Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

672 results about "Transparent ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Many ceramic materials, both glassy and crystalline, have found use as optically transparent materials in various forms from bulk solid-state components to high surface area forms such as thin films, coatings, and fibers. Such devices have found widespread use for various applications in the electro-optical field including: optical fibers for guided lightwave transmission, optical switches, laser amplifiers and lenses, hosts for solid-state lasers and optical window materials for gas lasers, and infrared (IR) heat seeking devices for missile guidance systems and IR night vision.

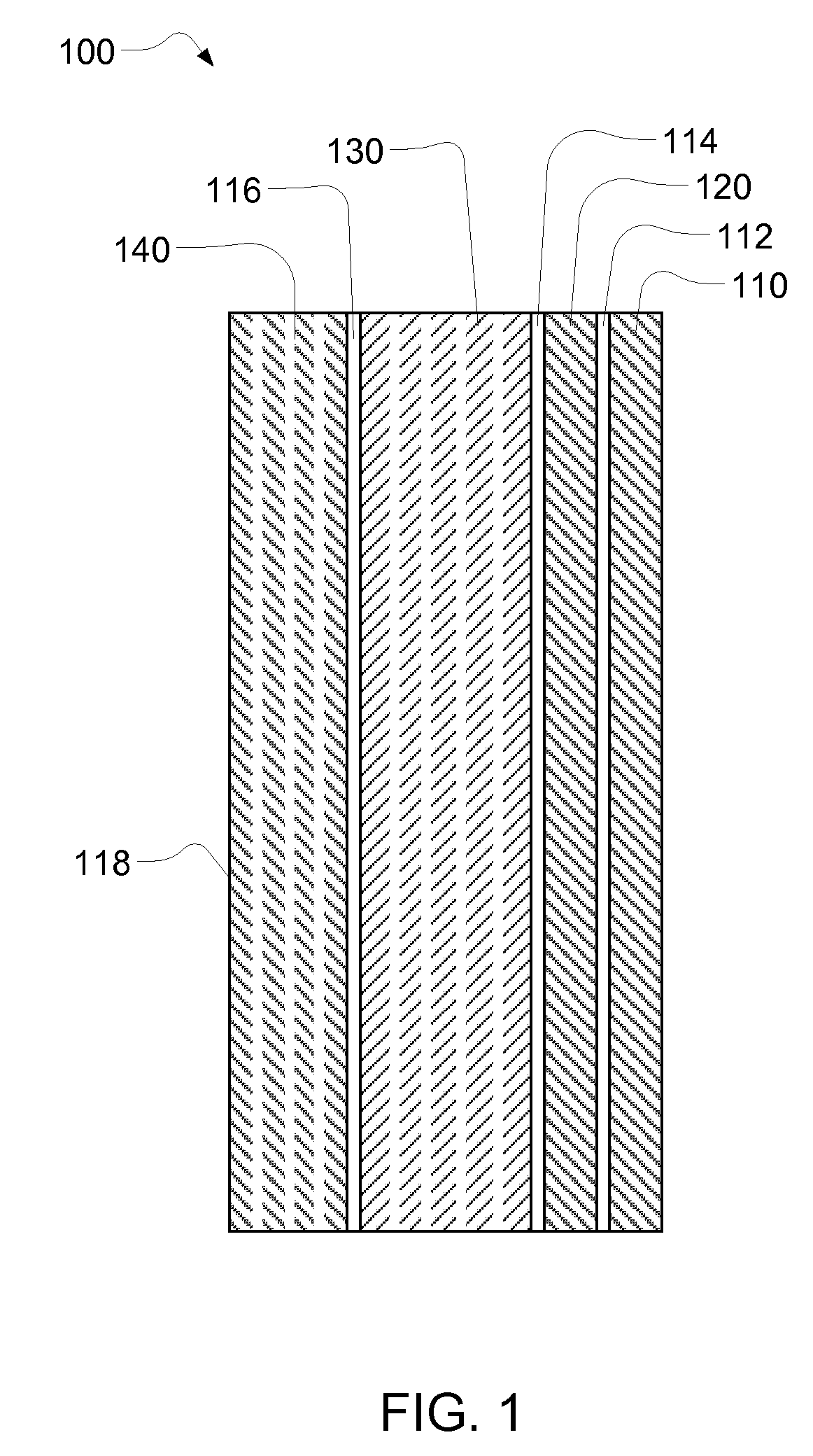

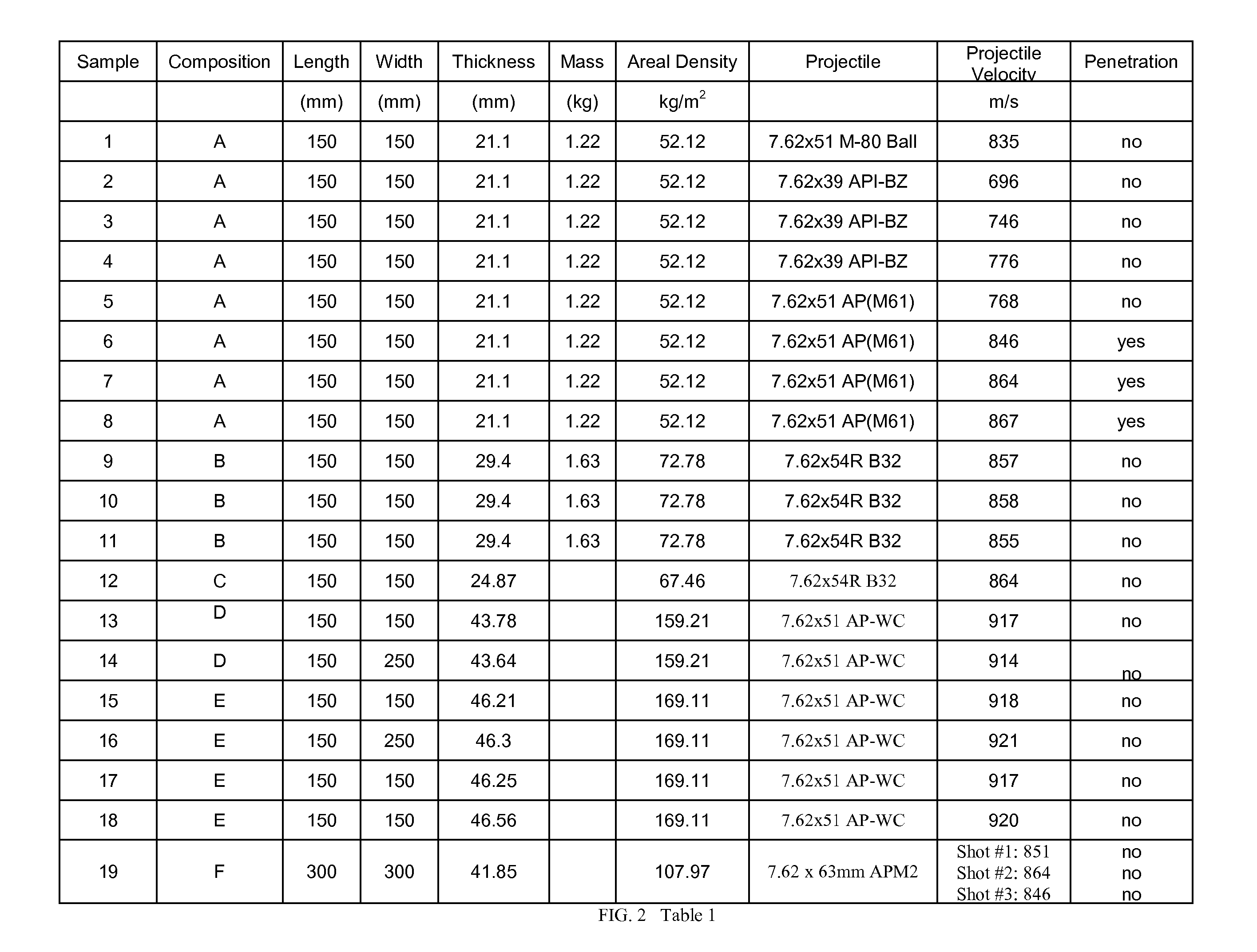

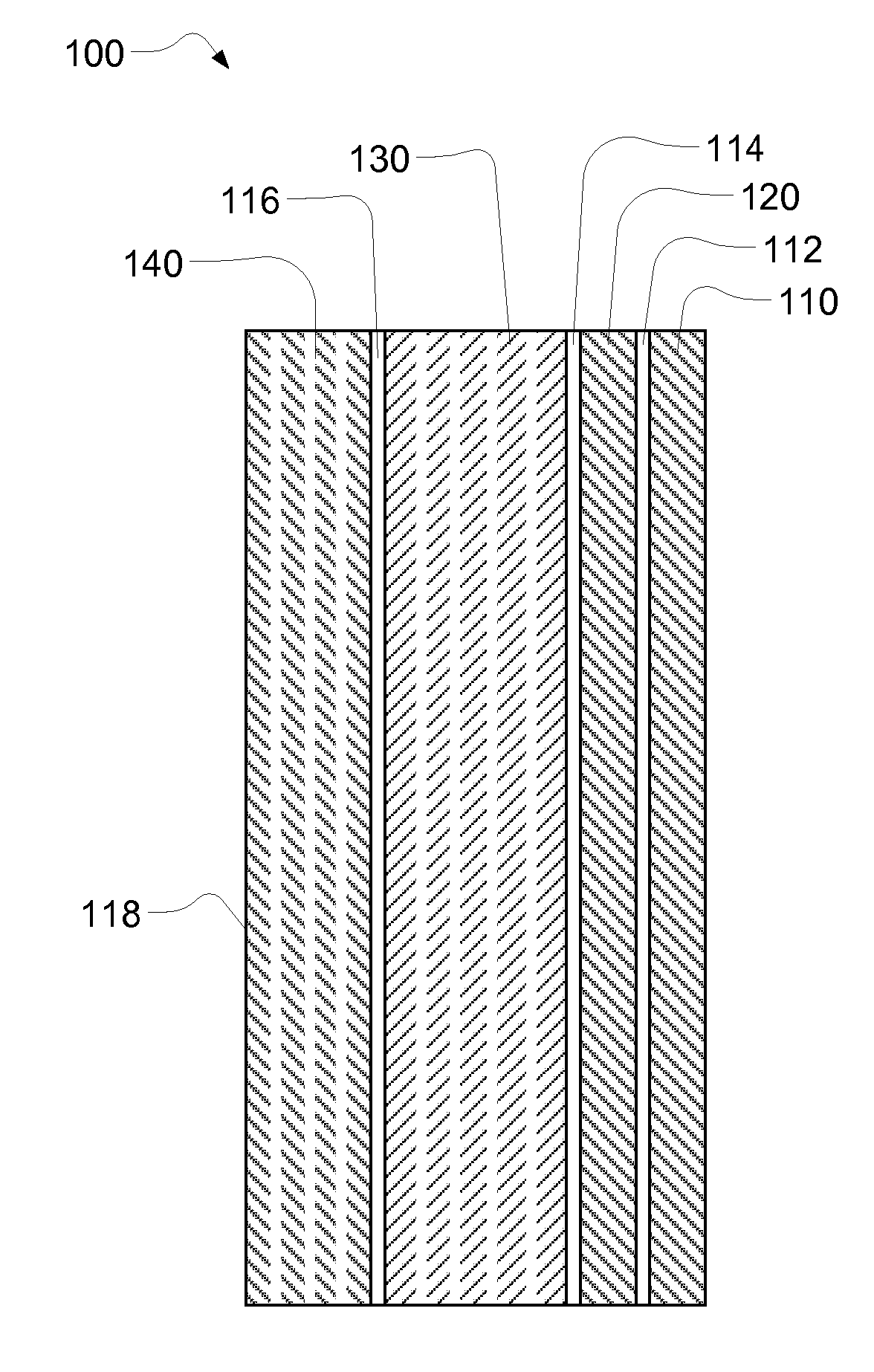

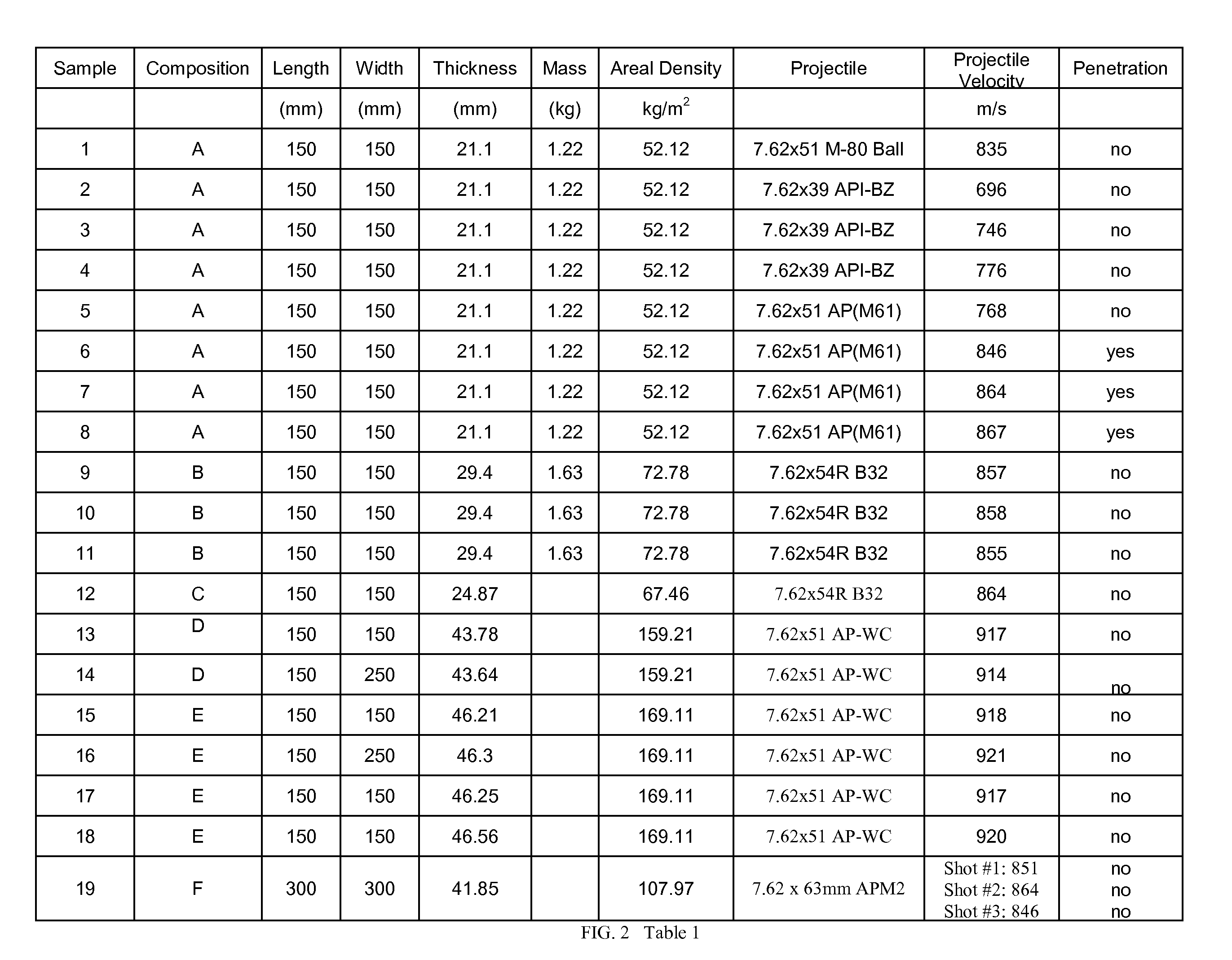

Transparent ceramic composite armor

InactiveUS7584689B2Prevent penetrationAdditive manufacturing apparatusGlass/slag layered productsCeramic compositeSingle crystal

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

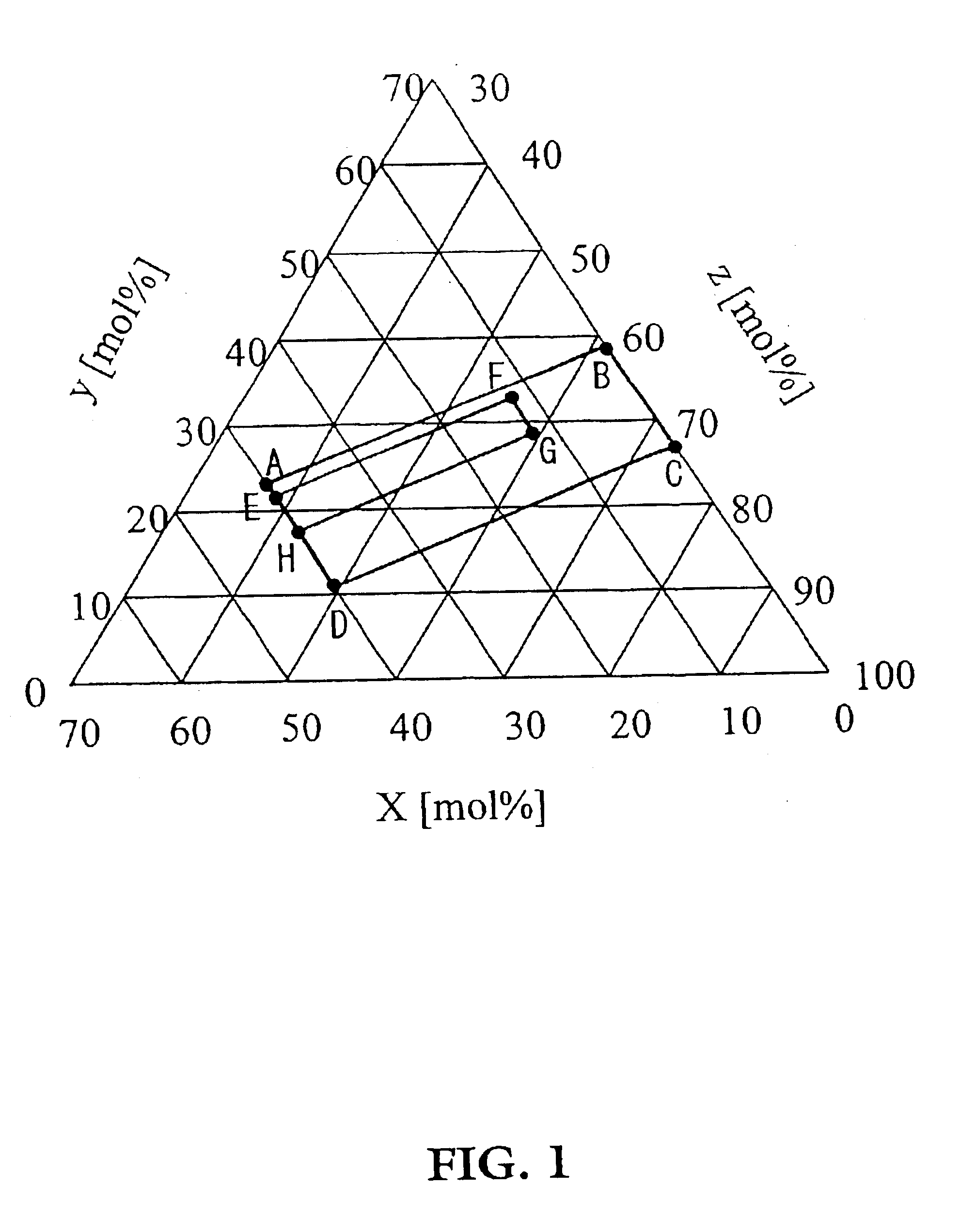

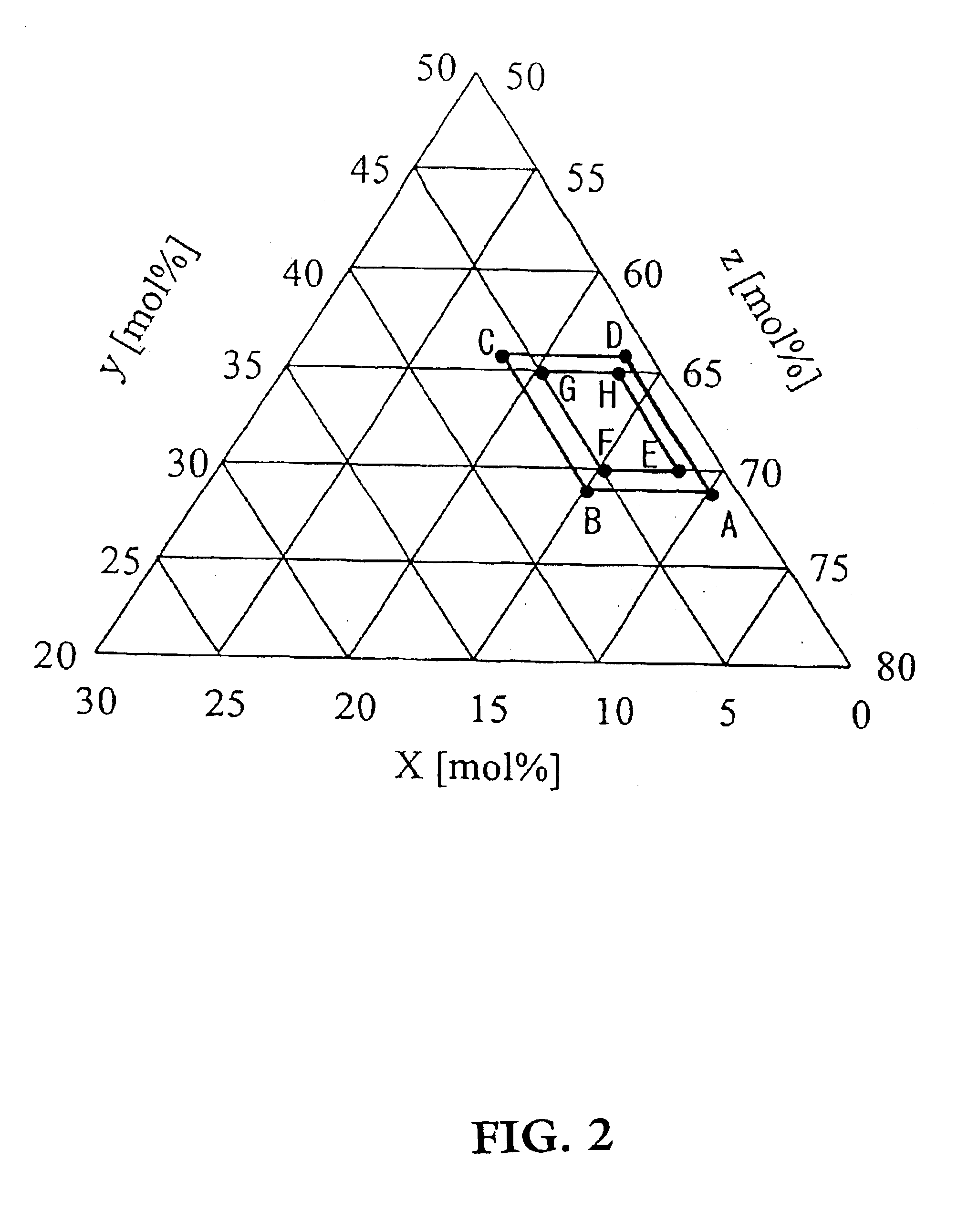

Transparent ceramic and method for production thereof, and optical element

InactiveUS6908872B2Induces no double refractionSmall sizeLamination ancillary operationsOther chemical processesRefractive indexTransparent ceramics

A ceramic material powder for a translucent ceramic is molded with a binder, and the resulting green compact is embedded in a ceramic powder having the same composition with the ceramic material powder. After removing the binder, the green compact embedded in the ceramic powder is fired in an atmosphere having an oxygen concentration higher than that in the removal procedure of the binder and thereby yields a translucent ceramic represented by Formula I: Ba{(SnuZr1-u)xMgyTaz}vOw, Formula II: Ba(ZrxMgyTaz)vOw or Formula III: Ba{(SnuZr1-u)xZntMg1-t)yNbz}vOw. The translucent ceramic has a refractive index of 1.9 or more and is paraelectric.

