Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1049 results about "Autoclaved aerated concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Autoclaved aerated concrete (AAC) is a lightweight, precast, foam concrete building material suitable for producing concrete masonry unit (CMU) like blocks. Composed of quartz sand, calcined gypsum, lime, cement, water and aluminum powder, AAC products are cured under heat and pressure in an autoclave. Invented in the mid-1920s, AAC simultaneously provides structure, insulation, and fire- and mold-resistance. Forms include blocks, wall panels, floor and roof panels, cladding (façade) panels and lintels.

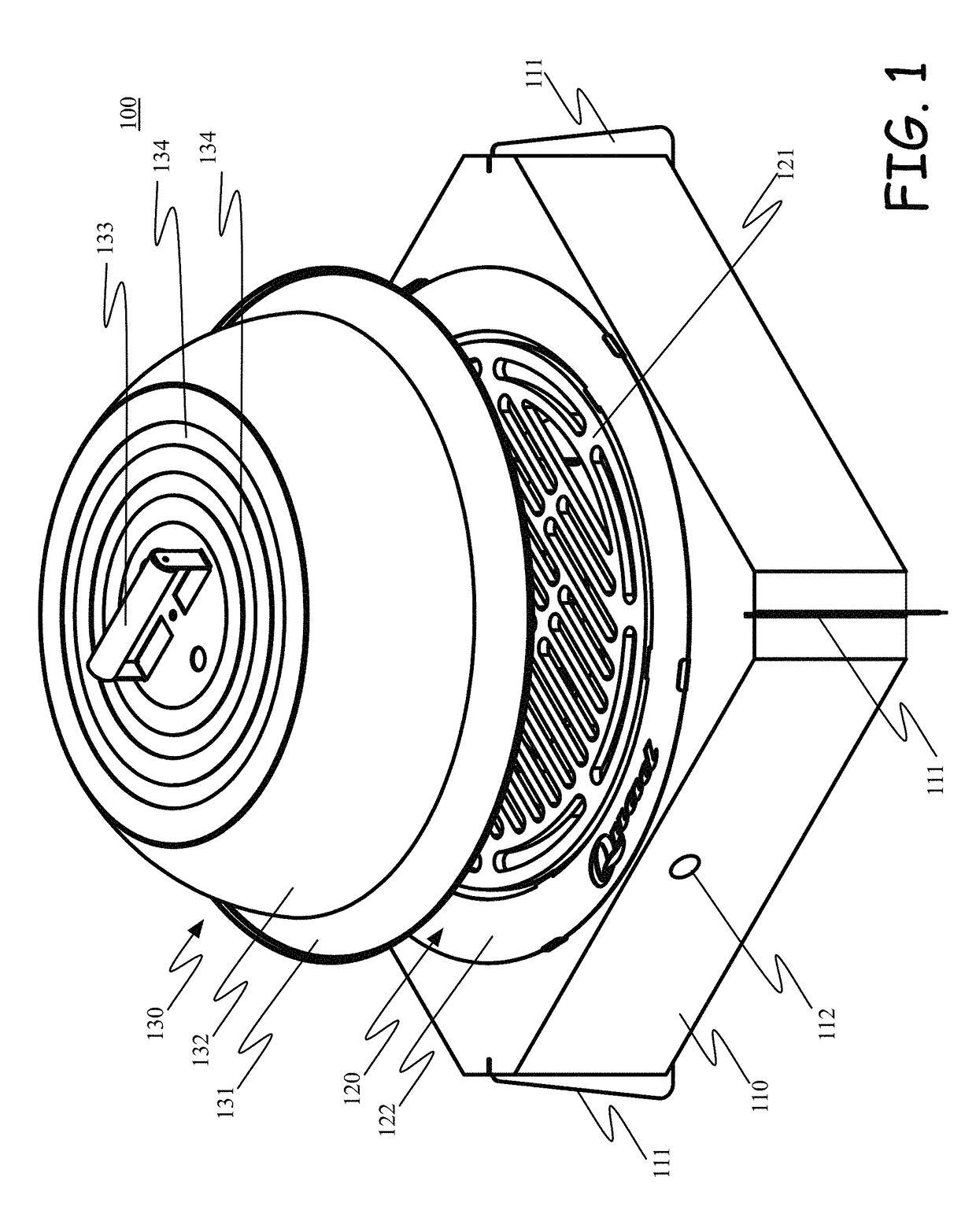

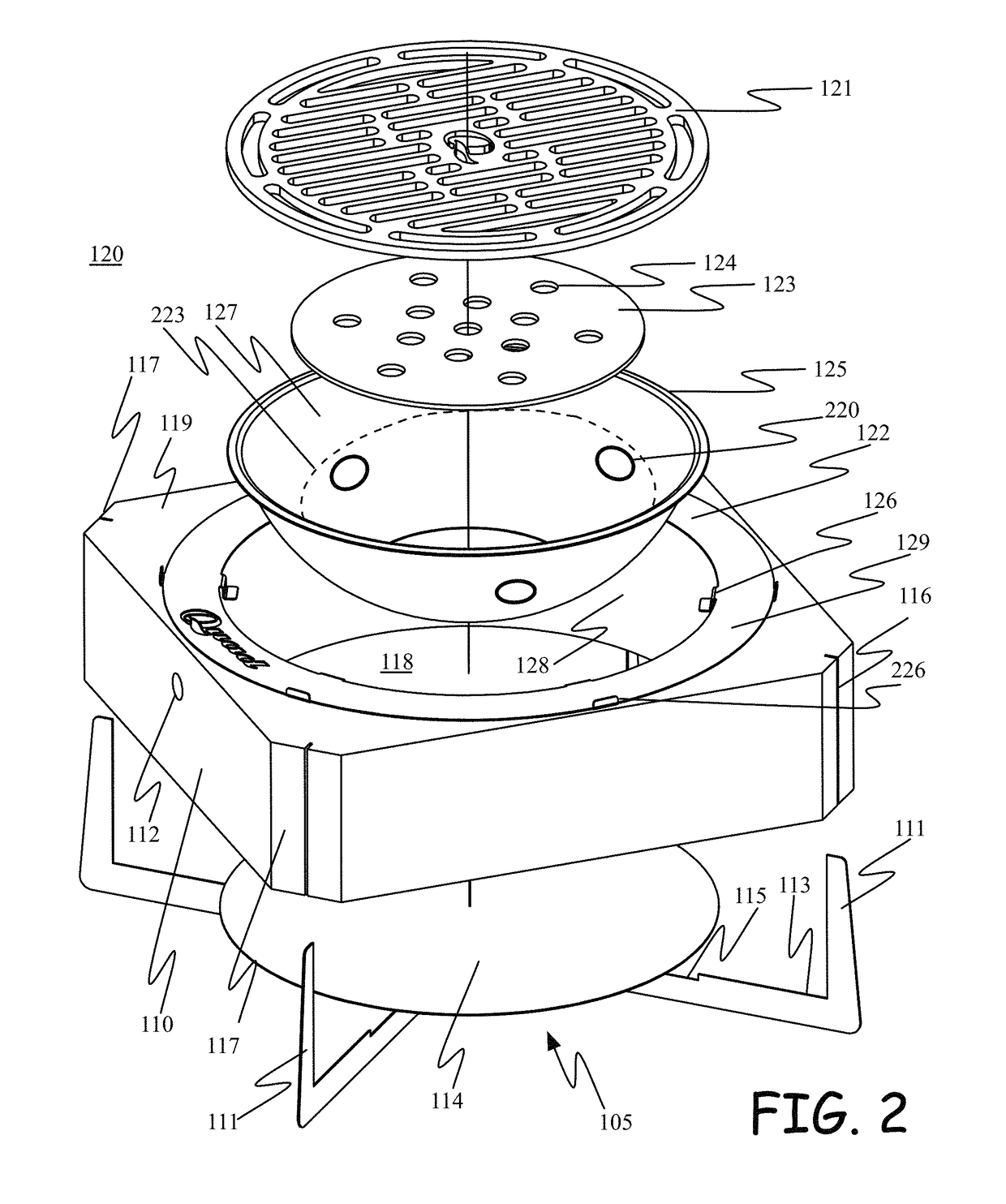

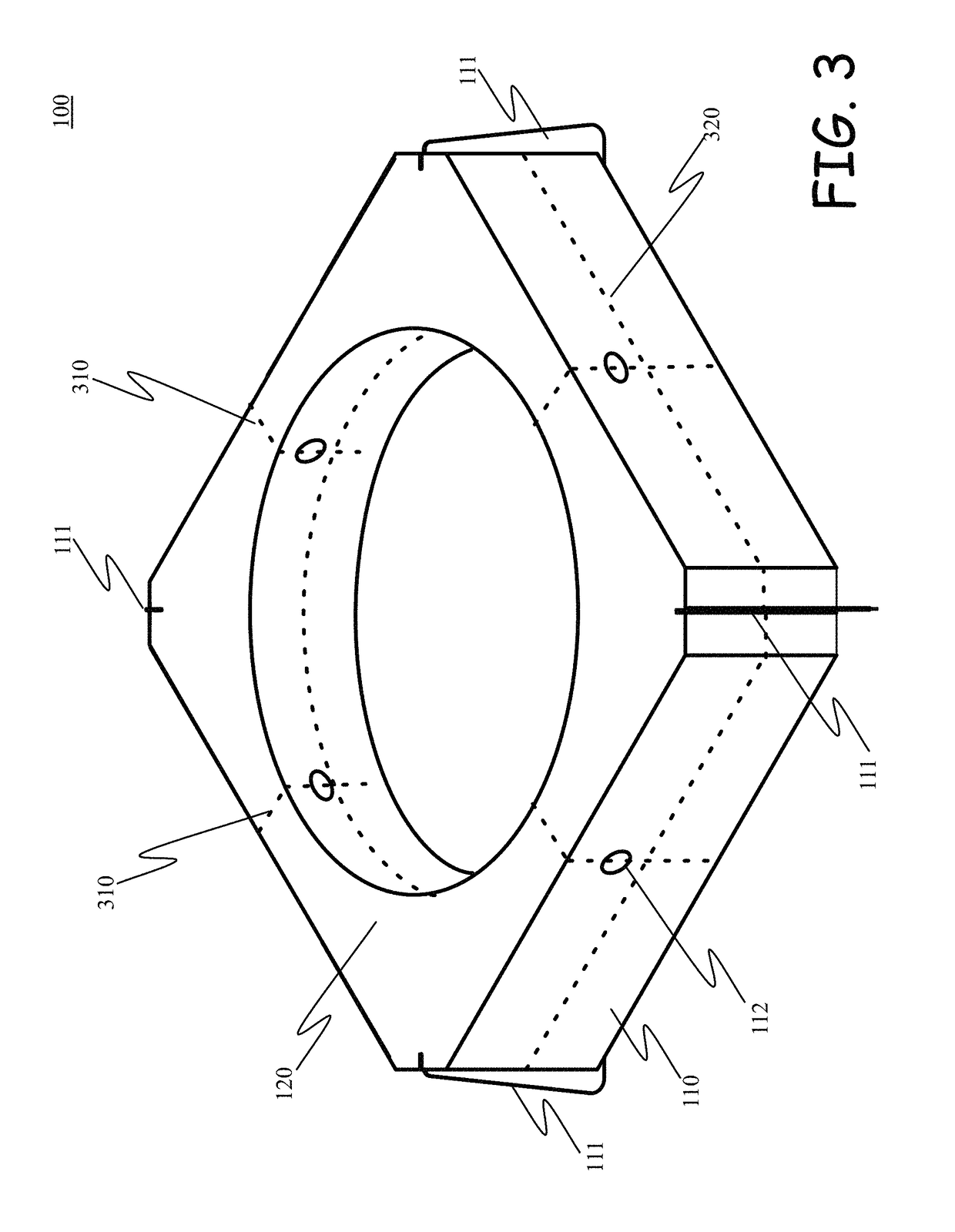

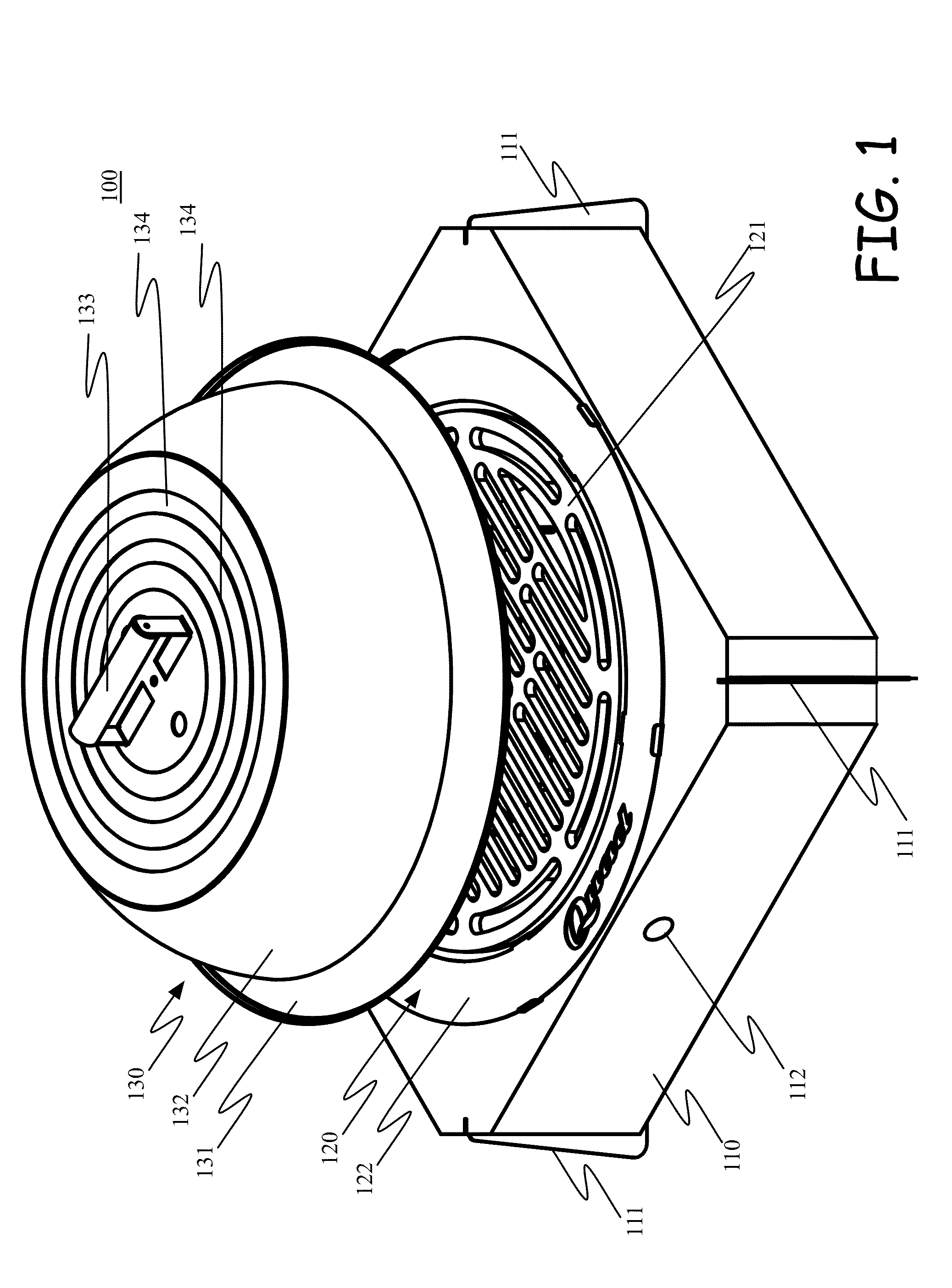

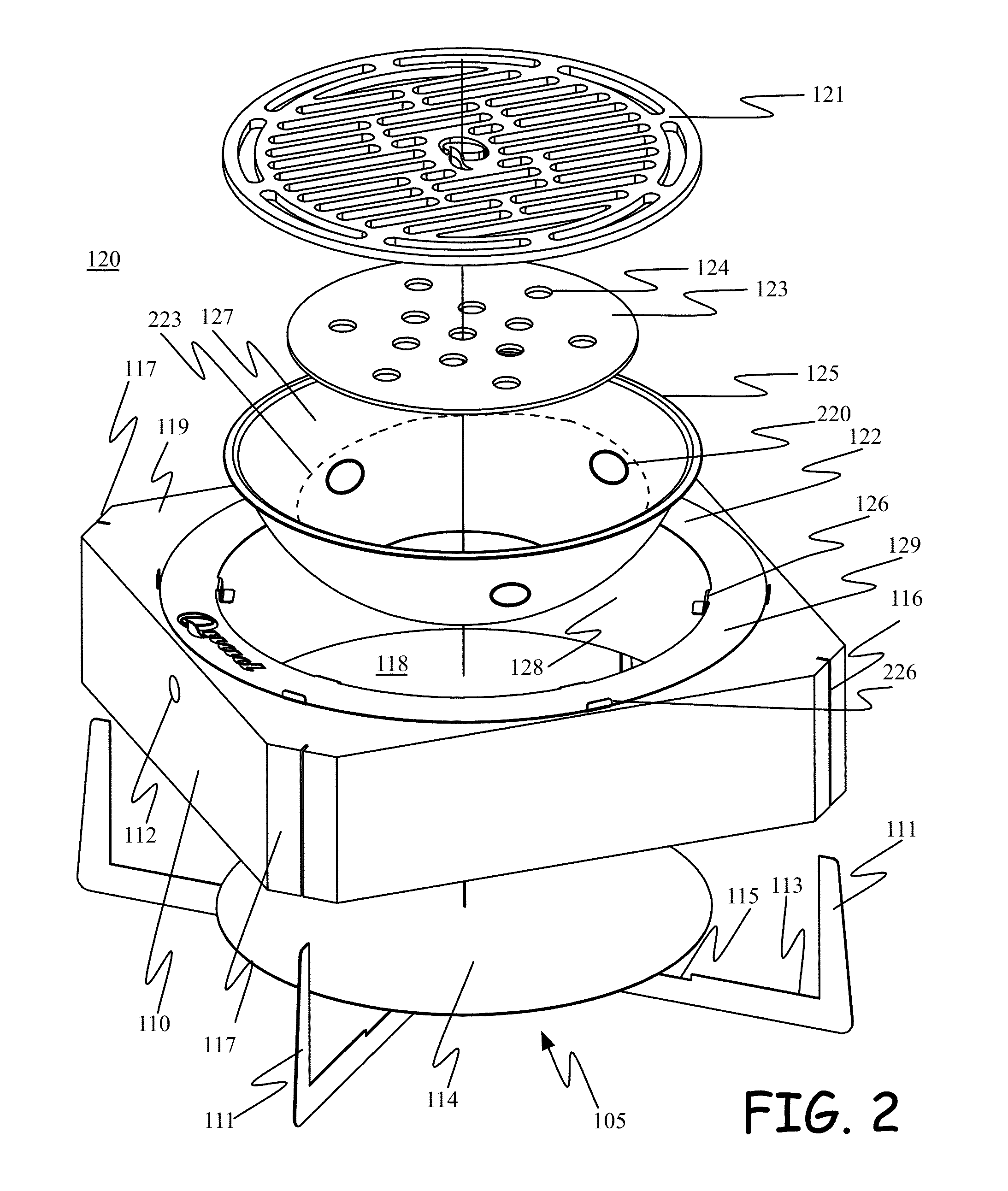

Versatile cooker

A versatile cooker that includes a crucible or base, a fire bowl with a cooking surface on top of it and, a cover / lid or dome that rests over the cooking surface. An exemplary embodiment of the cooker can be described as a naturally fired outdoor cooker constructed of a light weight, thermally insulated material such as Autoclaved Aerated Concrete (AAC) as the crucible, a stainless steel fire bowl and a dome lid. A grilling surface constructed out of carbon steel and ceramic disks are used as internal heat sinks.

Owner:COOKING WITH FIRE

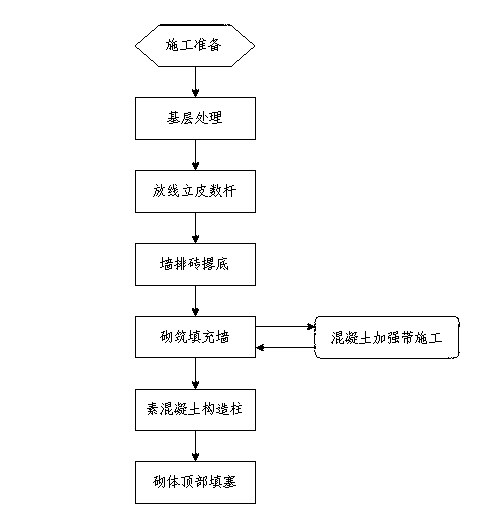

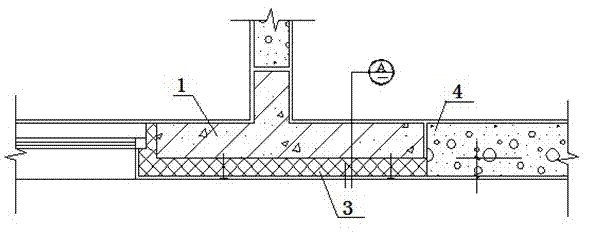

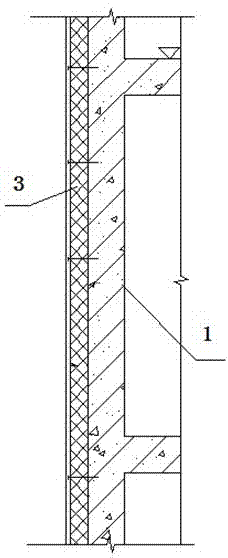

Construction method for preventing and treating cracks between concrete structure and filler wall

The invention discloses a construction method for preventing and treating cracks between a concrete structure and a filler wall. The construction method particularly comprises the following operation steps of step one, preparing construction; step two, treating a basic layer; step three, conducting paying off wire and setting up height pole; step four, conducting brick laying and putting down the bottom row of bricks; step five, masoning the filler wall; step six, constructing plain concrete constructional columns; step seven, filling the top of masonry. The construction method for preventing and treating the cracks between the concrete structure and the filler wall has the advantages of being wide in application range, and applicable to masonry construction of the filler wall with hollow bricks, autoclaved aerated concrete blocks and the like of the industrial and civil construction concrete structure; when the method compared with traditional processes, being capable of saving cost due to the fact that the main difference in procedure is that the plain concrete constructional columns, concrete reinforcing bands, wall crown filled with hard concrete and other portions replace the masonry; fundamentally solving the problem that cracks of a plaster layer and a coating layer caused by the cracks of the contact surface of the concrete structure and the filler wall, improving a project impression level and project quality, eradicating leakage risks of outer wall surfaces, reducing reworking cost and maintenance cost, saving materials, reducing production of construction waste, lowering a complaint rate of users, and being capable of setting up a corporate image in society and considerable in social benefit.

