Method for preparing waterproof poromeric sterilizing polyurethane elastomer

A polyurethane elastomer, waterproof and breathable technology, which is applied in the field of polyurethane elastomer preparation, can solve the problems of high surface adhesion, poor mechanical properties, difficult demoulding and use, etc., and achieves mature technology, good mobility, and rapid sterilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、3

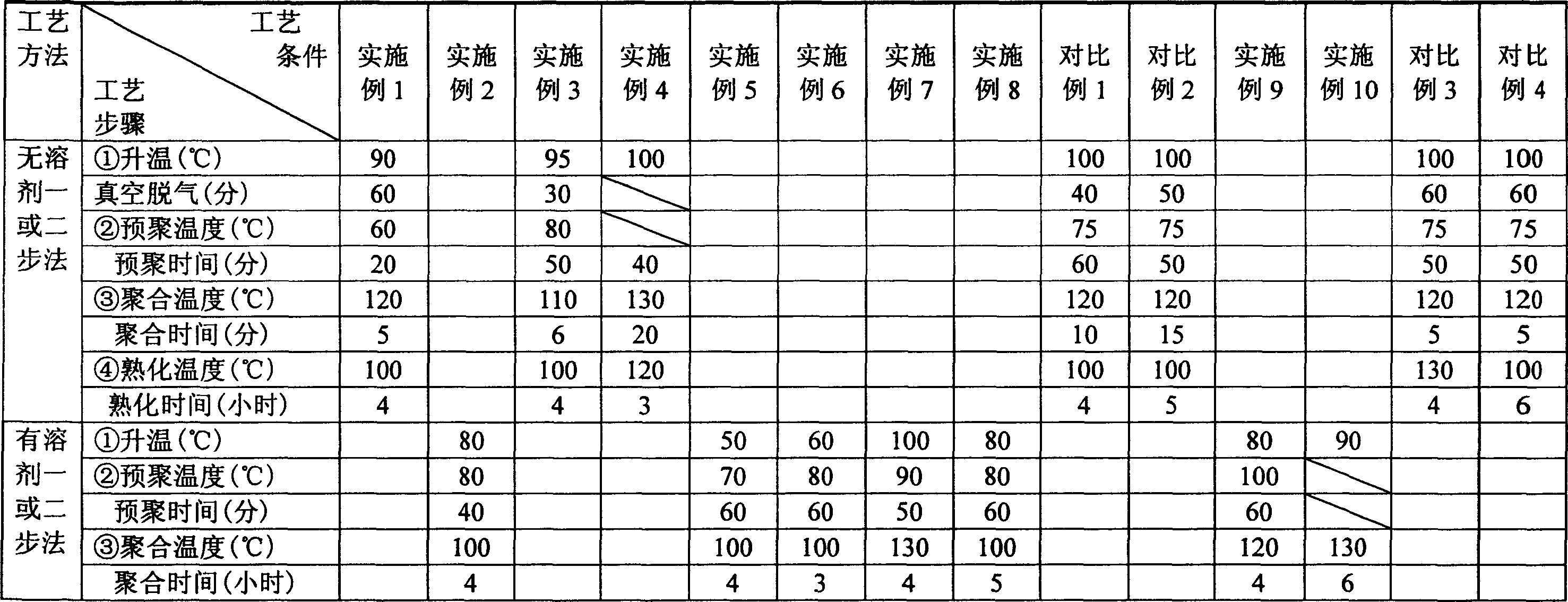

[0048] What these two examples adopted is solvent-free two-step synthesis technique. Add polymer diols with corresponding molecular weights into a reactor equipped with a stirrer, thermometer and nitrogen protection, heat up to the corresponding temperature, and then vacuum degassing for a certain period of time; after cooling down to the corresponding temperature, add diisocyanate and prepolymerize React for a certain period of time; then add chain extender and bactericidal end-capping agent, stir rapidly, and heat up to the corresponding temperature for polymerization reaction for a certain period of time; finally pour it out into the preheated polytetrafluoroethylene tray and mature at the corresponding temperature After a certain period of time, a white polyurethane elastomer can be obtained. See Table 1 for specific component varieties, proportions and process conditions.

Embodiment 2、5~9

[0050] What this group of embodiment adopts is to have solvent two-step synthesis technique. Add polymer diols with corresponding molecular weights into a reaction kettle equipped with a stirrer, a thermometer, nitrogen protection and a solvent, and raise the temperature to the corresponding temperature; then add diisocyanate that has been dissolved in the solvent, stir, mix and Prepolymerize at high temperature for a certain period of time; then add the chain extender and end-capping agent that have been dissolved in the solvent, and heat up to the corresponding temperature for polymerization reaction for a certain period of time; finally, pour the reactant into the mixed solution of methanol and water for precipitation, and obtain after drying White elastomer. See Table 1 for specific component varieties, proportions and process conditions.

Embodiment 4

[0052] In this example, a solvent-free one-step synthesis process was adopted. Add the corresponding molecular weight polymer diol, chain extender and bactericidal end-capping agent into the reaction kettle equipped with agitator, thermometer and nitrogen protection, stir and mix, and heat up to the corresponding temperature, vacuum degassing for a certain period of time ; Then add diisocyanate, polymerize for a certain period of time; then pour the reaction mixture into a preheated polytetrafluoroethylene tray, and ripen for a certain period of time at the corresponding temperature to obtain a white polyurethane elastomer. See Table 1 for specific component varieties, proportions and process conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com