Dyeing and finishing process for improving color fastness to light of light-colored fabric of FDY (Fully Drawn Yarn) polyester filament yarn warp and weft four-way elastic textile

A polyester filament and four-way stretch technology, which is applied in the dyeing and finishing process of FDY polyester filament four-way stretch light-colored fabrics, can solve the problem of poor light fastness of fluorescent whitening agents, low productivity, fabric The surface is prone to wrinkles and other problems, and the effect of improving color fastness to light, improving production efficiency, and improving slow dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

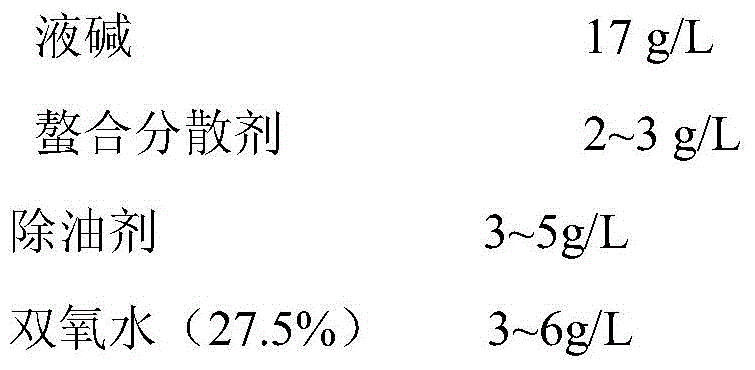

[0059] A dyeing and finishing process for improving the color fastness to light of FDY polyester filament four-way stretch light-colored fabrics, using FDY polyester filament four-way stretch without fluorescent whitening agent as the gray fabric, including the process steps of gray fabric preparation→sewing→ Open width shrinking→preshrinking and pretreatment→dehydration, opening width→presetting→alkali weight reduction→water washing, neutralization→high temperature and high pressure airflow dyeing machine dyeing→reduction cleaning, neutralization, water washing→dehydration, opening width→softening and shaping →Inspection→Packing in rolls, the following dyeing auxiliaries formula is used in the dyeing process:

[0060] where X+Y+Z≤0.5

[0061] Bath ratio: 1:3.

[0062] Described efficient dispersant is sodium lignosulfonate;

[0063] The dyeing process is carried out in a high-temperature and high-pressure overflow dyeing machine with a heating rate of 1°C / min, heat preser...

Embodiment 2

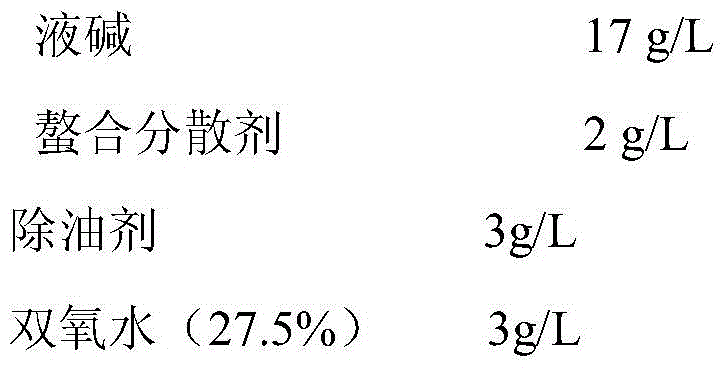

[0095] A dyeing and finishing process for improving the color fastness to light of FDY polyester filament four-way stretch light-colored fabrics, using FDY polyester filament four-way stretch without fluorescent whitening agent as the gray fabric, including the process steps of gray fabric preparation→sewing→ Open width shrinking→preshrinking and pretreatment→dehydration, opening width→presetting→alkali weight reduction→water washing, neutralization→high temperature and high pressure airflow dyeing machine dyeing→reduction cleaning, neutralization, water washing→dehydration, opening width→softening and shaping →Inspection→Packing in rolls, the following dyeing auxiliaries formula is used in the dyeing process:

[0096]

[0097] where X+Y+Z≤0.5

[0098] Bath ratio: 1:4.

[0099] The high-efficiency dispersant is sodium lignosulfonate.

[0100] The dyeing process is carried out in a high-temperature and high-pressure overflow dyeing machine, the heating rate is 1°C / min, a...

Embodiment 3

[0132] A dyeing and finishing process for improving the color fastness to light of FDY polyester filament four-way stretch light-colored fabrics, using FDY polyester filament four-way stretch without fluorescent whitening agent as the gray fabric, including the process steps of gray fabric preparation→sewing→ Open width shrinking→preshrinking and pretreatment→dehydration, opening width→presetting→alkali weight reduction→water washing, neutralization→high temperature and high pressure airflow dyeing machine dyeing→reduction cleaning, neutralization, water washing→dehydration, opening width→softening and shaping →Inspection→Packing in rolls, the following dyeing auxiliaries formula is used in the dyeing process:

[0133] where X+Y+Z≤0.5

[0134] Bath ratio: 1:3.

[0135] The high-efficiency dispersant is an acrylic acid maleic anhydride copolymer.

[0136] The dyeing process is carried out in a high-temperature and high-pressure overflow dyeing machine, the heating rate is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com