Owner:MURATA MFG CO LTD

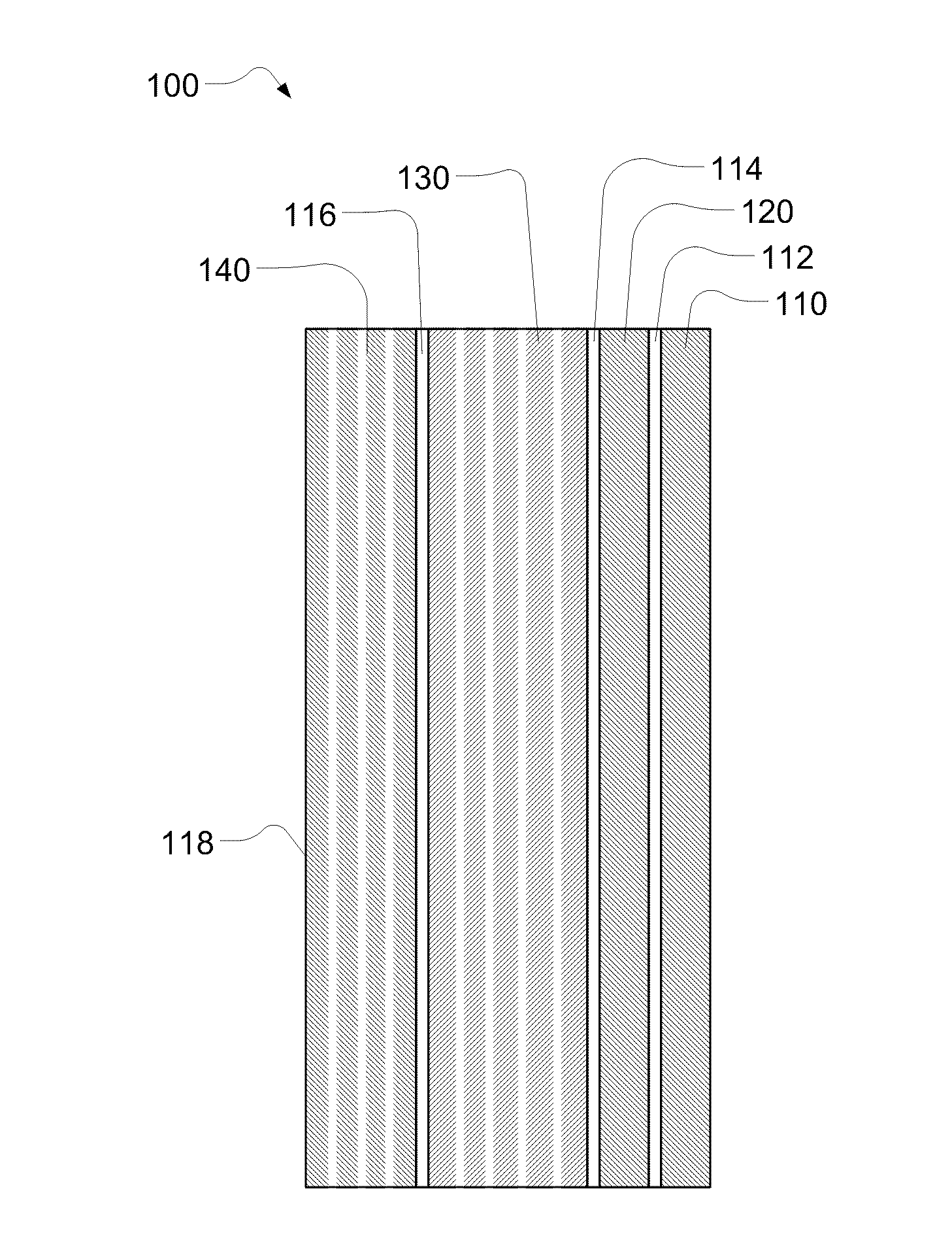

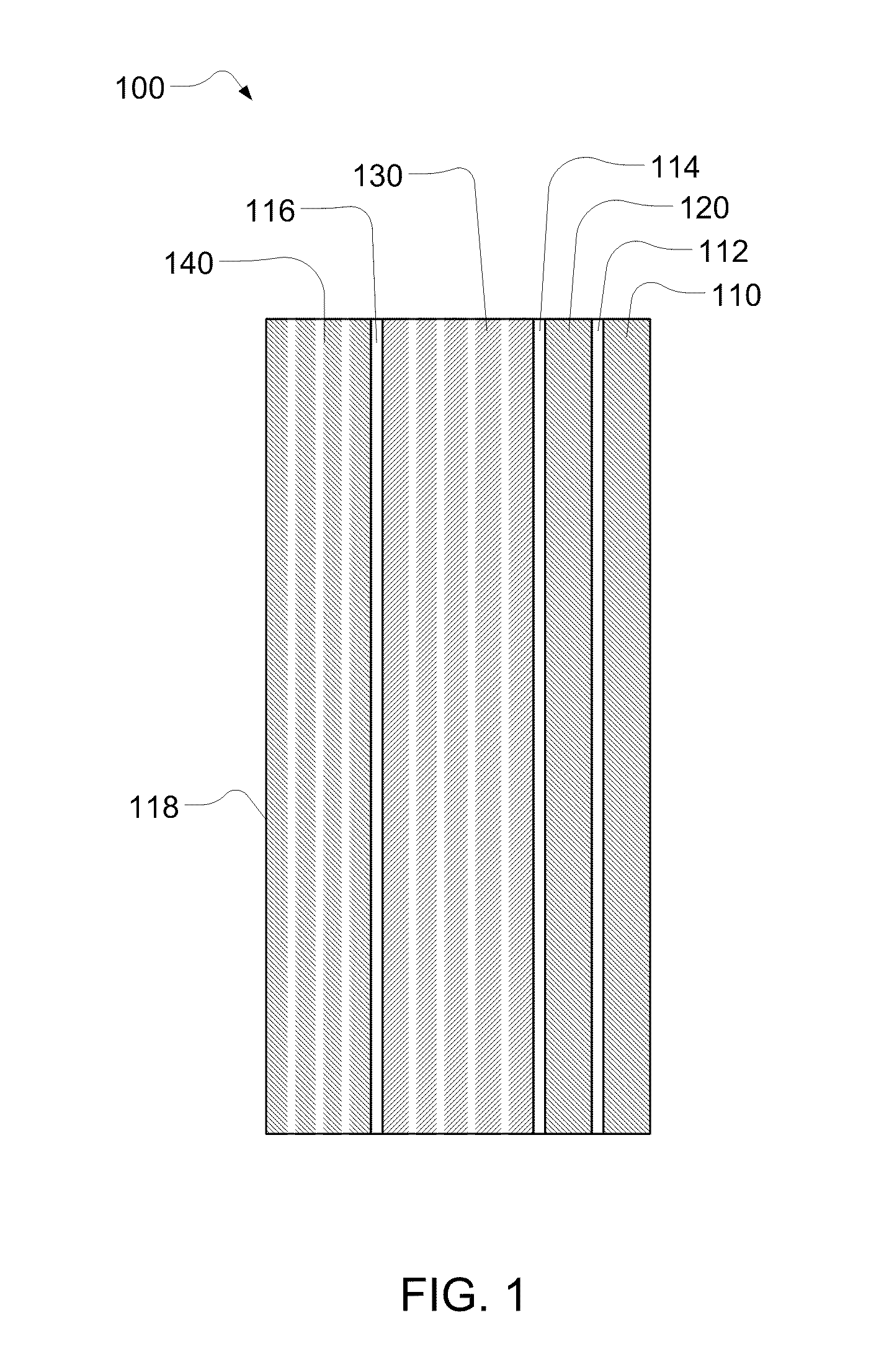

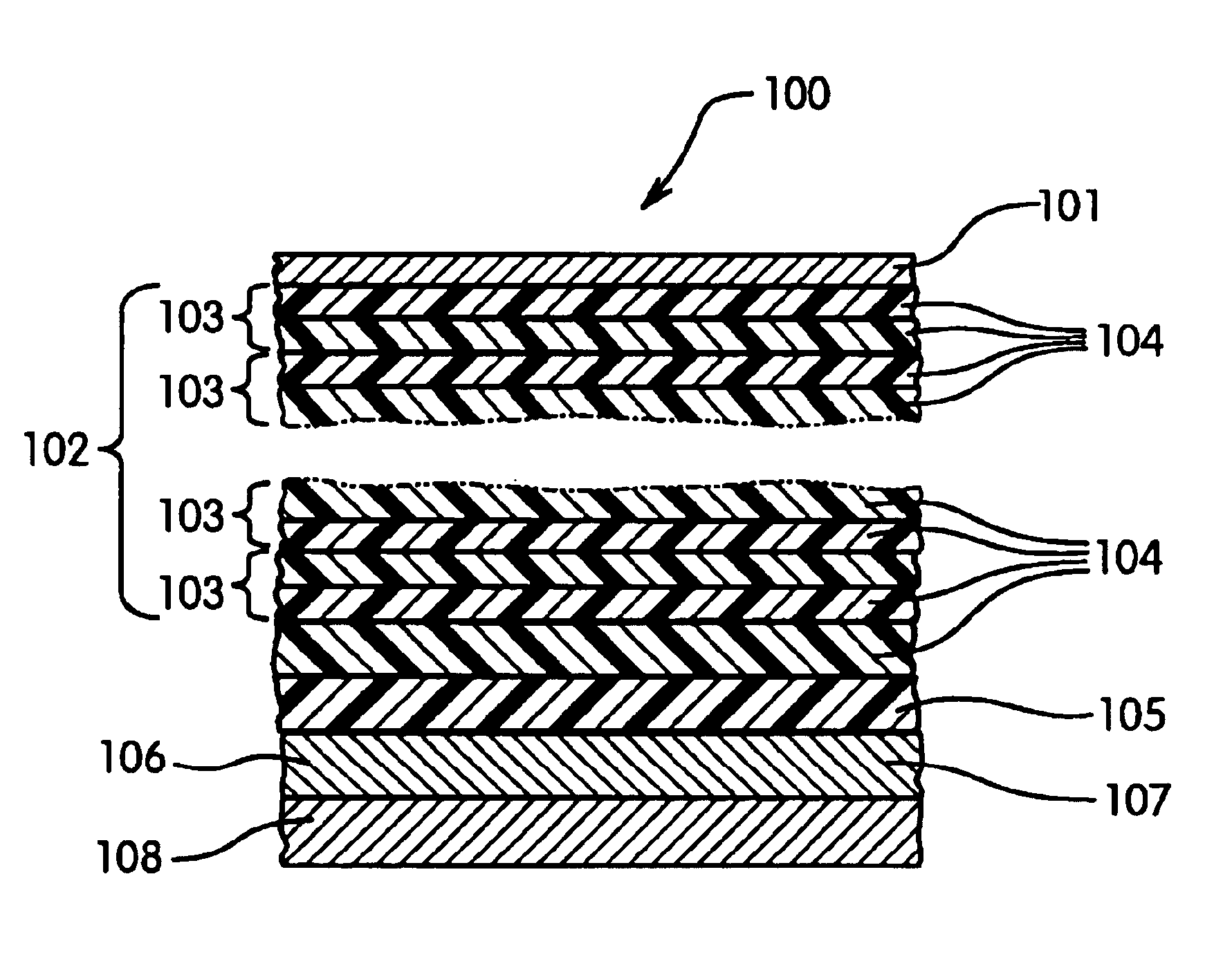

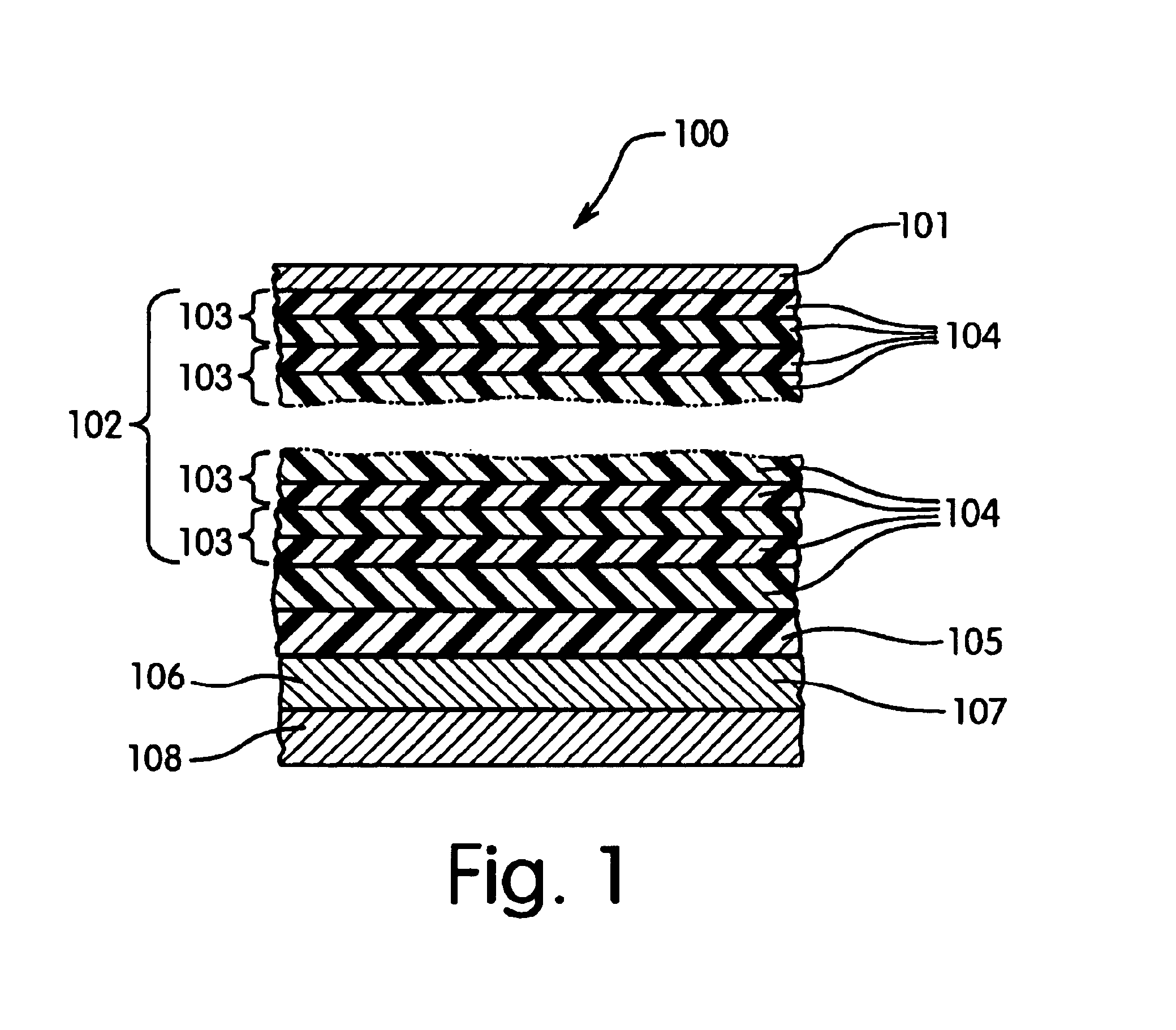

Transparent ceramic composite

InactiveUS20070068375A1Prevent penetrationAdditive manufacturing apparatusGlass/slag layered productsCeramic compositeSingle crystal

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Transparent ceramic composite

InactiveUS20070068376A1Prevent penetrationAdditive manufacturing apparatusGlass/slag layered productsCeramic compositeSingle crystal

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Method of fabricating translucent phosphor ceramics

One embodiment provides a method for fabricating a translucent phosphor ceramic compact comprising: heating a precursor powder to at least about 1000° C. under a reducing atmosphere to provide a pre-conditioned powder, forming an intermediate compact comprising the pre-conditioned powder and a flux material, and heating the intermediate compact under a vacuum to a temperature of at least about 1400° C. In another embodiment, the compact may be a cerium doped translucent phosphor ceramic compact comprising yttrium, aluminum, oxygen, and cerium sources. Another embodiment may be a light emitting device having the phosphor translucent ceramic provided as described herein.

