High-elastic and high-fluffy ultra-cotton-imitated fabric and production technology of same

A production process, super-cotton imitation technology, applied in the direction of fabric, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of fabric hand, fluffy elasticity, and false to real, etc., to achieve good color fastness, strong texture, good quality The effect of wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments.

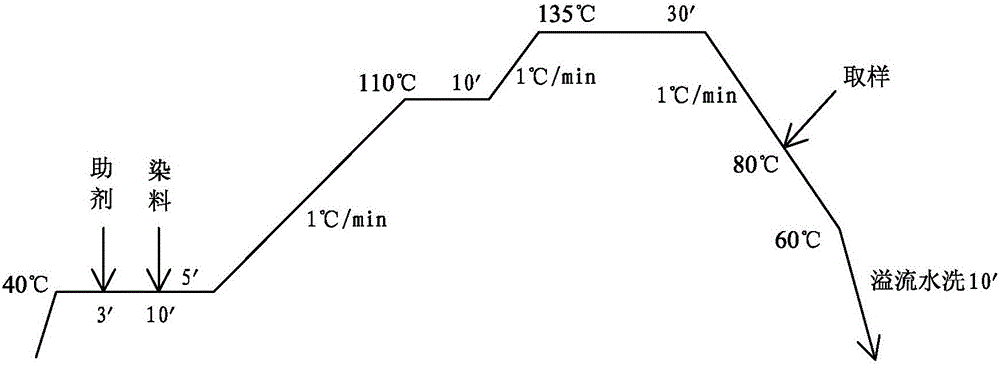

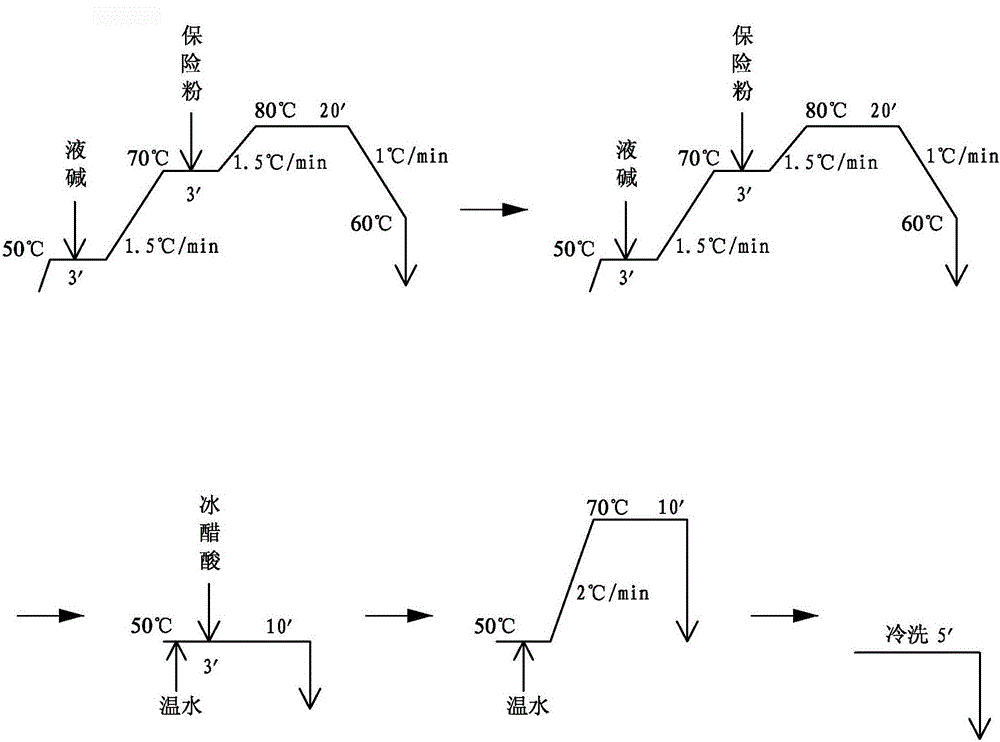

[0031] refer to figure 1 and figure 2 , a production process of high-elasticity and high-loft super-cotton imitation fabric, comprising the following processes in turn:

[0032] ①Weaving: Weaving T160D super-imitation cotton and 70D spandex yarn into gray fabric with single-sided weft-knitted plain stitch structure through single-side circular knitting machine. The length is 10.5cm / 100G.

[0033] ②Open-width washing, the gray cloth is washed and degreased in the open-width washing machine;

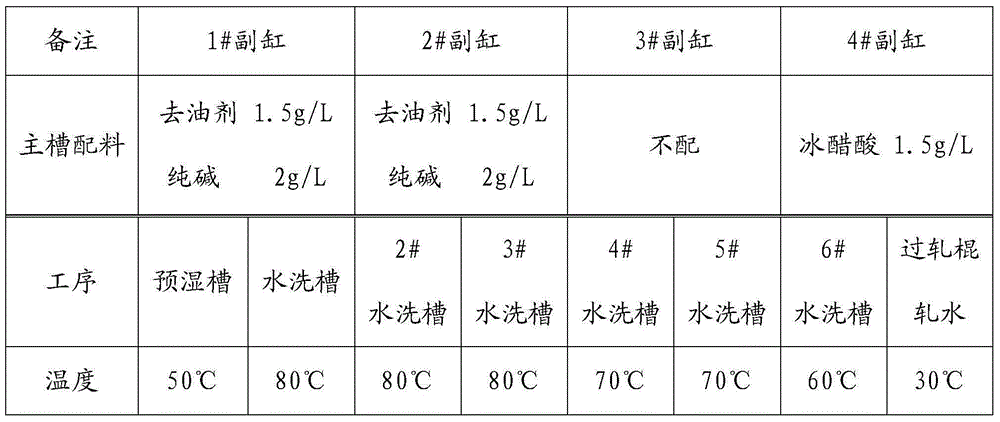

[0034] The process flow of open-width washing is as follows: into the cloth spreader → pre-wet tank → washing tank → refining box → 2# washing tank → 3# washing tank → 4# washing tank → 5# washing tank → 6# washing tank → over-rolling roll Water rolling→vacuum water absorption→cloth falling by left and right devices, in which the gray cloth is refined in the refining box;

[0035] The formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line length | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com