Owner:CHINA AEROSPACE CONSTR GROUP +1

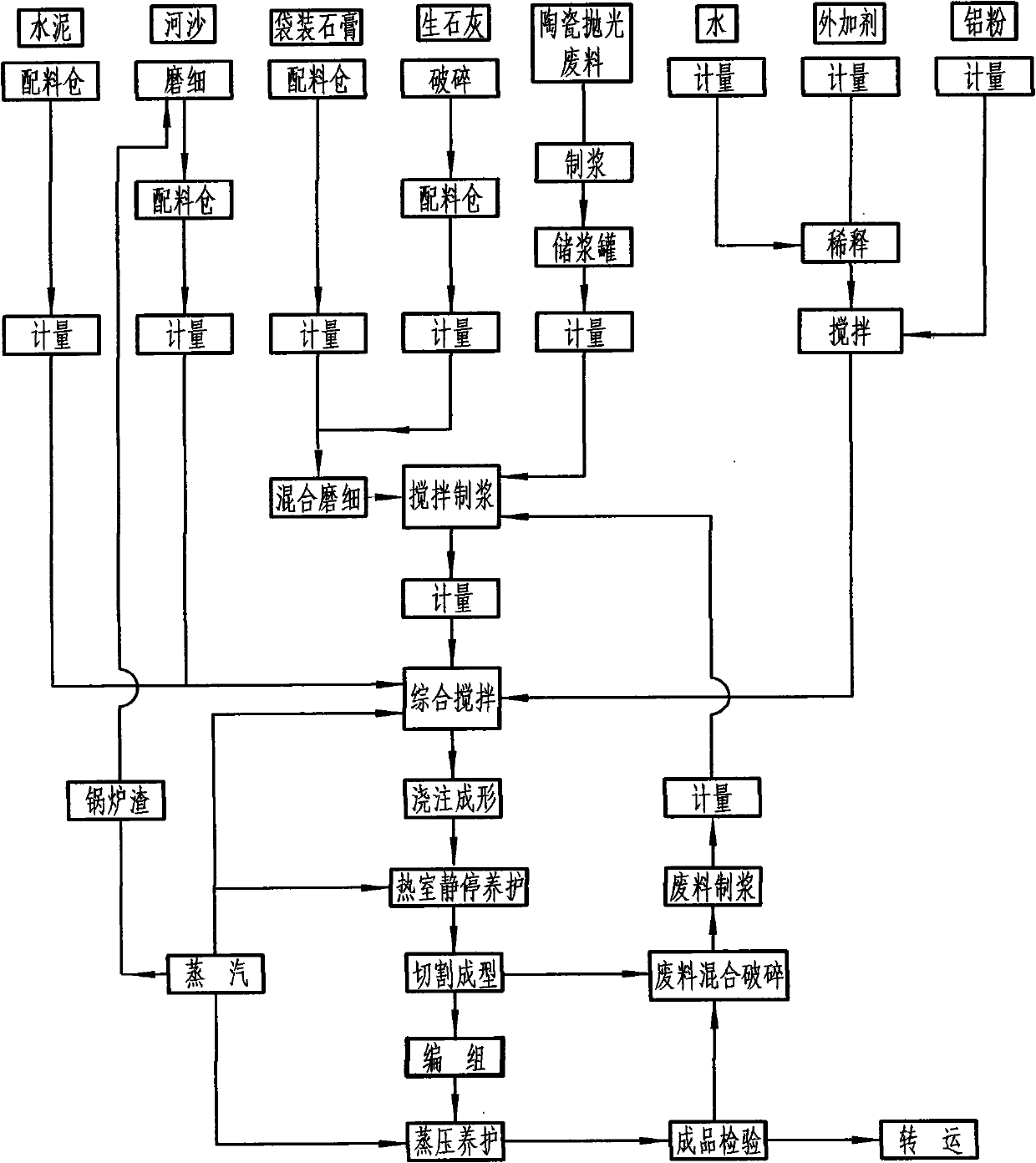

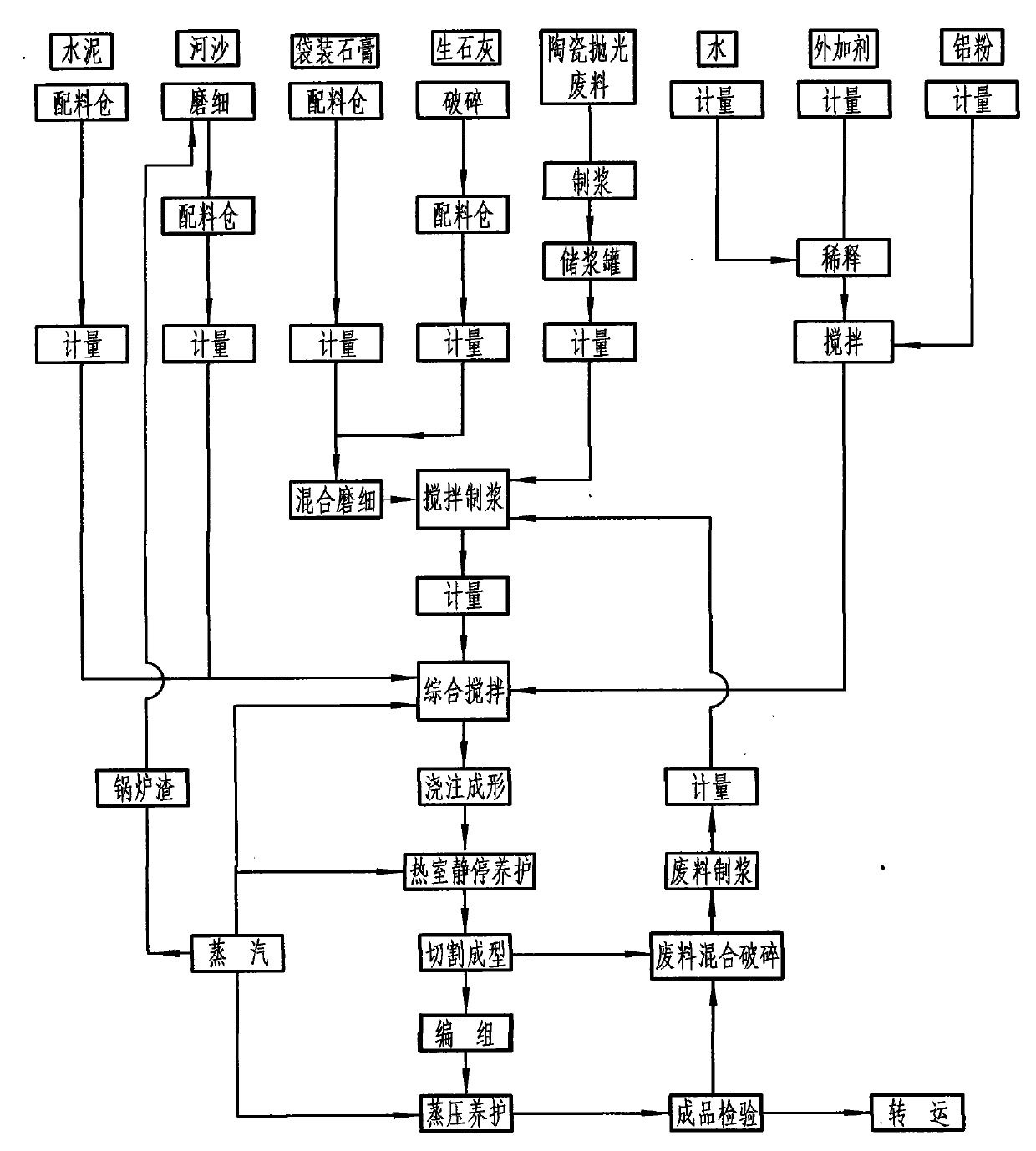

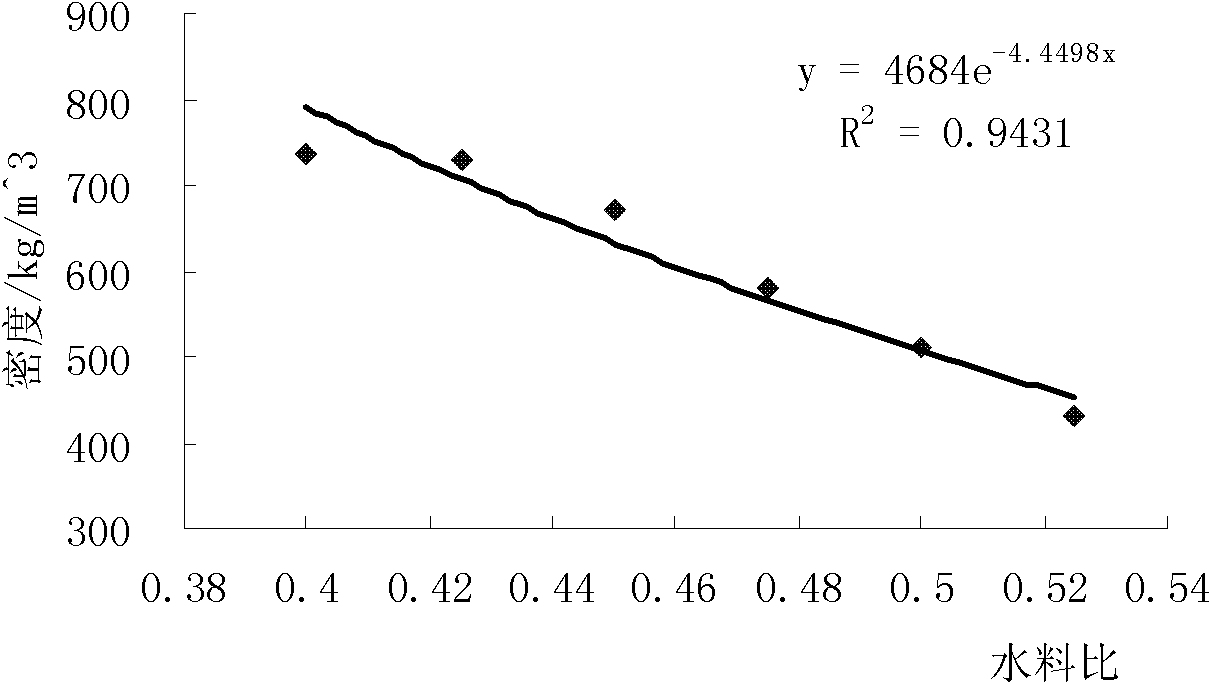

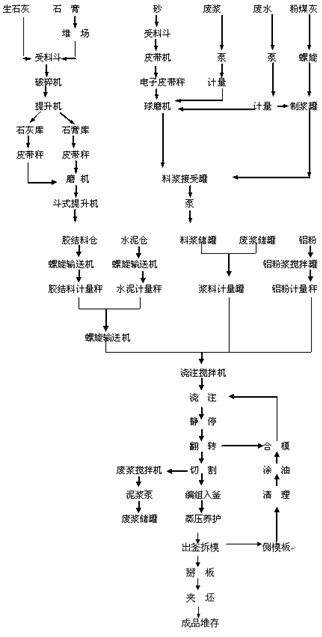

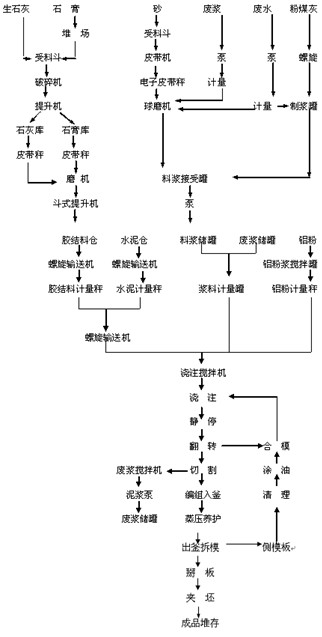

Autoclaved aerated concrete building block and preparation method thereof

The invention discloses an autoclaved aerated concrete building block, which is prepared by adding water into 50 to 55 weight parts of ceramic polishing waste, 10 to 15 weight parts of fine sand, 20 to 24 weight parts of calcined lime, 10 to 20 weight parts of cement, 0.05 to 0.09 weight part of aluminum powder and 3 to 5 weight parts of gypsum. The invention also discloses a preparation method for the autoclaved aerated concrete building block, which comprises the production processes of raw material fetching, slurry preparation, proportioning and pouring, standing and curing in a hot chamber, blank cutting, grouping, autoclaved maintenance, finished product inspection, recycle of waste liquid, waste slag and waste products and the like. The obtained autoclaved aerated concrete building block has the characteristics of high forming speed, light weight, high strength, heat insulation, sound insulation, good fireproof performance, low elasticity, seismic resistance, convenient construction and the like. The preparation method realizes utilization of the ceramic polishing waste, reduces the discharge of wastes of the ceramic industry, and is favorable for protection of ecological environment.

Owner:周石镭 +3

Process for preparing sludge autoclaved aerated concrete building block

InactiveCN101850574AHigh porosityMeet production requirementsSludge treatment by de-watering/drying/thickeningSolid waste managementBrickSludge

The invention belongs to the technical field of environmental engineering, and particularly relates to a process for preparing a sludge autoclaved aerated concrete building block. The process mainly comprises the following steps of: (1) quickly stirring and mixing spare dried sludge, water and lime, coal ash, cement, gypsum and aluminum powder with physical and chemical properties meeting the brick making requirements in a certain ratio and in turn; (2) feeding the mixture obtained in the step (1) into a die, and putting the die into a thermostatic curing box of 40 DEG C or 60 DEG C to perform foaming and curing for 4 hours; (3) putting the blank foamed and cured in the step (2) into an autoclave, and curing the blank for over 8 hours by adopting a stepwise buck-boost curing mode; and (4) piling the product discharged from the autoclave outdoors for over 2 days. The process can reach hazard-free and recycling treatment of urban sludge, save clay resources and save the brick making cost, and has remarkable economic, social and environmental benefits.

Owner:HUNAN UNIV OF SCI & TECH

Haydite autoclaved aerated concrete and production method

InactiveCN101497517AImprove featuresLight weightSolid waste managementCeramic shaping apparatusSlagExpanded clay aggregate

The invention discloses a ceramsite autoclaved aerated concrete and a production method. The concrete consists of ceramsite, coal ash, sand, quartz tailing powder or silicon slag, lime, cement, gypsum, aluminum powder or aluminum paste powder, and admixture. The production method comprises the steps of measuring raw materials, blending and stirring, pouring and feeding a die, generating gas by static electricity, mold stripping, autoclaving, mechanical cutting and the like. The concrete has precise dimension and good performance.

Autoclaved aerated concrete building block and manufacturing method thereof

InactiveCN101172819AHigh strengthSolid waste managementCeramicwareAluminium powderUltimate tensile strength

The invention relates to an autoclaved aerated concrete block and the manufacturing method thereof. According to the weight share, the autoclaved aerated concrete block contains the main raw materials as follows: 65 to 70 parts of fly ash, 18 to 22 parts of lime, 6 to 9 parts of cement, 2.5 to 3.5 parts of gypsum, 7 to 805 parts of aluminium powder and 64 to 70 parts of water, wherein, the fly ash is dry powder fly ash. The manufacturing method of the autoclaved aerated concrete block includes the following steps: putting the materials for mixing, teeming, stopping to conserve, cutting and then autoclaving, then the finished product is obtained, wherein, autoclaving is processed in an autoclave, and the autoclaving is divided into the steps of vacuumizing, pressurizing, stabilizing the pressure and releasing the pressure. The autoclaved aerated concrete block adopting the manufacturing method above has high strength and can completely replace the solid clay brick to be used in the places which have high strength requirements for walling material, such as external wall bearing wall, etc.

Owner:SUZHOU JINTONG NEW TYPE BUILDING MATERIAL

Autoclaved aerated concrete block and manufacturing method thereof

InactiveCN103964774ALow costEasy constructionSolid waste managementCeramicwareFoaming agentUltimate tensile strength

The invention relates to an autoclaved aerated concrete block and a manufacturing method thereof, belongs to the technical field of building materials, and aims at solving the problems of high manufacturing cost and poor quality of products of the autoclaved aerated concrete block in the prior art. The autoclaved aerated concrete block comprises main materials, water and a foaming agent; the main materials include the following components (in percentage by weight): 65%-75% of tailing sand, 8%-12% of quick lime, 15%-18% of cement, and 2%-5% of gypsum; the material-to-water ratio ranges from 0.57 to 0.62; the foaming agent is added proportionally by 500g / m3 according to the total volume of the materials. The autoclaved aerated concrete block has the advantages of low manufacturing cost, convenient construction, environmental protection and energy conservation; the block further has the advantages of low weight, high heat retaining property, high anti-permeability, good fireproof performance, good sound insulation and sound absorption properties, accurate size, high strength and no radioactivity.

Owner:SHENGZHOU SIMINGSHAN NEW BUILDING MATERIAL CO LTD

Autoclaved aerated concrete block and manufacturing process thereof

InactiveCN103964781ASolve fair useAvoid influenceSolid waste managementEcological environmentPhosphate

The invention provides an autoclaved aerated concrete block and a manufacturing process thereof. The autoclaved aerated concrete block comprises the following raw materials by weight parts: 60-70 parts of coal ash (sand), 15-20 parts of lime, 5-10 parts of cement, 2-4 parts of gypsum and 5-8 parts of wastes, wherein aluminum powder accounts for 0.075% of the total weight of dry materials, and the water-material ratio is 0.6-0.65. The manufacturing process comprises the following steps: storing and processing the raw materials; dosing, stirring, and pouring; standing, cutting, and grouping; autoclaving to obtain a finished product of the autoclaved aerated concrete block. According to the process, industrial solid wastes-phosphogypsum are used as the raw materials, wastewater and leftover materials discharged in a production process are recycled, the produced aerated concrete block completely meets the national standards, the influence on the aerated concrete block caused by phosphate impurities in the phosphogypsum is avoided, the problems of reasonable utilization of the leftover materials and waste slurry are solved, the industrial solid wastes are treated and turn into wealth, the ecological environment is protected, and the novel process is energy-saving and environment-friendly.

Owner:FUZHOU HENGSHUN ENVIRONMENTAL PROTECTION BUILDINGMATERIALS CO LTD

Autoclaved aerated concrete block made of gold tailings and its production process

InactiveCN1631836AKeep healthyTake advantage ofSolid waste managementSlagAutoclaved aerated concrete

The invention relates to gold tail mine concrete block and its productive technique, which belongs to wall material for building and productive technical field. Its characteristics is that the main raw material for making concrete block includes slag, cement, burnt lime, aluminum powder and water, and their mess ratio is: slag 60~70%, cement-6~10%, burnt lime-20~30% aluminum powder -0.01~0.05% and the water content can be changed according to the requirement of gold tail slime density. The invention can reach the purposes of environmental protection, energy saving, using the waste, increasing the building's quality and assuring people's health, it can use waste slag completely, with good resistance to coldness and without radioactive harm, can be compound with mortar so that solve the problem of wall surface falling down.

Owner:QIXIA HONGJIAN NOVEL BUILDING MATERIAL

Autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and preparation method thereof

InactiveCN103193447AStable compressive strength"Light weightSolid waste managementCeramicwareBrickAluminium powder

The invention provides an autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and a preparation method thereof. The brick is prepared from the following materials by weight percent: 65%-68% of pulverized fuel ash, 17%-23% of lime, 6%-10% of cement, 2%-4% of desulfurization gypsum, 1%-1.5% of water-soluble aluminum powder, 0.5% of fatty acid soap and 0.5% of gleditsia sinensis powder. The preparation method comprises steps of: adding water to pulverized fuel ash and desulfurization gypsum which are screened mechanically and grinding together to form slurry, wherein the fineness of the pulverized fuel ash has to reach the condition that the residual of a 0.08mm square hoe sieve is not more than 15%; carrying out stirring, pouring, cutting and thermal, static and suspension curing on the slurry together with the lime, the cement and the aluminum powder suspension liquid which are weighed according to a weight ratio of a formula; utilizing an autoclave with good sealing for heating with 180-200 DEG C saturated steam under proper pressure (1.0-1.2Mpa); and steam curing for 8-10 hours so as to produce the aerated concrete brick. The aerated concrete brick has the characteristics of light weight, high strength, good heat insulation performance, good fire resistance and sound absorption, labor saving and energy saving, waste recycling and the like; and the aerated concrete brick meets constructional engineering requirements and environment protection requirements, and the wastes of enterprises are reasonably used.

