Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Raw materials are renewable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin

InactiveCN104744204AWide variety of sourcesRaw materials are renewableHydrocarbon from oxygen organic compoundsEthylene productionIridiumPtru catalyst

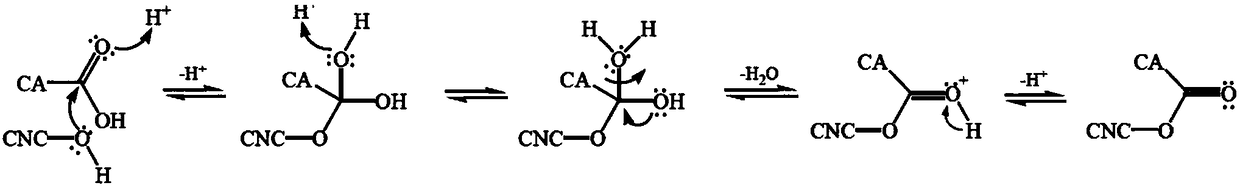

The invention relates to a method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin. A catalyst used in the method provided by the invention comprises two active components, namely an acid site being one or combination of more than one of transition metal elements niobium, tantalum, zirconium, molybdenum, tungsten and rhenium and a hydrogenation or hydrogen transfer active site being one or more than one of ruthenium, platinum, palladium, iridium, iron, cobalt, nickel and copper. According to the method provided by the invention, a phenol group, a guaiacol group, a syringa phenolic group compound, natural lignin and industrial lignin are taken as raw materials, water is taken as a solvent, high selectivity catalytic hydrodeoxygenation is carried out at the temperature of 180-350 DEG C and hydrogen pressure of 0.1-5MPa or with methyl alcohol, isopropyl alcohol and formic acid as hydrogen sources, so that C6-C9 aromatic hydrocarbon is obtained, the highest mass yield of aromatic hydrocarbon is 10%, and content of aromatic hydrocarbon in product oil can be up to more than 75%. The method provided by the invention has the advantages that reproducible natural biomass can be used as a raw material, and the raw material is cheap and available; the water is taken as the solvent, so that a reaction process is environment-friendly; and content of aromatic hydrocarbon in the product is high, and reaction conditions are mild.

Owner:EAST CHINA UNIV OF SCI & TECH

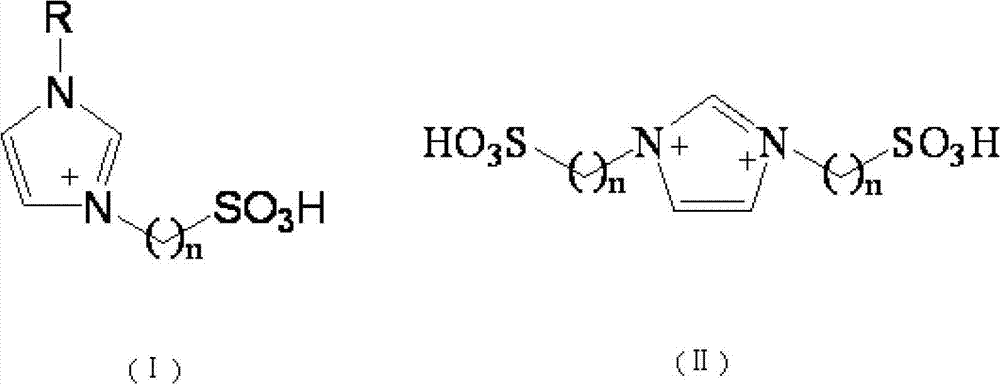

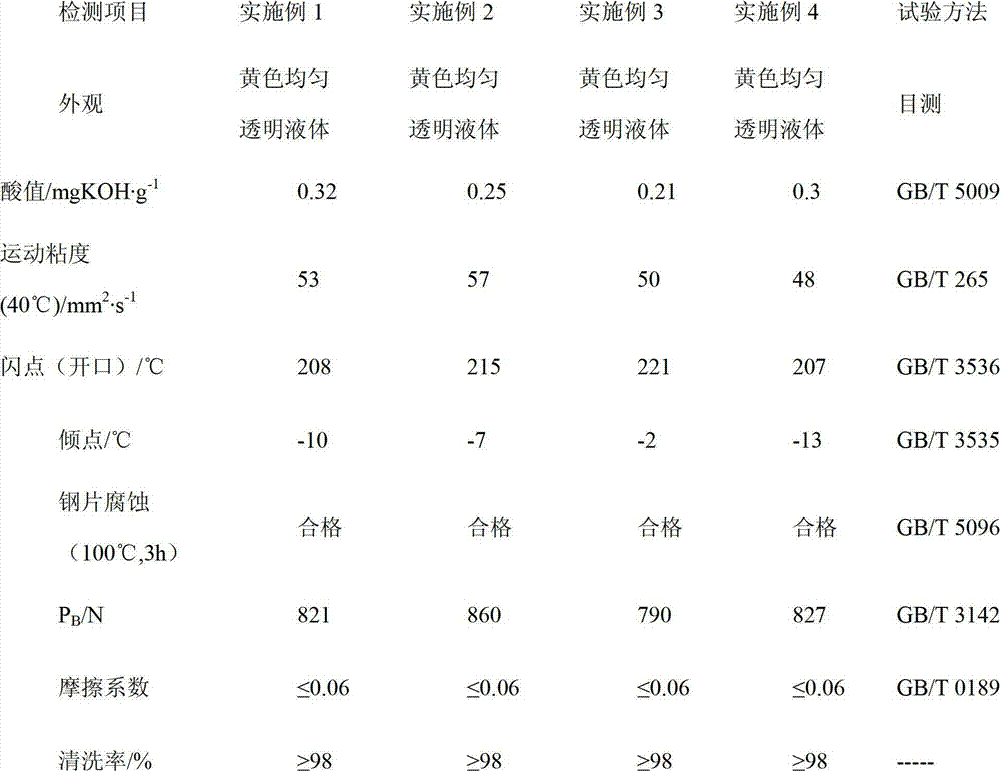

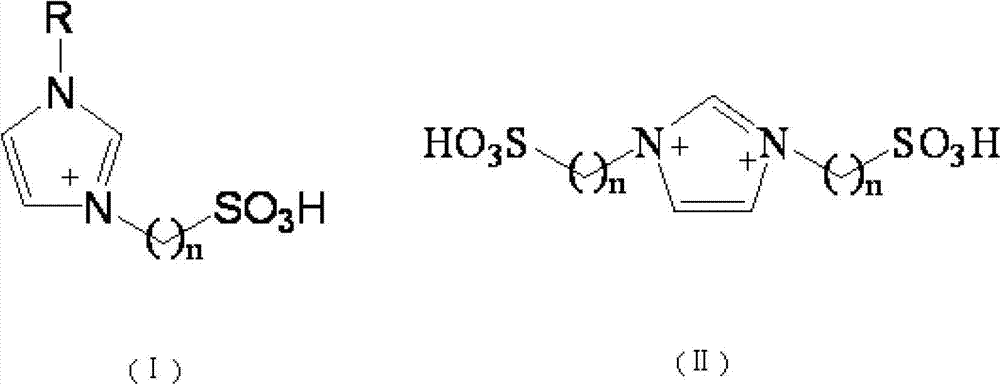

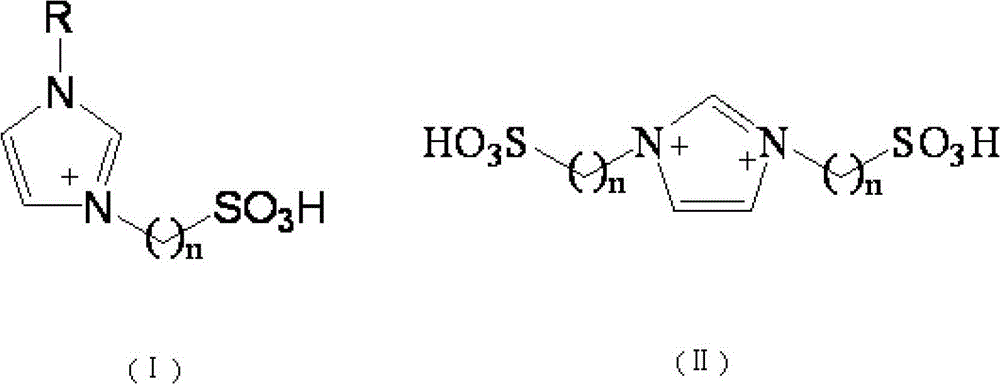

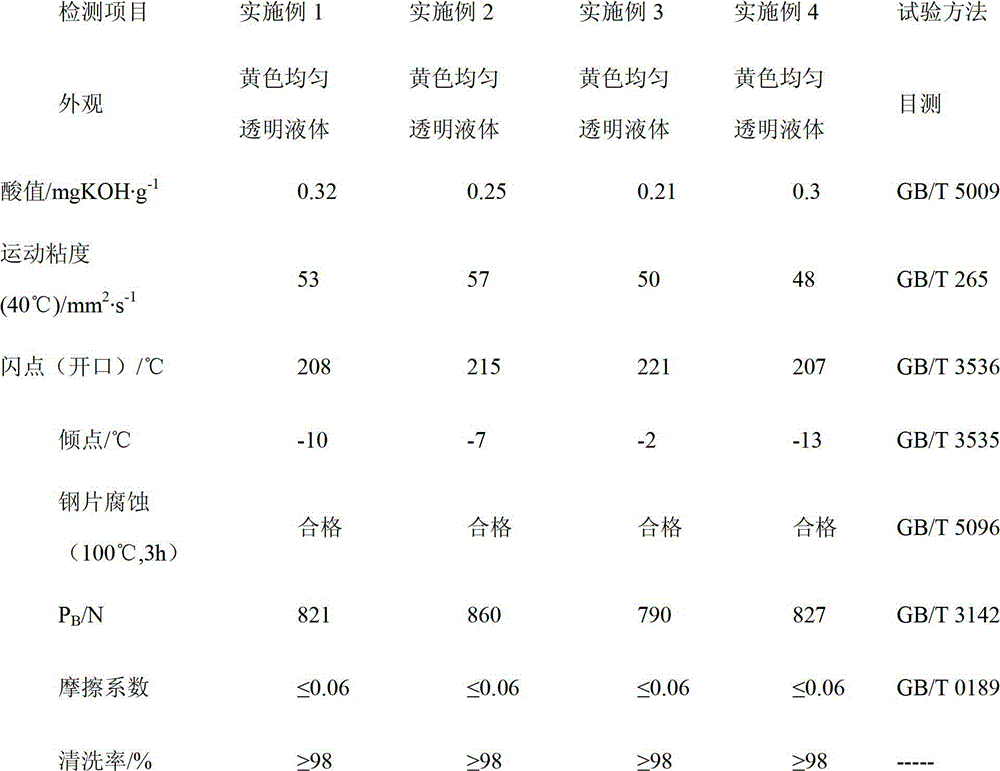

Green environment-friendly soluble stamping and drawing oil and preparation method thereof

ActiveCN102787007AGood cooling and lubricating effectGood emulsificationFatty acid chemical modificationLubricant compositionIonHydrogen peroxide

