Preparation method of heat-resistant polyphenylene sulfide fiber

A polyphenylene sulfide fiber, polyphenylene sulfide technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of filter bag strength loss, fiber oxidation, reduction of dust removal effect and service life, etc. Reasonable, accurate and detailed results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with accompanying drawing:

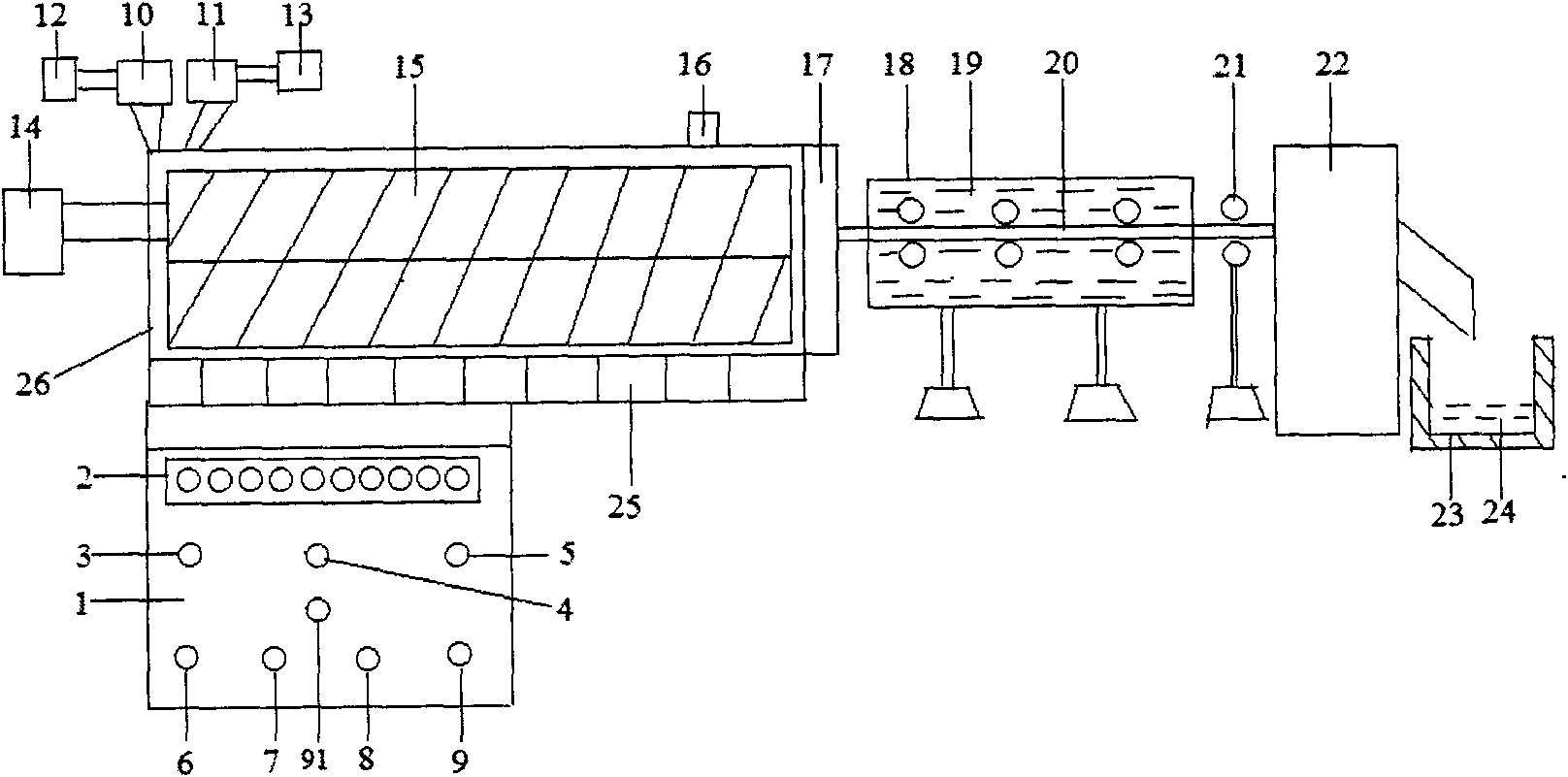

[0080] figure 1 As shown, it is a diagram of the working state of the twin-screw extruder, and the positions of each part must be correct, proportioned according to the amount, and operated in sequence.

[0081] Quantities of the chemical substances and materials used in the preparation are determined according to a preset range, with grams, milliliters, and centimeters as measurement units.

[0082] The preparation of silica + polyphenylene sulfide masterbatch is carried out on a twin-screw extruder, which is completed under the conditions of heating, electric metering feeding, twin-screw extrusion, water cooling, and pelletizing by a pelletizer; Place the twin-screw 15 on the top of the base 25 of the extruder 26. The twin-screw 15 is left and right meshing connection, and the two screws are meshed in the same direction. The screw motor 14 is on the left side of the twin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com