Owner:SCHOTT AG

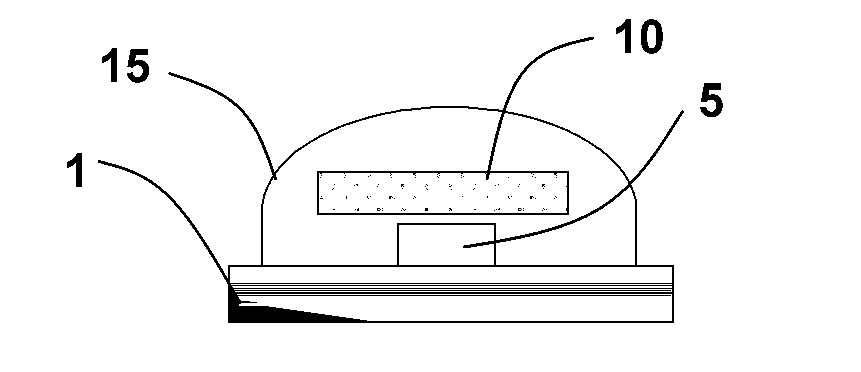

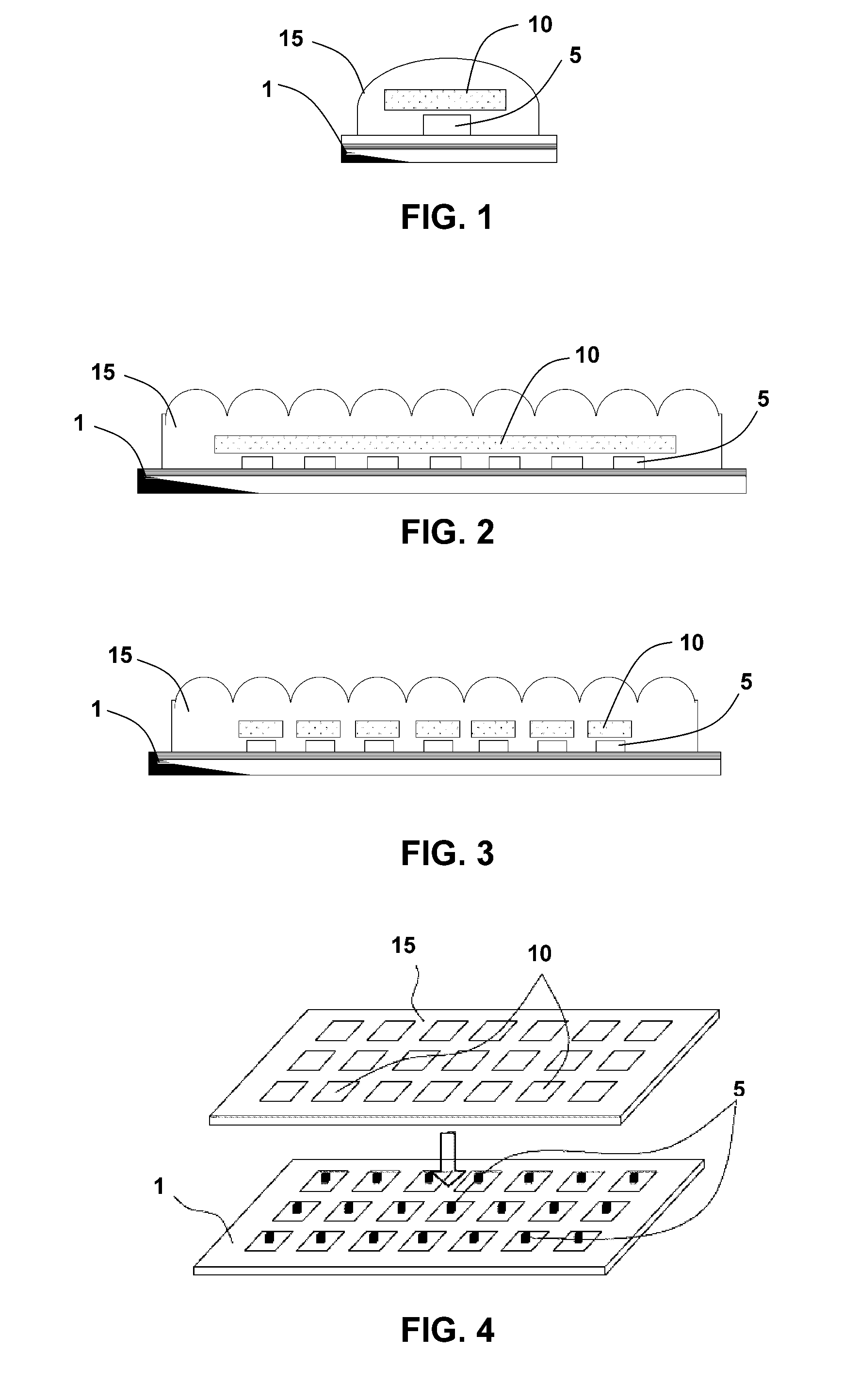

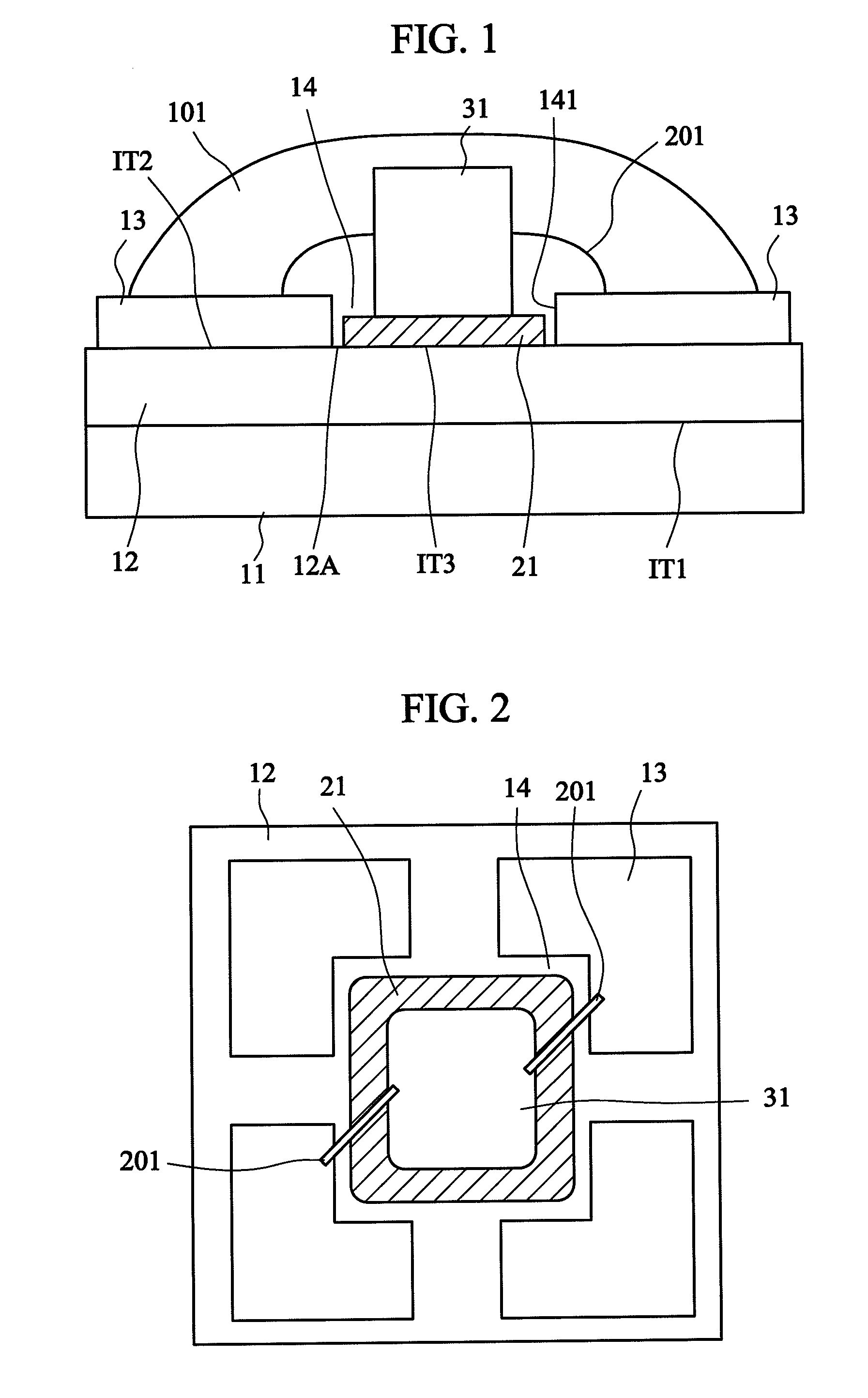

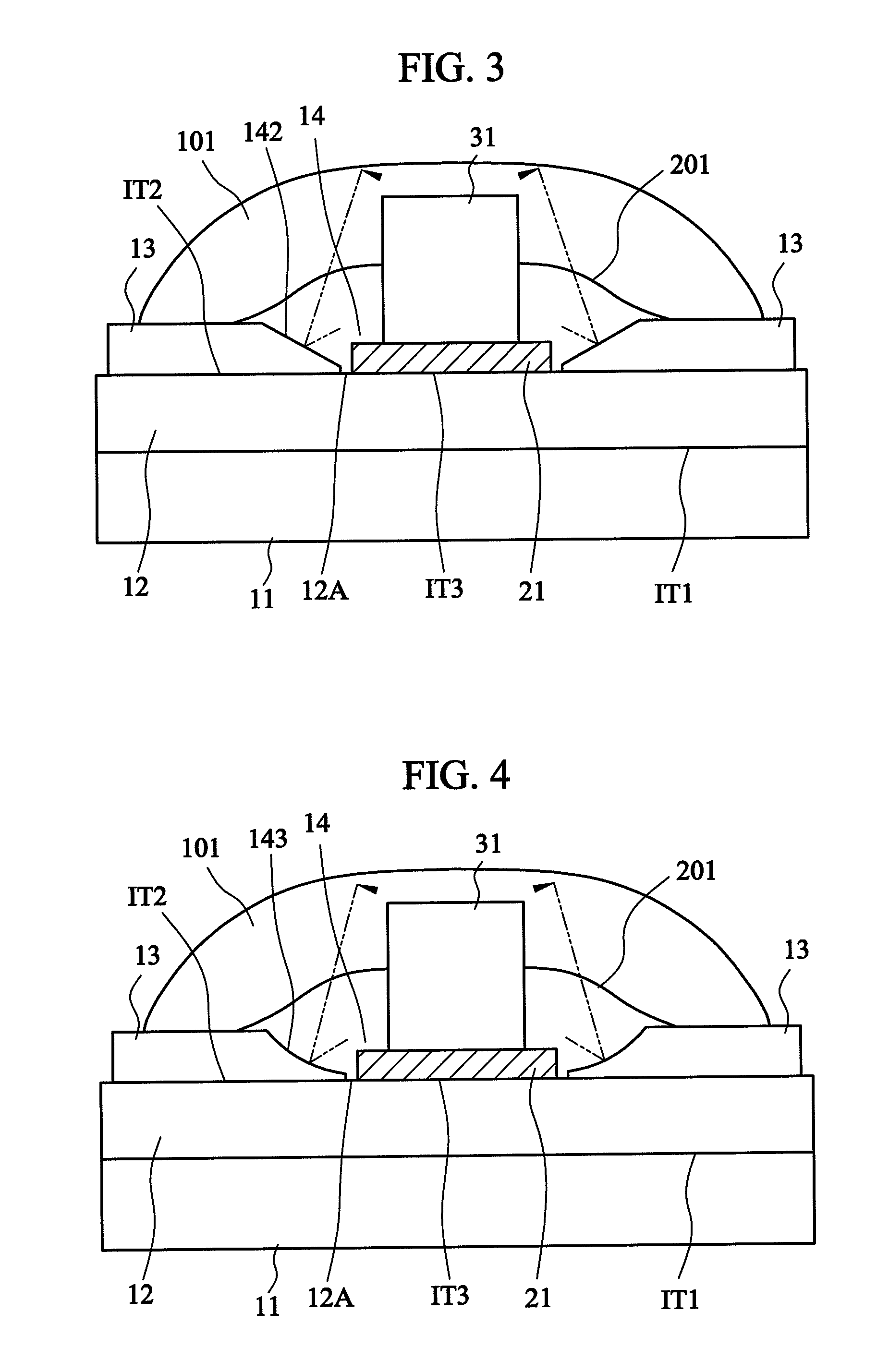

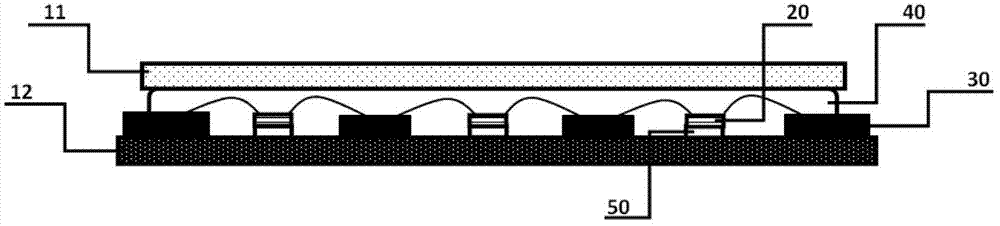

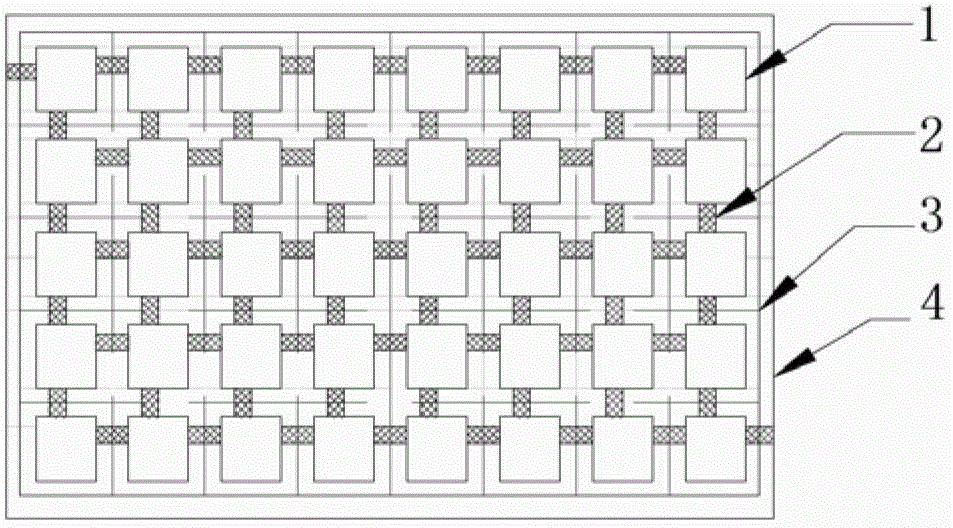

Fully reflective and highly thermoconductive electronic module and method of manufacturing the same

ActiveUS20100212942A1Improve thermal conductivityImprove abilitiesLamination ancillary operationsCircuit optical detailsOptoelectronicsSurface binding

A fully reflective and highly thermoconductive electronic module includes a metal bottom layer, a transparent ceramic layer and a patterned metal wiring layer. The metal bottom layer has a lower reflective surface. The transparent ceramic layer has an upper surface and a lower surface. The lower surface of the transparent ceramic layer is bonded to the lower reflective surface of the metal bottom layer. The metal wiring layer is bonded to the upper surface of the transparent ceramic layer. The lower reflective surface reflects a first light ray, transmitting through the transparent ceramic layer, to the upper surface of the transparent ceramic layer. A method of manufacturing the fully reflective and highly thermoconductive electronic module is also disclosed.

Owner:NAT TAIWAN UNIV

Transparent Ceramic Composite

InactiveUS20090308239A1Prevent penetrationAdditive manufacturing apparatusArmoured vehiclesCeramic compositeVolumetric Mass Density

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

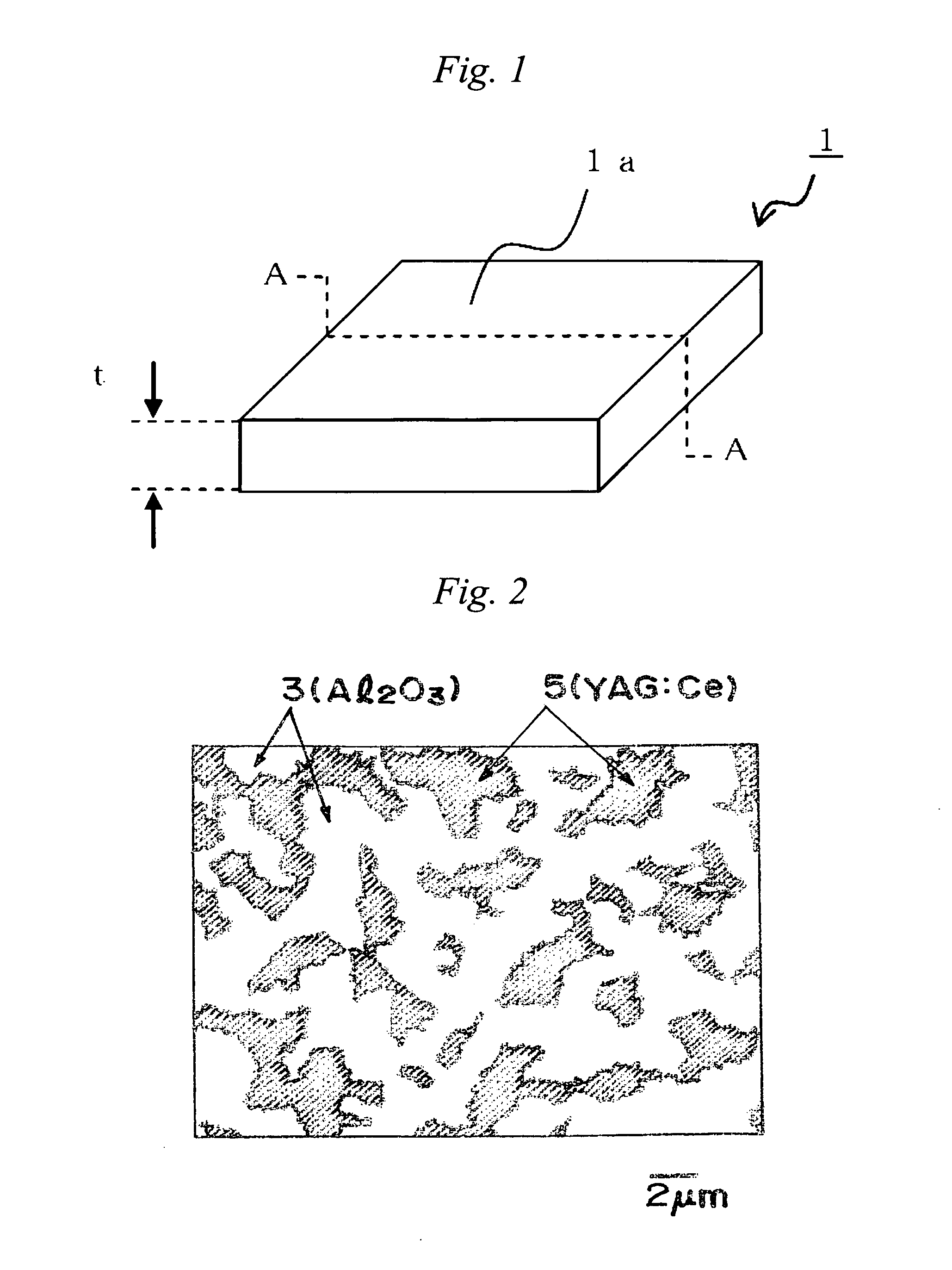

Ceramics composite

ActiveUS20120045634A1Increase resistanceSuppress deterioration of emission intensitySynthetic resin layered productsCeramic layered productsCeramic compositeFluorescence

The present invention relates to a ceramics composite including an inorganic material which includes: a matrix phase including a translucent ceramics; and a phosphor phase including YAG containing Ce, in which a content of the phosphor phase is from 22% by volume to 55% by volume based on the whole phase including the matrix phase and the phosphor phase, a content of Ce in the YAG is 0.005 to 0.05 in terms of an atomic ratio of Ce to Y (Ce / Y), and the ceramics composite has a thickness in a light outgoing direction of 30 μm to 200 μm.

Owner:COORSTEK INC

Resistant surface reflector

InactiveUS6709119B2High stability against wipingAvoid disadvantagesMirrorsMountingsSurface layerSilicon oxide

A reflector with high total reflection which is resistant to mechanical stresses. The reflector includes a reflector body and superimposed thereon (a) a functional coating such as a varnish, (b) a reflecting layer structure composed of a reflecting metallic layer and optionally arranged thereon one or several transparent ceramic layers, for example, layers having an optical depth of lambda / 2. The reflecting layer structure contains, as its surface layer, a protective layer. The protective layer is a silicon oxide of general formula SiOx, wherein x is a number from 1.1 to 2.0, or it is aluminum oxide of formula Al2O3, in a thickness of 3 nm or more. The protective layer protects the underlying layers from mechanical damages. In the DIN 58196 abrasion test the protected surface does not show any damages after 50 test cycles with 100 abrasion strokes.