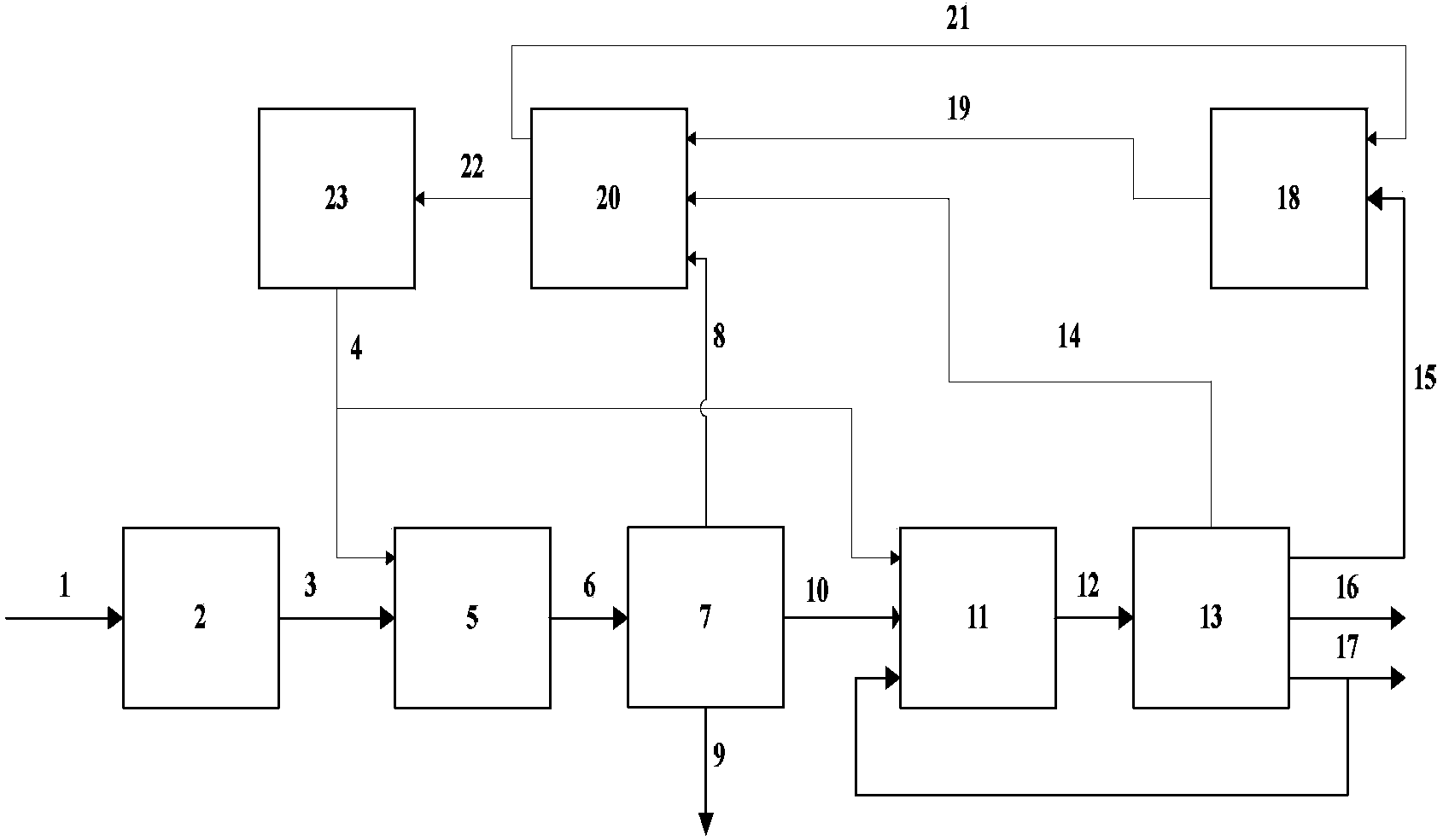

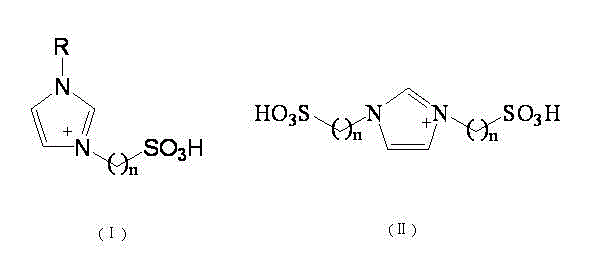

The invention discloses a green environment-friendly soluble stamping and drawing oil and a preparation method thereof. The preparation method comprises the following steps: with sulfonic acid ionic liquid as a catalyst and waste grease, non-edible vegetable oil or fatty acid methyl ester / fatty acid ethyl ester as a raw material, adding hydrogen peroxide and carrying out heating and stirring for a reaction so as to prepare epoxidized modified grease, wherein the molar ratio of the raw material to hydrogen peroxide is 1: 1 to 1: 5; with trimethylol propane and fatty acid or fatty acid methyl ester / fatty acid ethyl ester as raw materials and sulfonic acid ionic liquid as a catalyst, carrying out heating and stirring for a reaction so as to prepare hydroxyalkylated fatty acid ester, wherein the molar ratio of trimethylol propane to fatty acid or fatty acid methyl ester and fatty acid ethyl ester is 1: 1.5 to 1: 5, and the molar ratio of trimethylol propane to ionic liquid is 1: 0.001 to 1: 0.2; uniformly mixing epoxidized modified grease, hydroxyalkylated fatty acid ester and an extreme pressure agent under stirring to obtain the mixture component A; uniformly mixing a surfactant andan osmotic agent at a normal temperature and a normal pressure under stirring so as to obtain the mixture component B; and adding the component A, the component B, an antirust agent and other additives into a reaction kettle and carrying out stirring at a temperature of 40 to 80 DEG C for 10 min to 1 h so as to obtain a final product.

Owner:广州市联诺化工科技有限公司

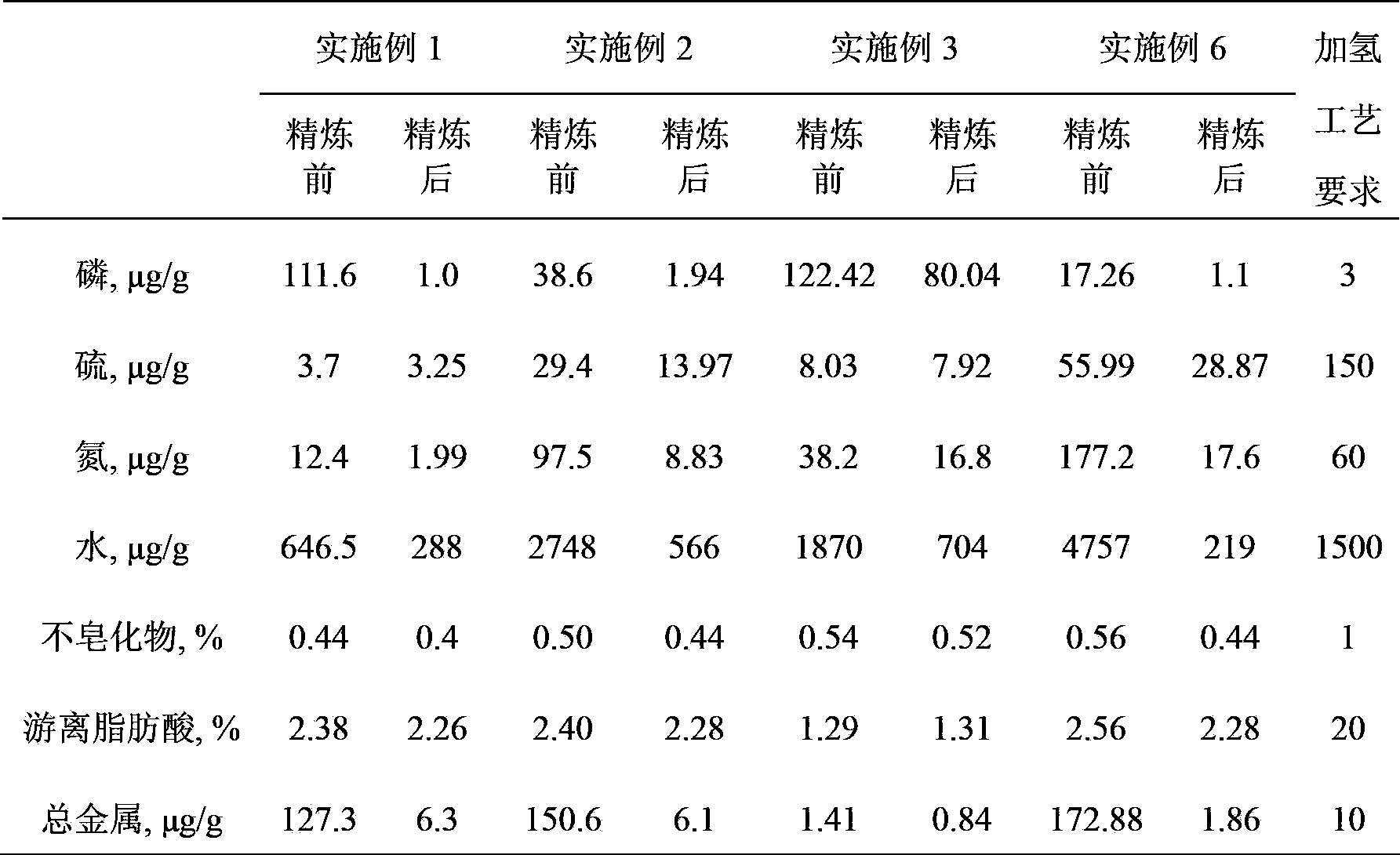

Method for production of diesel oil fraction and aviation fuel fraction by use of animal and plant oils and fats

The invention relates to a method for production of a diesel oil fraction and an aviation fuel fraction by use of animal and plant oils and fats, and the method comprises the following steps: a) performing refining processing on the animal and plant oils and fats; b) performing catalytic hydrogenation and deoxidation to obtain saturated linear alkanes and propane; c) performing hydroisomerization and hydrocracking processing to obtain an alkane material flow with higher branched chain degree; d) separating to obtain liquid hydrocarbons and gaseous hydrocarbons with the boiling point within the boiling point range of diesel oil, aviation fuels and naphtha; e) directly collecting the diesel oil fraction as a product, or cycling in whole or in part to continue isomerization and cracking reaction to increase production of the aviation fuel fraction; and f) mixing propane gaseous hydrocarbon and naphtha for steam reforming hydrogen production reaction, separating and purifying the obtained hydrogen to enter into a circulating hydrogen system; the method is used in the production of the renewable diesel oil and aviation fuels with excellent combustion performance and cold flow performance, and meanwhile efficient utilization of by-products and in-system supplement of hydrogen consumption can be realized.

