Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

330 results about "Inorganic solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inorganic nonaqueous solvent is a solvent other than water, that is not an organic compound.

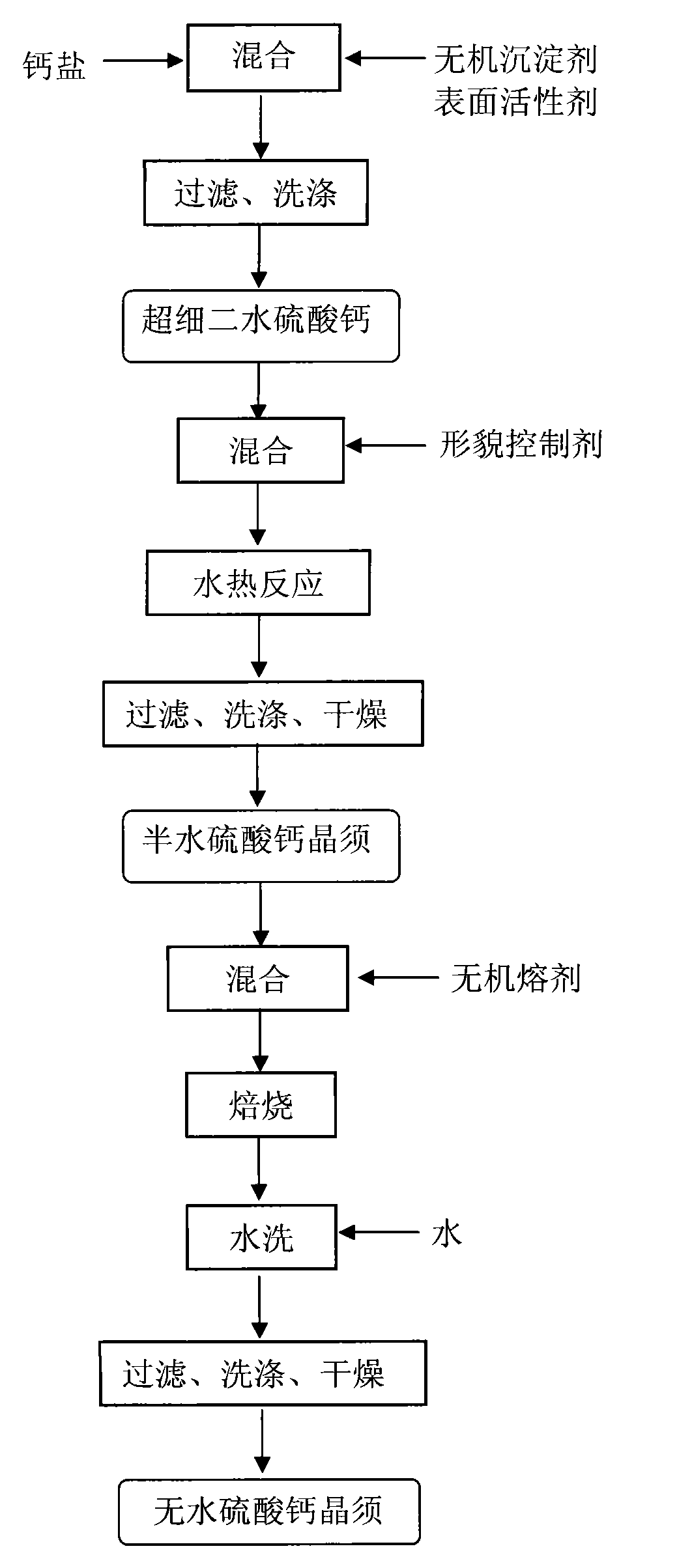

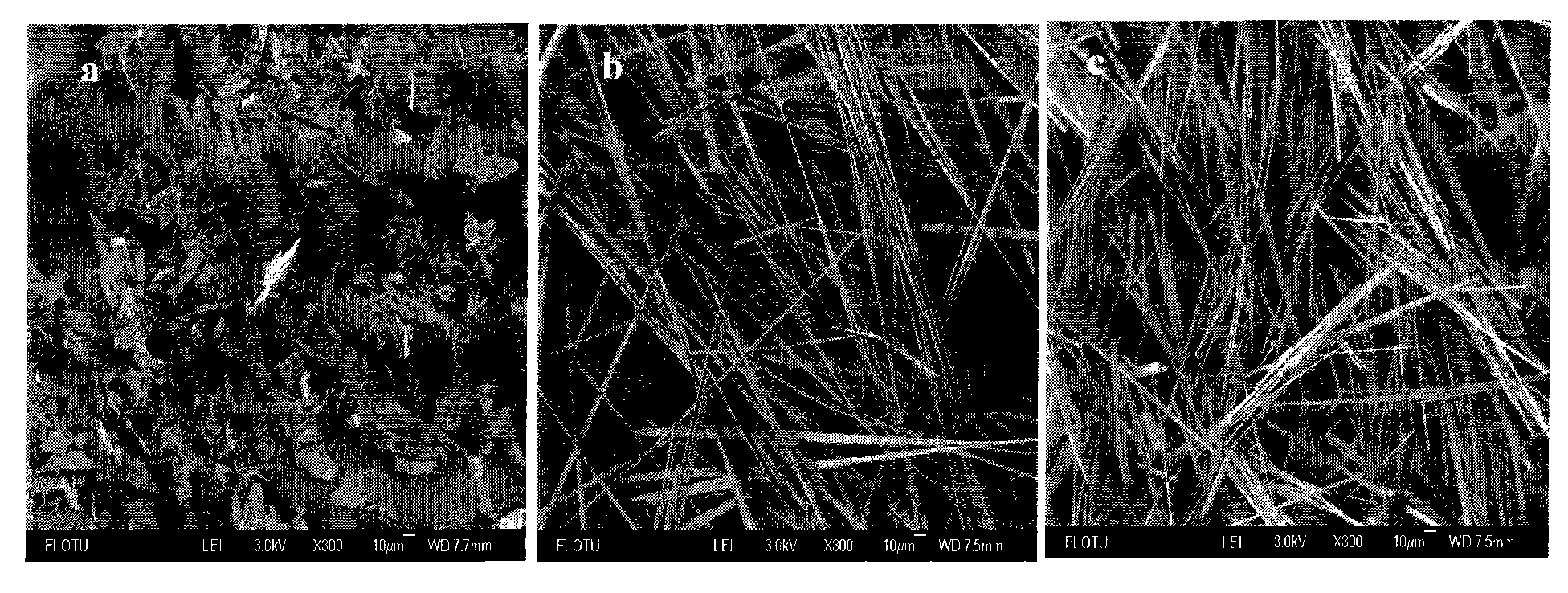

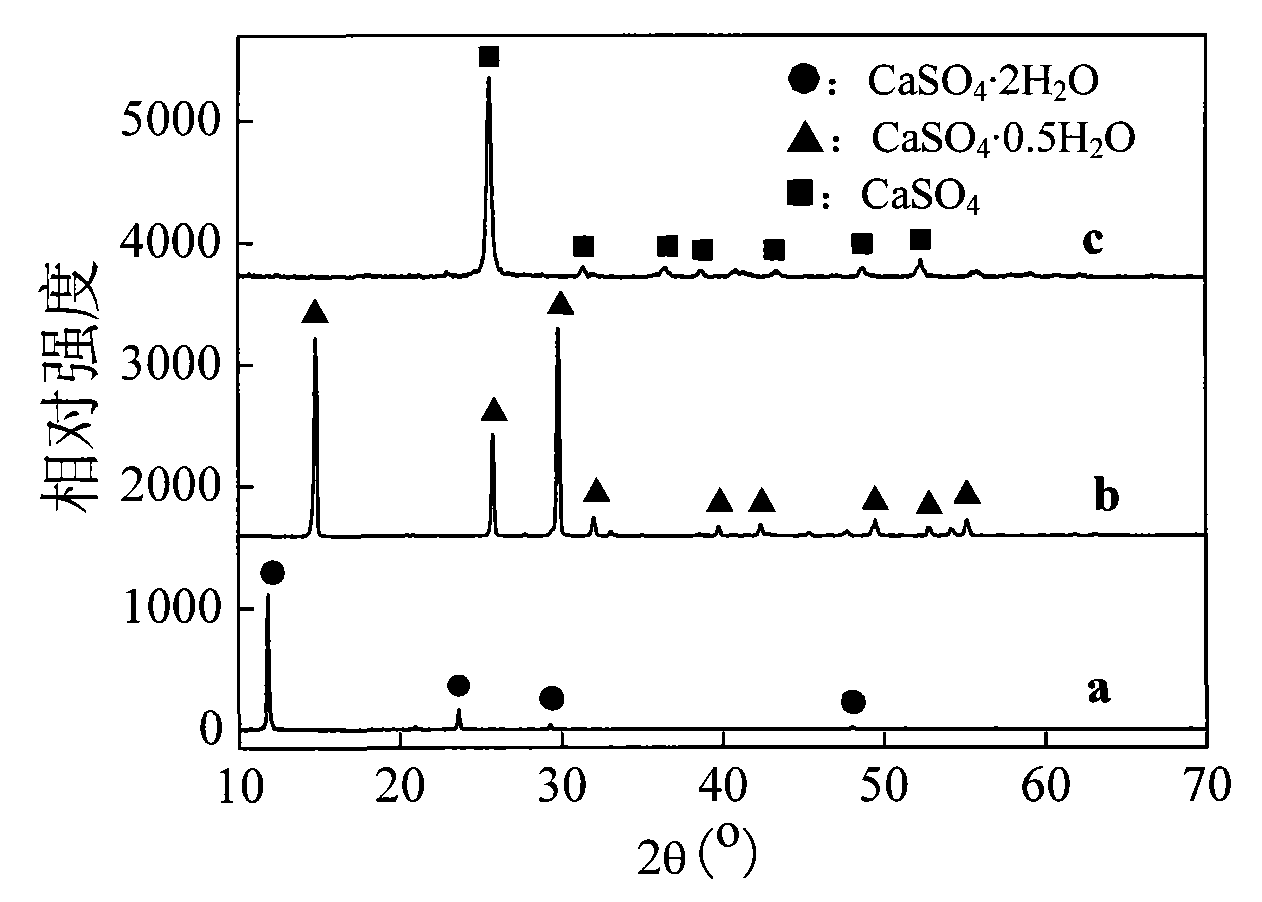

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

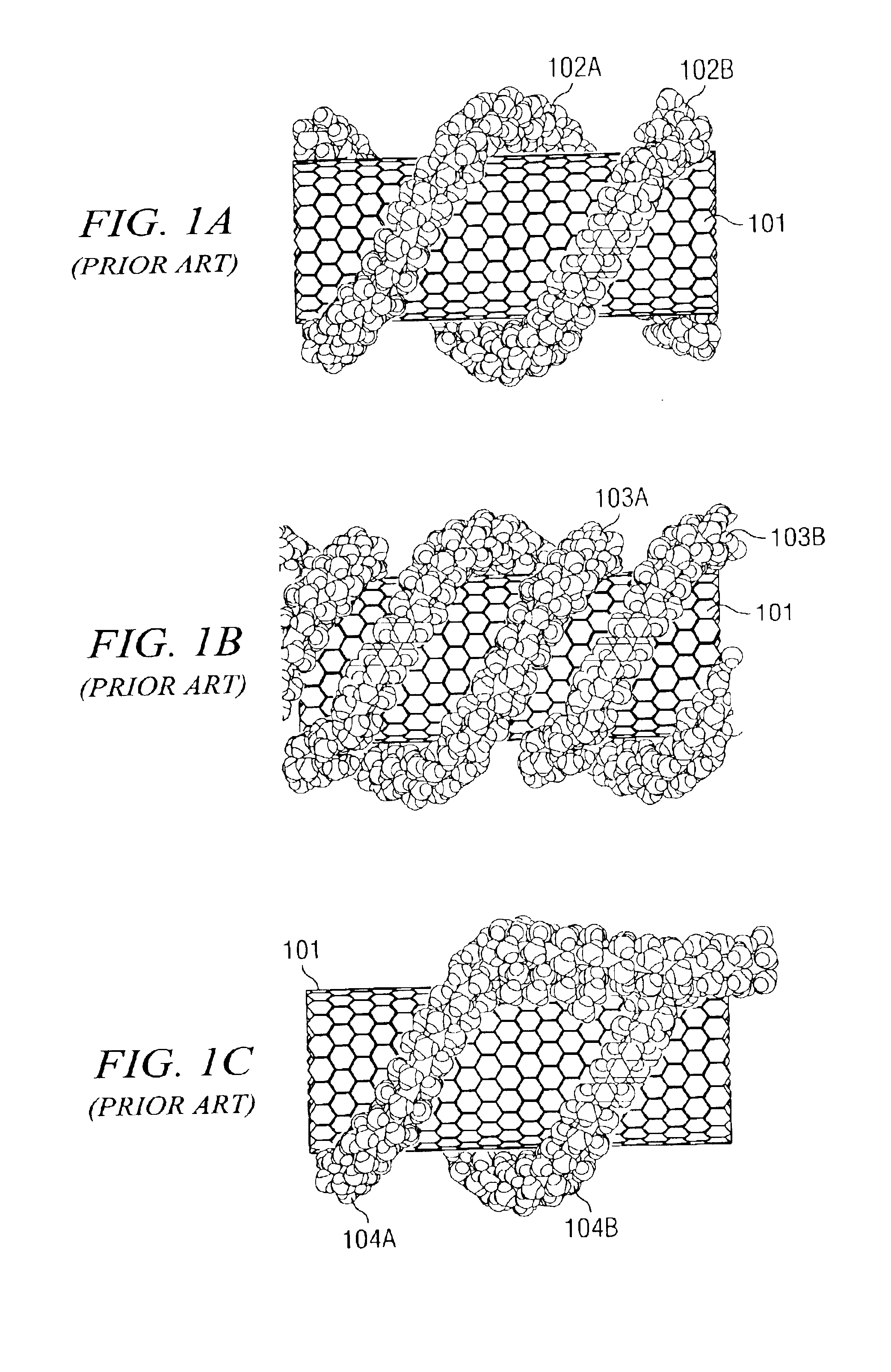

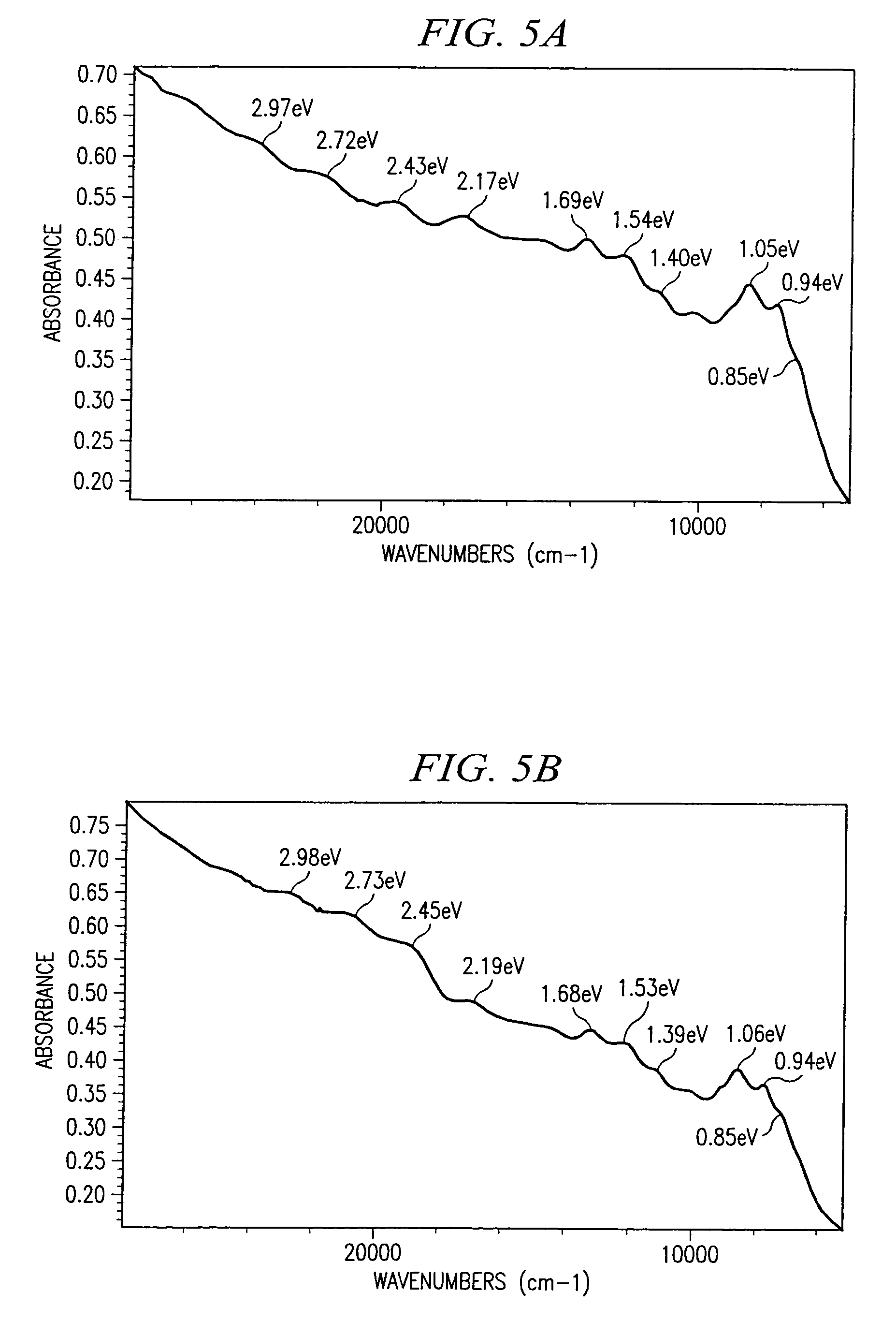

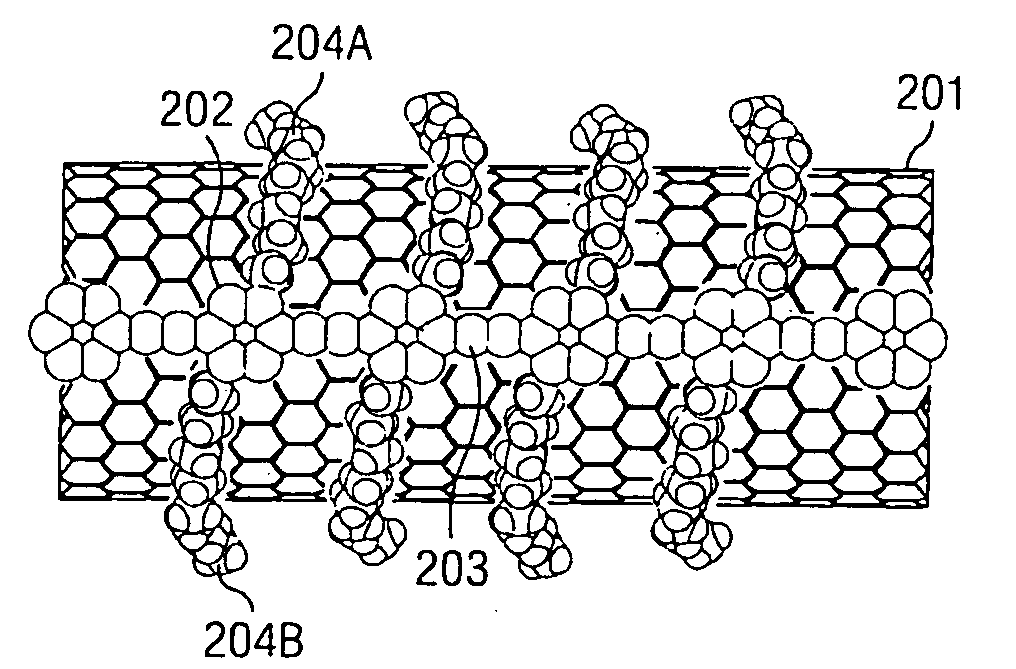

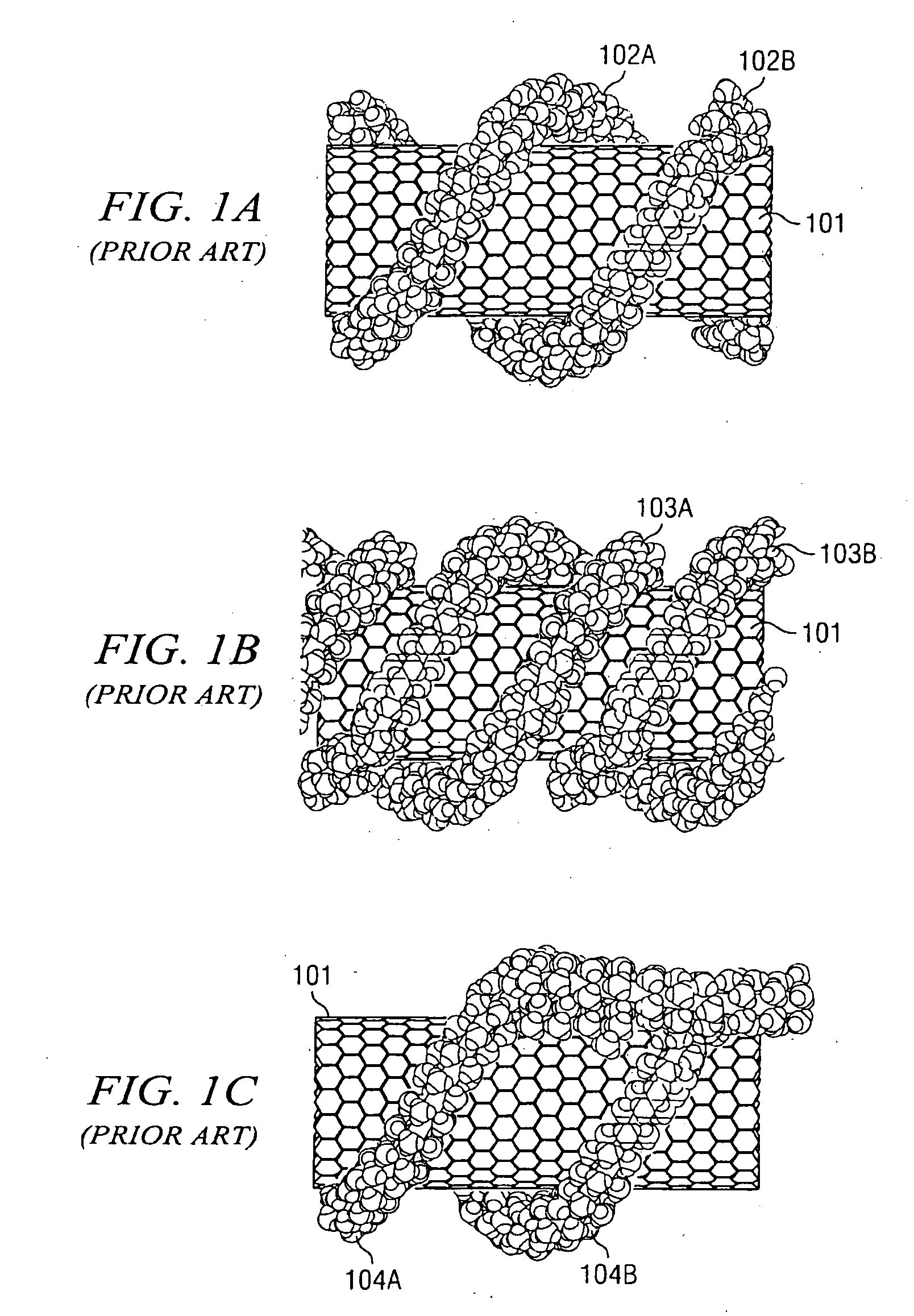

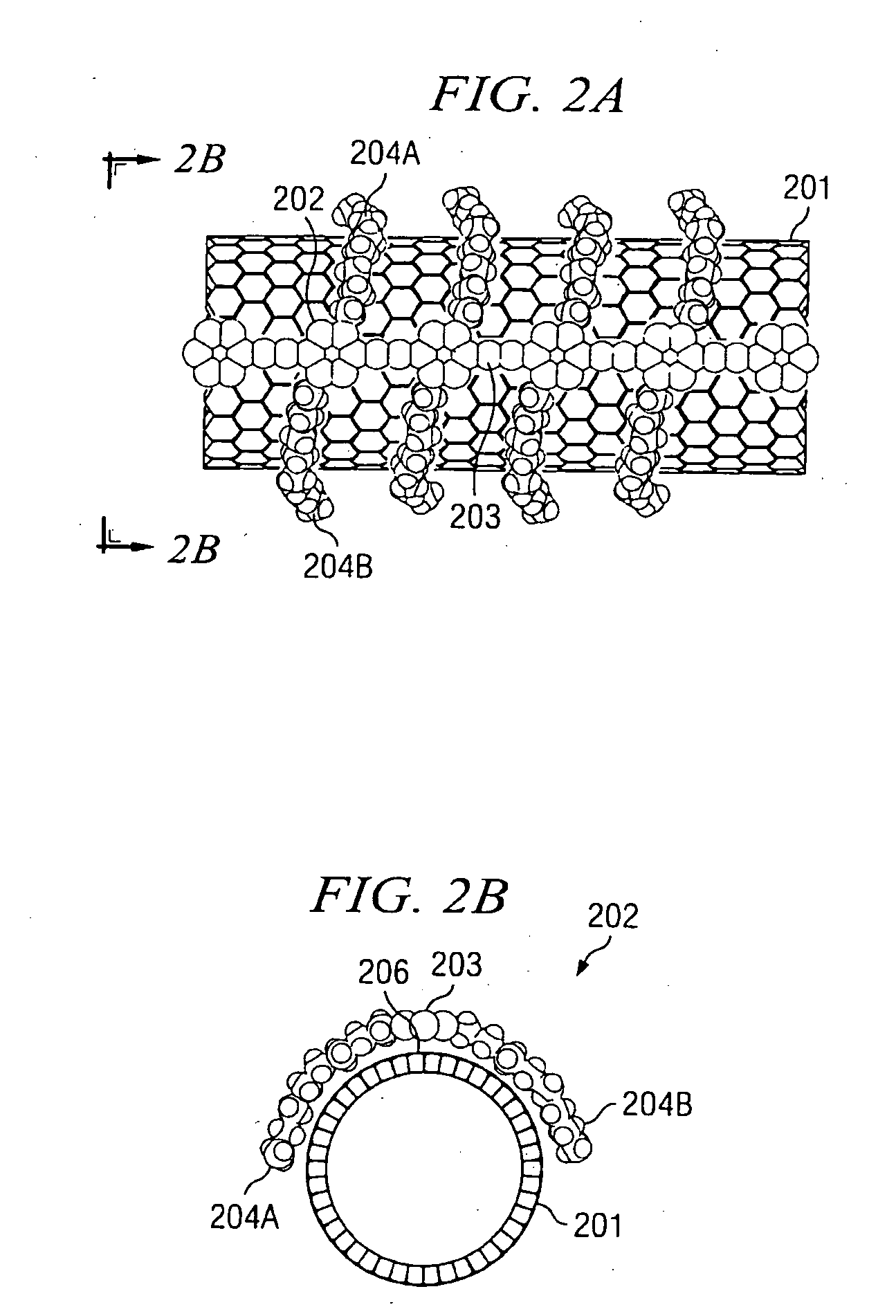

Polymer and method for using the polymer for noncovalently functionalizing nanotubes

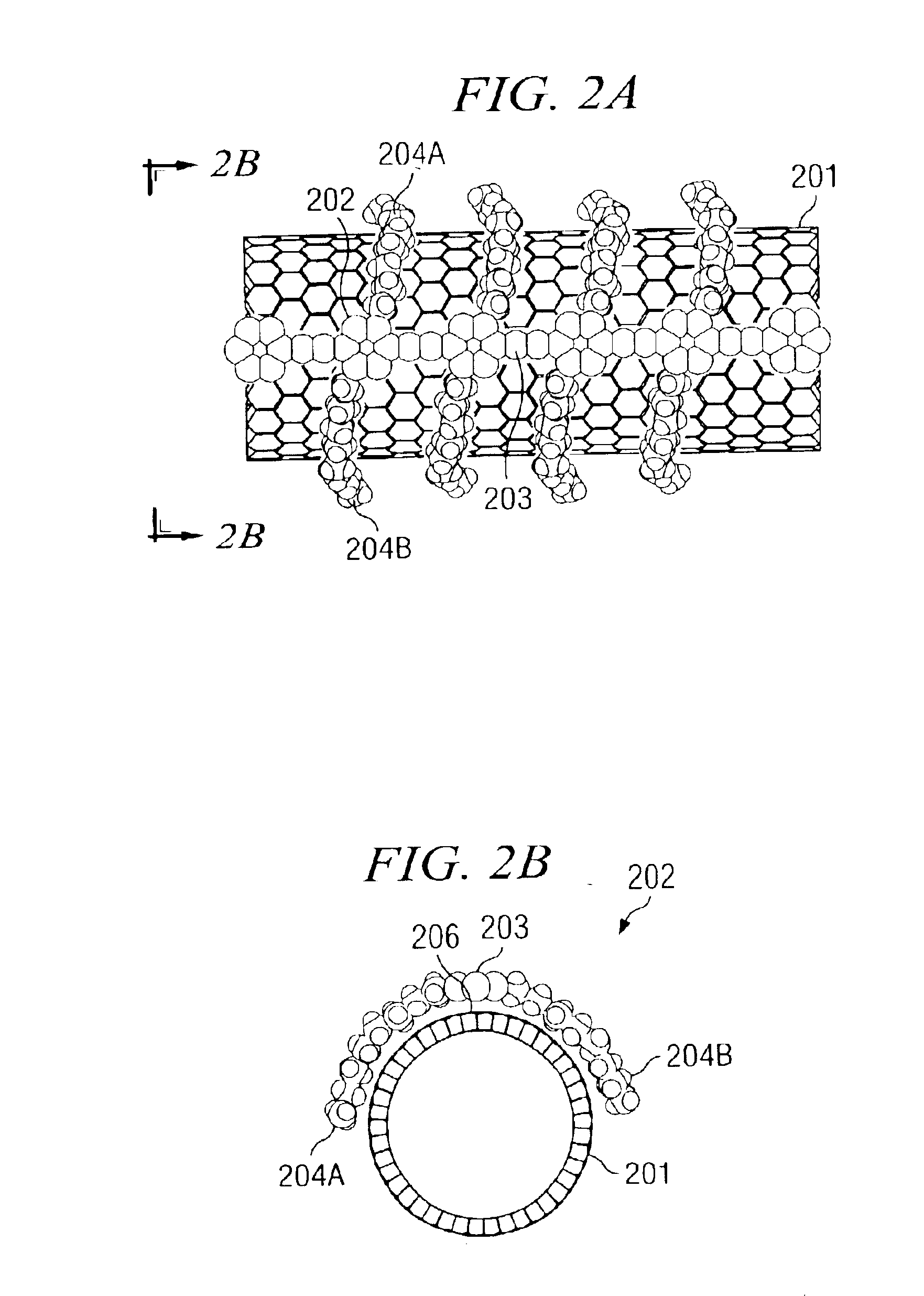

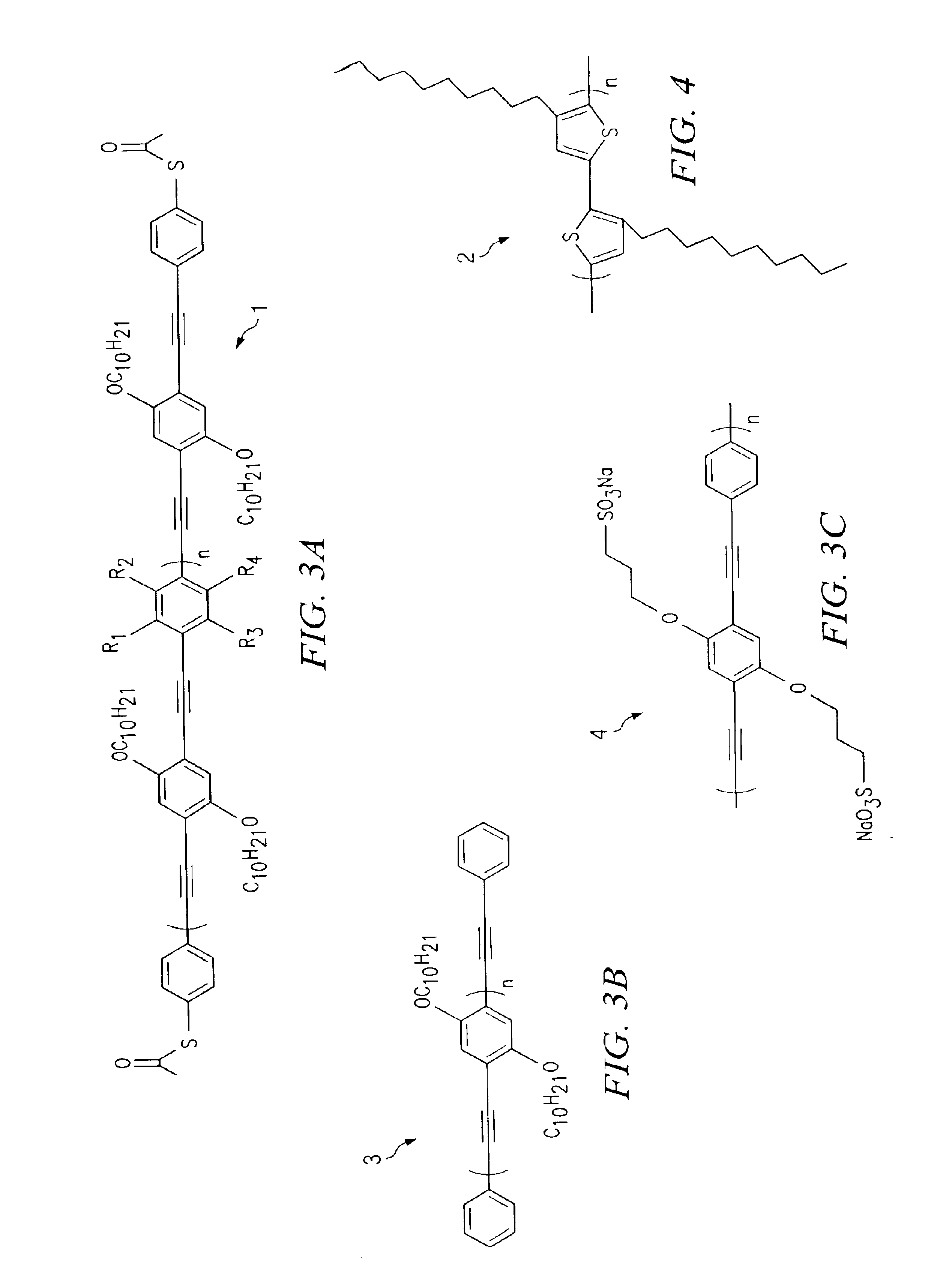

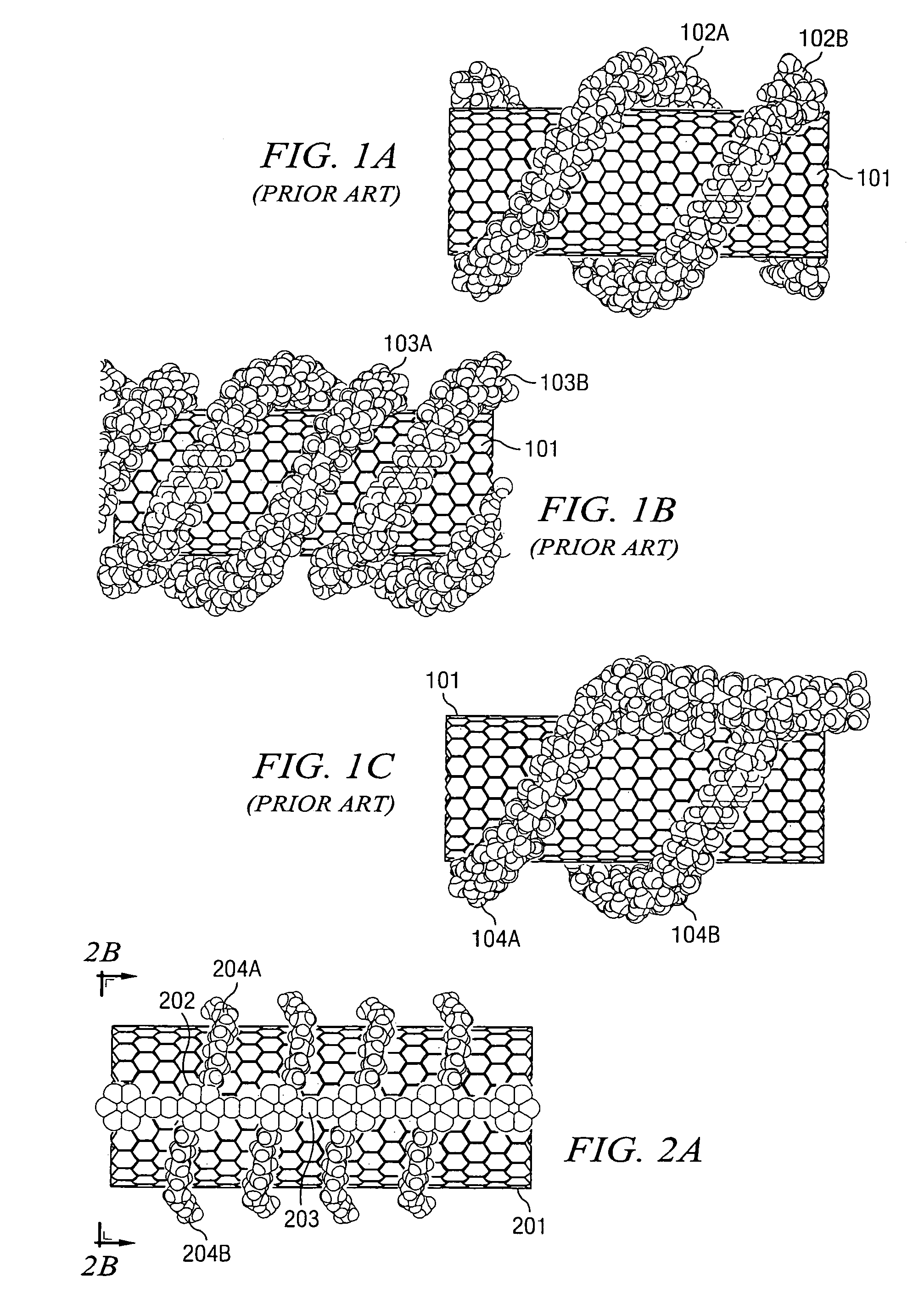

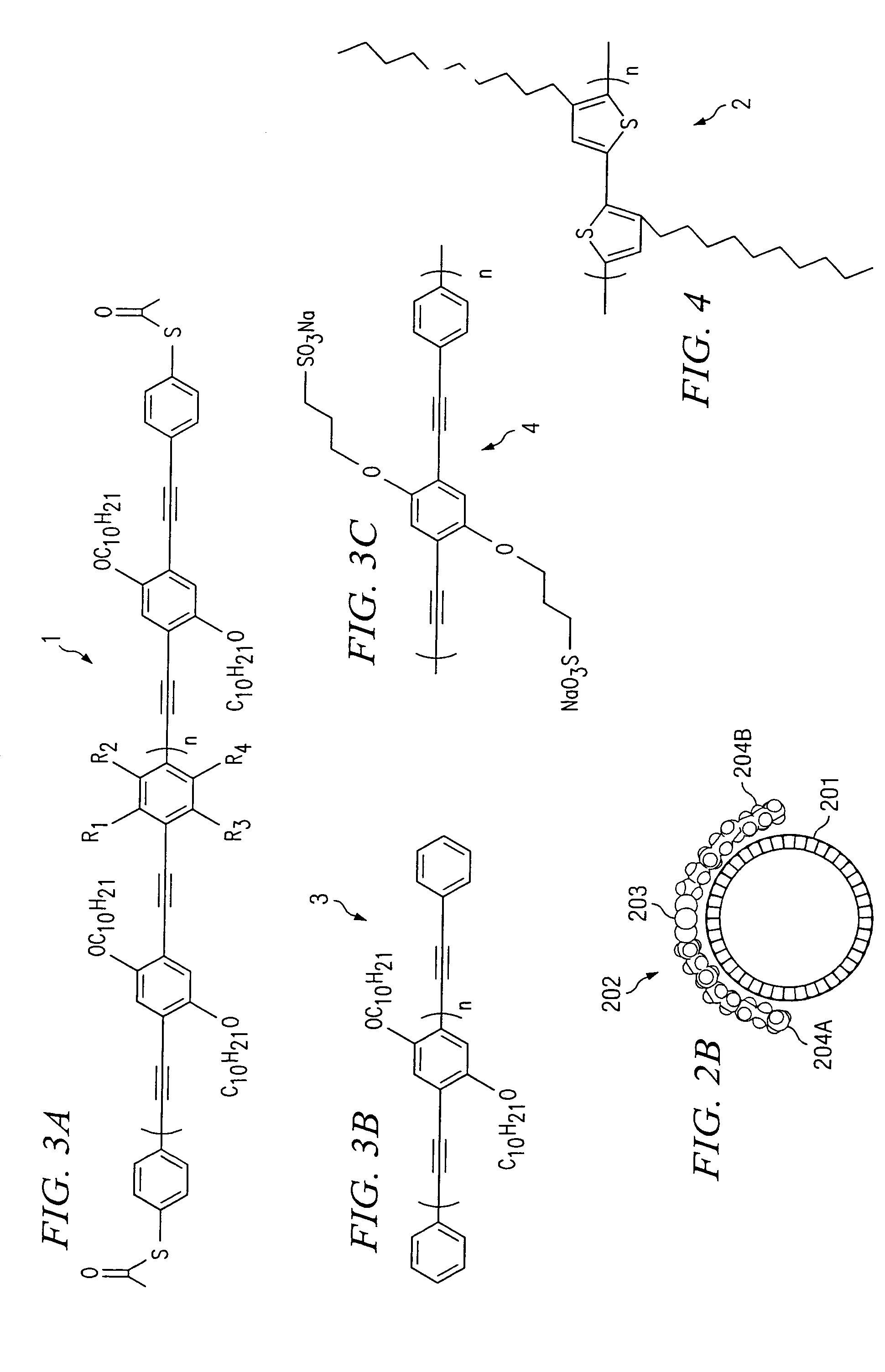

A new, non-wrapping approach to functionalizing nanotubes, such as carbon nanotubes, in organic and inorganic solvents is provided. In accordance with certain embodiments, carbon nanotube surfaces are functionalized in a non-wrapping fashion by functional conjugated polymers that include functional groups. Various embodiments provide polymers that noncovalently bond with carbon nanotubes in a non-wrapping fashion. For example, various embodiments of polymers are provided that comprise a relatively rigid backbone that is suitable for noncovalently bonding with a carbon nanotube substantially along the nanotube's length, as opposed to about its diameter. In preferred polymers, the major interaction between the polymer backbone and the nanotube surface is parallel π-stacking. In certain implementations, the polymers further comprise at least one functional extension from the backbone that are any of various desired functional groups for functionalizing a carbon nanotube.

Owner:UNIV OF PITTSBURGH THE +1

Polymer and method for using the polymer for solubilizing nanotubes

A new, non-wrapping approach to solubilize nanotubes, such as carbon nanotubes, in organic and inorganic solvents is provided. In accordance with certain embodiments, carbon nanotube surfaces are functionalized in a non-wrapping fashion by functional conjugated polymers that include functional groups for solubilizing such nanotubes. Various embodiments provide polymers that noncovalently bond with carbon nanotubes in a non-wrapping fashion. For example, various embodiments of polymers are provided that comprise a relatively rigid backbone that is suitable for noncovalently bonding with a carbon nanotube substantially along the nanotube's length, as opposed to about its diameter. In preferred polymers, the major interaction between the polymer backbone and the nanotube surface is parallel π-stacking. The polymers further comprise at least one functional extension from the backbone that are any of various desired functional groups that are suitable for solubilizing a carbon nanotube.