Owner:CONSTELLIUM SWITZERLAND +1

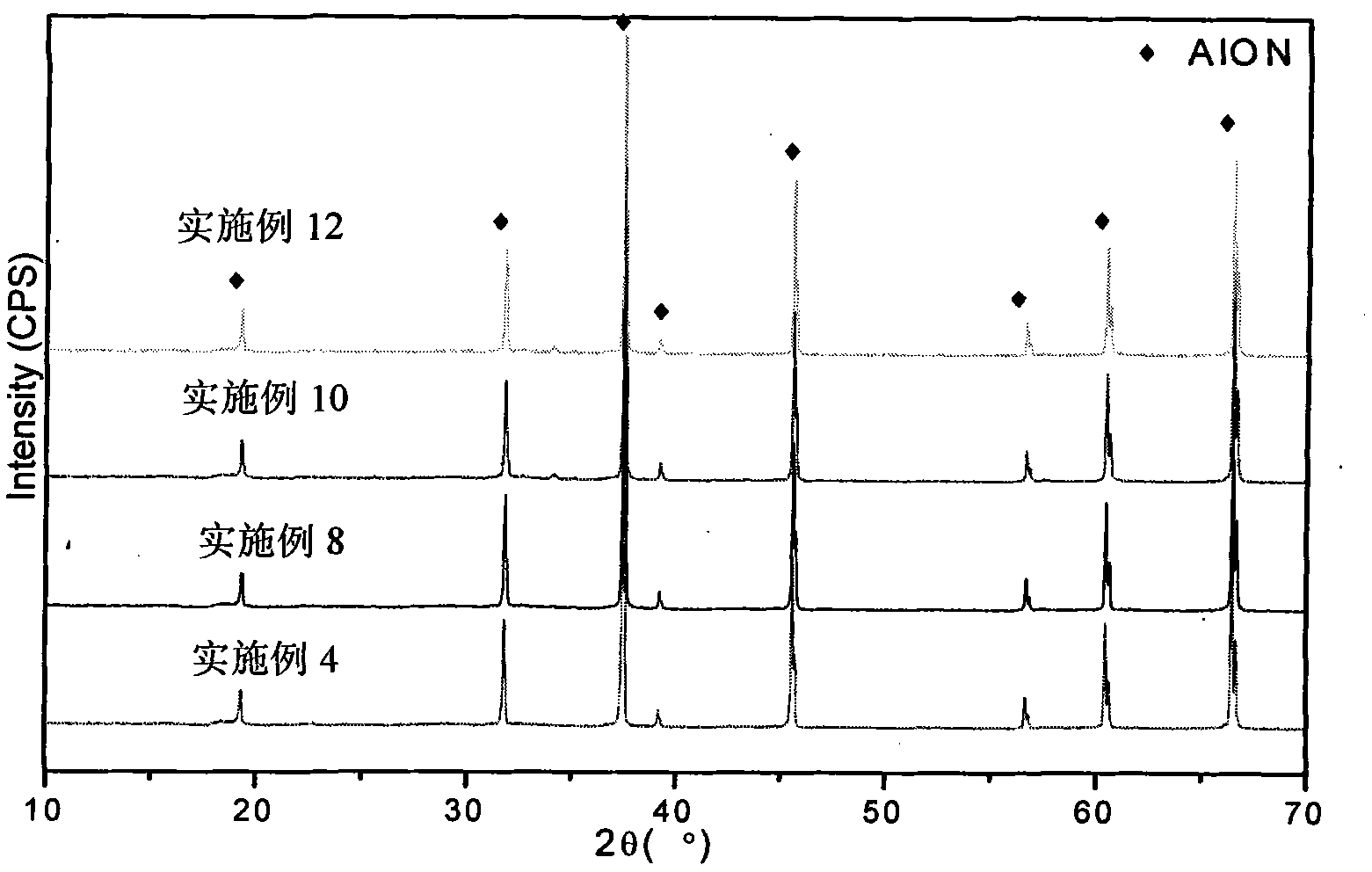

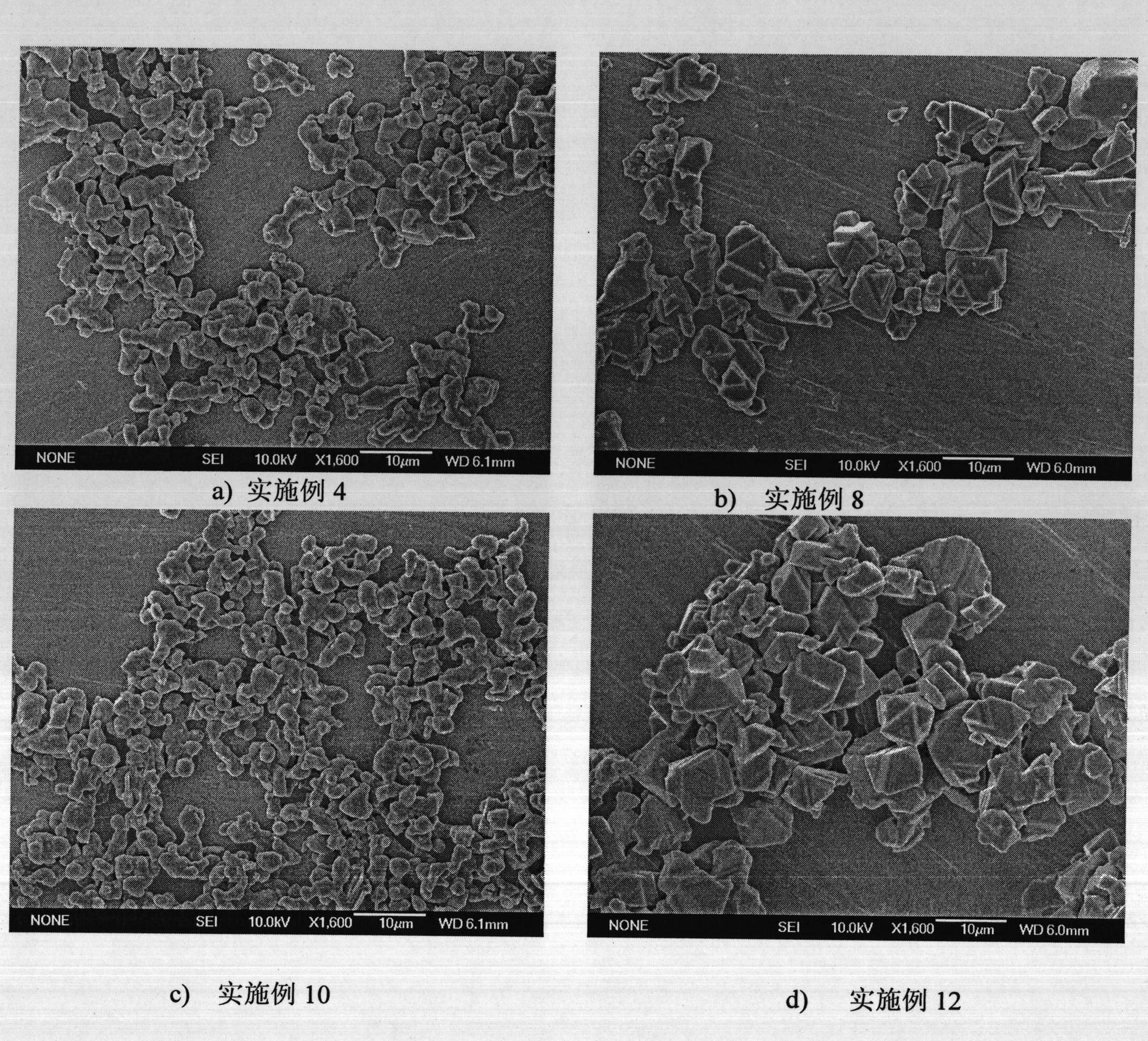

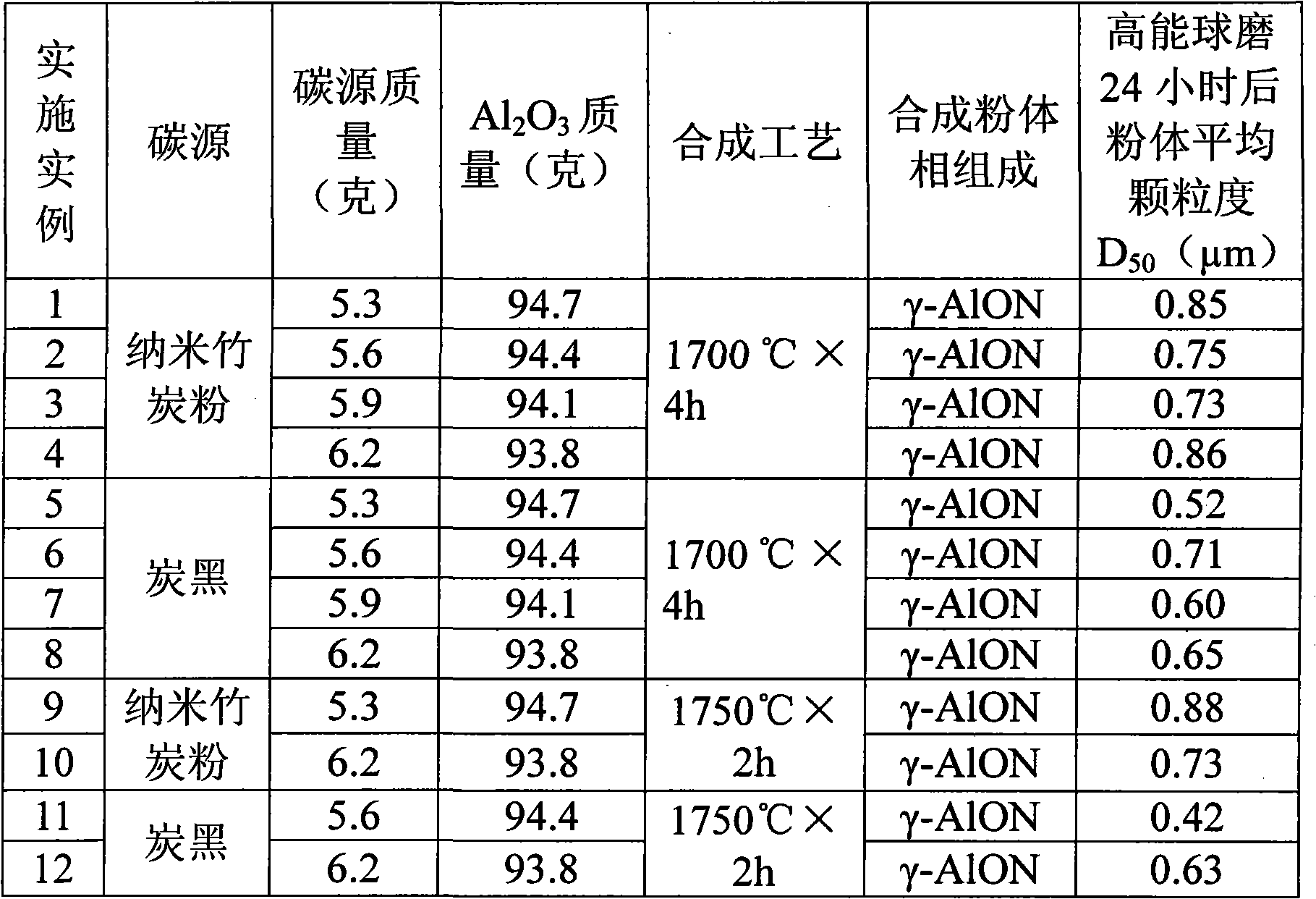

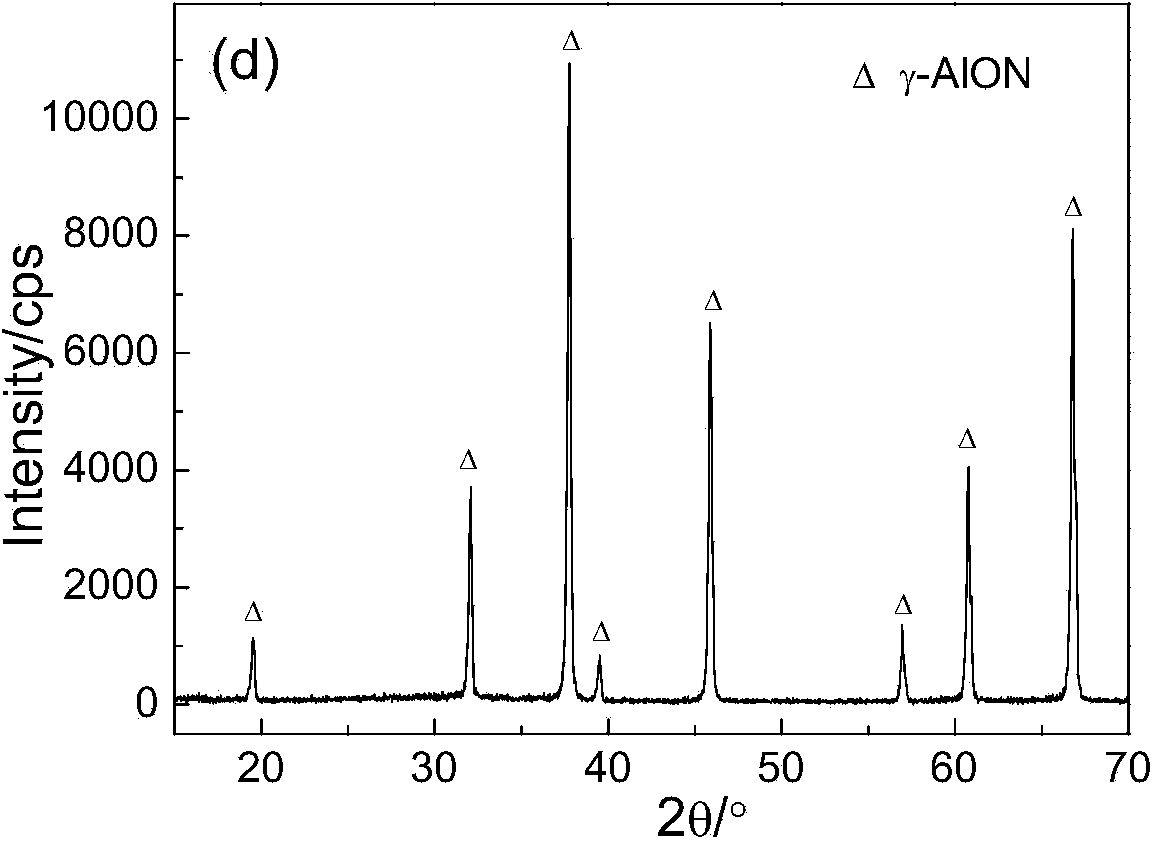

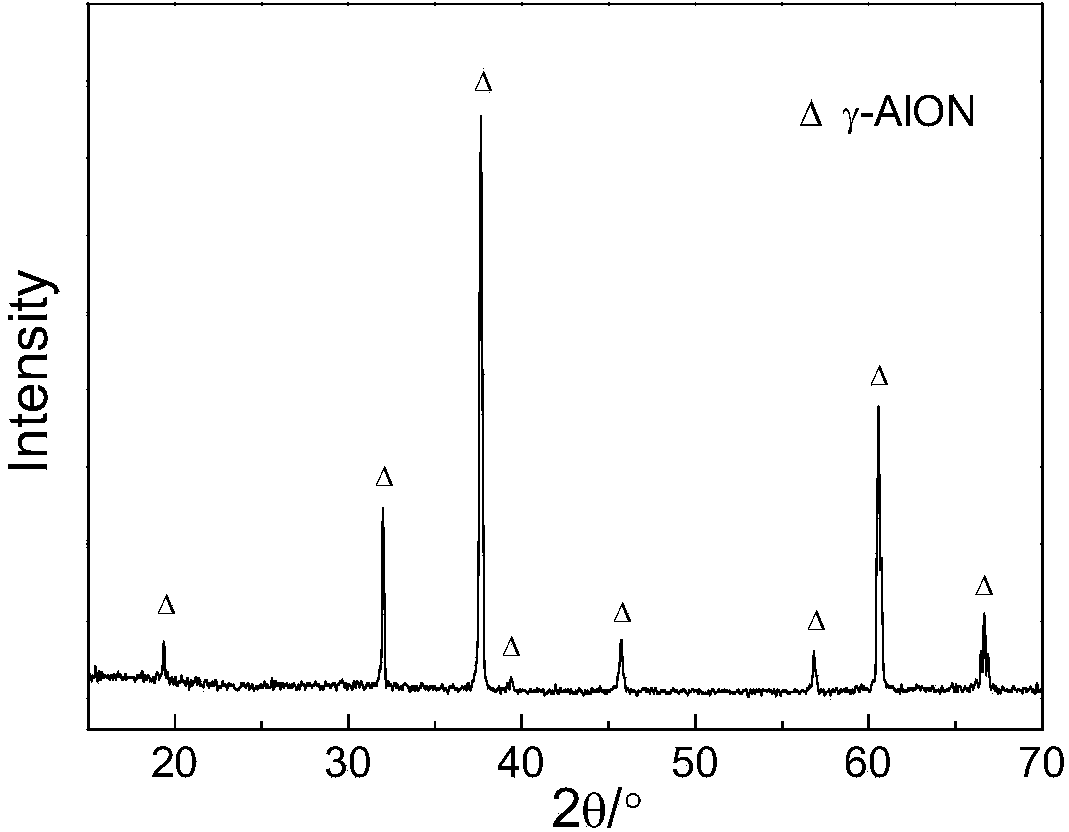

Preparation method of superfine and high-purity gamma-ALON transparent ceramics powder

The invention relates to a preparation method of superfine and high-purity gamma-ALON transparent ceramics powder, belonging to the filed of transparent ceramics material preparation. In the invention, the gamma-ALON transparent ceramics powder is prepared by combining a high energy ball mill with a carbothermic reduction nitriding method. The method of the invention is characterized by comprising the following steps: taking the gamma-Al2O3 powder with high specific surface area and carbon source, i.e. carbon black or nanometer powdered carbon as raw materials, mixing evenly by a wet process high energy ball mill and then drying; placing into a combined crucible of alumina and graphite to carry out the carbothermic reduction nitriding reaction; decarburizing by low-temperature process; and finally obtaining superfine and high-purity gamma-ALON transparent ceramics powder after being crushed by the high energy ball mill. The invention can synthesize pure phase alumina powder under the lower resultant temperature, has simple and feasible process, saves cost, and is suitable for industry production.

Owner:SHANGHAI FRP RES INST

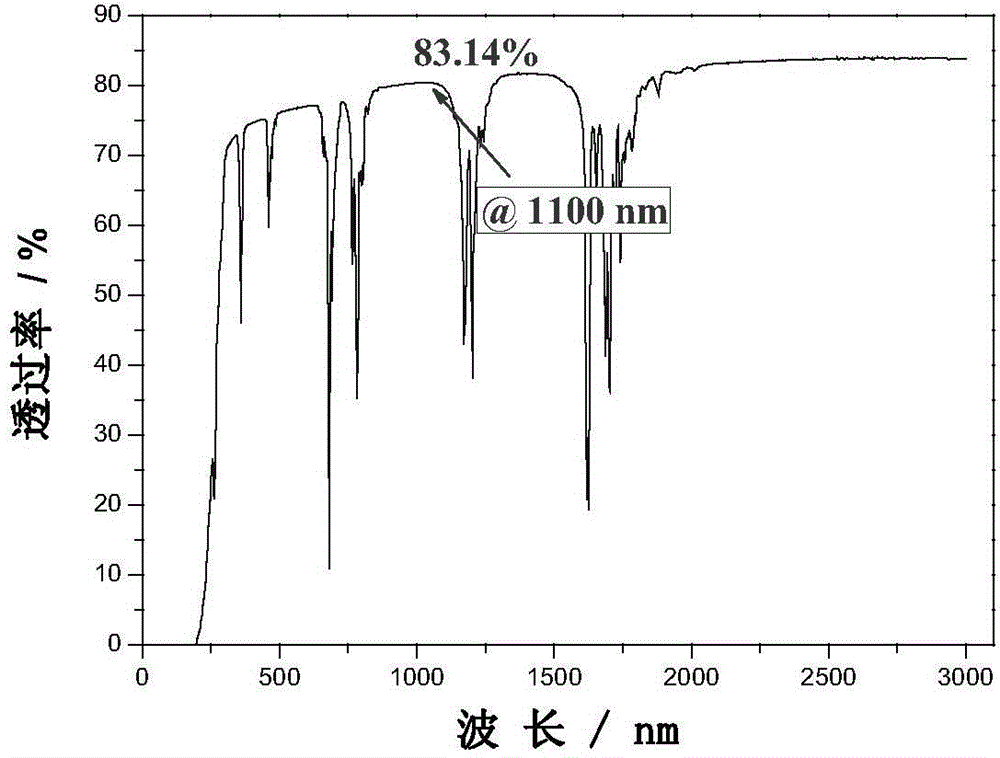

Method for preparing yttrium oxide-based transparent ceramic employing two-step sintering method

The invention relates to a method for preparing yttrium oxide-based transparent ceramic employing a two-step sintering method. The method comprises the following steps: weighing raw material powder at the molar ratio of metal elements required for (Y1-xREx)2O3 (x is smaller than or equal to 0.3 and greater than or equal to 0.0); adding a sintering aid and a solvent, drying ball-milled slurry; sieving and burning; burning by virtue of a muffle furnace after molding, so as to obtain a Y2O3 biscuit; sintering through a two-step sintering process; and finally carrying out high-temperature isostatic pressing sintering, annealing and polishing, so as to obtain the yttrium oxide-based transparent ceramic. The Y2O3-based transparent ceramic prepared by the method has good uniformity; the average crystallite size is 100-300nm; the mechanical property of the Y2O3-based transparent ceramic is effectively improved; the transmittance at 1100nm is high; the method is suitable for a gain medium of a high power laser; the two-step sintering temperature is relatively low; and two-step sintering can be finished within a short period of time, so that the experiment cycle is shortened; and the production cost is reduced.

Owner:徐州市江苏师范大学激光科技有限公司

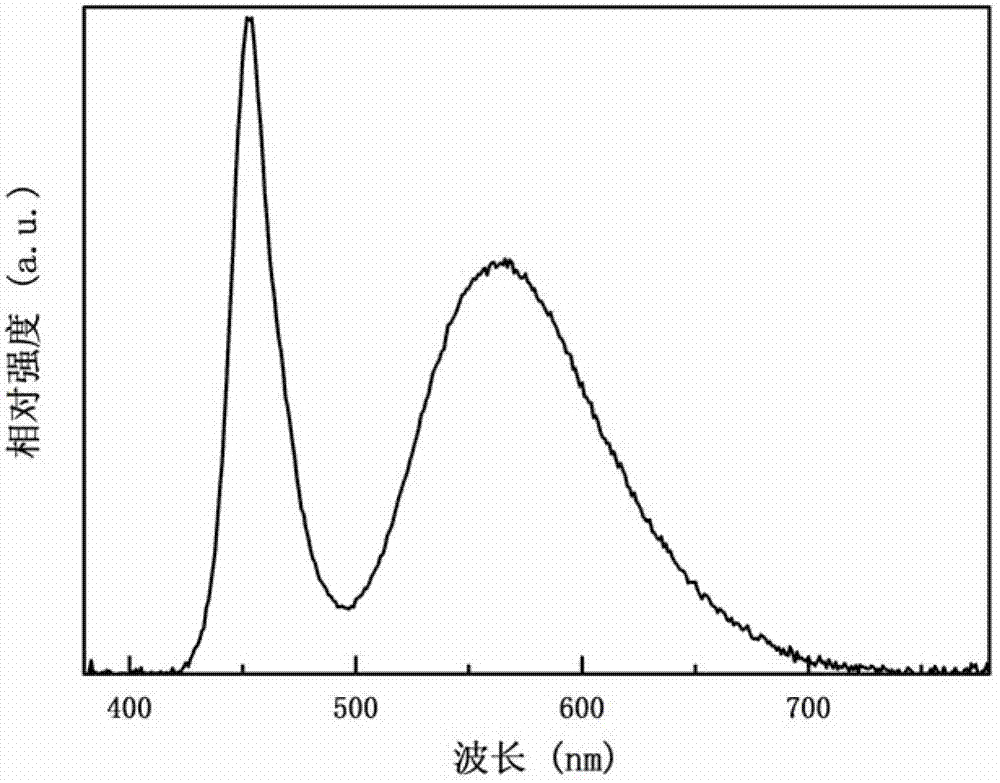

White-light LED (light-emitting diode) containing novel solid-state transparent fluorescent materials and preparation method thereof

ActiveCN103205254AHigh thermal conductivityHigh crystallinitySolid-state devicesCeramic layered productsCrystallinityLight-emitting diode

The invention provides a transparent fluorescent body, and particularly relates to a transparent ceramic fluorescent body, a transparent glass fluorescent body and a transparent composite fluorescent body, and a white-light LED (light-emitting diode) applying the three transparent fluorescent bodies. According to the technical scheme provided by the invention, fluorescent powder in the traditional white-light LED light source is replaced by the transparent fluorescent materials, so as to realize white-light LED; and because the transparent fluorescent bodies have the advantages of being high in thermal conductance, high in stability and high in crystallinity, avoiding the colour temperature drift of the white-light LED light source caused by a high temperature, improving the stability of the white-light LED light source and improving the lighting effect of the white-light LED light source.

