Green environment-friendly soluble stamping and drawing oil and preparation method thereof

A stamping and drawing, green and environmentally friendly technology, applied in the petroleum industry, fatty acid production, lubricating compositions, etc., can solve the problems of complex processing steps, large pollution to the environment, non-reusable, etc., and achieve long-term anti-rust effect and physical and chemical properties. The effect of stable, excellent lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Epoxidized Jatropha oil: 52%

[0050] Trimethylolpropane oleate: 10%

[0051] Span60 and Tween80: 18%

[0052] Fatty alcohol polyoxyethylene ether: 7%

[0053] Sulfurized fatty acid ester: 10%

[0054] Lauric acid: 1.3%

[0055] Lauric acid: 0.7%

[0056] Ethanol: 1%

[0057] According to the above materials and weight percentages, the preparation method and steps are:

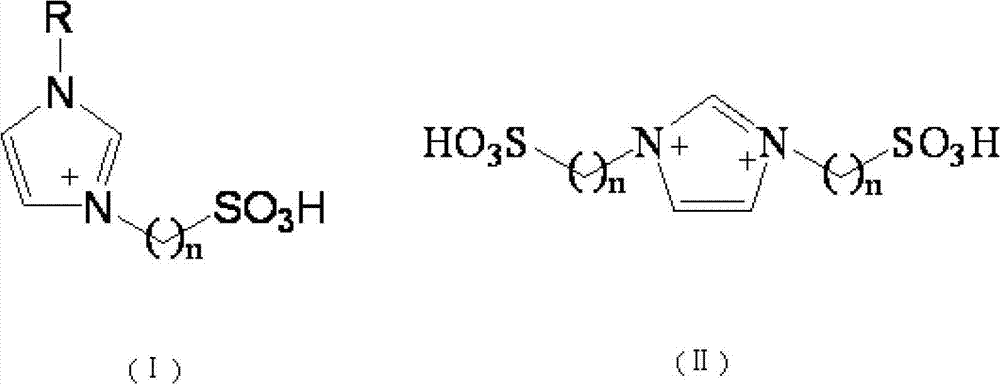

[0058] a) Add jatropha oil, hydrogen peroxide and bissulfonic acid imidazole hydrogen sulfate ionic liquid at a material ratio of 1:1:0.05 into the reaction kettle and mix, stir and react at 100°C for 30 min. After the reaction is over, the liquid is automatically stratified, and the lower layer is separated for recycling to obtain the upper layer of epoxidized modified Jatropha oil;

[0059] b) Trimethylolpropane, methyl oleate and bissulfonic acid imidazole hydrogen sulfate ionic liquid are added to the reaction kettle at a material ratio of 1:2.5:0.04, and the mixture is stirred and reacted at 140°C for 3 hours. ...

Embodiment 2

[0064] Epoxidized methyl oleate: 45%

[0065] Epoxidized methyl linoleate: 10%

[0066] Trimethylolpropane oleate: 6%

[0067] Trimethylolpropane linoleate: 4%

[0068] Trimethylolpropane stearate: 2%

[0069] Span80 and Tween60: 13%

[0070] Polyglycerol: 6%

[0071] Sulfurized isobutylene: 11%

[0072] Sebacic acid: 1.3%

[0073] Lauric acid: 0.7%

[0074] Methyl acetate: 1%

[0075] According to the above materials and weight percentages, the preparation method and steps are:

[0076] a) Add methyl oleate, methyl linoleate, hydrogen peroxide and sulfoimidazole p-toluenesulfonate ionic liquid into the reactor at a ratio of 1:0.2:4:0.05, and mix at 120 The reaction was stirred at ℃ for 4h. After the reaction, the liquid is automatically stratified, and the lower layer is separated for recycling to obtain the upper layer epoxidized methyl oleate and epoxidized methyl linoleate mixture components;

[0077] b) Add trimethylolpropane, linoleic acid, linolenic acid, stearic acid and sulfoimidazol...

Embodiment 3

[0082] Epoxidized waste oil: 50%

[0083] Trimethylolpropane oleate: 10%

[0084] Trimethylolpropane palmitate: 4%

[0085] Span60 and Tween80: 17%

[0086] Glycerin: 3%

[0087] Dipentene sulfide: 10%

[0088] Brazilian acid: 1.3%

[0089] Lauric acid: 0.7%

[0090] Ethylene glycol: 1%

[0091] Mixture of BIT-20 and IPBC-20: 1%

[0092] Methylbenzotriazole: 1%

[0093] Corrguard SI: 1%

[0094] According to the above materials and weight percentages, the preparation method and steps are:

[0095] a) Add waste oil, hydrogen peroxide and sulfonic imidazole trifluorosulfate ionic liquid into the reaction kettle at a material ratio of 1:5:0.2 and mix, and stir for 3 hours at 80°C. After the reaction, the liquid is automatically stratified, and the lower layer is separated for recycling, and the upper layer epoxidized waste oil can be obtained;

[0096] b) Add trimethylolpropane, ethyl linoleate, ethyl palmitate and sulfoimidazole trifluorosulfate ionic liquid into the reactor at a ratio of 1:1.5:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com