Owner:UNIVERSITY OF PITTSBURGH +1

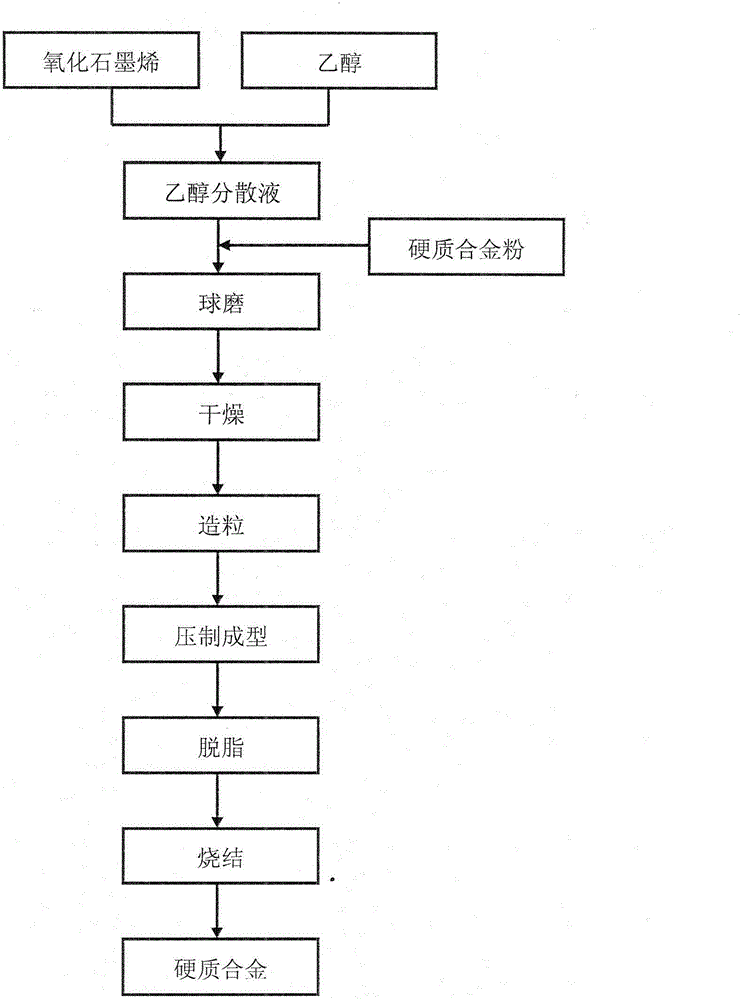

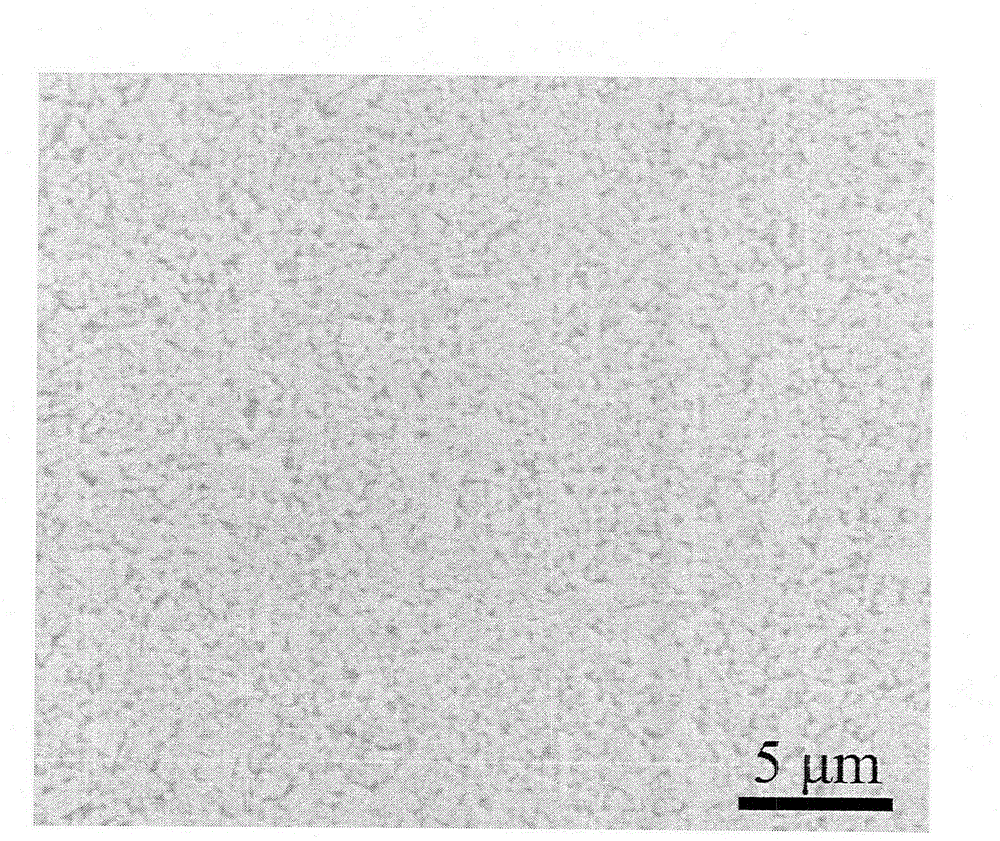

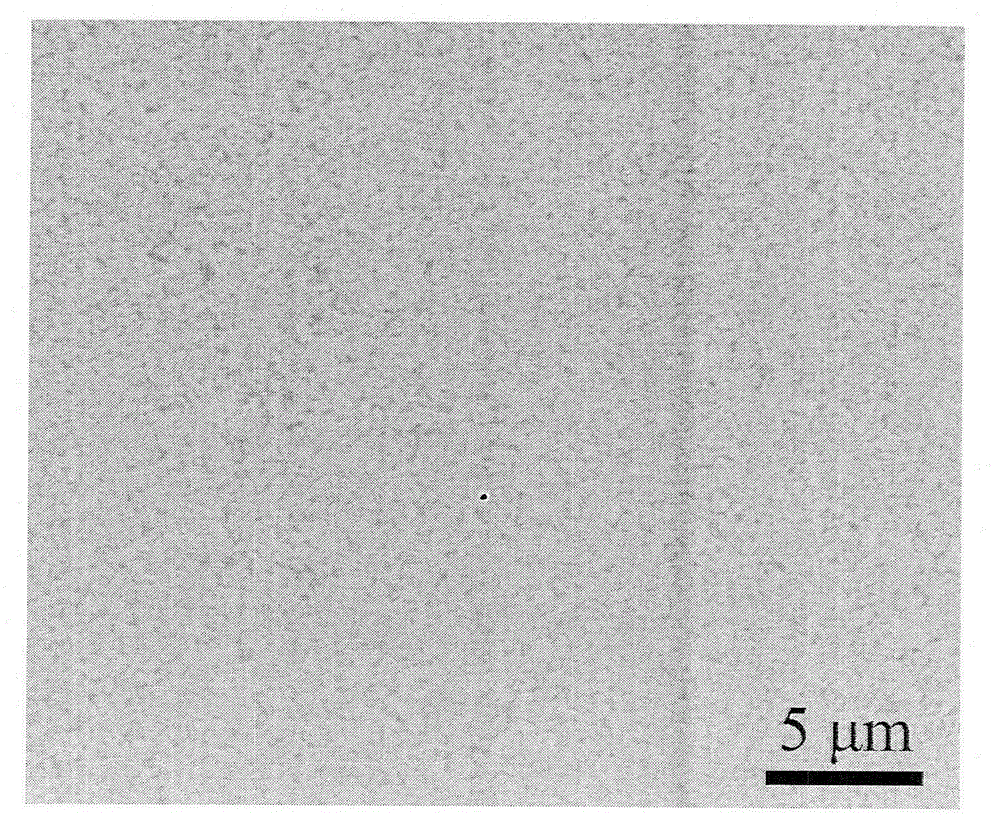

Graphene-modified hard alloy, preparation technology and application thereof

ActiveCN102719719AGood dispersionTo overcome the deficiency of poor uniformity of additionAlloyCemented carbide

The invention discloses a grapheme-modified hard alloy, a preparation technology and an application thereof. The preparation technology comprises the steps of: uniformly dispersing a graphene material, especially uniformly dispersing graphene oxide into an inorganic solvent and / or organic solvent to form graphene dispersing liquid, and then mixing with hard alloy powder, and ball-milling, drying, pelleting, pressing and molding, degreasing and sintering in sequence to prepare a target product. The graphene oxide has good dispersibility in the solvent, so that the graphene oxide can be well wrapped on the surface of the hard alloy powder due to a huge surface area, and can be well dispersed and combined with the hard alloy in the subsequent molding process; meanwhile, the carbon content of the hard alloy can be adjusted by adding the high-activity graphene oxide, and mechanical enhancement of the graphene oxide on the hard alloy can be achieved. The preparation technology disclosed by the invention can be integrated with the conventional industrial preparation route of the hard alloy and is suitable for industrial production, and the overall performance of the hard alloy is obviously improved.

Owner:SUZHOU OUMEIKE CARBIDE TOOL

Method for cleaning polyphenylene sulfide melt spinning spinneret

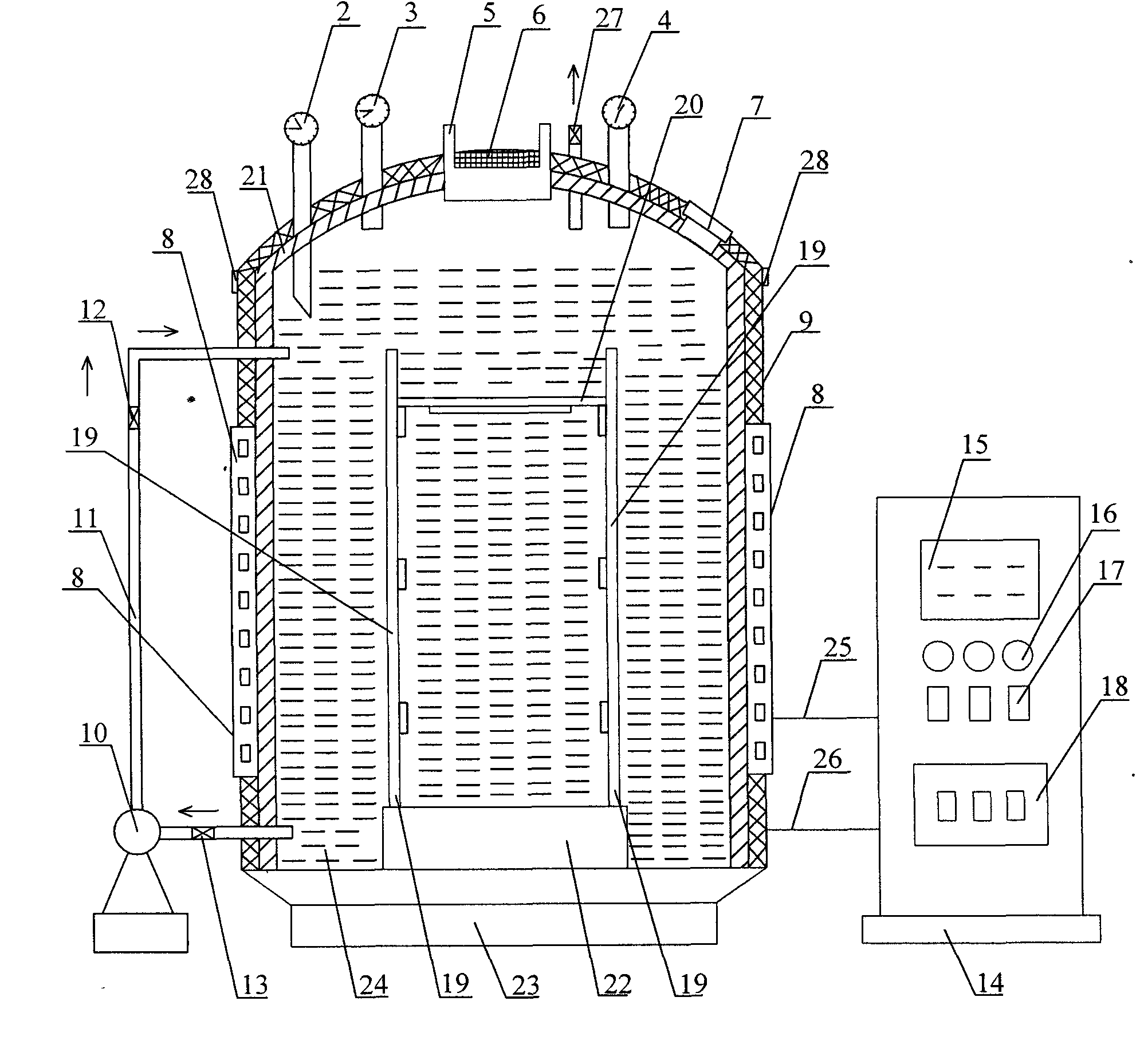

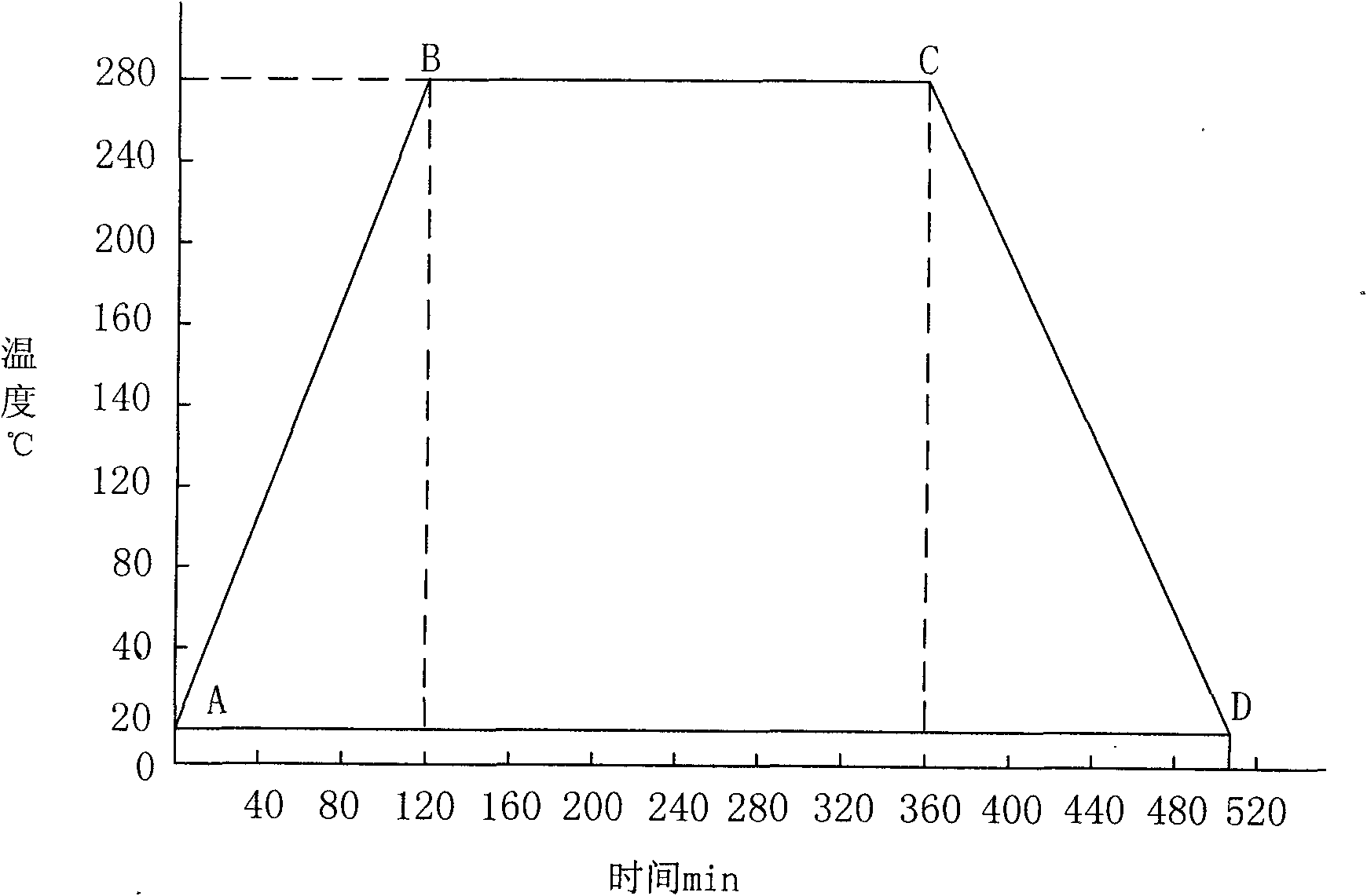

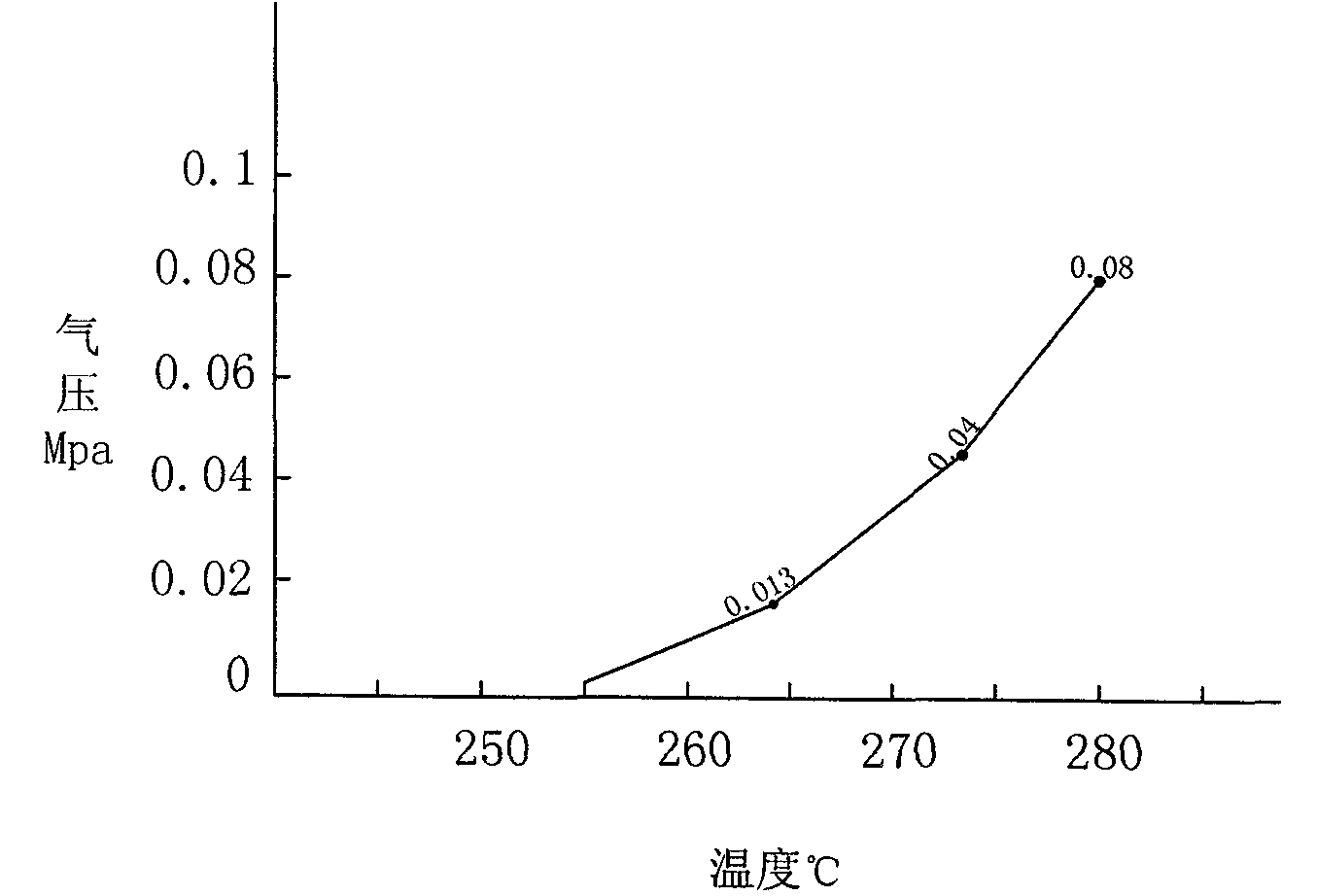

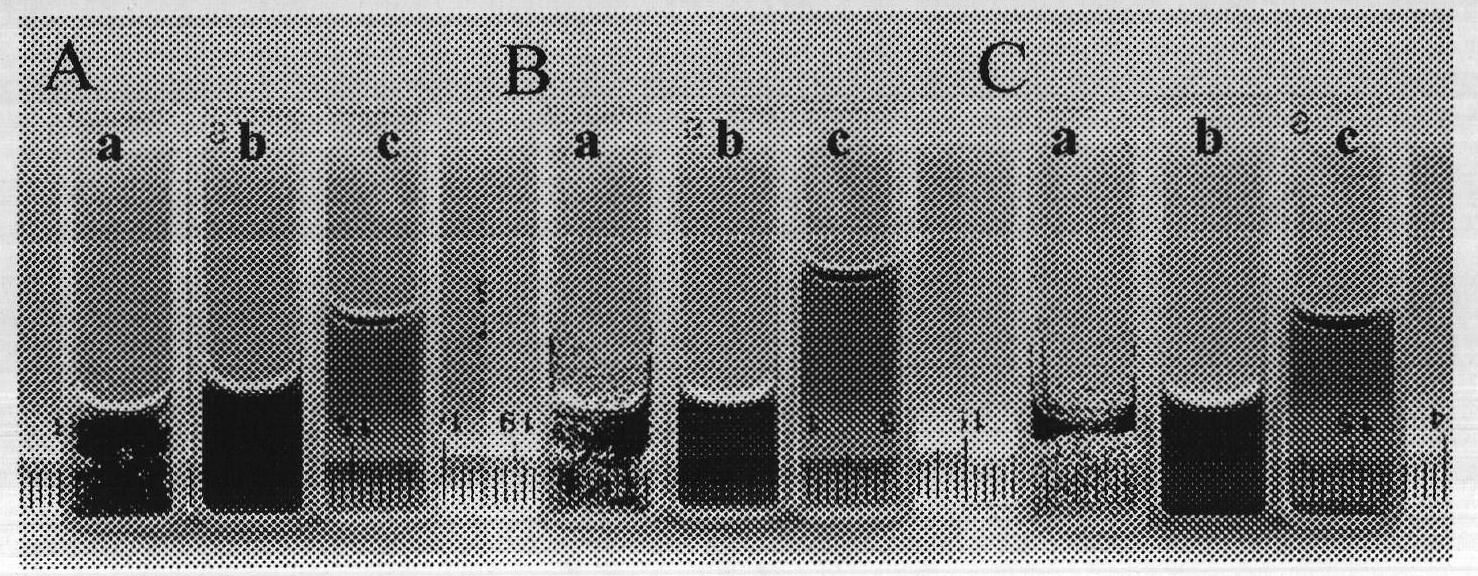

The invention relates to a method for cleaning a polyphenylene sulfide melt spinning spinneret. Regarding that high polymer has the characteristics of high decomposition temperature, organic and inorganic solvent insolubility, based on the actual condition that the polyphenylene sulfide is firmly attached on the spinneret and is hard to clean, according to the principle that structural components of chemical substances are similar and compatible, the method adopts biphenyl-biphenyl ether served as cleaning agent to complete cleaning of the spinneret in a cleaning kettle at 280 DEG C and 0.08MPa under cleaning agent out-kettle circular flowing, and finally completes cleaning of the spinneret through calcining of a calcinator, ultrasonic cleaning and compressed air drying. The cleaning method has short technical process, few used equipment, good cleaning effect and cleaning rate of spinneret attachment reaching 99.999 percent, ensures that the spinneret has no phenomena of deformation, corrosion or decarburization, and is a perfect cleaning method for the polyphenylene sulfide melt spinning spinneret. Components and parts of other spinning machines attached with polyphenylene sulfide high polymer also can be cleaned by using the method.

Owner:TAIYUAN UNIV OF TECH

Method for preparing cerium oxide rhombus nano sheet-shaped material

ActiveCN101264922AProcess stabilityEasy to operateNanostructure manufactureRare earth metal compoundsCerium nitrateUltraviolet lights

The invention relates to a preparation method for cerium oxide rhombus nanometer sheet material, belonging to the technical field of preparation process for the inorganic nanometer material. The preparation method is characterized in that by using heating backflow method, three-valent cerium nitrate is organic or inorganic solvent in which surfactant and precipitant exist, then the solution goes through ultrasonic dispersion for 20 to 30 minutes, and enters heating backflow reaction process; the temperature for the heating backflow reaction is 90 to 140 DEG C, and the reaction time lasts 2 to 10 hours; subsequently, suction filtering or centrifugal separation is conducted, the resultant precipitate is washed to be neutral, then washed by alcohol, and dried under 60 DEG C; next, the precipitate is calcined under the temperature of 400 to 600 DEG C for 2 to 6 hours, finally, the CeO2 rhombus nanometer sheet microcrystal material is obtained. Furthermore, the acquired CeO2 material enjoys tremendous potential application prospects in the fields of shielding ultraviolet light and automobile exhaust catalysis.

