Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277 results about "Monobasic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A monobasic acid is an acid that has only one hydrogen ion to donate to a base in an acid-base reaction. Therefore, a monobasic molecule has only one replaceable hydrogen atom. Examples are HCl and HNO₃.

Long carbon-chain dibasic acid prepared from fatty acids or derivatives thereof and preparation method for the long carbon-chain dibasic acid

ActiveCN101121653AReduce dependencePromote the development of deep processingOrganic chemistryMicroorganism based processesAlkaneCarbon chain

The invention discloses a biological preparation method of the long carbochain biatomic acid with the fatty acid or the ramification of the fatty acid as the starting material. The number of carbon atoms is between 9 and 20. The long carbochain biatomic acid with the total content of the biatomic acid no less than 95 percent and the content of the atomic acid no more than 0.5 percent is further refined; then the total content of the biatomic acid is no less than 98.5 percent and the content of the atomic acid is no more than 0.05 percent. The long carbochain biatomic acid can replace the current long carbochain biatomic acid produced in a chemical or biological method (with the alkanes as the raw material) to be used in each field. At the same time, the invention provides the preparation process of the long carbochain biatomic acid; the process begins from the fatty acid or the ramification of the fatty acid; first the bio-fermentation is used to produce the long carbochain biatomic acid; then after the special purification process, the required biatomic acid can be acquired.

Owner:CATHAY R&D CENT CO LTD

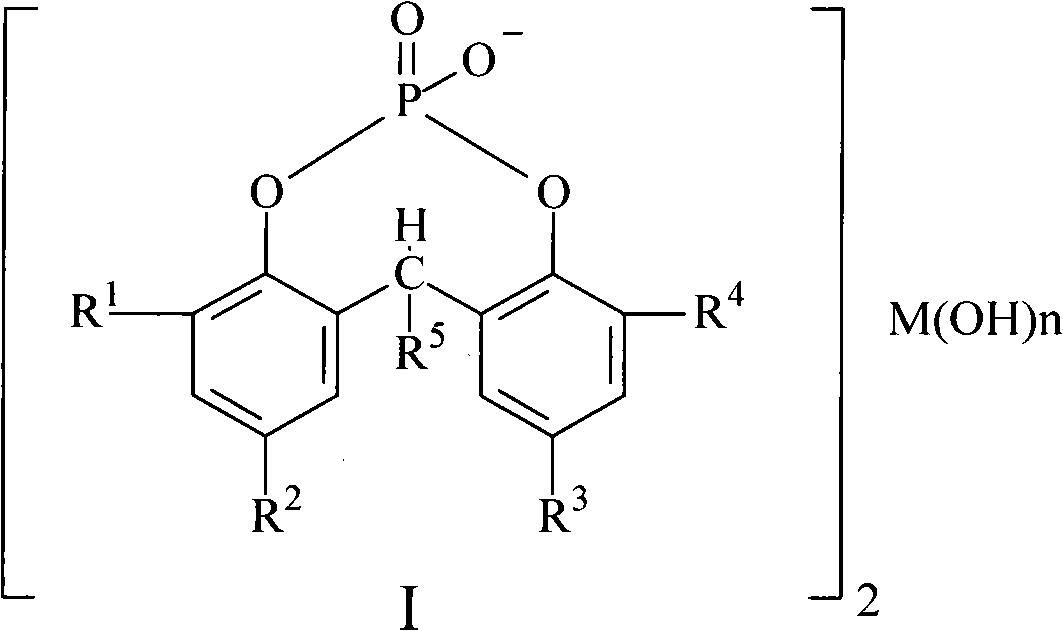

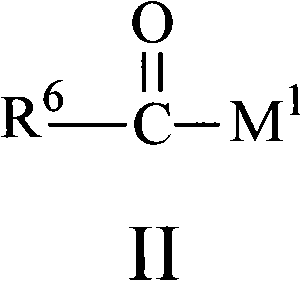

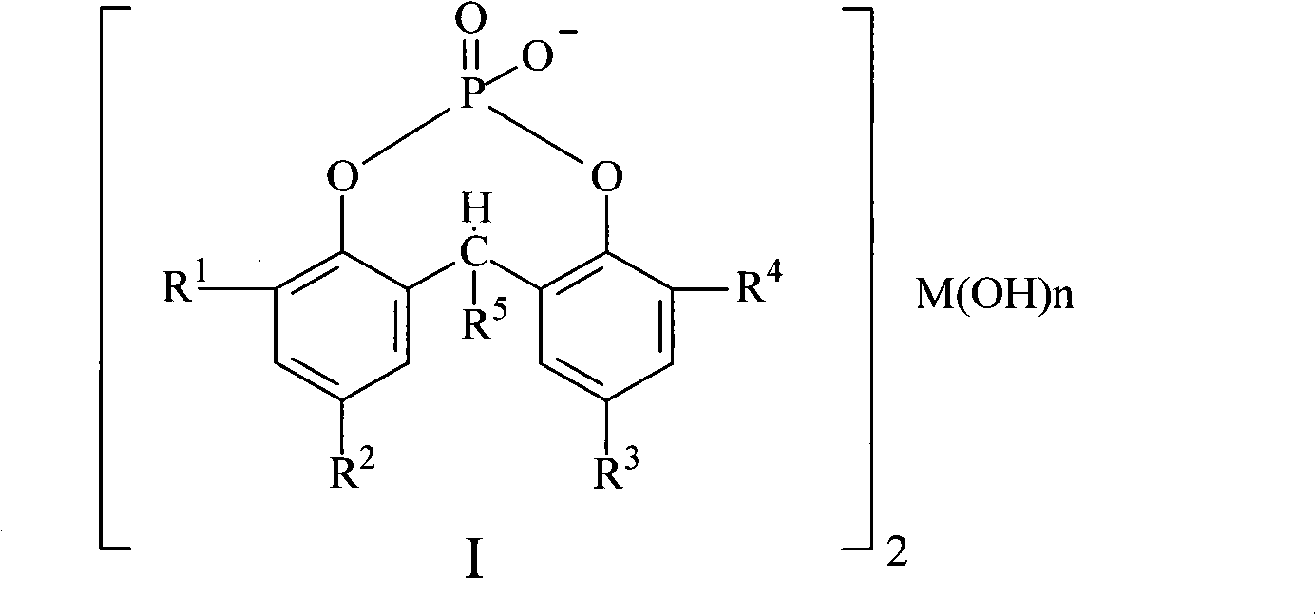

Polypropylene transparent nucleater

The invention discloses a polypropylene transparent nucleating agent, which consists of one or two compounds in category A accounting for 90 to 10 percent by weight and one or two compounds in category B accounting for 10 to 90 percent by weight. The compound(s) in category A is (are) multivalent metal salt(s) substituting for diaryl phosphoric acid; and the compound(s) in category B is (are) alkali metal salt(s) of monobasic fatty acid. The polypropylene transparent nucleating agent disclosed by the invention overwhelms the defects of organic phosphates in use, such as too high melting point, limited compatibleness with resin, poor dispersibility, causing flaws on the surfaces of products easily and so on. By adopting the invention, the polypropylene transparent nucleating agent improves the rigidity, the tensile strength, the creep resistance, the heat distortion temperature of polypropylene and so on, brings high transparency to polypropylene, and reducing the forming cycle. Products got by adopting the invention are of high quality.

Owner:JIANGSU TAIHU CHEM

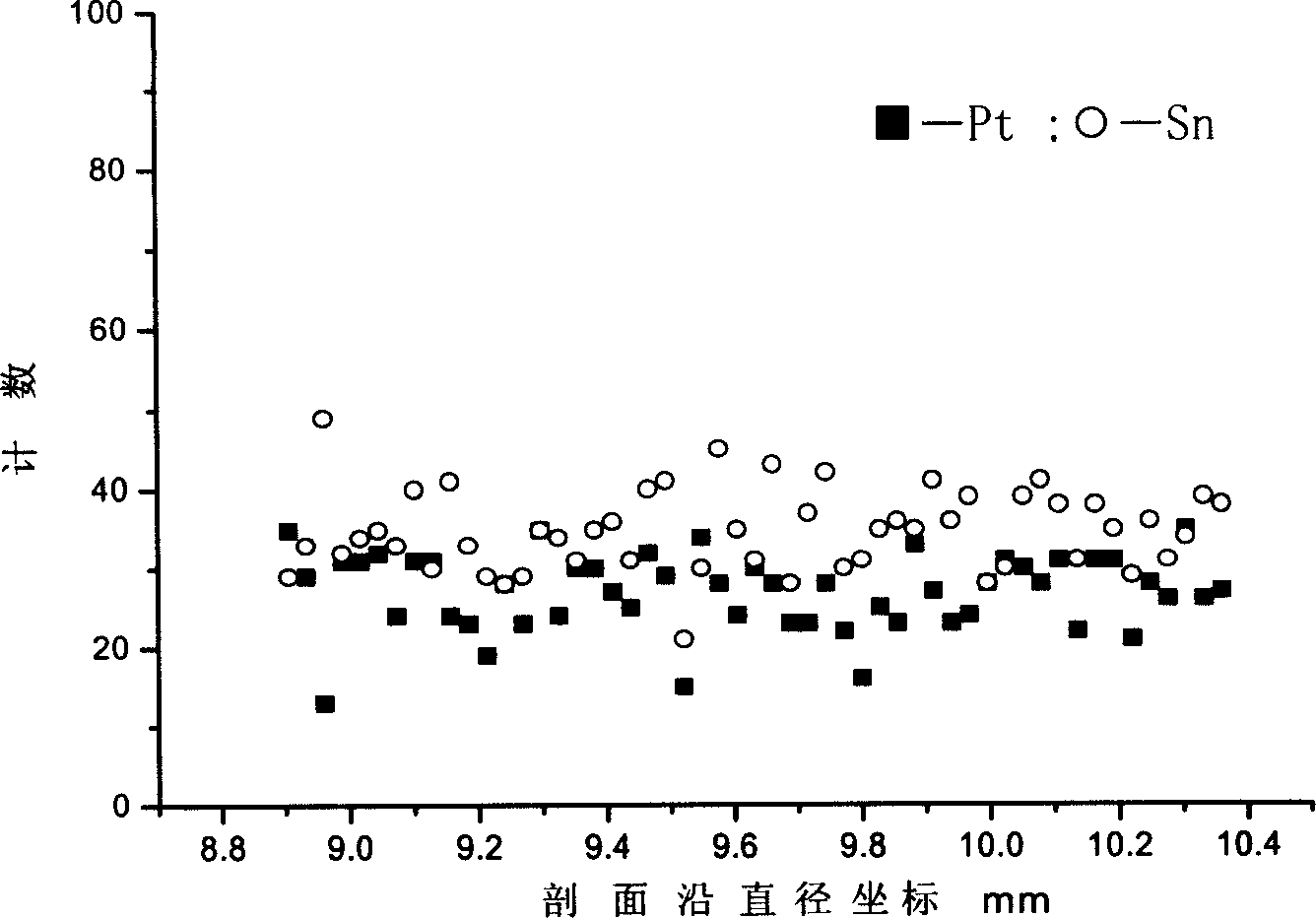

Process for preparing poly metal reforming catalyst

The polymetal catalyst for reforming includes high temperature inorganic oxide carrier and the active components, including VIII metal in 0.01-2.0 wt% of the carrier, IVA metal in 0.01-5.0 wt% of the carrier, RE metal in 0.01-2.0 wt% of the carrier and halogen in 0.1-10.0 wt% of the carrier. The preparation process of the catalyst includes first introducing IVA metal and RE metal into the high temperature inorganic oxide carrier, the subsequent soaking of the carrier inside the soaking liquid comprising water soluble compound of VIII metal, monobasic acid and organic amine, and final drying and roasting of the soaked solid. The said preparation process can avoid the loss of RE metal in soaking VIII metal to raise the activity stability of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for coproduction of high purity aminic acid and acid sodium phosphate by reaction of calcium formate and peroxyphosphoric acid

