Online injection product quality detection device and method based on infrared imaging

A technology of injection molding products and infrared imaging, which is applied in the direction of measuring devices, material thermal analysis, instruments, etc., can solve the problems of low detection efficiency, low degree of automation, and no automatic feedback of product quality indicators, so as to achieve fast processing results and improve real-time The effect of high quality and accuracy, convenient collection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

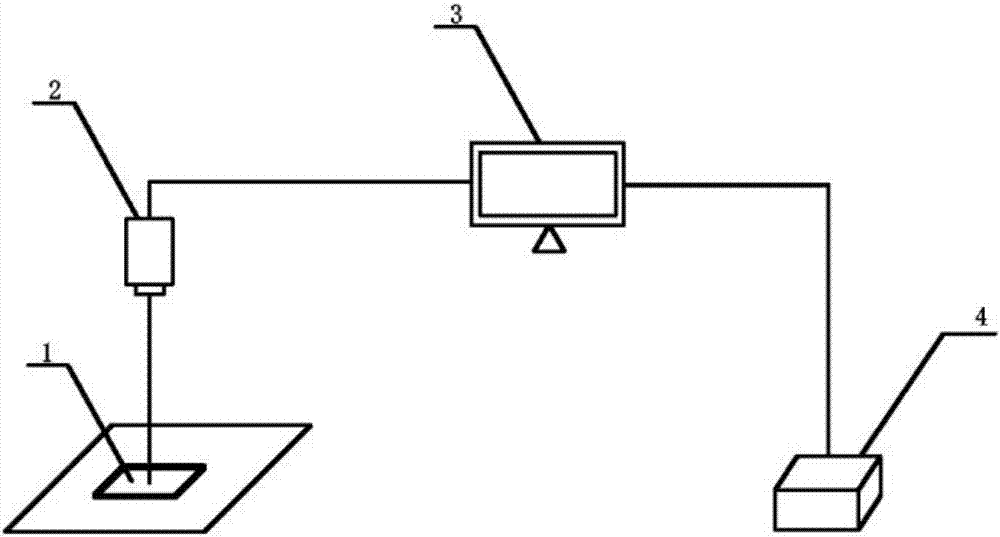

[0022] Such as figure 1 , 2 shown. The invention discloses an online quality inspection device for injection molded products based on infrared imaging, which comprises an infrared detection and acquisition module 2, an image display and processing module 3 and a process parameter control module 4 sequentially connected by telecommunication.

[0023] The infrared detection and collection module 2 is an infrared imager, which is used for all-round detection and thermal image collection of injection molded products, and transmits the collected images to the image display and processing module 3 for display and processing in real time.

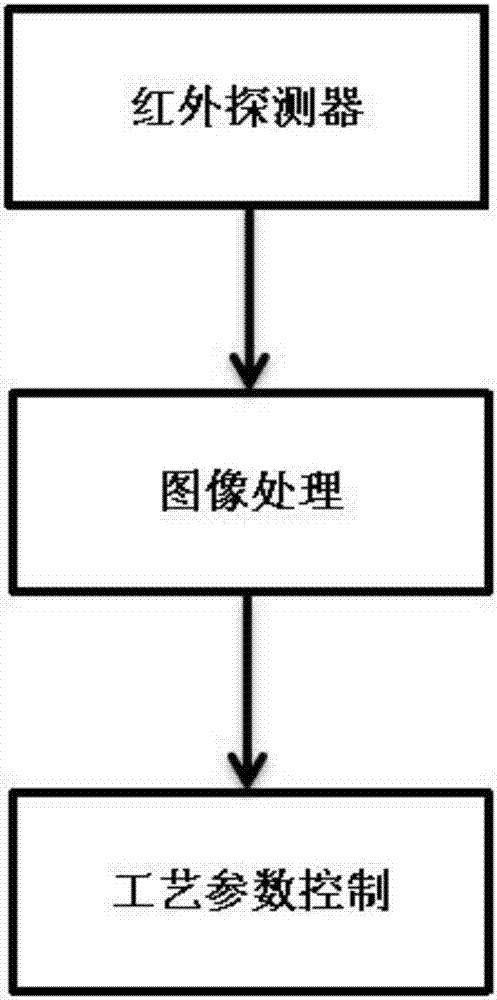

[0024] The online detection and control method of injection molded product quality based on infrared imaging technology in the present invention can be realized through the following steps:

[0025] During the injection molding process, the infrared thermal imager is used to conduct all-round detection and thermal image acquisition of the inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com