Owner:SHANGHAI UNIV

Method for preparing ionic liquid functionalized graphene material

The invention discloses a method for preparing an ionic liquid functionalized graphene material. The graphene material is prepared by a chemical method which comprises the following steps: carrying out ultrasonic dispersion on the graphene oxides in the secondary water, removing a handful of non-dispersed oxides through centrifugation to obtain yellow colloid solution, weighing certain amount of ionic liquid with terminal group of -NH2 and dissolving the ionic liquid in the above mixed liquid, carrying out heating and ultrasonic treatment to obtain black dispersion and filtering, washing and drying the black dispersion to obtain the ionic liquid functionalized graphene material. The method is simple, convenient and practicable and the obtained graphene material has better dispersibility and dissolubility in numerous organic and inorganic solvents.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

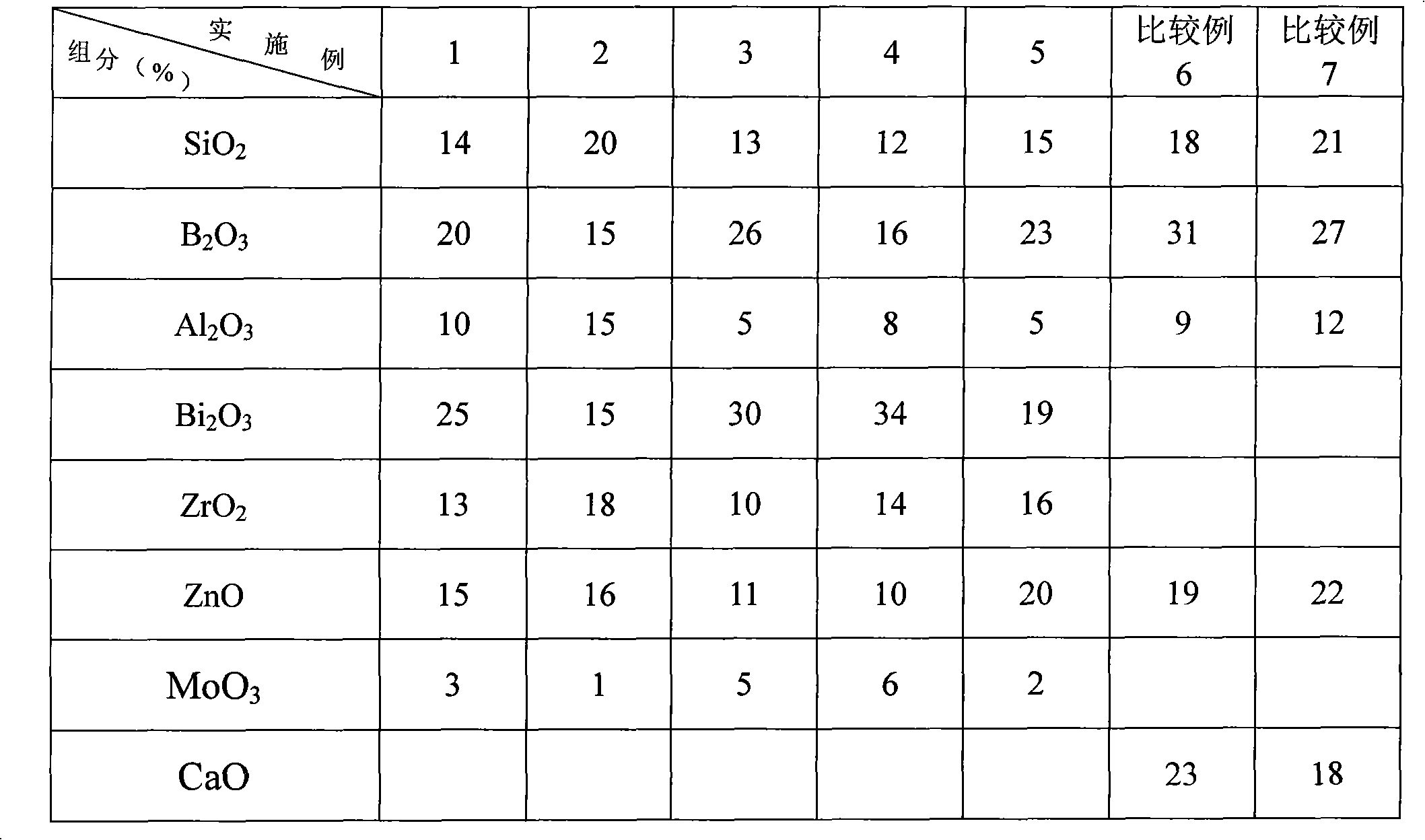

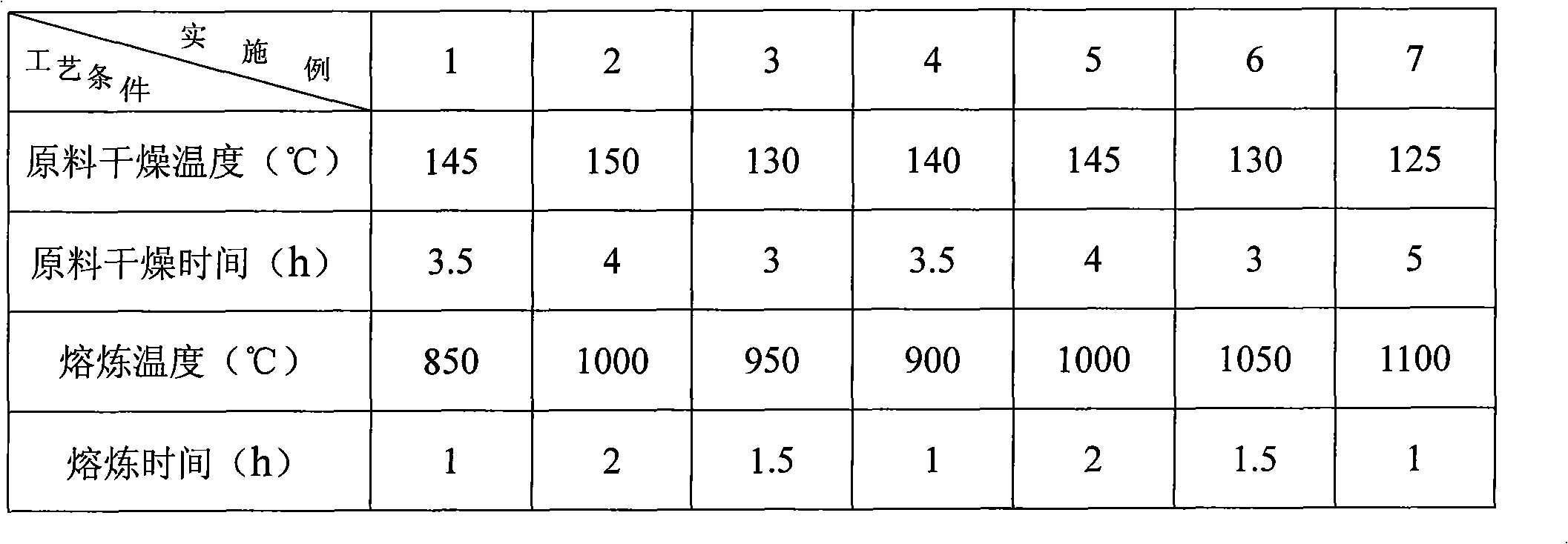

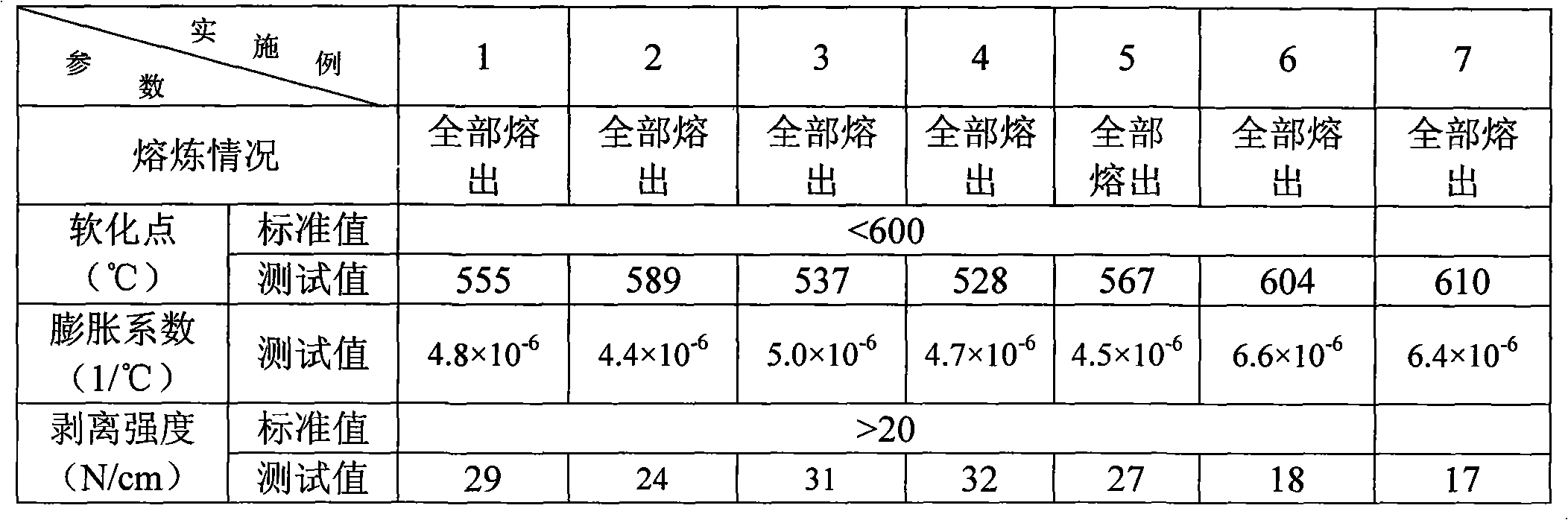

Inorganic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555388ASmall expansion coefficientLess bendingFinal product manufactureInorganic adhesivesAdhesiveSilicon solar cell

The invention provides inorganic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The inorganic adhesive comprises the following components by the weight part: 10% to 20% of SiO2, 15% to 30% of B2O3, 5% to 15% of Al2O3, 15% to 35% of Bi2O3, 10% to 18% of ZrO2, 10% to 25% of ZnO and 1% to 8% of MoO with the total amount being 100%. The preparation method comprises the following steps: putting the components forming the inorganic solvent into a mixer to mix the components uniformly; loading the mixed components into a porcelain crucible and placing the porcelain crucible into a baking oven to be dried at the temperature of 120 to 150 DEG C for 3 to 5 hours; then, placing the porcelain crucible into a high-temperature furnace to melt at the temperature of 800 to 1,100 DEG C for melting for 1 to 2 hours; carrying out water-quenching and oven-drying; milling the components with a planetary ball mill until the particle size is lower than 10 mum; and oven-drying the components to obtain the final product of the inorganic adhesive. The glass powder has lower softening temperature and high adhesion when the aluminum paste prepared from the inorganic solvent is used for sintering, so that the aluminum powder layer can be firmly adhered to silicon chips; the expansion coefficient is lower after sintering; the bending degree of cell chips is lower; and the breakage rate is reduced.

Owner:WUXI RUXING TECH DEV +1

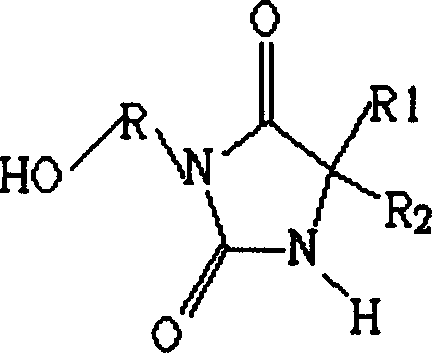

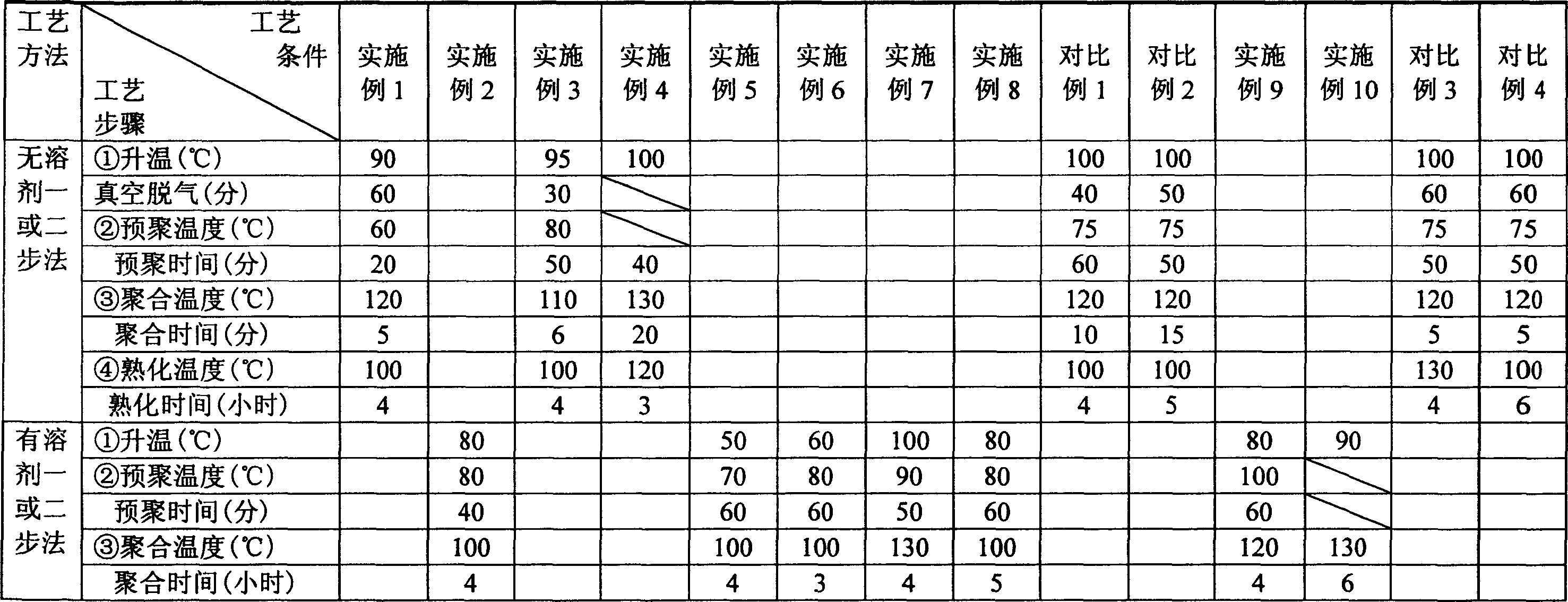

Method for preparing waterproof poromeric sterilizing polyurethane elastomer

The invention relates to a method for preparing water-proof antibacterial polyurethane elastomer. Use one-step or two-step synthesizing method which inorganic solvent which is easy and useful to control, or that with organic solvent, with the polymer diatomic alcohol of 20-75%, diisocyanate and chain-extending agent of 25-80%through a certain technique mol ratio of diisocyanate chain-extending agent is 1.03-1.2, while the antibacterial blocking agent is 1.5-2times of the mole number difference of diisocyanate and polymer diatomic alcohol+ chain-extending agent. The antibacterial polyurethane elastomer made by the invention has outstanding mechanical property and permeability of water steam, as well as antibacterial effect, including gram-positive bacterium and gram-negative bacterium; it can be applied to produce protective product like medical protective glove, safeguard and various kinds of coating material.

Owner:SICHUAN UNIV

Polymer and method for using the polymer for noncovalently functionalizing nanotubes

A new, non-wrapping approach to functionalizing nanotubes, such as carbon nanotubes, in organic and inorganic solvents is provided. In accordance with certain embodiments, carbon nanotube surfaces are functionalized in a non-wrapping fashion by functional conjugated polymers that include functional groups. Various embodiments provide polymers that noncovalently bond with carbon nanotubes in a non-wrapping fashion. For example, various embodiments of polymers are provided that comprise a relatively rigid backbone that is suitable for noncovalently bonding with a carbon nanotube substantially along the nanotube's length, as opposed to about its diameter. In preferred polymers, the major interaction between the polymer backbone and the nanotube surface is parallel π-stacking. In certain implementations, the polymers further comprise at least one functional extension from the backbone that are any of various desired functional groups for functionalizing a carbon nanotube.

Owner:UNIVERSITY OF PITTSBURGH +1

Method for preparing bioceramic and biodegradable aliphatic polyester composite materials

InactiveCN1631973AHigh strengthToughness adjustablePigment treatment with macromolecular organic compoundsLactideOxygen

The invention has supplied a method to prepare aliphatic polyester compound material of biological ceramic and biological degradation. Biological ceramic nm / mm particle reacts with glycolic acid in the dehydrating condition of boiling with toluene, or with biological ceramic and glycolic acid in inorganic solvent. By graft on the surface of the biological ceramic particle, acquire the chemical strycture of -biological ceramic, then without water and oxygen, with stannous octoate as initiator, initiate hydroxyl group of glycolic acid loaded with caprolactone, lactide, diglycolide and cyclic ester, acquiring the product of them and nm / mm compound material of copolymer. The biological ceramic modified by glycolic acid and loaded with polyester of surface graft can be used for polyester material directly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Field complete pollution level detection method for running composite insulator

InactiveCN102053043ASolve the difficulty of accurate measurementSimple methodWeighing by removing componentWithdrawing sample devicesComposite insulatorsWater insoluble

The invention relates to a field complete pollution level detection method for a running composite insulator. The method is simple; and by combining an inorganic solvent and an organic solvent and sampling twice, the surface of the insulator can be cleaned, and the measurement accuracy is ensured. The method comprises the following steps of: (1) scrubbing pollutants to a polluted liquid storage from the upper and lower surfaces of the insulator by adopting distilled water or deionized water, and then measuring the equivalent salt density of the insulator; (2) filtering the polluted liquid in the step 1, drying, weighing, and calculating washing ash density; (3) scrubbing insoluble and water-insoluble substances to the polluted liquid storage from the upper and lower surfaces of the washed insulator by adopting alcohol and using absorbent cotton, filtering the polluted liquid, drying, weighing, and calculating the alcohol cleaning ash density of the surface of the insulator; and (4) adding the washing ash density and the alcohol cleaning ash density to obtain complete ash density of the surface of the insulator.

Owner:SHANDONG ELECTRIC POWER RES INST

Nanoporous articles and methods of making same

Owner:ENTEGRIS INC

Anti-adhesion fiber membrane with hemostasis and antibiosis functions and preparation method thereof

InactiveCN102397580AIncrease embedding volumeHigh embedding rateAbsorbent padsBandagesFiberSurgical operation

The invention discloses an anti-adhesion fiber membrane with hemostasis and antibiosis functions and a preparation method thereof. The preparation method comprises the following steps of: dissolving medicinal molecules into an organic or inorganic solvent to prepare a medicinal molecular solution; dissolving different high molecular materials into medicinal solutions of a hemostasis agent and an antibiosis agent respectively to prepare a high molecular solution; and performing electrostatic spinning on a mixed solution of organic high molecules and the hemostasis agent and a mixed solution of high molecules and the antibiosis agent to obtain a compound fiber material. In the invention, nanofiber is produced by using an electrostatic spinning technology; an organic high molecular solution and the medicinal molecules are mixed for electrostatic spinning to obtain the compound fiber material; by adjusting the high molecular material, the embedding amount and embedding rate of medicaments are increased, a fiber material which can keep the medicinal bioactivity and is used for controlling the release of different medicaments at different stages is prepared, and dual effects of preventing postoperative adhesion and postoperative infection can be achieved; and moreover, the entire preparation process is simple, has low cost, and has wide application prospect in the field of surgical operation.

Owner:WUXI ZHONGKE GUANGYUAN BIOMATERIALS

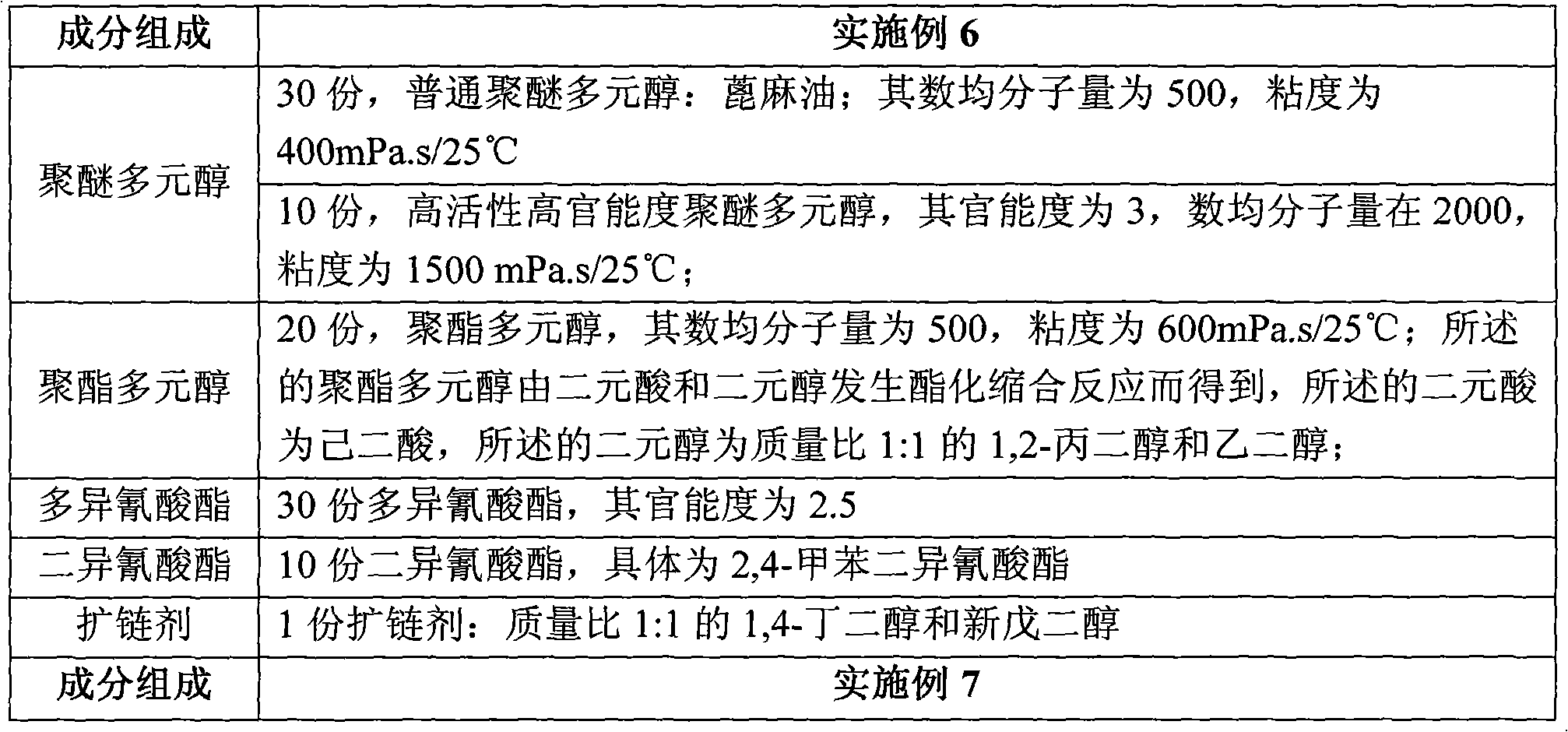

One-component solvent-free polyurethane adhesive and preparation method thereof and raw material composition

ActiveCN101787253AFast curingIncrease productivityPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a one-component solvent-free polyurethane adhesive and a preparation method thereof and a raw material composition. The preparation method of the adhesive comprises the following steps of: evenly mixing polyether glycol, polyester polyol and a chain extender, carrying out a polyurethane synthetic reaction on the mixture and diisocyanate and polyisocyanate; testing the NCO value of a reactant and carrying out end point control, wherein various raw materials for the synthetic reaction are 40-70 parts by weight of polyether glycol, 0-20 parts by weight of polyester polyol, 30-50 parts by weight of polyisocyanate, 10-30 parts by weight of diisocyanate and 0-2 parts by weight of chain extender; and the polyether glycol with high activity and high functionality contained in the one-component solvent-free polyurethane adhesive accounts for 20-90 percent of the total weight of the polyether glycol. The one-component solvent-free polyurethane adhesive can be quickly cured, has the advantages of high production efficiency, lower viscosity for adhesive spreading at normal temperature, convenient use, no organic and inorganic solvents and no pollution; in addition, the invention is one component and belongs to a polyurethane adhesive with high efficiency, convenient construction and environmental protection.

