alumina powder and carrying out thermal degreasing for 56-60h hot.

Owner:XI AN JIAOTONG UNIV

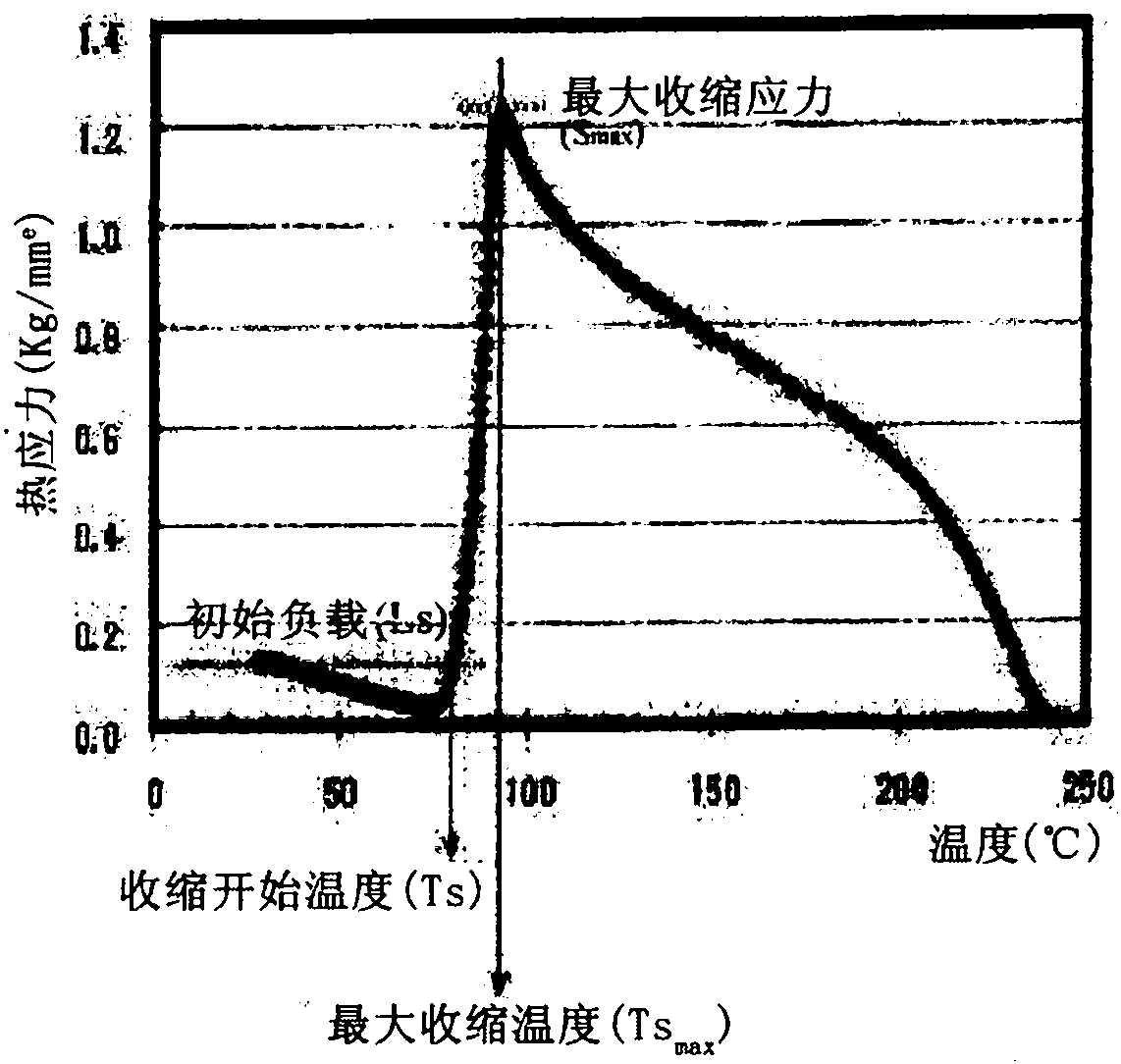

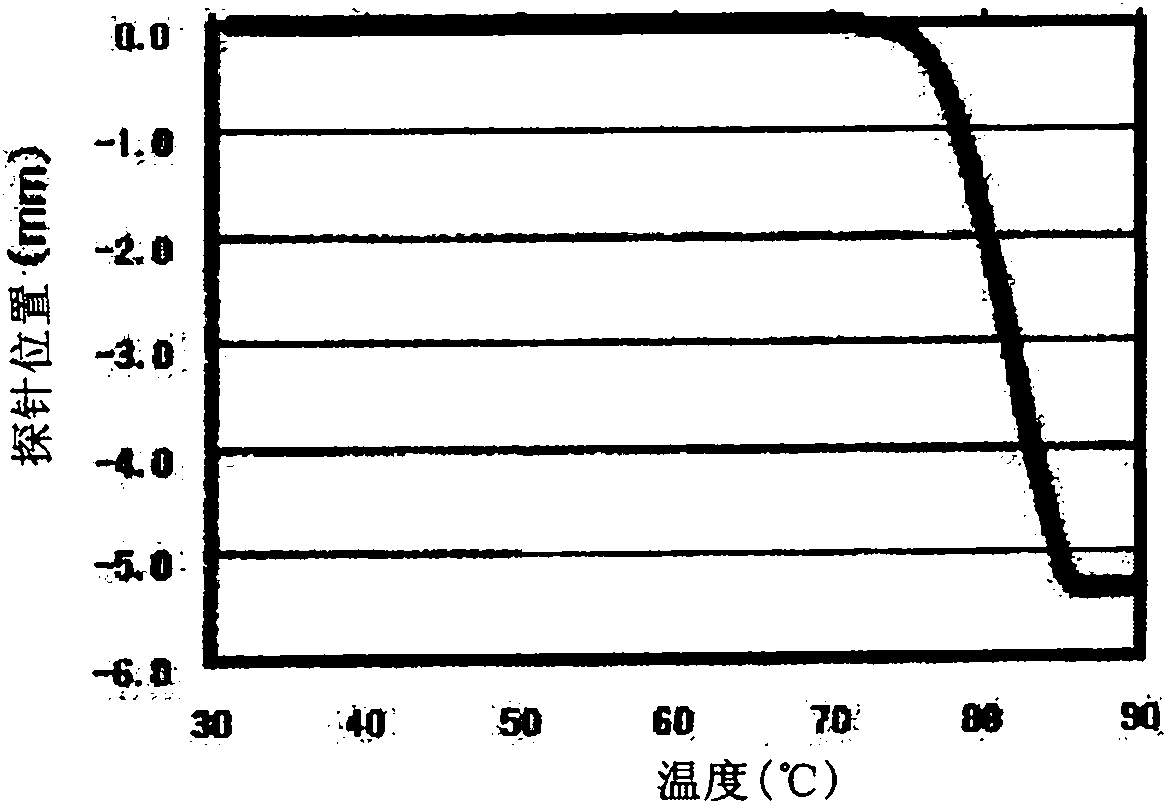

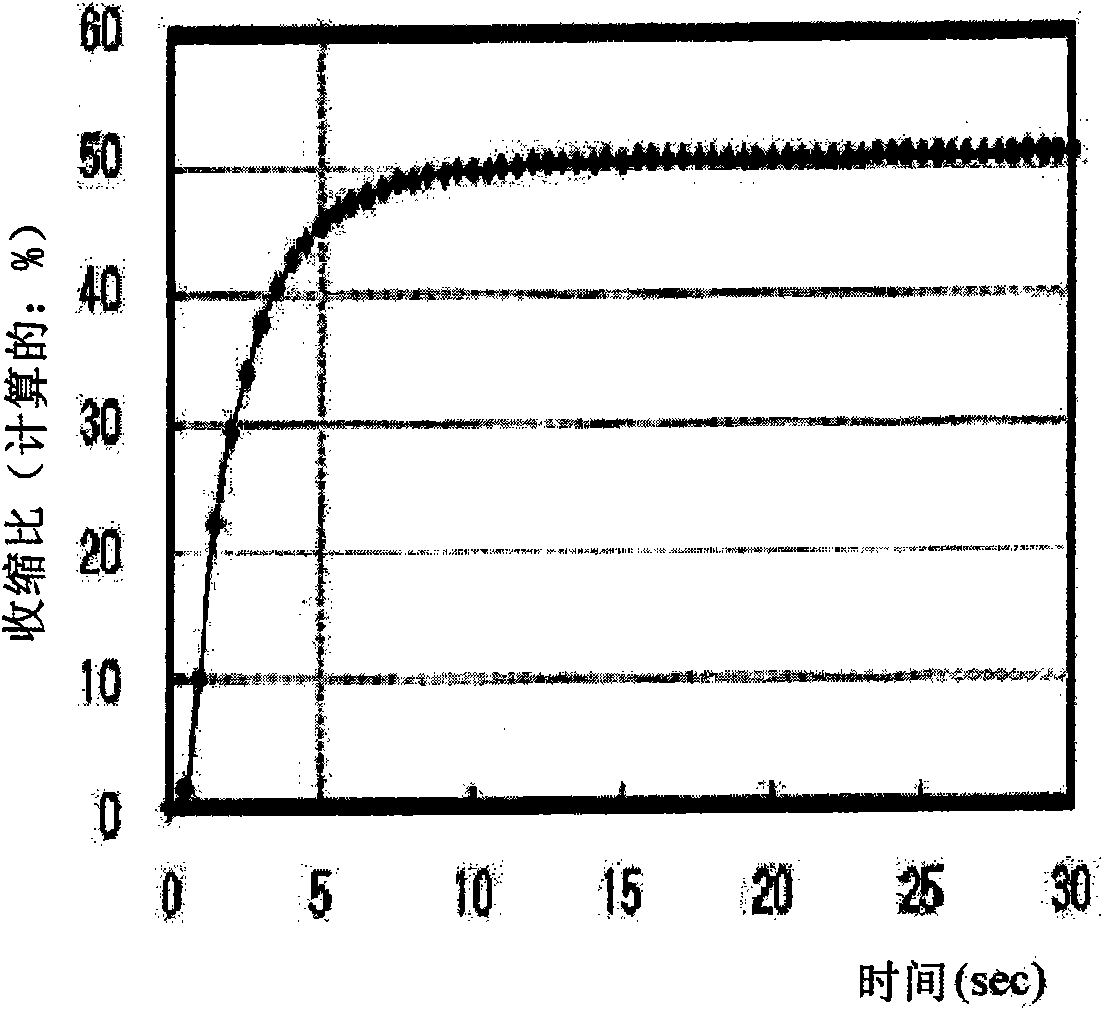

Thermo-shrinkable polyester film

ActiveCN101910261AAvoid damageInhibit deteriorationSynthetic resin layered productsFlat articlesPolyesterBiochemical engineering

Disclosed is a thermo-shrinkable polyester film in which shrinkage uniformity is ensured in a shrinking process thus realizing superior quality of the outer appearance without causing a poorly printed state, reducing the production cost of the shrinking process and improving the productivity.