InactiveCN101475463ASimple production processReduce manufacturing costPreparation from carboxylic acid saltsPhosphorus compoundsCalcium hydroxideHydrogen

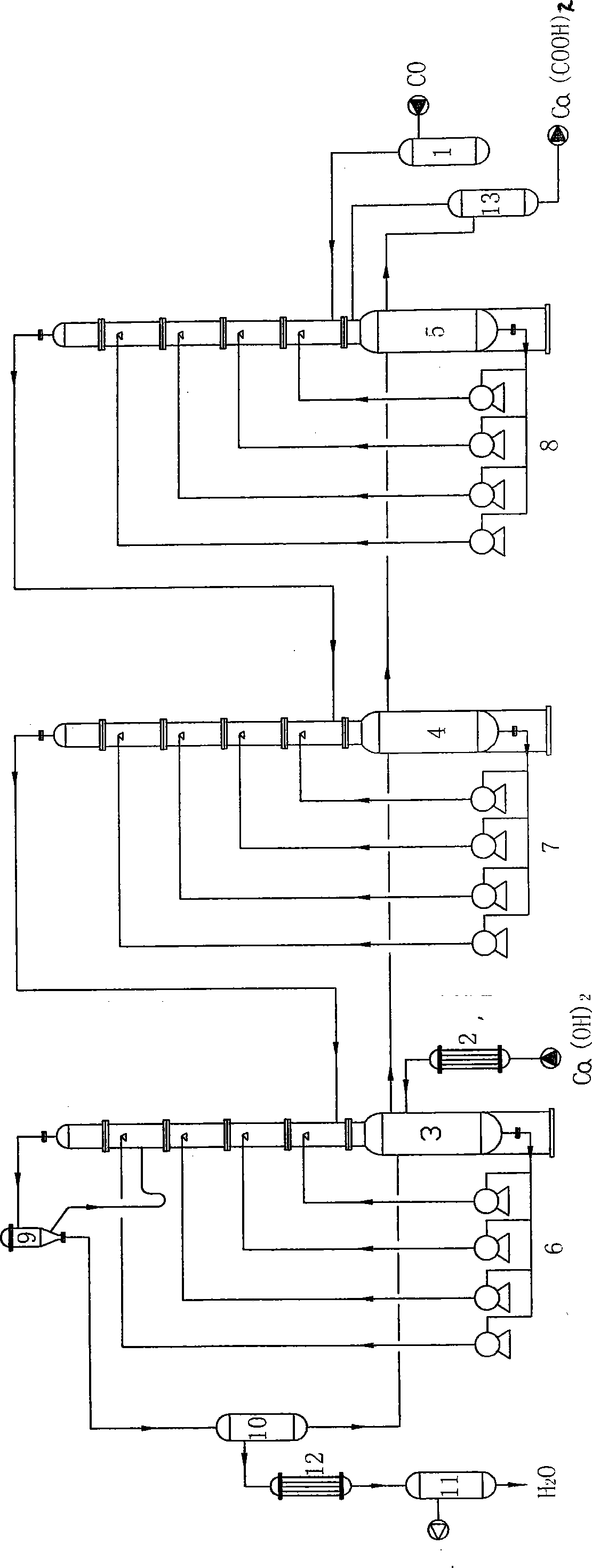

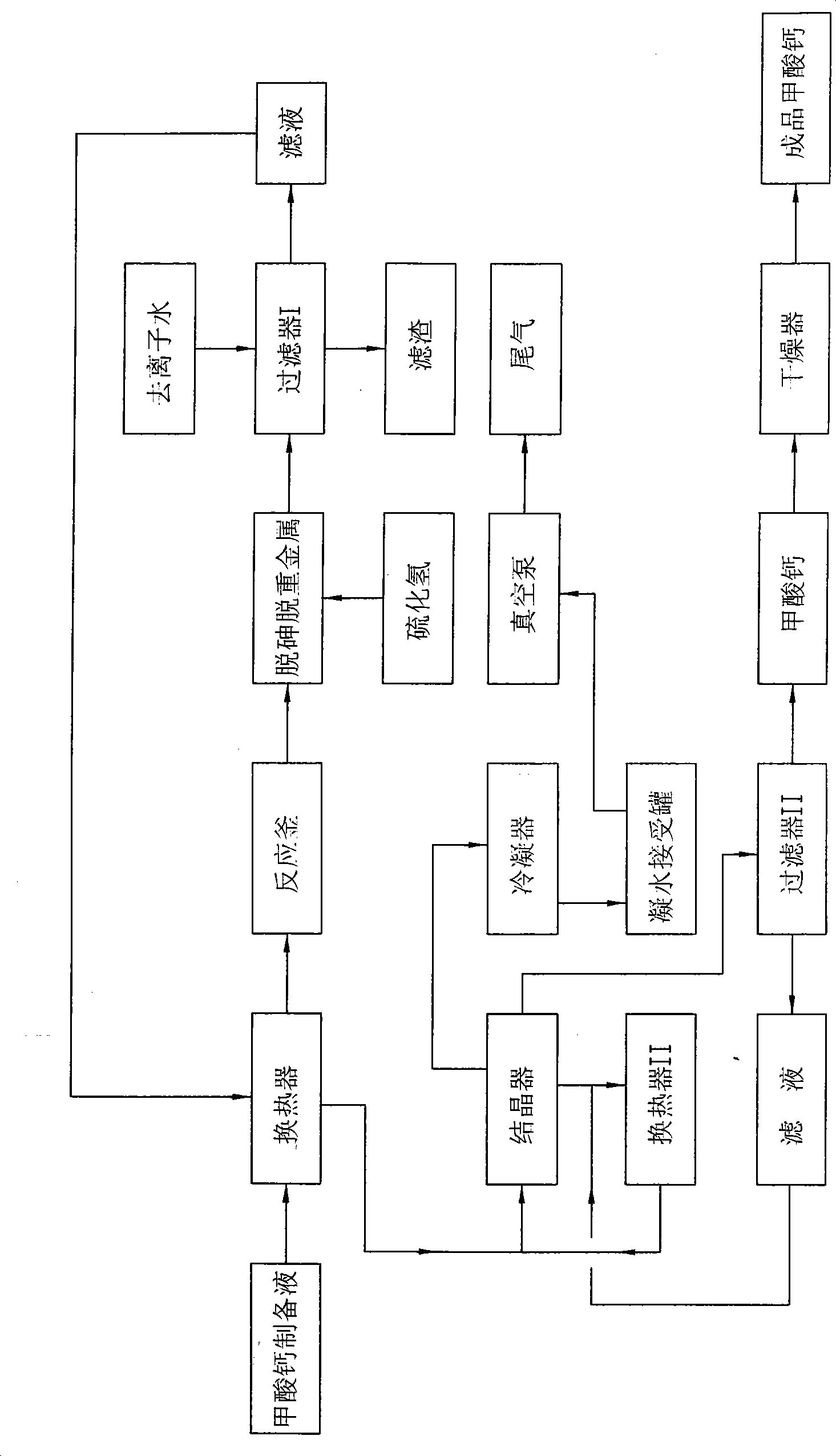

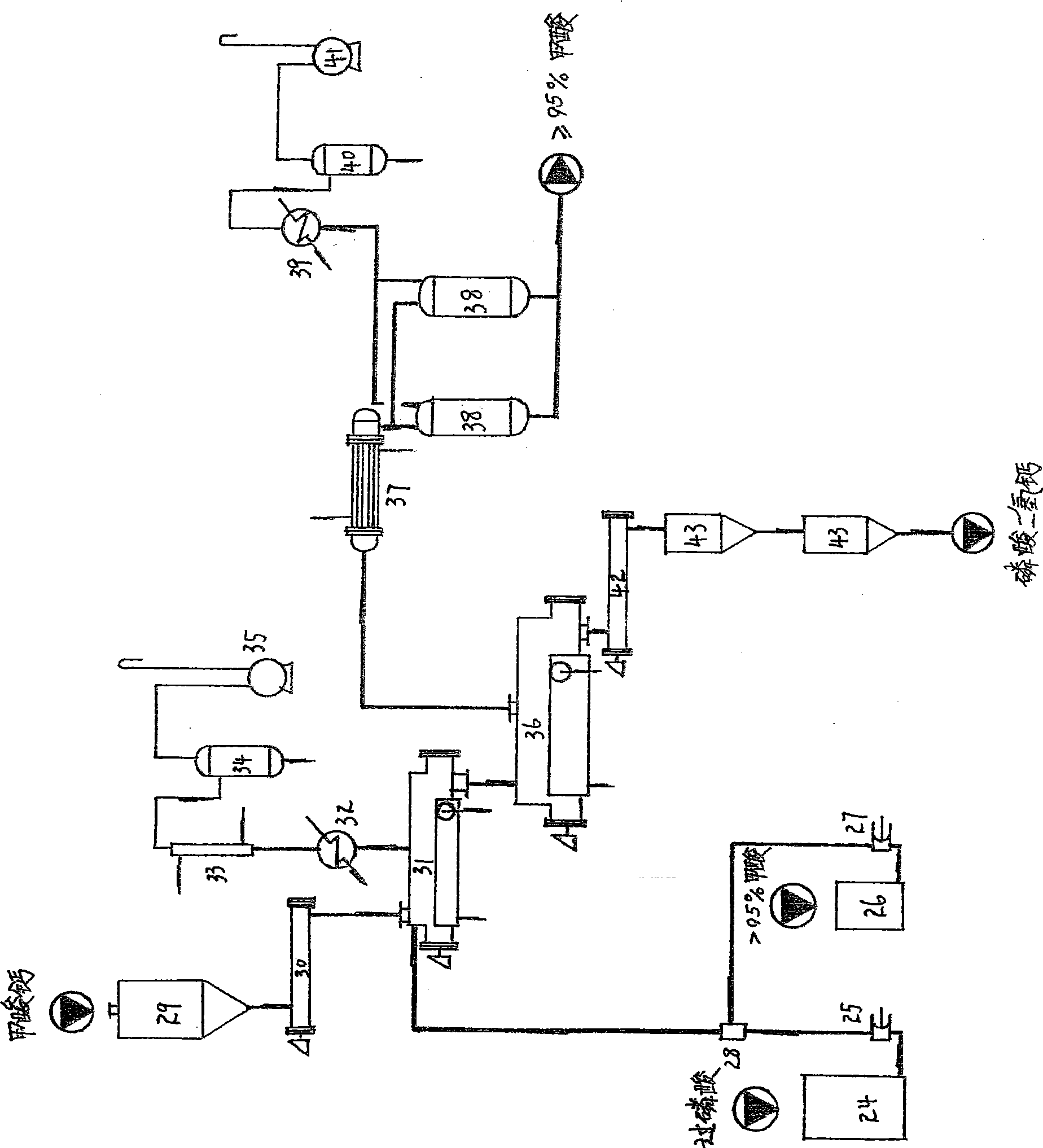

The invention relates to a method for coproducing high-purity methanoic acid and monobasic sodium phosphate by reaction of calcium formate and ultraphosphate. The method comprises the following steps that: carbon monoxide enters a reaction tower III; calcium hydroxide enters a reaction tower I to perform a counterflow reaction with carbon monoxide from a reaction tower II, a reaction solution overflows to the reaction tower II to perform the counterflow reaction with the carbon monoxide from the reaction tower III, the reaction solution enters the reaction tower III to perform the couterflow reaction with the carbon monoxide, the reaction solution overflows into a discharge tank from the reaction tower III to prepare a calcium formate preparation solution; the calcium formate preparation solution enters a reaction kettle, methanoic acid is dripped into the reaction kettle, sulfureted hydrogen is introduced into the reaction kettle, the mixture is separated and filtered through a filter I, a filtrate enters a continuous crystallizer, a crystalline liquid enters a filter II, and the filtered calcium formate is prepared into a finished product calcium formate through a drier; ultraphosphate, the methanoic acid and the calcium formate are conveyed into a horizontal double screw reactor to generate the methanoic acid and monobasic calcium phosphate; the methanoic acid and the monobasic calcium phosphate enter a methanoic acid distilling still for reduced pressure distillation; and the monobasic calcium phosphate is delivered to a monobasic calcium phosphate measurement receiving tank, while the monobasic acid enters a methanoic acid receiving tank. The method has high yield of the methanoic acid and low manufacturing cost.

Owner:曹勇

Method for preparing lithium lubricating grease

ActiveCN102796603AWith energy saving and emission reductionReduce energy consumptionLubricant compositionBase oilAqueous solution

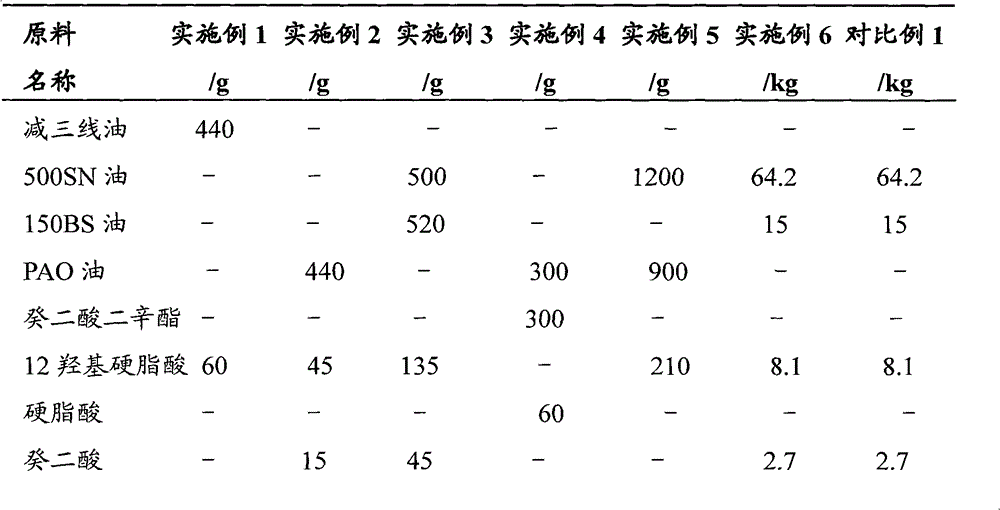

The invention provides a method for preparing lithium lubricating grease. The method comprises the following steps of: 1) adding one third to one second of the weight of the entire base oil into a grease kettle, adding a calculated amount of monobasic acid or monobasic acid and at least one kind of dibasic acid or polybasic acid, raising the temperature, and stirring to ensure that the acid and the base oil are fully mixed; 2) raising the temperature to 40 to 80 DEG C, adding one third to one second of a calculated amount of lithium hydroxide monohydrate crystals under stirring, and fully mixing; 3) raising the temperature to 82 to 