Owner:SHIYAN JINSHA WALL MATERIALS

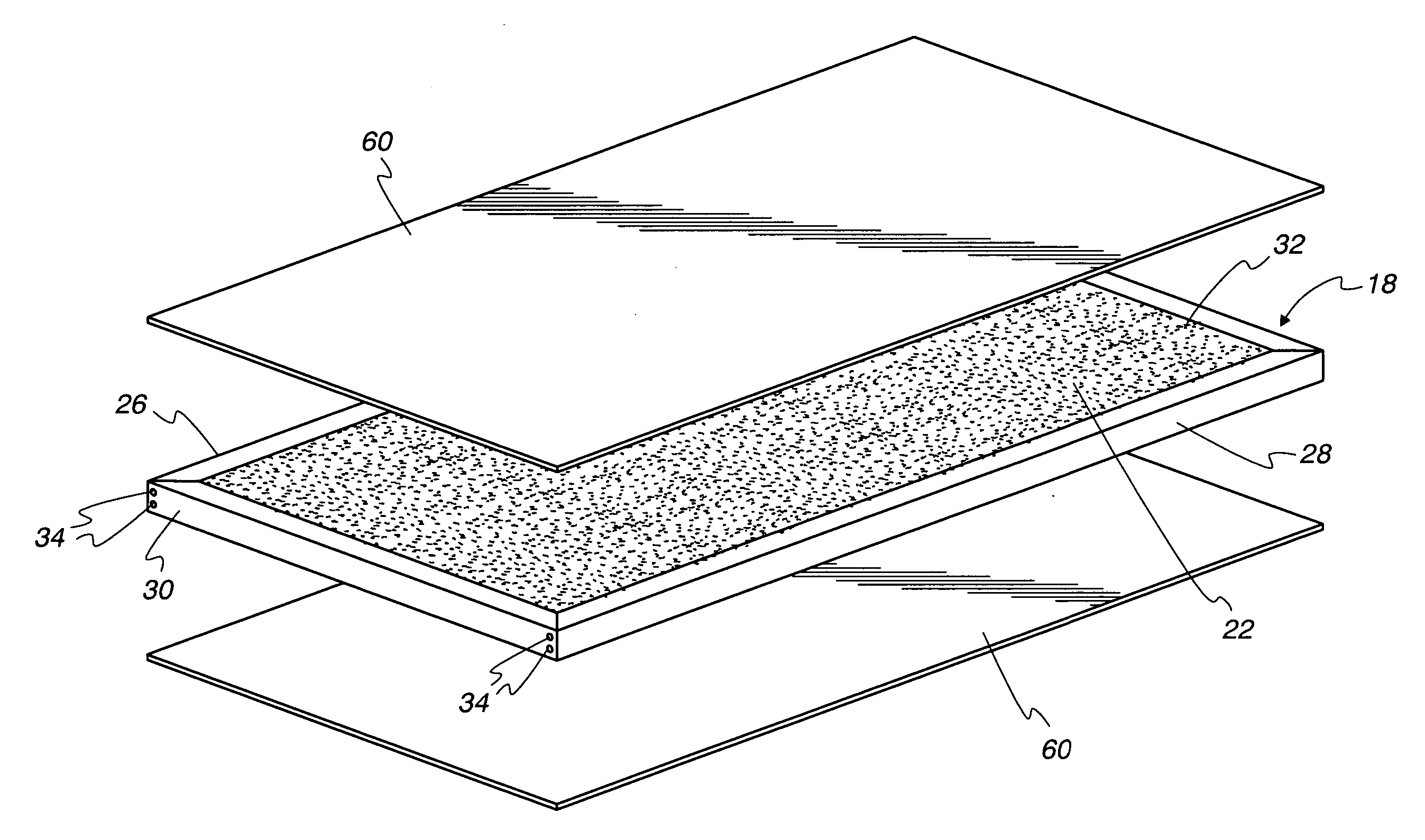

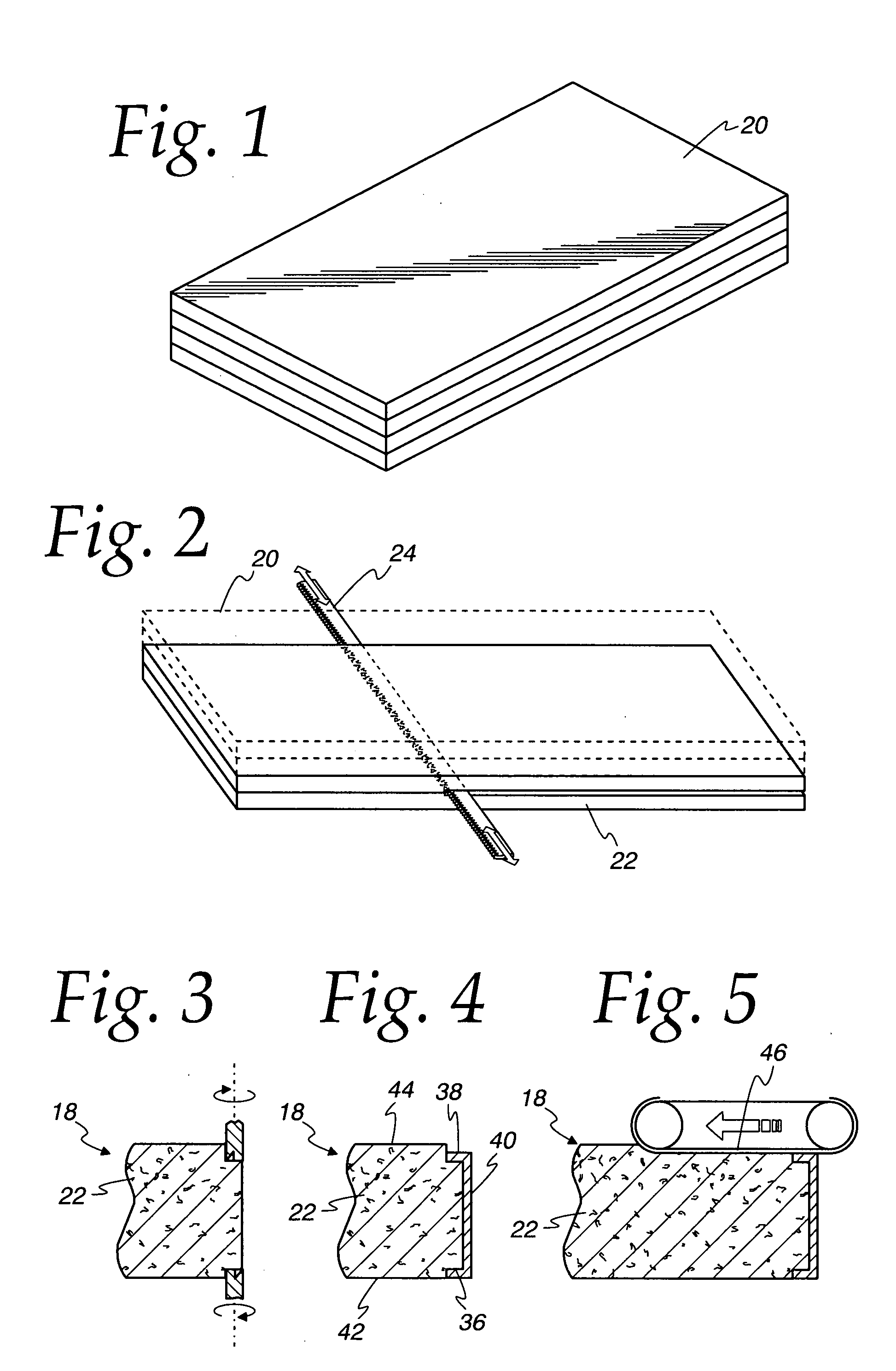

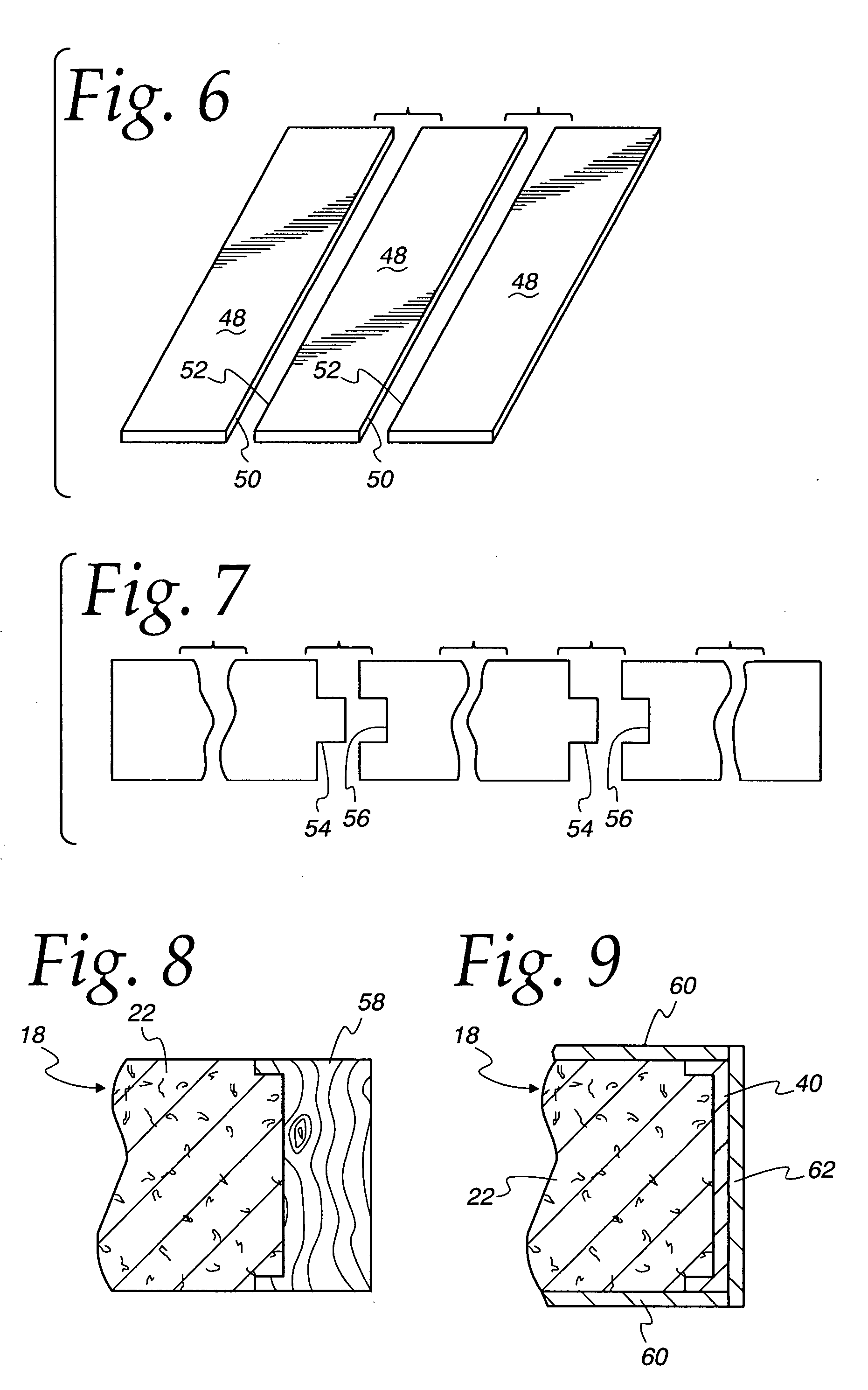

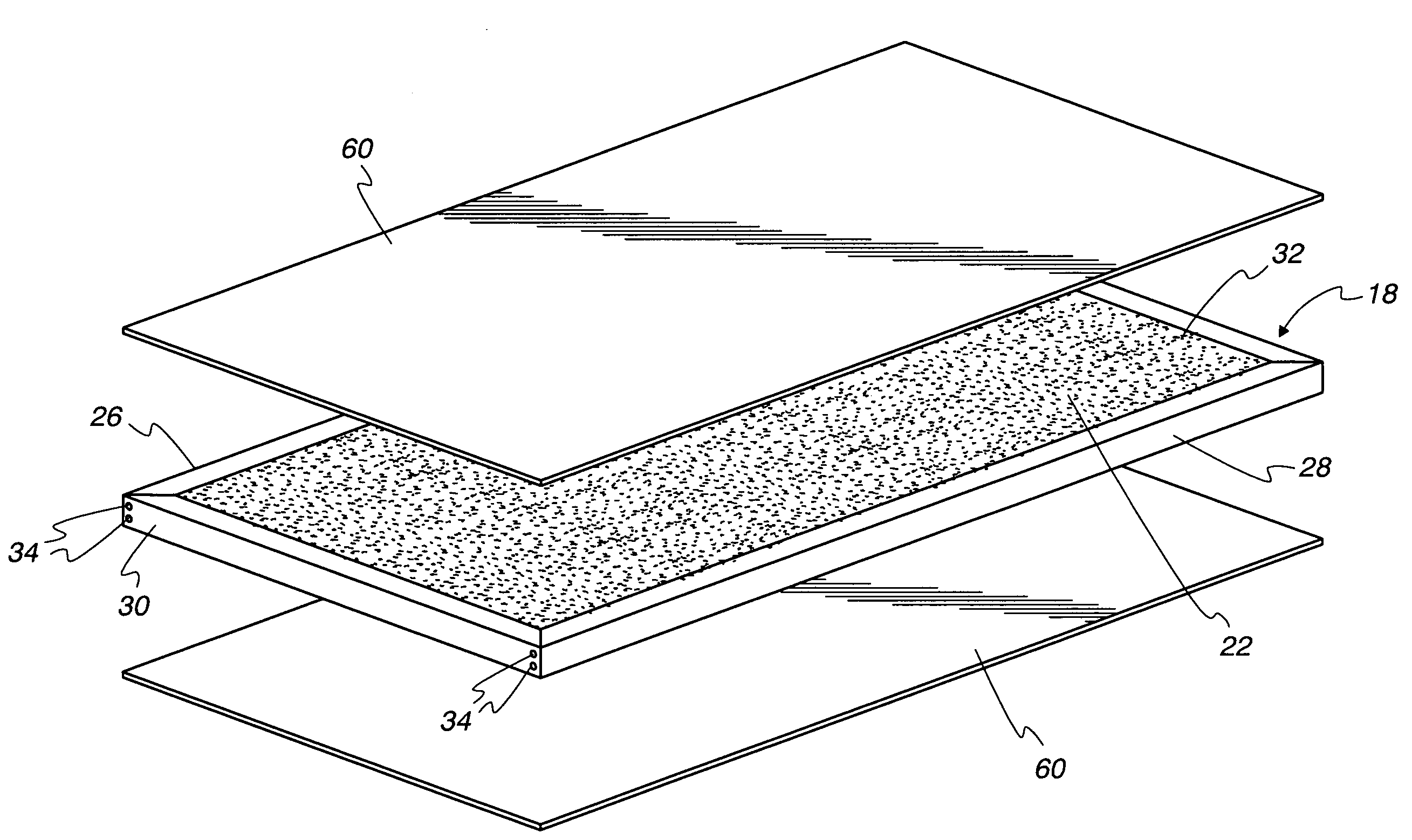

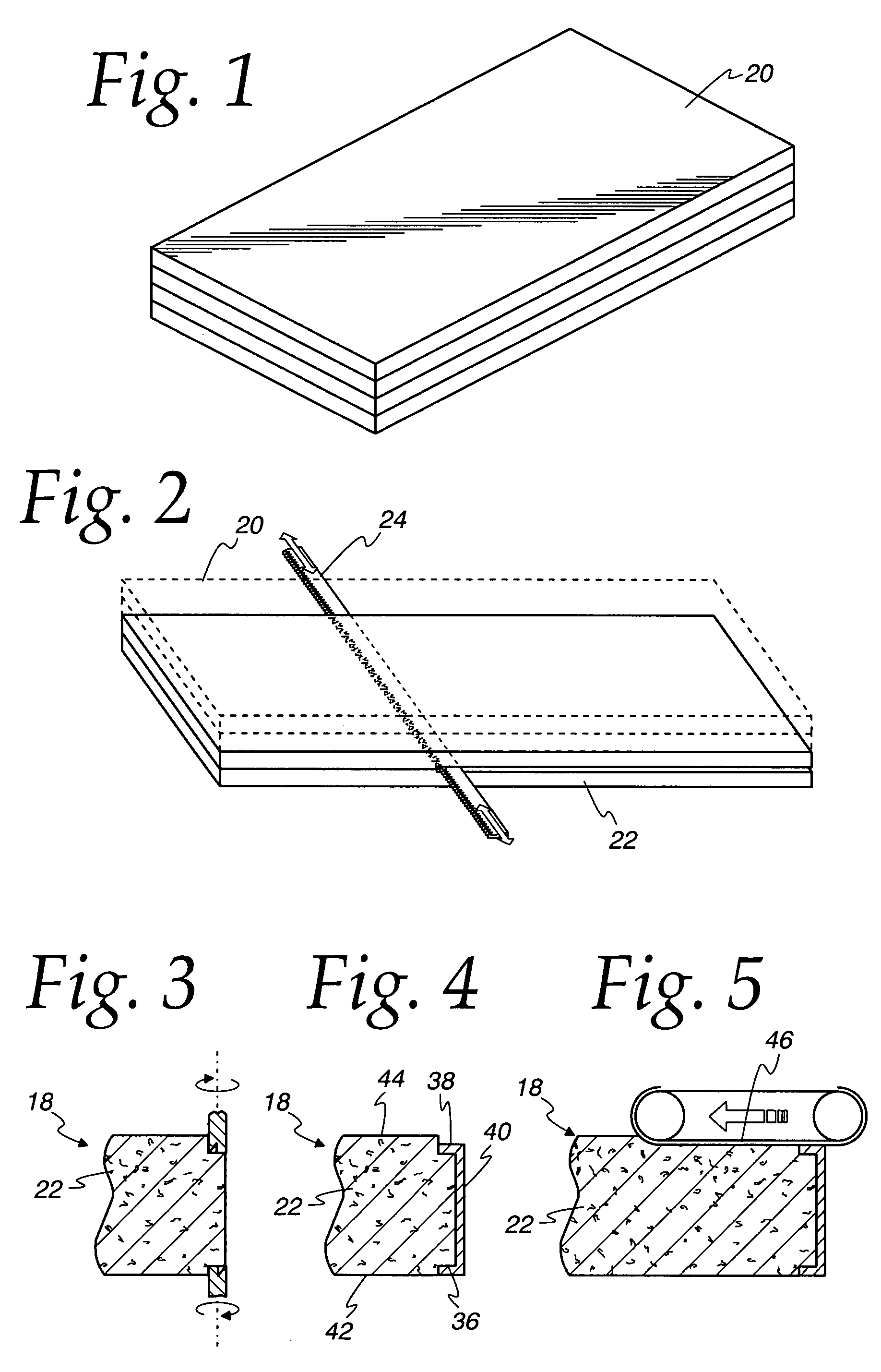

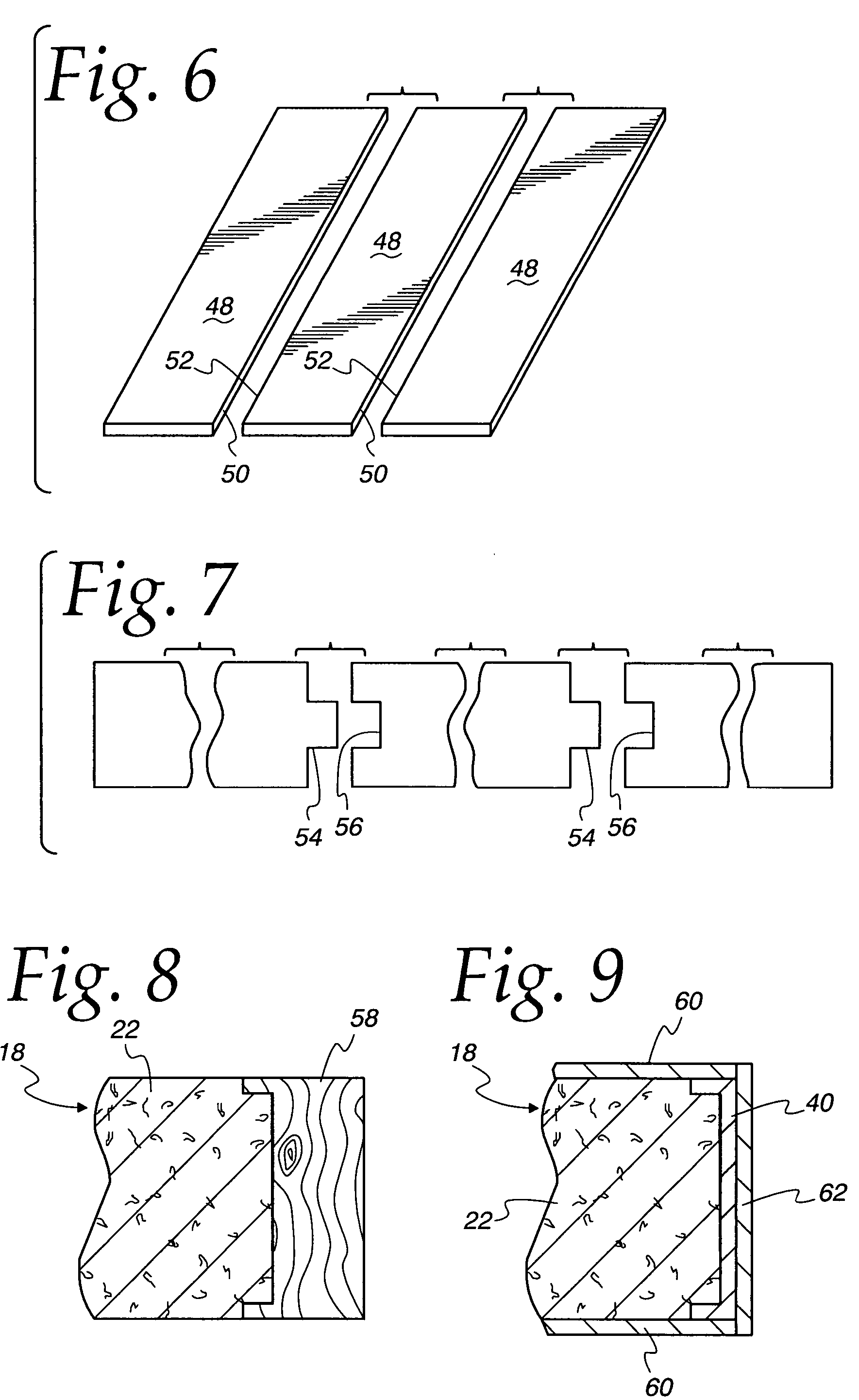

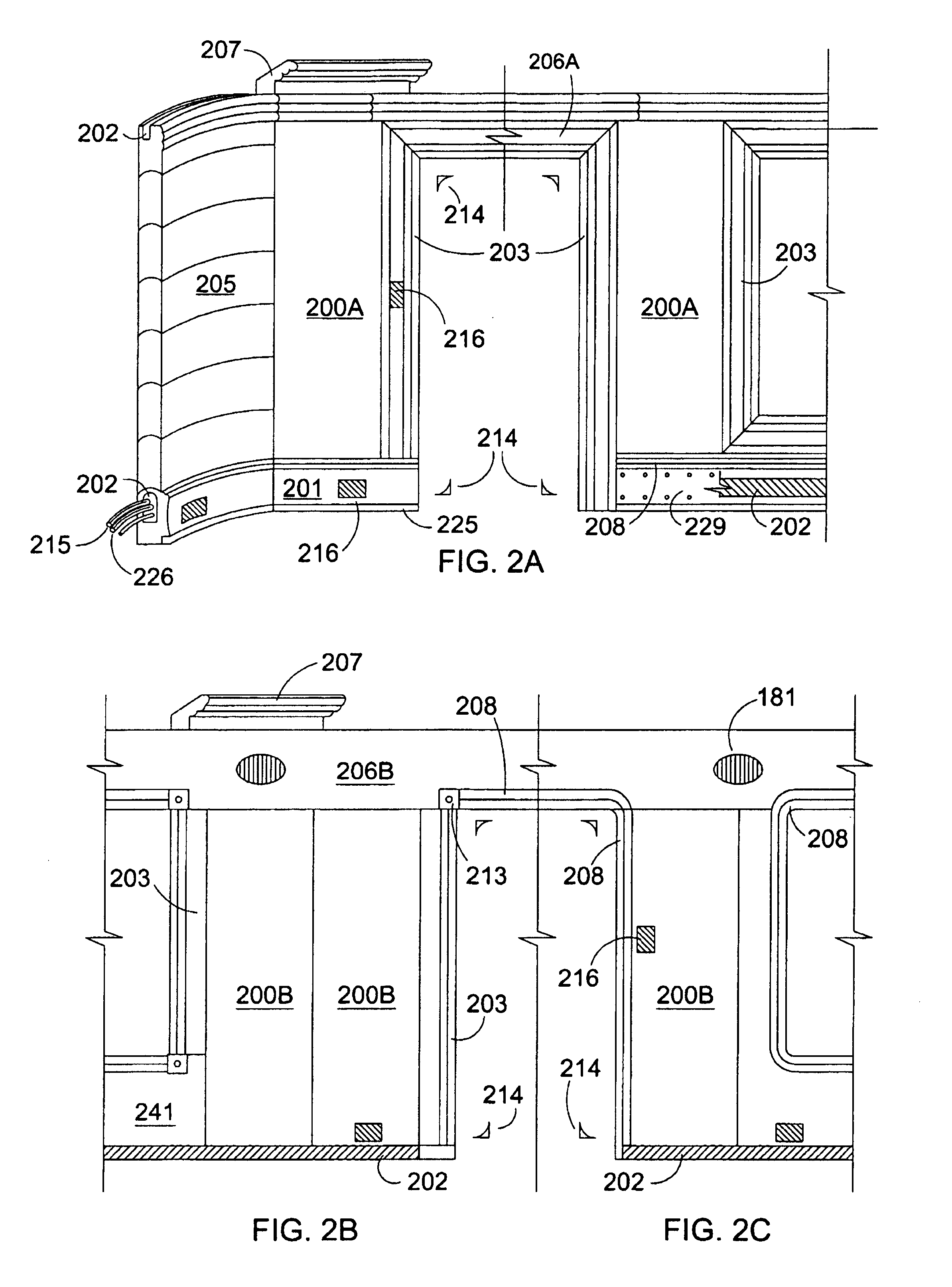

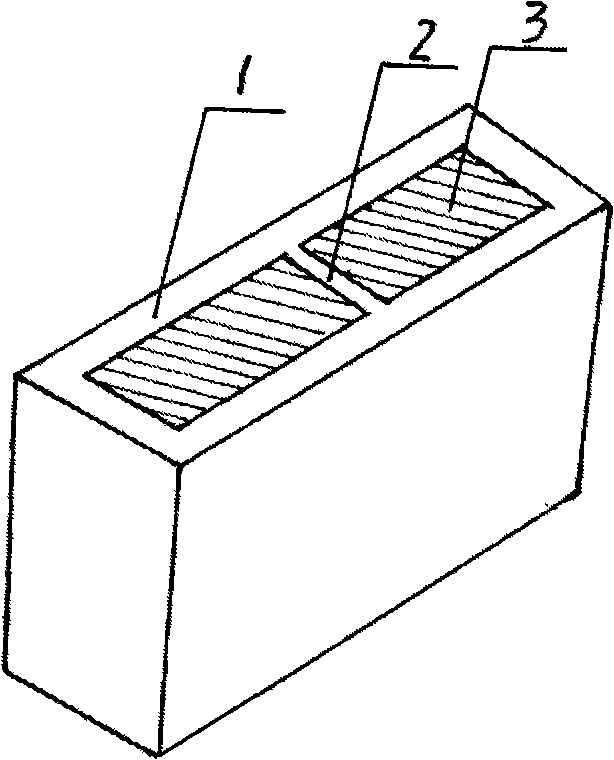

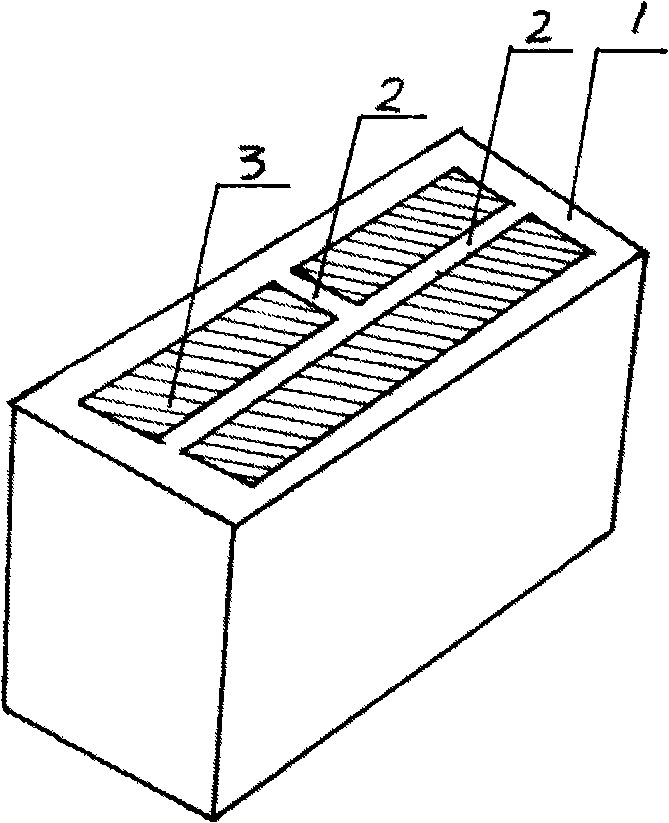

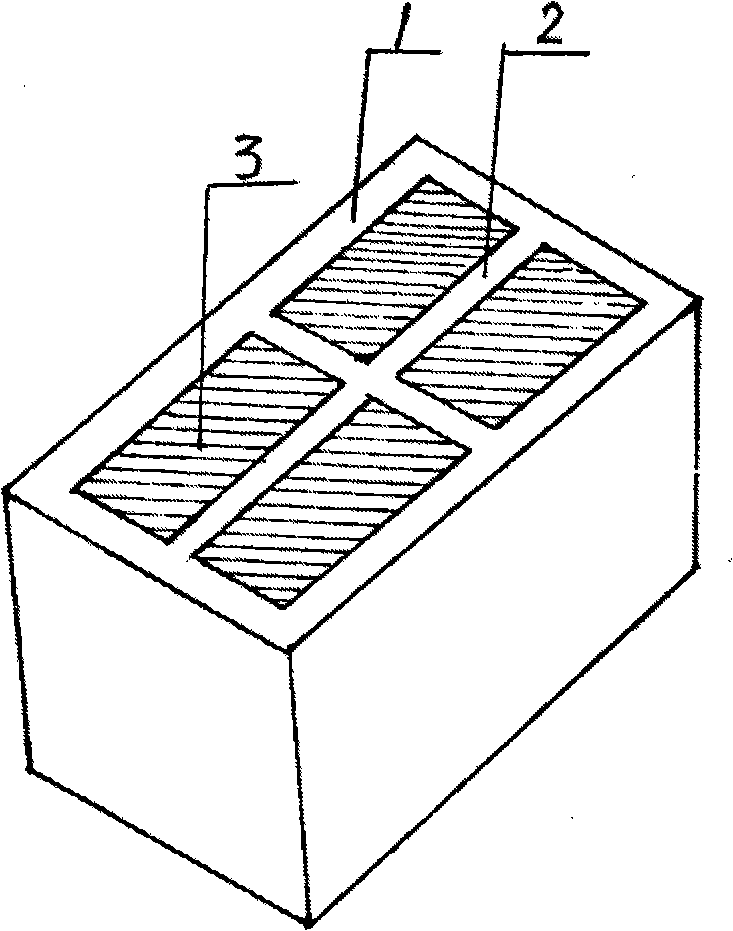

Composite door, door core and method of manufacture

InactiveUS20080016820A1Eliminate needLamination ancillary operationsFireproof doorsEngineeringAutoclaved aerated concrete

A method for making the core of a door of autoclaved aerated concrete (AAC). A billet of AAC is provided from which slabs are cut to the approximate dimensions of the door core. A reinforcing band is secured about the perimeter of a slab or a pair of slabs sandwiching a reinforcing panel. The thickness of the slab, or the pair of slabs and reinforcing panel, is then sized for the door core as by sanding. The door is finished by applying skins to the core surfaces and trim to the reinforcing band.

Owner:INNO TECH PLASTICS

Composite door, door core and method of manufacture

InactiveUS7617606B2Eliminate needLamination ancillary operationsMetal-working apparatusEngineeringAutoclaved aerated concrete

A method for making the core of a door of autoclaved aerated concrete (AAC). A billet of AAC is provided from which slabs are cut to the approximate dimensions of the door core. A reinforcing band is secured about the perimeter of a slab or a pair of slabs sandwiching a reinforcing panel. The thickness of the slab, or the pair of slabs and reinforcing panel, is then sized for the door core as by sanding. The door is finished by applying skins to the core surfaces and trim to the reinforcing band.