Owner:KOLON IND INC

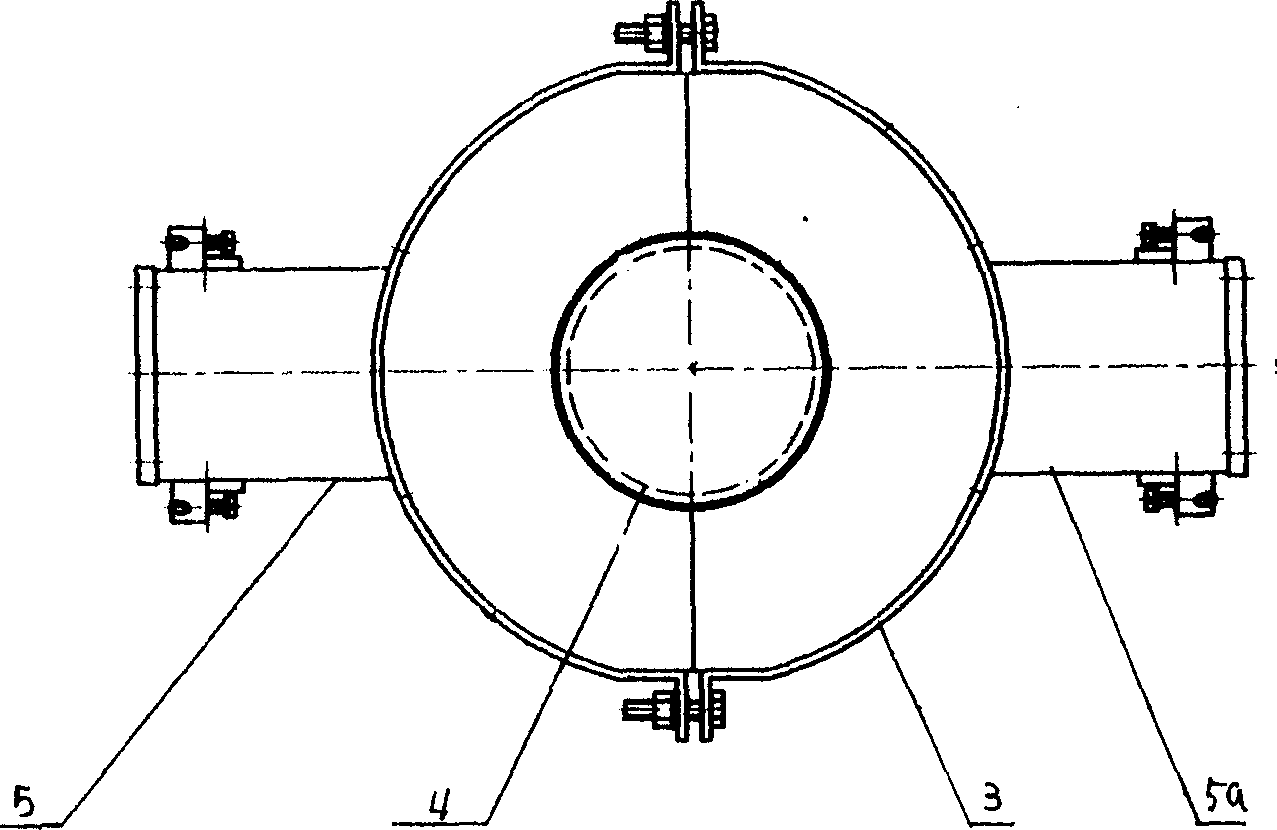

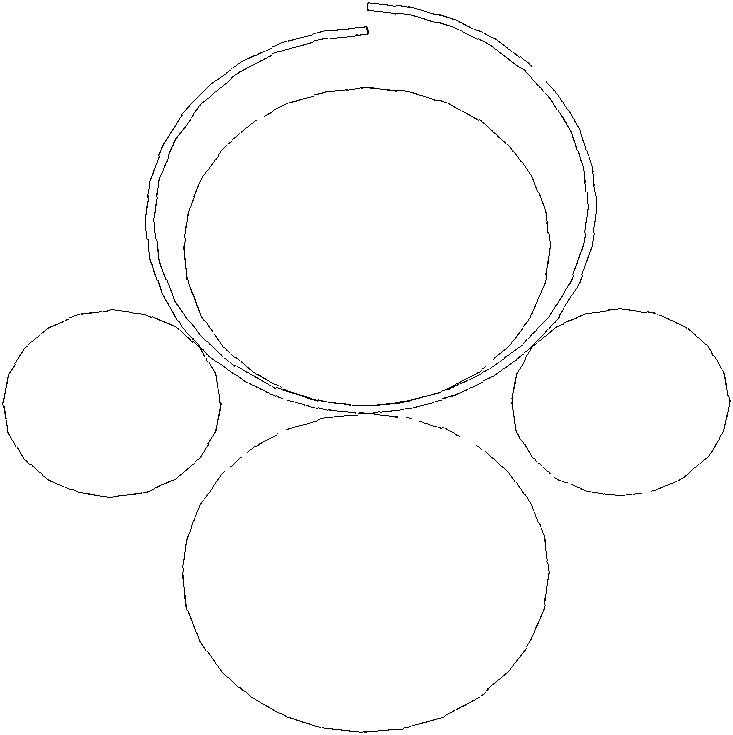

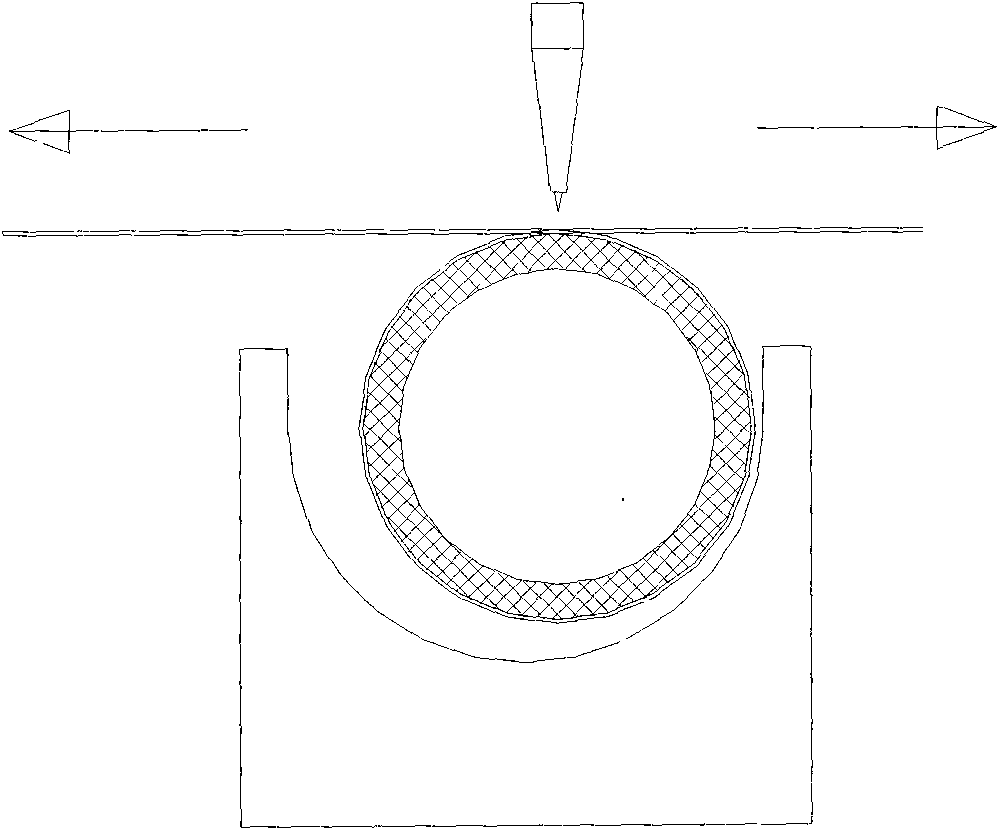

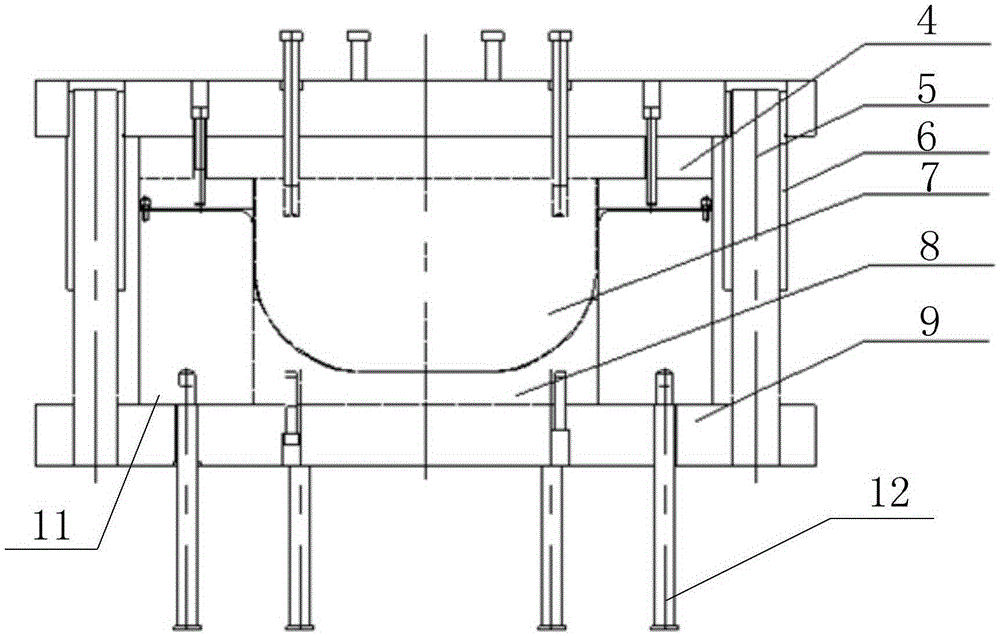

Packaging process for three-way catalytic converter

InactiveCN101608566AEasy to shapeImprove roundnessExhaust apparatusSilencing apparatusManufacturing technologyEngineering

The invention discloses a packaging process for a three-way catalytic converter, which relates to the technical field of mechanical manufacture, and aims to solve the technical problems that the bonding type has defects in the production of the three-way catalytic converters according with Europe IV standard. The flow of the packaging process comprises: 1) measuring the outside diameter of a carrier and the weight of a pad; 2) packaging the carrier first and favorably attaching the packaged pad to the carrier, and then pressing the packaged pad into the shell by a power source; 3) performing multiple contraction on workpieces by an outside diameter contracting device of the three-way catalytic converter on the basis of data obtained by measuring the outside diameter of the carrier and the pad; 4) flaring two end ports of the workpieces without damaging the carrier, and keeping the flared end surface straight to ensure that the space between two annual welding seams is consistent and equal; and 5) performing assembly welding, namely respectively inserting two end cones into flares at two ends of the workpieces and welding the flares along the end surfaces of the flares. The packaging process for the three-way catalytic converter has the characteristics of strong adaptability, even contraction and deformation, can avoid the breakage of the carrier and the damage of the pad, and has good circularity of the appearance.