120 DEG C, and adding an aqueous solution of residual lithium hydroxide monohydrate for saponification reaction; and 4) after full saponification reaction, raising the temperature and dehydrating, continuing to raise the temperature to 200 to 220 DEG C, adding the residual base oil serving as quenching oil, reducing the temperature and cooling, adding necessary additives, homogenizing, grinding, and degassing to obtain finished lubricating grease. The method for preparing the lithium lubricating grease has the advantages of energy conservation, emission reduction and energy consumption reduction, can be used for lithium or complex lithium lubricating grease, and is particularly suitable for a process for preparing the lithium or complex lithium lubricating grease in an atmospheric kettle.

Owner:CHINA PETROLEUM & CHEM CORP +1

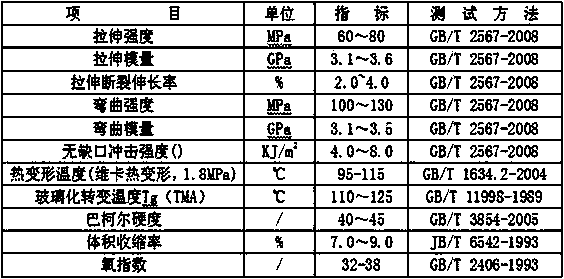

Mono-acid blocked unsaturated polyester resin and preparation method for same

The invention belongs to the technical field of unsaturated polyester resin, and particularly relates to a mono-acid blocked unsaturated polyester resin, formed by using dibasic alcohol, saturated dibasic acid, unsaturated dibasic acid, a monobasic acid blocking agent and a diluting agent as raw materials, and then performing condensation polymerization; and the raw materials comprise, in parts by weight, (1) 19-28 parts of dibasic alcohol, (2) 10-25 parts of saturated dibasic acid, (3) 15-27 parts of unsaturated dibasic acid, (4) 1-7 parts of monobasic acid blocking agent, and (5) 28-37 parts of diluting agent. The invention further provides a preparation method for the mono-acid blocked unsaturated polyester resin. The product obtained by the preparation method provided by the invention is better in compatibility, better in hydrolytic stability and higher in hardness compared with common unsaturated resin, as well as high in strength.

Owner:湖州红剑聚合物有限公司

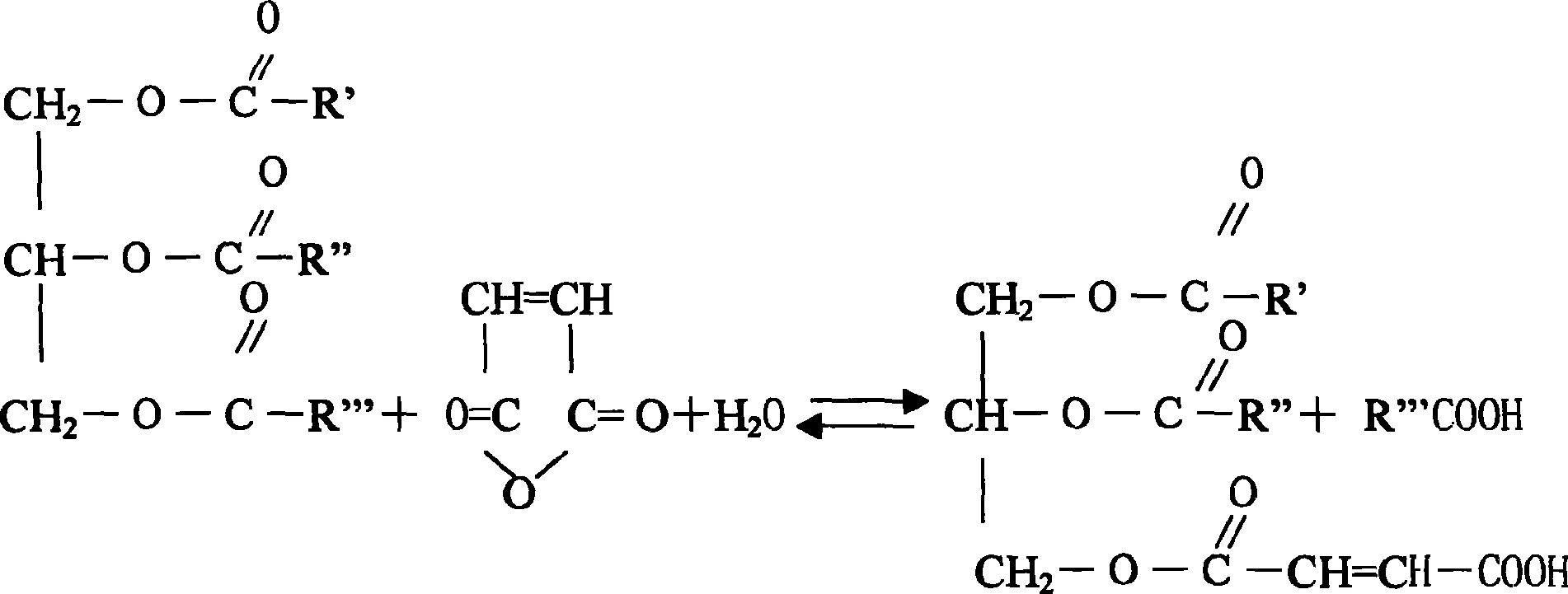

Method for synthesizing unsaturated polyester resin by utilizing glycerol

ActiveCN102219882AExcellent physical and chemical propertiesReduce manufacturing costCross-linkGlycerol

The invention provides a method for synthesizing unsaturated polyester resin by utilizing glycerol. In the method, a weight ratio of synthetic raw materials, namely the glycerol to dihydric alcohol is 1:4-3:2. In addition, the synthetic raw materials also comprise components such as monobasic acid, dibasic acid, a cross-linking agent, a polymerization inhibitor, a defoaming agent and the like. In the method, a part of dihydric alcohol which is used in the conventional production method is replaced by a large amount of glycerol effectively, so the production cost of products is reduced substantially; meanwhile, the produced unsaturated polyester resin has high physical properties such as physical strength, toughness, rigidity and the like.