Owner:HUAFON MICROFIBER SHANGHAI

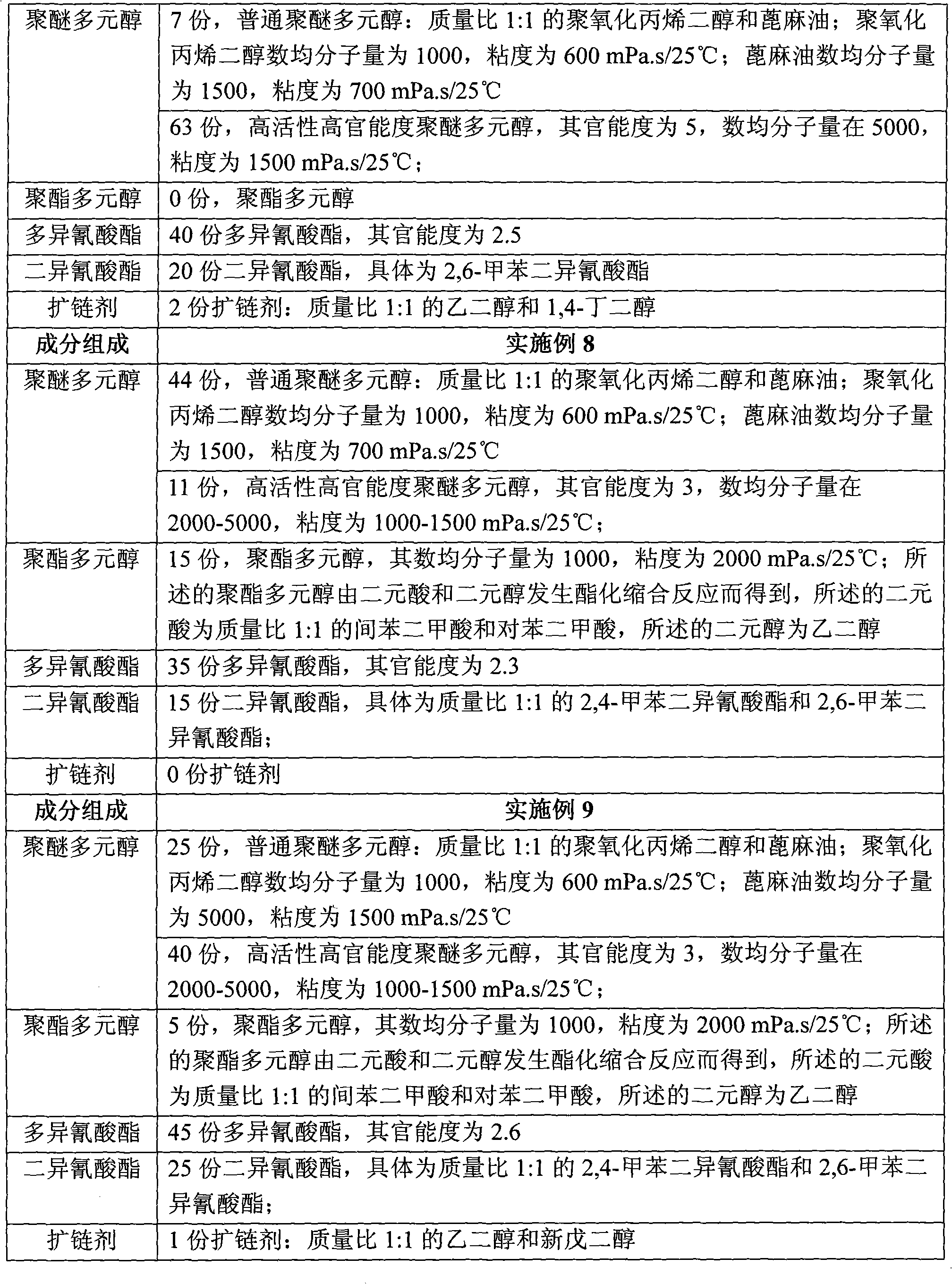

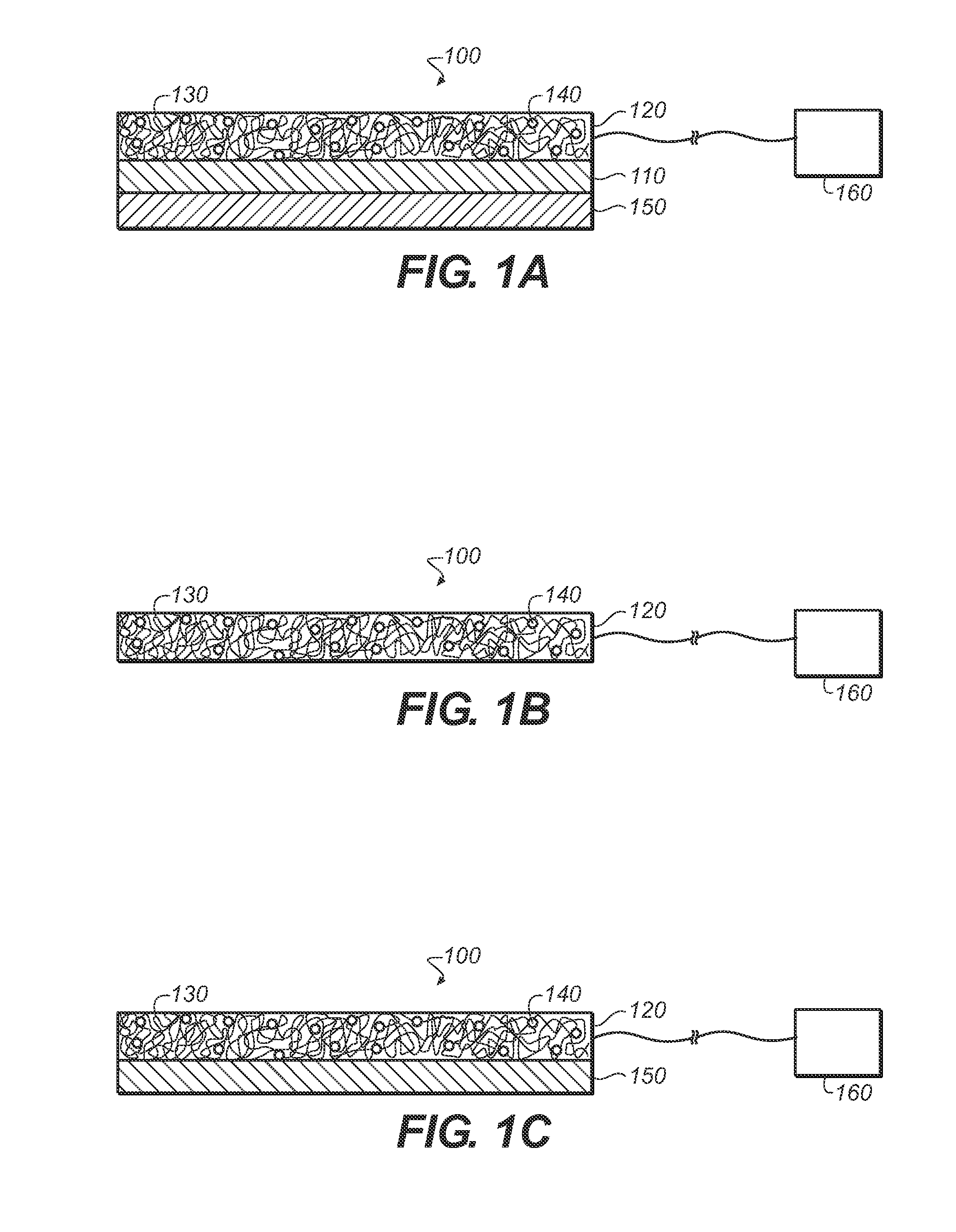

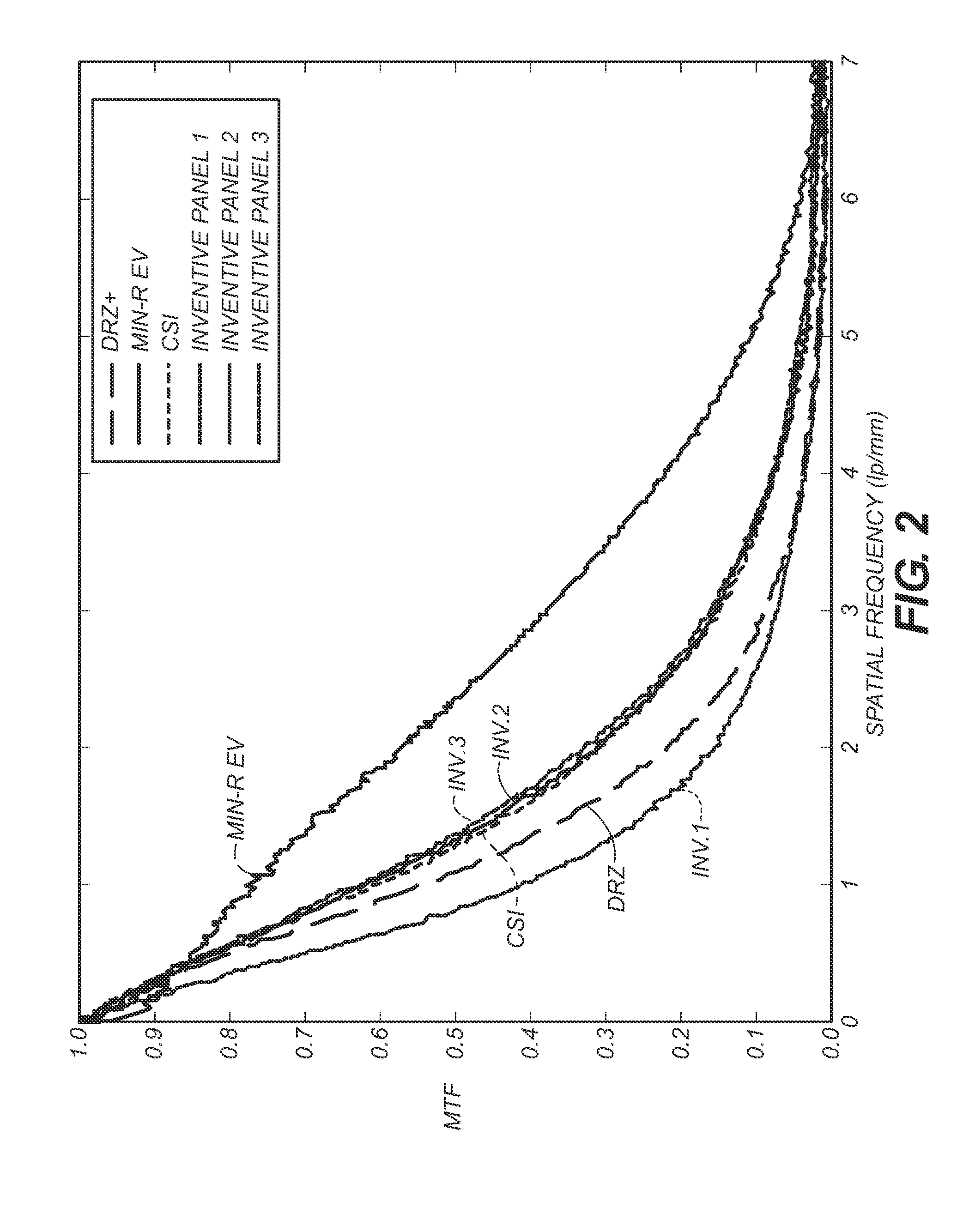

Radiation sensing thermoplastic composite panels

ActiveUS20140291528A1Synthetic resin layered productsMaterial analysis by optical meansPolyolefinPhotodetector

A storage phosphor panel can include an extruded inorganic storage phosphor layer including a thermoplastic polyolefin and an inorganic storage phosphor material, where the extruded inorganic storage phosphor panel has a DQE comparable to that of a traditional extruded inorganic solvent coated inorganic storage phosphor screen. Also disclosed is an inorganic storage phosphor detection system including an extruded inorganic storage phosphor panel that can include an extruded inorganic storage phosphor layer including a thermoplastic olefin and an inorganic storage phosphor material; and photodetector(s) coupled to the extruded inorganic storage phosphor panel to detect photons generated from the extruded inorganic storage phosphor panel. Further disclosed is a method of making an extruded inorganic storage phosphor panel that can include providing thermoplastic particles including at least one thermoplastic polyolefin and an inorganic storage phosphor material; and melt extruding the thermoplastic particles to form an extruded inorganic storage phosphor layer.

Owner:CARESTREAM DENTAL TECH TOPCO LTD

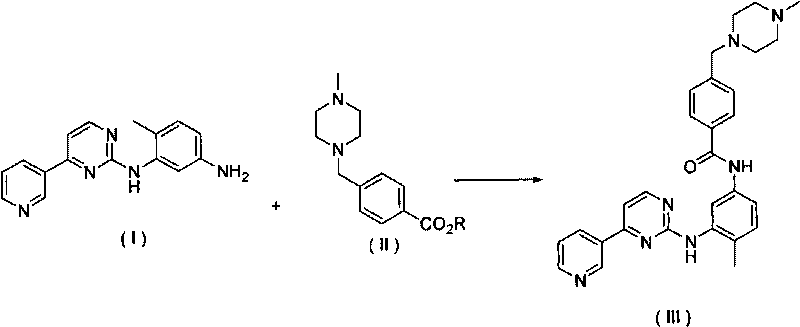

Method for synthesizing Imatinib

ActiveCN101735196AThe aminolysis reaction is clean and completeHigh yieldOrganic chemistryAntineoplastic agentsImatinibCombinatorial chemistry

The invention discloses a method for synthesizing Imatinib, comprising the following steps: under the action of alkali, 4-methyl-N-3-(4-pyridine-3-radix-pyrimidine-2-radix)-1,3-phenylenediamine shown in the formula (I) reacts with 4-(4-methylpiperazine-1-methyl)-benzoate shown in the formula (II) in an aprotic inorganic solvent to form the Imatinib shown in the formula (III), namely 4-(4-methylpiperazine-1-methyl)-N-[4-methyl-3-[4-(3-pyridyl) pyrimidine-2-amino]-benzamide. In the above chemical structure general formula, R represents fatty alkyl, phenyl, substituted phenyl, benzyl or substituted benzyl containing 1-10 carbon atoms. The invention provides the new method for synthesizing Imatinib, which has mild reaction conditions and high yield and is environment-friendly.

Owner:FUJIAN SOUTH PHARMA CO LTD

Biodegradable hydrogel and method for preparing same

The invention discloses a biodegradable hydrogel and method for preparing same which consists of, preparing microporous konjak gluglucosan aqueous gel, preparing refined konjaku flour, dissolving in distilled water, agitating, charging inorganic solvent, adjusting pH, carrying out crossbridging under a controlled temperature and time, water scrubbing the product yield, repeated frost thawing, freeze-drying, then swelling the konjak gluglucosan gel into the aqueous solution of acroleic acid, cross linking agent, and initiating agent, carrying out polymerization under a controlled temperature and time, and water scrubbing the obtained outcome yield.

Owner:WUHAN UNIV

High temperature resistant inorganic adhesive

InactiveCN101307212AEasy to operateSmall coefficient of thermal expansionInorganic adhesivesSoluble glassHeat resistance

The invention provides a high temeperature resistant inorganic cementing compound, relating to an inorganic cementing compound. The invention overcomes the disadvantages that the prior cementing compound has poor heat resistance and low connecting intensity of a glued joint metal material and a composite material. The high temperature resistant inorganic cementing compound consists of an inorganic solvent and a curing toughening agent which are mixed according to a mass ratio of 1 to 0.7-1.5, wherein, the inorganic solvent is a reaction solution of aluminium phosphate and cupric oxide, soluble glass or a aluminium phosphate solution; the curing toughening agent consists of 50 to 95 portions of inorganic solidified agent and 5 to 50 portions of toughening strengthening agent by weight portion. The high temperature resistant inorganic cementing compound has good heat resistance and high connecting intensity of the glued joint metal material and the composite material.

Owner:HARBIN INST OF TECH

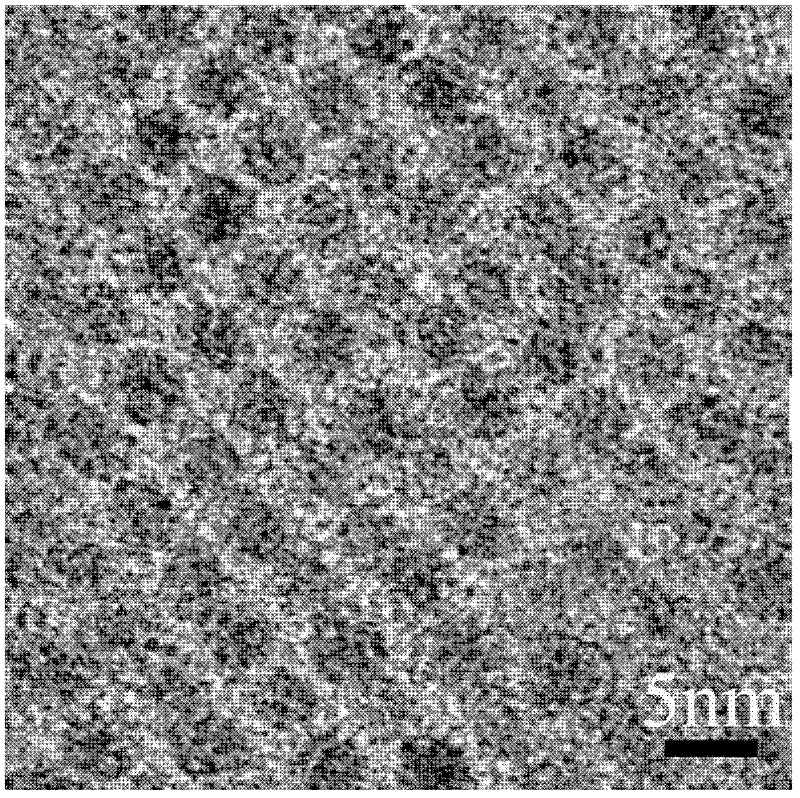

Nano metal leaf and preparation method thereof

InactiveCN102416468ARegulates the growth processUniform sizeMaterial nanotechnologyMetal leafMetal particle

The invention discloses a nano metal leaf and a preparation method thereof. Pure nano metal particles with controllable morphology and size are mixed and reacted at room temperature with a surface modifier which is dispersed in a polar organic solvent and has more than two active functional groups, and the nano metal leaf using the nano metal as a skeleton is obtained after the reaction is finished, wherein the radial size of the nano metal leaf is in several microns, the thickness of the nano metal leaf is in dozens of nanometers, and the nano metal leaf has laminar structure. The nano metalleaf is prepared at room temperature in one step by mixing different polar solvents, adding the specific surface modifier into the mixed polar solvent and adjusting the decomposition and self-assembly processes of the nano metal crystal; the prepared nano metal leaf has the advantages of uniform size, high controllability, high yield and good dispersibility in the polar inorganic solvent; the reaction conditions are easily controlled; and the nano metal leaf can be produced in a large scale.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method of printing and decorating packaging materials with electron beam curable inks

A method for printing and decorating packaging materials, such as paper, paper board and various flexible polymer films by electron beam exposure of plural layers of curable inks and coatings which do not substantially change viscosity during the printing process. The inks and coating are essentially free of volatile components such as organic solvents, inorganic solvents, water and low molecular weight fractions before, during and after exposure to electron beam irradiation. The method involves applying multiple layers of ink and an optional coating onto a substrate. The ink is an admixture of a colorant, and an unsaturated component such that the inks have a maximum of 10% volatile components. Thereafter these layers are simultaneously exposed with electron beam radiation to cause the ethylenically unsaturated components to polymerize or crosslink such that they become dried.

Owner:IDEON LLC

Biodegradable temperature-sensitive hydrogel and method for preparing same

The invention discloses a biodegradable temperature-sensitive hydrogel and method for preparing same which consists of, preparing microporous konjak gluglucosan aqueous gel, preparing refined konjaku flour, dissolving in distilled water, agitating, charging inorganic solvent, adjusting pH, carrying out crossbridging under a controlled temperature and time, water scrubbing the product yield, repeated frost thawing, freeze-drying, then swelling the konjak gluglucosan gel into the aqueous solution of N-isopropyl acrylamide, cross linking agent, and initiating agent, carrying out polymerization under a controlled temperature and time, and water scrubbing the obtained outcome yield.