Owner:PETROCHINA CO LTD

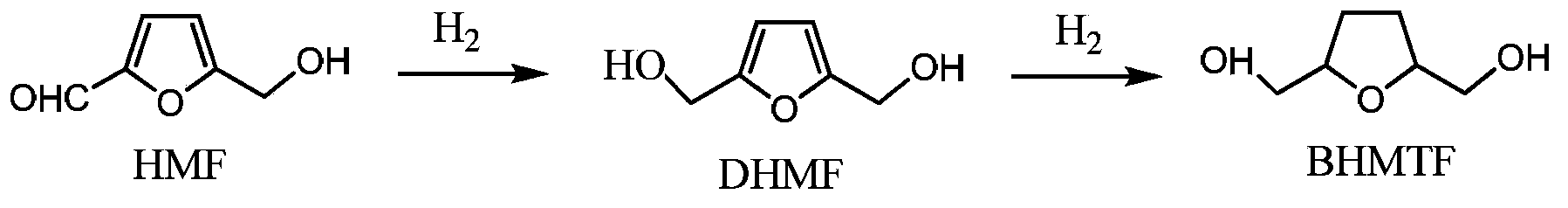

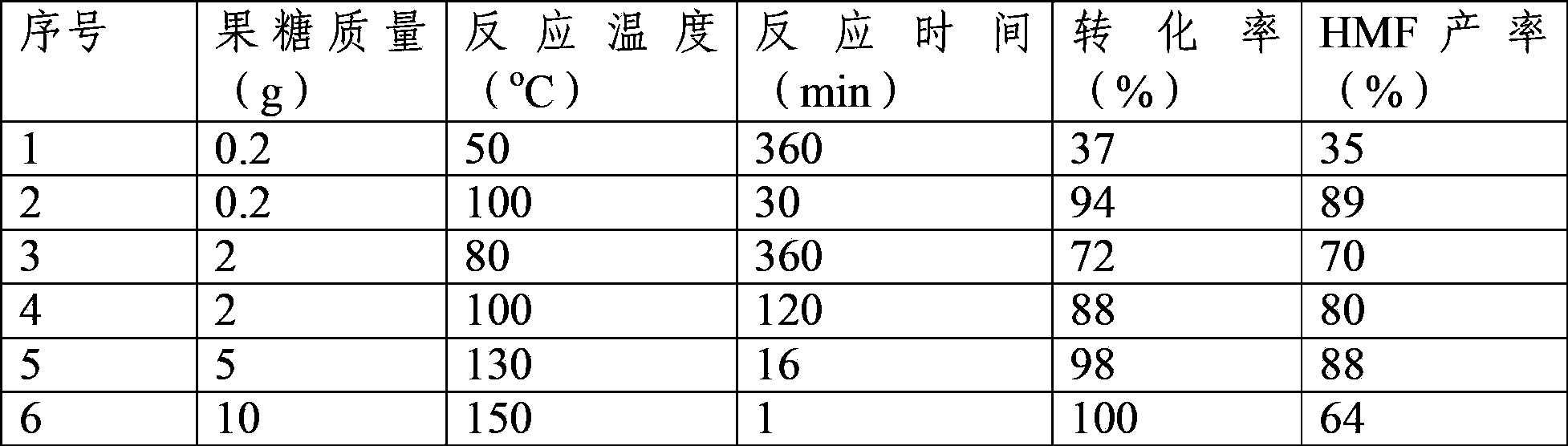

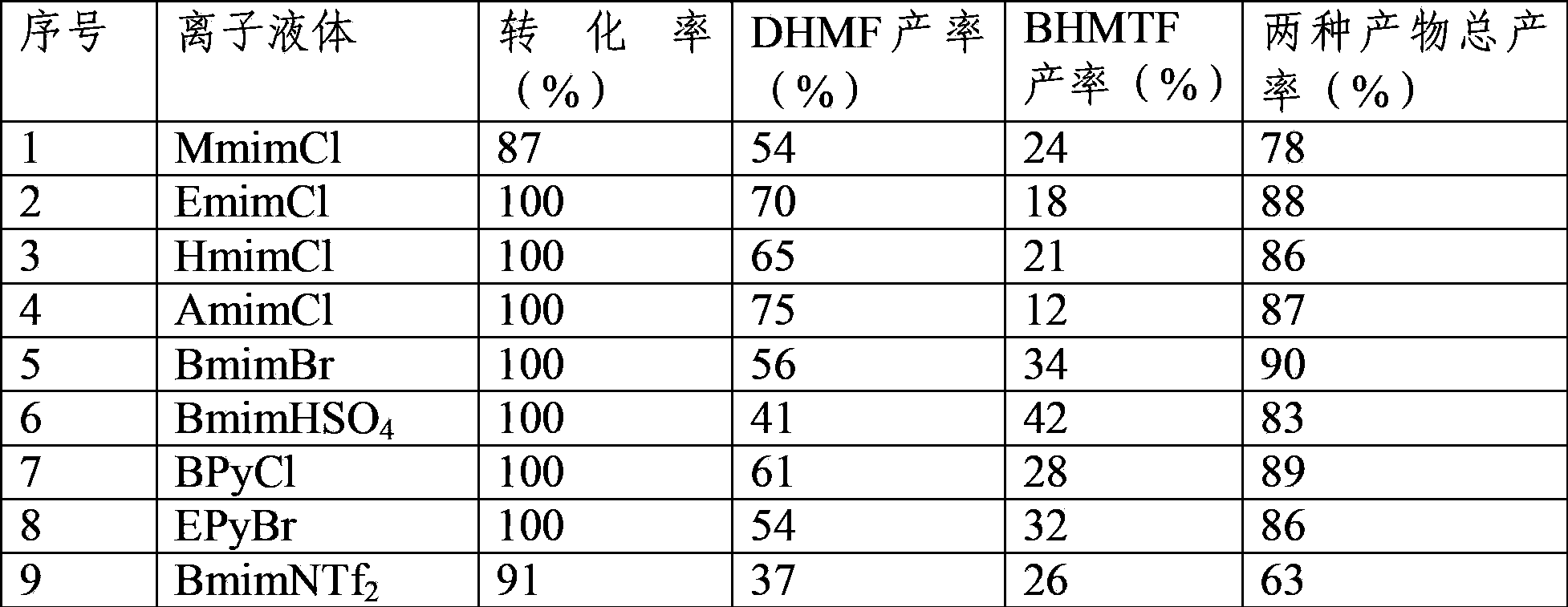

Method for preparing furyl glycol from fructosyl biomass

The invention relates to a method for preparing furyl glycol from fructose and fructosyl biomass, and specifically relates to a method for converting fructose and fructosyl biomass into 2,5-dihydroxy methyl tetrahydrofuran or 2,5- dihydroxy methyl furan through continuous dehydration and hydrogenation reaction in the presence of a catalyst under a proper temperature and pressure based on a mixed solvent ion liquid / water as a reaction medium. The method disclosed by the invention takes the biomass rich in fructose as the material to prepare a target product through a one-pot process, is coupled with multi-step reaction, simple in reaction step, cheap and reproducible in material, convenient to operate, and high in product yield; the invention provides a novel method for directly preparing chemicals from biomass.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for dyeing silk broadcloth by using plant dye solution extracted from lily

InactiveCN102587153ASafe to takeIncrease added valueDry-cleaning apparatus for textilesNatural dyesFiltrationPollen

The invention discloses a method for dyeing silk broadcloth by using the pollen of lily as a natural dye and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of: soaking fresh or dried dark-red lily pistil, heating and performing suction-filtration to obtain a dye solution; adding silk broadcloth fabric which is refined, and dyeing the silk broadcloth fabric; and adding different mordants for mordanting and thus obtaining silk fabric with different colors. The method has the advantages of low cost, simple process, high performance, high additional value, non-allergic and non-carcinogenic to skin, and the like; raw materials are inexpensive, easy to get, and reproducible; and taking of dyeing products is safe. Particularly, by taking plant ash as a mordant, pollution is avoided. The method is environment-friendly and energy-saving, and clothes which are made of fabric dyed by using the method are natural, environment-friendly and nonirritating to the skin.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Preparation method of polylactic acid/modified nanocellulose composite barrier material

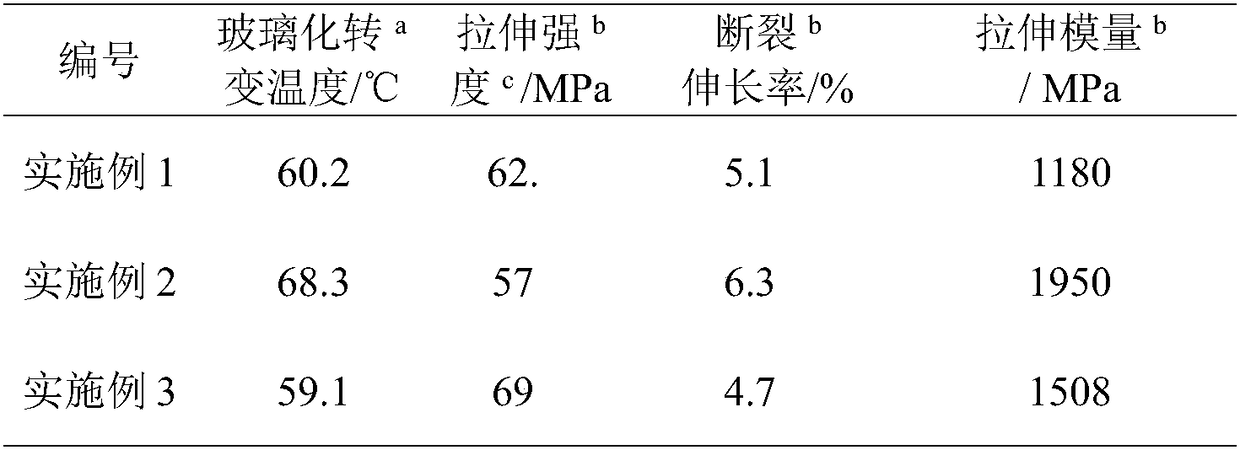

The invention discloses a preparation method of a polylactic acid / modified nanocellulose composite barrier material. The preparation method comprises the following steps: (1) modifying the nanocellulose through a carboxylic acid esterification method; (2) preparing the polylactic acid / modified nanocellulose composite barrier material through a Pickering emulsion method. According to the preparation method disclosed by the invention, chemical modification is carried out on the surface of the nanocellulose by adopting a carboxylic acid type substance; the carboxylic acid type substance can be used as a reactant and also has the effect of a solvent medium; a great use amount of an organic solvent is avoided by the method and the carboxylic acid type substance can be recycled and purified, andcyclically utilized, so that real environment-friendly and sustainable development is realized. The composite material is prepared by adopting the Pickering emulsion method; in a process of forming emulsion, the two materials are uniformly dispersed and a subsequent high-pressure homogenization process is not needed. The high-barrier composite material disclosed by the invention has good barrierperformance and mechanical properties and is a relatively ideal composite barrier material.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

