Clostridium butyricum and application thereof

A technology of Clostridium butyricum and Clostridium, which is applied in the direction of bacteria, microorganisms, biochemical equipment and methods, etc., can solve the problems of environmental pollution and high cost of raw materials, and achieve the effect of high tolerance, low cost and renewable raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Isolation and purification of strains

[0033] (1) Take 1 g of the collected sample, add it to 9 mL of Clostridium proliferation liquid medium, and culture for 24 hours at 37°C in a sealed enrichment;

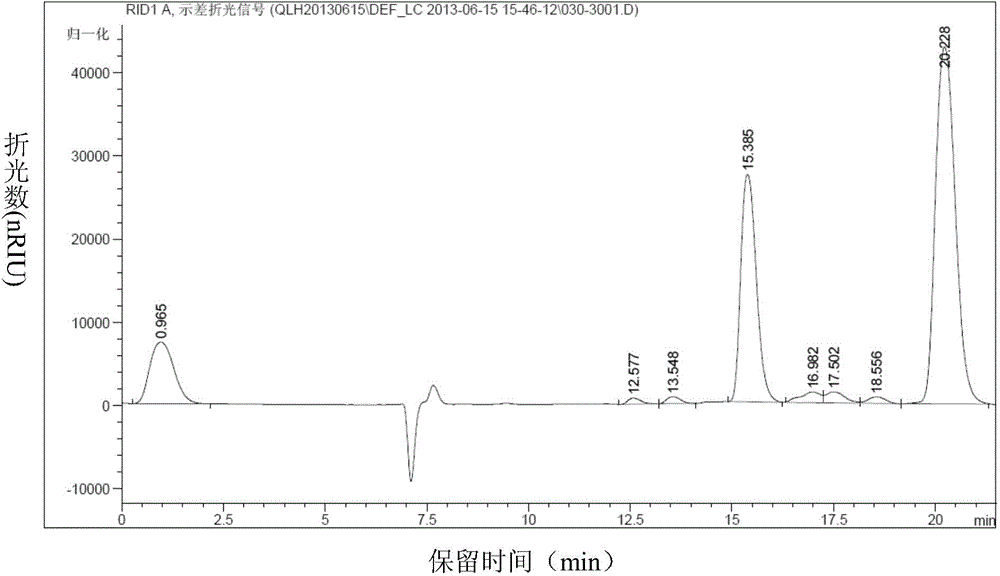

[0034] (2) Transfer to seed culture medium, perform anaerobic selective enrichment culture at 37°C for 24 hours, and then perform high-performance liquid chromatography to analyze the fermentation product, and select positive bacteria capable of producing 1,3-propanediol;

[0035] (3) In the anaerobic work box, a single colony was isolated by streaking on the plate, and the strains capable of producing 1,3-propanediol and culture characteristics, and the colony morphology were selected for 16SrDNA sequence analysis and identification, and finally obtained A Clostridium butyricum M01 capable of producing 1,3-propanediol;

[0036] The above-mentioned Clostridium proliferation liquid medium is: tryptone, 10g / L; beef extract, 10g / L; yeast powder, 3g / L; glucose, 5g / L; NaC...

Embodiment 3

[0048] Utilize the Clostridium butyricum M01 that embodiment 1 obtains to produce 1,3-propanediol in 5L fermentor, comprise the steps:

[0049] (1) Seed culture: use a sterile syringe to inoculate 1-10 mL of Clostridium butyricum M01 bacterial solution into a serum bottle containing 50-100 mL of seed medium, and culture on a shaker at 33-39°C and 120-200 rpm for 8-16 hours , to obtain the primary seed culture solution;

[0050] (2) Expanded cultivation of seeds: use a sterile syringe to inoculate 1-10 mL of seed solution into a serum bottle containing 50-100 mL of seed medium, and culture on a shaker at 33-39°C and 120-200 rpm for 2-8 hours to obtain two grade seed culture solution;

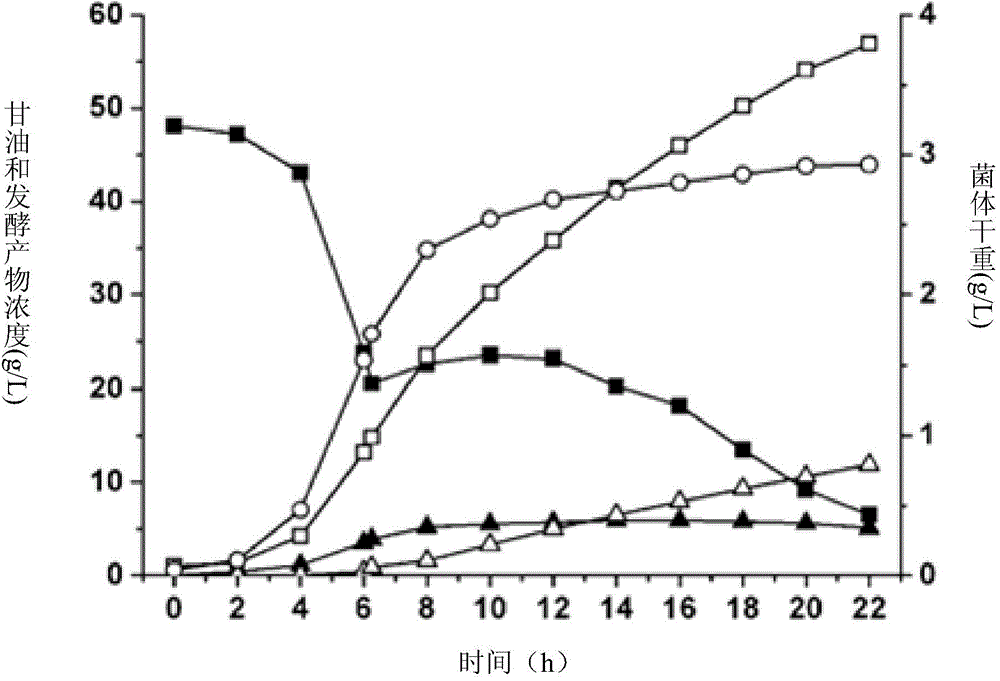

[0051] (3) Fermentation tank culture: Under the conditions of 37°C, 150rpm, and nitrogen gas 0.5vvm, the primary or secondary seed culture liquid and the fermentation medium were cultured in a fermenter at a volume ratio of 1:10, and the amount of fermentation medium was is 2L, and in the ferme...

Embodiment 4

[0054] Utilize the Clostridium butyricum M01 that embodiment 1 obtains to produce 1,3-propanediol in 100L fermentor, comprise the steps:

[0055] (1) Seed culture: use a sterile syringe to inoculate 1-10 mL of Clostridium butyricum M01 bacterial solution into a serum bottle containing 50-100 mL of seed medium, and culture on a shaker at 33-39°C and 120-200 rpm for 8-16 hours , to obtain the primary seed culture solution;

[0056] (2) Expanded cultivation of seeds: use a sterile syringe to inoculate 1-10 mL of seed solution into a serum bottle containing 50-100 mL of seed medium, and culture on a shaker at 33-39°C and 120-200 rpm for 2-8 hours to obtain two grade seed culture solution;

[0057] (3) Fermentation tank culture: Under the conditions of 37°C, 250rpm, and nitrogen gas 2.5vvm, the primary or secondary seed culture liquid and the fermentation medium were cultured in a fermenter at a volume ratio of 1:20, and the amount of fermentation medium was is 60L, and in the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com