Preparation method and application of antibacterial cellulose ester

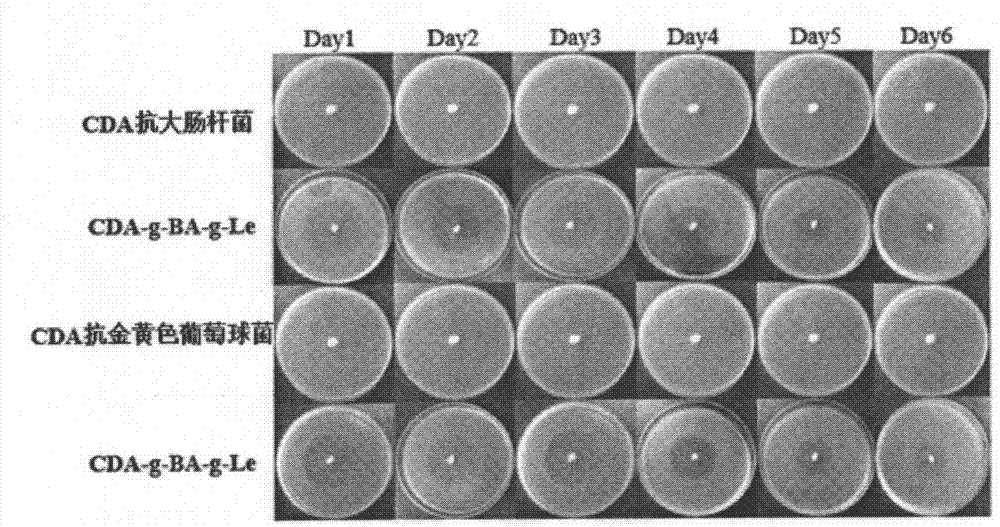

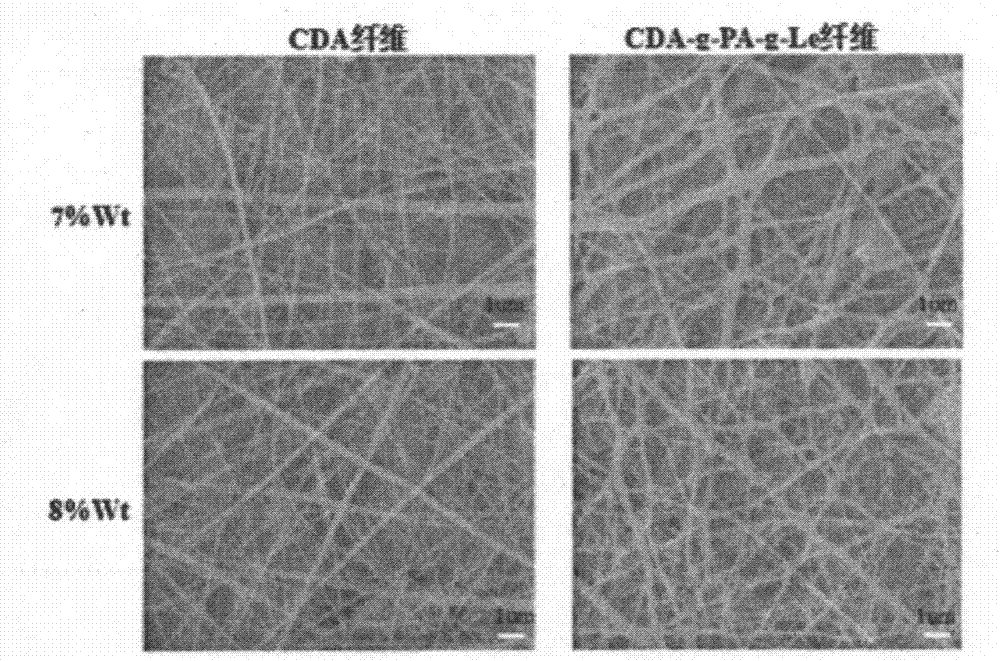

An antibacterial fiber and cellulose technology, which is used in medical science, bandages, absorbent pads, etc., can solve the problems of uneven separation effect of membranes, samples cannot enter the separation membrane, and the separation effect cannot be achieved, and achieve lasting and stable antibacterial performance, The effect of good antibacterial effect with little change in decomposition temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of preparation method of antibacterial cellulose ester:

[0051] (1) Take 1 g of cellulose diacetate (CDA), 0.36 g of phthalic anhydride in an equimolar amount, and 3.38 mL of catalyst triethylamine. The molar amount of the catalyst is 10 times the hydroxyl content of cellulose diacetate. First, dissolve 1g of cellulose diacetate in a 100mL three-necked round-bottomed flask filled with 20mL of acetone solution, put it on a magnetic stirrer, heat and stir at 60°C for about 2h, and raise the temperature to 65°C. After the cellulose acetate was completely dissolved, 0.36 g of phthalic anhydride and 3.38 mL of catalyst triethylamine were added to react for 24 hours. After the reaction, the reaction solution was slowly dropped into 100mL of absolute ethanol to precipitate and wash 3 times, and the esterified product was obtained by suction filtration, and the obtained esterified product was vacuum-dried at 40°C for 8 hours to obtain cellulose diacetate and acid anhydr...

Embodiment 2

[0057] A kind of preparation method of antibacterial cellulose ester:

[0058] (1) Weigh 1 g of purified cellulose diacetate, 0.25 g of equimolar amount of succinic anhydride, and 3.38 mL of catalyst triethylamine. The molar amount of the catalyst is 10 times the hydroxyl content of cellulose diacetate. First, dissolve 1g of cellulose diacetate in a 100mL three-necked round-bottomed flask filled with 20mL of acetone solution, heat and stir for about 2 hours at 60°C on a magnetic stirrer, and raise the temperature to 65°C. After the cellulose was completely dissolved, 1.98 g of succinic anhydride and 3.38 mL of catalyst triethylamine were added to react for 24 hours. After the reaction, the reaction solution was slowly dropped into 100mL of absolute ethanol to precipitate and wash 3 times, and the esterified product was obtained by suction filtration, and the obtained esterified product was vacuum-dried at 40°C for 8 hours to obtain cellulose diacetate and Succinic anhydride g...

Embodiment 3

[0064] A kind of preparation method of antibacterial cellulose ester:

[0065] (1) Take 1 g of cellulose diacetate (CDA), 1.34 g of stearic anhydride (SA) in equimolar amounts, and 3.38 mL of catalyst triethylamine. Dissolve cellulose diacetate in 20mL of acetone solution, heat and stir on a magnetic stirrer at 60°C, the temperature rises to 65°C, after the cellulose diacetate is completely dissolved, add 1.34g of stearic anhydride, catalyst triethyl Amine 3.38mL, reacted for 10 hours.

[0066] (2) Add 0.1g N-hydroxysuccinimide (NHS), 0.15g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), 0.3g levofloxacin In 10mL DMF solution, activate overnight under ice bath conditions, add 0.13g Boc-EDA to react for 12h, then add 0.1g trifluoroacetic acid to remove Boc, add dropwise 0.3mL triethylamine to adjust pH after 1h, stir for 1h;

[0067] (3) Dissolve 0.3g of the esterified product CDA-g-SA in 10mL of DMF solution, add 0.1g of N-hydroxysuccinimide (NHS), 0.15g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com