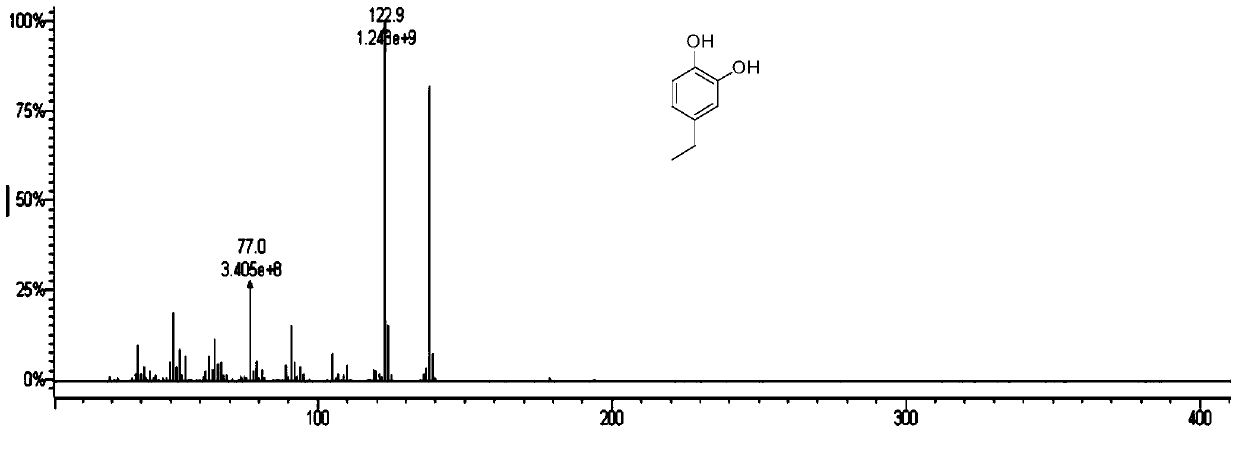

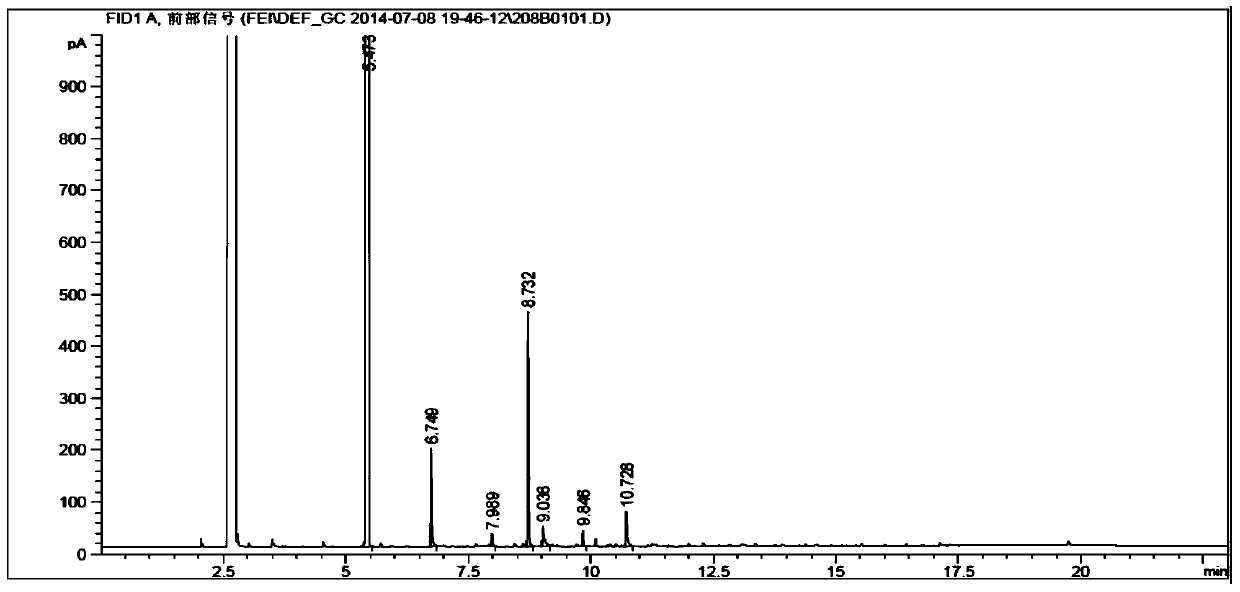

Method for preparation of benzene ring phenol compound from alkali lignin

InactiveCN105503540ARaw materials are renewableLow costOrganic chemistryOrganic compound preparationSolventRaney nickel

The invention relates to a method for preparation of a benzene ring phenol compound from alkali lignin. At a reaction temperature of 150DEG C-300DEG C, under a hydrogen pressure of 0.1MPa-13Mpa, under the action of a metal catalyst, in a solvent containing choline ionic liquid, alkali lignin is taken as the reaction raw material, hydrogenation degradation of alkali lignin is carried out to prepare the benzene ring phenol compound. Specifically, the solvent containing choline ionic liquid can be one of a solvent only containing choline ionic liquid, a mixed solvent composed of choline ionic liquid and an inorganic solvent, or a mixed solvent composed of choline ionic liquid and an organic solvent; and the metal catalyst is raney nickel and / or loaded metal catalyst. The method provided by the invention has the significant advantages of cheap and easily available raw materials, simple catalyst preparation process, easy recovery, easy separation of product and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Clostridium butyricum and application thereof

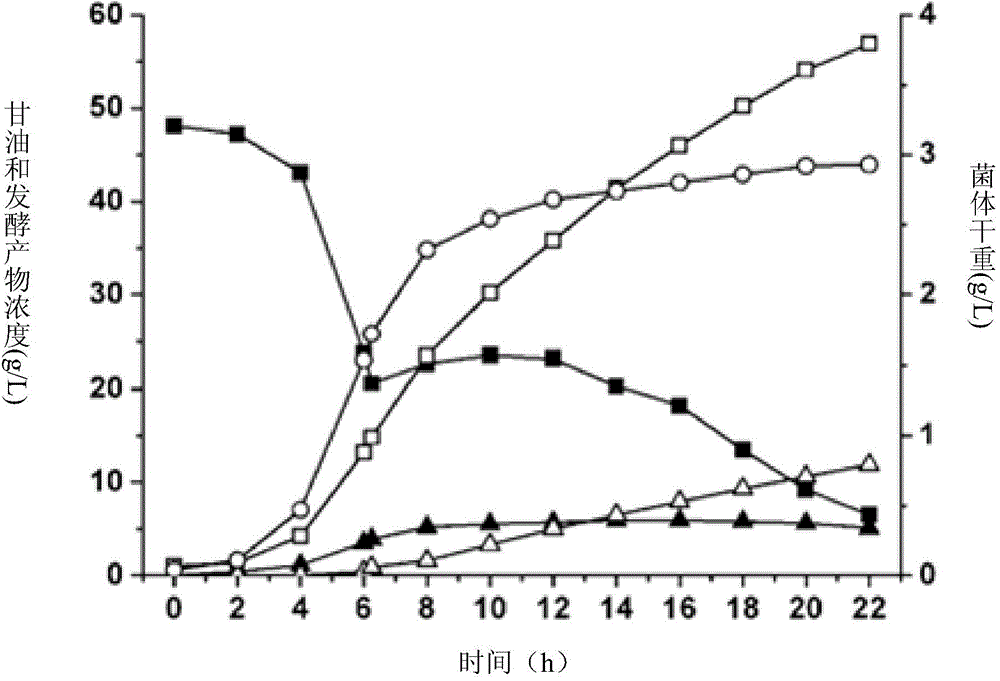

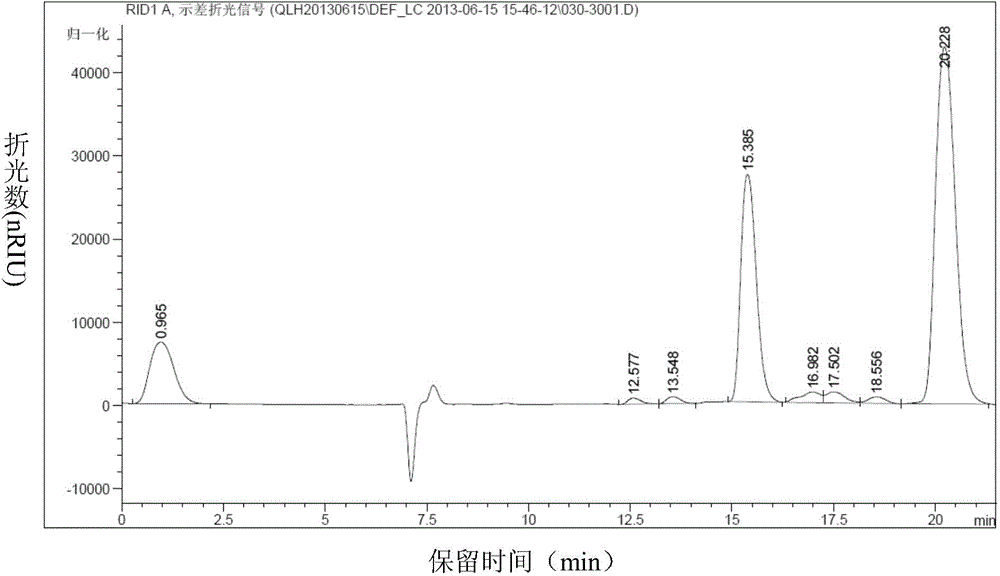

InactiveCN104560779AEasy to trainImprove toleranceBacteriaMicroorganism based processesMicroorganism1,3-Propanediol

The invention discloses clostridium butyricum and an application thereof. The clostridium butyricum is preserved in the China General Microbiological Culture Collection Center in September 1, 2014 and has a preservation number of CGMCC NO.9626. The clostridium butyricum disclosed by the invention is easy to culture, is relatively high in conversion rate and production intensity of 1,3-propylene glycol, and has relatively high tolerance to a substrate and a product.

Owner:XIAMEN UNIV

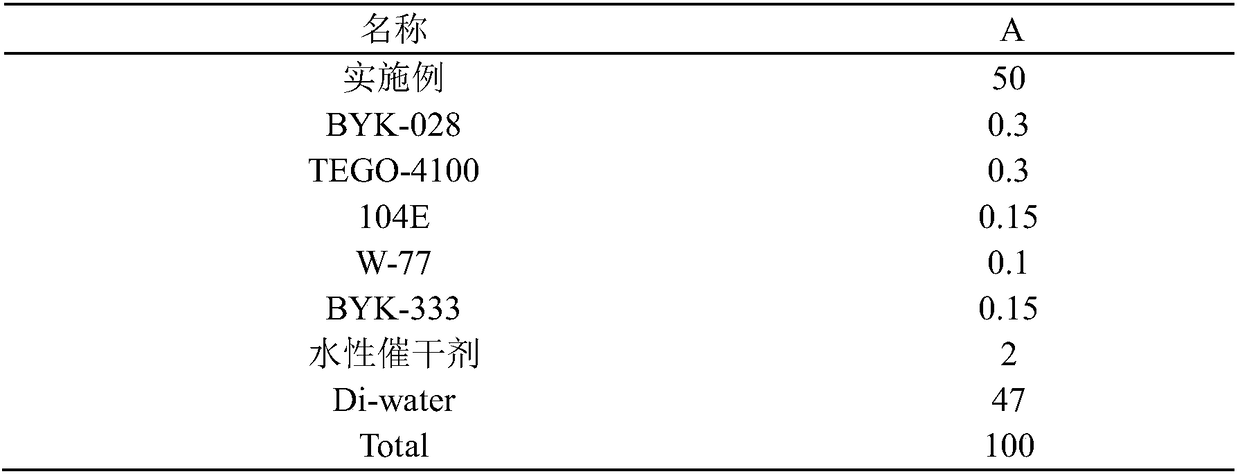

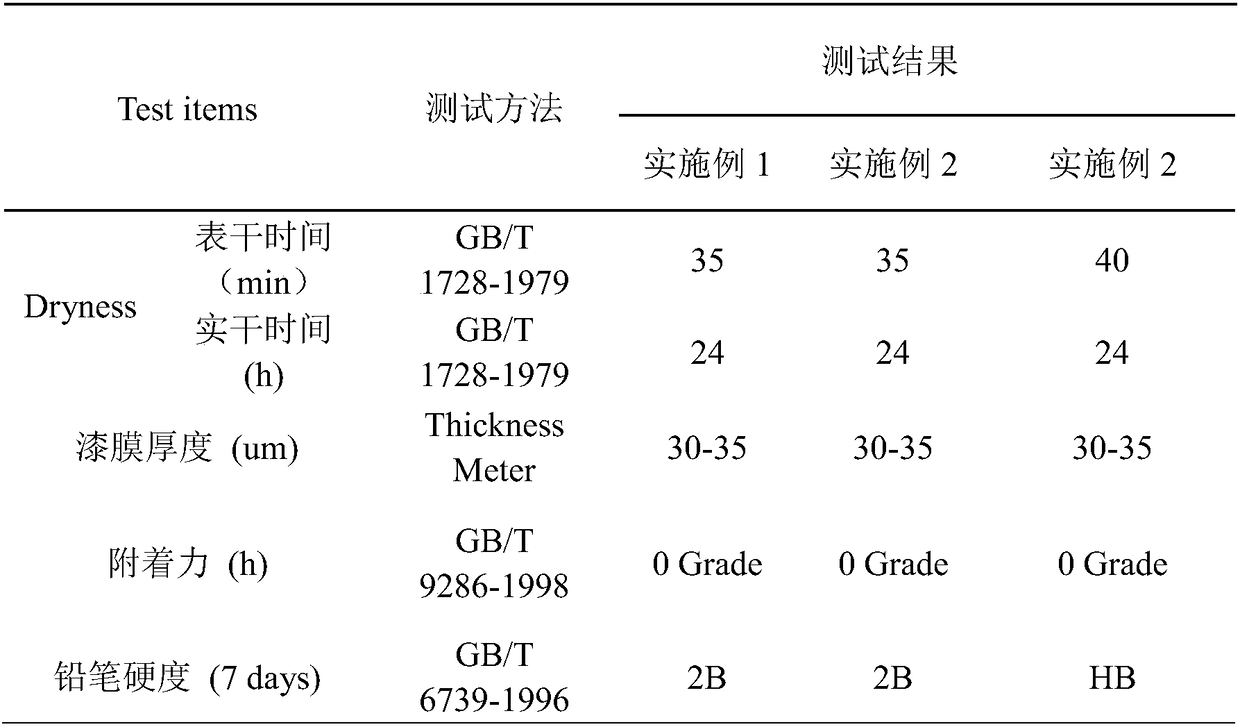

Preparation method of novel biological matrix non-soap type core-shell structure water-based acrylic acid emulsion