Owner:WUHAN UNIV

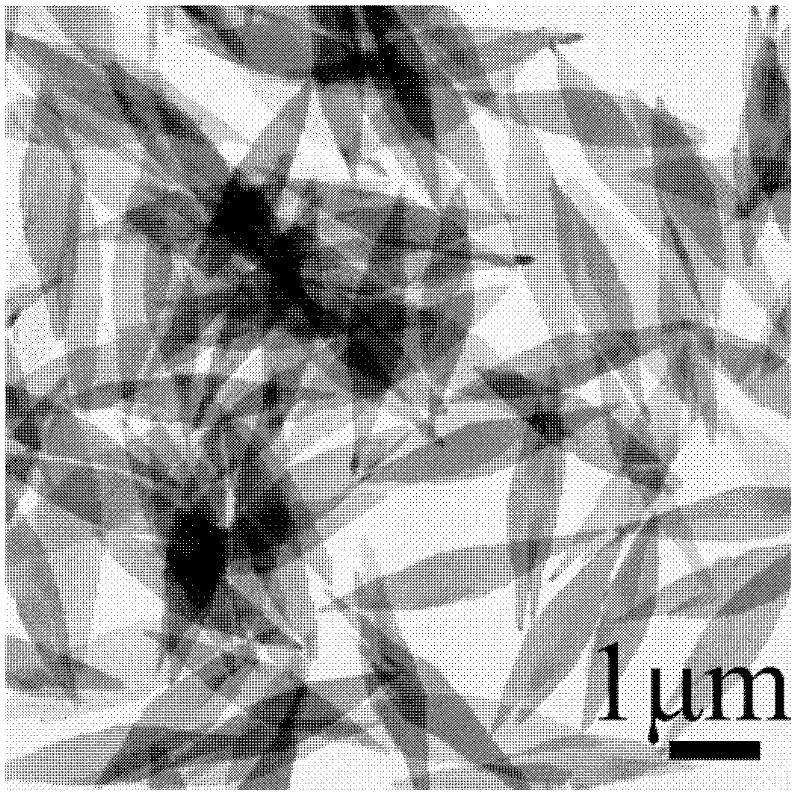

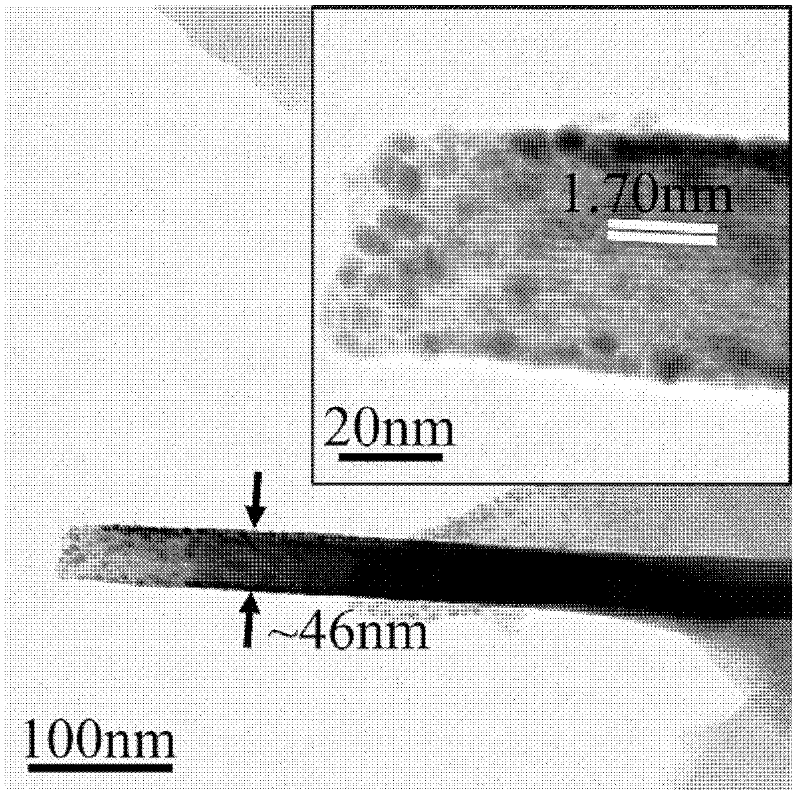

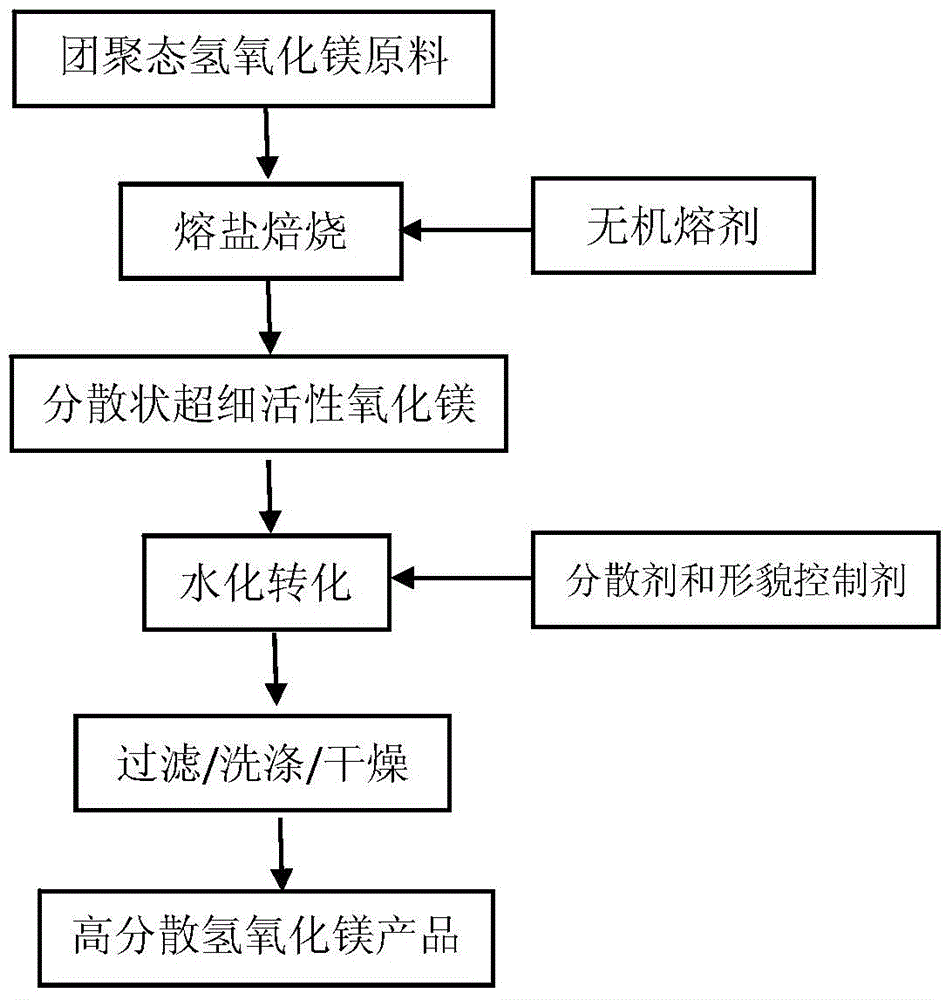

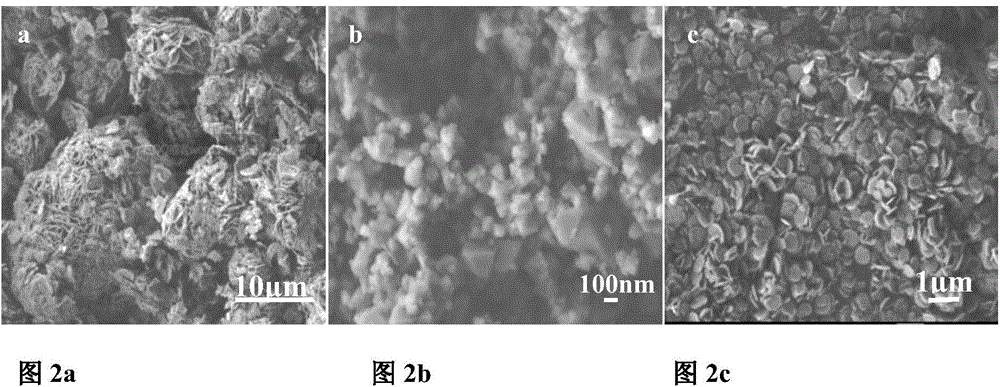

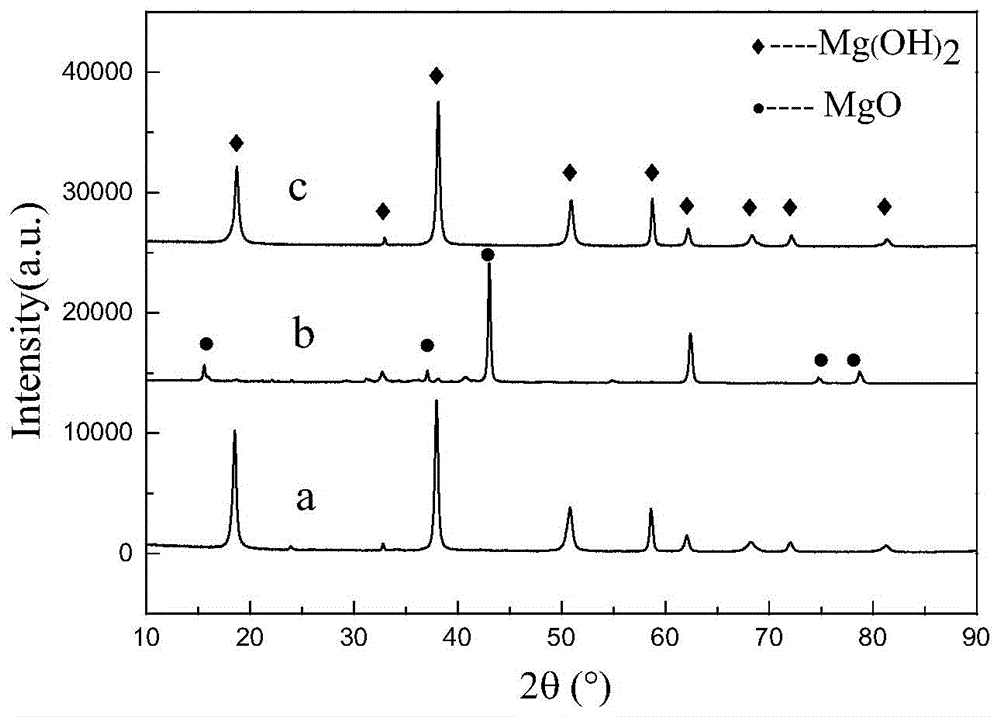

Method for preparing high dispersed magnesium hydroxide from agglomerated state magnesium hydroxide

ActiveCN104609449AImprove product added valueSimple processMagnesium hydroxideInorganic ChemicalWastewater

The invention relates to a method for preparing high dispersed magnesium hydroxide from agglomerated state magnesium hydroxide, and belongs to the technical field of the preparation of inorganic chemical industry materials. According to the method disclosed by the invention, the high dispersed magnesium hydroxide is prepared through the following steps: using agglomerated state magnesium hydroxide as a raw material, wherein the original average particle diameter is 0.1-3 microns, and the average agglomerated particle diameter is 5-50 microns, firstly, mixing the raw material with proper amount of inorganic solvent, and roasting the mixture for 0.5-6 hours at the temperature of 300-700 DEG C, so as to form dispersed superfine active magnesium oxide; then, adding the magnesia to an aqueous solution containing a dispersing agent and a morphological control agent, and performing hydration conversion for 0.5-6 hours at the temperature of 10-100 DEG C so as to obtain the high dispersed magnesium hydroxide of which the original average particle diameter is 0.1-3 microns, the average agglomerated particle diameter is 0.5-4.0 microns, the morphology is regular, and the particle diameters are homogeneous. The method disclosed by the invention is simple in technology, is mild in process, and is high in added value of a product. The magnesium hydroxide prepared by the method disclosed by the invention is regular in morphology and is good in dispersion, can be used as a basic inorganic chemical industry product to be used in the fields of flame resistance, foods, desulphurization, wastewater treatment and the like.