Owner:FUJIAN CAS CERAMIC OPTOELECTRONICS TECH CO LTD

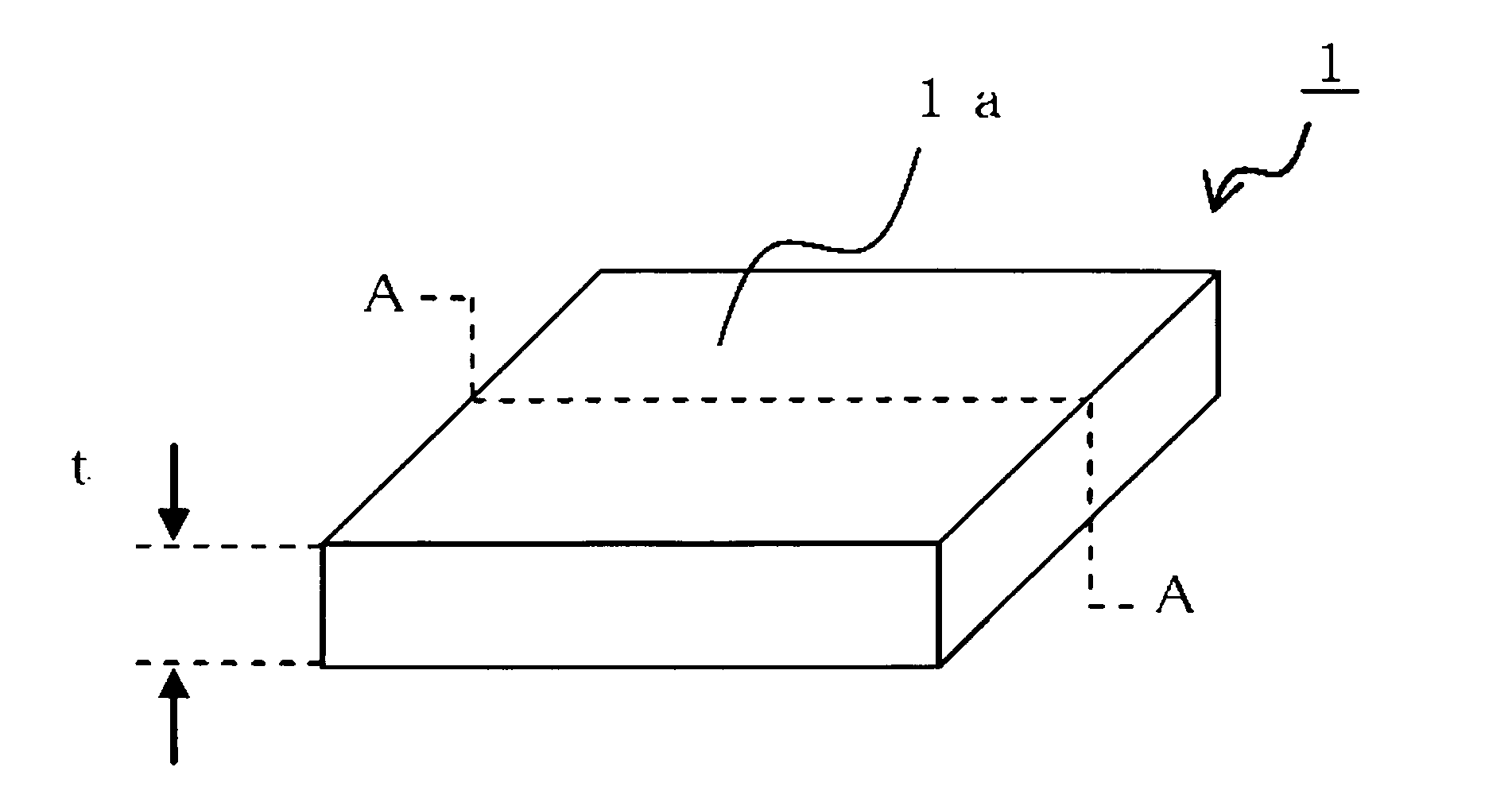

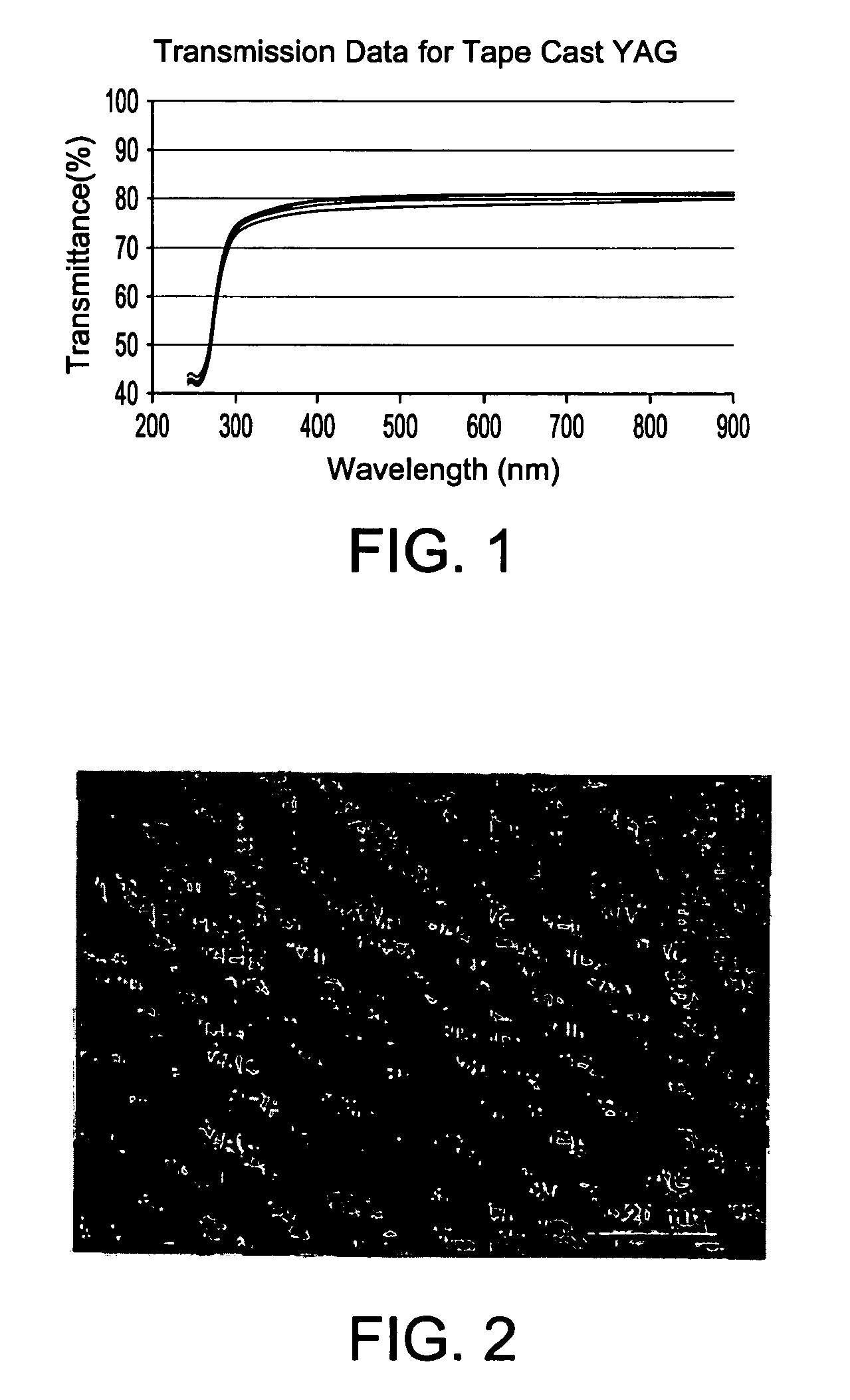

Method for manufacture of transparent ceramics

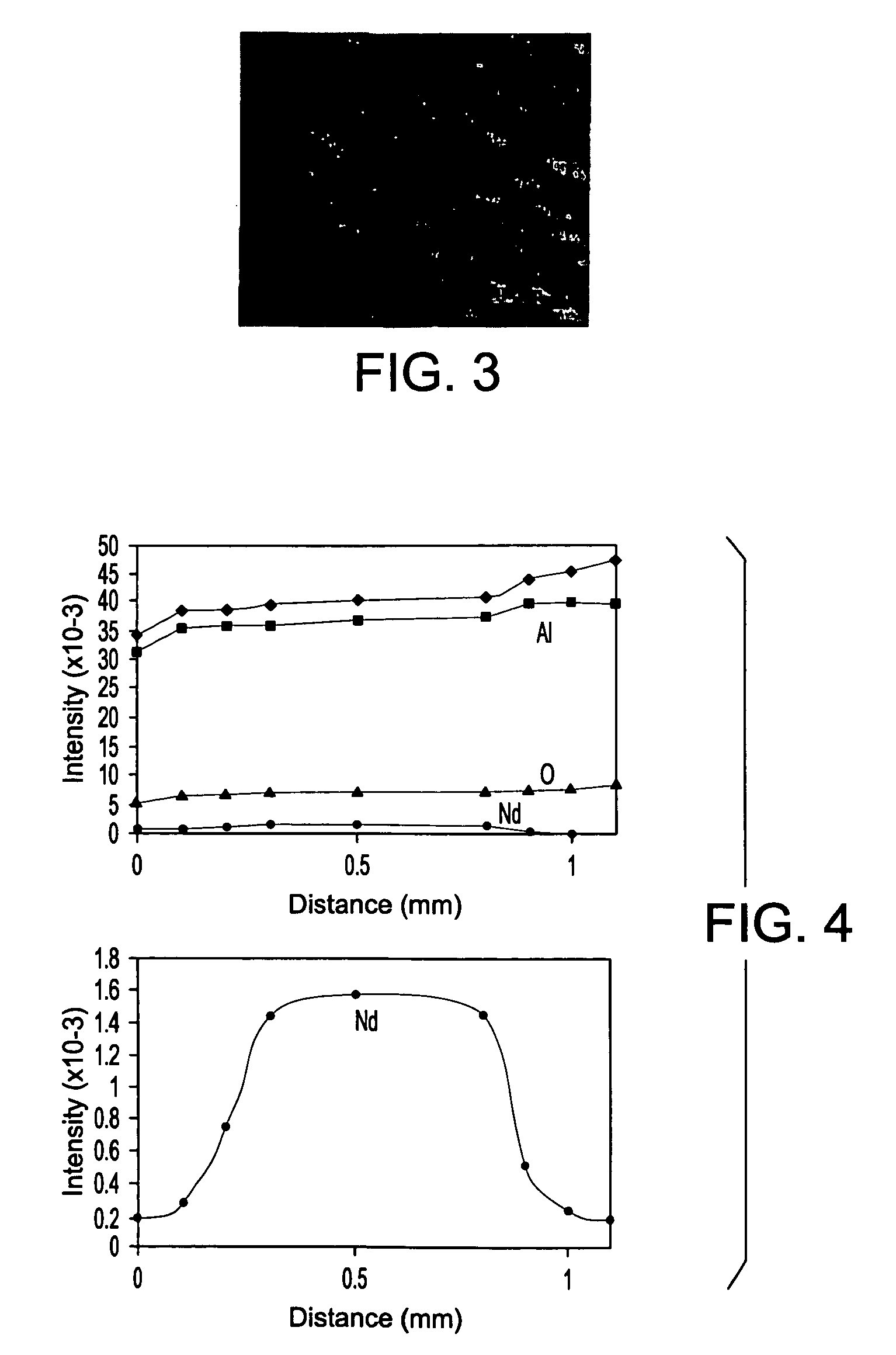

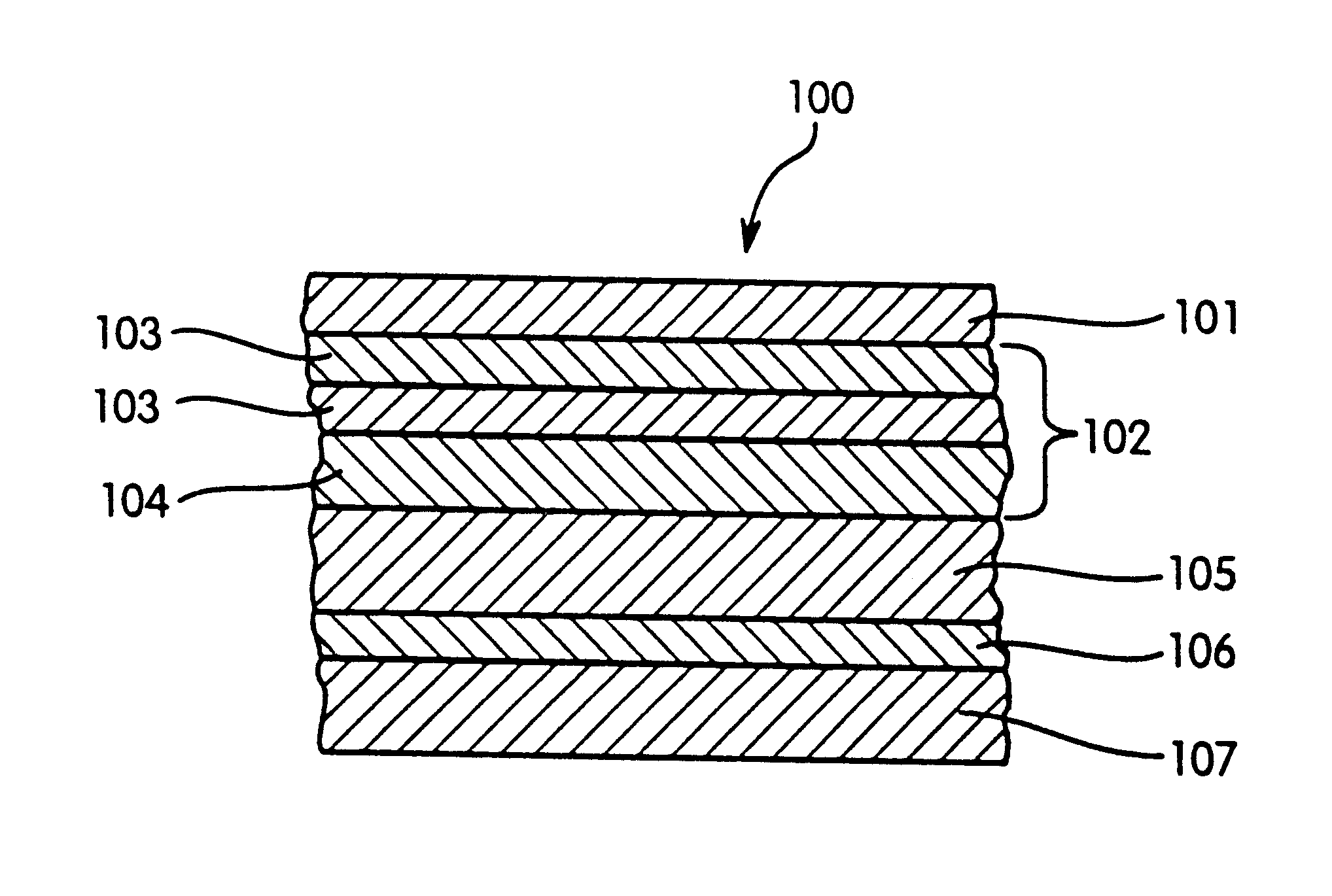

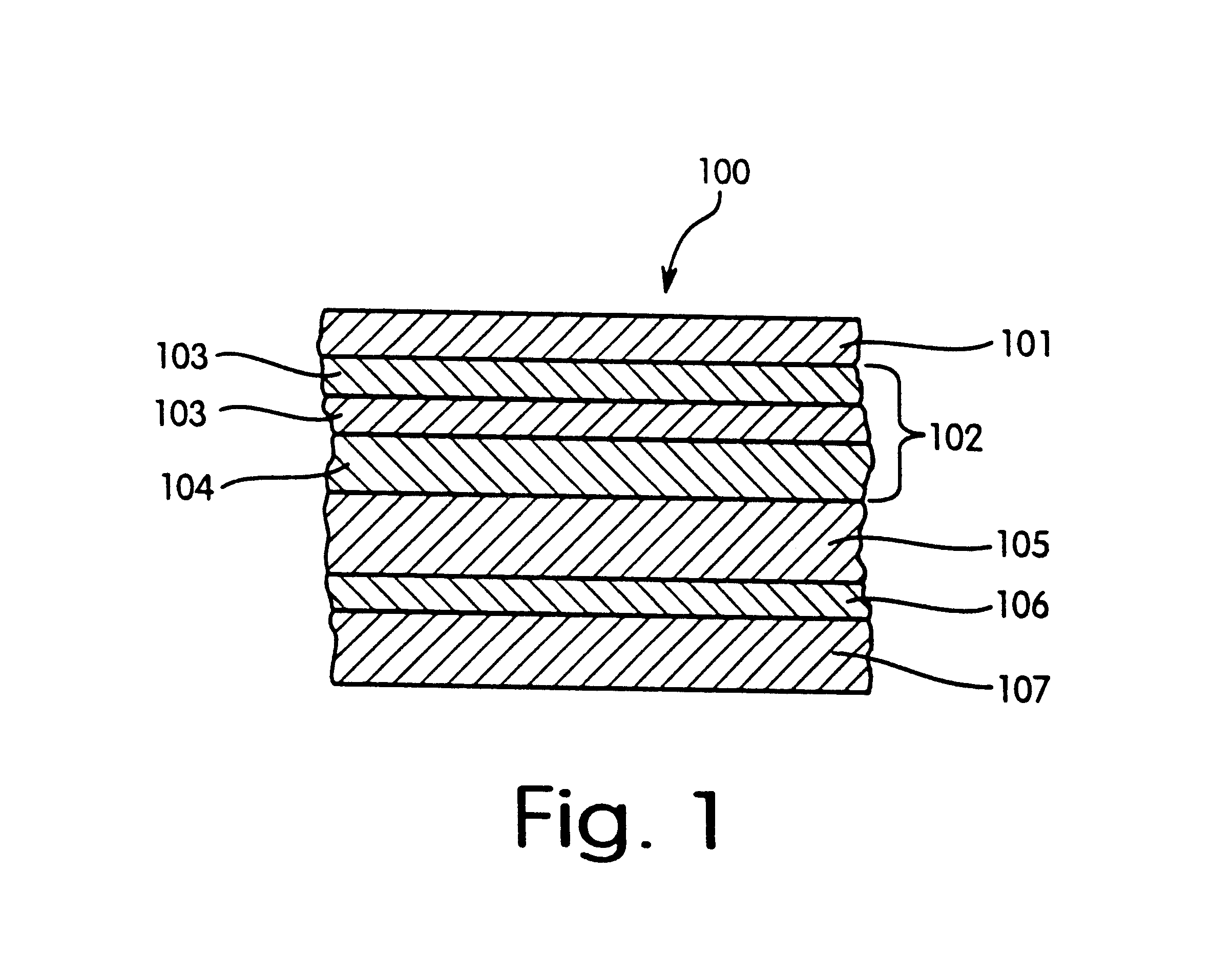

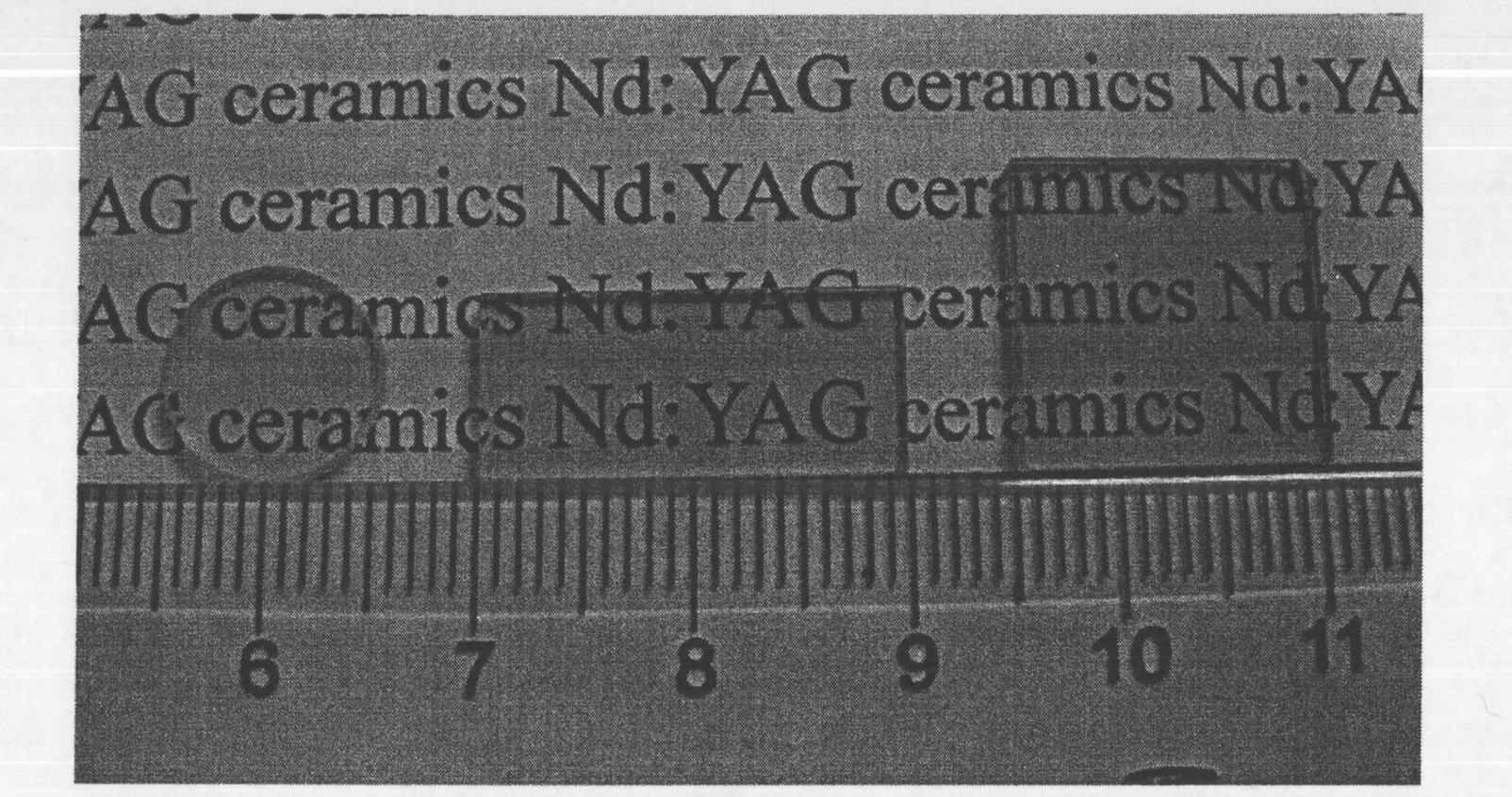

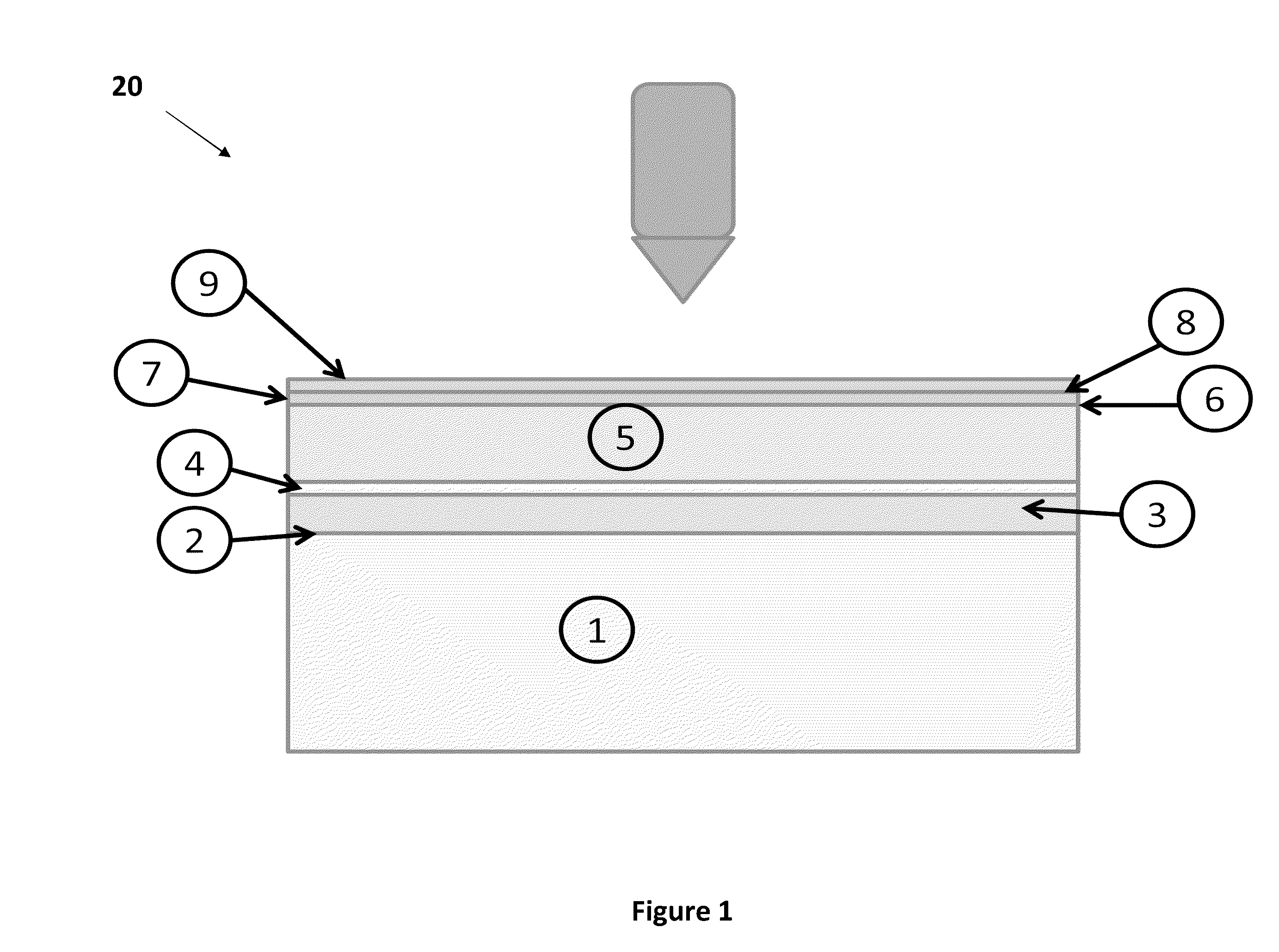

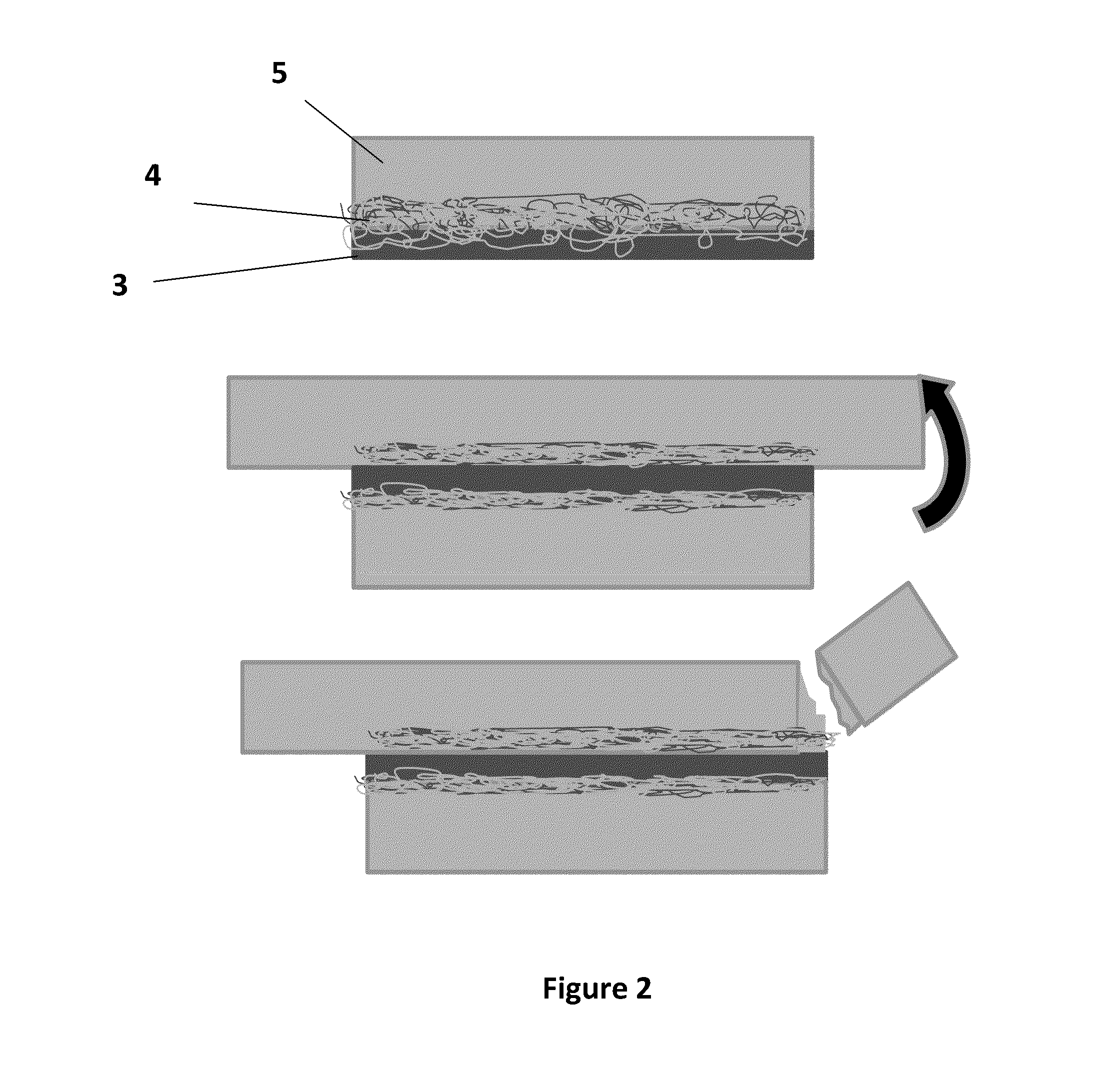

The disclosed invention relates to a method of manufacture of transparent ceramics such as yttrium aluminum garnet by tape casting. The method entails forming a mixture of ceramic oxide, dispersant and organic solvent, milling the mixture to produce a first slurry, mixing the first slurry with an organic binder and a plasticizer to form a treated slurry, milling the treated slurry to produce milled slurry, tape casting the milled slurry to produce cast tape, drying the cast tape to produce dried tape, stacking portions of dried tape to form an assembly, compressing the assembly to produce a preform, heating the preform to produce a green preform, and sintering the green preform to produce transparent yttrium aluminum garnet. The method may be used to produce a unitary ceramic product having differing transparent sections as well as transparent ceramic product having a dopant gradient across a portion of the thickness of the product.

Owner:PENN STATE RES FOUND

Reflector with a resistant surface

A reflector with high total reflection which is resistant to mechanical stresses. The reflector comprises a reflector body and superimposed thereon (a) a functional coating such as a varnish, (b) a reflecting layer structure composed of a reflecting metallic layer and optionally arranged thereon one or several transparent ceramic layers, for example, layers having an optical depth of λ / 2. The reflecting layer structure contains, as its surface layer, a protective layer. The protective layer is a silicon oxide of general formula SiOx, wherein x is a number from 1.1 to 2.0, or it is aluminum oxide of formula Al2O3, in a thickness of 3 nm or more. The protective layer protects the underlying layers from mechanical damages. In the DIN 58196 abrasion test the protected surface does not show any damages after 50 test cycles with 100 abrasion strokes.