InactiveCN108059695AEnvironmentally friendlyRaw materials are renewableCoatingsNatural sourceWater based

The invention discloses a preparation method of novel biological matrix non-soap type core-shell structure water-based acrylic acid emulsion. The preparation method comprises the following steps: 1) adding fatty acid, monobasic acid and polyol with natural source according to a certain proportion to prepare an alcohol acid intermediate; 2) adding a certain amount of polybasic acid and anhydride into the alcohol acid intermediate prepared in the step 1 according to a certain proportion and dissolving into water to prepare an alcohol acid aqueous solution; and 3) adding an acrylic acid comonomerin the alcohol acid aqueous solution in the step 2 at a time or in batches, adding an initiator, a reducing agent, a catalyst, a molecular weight regulator, reacting at 30 to 95 DEG C for 10 to 90 minutes, adding aids such as a crosslinking agent, a sterilizing agent, preservative, a stabilizer and a defoaming agent as required, and finally obtaining the novel biological matrix non-soap type core-shell structure water-based acrylic acid emulsion. The emulsion has the advantages of environmental friendliness, reproducible raw materials, low cost, high drying speed, wide and adjustable film-forming temperature and hardness and the like, and is favorable for application and popularization of biological matrix concept products.

Owner:科思创树脂制造(佛山)有限公司

Method for preparing 2,5-dimethyl furan by use of fructosyl biomass

The invention relates to a method for preparing a 2,5-dimethyl furan by use of a fructose and a fructosyl biomass, and specifically relates to a method which comprises the following step: on the basis of adopting a mixed reaction medium of an ionic liquid and an organic solvent, and under the conditions of appropriate temperature and pressure, performing continuous dehydration and hydrogenation reactions on the fructose and the fructosyl biomass in the presence of a catalyst so as to convert the fructose and the fructosyl biomass into the 2,5-dimethyl furan. The method is used for preparing the target product by use of the biomass which is rich in fructose and is taken as the raw material by virtue of a one-pot method; a plurality of steps of reactions are coupled, the reaction steps are simple, the raw materials is cheap and regenerative, the operation is convenient and the product yield is high; a new method for preparing chemicals directly by use of the biomass is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

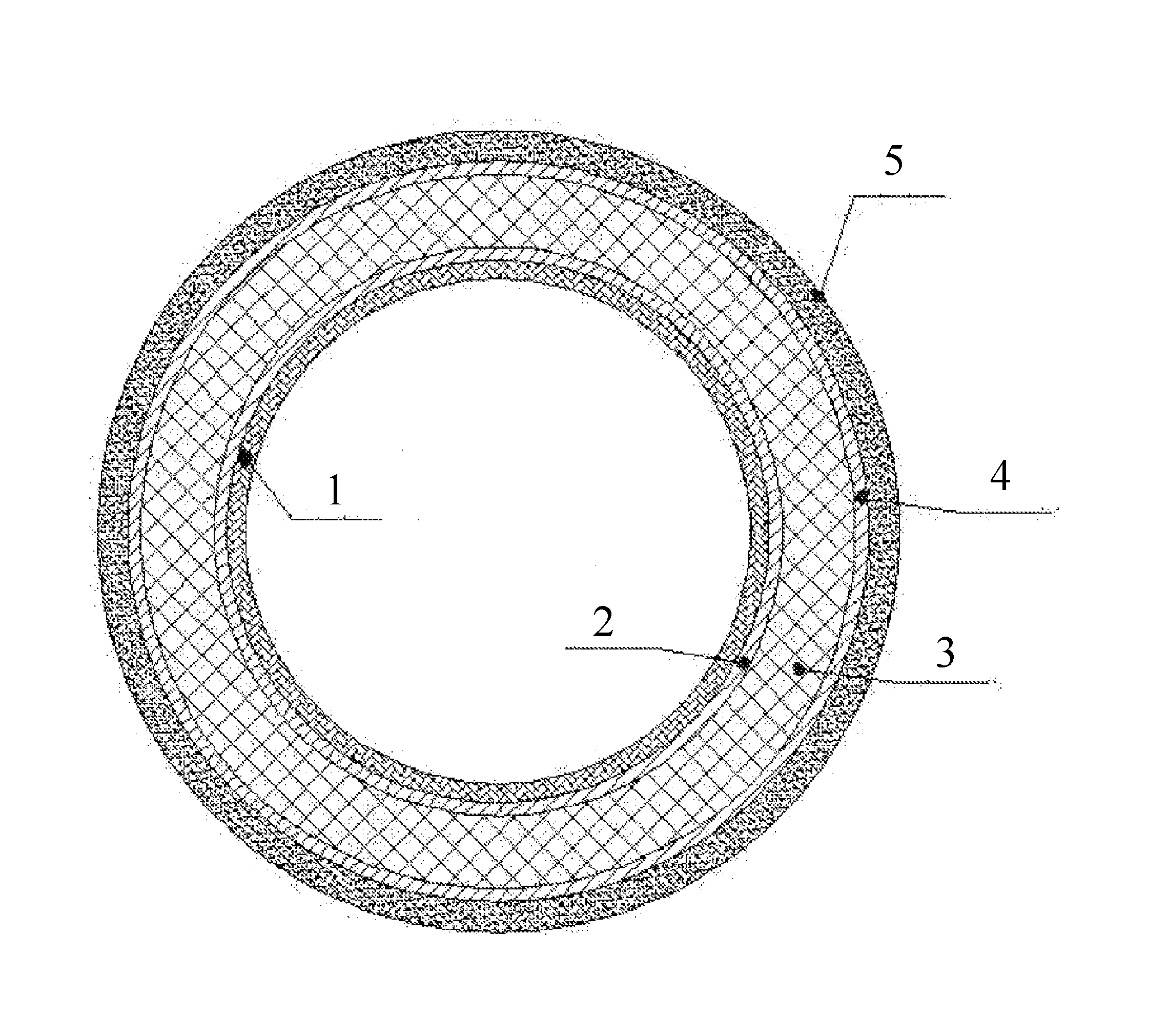

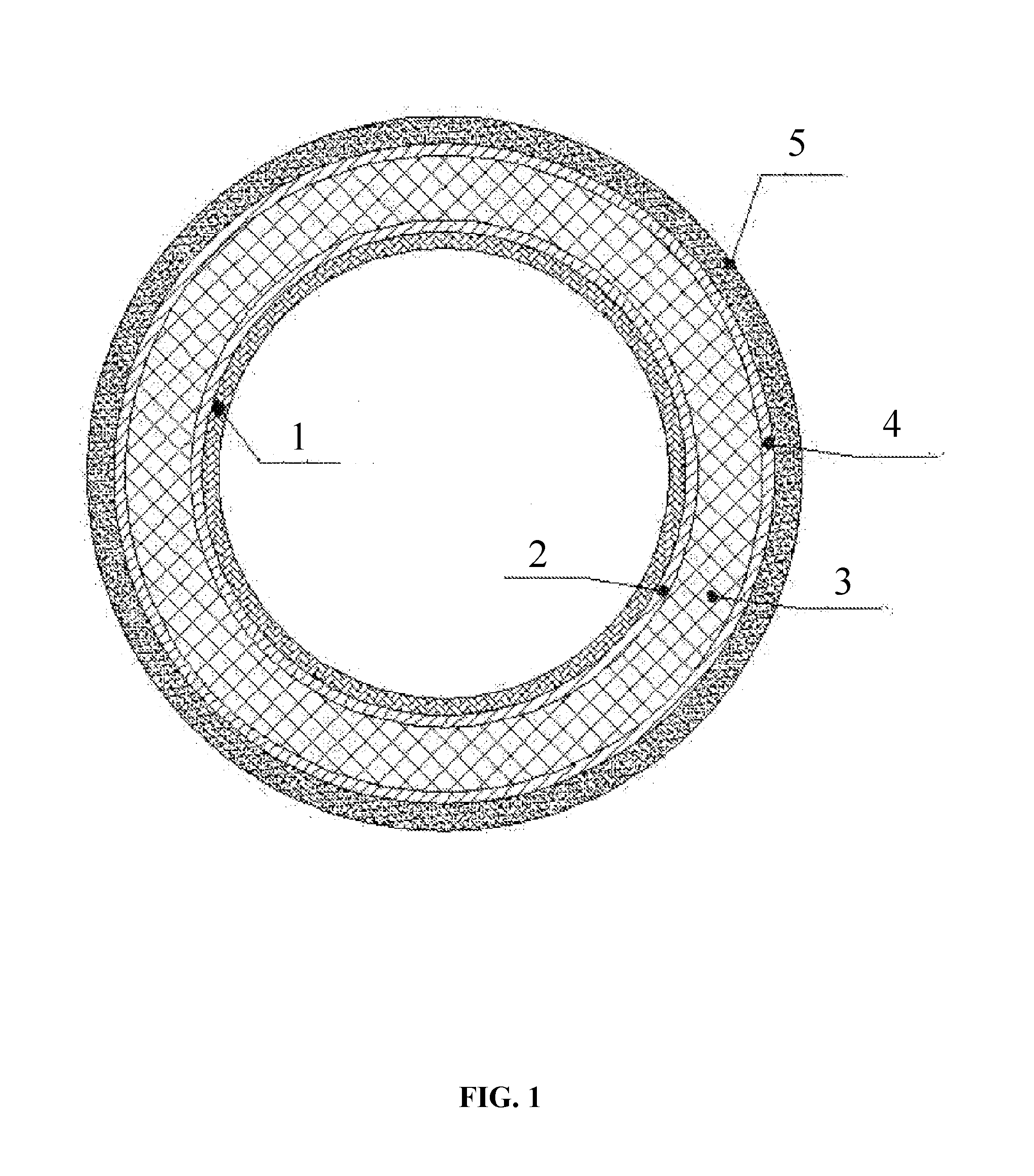

Thermosetting bamboo sand composite pressure pipe

ActiveUS20160245429A1Easy to packEasy to storeAgricultural articlesSynthetic resin layered productsAdhesiveEngineering

A thermosetting bamboo sand composite pressure pipe comprises a inner liner layer (1), an inner reinforcement layer (2), a sand adhesive layer (3), an outer reinforcement layer (4) and an outer protection layer (5) arranged respectively from an inside to an outside in a radial direction thereof. The inner reinforcement layer (2) formed by winding bamboo, a thickening layer (3) formed by stirred ore and adhesive, and the outer reinforcement layer (4) formed by winding bamboo are arranged sequentially from an inside to an outside between the inner liner layer (1) and the outer protection layer (5). The composite pressure pipe is energy-saving and environmental-friendly, raw production materials are recyclable, and a price is low.