Owner:ZHAOQING FUTIAN CHEM IND

Polyol ester lubricants, especially those compatible with mineral oils, for refrigerating compressors operating at high temperatures

InactiveUS20010038088A1Good hygroscopicityPromote undesirable corrosionHeat-exchange elementsRefrigeration componentsSolubilityRefrigeration compressor

A high quality lubricant for compressors operated during at least part of their compression cycle at temperatures above normal human comfort temperatures, such as most automotive air conditioners, especially those using chlorine free hydro-fluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including at least some iso-pentanoic acid along with one or more of iso-nonanoic acid, isooctanoic acid, and dibasic acids such as adipic. When the mixture includes about 7% adipic and amounts of branched C8-9 and C5 monobasic acids in a ratio of at least 0.75:1.00, the esters formed have excellent solubility for paraffinic and naphthenic mineral oils and are therefore especially well suited for lubricating vehicle air conditioners formerly containing chlorine containing heat transfer fluids and mineral oil lubricants.

Owner:COGNIS CORP

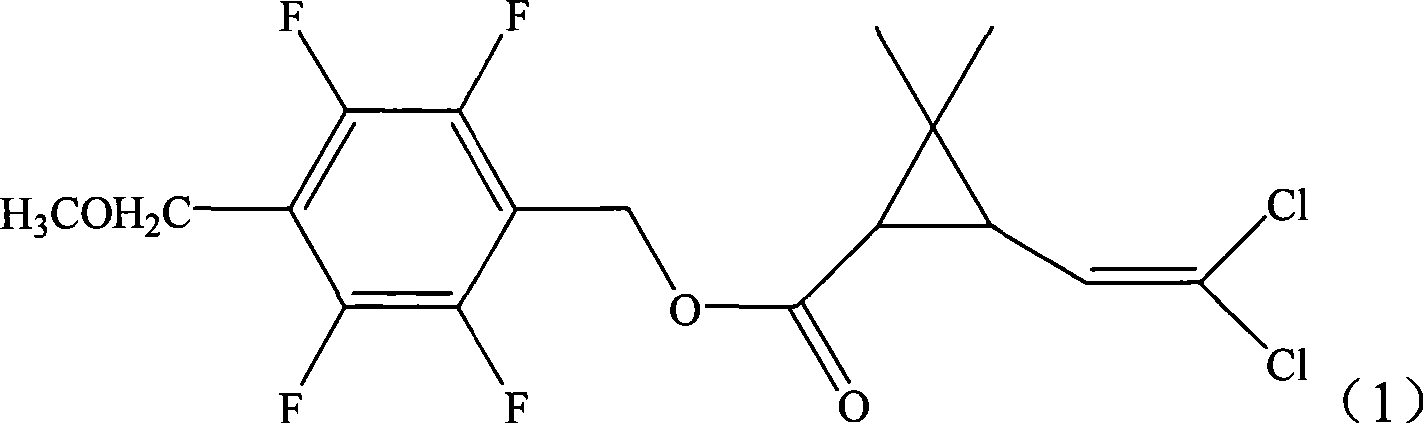

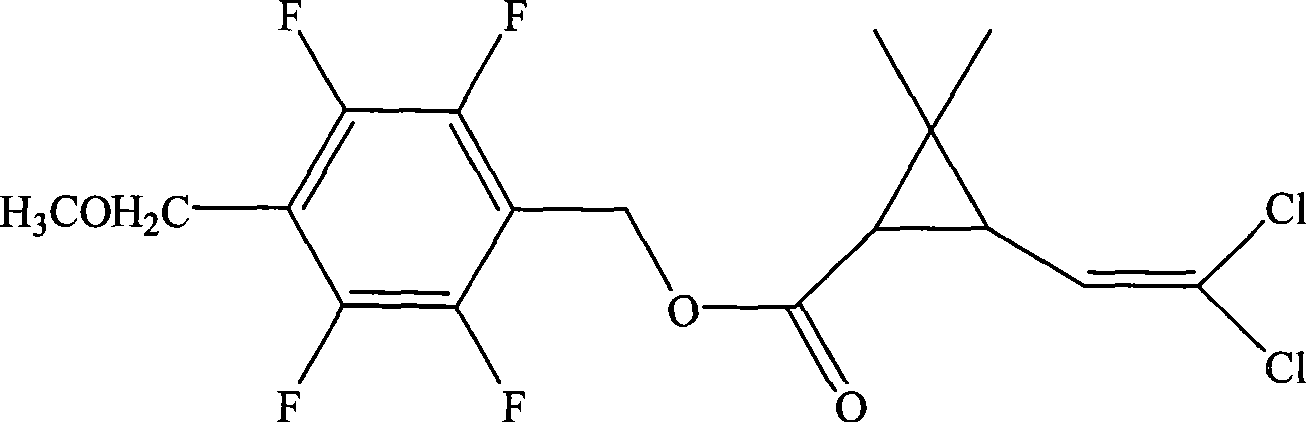

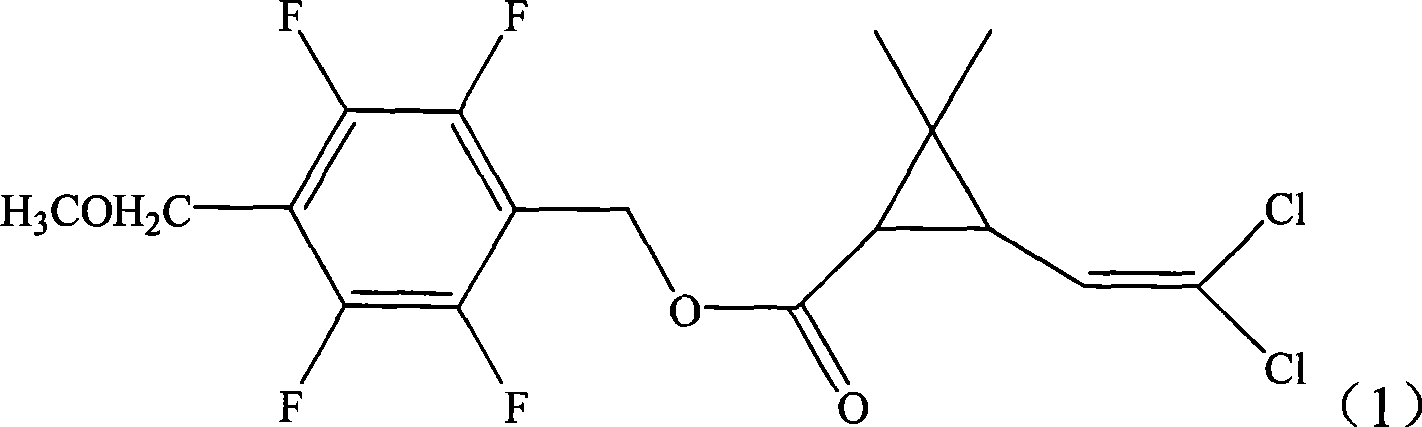

Insecticide mother liquor and use thereof

ActiveCN101543225AImprove solubilityImprove biological activityBiocideAnimal repellantsTricarboxylic acidDicarboxylic acid

The invention provides insecticide mother liquor comprising the components by weight: active ingredient A and solvent B represented by the right formula. The solvent B comprises one or more than two components from monobasic acid ester, dicarboxylic ester or tricarboxylic ester containing 8-20 carbon atoms. A accounts for 0.1-40% of the total weight of A and B. The total weight of A and B accounts for 88-100% of the mother liquor total weight. B greatly increases the insecticidal activity of A. The insecticide mother liquor has higher insecticidal activity.

Owner:JIANGSU YANGNONG CHEM +1

Lithium-base lubricating grease composition with low-pressure oil-separating and low-storage oil-separating performance

InactiveCN101240216AIncrease pressureExcellent storage oil separation performanceThickenersAdditivesChemistryOil separation

The invention relates to a lithium base grease constituent which has low-pressure oil separation performance and low storage oil separation performance, and comprises base oil, thickening agent, solid fillers and additive, wherein the thickening agent are the metal salts which were produced through the reaction between one or more an acid of the C12 to C24 fatty acid and the lithium hydroxide; the grease constituent contents one or more solid packing which come from bentonite, graphite, molybdenum disulfide and silicon dioxide, and the solid packing is in the amount of 0.1 to 15wt percent of the grease constituent. The lithium base grease constituent is compared with the existing lithium base grease: the lithium base grease constituent Not only has good low-pressure oil separation performance and low storage oil separation performance, but also has good shear stability, colloidal stability, good performance and good high-temperature extreme pressure, anti-wear performance, and can be widely used in Bearings, gears and other industrial equipments which have high demands of oil separation performance.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

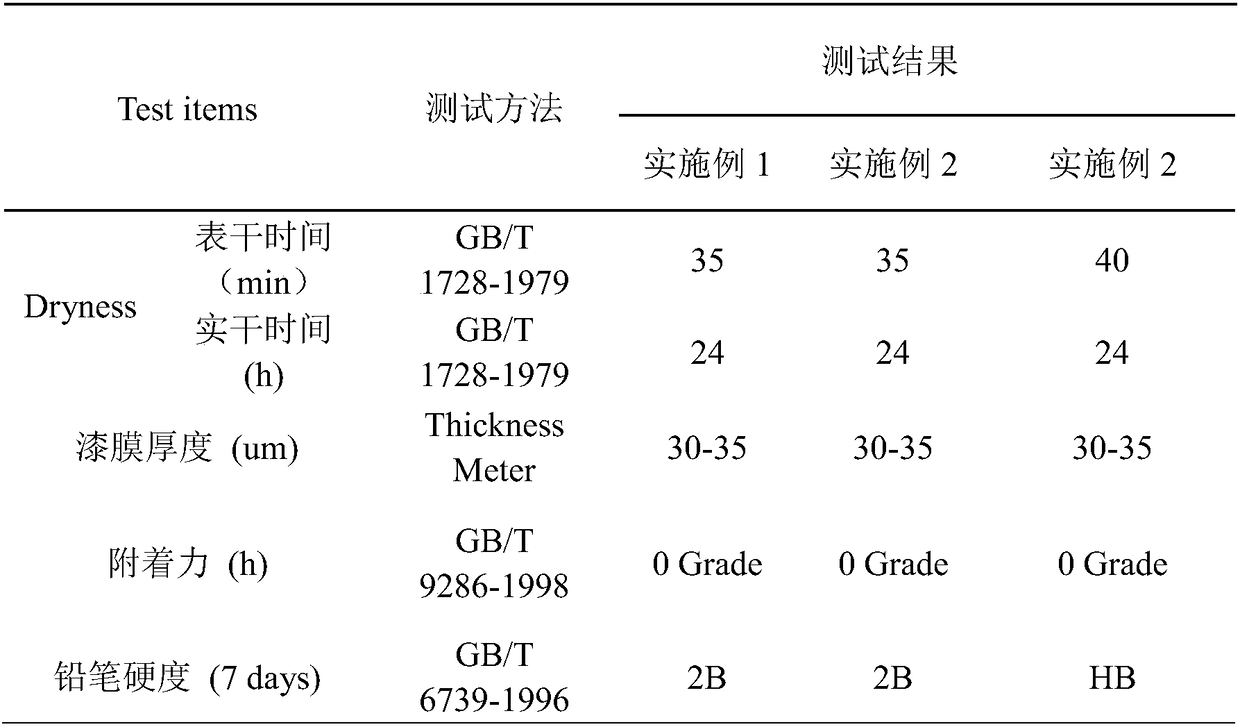

Air-seasoning alkyd resin prepared from discarded edible oil and application of air-seasoning alkyd resin

