Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1502results about How to "Advanced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

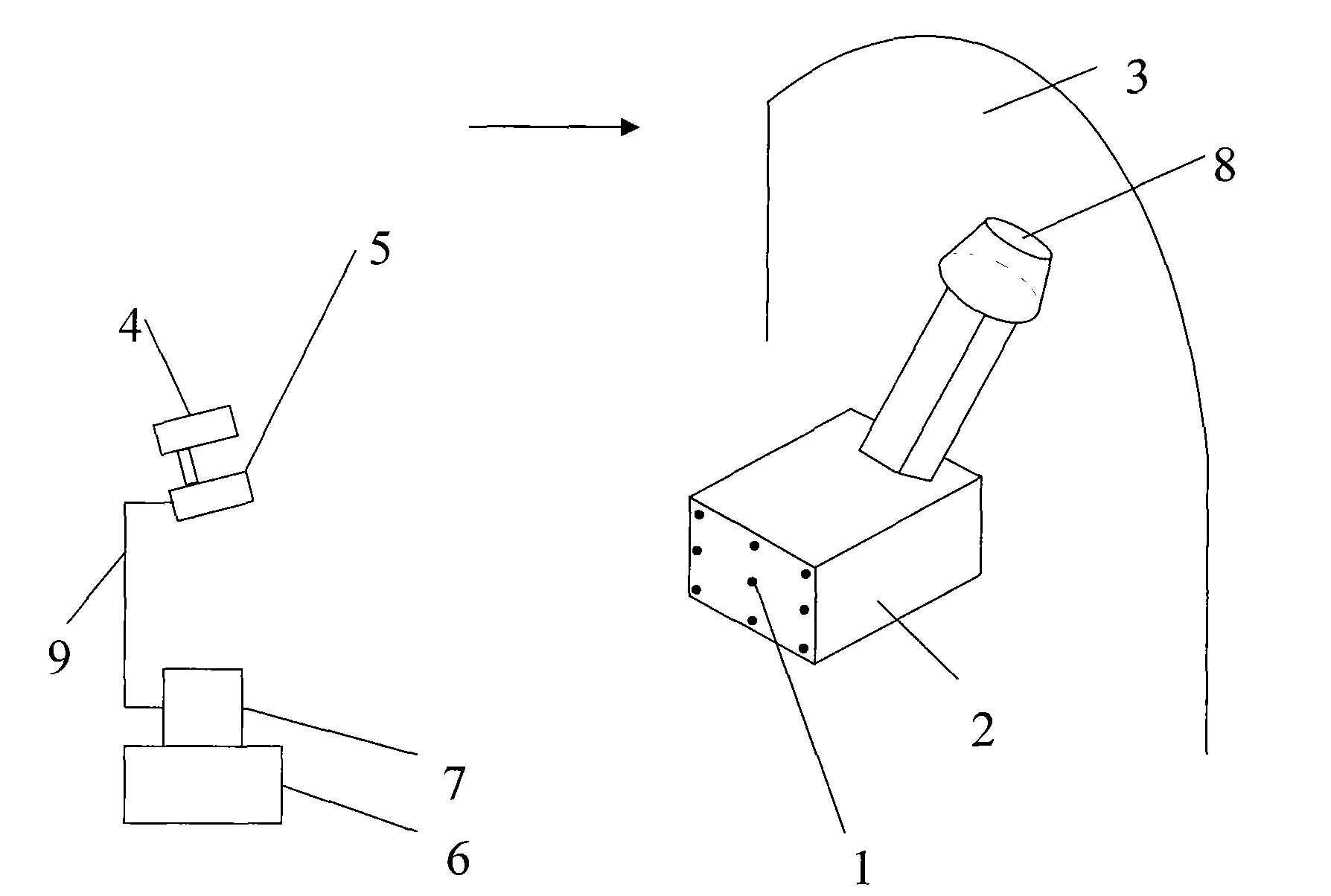

Intelligent force control robot grinding system and method

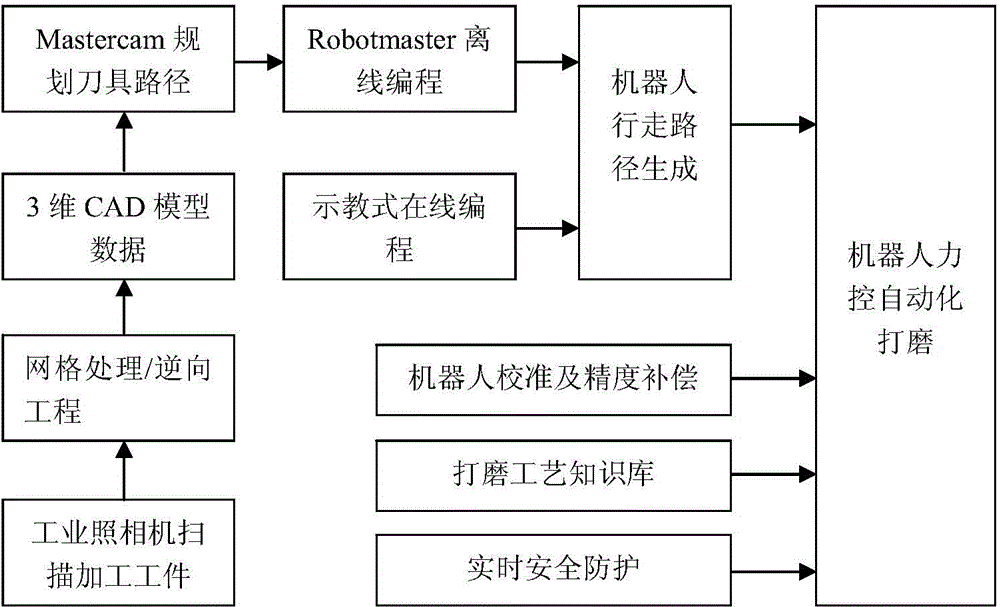

ActiveCN104972362ARealize automatic processingImprove machining accuracyAutomatic grinding controlSurface finishControl theory

The invention relates to an intelligent force control robot grinding system. The intelligent force control robot grinding system comprises a computer, an industrial camera, a robot, a robot controller, a calibration and compensation system, a safety protection unit, a force sensor and an automatic knife changing system. The computer is connected with the industrial camera. The robot controller is connected with the computer, the robot, the calibration and compensation system, the safety protection unit, the force sensor and the automatic knife changing system. A method comprises the steps that the computer receives workpiece scanning data collected by the industrial camera, generates a knife path and converts the knife path into the robot posture and the tail end path; calibration and compensation are carried out; the robot controller controls all joints to move while the robot posture and the tail end path are adjusted. Hardware of a high-precision force control grinding system is achieved, the path self-calibration and online compensation technology is adopted, and the machining of a complex hook face with the high requirements for machining precision and surface smoothness can be finished.

Owner:宏阔(南通)智能装备有限公司

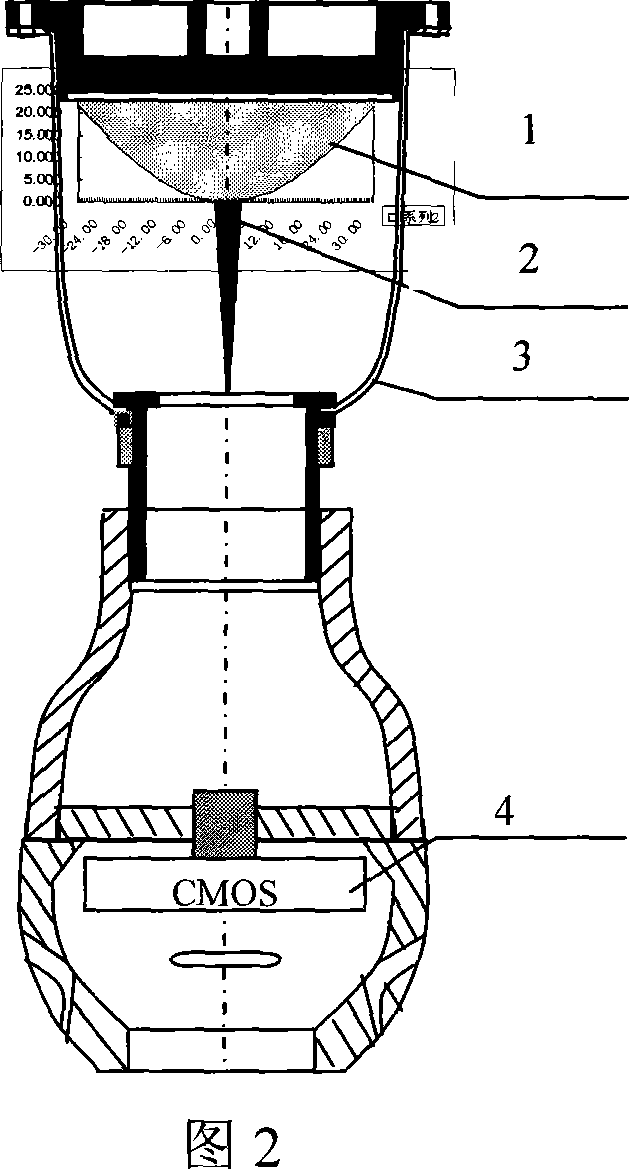

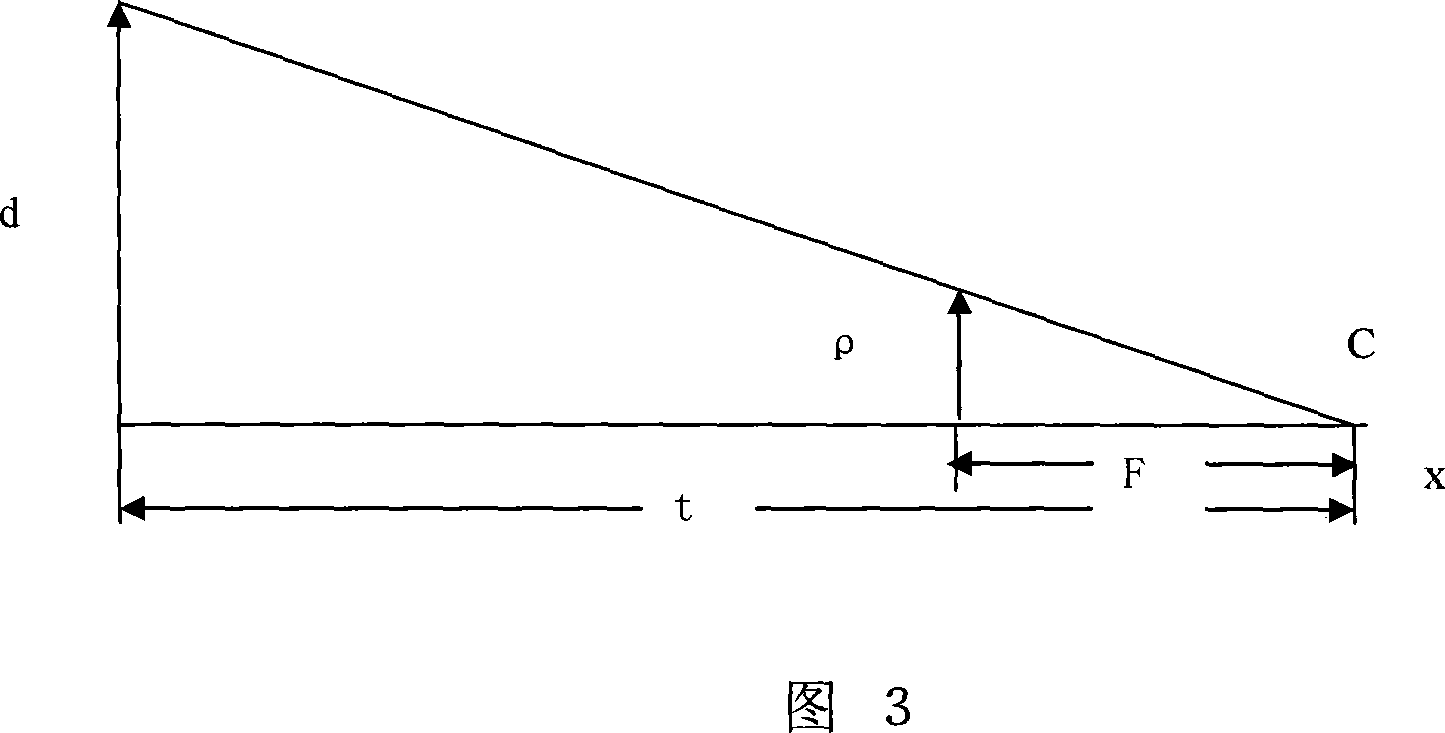

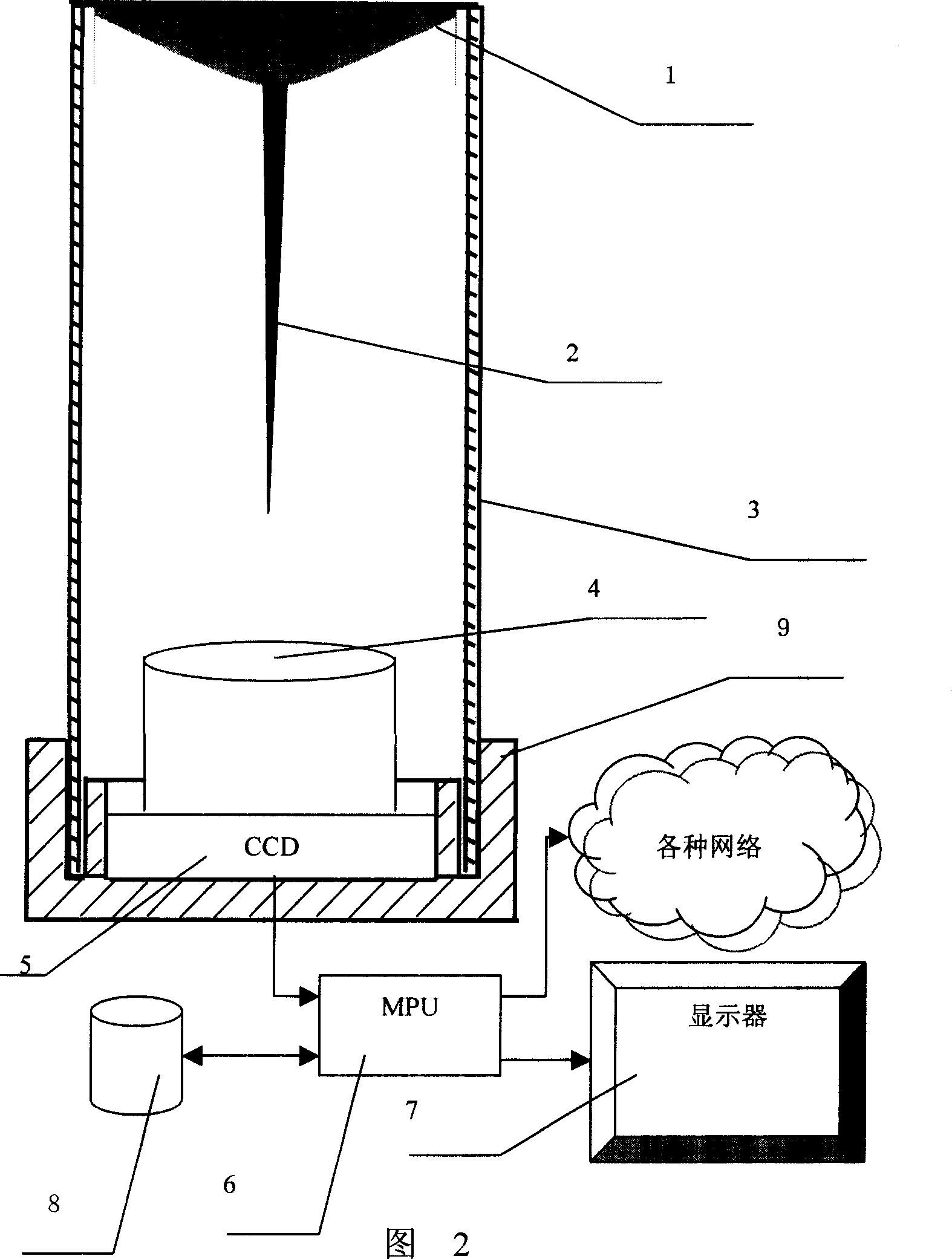

Intelligent tunnel safety monitoring apparatus based on omnibearing computer vision

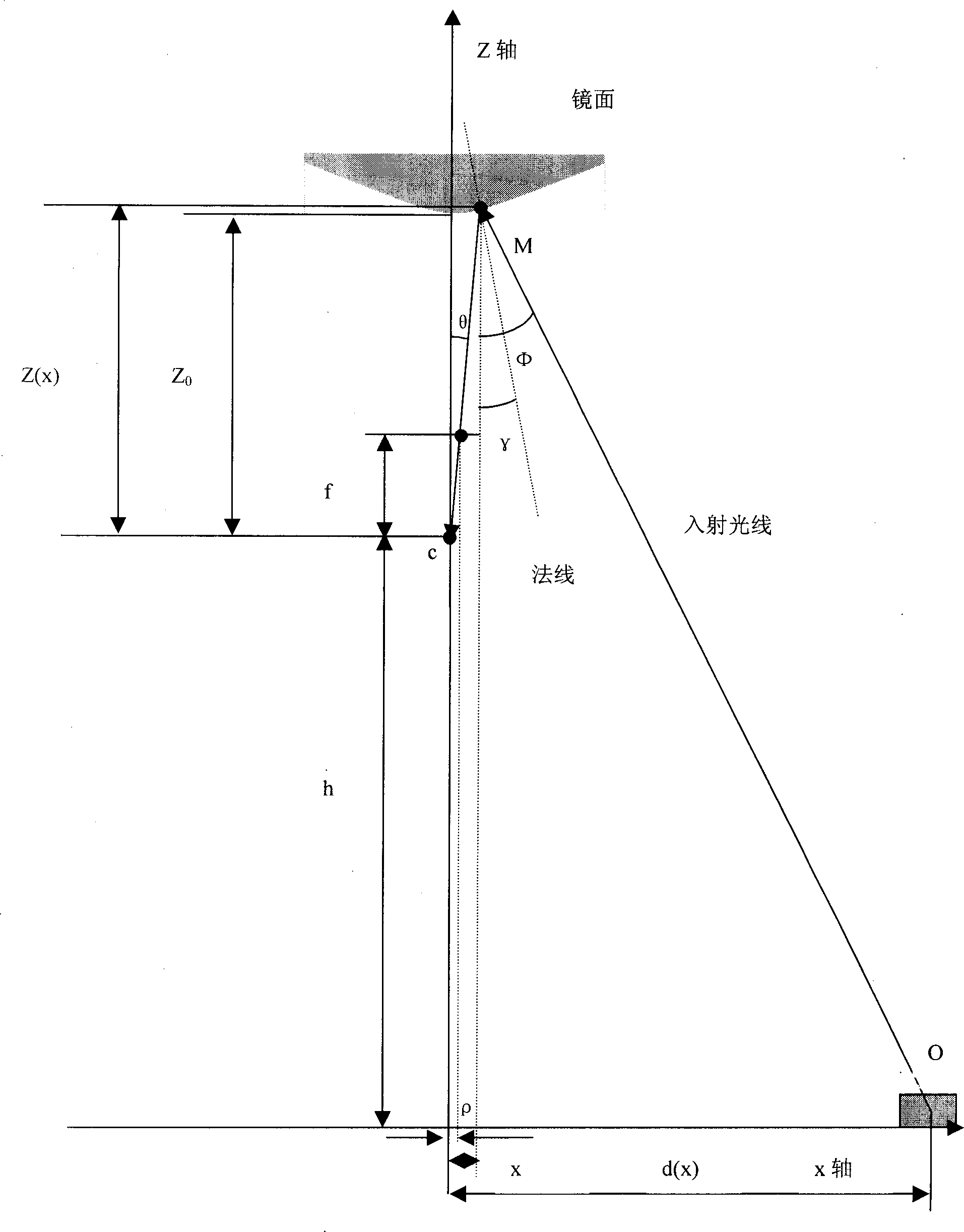

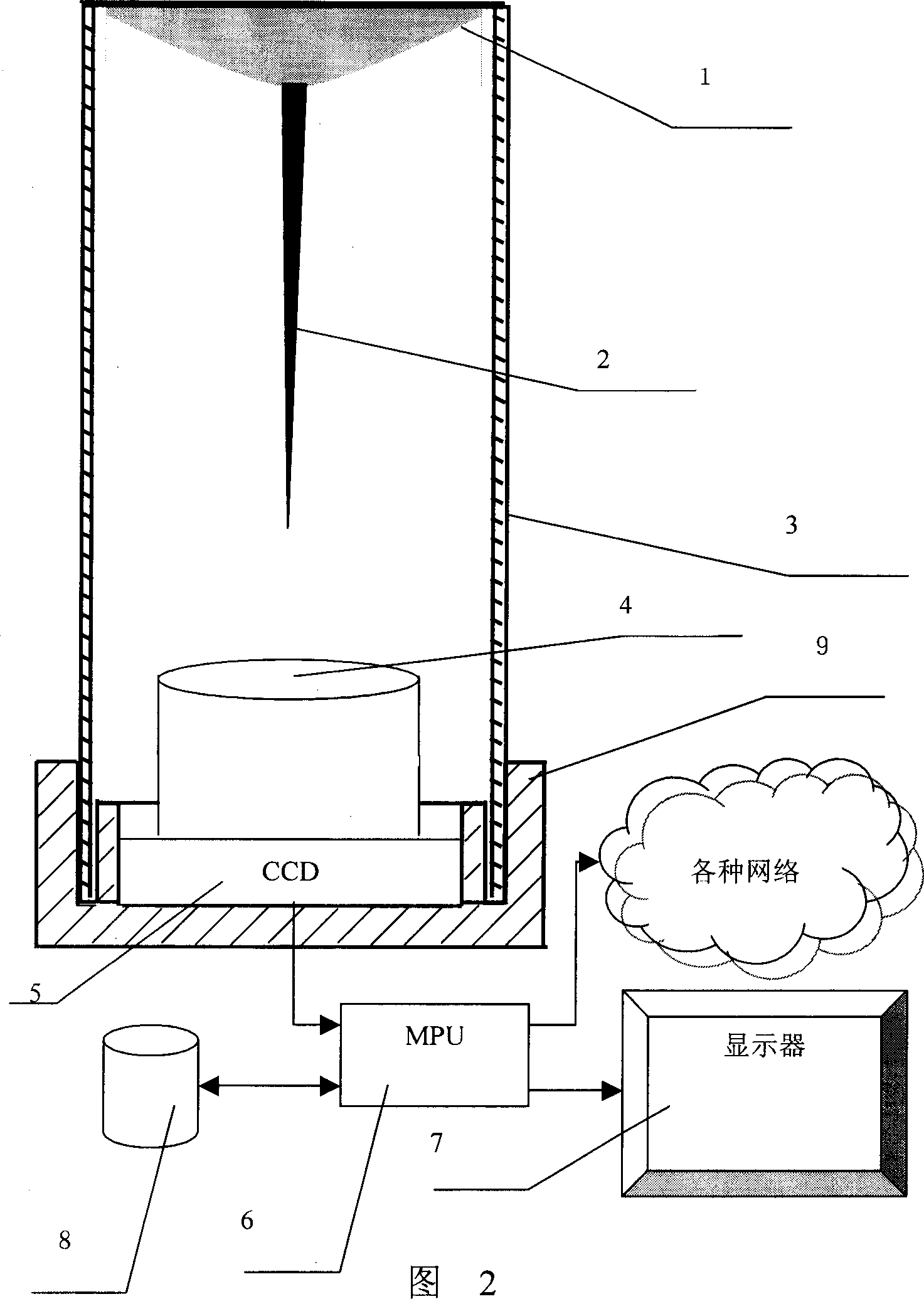

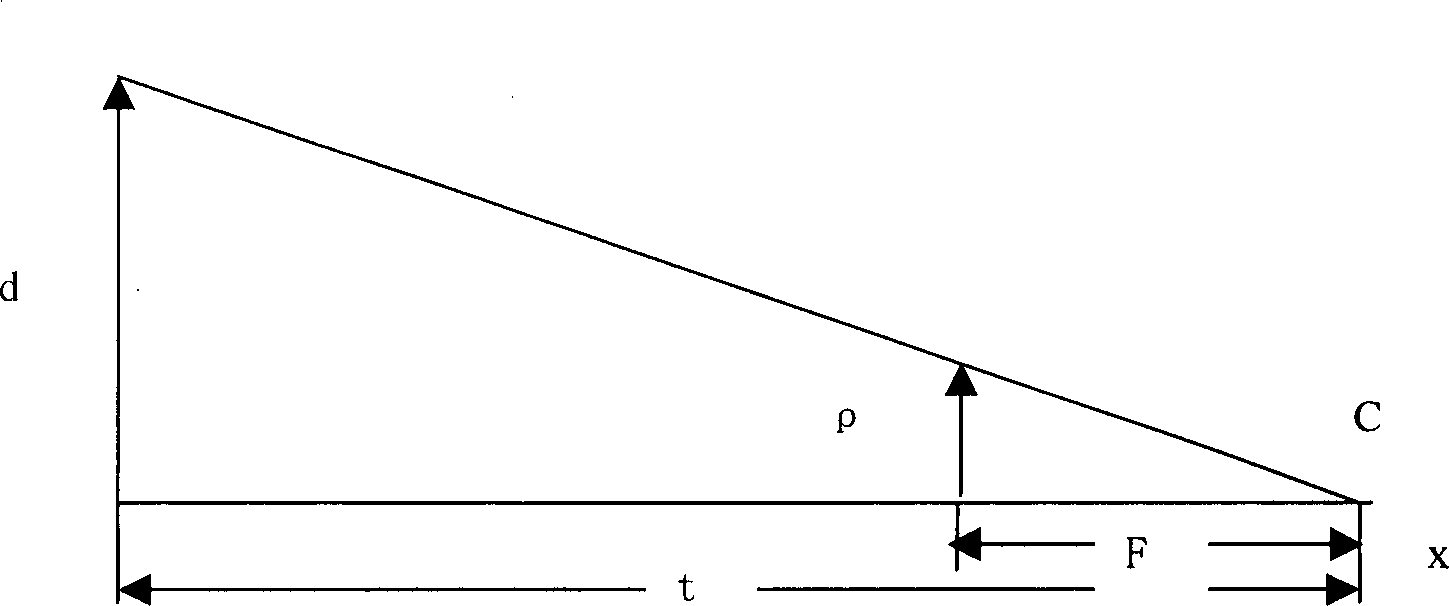

InactiveCN1852428ACarry out the function of monitoringLow maintenanceImage analysisClosed circuit television systemsDisplay deviceVision sensor

The monitoring equipment includes microprocessor, video sensor in use for monitoring site of tunnel, and communication module for communication outside. Microproceesor includes following modules: reading module for image dada in use for reading information of video image transferred from video sensor; file storage module in use for storing data collected by video sensor to storage device; real time playing module on site connected to external display device is in use for playing monitored image on site in real time. Output of the video sensor is connected to microprocessor through communication. Using all directional computer vision sensor monitors tunnel site, processes and analyzes images. Using detected variation character for fire flame in early phase, the invention finds early fire in tunnel as well as obtains traffic data including vehicle flowrate, and occupancy ratio, speed, and traffic accident etc.