Owner:INNO TECH PLASTICS

Autoclaved aeolian sand aerated concrete building block and wallboard

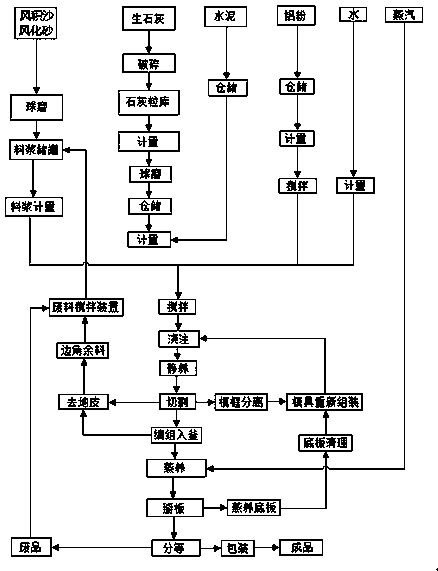

The invention provides an autoclaved aeolian sand aerated concrete building block and wallboard which are prepared by the following method: performing ball milling on aeolian sand or weathered sand to obtain slurry with the mass percentage concentration of 50 to 70%; crushing quick lime, grinding into quick lime powder; mixing aluminum powder; according to mass percentage, respectively taking cement, the slurry and the quick lime powder for mixing into a base material, proportionally adding the aluminum powder and gypsum, and stirring evenly to obtain finished product slurry; according to an autoclaved aerated concrete building block production process in the prior art, pouring, curing and cutting to form a green body or a workblank, removing wastes on the green body or the workblank, grouping into a reactor; performing autoclaving and maintaining and other processes, and packaging qualified products to obtain the autoclaved aeolian sand aerated concrete building block or wallboard; collecting produced waste to prepare waste slurry; and adding the waste slurry into the finished product slurry for using again. The concrete building block and wallboard can be prepared into building and environmental protection materials with good performances by comprehensive utilization of the aeolian sand and the weathered sand, and the river sand and ore sand collection and waste of resources can be reduced.