The invention discloses air-seasoning alkyd resin prepared from discarded edible oil. The alkyd resin comprises the following raw materials of 10-20 parts of discarded edible oil, 10-20 parts of dry vegetable oil, 6-12 parts of polyhydric alcohols, 0.01-0.02 part of catalyst, 10-15 parts of binary acid or anhydride, 2-8 parts of monoacid and 45-55 parts of diluent. Compared with the prior art, the air-seasoning alkyd resin has the advantages that the discarded edible oil with low price is adopted to replace part of dry vegetable oil or vegetable oil acids used in the traditional formula, the cost of per ton of the prepared air-seasoning alkyd resin can be reduced by about 800yuan, and the property of the air-seasoning alkyd resin is not lower than that of an existing product.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Photosensitive resin composition

InactiveCN1433532AHave patienceExcellent gold plating resistanceSemiconductor/solid-state device detailsSolid-state devicesResistElectrolysis

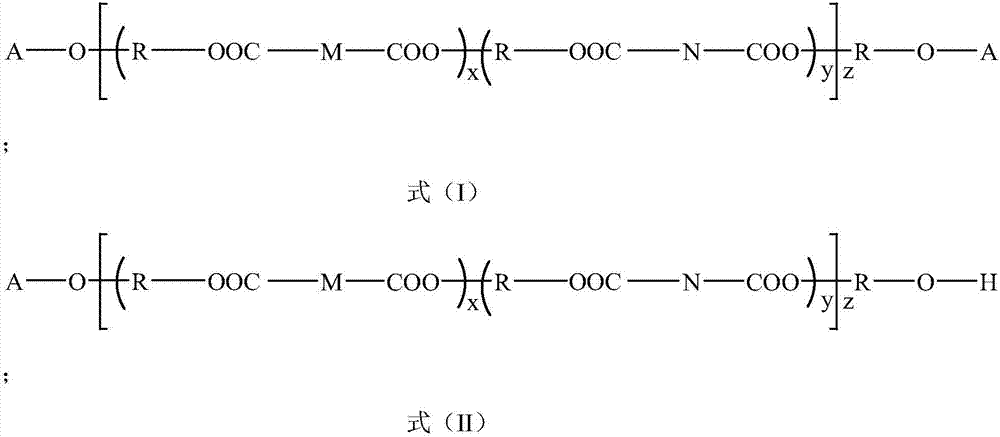

A photosensitive resin composition according to the invention includes (A) a photosensitive resin, (B) an epoxy resin, (C) a photopolymerization initiator, and (D) a polymerizable unsaturated compound and / or a solvent, which photosensitive resin (A) is obtained by allowing an epoxy resin (a) to react with a compound (b) having one primary alcoholic hydroxyl group and one functional group selected from a carboxyl group and a secondary amino group per molecule and an unsaturated monobasic acid (c) to yield a reaction product (I) and allowing a saturated or unsaturated polybasic acid anhydride (d) to react with the reaction product (I). The photosensitive resin composition of the invention is used as a solder resist in printed circuit boards, can be satisfactorily developed in a dilute basic aqueous solution and can yield a cured film that is excellent in flexibility, water resistance, adhesion, solder heat resistance, electroless gold plating resistance and pressure cooker test (PCT) resistance.

Owner:SHOWA DENKO KK

Preparation method of inorganic nano-hybrided and positively-charged polyelectrolyte complex pervaporation membrane

The invention discloses a preparation method of an inorganic nano-hybrided and positively-charged polyelectrolyte complex pervaporation membrane. An inorganic nanoparticle hybrided anionic polyelectrolyte aqueous solution is prepared; a cationic polyelectrolyte aqueous solution with pH (potential of hydrogen) being 5.8-10.0 is prepared; the inorganic nanoparticle hybrided anionic polyelectrolyte aqueous solution is dropwise added to the cationic polyelectrolyte aqueous solution, and an inorganic nano-hybrided and positively-charged polyelectrolyte complex is obtained; the complex is dispersed in a monobasic acid aqueous solution, filtered and left to stand for defoaming, a polysulfone ultrafiltration membrane is coated with the complex through a film wiping knife, and the inorganic nano-hybrided and positively-charged polyelectrolyte complex pervaporation membrane is obtained after drying. The inorganic nano-hybrided and positively-charged polyelectrolyte complex with different composition can be obtained by doping inorganic nanoparticles at different mass percentages and adjusting the pH value of the cationic polyelectrolyte solution. The prepared inorganic nano-hybrided and positively-charged polyelectrolyte complex pervaporation membrane has excellent separation performance and high stability.

Owner:ZHEJIANG UNIV

Dy (III)-Ni (II) mixed-metal magnetic complex constructed by mixed ligand as well as preparation method and application of complex

InactiveCN104098613AHigh yieldGood reproducibilityOrganic chemistryOrganic/organic-metallic materials magnetismPhenyl groupMonobasic acid

The invention relates to a Dy (III)-Ni (II) mixed-metal magnetic complex constructed by mixed ligand as well as a preparation method and an application of the complex. A chemical formula of the complex is [DyNi (L1) (L2)5], wherein L1 represents phenanthroline or 2, 2'-dipyridyl, and L2 represents monovalent anion of phenyl aromatic monobasic acid. The complex is prepared by adopting a hydrothermal method, and has higher yield and good reproducibility; the magnetic complex material is the first case of the Dy (III)-Ni (II) mixed-metal magnetic complex containing phenyl aromatic monobasic acid and nitrogen heterocyclic neutral ligand, and the alternating current magnetic susceptibility of the complex has an obvious frequency dependence phenomenon, namely slow-relaxation magnetic behavior, in the low-temperature area; and accordingly, the complex can be taken as a molecular magnetic material and has a huge application value in the aspects of high-density information storage equipment and the like.

Owner:TIANJIN NORMAL UNIVERSITY

Marine lubricant

ActiveUS20110077177A1Precision lubricationImprove efficiencyAdditivesBase-materialsAlcoholAlkaline earth metal

The present invention relates to a cylinder lubricant having a BN, determined according to the ASTM D-2896 standard, of greater than or equal to 40 milligrams of potassium hydroxide per gram of lubricant, comprising a lubricant base oil for a marine engine and at least one overbased detergent that is based on alkali or alkaline-earth metals, and which also contains an amount of 0.01% to 10% by weight relative to the total weight of the lubricant, of one or more compounds (A) chosen from esters of saturated fatty monoacids comprising at least 14 carbon atoms and of alcohols comprising at most 6 carbon atoms.

