Polypropylene transparent nucleater

A transparent nucleating agent, polypropylene technology, applied in the field of polyolefin nucleating agent, to achieve the effect of improving rigidity, good product quality and good nucleation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

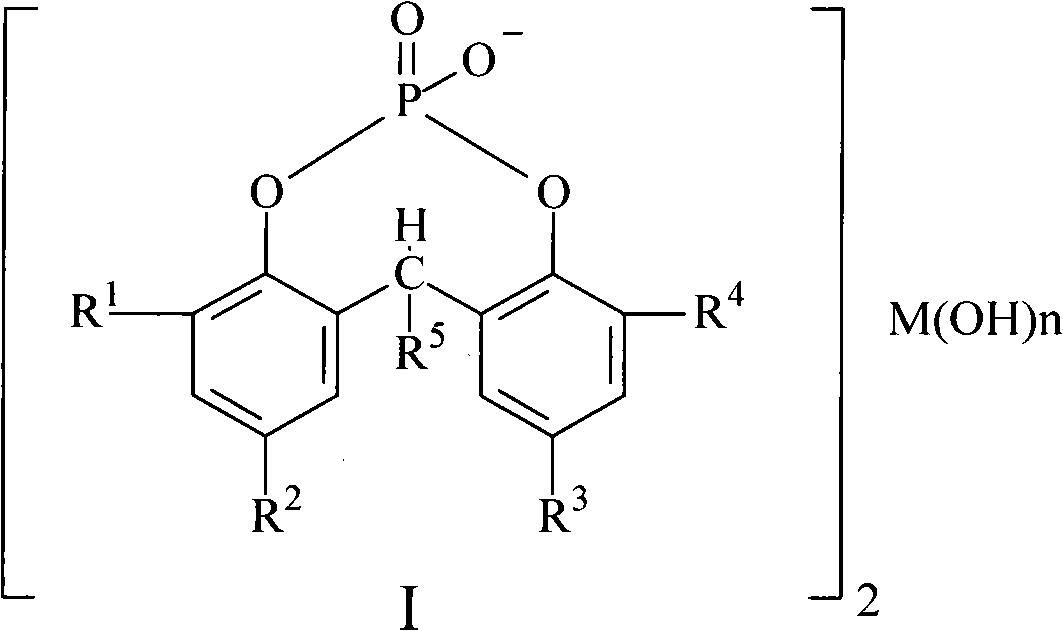

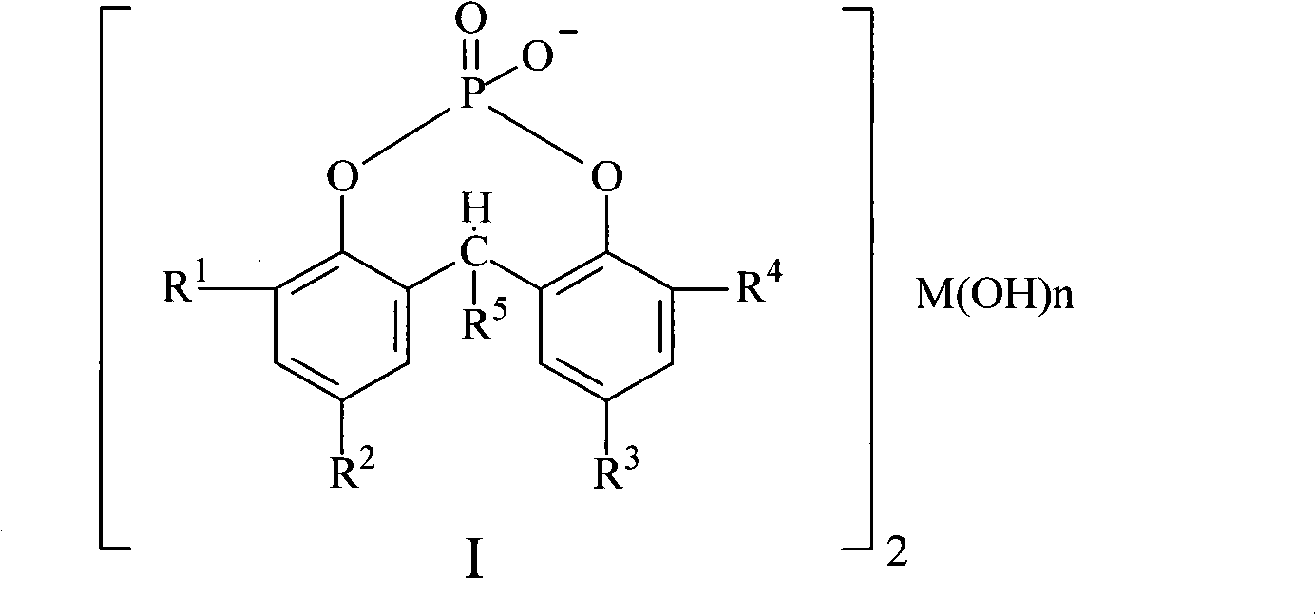

[0033] (Example 1): Preparation of type A compound.

[0034] 4g (0.1mol) of sodium hydroxide and 48.6g (0.1mol) of 2'-methylenebis(4,6-di-tert-butylphenoxy)phosphoric acid were added to 200mL of methanol, and stirred at room temperature for half an hour. Slowly add a solution made of calcium chloride 5.5g (0.05mol) and 60mL of water into the clear and transparent solution. After the addition is complete, heat up to 50°C and stir for 2 hours, cool, filter, wash with water, and dry to obtain the product of this example. Class A compound, denoted as A 1 , whose structural formula is shown in Table 1.

example 2~ example 4

[0036] The preparation method is basically the same as that of Example 1, except that the structural formula is shown in Table 1.

[0037] Table 1

[0038]

example 5

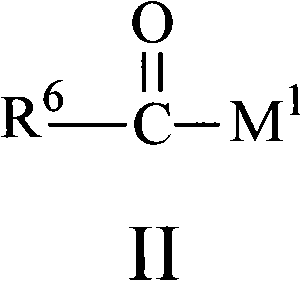

[0039] (Example 5): Preparation of Class B compound.

[0040] Stearic acid and sodium hydroxide of equal substance amount are stirred and reacted in water, filtered, washed with water, and dried to obtain the B class compound sodium stearate of this example, denoted as B 1 , see Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com