Owner:ZHEJIANG UNIV OF TECH

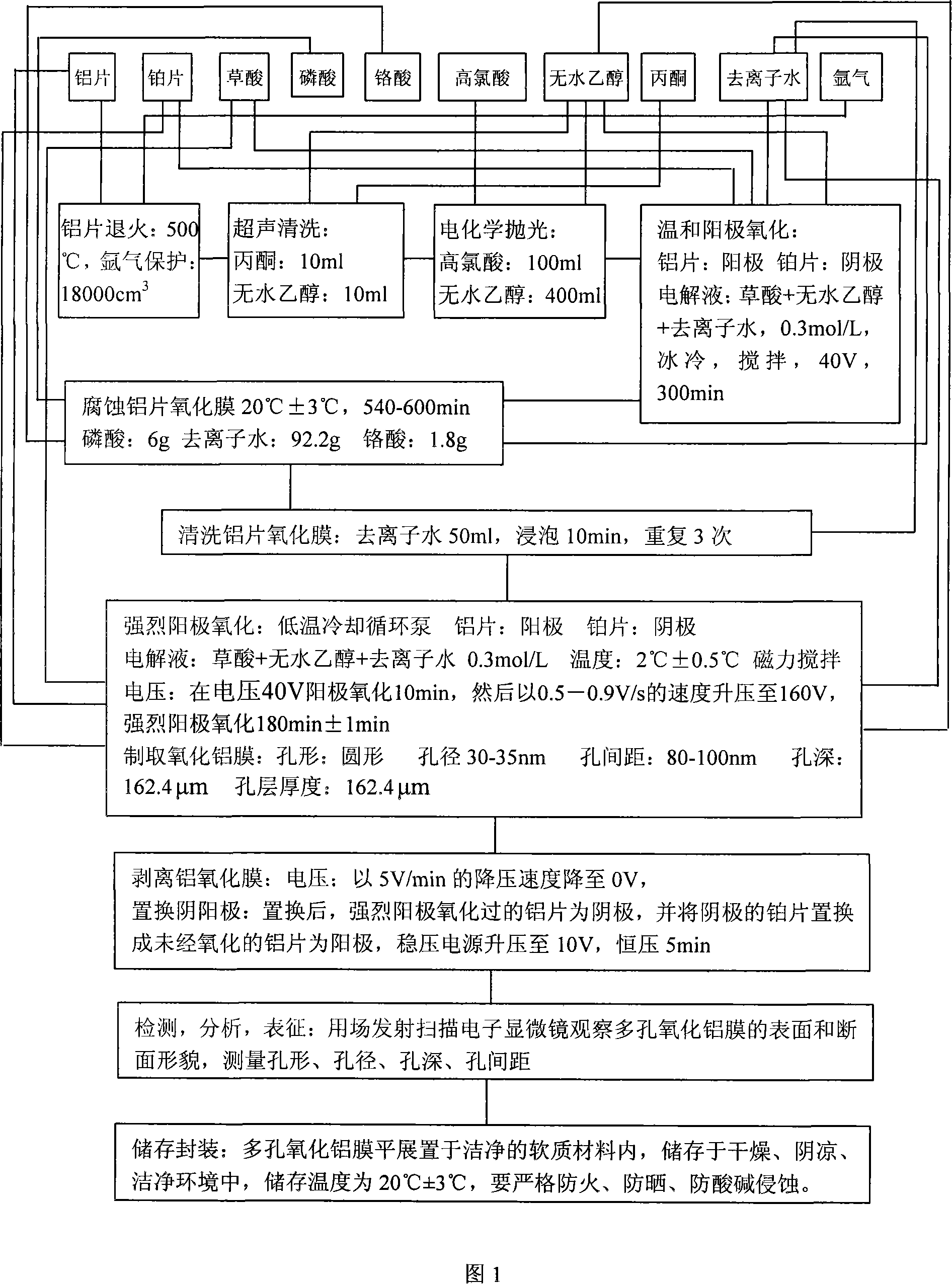

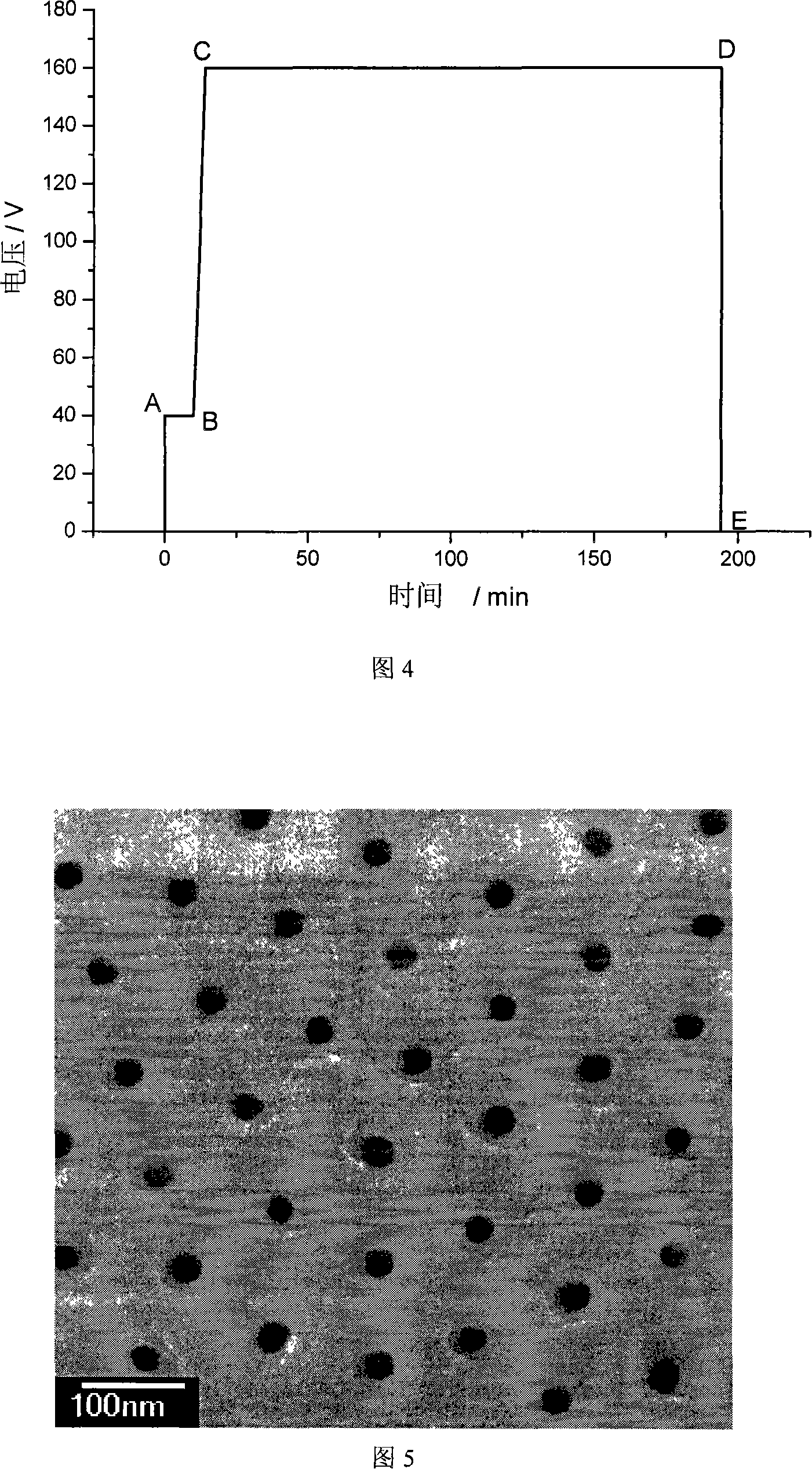

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

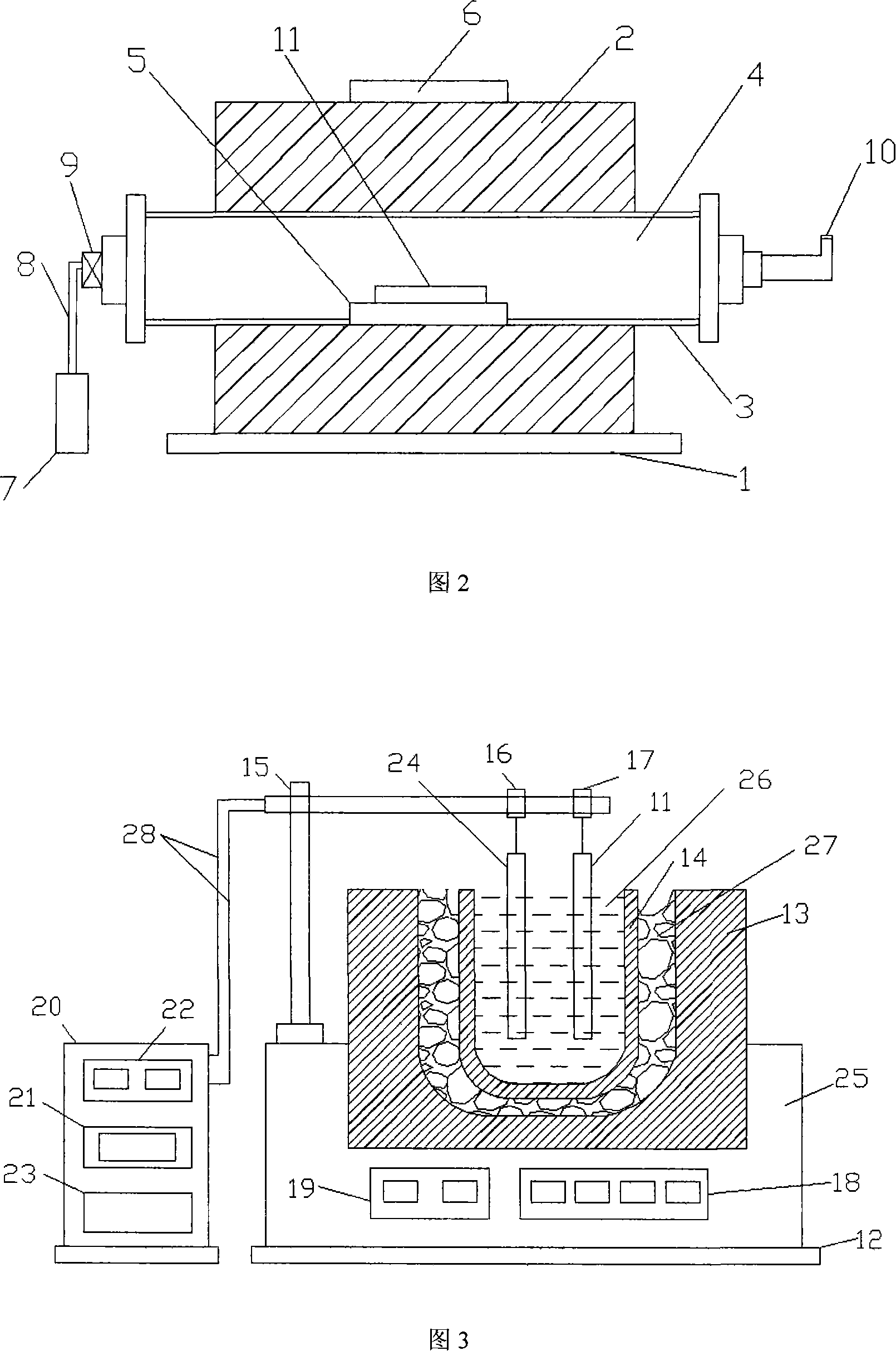

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

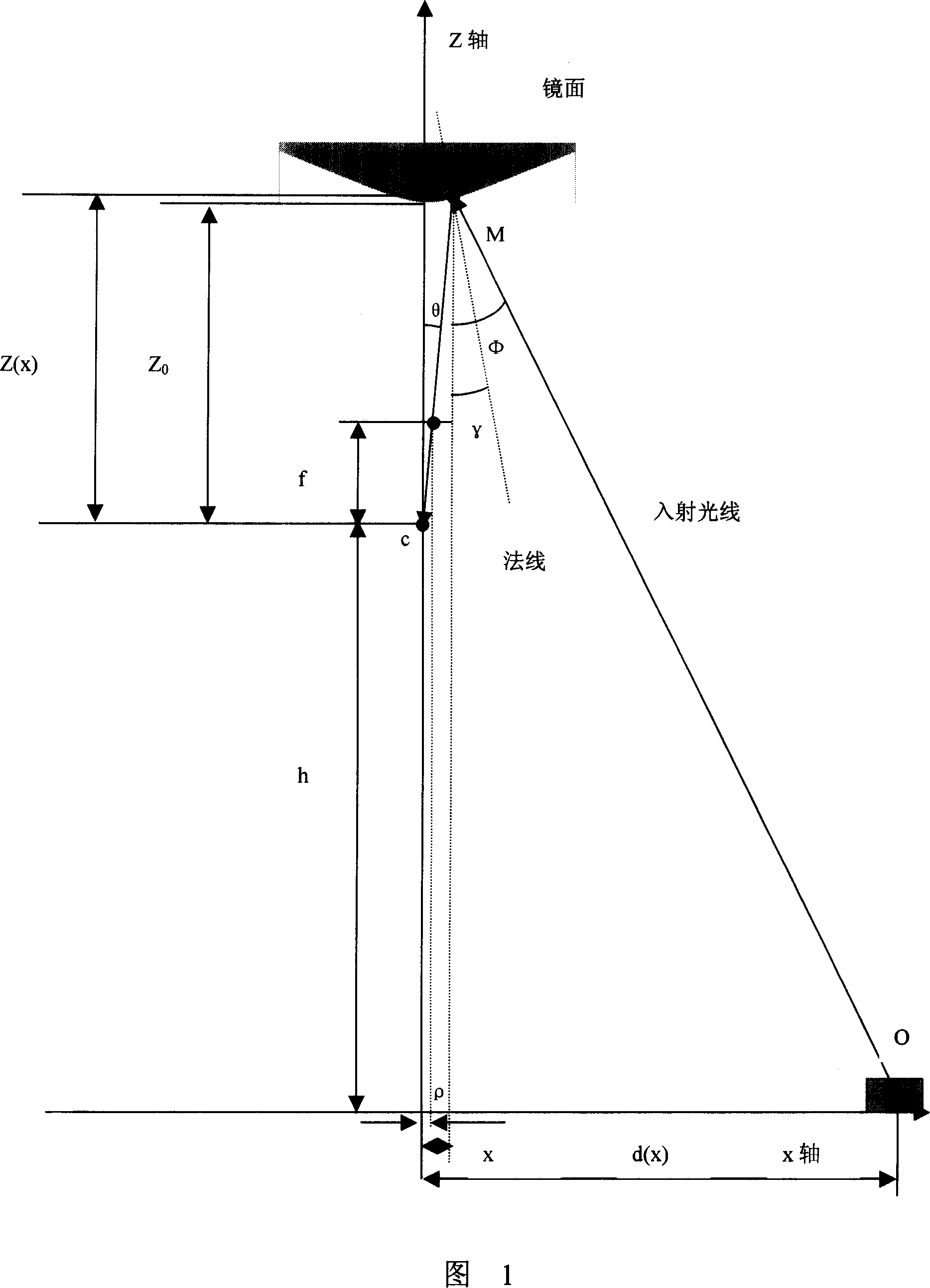

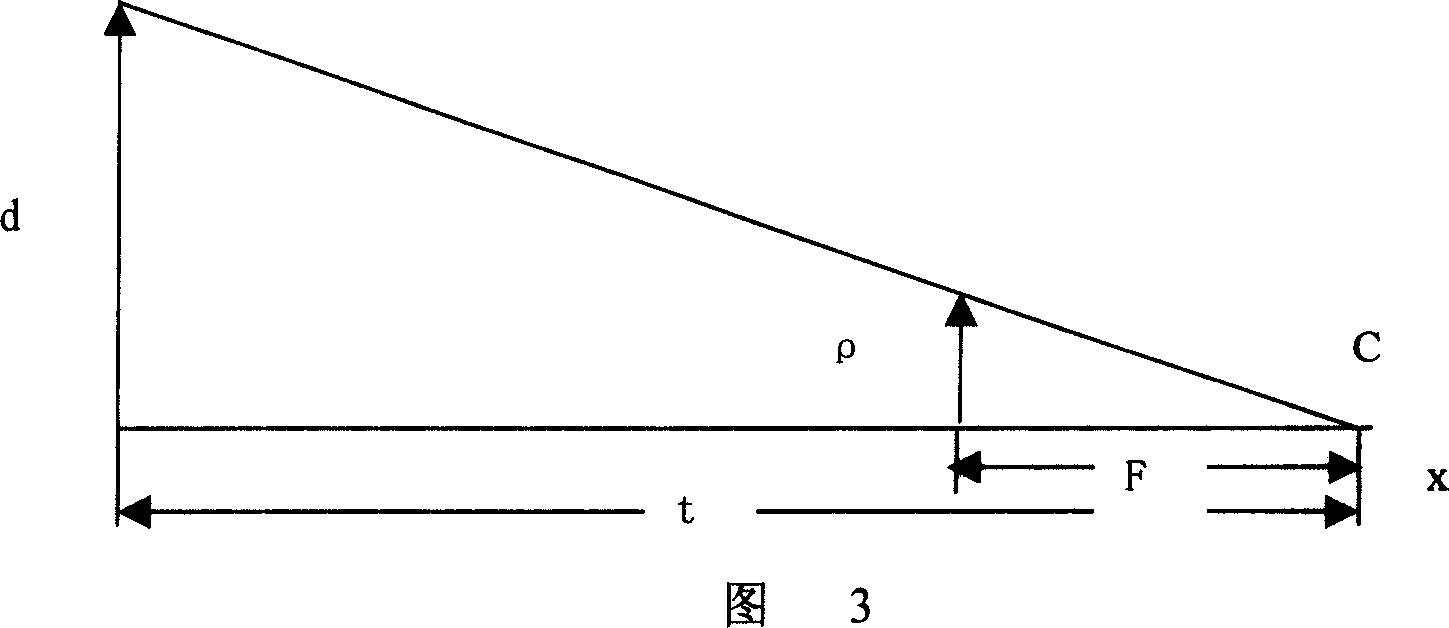

Parking inducing system based on computer visual sense

InactiveCN101064065AIncrease profitWill not affect businessIndication of parksing free spacesCharacter and pattern recognitionCode moduleDriver/operator

This invention relates to one park guide system based on computer visual sense, which comprises park label identification device on each field, car position information system statistic distribution device and one park guide controller, wherein the park guide controller comprise car position information receive module, position information code module to convert the collected car information into digital codes; the said codes is of 28 with previous 22 for park physical position information and afterwards 6 for detail position information; park position information process module generates each record for each car to establish one inquire entrance with relative digital codes for distribution.

Owner:汤一平

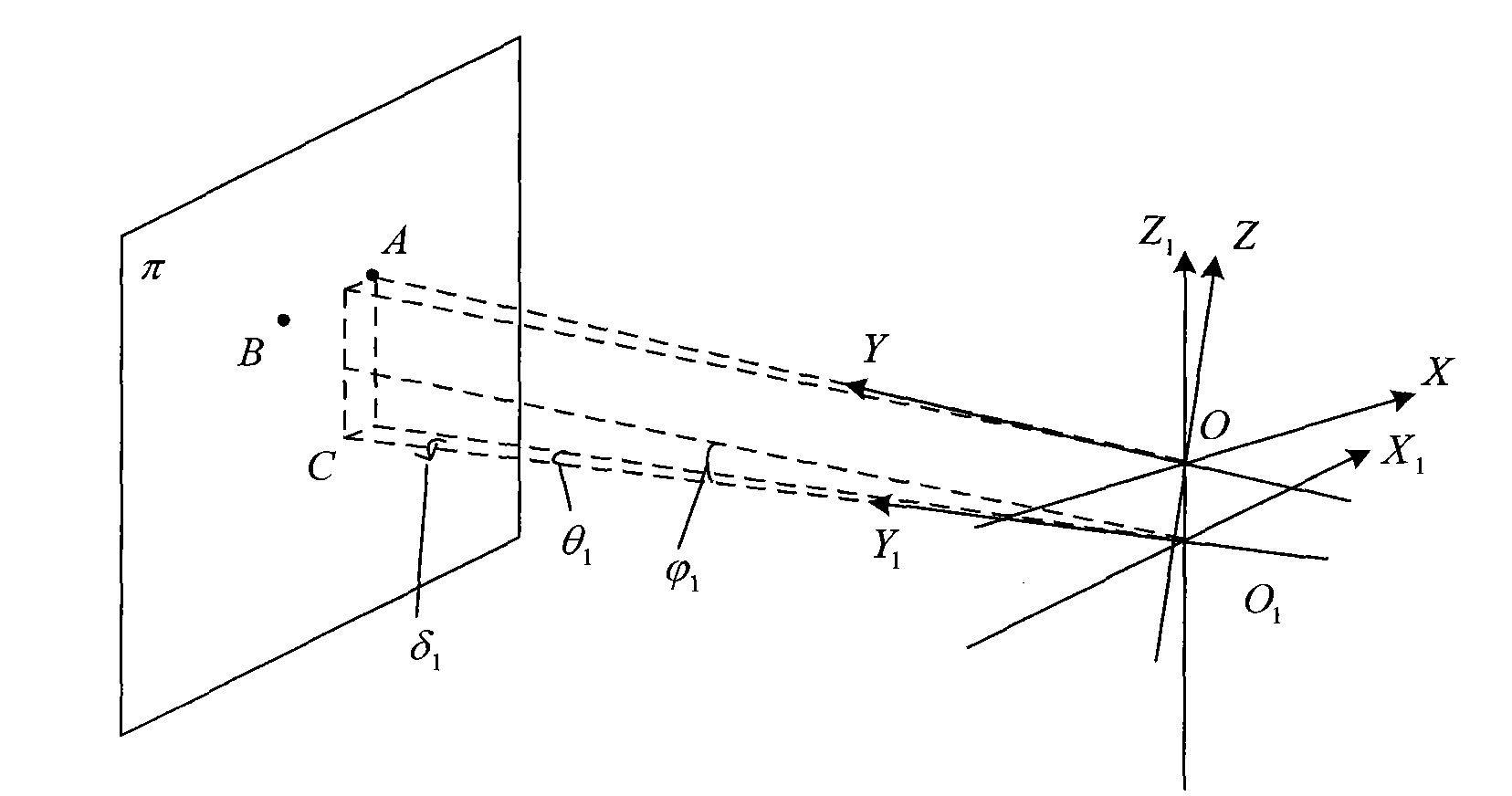

Method for automatically measuring special position of tunnel boring machine

ActiveCN101819036AIdeal mining pose measurement methodAdvancedAngle measurementView cameraTunnel boring machine

The invention relates to a method for automatically measuring the special position of a tunnel boring machine. According to the practical situation of the tunneling operation of the tunnel boring machine in a small underground space of a coal mine, an industrial view camera, an industrial computer, a laser orientation instrument and an image acquisition card are arranged on the back part of the tunnel boring machine. The position of the tunnel boring machine on a coal petrography cross section is measured and calculated, the most reasonable position of a machine body is determined, a command on an excavating operation is made and operators are far away from hazardous areas so as to reduce sudden accidents, enhance excavating safety and keep the tunnel boring machine on a best and most reasonable position and in a best and most reasonable state. A maximum cover angle is + / -60 degrees, a displacement detection deviation is less than 10 millimeters, the detection accuracy of a deflection angle is + / -12 gon, the detection accuracy of a pitch angle is + / -6 gon and the detection accuracy of a roll angle is + / -6 gon so as to improve excavating quality and efficiency. The method is advanced, reasonable and correct, is a very ideal method for measuring the excavation position of a coal extraction tunnel boring machine and can be used in tunnel excavation operation.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

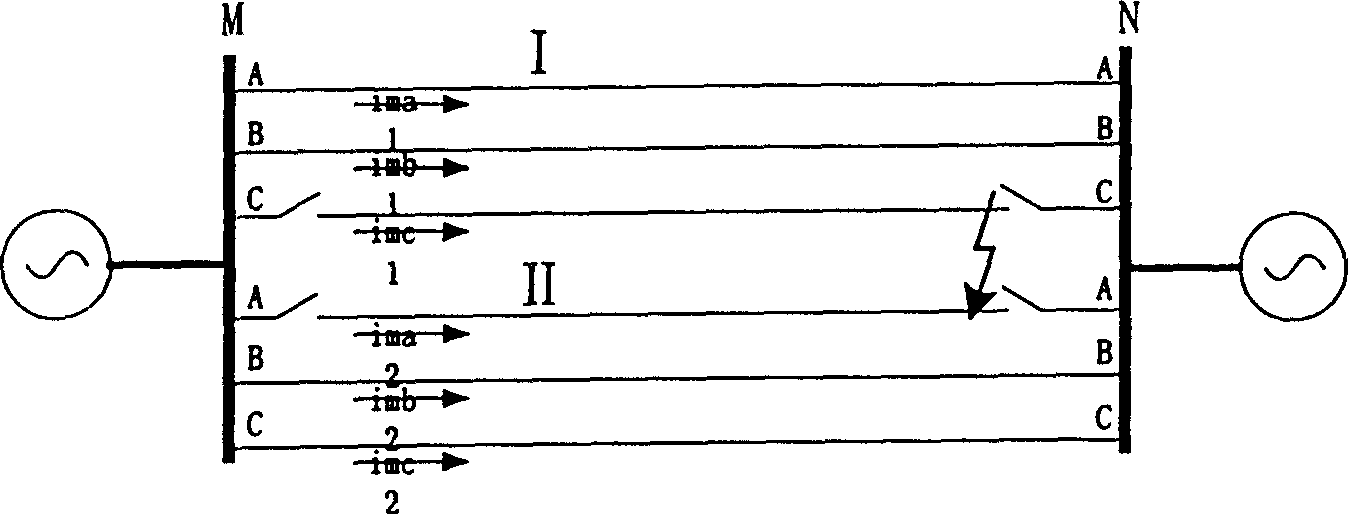

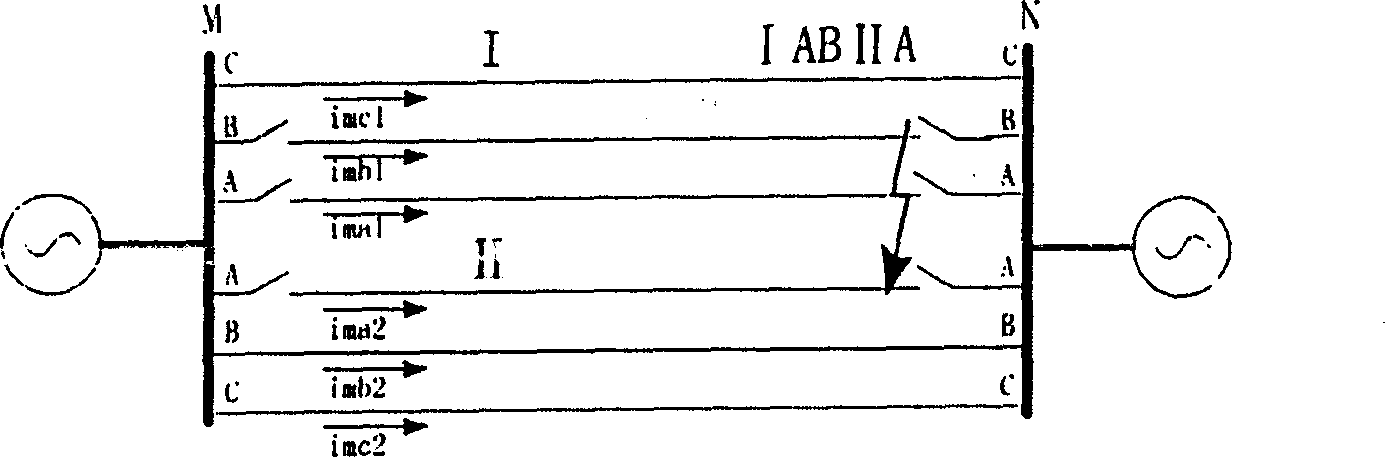

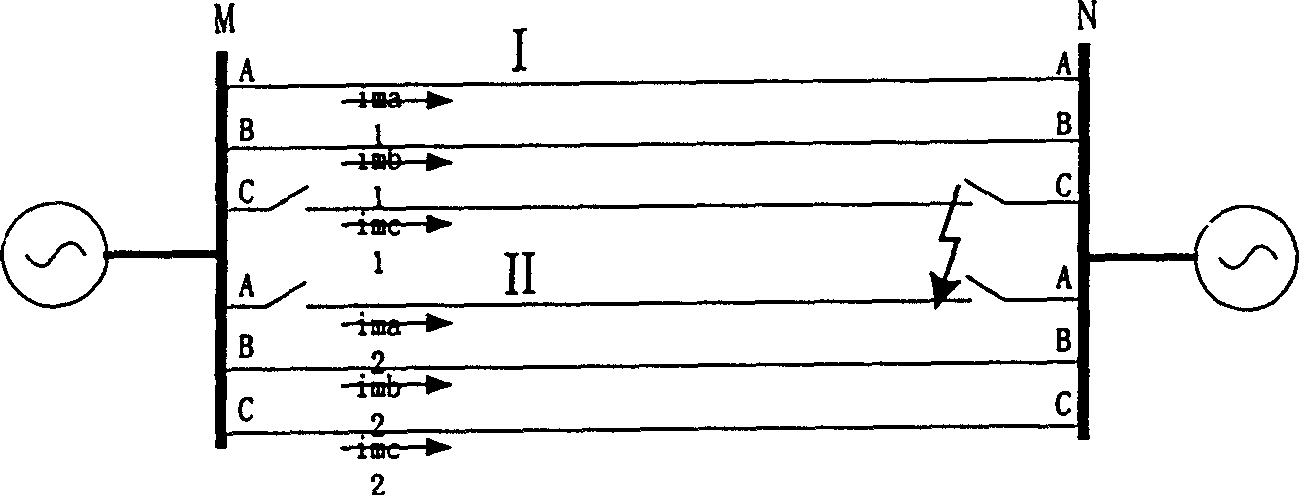

Re-switch on method for electric tansmission device

ActiveCN1588729ASolve the problem of correct phase selection and quick tripAdvancedEmergency protective arrangements for automatic disconnectionPhase splittingUltra high voltage

This invention relates to reclosing method for power transmission line. For joint parallel double circuit type: each circuit being equiped with individual protector, main protection being phase-splitting current differential protection or phase-command longitudinal protection; for various type single circuit fault or overline fault withni a zone, tripping fault being detected, determinnig no serious permanent fault, sequentially reclosing the tripping phases. For double-circuit fault, there must be two different type circuit being of no fault for reclosing, if not, two circuits must be tripped-off. This invention method increases the reclosing rate, together with minimizing the shock to the system after reclosing permanent fault.

Owner:NR ELECTRIC CO LTD

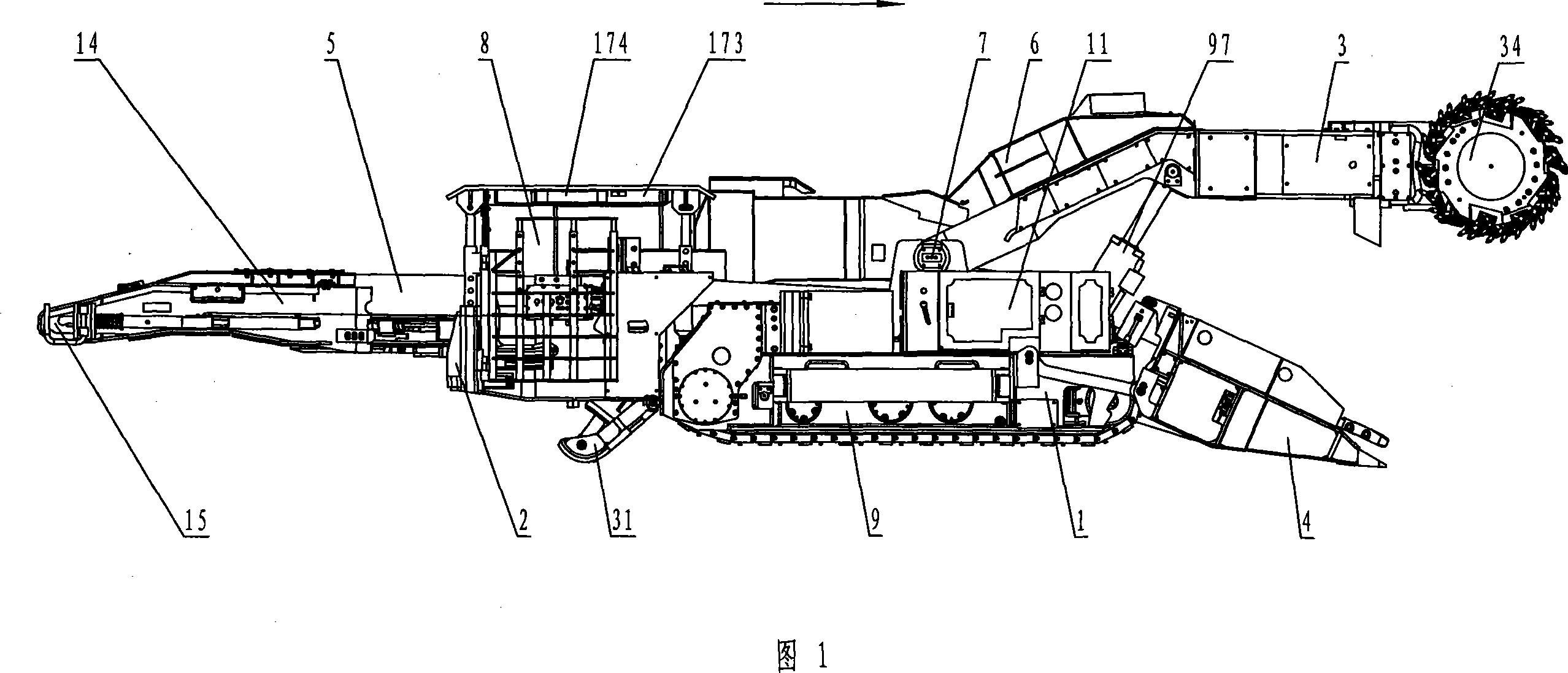

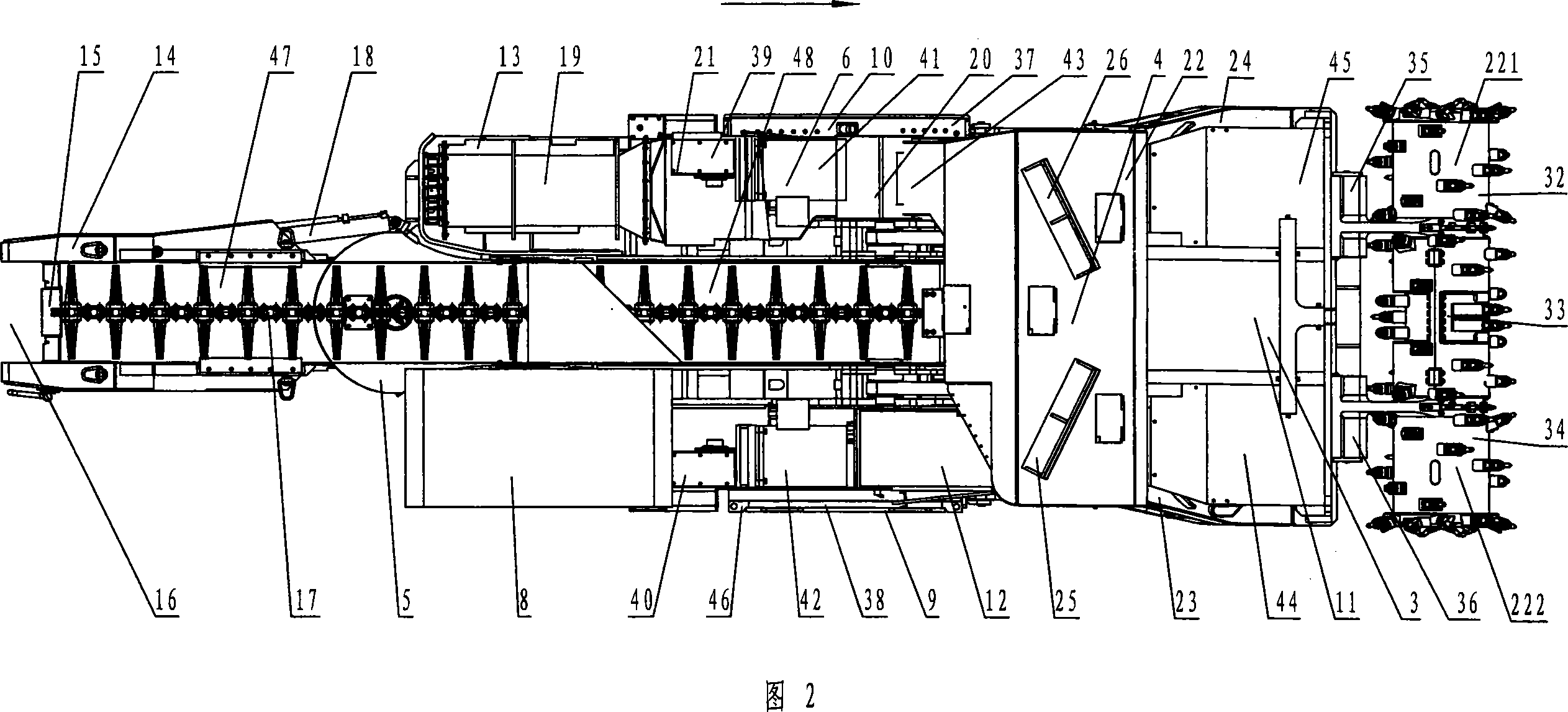

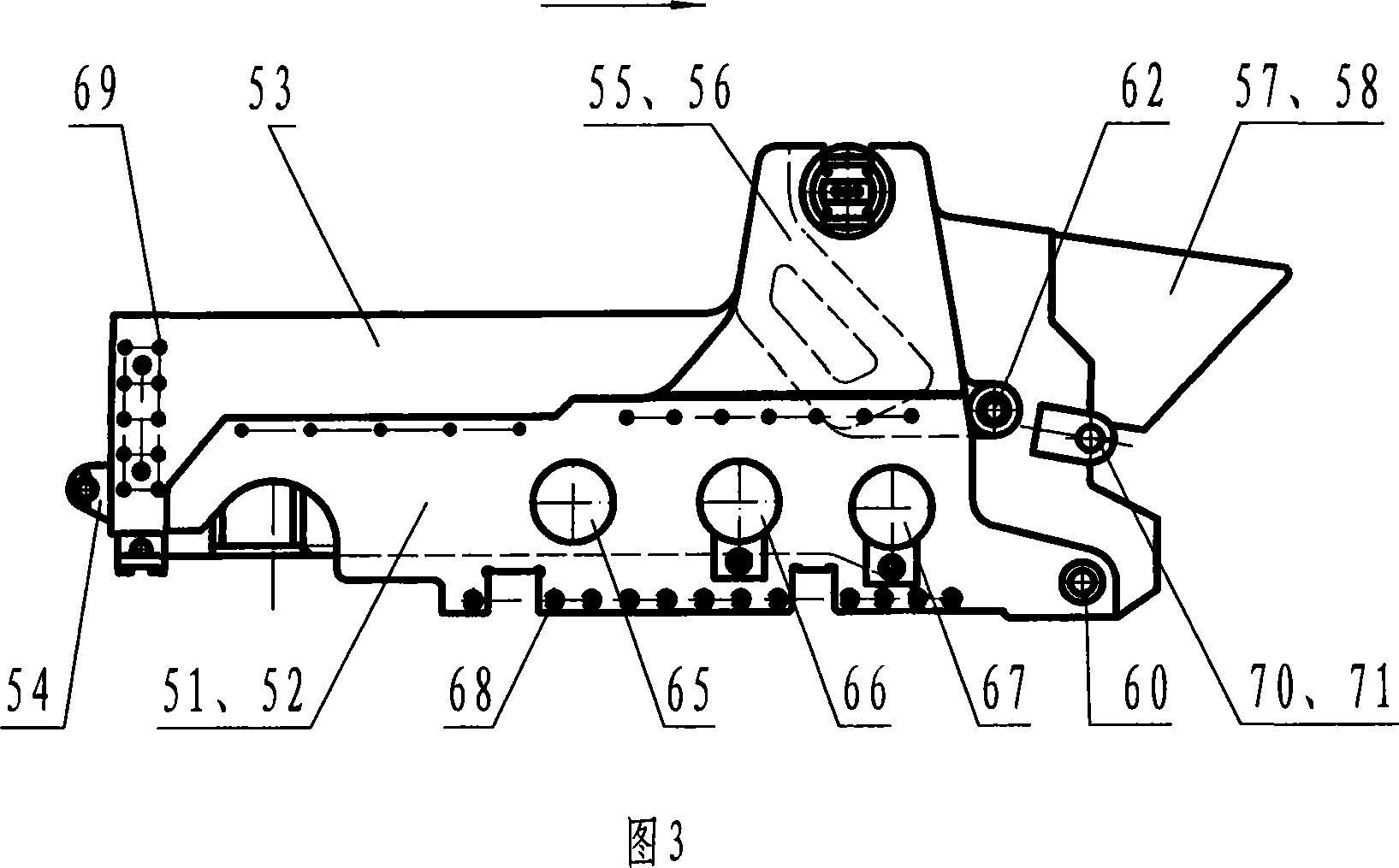

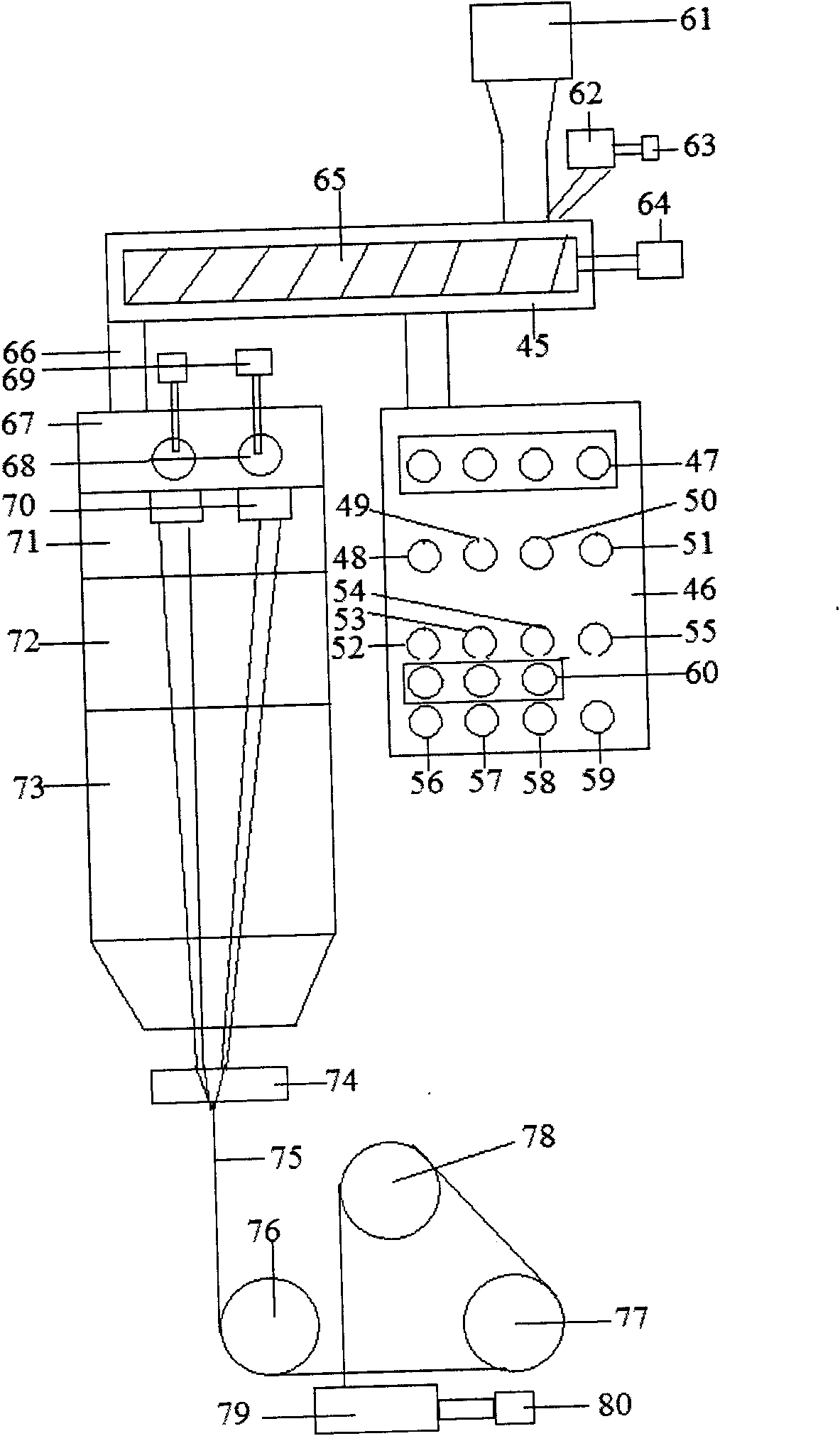

Underground continuous tunnelling machine

ActiveCN101050703AAdvancedFill the research gapDriving meansPropulsionAgricultural engineeringElectric control

