Preparation method of breathable and bacteriostatic fabric

A fabric and nitrogen replacement technology, applied in the field of fabrics, can solve the problem that the amount of pure natural extraction cannot meet the market demand, achieve excellent antibacterial effect, solve poor antibacterial effect, and improve hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing mildew-proof polyester high-strength yarn, specifically comprising the following steps:

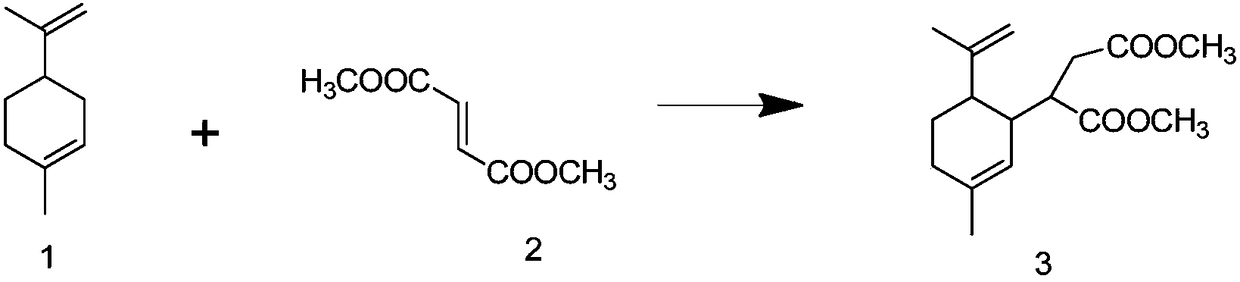

[0047] Synthesis of S1, dipentene-4-methyl succinate 3

[0048]

[0049]Add 120 mol of dipentene 1, 130 mol of methyl succinate 2 and 0.15 mol of catalyst iodine into the autoclave, blow in nitrogen to replace the air in the autoclave, heat up in a closed manner, and raise the temperature to 250 °C at a rate of 15 °C / min. ℃, heat preservation for 1 hour, dipentene-4-methyl succinate 3 was obtained, and the yield was 98.9%;

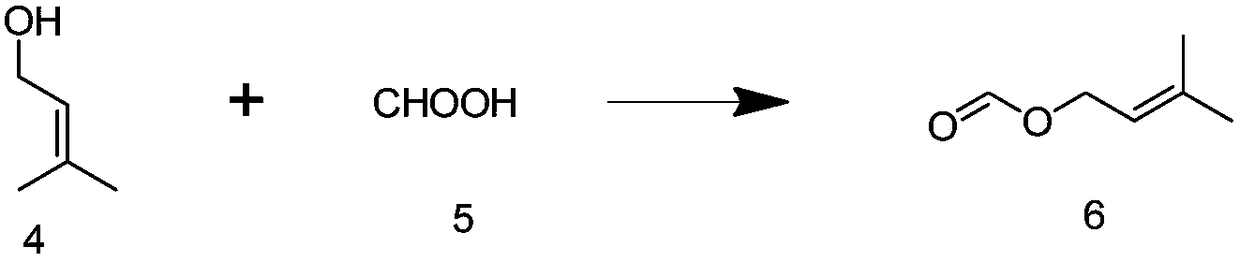

[0050] Synthesis of S2, isopentenyl formate 6

[0051]

[0052] Add 150 mol of prenyl alcohol 4 and 600 mol of formic acid 5 into the reaction flask, stir and react at 35° C. for 4 h to obtain prenyl formic acid ester 6 with a yield of 98.6%;