Owner:上海连能环保科技股份有限公司

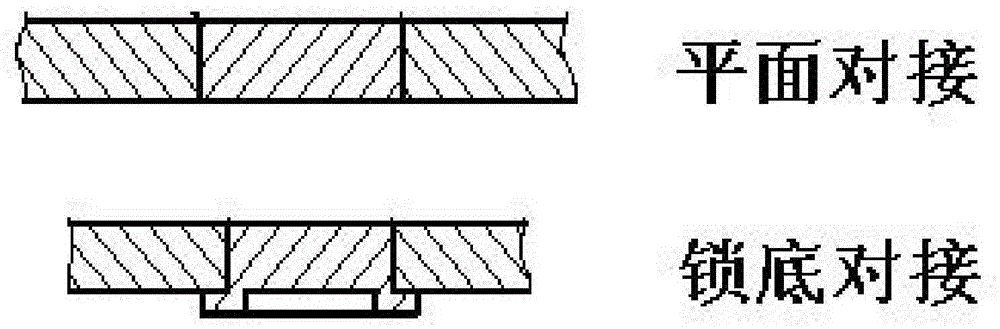

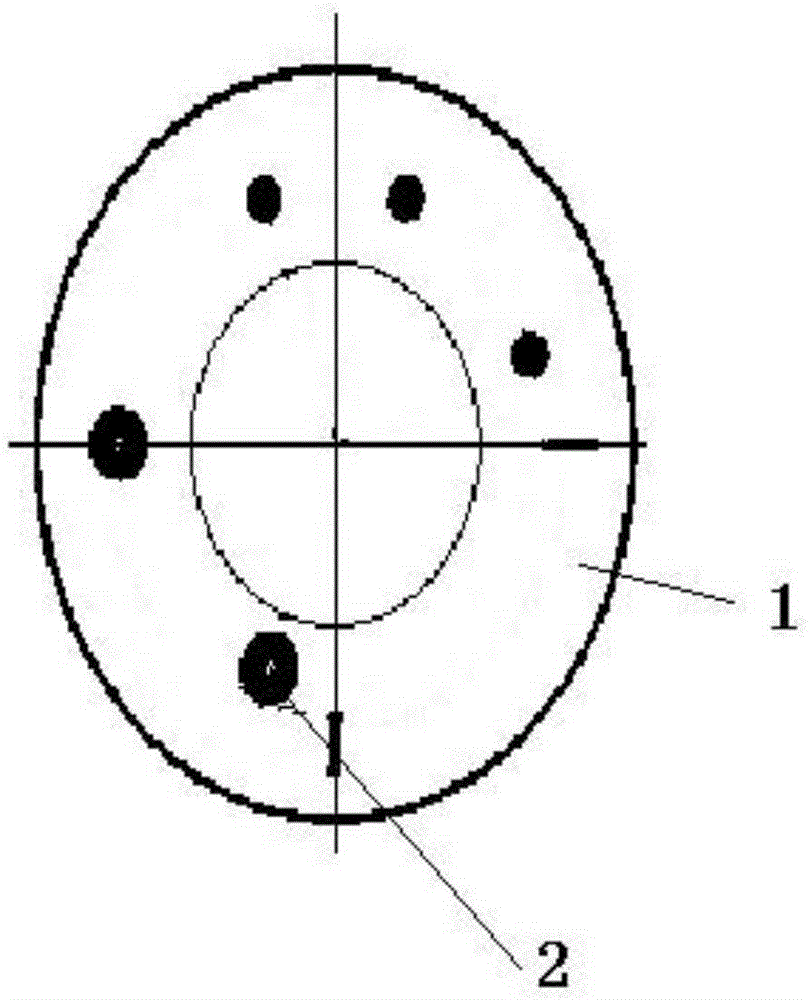

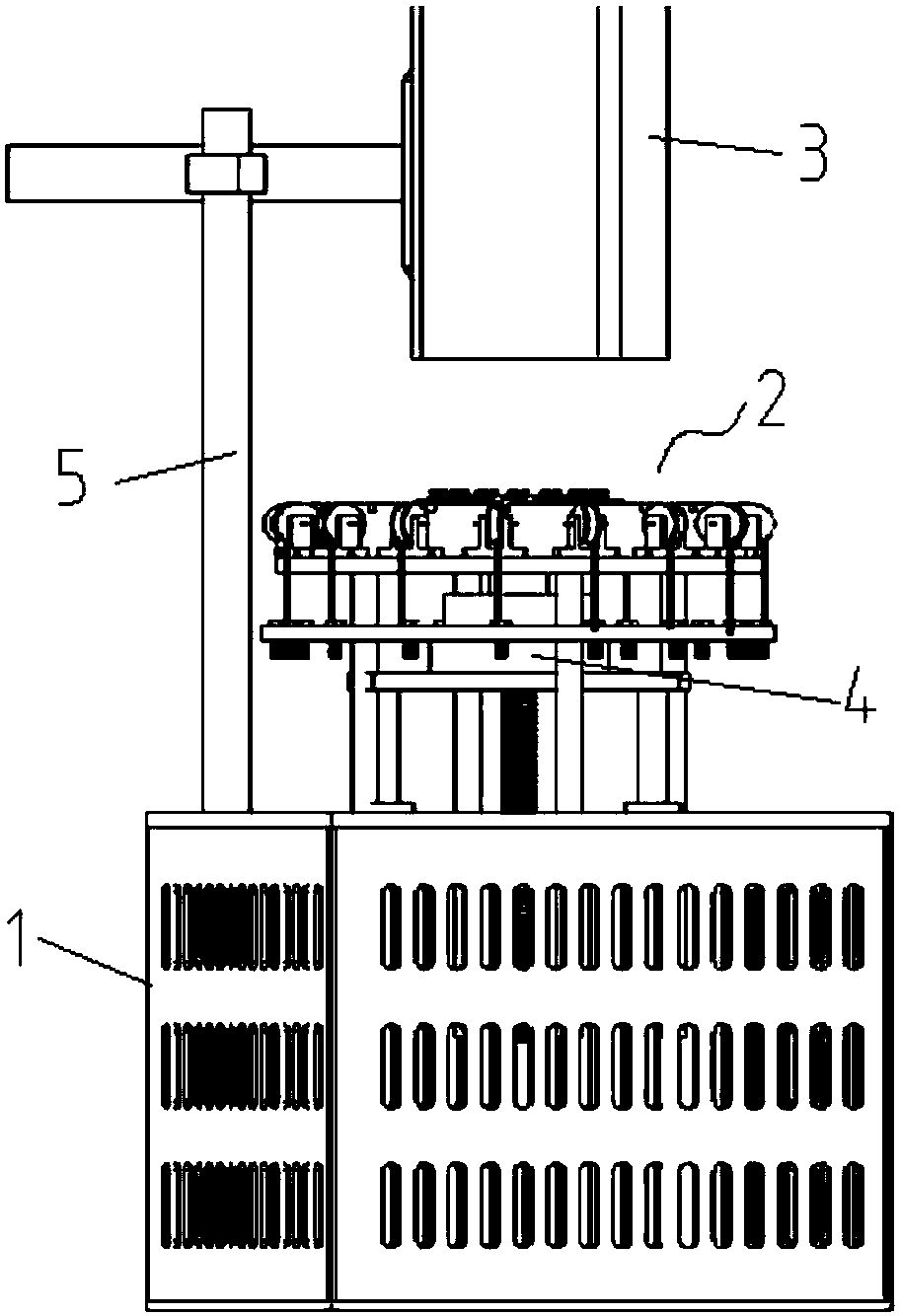

Electron beam welding method applicable to small-diameter flange plates on thin-wall top cover

ActiveCN106670640AIncrease foilPlay full without depressionElectron beam welding apparatusWorkpiece edge portionsButt jointEngineering

The invention belongs to the technical field of electron beam welding, and particularly relates to an electron beam welding method for multiple small-diameter flange plates at different circumferential positions of a large-size thin-wall space curved face top cover. A flange plate structure applicable to top cover flange plate electron beam welding is designed, a welding joint portion of each flange plate is of a butt joint lock bottom structure, and assembling precision and welding quality are effectively ensured. Meanwhile, according to the hole size in the position, to which each flange plate is assembled and welded, on the top cover, the diameter of the welding face of the corresponding flange plate is adjusted, and it is ensured that the assembling gap between the corresponding flange plate and the top cover meets welding requirements. By using a tool, by the adoption of elastic prestress deformation, welding stress is counteracted, deformation is reduced, electron beam welding for the flange plates distributed at different positions of the space curved face top cover is achieved, and satisfying welding quality is obtained.