Owner:ALANOD ALUMINUM VEREDLUNG +1

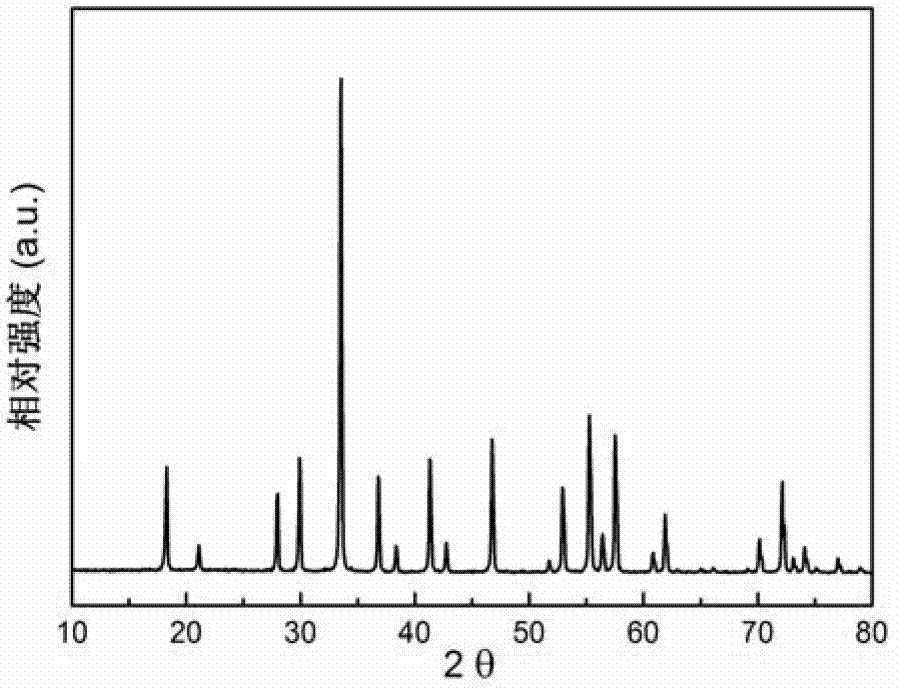

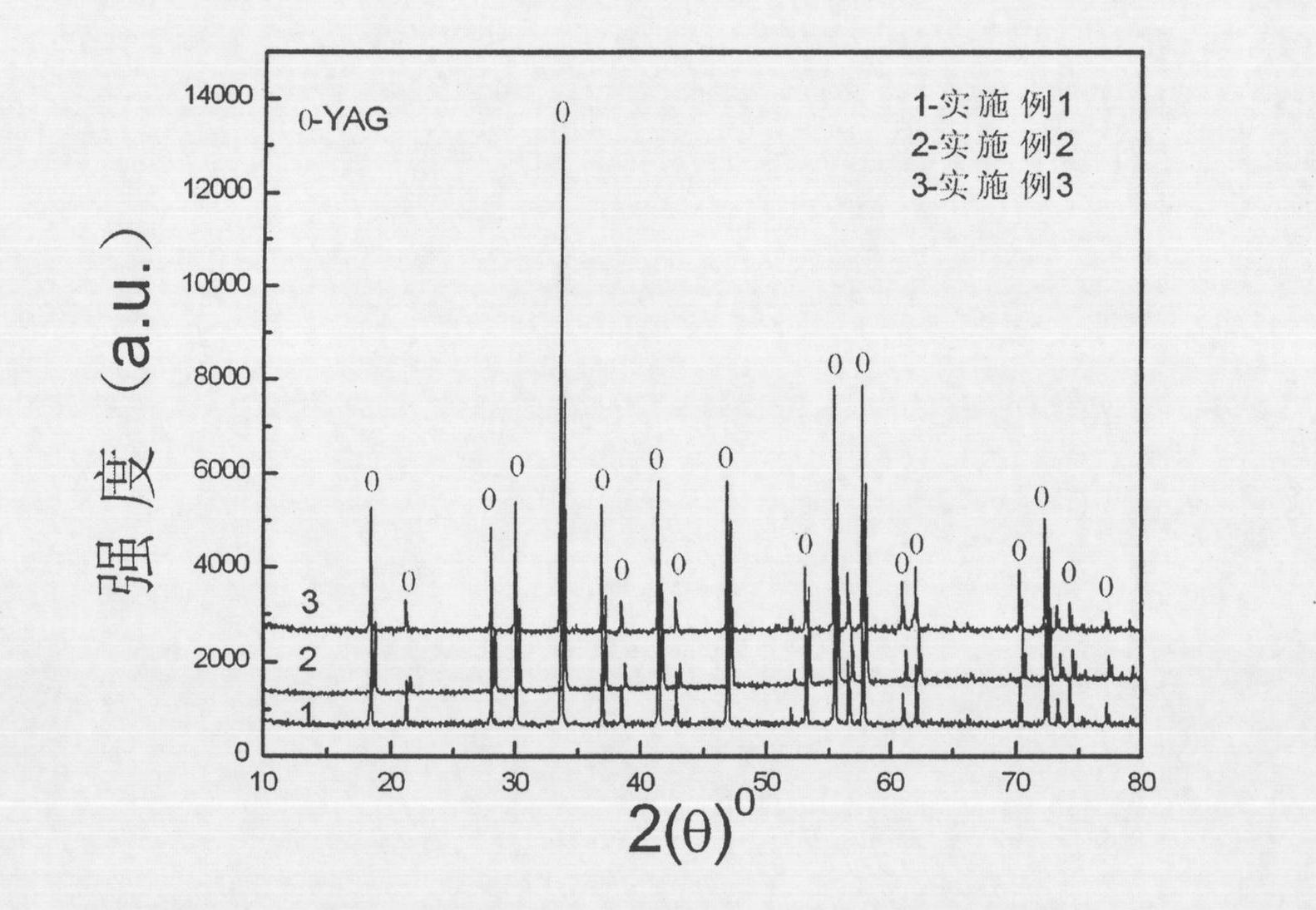

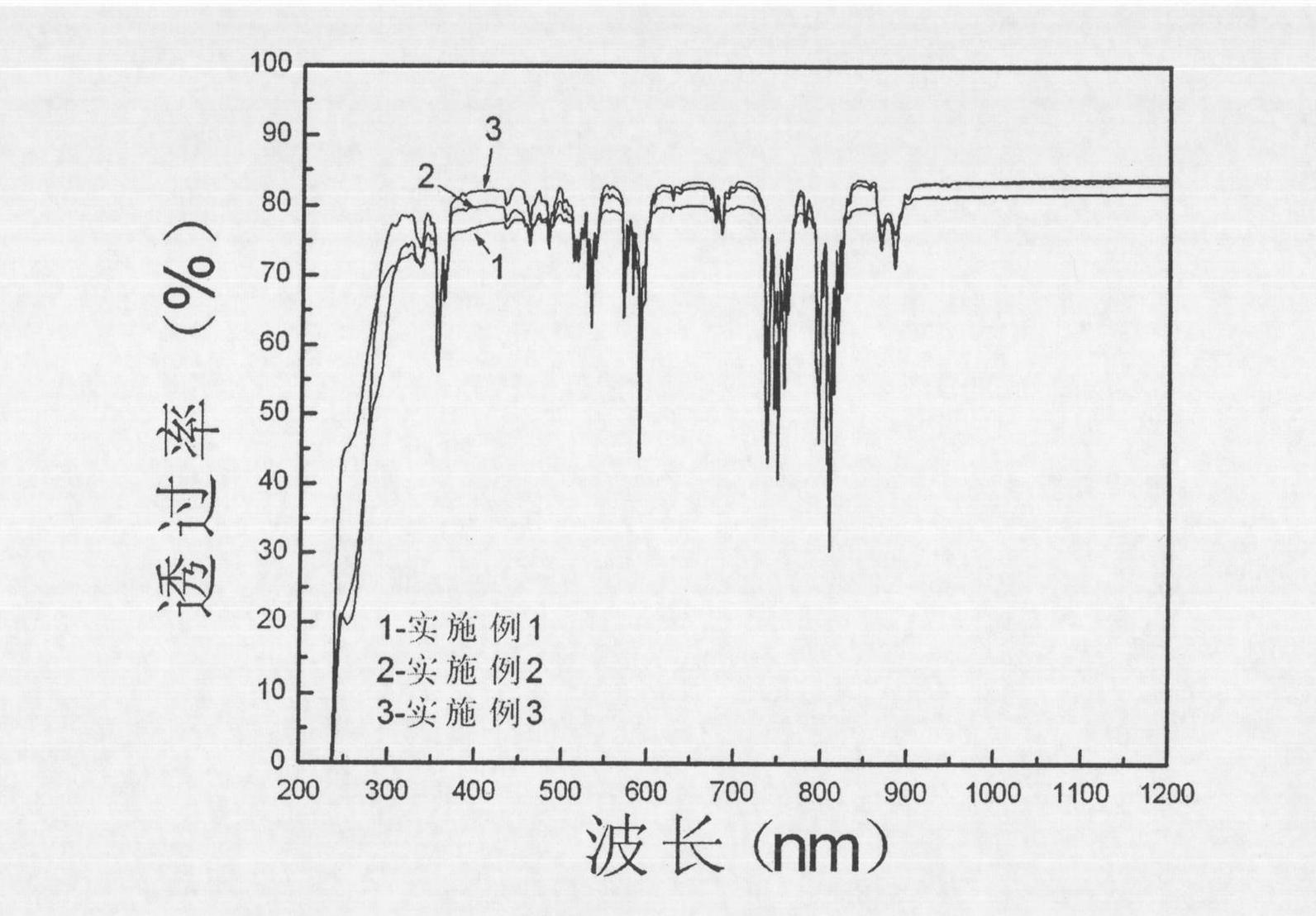

Method for preparing Re:YAG polycrystalline transparent ceramic by using different molding modes

The invention relates to a method for preparing Re:YAG polycrystalline transparent ceramic by using different molding modes, which adopts commercial high-purity Y2O3, Al2O3 and Re2O3 as raw materials, adopts MgO, CaO or TEOS (tetraethyl orthosilicate) as sintering additive, and prepares a raw blank by a cold isostatic pressing, slip casting or tape casting process to react and sinter the transparent polycrystalline Re:YAG ceramic. The method comprises the following steps: mixing and adding the oxides into a liquid medium; adding a certain amount of dispersant, adhesive, plasticizer, pressing agent and defoaming agent, carrying out ball milling, and mixing; treating the slurry under different conditions in different molding modes to obtain the raw blank; and sintering the degreased raw blank in a vacuum furnace. For the Re:YAG ceramic sintering body with thickness of 1.5mm, the transmission rate of straight light in the wavelength of 1064nm is not lower than 80% after the Re:YAG ceramic sintering body is subjected to double-sided polishing. For the raw blank which is prepared by different molding modes and is sintered for 10 hours at 1750 DEG C, sizes of ceramic grains are different, wherein regarding the raw blank prepared by cold isostatic pressing, the average grain of the ceramic is 13.5mu m; regarding the raw blank prepared by slip casting, the average grain of the ceramic is 3.5mu m; and regarding the raw blank prepared by tape casting, the average grain of the ceramic is 1.5mu m.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Delamination-and abrasion-resistant glass window

InactiveUS20140127500A1Sufficient powerSynthetic resin layered productsGlass/slag layered productsField conditionsAdhesive

The transparent window is suitable for use in applications that require a host of very demanding performance criteria. In the window, a transparent polymer is chemically bonded to an adhesive at an interface between the two, which enables the window to resist delamination. The window also has a polymer or plastic strike face with a coating that enables it to endure rigorous field conditions and still pass critical rock strike tests. The window also has a bulk layer with at least one layer of a glass, glass-ceramic, or transparent ceramic material.

Owner:ORAN SAFETY GLASS INC

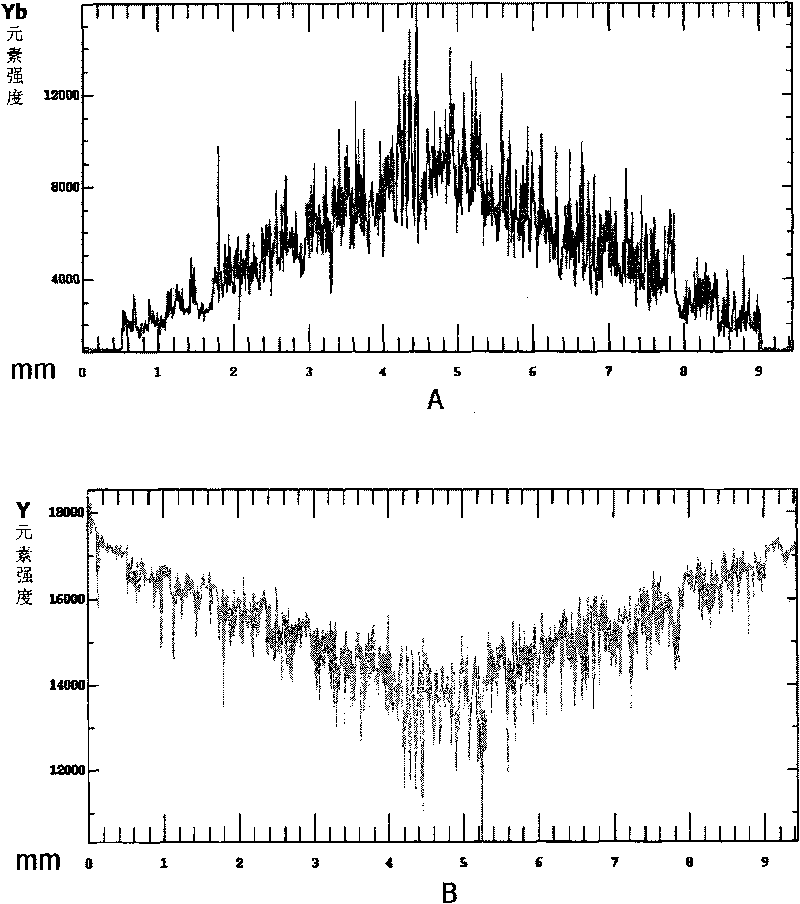

Method for preparing yttrium aluminium garnet transparent ceramic with composite structure

The invention provides a method for preparing yttrium aluminium garnet (YAG) transparent ceramic with a composite structure. The method comprises the following steps: by using Re:YAG powder and high-purity Y2O3, Al2O3 and Re2O3 as raw materials, adding a certain amount of dispersing agent, binder, plasticizer and defoaming agent to mix slurry in a ball-milling manner; preparing different doped and bound composite structures of ceramic biscuits, such as Sm:YAG / Nd:YAG, Cr:YAG / Yb:YAG and YAG / Nd:YAG, different multi-segment doped Re:YAG ceramic biscuits, such as YAG / Cr:YAG / Nd:YAG / YAG, a core-shell structured composite ceramic biscuit, and a layered composite structure of transparent ceramic biscuit in a vacuum pressure slip casting manner. Different composite structures of Re:YAG transparent ceramics are obtained by the following processing steps: biscuit degreasing, vacuum sintering, hot isostatic pressing sintering, annealing and the like. The linear transmittance of the transparent ceramic after being polished at double sides in a visible near infrared region can be up to over 80%.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method of yttrium aluminium garnet doped transparent laser ceramics

The invention discloses a preparation method of yttrium aluminium garnet doped transparent laser ceramics. The method includes using an alcohol-aqueous system stepping chemical co-precipitation method to firstly prepare high-dispersity and high-activity nanometer Y2O3 oxide powders, Al2O3 oxide powders and rare earth (Re) oxide powders, weighing raw materials of the powders according to a stoichiometric ratio of Y<3-x>RexAl5O12 when the powders are prepared, placing the powders, sintering aids, dispersing agents and absolute ethyl alcohol into a ball-milling tank for ball milling, drying ball-milling mixing slurries into powders, forming the powders into green bodies with certain shapes by dry pressing, and then subjecting the green bodies to isostatic cool pressing to obtain ceramic biscuits. The ceramic biscuits are subjected to binder removing, vacuum sintering, powder-burying hot-pressing post-processing, annealing and optical polishing to obtain Re:YAG transparent ceramics. The preparation method has the advantages of being controllable, high in repeatability, low in cost and high in transmittance.

Owner:北京雷生强式科技有限责任公司

Method for manufacturing LED with transparent ceramics

ActiveUS20120178193A1Improve performanceSemiconductor/solid-state device manufacturingLuminescent compositionsEpoxySemiconductor chip

A method for manufacturing an LED (light emitting diode) with transparent ceramic is provided, which includes: adding quantitative fluorescent powder into transparent ceramic powder, wherein the doped ratio of the fluorescent powder is 0.01-100 wt %; preparing the fluorescent transparent ceramic using ceramic apparatus and process, after fully mixing the raw material; assembling the prepared fluorescent transparent ceramic and a semiconductor chip to form the LED device. The method assembles the fluorescent transparent ceramic and a semiconductor chip to form the LED device by replacing the fluorescent powder layer and the epoxy resin package casting of the traditional LED with fluorescent transparent ceramic. The fluorescent transparent ceramic is used as the package cast and fluorescent material, and the LED device manufactured through the method has more excellent performance.

Owner:BRIGHT CRYSTALS TECH

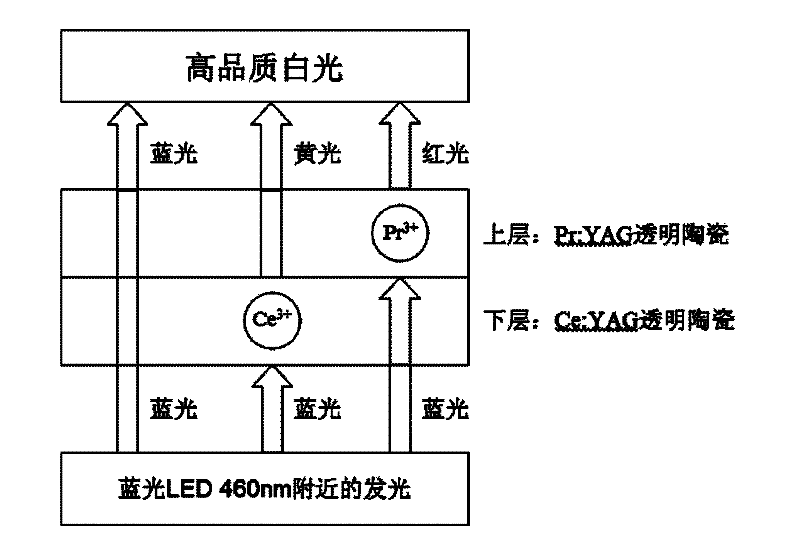

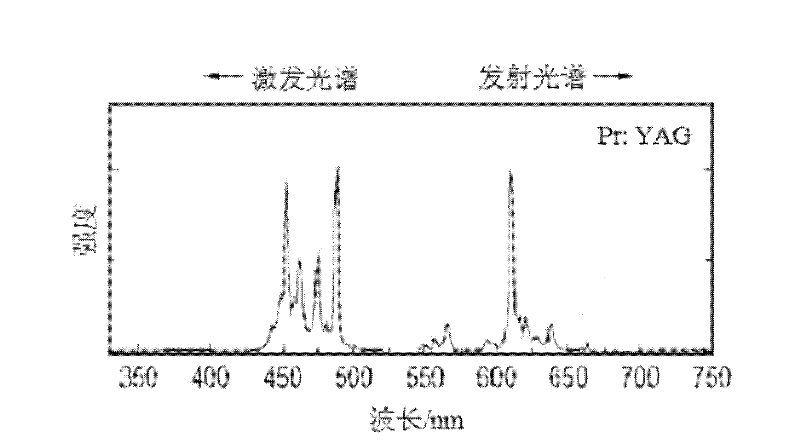

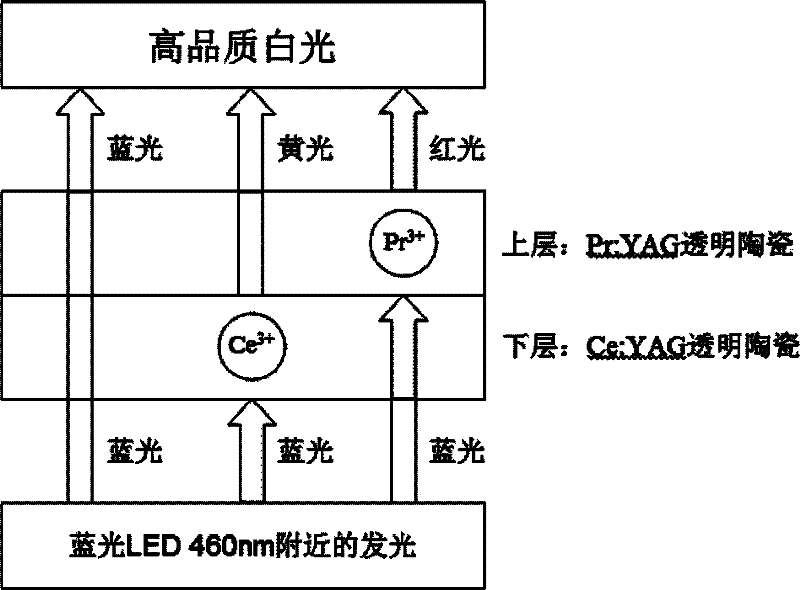

Composite transparent ceramic used for white-light LED fluorescence conversion and preparation method thereof

InactiveCN102501478AHigh luminescence quenching temperatureStable physical and chemical propertiesCeramic layered productsChemical compositionFluorescence

A composite transparent ceramic used for white-light LED fluorescence conversion and a preparation method thereof are provided. The composite transparent ceramic is composed of an upper and a lower layer of transparent ceramic bonded; chemical composition of the upper layer of transparent ceramic is (PrxY1-x)3Al5O12, wherein 0.0003<=x<=0.06; and chemical composition of the lower layer of transparent ceramic is (CeyY1-y)3Al5O12, wherein 0.0003<=y<=0.06. When a blue-light LED excites the composite transparent ceramic, yellow light generated by the lower layer of transparent ceramic mixes with red light generated by the upper layer of transparent ceramic and blue light transmitted through the upper layer of transparent ceramic to form high-quality white light, to thereby obtain the characteristics of high color rendering index and mild color temperature. In addition, the inventive composite transparent ceramic has the advantages of high shine quenches temperature, stable physicochemical properties, low cost, etc.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Sintering method of yttrium oxide base transparent ceramic

The invention belongs to the field of ceramic material preparation, in particular relates to a sintering method of yttrium oxide base transparent ceramic. The method of the invention includes the following steps: mixed powder after cold isostatic pressing moulding is heated to 1200-1600 DEG C and then instantly cooled to 350-800 DEG C, heat preservation is carried out, and finally the mixed powder after heat preservation is sintered under vacuum for 2-10 hours. The sintering method of the invention utilizes special sintering performance of nano powder, firstly treatment at low temperature (about 40% of melting-point) is carried out, so that sample is densified (reaching about 90% of theoretical density) while grain growth is effectively controlled, and warming sintering is further carried out under vacuum to obtain micro crystal transparent ceramic. The sintering method of the invention can effectively control grain growth in sintering process and is benefit for air hole exhaust, and sintering sample has favourable transmission without annealing treatment. The sintering method of the invention also has the characteristics of lower cost and easy operation.

Owner:江苏先进无机材料研究院

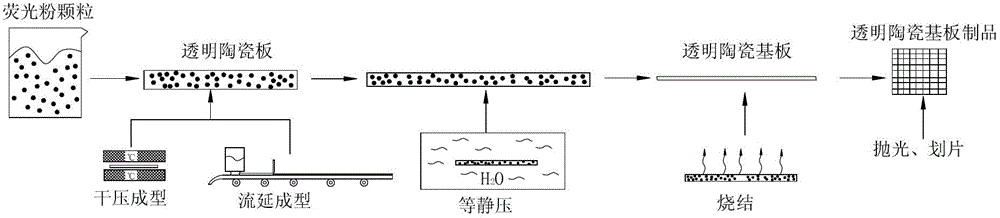

Method for producing transparent ceramic fluorescence substrate used for LED

InactiveCN102718492AImprove light uniformityEliminates concentration inequalitiesFluorescenceSilica gel

The present invention discloses a method for producing a transparent ceramic fluorescence substrate used for a LED, which comprises the following steps: (1) mixing; (2) granulating; (3) molding; (4) isopressing; (5) dumping and sintering; (6) polishing and grinding; and (7) scribing. The substrate prepared by the method of the invention can realize all the functions of a traditional substrate, and has fluorescent characteristics, the LED chips can be directly fixed on the substrate for realizing the white light of the LED, because that various concentrations of fluorescent powder in silica gel and resin can be eliminated, the consistency of the LED products can be enhanced, the substrate prepared by the method of the invention has the advantages of good light uniformity, easy thickness control, and the method provided by the invention belongs to the planarization process, and is suitable for integrated large-scale production.

Owner:SUZHOU JINGPIN OPTOELECTRONICS

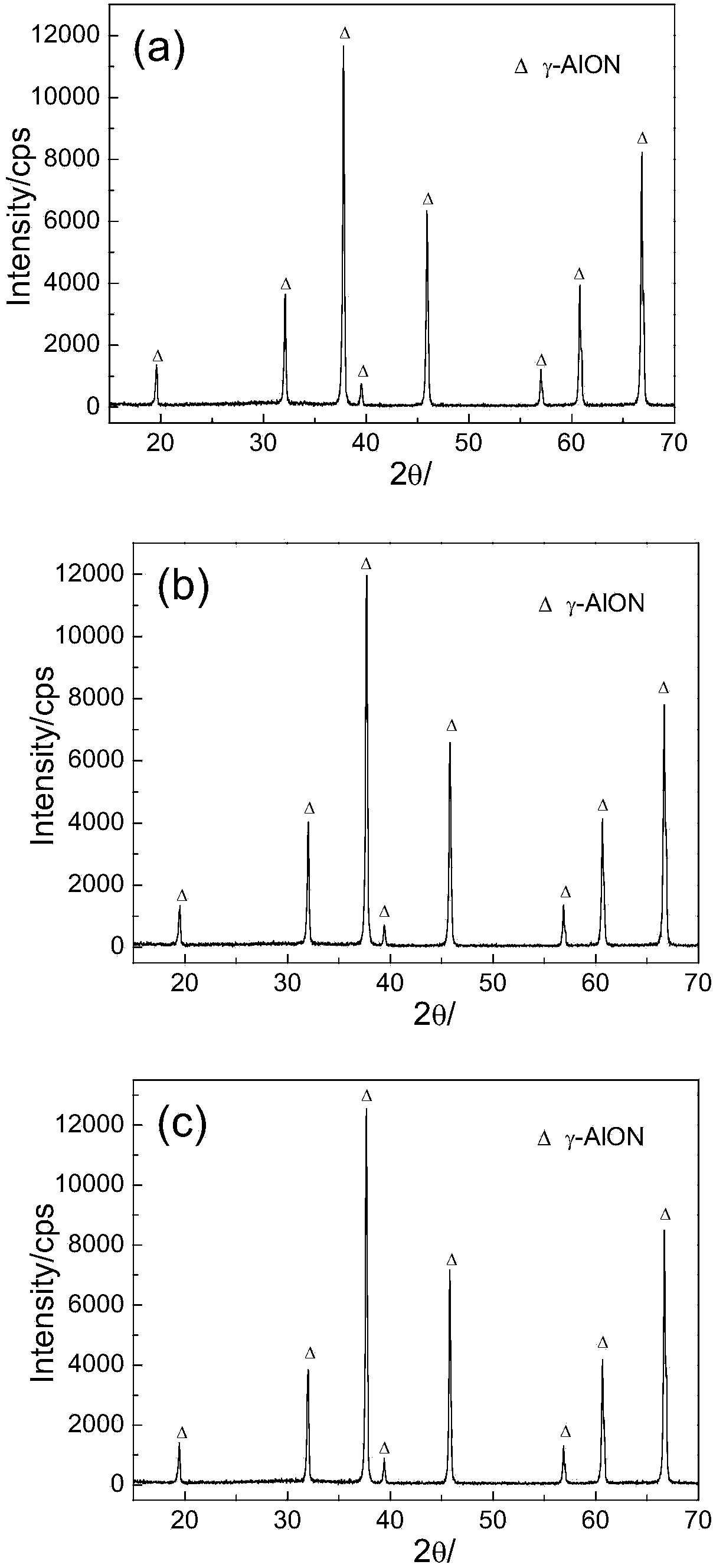

Preparation method for gamma-AlON transparent ceramic powder

The invention relates to a method for preparing pure-phase gamma-AlON transparent ceramic powder by carbothermal reduction of gamma-Al2O3, and belongs to the field of preparation of transparent ceramic materials. According to the preparation method, nano-alpha-Al2O3 and activated carbon are taken as raw materials; powder is filled in a graphite crucible loosely, wherein an aluminum oxide plate is paved at the bottom of the graphite crucible; an air hole which penetrates through the powder is preformed at the aluminum oxide plate; a graphite cover provided with fine and dense air holes is used for covering the hole; the pure-phase gamma-AlON transparent ceramic powder is prepared by adopting a two-step heating process in a flowing nitrogen environment with a micro positive pressure. By the adoption of the preparation method, the vacuumizing difficulty can be effectively reduced, powder is prevented from scattering in a vacuumizing stage, the time required for discharging adsorbed gas can be greatly shortened, the vacuumizing speed is high, and the preparation efficiency of the gamma-AlON powder is greatly improved; the obtained gamma-AlON powder phase has stable and reliable compositions and can be used for pressure-less sintering preparation of AlON transparent ceramics with high transmittance; the process is simple and is easy to operate, and is suitable for industrial production.

