Thermo-shrinkable polyester film

A heat-shrinkable polyester film technology, applied in the field of polyester film, can solve problems such as poor printing status, reduced yield, and defective label appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

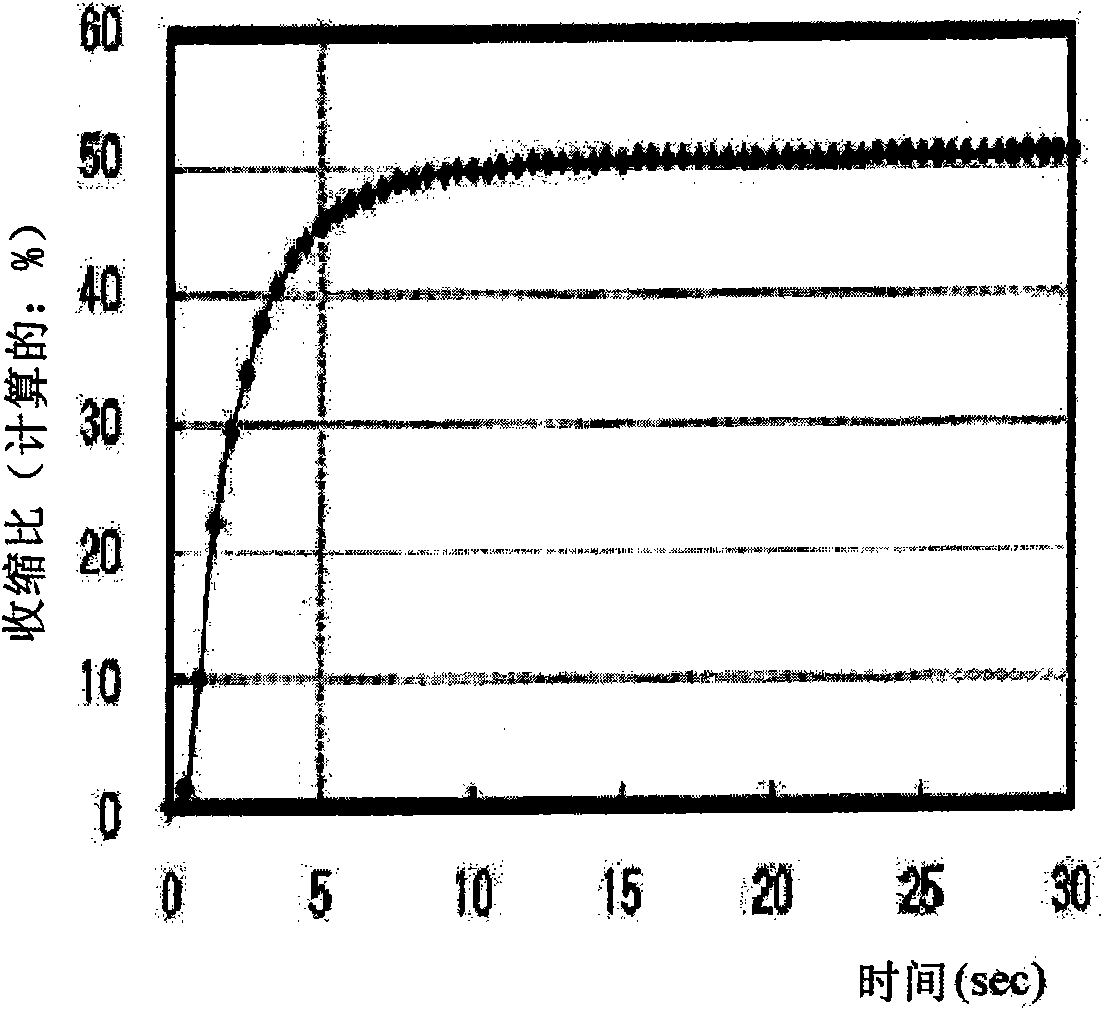

[0061] Shrinkable films are manufactured based on the principle that low-temperature uniaxial stretching enables maximum uniaxial orientation and also prevents the release of residual stress due to heat treatment, so that the uniaxially oriented molecular chains can maintain this residual Stress, and then shrink under the action of said residual stress during the last shrinkage process.