Owner:CAPITAL AEROSPACE MACHINERY +1

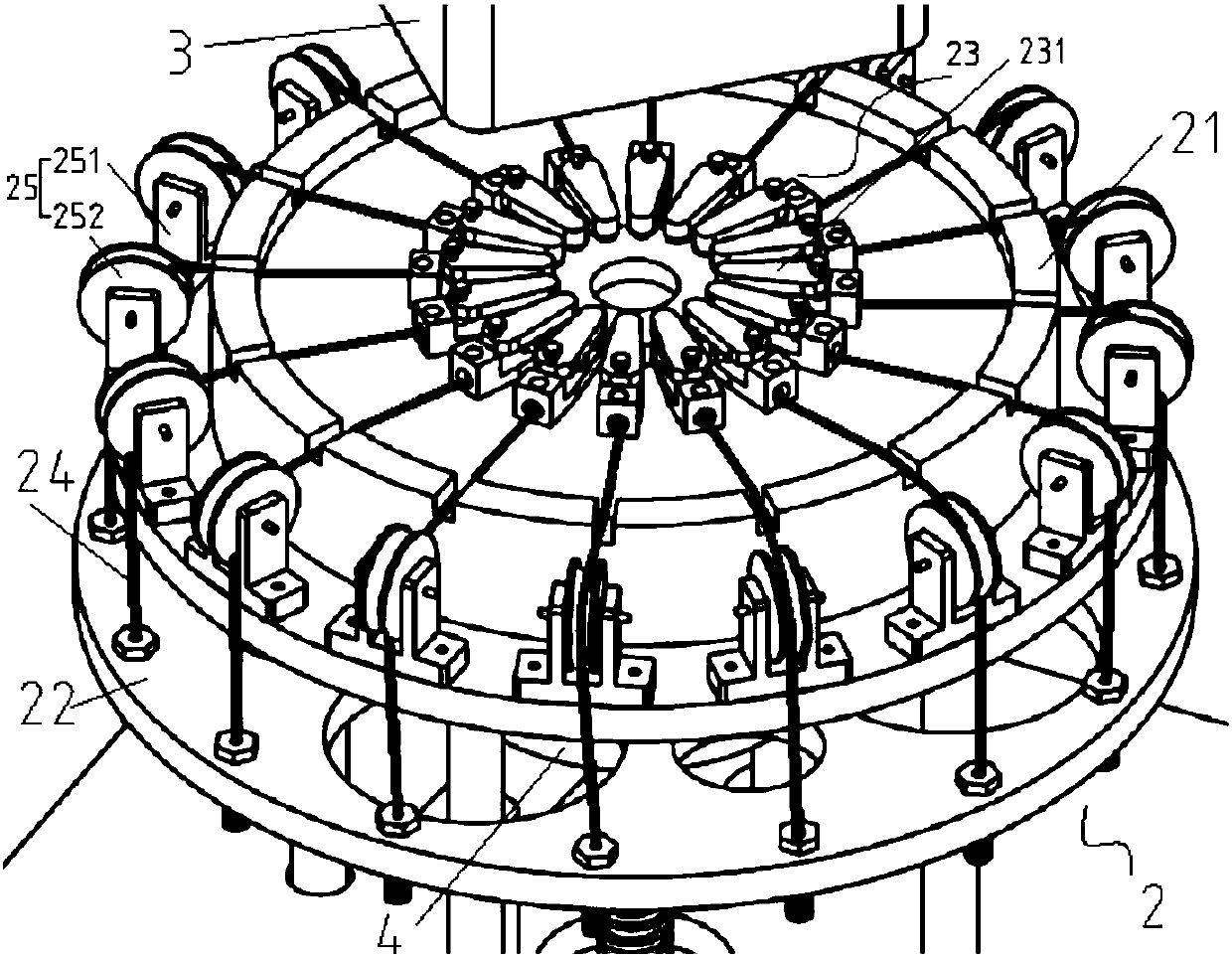

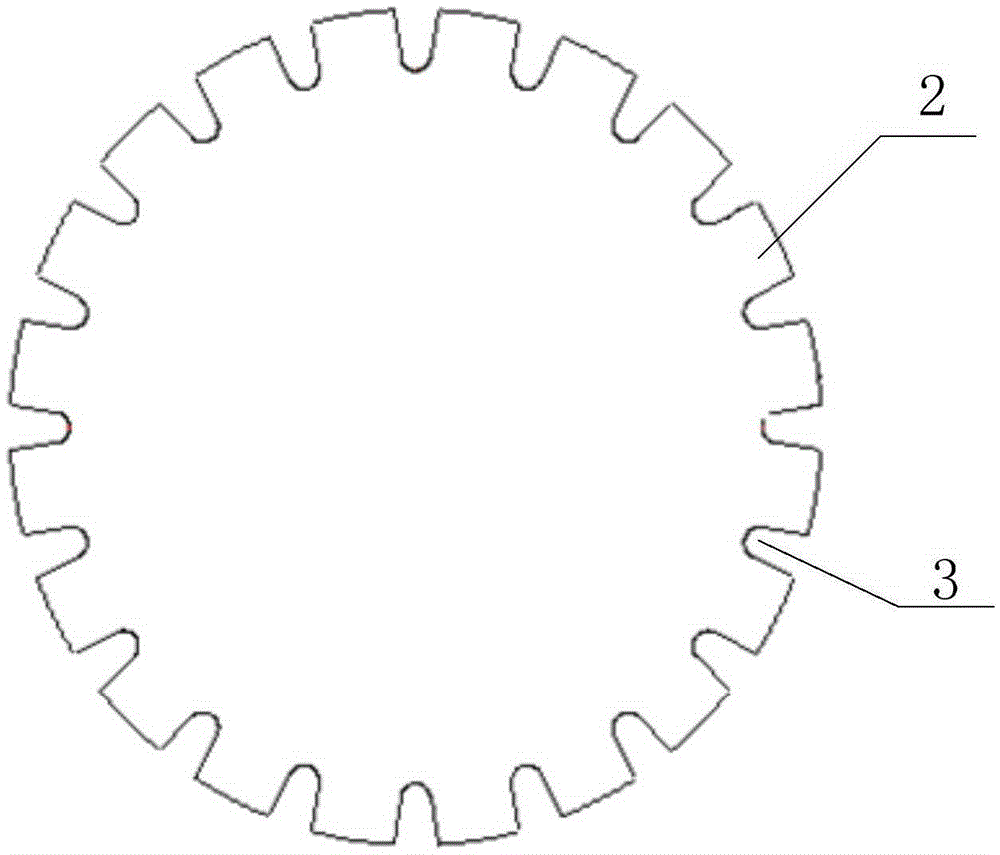

High elastomer material equiaxial tensile testing machine

PendingCN107664603AEven by forceUniform deformationMaterial strength using tensile/compressive forcesElastomerEngineering