The present invention relates to a coal mine underground continuous excavating machine. Its main mechanism includes the following several portions: main machine frame, rear machine frame, cutting mechanism, scooping plate mechanism, conveying mechanism, dust-removing mechanism, traveling mechanism, driving mechanism, hydraulic mechanism, electric control circuit and stable mechanism. Said invention also provides the connection mode of all the above-mentioned portions, and also provides the working principle of said excavating machine and its operation method.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Method for extracting platinum, rhodium and palladium from failed platinum alloy gauze

ActiveCN102586607AAdvanced and reasonable technologyAdvancedProcess efficiency improvementAlloySodium nitrite

The invention relates to a method for extracting platinum, rhodium and palladium from a failed platinum alloy gauze, which comprises the following steps of: separating to extract precious metals such as the platinum, the rhodium and the palladium from the failed platinum alloy gauze; dissolving through hydrochloric acid and nitric acid; removing nitro group, transforming sodium and leaching; obtaining platinum, rhodium and palladium complexing solution; adopting an ammonium chloride precipitation method to separate the platinum; adopting a sodium nitrite complexometry to separate the palladium and the rhodium; adopting a six nitroso rhodium acid ammonium method to purify the rhodium; adopting a dichlorodiamminopalladium method to purify the palladium; carrying out reduction to obtain spongy platinum, spongy palladium and rhodium powder through adding hydrazine hydrate; vacuum drying and roasting; and purifying again. The extracting method has advanced and reasonable process, and accurate and detailed parameters; the purity of the extracted spongy platinum, spongy palladium and rhodium powder is great than 99.9 percent, and the quality is stable; and the method is a very ideal method for extracting the precious metals such as the platinum, the rhodium and the palladium from the failed platinum alloy gauze.

Owner:太原瑞麟贵金属回收有限公司

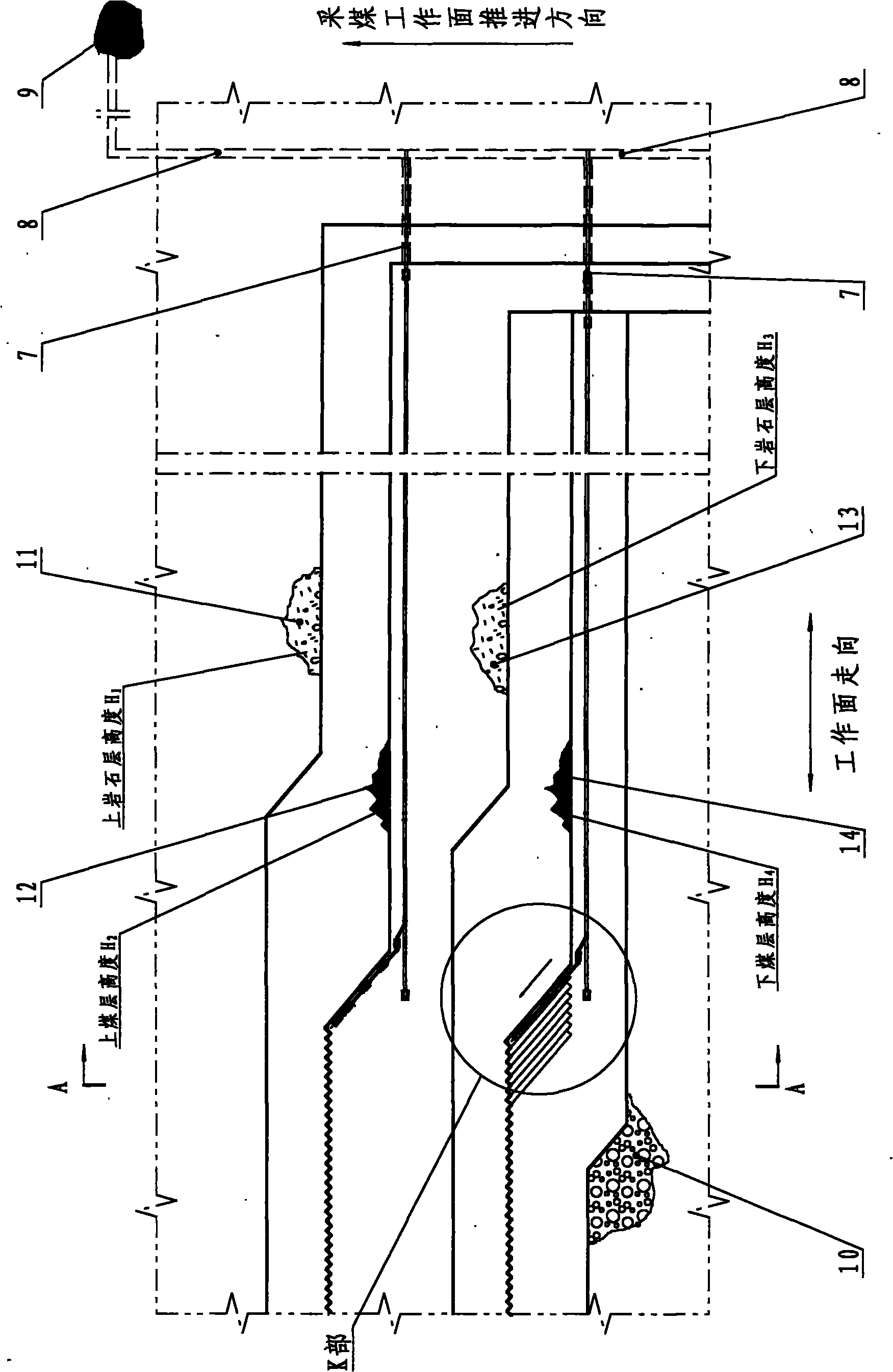

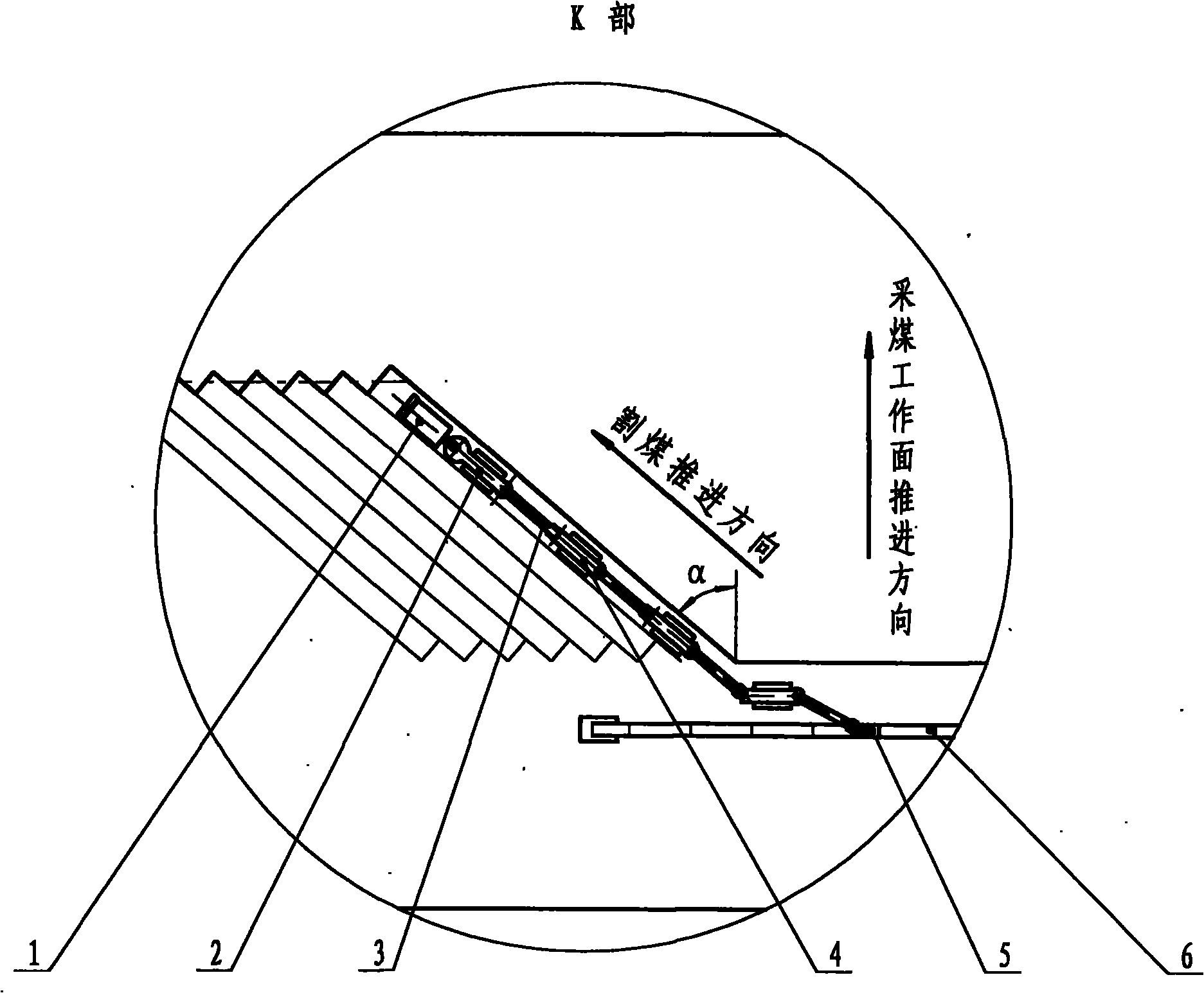

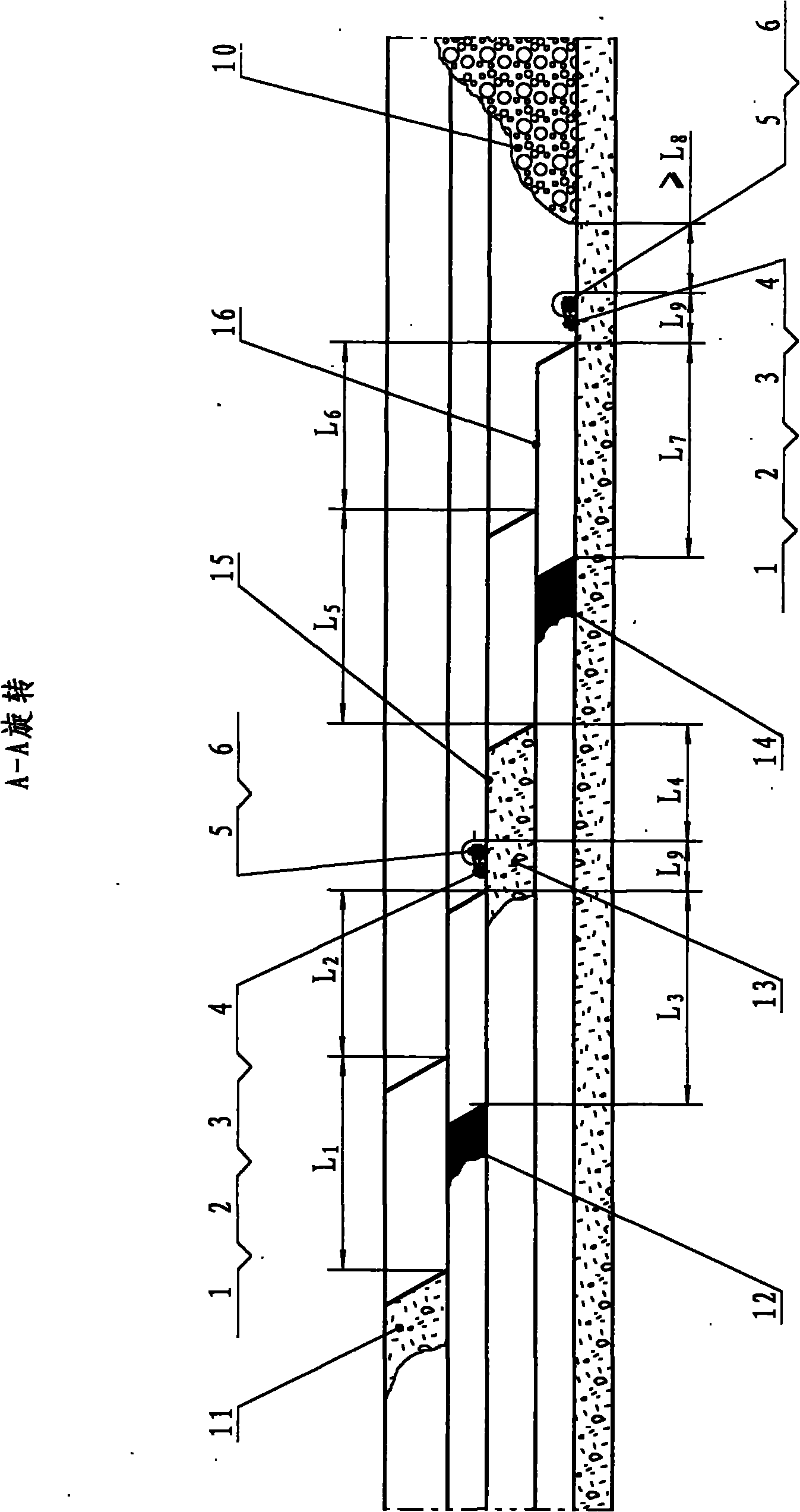

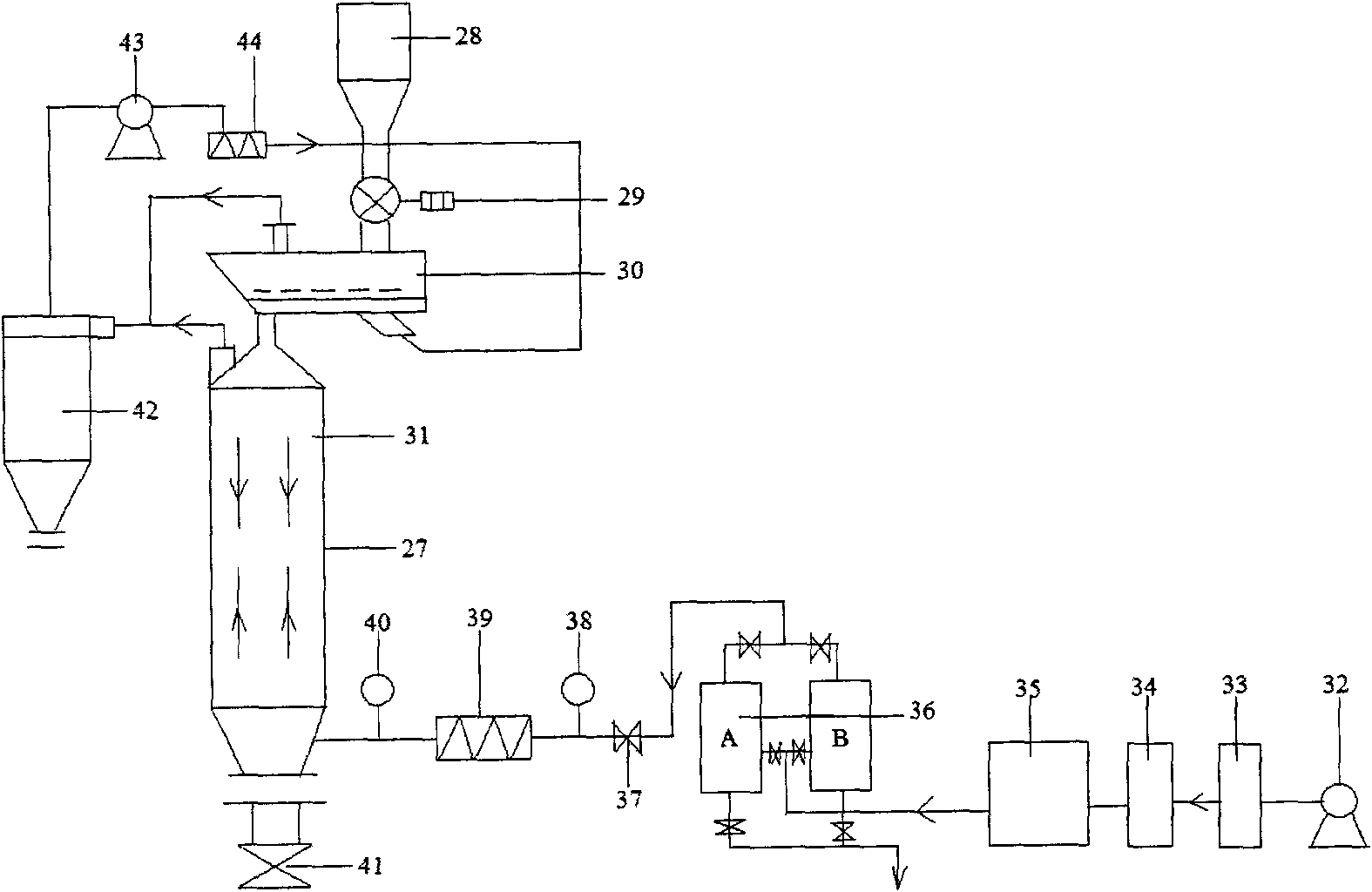

Continuous coal mining process method of open-pit coal mine

The invention relates to a continuous coal mining process method of an open-pit coal mine, the used main devices comprises a continuous coal mining machine, a walking type crushing machine of a continuous conveying machine unit, a bridge type transloading machine, a walking type transloading machine, an unloading car, a working face belt type conveyor, an outward transport heading belt type conveying machine and an outward transport machine lane belt type conveying machine, and the continuous coal mining process method adopts the continuous mining-continuous conveying way, and adopts the automatic mining, crushing, transloading, unloading and transportation. The coal mining method has advanced process, reasonable design, compact and continuous arrangement of the devices, safety, stability and reliability, high excavating efficiency, multi-stage transportation, smooth conveying and small occupied area, and can effectively improve the recovery rate of resources, reduce the consumption of fuel oil, reduce the carbon emission, be applicable to needs on low carbon, energy conservation and environmental protection and be a very ideal continuous coal mining process method of the open-pit coal mine.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

All-round computer vision-based electronic parking guidance system

InactiveCN101059909AWide detection rangeInstallation and maintenance without interferenceArrangements for variable traffic instructionsDetection of traffic movementGuidance systemVision based

An electric park induce system based on omnibearing computer vision comprises a microprocessor, an omnibearing vision sensor for detecting the park condition in a parker, and a communication module communicated with outer space, wherein the vision sensor is mounted above the park, the microprocessor detects the condition of each park part to provide dynamic internal induction and external induction to park. The inventive park check method has wide check range, non-interference installment, low energy consumption in maintenance, abundant check parameters, visual property, reliable check, high accuracy, easy statistic, simple operation, expandable property, or the like.

Owner:ZHEJIANG UNIV OF TECH

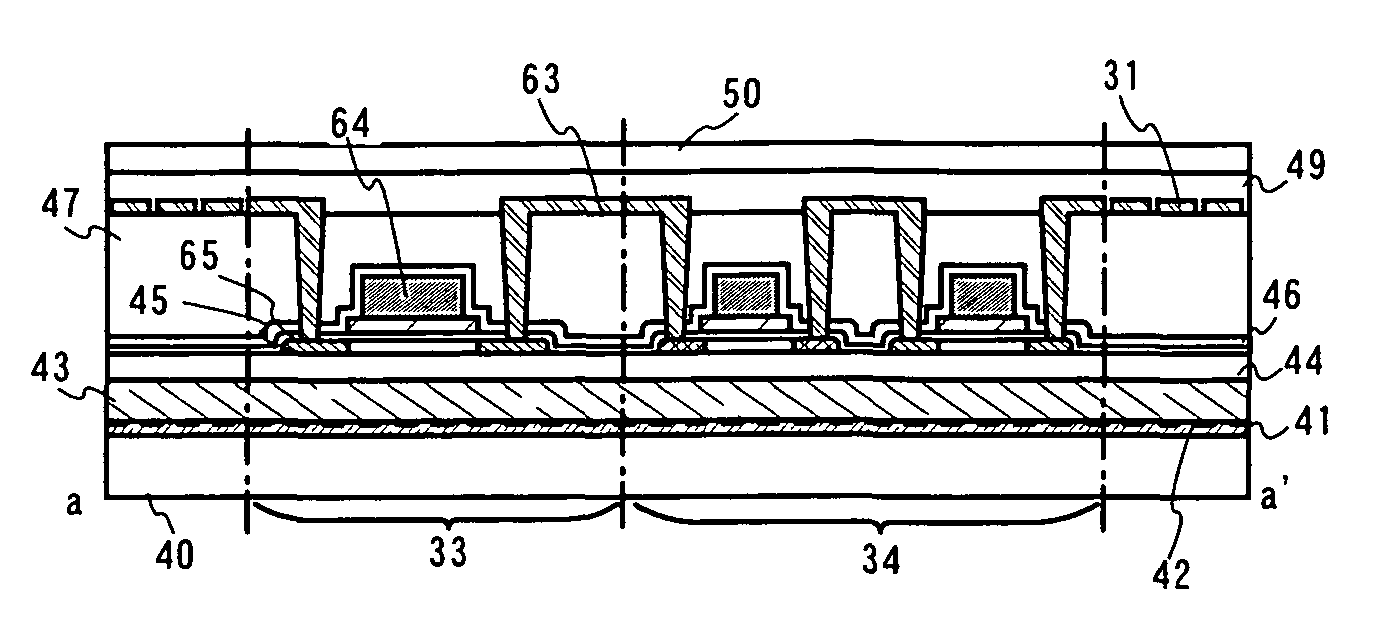

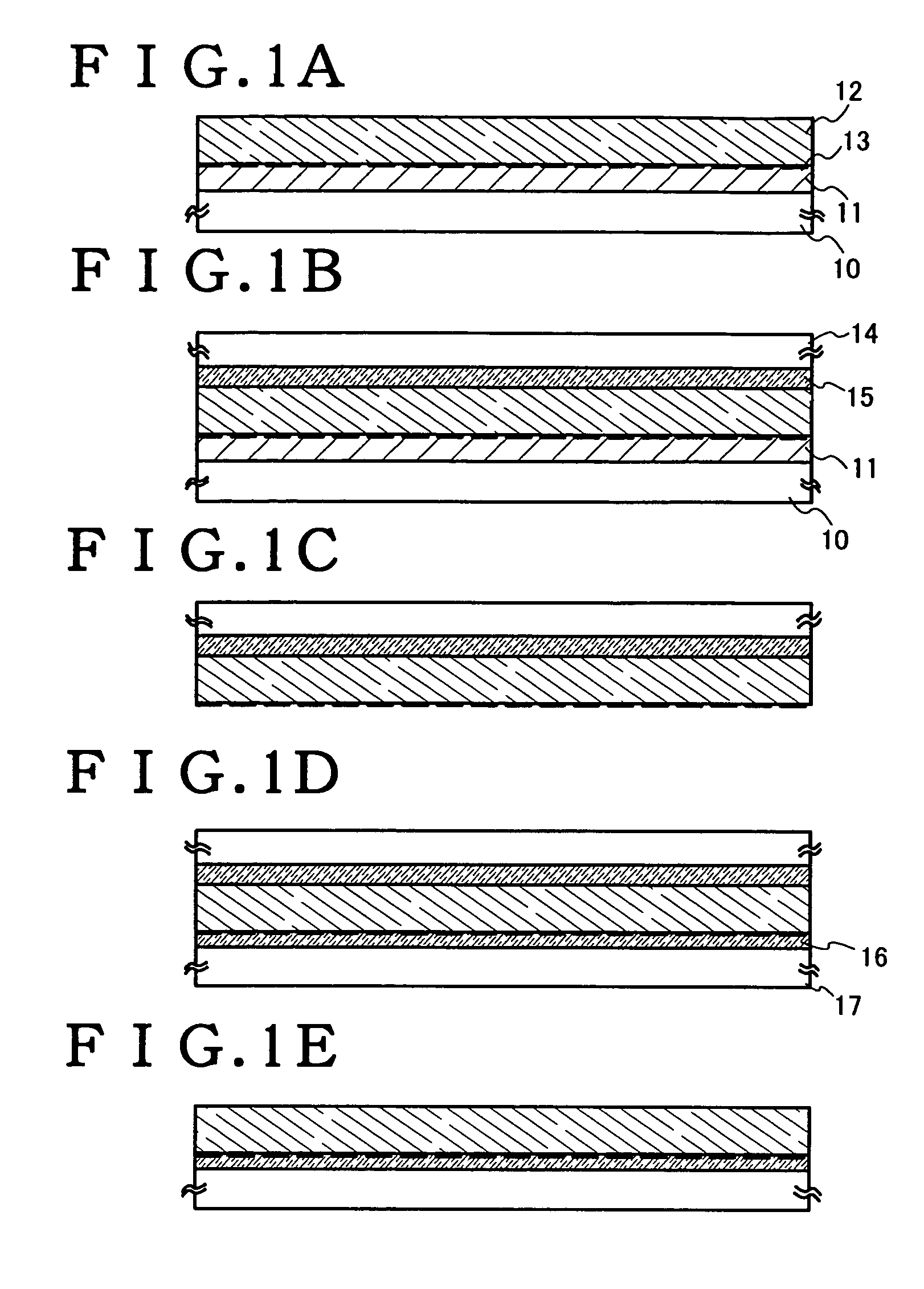

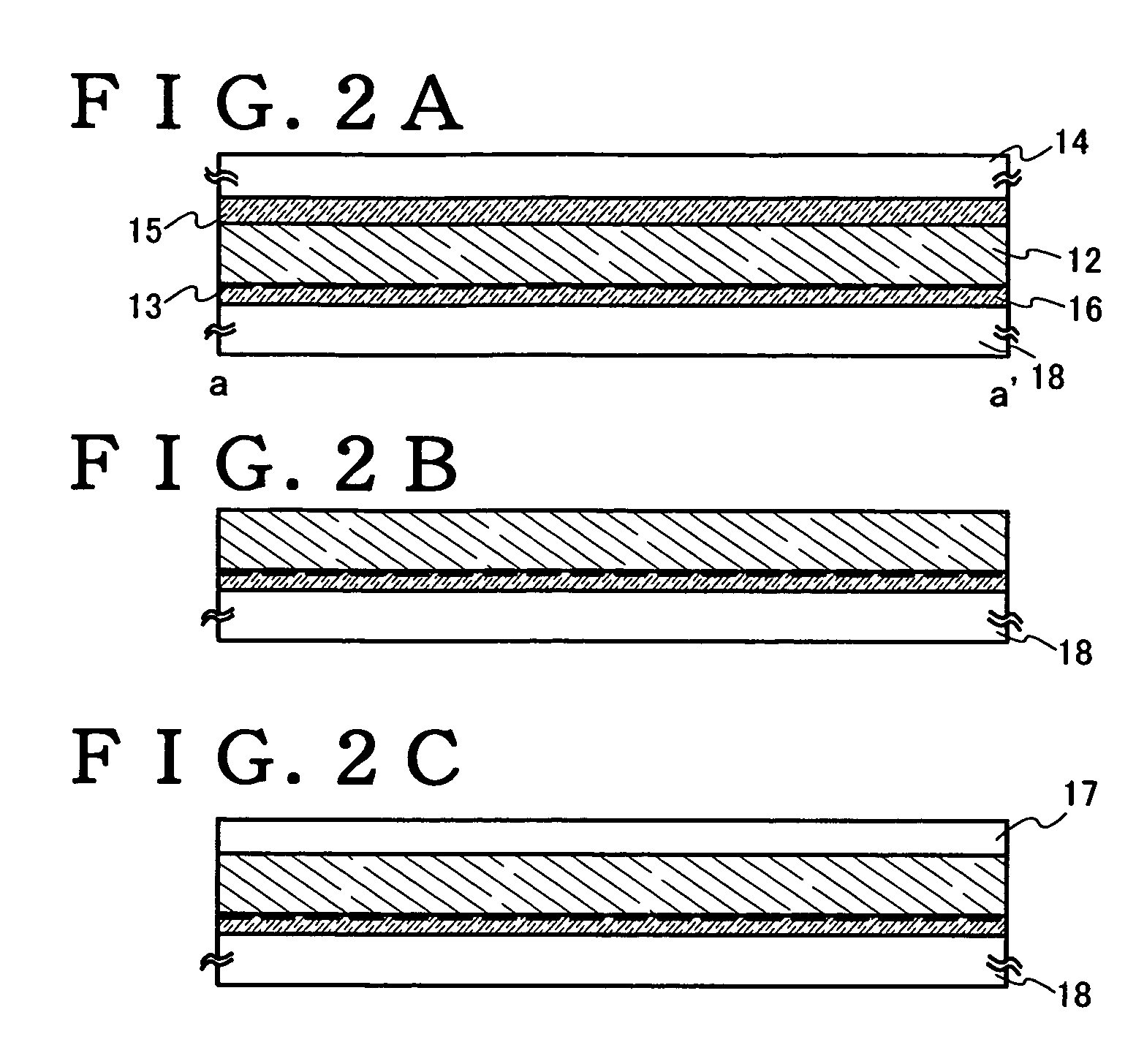

Thin film integrated circuit device, IC label, container comprising the thin film integrated circuit, manufacturing method of the thin film integrated circuit device, manufacturing method of the container, and management method of product having the container

InactiveUS7973313B2Efficiency of information managementIncrease capacitanceTransistorSolid-state devicesSiliconSemiconductor

The present invention provides an ultrathin thin film integrated circuit and a thin film integrated circuit device including the thin film integrated circuit device. Accordingly, the design of a product is not spoilt while an integrated circuit formed from a silicon wafer, which is thick and produces irregularities on the surface of the product container. The thin film integrated circuit according to the present invention includes a semiconductor film as an active region (for example a channel region in a thin film transistor), unlike an integrated circuit formed from a conventional silicon wafer. The thin film integrated circuit according to the present invention is thin enough that the design is not spoilt even when a product such as a card or a container is equipped with the thin film integrated circuit.