Owner:YE LING +1

Tung oil-based polyol and preparation method thereof

ActiveCN105646225AHigh reactivityRaw materials are renewableOrganic compound preparationCarboxylic acid esters preparationDistillationReaction temperature

The invention discloses a tung oil-based polyol and a preparation method thereof. The preparation method comprises following steps: tung oil, an organic metal complex catalyst, and a hydroxylation reagent are mixed at a certain ratio, and are heated to 50 to 70 DEG C; under violent stirring, a hydrogen peroxide solution is added dropwise, adding speed is controlled so as to maintain the reaction temperature to be 70 to 90 DEG C, after adding of the hydrogen peroxide solution, reaction temperature is maintained for 3 to 5, and reaction is stopped; an obtained reaction system is subjected to filtering so as to separate the solid catalyst, is allowed to stand for layering so as to separate a water phase, and is subjected to reduced pressure distillation so as to obtain the tung oil-based polyol. The yield of the tung oil-based polyol is higher than 92%; product hydroxyl value ranges from 120 to 270mgKOH / g; acid value is lower than 1.0mgKOH / g; water content is lower than 0.1wt%; and the tung oil-based polyol can be used for preparing polyurethane materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of novel monohydroxy biology-based epoxy resin

ActiveCN102796063ASimple processMild reaction conditionsOrganic chemistryChemical industryPolymer science

The invention discloses a preparation method of novel monohydroxy biology-based epoxy resin, which belongs to the technical field of chemical industry. The method comprises the following steps of: reacting cardanol glycidyl ether with unsaturated fatty acid or cardanol to generate monohydroxy unsaturated biology-based resin A; and performing epoxidation on unsaturated double bonds on an aliphatic chain of the resin A to obtain monohydroxy epoxy resin with high biology content. The novel epoxy resin has the characteristics of environment-friendly and reproducible raw materials, simple synthesis process, high stability, high heat resistance and high electric insulating property after curing, and the like; the biology content is over 90 percent, and the epoxy value is up to 0.28-0.51eq / 100g; and the method is suitable for the fields of coatings, composite materials, casting materials, electronic electrical appliance materials, bonding agents, resists and the like.

Owner:JIANGNAN UNIV

Application of hydrotalcite-based catalyst in conversion of high-concentration sugar into 1,2-propylene glycol

ActiveCN110711588AEasy to manufactureLow costOrganic compound preparationHydroxy compound preparationHigh concentrationCatalytic transformation

The invention provides application of a hydrotalcite-based catalyst in conversion of high-concentration sugar into 1,2-propylene glycol, and belongs to the technical field of energy and chemical engineering. A hydrotalcite precursor is prepared by adopting a coprecipitation method, then metal is introduced by utilizing dipping, adsorption and exchange methods, a metal-promoted metal-composite oxide catalyst is obtained by roasting and reduction, and the catalyst shows relatively high selectivity in a reaction of catalytically converting high-concentration sugar into 1,2-propylene glycol. The catalyst provided by the invention has the advantages of simple synthesis, high catalyst activity, good stability and the like, and the reaction has the characteristics that the raw materials are renewable resources and the atom economy is high. Besides, compared with other technologies for preparing 1,2-propylene glycol by taking biomass as a raw material, the process has the advantages of simplereaction process, high space-time yield, convenience in industrial production and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

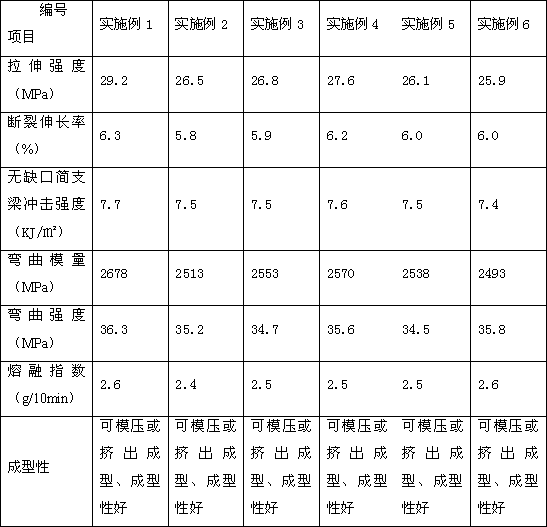

A kind of preparation method of carbon fiber precursor lignin/polylactic acid fiber

ActiveCN104911745BImprove qualityReduce manufacturing costConjugated synthetic polymer artificial filamentsCarbon fibersMelt spinning

The invention relates to a method for preparing a carbon fiber precursor lignin / polylactic acid fiber. The method comprises the following steps: carrying out intermittent heat treatment on purified lignin powder and polylactic acid slices in a vacuum drying oven; mixing the lignin powder subjected to heat treatment with the polylactic acid slices; pelleting at 160-250 DEG C through double screw rods to obtain lignin / polylactic acid composite master batches; and spinning the dried lignin / polylactic acid composite master batches at 190-250 DEG C through a melt-spinning machine, so as to obtain the carbon fiber precursor lignin / polylactic acid fiber. The carbon fiber precursor lignin / polylactic acid fiber provided by the invention has the advantages of renewable raw materials, excellent fiber quality, small diameter of obtained fiber, high strength and low cost; continuous production can be carried out; the carbon fiber precursor lignin / polylactic acid fiber is expected to be applied to the fields such as automobiles, high-speed rails, buildings and sports goods as a reinforcing material after being carbonized; and the market prospect is wide.

Owner:DONGHUA UNIV

Degradable and environment-friendly anti-seepage film for oil field and preparation method of degradable environment-friendly anti-seepage film

InactiveCN106009564AReduce processing energy consumptionEnvironmental protection is goodFiberEnvironmental resistance

The invention discloses a degradable and environment-friendly anti-seepage film for an oil field and a preparation method of the degradable and environment-friendly anti-seepage film. The degradable and environment-friendly anti-seepage film is prepared from the components by weight as follows: polylactic acid, poly (butyleneadipate-co-terephthalate), plant fibers, glycerin or epoxidized soybean oil and inorganic filler. The preparation method comprises specific preparation steps as follows: weighing the polylactic acid, poly (butyleneadipate-co-terephthalate), the plant fibers, glycerin or the epoxidized soybean oil and the inorganic filler; adding the raw materials to a high-speed mixer for uniform mixing; adding the mixture to a hopper of a twin-screw extruder, and obtaining modified resin after brace granulating; placing the modified resin in a drying machine for full drying, and putting the dried modified resin in a cast sheet machine to obtain the degradable, environment-friendly and anti-seepage film for the oil field. The film can be completely biodegraded in the nature after used, degradation products meet EN13432 standards for compostable and are non-toxic and harmless to soil, and the technical standard for environment requirements is high. The preparation method is simple in process, easy to control and suitable for industrial mass production.

Owner:新疆加福萨斯石油设备有限公司

Biodegradable rice hull powder based composite and preparation method thereof

The invention relates to a biodegradable rice hull powder based composite comprising the following components in parts by weight: 500 parts of rice hull powder, 20-30 parts of glass fiber, 4-6 parts of nano-montmorillonite, 4-6 parts of surface modifier, 4-6 parts of antioxidant, 110-130 parts of polylactic acid, 8-12 parts of thermoplastic resin, 10-15 parts of titanium dioxide and 10-12 parts oflubricant. The biodegradable rice hull powder based composite adopts clean and dry rice hull powder as a matrix so as to have the characteristic that the raw materials are regenerative, green and environment-friendly; due to the addition of the one-dimensional glass fiber, the two-dimensional lamellar nano-montmorillonite and the three-dimensional nanometer titanium dioxide, the rigidity and strength of the material are guaranteed; and due to the adoption of the thermoplastic resin, the toughness is enhanced.

Owner:XIAMEN HUSKS NEW MATERIAL TECH CO LTD

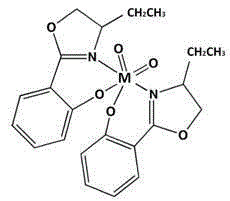

Biomass-based furan dicarboxylic acid-metal hybrid material and preparation method and application thereof

ActiveCN109796430AEasy to prepareRaw materials are renewableOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingFuranKetone

The invention discloses a biomass-based furan dicarboxylic acid-metal hybrid material. The porous hybrid material with uniform acid-base active site distribution is obtained through the steps that with furan dicarboxylic acid as an organic ligand, metal ions as an inorganic center and formic acid as an acid-base site regulator, the furan dicarboxylic acid and the metal ions are self-assembled through a solvothermal method, and then washing and drying are conducted. The invention further discloses a method for selectively catalyzing an MPV reduction reaction by using the hybrid material. The method comprises the steps that aldehyde or ketone is dissolved in alcohol, and with the furan dicarboxylic acid-metal hybrid material as a catalyst, a reaction is conducted for 0.5-8 h at 80-180 DEG C,wherein the mass ratio of the catalyst to the aldehyde or ketone is 1:(1-10), and the concentration of the aldehyde or ketone in the alcohol is 0.1-1.0 mol / L. The furan dicarboxylic acid-metal hybridmaterial is stable in structure and has high applicability to the MPV reduction reaction of different kinds of aldehyde or ketone, and under the same conditions, the catalytic efficiency of the hybrid material is significantly higher than that of corresponding metal oxide.

Owner:NANJING AGRICULTURAL UNIVERSITY

Iron-based soil remediation agent and preparation method thereof

ActiveCN110964536ATo achieve arsenic removalPlay an adsorption roleOrganic fertilisersSoil conditioning compositionsOXALIC ACID DIHYDRATEArsenic pollution

The invention provides an iron-based soil remediation agent and a preparation method thereof. The iron-based soil remediation agent is prepared by uniformly spraying a Rujin bacterium stock solution on a mixture of biogas residues, straw powder and pig manure mixed with oxalic acid, then compacting, stacking, sealing and fermenting to obtain odorless biogas residues, then mixing a ferric salt, a calcium salt and biochar, drying, and then extruding and crushing an obtained product with the odorless biogas residues, polyacrylic acid and manganese dioxide through a screw. The iron-based soil remediation agent provided by the invention has good adsorption performance; in addition, arsenic in the soil can be converted into Fe-As and Ca-As complexes; meanwhile, abundant organic humus is contained, arsenic adsorbed by the arsenic complex and the soil can be converted into effective-state arsenic, the arsenic content in the soil is effectively reduced, the remediation effect on the arsenic-contaminated soil is good, the preparation process is simple, the cost is low, the raw materials are renewable, and the method has the advantages of being good in environment friendliness and the like.