Owner:DALIAN MARITIME UNIVERSITY

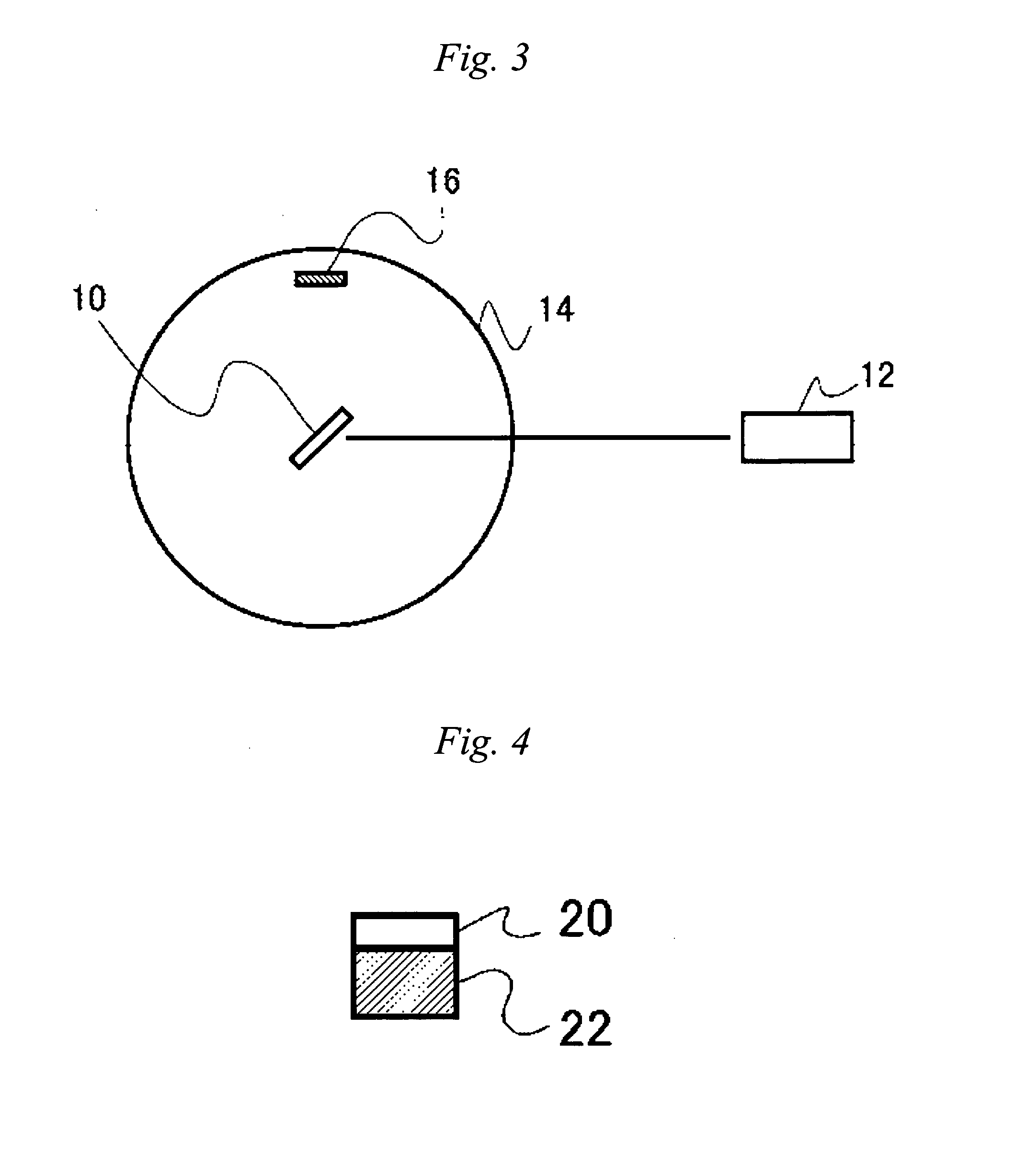

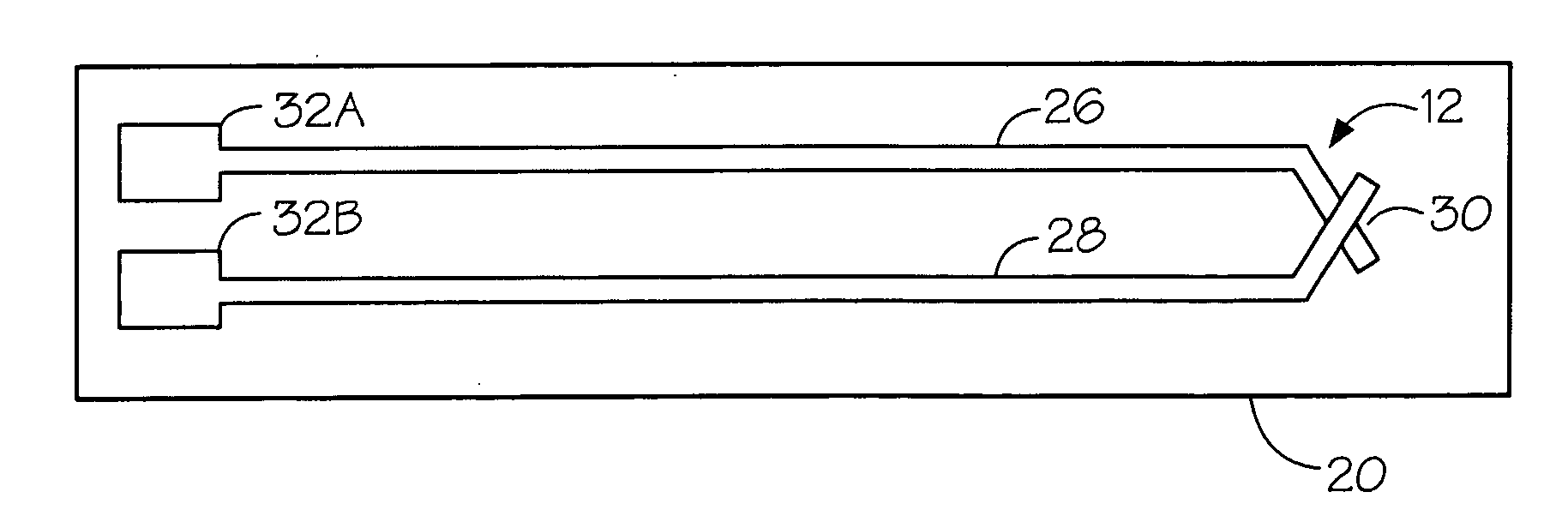

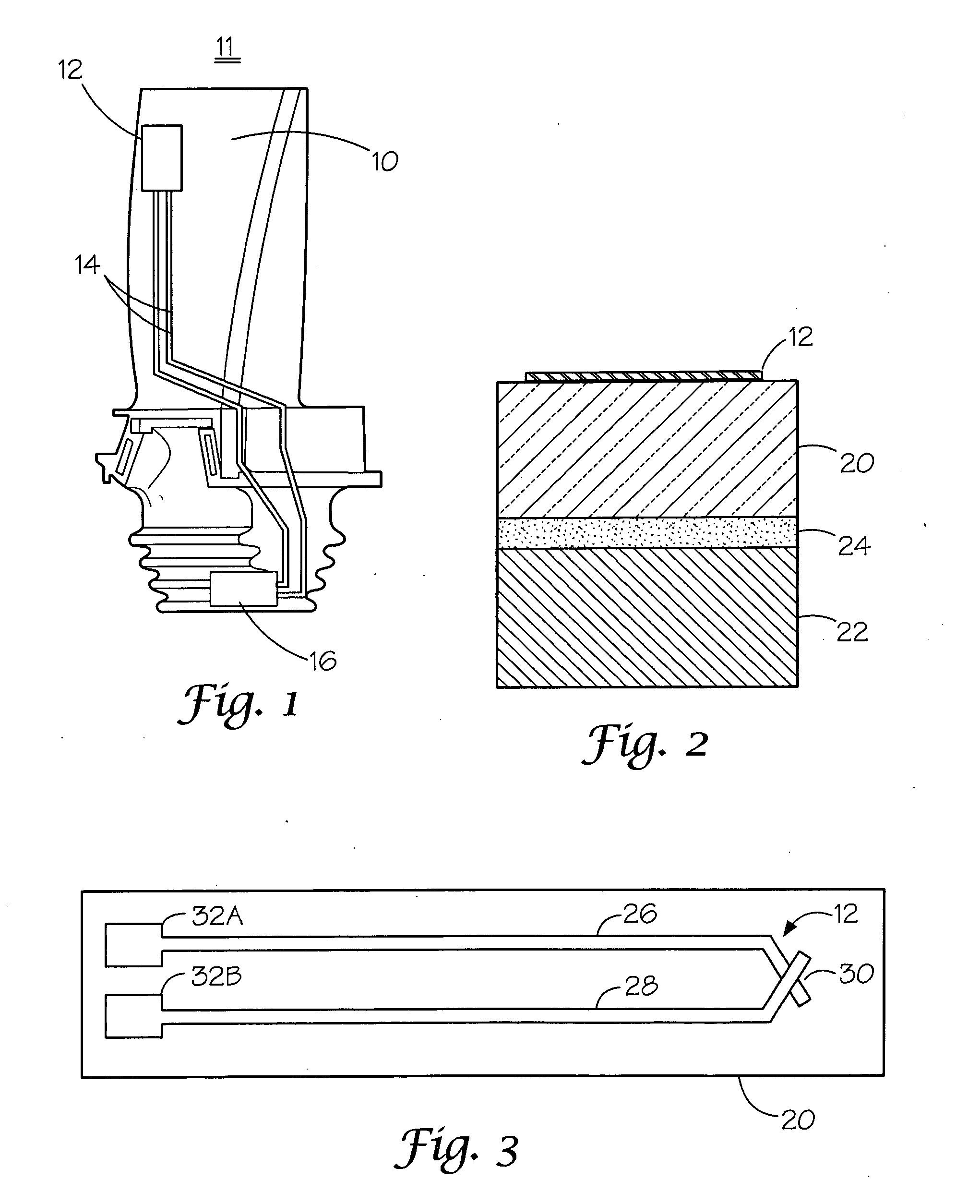

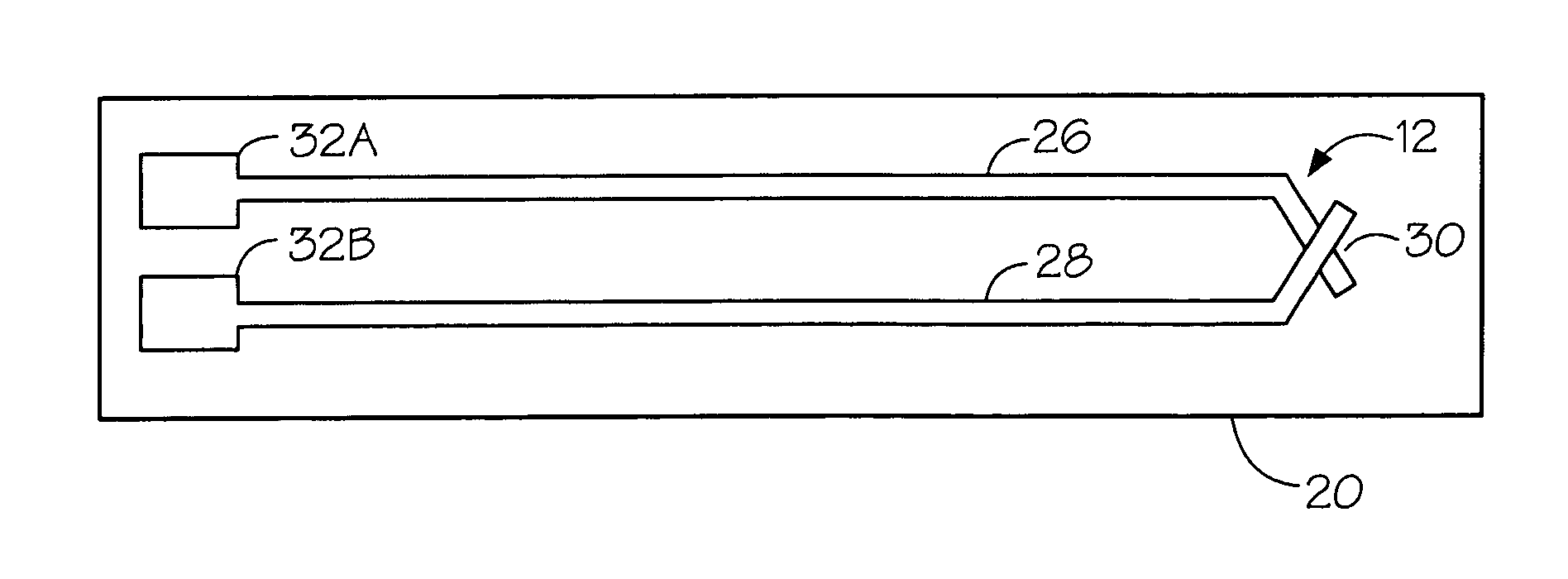

Thermocouple for Gas Turbine Environments

ActiveUS20100027584A1Thermometer detailsThermometers using electric/magnetic elementsThin film thermocouplesEngineering