The invention discloses a high elastomer material equiaxial tensile testing machine. The high elastomer material equiaxial tensile testing machine comprises a rack and a tensile mechanism arranged onthe rack, wherein the tensile mechanism comprises a circular platform, a rotary table, a circular fixture, a pulling rope and a pulley mechanism, the circular platform and the rotary table are coaxially and sequentially arranged on the rack, the rotary table is driven by a driving mechanism arranged in the rack, the circular fixture is arranged on the circular platform, one end of the pulling ropeis connected with the circular fixture, and the other end of the pulling rope is connected with the rotary table by virtue of the pulley mechanism. A circular sample is placed on the circular fixture, and the circular fixture clamps the circular sample, the driving mechanism drives the rotary table to rotate, the rotary table pulls the circular fixture by virtue of the pulling rope and the pulleymechanism, and the circular fixture stretches the circular sample, so that the circular sample is uniformly expanded and contracted, and the equiaxial tensile effect is realized. The high elastomer material equiaxial tensile testing machine disclosed by the invention enables stress and deformation of the circular sample to be more uniform and is more applicable to carrying out a stress-strain relation test on a high elastomer material, and the strain measurement accuracy is higher.

Owner:易瑞博科技(北京)有限公司

PVC (polyvinyl chloride) heat shrinking film and preparation method thereof

The invention discloses a PVC heat shrinking film which is prepared by raw materials in parts by weight as follows: 90-100 parts of PVC resin, 1-5 parts of an assistant, 2-5 parts of a lubricating agent, 1-3 parts of a plasticizer and 2-5 parts of an antioxidant. The invention further discloses a preparation method of the PVC heat shrinkage film. The PVC heat shrinkage film obtained by adopting the preparation method has better transparency compared with a common PVC heat shrinkage film, and is uniform in shrinkage, high in shrink rate and environment-friendly; and the preparation method is simple and easy to operate, and can realize large-scale production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

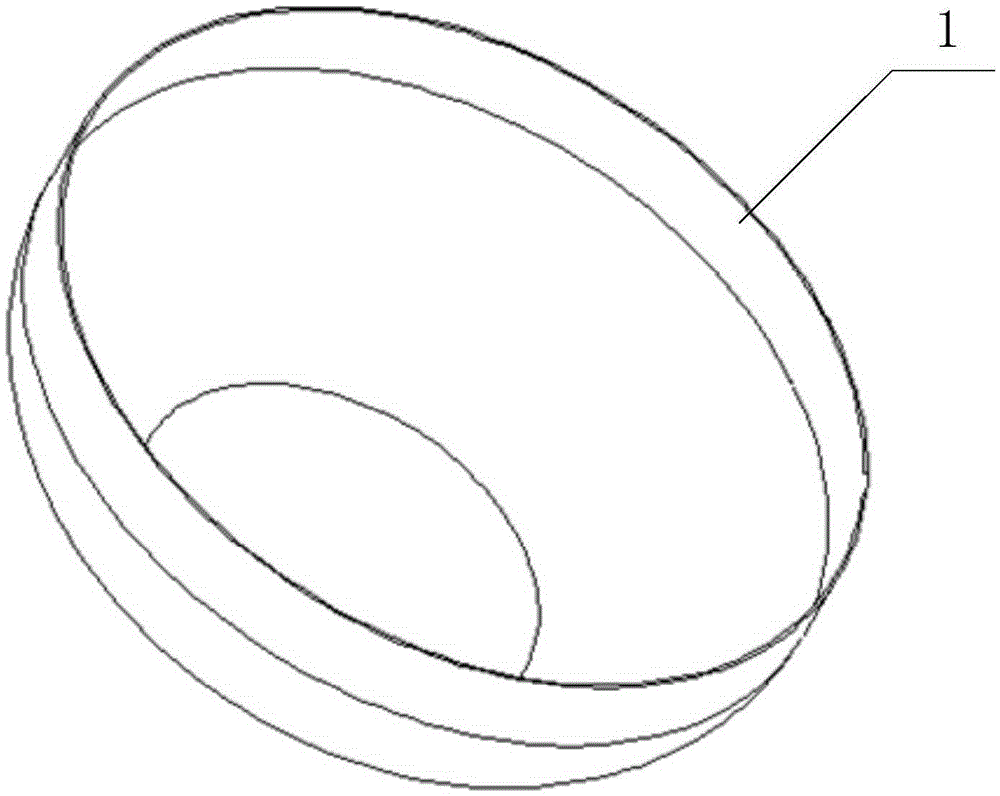

Drawing forming device and method of rotary part

ActiveCN105414299AAvoid wrinklesImprove wear resistanceMetal working apparatusEngineeringMaterials processing

The invention relates to the technical field of metal material machining, in particular to a drawing forcing device and method of a rotary part. The device comprises an upper combined die, a male die, a female die, a female die frame, a lower die, a guide column, a guide sleeve, an ejection rod and an ejection plate. The male die is fixedly connected with the lower end of a lower combined die, the female die is arranged in the female die frame, the female die is fixedly connected with the upper end of the lower die, the lower end of the ejection rod is connected with the ejection plate, and the upper end of the ejection rod penetrates the lower die to be fixedly connected with the female die frame; and the female die is arranged below the male die, and the axis of the male die coincides with the axis of the female die. One end of the guide sleeve is fixedly connected with the upper combined die, and fixedly connected with the lower die, and the other end of the guide column is inserted in the other end of the guide sleeve in a penetrating manner. The method comprises blank manufacturing, blank positioning, blank drawing, blank annealing, die pressure maintaining and mechanical machining. According to the drawing forcing device and method of the rotary part, the problem that in the drawing process of the rotary part, ripping, wrinkling and scrapping are prone to appearing is solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com