Owner:HANGZHOU WEISHINUOWEI TECH

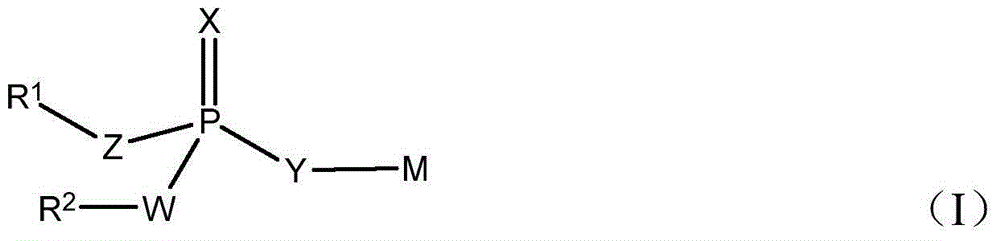

Bio-based alkyl thiophosphoric acid or derivative thereof and preparation method and application of bio-based alkyl thiophosphoric acid or derivative thereof

InactiveCN106146549AWith greenRaw materials are renewableGroup 5/15 element organic compoundsAdditivesSulfurHeteroatom

The invention discloses a bio-based alkylthiophosphoric acid or a derivative thereof, a preparation method and an application thereof. This bio-based alkyl phosphorothioate has a structure shown in formula (I): where R 1 , R 2 , at least one of X, Y, Z, W, M from bio-based raw materials; R 1 , R 2 Independently be a hydrocarbon group, a hydroxyl group, a carbonyl group or a heteroatom; and at least one of X, Y, Z, W contains a sulfur atom, and the rest are arbitrarily selected from O, S atoms; and M is H or another one having the formula (I) Derivative groups of molecules of the shown structure. In the synthesis process of the bio-based thiophosphoric acid or its derivatives of the present invention, at least one raw material is derived from bio-based raw materials, that is, natural and renewable raw materials, which have the advantages of greenness, environmental friendliness, renewable raw materials, and energy saving. It can be widely used in the fields of lubricating oil, grease, mine flotation agent, pesticide, flame retardant and rubber accelerator.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of bacterial-cellulose-based composite for flocculating decolorization of printing-dyeing wastewater

InactiveCN107164425AConducive to loadEfficient flocculation decolorization effectMicroorganism based processesFermentationFlocculationDyeing wastewater

The invention discloses a preparation method of bacterial-cellulose-based composite for flocculating decolorization of printing-dyeing wastewater. The method is characterized in that bacteria are dynamically fermented and cultured to obtain bacterial cellulose secreted in a medium, and a porous absorbing material is supported in the purified bacterial cellulose to obtain the bacterial-cellulose-based composite for flocculating decolorization of printing-dyeing wastewater. The preparation method is simple to perform and low in production cost; the composite prepared herein is effectively applicable to the flocculating decolorization of printing-dyeing wastewater and the like, and the composite itself is green and biodegradable and has important applicable value in the field of flocculating decolorization.

Owner:ZHEJIANG SCI-TECH UNIV

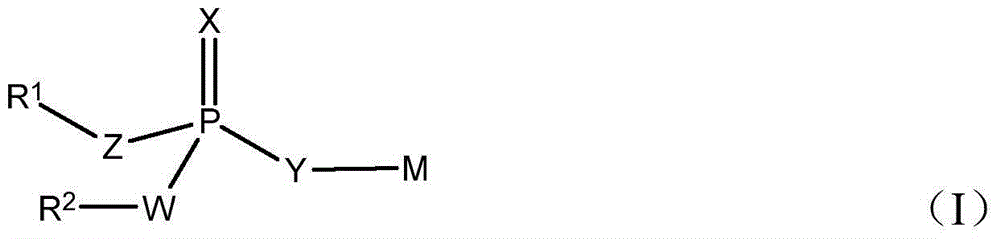

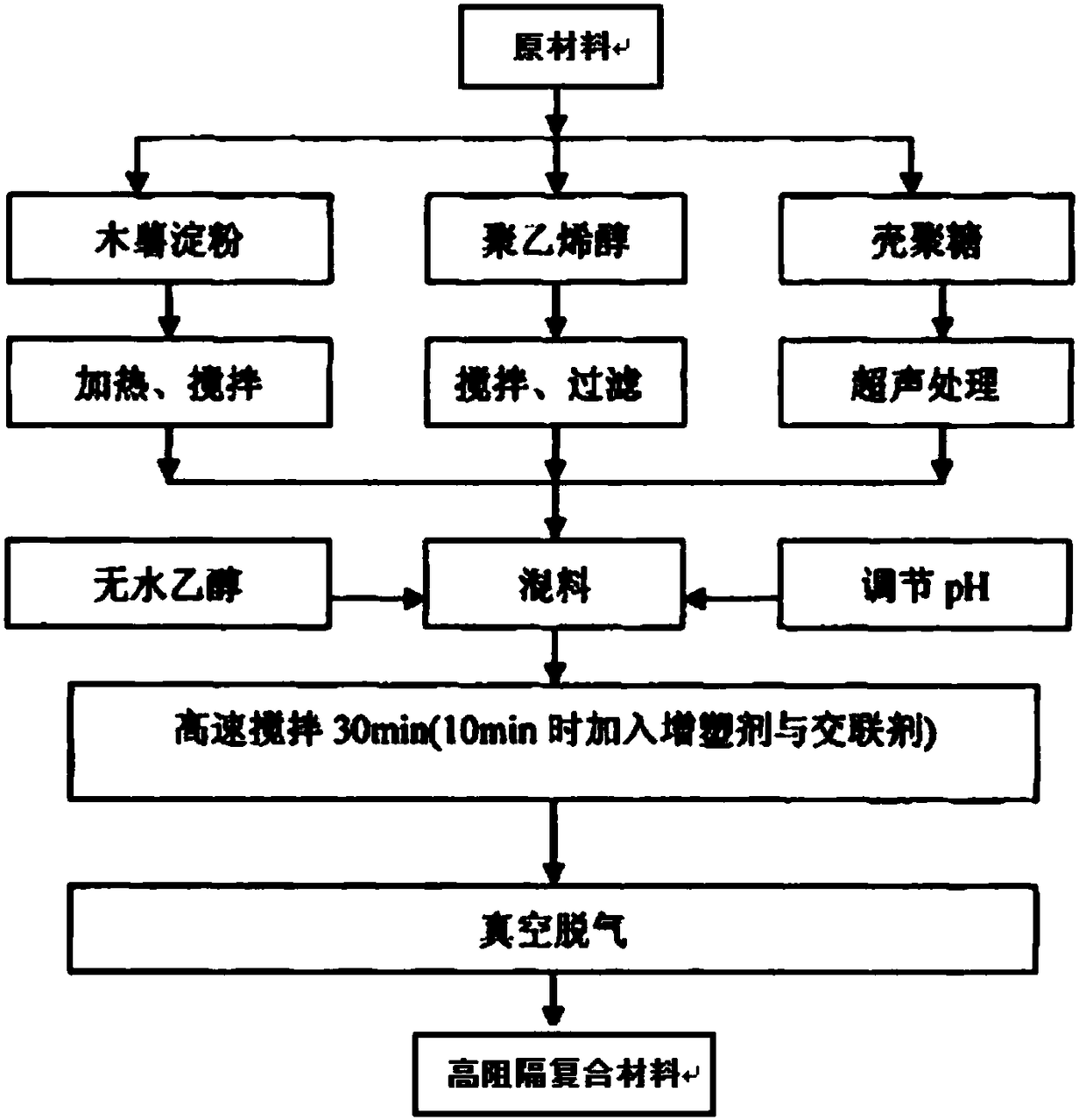

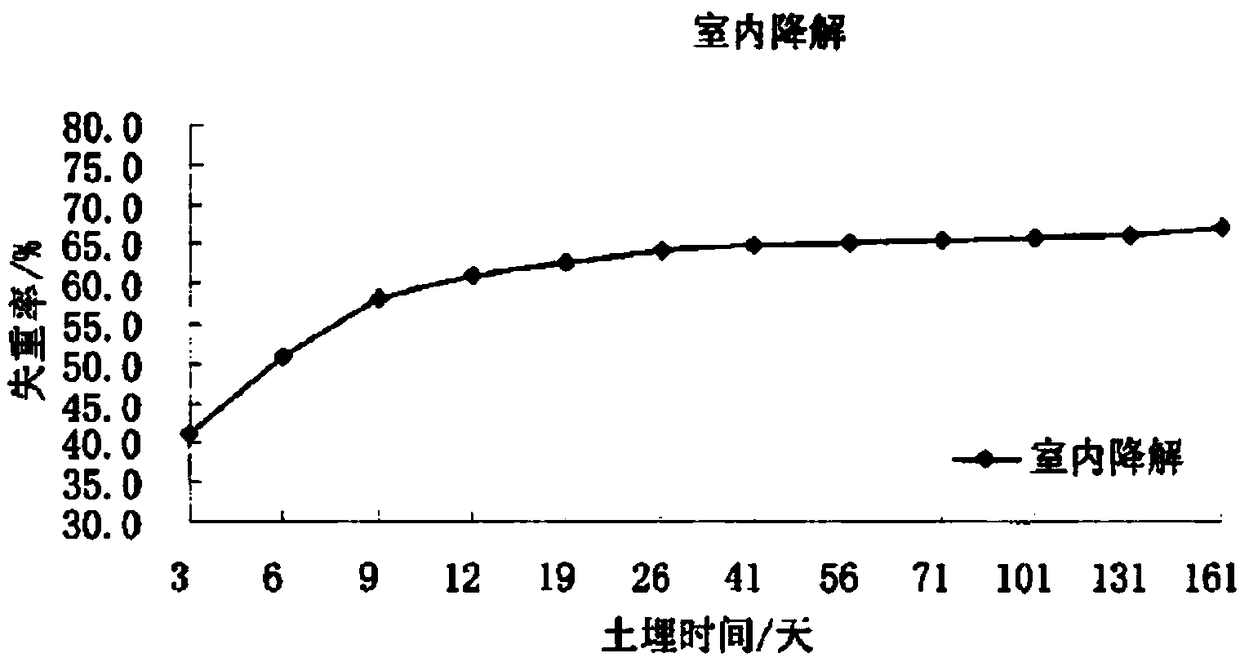

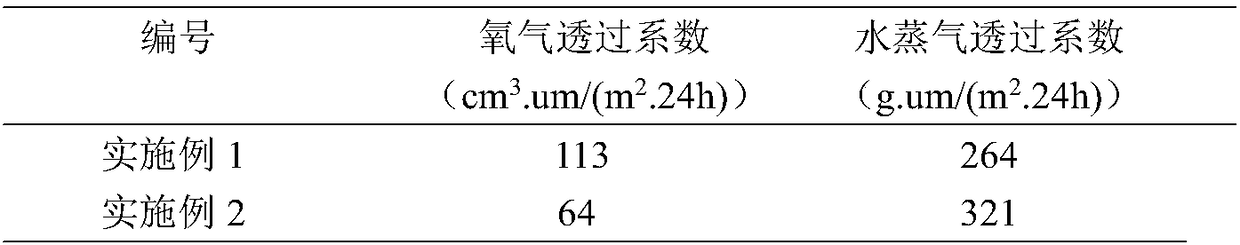

Degradable high-barrier composite material and preparation method thereof

The invention discloses a degradable high-barrier composite material and a preparation method thereof. The preparation method of the composite material comprises the following steps: dissolving 6.0 gof tapioca starch in 100 ml of distilled water, and keeping in a water bath at 80 DEG C for stirring in for 30 min to obtain a tapioca starch solution; dissolving 9.0 g of polyvinyl alcohol in 100 mlof distilled water, and keeping in a water bath at 95 DEG C for stirring for 30 min to obtain a polyvinyl alcohol solution; dissolving 3.0 g of chitosan in 100 ml of a 5% acetic acid solution, and ultrasonically dispersing in an ultrasonic cleaner for 30 min to obtain a chitosan solution; adding the polyvinyl alcohol solution and the chitosan solution to the tapioca starch solution, adding 10mL ofan absolute ethanol solution for defoaming treatment, adjusting the pH of the solution to 4.0, stirring in a water bath at 90 DEG C for 30 min, adding a certain amount of plasticizer and cross-linking agent, after the stirring reaction is finished, performing vaccum degassing on a film solution, and finishing the vaccum degassing until no bubble is produced in the solution to obtain a tapioca starch / polyvinyl alcohol / chitosan thin composite material. The high barrier composite material has the advantages of good barrier property, degradability and the like, and is an ideal composite material.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Thermosetting bamboo sand composite pressure pipe

ActiveUS9903513B2Raw materials are renewableEconomical priceAgricultural articlesSynthetic resin layered productsAdhesiveEngineering

A thermosetting bamboo sand composite pressure pipe comprises a inner liner layer (1), an inner reinforcement layer (2), a sand adhesive layer (3), an outer reinforcement layer (4) and an outer protection layer (5) arranged respectively from an inside to an outside in a radial direction thereof. The inner reinforcement layer (2) formed by winding bamboo, a thickening layer (3) formed by stirred ore and adhesive, and the outer reinforcement layer (4) formed by winding bamboo are arranged sequentially from an inside to an outside between the inner liner layer (1) and the outer protection layer (5). The composite pressure pipe is energy-saving and environmental-friendly, raw production materials are recyclable, and a price is low.