Owner:SEMICON ENERGY LAB CO LTD

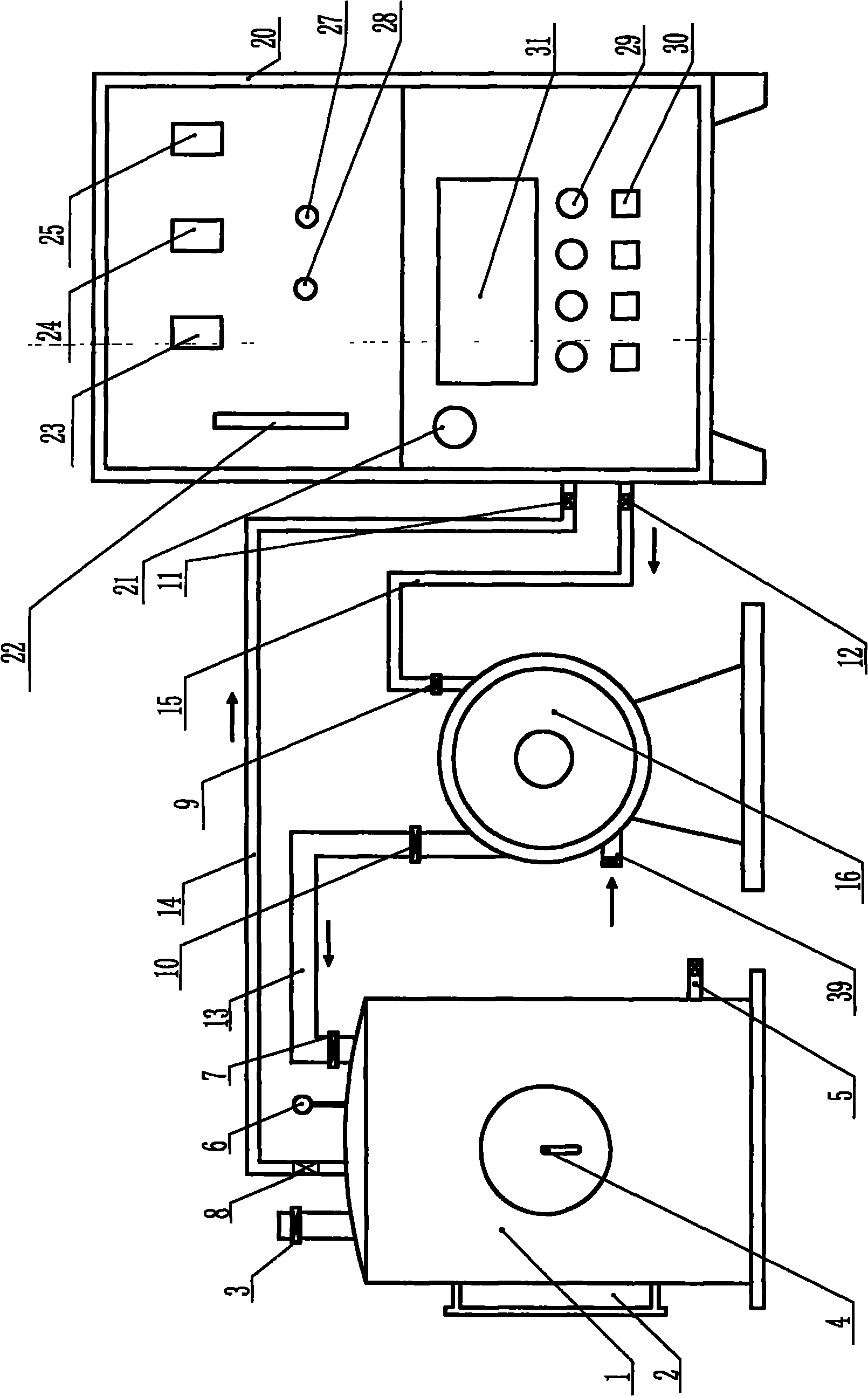

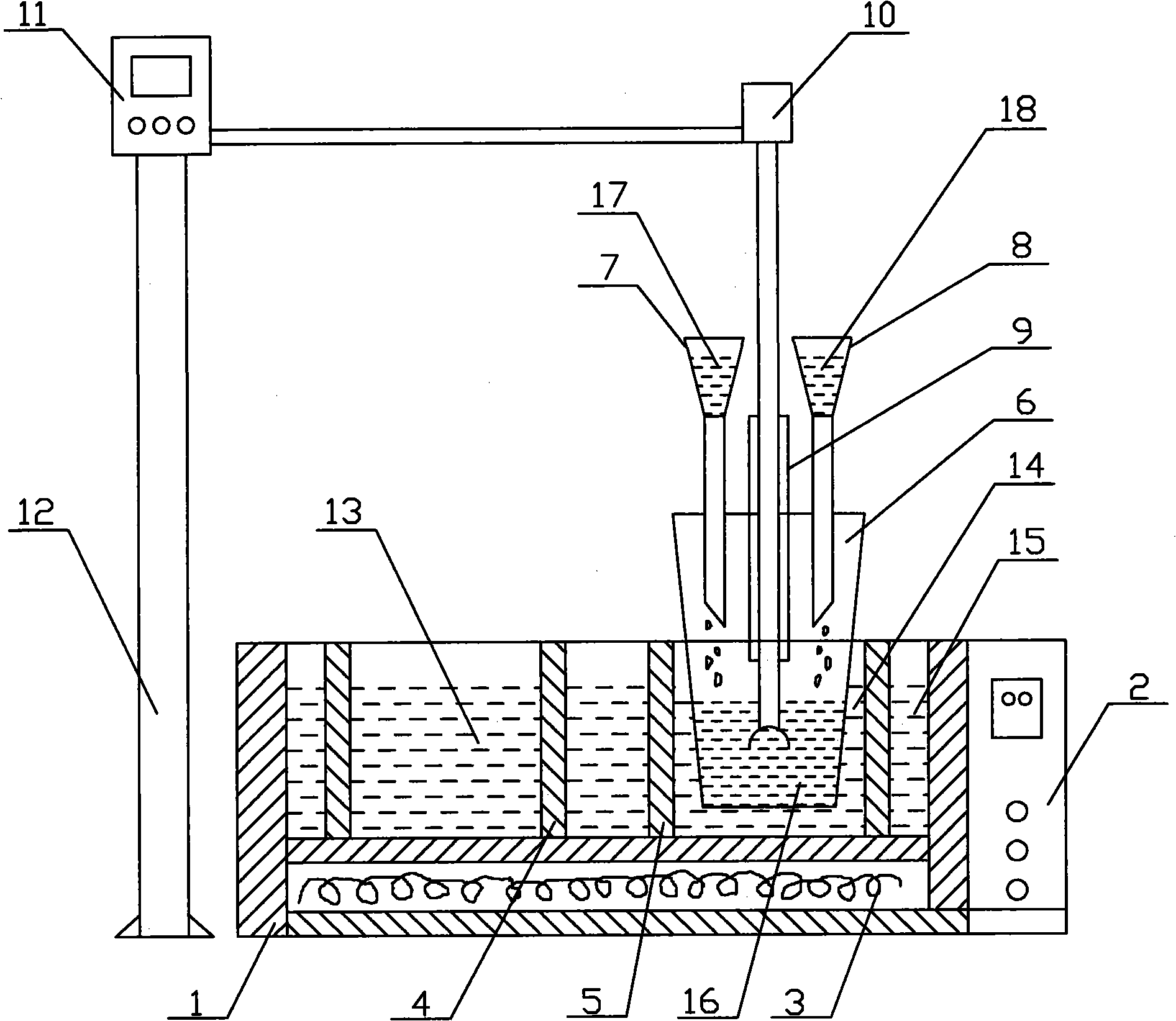

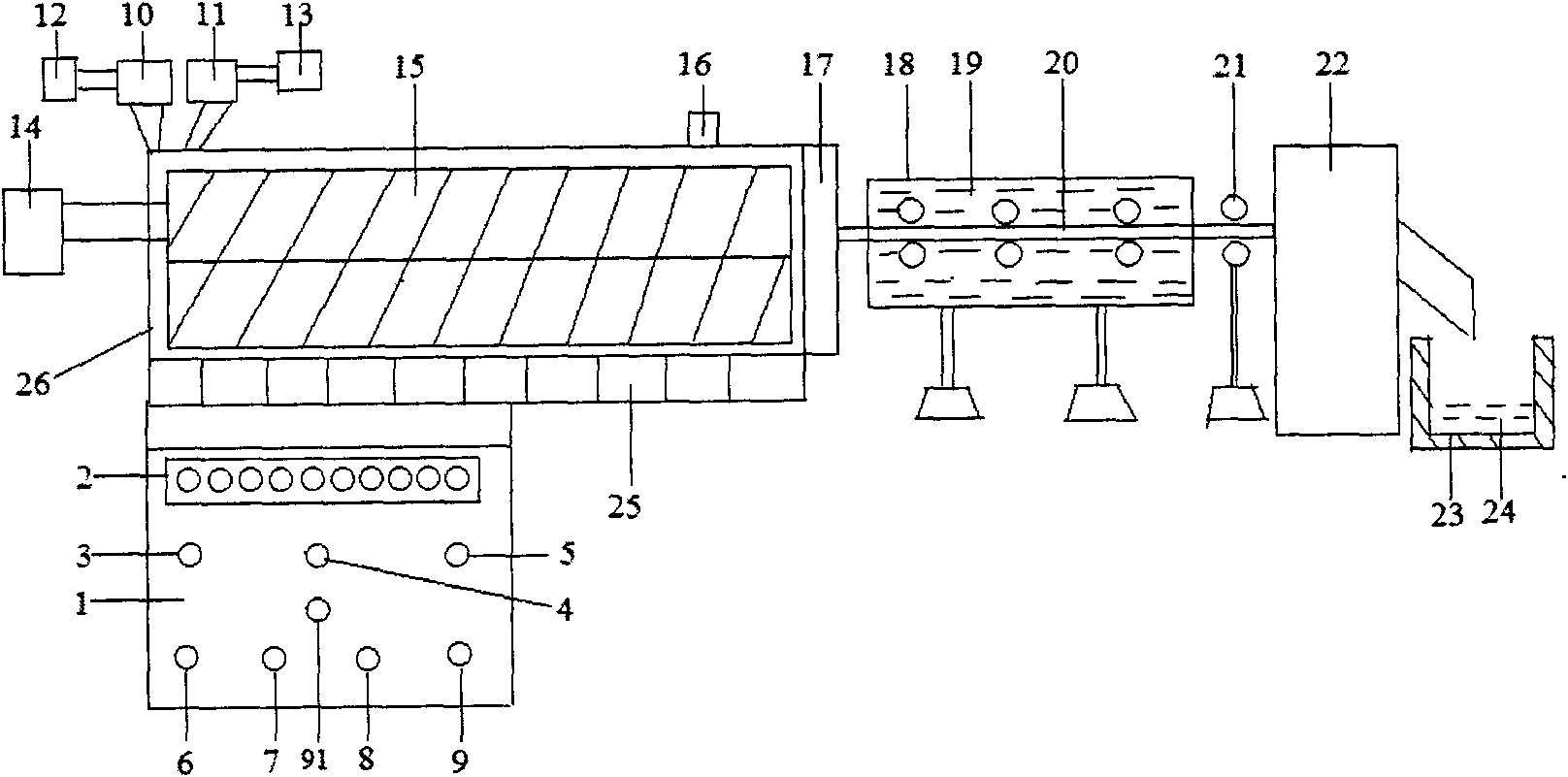

Coal mine underground mobile gas beam tube sampling and monitoring device

InactiveCN101788546AAdvanced and reasonable designCompact structureMining devicesMaterial analysisInformation processingBeam tube

The invention relates to a coal mine underground mobile gas beam tube sampling and monitoring device which mainly structurally comprises a gas-water separator, a vacuum pump, a gas sampling and monitoring control cabinet, an oxygen sensor, a methane sensor, a carbon monoxide sensor, a circuit board, a sampling beam tube, a dust precipitator, a dehumidifier, a gas control valve, a gas flow meter, a pressure gauge and a negative pressure gauge; beam tube sampling, dust precipitation and dehumidification, gas-water separation, flow control, sensor information capturing, control cabinet monitoring and control and micro-computer information processing are adopted for pre-warning, forecasting, analyzing and displaying fire gas concentration, and working out the gas change law; the device has the advantages of advanced and reasonable design, compact structure, easy operation and convenient operation, can move in a long distance in coal mine underground to acquire and monitor the fire gas in different coal bed gob areas or closed spaces, the monitoring distance can reach 5000m, the measurement data is accurate and reliable, and the accuracy can reach 96 percent; and the device can also be used on the ground or other ores.

Owner:邬剑明

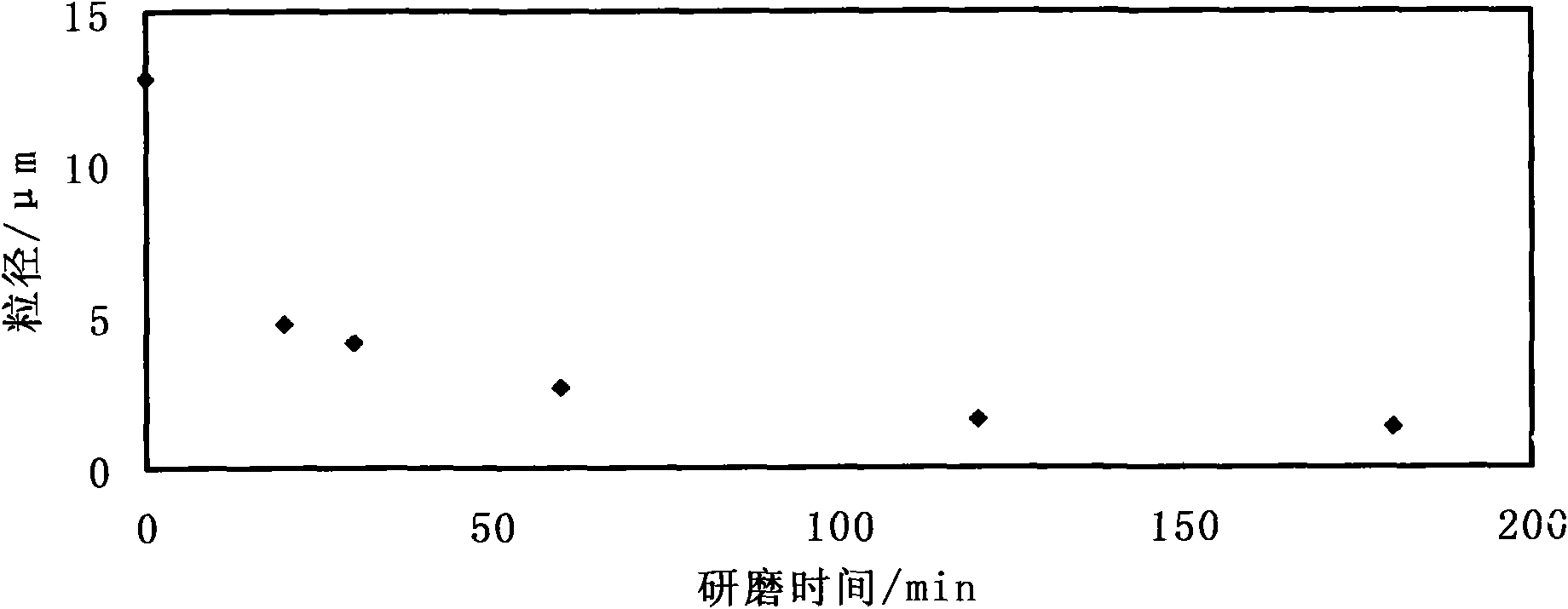

Novel technique for preparing fine calcium carbonate

The invention provides a new method which takes carbide slag, quick lime or slaked lime as calcium material to react with amino acids for preparing fine calcium carbonate. The method provides a very good scheme for the problems dealing with industrial waste carbide slag, so the method has very good environment-friendly, social and economic benefits.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

Novel method for producing superfine calcium carbonate by using carbide slag as raw material

InactiveCN101993104ASolve the possibility of industrializationRealize the possibility of industrializationCalcium/strontium/barium carbonatesCosmetic preparationsSlagCarbide

The invention relates to a method for preparing superfine calcium carbonate by adopting glycine as a dissolving agent, a modifying agent and an acid-binding agent, extracting effective calcium from calcium sources, such as carbide slag or lime, and the like and charging carbon dioxide into a reactor for calcifying, filtering and washing and application of the superfine calcium carbonate to paper making, paint production, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

Numerical control machining process design system and method of aircraft complex components facing process object

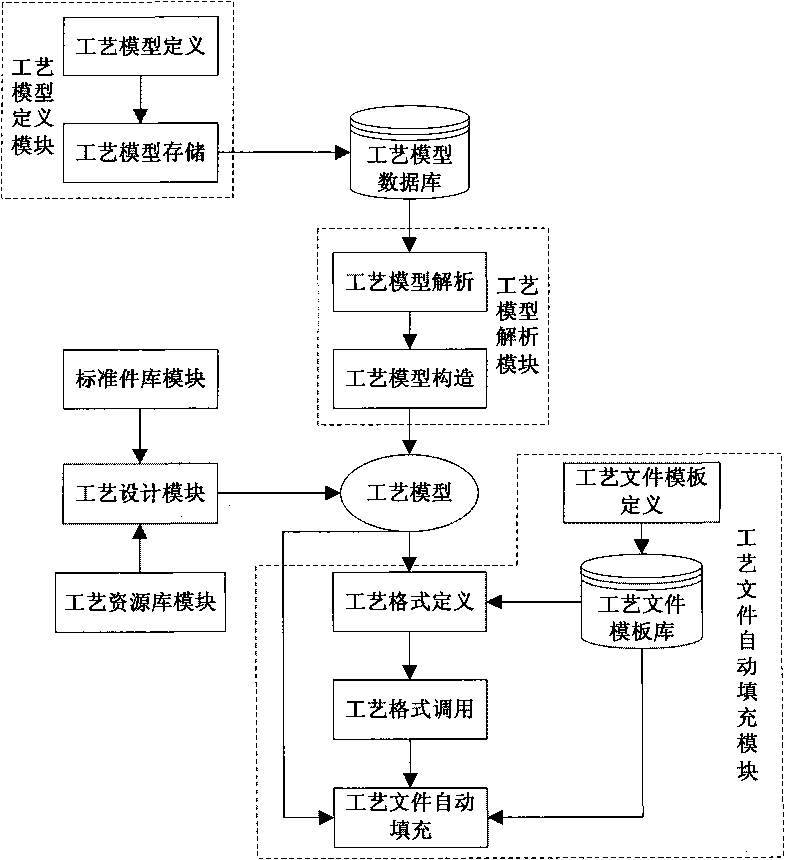

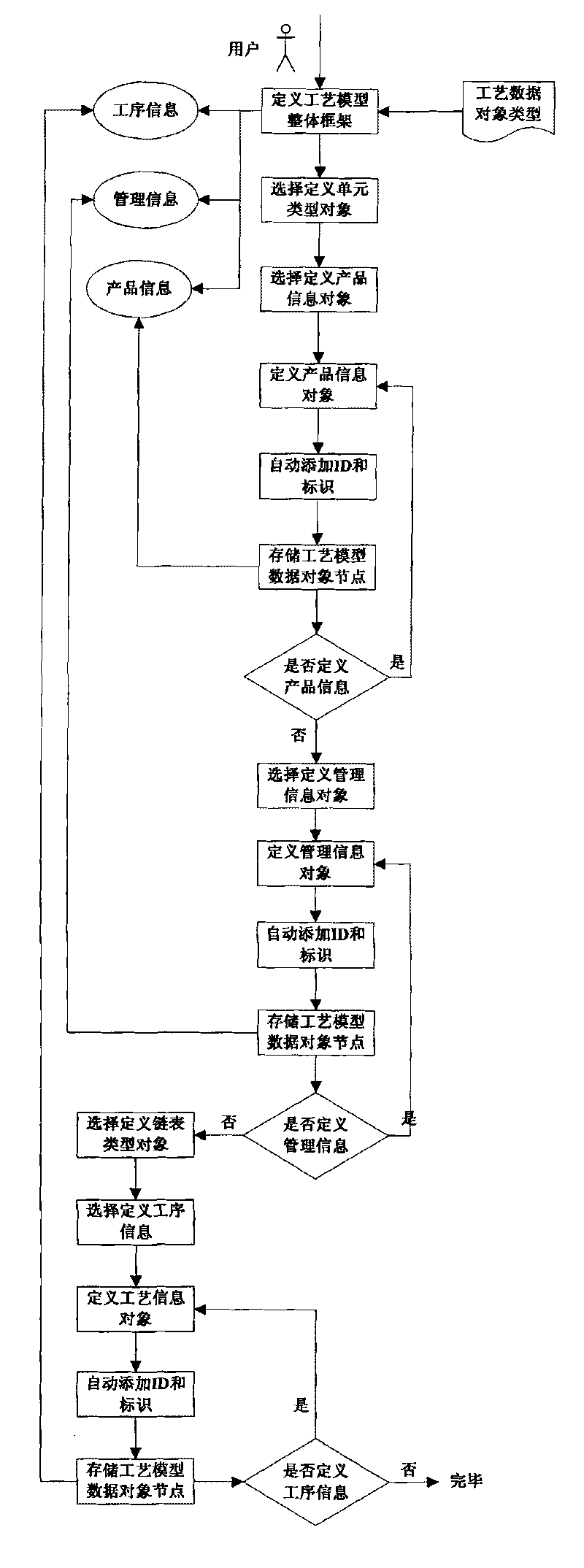

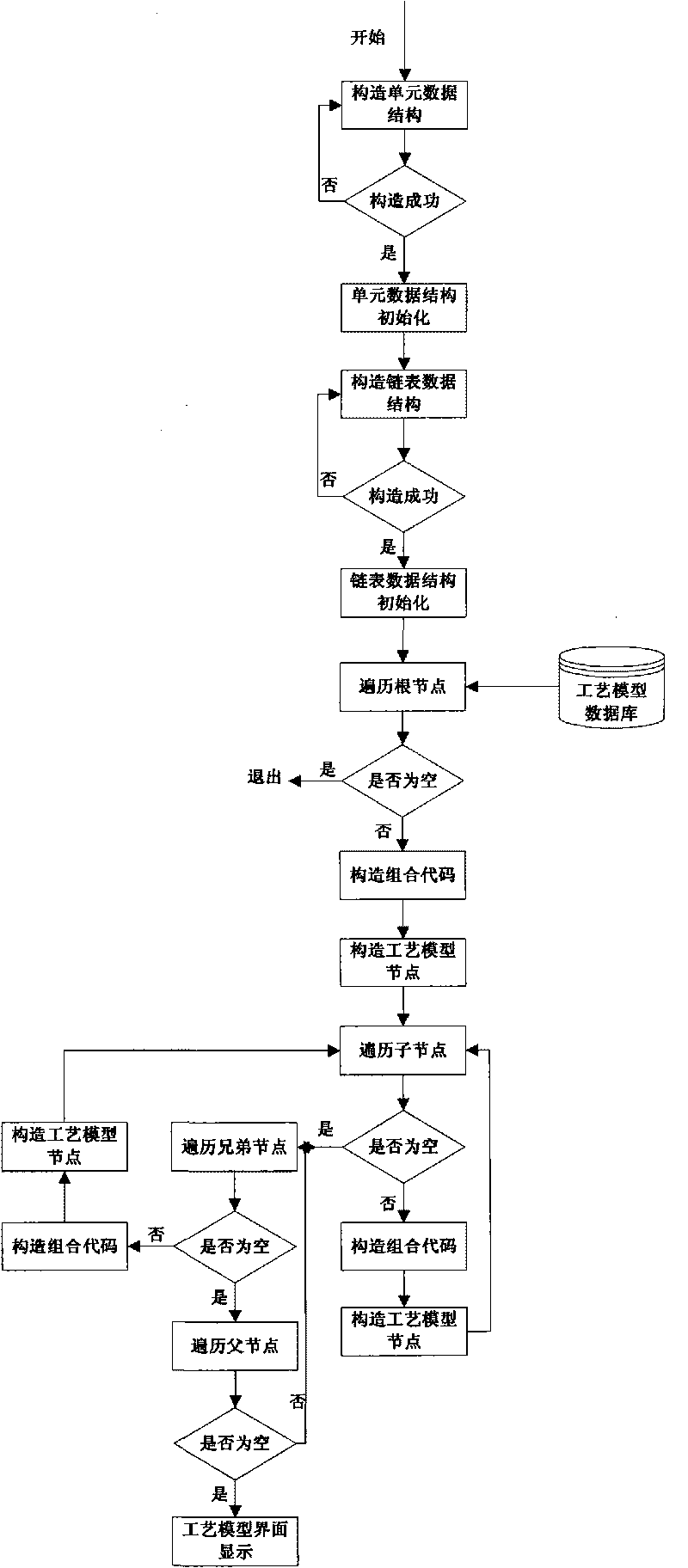

InactiveCN101763064AImplement autofillRealize batch outputProgramme controlComputer controlNumerical controlFast filling

The invention discloses a numerical control machining process design system and a method of aircraft complex components facing a process object. The system consists of six modules, namely a process model definition module, a process model analysis module, a process design module, a process file automatic filling module, a standard part library module facing a process model and a process resource library module facing the process model. The method is realized by five processes, namely process model definition, process model analysis, process design facing the process model, process format definition and automatic filling of a process file by calling a process format. The system can define the process model in a way of facing the process object, and on the basis, process aided design and fast filling and generation of the process file can be carried out, and effective separation of process design data and the process file can be realized, thus liberating a process designer from process file compiling to ensure the process designer to concentrate on process method design.

Owner:SHENYANG AIRCRAFT CORP +1

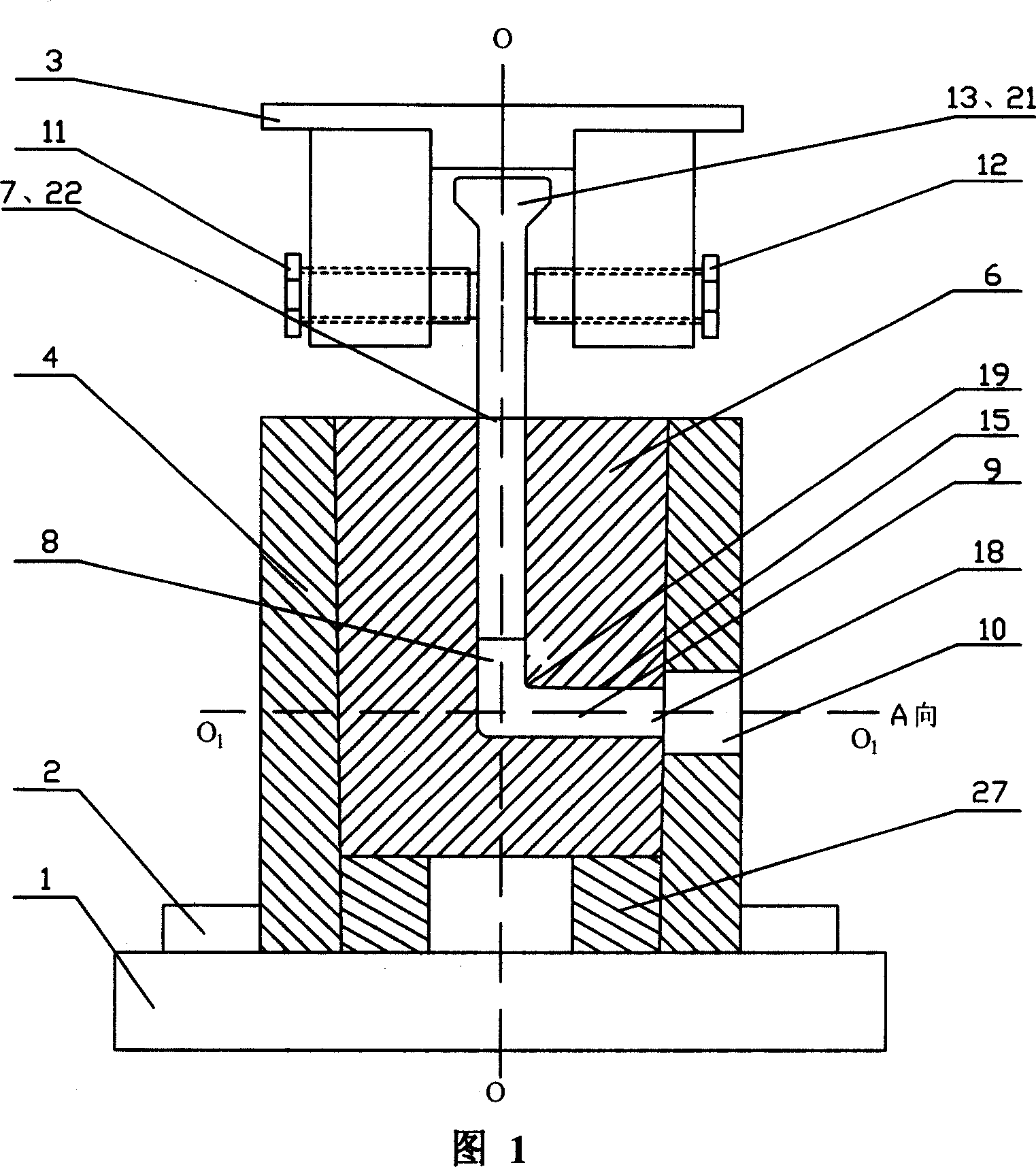

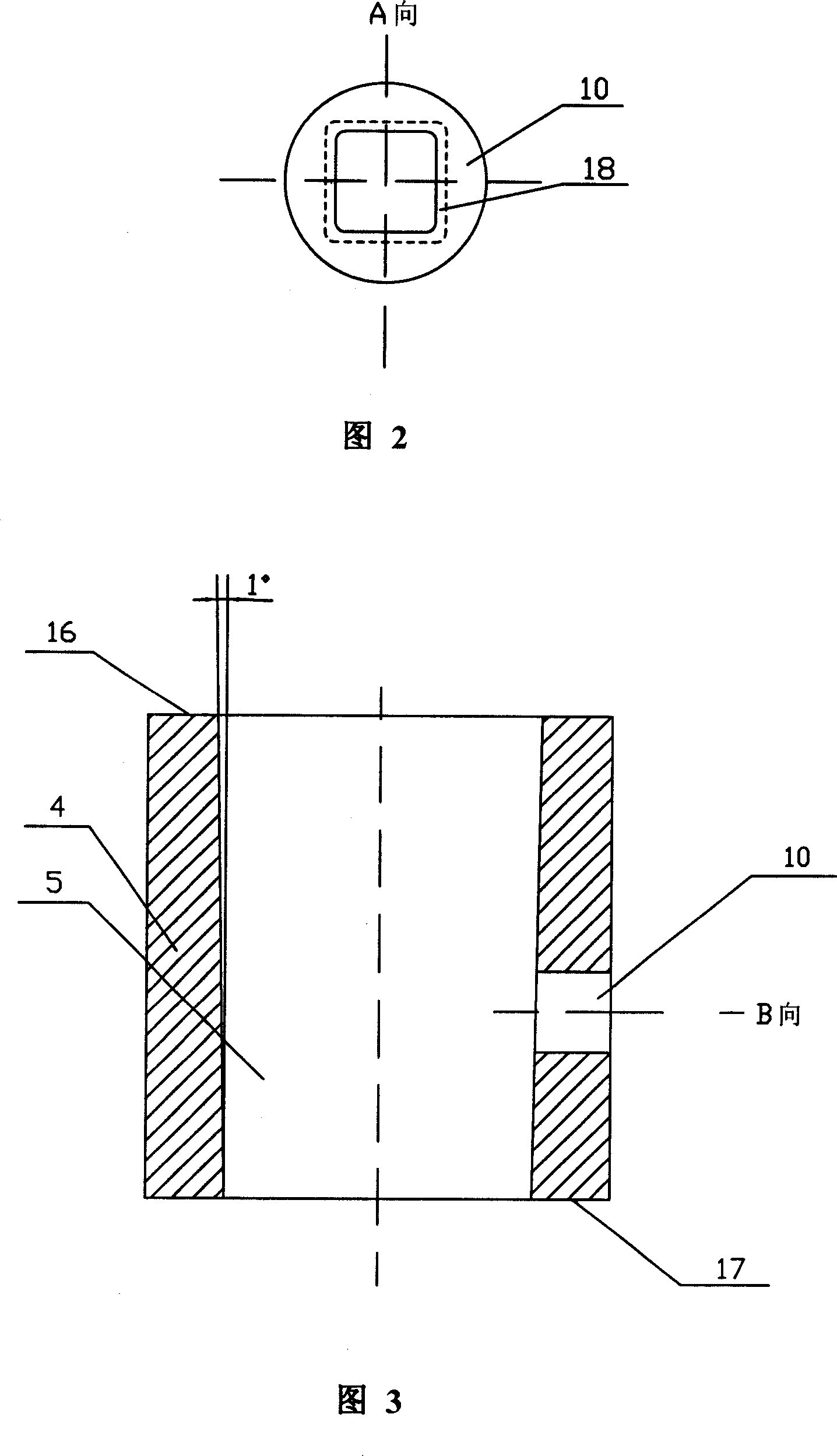

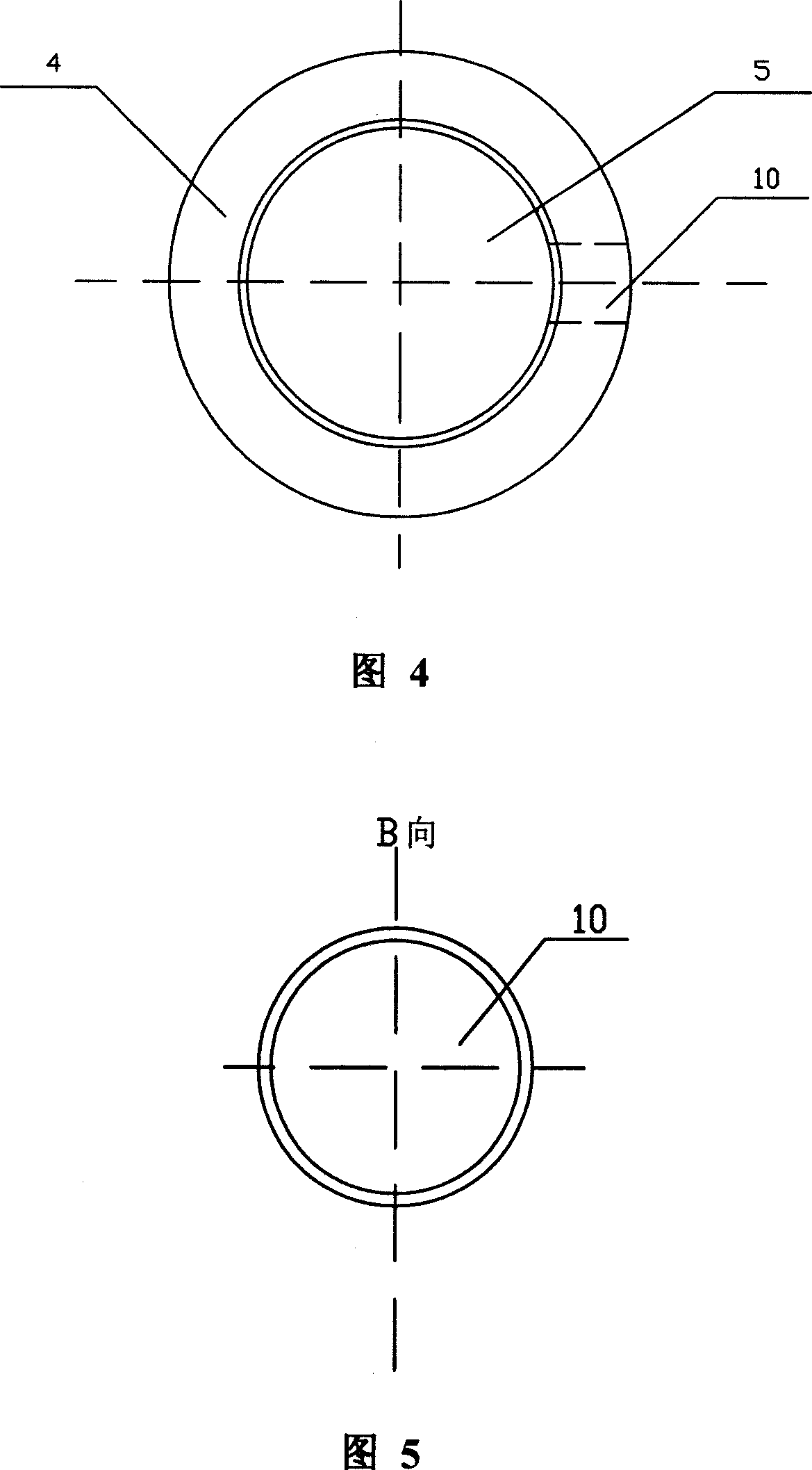

L-shaped extrusion device for producing ultra-fine crystal block body material

The extrusion apparatus for preparing superfine crystal block material has one structure comprising a die holder, a connecting seat, a conic die case, a conic die core, a wedged extruding rod with reduced extrusion force to avoid cracking of the block, a turning unit, a square vertical channel, a square horizontal channel and a product outlet. The product has high crystal grain fining and smooth surface, and the extrusion apparatus has simple structure, excellent mechanical performance, easy installation and use, and no pollution.