Owner:TSINGHUA UNIV

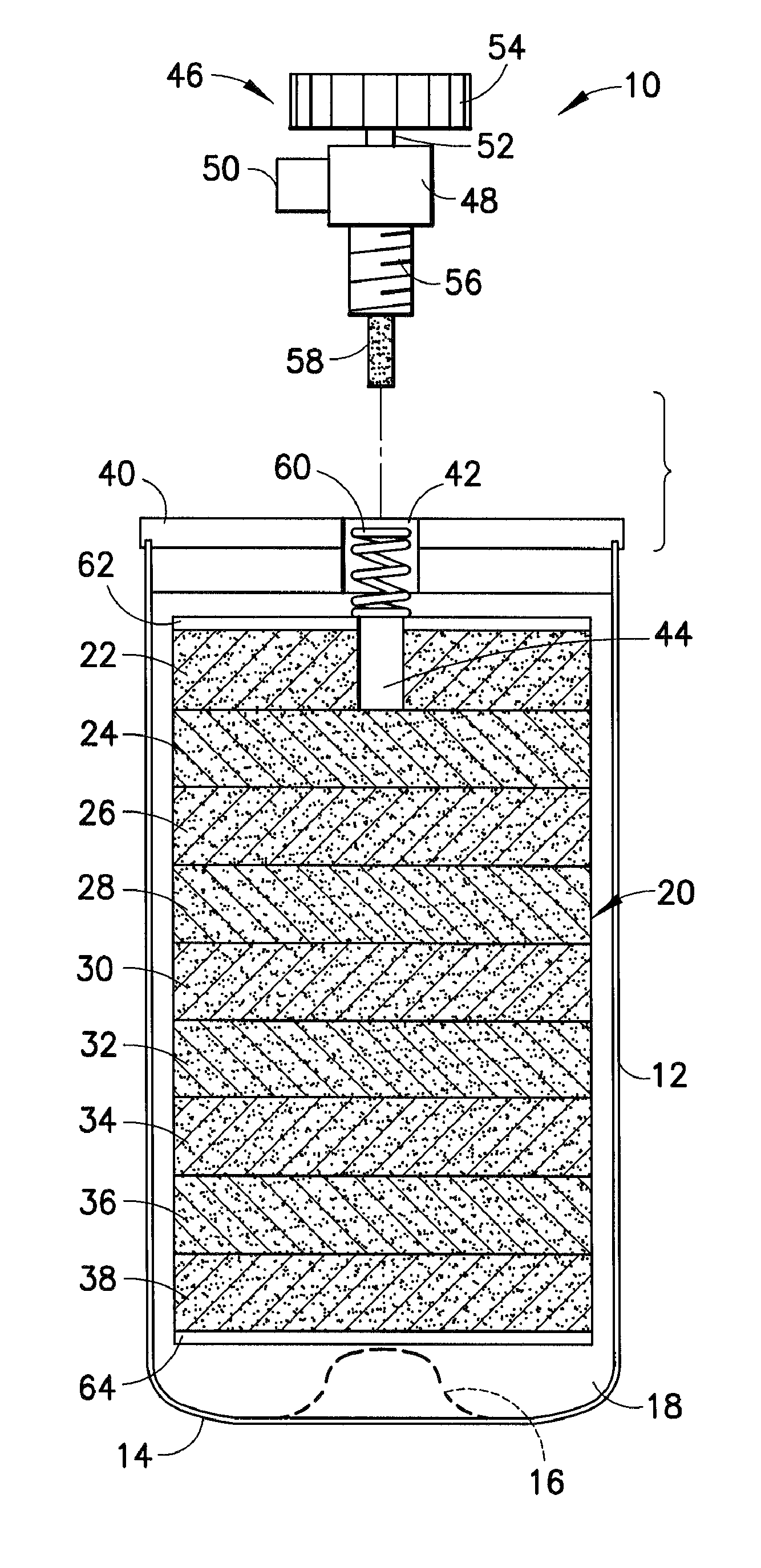

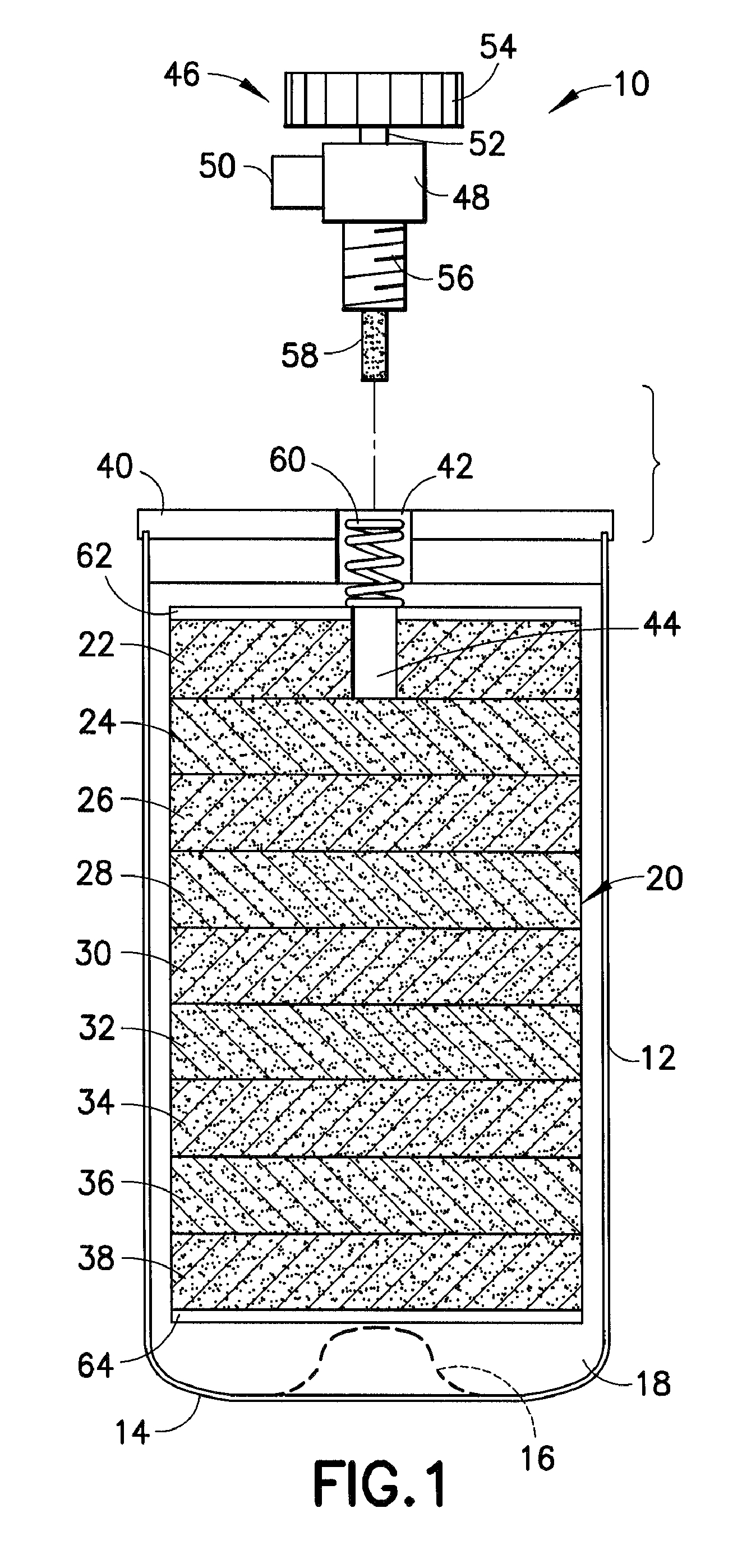

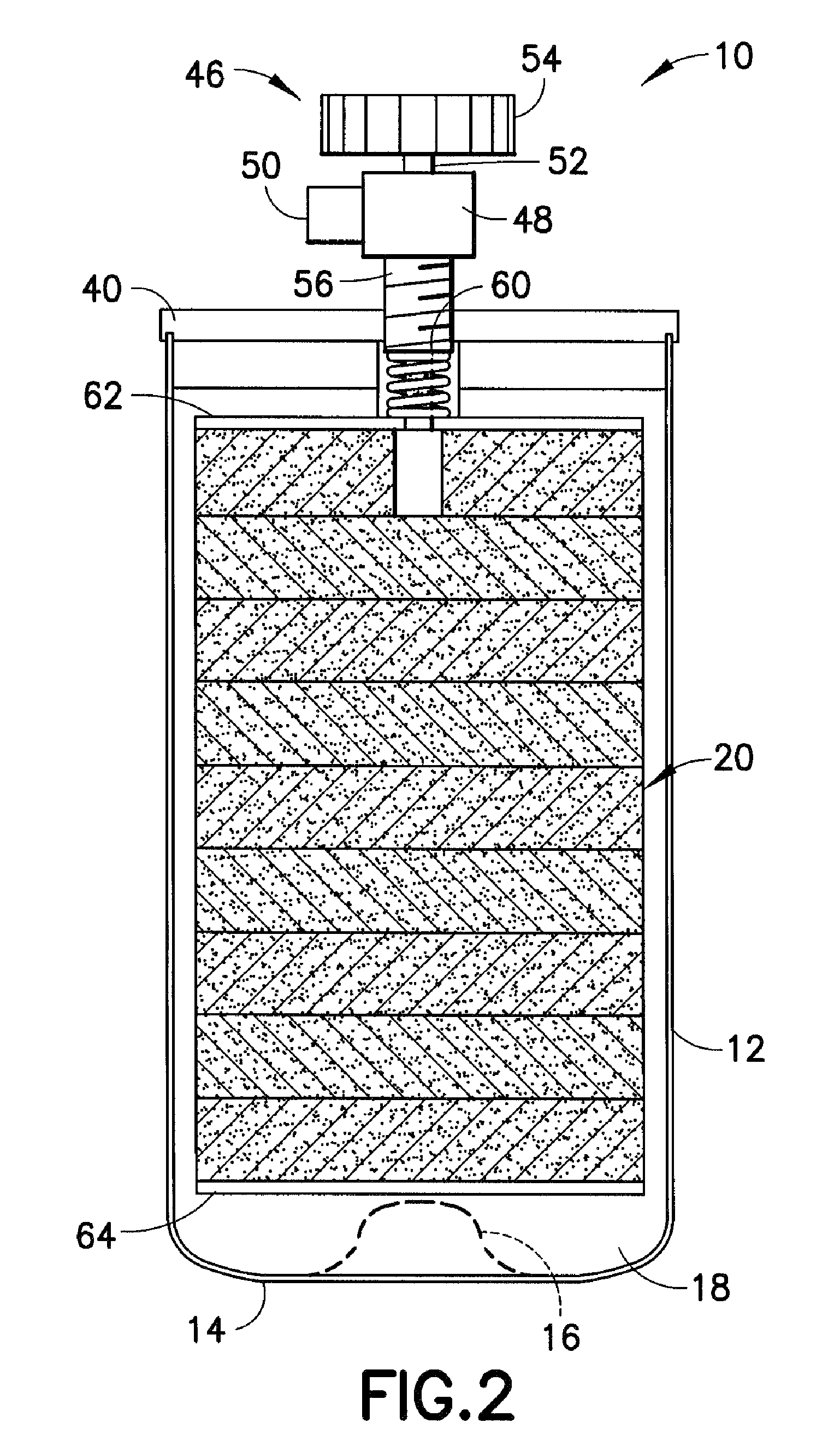

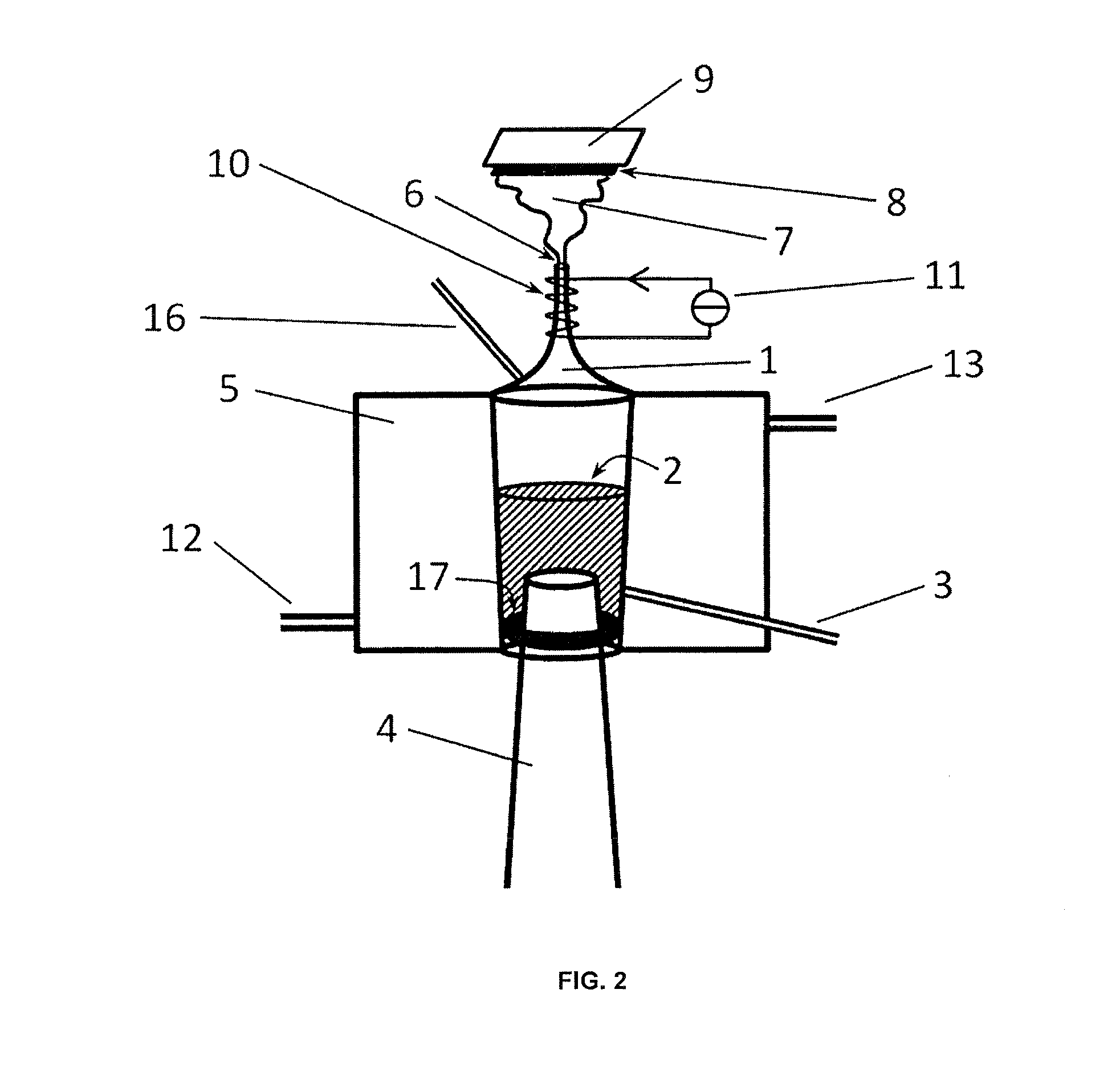

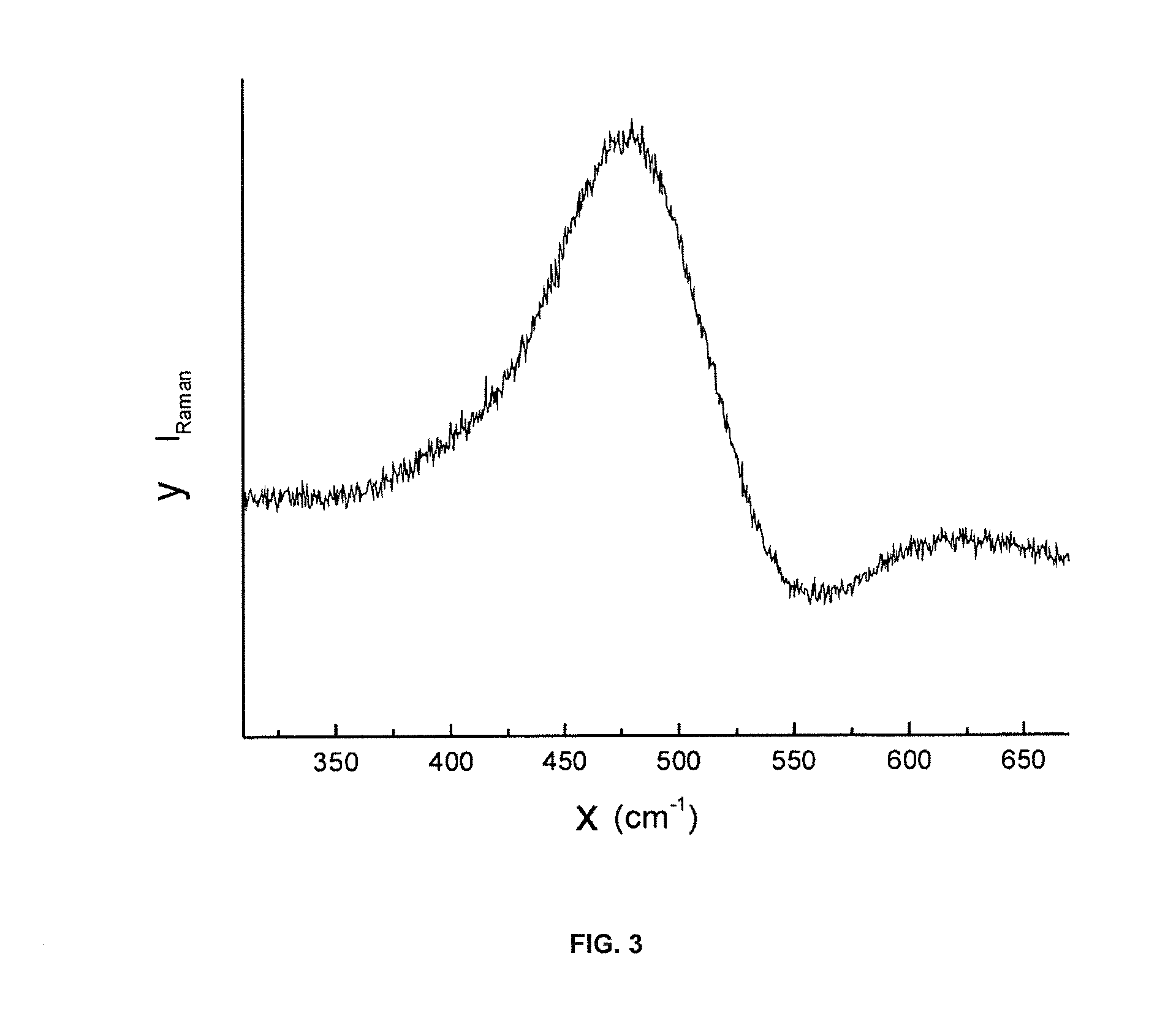

Method and device for polymerizing a composition comprising hydridosilanes and subsequently using the polymers to produce silicon-containing layers

ActiveUS20160297997A1Liquid/solution decomposition chemical coatingSemiconductor devicesNoble gasCavitation

A method for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising the following steps: a) providing a substrate; b) providing a composition including at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or including at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or one branched hydridosilane of the general formula SinH2n+2, where n≧3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≧3; c) polymerizing the composition from step b) by way of acoustic cavitation; and d) coating the surface of the substrate with reaction products from step c). A device for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising at least one reaction vessel (1) containing a composition that includes at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or branched hydridosilane of the general formula SinH2n+2, where n≧3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≧3, and / or containing the abovementioned hydridosilane solution or the pure liquid hydridosilane, to which at least monosilane and / or disilane and / or boron containing dopant and / or phosphorus containing dopant and / or a noble gas from the group Ar, He and / or nanoparticles and / or a polymerization initiator and / or a catalyst and / or surface tension modifying agents can be added, and an ultrasound source and / or a sound transducer (4) for generating acoustic cavitation and / or capillary waves, wherein the reaction vessel (1) has at least one closable opening (6), the substrate (8) to be coated is disposed opposite the opening (6), and the substrate (8) comprises a heating source (9) on the surface that faces away from the coating surface.

Owner:FORSCHUNGSZENTRUM JILICH GMBH

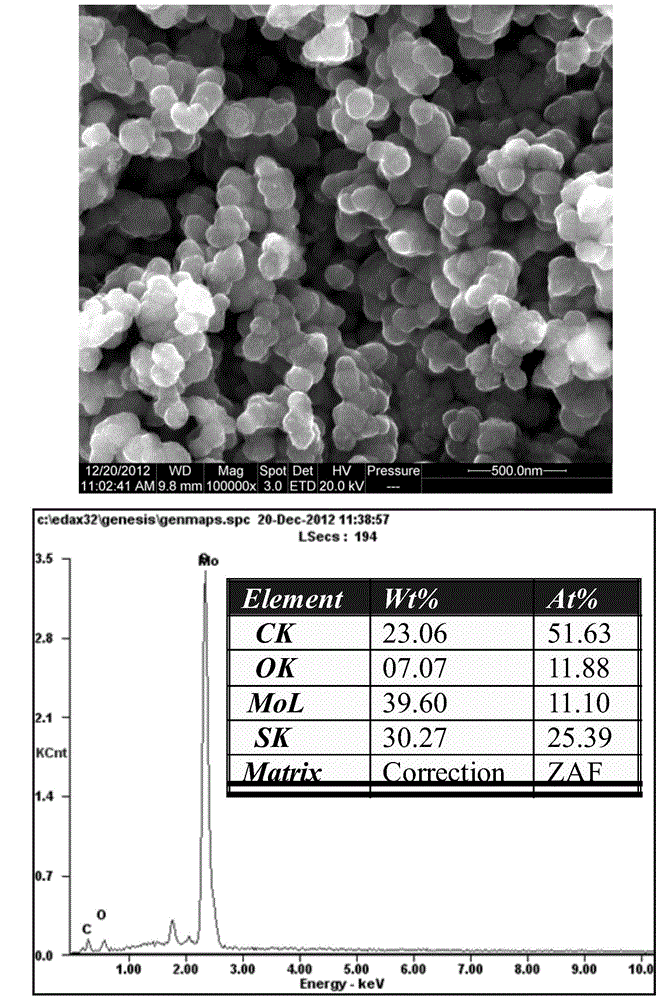

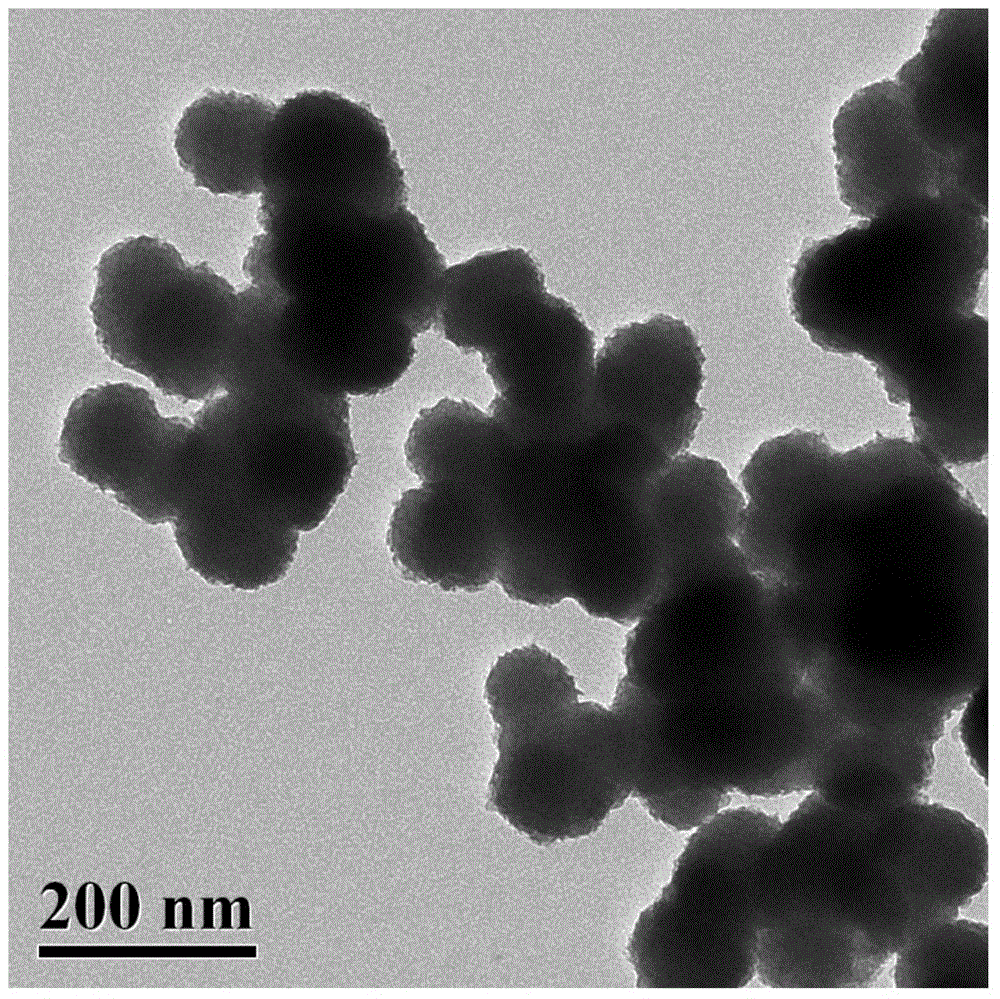

Highly dispersed nano molybdenum disulfide catalyst synthetic method

InactiveCN104689836AHigh sphericityUniform sizePhysical/chemical process catalystsHydrazine compoundNanoparticle

The invention discloses a highly dispersed nano molybdenum disulfide catalyst synthetic method, homemade ammonium tetrathiomolybdate is used as a raw material, hydrazine hydrate is used as a reducing agent for solvent thermal direct preparation of a highly dispersed nano molybdenum disulfide catalyst by use of solvents of different viscosity in the solvent with special proportion, and the highly dispersed nano molybdenum disulfide catalyst has good dispersion in both organic and inorganic solvents. The molybdenum disulfide agglomeration can be inhibited by use of solvent viscosity in the solvent thermal synthetic process, so that molybdenum disulfide nanoparticles with good dispersion and uniform size can be produced. The highly dispersed nano molybdenum disulfide catalyst synthetic method has the advantages of being simple, low in cost, short in synthesis time and high in application value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

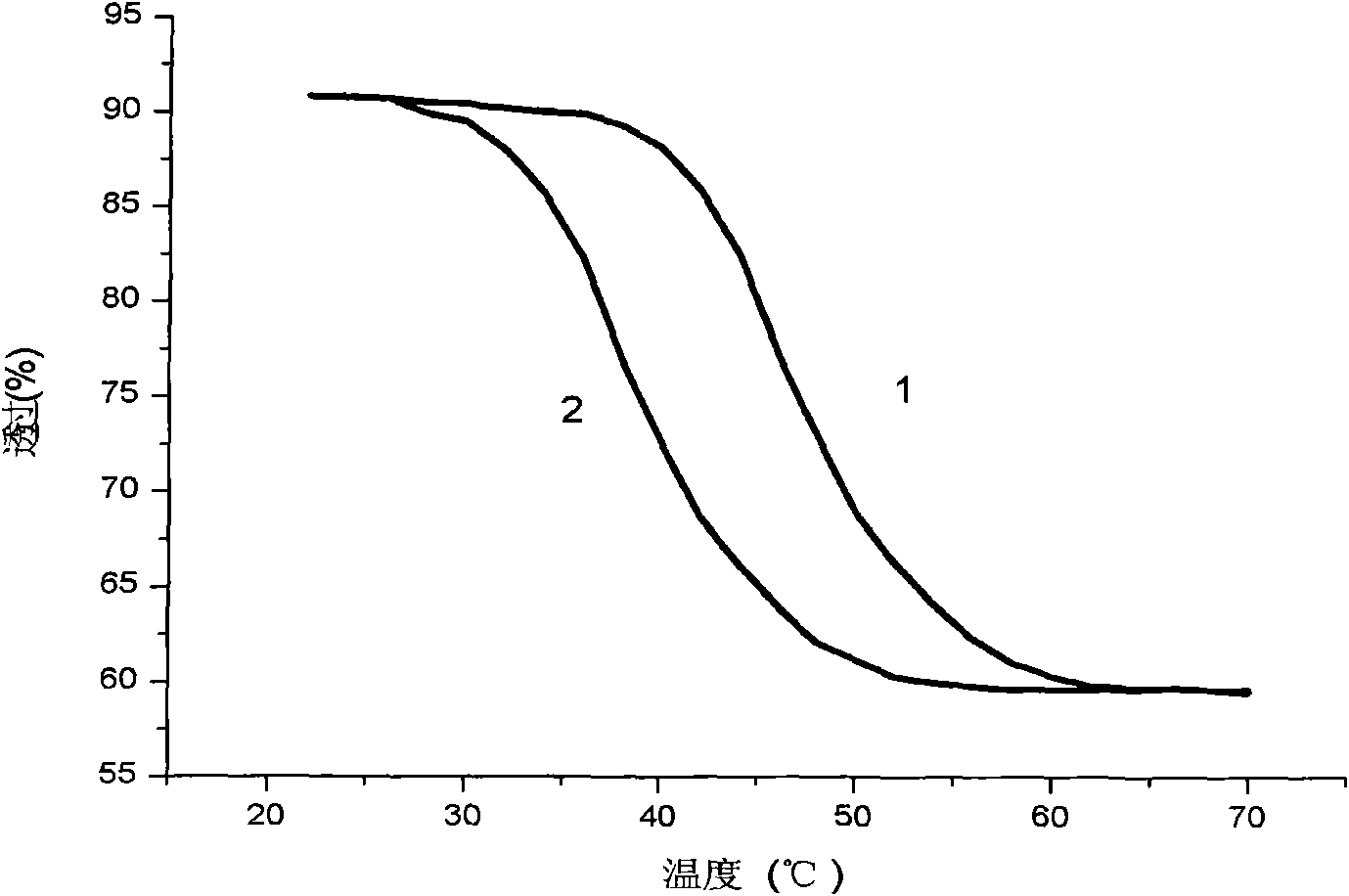

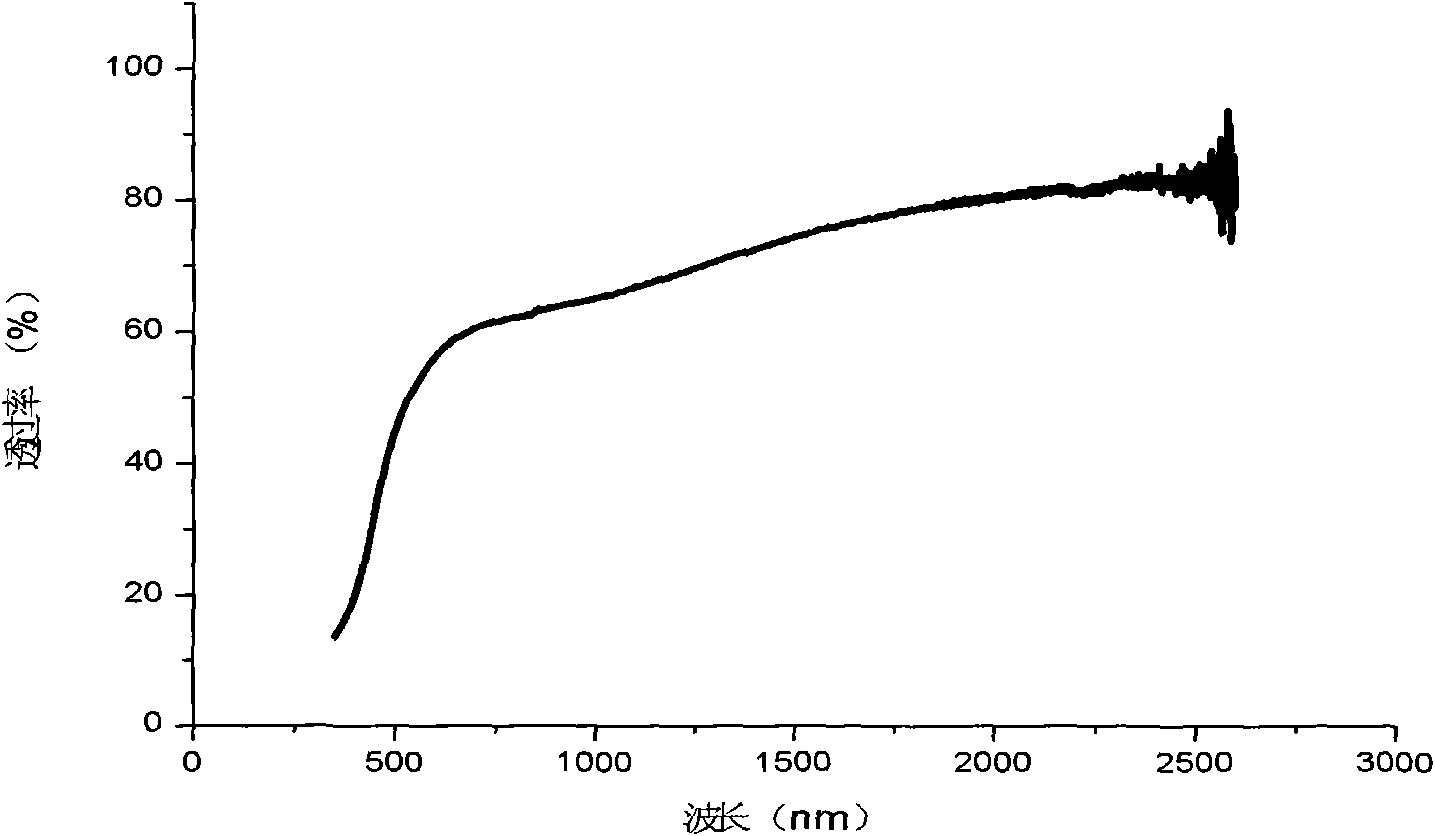

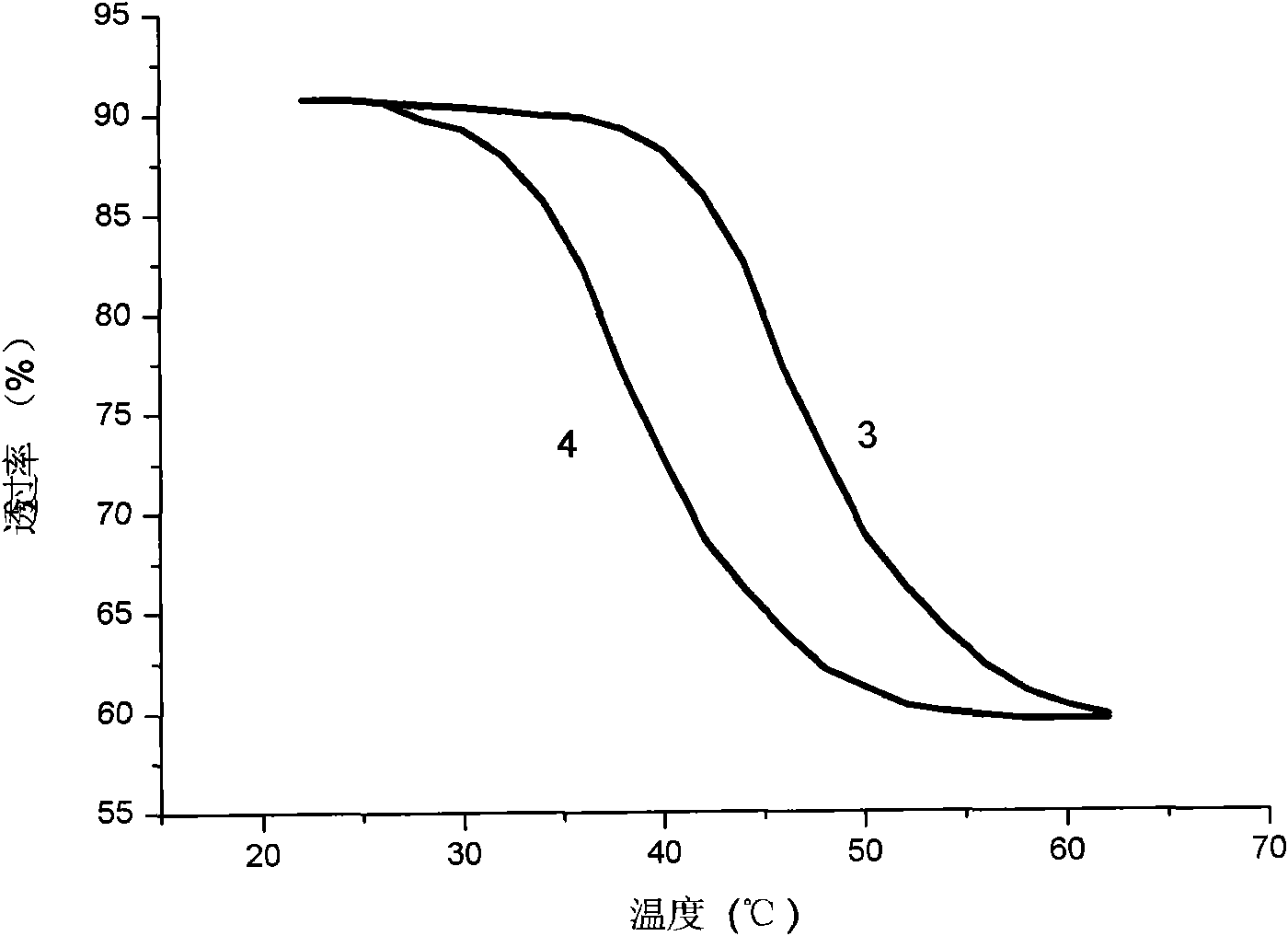

Vanadium-based multiple coating liquid, composite film and preparation method and application thereof