Owner:TOTAL RAFFINAE MARKETING

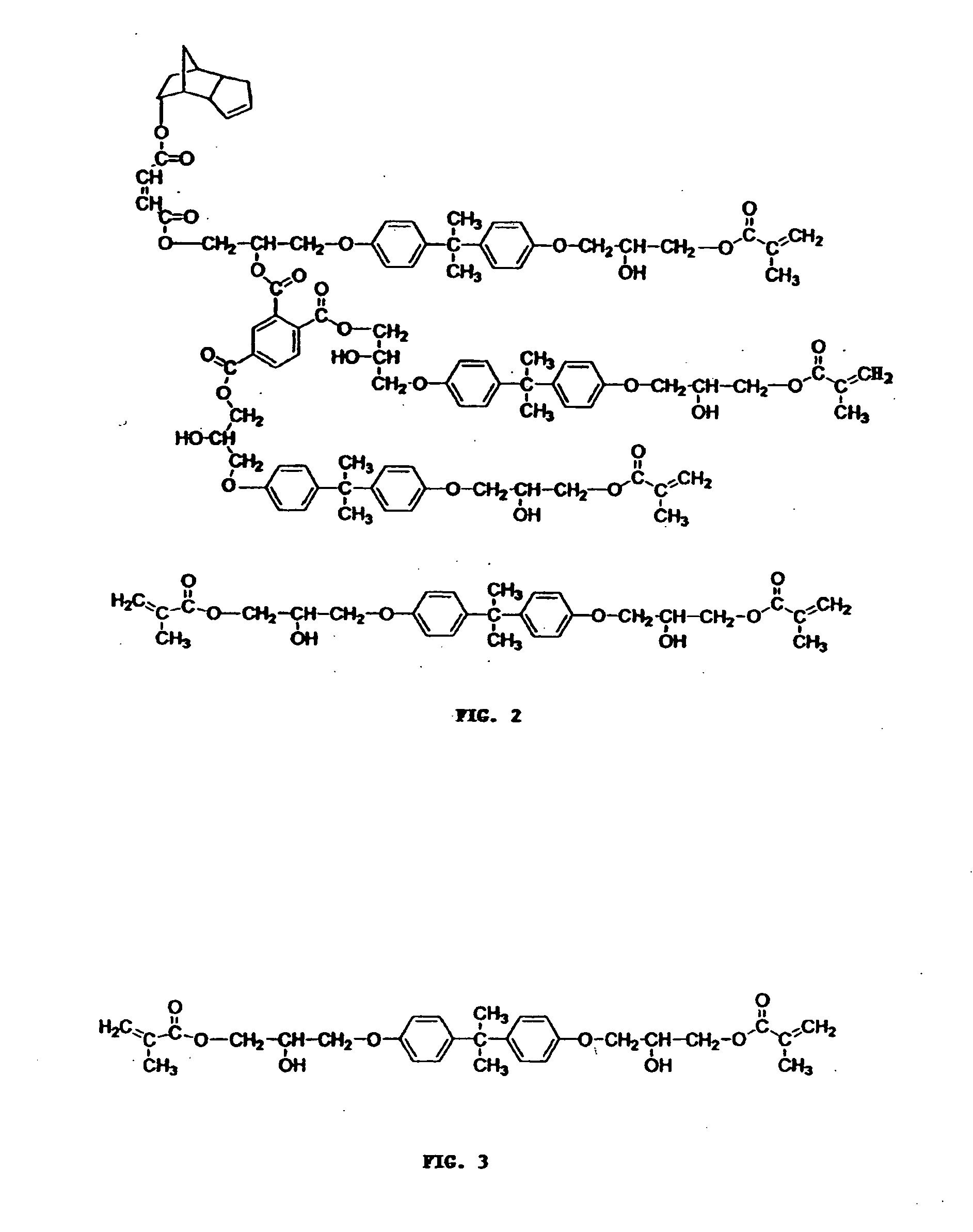

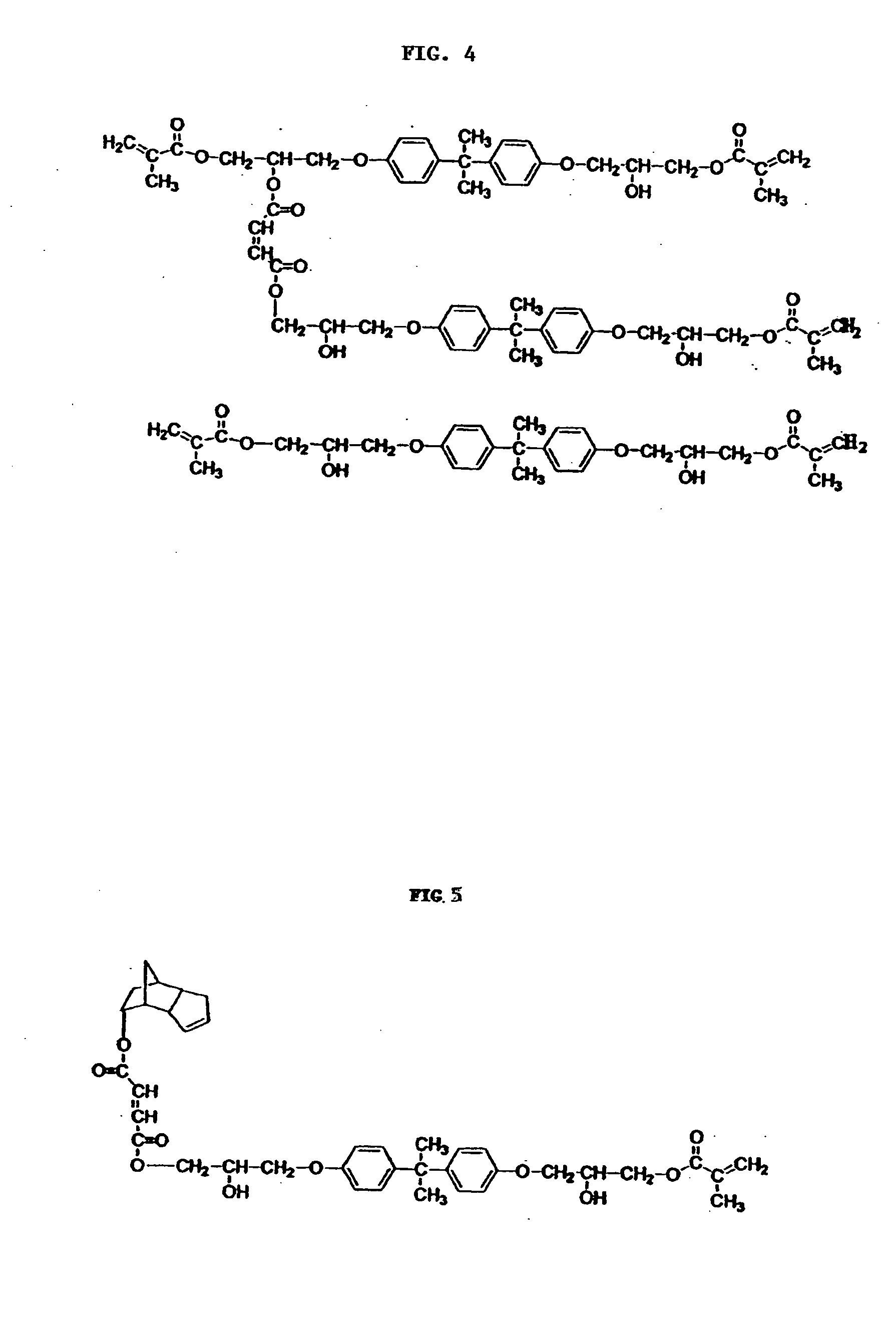

Tack-free low VOC vinylester resin and uses thereof

Low VOC vinyl ester resins exhibit improved cure in an oxygen containing environment. The vinyl ester resins comprise the reaction product of an epoxy resin having at least two epoxy groups per molecule; a polybasic anhydride; unsaturated monobasic acids comprising up to about 10 molar percent dicyclopentadienyl monomaleate based on the total unsaturated monobasic acids, wherein the vinyl ester resin has a viscosity of less than about 1200 cp measured at a shear of 500 s−1 in styrene at 70% non-volatile matter. Barrier coats and gel coats comprising such vinyl ester resins have acceptable tackiness and physical characteristics. A process to make such vinyl ester resins is also described.

Owner:COOK COMPOSITES & POLYMERS CO

Resin composition, composition for solder resist, and cured article obtained therefrom

A resin composition which is excellent in photosensitively and developability, gives a cured article excellent in flexibility, soldering heat resistance, resistance to thermal deterioration, and resistance to electroless gold plating, and is suitable especially for use in forming solder resists and interlayer dielectrics. The resin composition is characterized by containing an oligomer (A) obtained by reacting the following ingredients (a) to (d): an epoxy resin having at least two epoxy groups per molecule, a compound having two hydroxy groups and one carboxy group per molecule, a carboxy group per molecule, a carboxylated rubbery polymer, and a monobasic acid having an unsatuated group.

Owner:NIPPON KAYAKU CO LTD

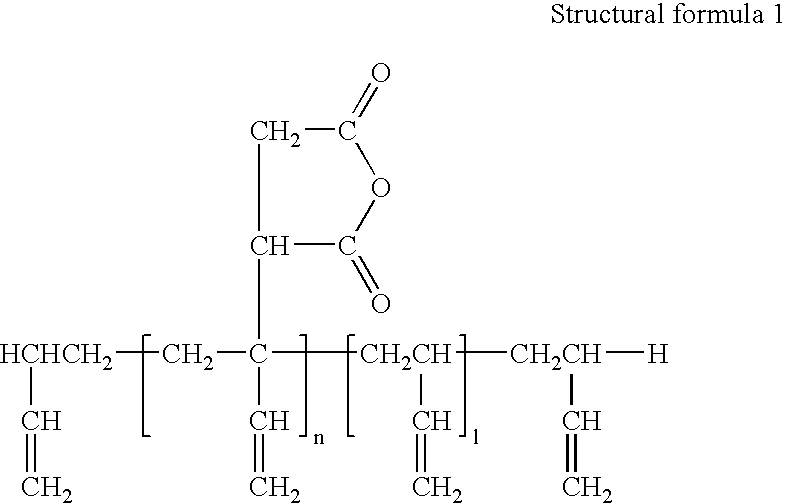

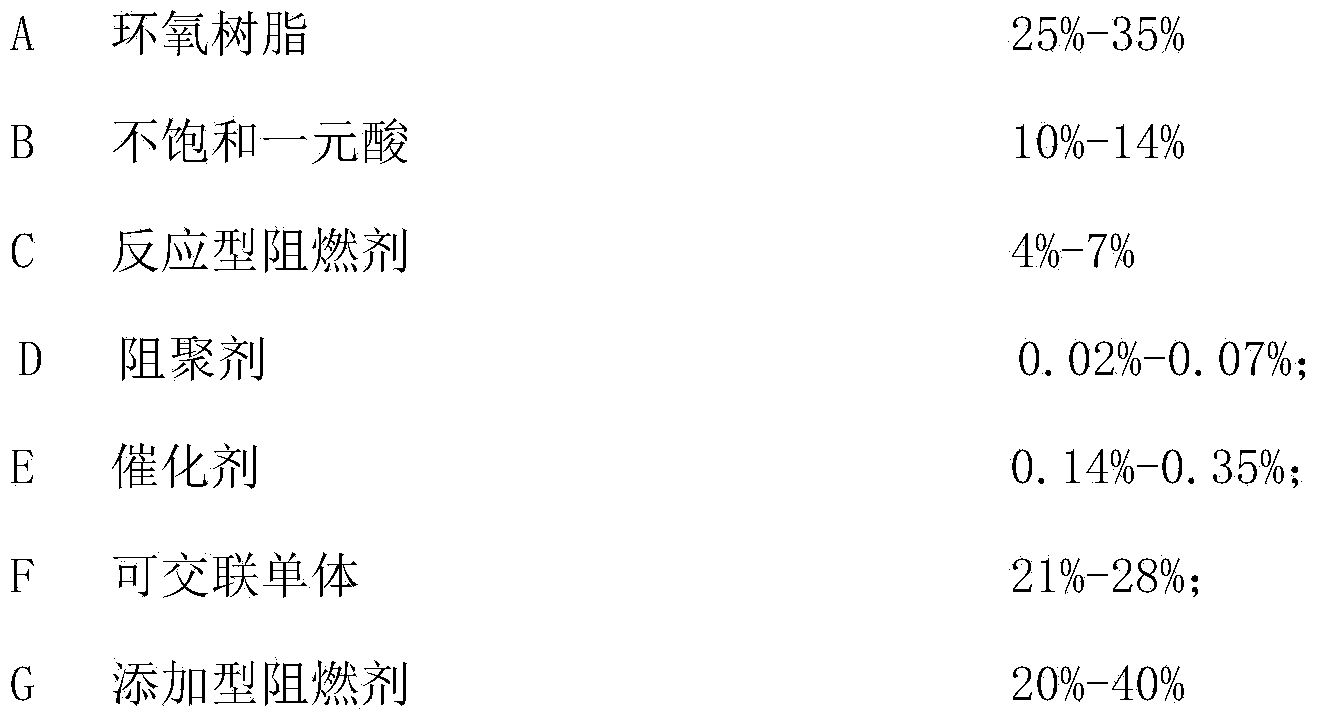

Low-smoke halogen-free high-temperature-resistant flame-retardant vinyl ester resin and preparation method thereof

The invention relates to a low-smoke halogen-free high-temperature-resistant flame-retardant vinyl ester resin and a preparation method thereof and belongs to the technical field of flame-retardant vinyl ester resins. The low-smoke halogen-free high-temperature-resistant flame-retardant vinyl ester resin is prepared by carrying out a series of reactions on substances such as an epoxy resin, unsaturated monobasic acid, a reactive flame retardant, an additive flame retardant, a catalyst, a polymerization inhibitor and a crosslinking monomer. The vinyl ester resin consists of raw materials at low price, the preparation cost is low, the comprehensive effects of the reactive flame retardant and the additive flame retardant are combined, and the flame-retardant effect is superior to that of like products in the market. The flame-retardant resin is low in smoke and halogen-free and can replace a brominated flame-retardant chemical modification vinyl-based resin with the halogen environment protection problem; and moreover, the flame-retardant resin is moderate in viscosity, good in construction performance and high in settling resistance, has outstanding corrosion resistance and high temperature resistance, can be used for building materials, automobile parts and the like and is particularly suitable for hand lay-up railway carriage parts and other low-smoke halogen-free flame-retardant glass fiber reinforced plastic products.