Owner:TAIYUAN UNIV OF TECH

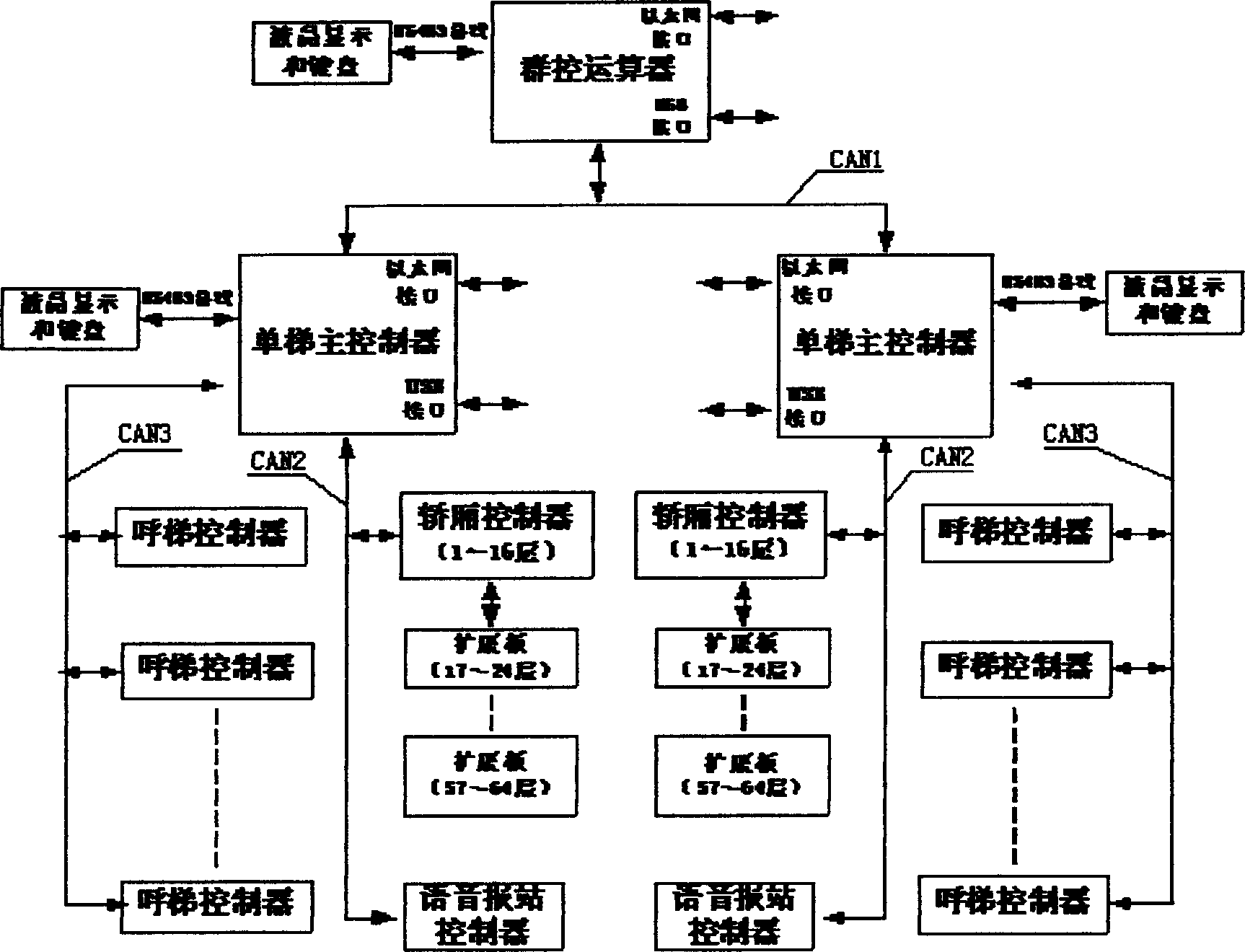

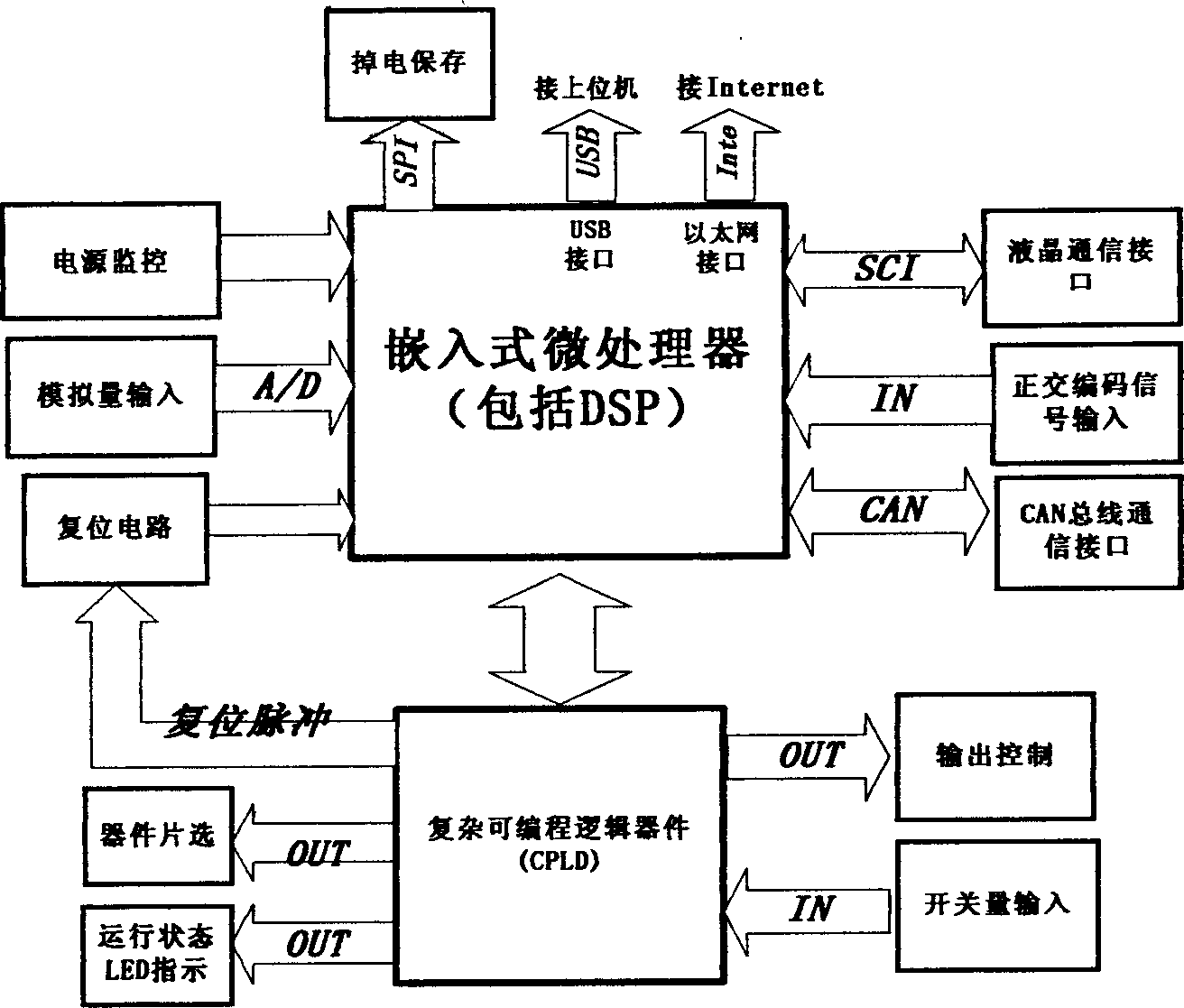

Intelligent method and device for controlling elevator based on distributed multipath CAN bus

An intelligent elevator controlling method and device based on distributed multi-channel CAN bus is disclosed. Said device is composed of a cluster operating controller, single-elevator controllers communiated with said cluster operating controller via CAN bus, and the cage controllers, floor calling controllers, LCD controllers and speech floor reporting controllers respectively for each of elevators. Its control method is also disclosed.

Owner:WUHAN UNIV OF TECH +1

Method for cleaning polyphenylene sulfide melt spinning spinneret

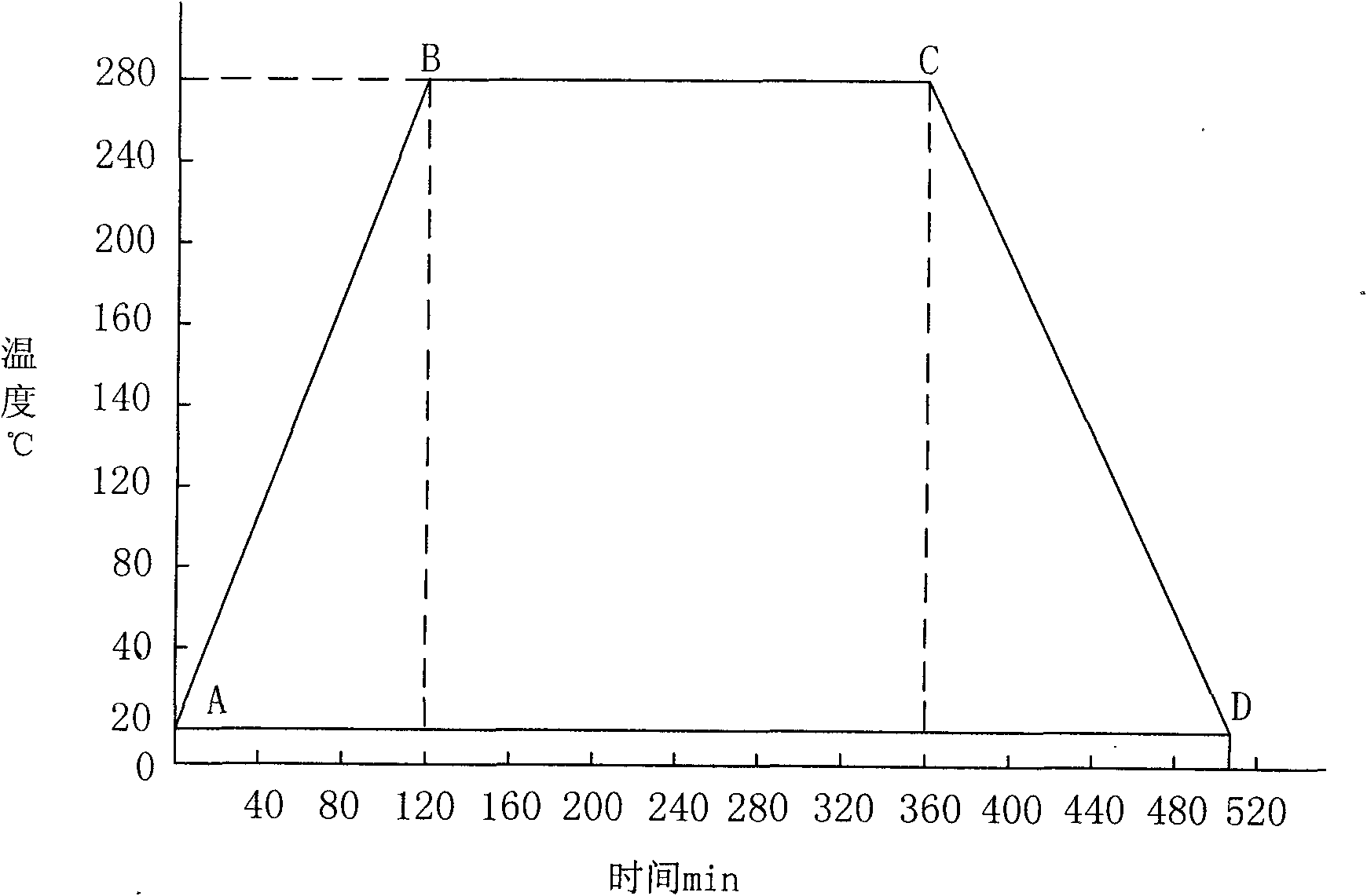

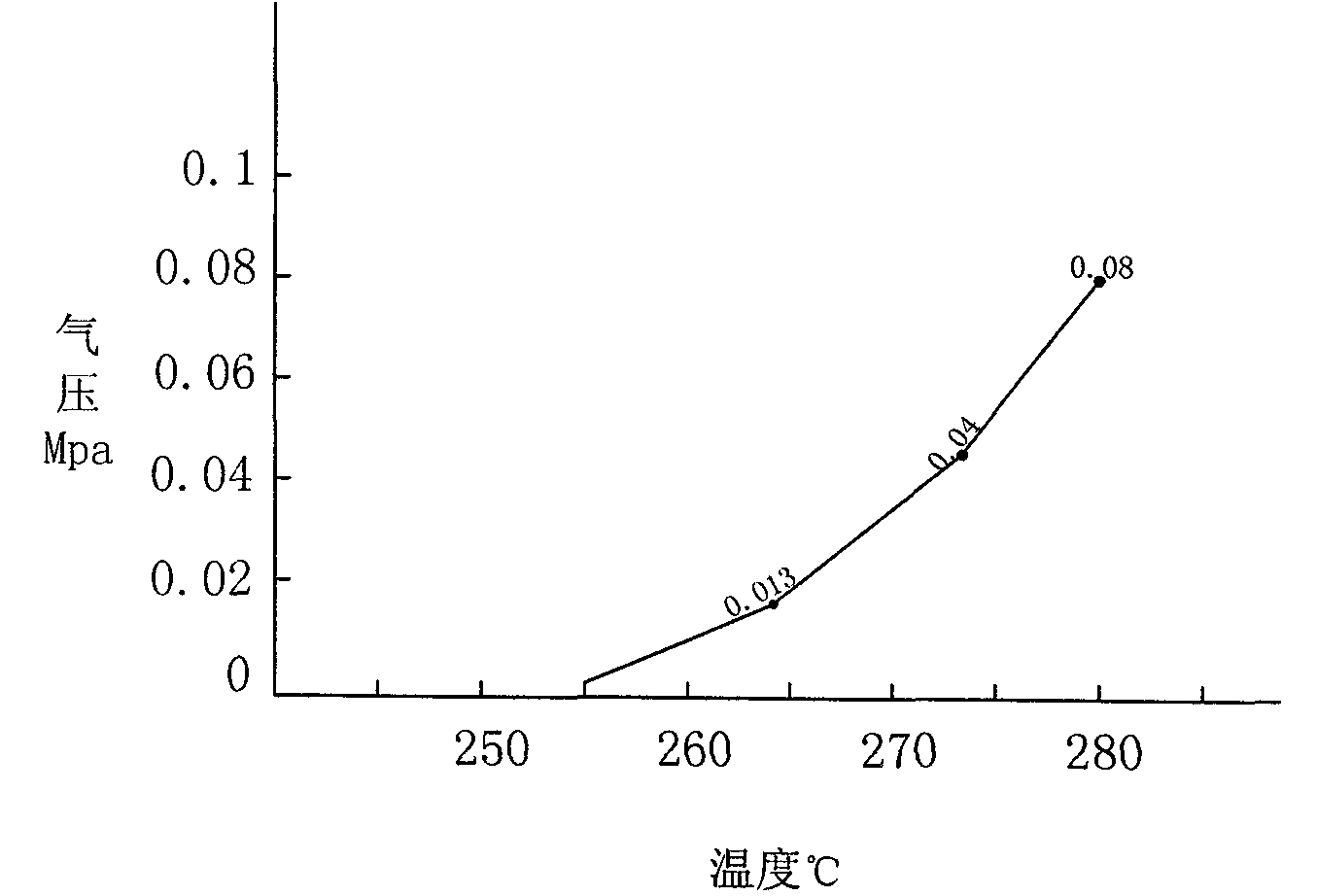

The invention relates to a method for cleaning a polyphenylene sulfide melt spinning spinneret. Regarding that high polymer has the characteristics of high decomposition temperature, organic and inorganic solvent insolubility, based on the actual condition that the polyphenylene sulfide is firmly attached on the spinneret and is hard to clean, according to the principle that structural components of chemical substances are similar and compatible, the method adopts biphenyl-biphenyl ether served as cleaning agent to complete cleaning of the spinneret in a cleaning kettle at 280 DEG C and 0.08MPa under cleaning agent out-kettle circular flowing, and finally completes cleaning of the spinneret through calcining of a calcinator, ultrasonic cleaning and compressed air drying. The cleaning method has short technical process, few used equipment, good cleaning effect and cleaning rate of spinneret attachment reaching 99.999 percent, ensures that the spinneret has no phenomena of deformation, corrosion or decarburization, and is a perfect cleaning method for the polyphenylene sulfide melt spinning spinneret. Components and parts of other spinning machines attached with polyphenylene sulfide high polymer also can be cleaned by using the method.

Owner:TAIYUAN UNIV OF TECH

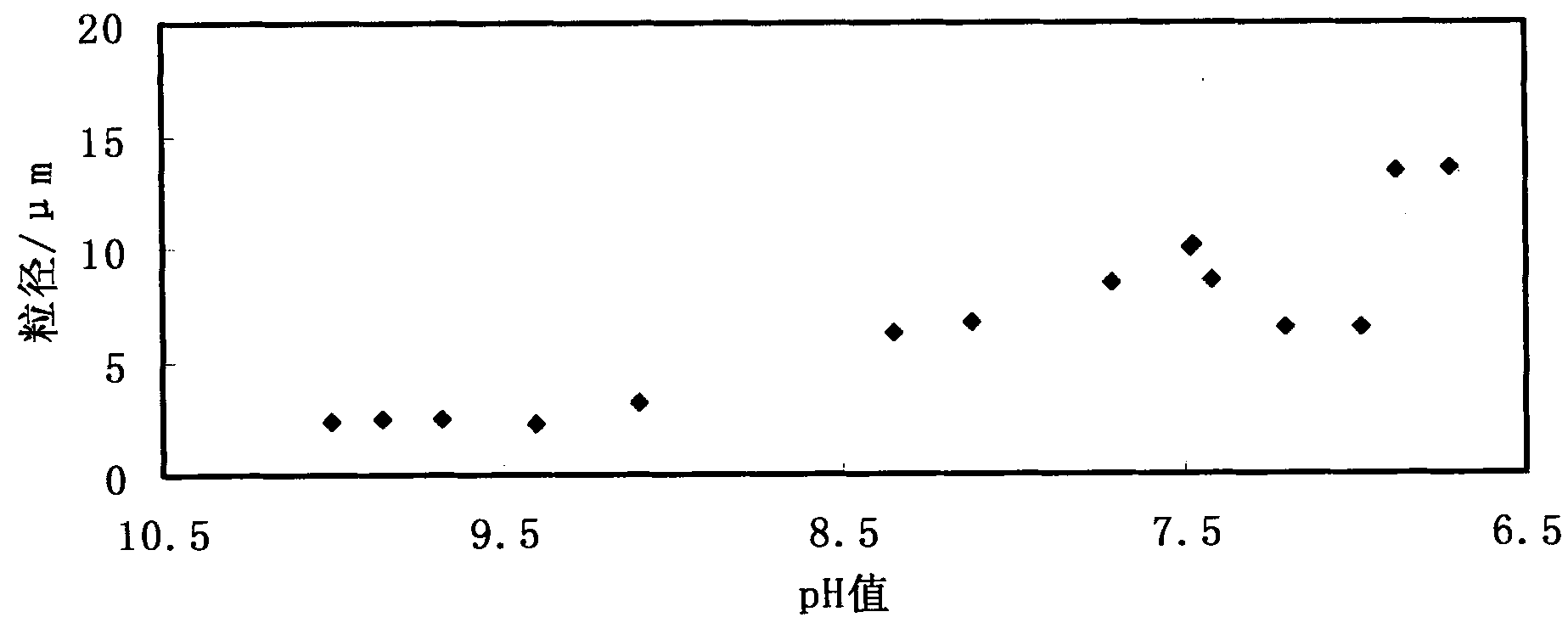

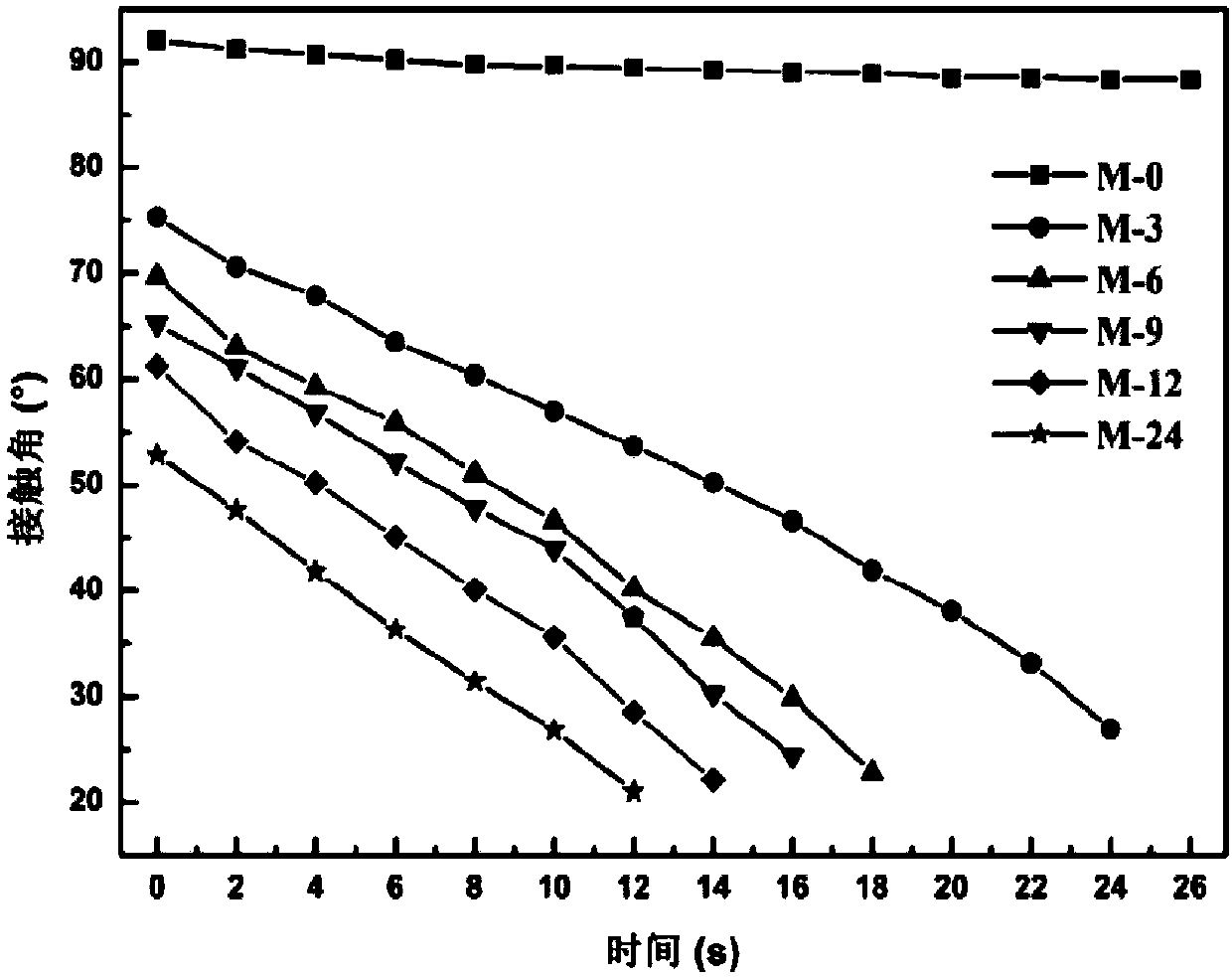

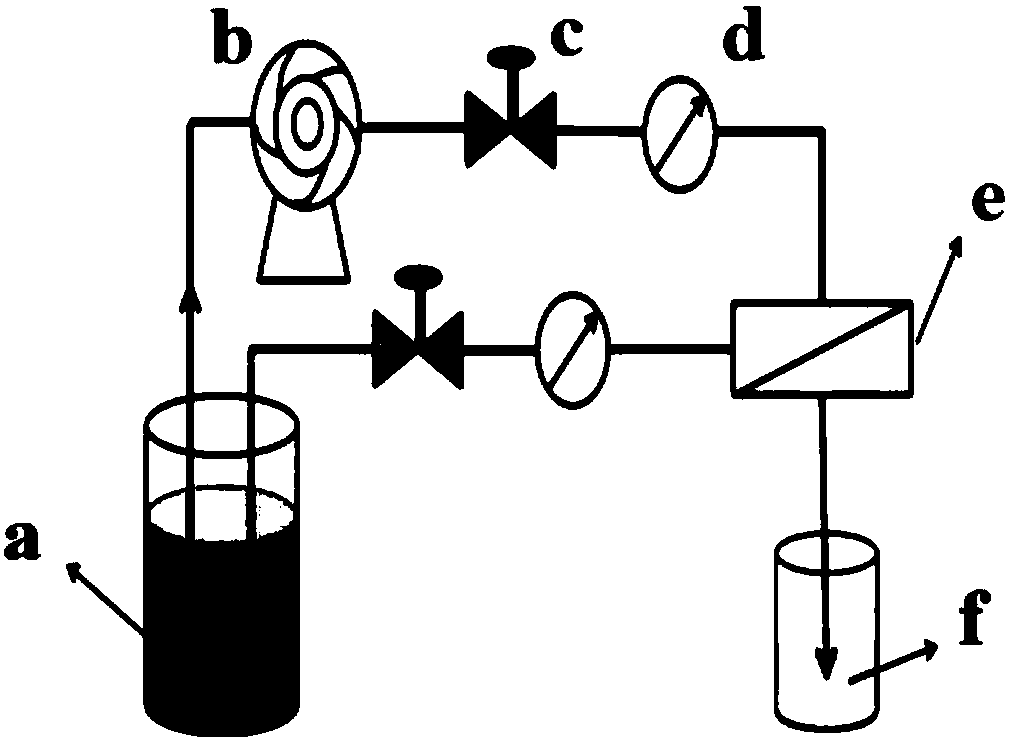

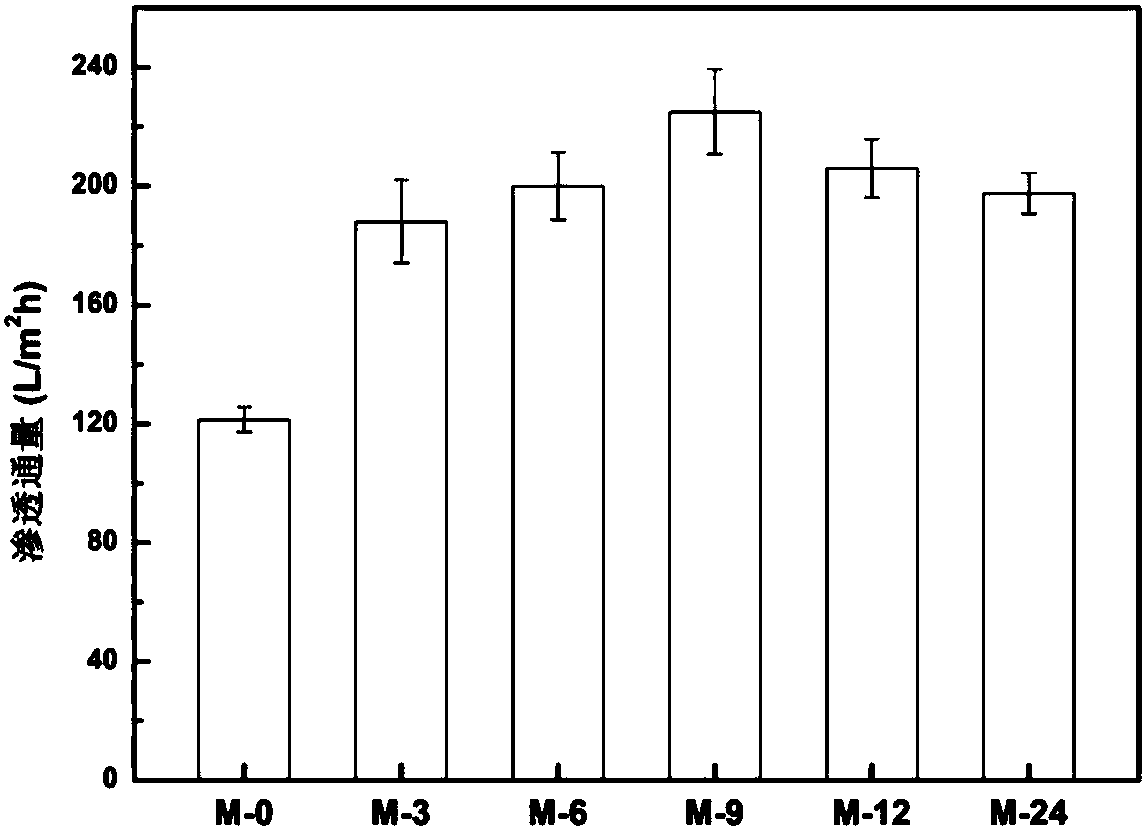

Plant polyphenol modified polymer membrane as well as preparation method and application thereof

ActiveCN107670513AAvoid performance damageAvoid pollutionMembranesSemi-permeable membranesHydrophilic coatingPolymer science

The present invention discloses a plant polyphenol modified polymer membrane as well as a preparation method and application thereof, in particular relates to the field of modified polymer membranes with anti-fouling properties. In the prior art, due to low surface energy of the polymer membrane, the polymer membrane is susceptible to contamination with proteins, oils and the like and causes a series of temporary or permanent pollution problems. The polymer membrane provided by the invention utilizes the super-strong adhesive ability of plant polyphenols and the coordination of polyphenols andmetal ions to build a hydrophilic coating on the surface of a hydrophobic polymer membrane. The polymer membrane provided by the invention has the advantages of simplicity, high efficiency, mild reaction condition and strong practicability. The controllable hydrophilic modification of a hydrophobic polymer can be realized by changing the conditions of the dip-coating time, the concentration of aplant polyphenol mixed solution, the pH, the temperature and the like, and a high permeation flux can be maintained in the course of cross-flow continuous work, so that the polymer membrane has a verygood application prospect in the field of water treatment. The invention also opens up an effective way, which is simple and easy to operate and has strong universality, for modification of polymer membranes under mild conditions.