ActiveCN101786798ALower phase transition temperatureSimple processCoatingsVanadium dioxideComposite film

The invention relates to a vanadium-based multiple coating liquid, a composite film and a preparation method and an application thereof, belonging to the field of film materials. In the invention, a vanadium-contained compound is used as a raw material. The preparation method comprises the following steps of: dissolving the vanadium-contained compound into an organic solvent or an inorganic solvent to be processed; then, adding a solution containing other element ions or low polymers to obtain a vanadium-based multiple coating liquid; coating the vanadium-based multiple coating liquid on a flexible or rigid substrate by adopting a common coating method; and thermally processing the substrate in an inert or reducing atmosphere to obtain a vanadium-based composite film. The invention can selectively modulate wavelength and transformation temperature and be applied to the building energy-saving field. Compared with a traditional process, the vanadium dioxide film prepared by the method not only has overhigh visible light transmission and adjustable transformation temperature, but also has the functions of preventing ultraviolet rays, sterilizing, solely cleaning, and the like by compounding other compounds.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Calcitriol solid lipidic dispersion and preparation method thereof

ActiveCN102973528AImprove stabilityImprove drug stabilityOrganic active ingredientsSkeletal disorderVitamin E AcetatePolyethylene glycol

The invention discloses a calcitriol solid lipidic dispersion and a preparation method thereof. Raw materials of the calcitriol solid lipidic dispersion comprise calcitriol, one or more lipidic carriers and solid carriers, wherein a mass ratio of calcitriol to the one or more lipidic carriers is 1: (90-200000); a mass ratio of the one or more lipidic carriers to the solid carriers is (1-2): 1; and the one or more lipidic carriers are selected from caprylic triglyceride, capric triglyceride, caprylic / capric triglyceride, laurin, caprylic dilaurin, capric dilaurin, vitamin E, vitamin E succinate, vitamin E polyethylene glycol succinate and vitamin E acetate. The calcitriol solid lipidic dispersion has high drug stability and can keep a constant treatment level. The preparation method does not adopt an inorganic solvent, is suitable for industrial production and is conducive to storage and taking. An experiment proves that the calcitriol solid lipidic dispersion has good stability and dispersion uniformity satisfying requirements.

Owner:SUN YAT SEN UNIV

Cleaning method for optical elements after precise polishing

InactiveCN105251745AGood removal effectHigh clean surfaceFlexible article cleaningCleaning using liquidsCleaning methodsEngineering

The invention relates to a cleaning method for optical elements after precise polishing. The method is especially applied to cleaning K9 glass and fused quartz elements processed through polishing platters by classical methods. The cleaning method includes the specific steps that the optical elements taken down from the platters are soaked in gasoline for over 30 minutes, soaked in carbon tetrachloride for two hours, subjected to ultra-sound treatment for 4-10 minutes in the ultrasound frequency of 40 kHz and 120 kHz successively and washed with 35-45 DEG C deionized water for 30-45 seconds; then the elements are subjected to ultrasound cleaning with an ethanol solution for 4-10 minutes and washed with the 35-45 DEG C deionized water for 30-45 seconds; finally, the elements are subjected to ultrasound cleaning with pure water for 4-10 minutes; and the elements are dried and the required products are obtained. The soaking and ultrasound cleaning methods are combined; organic solvents, inorganic solvents and the deionized water are used as media; the efficiency for cleaning up organic contaminants and polishing powder residual particles on the surfaces of the precisely polished elements is high; acidic and alkaline solutions are not involved in the cleaning process, chemical and physical damages to the surfaces of the elements are avoided, and the damage threshold value under ultraviolet laser irradiation is improved.

Owner:TONGJI UNIV

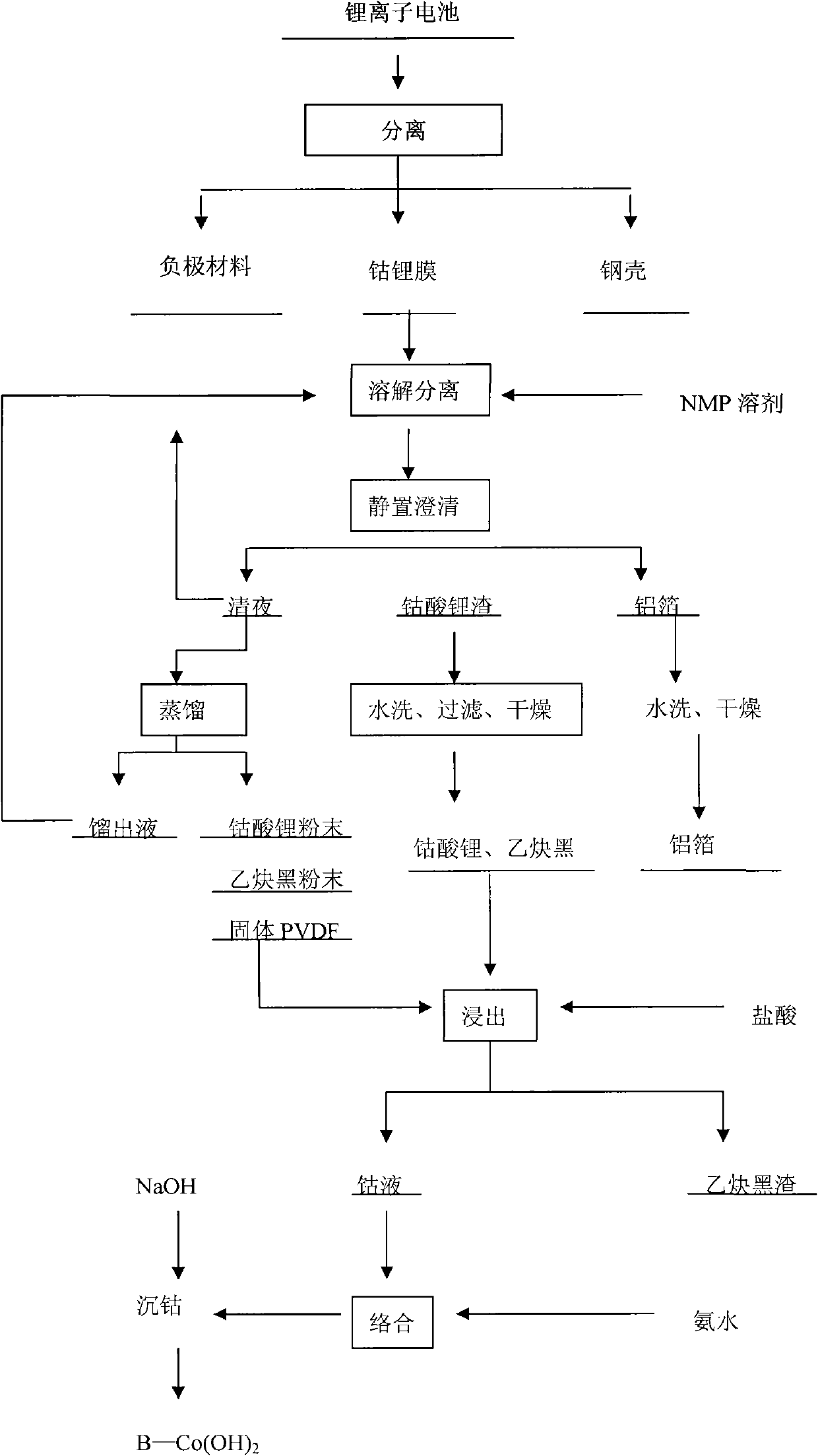

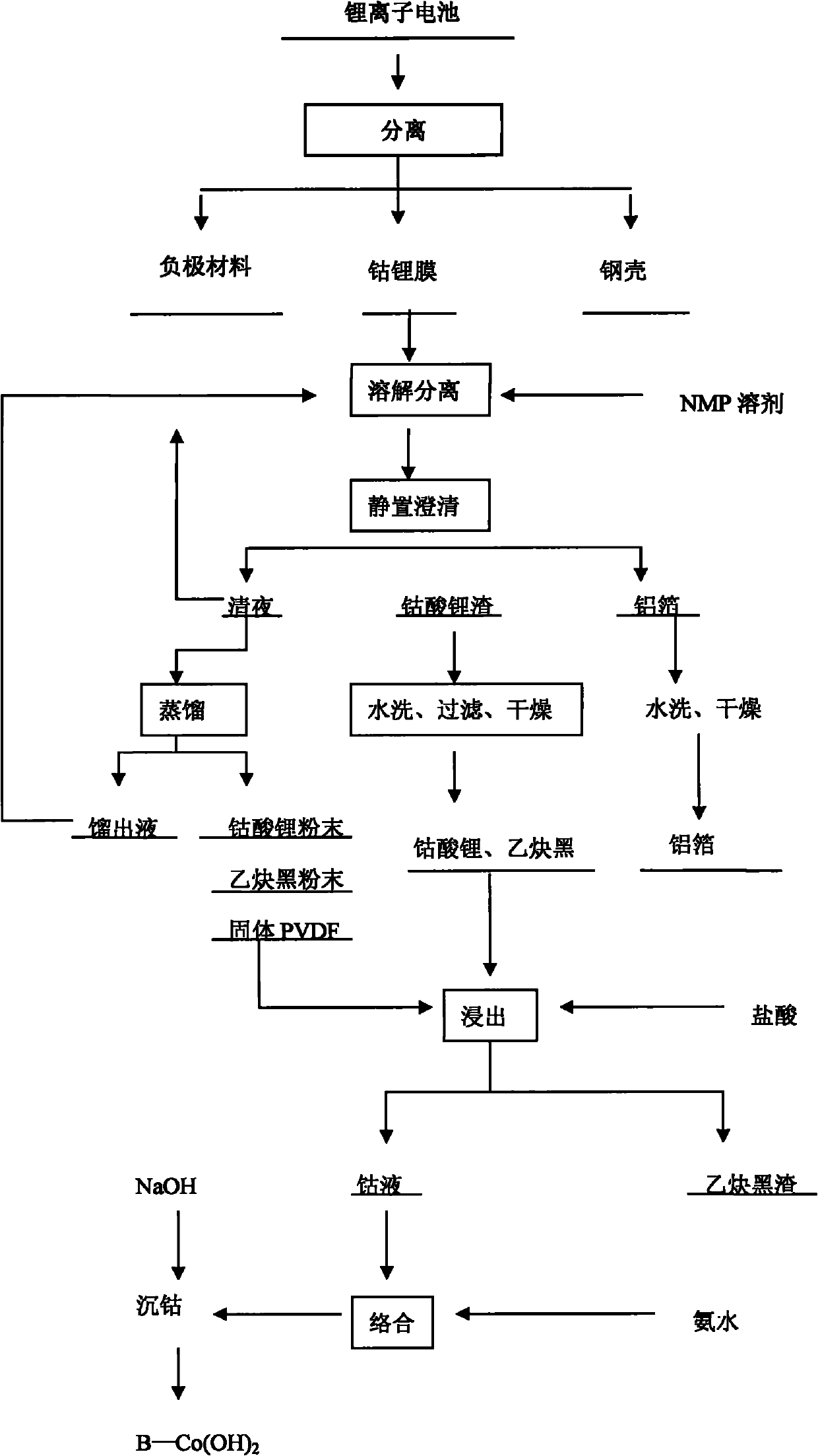

Process for treating wasted lithium cells

InactiveCN102005625ASimple recycling processIncrease recycled productsWaste accumulators reclaimingBattery recyclingSlagCobalt

The invention discloses a process for treating wasted lithium cells, comprising the following steps of: (1) separating recycled wasted cells, wherein negative electrode materials and steel shells are directly recycled and packed to be used raw materials for sale; (2) dissolving cobalt-lithium membranes obtained from separation with an NMP (N-methyl-2-pyrrolidone) solvent, clarifying, redissolving clear liquid, and washing separated aluminum foils with water and drying for sale; (3) carrying out water washing, filtering, drying and leaching on lithium cobaltite slag to obtain a cobalt solution; and (4) further complexing and precipitating the cobalt solution to obtain B-Co(OH)2. The invention has the advantages that the inorganic solvent is adopted for dissolving a binder PVDF (Polyvinylidene Fluoride) of the lithium cobaltite to enable the lithium cobaltite to fall off from the aluminum foil, and the elementary aluminum foils are directly recycled without the performing of cobalt-aluminum separation in the traditional lithium cell recycling process, therefore, the whole recycling process of wasted lithium cells is simplified and recycled products are increased.

Owner:苏州群瑞环保科技有限公司

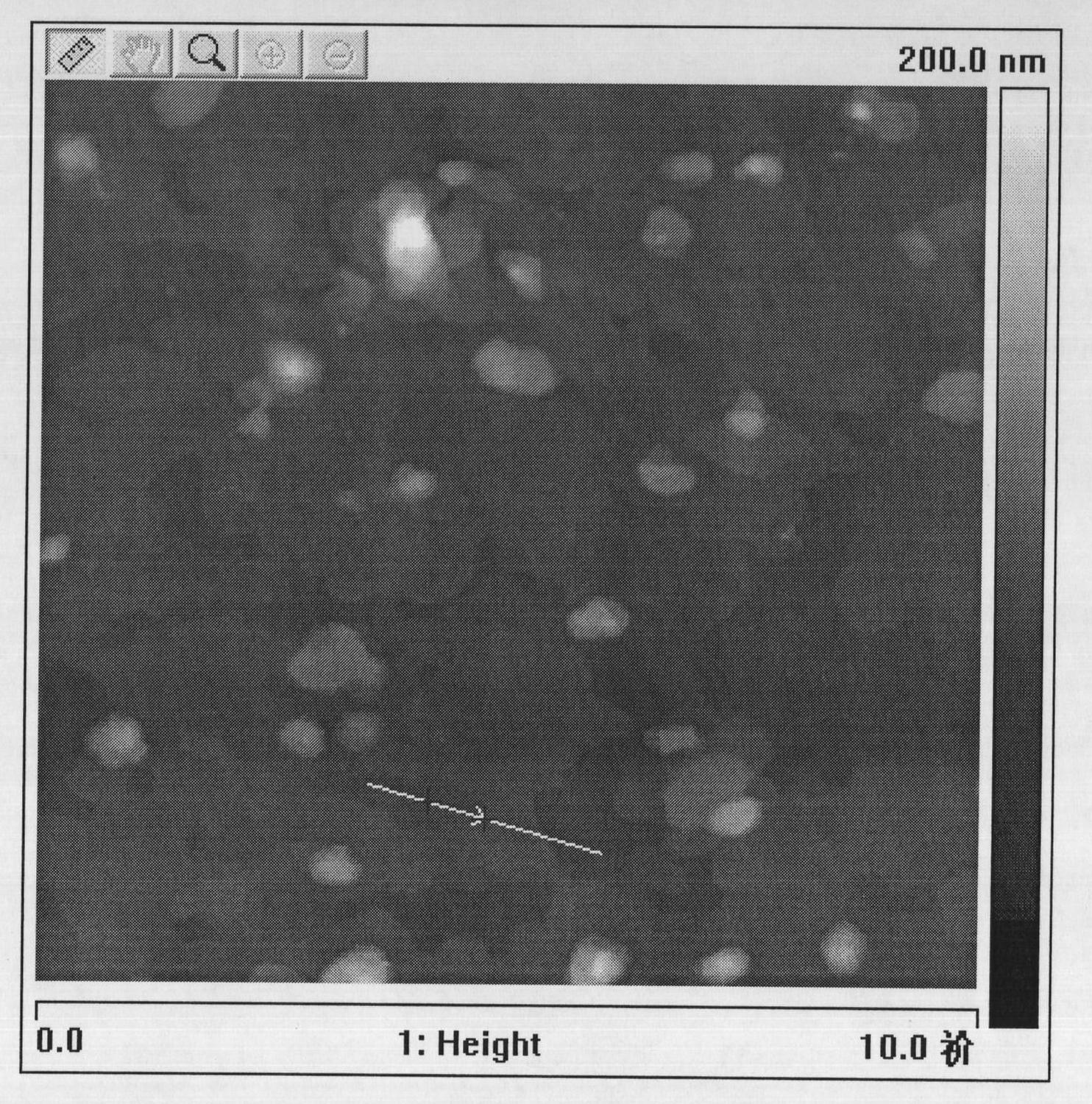

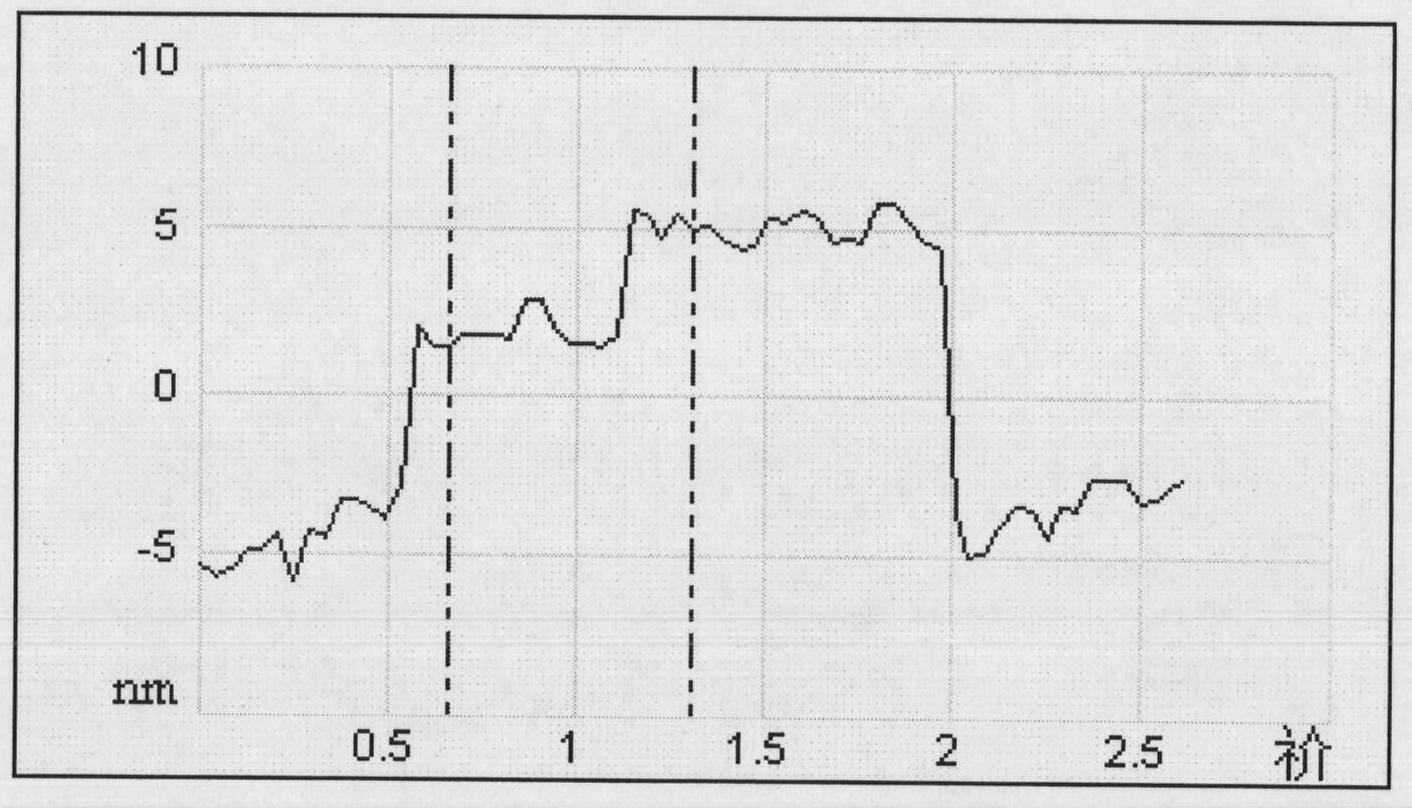

Transparent anti-fog film based on one or serveral graphene layers

InactiveCN102070999ASolve weak and hard to disperse problemsOther chemical processesLow voltageOptical transmittance

A transparent anti-fog film based on one or serveral graphene layers belongs to the technical field of surface treatment. The anti-fog film is used in the fields of surface anti-fogging and self-cleaning of the transparent material. The preparation method of the anti-fog film uses one or serveral layers of graphene as functional material and comprises the following steps: dispersing graphene in water or inorganic solvent evenly through stirring, supersonic treatment and other methods, wherein the concentration of the solution is 0.001-1mg / ml; evenly coating the solution with graphene on the surface of a material through hand painting, soaking, spin coating, spraying or other conduction methods; drying naturally or heating to form a continuous graphene conductive network; and preparing electrodes, and then fast heating under an applied voltage to obtain the anti-fog film. Microscopic analysis shows that one or serveral layers of graphene can be evenly dispersed on the surface of the material; compared with the other materials, the conductive network can be formed by using a small amount of graphene; after several coatings, the thickness of the anti-fog film is controlled to no more than 10nm; the light transmittance is more than 90%; and the anti-fog film is combined with the base well and can realize good anti-fogging effect under a lower voltage which is 1-30V.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com