Owner:JINGTAI FUHAI SUNSHINE BUILDING MATERIAL

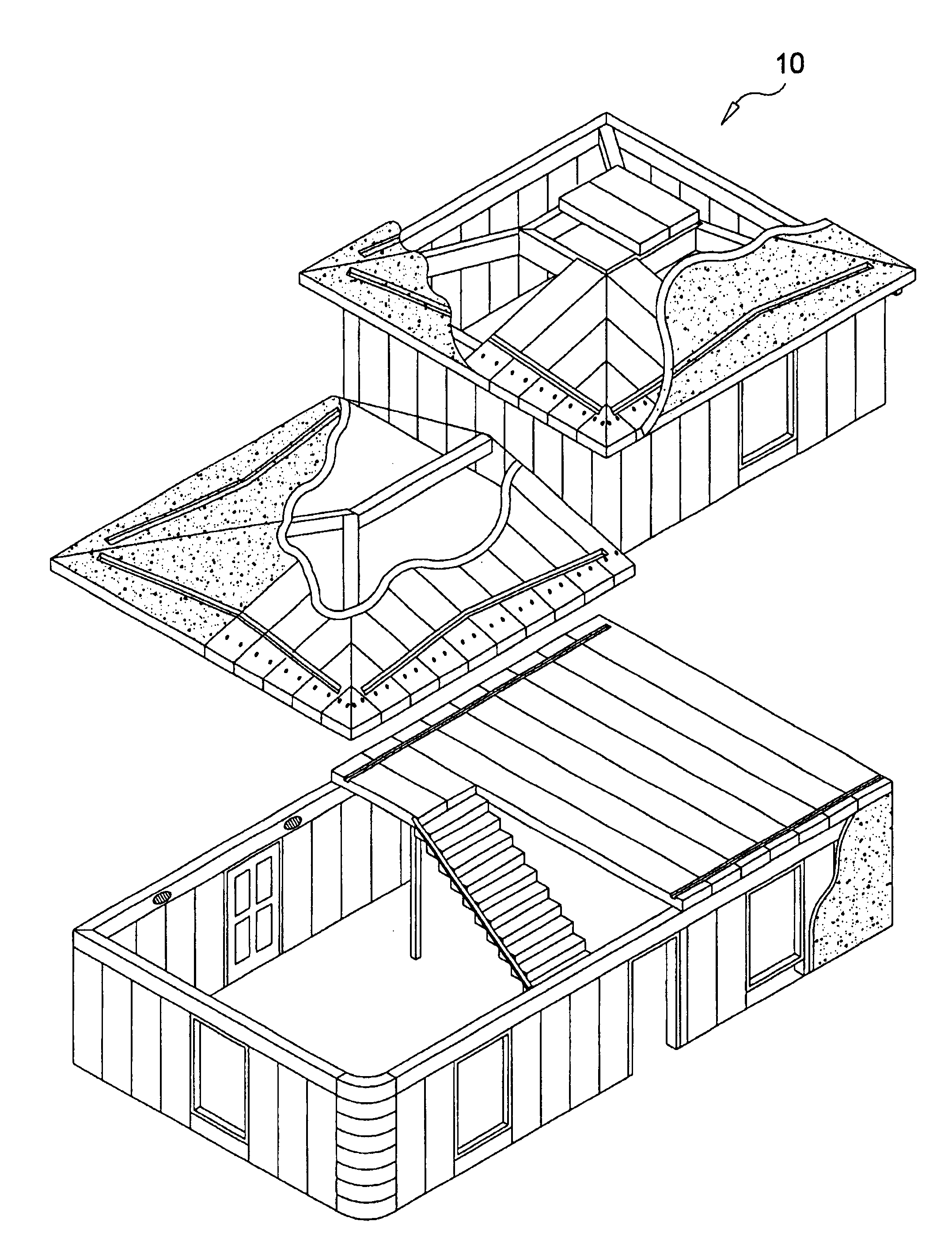

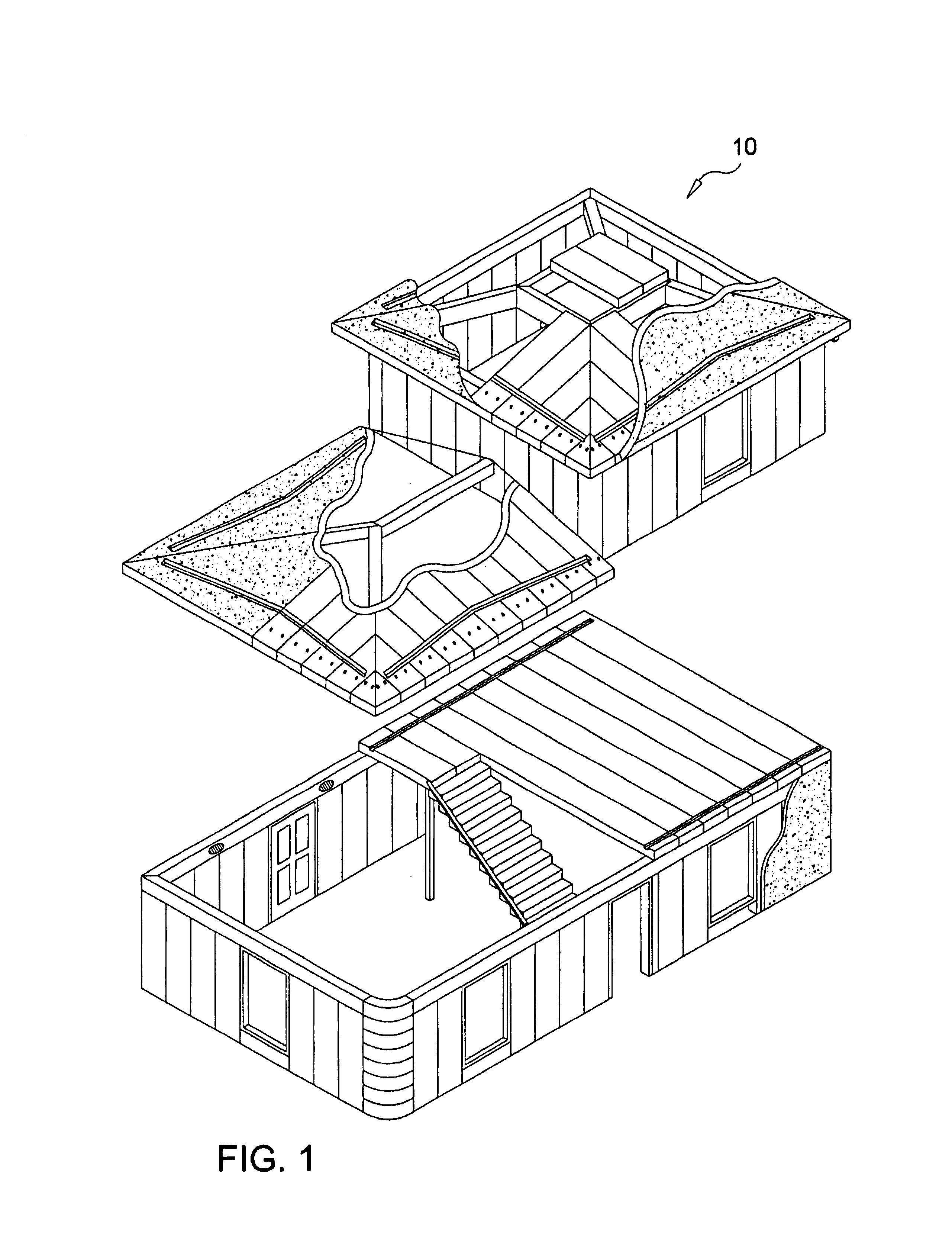

System for manufacturing structures of cementitious materials

InactiveUS7204060B2Overcome problemsBuilding roofsSolar heating energyHigh pressureAutoclaved aerated concrete

Owner:HUNT CHRISTOPHER M

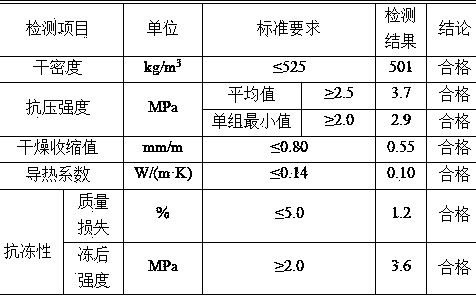

Self-heat-insulating fly ash autoclaved aerated concrete block and preparation method thereof

The invention relates to a self-heat-insulating fly ash autoclaved aerated concrete block which comprises the following components in parts by weight: 1400-2200kg of fly ash, 330-400kg of cement, 390-550kg of quicklime, 100-200kg of white lime, 50-100kg of desulfurized gypsum, 255-420kg of block waste, 2.15-2.90kg of aluminum powder paste and 0.20-0.50kg of foam stabilizer. According to the invention, the fly ash, desulfurized gypsum and excessive cut waste from a power plant are fully utilized, and meanwhile, the Level B04, Level B05, Level B06 and Level B07 self-heat-insulating fly ash aerated concrete blocks can be prepared. The block products contain a large amount of micro and macro pores, and are uniform in pore size, low in heat conductivity coefficient and favorable in self-heat-insulating property.

Owner:HENAN XIAN NEW BUILDING MATERIALS

Process for preparing vapour pressure air-entrained concrete light heat-insulation fireproof bricks by gold tailings

The invention relates to a firebrick preparation method, in particular to a method of preparing an autoclaved aerated concrete light heat insulating firebrick with gold tailings. The invention takes the gold tailings as the main raw material which is made by a pre-activating treatment, then a certain amount of cement, lime, foam stabilizer of nekal bx or soap pod powder and aluminum power paste are added, and then plaster and self-made compound admixtures are added to prepare into sizing agent. The later preparing procedures are as follows: pour mold for gas-forming and stilling, dry heat pre-curing, cutting and stacking, being steamed in a caldron and being taken out of the caldron, and finally the firebrick is formed. The firebrick is put into the caldron to steam for 5 to 7 hours under constant voltage; the steam pressure is 1.1 to 1.5 MPa, the temperature is from 185 DEG C to 195 DEG C. The firebricks prepared by the method have good effect of heat insulation in stove owing to low coefficient of heat conductivity, thereby being used in the low temperature section of ceramics kiln collapses, tunnels, resistance furnace and being capable of realizing energy saving. The firebricks prepared by the method also have the advantage of being light owing to the volume and density being less than those of the majority of light heat insulating firebricks.

Owner:福建省万旗非金属材料有限公司

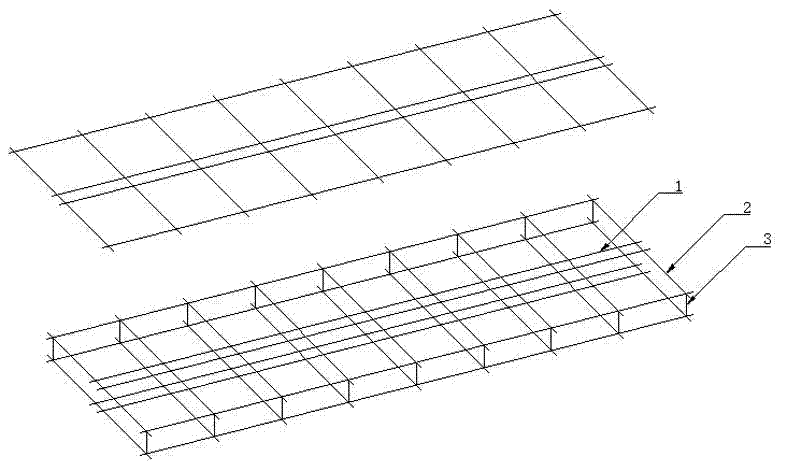

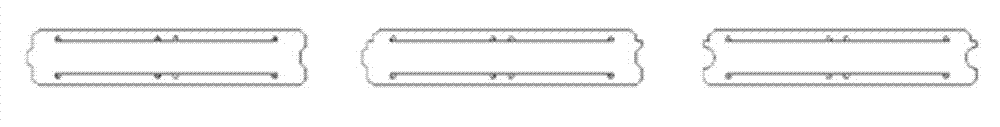

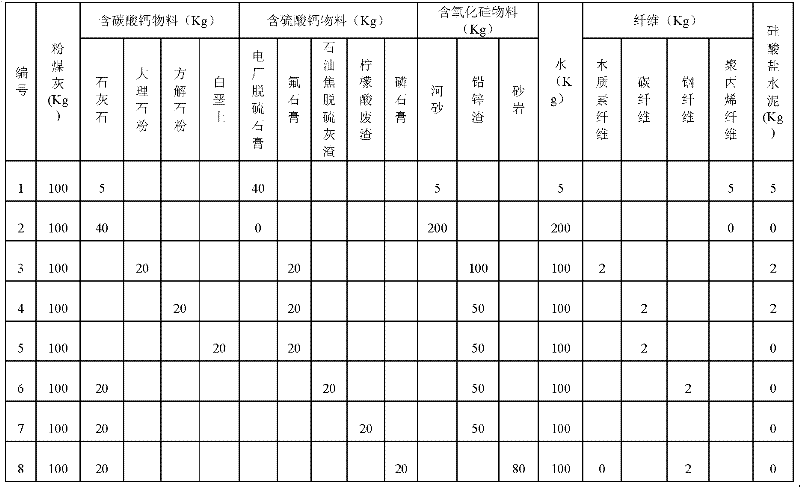

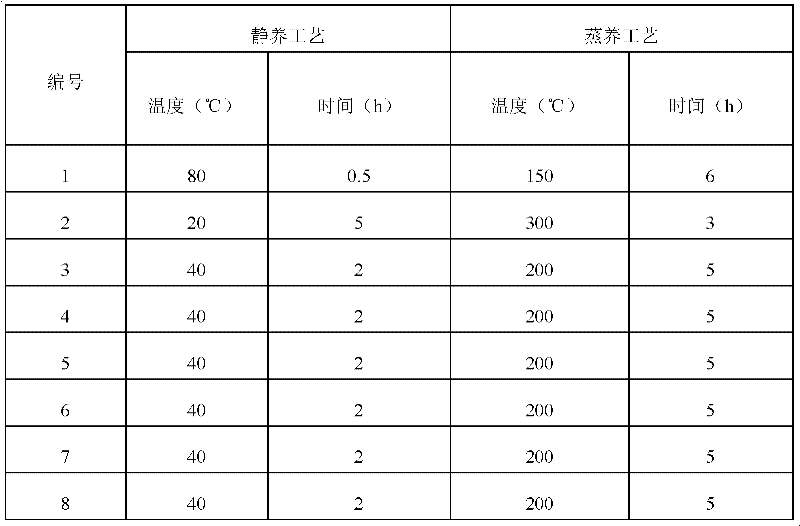

Light-weight autoclaved aerated concrete and preparation process thereof

ActiveCN104557107AImprove shrinkageImprovement in compressive strengthCeramicwareFiberShrinkage rate

The invention relates to a novel building material, and particularly relates to a light-weight autoclaved aerated concrete and a preparation process thereof. The autoclaved aerated concrete is prepared by adding a certain proportion of inorganic fiber into quartz sand, lime, cement, gypsum and aluminum powder paste as the main materials. Through adjusting the corresponding preparation process, not only is the low density of the product ensured, but also the material shrinkage rate and compressive strength are greatly improved, the defects of low strength, large shrinkage and easy cracking of the autoclaved aerated concrete are solved, and the light-weight autoclaved aerated concrete and the preparation process thereof can be widely popularized and used.