Owner:TIANJIN POLYTECHNIC UNIV

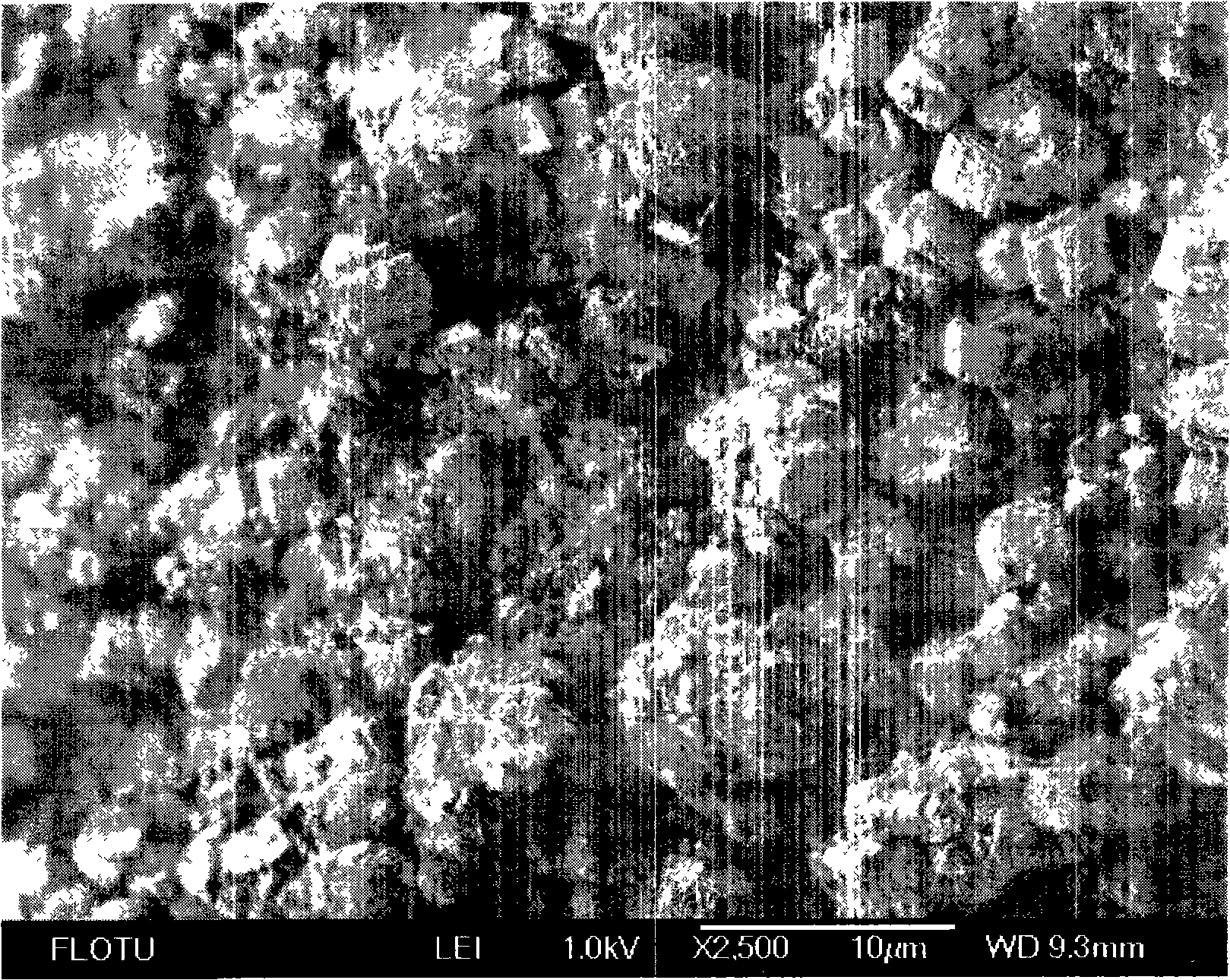

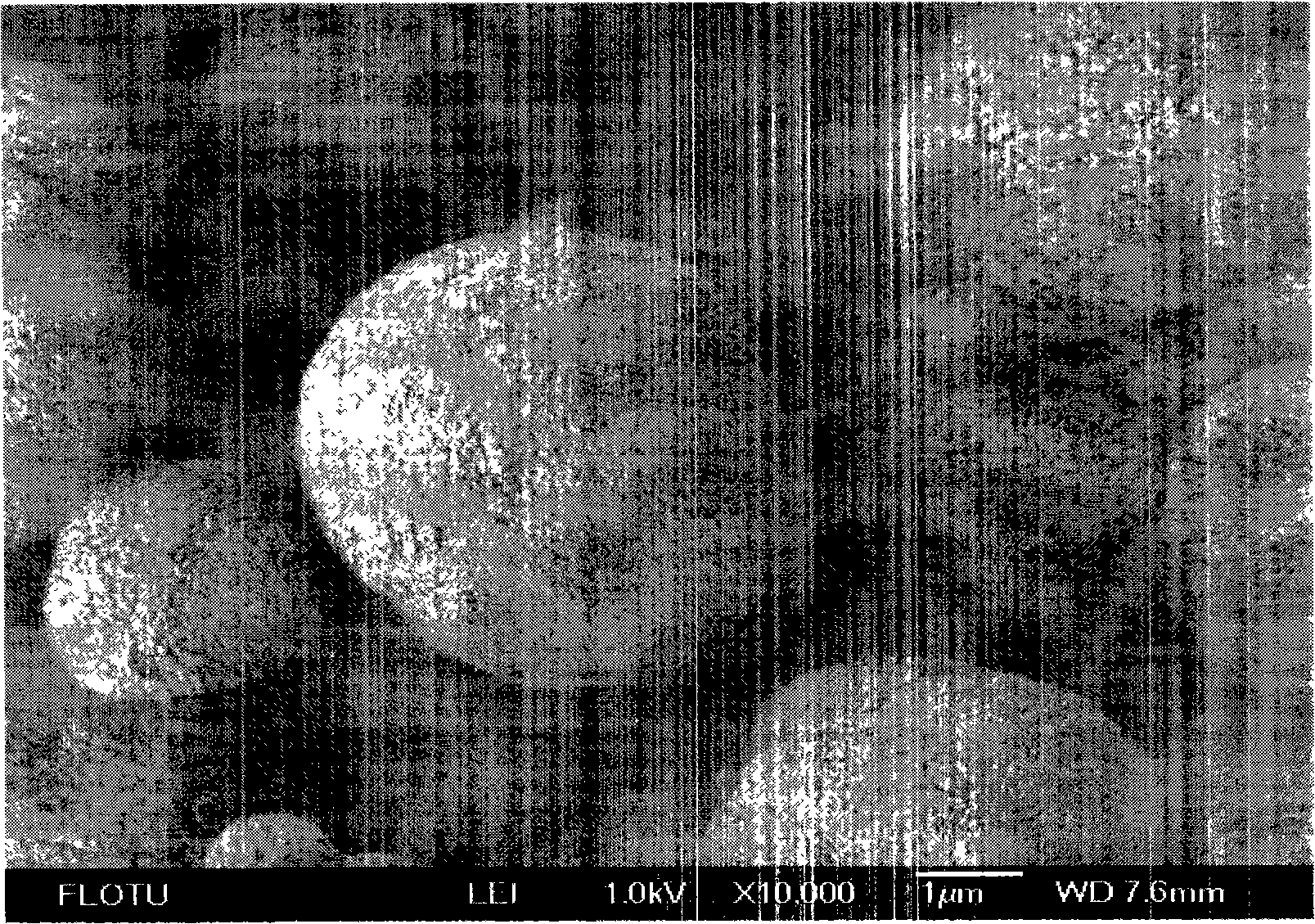

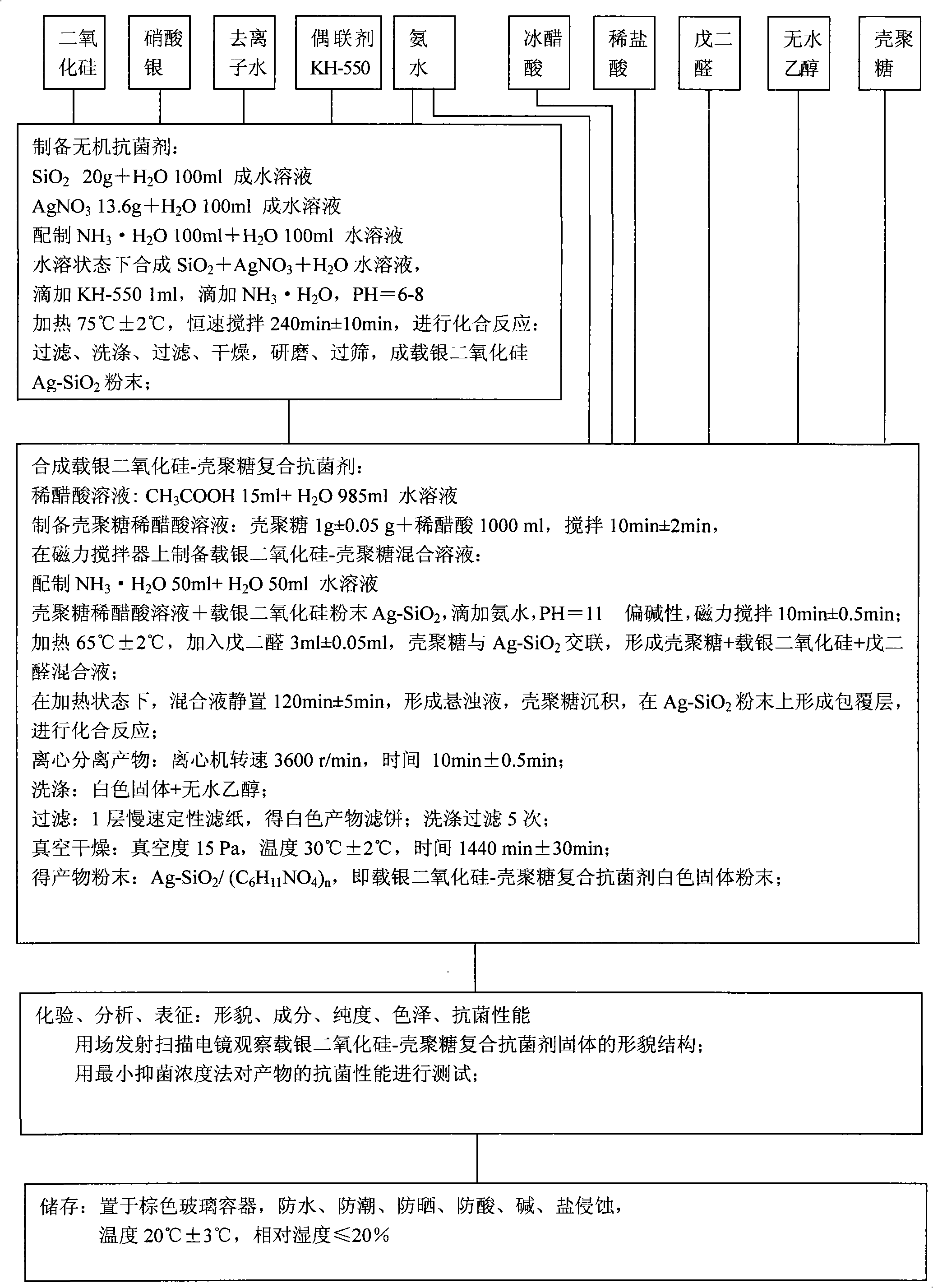

Preparation of silver-loaded silica-chitosan compound anti-bacteria agent

The invention relates to a preparing method for a silver-loaded silicon dioxide-chitosan compound antibacterial agent; the preparing method comprises the following steps: silver-loaded silicon of inorganic antibacterial agent is firstly prepared according to the antibacterial and bacteriostatic characteristics of the antibacterial agent; Ag-SiO2 is used as a carrier to prepare inorganic-organic compound antibacterial agent, namely, the silver-loaded silicon dioxide-chitosan compound antibacterial agent uses silicon dioxide as inorganic material, uses polymer chitosan as organic material, uses deionized water, silver nitrate, ammonia water, KH-550, glacial acetic acid, diluted hydrochloric acid, glutaric dialdehyde and absolute ethyl alcohol as agents, carries out chemical reaction by water bath synthesis, adjusts the pH value, carries out centrifugal separation, is washed, filtered and dried in vacuum, and finally the powdered product which is white, has laminated form, layered shape and crosslink structure is prepared. The preparing method has short technique process, little used equipment, rich material source and low cost; the purity of the product can be up to 97 percent, the yield of the product can be up to 98 percent, and compared with the product with single ingredient in the prior art, the antibacterial and bacteriostatic characteristics of the product can be improved by 90 percent; therefore, the preparing method of the invention is an ideal preparing method for the inorganic-organic compound antibacterial agent.

Owner:TAIYUAN UNIV OF TECH

Roof greening light host material made from industrial and agricultural wastes

ActiveCN101960980AReduce loadReduce weightSolid waste disposalCultivating equipmentsNatural resourceAdditive ingredient

The invention provides a roof greening light host material made from industrial and agricultural wastes and is characterized in that the industrial and agricultural wastes serve as the major ingredients to prepare a light roof greening planting substrate; the substrate is a compound with the following main materials: flyash, coal cinder, straw grains, garden wastes and yellow soil; the proportions of the materials are as follows: 11-20% of flyash, 10-22% of coal cinder, 20-25% of straw grain, 20-32% of garden waste and 18-20% of yellow soil. In the invention, the common industrial and agricultural wastes are applied to the light roof greening planting substrate, which facilitates reduction of the cost of roof greening materials, improves comprehensive utilization level of natural resources and promotes cyclic utilization of the industrial and agricultural wastes and protection of the natural environment. The material of the invention has the advantages of few component types, easily available materials, low cost, environmental protection and high efficiency and suitability for large-scale promotion throughout the country.

Owner:武汉市林业果树科学研究所 +1

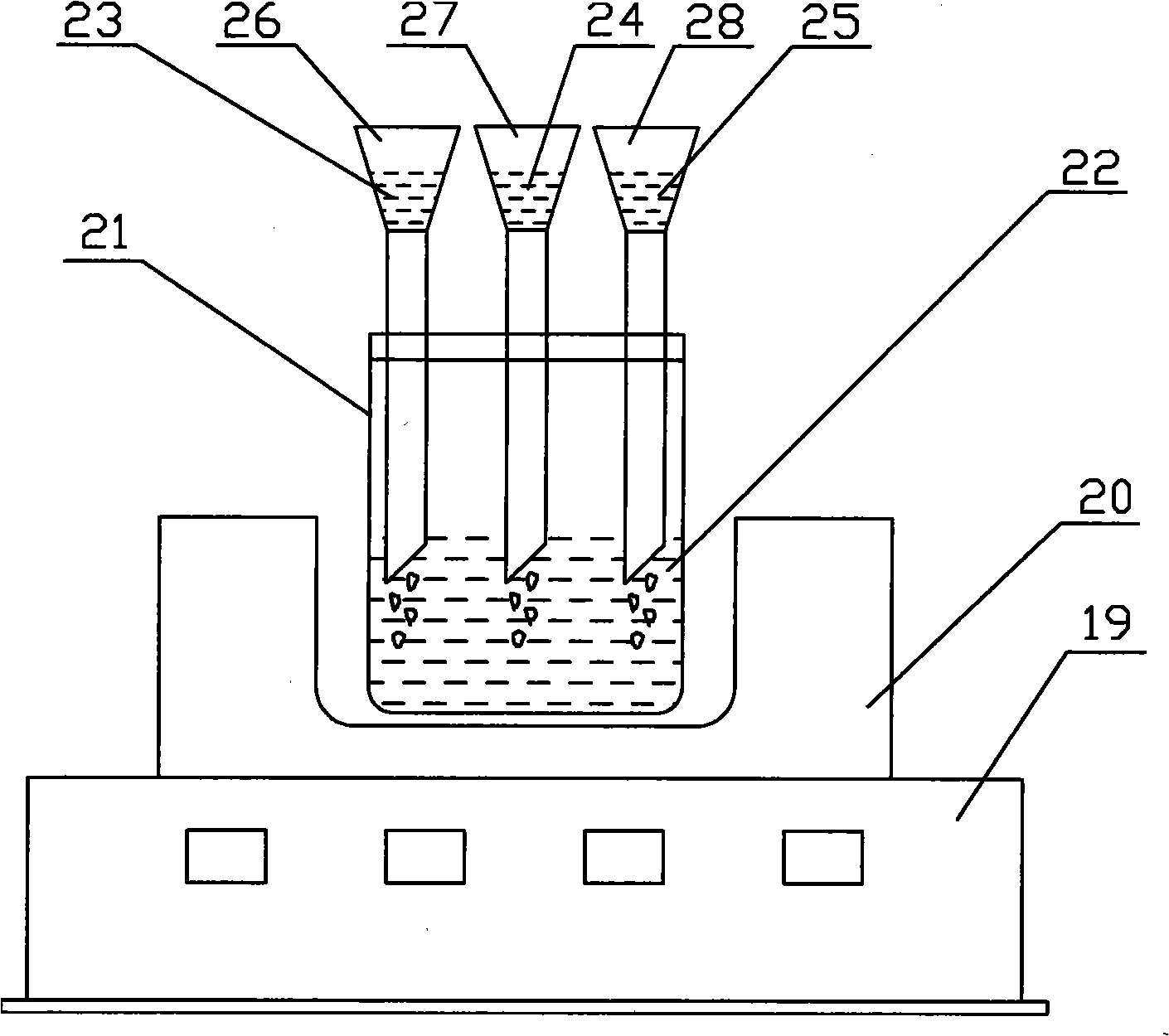

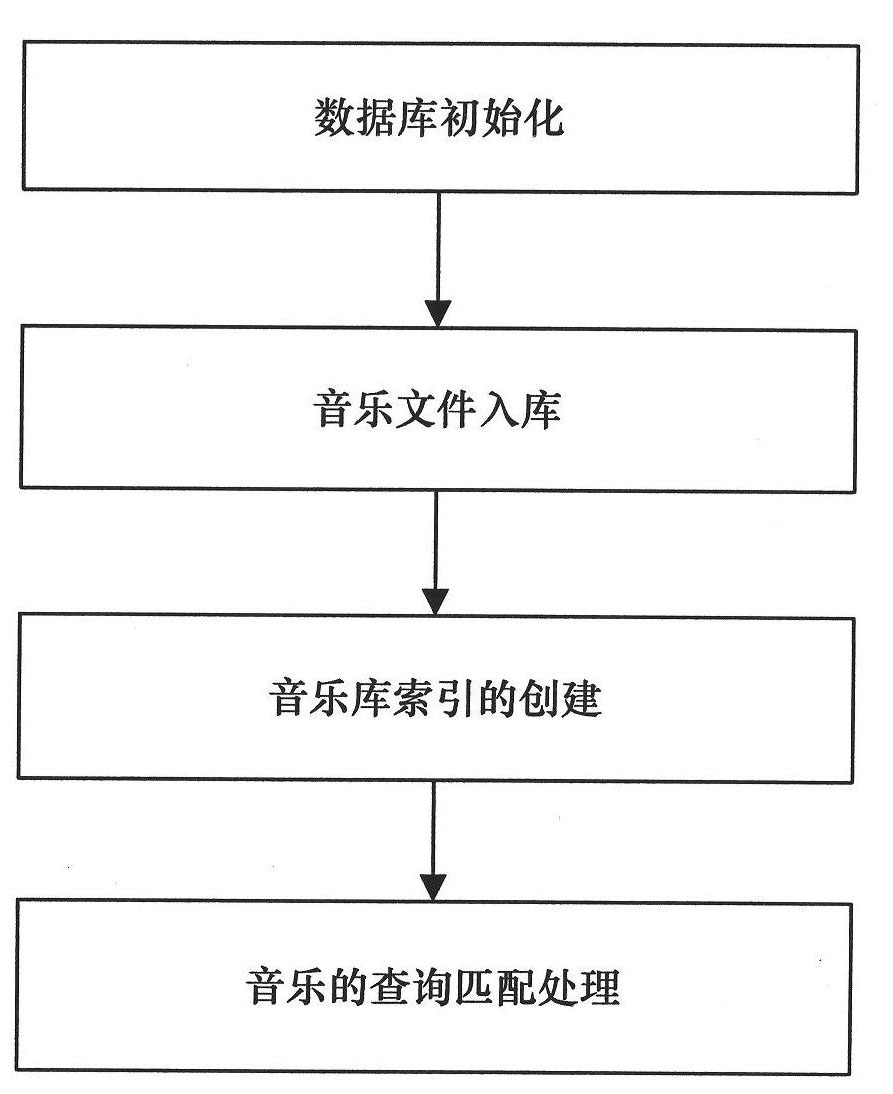

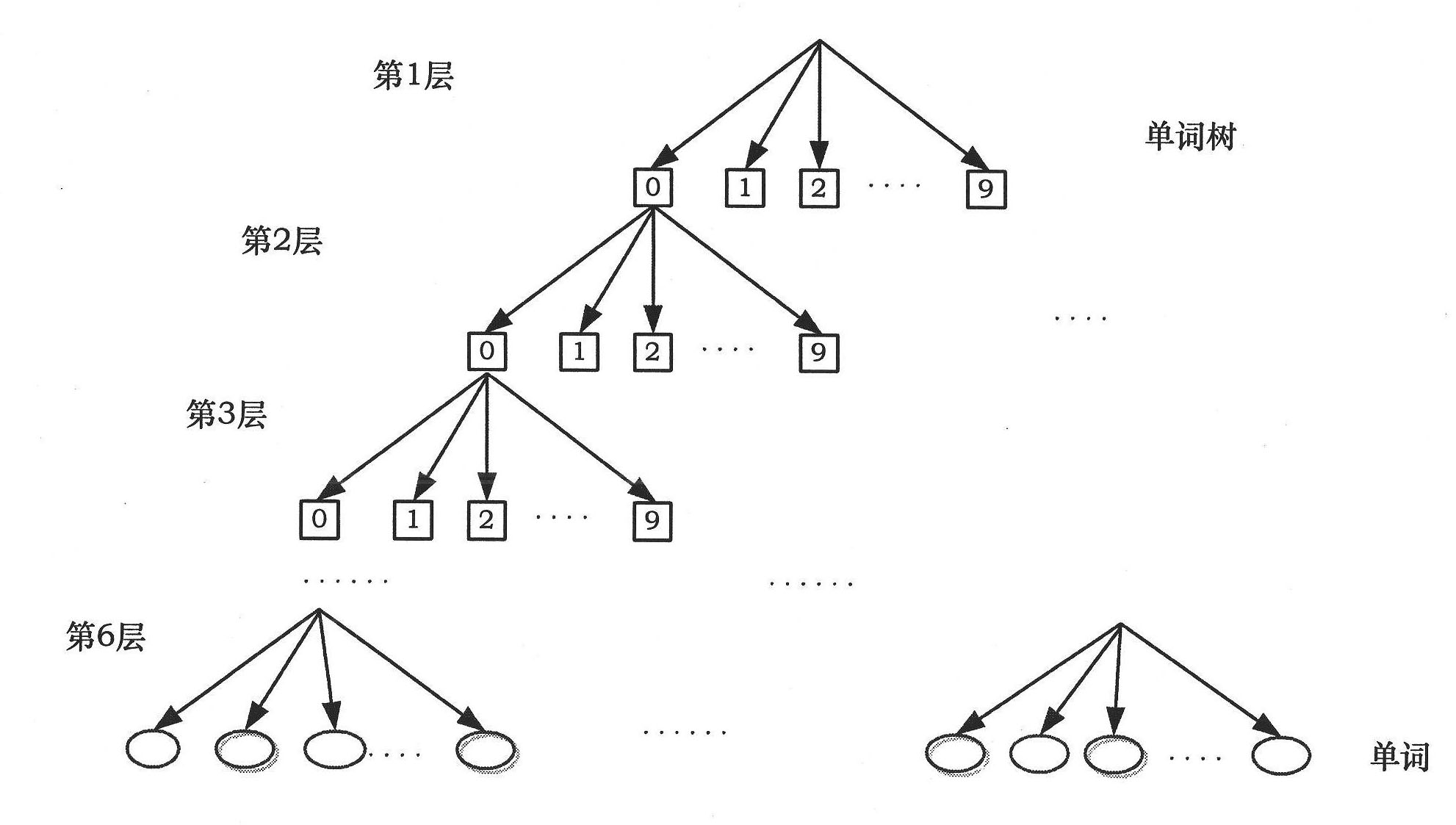

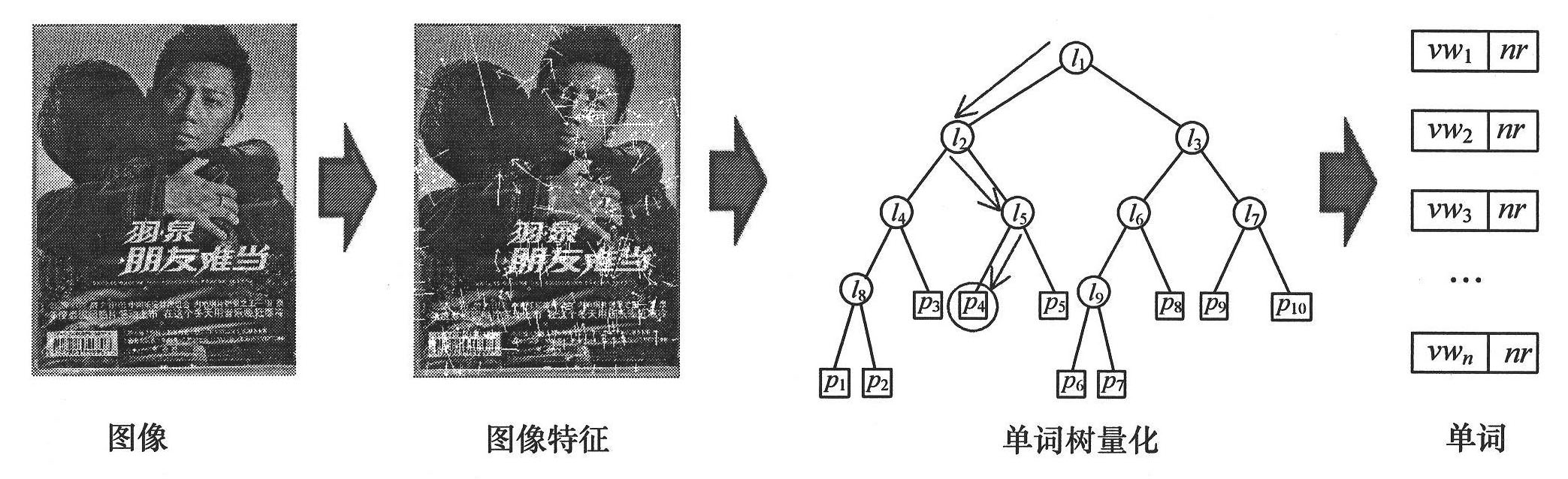

Method for managing immense amounts of music libraries based on mobile device

InactiveCN101950302AInnovativeAdvancedSpecial data processing applicationsImage QuantificationData management

The invention discloses a method for managing immense amounts of music libraries based on a mobile device, belonging to the technical field of databases, which can uses an image to search a corresponding music document in a music library. The method comprises the following steps: firstly initializing the music data storage space; using the characteristics of immense amounts of images to generate a word tree used for quantifying the images; storing the music document into the music library; preprocessing the image when the music image document is stored into the music library; extracting the characteristics of the music image document; establishing an index for the music document stored into the music library; shooting music-related images at any time and in anywhere by using the mobile device; and uploading the shot pictures and searching the music. The method of the invention utilizes an advanced image matching and searching technology and immense amounts of music library data managing technology, realizes the searching process from the image to the music document, has simple operation, and is more rapid and more accurate in the aspect of searching immense amounts of the music libraries.

Owner:李晓耕

Preparation method of heat-resistant polyphenylene sulfide fiber

InactiveCN102220659AReasonable workmanshipAccurate and detailed dataFilament forming substance formingFibre typesCorrosionFineness

The invention relates to a preparation method of heat-resistant polyphenylene sulfide fiber, comprising the following steps: aiming at the demand on high-performance industrial fabric, adding silica to a polyphenylene sulfide material, preparing masterbatch, extruding by double screws to form strips, dicing, drying in vacuum, extruding and spinning by a single screw, cooling, applying oil to an oil roller, thermally sizing, and winding to form a wire barrel to finally obtain heat-resistant silica and polyphenylene sulfide fiber, namely, SiO2 / PPS fiber, wherein the fiber is white long silk, the fineness is 400dtex, the breaking strength is 3.75 cN / dtex, the heat resistance temperature is 230 DEG C, and the silk has stable chemical and physical performances; the fiber can be used for manufacturing heat-resistant, corrosion-resisting dedusting filter bags and the like, which has high demand on the breaking strength; the preparation method has advanced and remarkable technology and accurate and detailed quantity parameters, and is capable of performing large-scale industrial production; and the preparation method is a very ideal preparation method of the heat-resistant polyphenylene sulfide fiber.