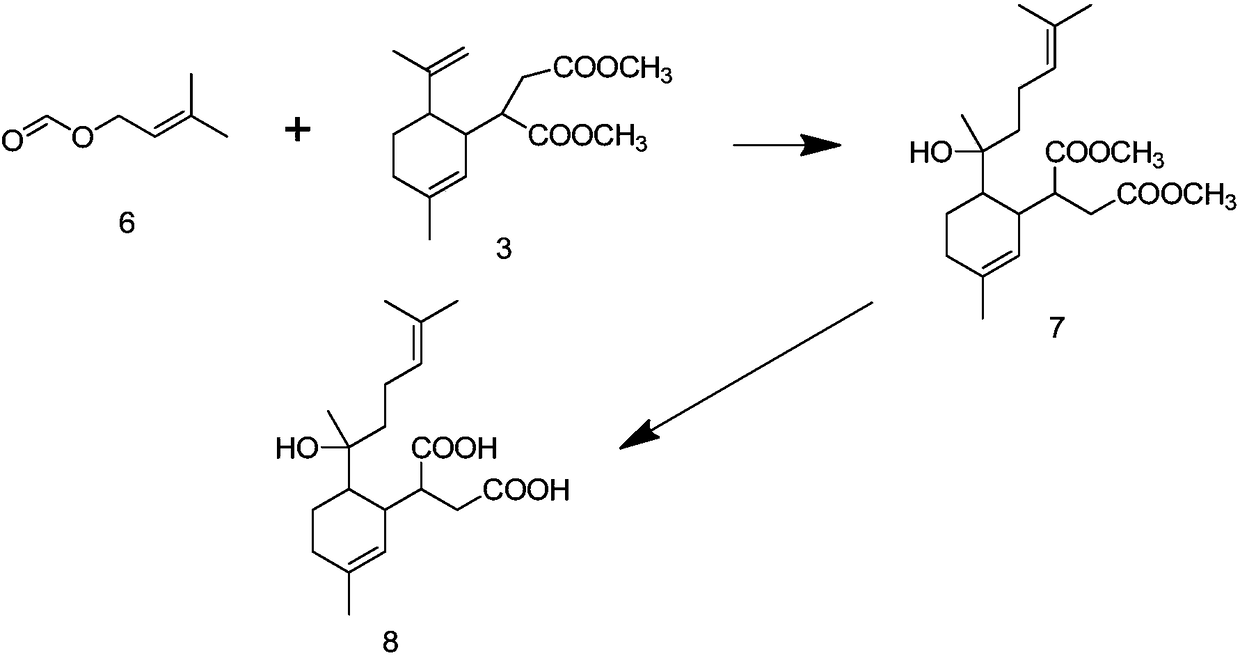

[0053] S3, the synthesis of bisabolol derivative 8

[0054]

[0055] Add dipentene-4-methyl succinate 3 prepared in step S1 to the reaction flask of step S2, add dichloromethane and pho...

Embodiment 2

[0067] A method for preparing mildew-proof polyester high-strength yarn, specifically comprising the following steps:

[0068] Synthesis of S1, dipentene-4-methyl succinate 3

[0069]

[0070] Add 120 mol of dipentene 1, 130 mol of methyl succinate 2 and 0.16 mol of catalyst iodine into the autoclave, blow in nitrogen to replace the air in the autoclave, heat up in an airtight manner, and raise the temperature to 250 °C at a rate of 15 °C / min. °C, heat preservation for 1 hour, dipentene-4-methyl succinate 3 was obtained with a yield of 99.2%;

[0071] Synthesis of S2, isopentenyl formate 6

[0072]

[0073] Add 150 mol of prenyl alcohol 4 and 660 mol of formic acid 5 into the reaction flask, stir and react at 35° C. for 4 h to obtain prenyl formic acid ester 6 with a yield of 98.8%;

[0074] S3, the synthesis of bisabolol derivative 8

[0075]

[0076] Add dipentene-4-methyl succinate 3 prepared in step S1 to the reaction flask of step S2, add dichloromethane and p...

Embodiment 3

[0089] A method for preparing mildew-proof polyester high-strength yarn, specifically comprising the following steps:

[0090] Synthesis of S1, dipentene-4-methyl succinate 3

[0091]

[0092] Add 120 mol of dipentene 1, 130 mol of methyl succinate 2 and 0.15 mol of catalyst iodine into the autoclave, blow in nitrogen to replace the air in the autoclave, heat up in a closed manner, and raise the temperature to 250 °C at a rate of 15 °C / min. °C, heat preservation for 1 h, dipentene-4-methyl succinate 3 was obtained with a yield of 98.7%;

[0093] Synthesis of S2, isopentenyl formate 6

[0094]

[0095] Add 150 mol of prenyl alcohol 4 and 710 mol of formic acid 5 into the reaction flask, stir and react at 35°C for 4 hours to obtain prenyl formic acid ester 6 with a yield of 98.9%;

[0096] S3, the synthesis of bisabolol derivative 8

[0097] Add dipentene-4-methyl succinate 3 prepared in step S1 to the reaction flask of step S2, add dichloromethane and phosphotungstic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com