Owner:山东京博环保材料有限公司

Autoclaved aerated concrete and preparation method thereof

The invention discloses an autoclaved aerated concrete and a preparation method thereof, and the autoclaved aerated concrete comprises mineral raw materials, an alkaline exciting agent, a foaming agent, a foam-stabilizing agent, a slow-release agent and the like. The mineral raw materials comprise 80-100wt.% of fly ash, and other mineral raw materials comprise mineral waste residue, metakaolin, silica fume, steel slag, circulating fluidized bed bottom ash and the like; the alkaline exciting agent mass is 40-55wt.% of the mineral raw material mass, the foaming agent mass is 0.13-5wt.% of the mineral raw material mass, the foam-stabilizing agent mass is 0.03-0.09wt.% the mineral raw material mass, and the slow-release agent mass is 2-3.5wt.% of the mineral raw material mass. The alkaline exciting agent including sodium silicate and NaOH / KOH, the mineral raw materials, the foaming agent and the foam-stabilizing agent are mixed for stirring, then are filled in a mould for prefabrication forming or casting forming, and maintained by autoclaving for 1-24h at 60-160 DEG C under 0.1-1MPa.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

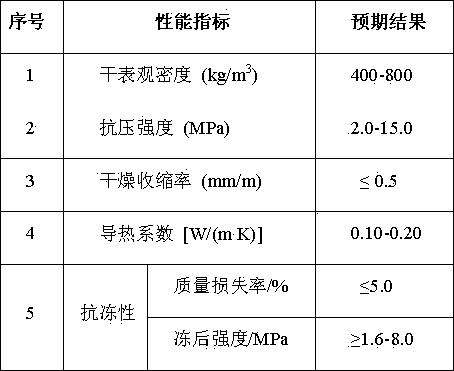

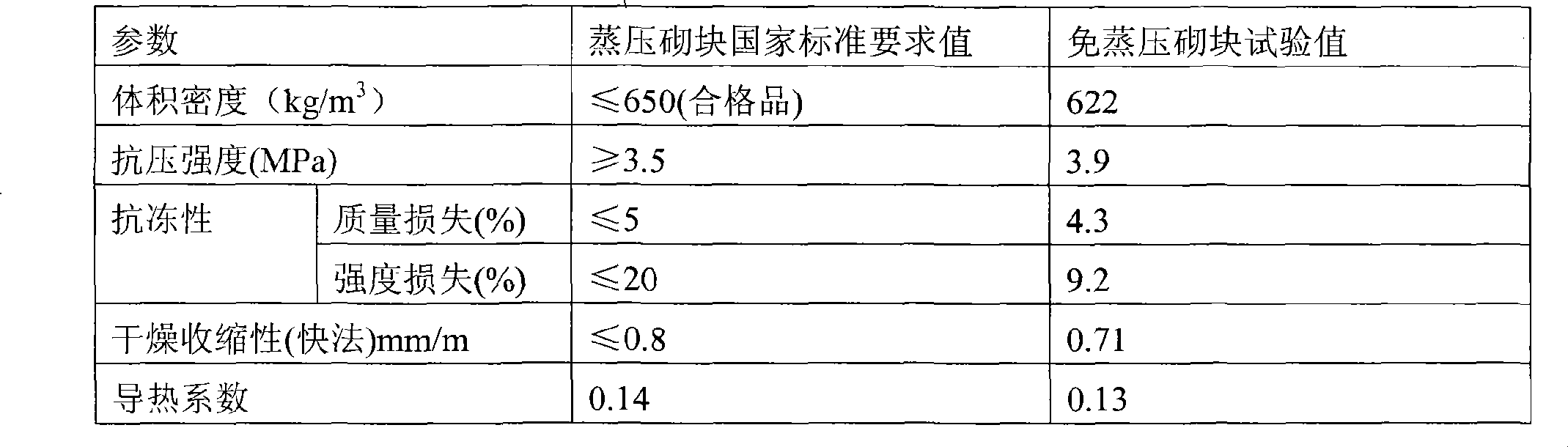

Preparation of 06 grade gypsum based autoclave-free aerated concrete building blocks

InactiveCN101439955AIncrease profitLess investmentSolid waste managementCeramic shaping apparatusThermal insulationSlurry

The invention relates to a method for preparing an aerated concrete block, in particular to the method for preparing a 06-grade gypsum based vapor pressure free aerated concrete block, which is characterized in that that the method comprises the following steps: 1) preparing raw materials; 2) selecting the raw materials; 3) preparing composite gelled materials; 4) dissolving retarder sodium citrate in water which accounts for 1 / 5 to 2 / 5 of the total amount, stirring the mixture and immediately adding the mixture to the composite gelled material, and stirring the mixture for 2 minutes to obtain liquid slurry; 5) adding a mixture of air-entraining agent aluminum powder and degreaser honeylocust fruit powder to the remaining water to be stirred into a suspension which is then immediately added to the liquid slurry, and stirring the mixture for 3 minutes to obtain mixed slurry; 6) pouring the mixed slurry into a test mold, and performing cutting and demolding after 6 to 8 hours of natural curing to obtain a blank body; and 7) performing damp heat curing on the blank body for 24 hours, and then drying and dehydrating the blank body naturally to obtain the finished product. The method has the advantages of simple process, low cost and high utilization rate of desulfurization construction gypsum; and the finished product has the characteristics of light weight, thermal insulation, sound absorption and insulation, vibration resistance and fire prevention, conditioning treatment, good water resistance, small dry-wet shrinkage, and stable performance.

Owner:中博建设工程集团有限公司 +1

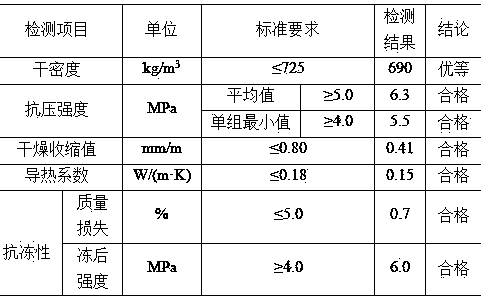

Steam-press air-entrainment concrete self-heat conserving building block by using sand of Yellow River and preparation method

The invention relates to a steam-press air-entrainment concrete self-heat conserving building block by using sand of Yellow River, which comprises the Yellow River sand and waste fly ash after the coal is burned in a power plant; the concrete self-heat conserving building block comprises the following components by weight percentage: 55-63% of the Yellow River sand, 5-16% of fly ash, 12.5-15% of quicklime, 2.5-3.0% of slaked lime, 1.0-2.0% of desulfurized gypsum, 0.08-0.12% of aluminum powder paste, 0.02-0.04% of foam stabilizer and the balance of cement. The building block takes the cheap Yellow River sand as a raw material, and has the advantages of light unit weight, strong processability, low heat conduction coefficient and good self-heat conserving effect.

Owner:HENAN XIAN NEW BUILDING MATERIALS

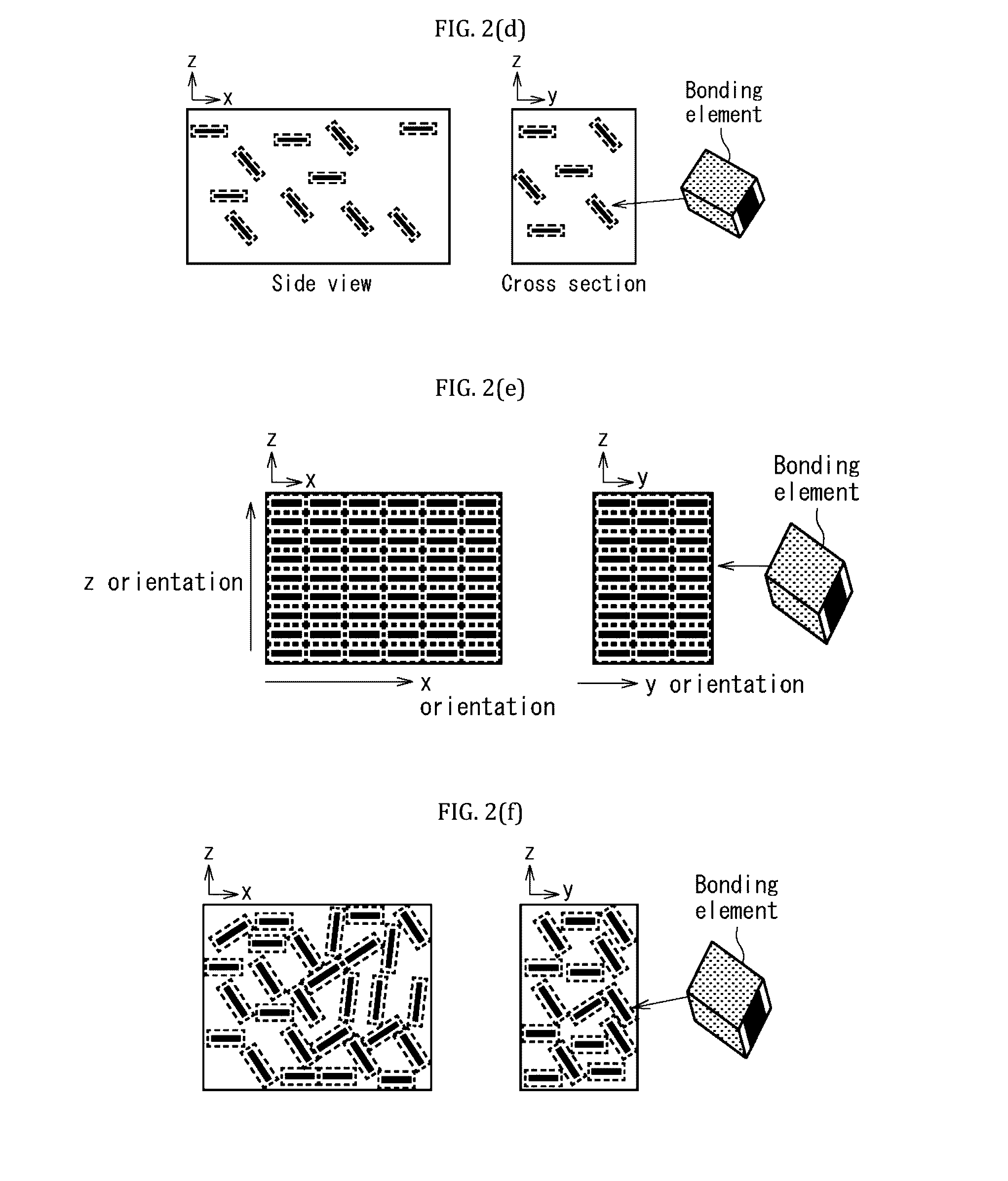

Lightweight composite materials produced from carbonatable calcium silicate and methods thereof

ActiveUS20160340261A1Avoid problemsSuitable for useSolid waste managementCeramic shaping apparatusCalcium silicateCompressive strength

An aerated composite material produced from carbonatable calcium silicate compositions (carbonation cured AAC) that has a compressive strength equivalent to autoclaved aerated concrete (ordinary AAC) at substantially the same density and a process of production of the same are provided. The composite material of the present invention comprises: a plurality of bonding elements, each including a core comprising calcium silicate, a first layer which partially or fully surrounds the core and is rich in SiO2, and a second layer which partially or fully surrounds the first layer and is rich in CaCO3; a plurality of filler particles having their particle sizes ranging from 0.1 μm to 1000 μm; and a plurality of voids; wherein the plurality of bonding elements and plurality of filler particles together form a bonding matrix and are substantially evenly dispersed in the matrix and bonded together, the plurality of voids are bubble-shaped and / or interconnected channels, a pore volume with a radius of 0.004 μm to 10.0 μm in the plurality of voids is 0.30 ml / composite material 1 g or less, and a estimated compressive strength expressed by the following formula (1): estimated compressive strength (absolute dry density=0.50)=compressive strength×(0.50÷absolute dry density)2 is 2.0 N / mm2 or greater.

Owner:SOLIDIA TECH +1

Method for producing autoclaved aerated concrete from double siliceous raw materials

InactiveCN101891499AIncluding lossQuality improvementSolid waste managementCeramic materials productionFoaming agentFly ash

The invention discloses a method for producing autoclaved aerated concrete from double siliceous raw materials. The autoclaved aerated concrete is mainly prepared by taking two siliceous raw materials of quartz sand and fly ash, cement, quick lime and gypsum powder as main raw materials, doping with aluminum powder paste serving as foaming agent, and preparing the autoclaved aerated concrete according to the conventional autoclaved aerated concrete process. The autoclaved aerated concrete is prepared from the following components by weight percent: 30%-36% of the quartz sand, 32%-38% of the fly ash, 7%-13% of the cement, 16%-22% of the quick lime and 2%-4% of the gypsum powder as well as the aluminum powder paste with the doping amount of 0.05-0.07%, wherein the ratio between water and the materials is 0.5-0.55. By using the two siliceous raw materials of the quartz sand and the fly ash as aggregates for preparing the autoclaved aerated concrete, the invention can greatly improve the quality of the autoclaved aerated concrete product and reduce the production cost thereof at the same time, thus effectively controlling the cost.

Owner:GUIZHOU CHANGTAIYUAN ENERGY SAVING BUILDING MATERIALS CO LTD +1

Biomass power plant ash-based autoclaving-free aerated concrete sound absorbing and insulating brick and preparation method thereof

ActiveCN105330219AImprove the sound absorption effectGood sound insulation effectSolid waste managementBrickHeat conducting

The invention provides a biomass power plant ash-based autoclaving-free aerated concrete sound absorbing and insulating brick and a preparation method thereof. The aerated concrete sound absorbing and insulating brick is basically prepared from, by weight, 10%-15% of cement, 45%-54% of coal ash, 12%-20% of rice hull ash, 1%-9% of perlite, 3%-5% of an excitant, 8%-12% of lime, 2%-4% of gypsum, water accounting for 49%-52% of the total weigh of dry materials, aluminite powder accounting for 0.07%-0.1% of the total weight of the dry materials, a water reducing agent accounting for 8.5%-8.8% of the total weight of the dry materials and a foam stabilizer accounting for 10% of the water reducing agent, wherein the dry materials are the combination of cement, coal ash, rice hull ash, perlite, excitants, lime and gypsum. According to the aerated concrete sound absorbing and insulating brick, resourceful utilization of biomass power plant ash is achieved, moreover, the brick has better sound absorbing and insulating performance and heat conducting performance. The preparation method of the brick has the advantages that operation is easy, and autoclaving is avoided.

Owner:WUHAN UNIV

Versatile cooker

A versatile cooker that includes a crucible or base, a fire bowl with a cooking surface on top of it and, a cover / lid or dome that rests over the cooking surface. An exemplary embodiment of the cooker can be described as a naturally fired outdoor cooker constructed of a light weight, thermally insulated material such as Autoclaved Aerated Concrete (AAC) as the crucible, a stainless steel fire bowl and a dome lid. A grilling surface constructed out of carbon steel and ceramic disks are used as internal heat sinks.