Owner:TAIYUAN UNIV OF TECH

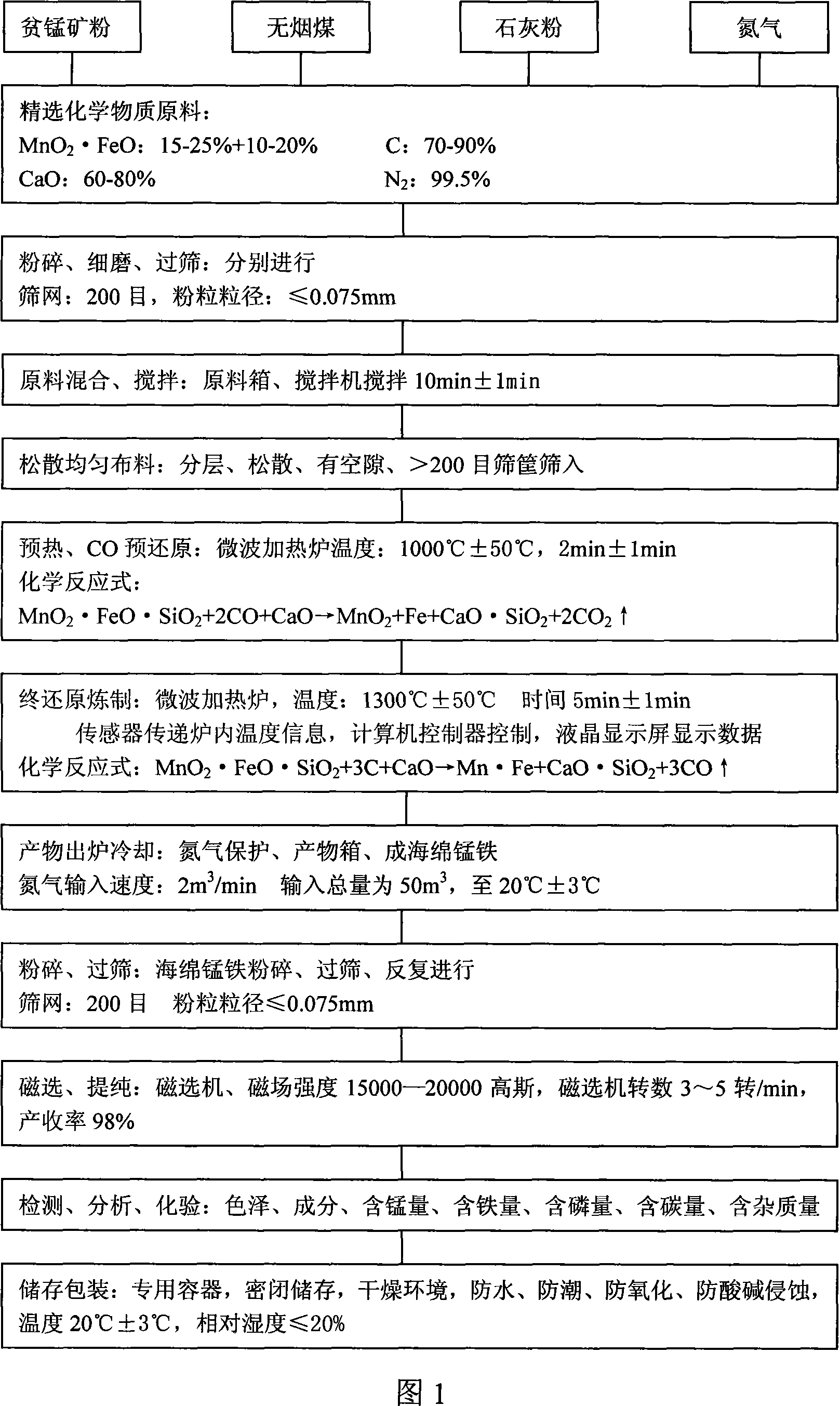

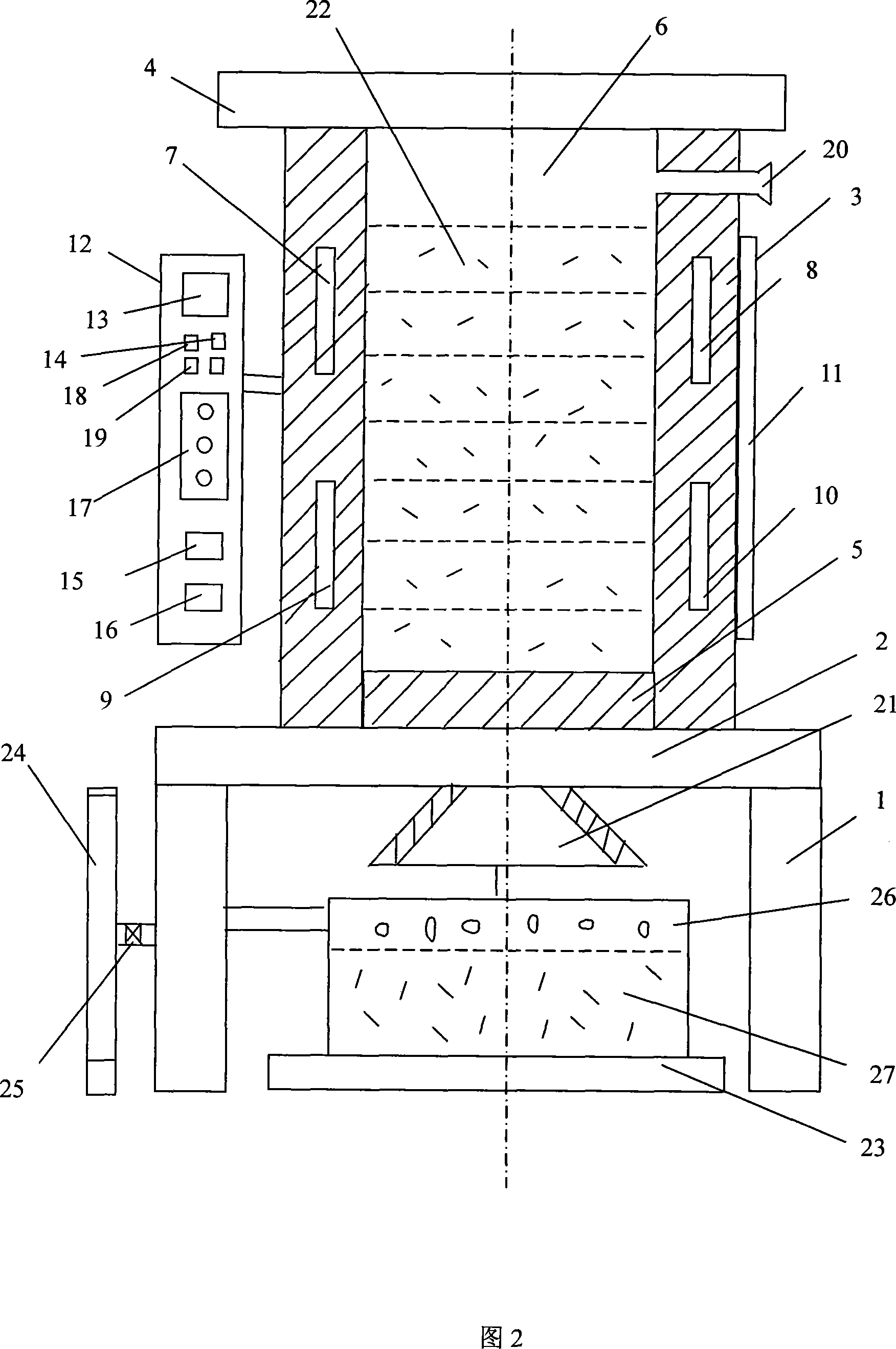

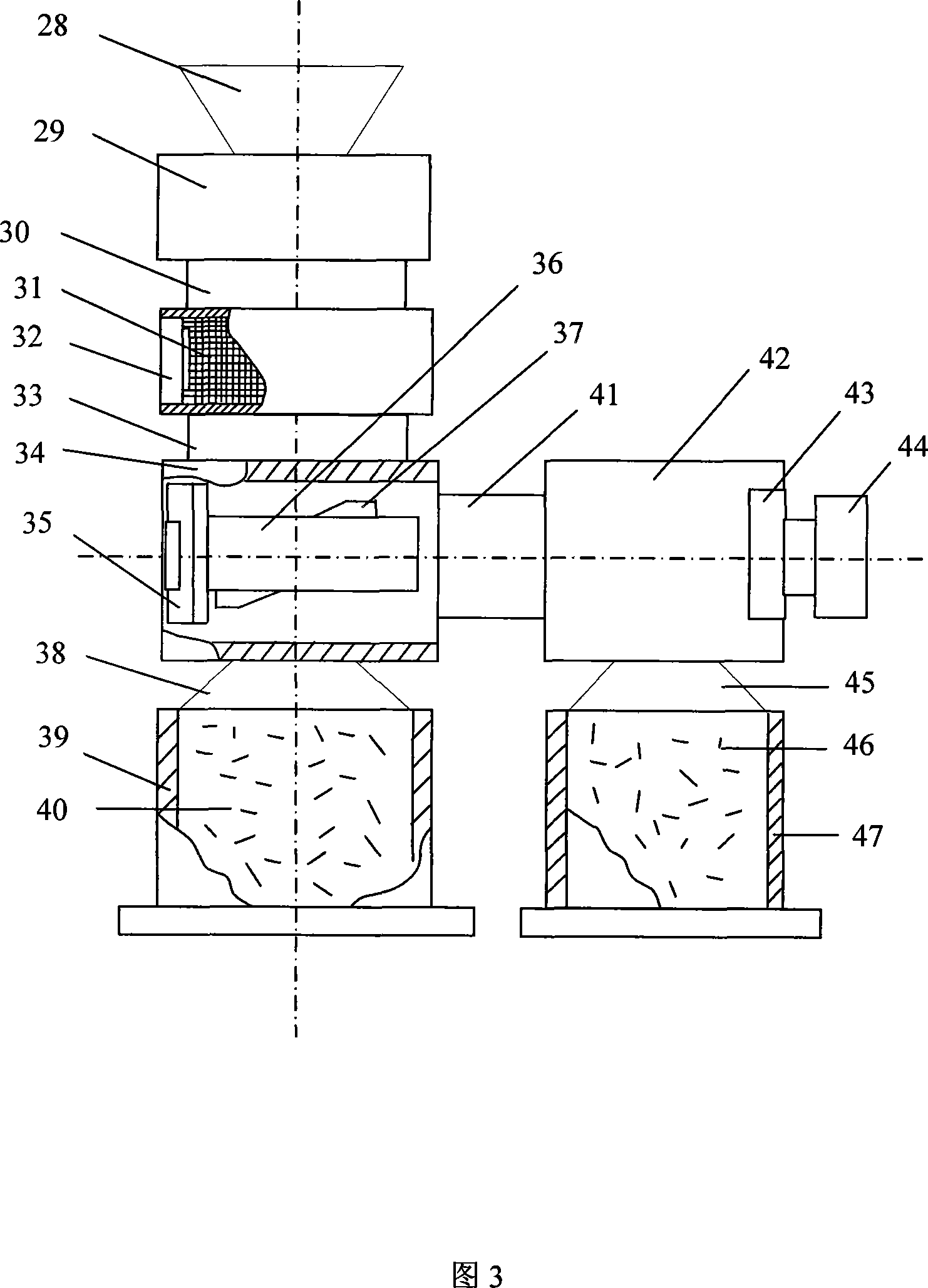

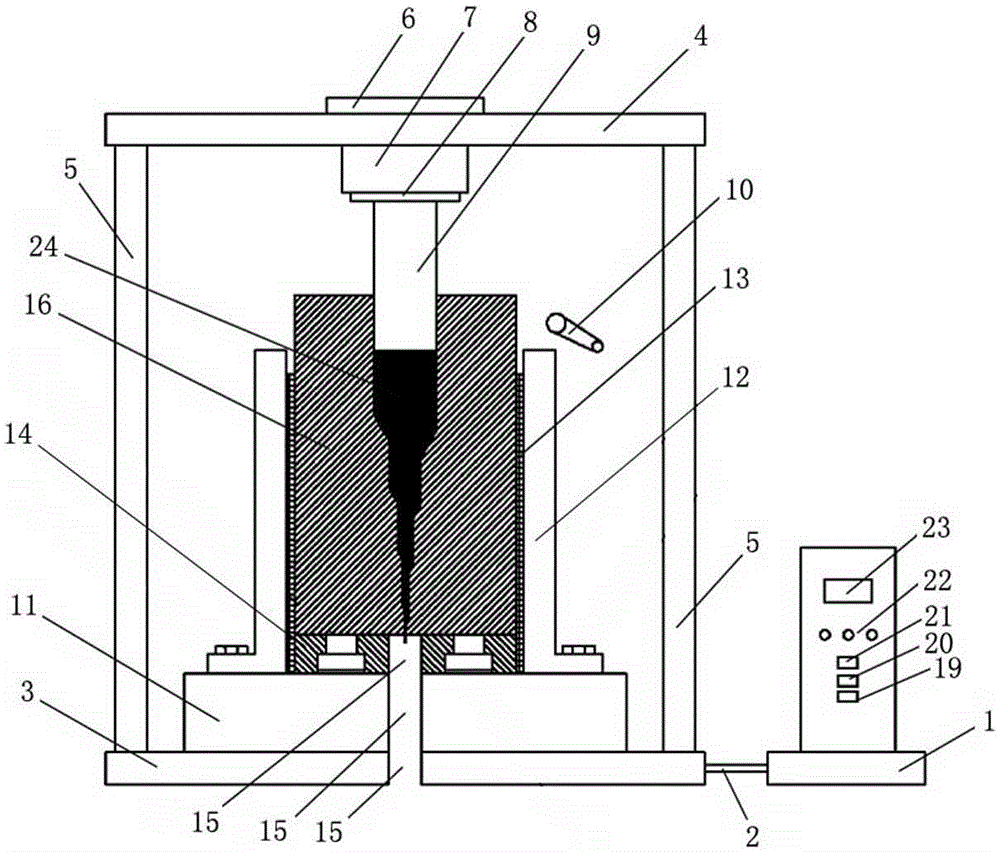

Method for preparing low-carbon metal manganese iron by using manganese-poor powdered ore

The invention relates to a low-carbon ferromanganese production method using low-grade manganese mineral powder. The low-grade manganese mineral powder which has rich reserves is heated by a micro-wave oven, reduced by carbon, smelted at high temperature, purified by magnetic separation to directly prepare low-carbon ferromanganese. And the production method saves sintered agglomeration process with large energy consumption and serious pollution. The low-carbon ferromanganese with high purity is made through the steps that: the material is carefully chosen, crushed, fine- grinded, sieved, mixed, stirred, preheated by the micro-wave oven, pre-reduced through carbon monoxide, finally reduced, smelted at high temperature, cooled under the protection of nitrogen and purified by magnetic separation. The preparation method has the advantages of short technological process, less using equipment, being suitable for large- scale industrialization production, the yield rate can reach 98 percent, wherein manganese content is 75 percent and iron content is 20 percent, and the content of carbon is less than 0.5 percent; the content of harmful material sulfur is also less than 0.5 percent; the content of phosphor is less than 0.2 percent. The products have the advantages of low carbon, low phosphor and sulfur containing, no agglomeration, no pollution to environment. The method is the ideal ferromanganese direct production method using low-grade manganese mineral powder and fills up a scientific research blank in the field in China.

Owner:TAIYUAN UNIV OF TECH

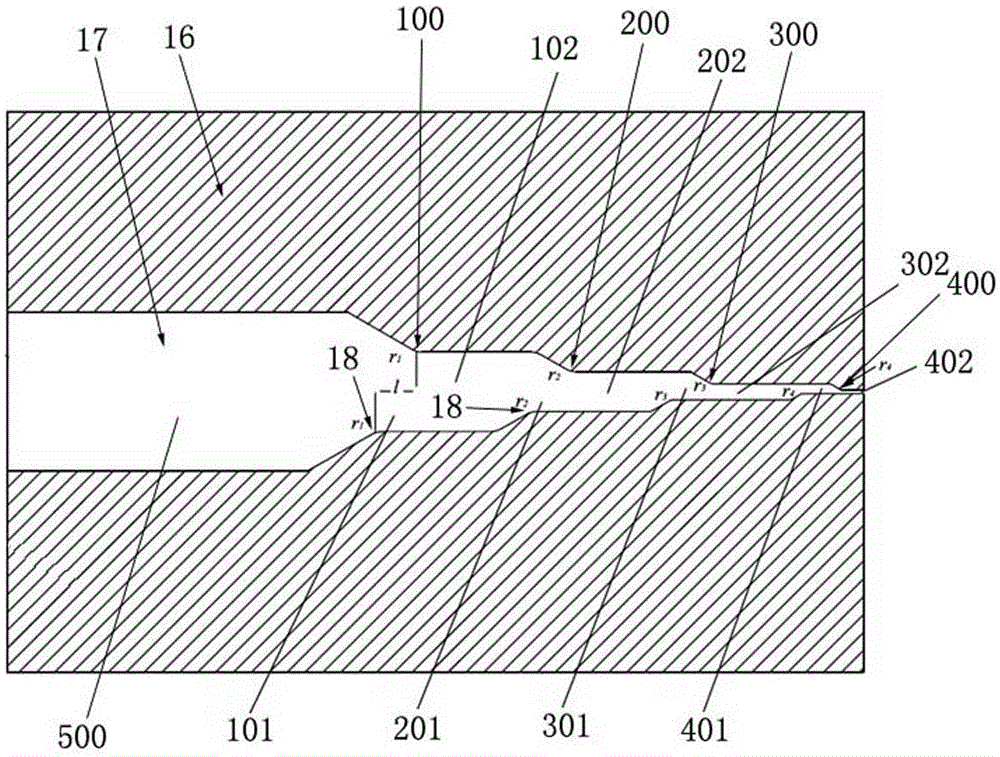

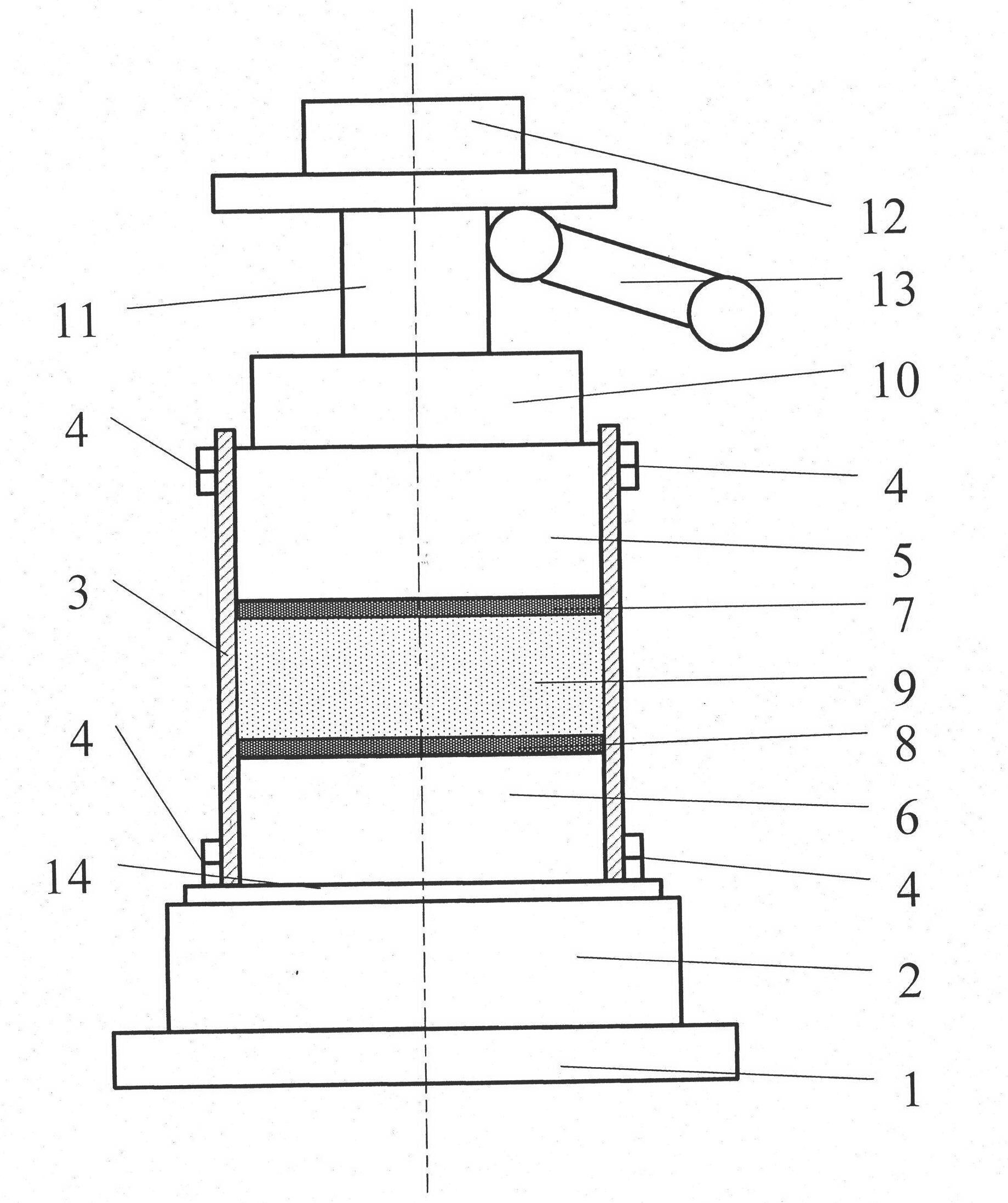

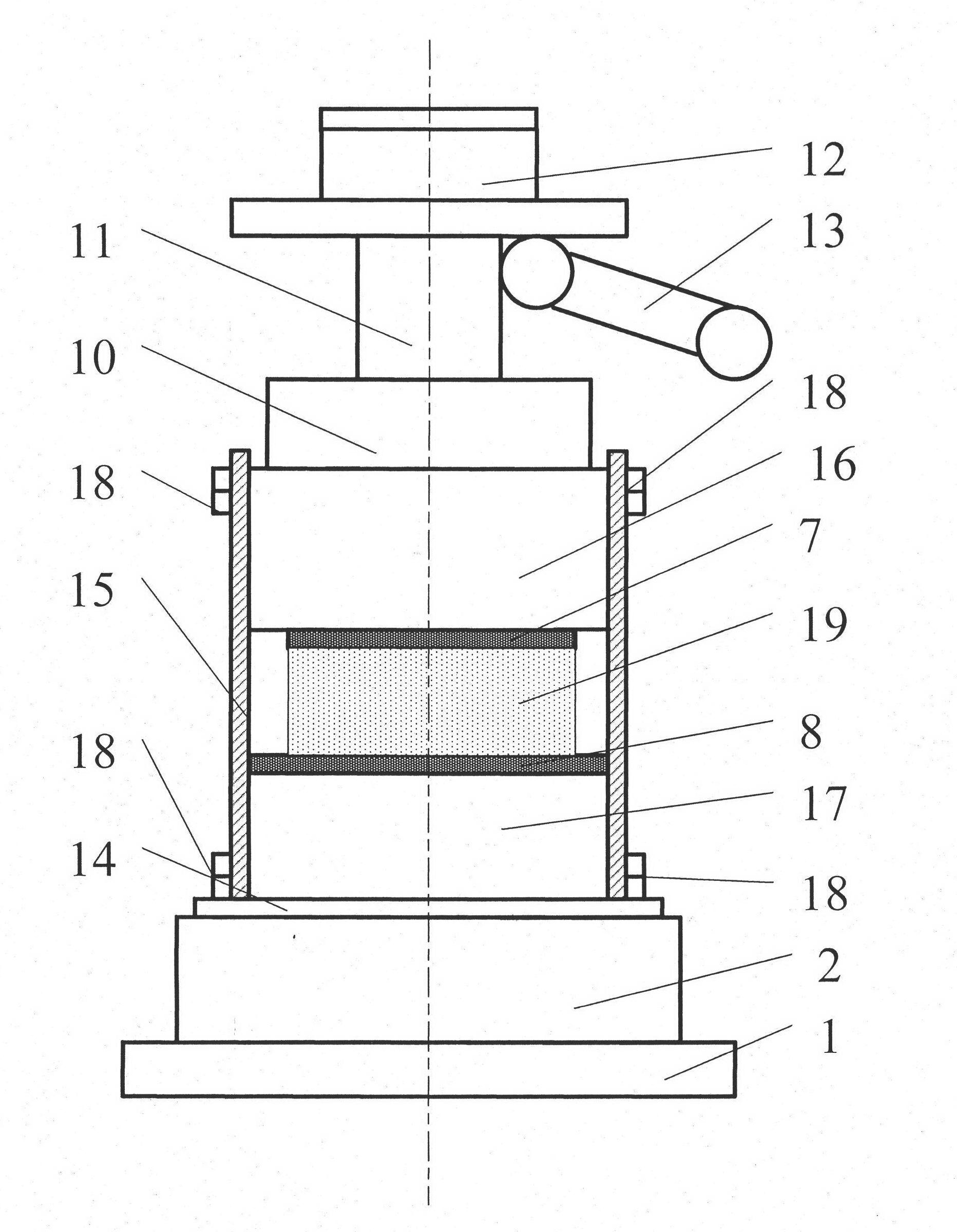

Continuous extrusion machining device used for magnesium alloy sheet strip with weak basal texture and extrusion machining method

ActiveCN105032964AAverage grain size reductionHigh strengthExtrusion diesAsymmetric distributionMachining process

The invention relates to a continuous extrusion machining device used for a magnesium alloy sheet strip with a weak basal texture and an extrusion machining method. The device comprises an extrusion system mainly composed of a pressure motor, an extrusion telescopic head, a male die and a female die, and multiple inclined steps gradually getting close to the axis of a die cavity are arranged at the two sides below the upper middle portion in the die cavity of the female die and are distributed asymmetrically. In the extrusion machining process, a magnesium alloy blank is placed in the die cavity of the female die and extruded by the descending male die, and as the male die descends continuously, the magnesium alloy blank is gradually thinned to form a magnesium alloy sheet with the weak basal texture. Due to step-by-step grain refinement and basal texture weakening, extrusion force in the extrusion process is greatly reduced, the average grain size of the magnesium alloy is greatly reduced compared with that of a magnesium alloy extruded normally, and the (0002) basal texture is reduced to 8.2 from 27.6 compared with that of a sheet obtained through normal extrusion.

Owner:TAIYUAN UNIV OF TECH

A kind of preparation method of aluminum-based boron carbide neutron absorbing plate

The invention relates to a method for preparing an aluminum-based boron carbide neutron absorption board. According to a requirement on nuclear device protection, the compact aluminum-based boron carbide neutron absorption board is formed by mixing aluminum powder, boron carbide powder, silicon powder, titanium powder and boracic acid crystal, performing powder metallurgy to make a rectangular board, and performing hot extrusion molding on the rectangular board on a pressing machine in a die in a heating state; the compound neutron absorption board is grey white; the neutron absorption rate is more than or equal to 90 percent, the boron carbide is distributed uniformly, and particles and a base body are tightly combined together; the micro hardness of the base body is up to 185.8HV and the micro hardness of the particles is up to 2,022.2HV; a corrosion resistance level on the surface of the board is -0.45 voltage, the anti-bending angle is more than or equal to 10 degrees, the tensilestrength is more than or equal to 200 MPa, the fracture elongation rate is 1.8 percent and the fracture contractibility rate is more than or equal to 1.0 percent. The preparation method is advanced and rational in process, and is full and accurate in parameter; and the preparation method is an ideal method for preparing the aluminum-based boron carbide neutron absorption board.

