Mono-acid blocked unsaturated polyester resin and preparation method for same

A polyester resin, unsaturated technology, applied in the field of monoacid-capped unsaturated polyester resin and its preparation, can solve the problem that the compatibility of the resin is greatly affected, it will not be used by ordinary customers, and the compatibility of glycerin is poor, etc. problem, achieve the effect of improving anti-yellowing, reducing water absorption and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

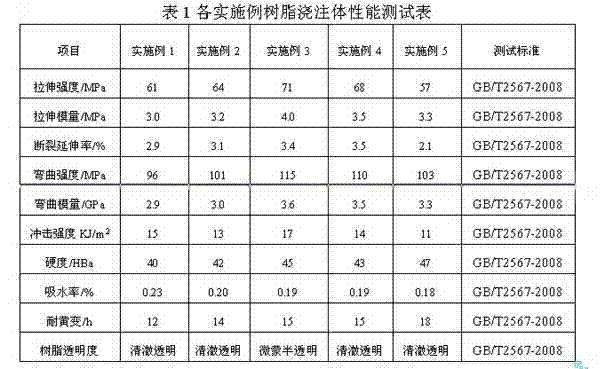

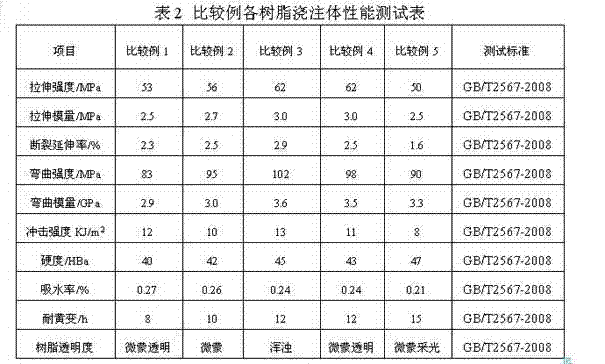

Examples

Embodiment 1

[0035] A monoacid-terminated unsaturated polyester resin, fed according to the following ratio:

[0036] (1) 13 parts of ethylene glycol

[0037] (2) Diethylene glycol 12 parts

[0038] (3) 14 parts of phthalic anhydride

[0039] (4) Maleic anhydride 22 parts

[0040] (5) 3 parts of benzoic acid

[0041] (6) 36 parts of styrene,

[0042] The preparation method of this monoacid end-capping type unsaturated polyester resin comprises the following steps:

[0043] Under the protection of high-purity nitrogen, first add (1) and (2) into the reaction pot according to the above-mentioned feeding ratio, start stirring at an average speed of 60r / min, and then put in (3)~(5) in proportion, start to heat up, and heat up to Keep warm at 150~160°C for 2 hours, the temperature of the distillation head should not exceed 105°C, then raise the temperature at a rate of 10°C per hour, and at 180~190°C at a rate of 5°C per hour, then gradually polycondense at 200~210°C for 2~ 6h, the reaction...

Embodiment 2

[0045] A monoacid-terminated unsaturated polyester resin, fed according to the following ratio:

[0046] (1) 13 parts of ethylene glycol

[0047] (2) Diethylene glycol 11 parts

[0048] (3) 3 parts of glycerin

[0049] (4) 13 parts of phthalic anhydride

[0050] (5) 7 parts of maleic anhydride

[0051] (6) Fumaric acid 18 parts

[0052] (7) 1.5 parts of benzoic acid

[0053] (8) Glacial acetic acid 0.5 parts

[0054] (9) 33 parts of styrene,

[0055] The preparation method of this monoacid end-capping type unsaturated polyester resin comprises the following steps:

[0056] Under the protection of high-purity nitrogen, first add (1)~(3) into the reaction pot according to the above-mentioned feeding ratio, start stirring at an average speed of 60r / min, and then put in (4)~(8) in proportion, and start to heat up. Keep warm at 150~160°C for 2 hours, the temperature of the distillation head does not exceed 105°C, then increase the temperature at a rate of 10°C per hour, and...

Embodiment 3

[0058] A monoacid-terminated unsaturated polyester resin, fed according to the following ratio:

[0059] (1) 11 parts of ethylene glycol

[0060] (2) Diethylene glycol 14 parts

[0061] (3) 3 parts of propylene glycol

[0062] (4) 20 parts of terephthalic acid

[0063] (5) Fumaric acid 22 parts

[0064] (6) 1 part of benzoic acid

[0065] (7) 0.5 parts of isooctanoic acid

[0066] (8) Lauric acid 0.5 parts

[0067] (9) 28 parts of styrene,

[0068] The preparation method of this monoacid end-capping type unsaturated polyester resin comprises the following steps:

[0069] Under the protection of pure nitrogen, first add (1)~(3) into the reaction pot according to the above-mentioned feeding ratio, start stirring at an average speed of 60r / min, then put in (4) in proportion, add 0.04 parts of tin oxyhydroxide, and start Heat up, heat up to 170~175°C for 2 hours, the temperature of the distillation head does not exceed 105°C, then heat up at a rate of 10°C per hour, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com