Owner:YE LING +1

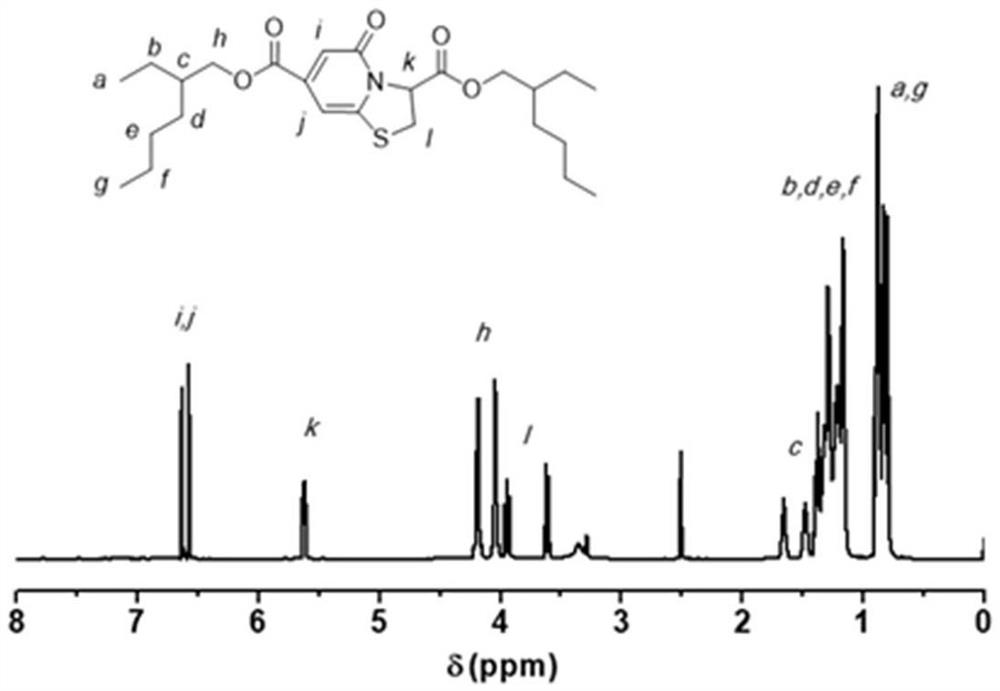

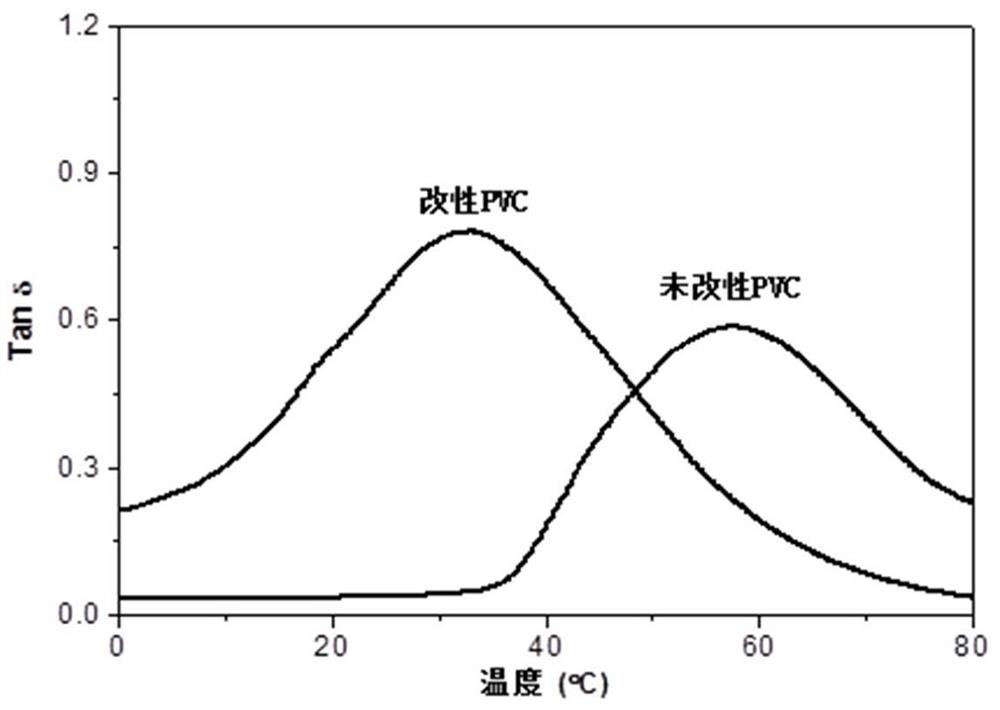

Plasticizer, and preparation method and application thereof

ActiveCN113248787AReduce manufacturing costReduce security risksOrganic chemistryPolymer scienceThiazole

The invention relates to the field of high polymer materials, and especially relates to a plasticizer, and a preparation method and application thereof. The application is application of a compound as shown in a formula (I) as the plasticizer. In the formula, R1 or R2 is selected from any one of alkyl, polyethylene glycol or methoxy polyethylene glycol. The invention provides construction of a novel thiazolidinone-based bio-based plasticizer for the first time. The pyridone diacid has the advantages of renewable raw materials, simple synthesis, low biotoxicity and the like, and can effectively reduce the production cost of the plasticizer, the environmental pressure and the safety risk in the use process, so that the bio-based plasticizer disclosed by the invention is expected to replace the traditional phthalate plasticizer.

Owner:SHENZHEN UNIV

A kind of epoxy-terminated waterborne polyurethane resin and preparation method thereof

Owner:中山大桥化工集团有限公司

Preparation method based on citric acid for copolycarbonate

The invention discloses a preparation method based on citric acid for copolycarbonate. The method comprises the following steps: performing a reaction on citric acid and concentrated sulfuric acid toprepare dimethyl acetone dicarboxylate, performing a Weiss-Cook condensation reaction on the dimethyl acetone dicarboxylate and methylglyoxal to prepare an intermediate disodium salt, performing decarboxylation on the intermediate disodium salt by using a mixed solution of glacial acetic acid and hydrochloric acid to prepare 3a-methyltetrahydropenten-2,5(1H,3H)-dione, performing reduction on the 3a-methyltetrahydropenten-2,5(1H,3H)-dione by using sodium borohydride, performing extraction by using trichloromethane, performing methanol recrystallization to obtain 3a-methyloctahydropenten-2,5-diol, and performing bulk polymerization on the 3a-methyloctahydropenten-2,5-diol, diphenyl carbonate and aliphatic diol by using lithium acetylacetonate as a catalyst to obtain the 3a-methyloctahydropenten-2,5-diol copolycarbonate. The synthetic method provided by the invention has a simple process and mild reaction conditions, and the raw materials are environmentally friendly, cheap and easy to obtain.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Green environment-friendly soluble stamping and drawing oil and preparation method thereof

ActiveCN102787007BImprove cooling effectImprove the lubrication effectFatty acid chemical modificationLubricant compositionOil and greaseVegetable oil

The invention discloses a green environment-friendly soluble stamping and drawing oil and a preparation method thereof. The preparation method comprises the following steps: with sulfonic acid ionic liquid as a catalyst and waste grease, non-edible vegetable oil or fatty acid methyl ester / fatty acid ethyl ester as a raw material, adding hydrogen peroxide and carrying out heating and stirring for a reaction so as to prepare epoxidized modified grease, wherein the molar ratio of the raw material to hydrogen peroxide is 1: 1 to 1: 5; with trimethylol propane and fatty acid or fatty acid methyl ester / fatty acid ethyl ester as raw materials and sulfonic acid ionic liquid as a catalyst, carrying out heating and stirring for a reaction so as to prepare hydroxyalkylated fatty acid ester, wherein the molar ratio of trimethylol propane to fatty acid or fatty acid methyl ester and fatty acid ethyl ester is 1: 1.5 to 1: 5, and the molar ratio of trimethylol propane to ionic liquid is 1: 0.001 to 1: 0.2; uniformly mixing epoxidized modified grease, hydroxyalkylated fatty acid ester and an extreme pressure agent under stirring to obtain the mixture component A; uniformly mixing a surfactant and an osmotic agent at a normal temperature and a normal pressure under stirring so as to obtain the mixture component B; and adding the component A, the component B, an antirust agent and other additives into a reaction kettle and carrying out stirring at a temperature of 40 to 80 DEG C for 10 min to 1 h so as to obtain a final product.

Owner:GUANGZHOU LANDNOK CHEM TECH

Tung oil polyol and synthesis method thereof

ActiveCN105712882AHigh reactivityRaw materials are renewableOrganic compound preparationCarboxylic acid esters preparationSynthesis methodsDistillation

The invention discloses tung oil polyol and a synthesis method thereof. The synthesis method comprises the following steps: mixing tung oil, carboxylic acid, a metal ion supported cation exchange resin catalyst, a hydroxylation reagent, and deionized water according to a certain ratio, heating the mixture to a temperature of 35 to 45 DEG C; dropwise adding a hydrogen peroxide solution under violent stirring, controlling the addition speed to maintain the temperature in a range of 40 to 65 DEG C, after addition, maintaining the reaction temperature for 3 to 5 hours, stopping the reactions; filtering the reaction system to separate out the solid catalyst, allowing the reaction system to stand still to carry out layering, separating water phase from the reaction system, neutralizing the oil phase, washing the oil phase by water, and subjecting the oil phase to reduced pressure distillation to obtain tung oil polyol. The yield of the prepared tung oil polyol is more than 92%, the hydroxyl value of the product is 120 to 270 mgKOH / g, the acid value is less than 1.0 mgKOH / g, the water content is less than 0.1 wt%, and the tung oil polyol can be used to prepare a polyurethane material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tung oil polyhydric alcohol with high hydroxyl value and preparation method thereof

ActiveCN106957241AHigh reactivityHigh hydroxyl valueImino compound preparationCross-linkDistillation

The invention relates to a preparation method for tung oil polyhydric alcohol with high hydroxyl value. The method comprises the following steps: (1) mixing tung oil, carboxylic acid, an acid catalyst, a hydroxylation reagent and deionized water, heating to 35-45 DEG C, dropwise adding a hydrogen peroxide solution while stirring while maintaining the temperature at 40-65 DEG C, and maintaining the reaction temperature for 2-8h after the ending of the dropwise adding, standing for layering after the ending of the reaction, and separating a water phase, thereby acquiring an oil phase; (2) mixing the oil phase with hydroxy-containing amine agents, adding ethyl alcohol and an inorganic acid catalyst, heating to 30-40 DEG C under nitrogen protection, dropwise adding an aldehyde agent while stirring, heating to 50-90 DEG C while violently stirring and continuously reacting for 1-5h after the ending of the dropwise adding, standing for layering after the ending of the reaction, neutralizing the oil phase, washing with water and performing reduced pressure distillation, thereby acquiring the tung oil polyhydric alcohol with high hydroxyl value. According to the invention, the hydroxylation agent is added in the epoxidation process, so that a cross-linking side reaction can be effectively avoided, a tung oil conjugated triene bond after loop opening is replaced, the cross-linking can be effectively avoided in the amine methylation process and the tung oil polyhydric alcohol with high hydroxyl value is acquired.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of high hydroxyl value tung oil polyol and preparation method thereof

ActiveCN106957241BHigh reactivityHigh hydroxyl valueImino compound preparationCross-linkDistillation

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com