Owner:DALIAN BAOYUAN NUCLEAR EQUIP +2

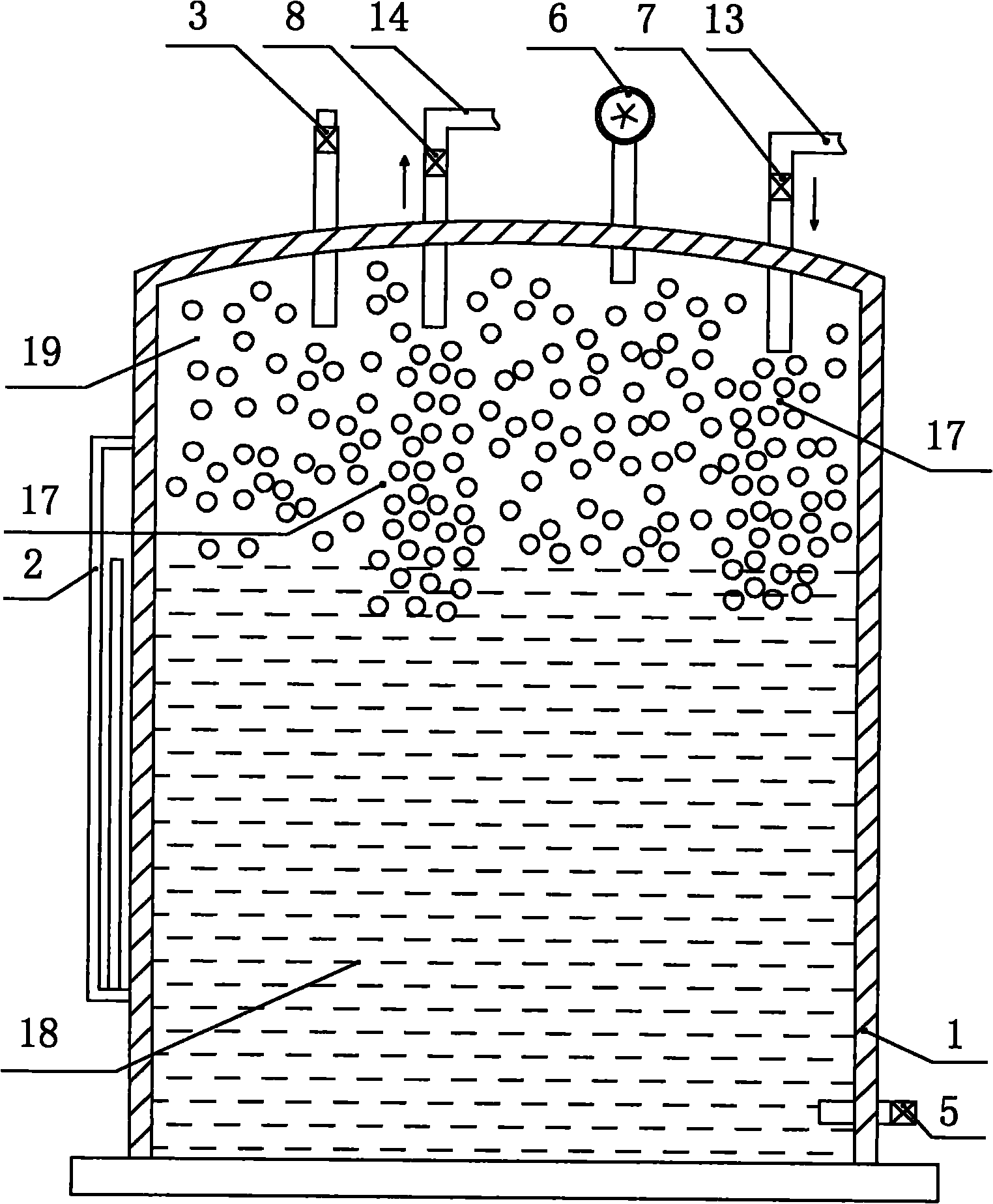

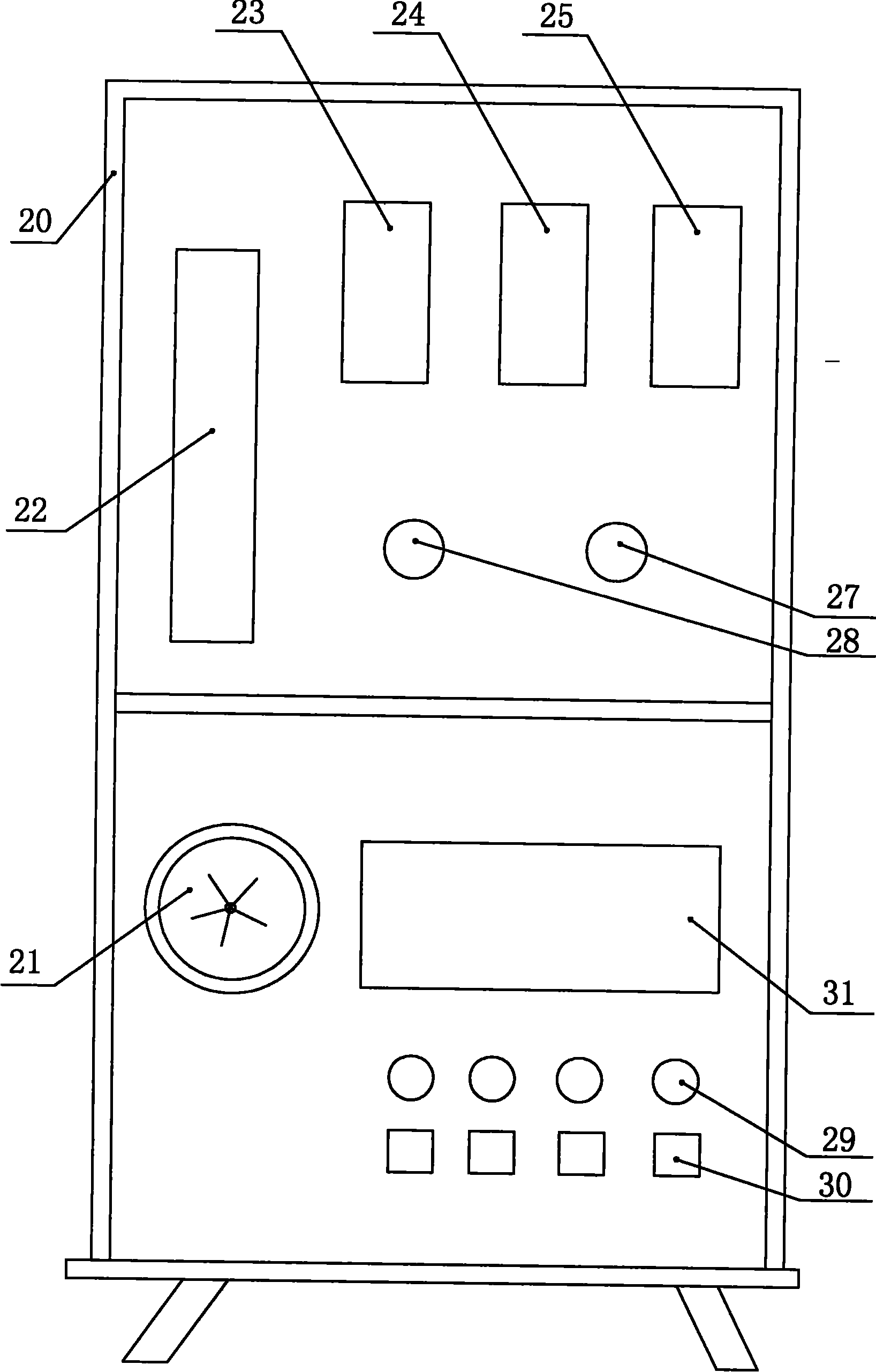

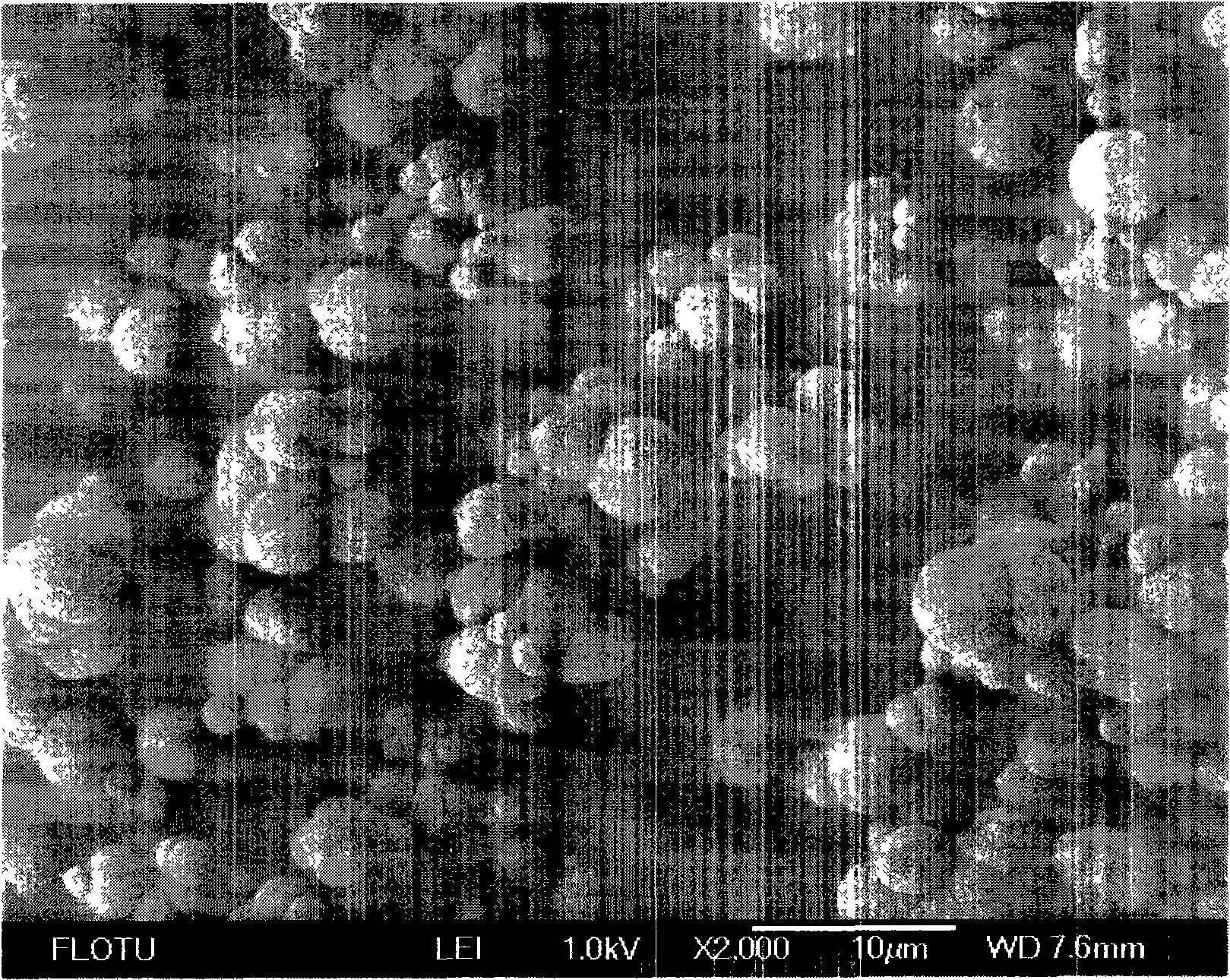

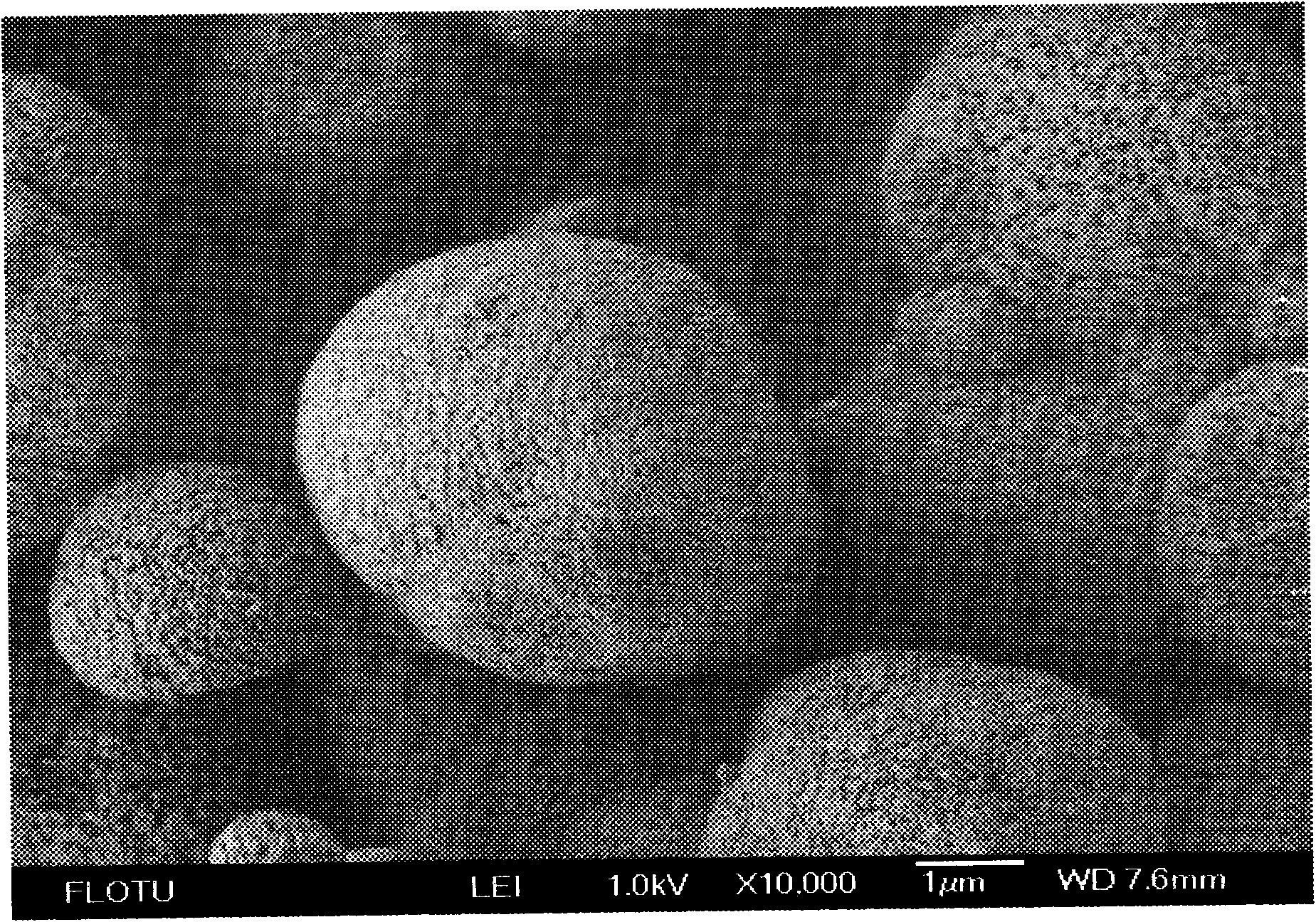

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

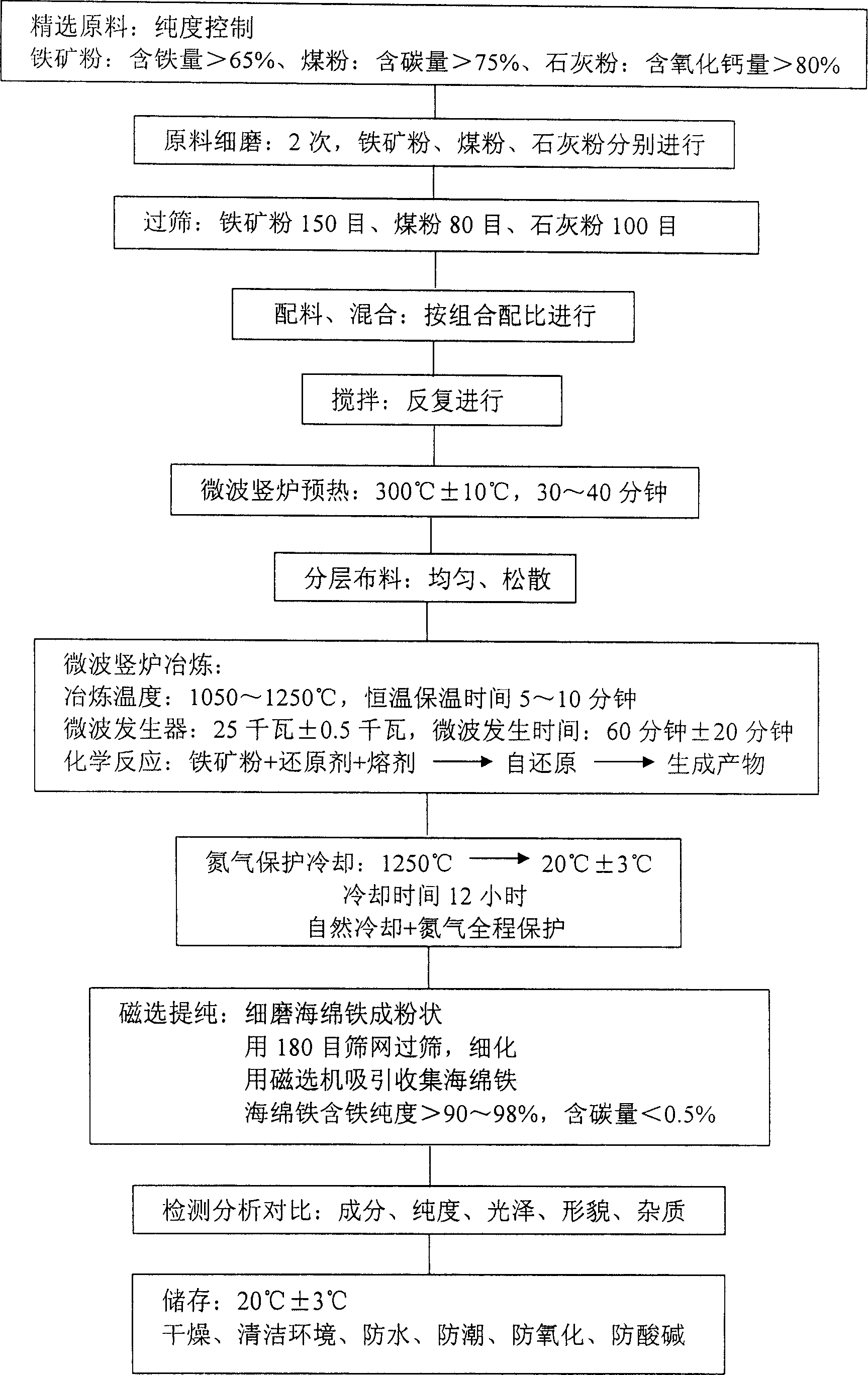

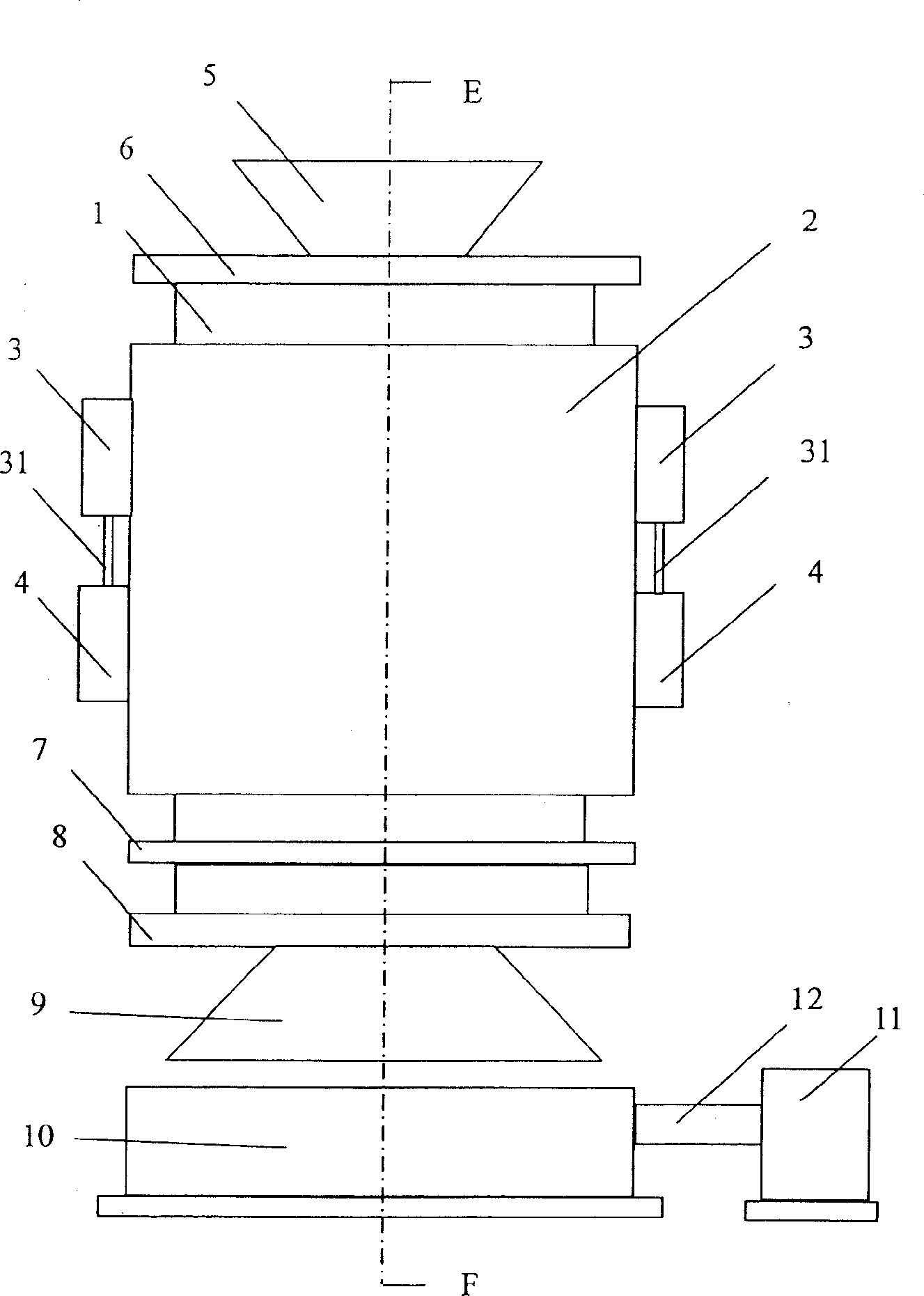

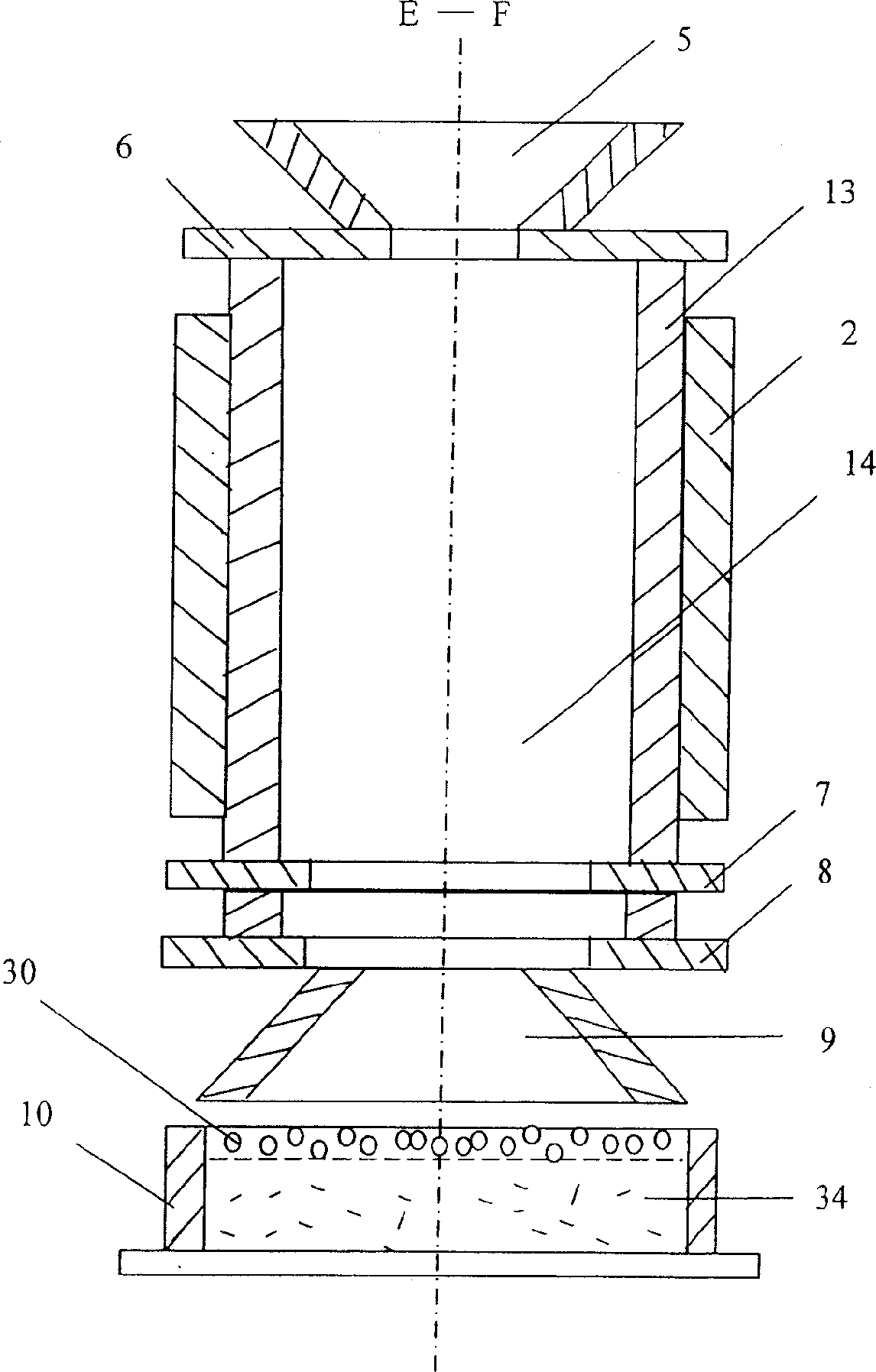

Method of manufacturing low carbon sponge iron using microwave vertical furnace

The invention relates to a method to make low carbon sponge iron by microwave shaft furnace. It adopts iron ore powder as raw material, common soft coal dust or anthracite dust as reducer to gain high quality low carbon sponge. It uses the feature that the iron ore powder, carbon powder, and lime powder has selective absorbing to microwave. Under the condition of sealing and high temperature, and under the effect of microwave generator, heater, and adjustor, it would take carbon heat self-reduction by absorbing the heat produced by microwave generator to gain low carbon sponge iron. The method has simple technology, shortens the reduction time period, saves coking coal and coke resource, and reduces environment pollution. The degree of metallization could reach 90-98%, and the carbon content could be lower than 0.5%. It is the ideal method to make low carbon sponge iron.

Owner:TAIYUAN UNIV OF TECH

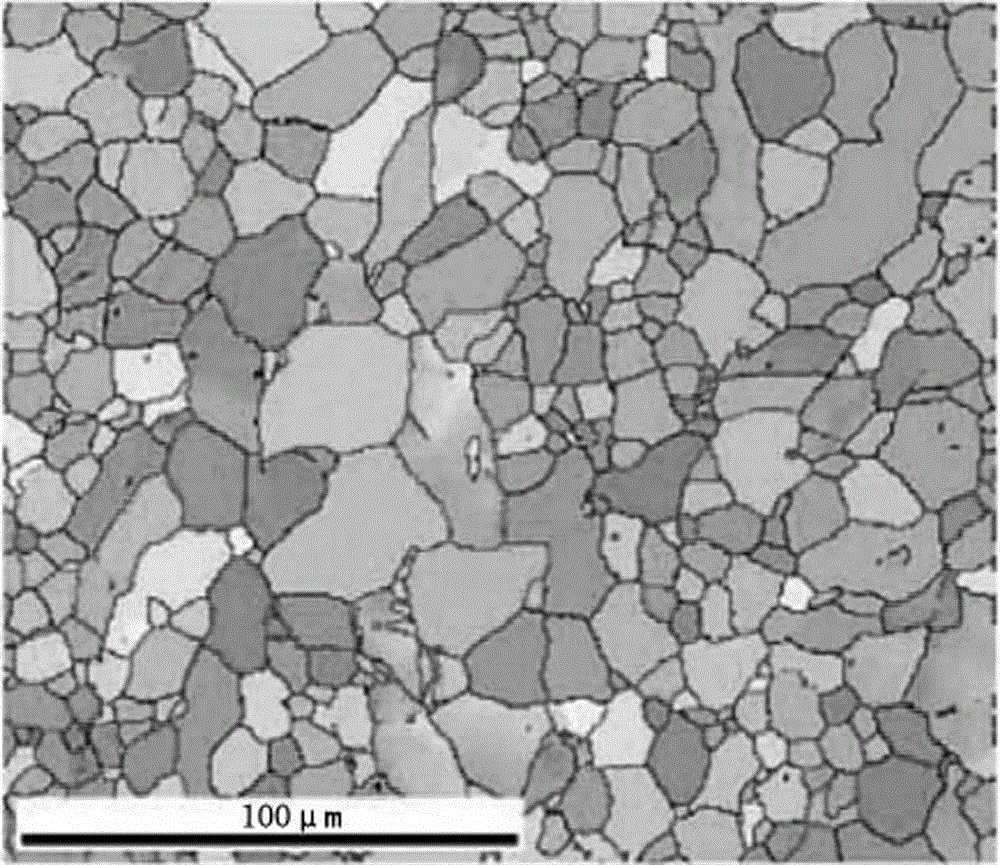

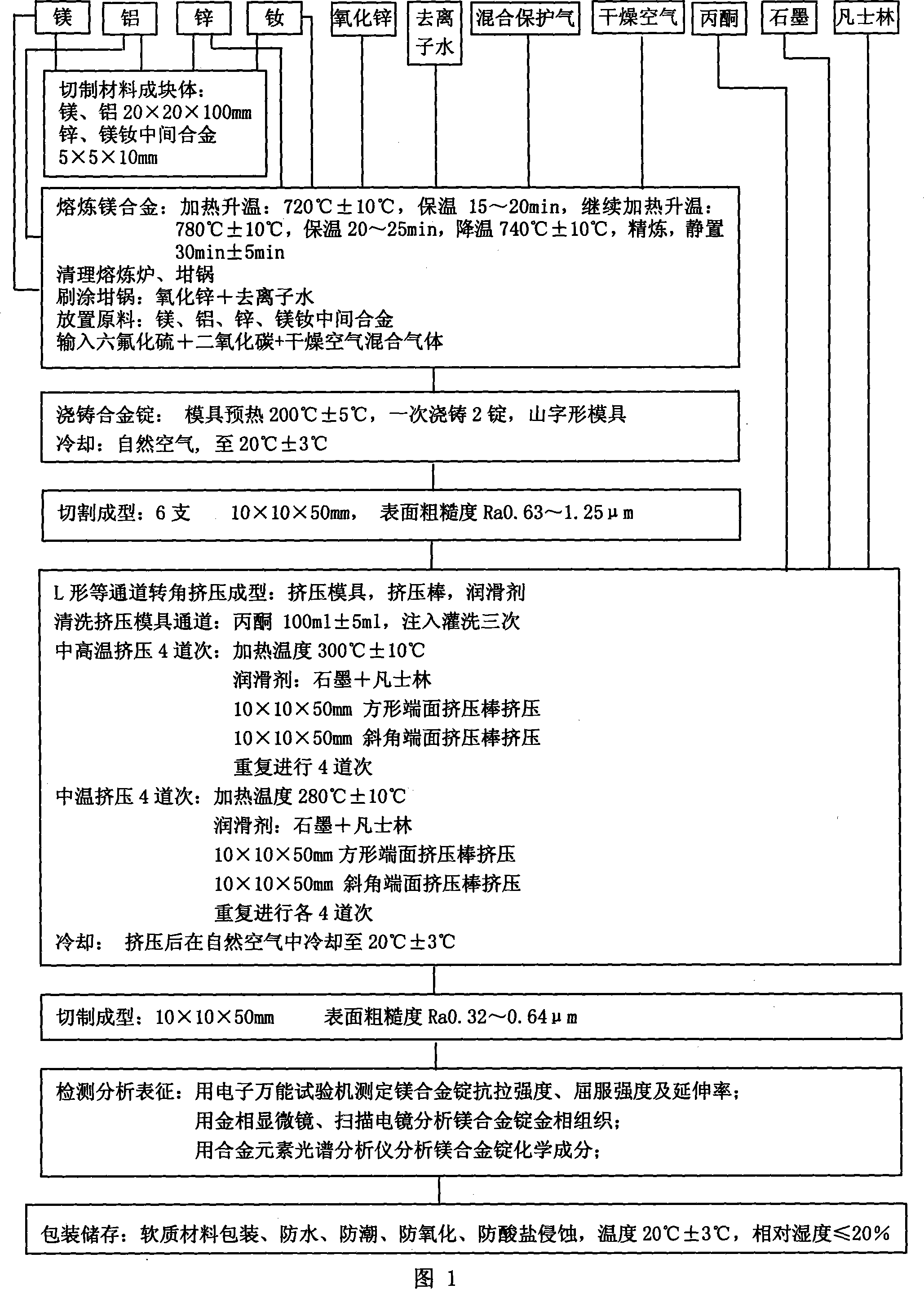

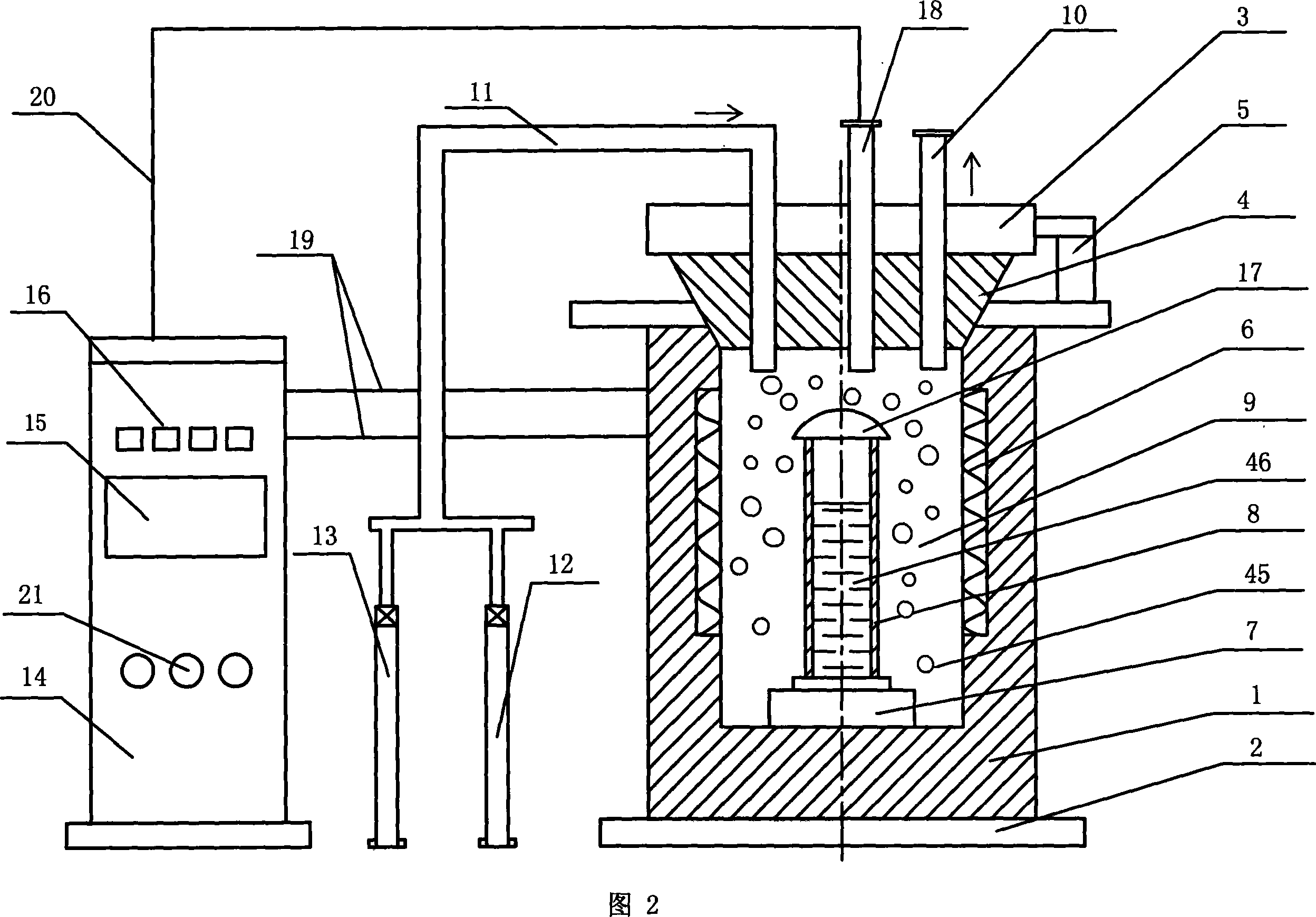

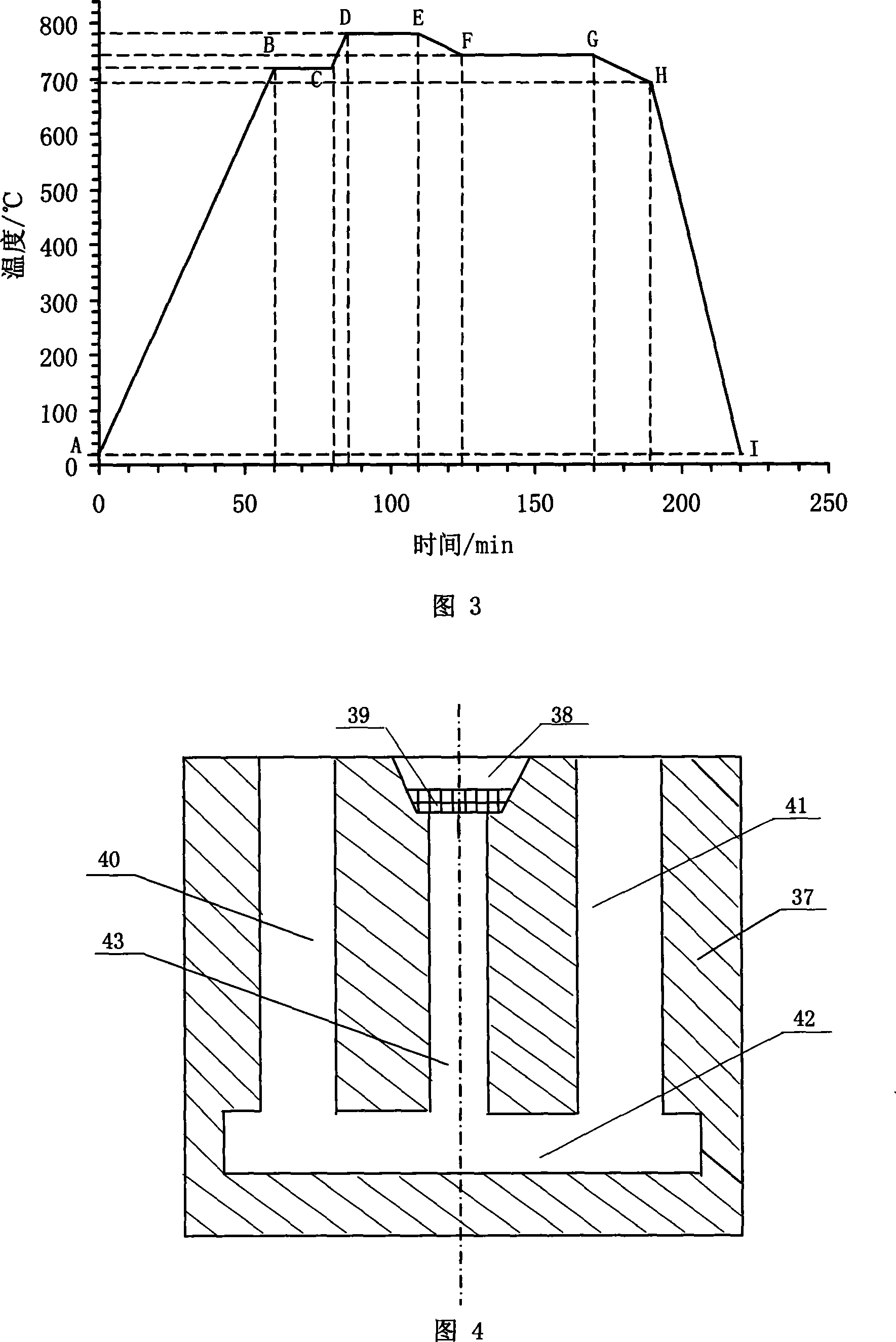

High-strength magnesium alloy and preparation method thereof

The present invention relates to a high intensity magnesium alloy and the preparation method. Magnesium, aluminum, zinc and neodymium are adopted as raw materials, which are melted in a melting furnace, under the protection of the mixed gases, and are melted down at the temperature of 720 plus or minus 10 degrees Celsius system, magnesium- neodymium alloy is added at the temperature of 780 plus or minus 10 degrees Celsius system, refined and the heat is preserved at the temperature of 740 plus or minus 10 degrees Celsius system and then the magnesium-aluminum-zinc-neodymium melt is obtained. When the temperature is lowered to 680-700 degrees Celsius system, the magnesium-aluminum-zinc-neodymium melt is discharged and cut into shapes after being moulded and cooled and then made into high intensity aluminum-magnesium alloy ingots after an 8-channel equal channel rotor angle pinch. The raw material mixture ratio of magnesium, aluminum, zinc and neodymium is 82 to 15 to 2 to 1 and aluminum makes up 15 percent. The aluminum material is abundant in resource, low in price and more economical and the lanthanon neodymium can change the metallurgical structure and mechanical property. The method has a short process flow and a slight pollution to the environment. The tensile strength, yield strength and elongation of the magnesium alloy ingots can be increased by 147.4 percent, 210.6 percent and 448.3 percent respectively. The metallurgical structure is compact and even and the average crystal grain size is less than or equal to 2 micrometers.

Owner:TAIYUAN UNIV OF TECH

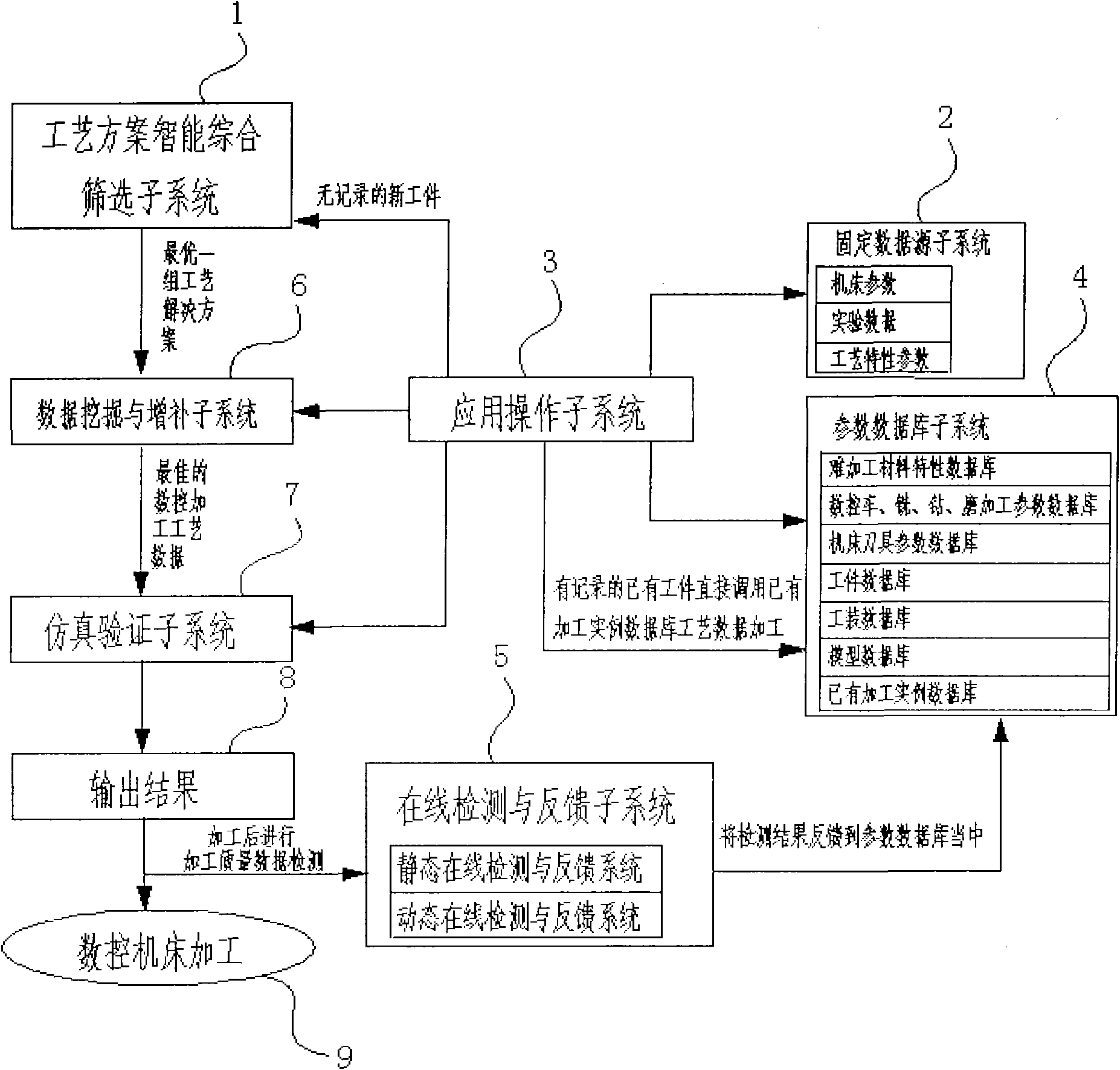

Intelligent screening system based on numerical control processing technology for difficult-to-machine metal

InactiveCN101930223AQuality improvementLow costBiological neural network modelsSpecial data processing applicationsNumerical controlOperational system

The invention discloses an intelligent screening system based on the numerical control processing technology for difficult-to-machine metal, which comprises the following subsystems: a parameter database subsystem, a fixed data source subsystem, an online detection and feedback subsystem, a technology intelligent comprehensive screening optimized scheme system, a data mining and supplementing subsystem, a simulation verification subsystem and an application operating system. The system has the characteristic of recognizing the reasonableness, the advancement and the high efficiency property of each technology scheme in the database, and is used for collecting the processing information of difficult-to-machine metal materials, the machine tool and cutter selection experience and cutting technological parameters accumulated in production practices and experiments. The roughness test data of the optimized cutting technological parameters is selected for processing, so that a reasonable and mature technological scheme is recommended for manufacturing enterprises, and the numerical control processing precision of the difficult-to-machine metal materials is controlled. The purposes of increasing the processing efficiency of the difficult-to-machine materials, reducing processing cost and acquiring high quality products are achieved.

Owner:曾谊晖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com