Owner:CHANGZHOU HUAKE POLYMERS

Flexible unsaturated polyester resin and preparation method and application thereof

InactiveCN101805429AHigh elongation at breakImprove impact toughnessPhysical propertyUnsaturated polyester

The invention relates to a flexible unsaturated polyester resin and a preparation method and application thereof. The resin is prepared by mixing and reacting a dibasic acid or anhydride, a monobasic acid and dibastic alcohol and diluting the reaction product with a diluent and comprises the following components in percentage by weight: 17 to 24 percent of dibastic alcohol, 3 to 5 percent of monobasic acid, 39 to 53 percent of dibasic acid or anhydride and 26 to 35 percent of diluent, wherein the monobasic acid is oleinic acid; and the diluent is styrene and diallyl phthalate which accounts for 2 to 5 percent of the total weight of the diluent. The preparation method comprises the following steps: performing polycondensation reaction on the dibastic alcohol and the dibasic acid or anhydride for 8 to 12 hours at the temperature of about 200 DEG C, wherein the acid value is 40 to 50mgKOH / g, reducing the temperature, adding the oleinic acid, performing polycondensation reaction for 2 to 3 hours, after the reaction is completed, reducing the pressure and performing vacuum treatment until the acid value is 25 to 35mgKOH / g, adding an additive, cooling, and adding the diluent to obtain the flexible unsaturated polyester resin. The prepared flexible unsaturated polyester resin has high elongation at break and impact toughness and certain strength, and meets the requirements on physical properties of articles.

Owner:上海新天和树脂有限公司 +2

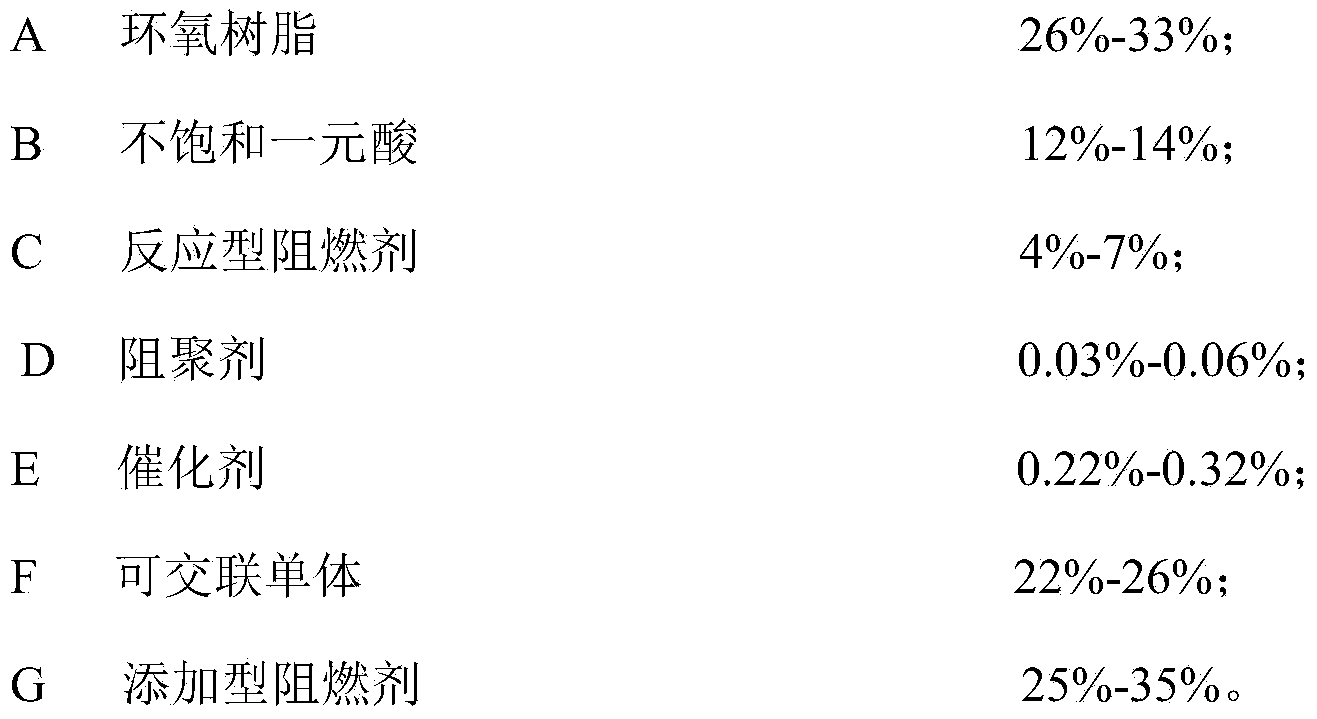

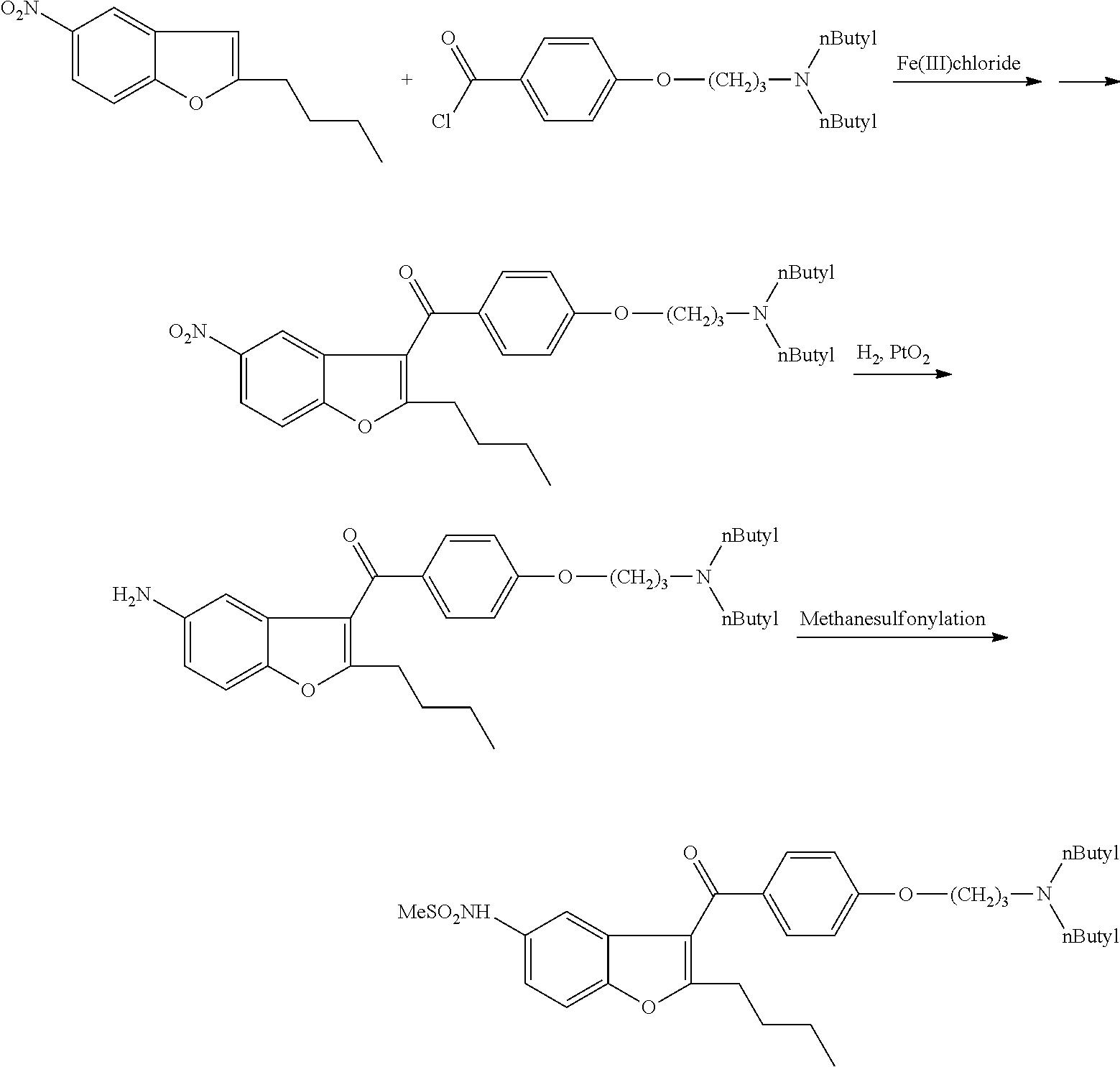

Process for preparation of dronedarone by mesylation

The invention relates to a novel process for preparation of N-[2-n-butyl-3-[4-[3-(di-n-butylamino)-propoxy]-benzoyl]-benzofuran-5-yl]methanesulfonamide (I) and pharmaceutical acceptable salts thereof, where a salt of (5-amino-2-butyl-1-benzofuran-3-yl) {4-[3-(di-n-butylamino)propoxy]phenyl}methanone of formula (II)—where A is a mono- or dibasic acid forming an acid addition salt with the compound of formula (II), n is 1 if A is dibasic acid and n is 1 or 2 if A is a monobasic acid—is reacted with a mesylating reagent in a heterogen reaction, if desired, in the presence of a phase transfer catalyst. The invention also relates to the novel salts of compound of formula (II), for the preparation thereof and their use in the preparation of dronedarone.