Owner:COOKING WITH FIRE

Special thin anti-crack plastering mortar for autoclaved aerated concrete

The invention discloses a special thin anti-crack plastering mortar for autoclaved aerated concrete and belongs to the technical field of building materials. According to the special thin anti-crack plastering mortar disclosed by the invention, a dry material is added with water by a mass ratio that water to dry material ratio is equal to 1:4, and then stirred for 3-5 minutes to prepare mortar, wherein the dry material consists of the following components in mass by percentage: 20%-35% of cement, 10%-30% of 40-70-mesh quartz sand, 30%-50% of 80-100-mesh quartz sand, 2%-7% of 200-mesh coarse whiting powder, 1.5%-4% of redispersible emulsion powder; 0.15%-0.5% of water-retaining agent; 0.2%-0.7% of wood fiber and 0.11%-0.45% of short fiber. Being prepared by adopting quartz sand of 40-70 meshes or 80-100 meshes, the special thin anti-crack plastering mortar for the autoclaved aerated concrete disclosed by the invention has an excellent anti-crack performance, realizes effective control on contraction percentage of the mortar, causes no cracks during large-area construction, achieves good caking property, and realizes organic combination between the mortar and the surface layer of the autoclaved aerated concrete.

Owner:山东高阳建材有限公司

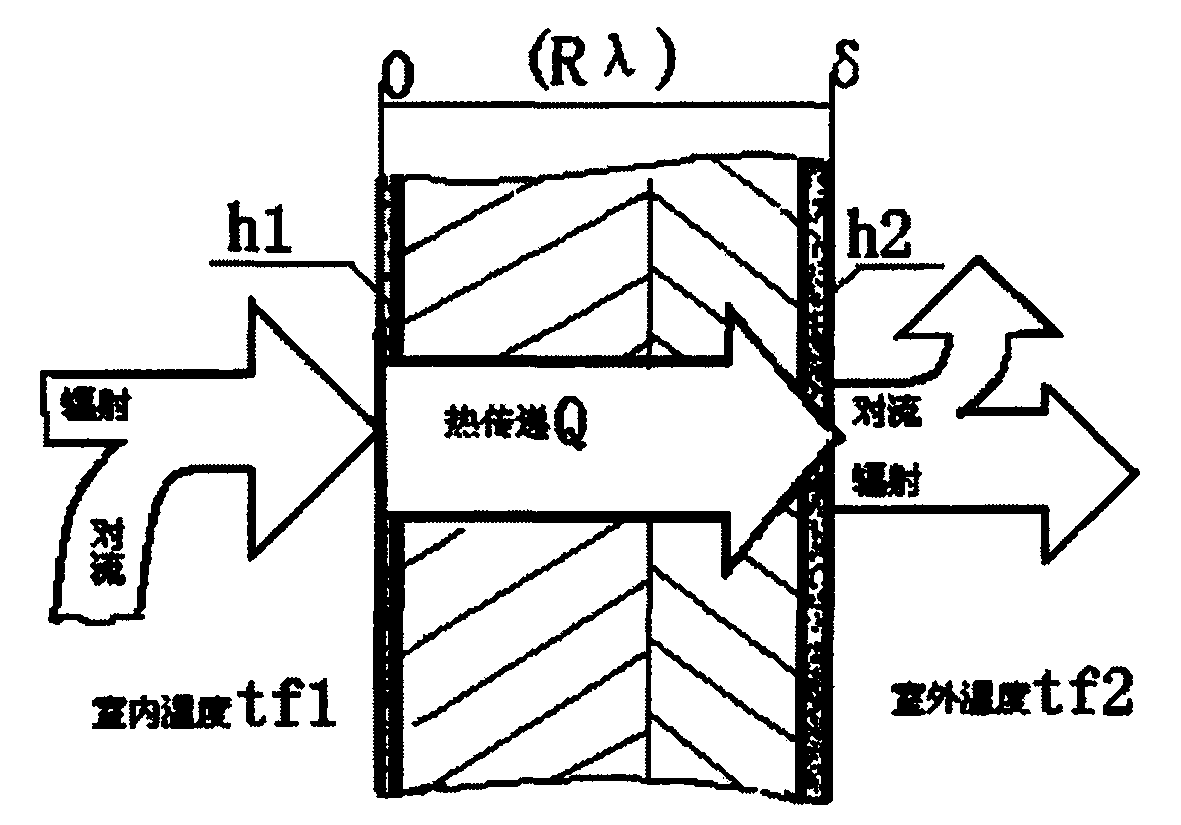

Steam pressurized concrete composite heat insulation building blocks and its production process

InactiveCN101265737AImprove thermal insulation performanceLight weightConstruction materialSolid waste managementSlurryAutoclaved aerated concrete

The invention discloses an autoclaved aerated concrete composite heat preservation building block and a production method thereof. The building block external wall and the building block are made of the autoclaved aerated concrete, the hole formed by the building block external wall and the building block rib is filled with heat preservation and insulation fillers for a second time. The building block adopts the autoclaved aerated concrete as the raw material and the preset mould core structure. The mould core is extracted after the slurry is poured so as to form a hollow structure in the building block body in the molding process, the void ratio of the hollow structure reaches 30%-70%. The light heat preservation and insulation material is filled for the second time after autoclaved curing the hollow structure block body, which reduces the production volume weight, improves the heat preservation and insulation performance of the material and facilitates the construction. Based on the application requirement, the absolute dry volume weight is adjustable in a range of 300-600kg / m<3>, the heat transfer coefficient amounts to less than 0.5W / m<2>.K, the method has a remarkable effect of energy saving, the single wall body material reaches 65% of the national building energy saving requirement, the energy-saving effect is obvious. The building block is widely applicable to industrial and civil building wall bodies.

Owner:ZHANGYE QINGTIAN BUILDING MATERIALS

Autoclaved aerated concrete plate produced by using Yellow River sand, and production method thereof

ActiveCN103693928AMeet the requirements of new building materialsProtect the ecologyConstruction materialCeramicwareRebarBiology

The present invention relates to an autoclaved aerated concrete plate produced by using Yellow River sand. The base material components of the concrete plate billet comprise 2450-3500 kg of Yellow River sand, 480-700 kg of cement, 420-620 kg of quick lime, 30-120 kg of slaked lime, 42-50 kg of desulfurized gypsum, 37-50 kg of magnesite, 4.0-4.5 kg of aluminum powder paste, and 0.05-0.1 kg of a foam stabilizer. According to the present invention, the Yellow River sand is adopted to replace the ordinary natural sand so as to be adopted as the siliceous material, and the prepared ALC plate has characteristics of high compressive strength, high stiffness, low deflection value, high bonding strength between the billet and the steel bar, good flatness, substantially-improved construction efficiency, project cost reduction, and broad market prospects.

Owner:HENAN XIAN NEW BUILDING MATERIALS

Preparation method for pulverized coal-ash-based porous artificial stone

InactiveCN102584322AImprove productivityShorten steaming timeSolid waste managementCeramicwareFiberWater vapor

The invention discloses a preparation method for a pulverized-coal-ash-based porous artificial stone. The preparation method is characterized in that the method comprises the steps of: adding materials containing calcium carbonate, calcium sulfate and silicon oxide, water, fibers and Portland cement into pulverized coal ash, evenly agitating, adding alkali-activator, metal aluminum powder and organic foaming agent, and evenly mixing; and statically curing, cutting into cement blocks or cement blank plates, and curing the cement blocks or cement blank plates in a vapor environment to obtain the pulverized-coal-ash-based porous artificial stone. The artificial stone mainly contains tobermorite and xonotlite, can replace the existing autoclaved aerated concrete and can be used as a load-bearing building block, a filler wall, a partition wall, a roof board or a wall board.

Owner:SHAANXI UNIV OF TECH

Prefab house made of autoclaved aerated concrete slabs and assembly method for prefab house

InactiveCN102518301AMeet the requirements for reuseImprove fire performanceBuilding material handlingDwelling buildingFloor slabFireproofing

The invention discloses a prefab house made of autoclaved aerated concrete slabs, which comprises a steel frame, an external wall panel, an internal wall panel, a roof panel and a floor slab, wherein the external wall panel is connected with the steel frame through hook bolts, the internal wall panel is fixed with the steel frame through a U-shaped fastener and / or pipe fastener, the roof panel and the floor slab are shelved on the steel frame, and the peripheries of the roof panel and the floor slab are tamped by cement plaster. The invention further discloses an assembly method for the prefab house made of the autoclaved aerated concrete slabs. The prefab house utilizes the autoclaved aerated concrete slabs as materials for walls, the floor slab and a roof, and heat insulation, fireproofing, sound insulation and impact resistance of the prefab house are improved. Besides, autoclaved lightweight concrete panels and a steel structure are fixed by means of bolt connection, and joints and corners are treated, so that breakage due to assembly and disassembly is prevented, and the requirement of the prefab house on reusability is met.

Owner:SHANGHAI FORCHN BUILDING IND TECH CO LTD

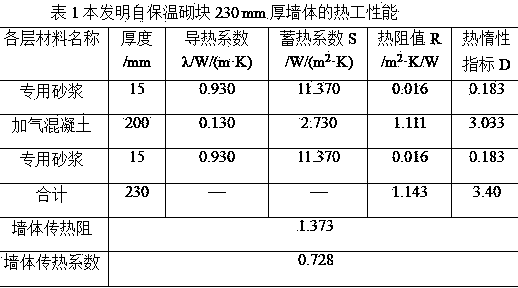

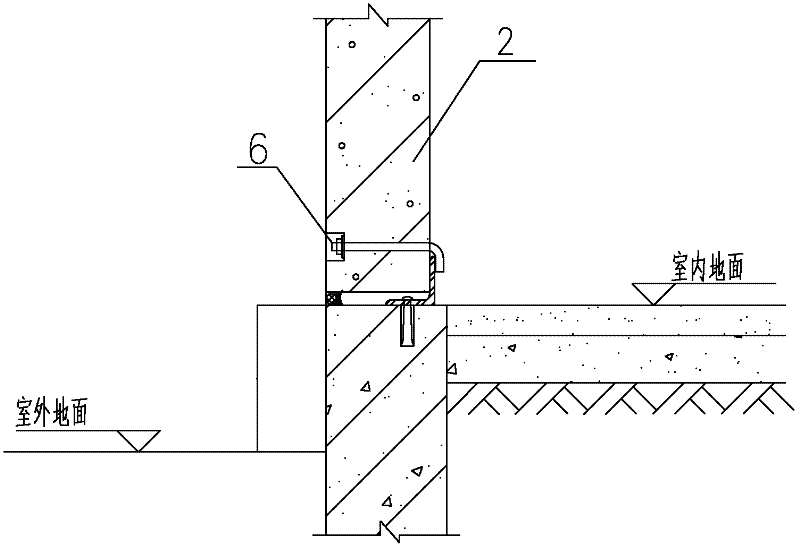

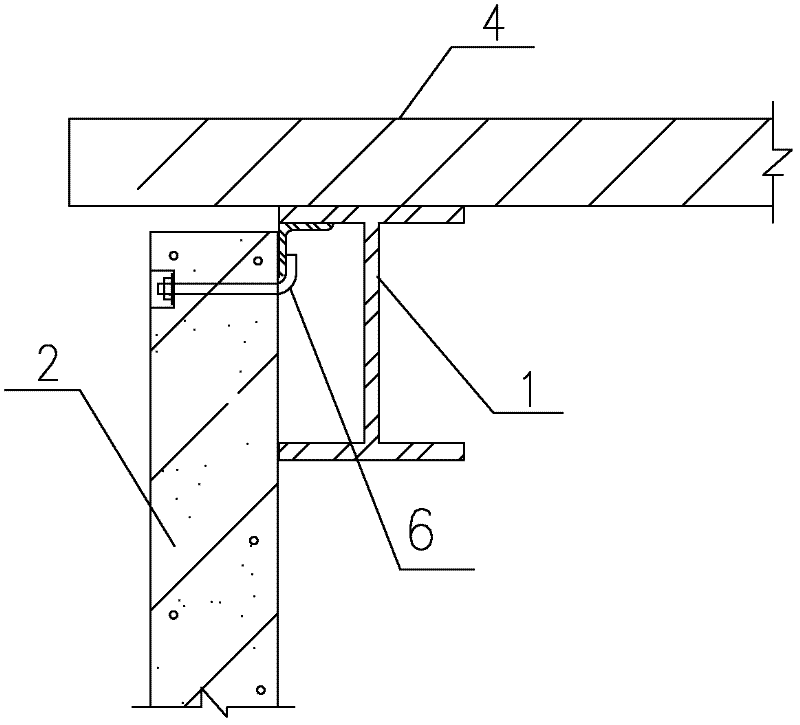

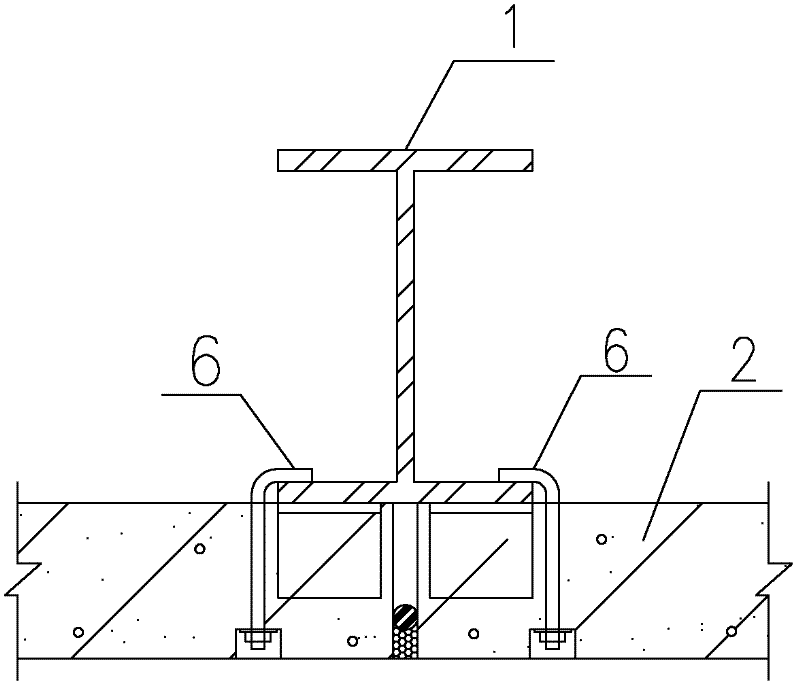

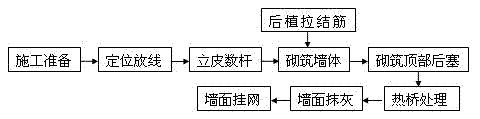

Construction process for self-heat-insulation system of autoclaved aerated concrete block wall

InactiveCN102251670AReduced risk of hollowing and crackingImprove water retentionClimate change adaptationPassive housesReinforced concreteThermal bridge

The invention discloses a construction process for a self-heat-insulation system of an autoclaved aerated concrete block wall. A wall building process is subjected to three necessary technical slot time, namely the time from building and walling of autoclaved aerated concrete blocks to curing lasts for at least 28 days; reserved clearances between the top of the autoclaved aerated concrete block wall and a beam and between the top and a board, namely rear blocking ports can be supplementarily built after at least seven days at interval; and the time from completion of the autoclaved aerated concrete block wall to wall plastering lasts for at least 30 days. By adopting the three necessary technical slot time, the construction surface is fully dried, thus greatly reducing the internal stress of materials due to drying shrinkage deformation and temperature change of the material and preventing crack and leakage of the wall. In addition, an inorganic heat-insulation material or aerated concrete blocks are used for heat insulation at the thermal bridge positions of reinforced concrete walls, posts and beams of outer walls according to thermotechnical calculation, thus eliminating thermal bridges and meeting the energy-saving requirement.

Owner:CHONGQING NO 3 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com