Method for preparing ionic liquid functionalized graphene material

A technology of ionic liquid and graphene, which is applied in the field of preparation of graphene materials, can solve problems such as poor solubility, achieve good dispersion, and the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

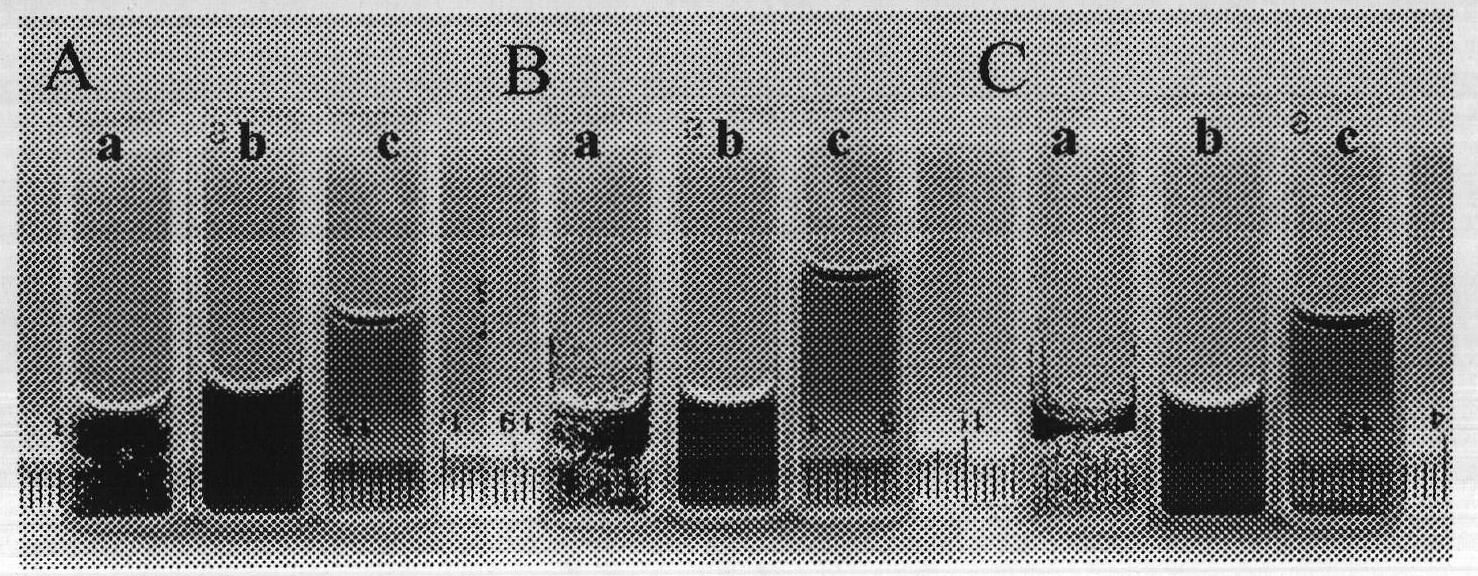

Image

Examples

Embodiment 1

[0013] According to the ratio of graphene oxide mass mg: secondary water volume ml: ionic liquid mass g: ionic liquid mass g ratio of 1: 4: 0.5, 5.0 mg of graphene oxide is dispersed in 20 ml of secondary water, 90 ° C ultrasonic Disperse for 1 hour, and centrifuge at 5000 rpm to remove undispersed oxides to obtain a yellow solution. Weighed 2.5 mg of 1-(3-aminopropyl)-3-methylimidazole bromide and dissolved it in the above mixture, and subjected to ultrasonic reaction at 20° C. for 10 hours to obtain a black dispersion. The above dispersion was centrifuged at 6000 rpm, and the centrifuged solid was washed with secondary water until the filtrate was neutral, and then vacuum-dried at 60° C. overnight to obtain an ionic liquid-functionalized graphene material.

Embodiment 2

[0015] According to the ratio of graphene oxide mass mg: secondary water volume ml: ionic liquid mass g: 1: 4: 1, 5.0 mg graphene oxide was dispersed in 20 ml secondary water, and ultrasonically dispersed at 80 ° C for 2 hours. Undispersed oxides were removed by centrifugation at 5000 rpm to obtain a yellow solution. 5 mg of 1-(3-aminopropyl)-3-methylimidazole bromide was weighed and dissolved in the above mixture, and subjected to ultrasonic reaction at 30° C. for 10 hours to obtain a black dispersion. The above dispersion was centrifuged at 7000 rpm, and the centrifuged solid was washed with secondary water until the filtrate was neutral, and then vacuum-dried at 60° C. overnight to obtain an ionic liquid-functionalized graphene material.

Embodiment 3

[0017] According to graphene oxide mass mg: secondary water volume ml: ionic liquid mass g: the proportioning ratio is 1:4:2, 5.0mg graphene oxide is dispersed in 20ml secondary water, 70 ℃ ultrasonic dispersion 4 hours, Undispersed oxides were removed by centrifugation at 5000 rpm to obtain a yellow solution. 10 mg of 1-(3-aminopropyl)-3-methylimidazole bromide was weighed and dissolved in the above mixture, and subjected to ultrasonic reaction at 40° C. for 9 hours to obtain a black dispersion. The above dispersion was centrifuged at 8000 rpm, and the centrifuged solid was washed with secondary water until the filtrate was neutral, and then vacuum-dried at 60° C. overnight to obtain an ionic liquid-functionalized graphene material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com