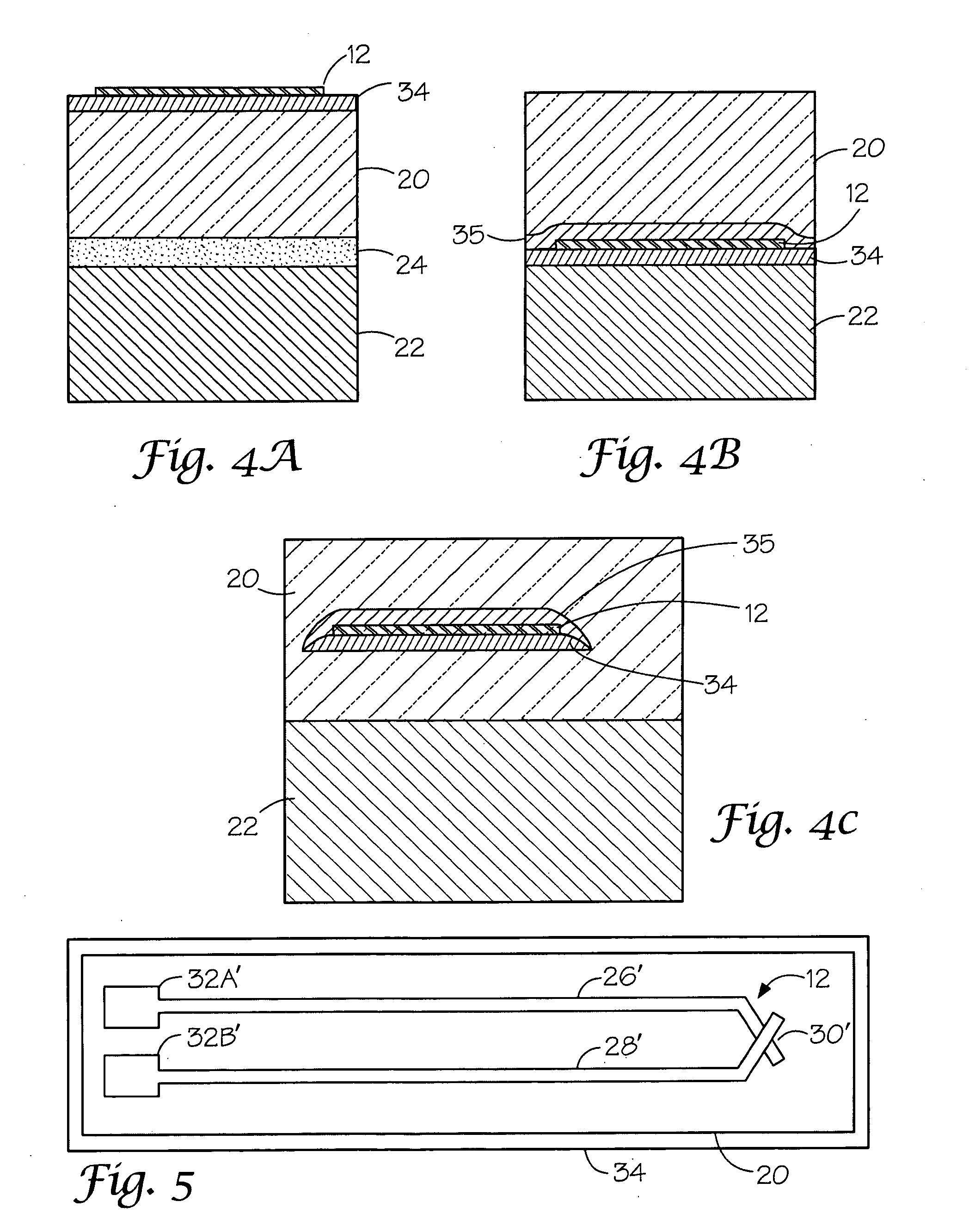

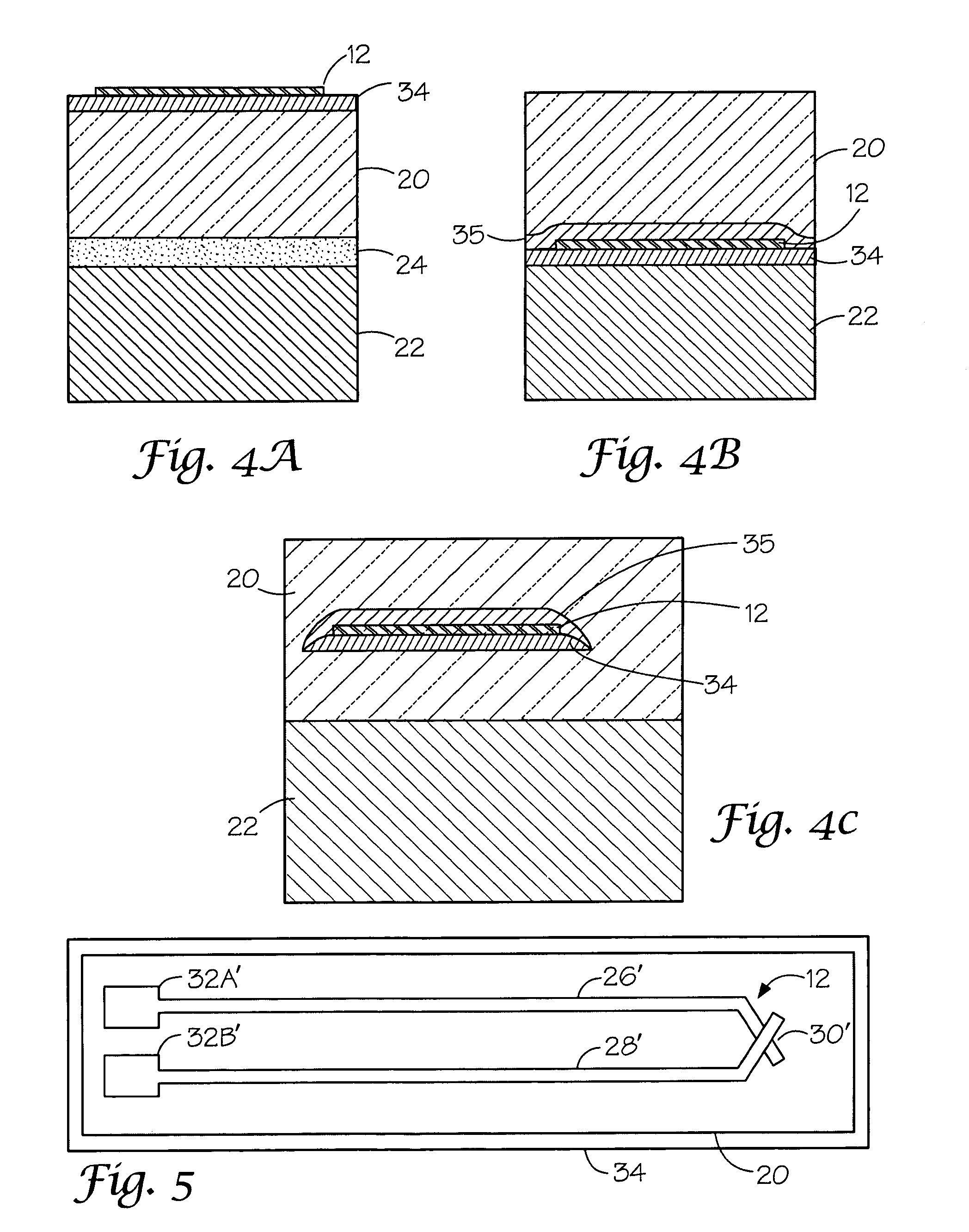

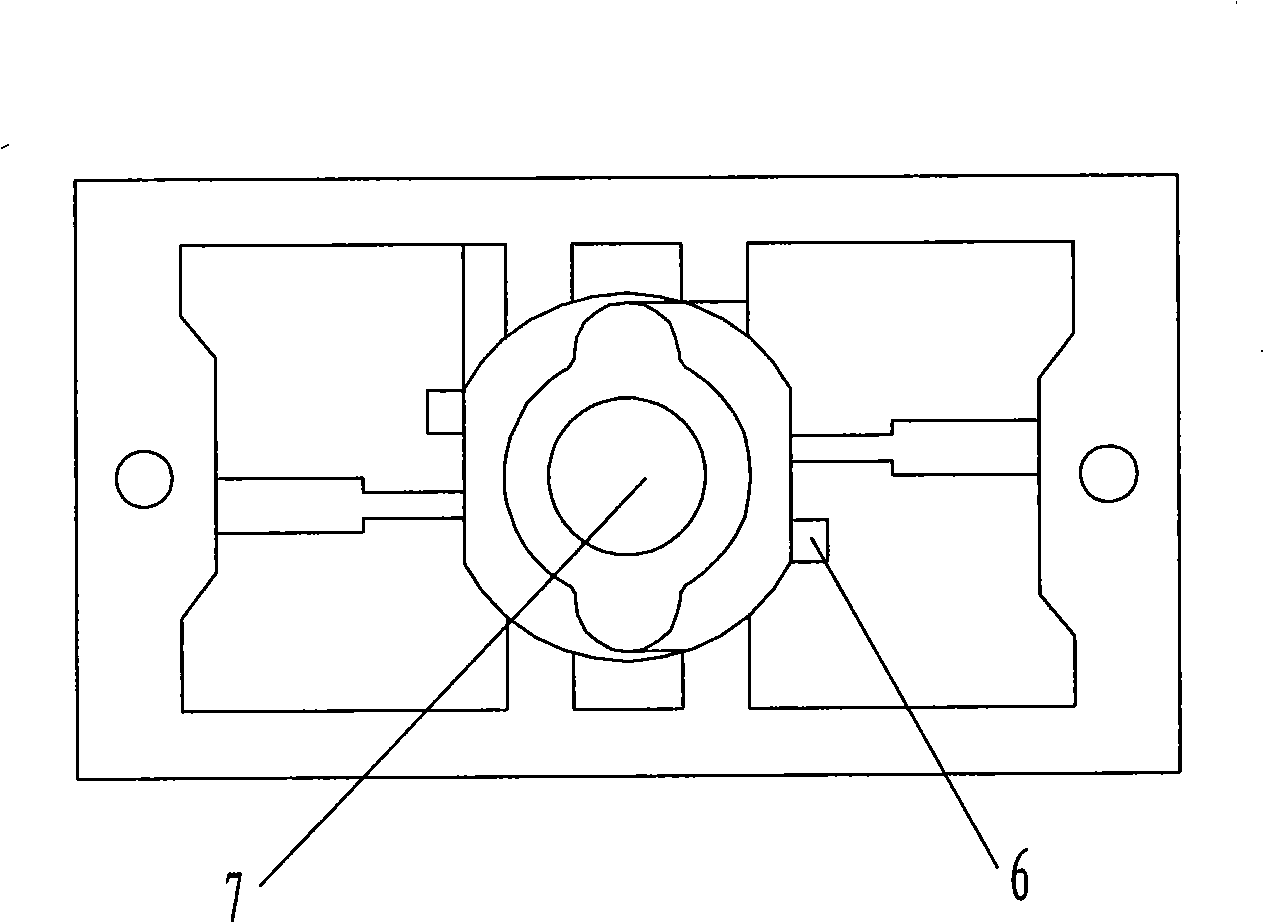

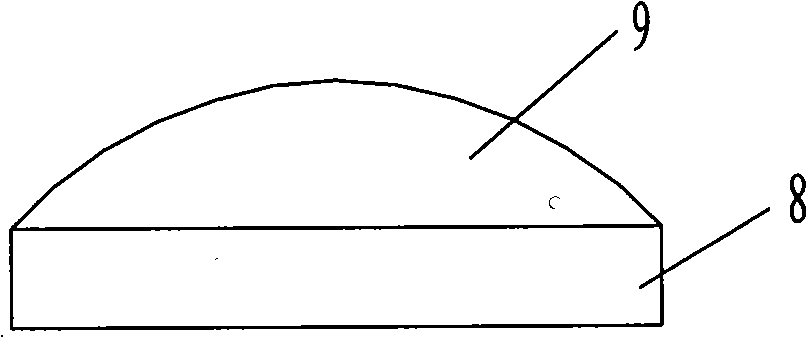

A thin-film thermocouple (12) is disclosed for use with a gas turbine component. The thermocouple may be formed on a non-planar substrate (22) having formed thereon an electrically insulating layer (34) capable of maintaining its insulating properties at gas turbine operating temperatures. A first thermocouple leg (26) made of pure platinum is then deposited on the dielectric layer (34). A second thermocouple leg (28) made of another pure metal or a transparent ceramic oxide is also formed on the dielectric layer (34) wherein the first and second thermocouple legs make ohmic contact at a first end of each leg to form a hot junction (30) for conversion of heat into an electrical signal. The thermocouple may be deposited on a surface of a thermal barrier coating or between a thermal barrier coating and an underlying metal substrate.

Owner:SIEMENS ENERGY INC

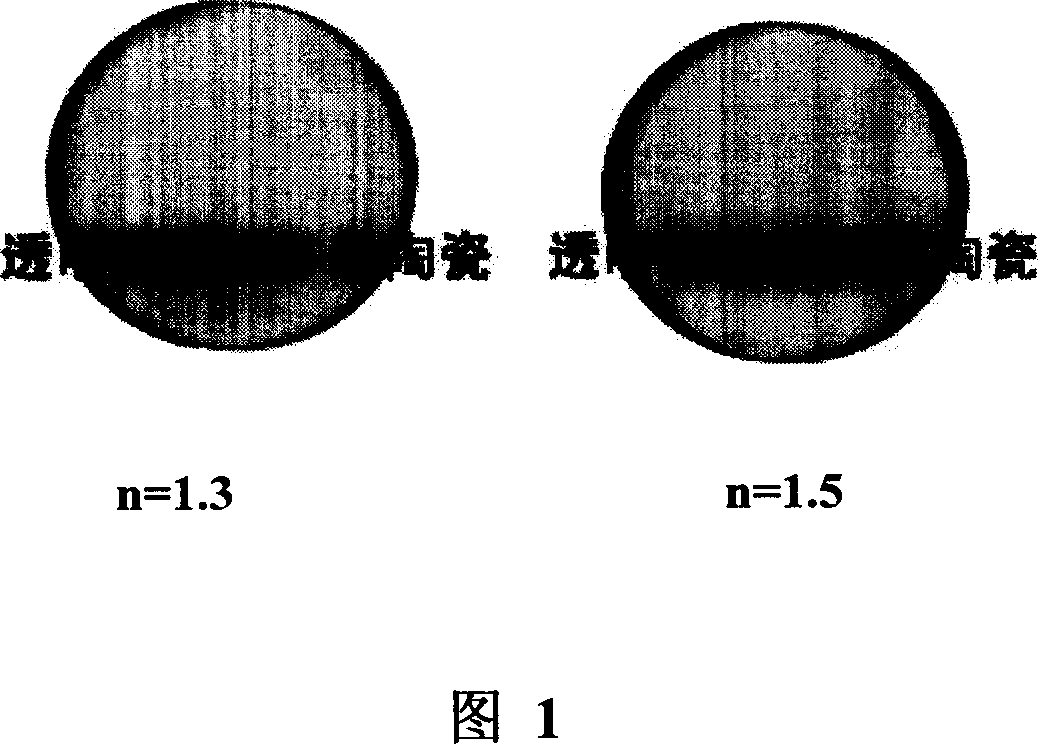

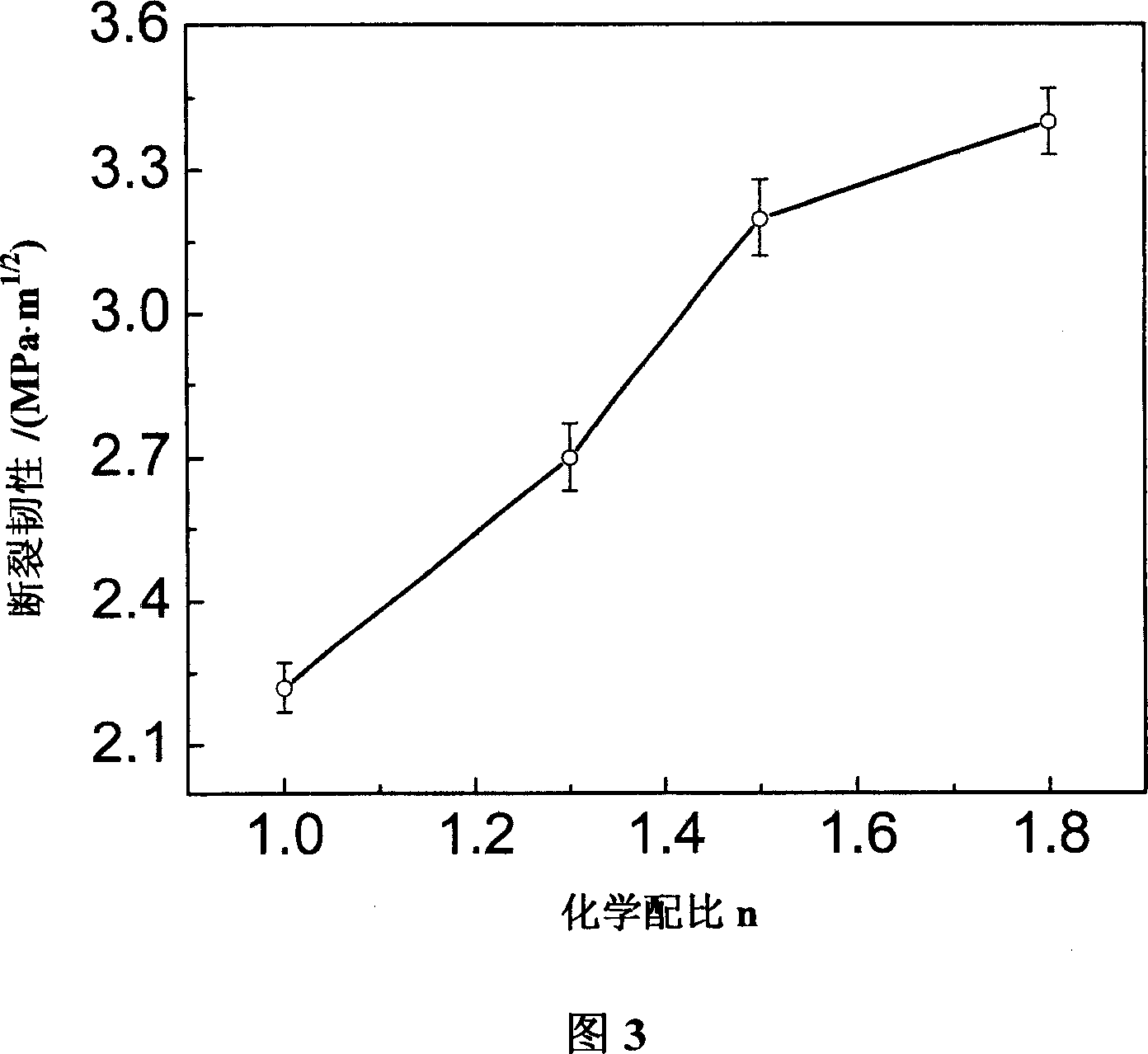

Prepn process of transparent toughened magnesia alumina spinel ceramic

The transparent toughened magnesia alumina spinel ceramic is prepared with chemically pure MgSO4 and NH4Al(SO4)2 as material and through the following steps: 1. preparing nanometer magnesia alumina spinel powder through a molten salt roasting process, adding adhesive, ball milling for 24-48 hr, and pelletizing to form pellet of 40-100 microns size; 2. molding magnesia alumina spinel pellet and cold isostatic pressing to form dense biscuit; and 3. vacuum furnace sintering and hot isostatic pressing furnace sintering. The magnesia alumina spinel ceramic has the general expression of MgO .nAl2O3, where, n is 1.3-1.6; transmissibility in visible light band over 80 %; and fracture toughness of 2.7 MPa.m1 / 2 for n=1.3 and 3.2 MPa.m1 / 2 for n=1.5.

Owner:SICHUAN UNIV

Preparation method of yttria-base transparent ceramics with designable component and structure

The invention belongs to the field of ceramics preparation, in particular to a preparation method of yttria-base transparent ceramics with designable component and structure. The invention uses the method of tape casting to prepare yttria-base ceramic powder doped with laser ions into a cast film; the cast film with different components is laminated to prepare a ceramic biscuit with complex shape and special component and performance by designing the component and structure; after the biscuit unsticks, biscuit density and uniformity are obviously superior to a sample shaped by dry pressing after cold isostatic pressing again. The sintering method of the invention can obtain transparent ceramics with higher performance if compared with the prior art.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

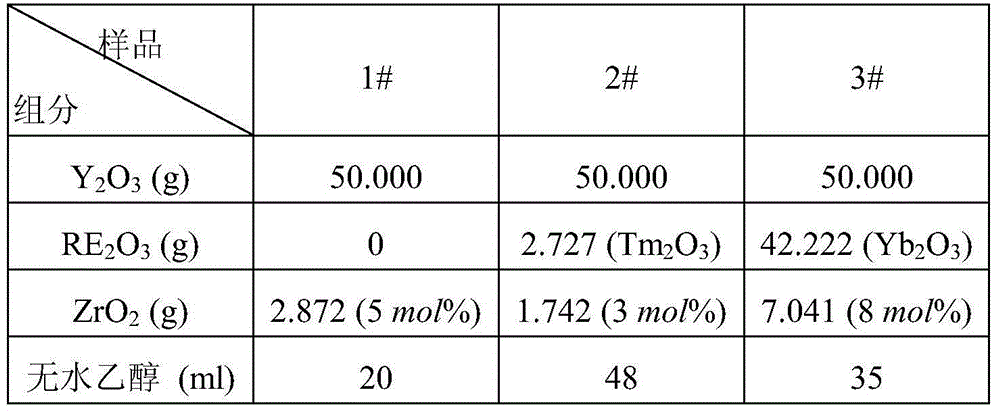

Preparation method of transparent yttria ceramics with high optical quality

The invention relates to a preparation method of transparent yttria ceramics with high optical quality, which belongs to the field of preparation of transparent ceramics. The preparation method comprises the following steps: adding anhydrous ethanol to the mixture of commercial high-purity Y2O3 powder serving as a raw material, ZrO2 serving as a sintering additive and zirconia balls serving as a grinding medium, and carrying out mixing and ball milling for 3-30 hours; adding a crylic acid salt dispersant in the powder to prepare water-based slurry of Y2O3, and adopting a porous resin mold or porous alumina ceramic mold to achieve slip casting; and finally, carrying out pressureless sintering in a vacuum or hydrogen atmosphere furnace to obtain the transparent yttria ceramics with high optical quality. The transmission rate of the Y2O3 transparent ceramics with thickness of 2mm is up to 81.3% at the wavelength of 1100nm. The invention has the advantages of simple process, low cost and no pollution, and is easy to control, and the transparent yttria ceramics with high optical quality can be prepared at lower sintering temperature in shorter holding time.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

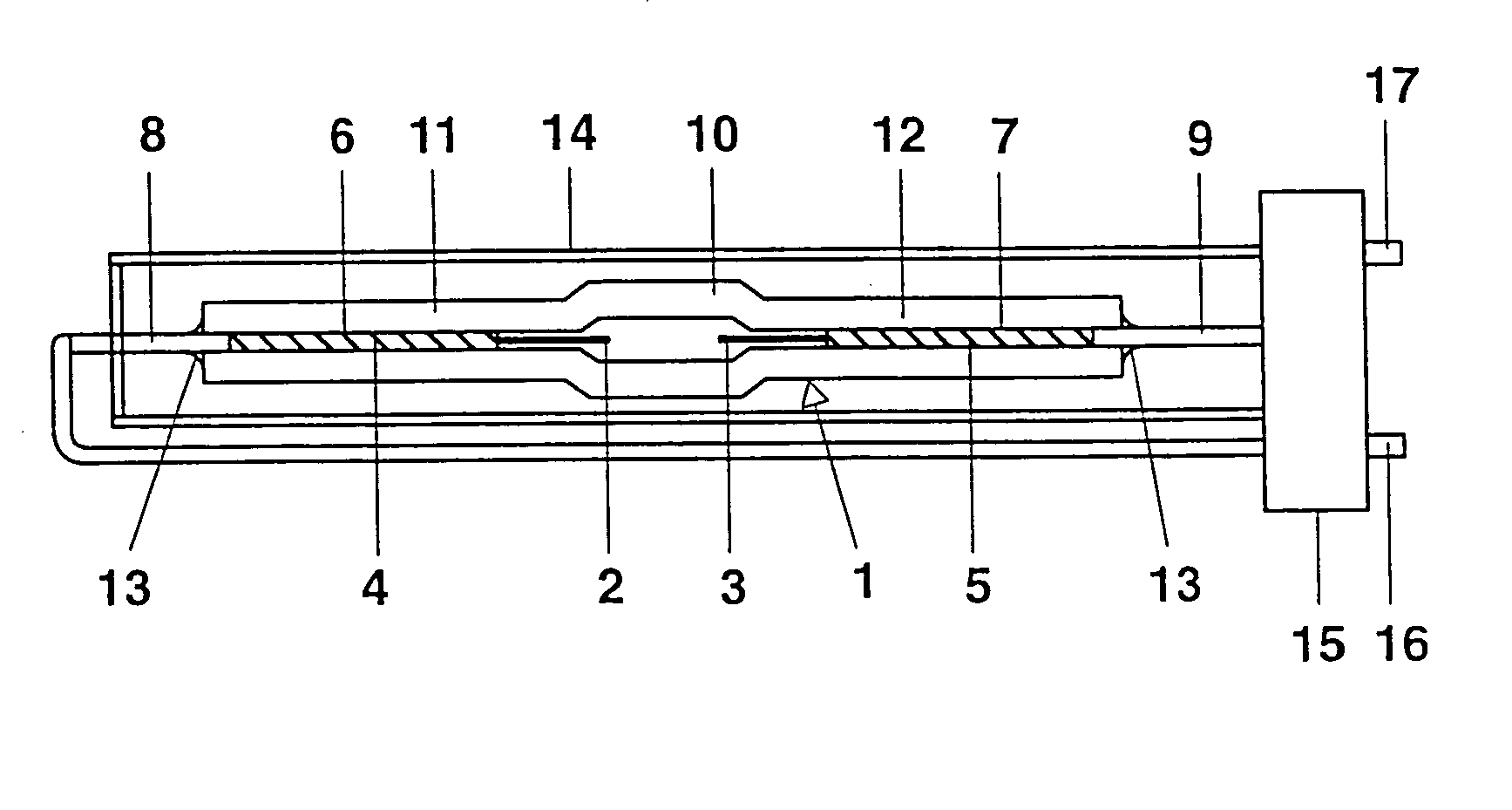

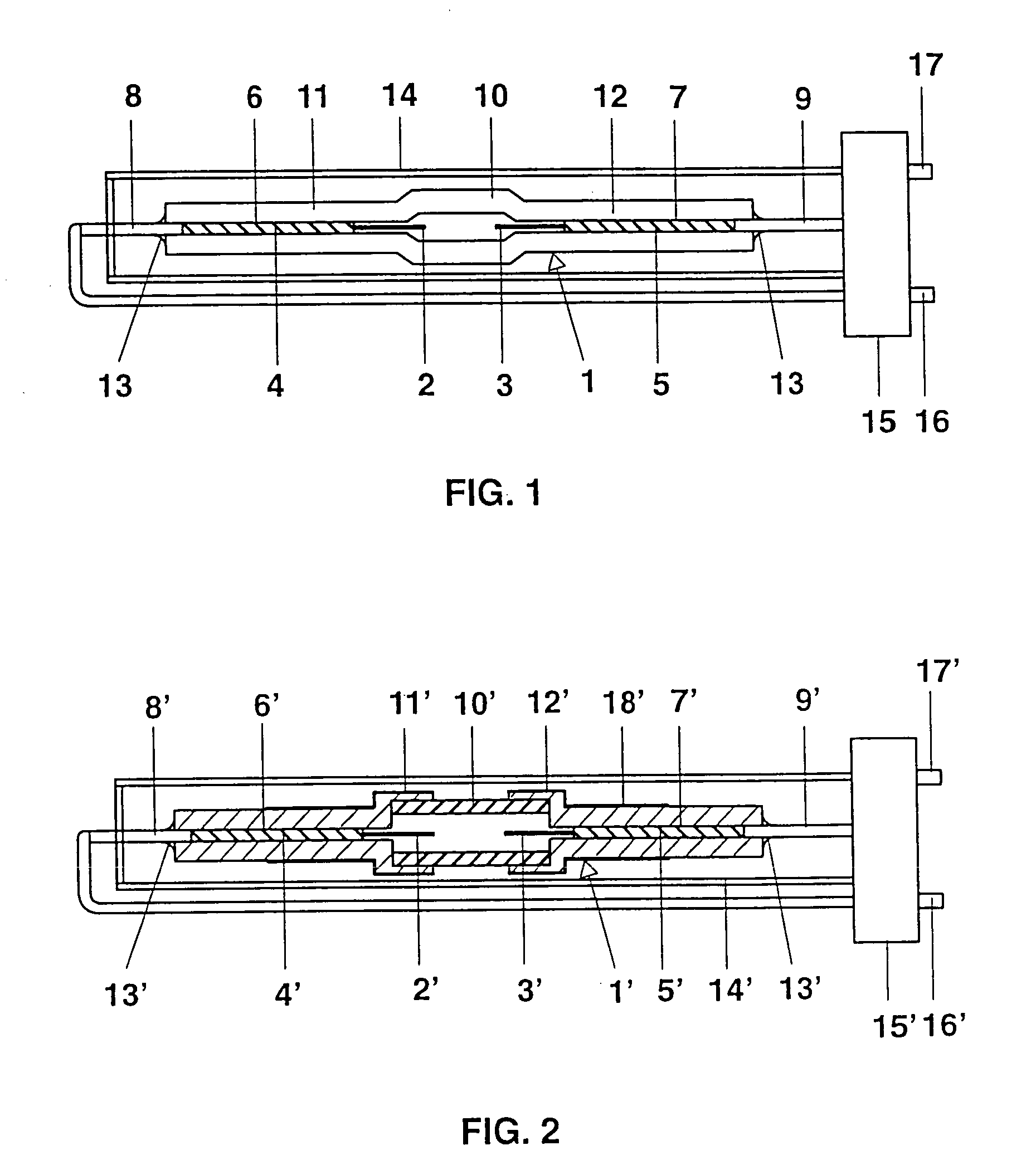

High-pressure discharge lamp for motor vehicle headlamps

InactiveUS20050174053A1Increase working voltageHigh voltageOptical signallingHigh-pressure discharge lampsElectric lightHigh pressure

A high-pressure discharge lamp for motor vehicle headlamps having a mercury-free ionizable fill which consists of xenon with a cold filling pressure of at least 2 000 hPa and metal halides. The discharge vessel has a tubular section (10) which consists of a transparent ceramic and has an internal diameter which is less than or equal to 2 mm and inside which there are arranged electrodes with a spacing less than or equal to 10 mm.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

Thermocouple for gas turbine environments

InactiveUS8033722B2Thermometer detailsThermometers using electric/magnetic elementsThin film thermocouplesEngineering

A thin-film thermocouple (12) is disclosed for use with a gas turbine component. The thermocouple may be formed on a non-planar substrate (22) having formed thereon an electrically insulating layer (34) capable of maintaining its insulating properties at gas turbine operating temperatures. A first thermocouple leg (26) made of pure platinum is then deposited on the dielectric layer (34). A second thermocouple leg (28) made of another pure metal or a transparent ceramic oxide is also formed on the dielectric layer (34) wherein the first and second thermocouple legs make ohmic contact at a first end of each leg to form a hot junction (30) for conversion of heat into an electrical signal. The thermocouple may be deposited on a surface of a thermal barrier coating or between a thermal barrier coating and an underlying metal substrate.

Owner:SIEMENS ENERGY INC

Method for preparing white light LED utilizing YAG transparent ceramic

InactiveCN101338879AHigh light transmittanceSolve efficiency problemsPoint-like light sourceSpectral modifiersUltraviolet lightsVolumetric Mass Density

The invention discloses a method for preparing a white-light LED by YAG transparent ceramics. Firstly, a bare blue-light or ultraviolet-light LED chip is fixed in a support reflector by insulating glue; a YAG transparent ceramic layer is coated or enclosed on the light emitting path of the blue-light or ultraviolet-light chip after the electrode lead is welded by an ultrasonic ball-bonding machine; the wavelength of the blue-light LED chip drops within 450nm-480nm, and the wavelength of the ultraviolet LED drops within 250nm-540nm; the ceramic granules used by the YAG transparent ceramic layer drops within 1nm-300nm. The color coordinate of the emitted light can be changed by adjusting the thickness and the granule density of the ceramic layer. The invention can efficiently settle the problem of the attenuation of wavelength conversion material under high temperature; in addition, the invention can also effectively settle the problems of inconsistency of yellow diaphragm, blue-light diaphragm and white-light diaphragm, etc in the existing methods of white-light LED fabrication; the operation process is relatively simple, the reliability is high and the cost is low.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com