Owner:SANOFI SA

Alkyd-amine impregnating varnish prepared from discarded edible oil

The invention discloses an alkyd-amine impregnating varnish prepared from discarded edible oil. The alkyd-amine impregnating varnish is prepared from the following raw materials in parts by weight of 10-20 parts of discarded edible oil, 1-5 parts of dry vegetable oil, 7-13 parts of polyhydric alcohols, 0.01-0.02 part of catalyst, 10-16 parts of binary acid or anhydride, 3-8 parts of monobasic acid, 3-8 parts of amino resin and 45-55 parts of diluent. Compare with the prior art, the alkyd-amine impregnating varnish disclosed by the invention has the advantages that the discarded edible oil with low price is adopted to replace the vegetable oil or vegetable oil acids used in the traditional formula to prepare the alkyd-amine impregnating varnish, the cost of per ton of the alkyd-amine impregnating varnish can be reduced by about 700yuan, and the property of the alkyd-amine impregnating varnish is not lower than that of an existing product.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

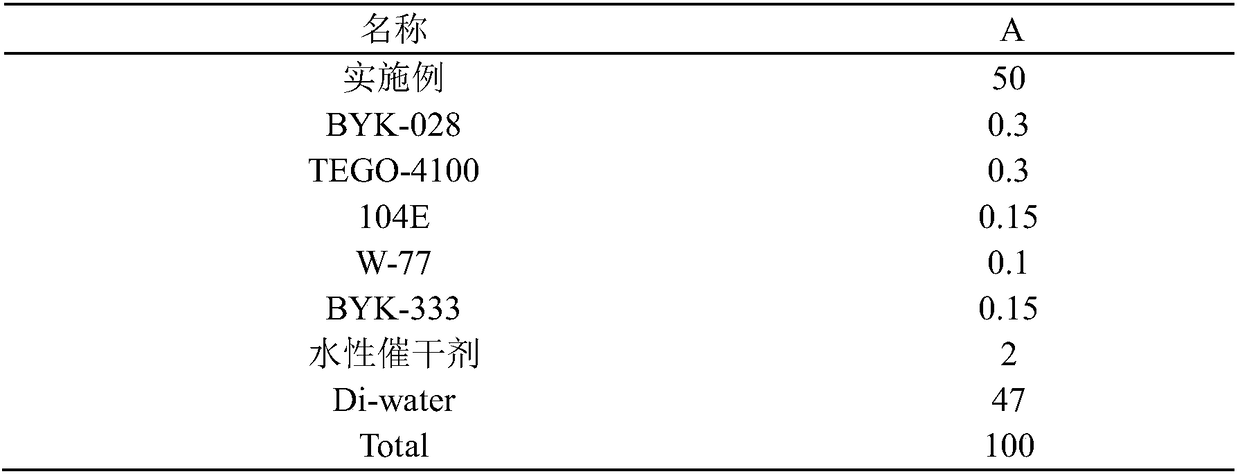

Preparation method of novel biological matrix non-soap type core-shell structure water-based acrylic acid emulsion

InactiveCN108059695AEnvironmentally friendlyRaw materials are renewableCoatingsNatural sourceWater based

The invention discloses a preparation method of novel biological matrix non-soap type core-shell structure water-based acrylic acid emulsion. The preparation method comprises the following steps: 1) adding fatty acid, monobasic acid and polyol with natural source according to a certain proportion to prepare an alcohol acid intermediate; 2) adding a certain amount of polybasic acid and anhydride into the alcohol acid intermediate prepared in the step 1 according to a certain proportion and dissolving into water to prepare an alcohol acid aqueous solution; and 3) adding an acrylic acid comonomerin the alcohol acid aqueous solution in the step 2 at a time or in batches, adding an initiator, a reducing agent, a catalyst, a molecular weight regulator, reacting at 30 to 95 DEG C for 10 to 90 minutes, adding aids such as a crosslinking agent, a sterilizing agent, preservative, a stabilizer and a defoaming agent as required, and finally obtaining the novel biological matrix non-soap type core-shell structure water-based acrylic acid emulsion. The emulsion has the advantages of environmental friendliness, reproducible raw materials, low cost, high drying speed, wide and adjustable film-forming temperature and hardness and the like, and is favorable for application and popularization of biological matrix concept products.

Owner:科思创树脂制造(佛山)有限公司

Process of producing alkyd resin using waste oil

The process of producing semi-finished paint self-dried alkyd resin with sewage ditch oil includes heating sewage ditch oil and monoacid in the pot to 70-90 deg.c and adding assistant, dewatering before heating to 140-160 deg.c slowly, adding maleic anhydride, heating to 240-260 deg.c in 1.5-3.0 hr to acidolyze sewage ditch oil, cooling to 180-200 deg.c and adding polyol, polybasic acid and reflux solvent, heating to and maintaining at 180-200 deg.c, heating to and maintaining at 240-250 deg.c to dewater, heating to 270-290 deg.c to polymerize to reach required acid number and viscosity, cooling and adding solvent to dilute, filtering at 100 deg.c and packing. The present invention is environment friendly.

Owner:福建豪迪涂料科技股份有限公司

Setoglaucine salt, preparation method thereof and medicinal composition containing the same

InactiveCN1907989AGood water solubilityImprove bioavailabilityPhosphorus organic compoundsAntineoplastic agentsOrganic acidSolubility

The invention discloses a chaetocin salt and preparing method and drug composition with chaetocin salt, which possesses structure formula (I) on the right, wherein R is salt of inorganic oxyacid or organic monobasic acid group and metal, ammonium salt or organic amine. The invention improves solubility greatly, which prevents tumour effectively.

Owner:ZHEJIANG TIANHUANG MEDICINAL PLANT PHARMA

Amide oligomer and polyamide paste rheological aid prepared by swelling same

InactiveCN101863792AEasy to addPrevent subsidenceThiol preparationOrganic compound preparationPolyamine CompoundOligomer

The invention discloses an amide oligomer and a polyamide paste rheological aid prepared by swelling the same. A preparation method for the amide oligomer comprises the following steps of: putting aliphatic binary acid, aliphatic polyamine compound and aliphatic monobasic acid with a polar group and ester thereof into a reactor, adding a catalyst into the reactor, and reacting the mixture at the temperature of between 150 and 200 DEG C to obtain the amide oligomer. The polyamide has proper melting point and relative molecular weight; and after micro pulverization, the polyamide is dispersed into a mixed solvent containing aromatic hydrocarbon and alcohol and subjected to the controlled swelling at a lower temperature to form the polyamide paste rheological aid. The obtained polyamide paste rheological aid serving as an additive provides excellent coating performance for a coating system, namely has high viscosity during standing and good viscosity stability, prevents the powder in thesystem from settling and caking, has thinner viscosity during coasting and is easy for construction; the leveling property and the flowing resistance of a coated film are well balanced; and the polyamide paste rheological aid has broad application prospect in the coating industry.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Low-cost halogen-free chemical flame-retardant vinyl ester resin and preparation method thereof

ActiveCN103641961ATo achieve the purpose of halogen-free flame retardantThe flame retardant effect is more stable and excellentGlass fiberPolymer science

The invention discloses a low-cost halogen-free chemical flame-retardant vinyl ester resin and a preparation method thereof and belongs to the technical field of flame-retardant vinyl ester resins. The low-cost halogen-free chemical flame-retardant vinyl ester resin is prepared by performing a series of reactions on bisphenol A epoxy, unsaturated monobasic acid 5-20, phosphoric acid, a catalyst, a polymerization inhibitor and a crosslinking monomer. The preparation method is simple, and three common problems of the conventional flame-retardant vinyl ester resin, namely poor brominated flame-retardant environment friendly effect, poor physical blending flame-retardant effect and stability and high cost in comparison with other flame-retardant methods, are solved. Moreover, the three wastes are avoided, the vinyl ester resin subjected to phosphoric acid ring opening modification has the performances of flame-retardant property, temperature resistance and corrosion resistance, and the product is high in stability, is an ideal substitute for a brominated flame-retardant chemical modification vinyl ester resin which is more than 30000 yuan per ton in the market and has the halogen-caused environment pollution problem, can be used for fiber reinforce plastic (FRP) products with anti-corrosion flame-retardant requirements as well as the engineering field, and also can be applied to the special fields of manufacturing of finished glass fiber reinforced plastic chimneys with flame-retardant high-temperature-resistant requirements.

Owner:浙江天和树脂有限公司 +1

High-flexibility polyester epoxy impregnated resin and preparation method thereof

InactiveCN107459797AHigh mechanical flexibilityGood high and low temperature impact cracking resistancePolyesterEpoxy

The invention discloses a high-flexibility polyester epoxy impregnated resin and a preparation method thereof. According to the high-flexibility polyester epoxy impregnated resin, non-flexible unsaturated resin and non-flexible epoxy resin commonly used in the polyester epoxy system impregnated resin of the prior art are replaced by flexible unsaturated polyester resin and flexible type pliable epoxy resin, and by adopting monobasic acid terminated and synthesized flexible unsaturated polyester resin and combining the flexible type pliable epoxy resin with excellent flexibility, the remarkable toughness effect can be achieved, the impregnated resin has excellent mechanical flexibility and good high-low-temperature impact and anti-cracking performance, so that the viscosity of the high-flexibility polyester epoxy impregnated resin can achieve 386mPa.s at 25 DEG C, has good permeation property and can be impregnated by sinking, dripping or VPI, and the resin has excellent electrical insulating performance, wet-heat-resistant performance and chemical-resistant performance.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Photothermosetting component

This invention is to provide a kind of photothermosetting component, which was composed of a base resin (A), a photopolymerizable photomonomer or photooligomer (B), a photoinitiator (C), an epoxide compound containing at least two epoxy groups (D), and an organic solvent. A base resin (A) is composed of containing at least two epoxy groups of epoxide compound (a), containing at least two double bonds of unsaturated monobasic acid (b), a saturated or unsaturated dibasic acid (c), and a saturated or unsaturated acid anhydride (d) according to the typical ratio. This photothermosetting component was coating on the substrate, and then dried by baking, exposed by light, developed, irradiated by ultraviolet light or heated, and cured to form a solder mask.

Owner:ADVANCE MATERIALS CORP

Preparation method of dicarboxylic dihydric alcohol ester plasticizer

InactiveCN106146300AHigh yieldEasy to separateOrganic compound preparationCarboxylic acid esters preparationPlastics industryAlcohol

A preparation method of dicarboxylic dihydric alcohol ester plasticizer includes the steps of conducting esterification reaction for 0.5-48 h with monobasic acid and dihydric alcohol as the raw materials under the catalysis effect at a temperature of 100-250 DEG C, and conducting reduced pressure distillation to obtain the dicarboxylic dihydric alcohol ester product. Dicarboxylic dihydric alcohol ester is non-toxic plasticizer and can replace phthalic acid ester to be used for the field of plastic industry, rubber industry and the like. The product prepared through the method is high in yield, easy to separate and friendly to the environment and has good application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing zirconium dioxide nano powder by low-temperature calcination of zirconium sol

ActiveCN105621480APrecisely adjustable doping amountAvoid expensiveMaterial nanotechnologyZirconium oxidesDispersityPollution

The invention provides a method for preparing zirconium dioxide nano powder by low-temperature calcination of zirconium sol. The method comprises the following steps: dissolving a raw material water-soluble zirconium inorganic salt in deionized water; adding an alkaline precipitant to generate a suspension, and centrifuging or filtering to obtain precipitate; adding mixed liquid of monobasic acid or monobasic acid and hydrogen peroxide into the precipitate, and continuously stirring for peptization to obtain a clear zirconium sol precursor; and finally, drying and dehydrating the zirconium sol precursor and calcining and decomposing in different temperature intervals, wherein amorphous zirconium dioxide nano powder as well as zirconium dioxide nano powder of which tetragonal phase can be kept stable without doping can be obtained, and the average particle size of the powder can be controlled between 3nm and 10nm. The preparation method of high-performance zirconium dioxide nano powder has the following advantages: the powder has small particle size, narrow distribution and good dispersity; the adopted raw material reagent is easily available and cheap; and the equipment requirements and operation technology are simple, the energy consumption is low, pollution is avoided, and industrial production is easy to realize.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com