[0062] Shrinkable polyester films are generally obtained by extrusion of copolyester-containing compositions. The problem with copolyester, on its own, is that it is very poorly resistant to heat.

[0063] Since the material has this problem, the heat-shrinkable polyester film has low heat resistance.

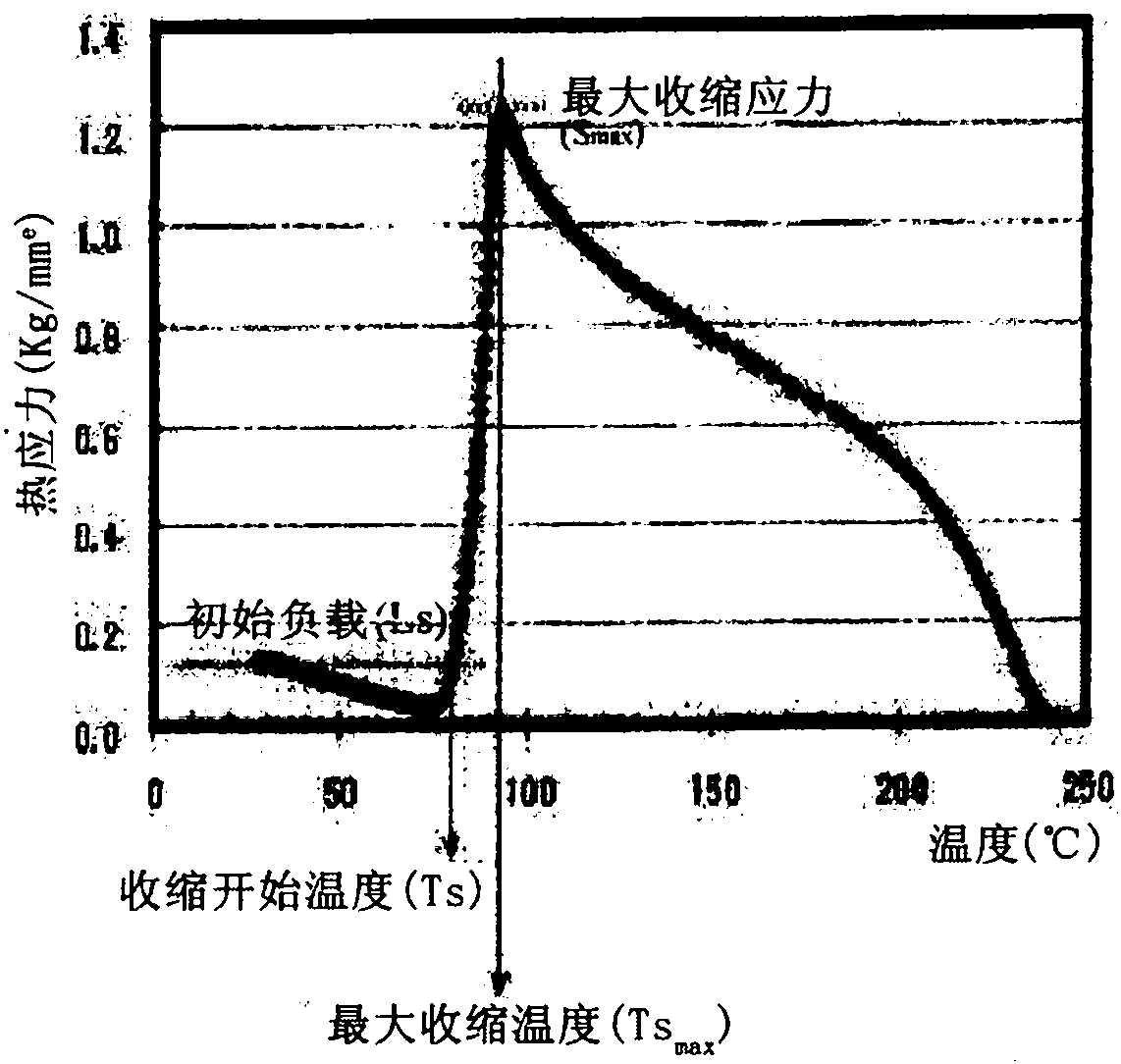

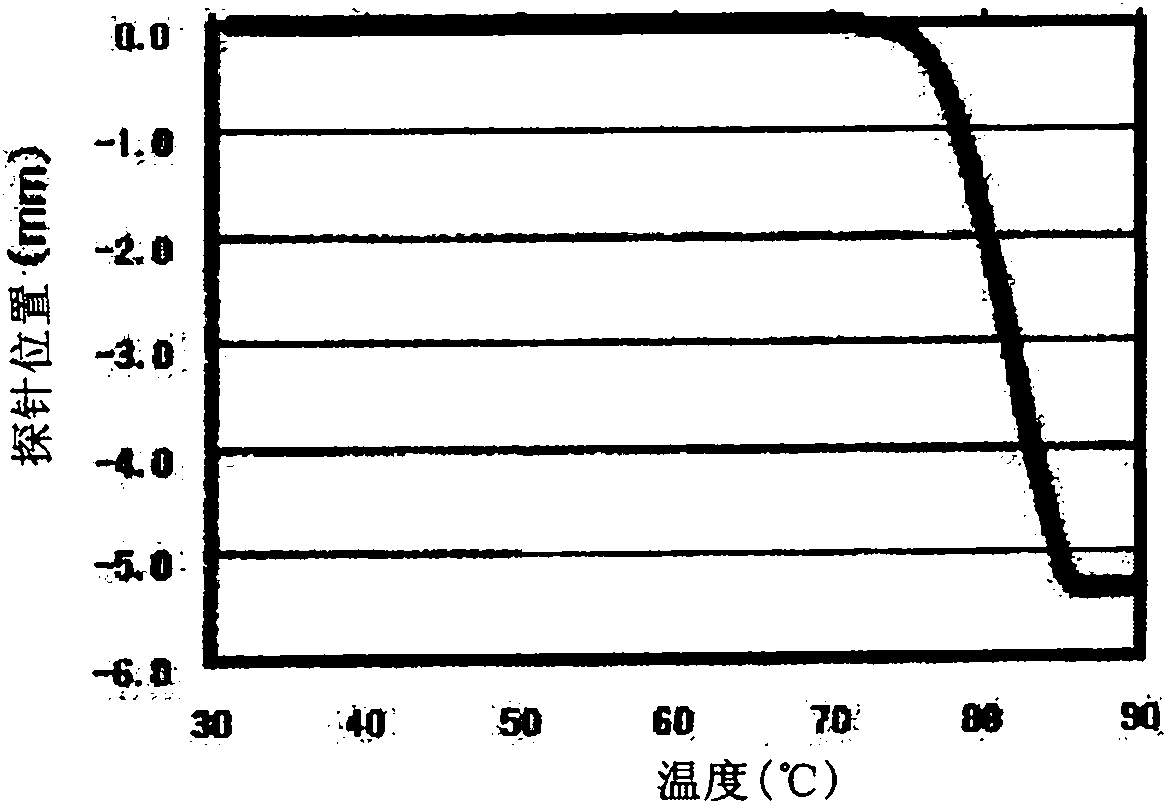

[0064] According to an embodiment of the present invention, the shrinkage start temperature of the heat-shrinkable polyester film in the main shrinkage direction is 72-88° C., wherein the shrinkage start temperature is defined as, when kept at room temperature and under a predetermined initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com